Aluminum electrolytic cell anode voltage signal acquisition device

An anode voltage and signal acquisition technology, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problems of shortening the life of the electrolytic cell, cracks at the bottom of the electrolytic cell, depolarization, etc., and achieve good measurement stability and accuracy. The effect of increasing the retractable distance of the probe and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

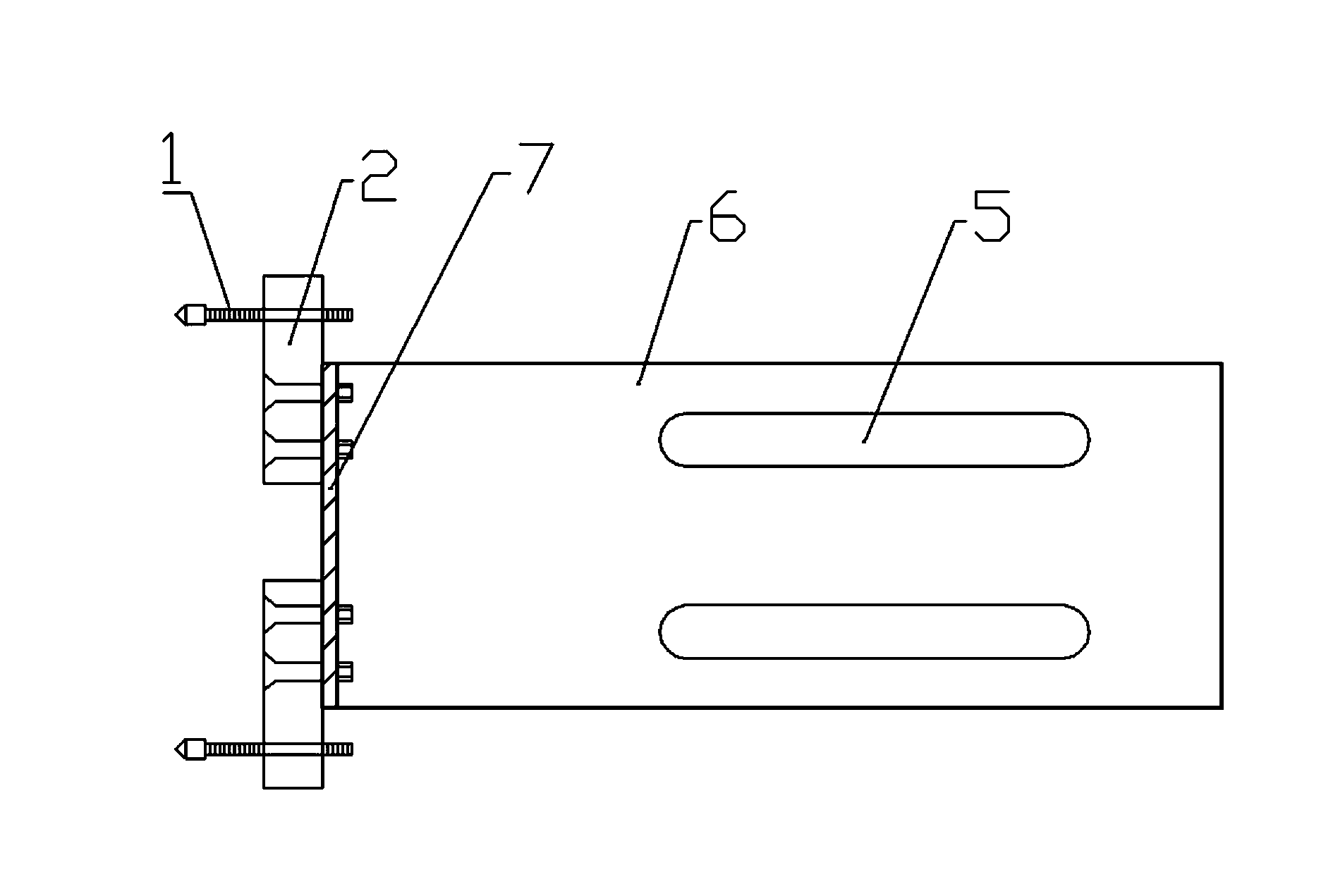

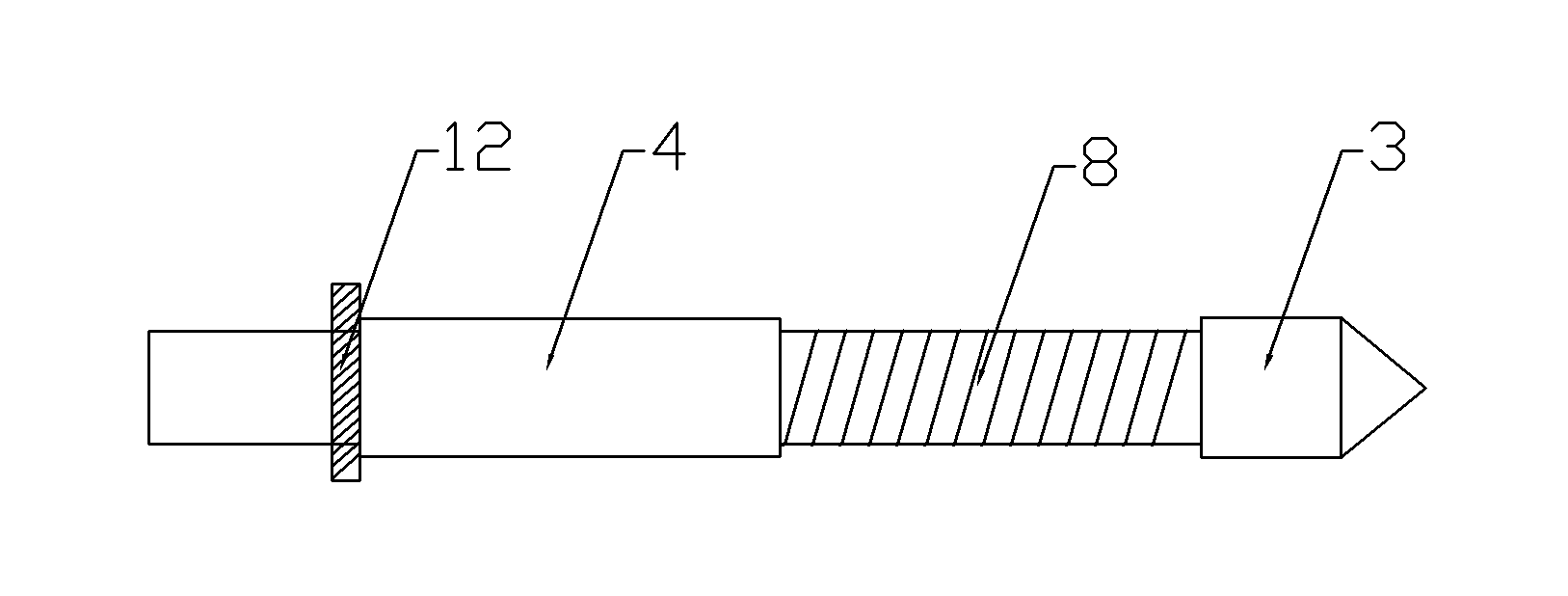

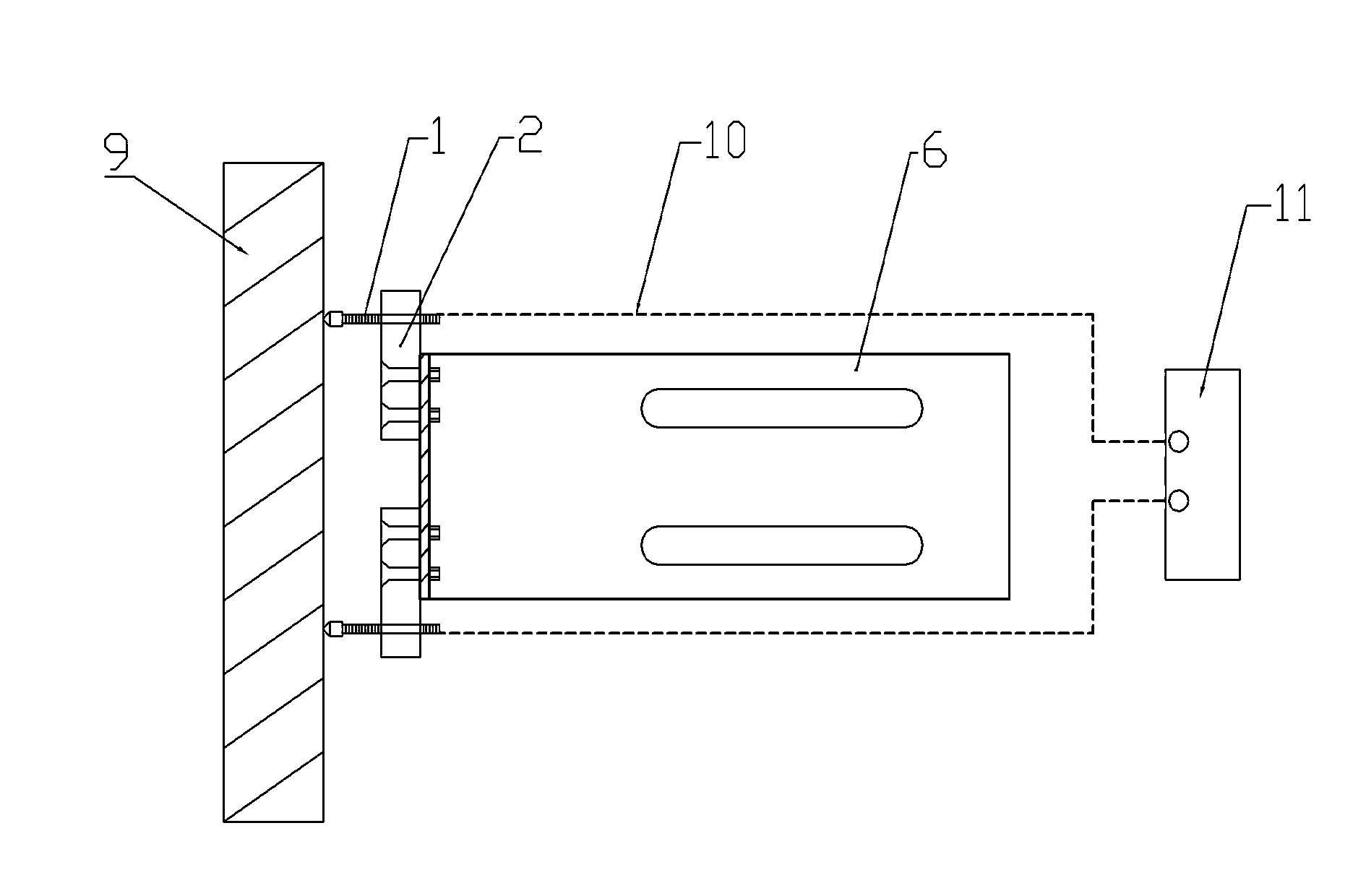

[0018] Embodiment one: see figure 1 . The aluminum electrolytic cell anode voltage signal acquisition device of the present invention comprises a millivolt voltage measuring probe 1 and a millivolt voltage monitoring bracket 6, the millivolt voltage monitoring bracket 6 is a strip plate, and one end (or both ends thereof) is provided There is a folded part 7, and the folded part 7 is