Patents

Literature

63results about How to "Improve slitting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

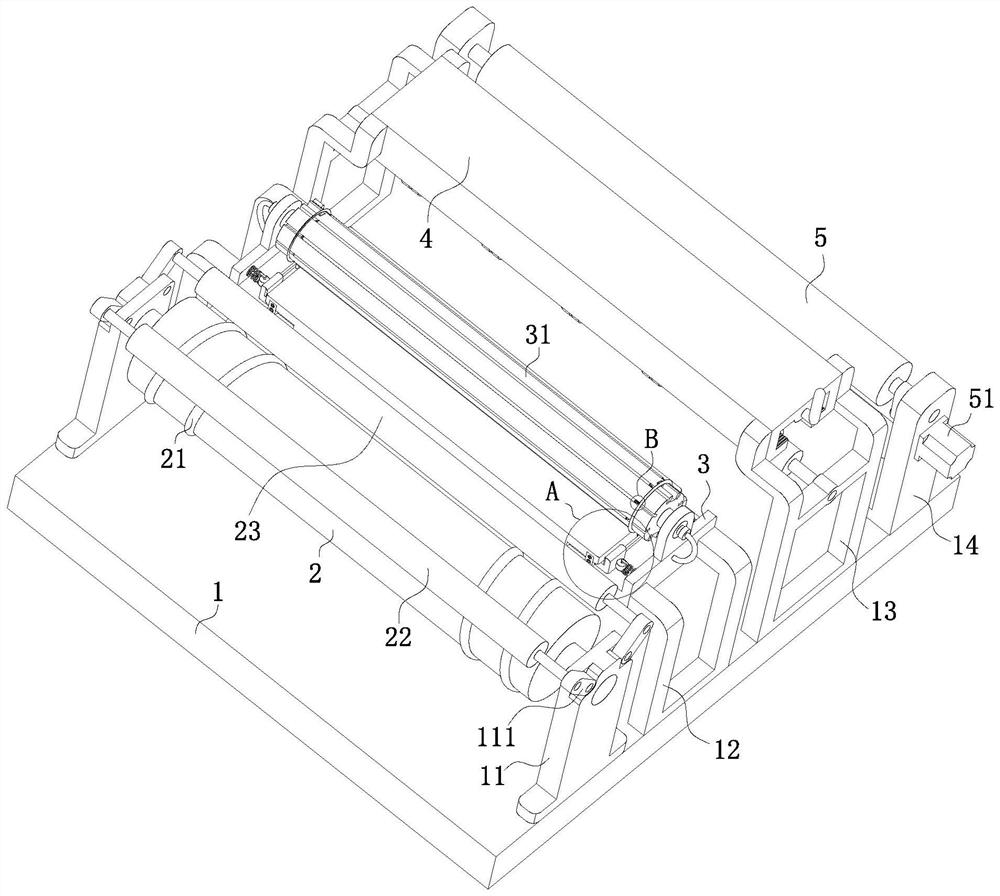

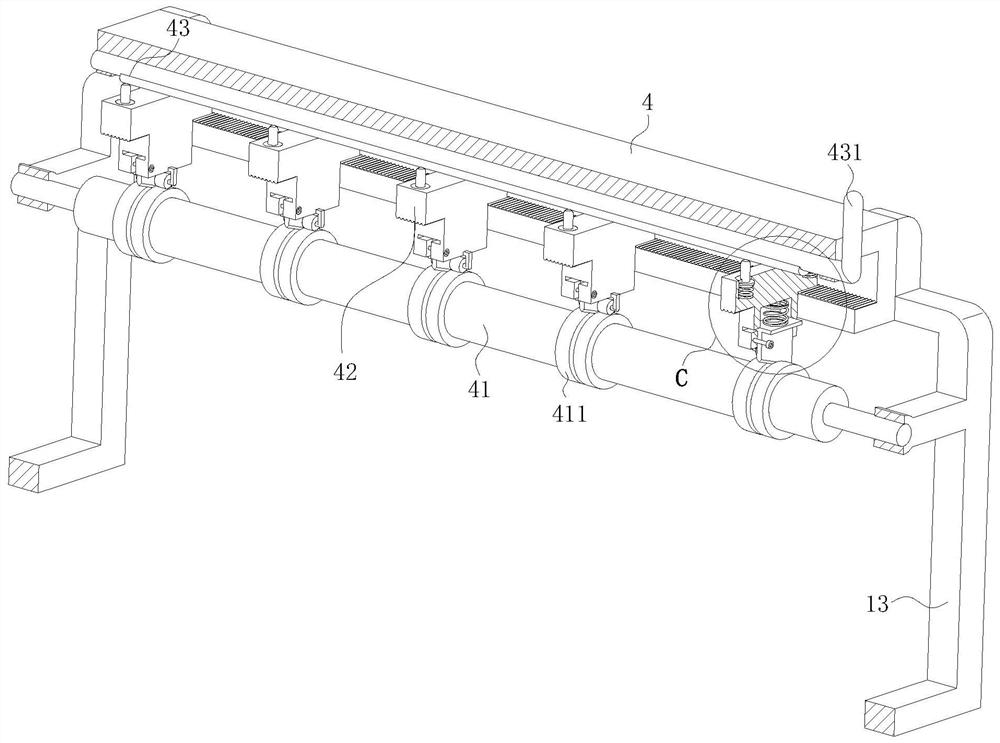

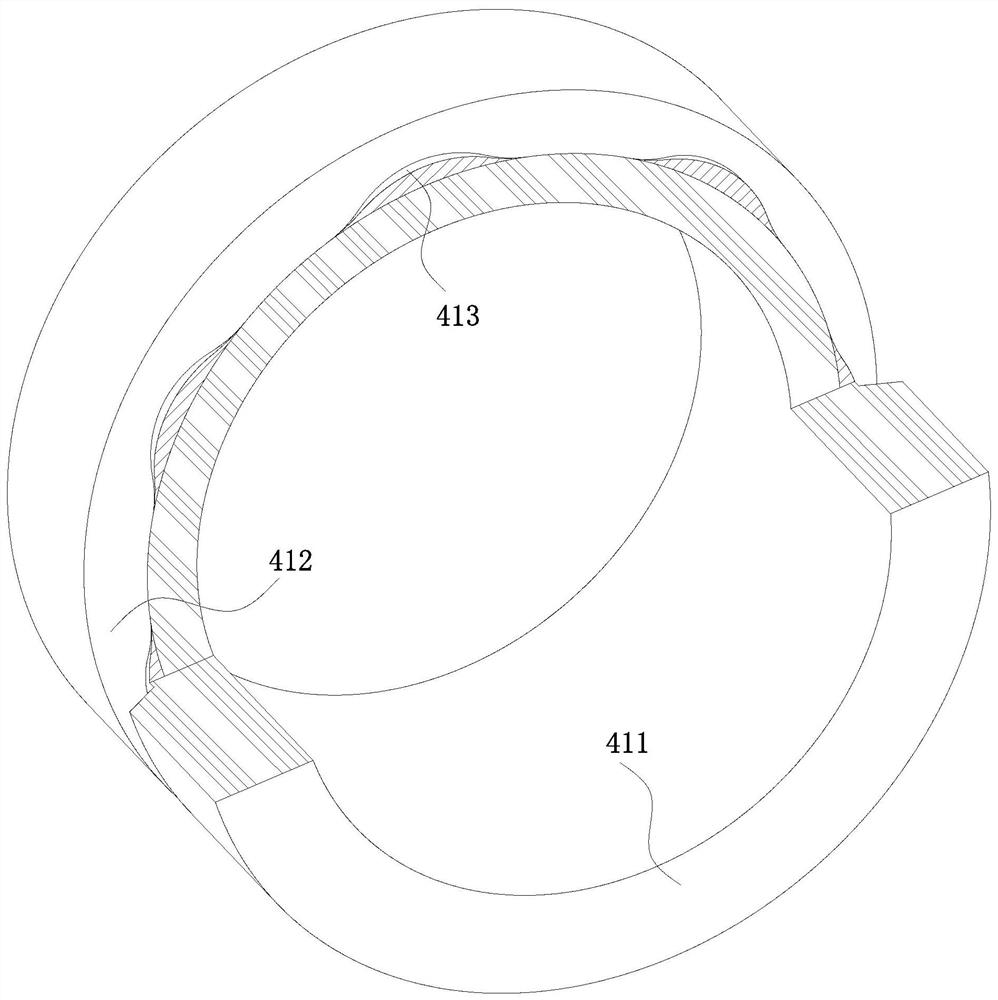

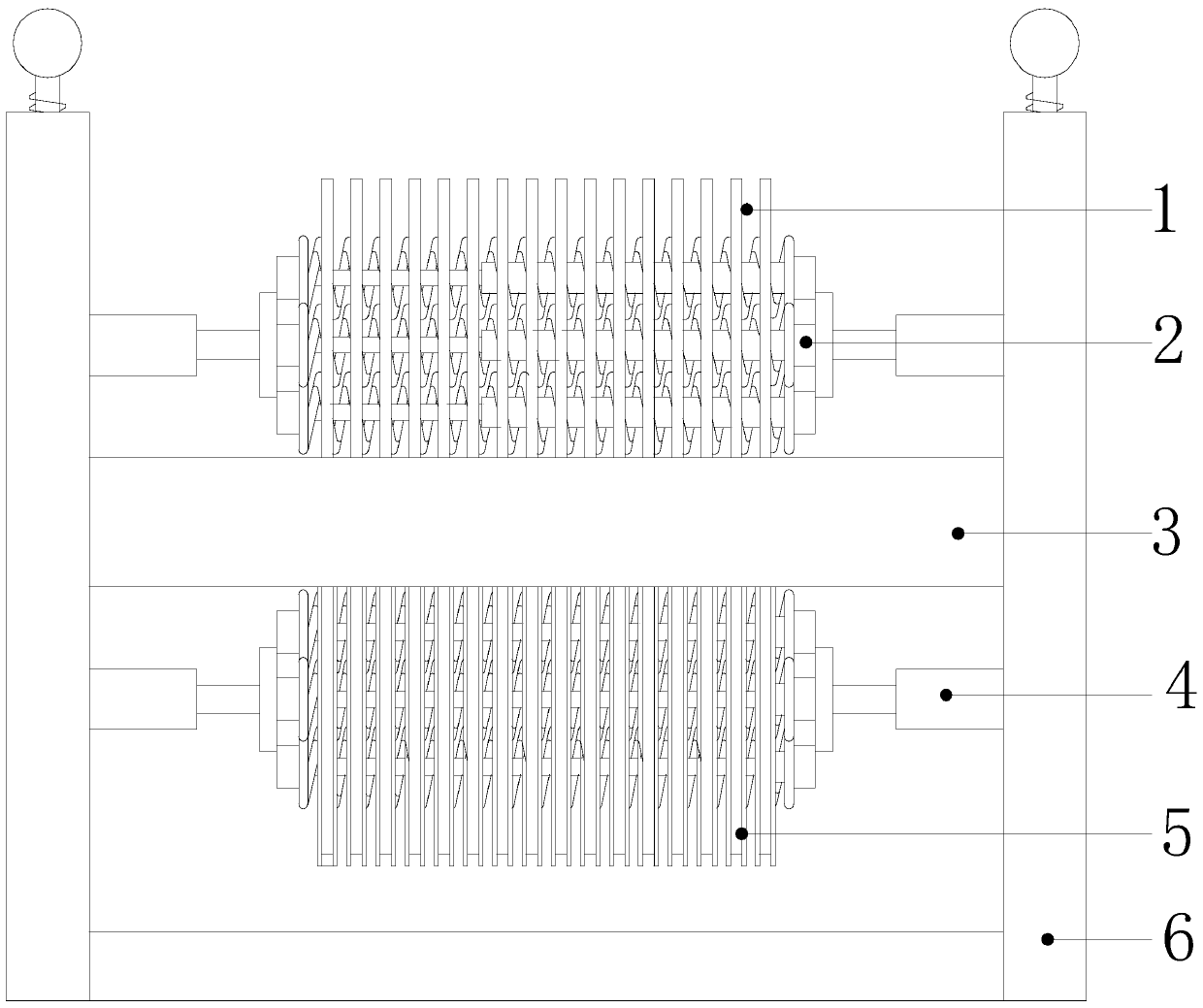

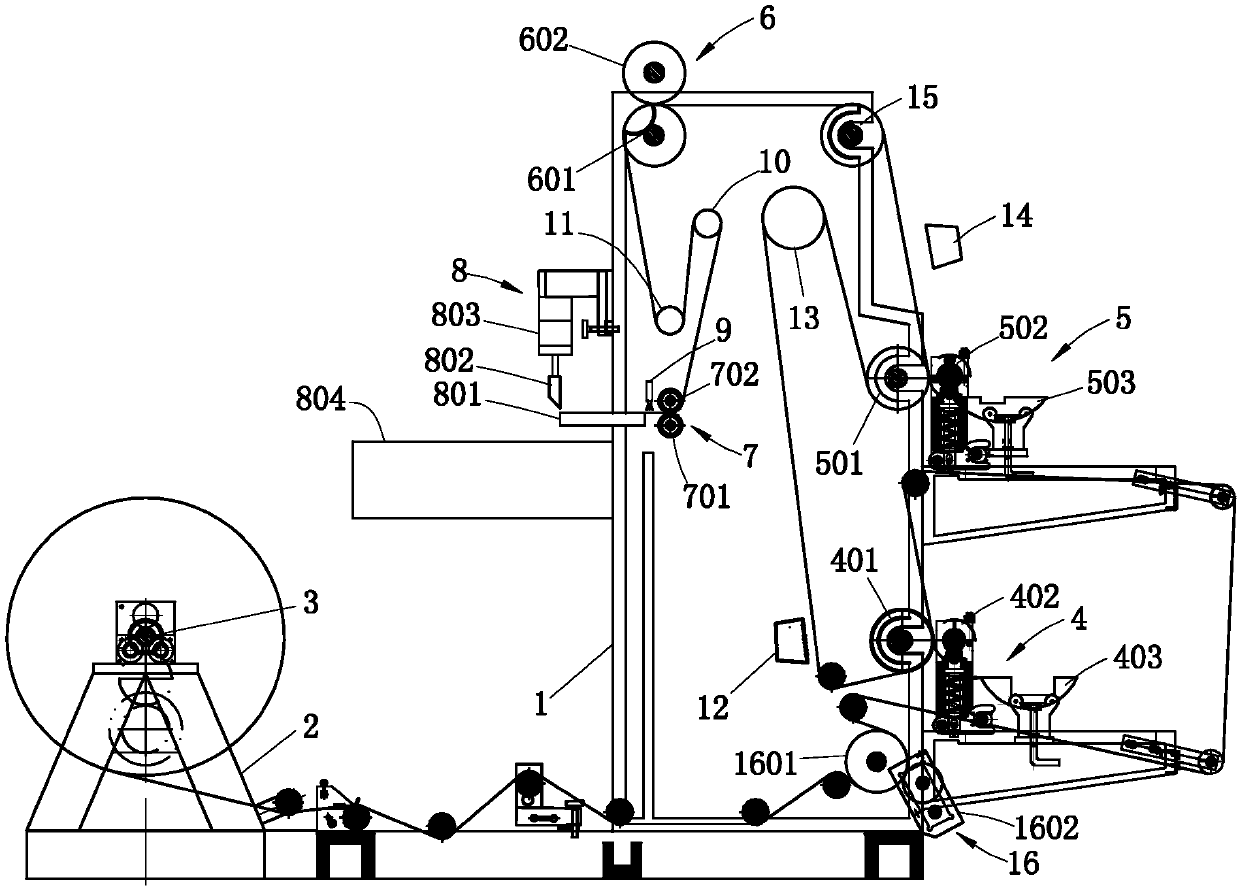

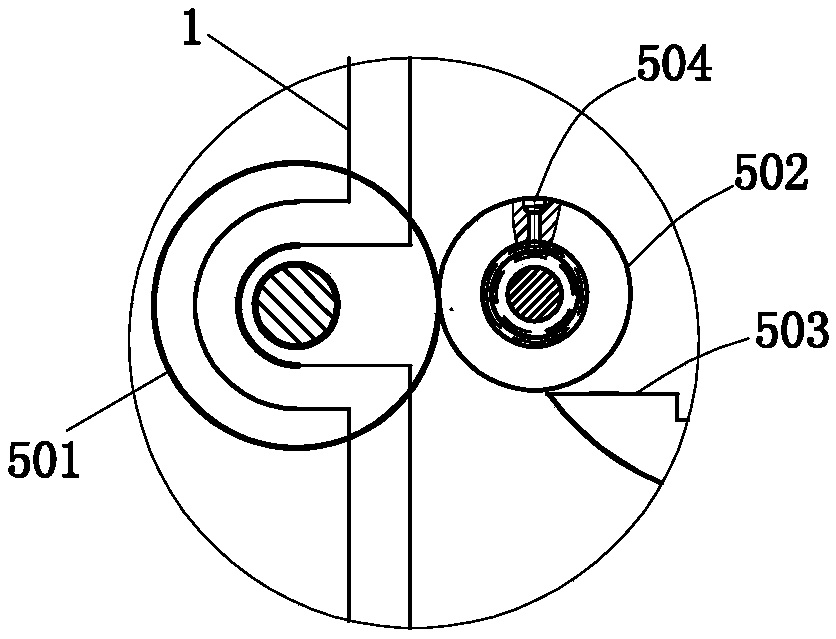

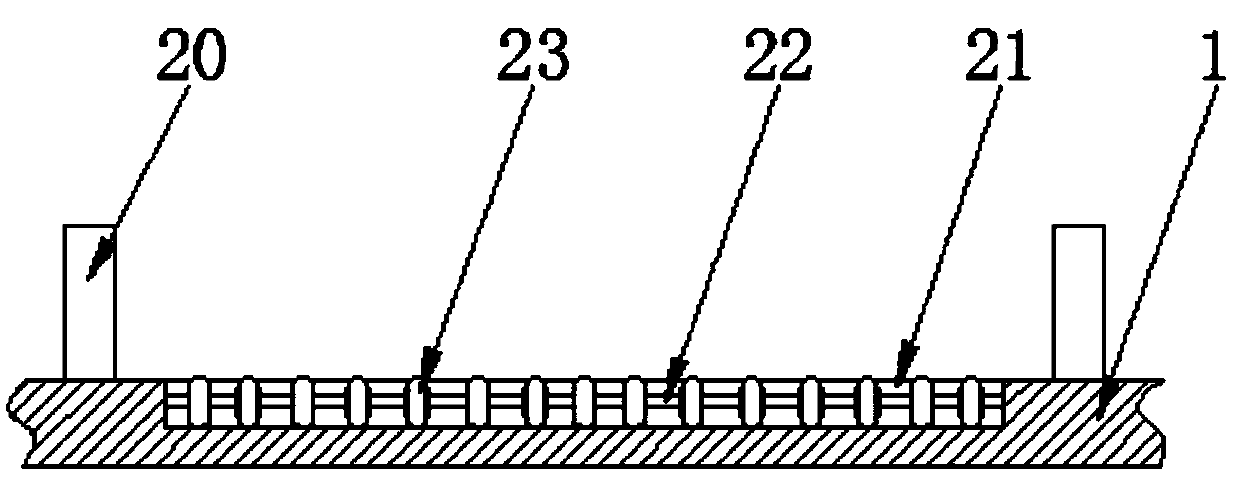

Automatic slitting machine for auxiliary material of flexible circuit board

The invention provides an automatic slitting machine for an auxiliary material of a flexible circuit board. A slitting mechanism of the automatic slitting machine comprises a cutter shaft and cutter sets, wherein the cutter shaft can penetrate through the cutter sets to be connected with the cutter sets. The cutter sets comprise the upper cutter set and the lower cutter set. The upper cutter set is composed of a plurality of cutter set units and ring-shaped upper gaskets, wherein each ring-shaped upper gasket is arranged between two adjacent cutter set units, and each cutter set unit comprises a clamping base, an upper annular circular cutter and a snap ring. The lower cutter set is composed of a plurality of lower annular circular cutters and ring-shaped lower gaskets, wherein each ring-shaped lower gasket is arranged between two adjacent lower annular circular cutters. When the upper cutter set and the lower cutter set are pressed tightly and respectively, cutting edges of the upper annular circular cutters correspond to cutting edges of the lower annular circular cutters in sequence so that each upper annular circular cutter and the corresponding lower annular circular cutter can be vertically attached to each other. According to the automatic slitting machine for the auxiliary material of the flexible circuit board, due to the facts that the upper cutter set of the slitting mechanism is provided with the cutter set units composed of the clamping bases, the upper annular circular cutters and the snap rings and the gaskets, and the upper cutter set is used in cooperation with the lower cutter set provided with the gaskets, the slitting accuracy is higher, and the material can be slit to the extent that the minimum width of the material is 5mm.

