Patents

Literature

44results about How to "Avoid grooves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

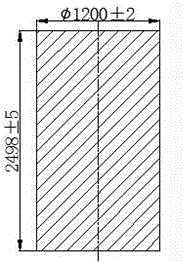

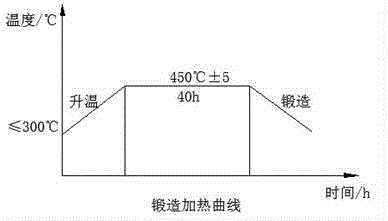

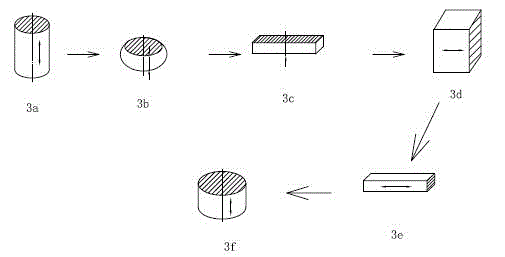

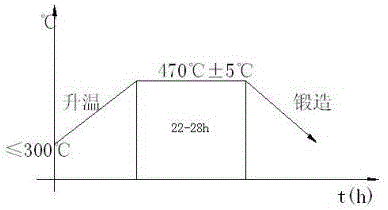

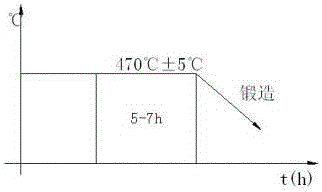

Forging forming technology of aluminum alloy straight-flanked ring with extra-large specification

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

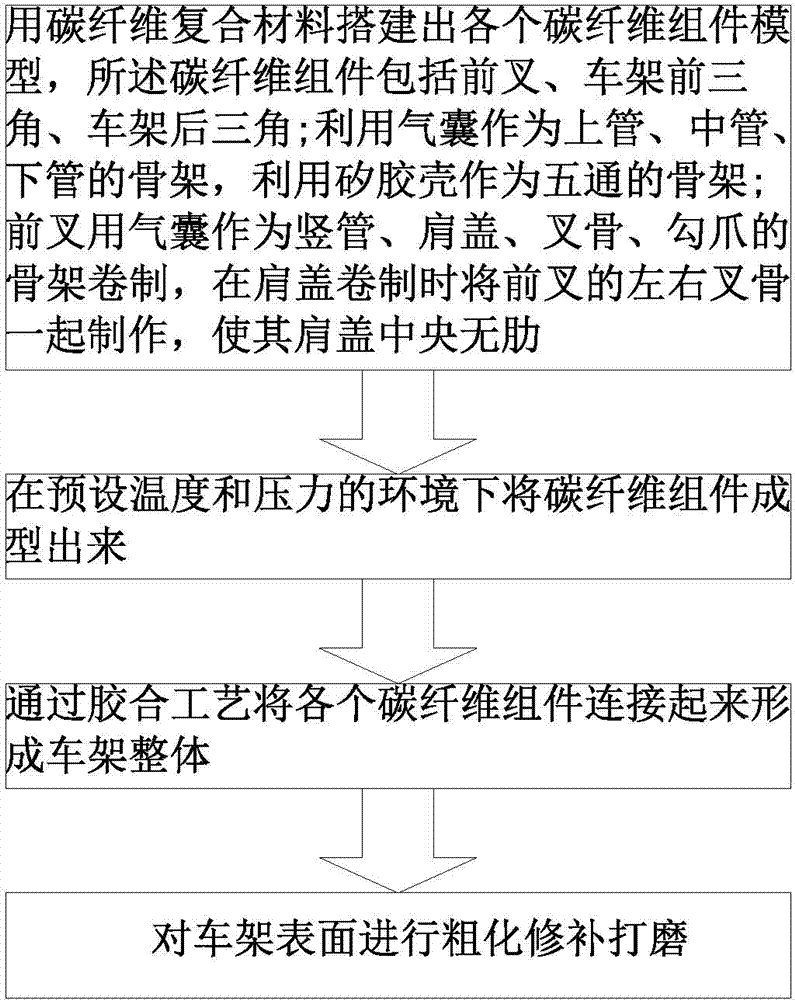

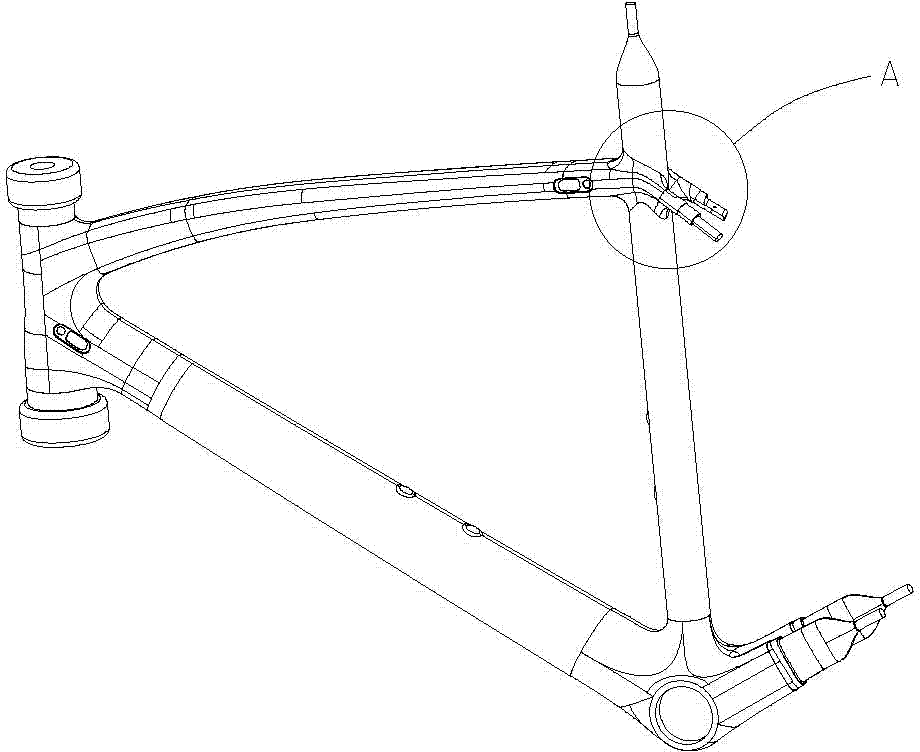

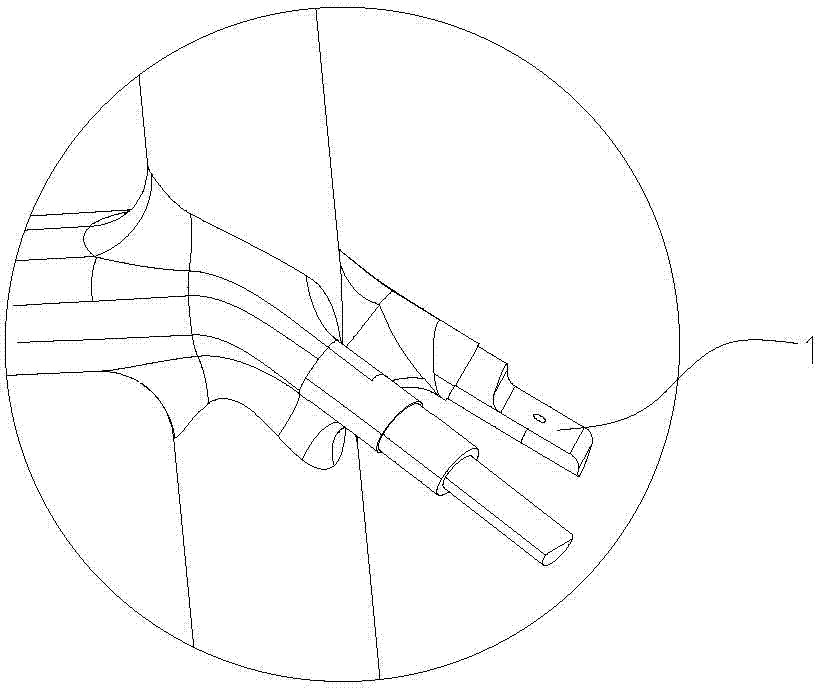

Carbon fiber bicycle frame production process

InactiveCN104494172AIncreased strength and rigidityStable structureCycle framesVehicle frameCarbon fiber composite

The invention relates to a carbon fiber bicycle frame production process, which comprises the following steps that (1) each carbon fiber component module is built by a carbon fiber composite material, and comprises a front fork, a front frame triangle and a rear frame triangle; a gas bag is used as a skeleton of a top tube, a seat tube and a down tube, and a silica gel shell is used as a skeleton of a bottom bracket; a gas bag for the front fork is used as a skeleton of a stem, a crown, a fork blade and a dropout to be rolled, and left and right fork blades of the front fork are produced together when the crown is produced by rolling, so that the center of the crown is ribless; (2) in a preset temperature and pressure environment, carbon fiber components are molded; (3) the carbon fiber components are connected by adopting a gluing process to form a whole frame; and (4) the surface of the frame is coarsely repaired and polished. The silica gel shell is used as the skeleton of the bottom bracket, so that the bottom bracket of the frame is reliably molded, and the strength of the molded bottom bracket connecting structure is high.

Owner:GUANGZHOU LEONIS MACHINERY

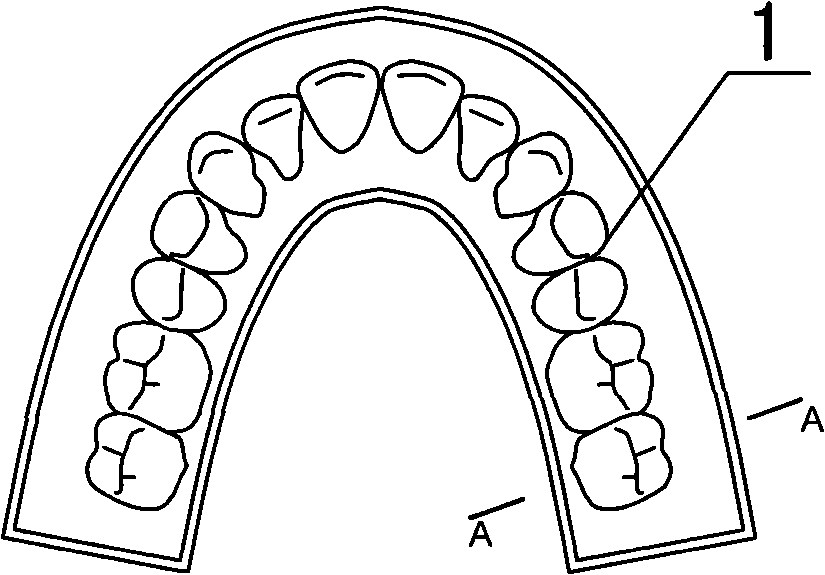

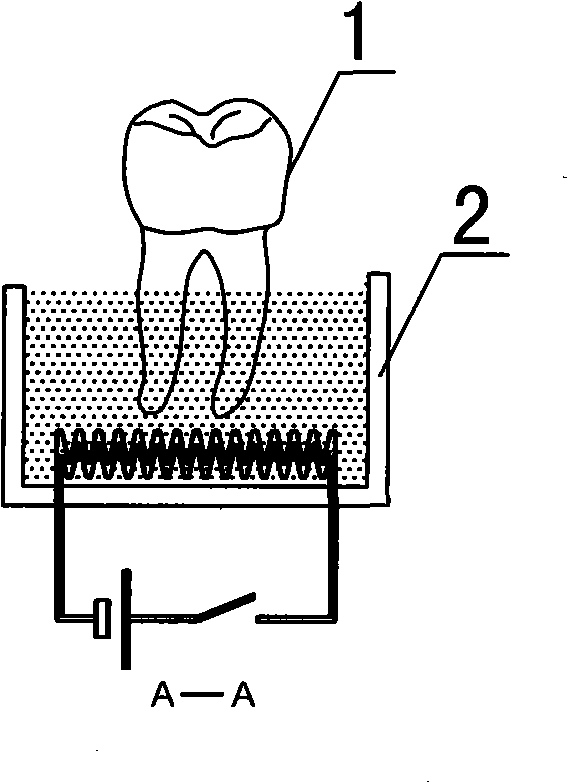

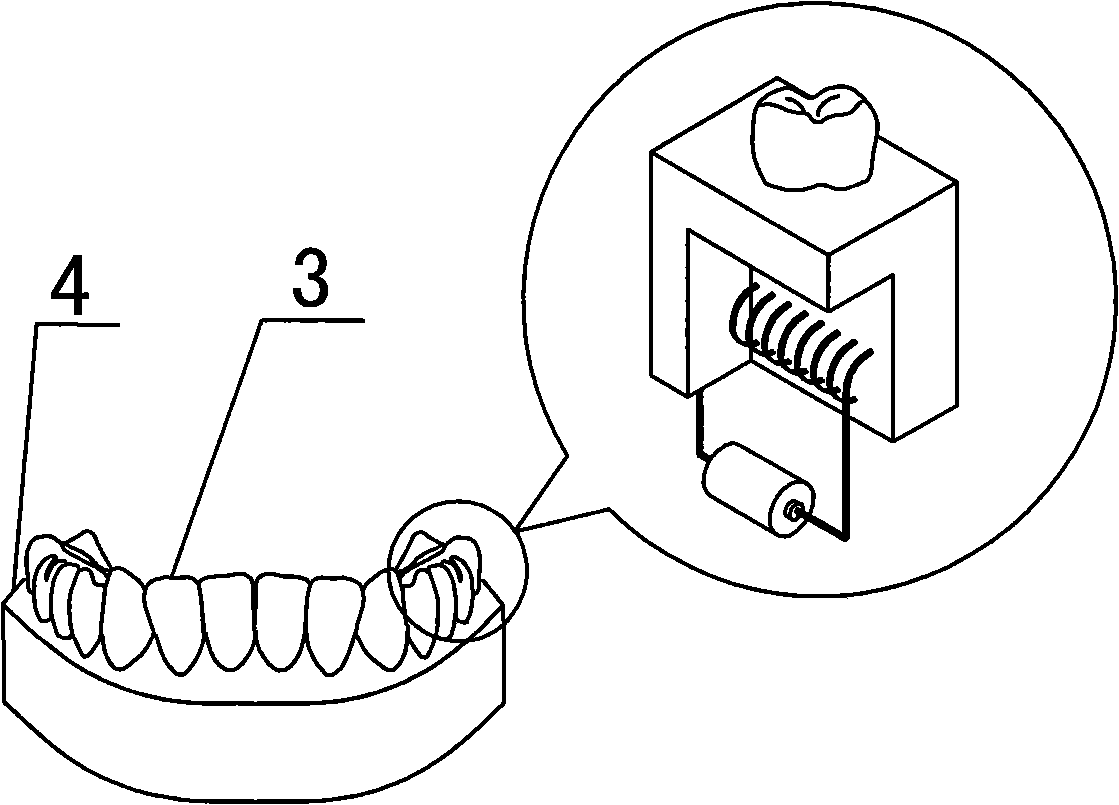

Method for producing macromolecule orthodontic tooth crown

ActiveCN101273921AGuaranteed accuracy and reliabilityEasy to controlOthrodonticsClosed loopEngineering

The invention relates to a manufacturing method of a polymer orthodontic bracket, which has high precision, low production cost, convenient usage and can be removed during the using process. The manufacturing method comprises the following operation steps: (1) a dental model is precisely duplicated and carried out the segmentation; (2) the dental model after the segmentation is reduced and arranged on a fixed object; (3) the precise adjustment of the position and the angle of a tooth after the segmentation is realized by using the automatic or manual method via the change of the physical state or the shape of the fixed object of the dental model; (4) the quality detection and the control of a closed loop are implemented by comparing the pre-adjusted position and the angle with the actual measurement position and the angle of the tooth; (5) the film pressing is carried out on the dental model after checking the angle and the position.

