Optical polyester film

An optical polyester film and biaxially oriented film technology, applied in the field of polyester film, can solve the problems of easy adhesion and poor film surface performance, and achieve the effect of improving quality, improving quality and increasing shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

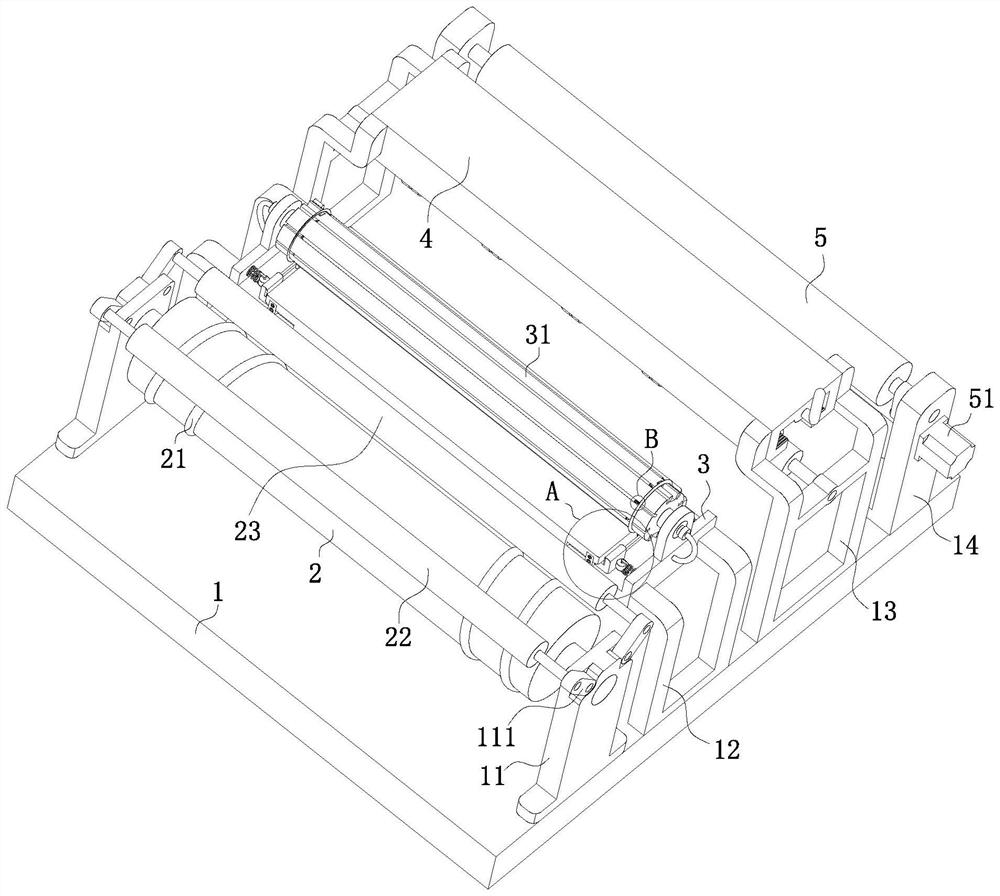

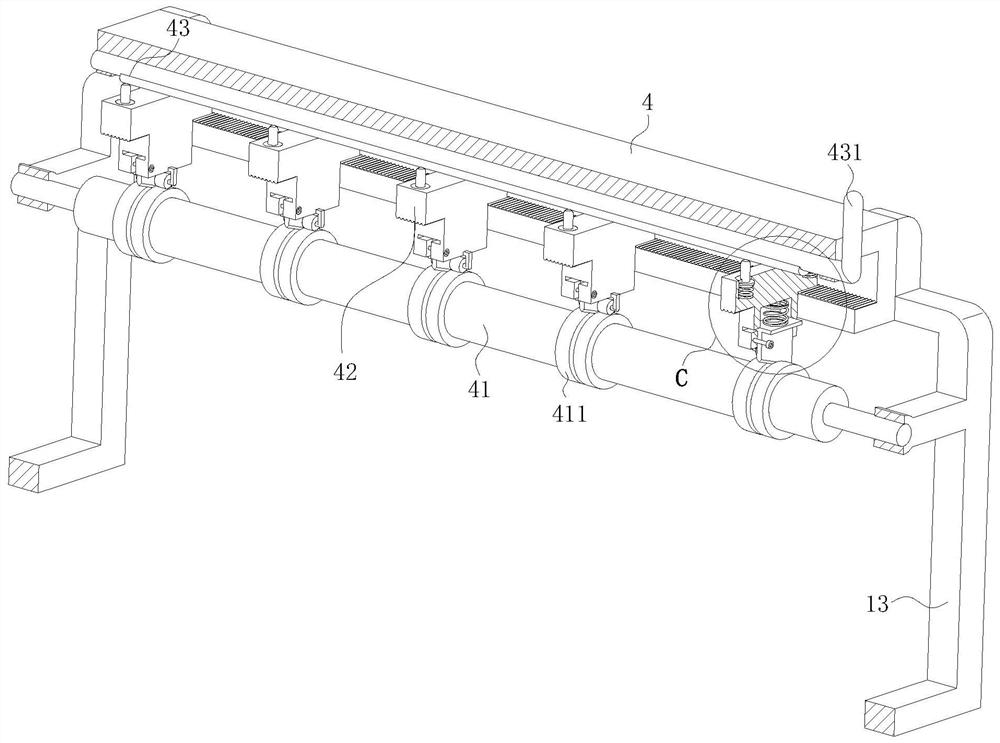

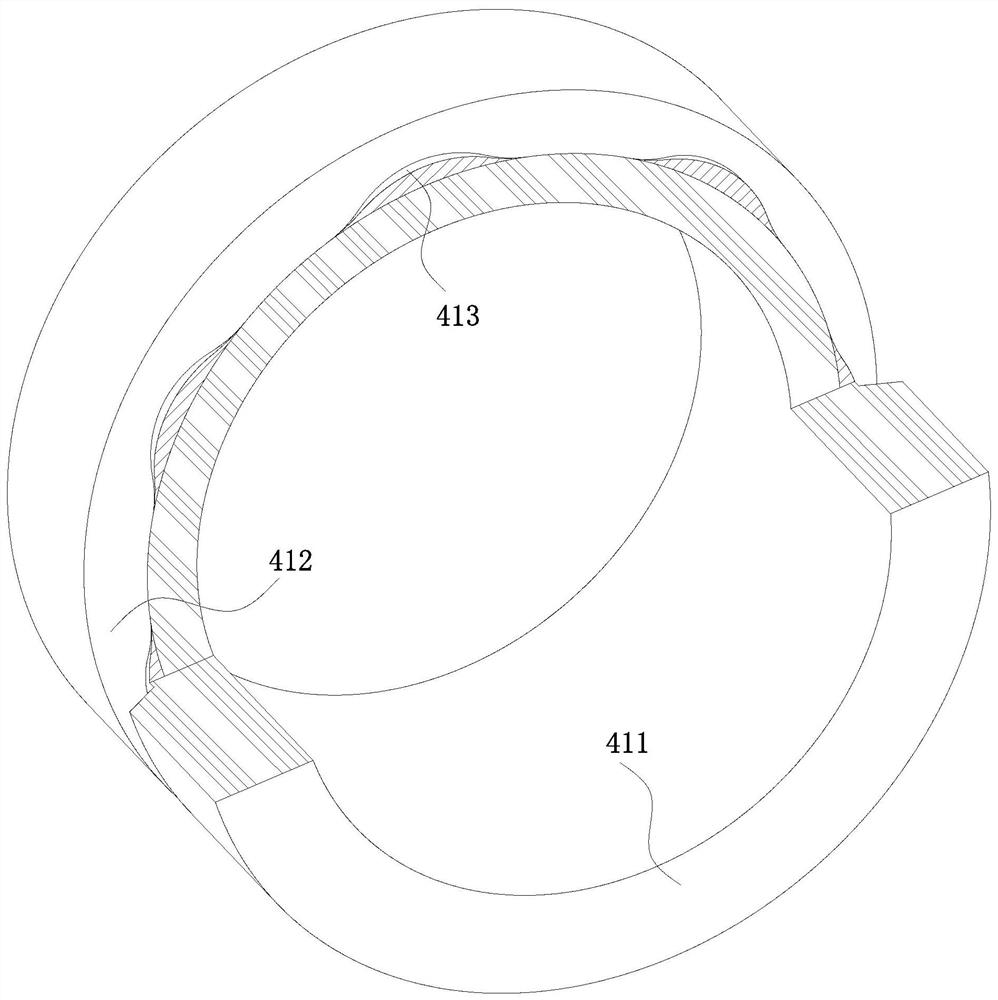

[0045] As an embodiment of the present invention, a plurality of mounting grooves 311 are evenly opened on the cutting roller 31; a mounting frame 314 is installed at the bottom of the mounting groove 311; Free movement; the mounting frame one 314 is fixedly equipped with a horizontal plate 315; the side walls on both sides of the mounting groove 311 are provided with accommodating grooves 317; the two ends of the horizontal plate 315 are inserted into the accommodating groove 317; A spring 316 is installed on the mounting frame 1 314; the spring 1 316 is located between the horizontal plate 315 and the bottom of the mounting groove 311; a round roller 313 is installed on the mounting frame 1 314; Protrude out of the surface of the cutting roller 31; the circular roller 313 is located between the two upper cutters 312 on the cutting roller 31; the rotation speed of the cutting roller 31 is greater than the gap between the film passing through the cutting roller 31 and the flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com