Owner:深圳市旗众智能科技有限公司

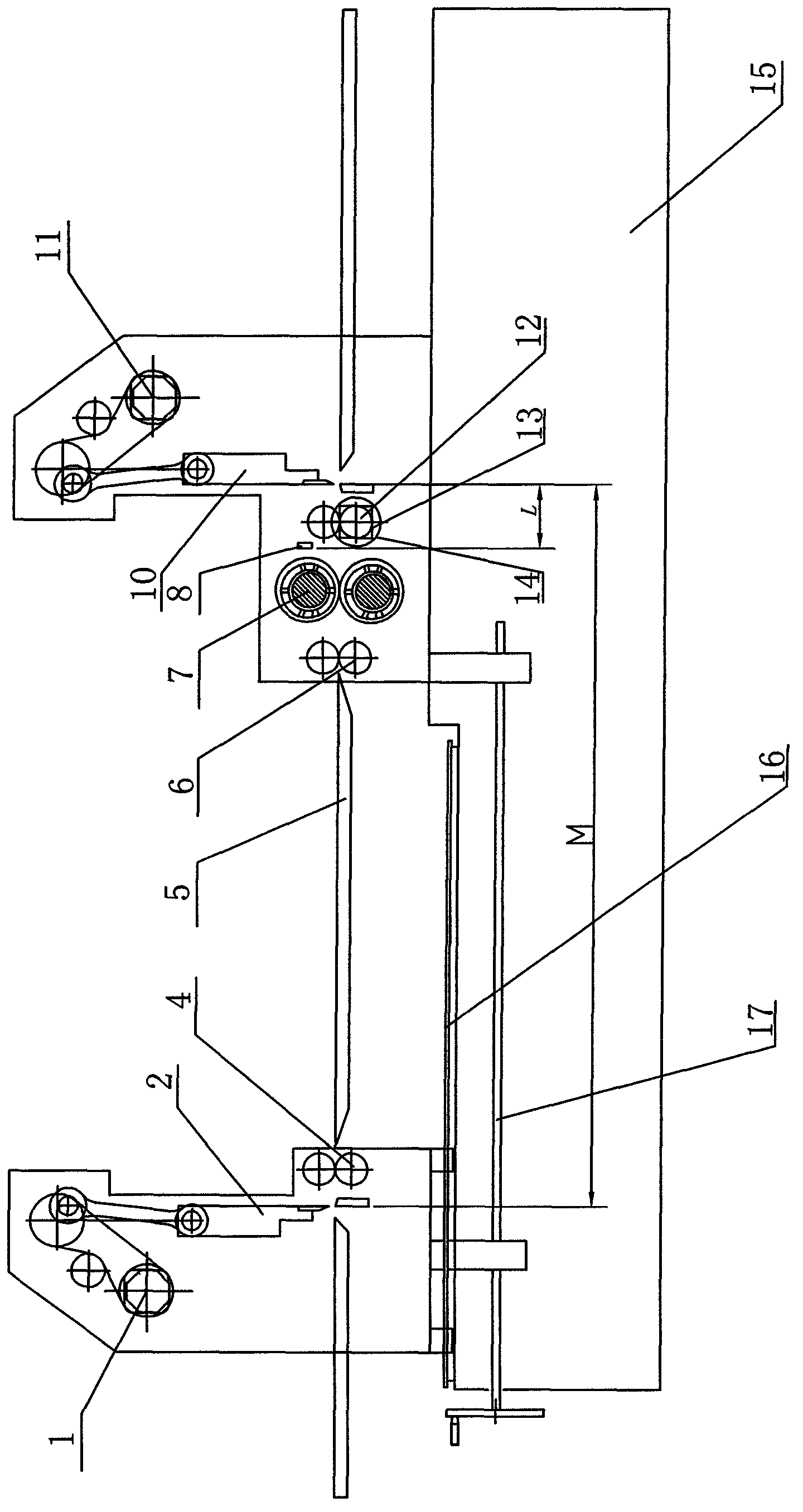

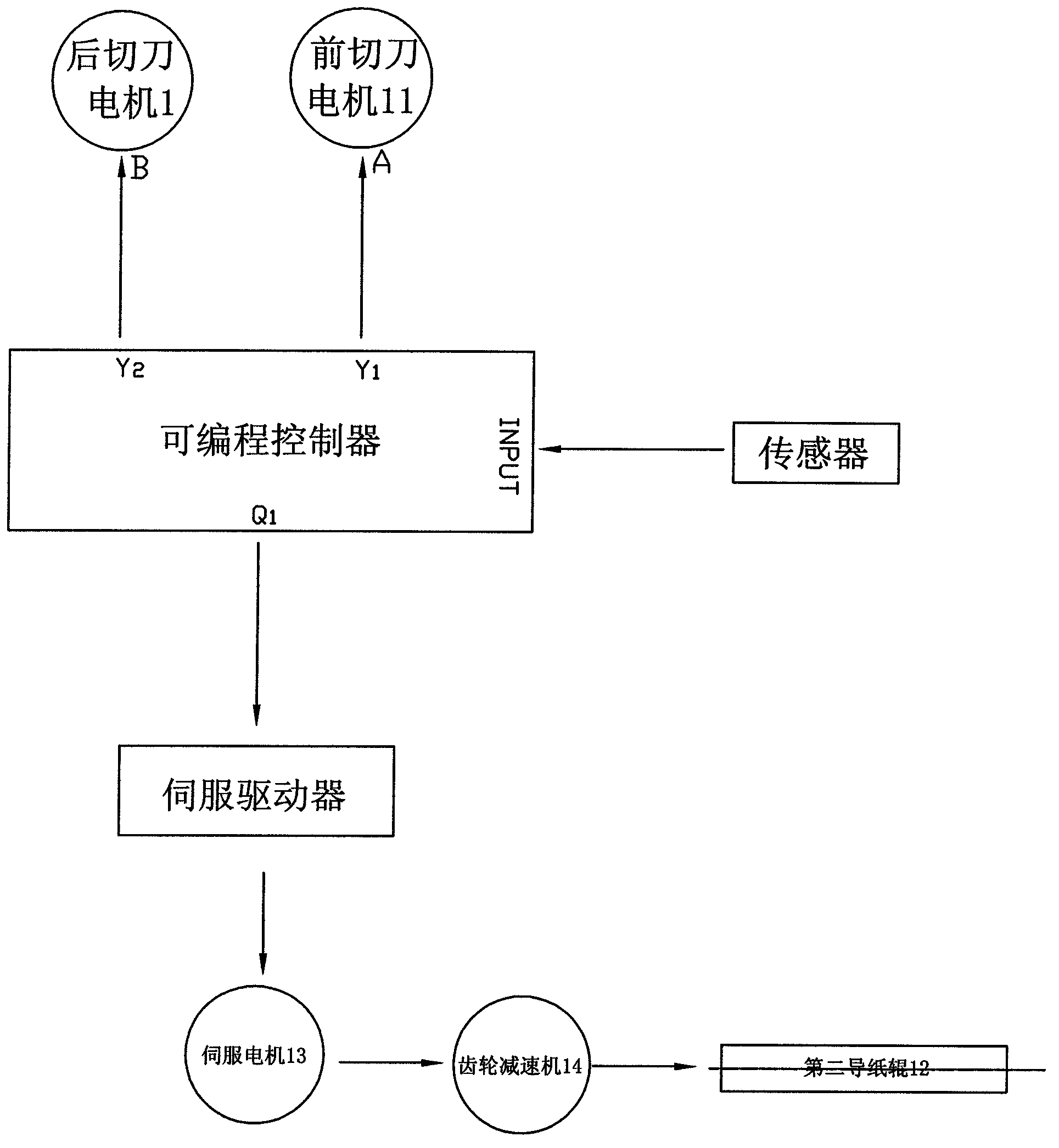

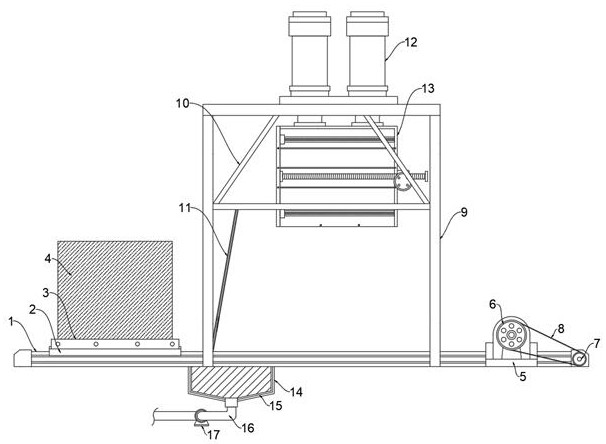

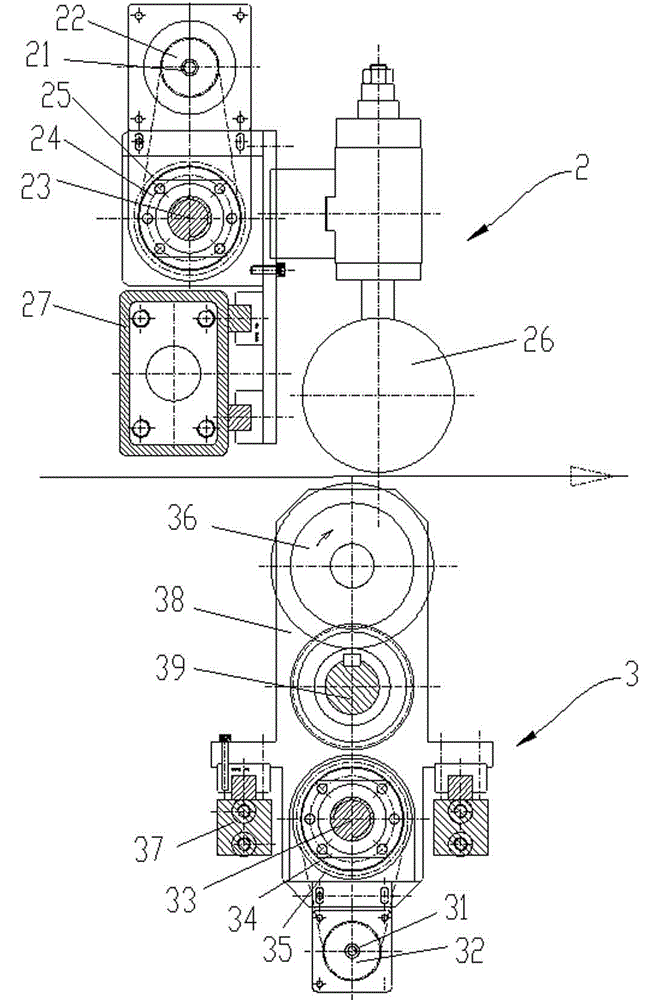

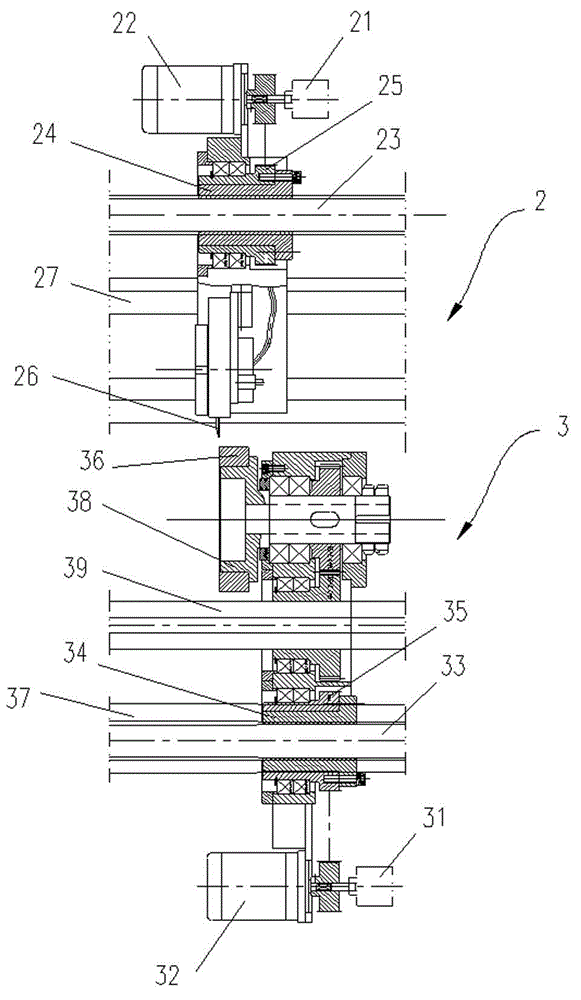

High-precision paperboard transverse and longitudinal slitting machine

ActiveCN103722587AHigh degree of automationImprove cutting efficiencyMetal working apparatusCardboardPulp and paper industry

The invention relates to paperboard slitting equipment, in particular to a high-precision paperboard transverse and longitudinal slitting machine. The high-precision paperboard transverse and longitudinal slitting machine comprises a longitudinal cutter assembly, a transverse slitting front cutter assembly, a transverse slitting rear cutter assembly, a second paper guide roller, a servo motor, a sensor and a programmable controller, wherein the transverse slitting front cutter assembly and the transverse slitting rear cutter assembly are arranged on the paper discharging side and the paper feeding side of the longitudinal cutter assembly respectively, the second paper guide roller is driven by the servo motor, the sensor is arranged at the paper feeding position of the second paper guide roller, the output end of the sensor is connected with the input end of the programmable controller, and corresponding output ends of the programmable controller are connected with the control end of the servo motor, the control end of a front cutter motor and the control end of a rear cutter motor respectively. The high-precision paperboard transverse and longitudinal slitting machine aims to achieve low waste of paperboard tailing, high working efficiency and high precision. Compared with the prior art, the high-precision paperboard transverse and longitudinal slitting machine has the advantages of being high in automation degree, capable of customizing the sizes of paperboards according to different requirements for small paperboards of customers, reducing material loss of paperboards, and meanwhile solves the problem that existing paperboard slitting machines are unsuitable for slitting narrow paperboards.

Owner:温州市本色机械有限公司

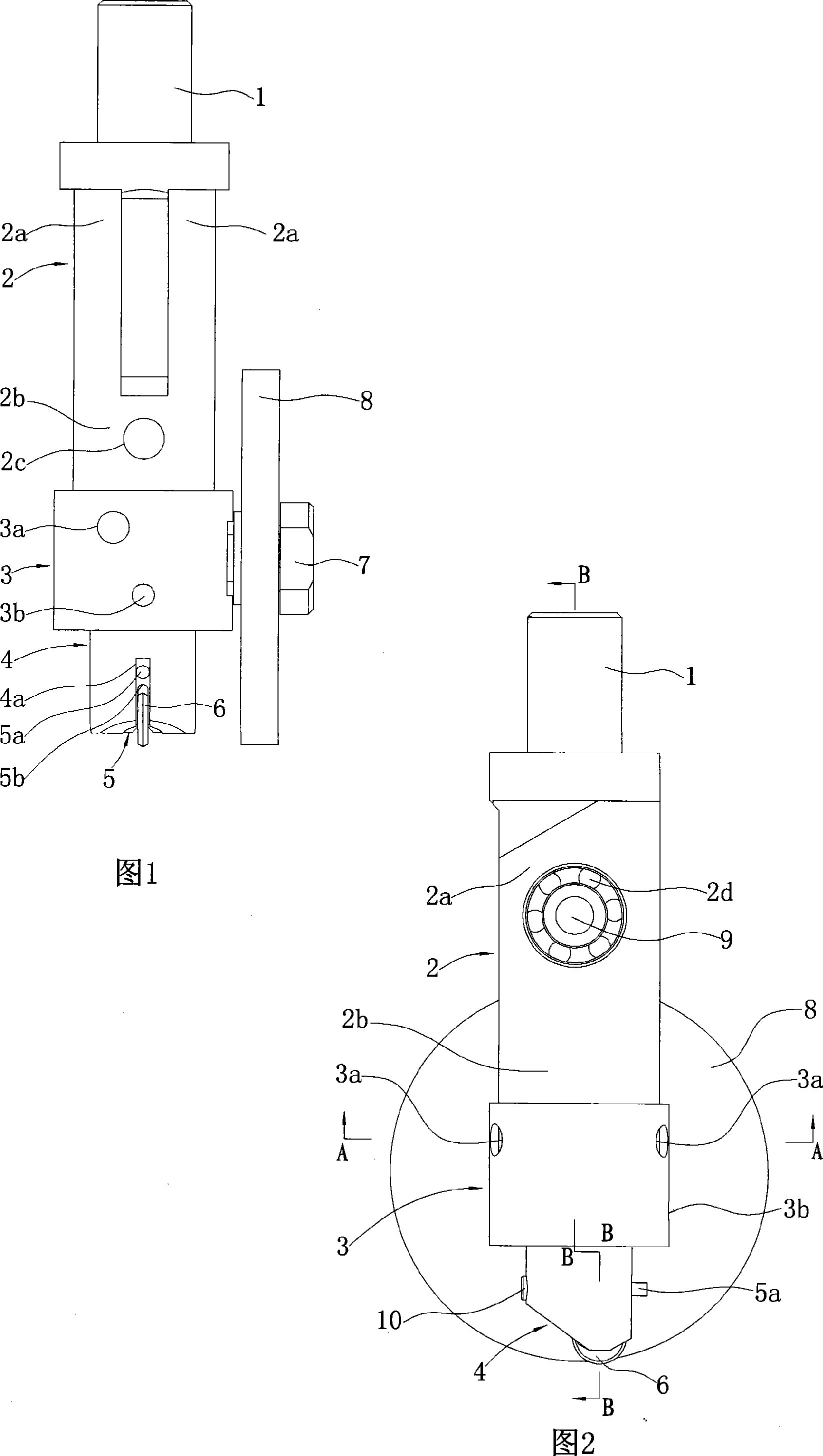

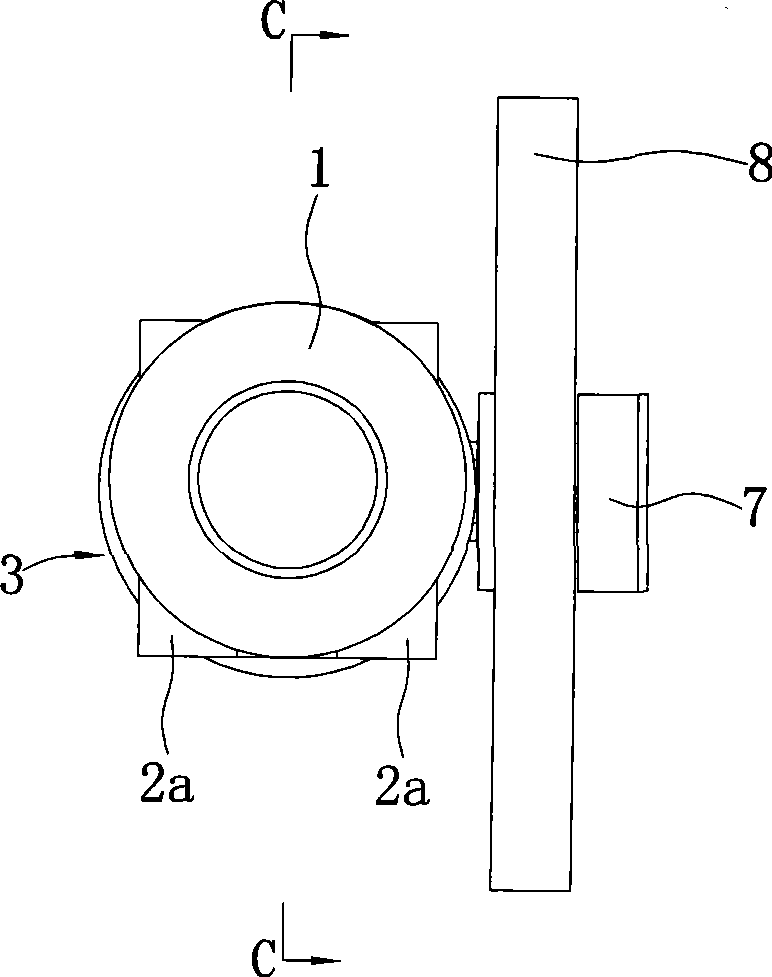

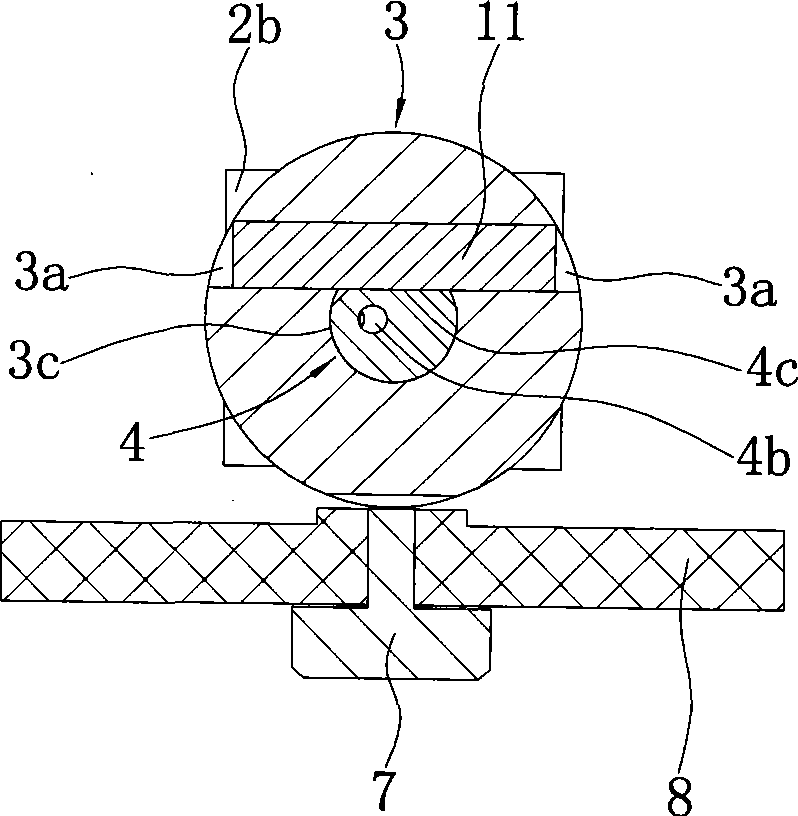

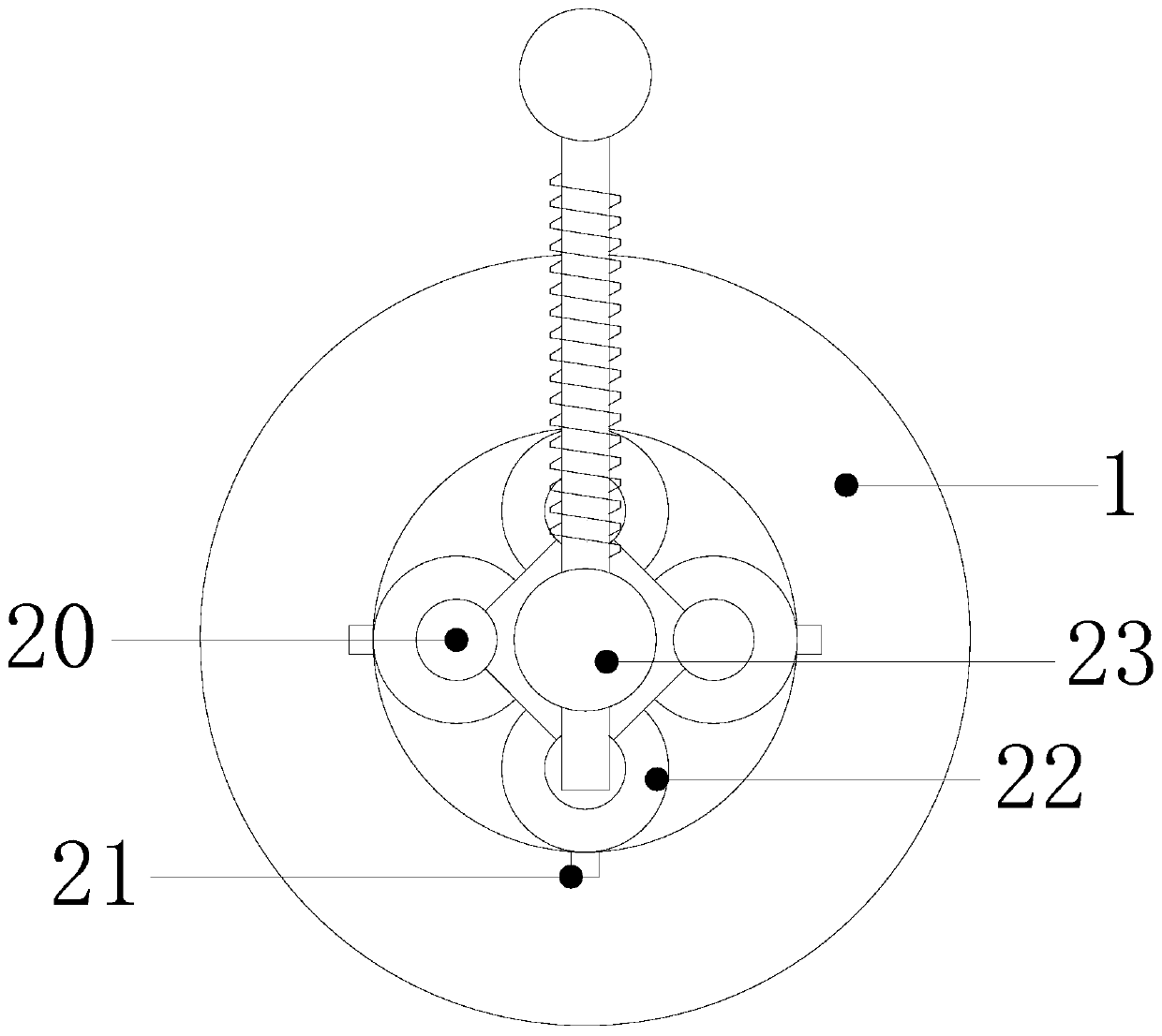

Precision glass cutting-table tool bit assembly

InactiveCN101423326AImprove slitting accuracyThere will be no bursting phenomenonGlass severing apparatusEngineeringScrew thread

The invention provides a precision glass cutting table cutter head assembly, wherein the lower part of a swinging block is fixedly connected with a fixing column, the inside of the fixing column is provided with a step hole, and the inside of an opening on the lower end of the step hole is provided with a bearing; the middle part of the fixing column is penetrated along the height direction, and is eccentrically provided with two horizontal pin holes which are symmetrical to each other, the shaft line of each pin hole is vertical to the axial line of the fixing column and the axial line of a pin shaft, an interval is arranged between the axial lines of the pin hole and the fixing column, the outer end of each pin hole is positioned on the outer column surface of the fixing column, and the inner end of each pin hole is communicated with the step hole; the upper part of a rotary column is communicated with a horizontal penetration square groove, the upper part of the rotary column is in rotary fit with the step hole, the middle part of the rotary column is connected with the fixing column through the bearing, and the lower part of the rotary column is provided with a cutter holder with a cutting wheel; a control pin orderly runs through one pin hole, a square groove and the other pin hole and then is arranged between the fixing column and the rotary column; and the middle part of the fixing column in the height direction is in screw-thread fit with a bolt passing through the center of a nylon wheel. When the assembly is used, the maximum clockwise or counterclockwise rotary angle of the cutting wheel is 15 degrees. A cutter box adopting the assembly has high slitting precision.

Owner:ANHUI JINGLING GLASS MACHINERY

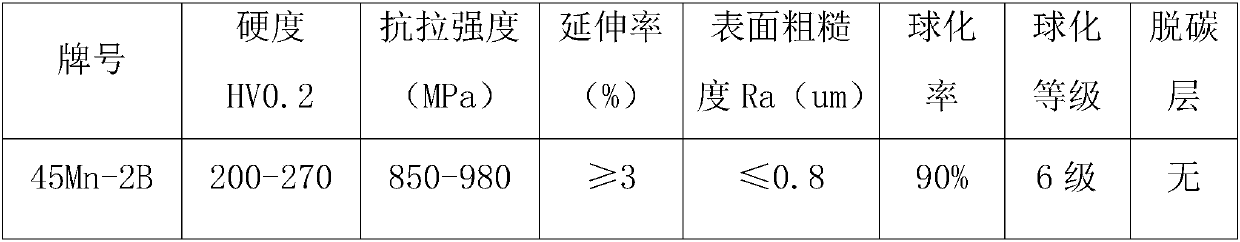

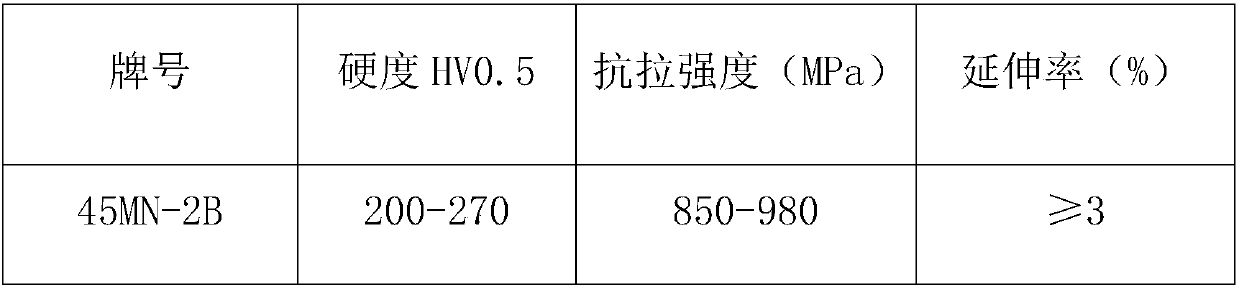

Wide steel strip for paper cutting blade and manufacturing method thereof

The invention provides a wide steel strip for a paper cutting blade. The wide steel strip is characterized in that the content of the chemical components of the steel comprises, by weight, 0.43%-0.47%of C, 0.17%-0.28% of Si, 0.7%-1.0% of Mn, 0-0.035% of P, 0-0.035% of S, 0.15%-0.3% of Cr, and the balance Fe; and the thickness of the wide steel strip 0.45-1.42mm, the width is 23-35 mm. According to the wide steel strip for the paper cutting blade, through repeated testing and trial, requirements of the steel for the paper cutting blade for the strength, the hardness, the size precision, the straightness and the quality requirement of the spheroidized structure can be completely met, and the wide steel strip has been favored by customers at present; and due to the fact that the developmentprospect of the cold-rolled wide steel strip for the paper cutting blade is very wide, the wide steel strip has great popularization and application values and is quite wide in prospect.

