Patents

Literature

797results about "Work cleaning devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

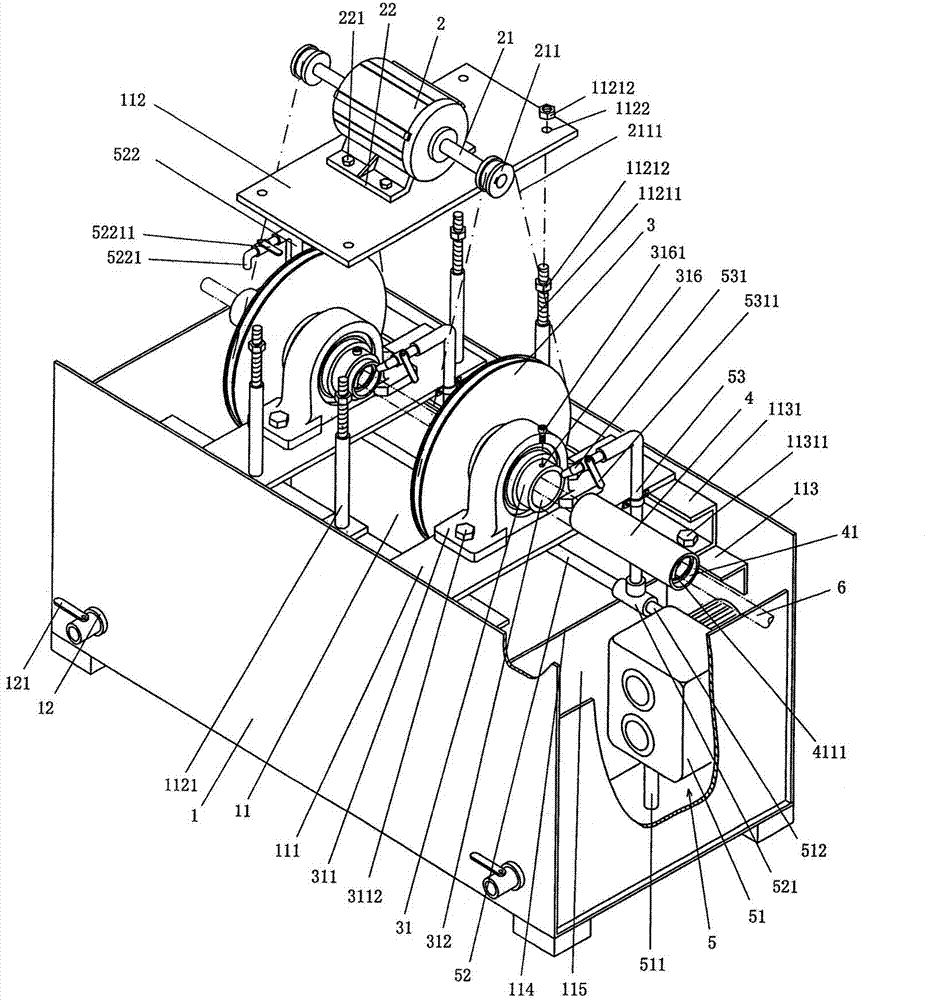

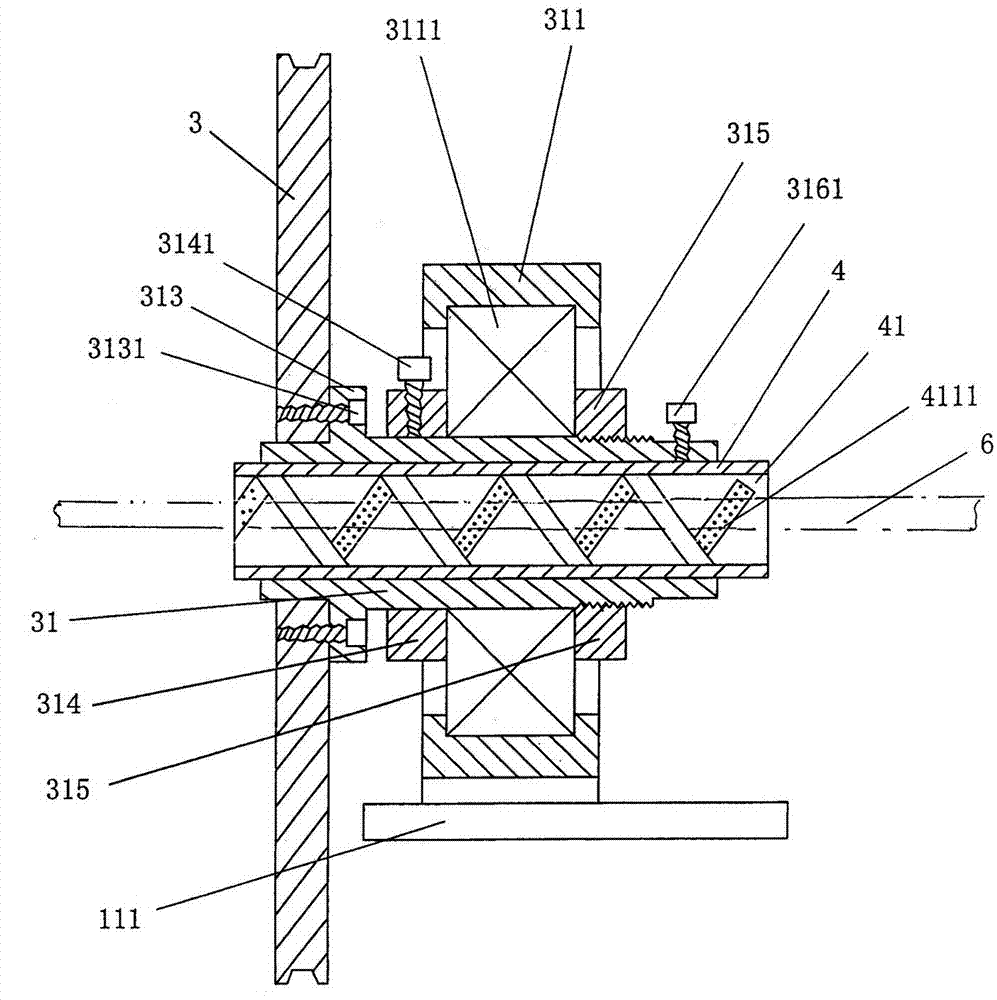

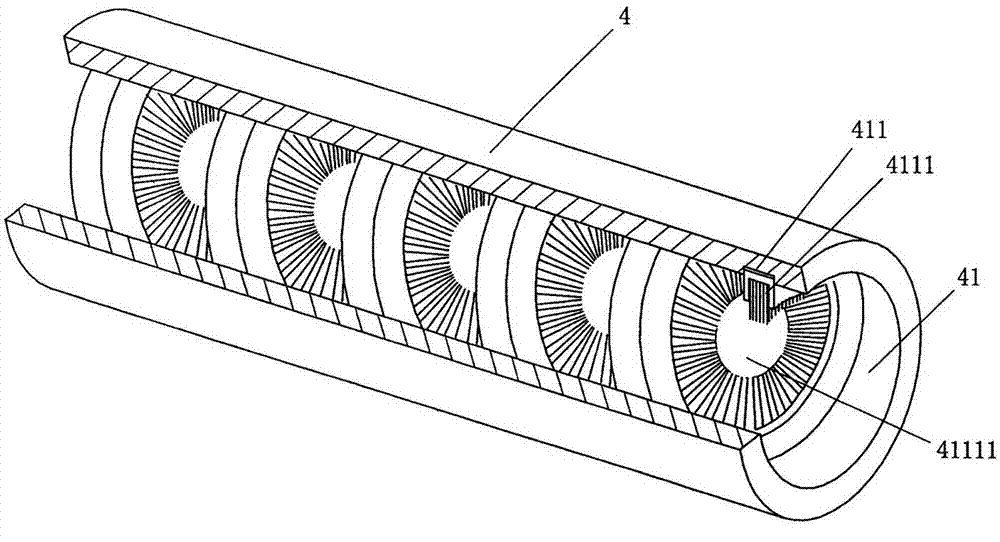

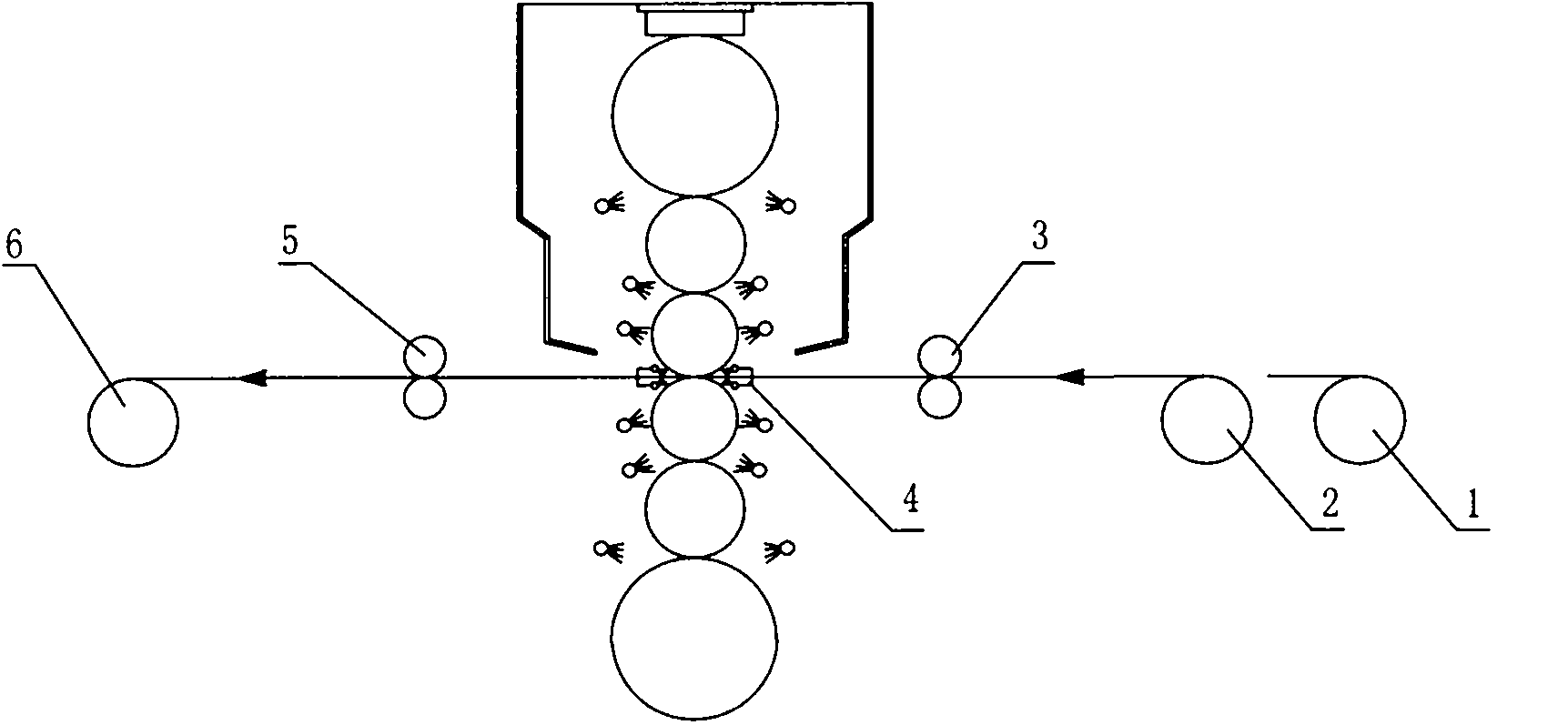

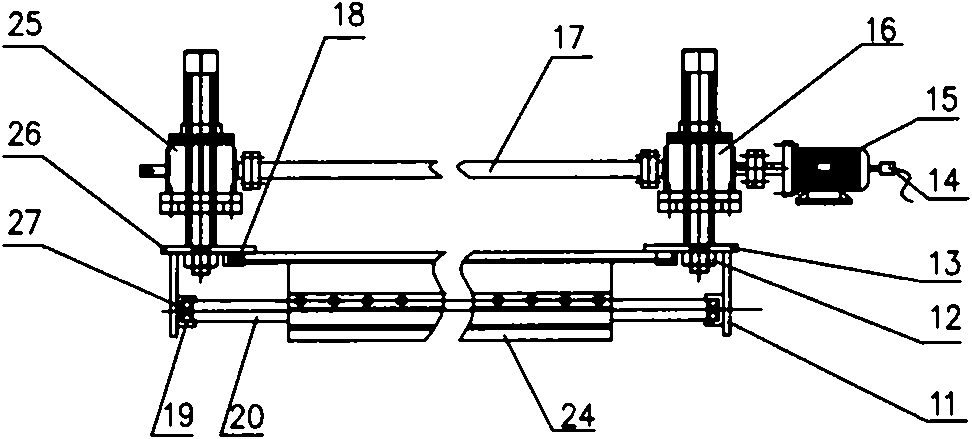

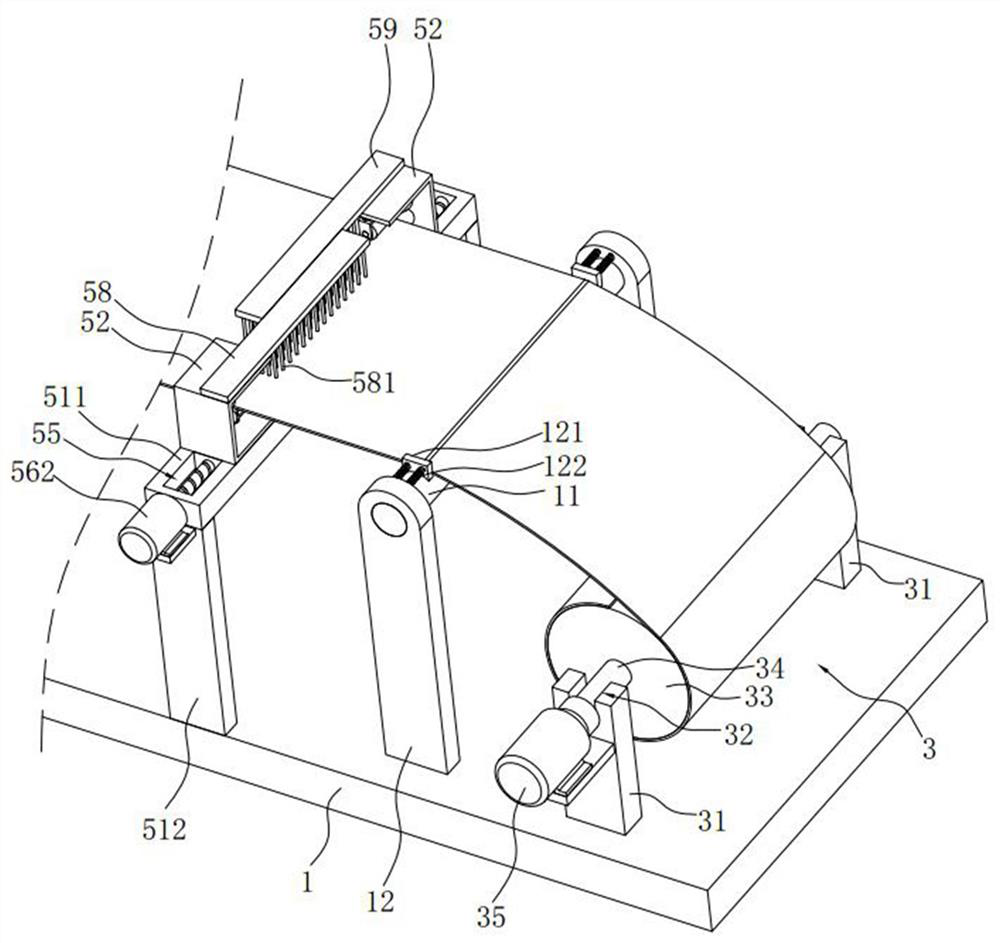

Steel pipe cleaning device

InactiveCN103920677ALong-lasting cleaning effectPlay a cleaning roleHollow article cleaningWork cleaning devicesDrive wheelControl engineering

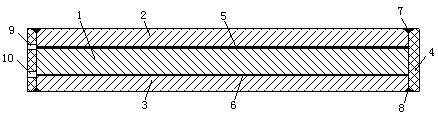

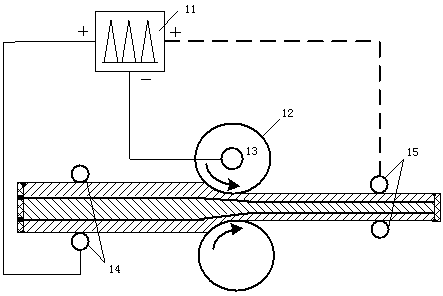

The invention provides a steel pipe cleaning device, and belongs to the field of metal pipe cleaning machines. The steel pipe cleaning device comprises a cleaning fluid box body and a circulating fluid supply mechanism. A cleaning fluid recycling cavity is formed in the right end of a cavity of the box body, bearing block fixing plates and a motor supporting plate are fixed to the left end of the cavity, shaft sleeve driving wheels are arranged on the bearing block fixing plates, a motor is arranged on the motor supporting plate, motor shaft driving wheels are fixed to the two ends of a motor shaft, one end of a driving belt is arranged on the motor shaft driving wheels, the shaft sleeve driving wheels are sleeved with the other end of the driving belt, one end of each shaft sleeve is fixed to the center of the corresponding shaft sleeve driving wheel, the other end of each shaft sleeve is supported by a corresponding shaft sleeve bearing block, the shaft sleeve bearing blocks are fixed to the bearing block fixing plates, a brush pipe is fixed into shaft sleeve cavities, brush positioning grooves are formed in the inner wall of a brush pipe cavity and in the length direction, and brushes are embedded into the positioning grooves. The circulating fluid supply mechanism is arranged in the cleaning fluid recycling cavity. The structure is simplified, and the brushes make good contact with the outer wall of a steel pipe; transition links are fewer; the brushes have the permanent cleaning effect on the steel pipe, and the cleaning quality is good.

