Quick measurement method for water content of pulverized coal injection by using electromagnetic wave resonant cavity

A resonant cavity and electromagnetic wave technology, which is applied in the direction of using microwaves to test moisture content, measuring devices, and using wave/particle radiation for material analysis, etc., can solve problems such as inability to quickly measure moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] Example: see Figure 5 and 6 .

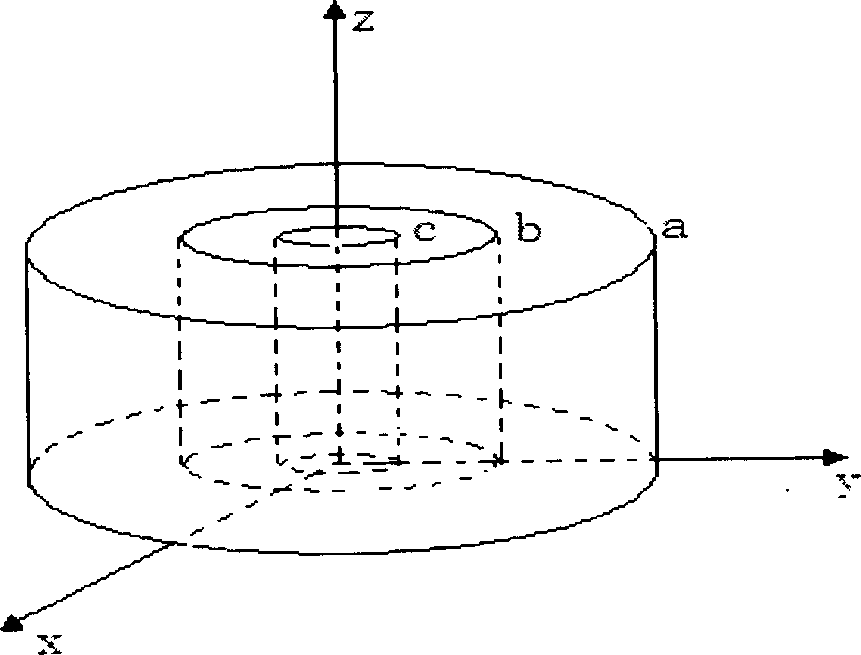

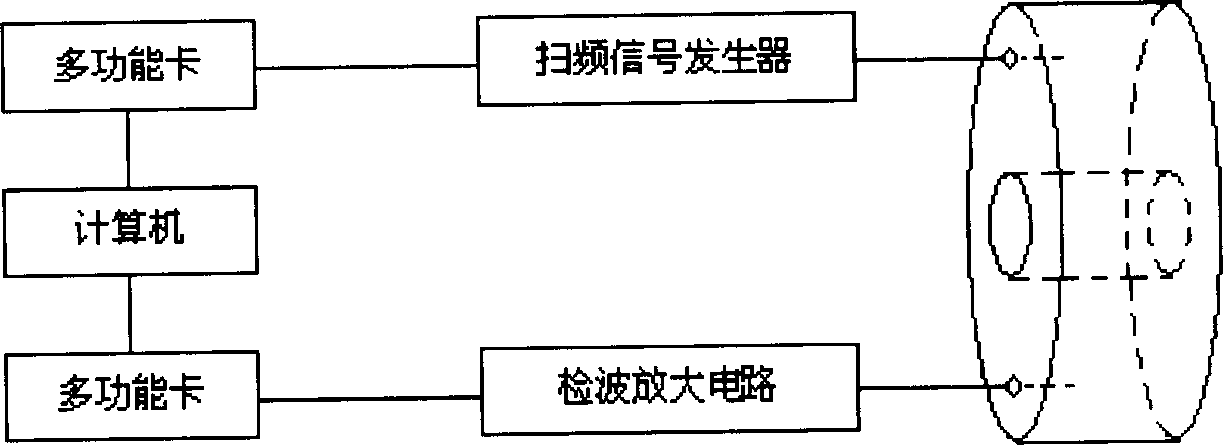

[0050] In this embodiment, the pulverized coal 1 flows into the hollow medium pipe 2, the hollow medium pipe is 100mm long, the inner diameter is 12mm, and the wall thickness is 1.5mm; the cylindrical metal resonant cavity 3 has a height of 14mm, a radius of 48mm, and is made of brass; The electromagnetic wave coupling device 4 is an electric coupling rod, the radius of the electric coupling rod is 1 mm, and the length is 4 mm; the central hole 5 of the cylindrical metal resonant cavity is 15 mm in diameter; 6 is a transmitting system composed of a frequency sweep circuit; 7 is an interface The circuits are respectively used to connect the computer with the transmitting system, connect the receiving system with the computer, and connect the computer with the temperature sensor; 8 is composed of a detection amplifier circuit and a DSP for the receiving system; 9 is a computer; 10 is a temperature measurement system, and the temperature s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com