Owner:浙江龙盛薄板有限公司

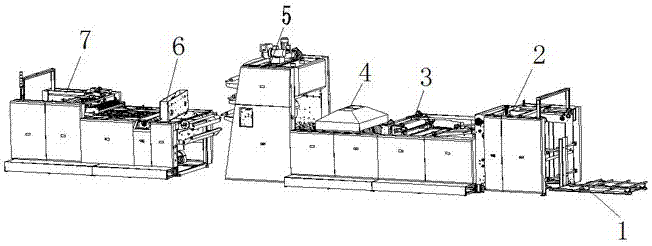

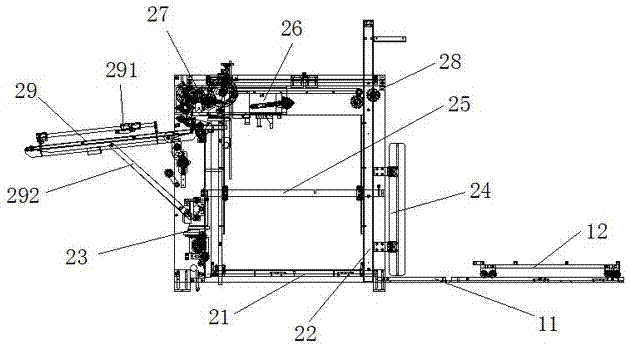

Windowing film laminating machine

InactiveCN107097520ALeveling and adjusting balanceImprove flatnessPrinting press partsFully automaticAutomation

The invention discloses a windowing film laminating machine comprising a pre-folded paper feeding frame, a paper conveying mechanism, a glazing oil head mechanism, a drying mechanism, a film laminating main machine, a chain cutter paper cutting mechanism and a paper collecting mechanism. Fully-automatic feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting of paper can be integrated together; the film laminating machine conducts operation automatically in the whole process, and the automation operation degree is high; a servo motor is adopted to drive the glazing oil head mechanism to smear glue on the paper, so that the whole machine conducts a series operation of feeding, conveying, glue smearing, drying, film sticking and pressurizing, cutting and collecting and the like on the paper with the consistent speed, and accordingly the high precision and good effect of glue smearing, film sticking and cutting of the paper, using is convenient and rapid, the cost is low, and the windowing film laminating machine is especially suitable for paper with a window; and the problems that labor strength is large, and the labor cost is high due to the fact that the paper is subjected to traditional manual operation of glue smearing, film sticking, cutting and the like are solved.

Owner:广东鑫佳机械科技有限公司

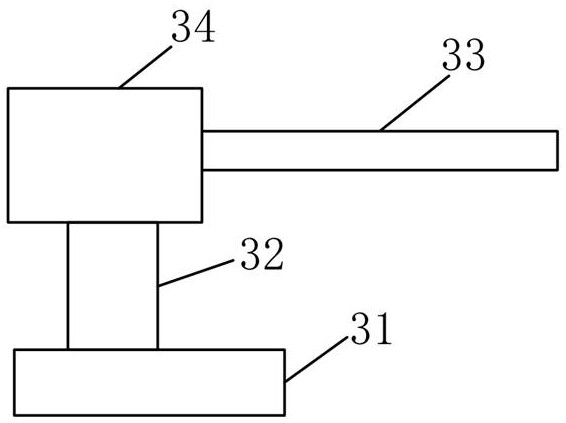

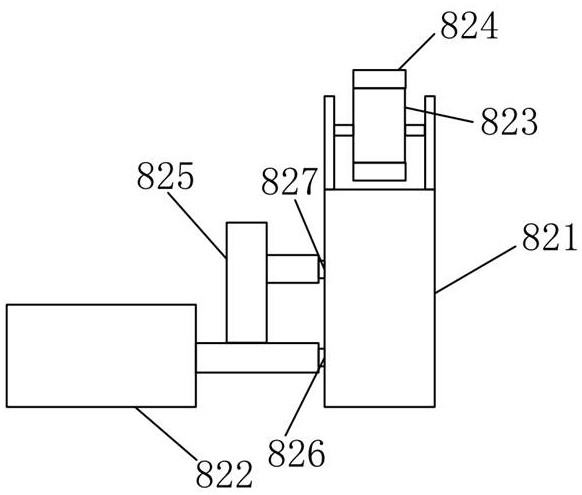

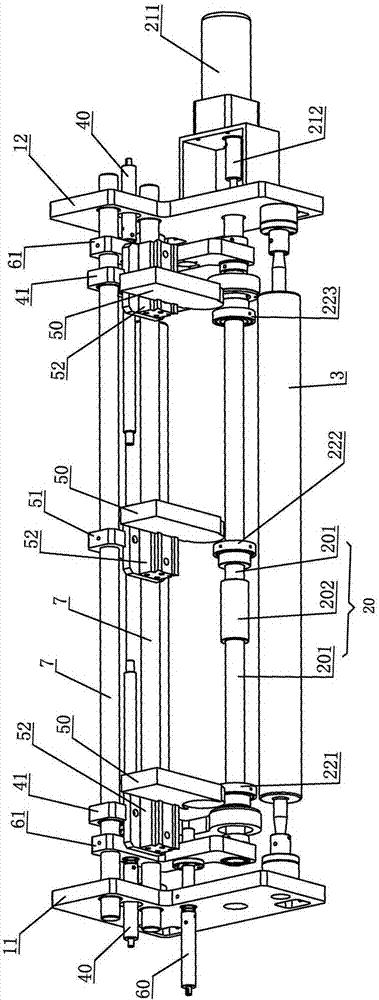

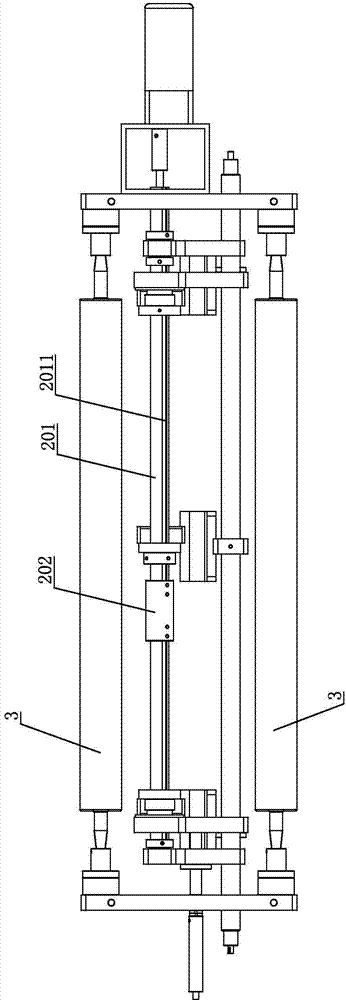

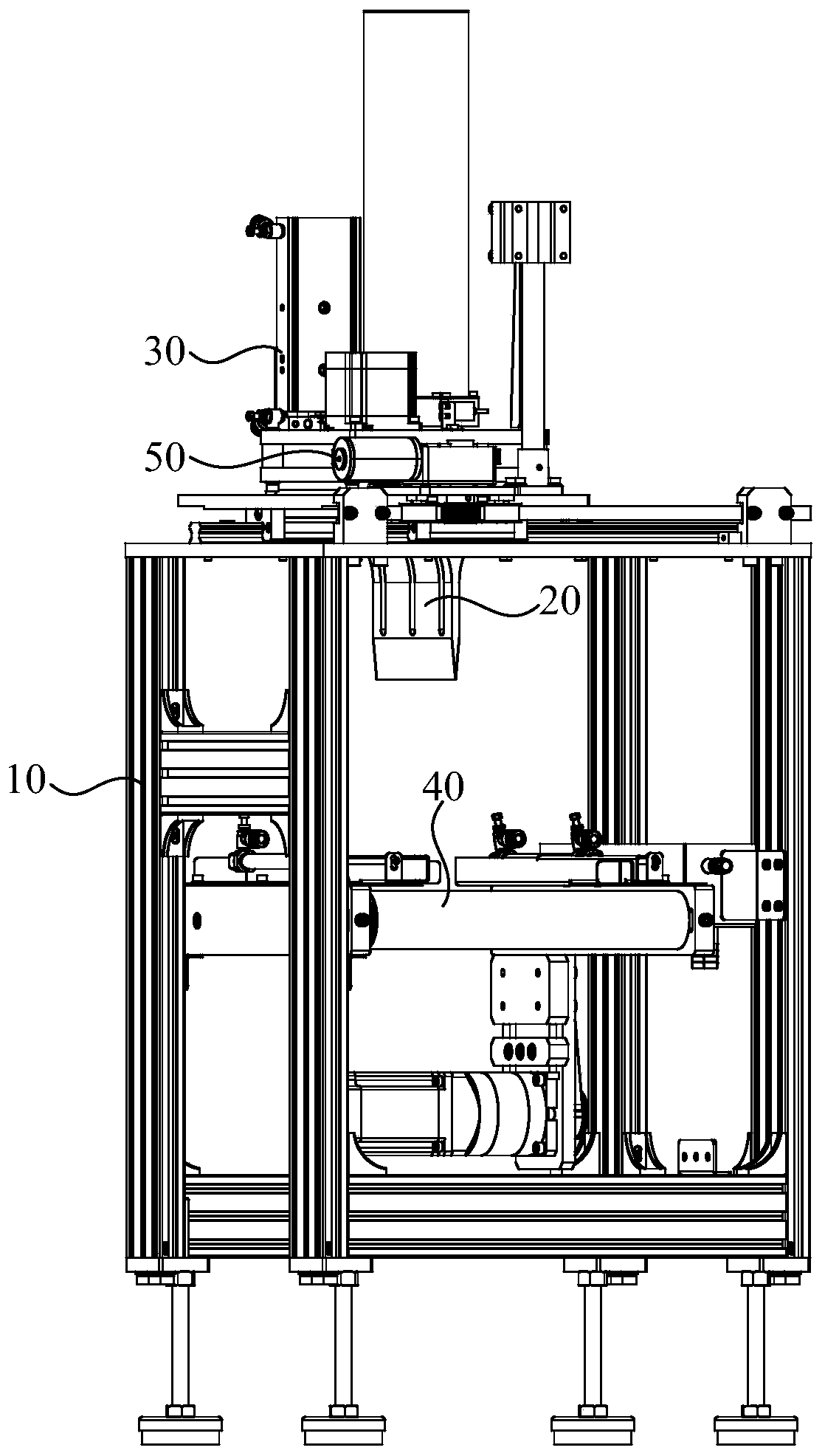

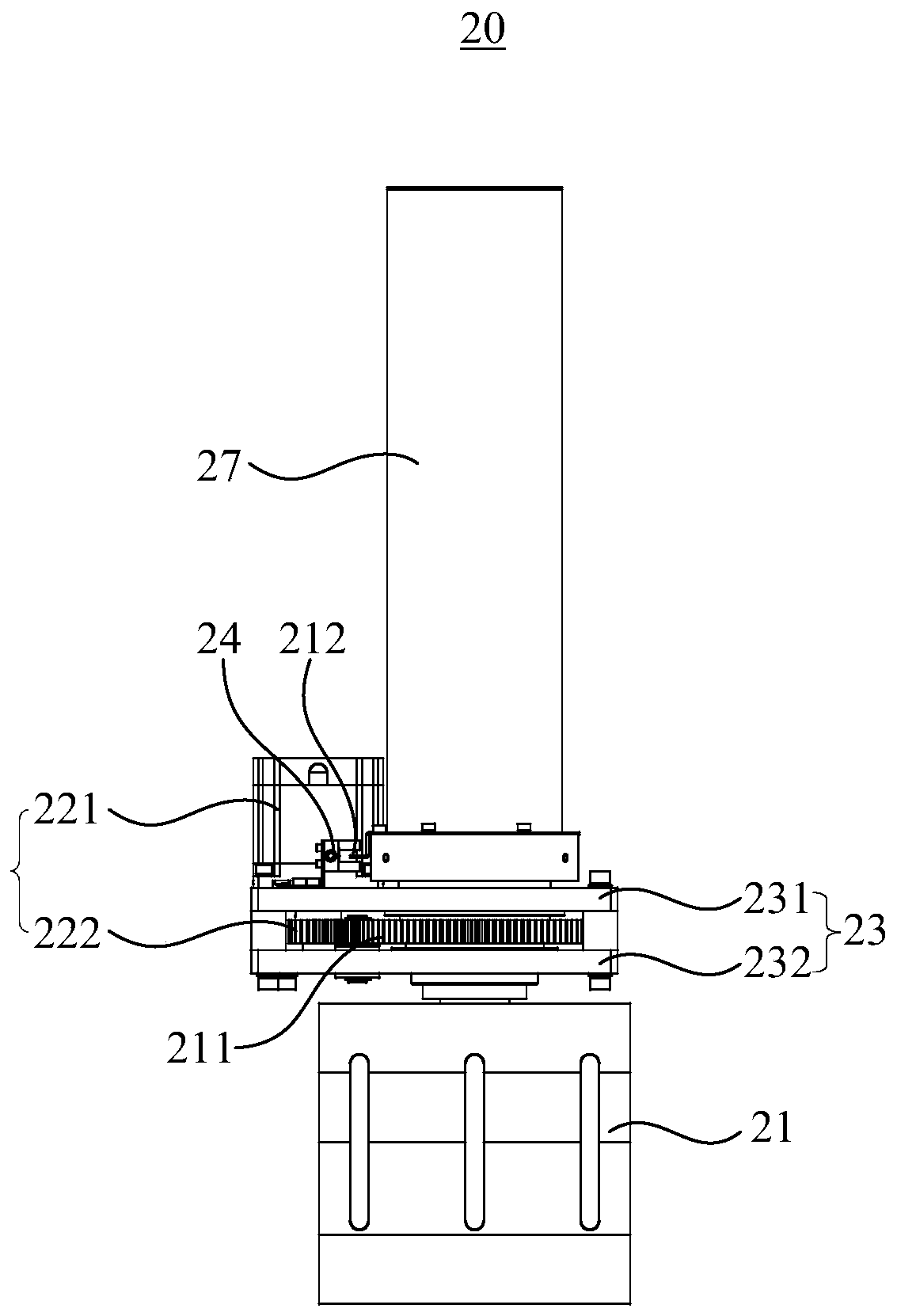

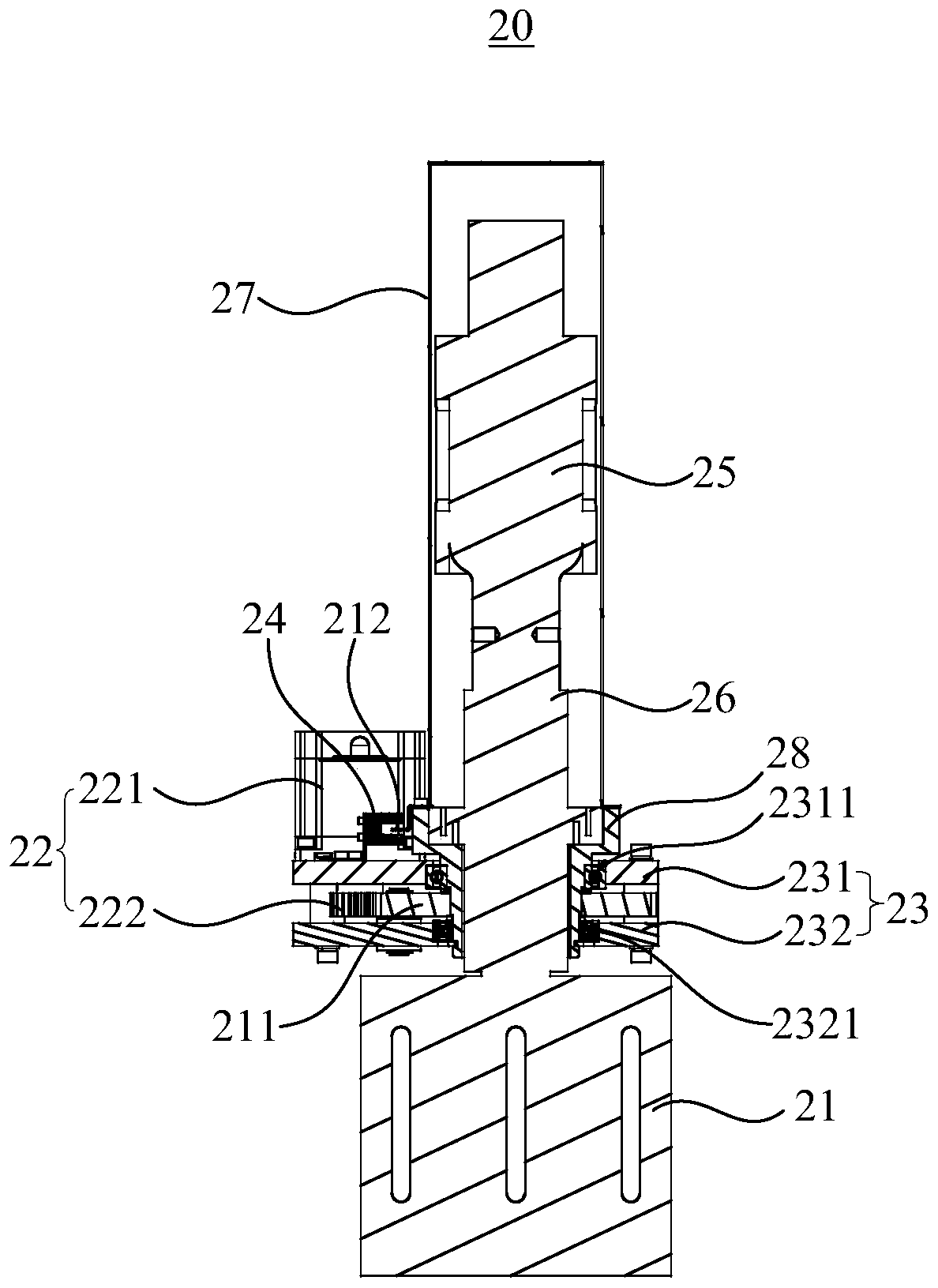

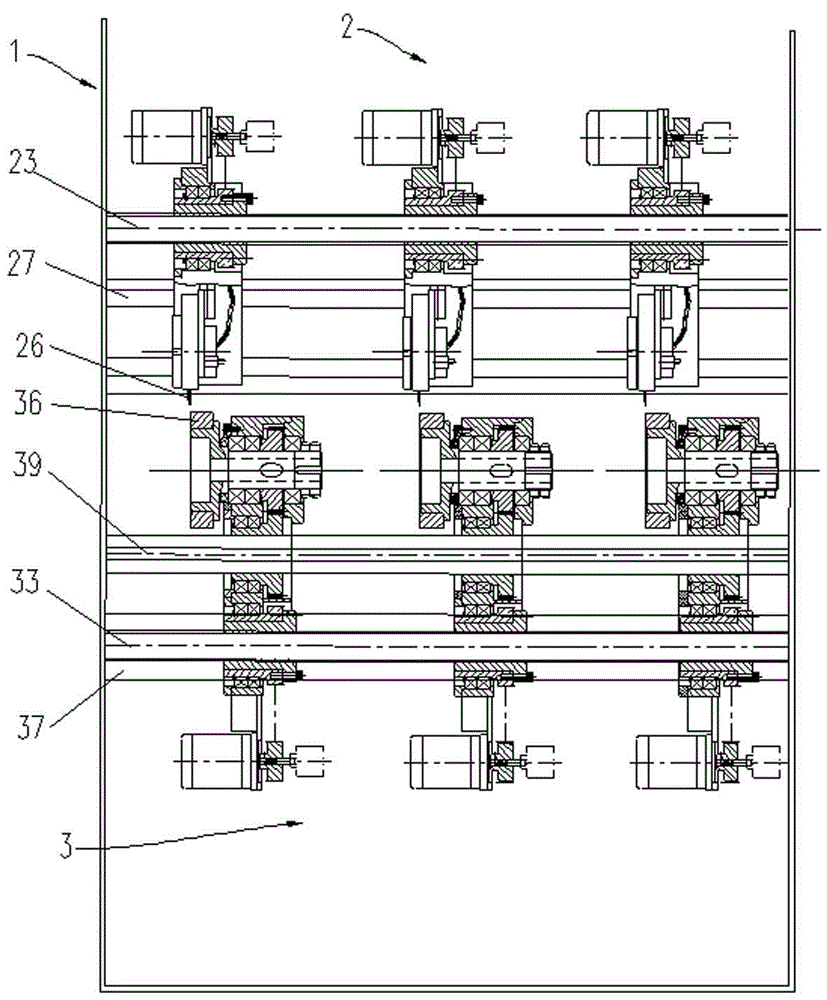

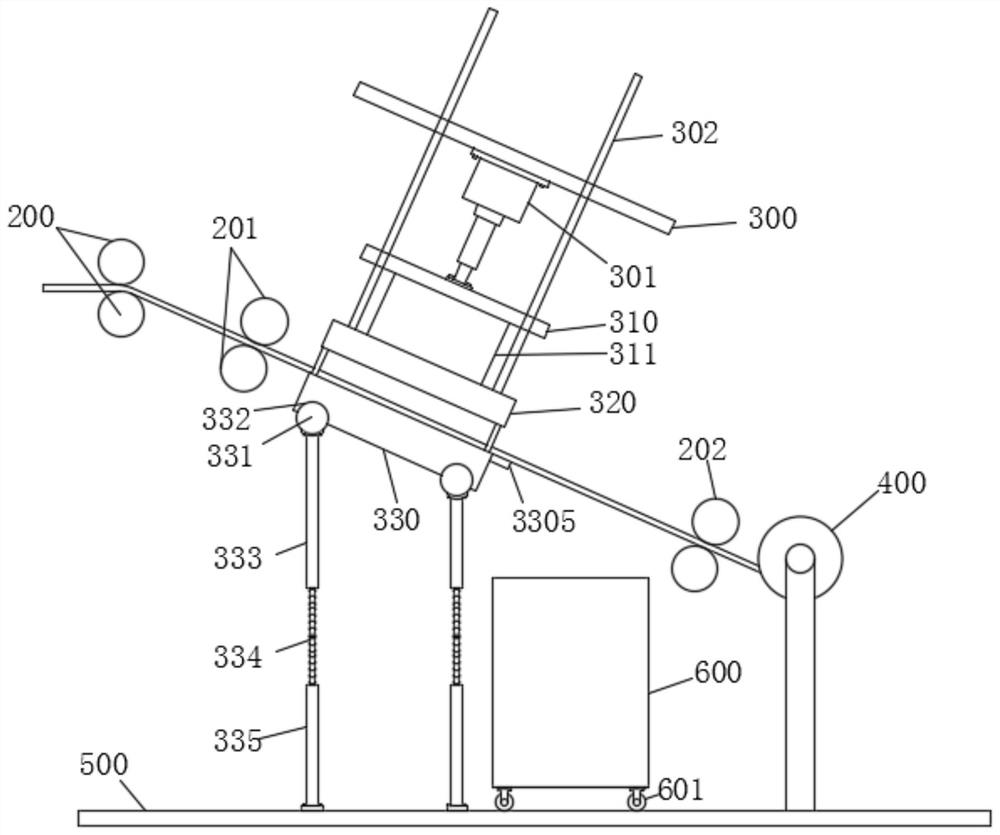

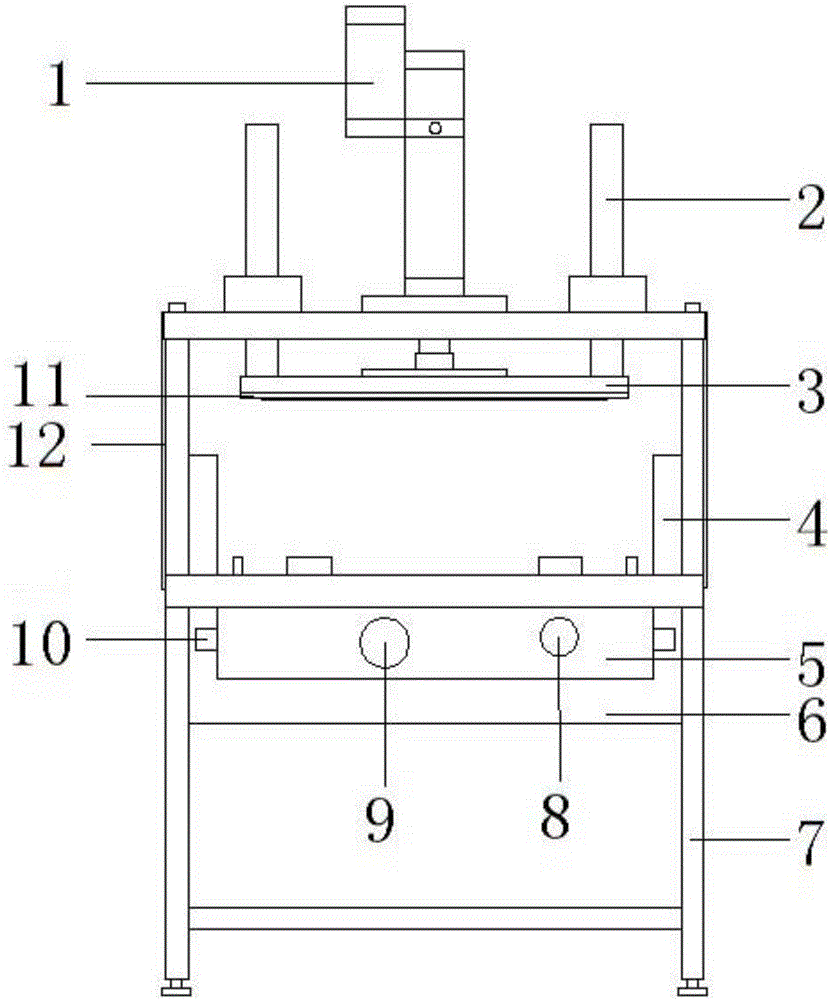

Semiconductor chip wafer rod transferring and slitting device

InactiveCN113276296AEasy to transfer and loadImprove slitting accuracyFine working devicesCircular discSemiconductor chip