Owner:CHANGSHU WATER SUPPLY & SEWERAGE WORKS CO LTD

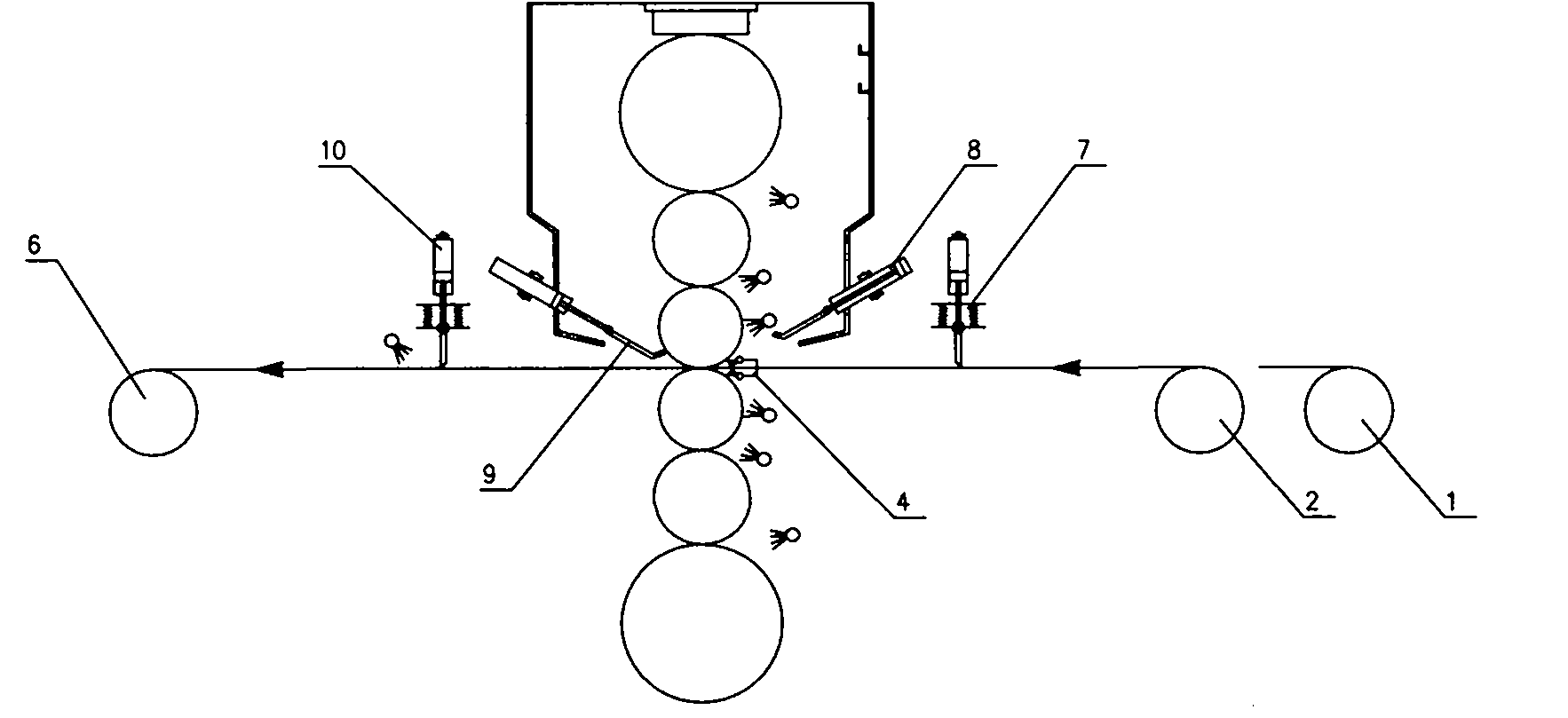

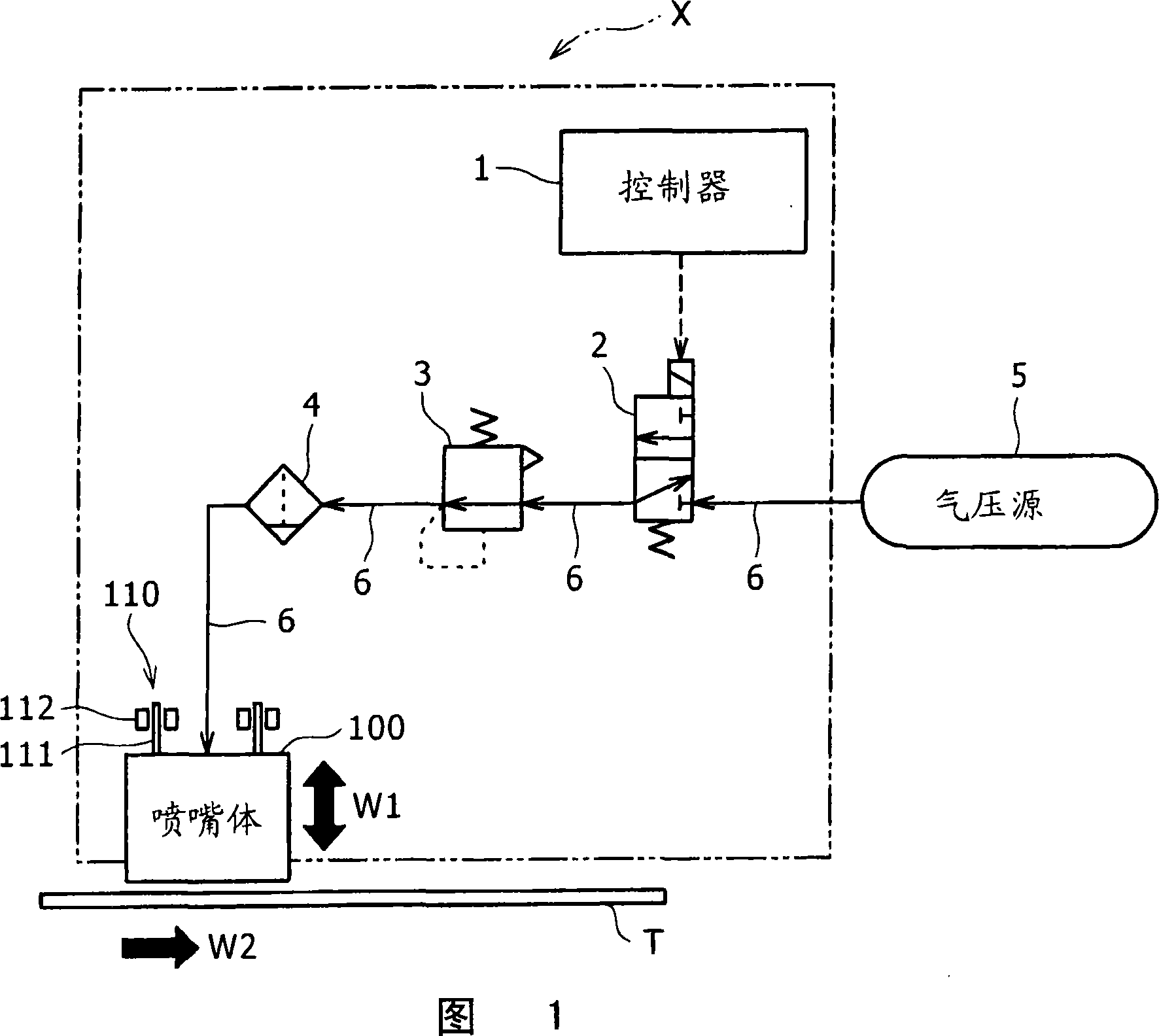

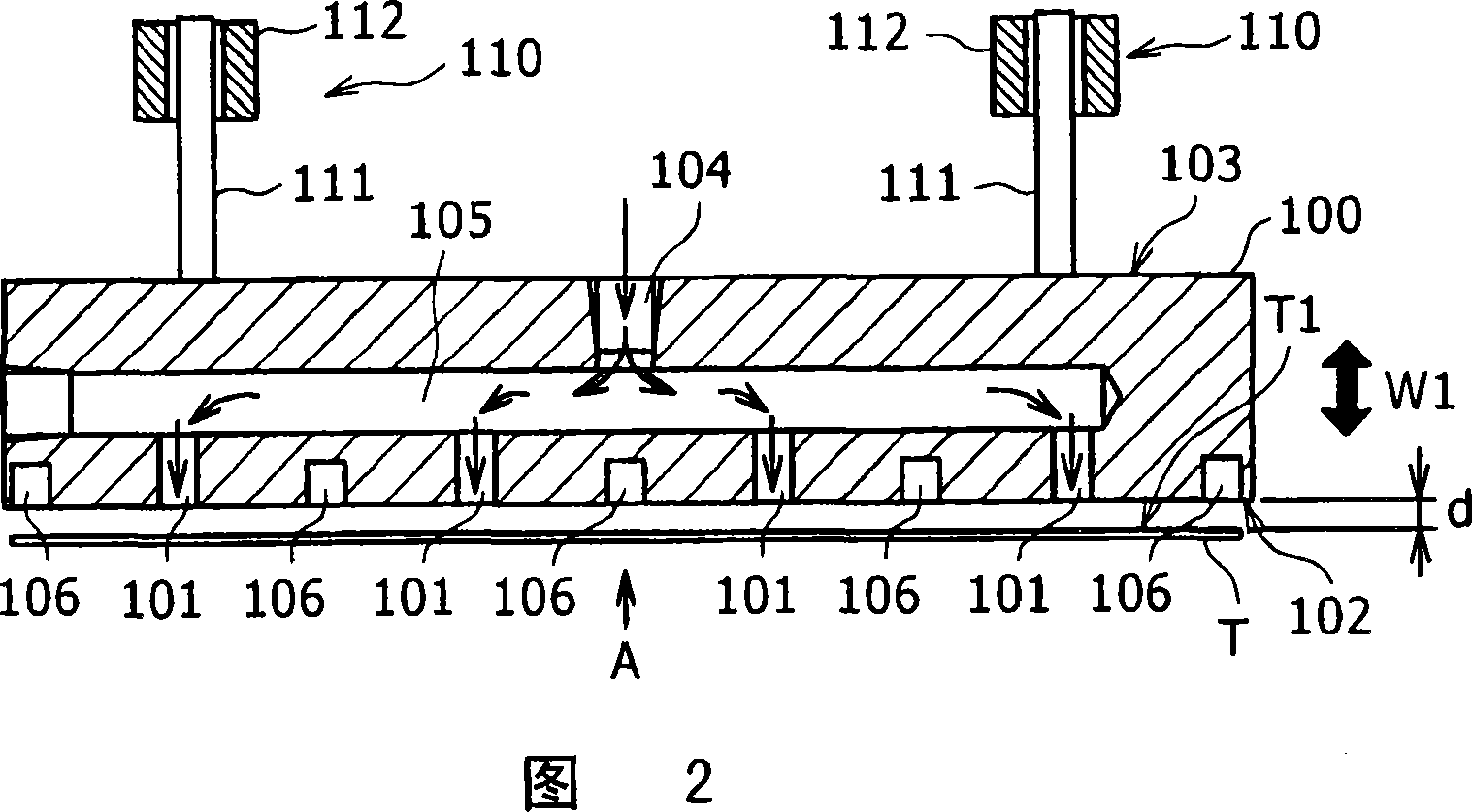

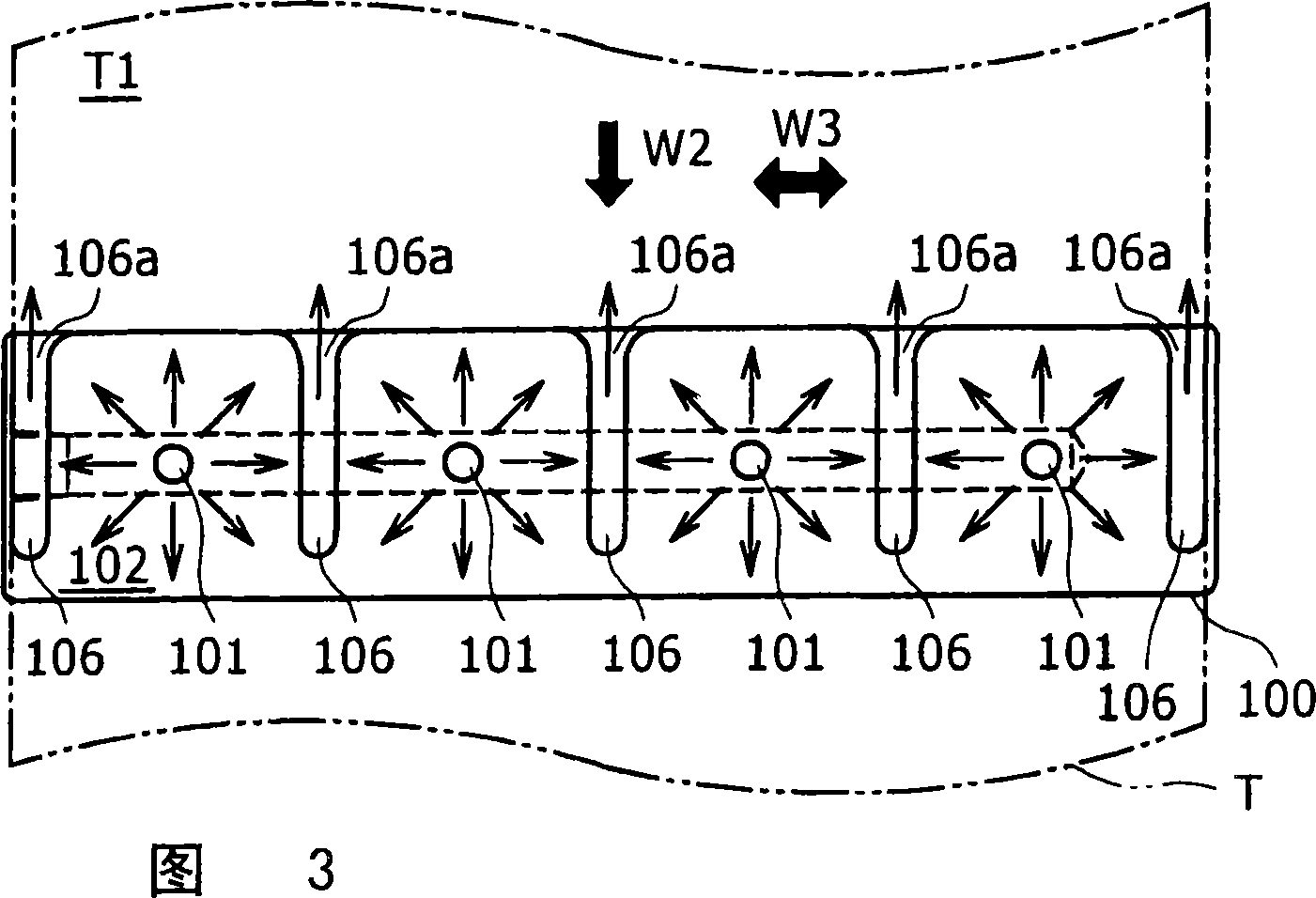

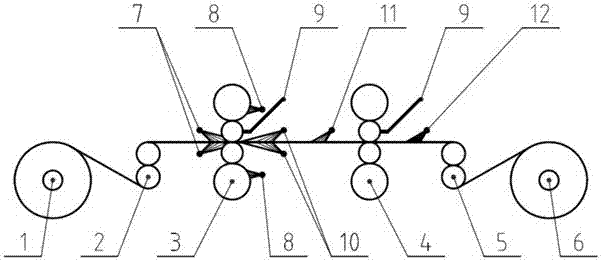

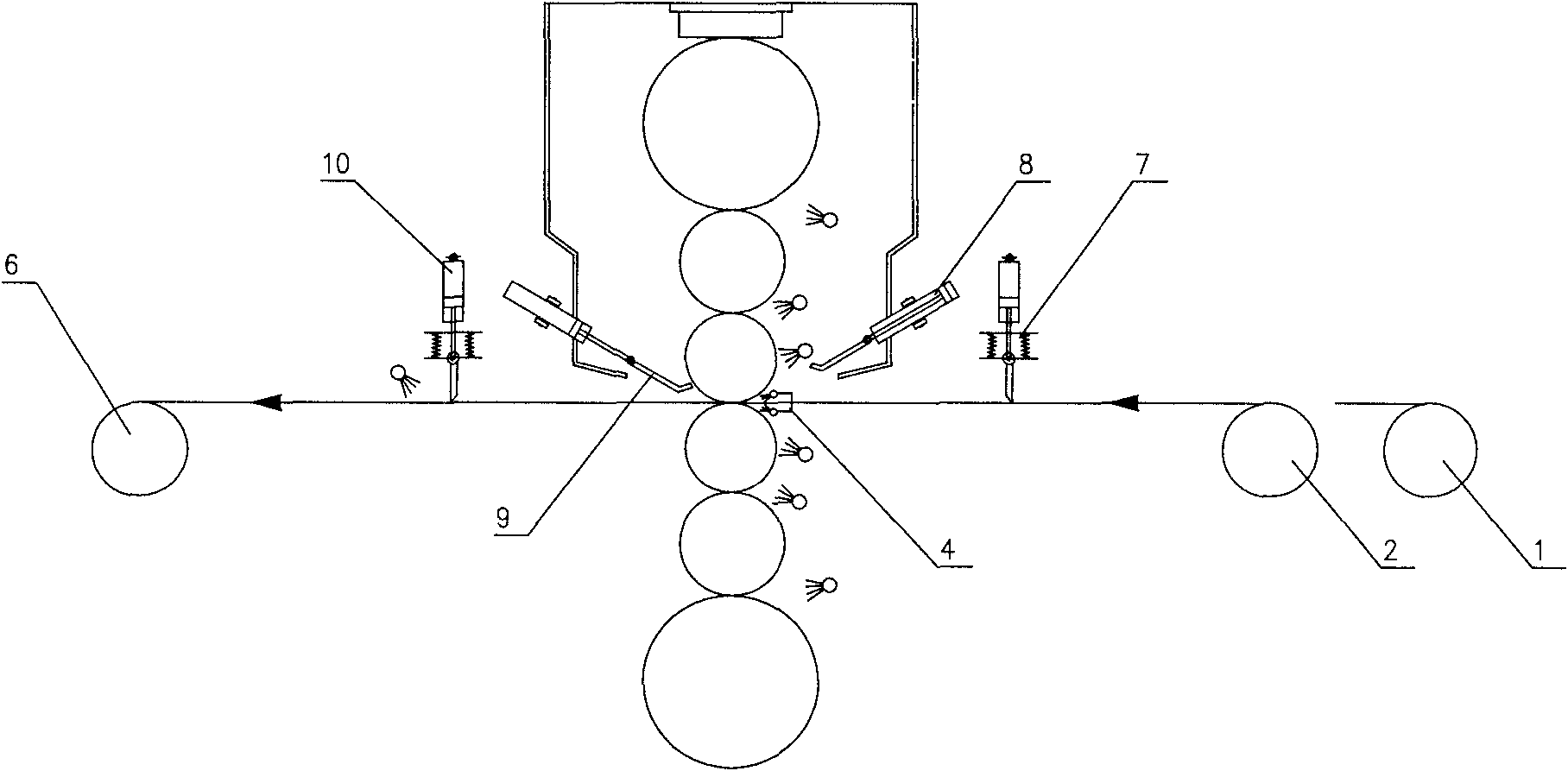

Blowing-free emulsion residue removal method

ActiveCN101829693AImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

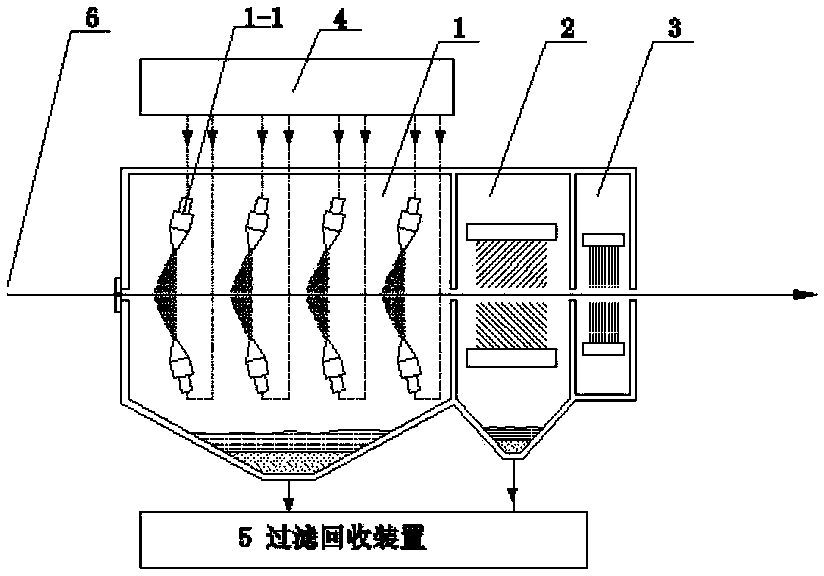

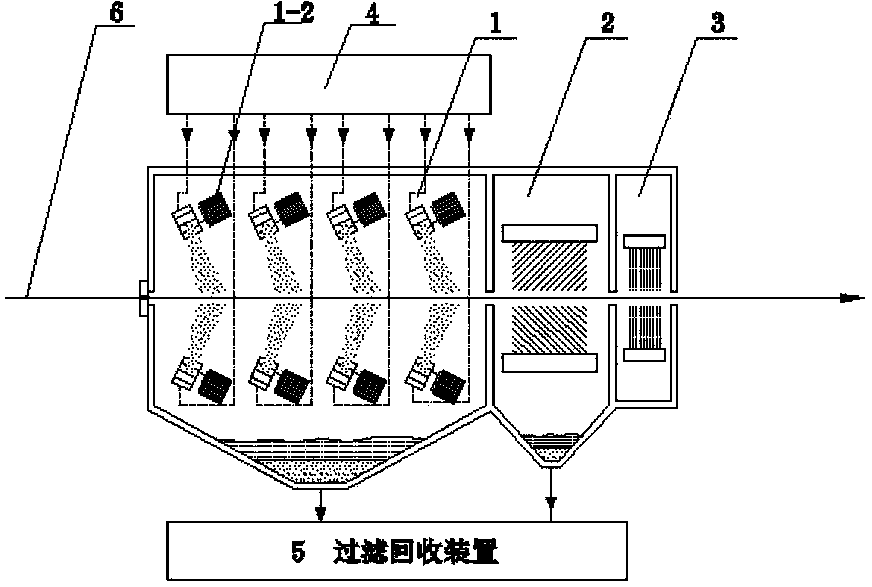

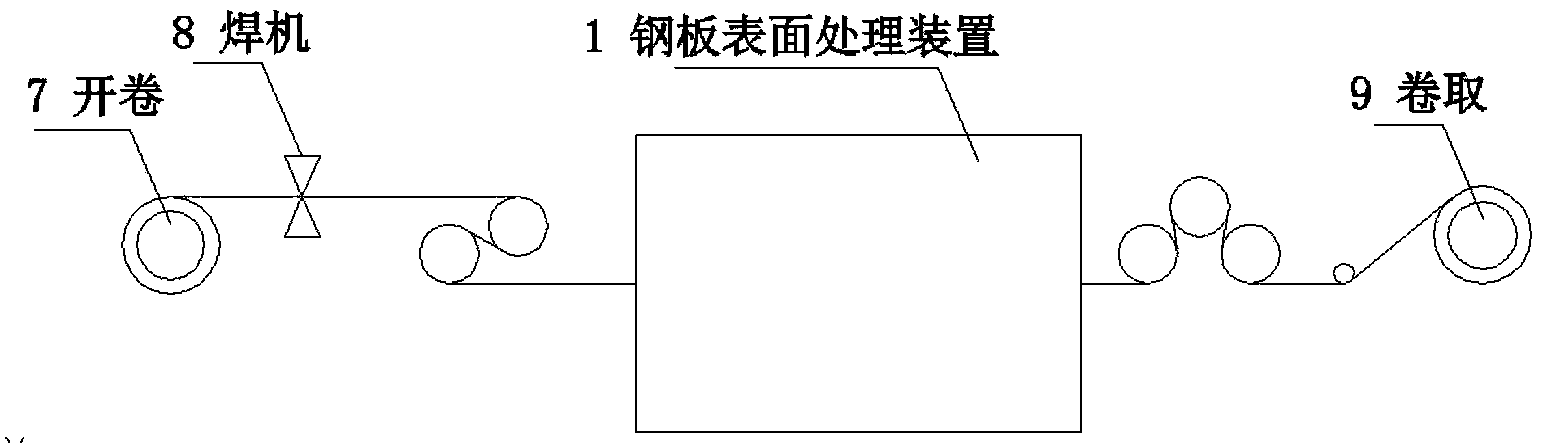

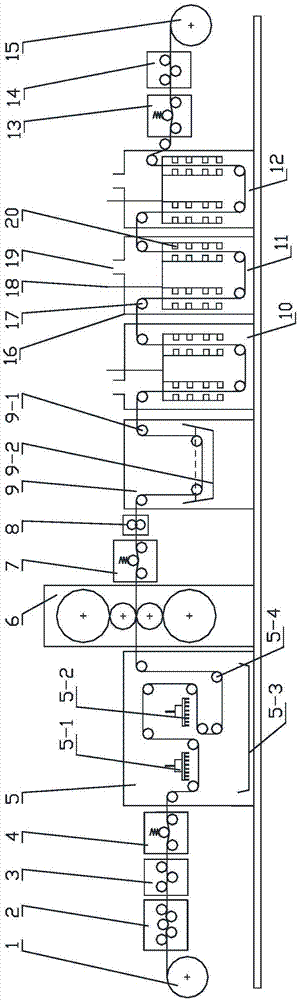

Steel plate surface treatment method and device

ActiveCN104056865AImprove cleanlinessReduce loadWork cleaning devicesMetal rolling arrangementsProcess functionSheet steel

An apparatus for treating a surface of a steal plate, sequentially comprising: a strip steel surface treatment unit (1) provided with a high-pressure ejection device (1-1) or a centrifugal throwing device (1-2), a strip steel surface cleaning unit (2), and a strip steel surface drying unit (3), one or both of the high-pressure ejection device and the centrifugal throwing device being arranged, and slurry, namely a mixture of solid abrasive and water, being sprayed onto the surface of the strip steel; and further comprising a slurry supply unit (4) and an abrasive filtering and recovery unit (5). Also disclosed is a method for treating a surface of a steal plate. In the treatment method, by spraying the solid mixed abrasive onto the surface of the strip steel, the surface roughness of the strip steel is controlled, and further, the oil, iron oxide scales and some dirty things on the surface of the strip steel can be cleared, thereby fully or partially replacing the smoothing process function.

Owner:BAOSHAN IRON & STEEL CO LTD

Lubrication system

A system is disclosed for applying a liquid lubricant to first and second components enclosed in a housing, with the lubricant applied to the second components being exposed to contamination by a liquid coolant applied to the exterior of the housing, and with the lubricant applied to the first components being substantially isolated from the liquid coolant. The system includes a partition internally subdividing the housing into a first chamber containing the first components and a second chamber containing the second components. Lubricant is delivered from a storage tank to the housing for application to the first and second components. A first conduit network communicates with the first chamber for returning the lubricant applied to the first components to the storage tank, and a second conduit network communicates with the second chamber for returning lubricant applied to the second components to the storage tank. A liquid coolant removal unit in the second conduit network removes liquid coolant from the lubricant being returned to the storage tank.

Owner:SIEMENS IND INC

Deposit removing device

Owner:KOBE STEEL LTD

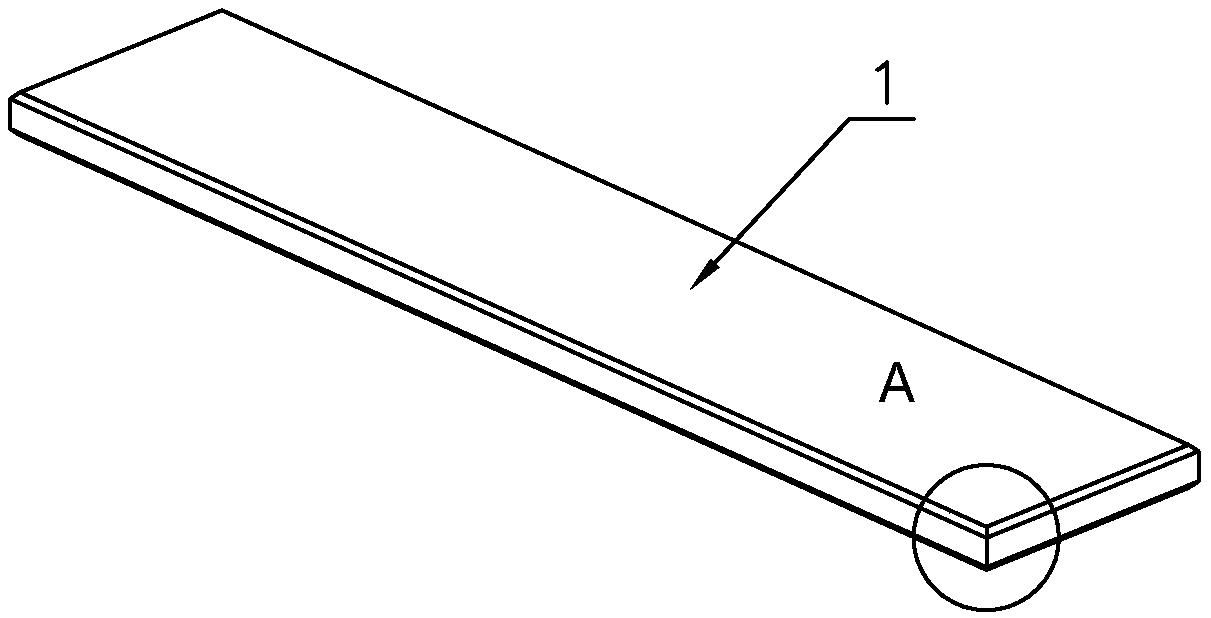

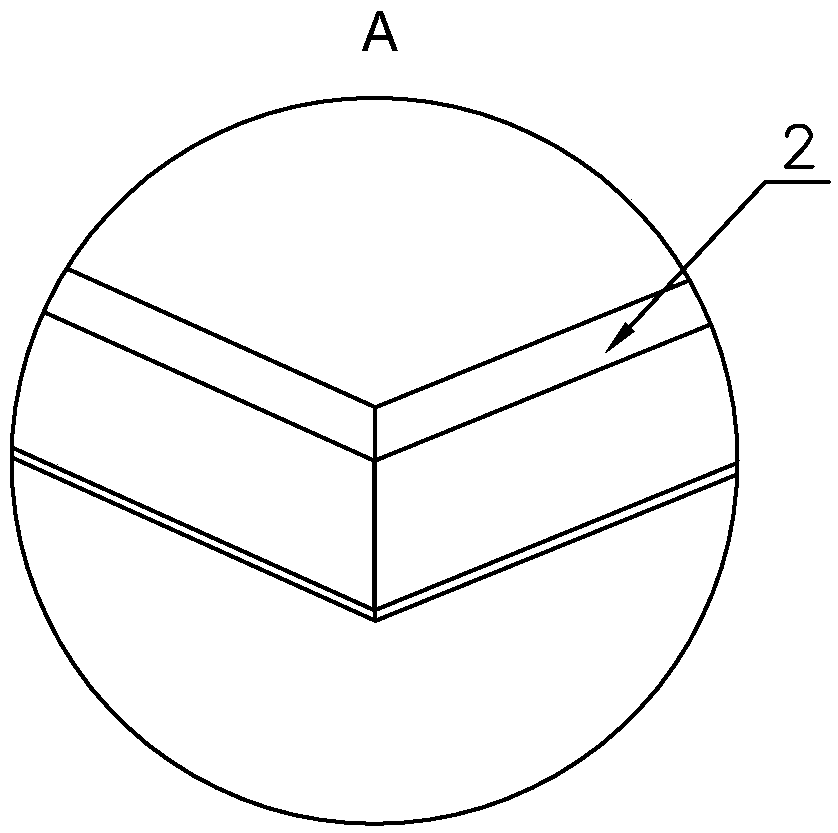

Production method for stainless steel two-sided composite board, roll

The invention discloses a production method for a stainless steel two-sided composite board, roll; the production method comprises the following steps: preparing one-step rolling blank: 1.1, processing the surfaces of a substrate and a composite board, the material of the substrate is carbon steel, the material of the composite board is stainless steel; 1.2, preparing file strip, cutting the carbon steel of 12-20mm on thickness into the strips, the width of the strips is the sum of the thickness of two composite boards with a plus of 0.3-0.5mm, and cleaning the surfaces of the strips according to the method in the step 1.1. The stainless steel and the carbon steel are combined together in a metallurgical bonding manner, the combination property of the material is improved; the product quality is superior to GB / T 8566-2008.

