Pole piece splitting machine

A slitting machine and pole piece technology, which is applied in electrode manufacturing, battery electrodes, cleaning methods and utensils, etc., can solve the problems of deviation of raw material pole pieces, low pole piece cutting precision, etc., so as to improve the cutting precision, The effect of improving the cutting accuracy and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

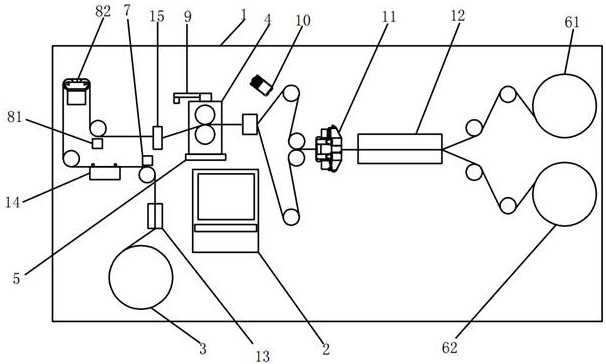

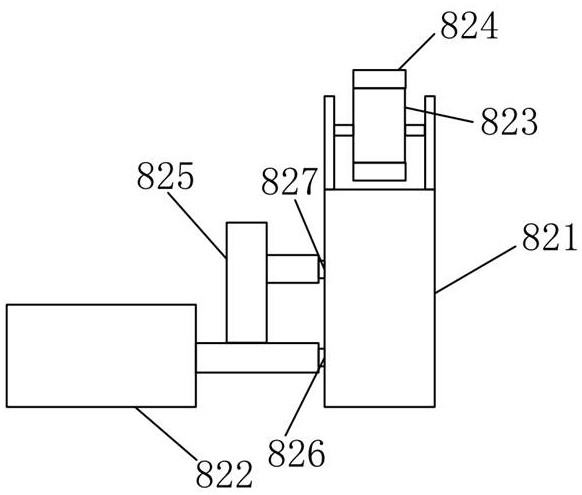

[0050] refer to figure 1 with figure 2 , the embodiment of the present application provides a pole piece slitting machine, including a base 1, a controller 2, an unwinding assembly 3, a die structure 4, a winding assembly, a first deviation correction sensor 7, a deviation correction system, and a translation assembly 5 And the first visual detection component 9, specifically:

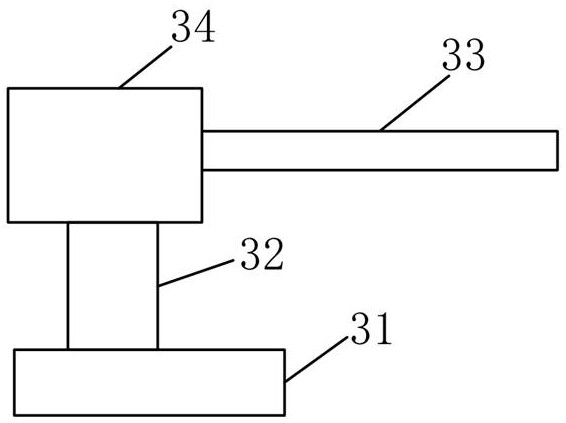

[0051]The above-mentioned unwinding assembly 3 includes a fixed seat 31, a movable seat 32 and a material reel 33; the fixed seat 31 is fixed on the base 1, the movable seat 32 is slidably arranged on the fixed seat, and the The material reel shaft 33 is arranged on the moving seat, wherein, the sliding direction of the moving seat 32 on the fixed seat 31 is the same as the axial direction of the material reel shaft 33; The edge of the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com