Disclosed is a semiconductor chip wafer rod transferring and slitting device. The device comprises: a supporting body, wherein the supporting body comprises a cabinet body, and the two sides of the lower end of the cabinet body are each provided with a pair of adjusting mechanisms; a feeding assembly, arranged at one end of the supporting body and comprising an upward moving mechanism, wherein the upward moving mechanism is provided with a pair of placing mechanisms; a transferring assembly, arranged at the upper end of the supporting body and comprising a translation mechanism, wherein the translation mechanism is provided with a pair of lifting mechanisms, and clamping mechanisms are arranged at the lower ends of the lifting mechanisms; a clamping assembly, arranged at the upper end of the supporting body and comprising a lower clamping component, wherein a downward pressing mechanism is arranged on one side of the lower clamping component, a turnover mechanism is arranged at the upper end of the downward pressing mechanism, and an upper clamping component is installed on the turnover mechanism; and a slitting assembly, arranged at the upper end of the supporting body and comprising a feeding mechanism, wherein the feeding mechanism is provided with a slitting mechanism. According to the device, the cutting operation of a wafer rod is facilitated, the cutting automation degree, the cutting efficiency and the cutting precision of the wafer rod are improved, the automatic transfer of the wafer rod is facilitated, the clamping and positioning of the wafer rod are facilitated, and the cutting quality of a wafer disc is improved.

Owner:SICHUAN HONGXINWEI TECH

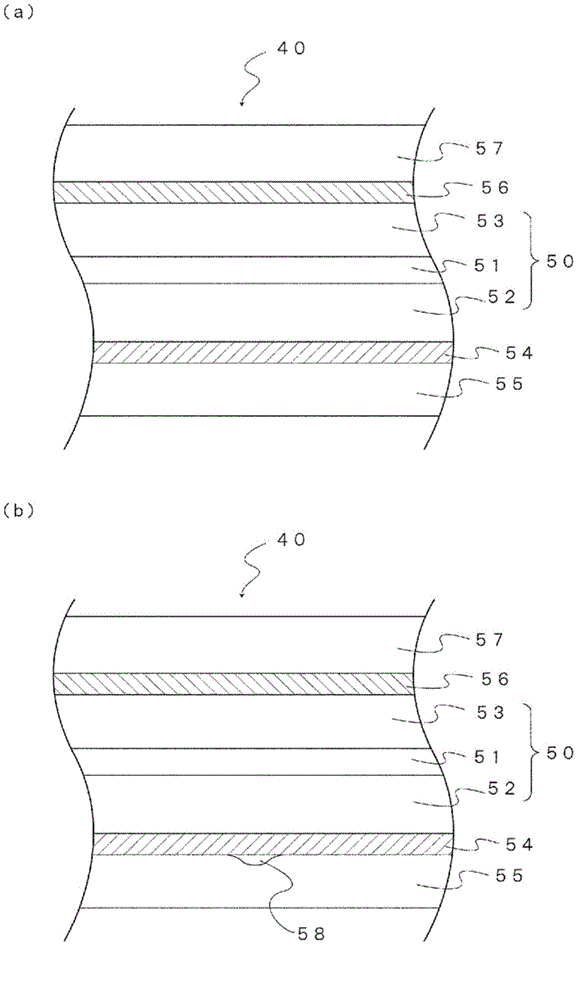

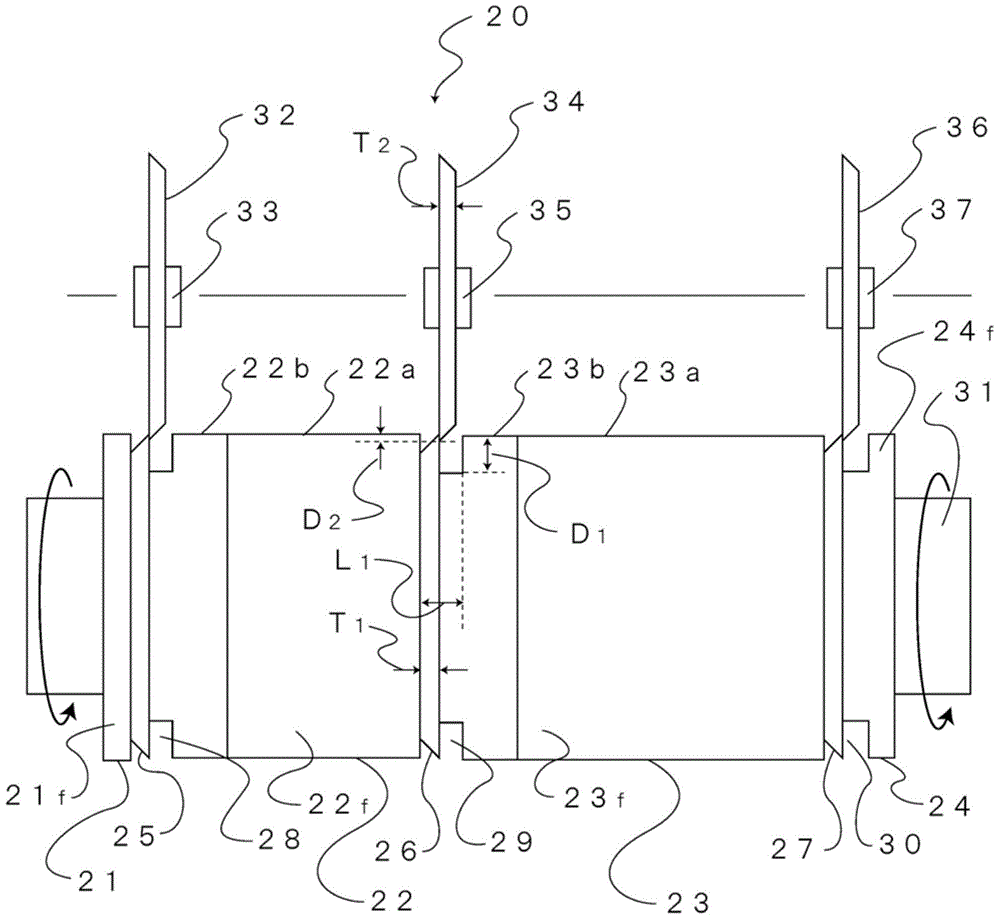

Device for forming optical film layer integrated bands, and method thereof

ActiveCN104972487AImprove uniformityInhibition of partial peelingMetal working apparatusEngineeringClosed angle

The invention provides a device for forming optical film layer integrated bands, and a method thereof, being able to improve the slitting precision of band-shaped optical film layer integrated body with high width and the uniformity of the facet shape at the end part of the highly slit band-shaped optical film layer integrated body. The device comprises a layer integrated body supporting roll, a plurality of first circular cutter knives and a plurality of second circular cutter knives. The layer integrated body supporting roll is provided with a peripheral surface connected with the optical film layer integrated body, and a plurality of grooves at the peripheral surface; each first circular cutter knife is provided with a closed angle point of a knife, and is arranged at the layer integrated body supporting roll and is arranged in each groove; and each second circular cutter knife is provided with a closed angle point of a knife, and is arranged at the position corresponding to the opposite side of the layer integrated body and the first circular cutter knife.

Owner:NITTO DENKO CORP

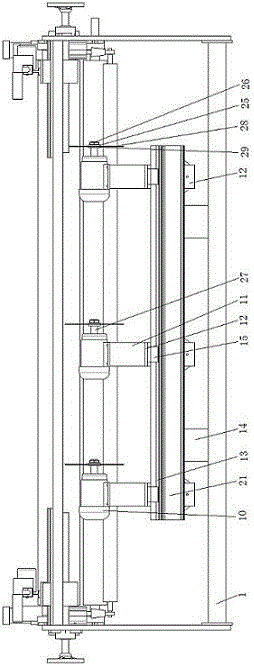

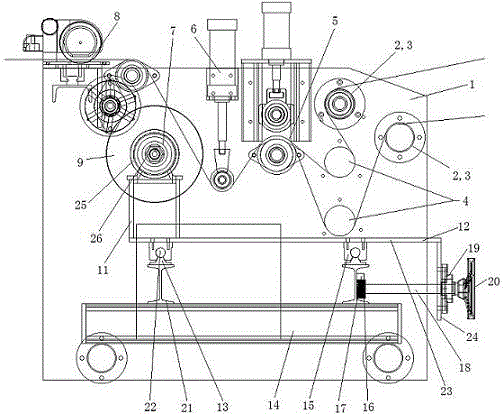

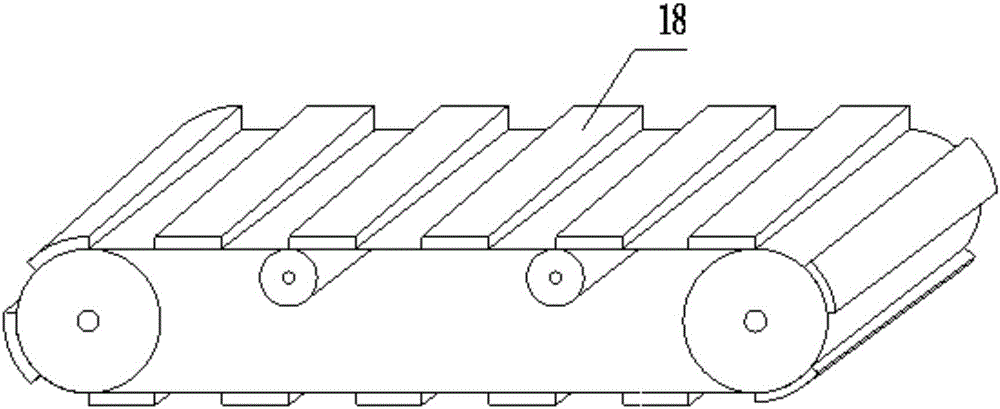

Lithium ion battery diaphragm cutting machine

ActiveCN106378818AMeet needsSimple structureSecondary cellsCell component detailsElectrical batteryPulp and paper industry

The invention discloses a lithium ion battery diaphragm cutting machine and relates to the technical field of production of lithium ion batteries. The lithium ion battery diaphragm cutting machine comprises a frame, a motor, a synchronous belt and a cutting device, wherein the frame comprises a support frame, roller frames and a cutting platform; the roller frames comprise a first roller frame, a second roller frame and a third roller frame; an unwinding roller is arranged at the upper part of the first roller frame; a first positioning roller is arranged at the lower part of the first roller frame; a second positioning roller and a finished product roller are arranged on the second roller frame; a residual material roller is arranged on the third roller frame; the motor is connected with the two positioning rollers via the synchronous belt; the cutting device is arranged on the cutting platform and comprises vertical plates, a threaded shaft, a sliding block, a blade, a limiting rod and a transverse plate; the threaded shaft is mounted at the upper parts of the two vertical plates; the sliding blocks is mounted on the threaded shaft; the blade is arranged at the lower part of the sliding block; the upper part of the sliding block is connected with the limiting rod; the transverse plate is arranged at the tops of the two vertical plates; a limiting elongated slot is formed in the transverse plate. The lithium ion battery diaphragm cutting machine is simple in structure, convenient to use, high in cutting efficiency and high in cutting accuracy; the demand of lithium ion battery diaphragms in small-batch production of lithium ion batteries can be met.

Owner:衡阳市鑫晟新能源有限公司

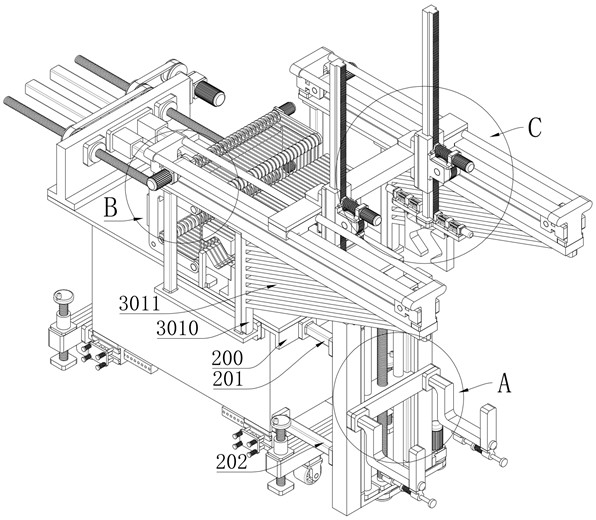

Pole piece splitting machine

ActiveCN113602885AImprove slitting accuracyHigh precisionElectrode manufacturing processesCleaning using toolsVisual inspectionEngineering

The invention discloses a pole piece splitting machine. The machine comprises a base table, a controller, an unwinding assembly, a cutting die structure, a winding assembly, a first deviation rectifying sensor, a deviation rectifying system, a translation assembly and a first visual inspection assembly. Raw materials are subjected to first-time deviation rectifying treatment based on the unwinding assembly and the first deviation rectifying sensor; a raw material pole piece subjected to the first-time deviation rectification is subjected to second-time deviation rectification treatment through the deviation rectifying system, so that the raw material pole piece can basically enter a desired advancing path; when the raw material pole piece subjected to the second-time deviation rectification treatment is about to enter the cutting die structure, after blank space position data on the raw material pole piece is inspected through the first visual inspection assembly, the controller controls the cutting die structure to move horizontally based on the blank space position data, so that the splitting precision is improved; and the unwinding assembly is used for performing deviation rectification treatment, so that one deviation corrector can be saved, and the cost is reduced.

