Stainless steel strip cold rolling process

A technology of stainless steel strip and process, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of affecting the quality of the steel strip, falling foreign objects on the steel strip, scratches on the steel strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

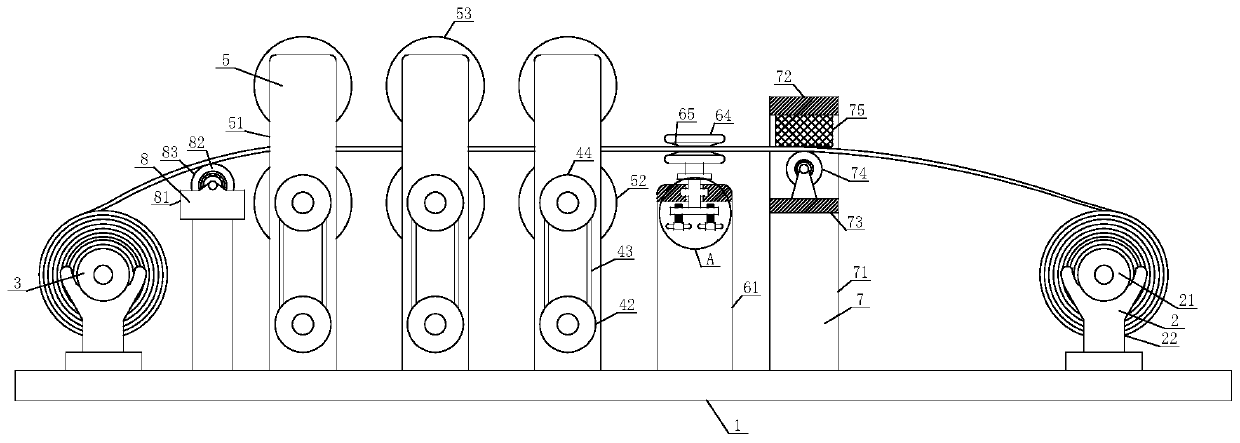

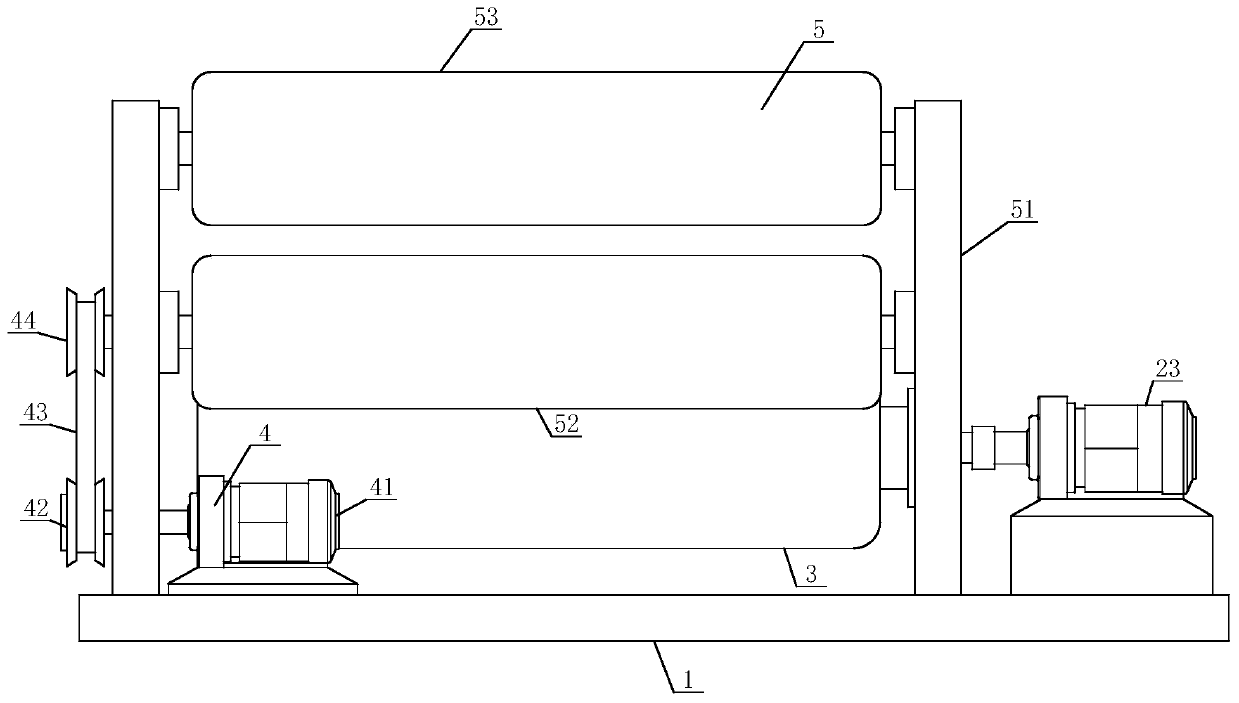

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

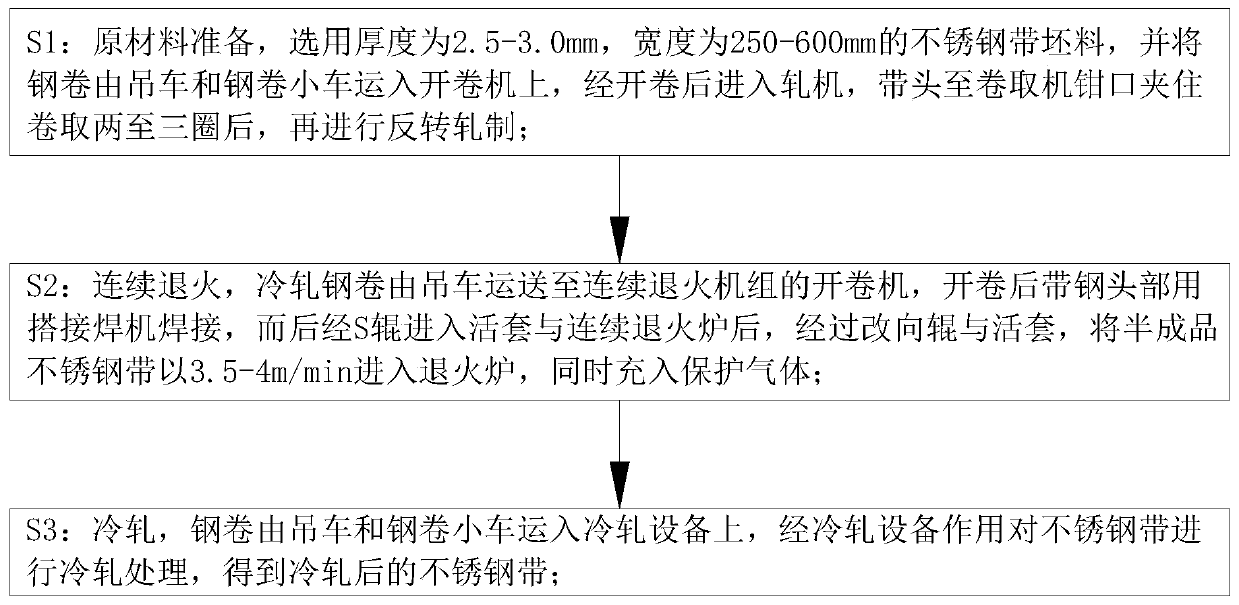

[0029] Such as Figure 1-Figure 6 Shown, a kind of stainless steel strip cold-rolling process of the present invention, this cold-rolling process comprises the following steps:

[0030] S1: Raw material preparation, select a stainless steel strip blank with a thickness of 2.5-3.0mm and a width of 250-600mm, and transport the steel coil to the uncoiler by a crane and a steel coil trolley, enter the rolling mill after uncoiling, and take the lead to the coiler clamp After clamping and coiling for two to three laps, reverse rolling is carried out;

[0031] S2: Continuous annealing. The cold-rolled steel coil is transported by a crane to the uncoiler of the continuous annealing unit. After uncoiling, the head of the strip steel is welded by a lap wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com