Owner:XIAN HENGHUI TECH

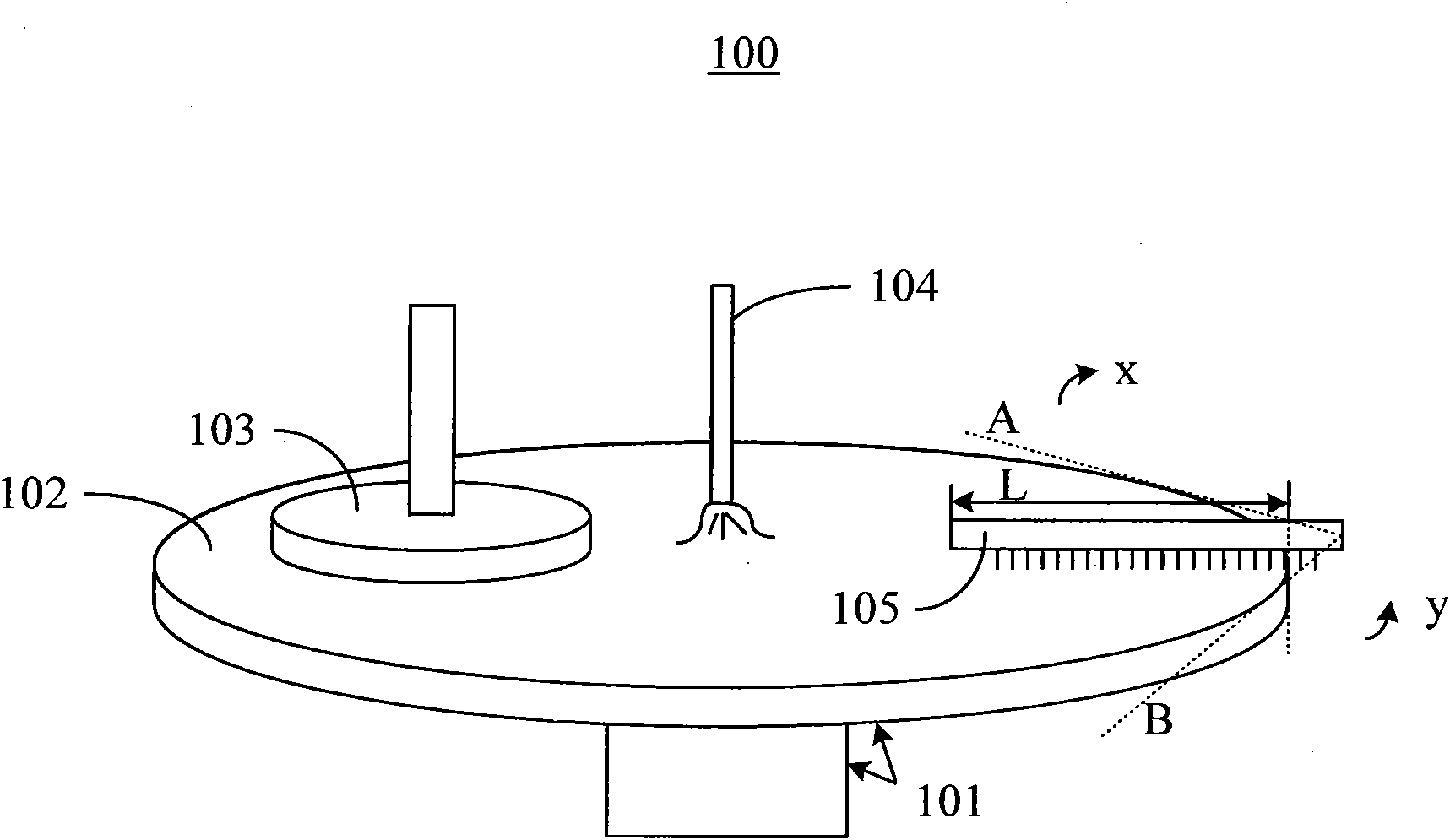

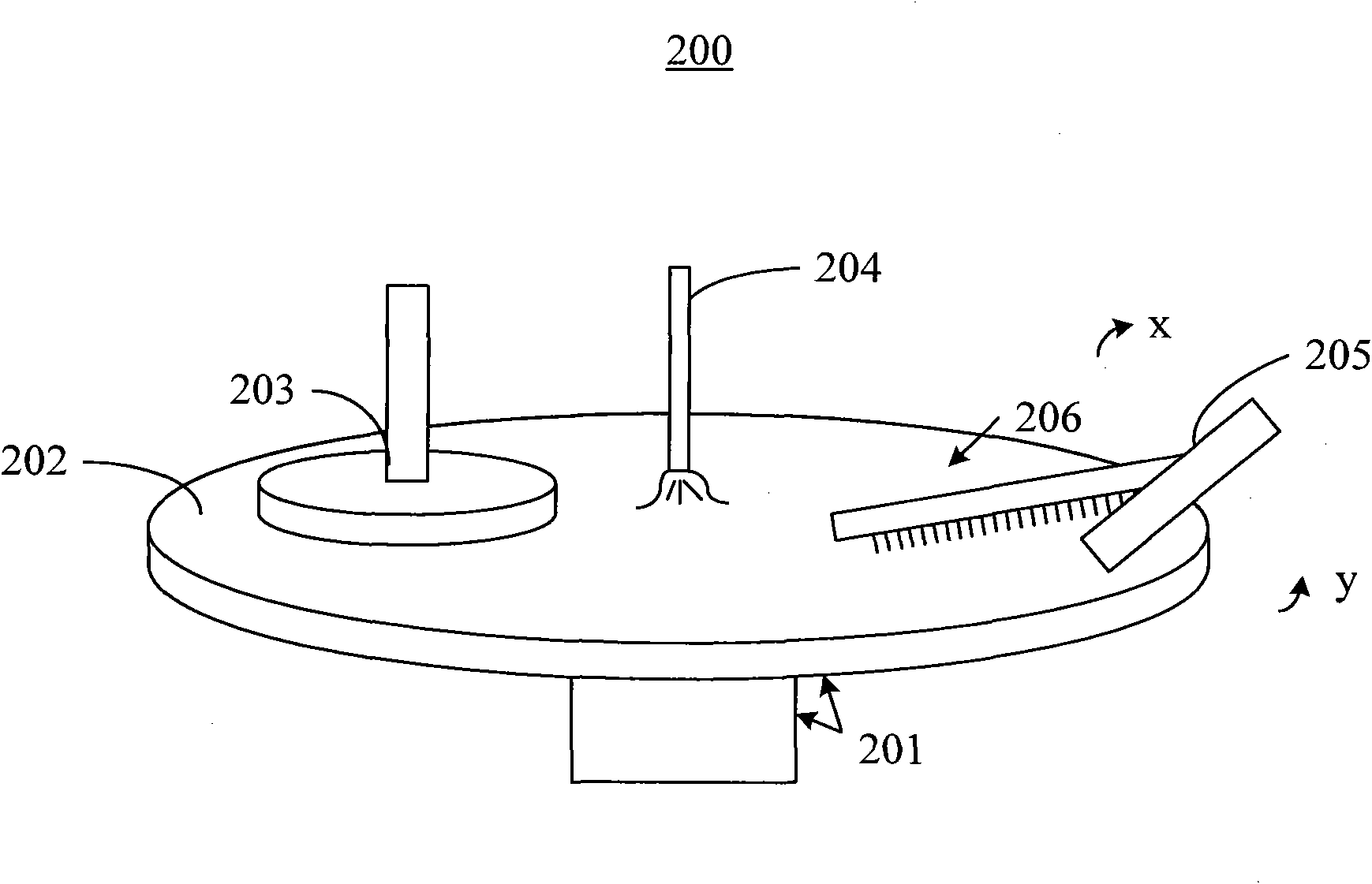

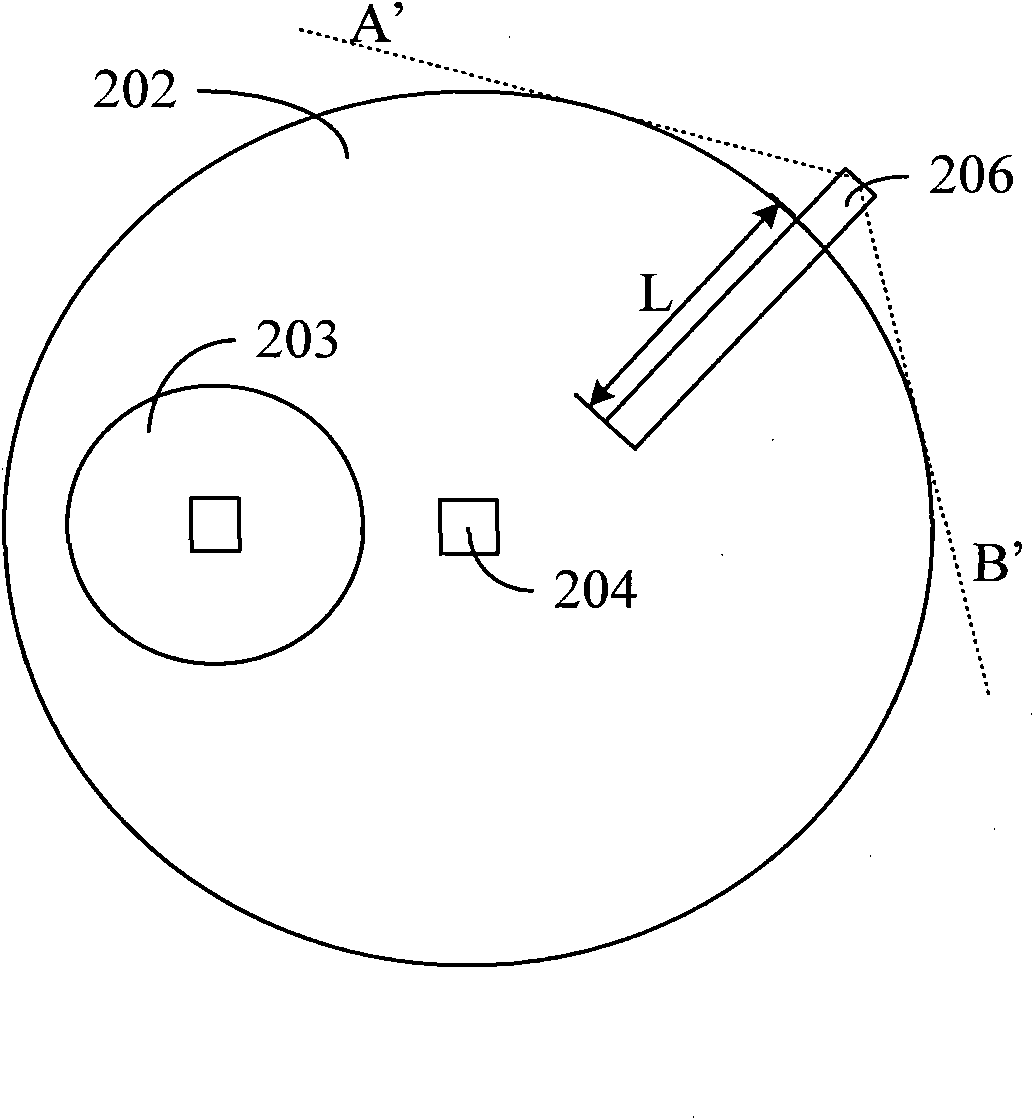

Chemical mechanical polishing equipment

InactiveCN102398212AGuaranteed final yieldGuaranteed reliabilityLapping machinesAbrasive surface conditioning devicesRelative motionEngineering

The invention relates to chemical mechanical polishing equipment, which comprises a rotating platform, a polishing pad fixed on the surface of the rotating platform, and a polishing head for fixing a chip. The chemical mechanical polishing equipment is used for polishing the chip through the relative motion between the rotating platform and the polishing head. The chemical mechanical polishing equipment also comprises a polishing pad cleaning element and a drive element, wherein the polishing pad cleaning element is in contact with the surface of the polishing pad so as to clean the surface of the polishing pad by utilizing the relative motion between the rotating platform and the polishing pad cleaning element; and the fixed end of the polishing pad cleaning element is rotatably fixed to the drive element, and the drive element can drive the polishing pad cleaning element to be contacted with or separated form the polishing pad, and can control the polishing pad cleaning element to carry out cleaning operation on the surface of the polishing pad. The chemical mechanical polishing equipment provided by the invention can be used for cleaning pollutants on the surface of the polishing pad, so that grooves or scrapes generated on the surface of the chip due to the existence of the pollutants can be avoided.

Owner:SEMICON MFG INT (SHANGHAI) CORP

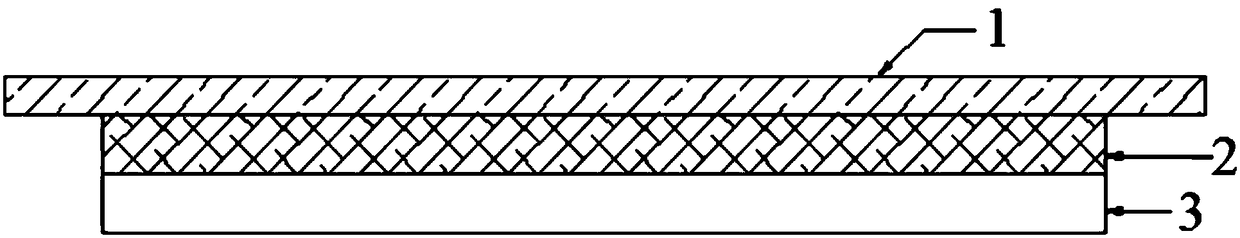

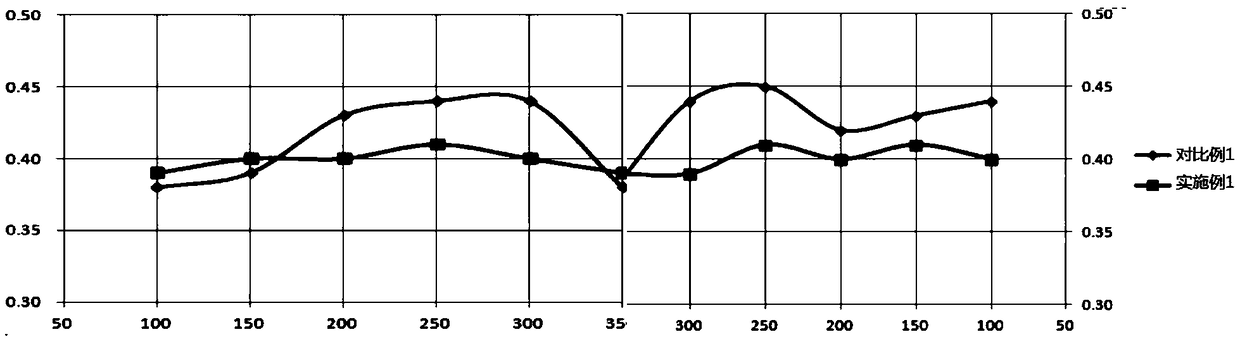

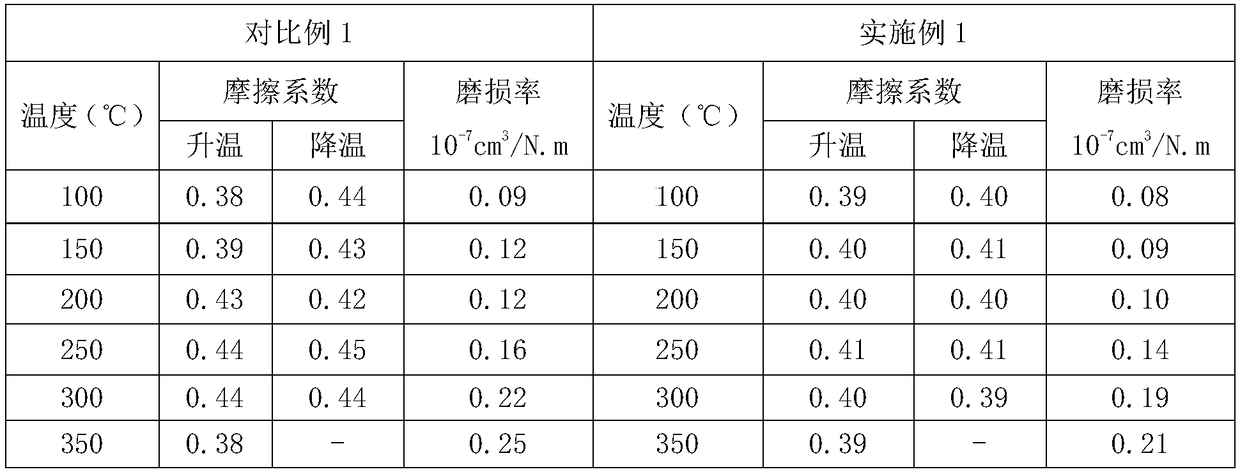

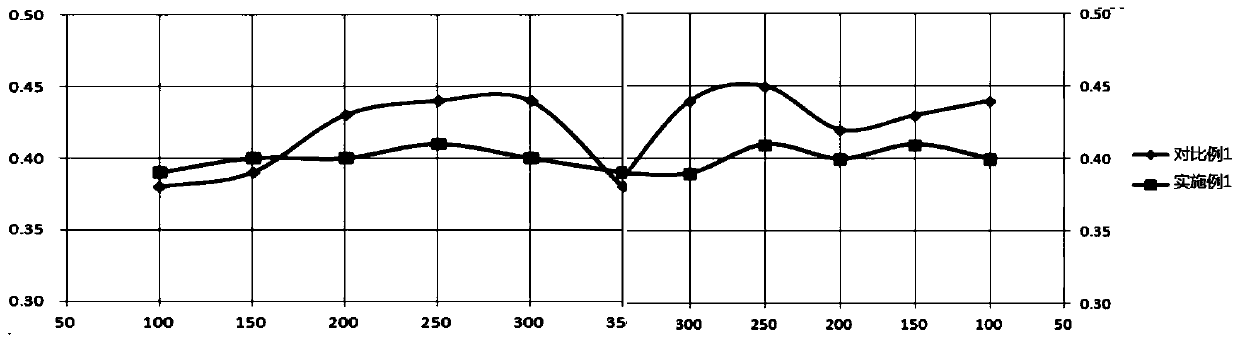

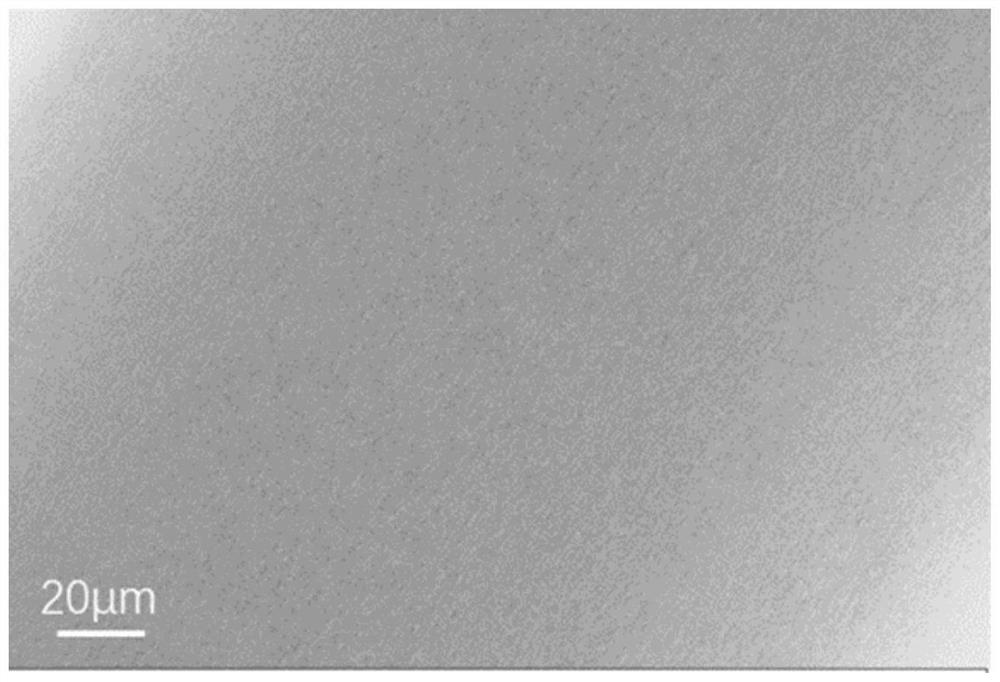

Low-wear disc type friction plate and preparing method thereof

ActiveCN109372911AGood adhesionHigh bonding strengthNoise/vibration controlOther chemical processesMetallurgyAdhesion strength

The invention provides a low-wear disc type friction plate. A buffer layer containing a magnetic material is added between a steel backing and a ceramic layer, adhesion between the buffer layer and the steel backing combination face can be improved, and the phenomenon that due to the brake high temperature (400 to 500 DEG C), the friction material buffer layer falls off from the steel backing face, and brake fails is avoided. The adhesion strength between the friction piece and the steel backing can be increased, iron hard points are prevented from appearing in the friction face, screeching and brake trembling generated in the brake process can be removed, brake disc scraping and grooves generated by the iron hard points can be avoided, and the service life of the brake disc can be prolonged.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