Owner:GUANGZHOU EHOLLY MACHINERY CO LTD

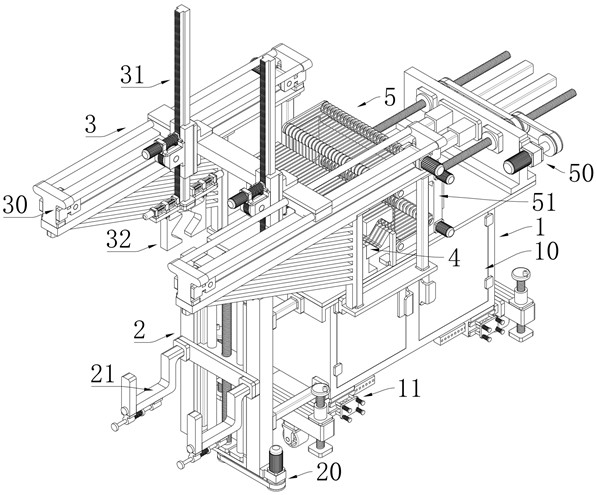

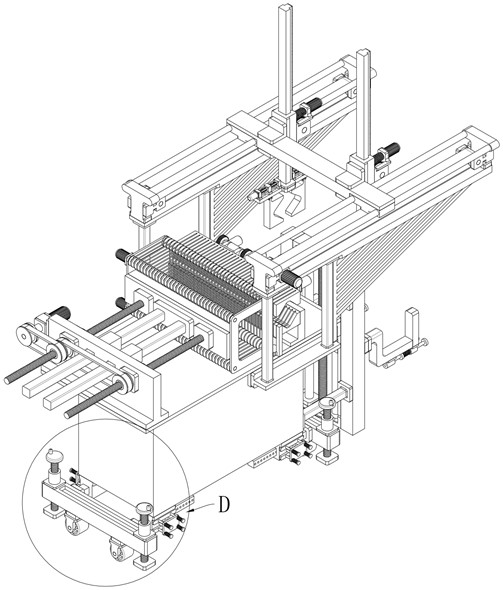

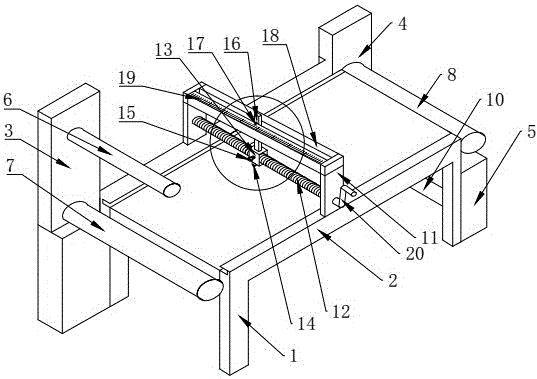

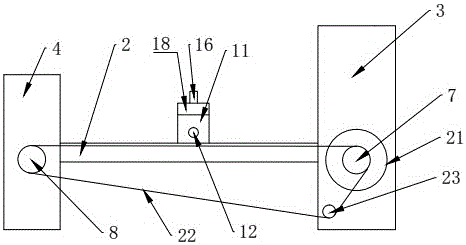

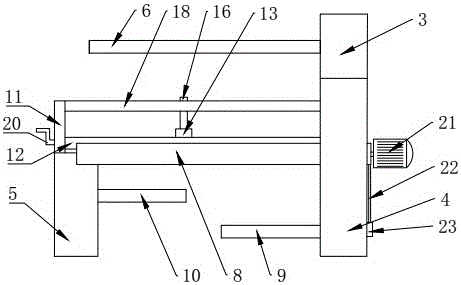

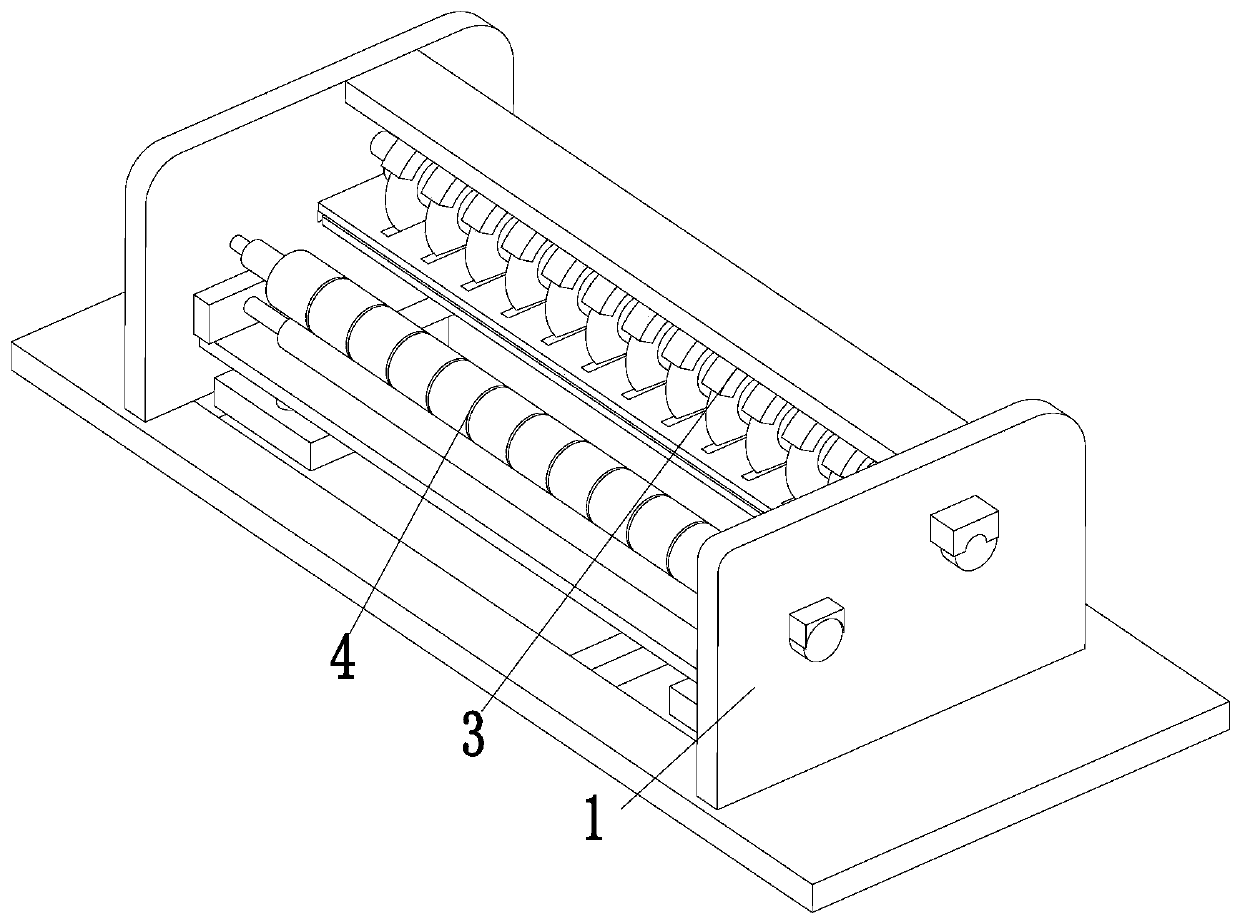

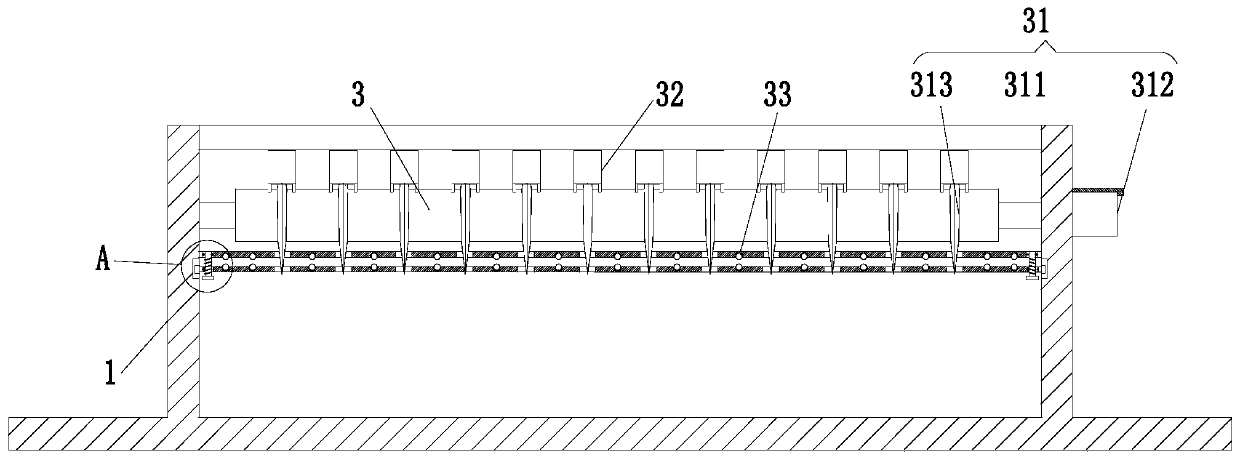

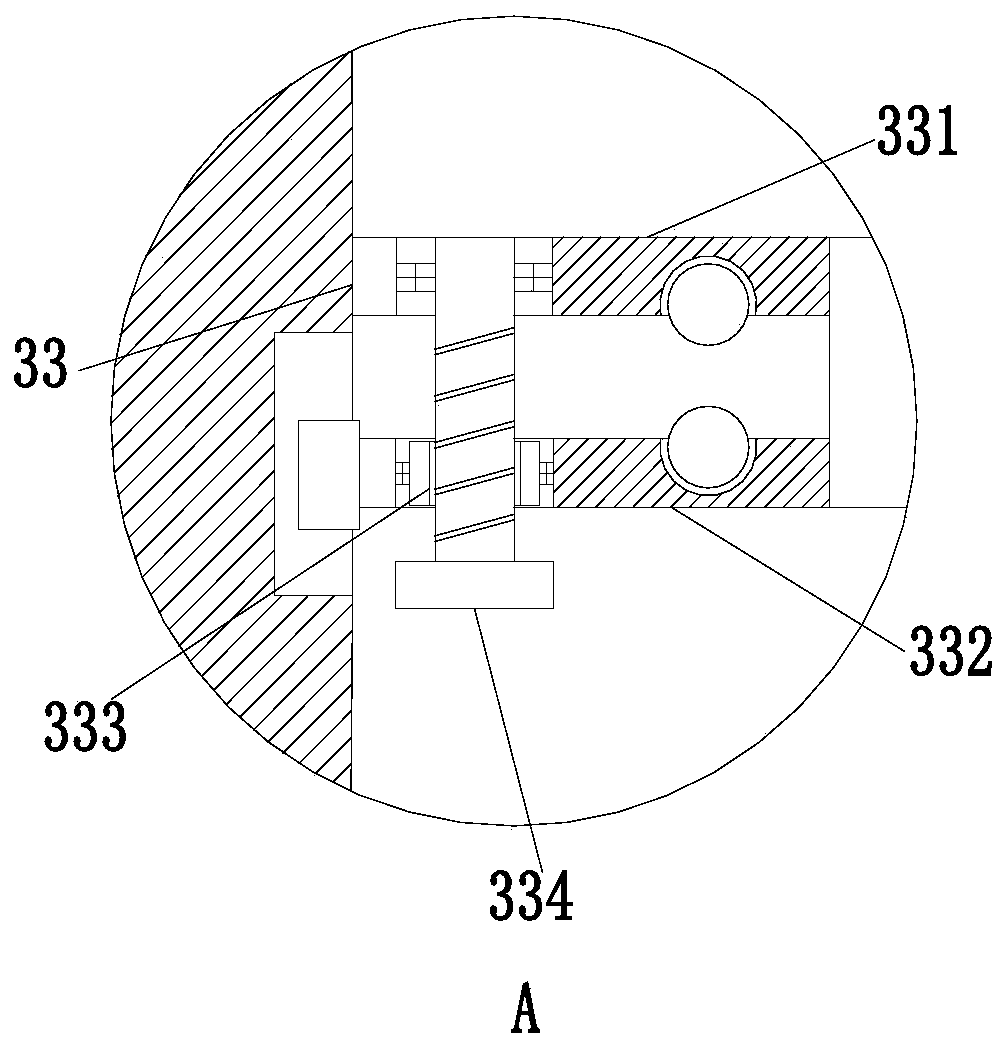

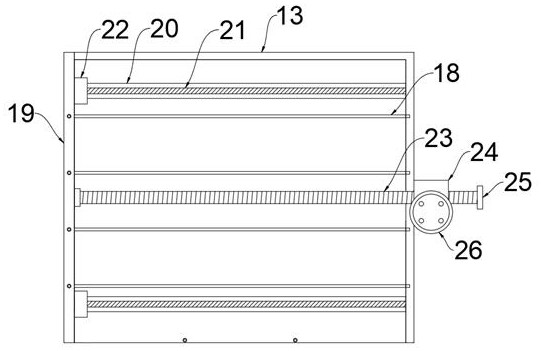

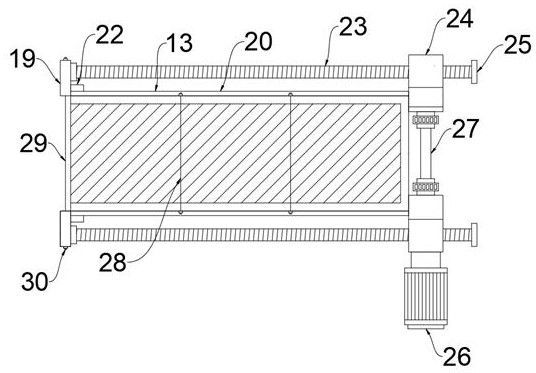

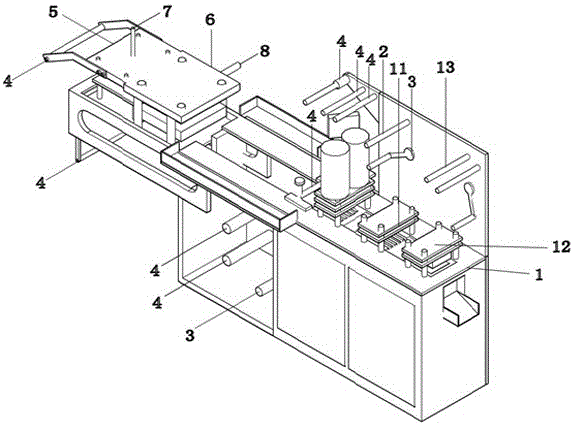

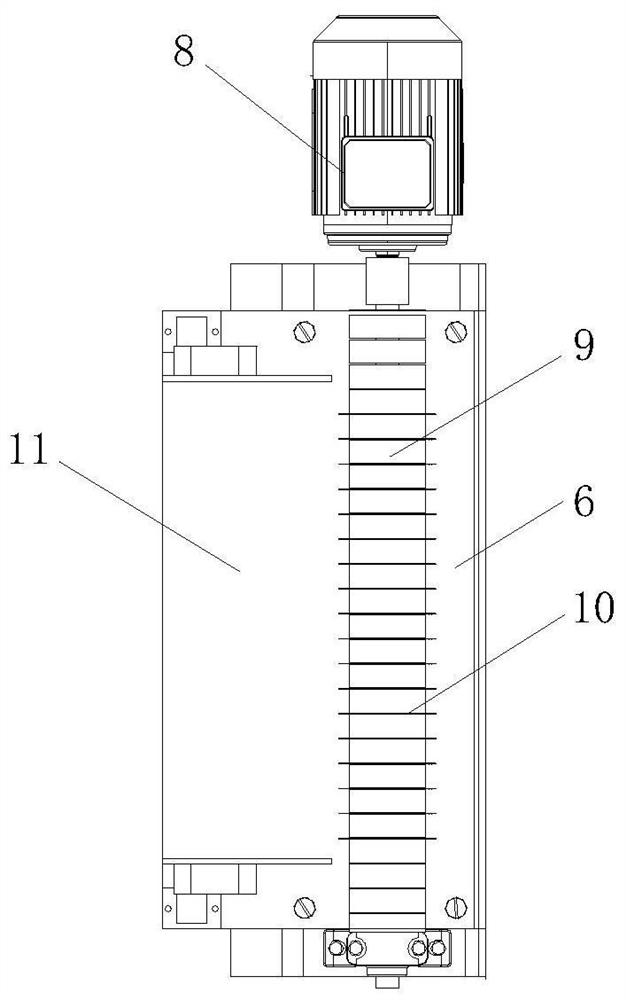

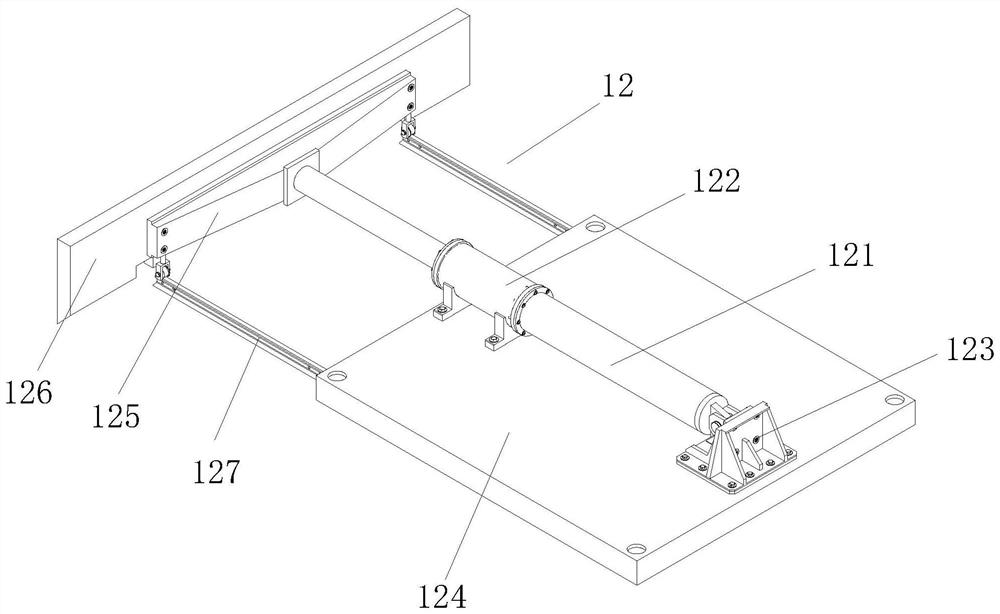

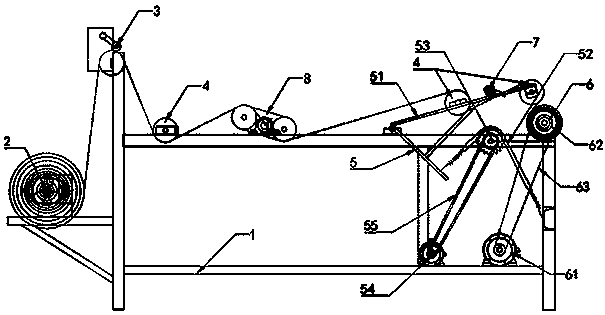

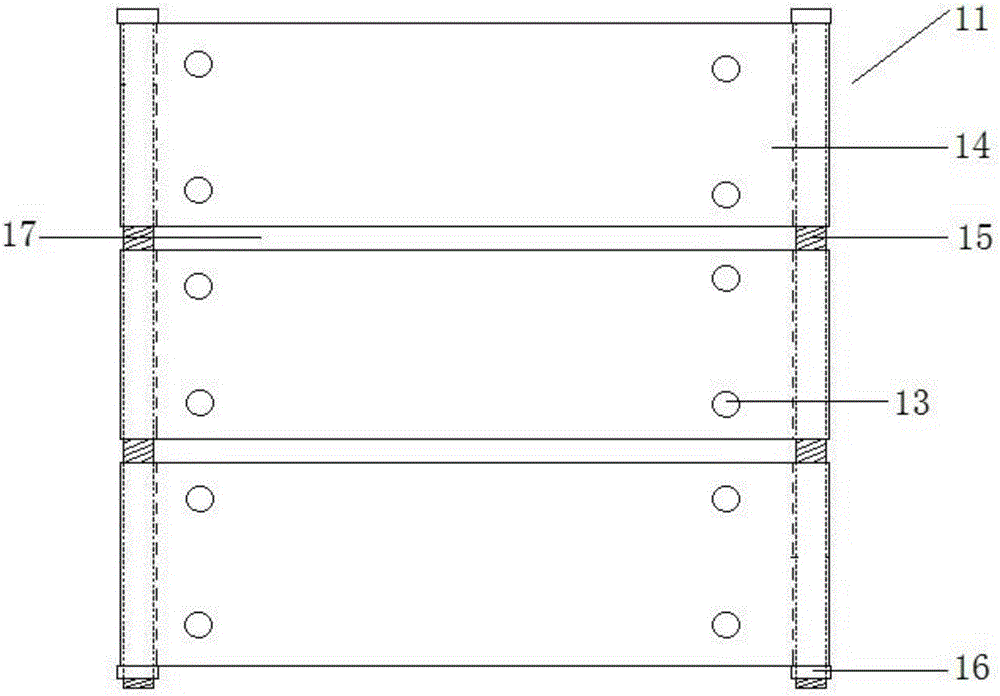

Double-layer cloth spreader with precision slitting mechanism

ActiveCN106758117AIngenious structural designSimple structureSevering textilesEngineeringCross-cutting

The invention relates to a double-layer cloth spreader with a precision slitting mechanism, comprising: a frame; a feeding mechanism, a rectifying mechanism, a feeding-pressing mechanism, the slitting mechanism, a trimming mechanism, a cross-cutting mechanism, a spreading mechanism and a conveying mechanism which are arranged on the frame; the splitting mechanism comprises a plurality of large-diameter slitting tools, a slitting motor corresponding to every slitting tool and driving the slitting tools, a motor support, a fixing plate, two parallel linear slides, a tool position adjusting device and a support base; the slitting tools are fixedly mounted on an output shaft of the slitting motor, the slitting motor is fixedly mounted at the top of the motor support, the bottom of the motor support is fixed to the fixing plate, one side of the fixing plate sleeves the two linear slides, the linear slides are fixedly mounted on the support base, the support base is fixedly mounted on the frame, and the tool position adjusting device is arranged on the fixing plate.

Owner:盐城精通源机械有限公司

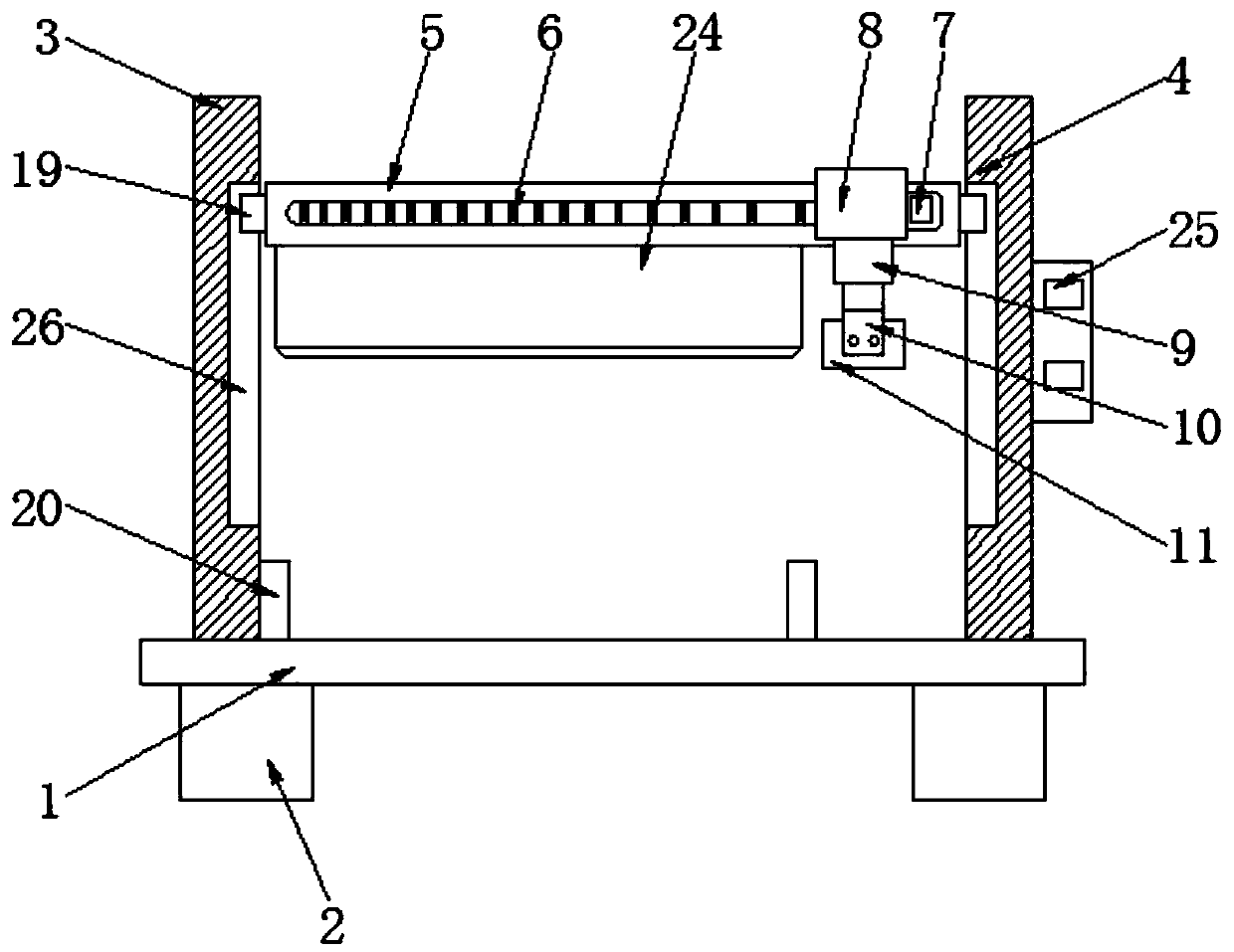

Automatic slitting machine for manufacturing non-woven fabric

ActiveCN111498575AImprove protectionImprove slitting accuracySevering textilesMetal working apparatusAssembly lineNonwoven fabric

The invention relates to an automatic slitting machine for manufacturing non-woven fabric. The automatic slitting machine comprises a support frame, an unwinding frame, a slitting device and a windingdevice. The support frame is of a U-shaped structure. The unwinding frame is mounted on the rear side in the support frame through a bearing. The slitting device is mounted in the middle in the support frame. The winding device is mounted on the front side inside the support frame. The automatic slitting machine can solve the problems that existing equipment cannot clean a slitting cutter in timewhen slitting the non-woven fabric, too much debris adhered to the surface of the slitting cutter affects the slitting precision, and the pressing plate distance is adjusted according to the non-woven fabric layer number, so that convex-concave wrinkles appear on the surface of the non-woven fabric, and the problem that the edge of a split finished product is uneven and the width specification isunstable can be solved; and meanwhile, the problems that when an existing device winds the split finished product, if the winding thickness is too thick, the wound split finished product may be loosened, and even winding and falling occur, and the assembly line requirement cannot be met can be solved.

Owner:HANGZHOU SHUNLONG TEXTILE COATING

Optical polyester film

InactiveCN111689286AQuality improvementImprove qualitySynthetic resin layered productsArticle deliveryPolymer sciencePolyethylene terephthalate glycol

The invention belongs to the technical field of a polyester film, and specifically belongs to an optical polyester film. The optical polyester film is a multi-layer co-extruded biaxially stretchable film; the surfaces of the two sides of a middle layer are each provided with a surface layer; the middle layer is made of polyethylene terephthalate (PET); each surface layer is composed of polyethylene terephthalate added with nano Al2O3 and an antistatic agent; the content of the nano Al2O3 in the surface layer is 5 wt% to 8 wt%; the content of the antistatic agent in the surface layer is 2 wt% to 3 wt%; the thickness of the surface layer is 3.5 micrometers; the thickness of the middle layer is 12-200 micrometers; the prepared optical polyester film provided by the invention has good surfaceproperties; the optical properties are not affected; and meanwhile the film is high in structural strength and long in service life.

Owner:孔维恒

High-speed double-width wall paper linking line slitting photogravure press

ActiveCN104760406ASolve the problem of misalignmentRotation speed synchronizationRotary intaglio printing pressPhotogravurePrinting press

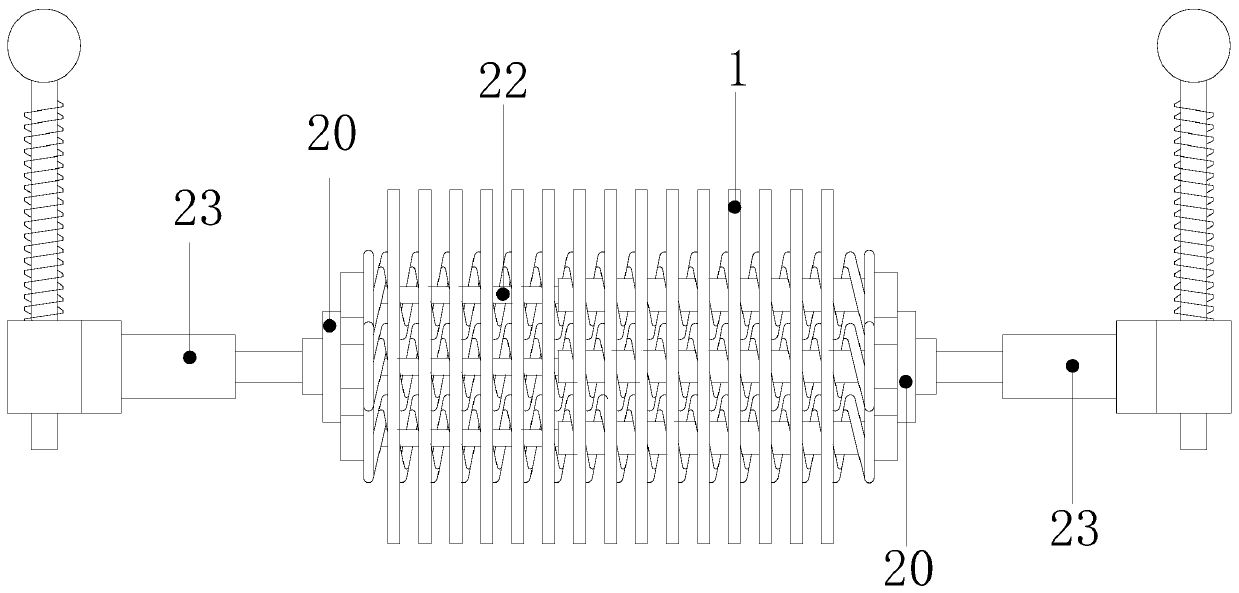

The invention discloses a high-speed double-width wall paper linking line slitting photogravure press. The high-speed double-width wall paper linking line slitting photogravure press comprises a frame; a left supporting base and a right supporting base are arranged on the frame; a cutter shaft rotated in relative to the frame and two space adjusting screw rods are mounted between the left supporting base and the right supporting base; one end of the cutter shaft is connected with a cutter shaft motor, and three lower cutters are installed on the cutter shaft, and three cutters include a left lower cutter, a right lower cutter and a middle lower cutter; the side of the lower cutter is provided with a pneumatic cutter matched up with the lower cutter; two space adjusting screw rods are screwed with linking plates, one end of each of the linking plate is connected with the left lower cutter or the right lower cutter, and the other end is connected with the pneumatic cutter matched up with the left lower cutter or the right lower cutter; the pneumatic cutter is installed on the cutter shaft. The structure needs not perform the secondary slitting by the slitter, thus the production efficiency is improved; the space adjusting screw rods are adjusted so as to adjust the slitting width, and the operation is convenient; the high-speed double-width wall paper linking line slitting photogravure press can effectively solve the problem of slitting misalignment of the double-width press due to the different flexibilities, and also prevent products from rough edges.

Owner:江门市智睿包装机械有限公司

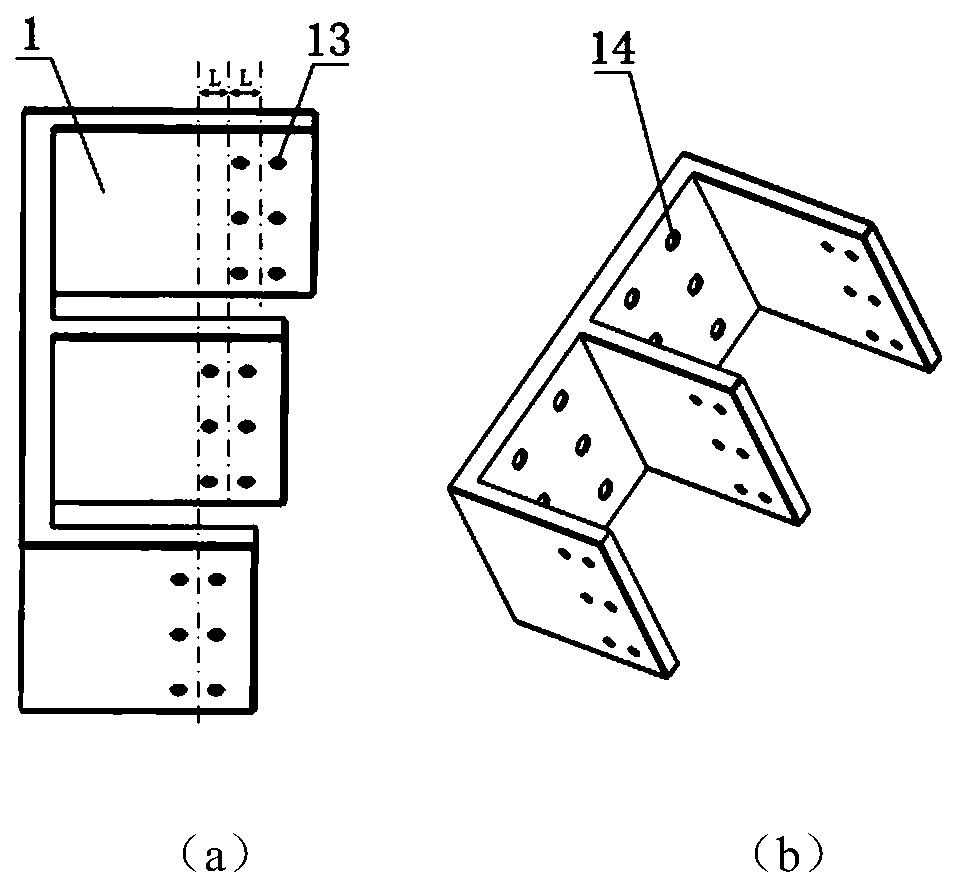

Cutter space one-time adjustable splitting cutter holder used for production and processing of lithium battery cover plate

The invention discloses a cutter space one-time adjustable splitting cutter holder used for production and processing of a lithium battery cover plate. The cutter space one-time adjustable splitting cutter holder structurally comprises upper splitting cutters, an upper cutter space adjusting device, a guide roller, a lower cutter space adjusting device, lower splitting cutters and a cutter holderbody, wherein the cutter holder body is provided with the lower cutter space adjusting device and the upper cutter space adjusting device in the sequence from down to up. Compared with the prior art,the cutter space one-time adjustable splitting cutter holder has the beneficial effects that, through the combination arrangement of connecting plates, ear clips, spring groups and rotary lifting groups, the space between each splitting two cutter is thus adjustable; based on the elasticity of the springs, spring rings of the springs can be enlarged or lessened in an equidistant mode, so that thespaces of a plurality of splitting cutters can be adjusted at one time, the adjusting frequency is high, and adjusting one by one is not needed, the speed of the space adjusting is fast, the requirements of the lithium battery cover plate at different splitting scales can be met, the application range is wide, the cost invested to the cover plate splitting is low, and the cutter space one-time adjustable splitting cutter holder is valuable to be popularized and used.

