Optical auxiliary measuring device and measuring method using the device

An auxiliary device and measurement technology, which is used in measurement devices, optical instrument testing, and machine/structural component testing. It can solve the problems of measurement error and low repeatability, and achieve high repeatability and stable measurement. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Before elaborating the present invention in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

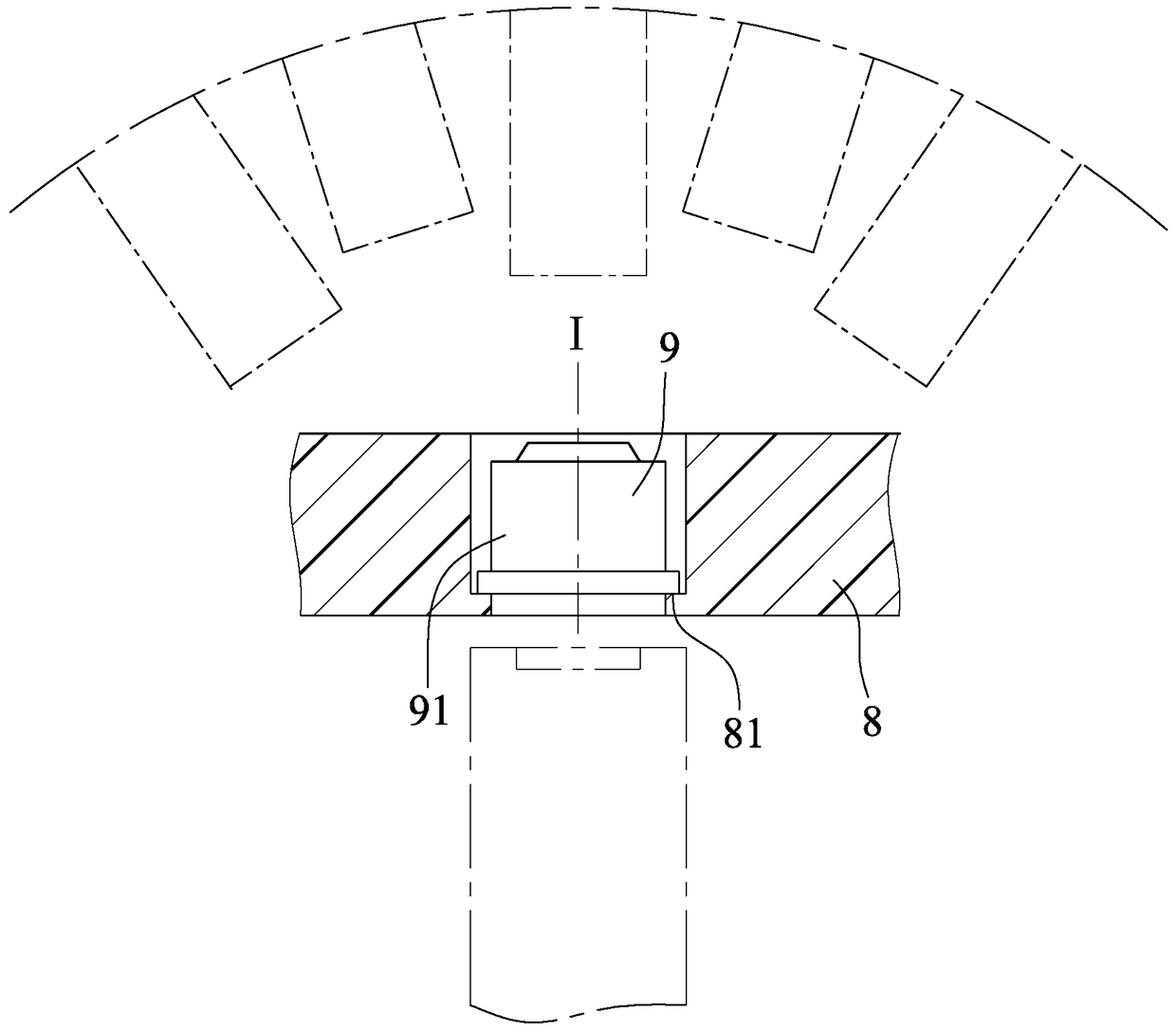

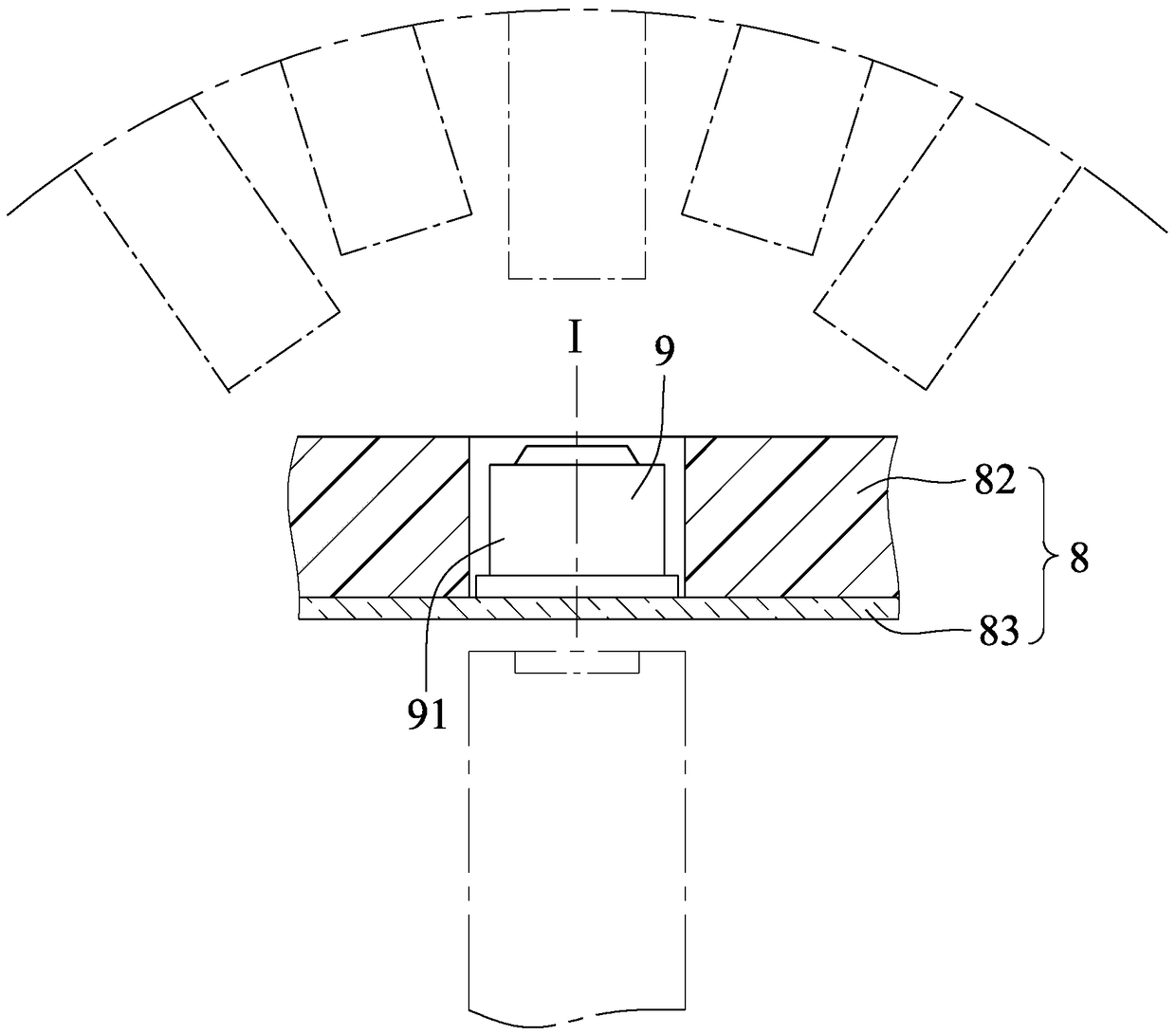

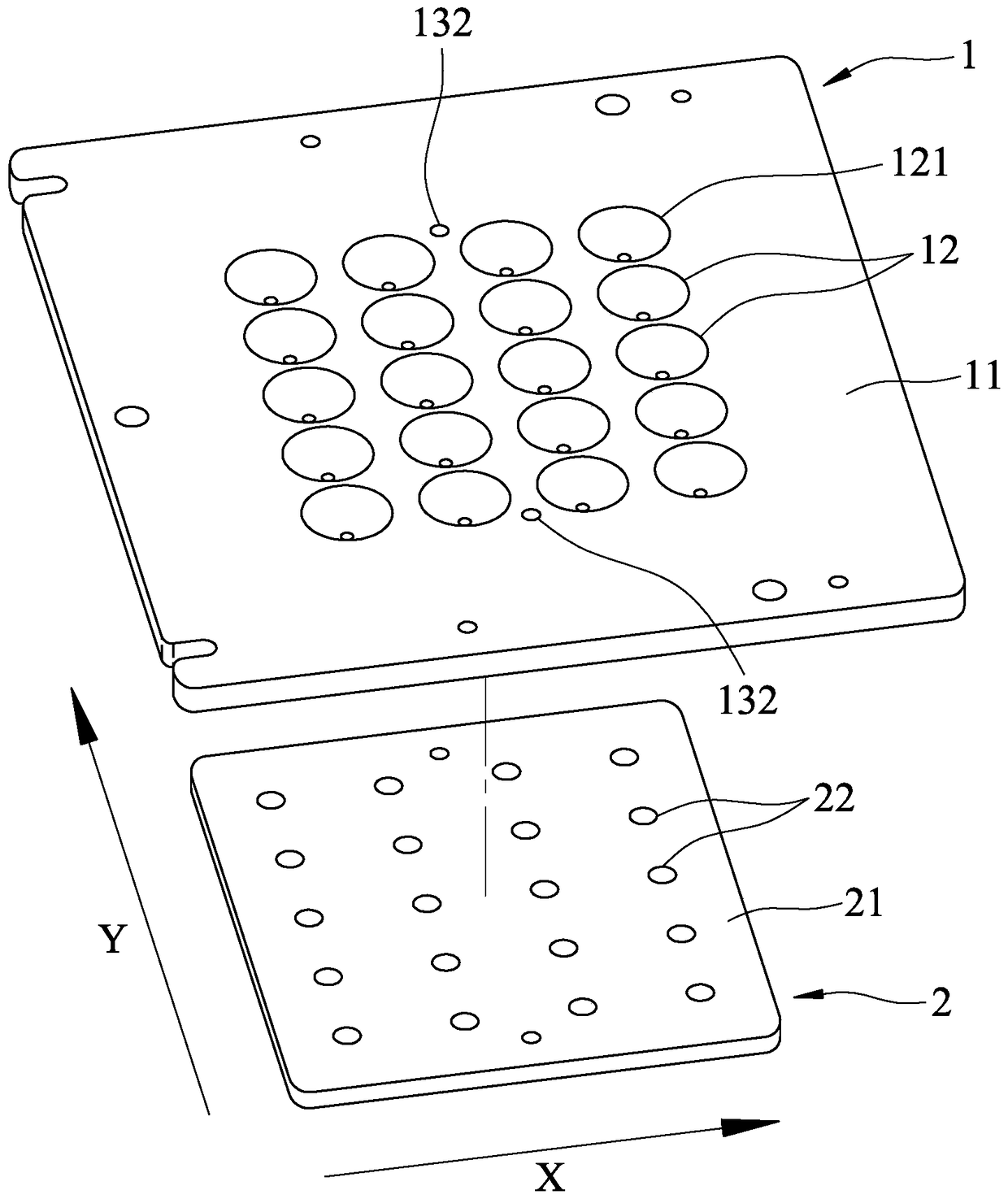

[0047] refer to image 3 , Figure 4 and Figure 5 , a first preferred embodiment of the optical measurement auxiliary device of the present invention is used for optical measurement of a plurality of objects to be measured 90. In this embodiment, the object to be measured 90 is an optical lens, and the optical measurement auxiliary The device includes: a suction unit 1 and a bearing unit 2 .

[0048] The pick-up unit 1 is used to pick up the object to be tested 90, and includes a body 11, a plurality of volumes that are spaced through the body 11 along a first direction X and a second direction Y perpendicular to the first direction X respectively. Measuring hole 12, and a gas channel 13 arranged in the body 11. The measuring holes 12 respectively have a first port 121 and a second port 122 formed on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com