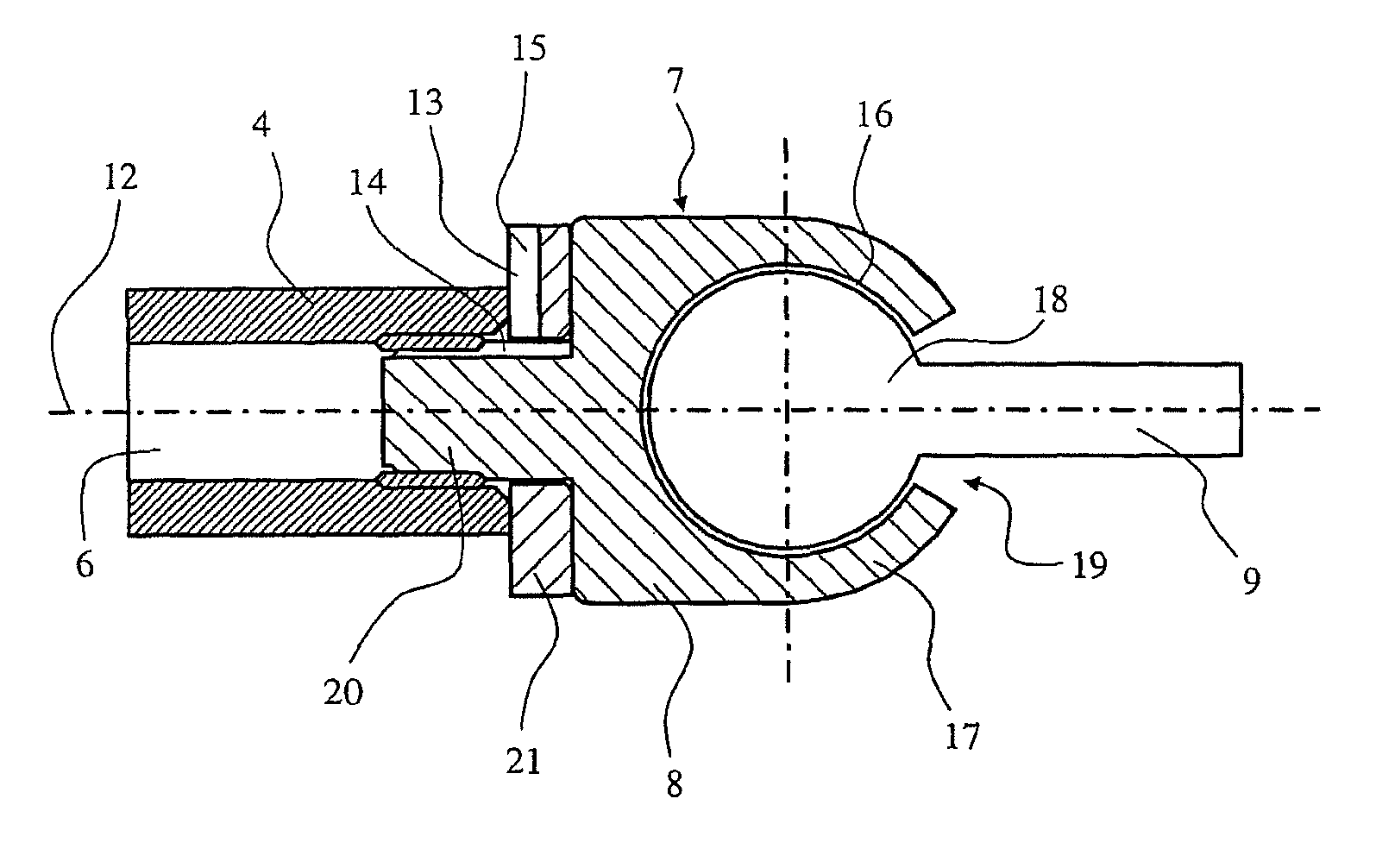

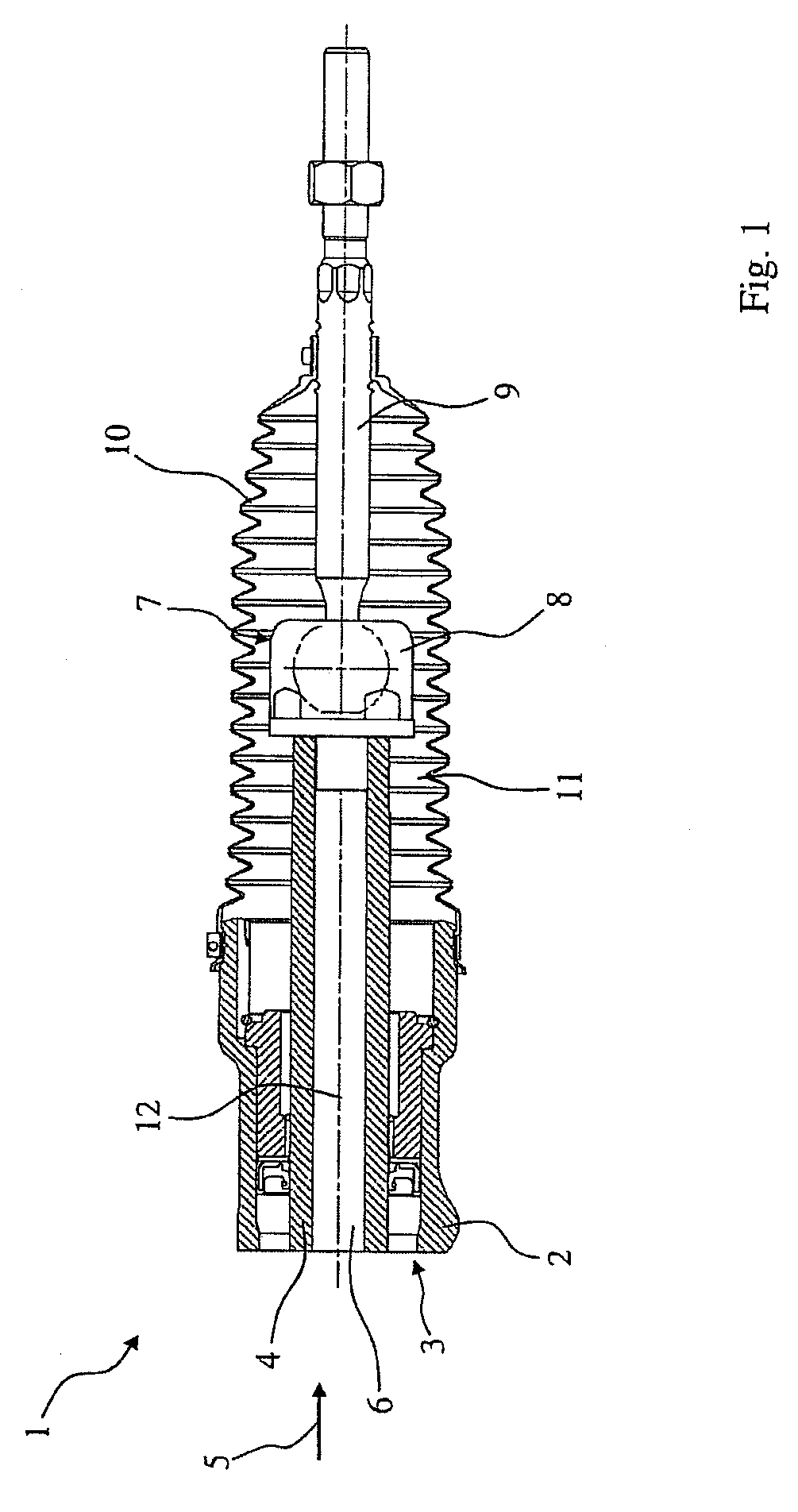

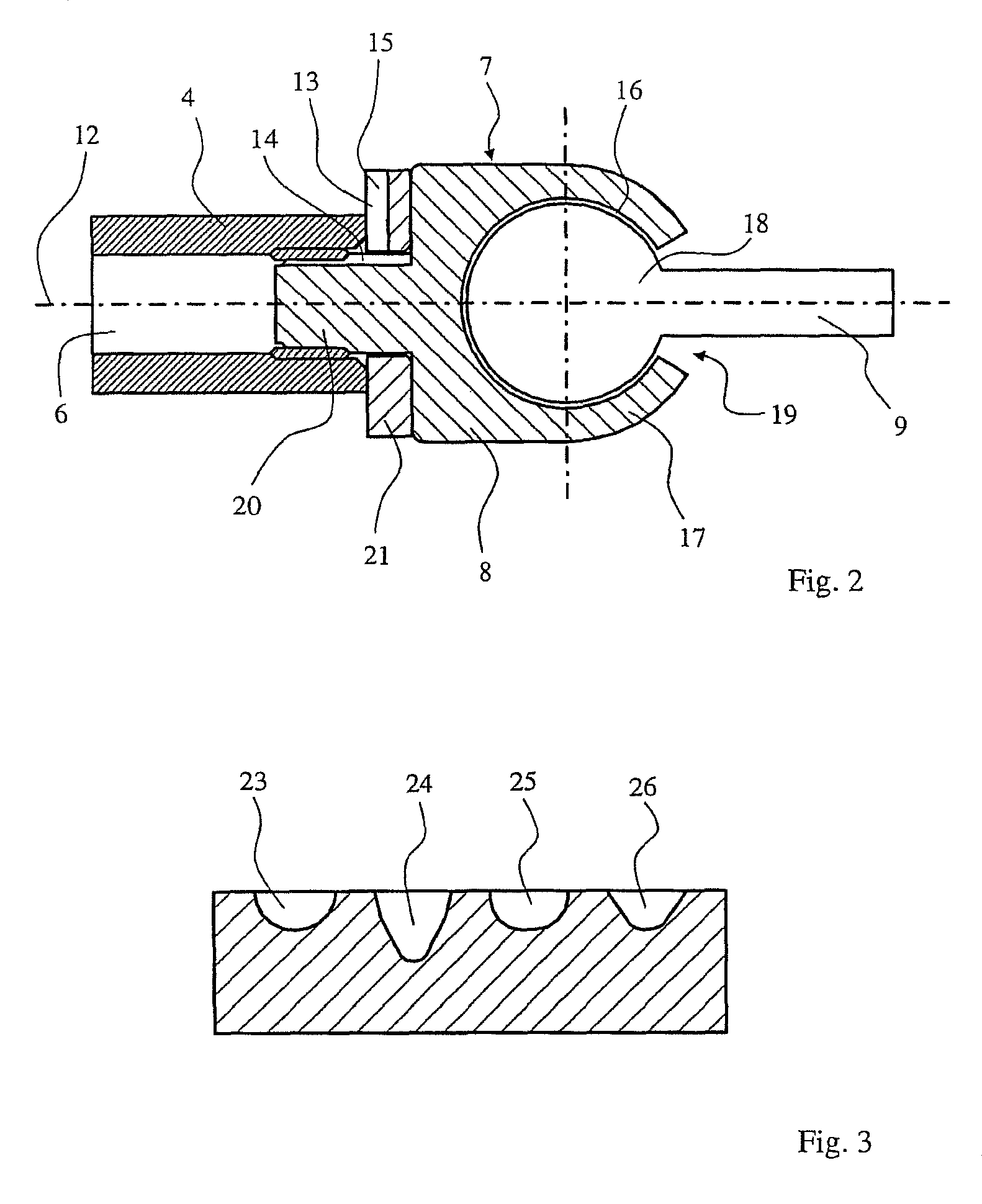

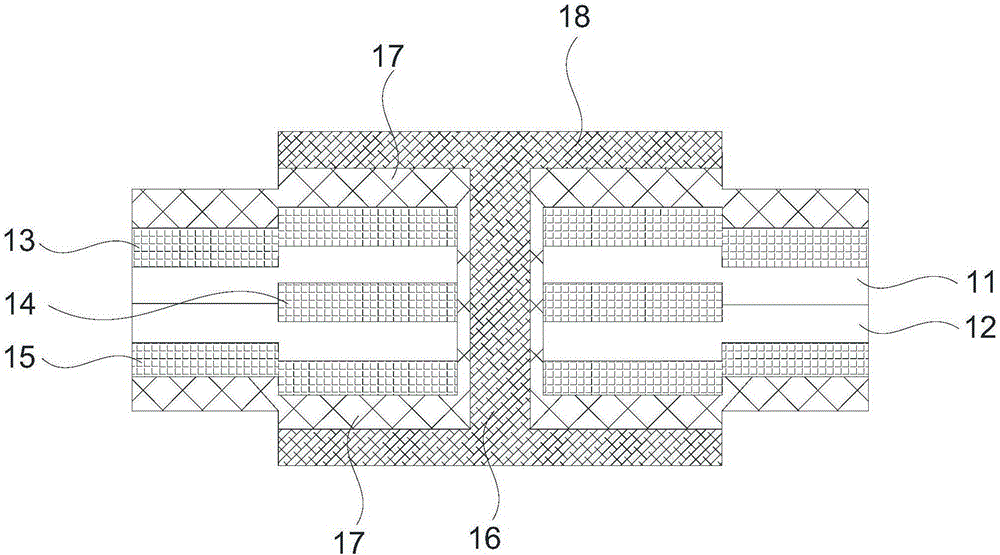

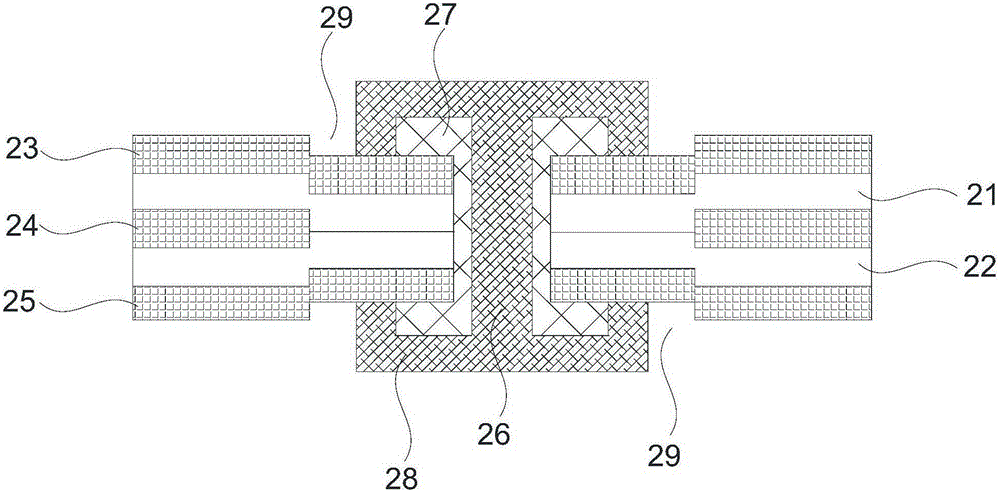

Joint arrangement for a vehicle

ActiveUS8348541B2Design is limitedPrevent surfaceSteering linkagesToothed gearingsInterior spaceEngineering

Owner:ZF FRIEDRICHSHAFEN AG

Manufacture method for plugging resin into soft and hard combined circuit board

InactiveCN105228375AGuaranteed thicknessAvoid the problem of copper surface depression at the via hole positionPrinted circuit aspectsMultilayer circuit manufactureEngineeringPolyresin

The invention discloses a manufacture method for plugging resin into a soft and hard combined circuit board, and relates to the technical field of circuit board production. The method comprises that S1) an internal circuit pattern is prepared in both a soft core board and a hard core board, and corresponding drilling positions of the circuit pattern are provided with isolated pads whose aperture is greater than that of a drill hole; S2) the soft core board and the hard core board are compressed by PP to form the soft and hard combined circuit board; S3) the drill hole into which resin needs to be plugged is drilled in the soft and hard combined circuit board; S4) copper deposition and electroplating are carried out on the inner wall of the drill hole; S5) the electroplated drill hole is filled with the resin, and the resin is solidified initially; and S6) and residual resin flowing out of the copper surface of the soft and hard combined circuit board is polished by a polishing plate. The isolated pads of the internal circuit in the drilling pole positions are reserved, the thickness of the drilling hole positions is ensured, the problem that the copper surface at the through hole position is recessed caused by low filling capability of NO-FLOW PP used in the soft and hard combined circuit board is solved, and rework of manual polishing due to the fact that the resin polishing plate is not clean is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

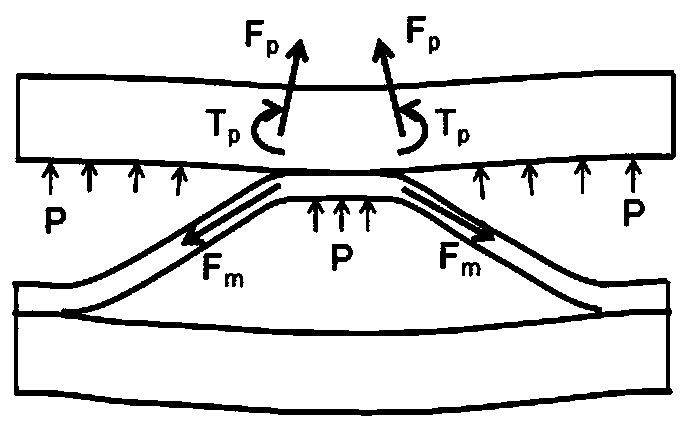

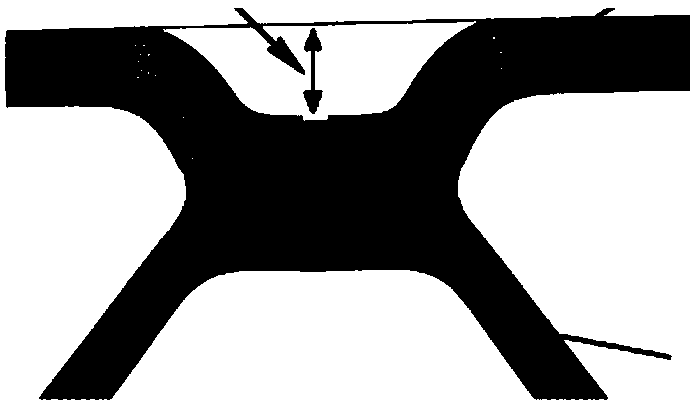

Three-layer hollow blade structure and manufacturing method thereof

ActiveCN108890219AAchieve weight lossAvoid groovesBlade accessoriesMachines/enginesEngineeringMachining

The invention relates to a three-layer hollow blade structure and a manufacturing method thereof. The method comprises the steps of machining multiple bosses on the inner surfaces of skin at the two sides through a mechanical machining or chemical processing method; coating the parts, except the bosses, on the inner surfaces of the skin with a diffusion bonding separating agent; machining inclinedcutting core plates with the variable cross-section thickness through a mechanical machining or chemical processing method; machining air inlet grooves in the thickness reducing ends of the inclinedcutting core plates; clamping the middle core plates between the skin at the two sides with the bosses, and conducting welding and edge sealing on the peripheries of a formed three-layer laminating structure; putting the three-layer laminating structure subjected to combined edge sealing into a hot isobaric furnace for diffusion bonding after vacuum encapsulation, so that the middle core plates and the skin at the two sides are connected at the bosses; filling the three-layer laminating structure after diffusion bonding with inert gas for super-plastic forming through the air inlet grooves inthe core plates, so that the core plates bulge with a non-diffusion-bonding area, except the bosses, of the skin and fit the molded surface of a super-plastic forming die.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

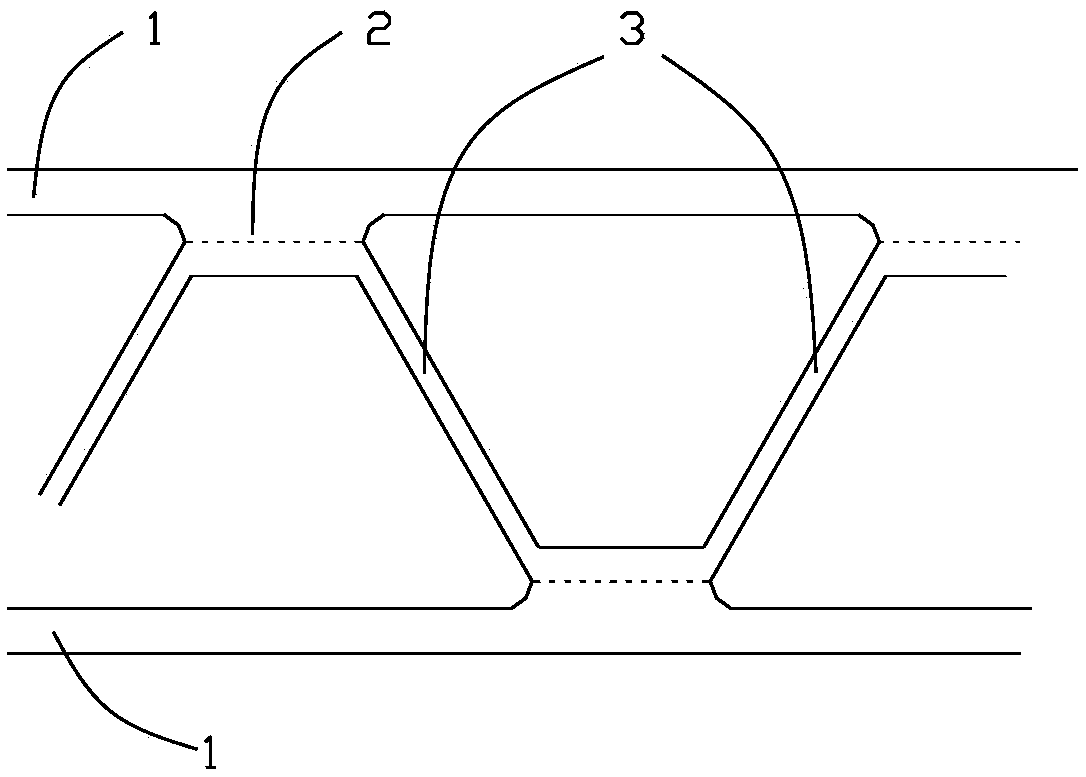

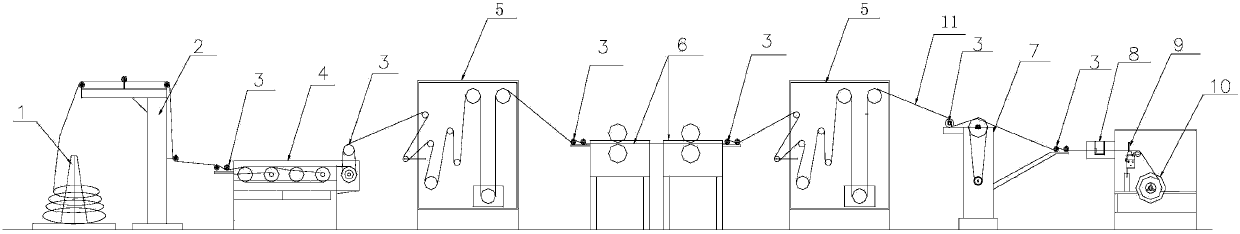

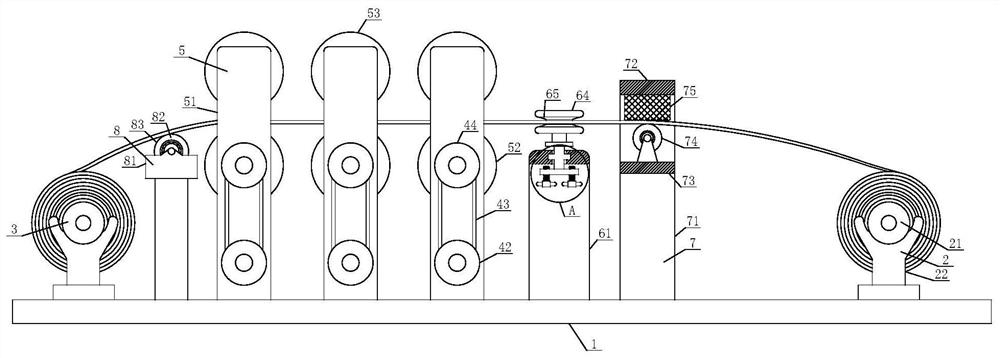

Compound type machining equipment for copper alloy flat wires

The invention discloses compound type machining equipment for copper alloy flat wires. The compound type machining equipment comprises a pay-off rack, multi-pass rolling equipment, online annealing equipment, two-time continuous pressing equipment, online annealing equipment, a tension rack and a finished product wire drawing machine, wherein the finished product wire drawing machine comprises a polycrystalline die, a winding displacement mechanism and a take-up mechanism. The compound type machining equipment disclosed by the invention adopts few machining procedures, is high in production efficiency and high in machining precision; the produced copper alloy flat wires are smooth in surfaces and good in quality.