Owner:NANTONG NAIWEITE POWER SUPPLY CO LTD

A production process of plastic packaging box

ActiveCN110015495BImprove stabilityCause scratchesNon-removalbe lids/coversTray containersPlastic packagingInjection moulding

Owner:JILIN LONGYUN CHEM IND

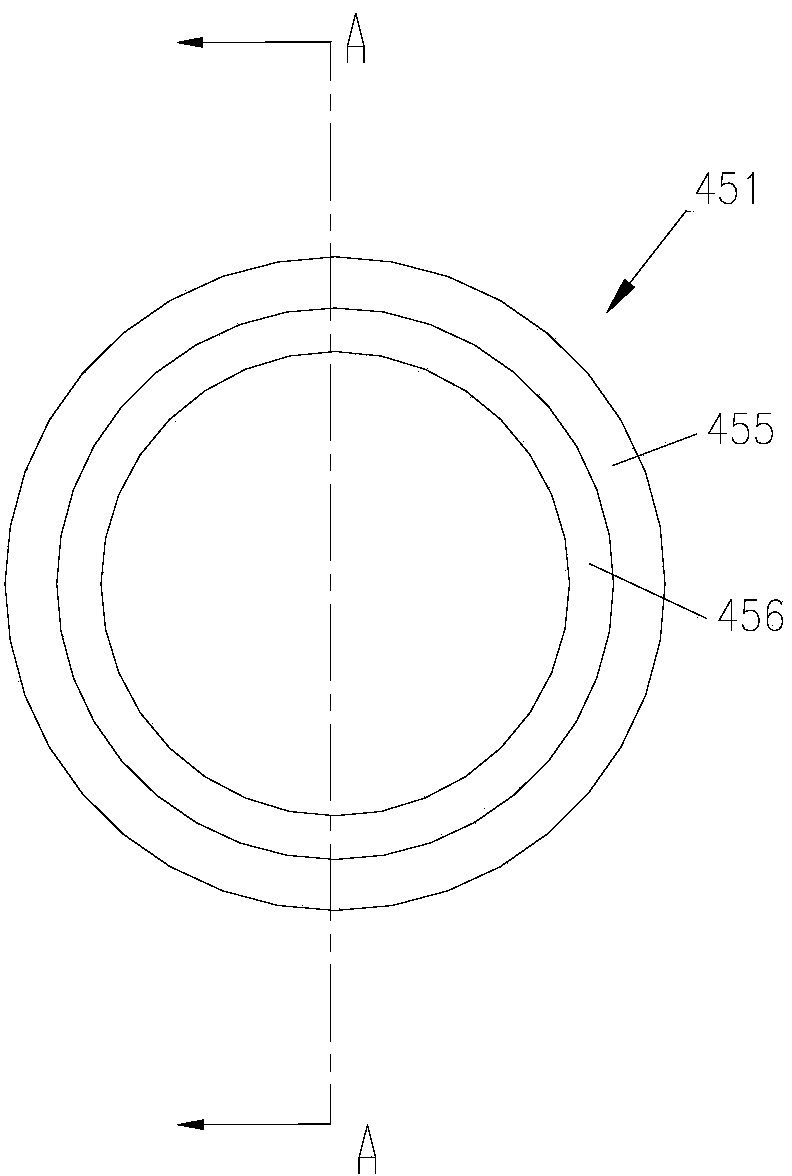

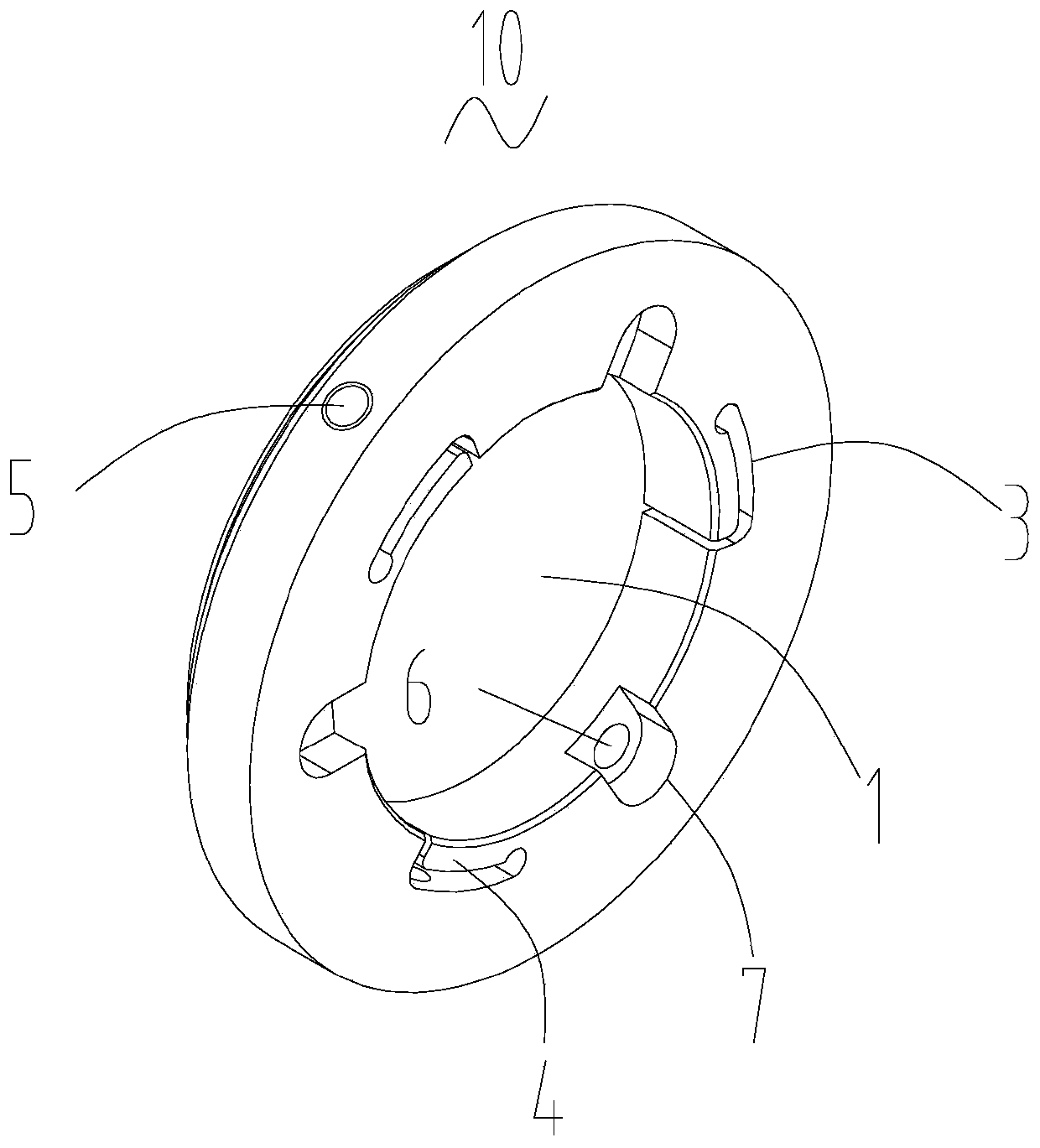

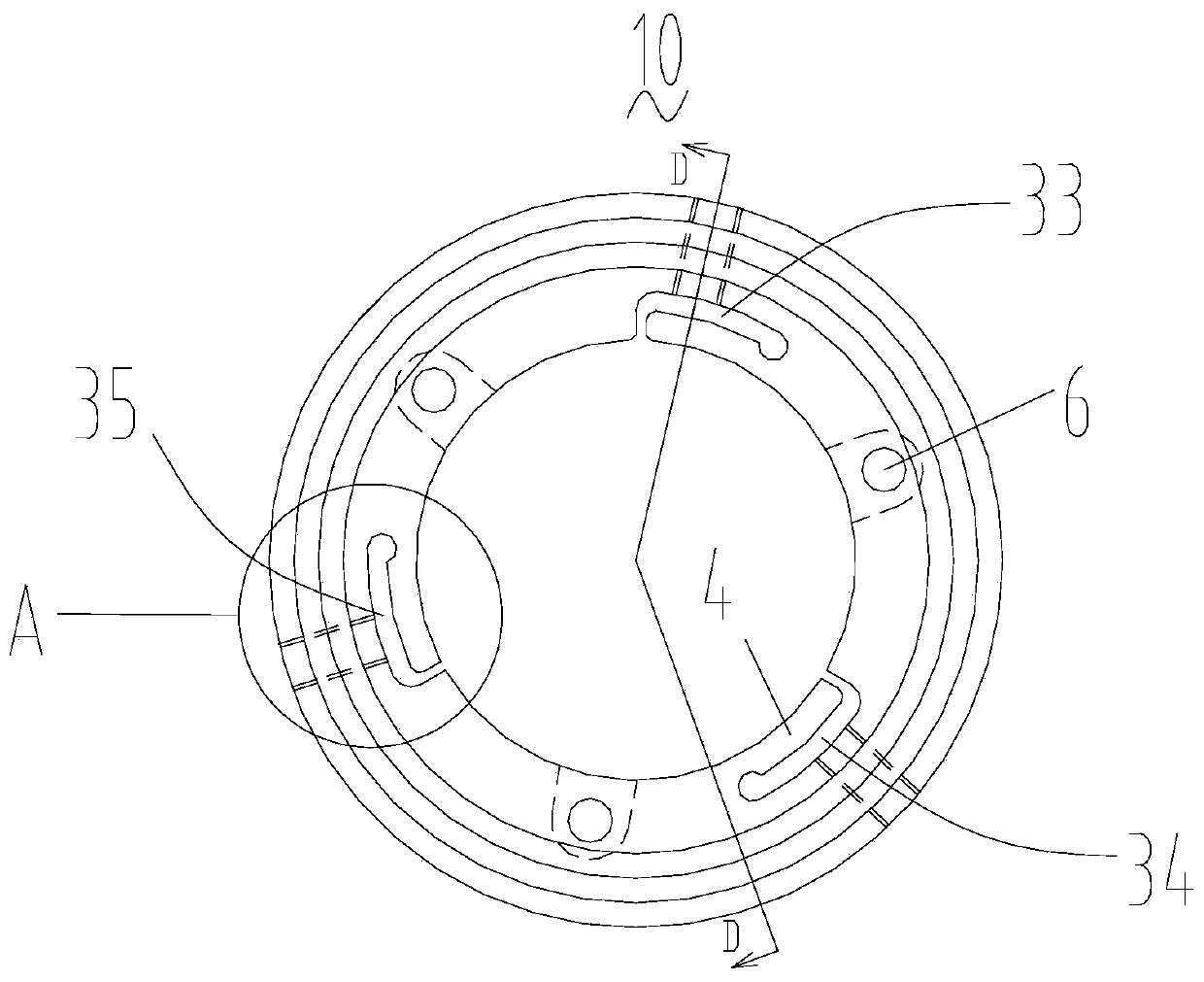

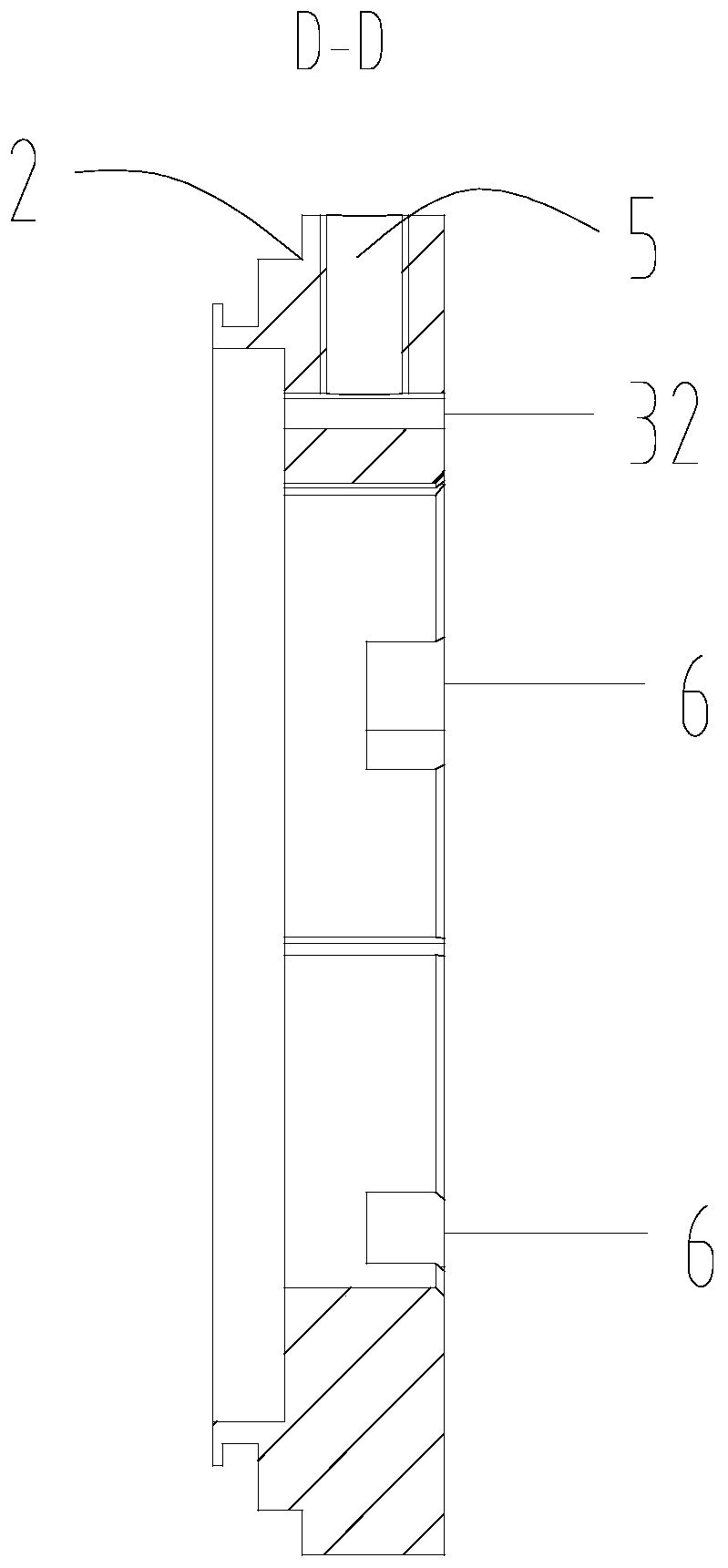

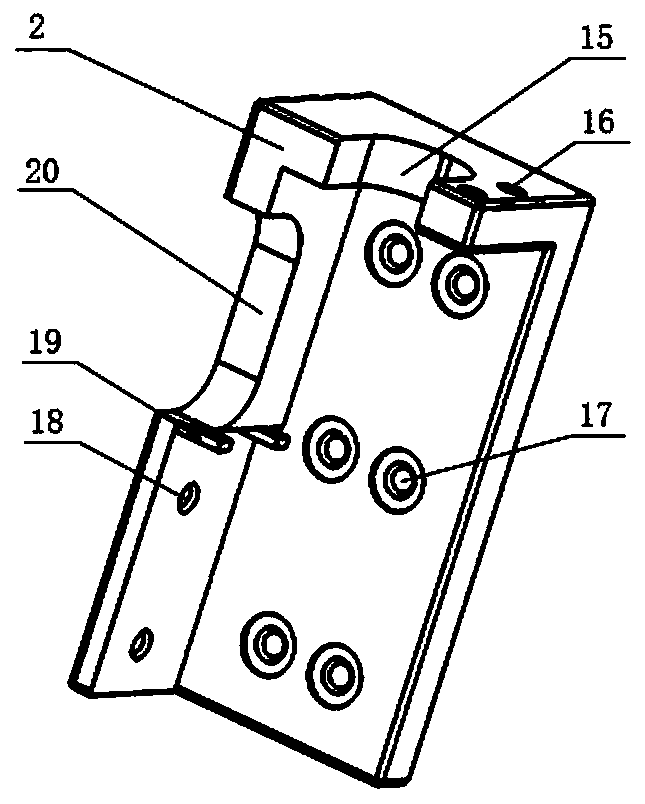

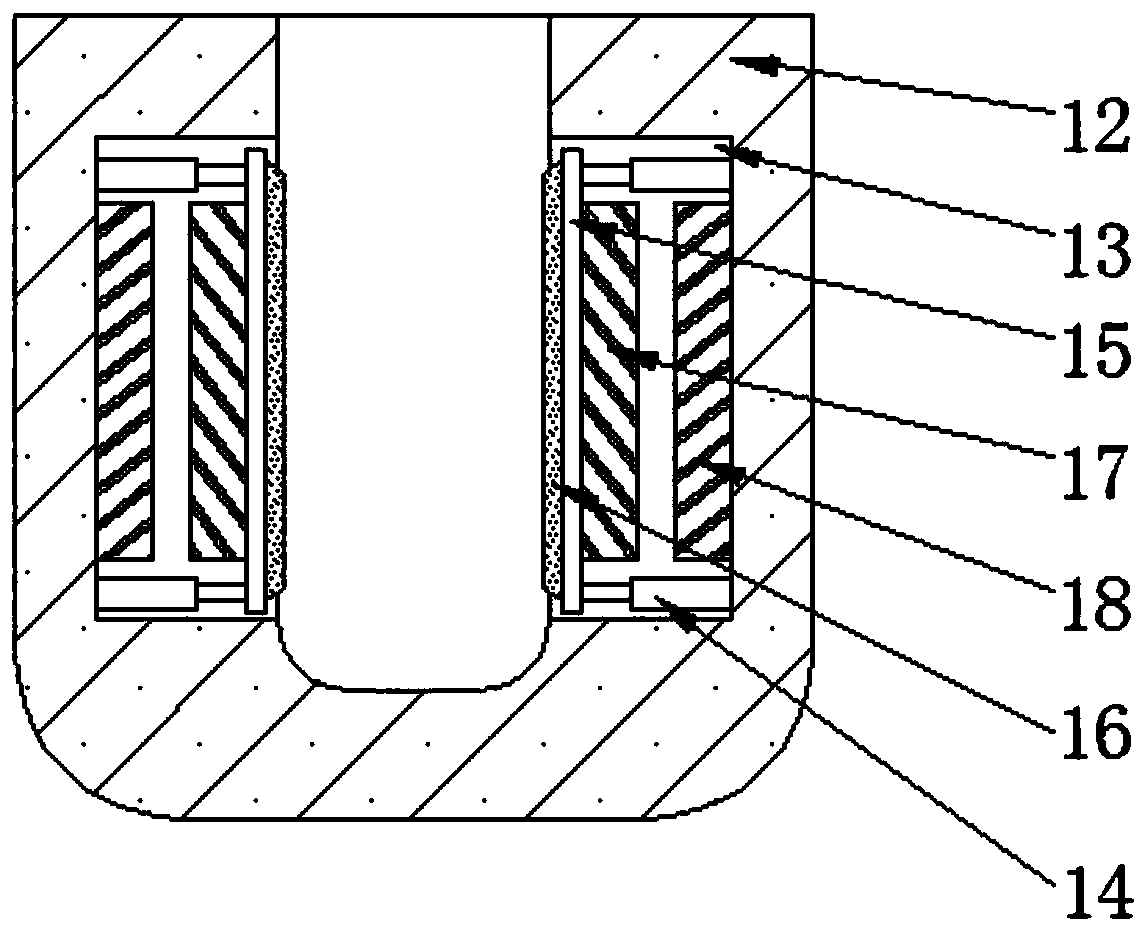

Adjusting device for upper knife holder and upper circular knife of upper knife shaft of splitting machine, and preparation method

PendingCN111331668AImprove the fastening relationshipReduce swingMetal working apparatusBobbinEngineering

The invention discloses an adjusting device for an upper knife holder and an upper circular knife of an upper knife shaft of a splitting machine, and preparation method, and relates to the technical field of a splitting machine. The adjusting device includes a round hole matched with the upper knife shaft and a clamping slot used for clamping the upper circular knife. At least one locking slit isformed in the side area, close to the upper shaft, of the upper knife holder. The locking slit includes a short-sided slit and a long-sided slit. The short-sided slit extends along the axial directionof the upper knife holder. The long-sided slit extends along the circumferential direction of the upper knife holder. One end of the short-sided slit communicates with the long side of the slit, theother end of the short-sided slit communicates with the circular hole. By arranging the locking slit and the locking screw hole on the inner diameter side area of the upper knife holder, the upper knife holder improves the fastening relationship between the upper knife holder and the upper knife shaft, lowers the swing of the upper circular knife, improves the splitting accuracy, increases the convenience of knife changing and tool setting, and improves the splitting efficiency of bobbin paper.