Owner:洛阳荣强新材料科技有限公司

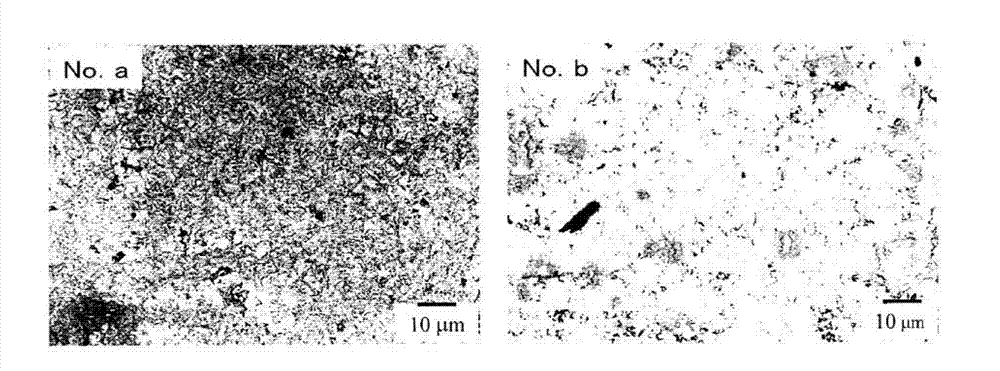

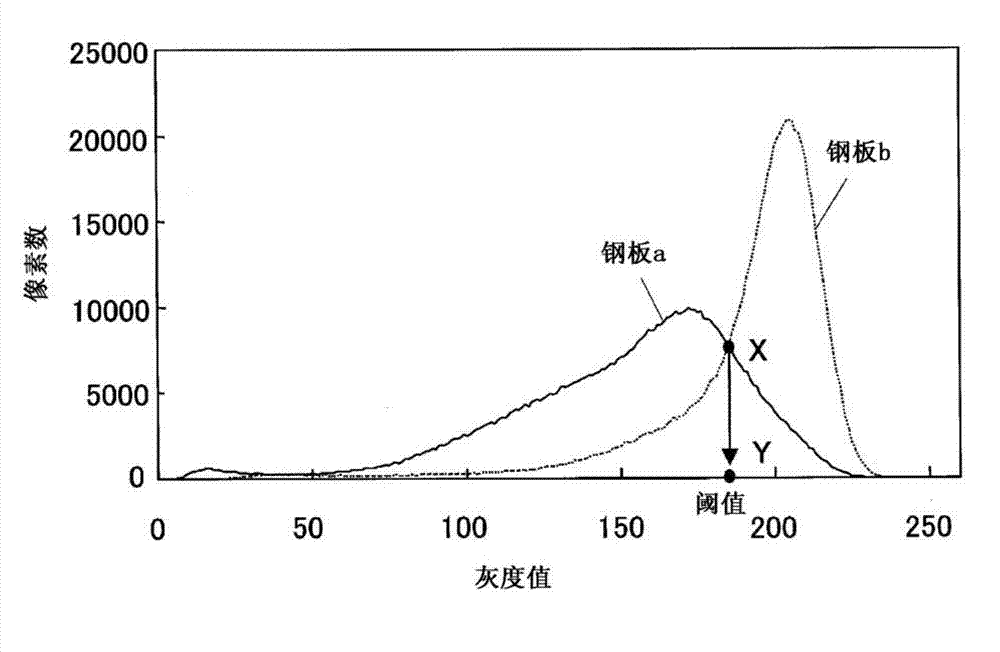

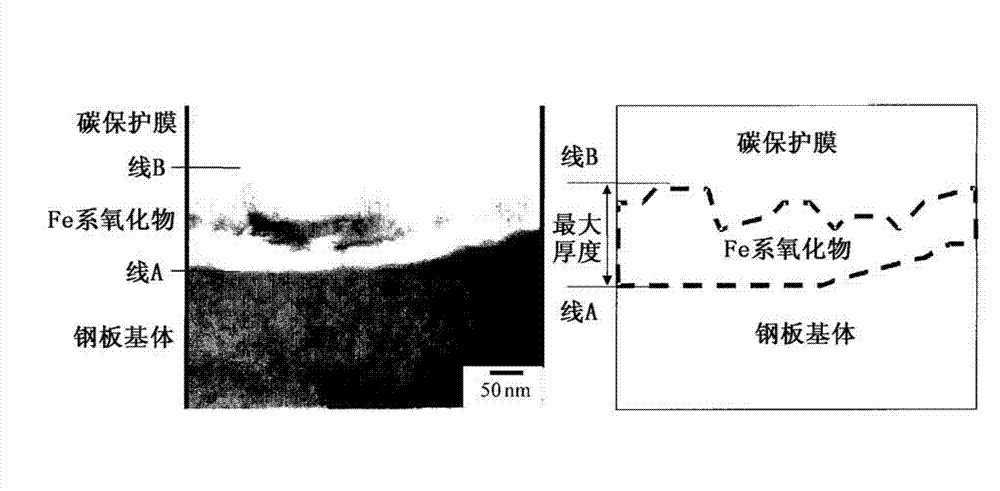

Method for producing cold-rolled steel sheet, cold-rolled steel sheet, and vehicle member

ActiveCN102959130AImprove corrosion resistanceEasy to handleFurnace typesThin material handlingWarm waterSalt water

Provided is a method for producing a cold-rolled steel sheet which exhibits excellent chemical conversion processability and corrosion resistance after coating in harsh corrosive environments such as in a warm salt water immersion test or a compound cyclic corrosion test, and comprises the steps of: pickling a cold-rolled steel sheet preferably containing 0.5 to 3.0 mass % of Si and subjected to continuous annealing after being cold-rolled, and removing an Si-containing oxide layer on the surface layer of the steel sheet; picking the cold-rolled steel again; and restricting the surface coverage of an iron-based oxide on the surface of the steel sheet to 40% or less, and more preferably restricting the maximum thickness of the iron-based oxide to 150 nm or less. Also provided are a cold-rolled steel sheet produced by means of the aforementioned method, and a vehicle member using said steel sheet.