Owner:WUHU CHUJIANG ALLOY COPPER

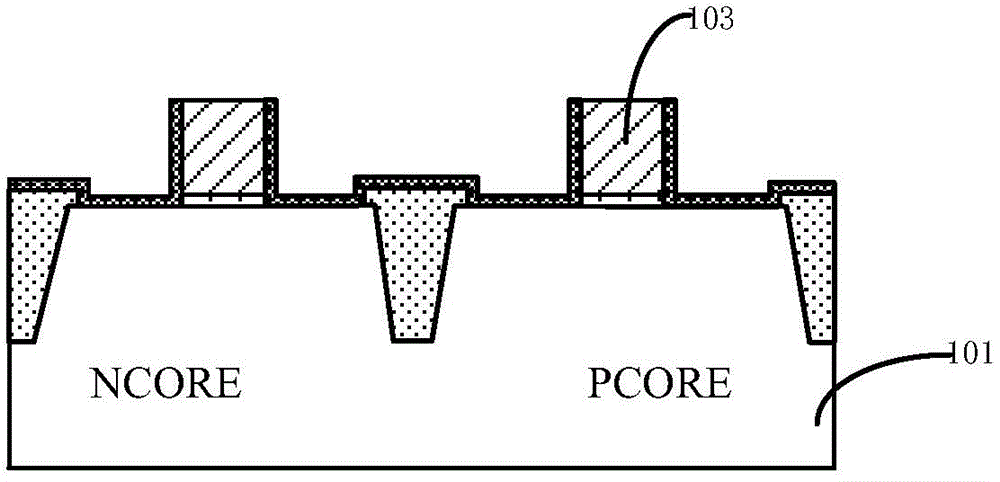

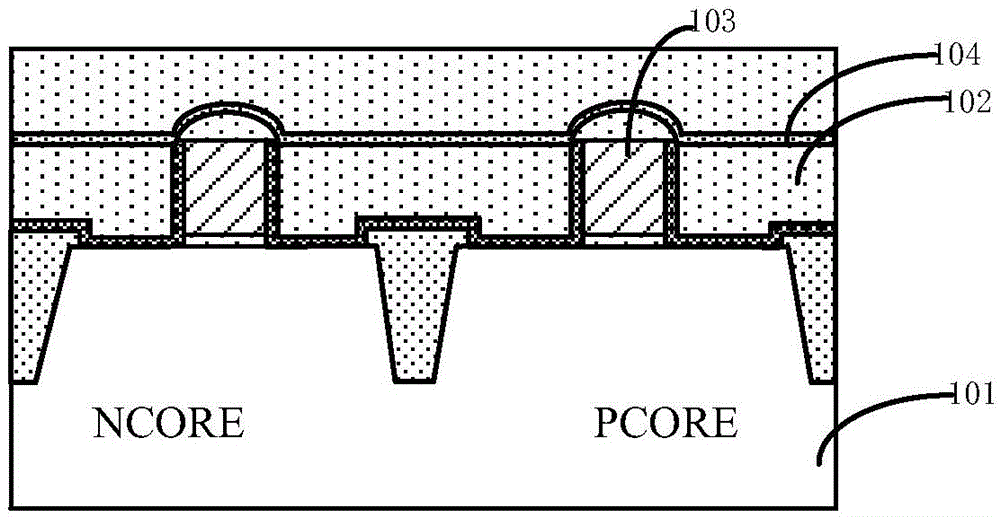

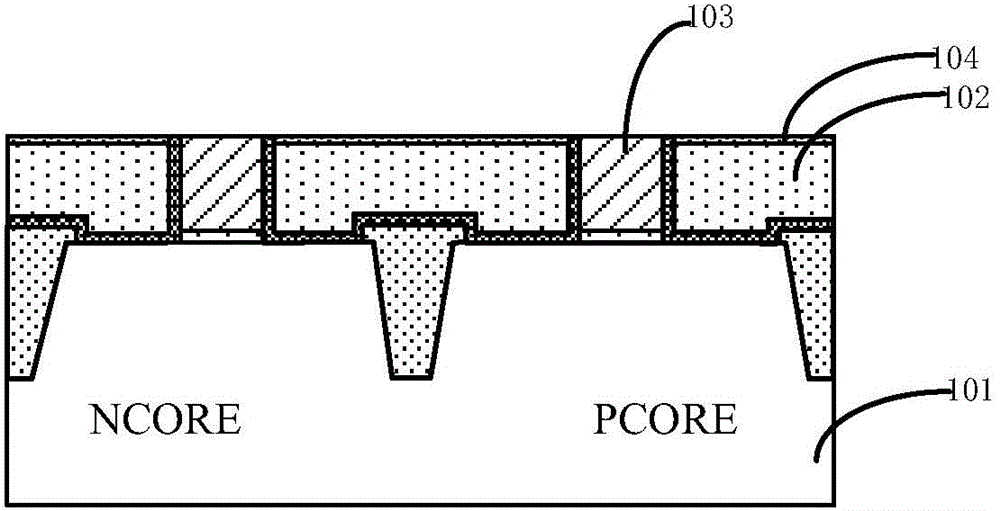

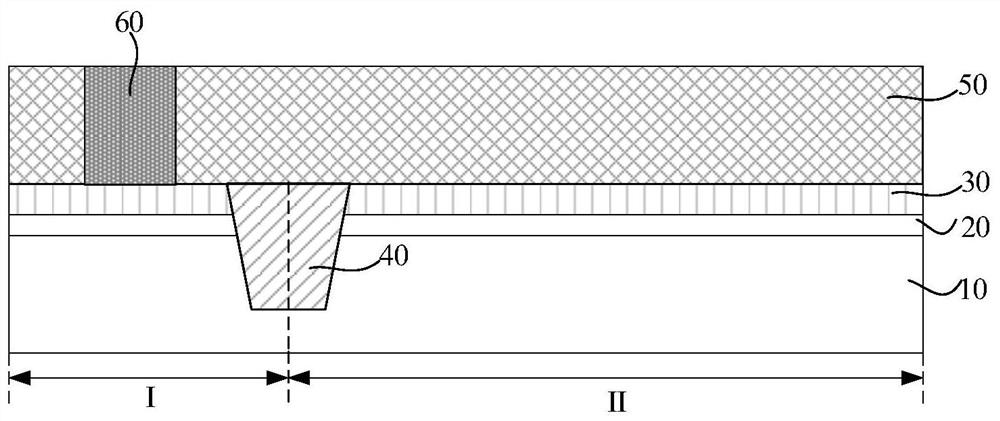

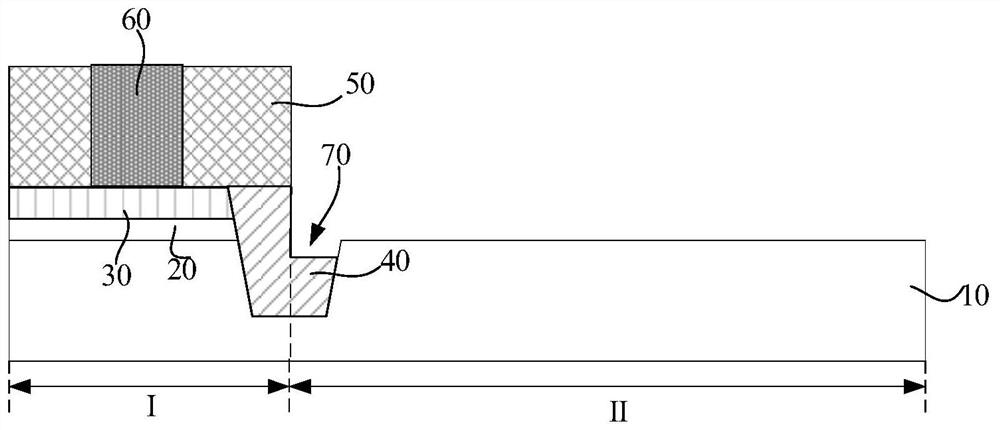

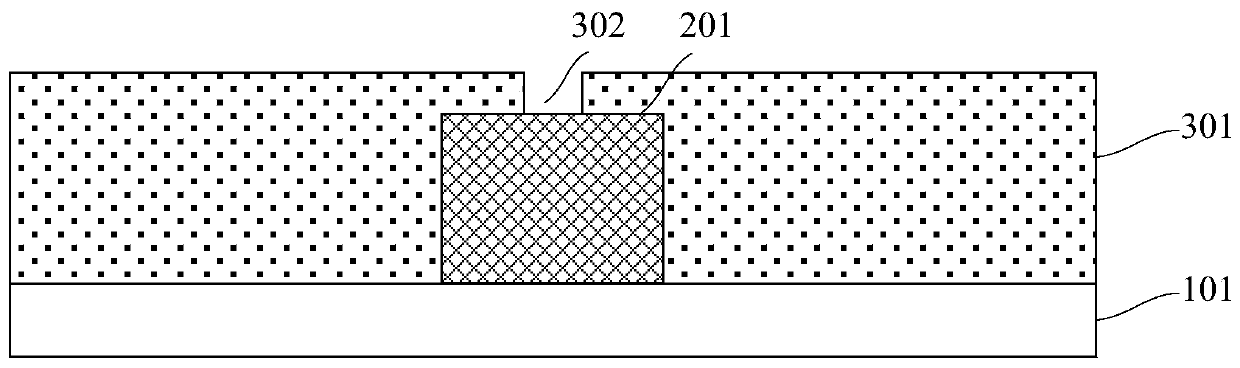

Semiconductor device, manufacturing method therefor, and electronic device

InactiveCN105845627AReduce lossesImprove performanceTransistorSemiconductor/solid-state device manufacturingPower semiconductor deviceDielectric layer

The invention relates to a semiconductor device, a manufacturing method, and an electronic device. The method comprises the steps: S1, providing a semiconductor substrate, and forming a virtual grid structure on the semiconductor substrate, wherein the virtual grid structure comprises a virtual grid dielectric layer; S2, depositing a first interlayer dielectric layer on the semiconductor substrate till the first interlayer dielectric layer reaches the a part below the top of the virtual grid structure; S3, forming a second interlayer dielectric layer on the first interlayer dielectric layer till the second interlayer dielectric layer reaches the a part above the top of the virtual grid structure, wherein the second interlayer dielectric layer and the virtual grid dielectric layer have a bigger etching selection ratio; S4, executing a flattening step till the virtual grid structure, and then removing the virtual grid structure. The method not only can reduce the loss of the interlayer dielectric layers in a process of removing a virtual grid electrode, but also can avoid a groove in a flattening process, and further improves the performance and yield of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

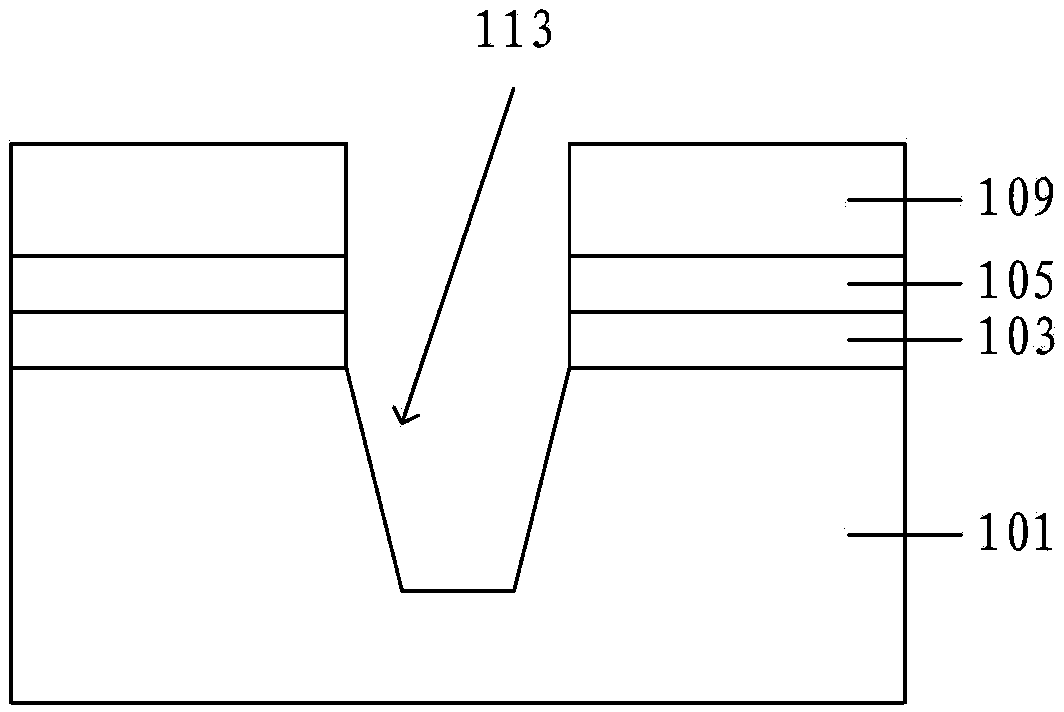

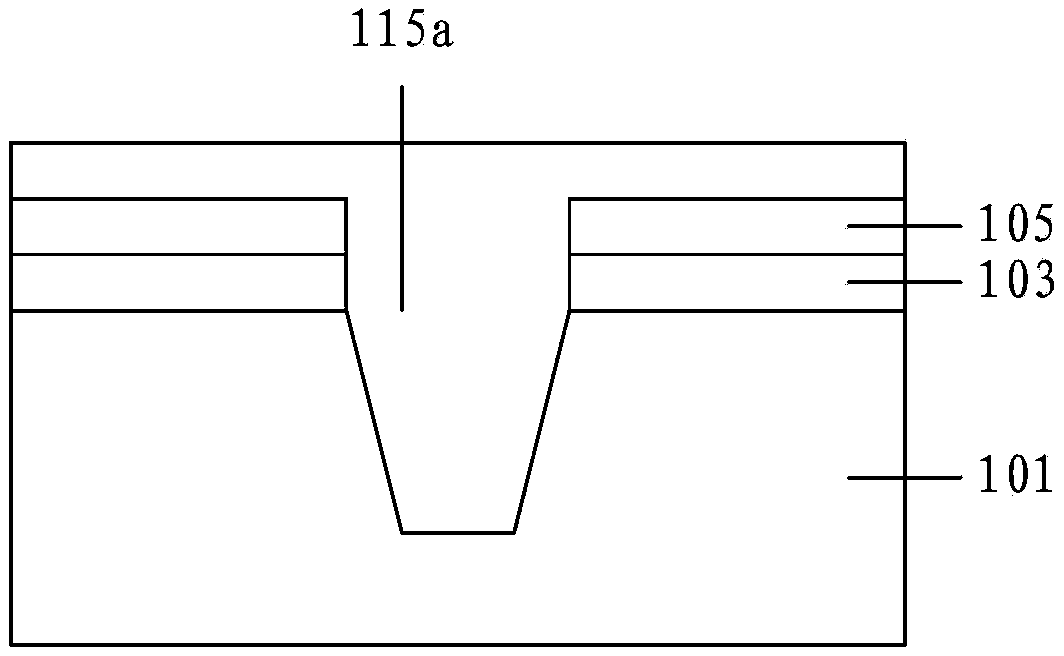

Shallow groove isolation structure forming method

ActiveCN103811403AEasy to shapeAvoid reactionSemiconductor/solid-state device manufacturingDevice materialElectrical performance

A shallow groove isolation structure forming method comprises providing a semiconductor substrate; forming into a substrate oxidation layer on the semiconductor substrate; forming into a mask layer on the substrate oxidation layer; etching the mask layer and forming into an opening which penetrates through the mask layer; performing oxidation treatment on the lateral wall of the opening and forming into an oxidation layer; etching the oxidation layer, the mask layer, the substrate oxidation layer and the semiconductor until the remaining partial thickness mask layer and the oxidation layer which is arranged on the lateral wall of the mask layer and forming into an isolation groove; forming into a shallow groove isolation structure inside the isolation groove. The shallow groove isolation structure forming method has the advantages of avoiding a groove is formed in a joint between the shallow groove isolation structure and the semiconductor, improving the shape of the formed shallow groove isolation structure and accordingly improves the electrical performance of a semiconductor device which comprises the formed shallow groove isolation structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