Owner:苏州市乾丰造纸机械制造有限公司

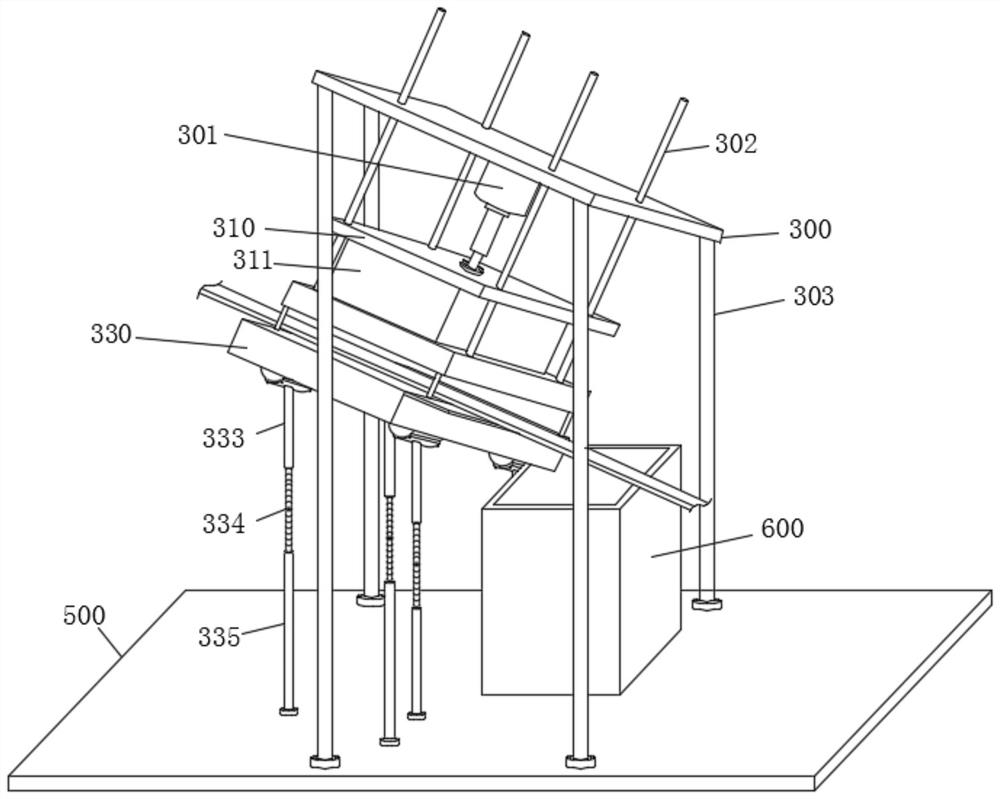

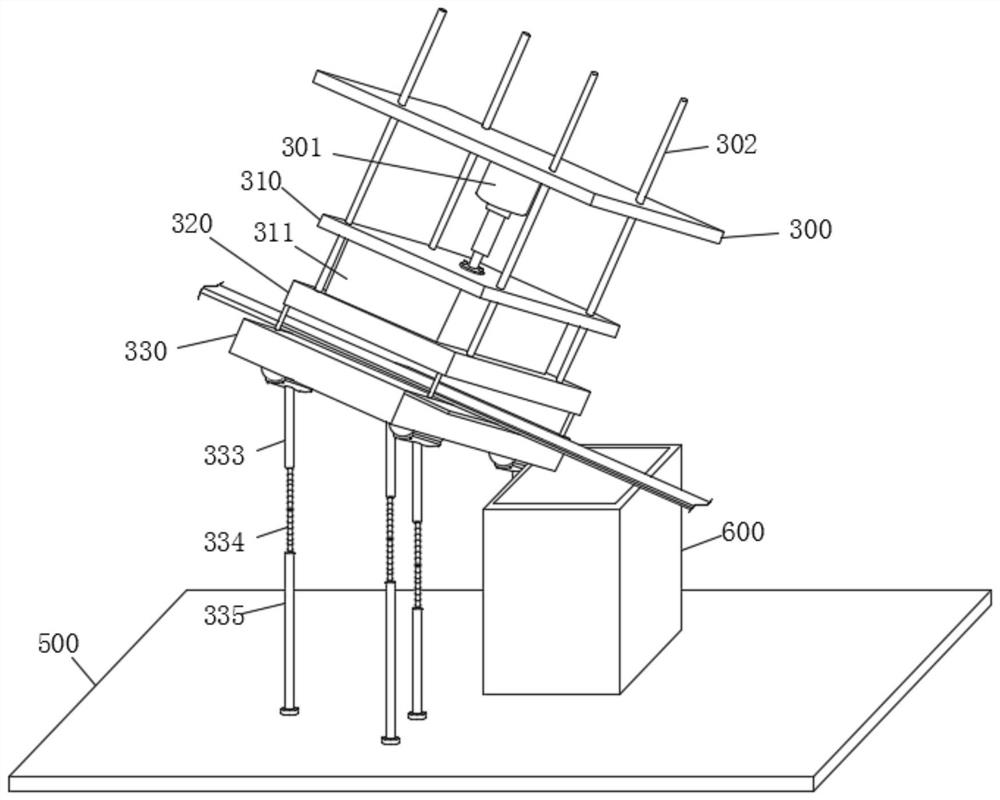

Aerated brick blank cutting device

PendingCN112223506AImprove cutting efficiencySmall footprintCeramic shaping apparatusMetal working apparatusBrickStructural engineering

The invention discloses an aerated brick blank cutting device, relates to the technical field of aerated brick blank processing, and aims at solving the problems that transverse cutting and longitudinal cutting work of an existing aerated brick blank needs to be completed in a segmented mode, the efficiency is low, and the occupied area of equipment is large. Two synchronous belt guide rails are arranged, sliding tables are installed on the two synchronous belt guide rails, the sliding tables are connected with the synchronous belt guide rails in a sliding mode, a hoisting bottom plate is installed on the upper surfaces of the sliding tables, a blank is arranged on the hoisting bottom plate, a machining frame is installed outside the synchronous belt guide rails, reinforcing rods are installed on two sides of the outer wall of the machining frame correspondingly, a beveling blade is installed on one side of the lower surface of the reinforcing rod, and the beveling blade is fixedly connected with the machining frame.

Owner:禹州市开元新型建材有限公司

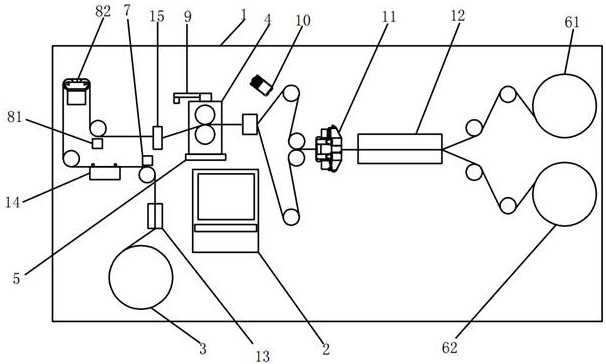

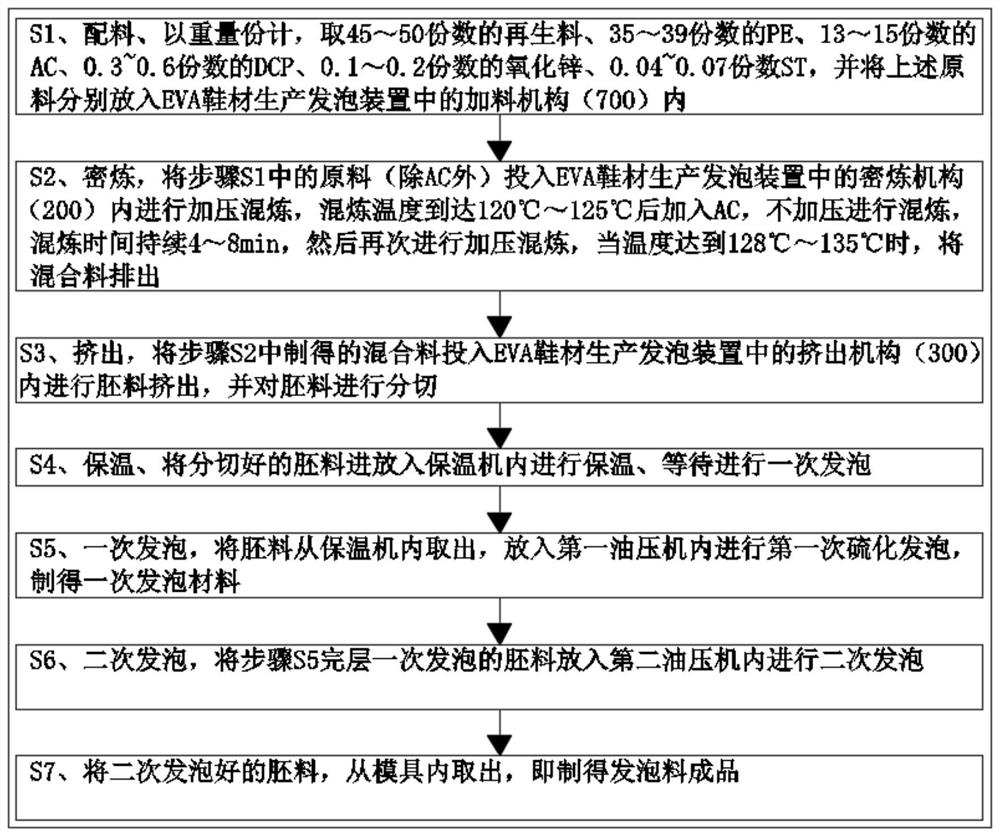

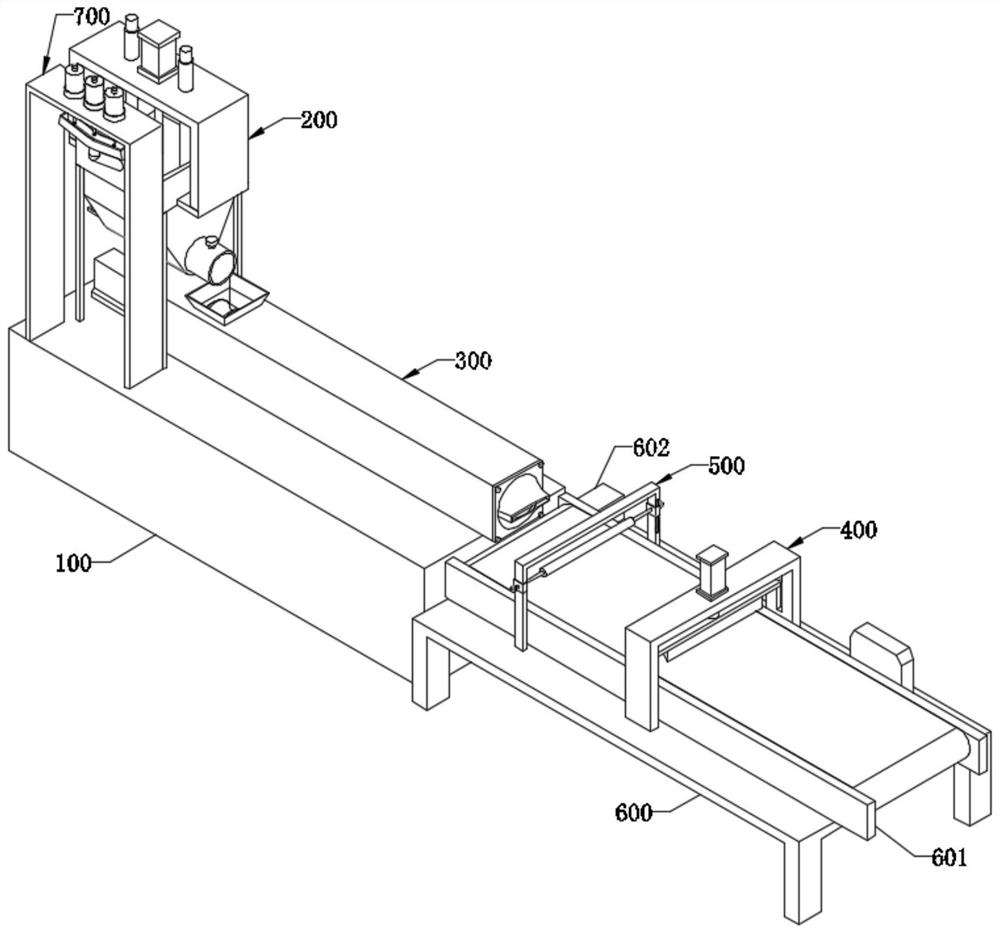

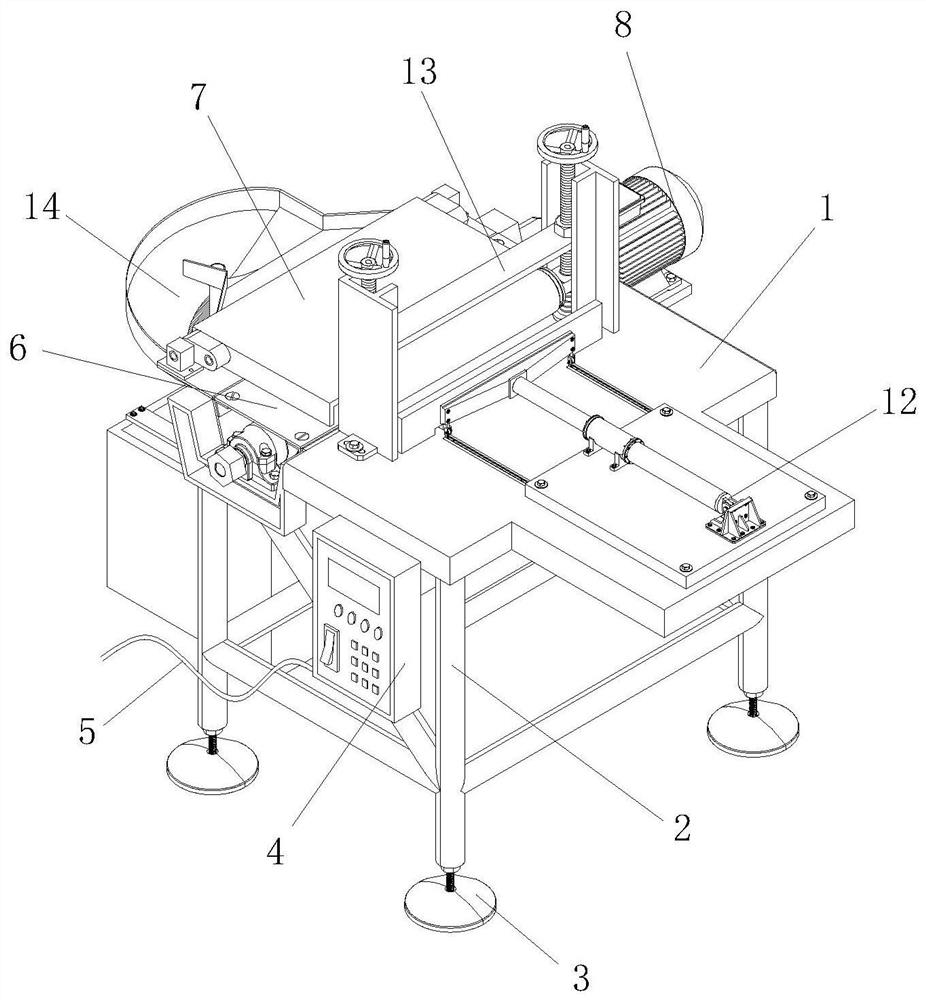

Foaming process and device for EVA shoe material production

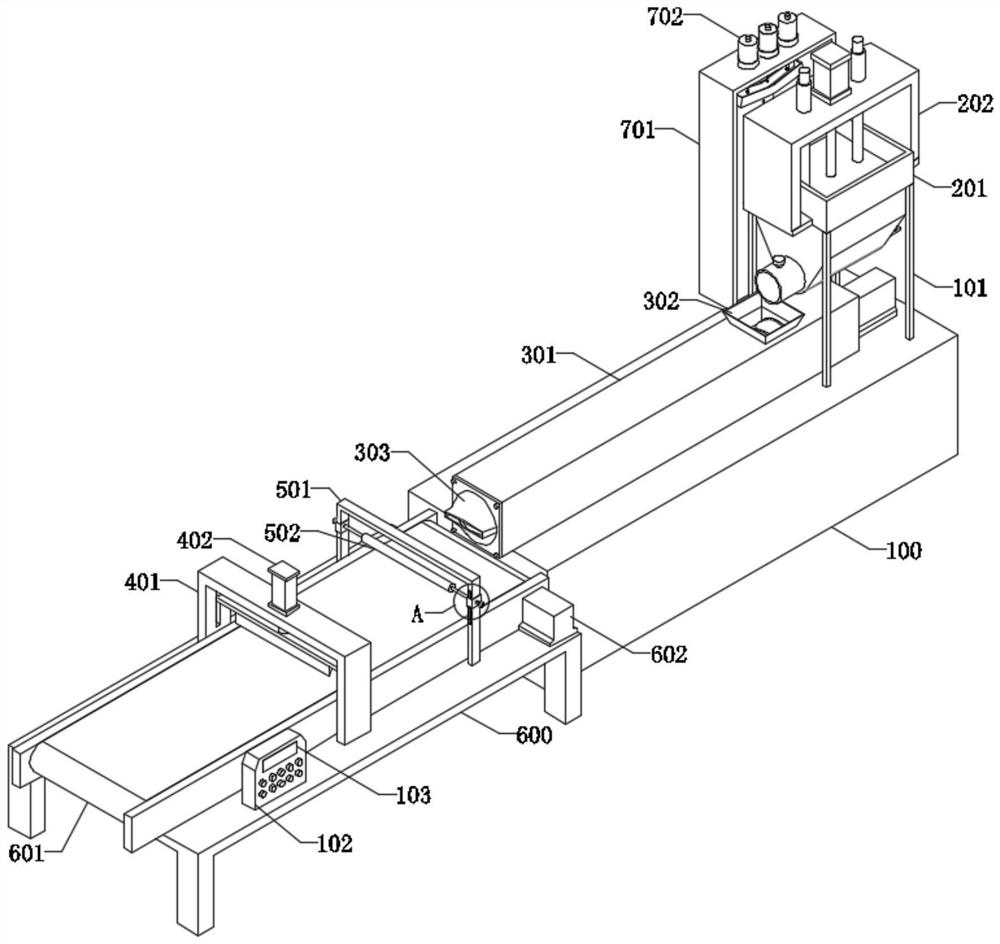

ActiveCN113929954AImprove slitting accuracyIncrease productivityDomestic articlesEngineeringProcess engineering

The invention discloses a foaming process and device for EVA shoe material production. The device comprises a base, a fixing frame, an internal mixing mechanism, an extrusion mechanism, a conveying assembly, a slitting mechanism and a feeding mechanism. According to the EVA shoe material production foaming device, the internal mixing mechanism, the extruding mechanism and the conveying assembly are matched with the slitting mechanism to achieve integrated production, not only is the slitting precision improved, but also manpower consumption is effectively reduced, and the production efficiency is improved; the automatic feeding function is achieved through the arranged feeding mechanism, physical output during manual material adding is further reduced, manual participation is not needed during material adding, the phenomenon that workers inhale a large amount of dust is avoided, and further guarantee is provided for the health of the workers; and through an arranged thickness adjusting assembly, the thickness of extruded blanks is rapidly adjusted, the device adapts to different production processes, and meanwhile, the device is simple in structure and convenient to use and maintain.

Owner:晋江市凯华鞋材有限公司

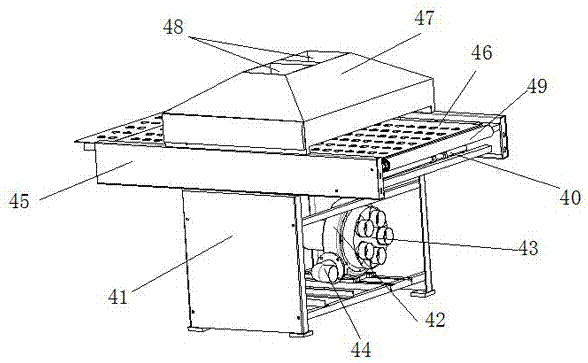

Food slitting device and baking machine

PendingCN110524589AEasy to cutRealize full automationBaking ovenMetal working apparatusCooking & bakingEngineering

The invention relates to a food slitting device and a baking machine. The food slitting device comprises a machine frame, a cutter mechanism, a vertical driving mechanism and a conveying mechanism, wherein the vertical driving mechanism and the conveying mechanism are both arranged on the machine frame. The vertical driving mechanism is connected with the cutter mechanism so as to drive the cuttermechanism to move up and down; the cutter mechanism comprises an ultrasonic cutter and a rotary driving assembly; the rotary driving assembly is used for driving the ultrasonic cutter to rotate, theconveying mechanism is used for conveying food to the cutting position of the ultrasonic cutter, the food slitting device can replace manual work to slit the food, the food is effectively prevented from being damaged, the slitting efficiency is improved, and potential safety hazards are reduced.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

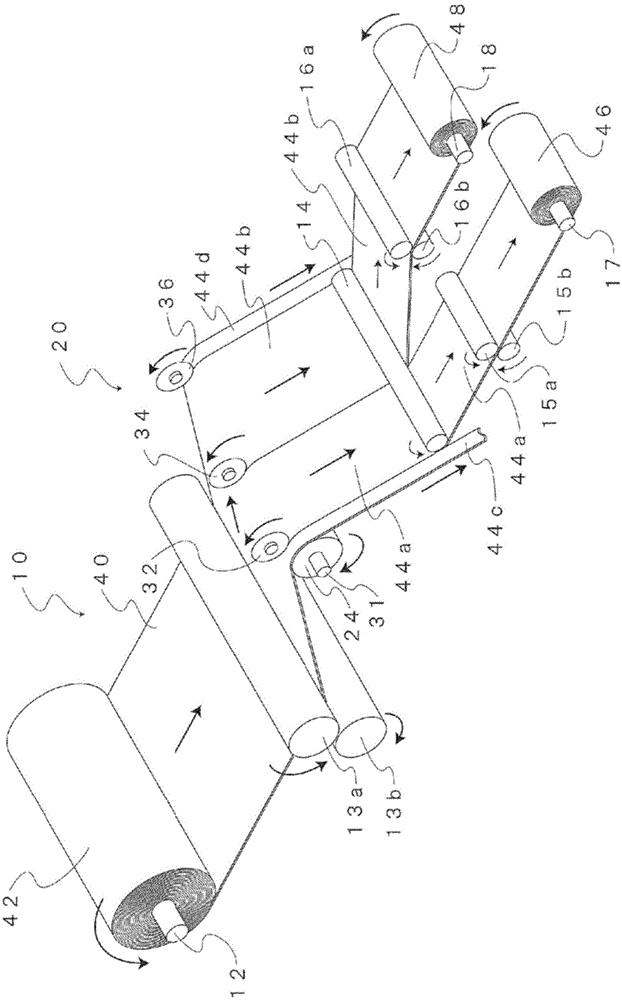

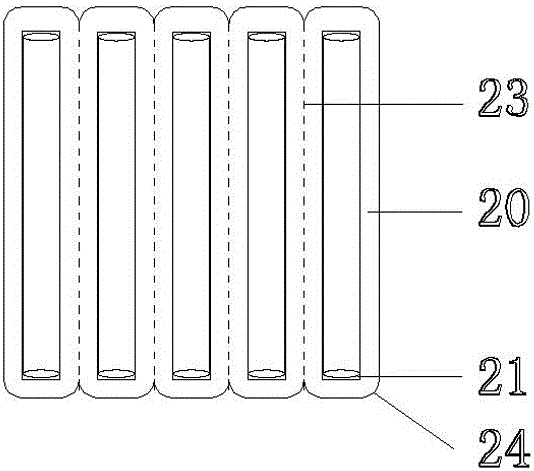

Preparation method of ultra-thin and ultra-soft prepreg tows for automatic fiber laying

The invention relates to a preparation method of ultra-thin and ultra-soft prepreg tows for automatic fiber laying. The prepreg tows are epoxy resin-based or bismaleimide resin-based carbon fiber reinforced prepregs; and the method is characterized in that before the wide ultra-thin and ultra-soft prepreg tows are slit, a layer of stiff material film capable of being bonded with the prepreg tows is attached to the lower surfaces of the prepreg tows, the stiff material film playing a supporting role is slit together when the prepreg tows are slit by a cutter, the slit prepreg tows are automatically wound, and the slit material film is subjected to waste collection through automatic waste winding. According to the method, the prepreg tows with high edge quality and high width precision can be obtained, and the adverse effect of too thin and too soft prepregs on slitting is eliminated.

Owner:AVIC COMPOSITES +1

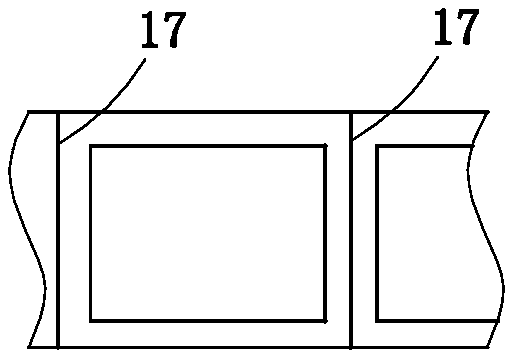

Printing method and equipment for test paper

InactiveCN107901582AImprove production efficiencyReduce manufacturing costRotary letterpress machinesRelief printingPaper tapePaper production

The invention discloses a printing method and equipment for test paper, and belongs to the technical field of printing equipment. The method comprises the following steps that (1) unrolling is carriedout, specifically, roll paper is placed on a unrolling roller, and the unrolling roller is rotationally arranged on an unrolling support; (2) printing is carried out, specifically, a paper tape is sequentially wound around a front side printing mechanism and a reverse side printing mechanism, and when the reverse side of the test paper is printed, a marking belt is printed at the middle positionof a white space which is arranged between every two adjacent formats of the test paper; (3) traction is carried out, under the action of a traction mechanism, the paper tape is sequentially conveyedto the downstream; (4) paper feeding is carried out, specifically, the paper tape is fed into a cutting device by using a paper feeding mechanism; and (5) identifying and cutting are carried out, specifically, the positions of the marking belts are identified by using a sensor, and the test paper are cut off at the positions of the marking belts. According to the printing method and equipment, printing and slitting can be realized on a flexographic printing machine, and therefore the production efficiency of the test paper can be improved, the production cost of the test paper can be lowered,and the printing method and equipment are widely applied to test paper printing.

