Anti-static aluminum-plastic composite packaging bag and processing equipment thereof

An aluminum-plastic composite and processing equipment technology, applied in the field of packaging bags, can solve the problems of poor cutting accuracy, small contact area, easy to strangle the user's hand, etc., to prevent the contact area from being too small, improve the contact area, The effect of improving the cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as Figure 4-Figure 6 As shown, an antistatic aluminum-plastic composite packaging bag according to an embodiment of the present invention includes:

[0048]The bag body 100, the opening of the bag body 100 is integrally formed with a handle 101, the handle 101 is arranged in an arc shape, and the side of the handle 101 close to the opening of the bag body 100 is integrally formed with an arc Shaped sheet 102, there is a gap 103 between the two ends of the arc-shaped sheet 102 and the handle 101, the two ends of the arc-shaped sheet 102 are round and smooth transition settings, the four corners of the bag body 100 is arc angle 104;

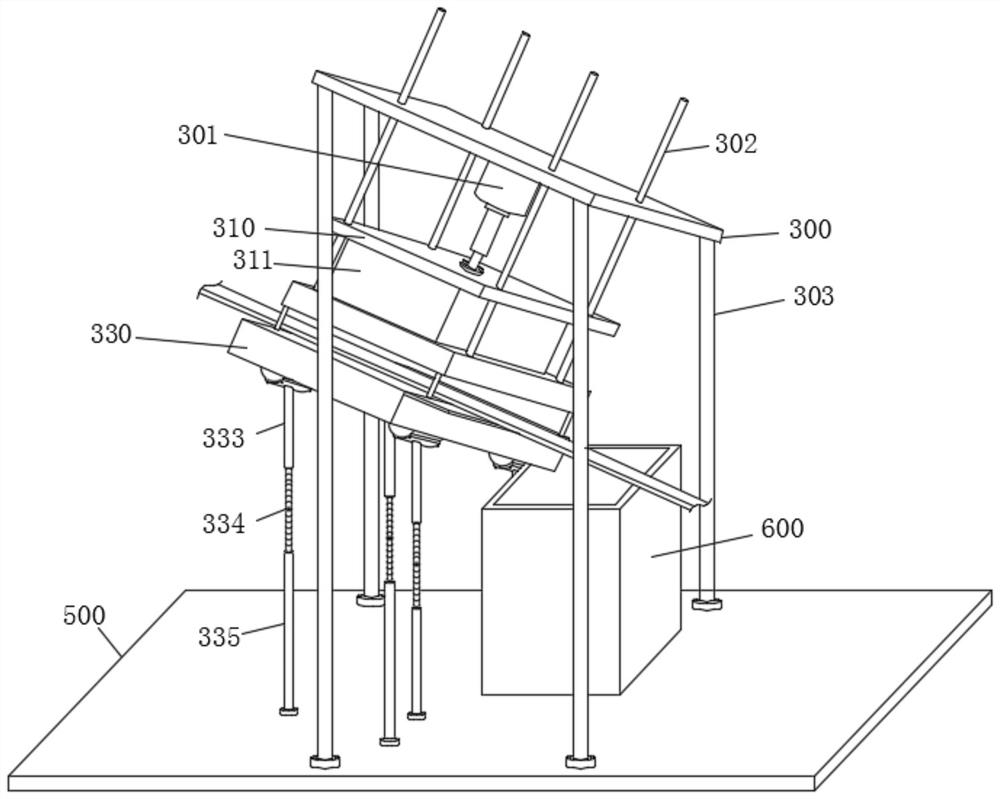

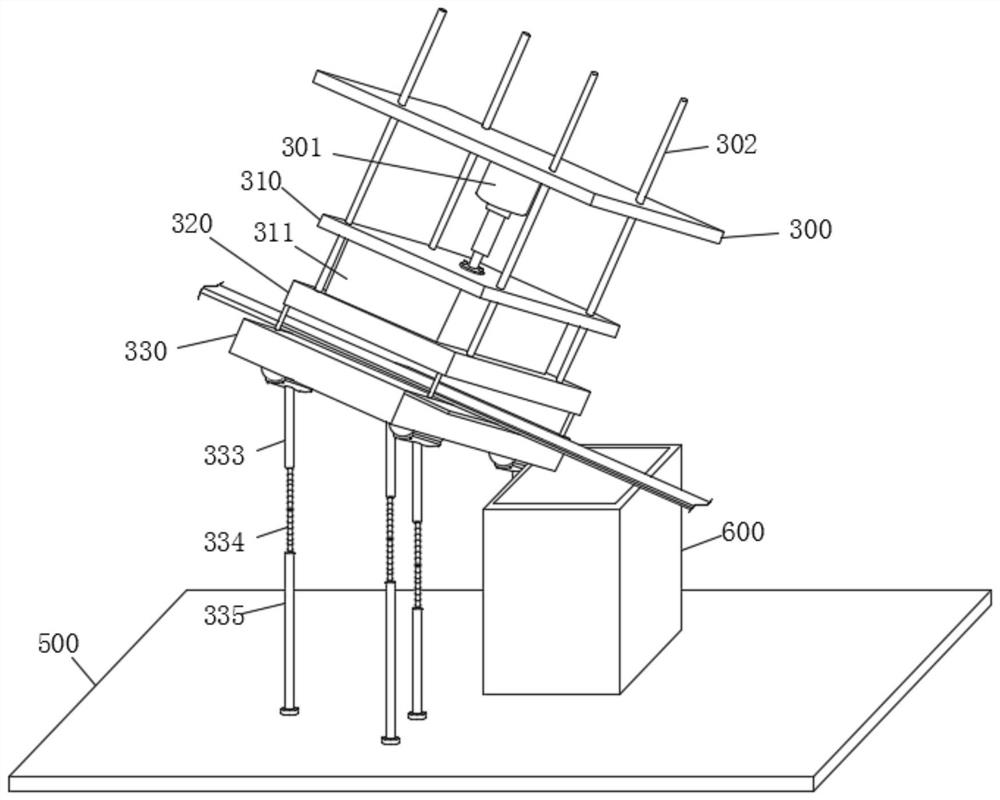

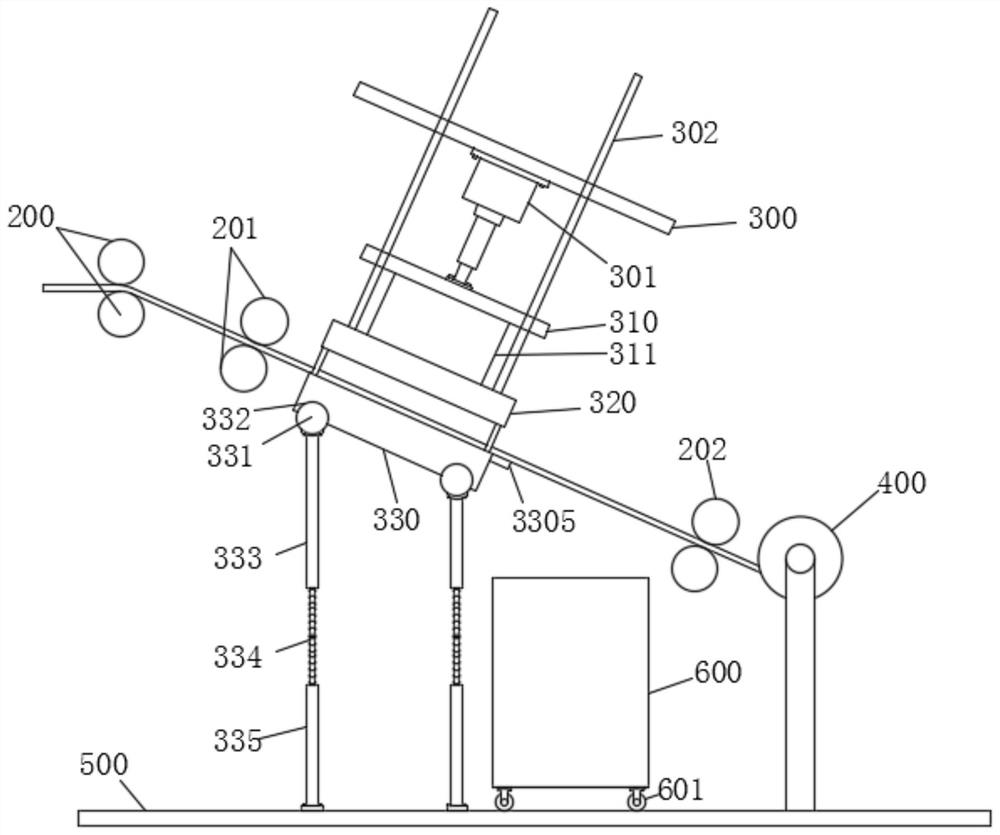

[0049] Such as figure 1 , figure 2 , image 3 with Figure 7 As shown, the present invention also provides a processing equipment for antistatic aluminum-plastic composite packaging bags, including a transmission mechanism, a cutting mechanism, a winding mechanism, an adjustment mechanism, a material receiving mechanism and a con...

Embodiment 2

[0067] The differences between this implementation and Example 1 are:

[0068] Such as Figure 8 with Figure 9 As shown, round rods 3302 are installed on the four corners of the top of the rectangular operating platform 330, the outer wall of the round rod 3302 is welded with a ring 3303, and the four corners of the knife guide plate 320 are provided with sockets 3202, when the When the round rod 3302 is inserted into the insertion hole 3202 , the circular ring 3303 carries the knife guiding plate 320 .

[0069] By adopting the above technical solution, when the round rod 3302 is inserted into the insertion hole 3202 , the cutter guide plate 320 is carried by the ring 3303 , which facilitates the installation of the cutter guide plate 320 .

Embodiment 3

[0071] The differences between this implementation and Embodiment 2 are:

[0072] Such as Figure 8 with Figure 9 As shown, the top outer wall of the round rod 3302 is provided with an external thread 3304, the top of the round rod 3302 is covered with a nut 3203 to fix the cutter guide plate 320, and the top of the jack 3202 is provided with Reaming slot 3204 , the nut 3203 is located inside the reaming slot 3204 .

[0073] By adopting the above technical solution, the stability of the cutter guide plate 320 is improved through the limiting effect of the nut 3203 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com