Method for producing macromolecule orthodontic tooth crown

A manufacturing method, polymer technology, applied in orthodontics, dentistry, dental prosthetics, etc.

Active Publication Date: 2010-08-25

XIAN HENGHUI TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The advantages of plastic braces orthodontics are: beautiful, removable, hygienic, quantitative, and can improve the work efficiency of orthodontists; but there are still some improvements in the technology and production process of orthodontic braces currently used in Europe and the United States Space, such as manufacturing methods, product accuracy, production costs, measuring instruments and quality inspection methods, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

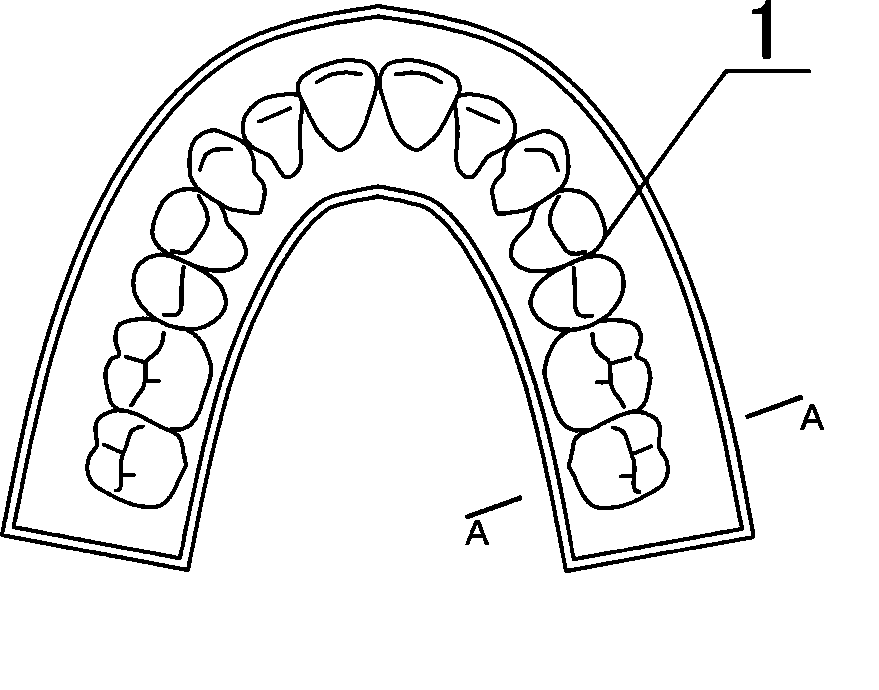

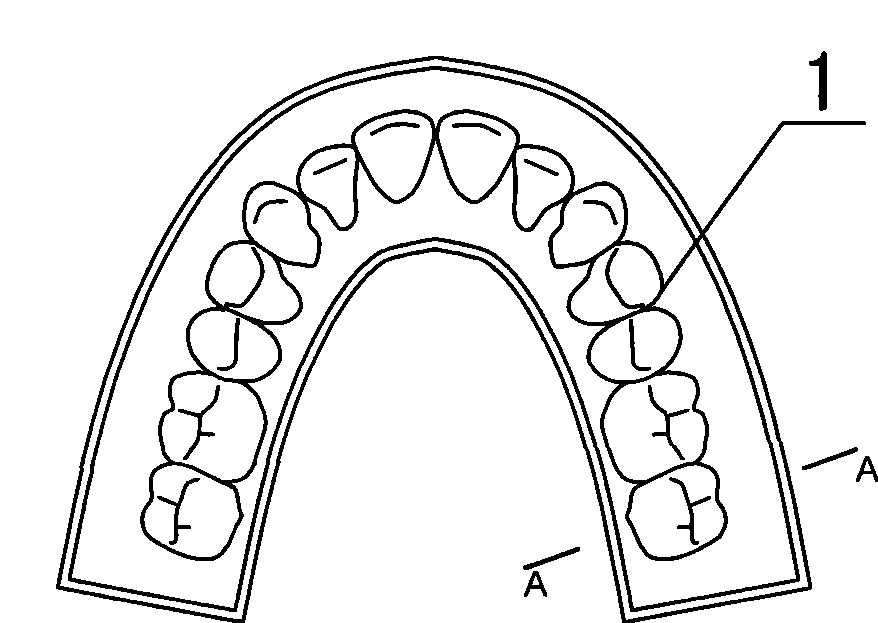

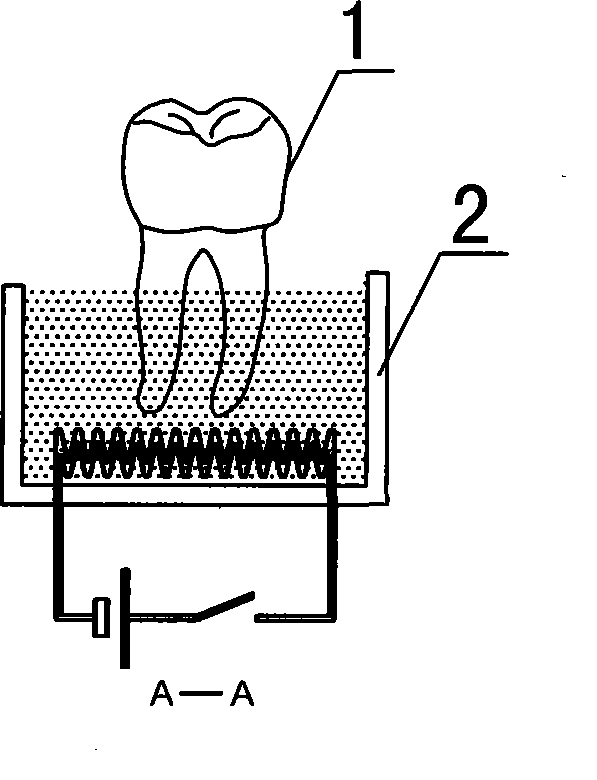

The invention relates to a manufacturing method of a polymer orthodontic bracket, which has high precision, low production cost, convenient usage and can be removed during the using process. The manufacturing method comprises the following operation steps: (1) a dental model is precisely duplicated and carried out the segmentation; (2) the dental model after the segmentation is reduced and arranged on a fixed object; (3) the precise adjustment of the position and the angle of a tooth after the segmentation is realized by using the automatic or manual method via the change of the physical state or the shape of the fixed object of the dental model; (4) the quality detection and the control of a closed loop are implemented by comparing the pre-adjusted position and the angle with the actual measurement position and the angle of the tooth; (5) the film pressing is carried out on the dental model after checking the angle and the position.

Description

Manufacturing method of polymer orthodontic braces 1. Technical field: The invention relates to a manufacturing method of orthodontic braces, in particular to a manufacturing method of polymer orthodontic braces. 2. Background technology: The traditional orthodontic method uses devices such as brackets and arched wires, which are large in size and have a strong sense of foreign body, making it uncomfortable for patients to wear; the contrast with the color of the teeth is large, and it is not beautiful enough; it cannot be removed during the entire treatment period, and it is easy to produce tartar and damage tooth enamel , with many edges and corners, it is easy to accumulate foreign matter on the surface of the teeth, and it is not convenient for oral cleaning, which is not conducive to oral hygiene. In recent years, with the widespread application of computer technology and new manufacturing processes in the orthodontic field, plastic braces orthodontics have begun to b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A61C7/00

Inventor 刘震寰刘岗梁文家

Owner XIAN HENGHUI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com