Owner:JFE STEEL CORP

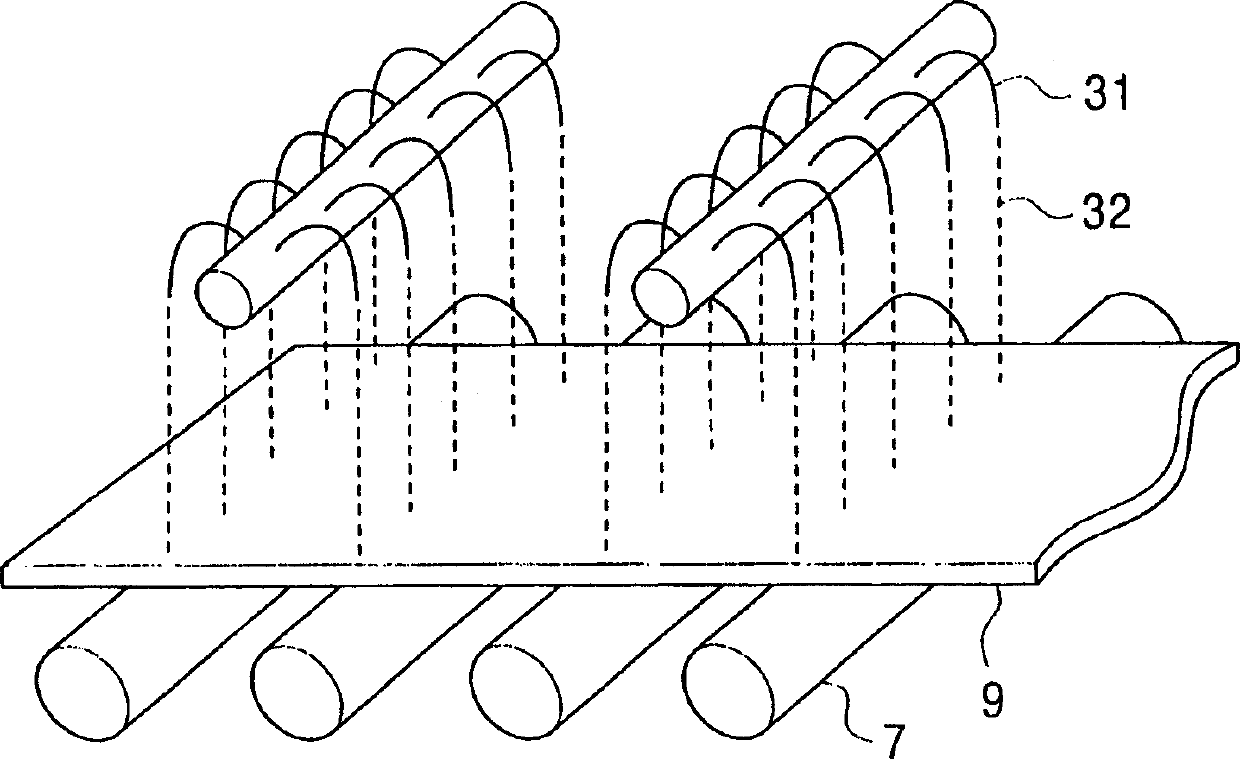

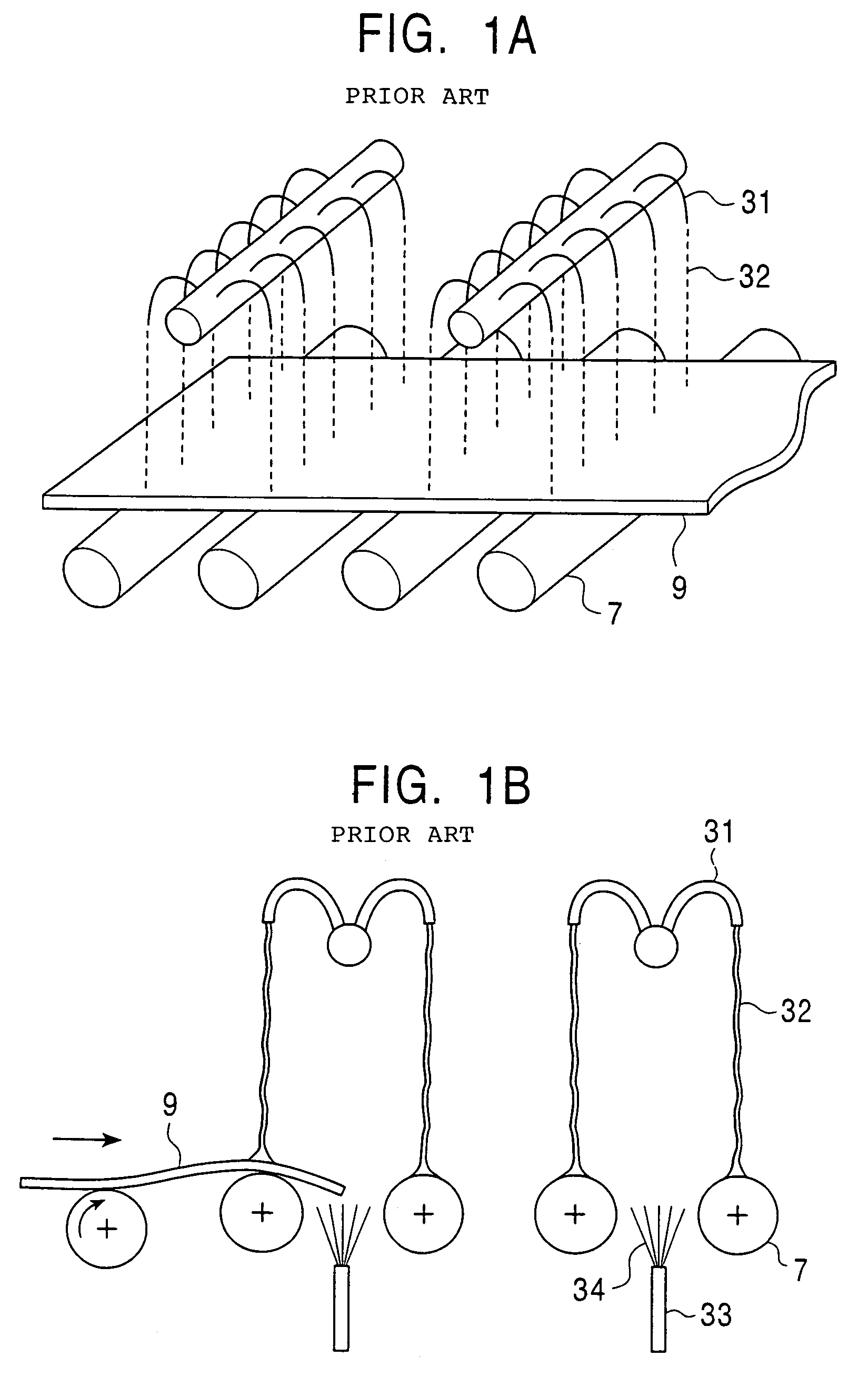

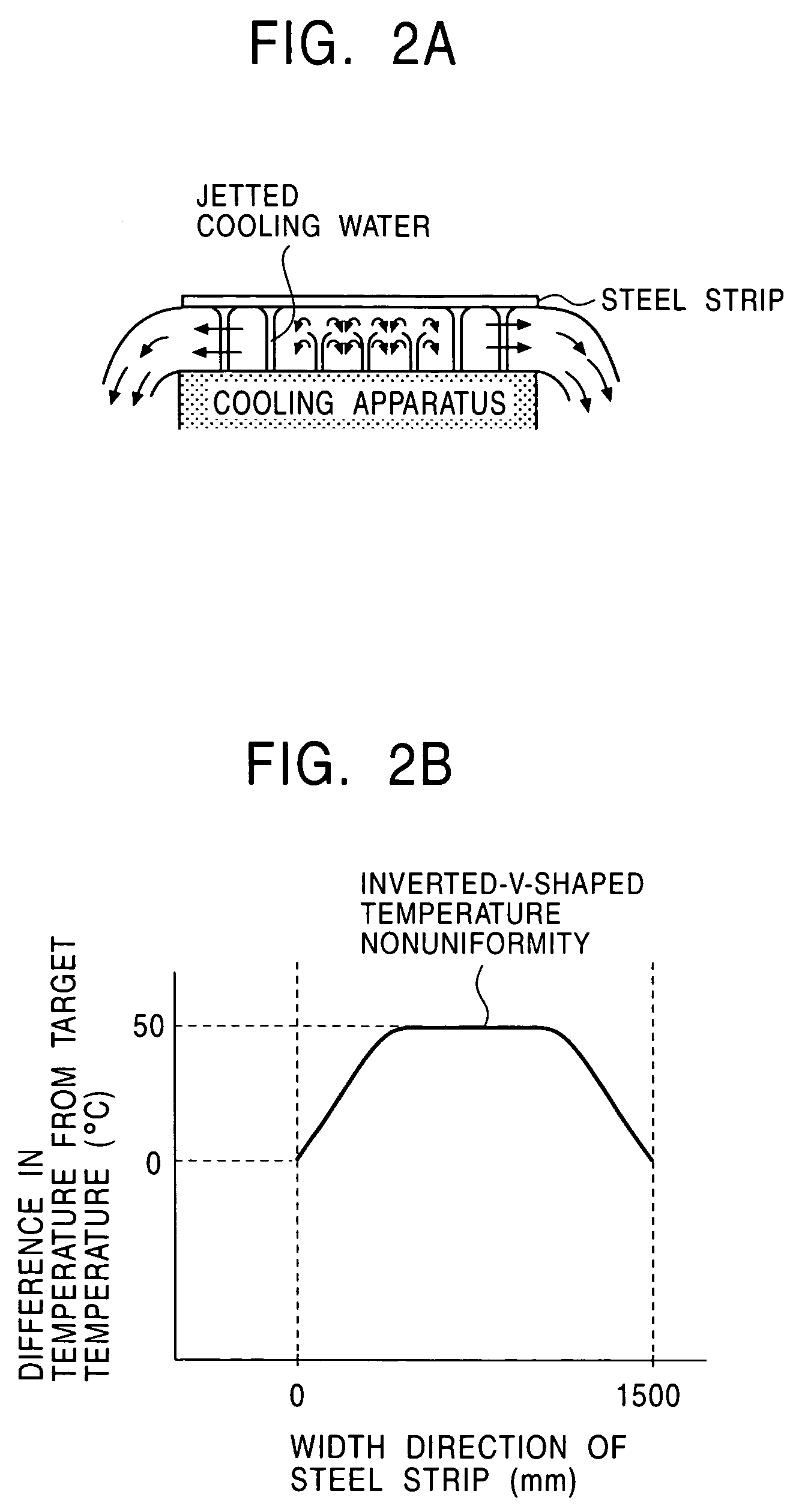

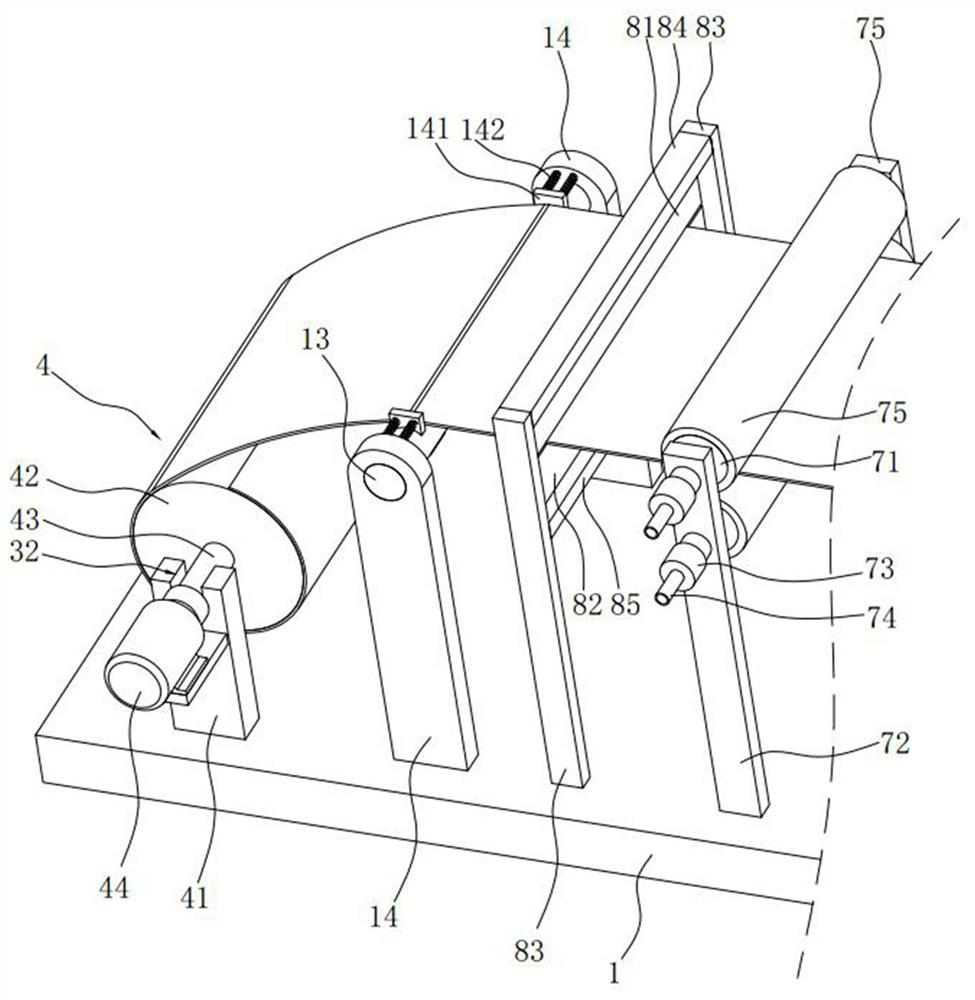

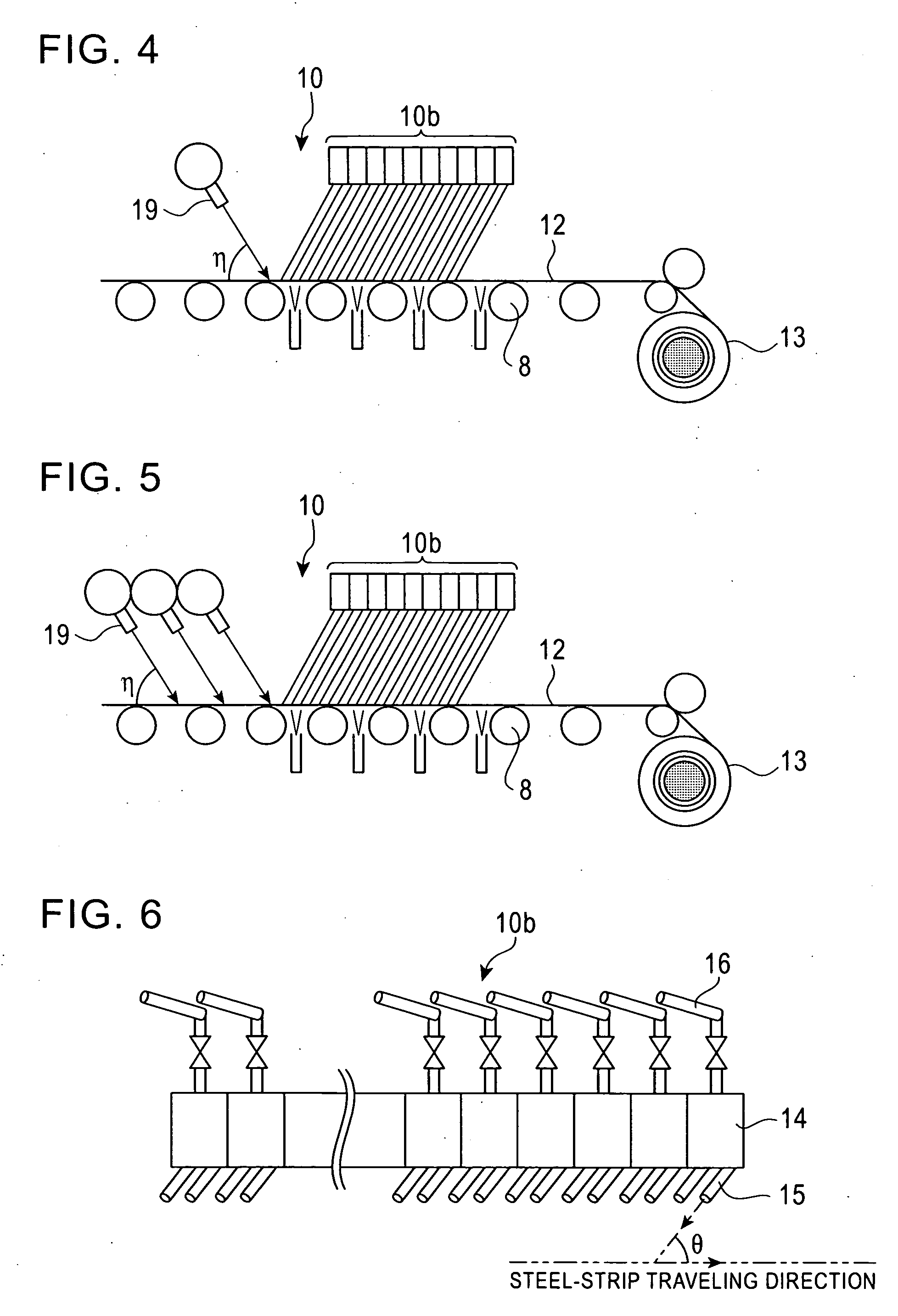

Cooling device, manufacturing method, and manufacturing line for hot rolled steel band

The present invention relates to a cooling apparatus for hot rolled steel strip comprising: an upper means for cooling an upper side of a steel strip transported by transporting rolls after hot rolling, located above the upper side of the steel strip; and a bottom means for cooling the bottom side of the steel strip, located under the bottom side of the steel strip, each means for cooling including: a protecting member having at least one cooling water hole