Vertical gravity gradient measuring sensor based on atom interference effect

A technology of gravity gradient and atomic interference, which is applied in the field of gravity survey, can solve problems such as stability problems, surface deviation, and complex measurement devices, and achieve the elimination of system measurement deviation and noise, double the time of atomic groups floating in the air, improve accuracy and The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and embodiment describe in detail:

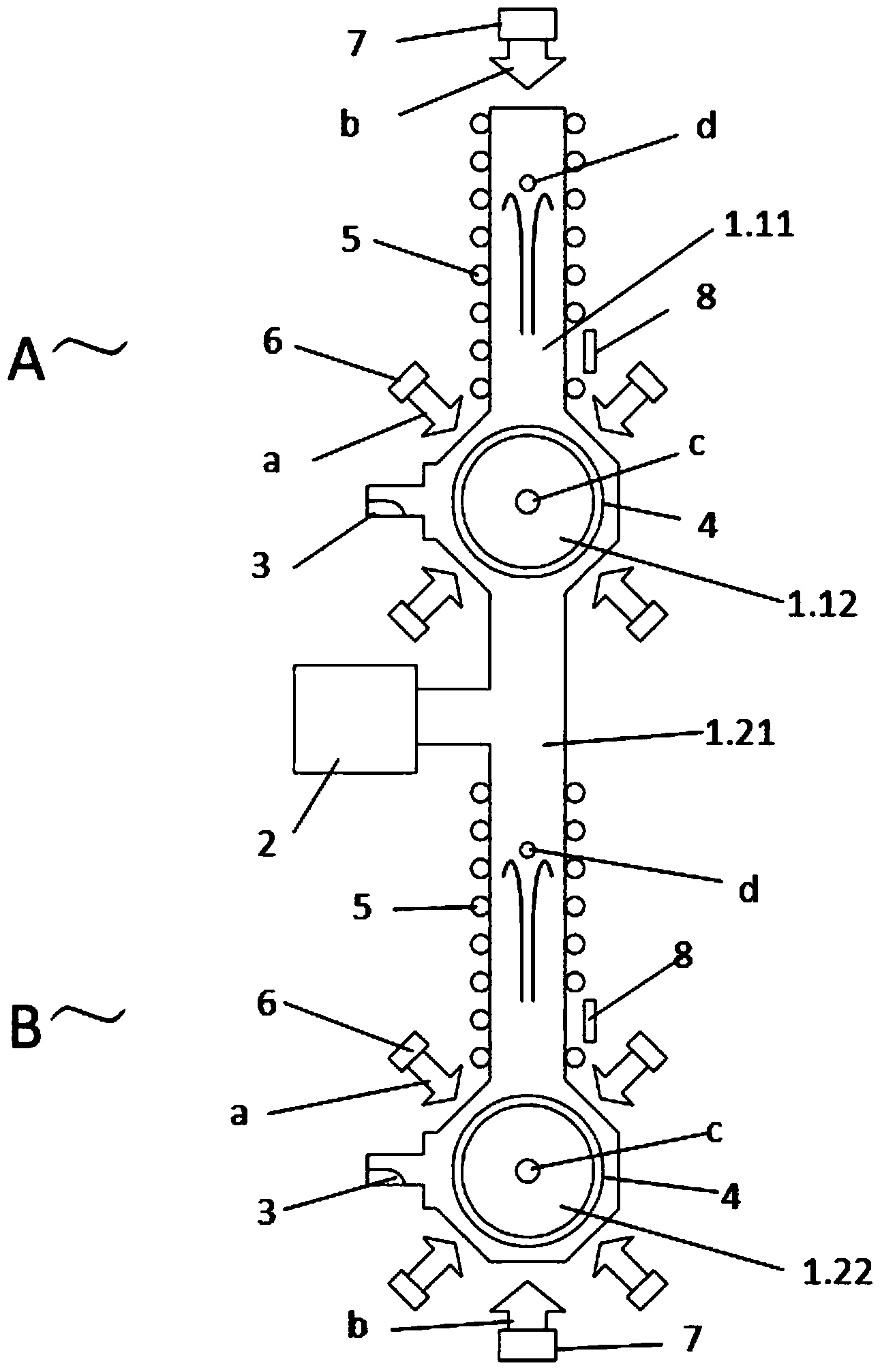

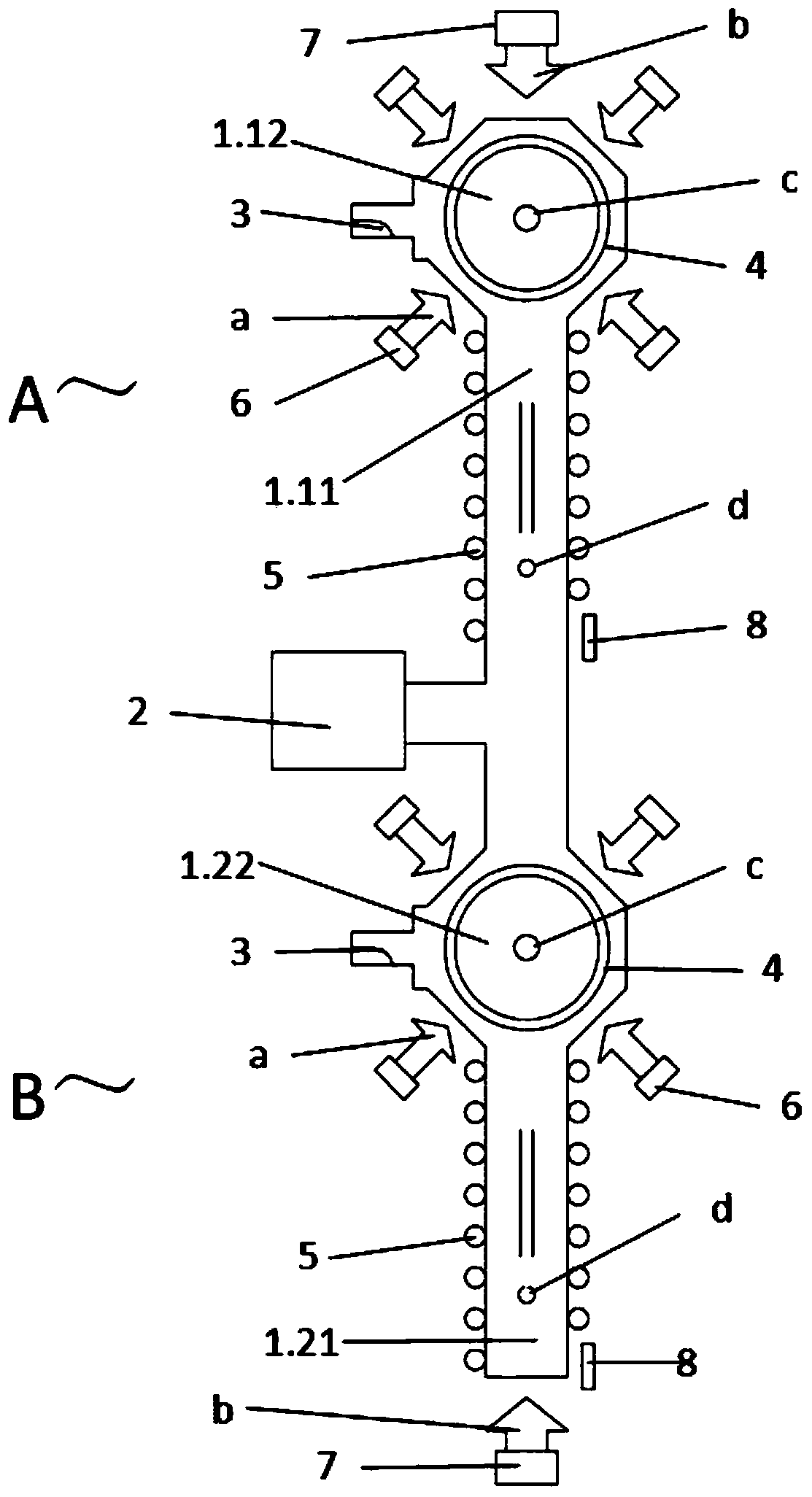

[0053] 1. Overall

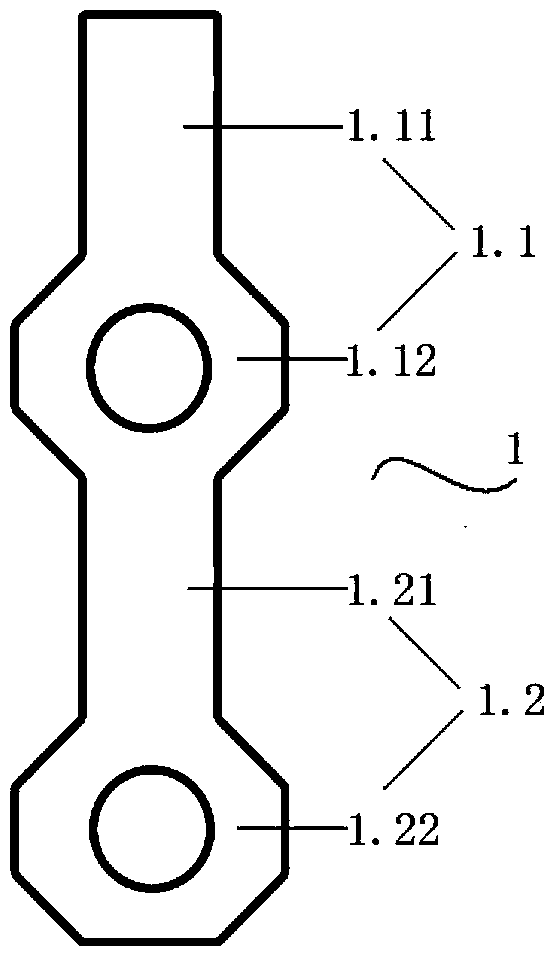

[0054] Such as figure 1 , 2 , the sensor includes two first and second unit devices A and B with the same structure, each unit device includes a first vacuum container 1.1 or a second vacuum container 1.2, a vacuum pump 2, an alkali metal sample 3, a reverse magnetic field Coil pair 4, bias magnetic field coil 5, trapping laser beam emitter 6, Raman laser beam emitter 7 and photodetector 8; the alkali metal sample 3 of each unit device is arranged in the first vacuum container 1.1 or the second vacuum In the container 1.2, the inside of the first vacuum container 1.1 or the second vacuum container 1.2 communicates with the vacuum pump 2; with the cold atomic group c preparation area as the center, six directions of spatial symmetry are respectively provided with six trapping lasers whose emission directions point to the center The beam emitter 6 is symmetrically pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com