provided with a strip-shaped insulating plate fixing hole, and the folded part at one end is fixed and installed with the insulating plate 2 through the insulating plate fixing hole, and two millivolt voltage measuring probes 1 is installed on the insulating board 2.

[0019] For the convenience of installation, the anode voltage signal acquisition device of the aluminum electrolytic cell is provided with upper and lower front and rear distance adjustment holes 5 parallel to the middle of the millivolt voltage monitoring bracket 6 .

Embodiment 2

[0020] Embodiment two: see figure 1 . The aluminum electrolytic cell anode voltage signal acquisition device of this embodiment is different from Embodiment 1 in that further, the insulating plate 2 adopts a strip-shaped high-temperature-resistant insulating plate, on which there are countersunk screw holes, through which the The head screw is fixed on the folded part of one end of the millivolt voltage monitoring bracket 6, and a probe fixing hole is respectively arranged at both ends of the high temperature resistant insulating board, and two millivolt voltage measuring probes are installed on the probe respectively. In the needle fixing hole, the distance between the two millivolt voltage measuring probes is between 100 and 150mm.

Embodiment 3

[0021] Embodiment three: see figure 1 . The aluminum electrolytic cell anode voltage signal acquisition device of this embodiment is different from Embodiment 1 in that two insulating plates 2 are used, which are respectively fixed at both ends of the folded part 7 at one end of the millivolt voltage monitoring support 6, and each insulating plate There are countersunk screw holes for fixing the insulating plate and the folded edge part, and a probe fixing hole for installing the millivolt voltage measurement probe; the distance between the two millivolt voltage measurement probes is 100 Between ~150mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com