Double-layer cloth spreader with precision slitting mechanism

A spreading machine, double-layer technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of noise pollution in the workshop, incomplete separation of cloth, and difficulty in size adjustment, so as to simplify the structure, realize portability and Precise, easy-to-cut results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

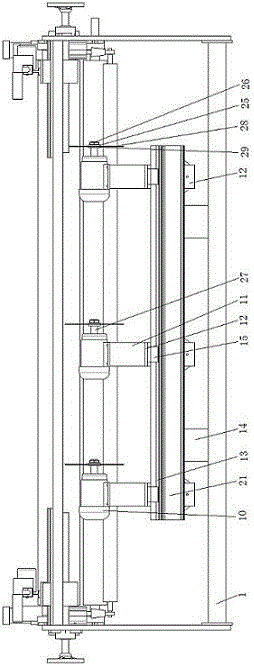

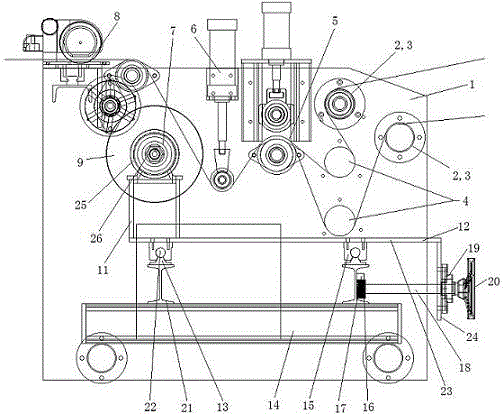

[0021] Embodiment 1: as figure 1 — Figure 4 , a double-layer spreading machine with a precision cutting mechanism, including a frame 1 and a feeding mechanism 2 arranged on the frame 1, a deviation correction mechanism 3, a storage mechanism 4, a feeding and mixing mechanism 5, a cutting mechanism Mechanism 7, edge trimming mechanism, cross-cutting mechanism 8, material pulling mechanism and conveying mechanism, described discharging mechanism 2, correction mechanism 3 and storage mechanism 4 are arranged on one side of feeding and mixing mechanism 5, and described cutting mechanism 7. The trimming mechanism, the cross-cutting mechanism 8, the pulling mechanism and the conveying mechanism are arranged on the other side of the feeding and mixing mechanism 5 in sequence. And between the cutting mechanism 7 and the feeding and mixing mechanism 5, a pressing mechanism 6 is also arranged. The pressing mechanism 6 drives the pressing shaft to reciprocate up and down through the cy...

Embodiment 2

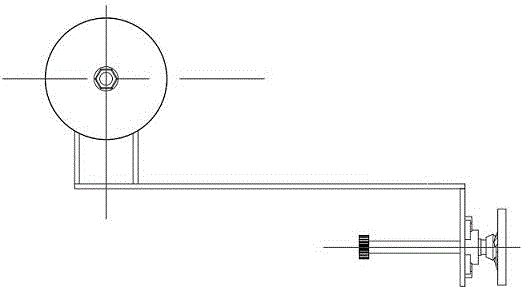

[0022] Embodiment 2: as figure 1 — Figure 4, as an improvement of the present invention, the tool position adjustment device includes a rack and pinion transmission mechanism, a distance adjustment shaft 18 and a manual / automatic distance adjustment mechanism, and the rack and pinion transmission mechanism includes a gear 16 and a gear meshed with the gear Rack 17, the distance adjustment operation of the rack and pinion transmission mechanism is simple, and the wear resistance is good, which is conducive to prolonging the service life of the tool position adjustment device. The gear is fixedly sleeved on one end of the distance adjustment shaft 18, the rack is set sideways on the installation part between the linear slide rail 13 and the support base 14, and the manual / automatic distance adjustment mechanism is fixedly arranged on a fixed plate 12, and is connected with the other end of the distance adjustment shaft 18 in transmission. During use, the distance-adjusting sh...

Embodiment 3

[0023] Embodiment 3: as figure 1 — Figure 4 , as an improvement of the present invention, the manual / automatic distance adjustment mechanism includes an adjustment handwheel 20 and a bearing with seat 19, and a through hole is opened on the fixed plate 12, and the bearing with seat 19 is arranged on the fixed plate 12 and the bearing hole of the bearing with seat 19 communicates with the through hole, the distance adjusting shaft 18 passes through the through hole and the bearing hole in turn and is fixedly connected to the bearing with seat 19, and the adjusting hand wheel 20 is fixedly installed on the seat on the bearing 19. By rotating the adjusting handwheel 20, the belt seat bearing 19 is driven to rotate clockwise or counterclockwise, thereby driving the gear at the other end of the distance adjusting shaft 18 to move up and down on the rack through the belt seat bearing 19 transmission, so as to realize the left and right of the cutting tool 9 position to adjust. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com