Owner:王奕苏

Damp-proof moisture-retention cigarette package structure and production equipment thereof

ActiveCN106697375AAvoid attenuationAvoid elevationPackaging cigaretteControl systemMechanical engineering

The invention provides a damp-proof moisture-retention cigarette package structure and production equipment thereof, relates to the technical field of cigarette package equipment, solves the problem that cigarettes are squeezed under the situation that a conventional cigarette package is adopted, and overcomes the defects that special-purpose production equipment with high integration level does not exist, the amount of required equipment is large, the operation is complicated, and the efficiency is not high. The production equipment specifically comprises a baseplate cutting and winding mechanism, an encapsulation layer printing and coating mechanism, a substrate unwinding and shaping mechanism, an encapsulation layer unwinding and paving mechanism and a package trimming mechanism, wherein the baseplate cutting and winding mechanism comprises a pneumatic device, a pneumatic cutter and a winding shaft; the pneumatic device is used for providing power to control the pneumatic cutter to rise and fall to perform cutting; the winding shaft is controlled by a variable-frequency variable-speed motor; the encapsulation layer printing and coating mechanism comprises a printing plate, a pressing and printing roll, a drying device and a coating roll. The production equipment provided by the invention is high in functional integration level, simple to operate, high in efficiency, high in shaping speed, good in shaping effect, high in cutting precision and high in working efficiency; and a control system is simple and reasonable in structure.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

Longitudinal cutting device of paper cutter and control method of longitudinal cutting device

InactiveCN103332522AReduce labor intensityHigh adjustment accuracyControl using feedbackArticle deliveryBall screwElectric machinery

The invention relates to a longitudinal cutting device of a paper cutter and a control method of the longitudinal cutting device. The longitudinal cutting device of the paper cutter comprises a rack, an upper cutter device, upper control devices, a lower cutter device and lower control devices, wherein the upper cutter device comprises upper motors provided with upper encoders, an upper ball screw which extends perpendicular to a conveying direction of paper, and is fixedly arranged on the rack, upper nuts which are arranged on the upper ball screw and driven to rotate by the upper motors, upper shaft sleeves arranged on the upper nuts in a sleeving manner, and upper cutters which are fixedly arranged on the upper shaft sleeves and located above a paper surface; in a process that the upper nuts rotate relative to the upper ball screw, the upper shaft sleeves slide perpendicular to the conveying direction of the paper; and the upper encoders are used for detecting positions of the upper cutters and used for converting position data into a digital signal. The longitudinal cutting device of the paper cutter and the control method of the longitudinal cutting device are short in cutter adjustment time and high in adjustment precision.

Owner:何春明

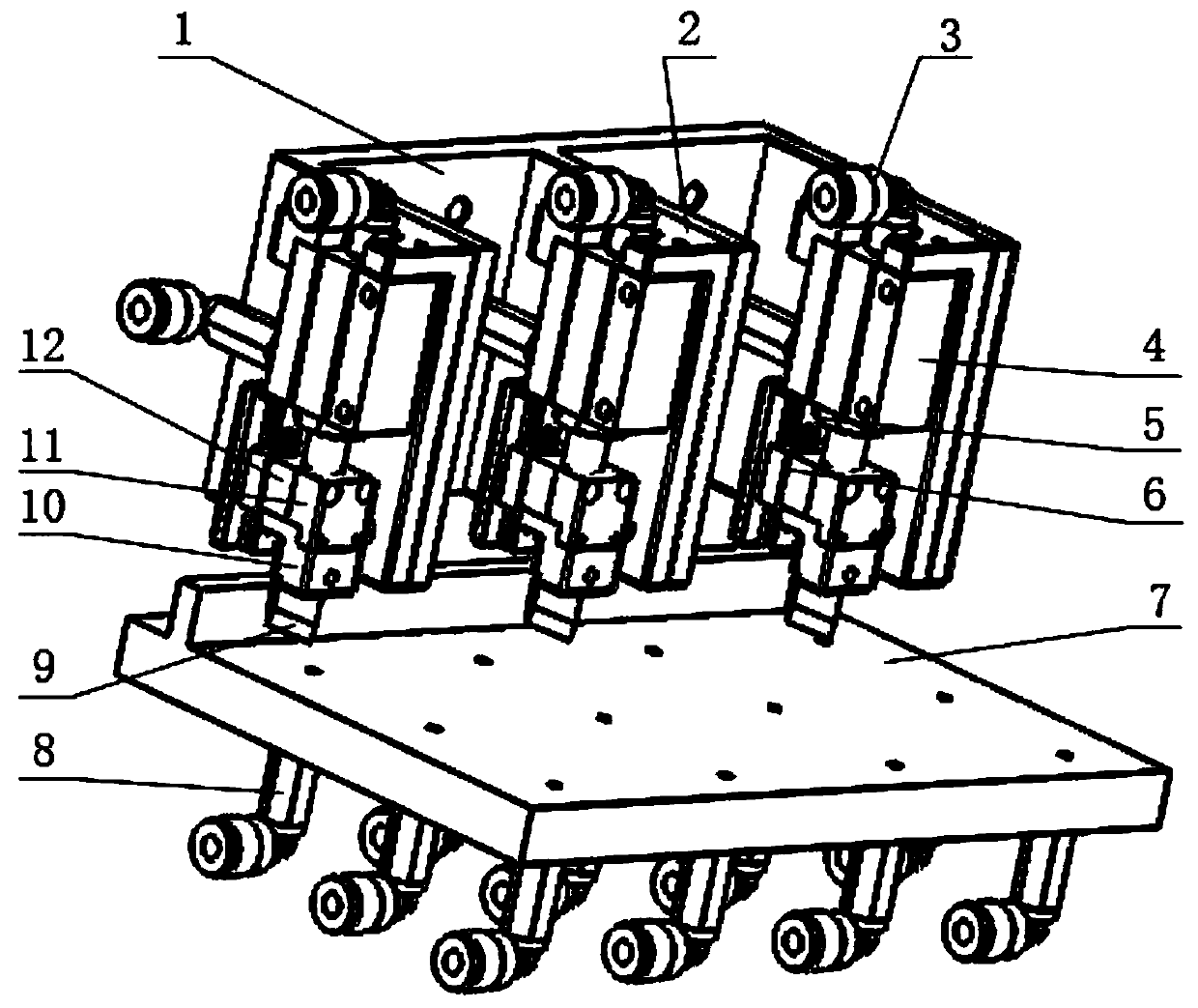

Air cylinder pushing type device for cutting carbon fiber prepreg and method

ActiveCN111438718AAdjustable slitting widthImprove cutting efficiencyMetal working apparatusFiberCarbon fibers

The invention discloses an air cylinder pushing type device for cutting carbon fiber prepreg and a method. The device comprises a component mounting plate, air cylinder guiding rail connecting pieces,air cylinders, cutting knives and a cutting board; a plurality of bosses in different lengths are arranged on the component mounting plate; the air cylinder guiding rail connecting pieces are arranged on all the bosses; the distance between each air cylinder guiding rail connecting piece and the adjacent air cylinder guiding rail connecting piece in the length direction of the corresponding bossis L, and L is the width of the prepreg required to be cut; the air cylinders are arranged on the air cylinder guiding rail connecting pieces; tool components capable of moving are arranged on pistonsof the air cylinders; the cutting knives are arranged on the tool components; and the cutting board is arranged at the lower end of the component mounting plate. According to the device and the method, the cutting width of the prepreg is adjustable, the cutting module can be extended, the prepreg cutting width and the narrow prepreg cutting number can be controlled, the cutting efficiency is improved, and the flexibility of the device is increased.

Owner:XI AN JIAOTONG UNIV

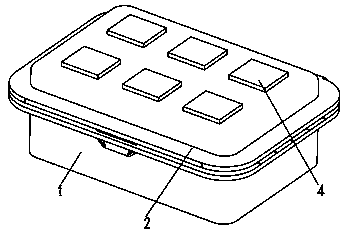

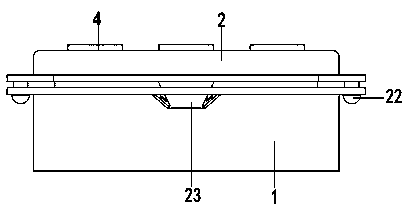

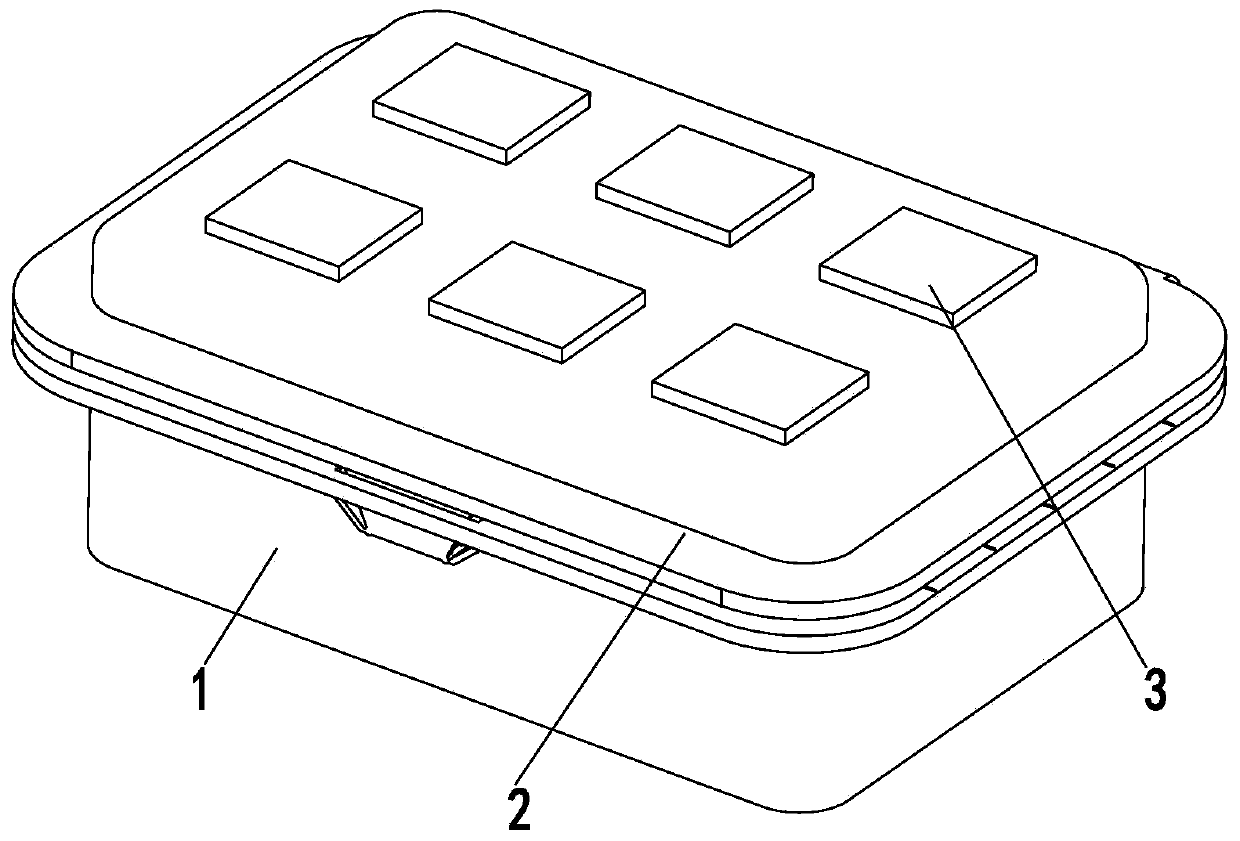

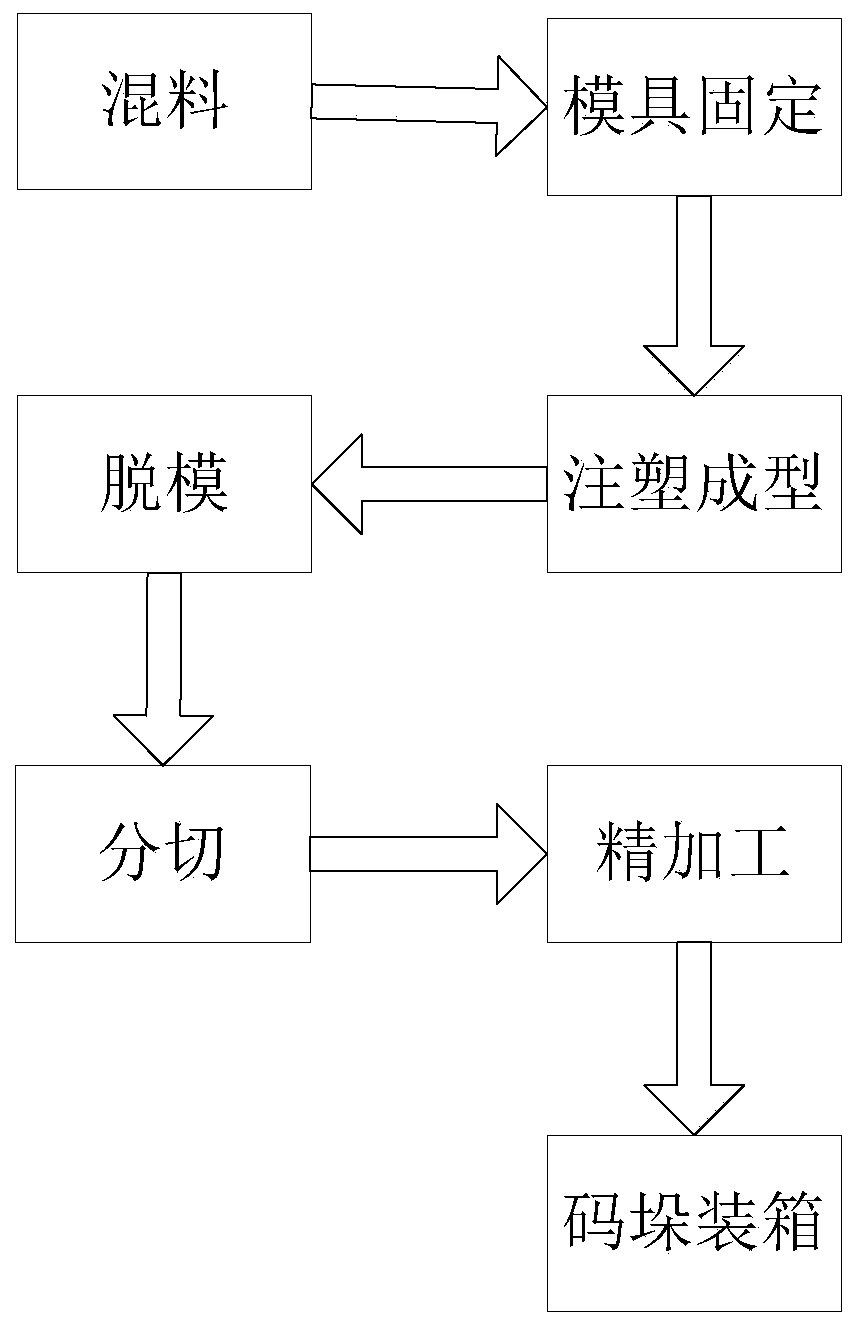

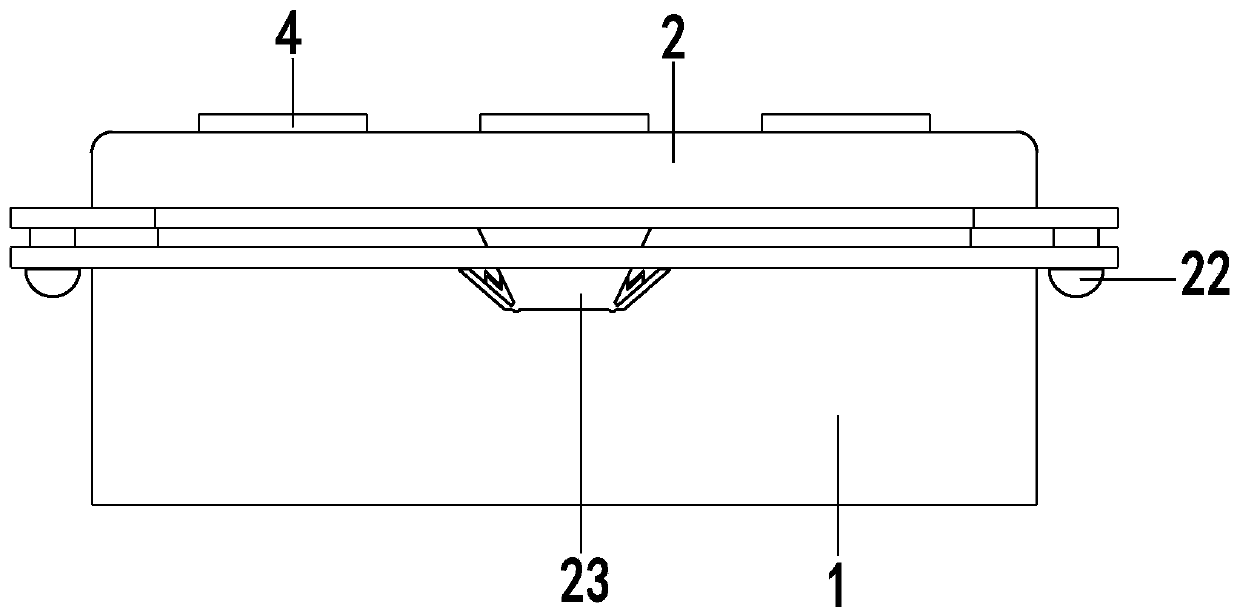

Plastic packaging box and production process thereof

ActiveCN110015495AImprove stabilityCause scratchesNon-removalbe lids/coversTray containersPlastic packagingInstability

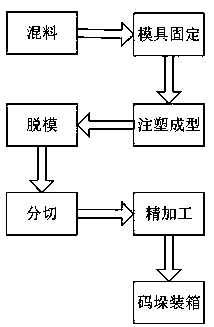

The invention relates to a plastic packaging box. The plastic packaging box comprises a box body, a box cover, a connection bar and lugs, wherein the box body is connected with the box cover through the connection bar; grooves are formed in the lower end of the box body in the form of front-rear symmetry, the lugs are arranged at the upper end of the box cover in the form of front-rear symmetry, and the grooves form one-to-one correspondence with the lugs in position; and the box cover comprises a cover body, an auxiliary buckle, a clamping block, an elastic sheet and a press sheet. The invention further provides a production process for the plastic packaging box. The production process for the plastic packaging box comprises the steps of material mixing, injection die fixing, injection forming, die release, slitting, finish machining, and stacking and boxing, wherein a slitting device comprises a base plate, a workbench, a working cylinder, an installation frame, a location frame anda slitting tool. The plastic packaging box has the advantages of being firm in connection firmness for the box cover and the box body, high instability during stacking and transporting; and the slitting device has the advantages of being high in slitting accuracy, free from causing scratches to the plastic packaging box, capable of directly carrying out stacking, and the like.

Owner:JILIN LONGYUN CHEM IND

Safety automatic slitting device for traditional Chinese medicinal material processing

InactiveCN112060144AIncrease the feeding speedImprove work efficiencyMetal working apparatusElectric machineryDrive motor

The invention discloses a safety automatic slitting device for traditional Chinese medicinal material processing, which comprises a working platform, a support frame, a slitting table, a driving motor, a rotating roller, slitting knives, a discharging hopper, an automatic pushing mechanism, a transmission guide device and a buffer receiving device. According to the safety automatic slitting device, by arrranging the automatic pushing mechanism, under pushing of an electric push rod, a pushing plate can push to-be-slit traditional Chinese medicinal materials without manual pushing, the safety is improved, and meanwhile, the working efficiency is improved; moreover, the transmission guide device is arranged, after the upper ends of the pushed traditional Chinese medicinal materials are pressed by a transmission guide roller, the traditional Chinese medicinal materials are positioned and guided to the slitting knives to be slit, the stability of the traditional Chinese medicinal materialsis improved, and the slitting precision is improved; and by arranging the buffer receiving device, the slit traditional Chinese medicinal materials slide into a collecting box through a lower slidingway in a buffering mode, the traditional Chinese medicinal materials are prevented from being impacted and flying out, and therefore the traditional Chinese medicinal materials are conveniently and rapidly collected.

Owner:张毅斌

Anti-static aluminum-plastic composite packaging bag and processing equipment thereof

ActiveCN112591291AAvoid edges and cornersAvoid scratchesBag making operationsPaper-makingStructural engineeringWaste material

The invention discloses an anti-static aluminum-plastic composite packaging bag which comprises a bag body. A lifting handle is integrally formed at an opening of the bag body, the lifting handle is arranged in an arc shape, an arc-shaped piece is integrally formed at the side, close to the opening of the bag body, of the lifting handle, gaps are reserved between the two ends of the arc-shaped piece and the lifting handle, and the two ends of the arc-shaped piece are arranged in a smooth transition manner; and the four corners of the bag body are arc-shaped corners. According to the bag, edgesand corners of the bag body are prevented from being generated and scratching a user, the contact area between the lifting handle and the palm of the user is greatly increased, and the hand of the user is prevented from being hurt by tying due to the too small contact area between the lifting handle and the palm of the user. The invention further provides processing equipment for the anti-staticaluminum-plastic composite packaging bag. The processing equipment comprises a conveying mechanism, a cutting mechanism, a winding mechanism, an adjusting mechanism, a receiving mechanism and a control mechanism. The processing equipment automatically and continuously cuts, processes and manufactures bags, the cut bags automatically fall into a material receiving groove, and waste materials are wound by the winding mechanism, so that the working efficiency is high, the adjusting performance is good, and the cutting precision is high.

Owner:LIANYUNGANG ZHONGYUAN PACKAGING CO LTD

Non-woven fabric cutting device

The invention discloses a non-woven fabric cutting device. The non-woven fabric cutting device is characterized in that a rack is provided with an unwinding mechanism, a length counter, cloth guide rollers, a liftable cutting assembly and a winding mechanism in sequence from left to right; the liftable cutting assembly is composed of a triangular frame, a chain belt, a double-gear shaft, a liftingdriving device and a transmission chain belt, the left end of the bottom side of the triangular frame is movably connected to the rack through a pin shaft, a cutting blade is arranged on the triangular frame, and the cloth guide rollers are arranged on the two sides of the cutting blade; the lifting driving device drives the double-gear shaft to rotate through the transmission chain belt; the chain belt is connected with the double-gear shaft, springs are arranged at the two ends of the chain belt, and the chain belt is connected with the left end of the bottom side of the triangular frame through the spring at the left end and is connected with the rack through the spring at the right end. The non-woven fabric cutting device is simple in structure, convenient to use, high in cutting precision and suitable for cutting fabric with different sizes.

Owner:YANCHENG CITY LONG XIANG MACHINERY MFG PLANT

Automatic paperboard slitting device for carton processing

InactiveCN109572047AEasy to polishGuaranteed sharpnessBox making operationsGrinding drivesCardboardCarton

The invention discloses an automatic paperboard slitting device for carton processing. The automatic paperboard slitting device comprises a base and supporting legs, the two sides of the bottom of thebase are fixedly connected with the tops of the supporting legs. The invention relates to the technical field of carton processing. According to the automatic paperboard slitting device for carton processing, a motor sliding rail is fixedly connected to one side of a support, the surface of the motor sliding rail is provided with a linear motor, one end of an output shaft of the linear motor is fixedly connected with a mounting block, one side of the mounting block is slidably connected with the surface of the motor slide rail, and one side of the mounting plate is fixedly connected with a grinding device through bolts. Slitting blades can be conveniently ground, the sharpness of the slitting blades is ensured, the slitting scrapping rate is reduced, and the cost is effectively reduced; limiting plates are fixedly connected to the two sides of the top of the base, second sliding grooves are formed in the top of the base, paperboards can be limited, misalignment of the paperboards during slitting is avoided, and the slitting accuracy of the paperboards is effectively improved.

Owner:TIANJIN HAILICHENG PAPER PROD CO LTD

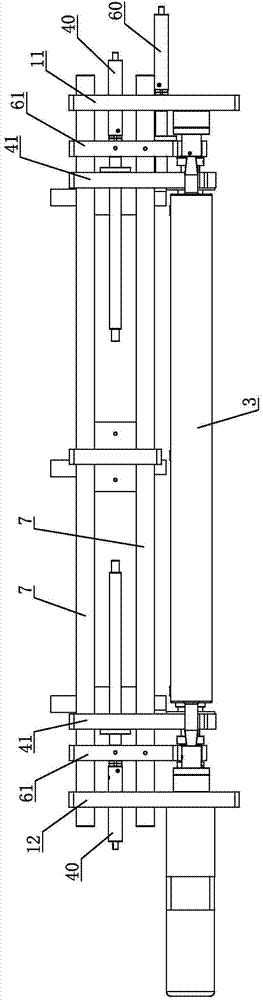

CIGS flexible cell slice cutting machine and its use method

ActiveCN106328768AImprove slitting accuracyImprove cutting efficiencyFinal product manufactureSemiconductor devicesAgricultural engineeringPressure increase

The invention discloses a CIGS flexible cell slice cutting machine and its use method. The cutting machine comprises an upper knife mold, a lower knife mold, a frame and a guide post, wherein the lower knife mold is arranged right under the upper knife mold and a cell slice is placed on the lower knife mold. The upper knife mold comprises a plurality of cutting tools and upper knife mold clamping units. Between every two upper knife mold clamping units, a cutting tool is fixedly arranged. The upper knife mold is connected with the frame through the guide post; and the upper knife mold driven by a pressure increasing cylinder moves reciprocally towards the low knife mold. The cutting machine provided by the invention can achieve high cutting efficiency. The cooperation of the upper knife mold and the lower knife mold can reach cutting precision of 0.1 mm. Due to its high efficiency, a plurality of cell slices can be cut at one attempt.

Owner:山东智汇时代信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com