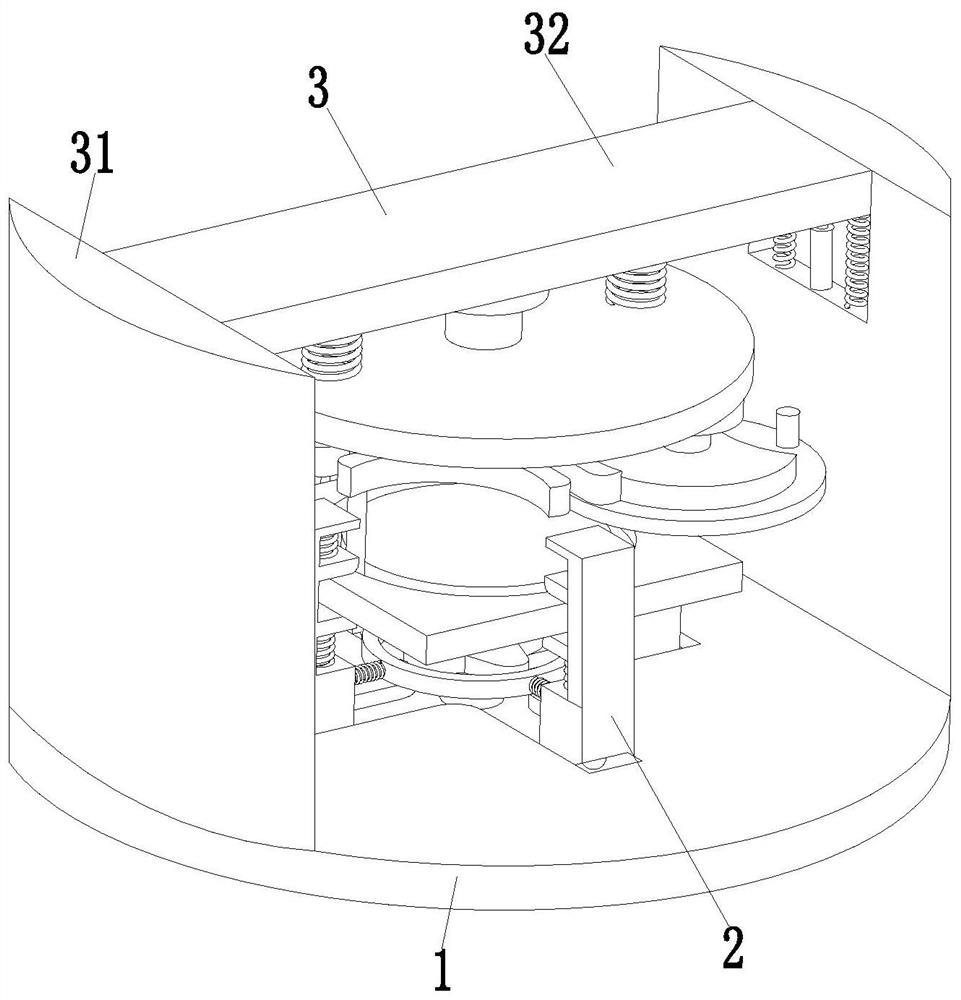

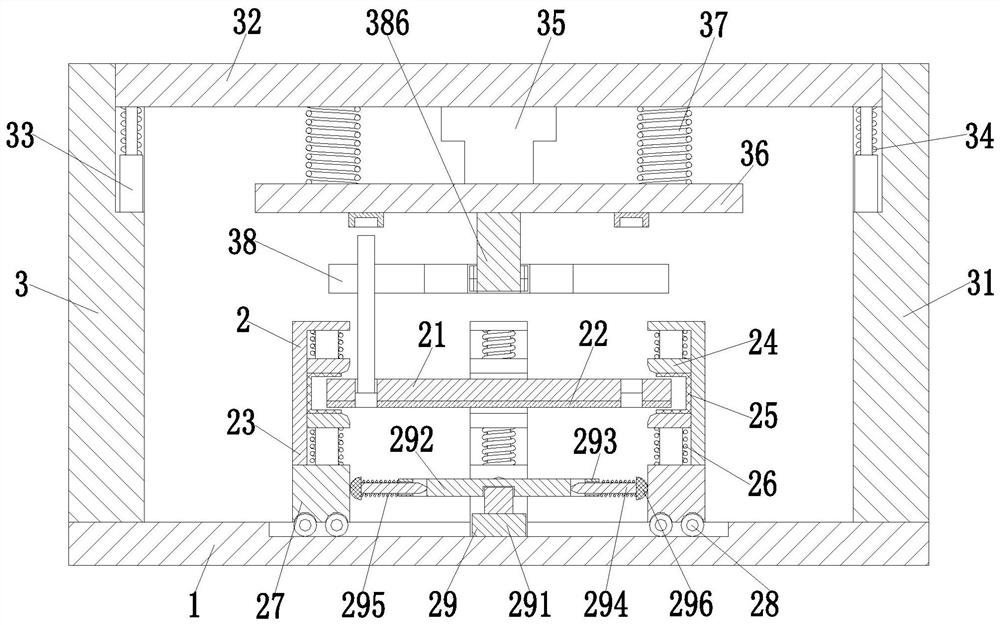

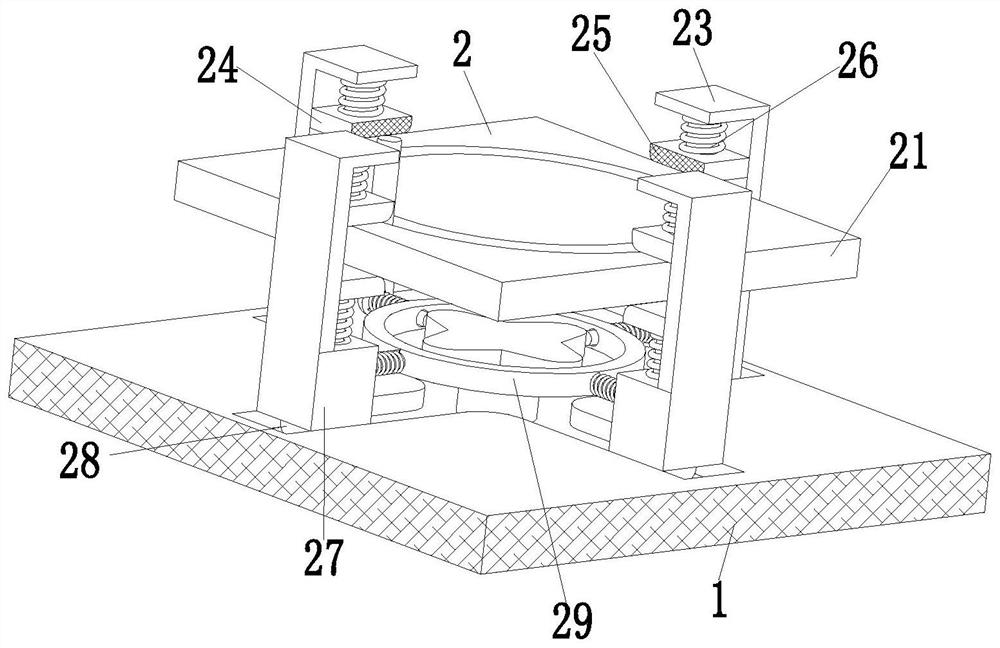

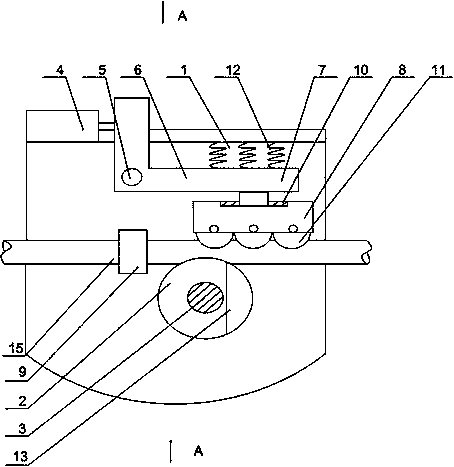

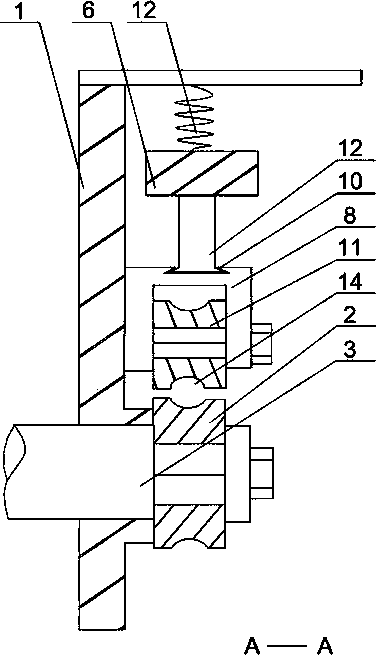

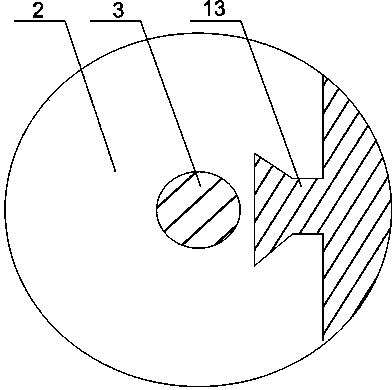

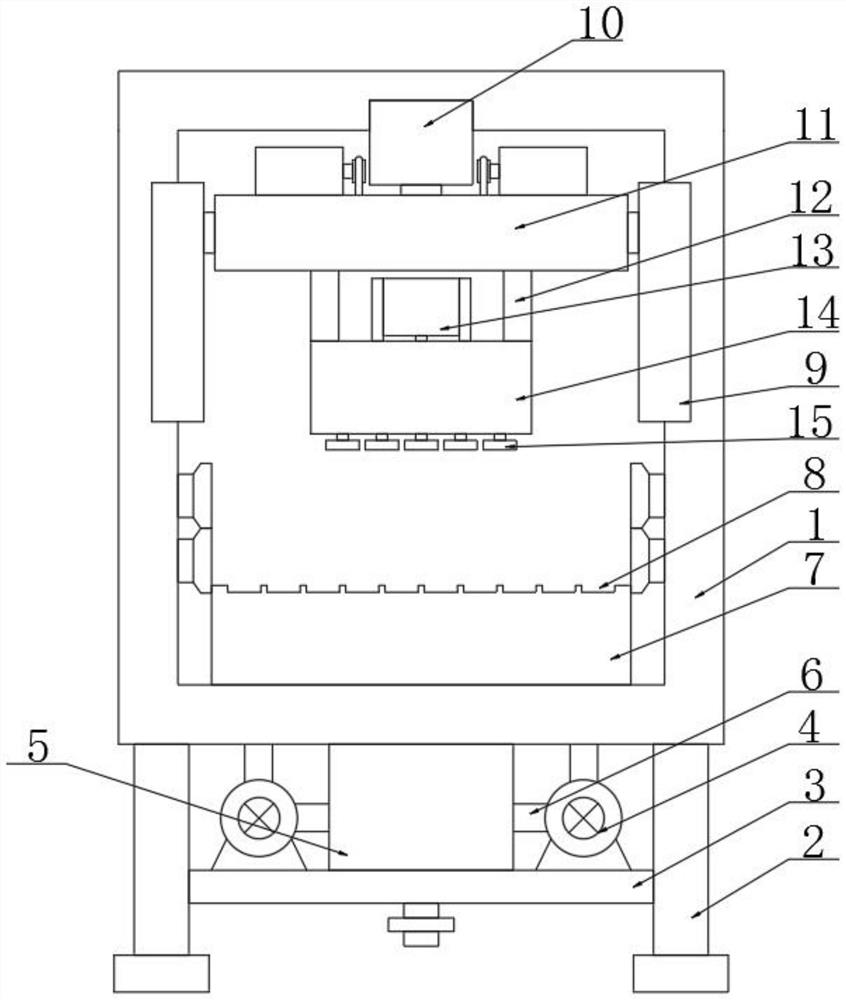

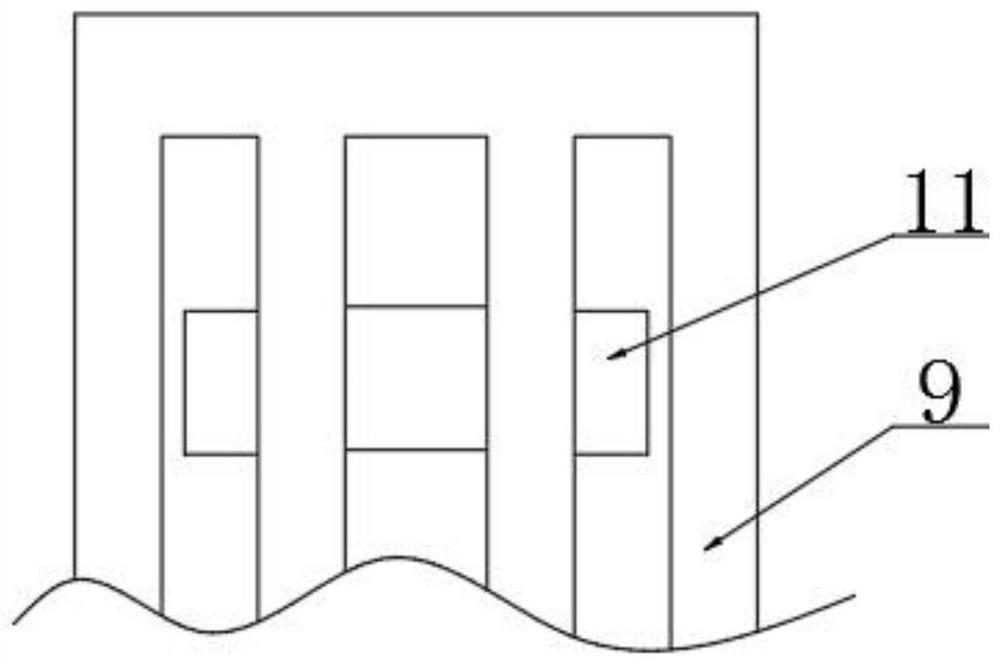

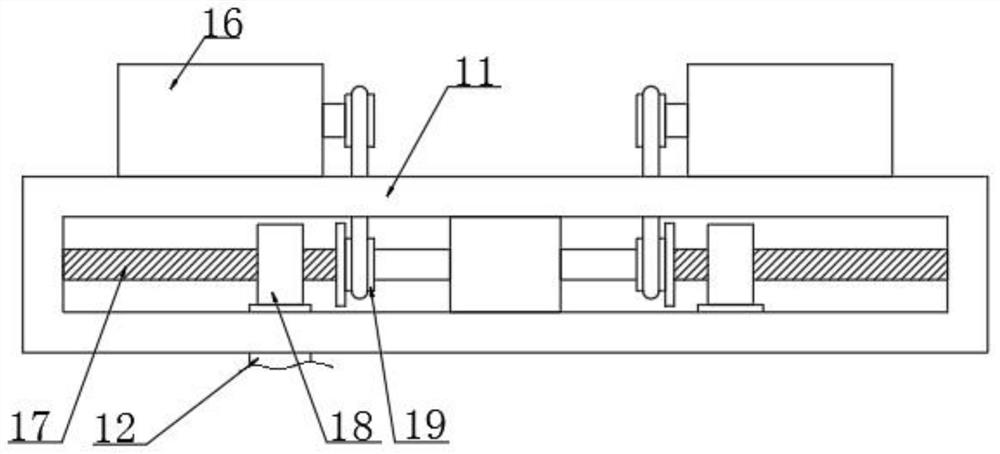

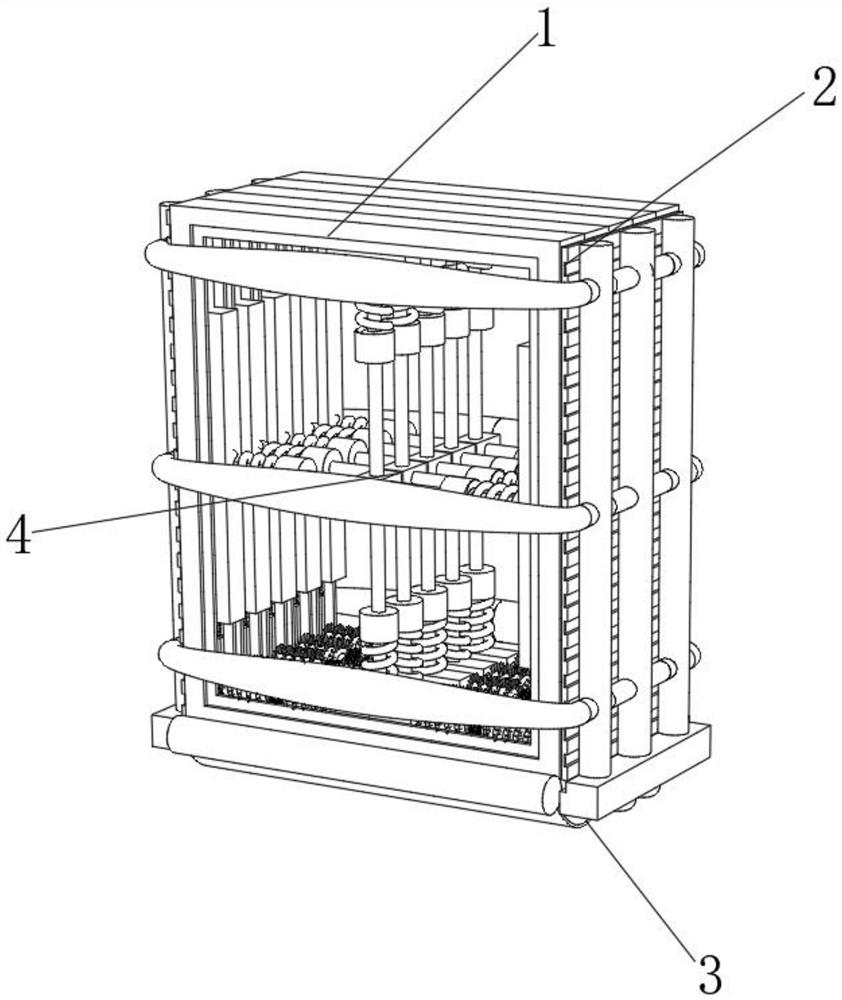

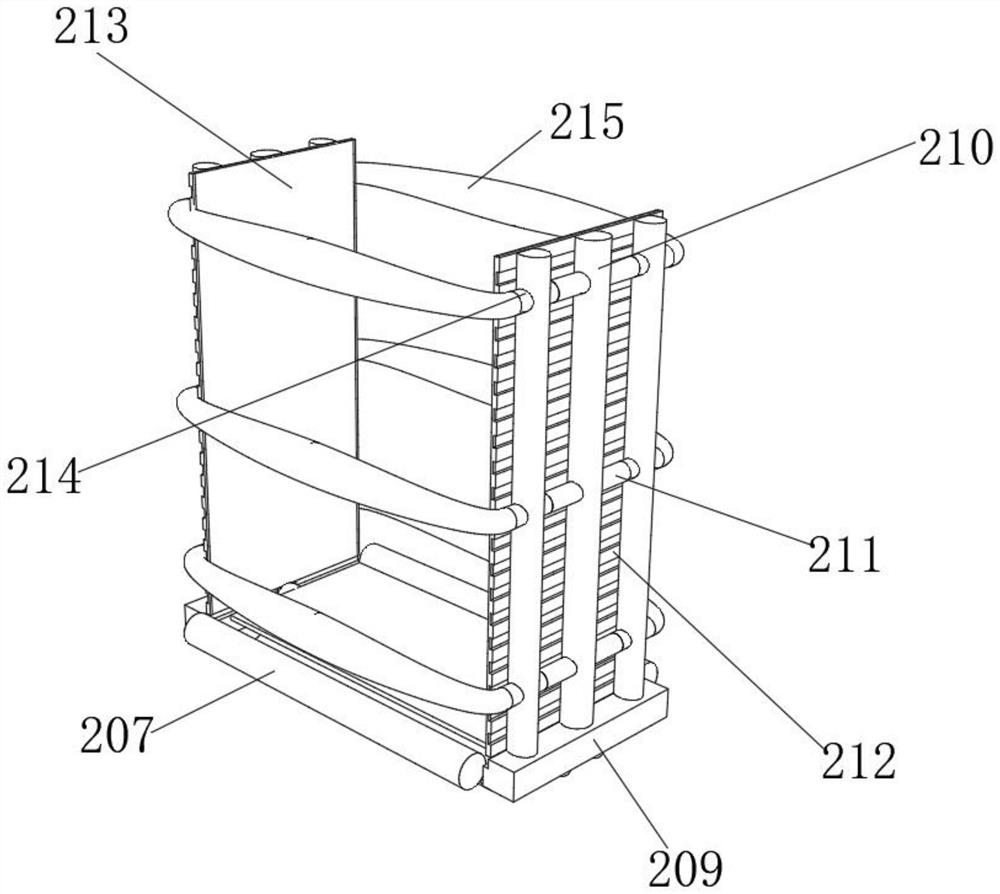

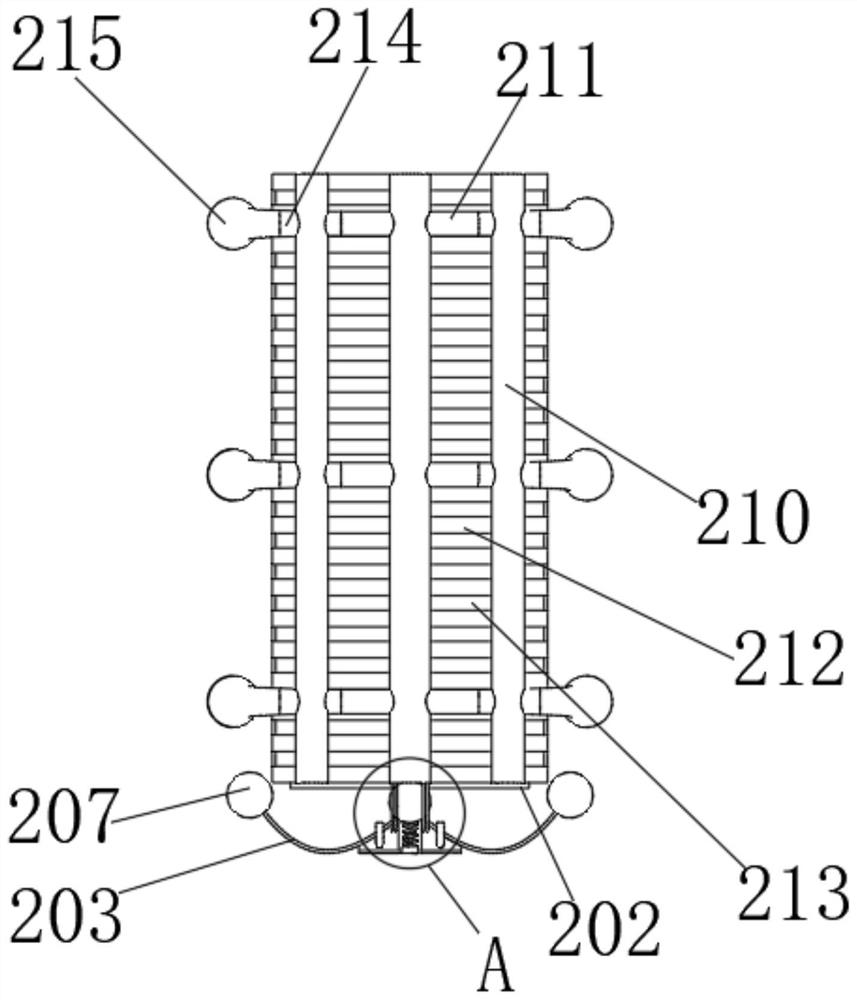

Auxiliary machining system for building steel structure embedded part

InactiveCN112518199ASolve the support strengthSolve the support stabilityWelding/cutting auxillary devicesAuxillary welding devicesConstruction engineeringMachining system

The invention relates to an auxiliary machining system for a building steel structure embedded part. The auxiliary machining system comprises a bottom plate, a clamping and fixing mechanism and a four-corner positioning mechanism. A sliding groove is formed in the middle of the upper end face of the bottom plate. The clamping and fixing mechanism is mounted in the sliding groove in a sliding fit mode. The four-corner positioning mechanism is arranged above the clamping and fixing mechanism. The problems that an existing device cannot guarantee the positioning precision of steel bars on a steelplate, consequently, the positions of the steel bars are uneven, and the supporting strength and supporting stability of the embedded part are affected can be solved, and the problems that an existing embedded part machining device cannot conduct adjusting, clamping and fixing according to the length and thickness of the embedded part steel plate, applicability is poor, time and labor are wastedwhen a clamp is replaced repeatedly, efficiency is poor, the steel plate is clamped unstably, the welding precision of the steel bars and the steel plate is affected, and grooves are easily caused during welding, so that the quality of the embedded part is affected can be further solved.

Owner:南京俏美骏科技有限公司

Exhaust pipe bending machine

InactiveCN103978077AEasy to useGuarantee the quality of the bent pipeMetal-working feeding devicesPositioning devicesExhaust pipeMechanical engineering

The invention discloses an exhaust pipe bending machine. The exhaust pipe bending machine comprises a rotary disc, and the rotary disc is provided with a pipe bending groove and connected with a rotating handle through a hinge; one end of the rotating handle is provided with a connecting rod, and the other end of the rotating handle is connected with an air cylinder; a plurality of the wheels are mounted inside a wheel seat, and every wheel is provided with a guide groove matched with the pipe bending groove; the pipe bending groove is composed of a movable unit and a fixed unit, wherein the fixed unit is rotatably mounted on the rotary disc through a rotating shaft and provided with a slot, the movable unit is provided with a protrusion, and the protrusion and the slot are matched with each other. When the rotating handle is pressed downwards, the connecting rod can slide at a certain distance in a trapezoid groove to guarantee stress uniformity on the wheel seat; the plurality of wheels enlarge the contact area between the guide grooves and the portion to be bent of an exhaust pipe and guarantee the stress uniformity of the portion to the bent to reduce direct fracture of the exhaust pipe or cracks in the portion to be bent of the exhaust pipe, and further the rejection rate of the exhaust pipe can be reduced.

