Precise high-Q-value four-terminal-pair high-frequency inductor standard device

A four-terminal pair and standard device technology, applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve the problems of unsatisfactory measurement and calibration laboratories, poor inductance accuracy and stability, and difficult operation, etc., to achieve measurement repeatability and Good stability, wide frequency range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

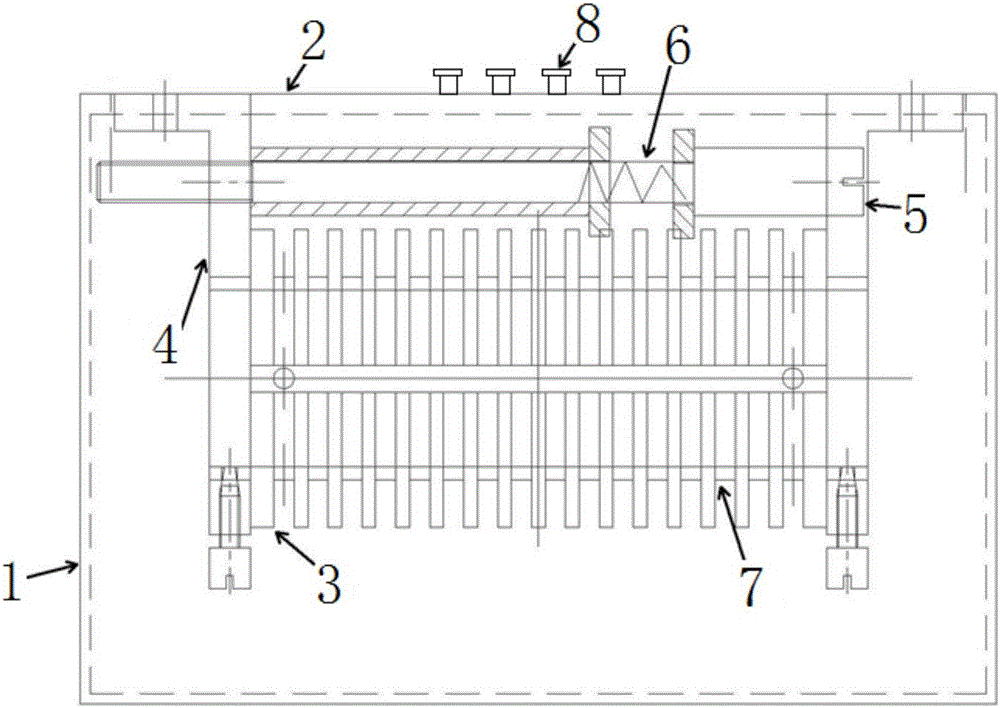

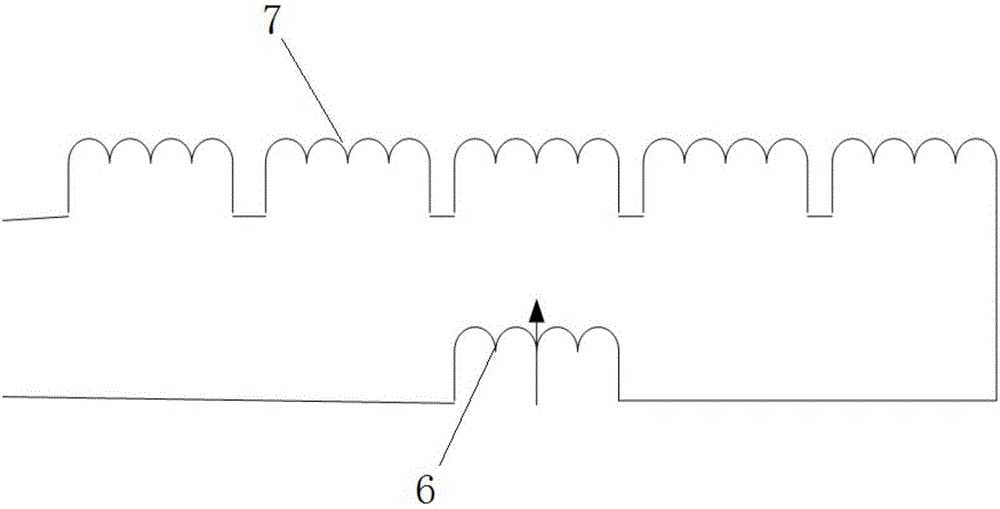

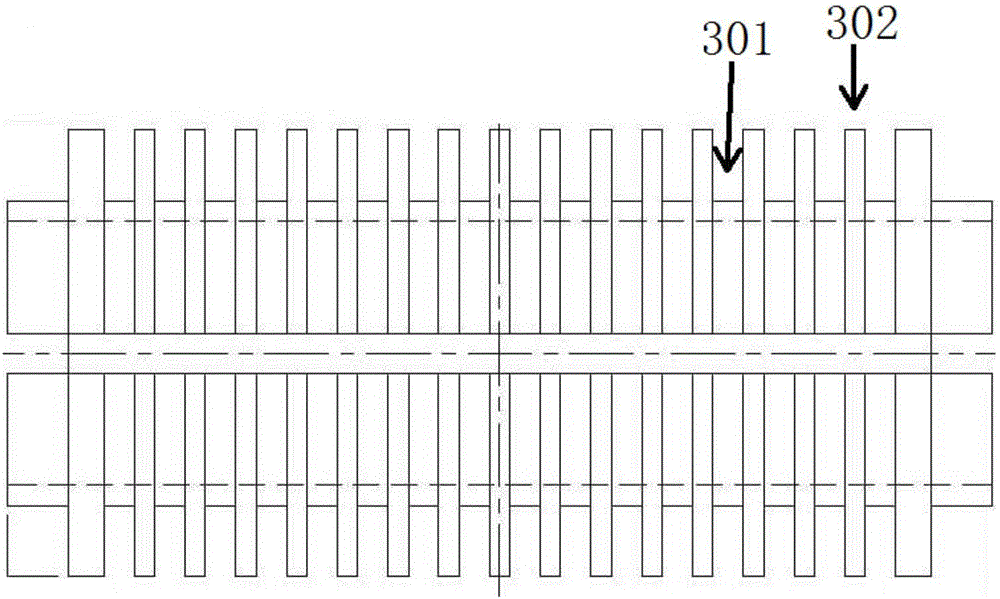

[0023] Such as figure 1 , figure 2 and Figure 8 As shown, the present invention is realized in such a way that the four-terminal pair high-frequency inductance standard includes a metal shielding box 1 and an upper cover plate 2 that is closed on the top of the metal shielding box 1, and its structural feature is that the metal shielding The main inductance winding 7 and the fine-tuning inductance 6 arranged on the adjustment rod 5 are fixed inside the box 1, and a number of BNC connectors 8 are arranged on the upper surface of the upper cover 2, and the BNC connectors 8 are connected in pairs and electrically connected to both ends of the main inductance winding 7; the present invention adopts a metal shielding box structure, and the metal shielding box 1 and the upper cover plate 2 are combined to form a closed metal box body, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com