Owner:CHENGDU LINGCHUAN SPECIAL IND

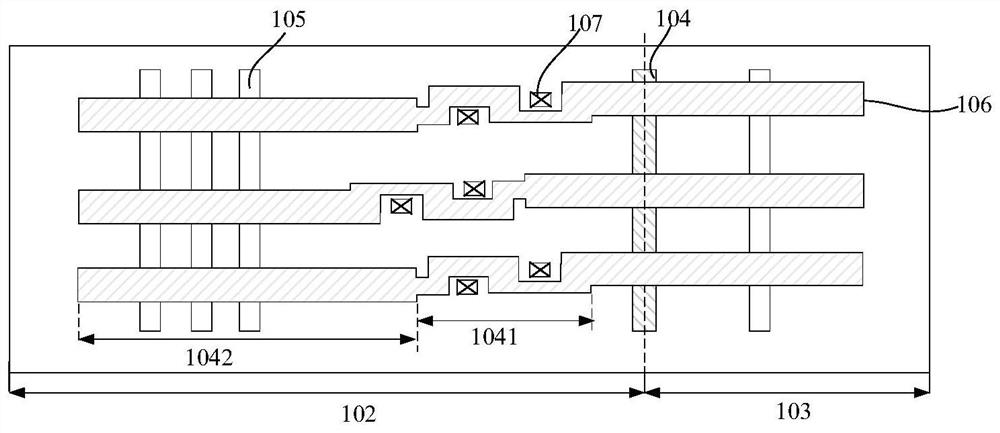

Mask plate of flash memory device and manufacturing method

PendingCN112071844AImprove performanceAvoid groovesSolid-state devicesOriginals for photomechanical treatmentEngineeringGate oxide

The invention provides a mask plate of a flash memory device and a manufacturing method, the mask plate of the flash memory device comprises an active area mask plate and a floating gate mask plate, the active area mask plate comprises a storage mask plate area and a peripheral mask plate area, a first active area pattern is arranged at the junction of the storage mask plate area and the peripheral mask plate area. According to the manufacturing method of the flash memory device, a first active area can be defined at the junction of a storage area and a peripheral area through an active area mask plate, and when a dielectric layer, a control gate layer, a floating gate layer and a floating gate oxide layer of the peripheral region are etched, due to the fact that the first active area is defined at the junction of the storage area and the peripheral area, in the etching process, if over-etching is generated, the over-etched etching object is the semiconductor substrate of the first active area, and compared with the prior art, the etching selection ratio can be improved, so that defects are avoided, and the performance of the flash memory device is further improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

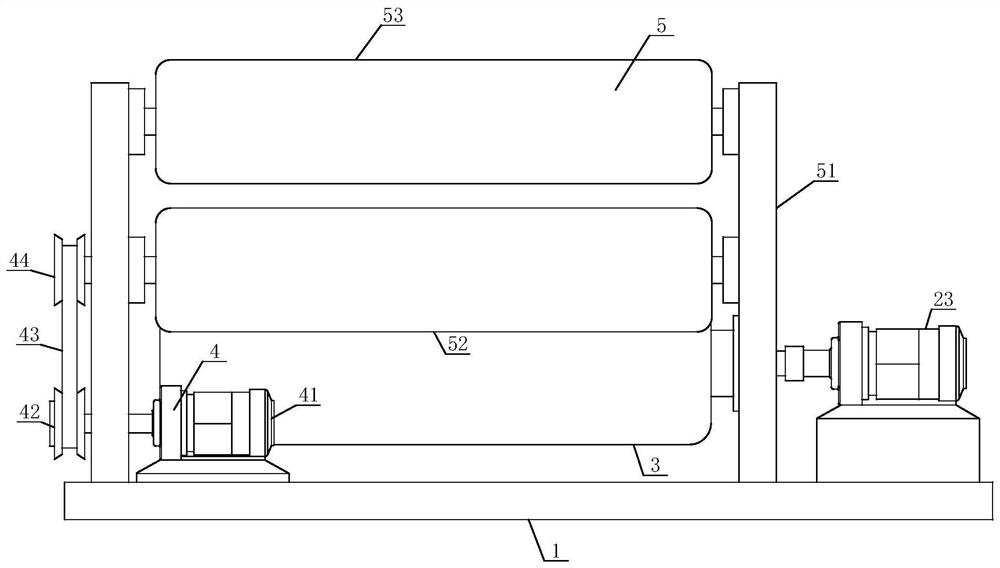

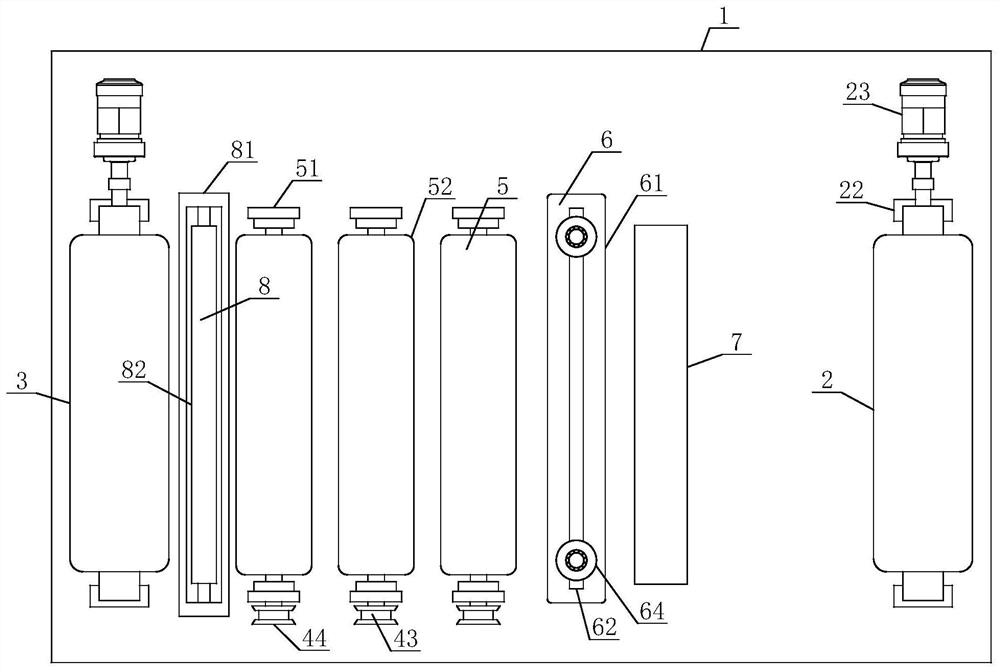

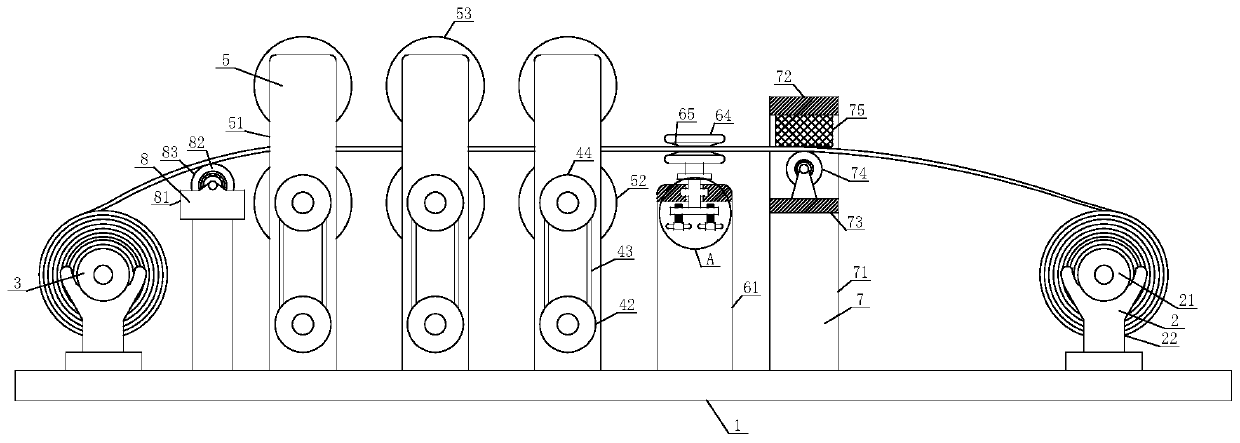

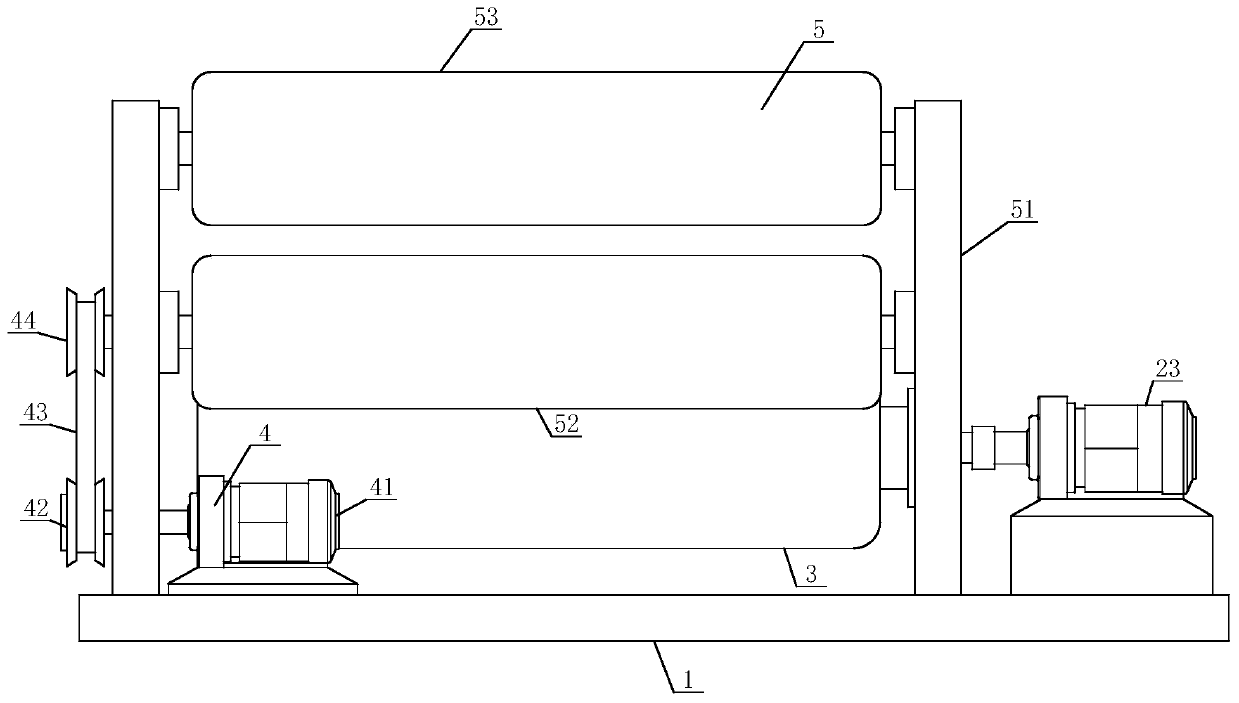

A stainless steel strip cold rolling device

ActiveCN110369508BAvoid offsetAvoid scratchesMetal rolling stand detailsGuiding/positioning/aligning arrangementsForeign matterMetallurgy

The invention relates to the field of stainless steel strips, in particular to a stainless steel strip cold rolling device. The stainless steel strip cold rolling device comprises a base, a feeding coil, a collecting coil, a power mechanism, a cold rolling mechanism, a guide mechanism, a foreign matter removing mechanism and a cooling mechanism, wherein the feeding coil and the collecting coil arerespectively fixed on two sides of the upper end of the base; the cold rolling mechanism is fixed to the middle of the upper end of the base and driven by the power mechanism; the power mechanism isfixedly connected to the upper end of the base; and the guide mechanism and the foreign matter removing mechanism are arranged on the right side of the cold rolling mechanism. Due to the arrangement of the guide mechanism and the foreign matter removing mechanism, a steel strip to be processed can be positioned by utilizing a guide wheel and a wheel groove in the guide mechanism, the steel strip is prevented from deviating in the processing process, the foreign matter on the surface of the steel strip can be removed by utilizing a brush of the foreign matter removing mechanism when the steel strip passes through a bearing roller, and scratches and grooves on the surface of the steel strip due to the foreign matter are avoided when the steel strip is subjected to cold rolling.

Owner:东阳市和宇金属材料有限公司

Wire and preparation method thereof

The invention discloses a wire and a preparation method thereof. The wire is prepared from the following components according to weight percent: 0.45 to 0.95% of silicon, 7.5 to 9.5% of aluminum, 6.0to 10.5% of zinc, 0.1 to 0.3% of iron, 0.2 to 0.5% of magnesium, 0.05 to 0.65% of nickel, 0.08 to 0.14% of boron, 0.02 to 0.035% of yttrium, 0.015 to 0.018% of tin, 0.002 to 0.015% of tungsten, 0.1 to0.3% of chromium, 0.08 to 0.15% of manganese, 0.02 to 0.07% of zirconium, 0.03 to 0.08% of beryllium and the balance of copper and inevitable impurities. According to the wire and the preparation method, the strength and wear resistance of the material are guaranteed, additionally, the impact toughness and break resistance of the material are increased, and the overall performance indices of thestrength, wear resistance, break resistance and the like of the product fully reach the domestic advanced level of similar products.

Owner:安徽尚视信息科技有限公司

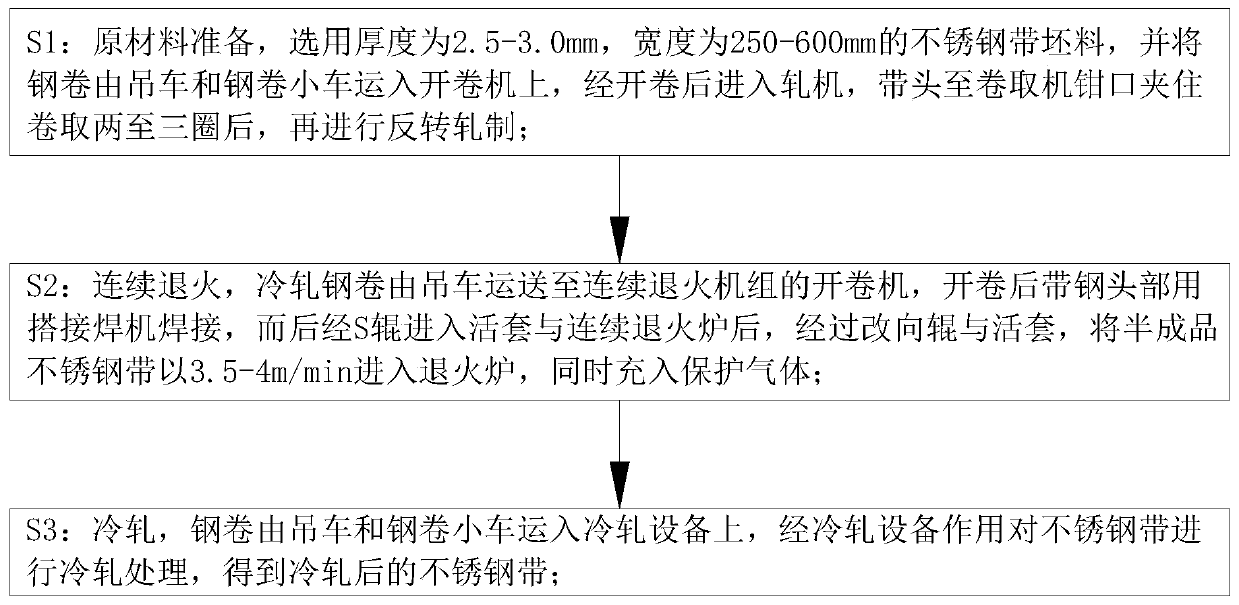

Stainless steel strip cold rolling process

InactiveCN110355204AAvoid offsetAvoid scratchesGuiding/positioning/aligning arrangementsFurnace typesForeign matterSteel belt

The invention relates to the field of stainless steel strips, in particular to a stainless steel strip cold rolling process. According to the process, the adopted cold rolling equipment comprises a base, a feeding coil, a winding coil, a power mechanism, a cold rolling mechanism, a guide mechanism, a foreign matter removing mechanism and a cooling mechanism, wherein the feeding coil and the winding coil are respectively fixed on two sides of the upper end of the base; the cold rolling mechanism is fixed in the middle of the upper end of the base and is driven by the power mechanism; the powermechanism is fixedly connected to the upper end of the base; and the guide mechanism and the foreign matter removing mechanism are arranged on the right side of the cold rolling mechanism. The guide mechanism and the foreign matter removing mechanism are arranged, the steel strips to be machined can be positioned by utilizing a guide wheel and a wheel groove in the guide mechanism so as to be prevented from deviating in the processing process; the foreign matter on the surface of the steel strip can be removed by utilizing a brush of the foreign matter removing mechanism when the steel strip passes through a bearing roller, and scratches and grooves on the surface of the steel strip due to the foreign matter are avoided when the steel strip is subjected to cold rolling.

Owner:朱良彬

Polishing device for spectacle lens production

InactiveCN112548763AWill not polluteAvoid groovesOptical surface grinding machinesGrinding drivesTransmission beltGear wheel

The invention relates to the technical field of spectacle lenses, and discloses a polishing device for spectacle lens production. A second motor at the top of a polishing box can drive a third rotating shaft to rotate, the third rotating shaft can drive a second rotating shaft to rotate through a second rotating wheel and a transmission belt when rotating, when the second rotating shaft rotates, asecond bevel gear is driven to rotate through a first bevel gear, the second bevel gear is fixedly installed on the outer side of a fourth rotating shaft, a fourth bevel gear is fixedly installed onthe outer side of the fourth rotating shaft, the fourth bevel gear is further connected with a third bevel gear in a meshing mode, the third bevel gear is fixedly mounted on the outer side of the first rotating shaft, so that the second bevel gear drives the first rotating shaft to rotate through the fourth rotating shaft, the fourth bevel gear and the third bevel gear, and a polishing disc is driven to rotate when the first rotating shaft, the second rotating shaft and the third rotating shaft rotate, so that grooves can be prevented from appearing when a lens is polished.

Owner:金得株

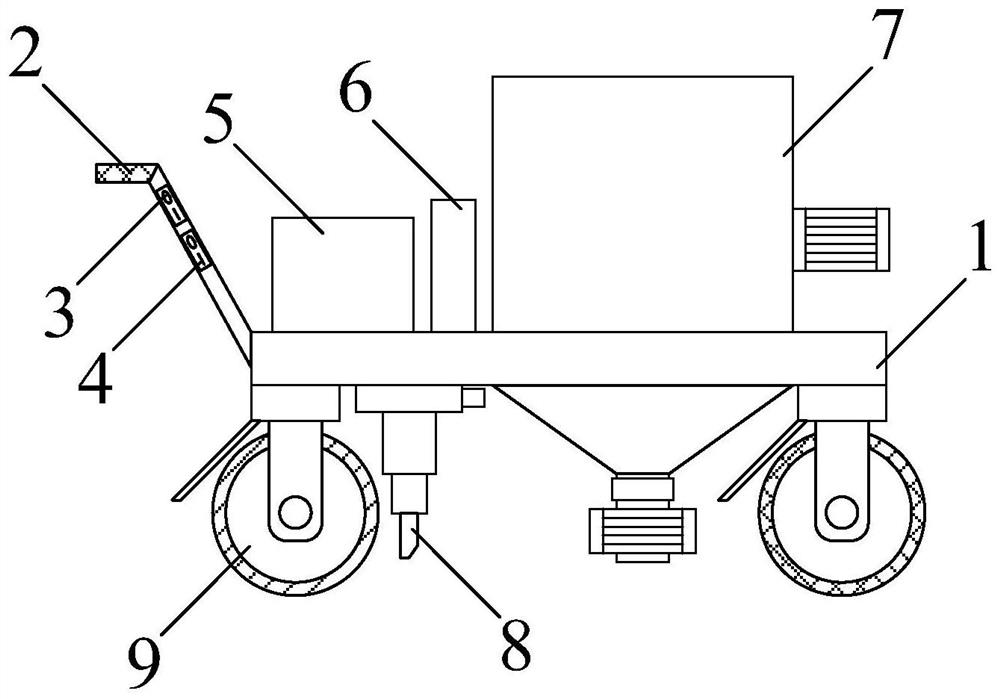

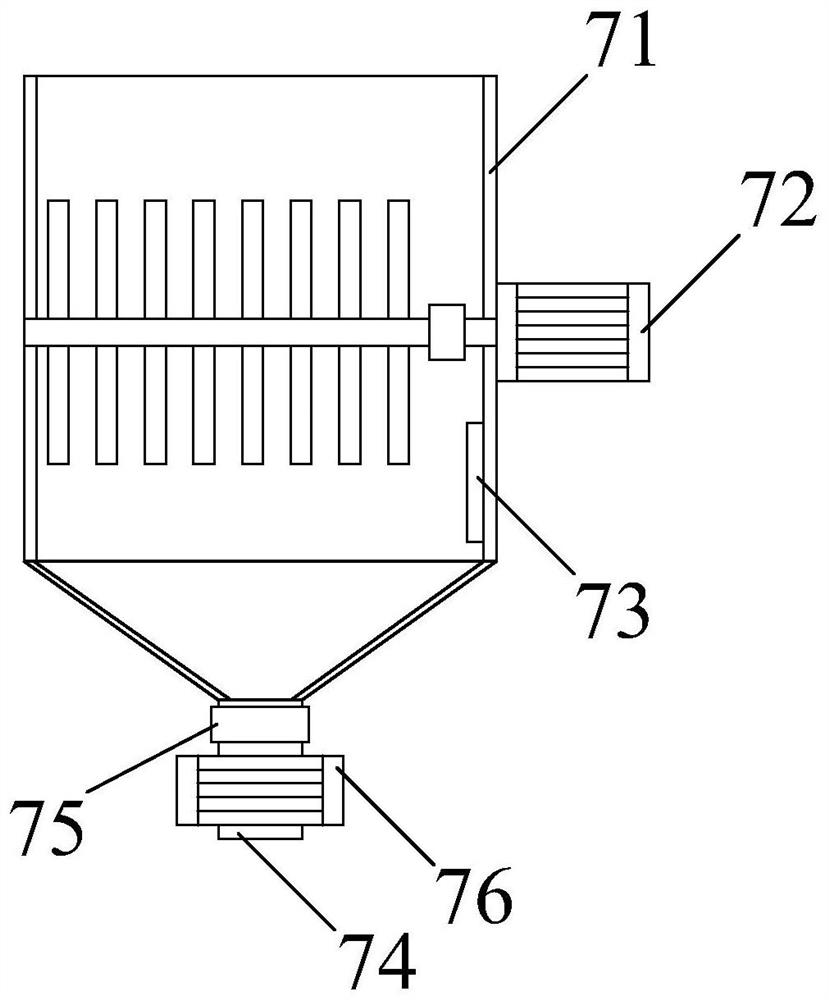

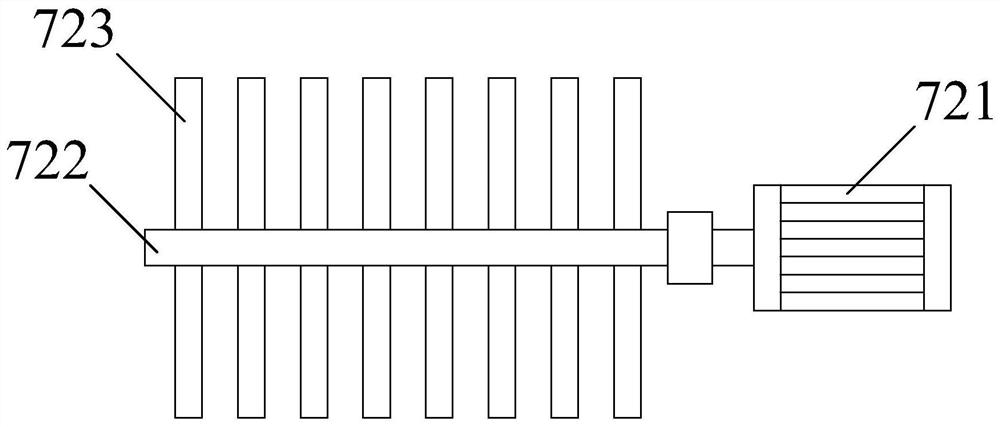

Blanking and scraping device for road paving

InactiveCN112227145AEasy to rollAvoid groovesRoads maintainenceElectric machineStructural engineering

The invention provides a blanking and scraping device for road paving. The device comprises a bottom plate, a handle, a first button switch, a second button switch, a storage battery, a PLC, a blanking assembly, a scraping assembly and universal wheels; through the arrangement of the scraping assembly, discharged materials are scraped to be flat through the scraping plate, so that the materials are in a flat state; subsequent rolling compaction of materials is facilitated, phenomenon of grooves in road is avoided, and road laying quality is guaranteed. A infrared distance measuring sensor is matched with the PLC to control the telescopic rod, so that the leveling operation can be conveniently carried out at different heights; according to the arrangement of the blanking assembly, an electromagnetic valve and a vibration motor are controlled to be powered on and operate through a first button switch, discharging operation is conducted through a discharging pipe, the vibration motor vibrates the discharging pipe, the phenomenon that materials are blocked in the discharging pipe is avoided, normal operation of the blanking assembly is guaranteed, the materials are heated through a heating plate, and the materials are in a warm state; and flowability of materials is ensured.

Owner:湖南太合科创生态有限公司

Manufacturing method of tin bismuth alloy welding wire

ActiveCN110369913AImprove plasticityEquivalent lowWelding/cutting media/materialsSoldering mediaMacroscopic scaleEquivalent weight

The invention relates to the technical field of welding wire preparation, in particular to a manufacturing method of a tin bismuth alloy welding wire. In the continuous rolling step, a tin bismuth alloy is subjected to hot rolling at the specific deformation rate and deformation temperature, on the high-temperature condition, bismuth atoms can be solidified and dissolved into crystal lattices of tin substantially, the equivalent weight of bismuth phases is reduced, and plasticity of the alloy is improved. Under the specific condition, the deformation ability of tin is improved remarkably, theyield strength is reduced, the softening ability is enhanced greatly, under external stress, rapid deformation occurs, the stress impact is neutralized, a base body does not crack, along with deformation, although the bismuth phases are cracked in the rolling and mutual rubbing process, at the low deformation speed, fine patterns are filled by tin rapidly, macroscopically, the alloy shows good plasticity, and the beneficial condition is provided for follow-up continuous wire drawing.

Owner:JIANGXI UNIV OF SCI & TECH

A kind of preparation method of tin-bismuth alloy welding wire

ActiveCN110369913BImprove plasticityEquivalent lowWelding/cutting media/materialsSoldering mediaAlloyUltimate tensile strength

Owner:JIANGXI UNIV OF SCI & TECH

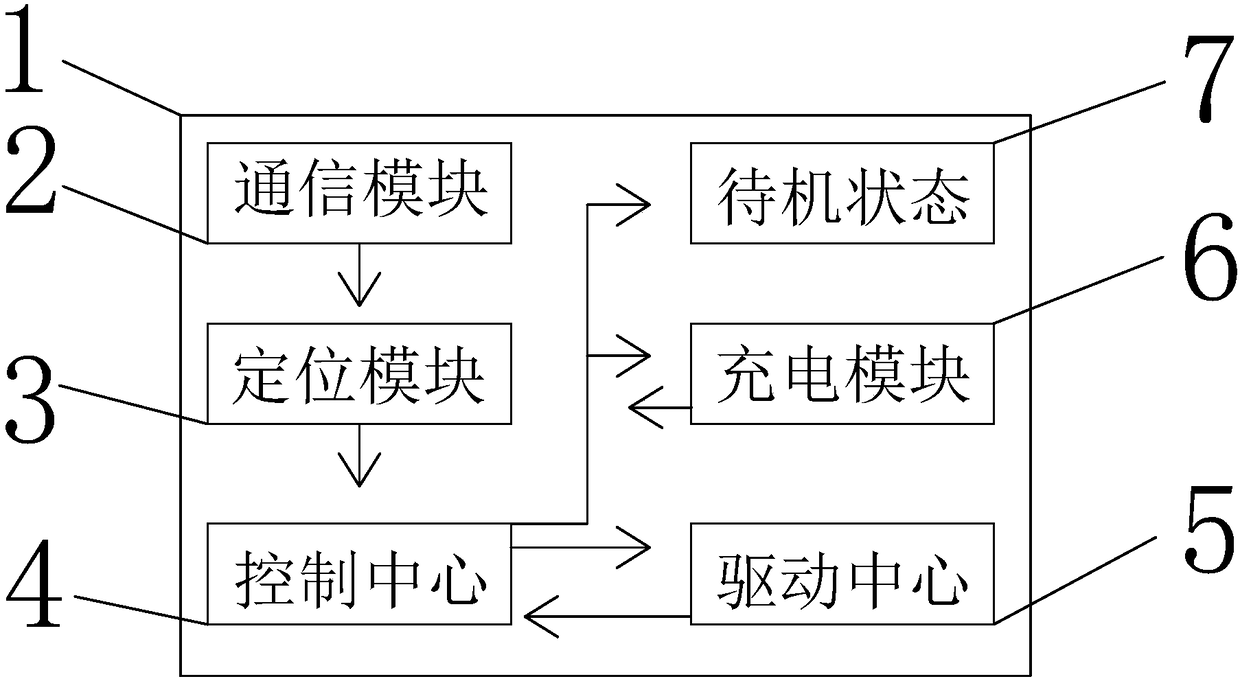

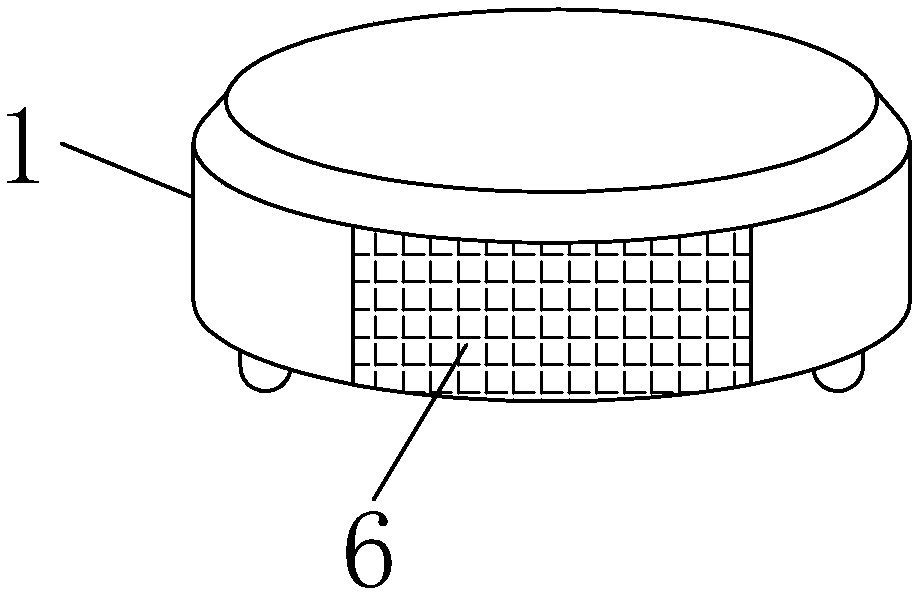

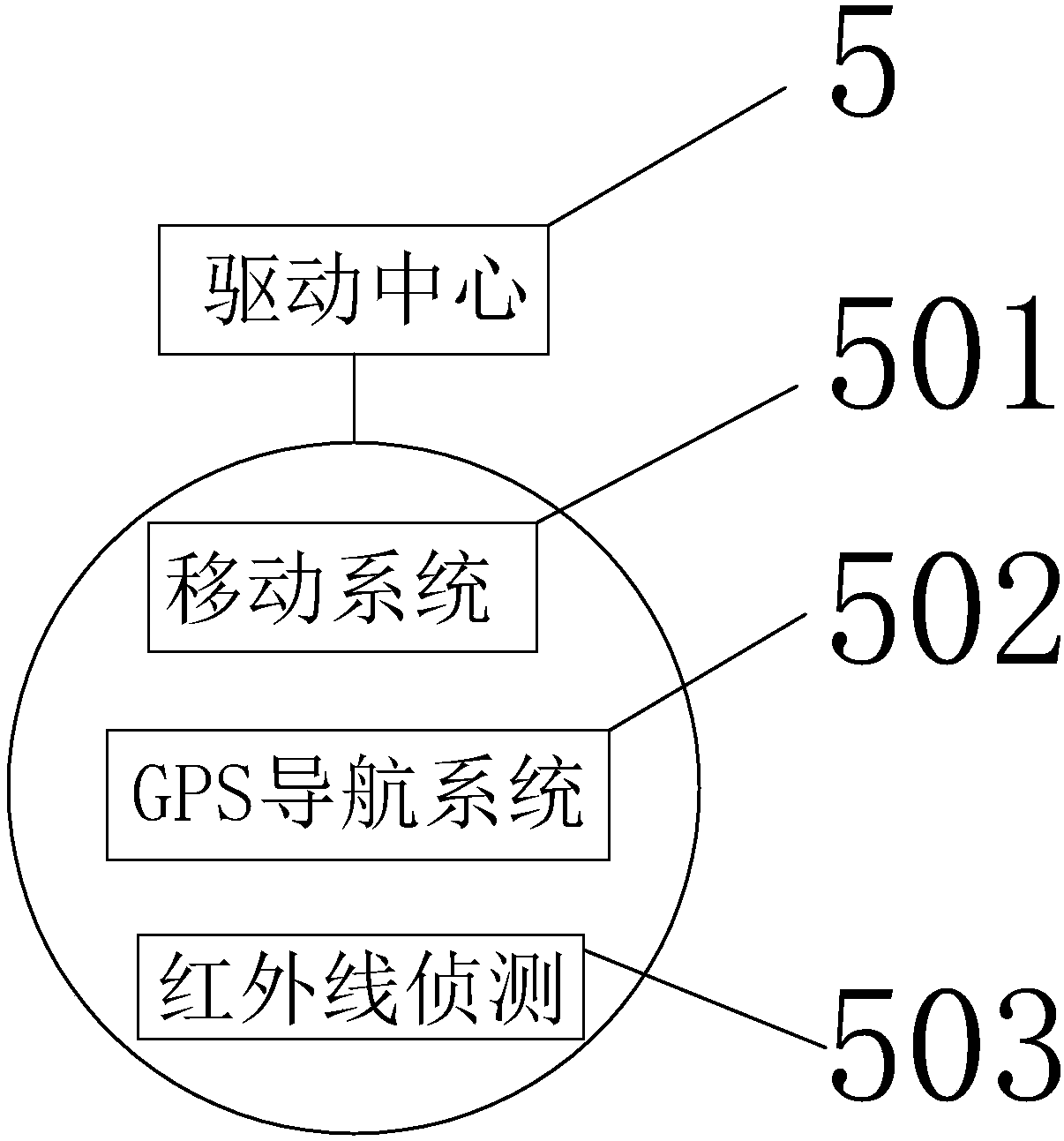

Intelligent charging management system

InactiveCN108599307AImprove practicalityAccurate positioning accuracyElectric powerExchanging data chargerInductive chargingManagement system

The invention discloses an intelligent charging management system. The intelligent charging management system comprises a main body, a driving centre and a standby state; a communication module is arranged in the main body; furthermore, the communication module is connected to a positioning module; the positioning module feeds back to a control centre; the driving centre is connected to the control centre; furthermore, the control centre is connected to a charging module; and the standby state receives signals of the control centre. The intelligent charging management system is provided with the charging module; furthermore, the existing mature wireless charging technology is adopted in the charging module; therefore, when the device charges equipment to be charged, the butt joint problemof joints in all types can be avoided; the practicability of the device system is improved; furthermore, the scheme has integrated design; the use range of the device is enlarged; the practicability of the device is further improved; furthermore, the positioning module is arranged; therefore, the system can position the main body and the equipment to be charged in the operation process; and simultaneously, the practicability of the device is improved.

Owner:ZHUHAI YUNMAI TECH CO LTD

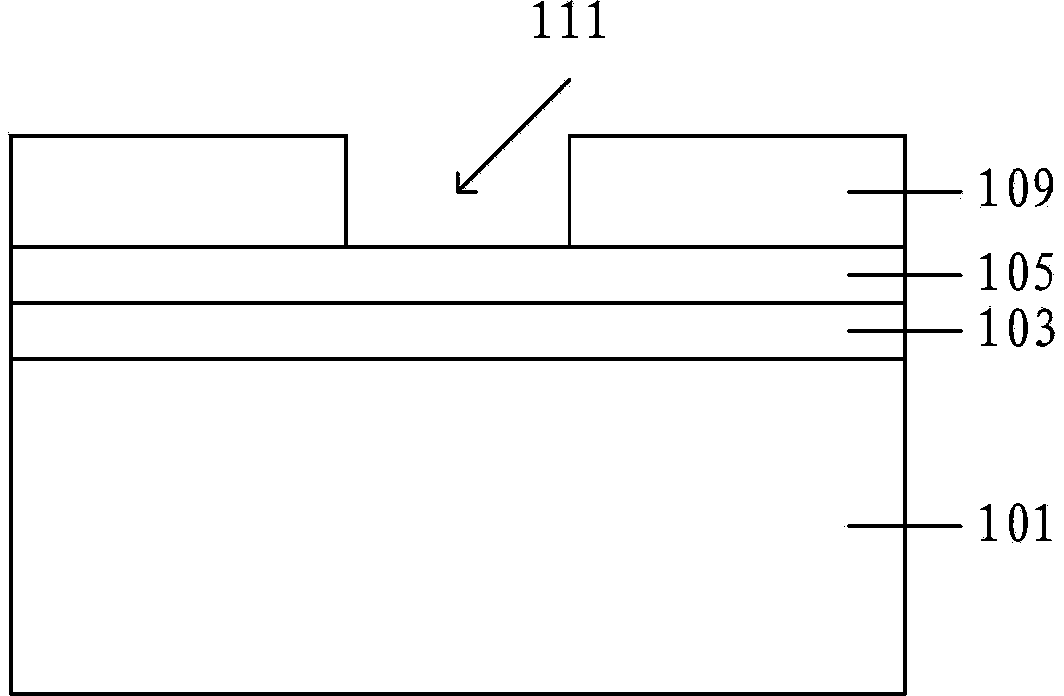

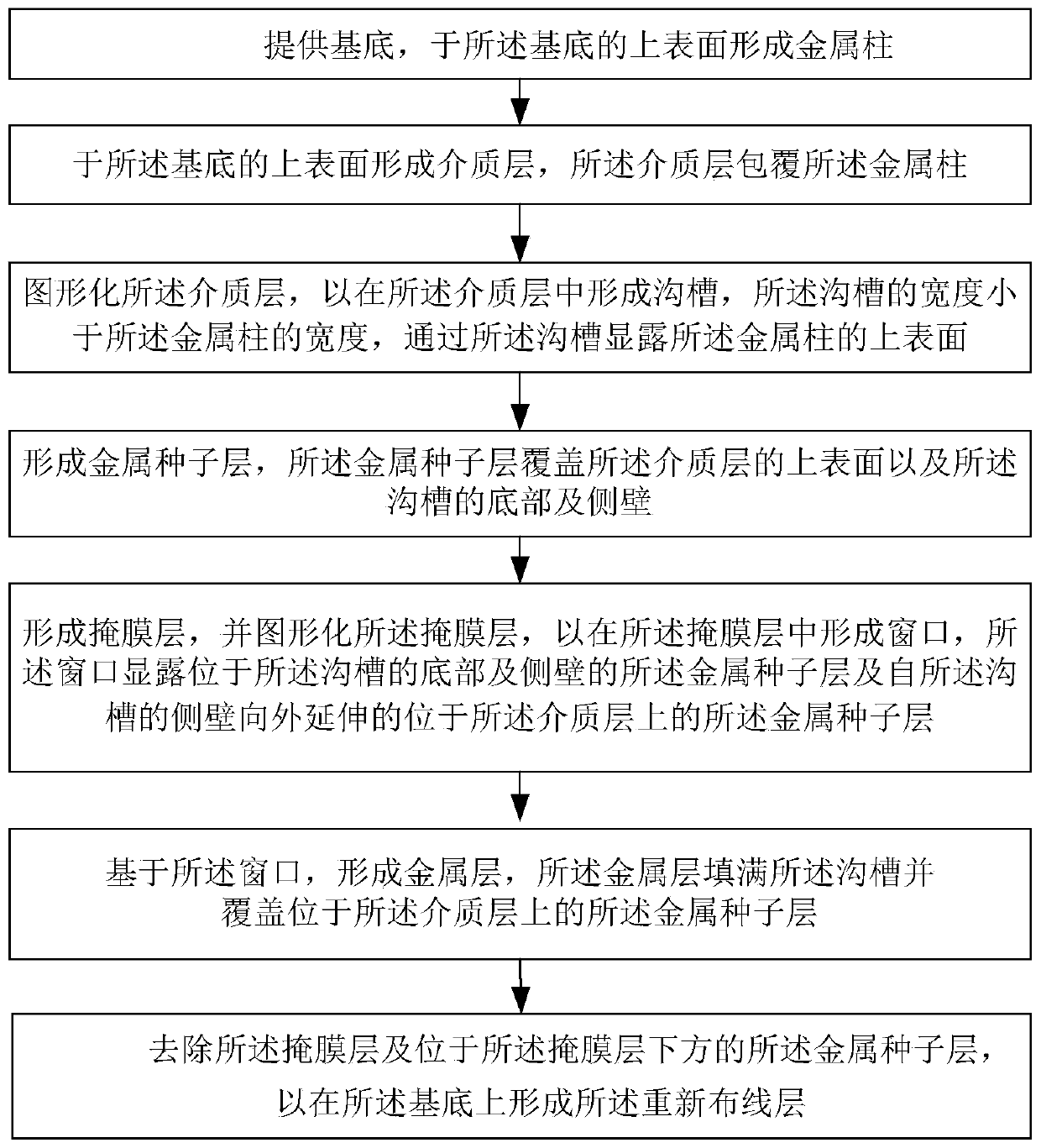

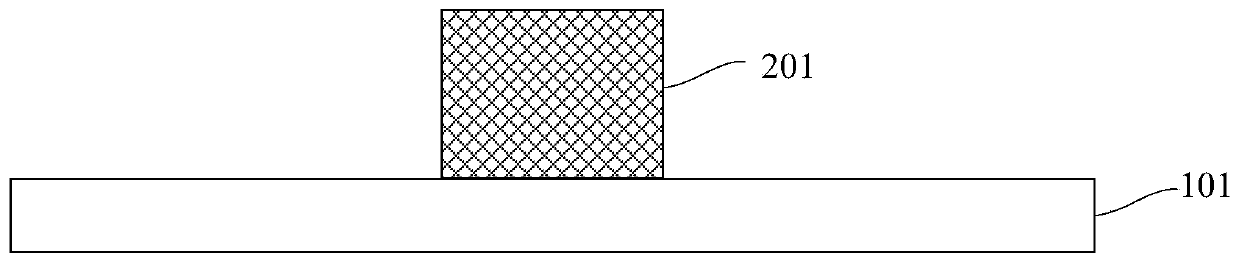

Preparation method of rewiring layer and semiconductor structure

PendingCN111489978AImprove flatnessAvoid groovesSemiconductor/solid-state device detailsSolid-state devicesPhysicsEngineering

The invention provides a preparation method of a rewiring layer and a semiconductor structure. The semiconductor structure comprises a substrate and the rewiring layer located on the upper surface ofthe substrate. The rewiring layer comprises a metal column; a dielectric layer, wherein the dielectric layer wraps the metal column, and the dielectric layer comprises a trench, the width of the trench being smaller than that of the metal column, and the upper surface of the metal column being exposed through the trench; a metal seed layer, which covers the upper surface of the dielectric layer and the bottom and the side wall of the trench; and a metal layer which fills the trench and covers the metal seed layer on the dielectric layer. According to the invention, the depth-to-width ratio oftrench filling in the dielectric layer is reduced by manufacturing the early-stage metal columns, and then the metal layer is manufactured, so that the flatness of the rewiring layer can be improved,grooves are prevented from being generated in the formed rewiring layer, the subsequent manufacturing process is facilitated, the process risk of multilayer stacking is reduced, and the process difficulty and cost are reduced.

Owner:SJ SEMICON JIANGYIN CORP

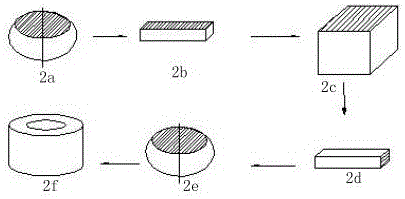

A Forging Forming Process of High Cylindrical Aluminum Alloy Forgings

Owner:WUXI PAIKE HEAVY CASTING & FORGING

A kind of wire rod and preparation method thereof

The invention discloses a wire rod and a preparation method thereof. The wire rod includes the following components in weight percentage: 0.45-0.95% of silicon, 7.5-9.5% of aluminum, 6.0-10.5% of zinc, 0.1-0.3% of iron, 0.2-0.5% of magnesium, Nickel 0.05‑0.65%, Boron 0.08‑0.14%, Yttrium 0.02‑0.035%, Tin 0.015‑0.018%, Tungsten 0.002‑0.015%, Chromium 0.1‑0.3%, Manganese 0.08‑0.15%, Zirconium 0.02‑0.07%, Beryllium 0.03 ‑0.08%, the balance being copper and unavoidable impurities. The invention guarantees the strength and wear resistance of the material, and at the same time improves the impact toughness and fracture resistance of the material, so that the comprehensive performance indicators such as strength, wear resistance and fracture resistance of the product can fully reach the advanced level of domestic similar products.

Owner:安徽尚视信息科技有限公司

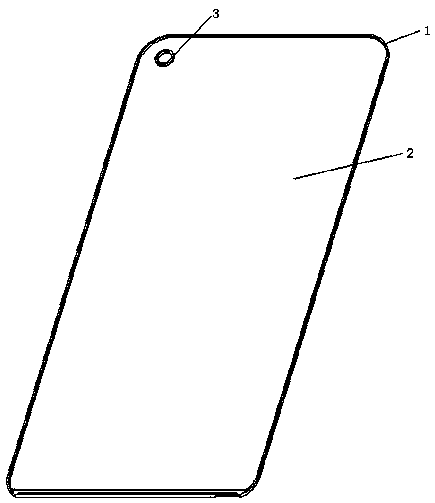

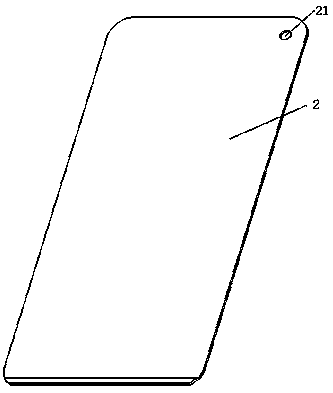

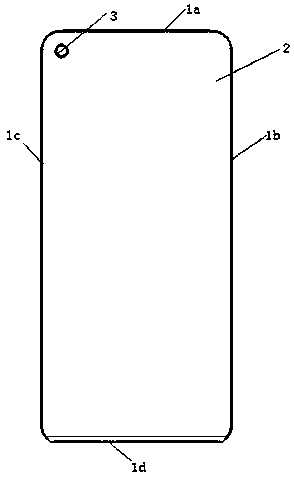

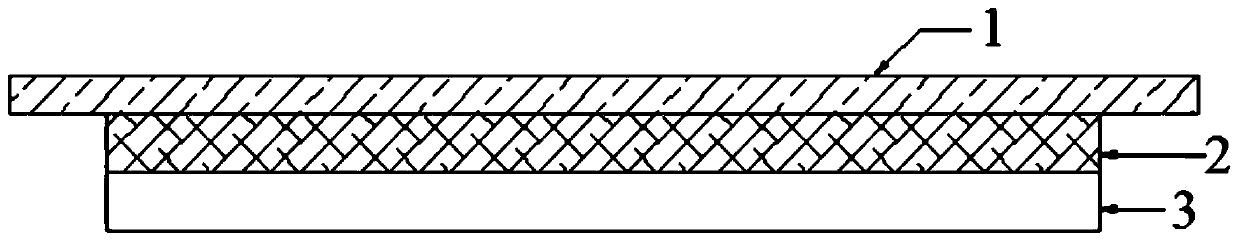

Rubber frame, backlight module and display device

The invention discloses a rubber frame, a backlight module and a display device. The rubber frame comprises a frame body and a base plate connected to bottom surface of the frame body, wherein a firstthrough hole is formed in the base plate, a positioning ring is arranged on the base plate, surrounds the first through hole and extends towards the front surface of the frame body, and an accommodating space for accommodating a camera is formed by the positioning ring and the first through hole. By arranging the front-mounted camera by virtue of the positioning ring, the situation that a groovefor the front-mounted camera is preserved in a house is avoided, the occupied space of the front-mounted camera is saved, and the area of a non-valid visual region is reduced, so that the screen-to-body ratio is increased.

Owner:SHENZHEN SOUTH POLE OPTOELECTRONICS TECH

A low-wear disc friction plate and its preparation method

ActiveCN109372911BGood adhesionHigh bonding strengthNoise/vibration controlOther chemical processesBrakeUltimate tensile strength

The invention provides a low-wear disc type friction plate. A buffer layer containing a magnetic material is added between a steel backing and a ceramic layer, adhesion between the buffer layer and the steel backing combination face can be improved, and the phenomenon that due to the brake high temperature (400 to 500 DEG C), the friction material buffer layer falls off from the steel backing face, and brake fails is avoided. The adhesion strength between the friction piece and the steel backing can be increased, iron hard points are prevented from appearing in the friction face, screeching and brake trembling generated in the brake process can be removed, brake disc scraping and grooves generated by the iron hard points can be avoided, and the service life of the brake disc can be prolonged.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

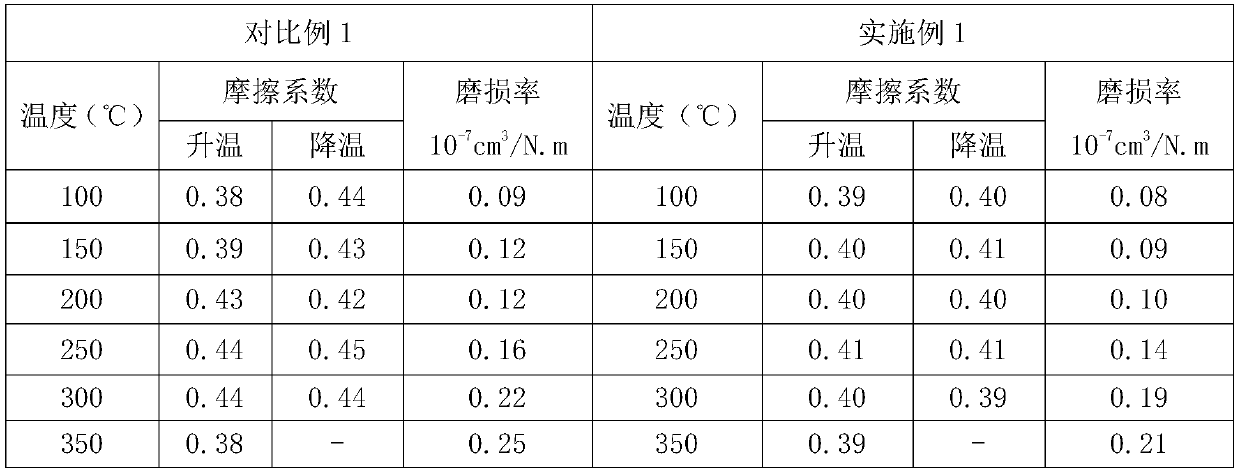

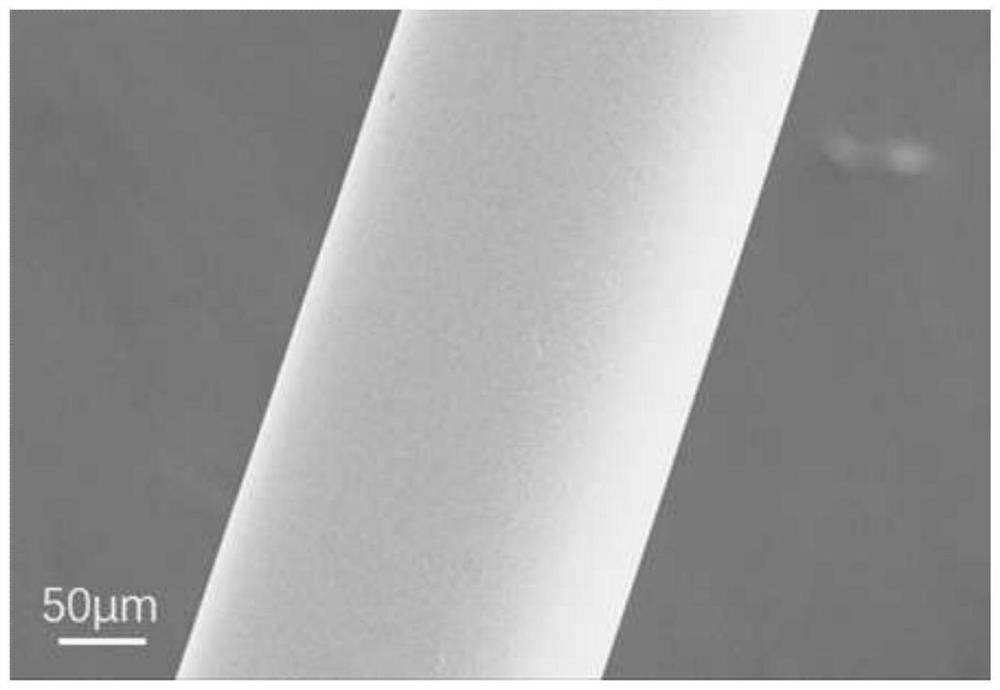

Electrolytic polishing solution and electrolytic polishing method for tungsten-based wires or sheets

ActiveCN113463178AActive ingredients are stableEasy to storeElectrolysis componentsElectrolysisAlcohol

The invention discloses an electrolytic polishing solution and electrolytic polishing method for tungsten-based wires or sheets, and relates to the technical field of metal surface treatment. The electrolytic polishing solution comprises quaternary ammonium base, absolute ethyl alcohol, 2-methyl-1-hexene, sodium sulfate and water, the concentration of the quaternary ammonium base is 20-40 g / L, the concentration of the absolute ethyl alcohol is 10-50 g / L, the concentration of the 2-methyl-1-hexene is 1-5 g / L, and the concentration of the sodium sulfate is 50-100 g / L. The tungsten-based wires or sheets to be treated are placed in the electrolytic polishing solution to serve as an anode, nickel serves as a cathode, the current density of a direct-current stabilized power supply is adjusted to be 1.0-4.0 A / cm<2>, and the stirring speed is 5-40 r / s. The method has the beneficial effects that the treated tungsten-based wires are bright and flat in surface, low in roughness, good in polishing effect, free of generation of hazardous gas in the polishing process, free of heating, high in ion flowing speed, safe, environmentally friendly, controllable and efficient.

Owner:NANCHANG UNIV

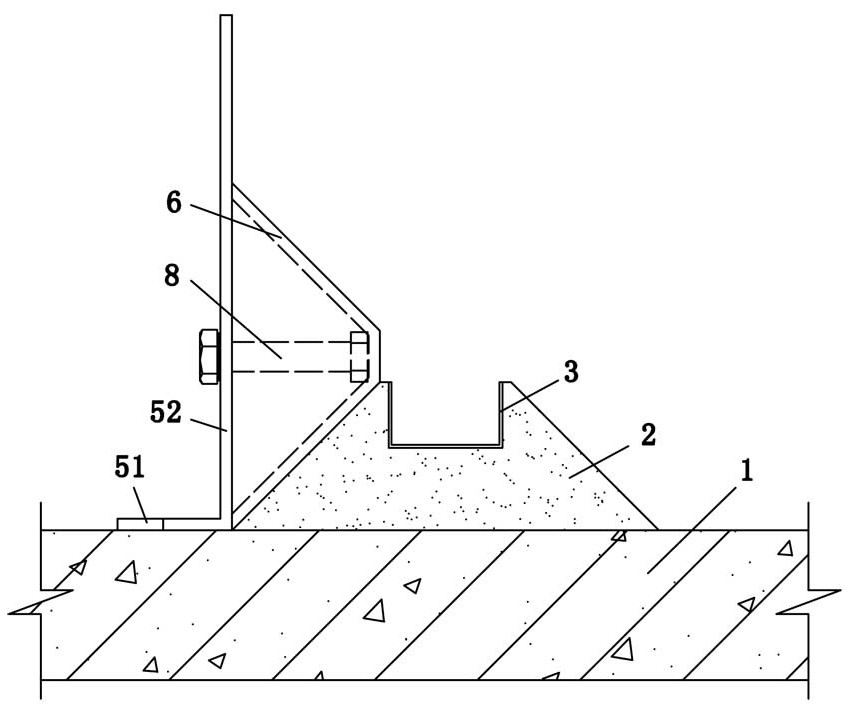

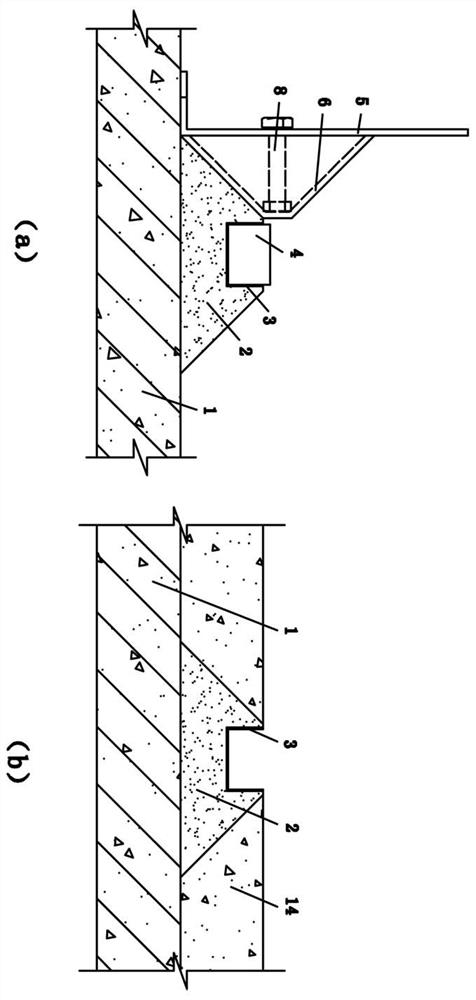

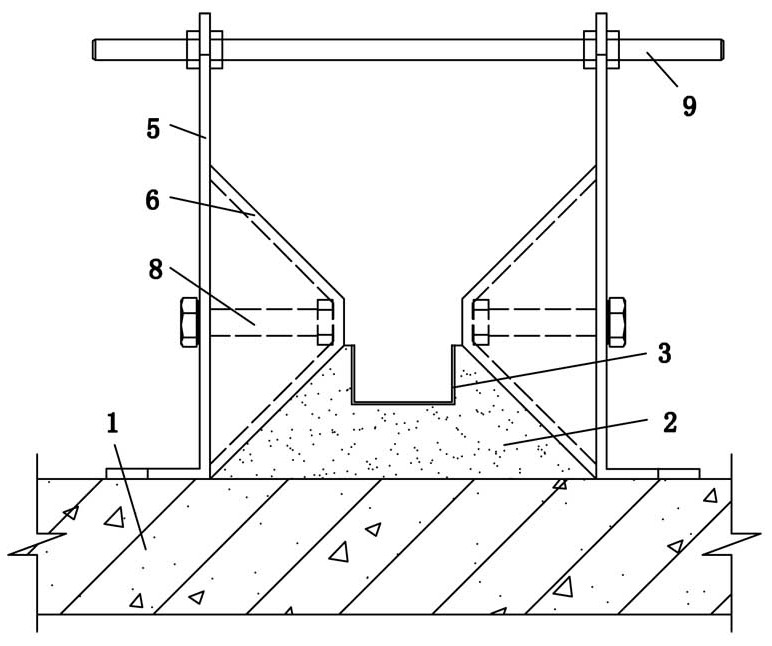

Separation joint construction structure and construction method of roof ground and table top layer

ActiveCN113718972AFlexible construction operationEasy constructionRoof coveringGrandstandsIsosceles trapezoidScreed

The invention relates to a separation joint construction structure of a roof ground and a table top layer. The separation joint construction structure comprises a foundation layer, a mortar layer is arranged on the foundation layer, and the section of the mortar layer is an isosceles trapezoid; pVC separation strips are embedded in the upper bottom face of the mortar layer to form separation seams, and sponge strips are arranged in the separation strips to prevent blocking; a side leveling seat is arranged on one side of the mortar layer, the side leveling seat comprises an L-shaped vertical plate and a target plate for leveling, the vertical plate is arranged on the foundation layer, the vertical plate is detachably connected with the target plate through a bolt, the cross section of the target plate is trapezoidal, and the lower bottom surface of the target plate is attached to the vertical plate; and the waist length of the standard plate is equal to that of the mortar layer, and the planes where the two waists are located are attached. The invention further relates to a separation joint construction method of the roof ground and the table top layer. According to different areas of the roof, the ground and the stand, the mortar layer can be manually built or a side flat seat is adopted as a mold, the mortar layer is formed through one-time pouring, the construction operation of the separation joint is flexible, and the forming appearance quality of the separation joint is guaranteed.

Owner:SHANGHAI BAOYE GRP CORP +1

Turnover aluminum alloy window frame protection device

InactiveCN114212359AAvoid groovesEasy to fixCleaning using toolsContainers to prevent mechanical damageStructural engineeringTransportation technology

The invention provides a turnover aluminum alloy window frame protection device, and relates to the technical field of door frame transportation. The turnover aluminum alloy window frame protection device comprises a window frame, a first protection mechanism, a second protection mechanism and a power supply connecting block, the first protection mechanism is arranged on the outer side of the window frame, the second protection mechanism is arranged between the inner sides of the window frame, and the power supply connecting block is fixedly connected to the middle of the second protection mechanism. Dust in the bottom end of the inner side of the window frame is collected in a centralized mode through a second protection mechanism, the situation that the effect of collecting the dust in the bottom end of the inner side of the window frame is affected by jolting of the window frame in the transportation process is prevented, and excessive dust in the bottom end of the inner side of the window frame is prevented from affecting use and installation of the window frame; the invention provides a turnover aluminum alloy window frame protection device. The problem that in the transportation process of an aluminum alloy window frame, the surface of the aluminum alloy window frame is extruded or collided to form a groove, and use of the aluminum alloy window frame is affected is solved.

Owner:李康

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com