slotted thereon, located near the surface of the steel strip; at least one cooling water header, located across the steel strip from the protecting member; and cooling water injection nozzles for injecting cooling water vertically onto the surface of the steel strip through the cooling water hole, projected on the cooling water header, wherein the top of the cooling water injection nozzle is positioned at a longer distance from the surface of the steel strip than the surface of the protecting member facing to the surface of the steel strip. The present invention allows to constantly transport the steel strip after hot rolling and to rapidly and homogeneously cool it.

Owner:JFE STEEL CORP

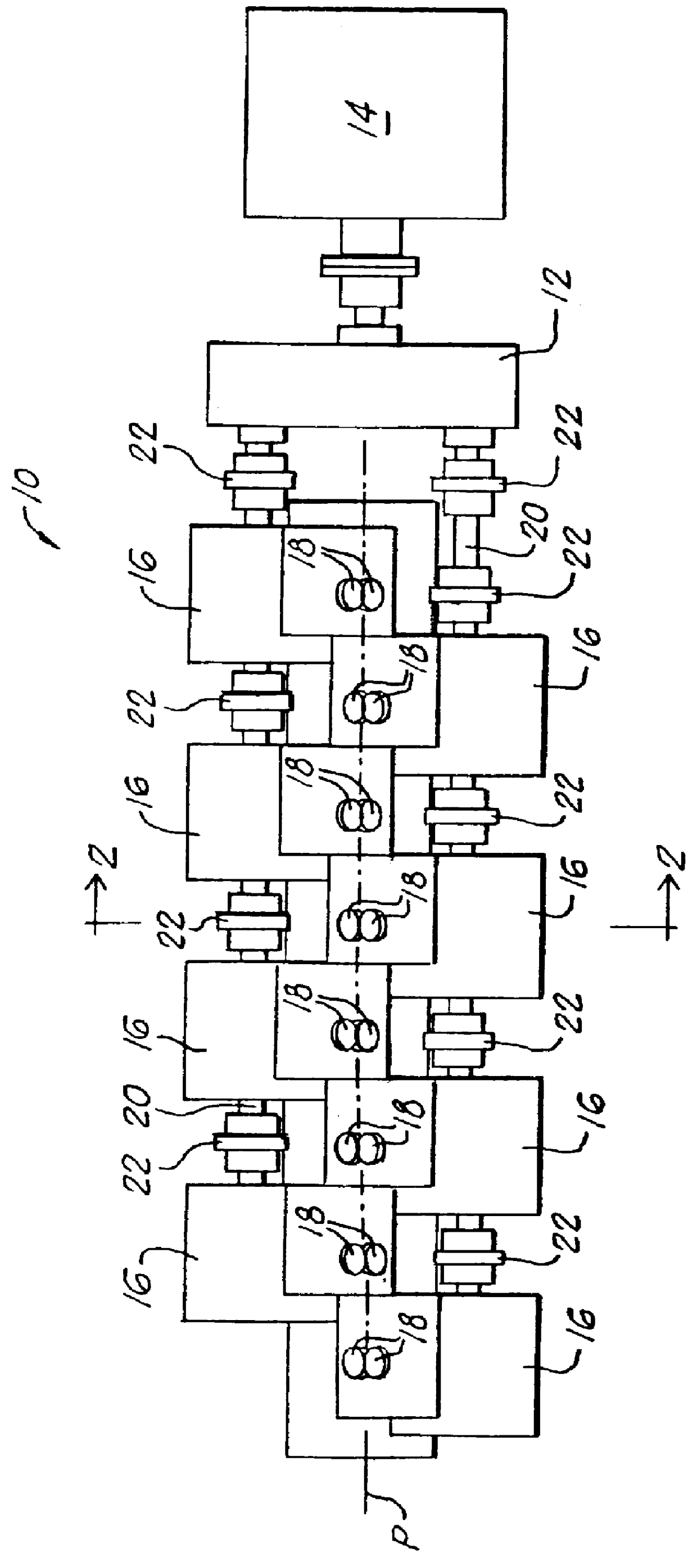

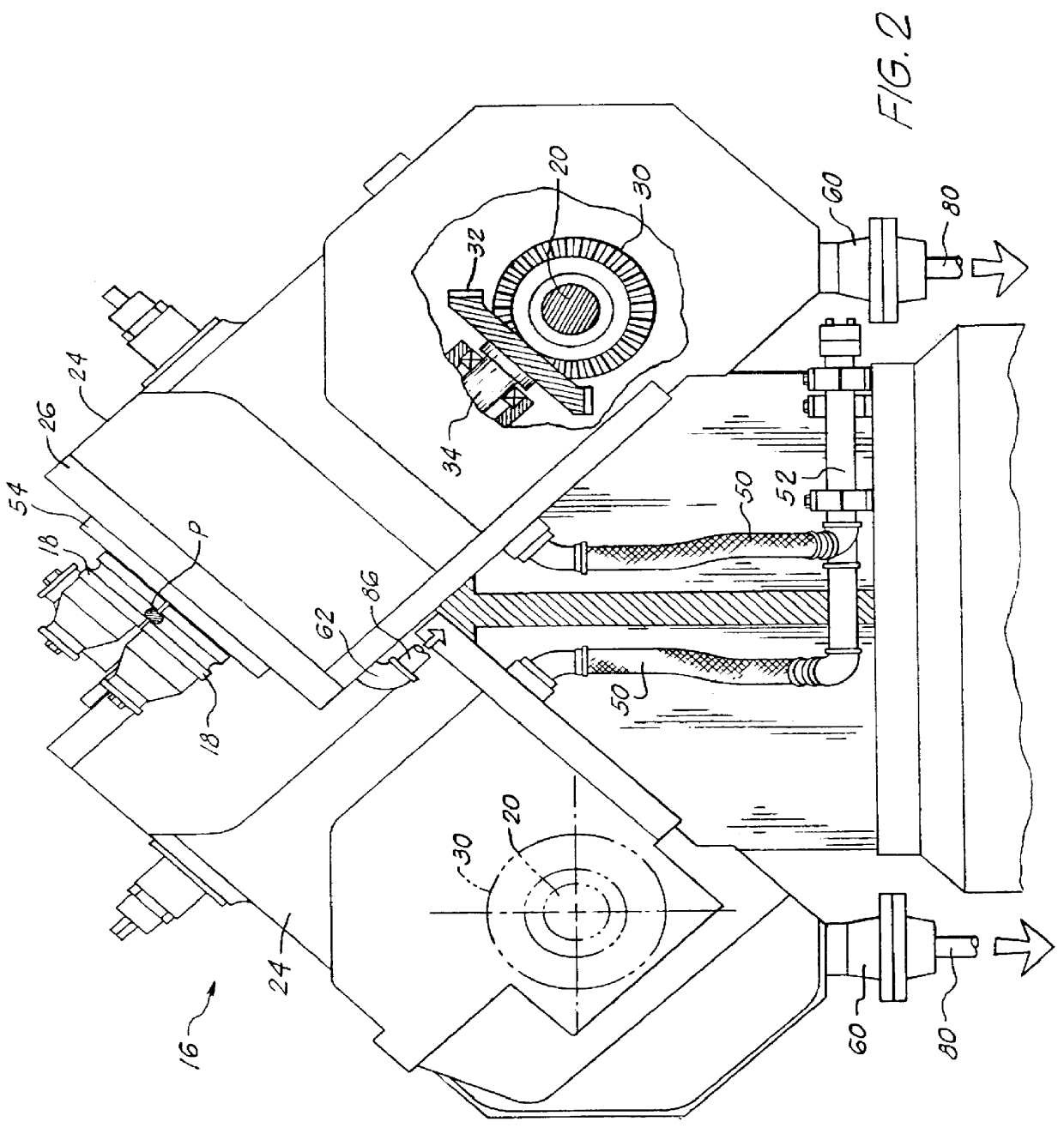

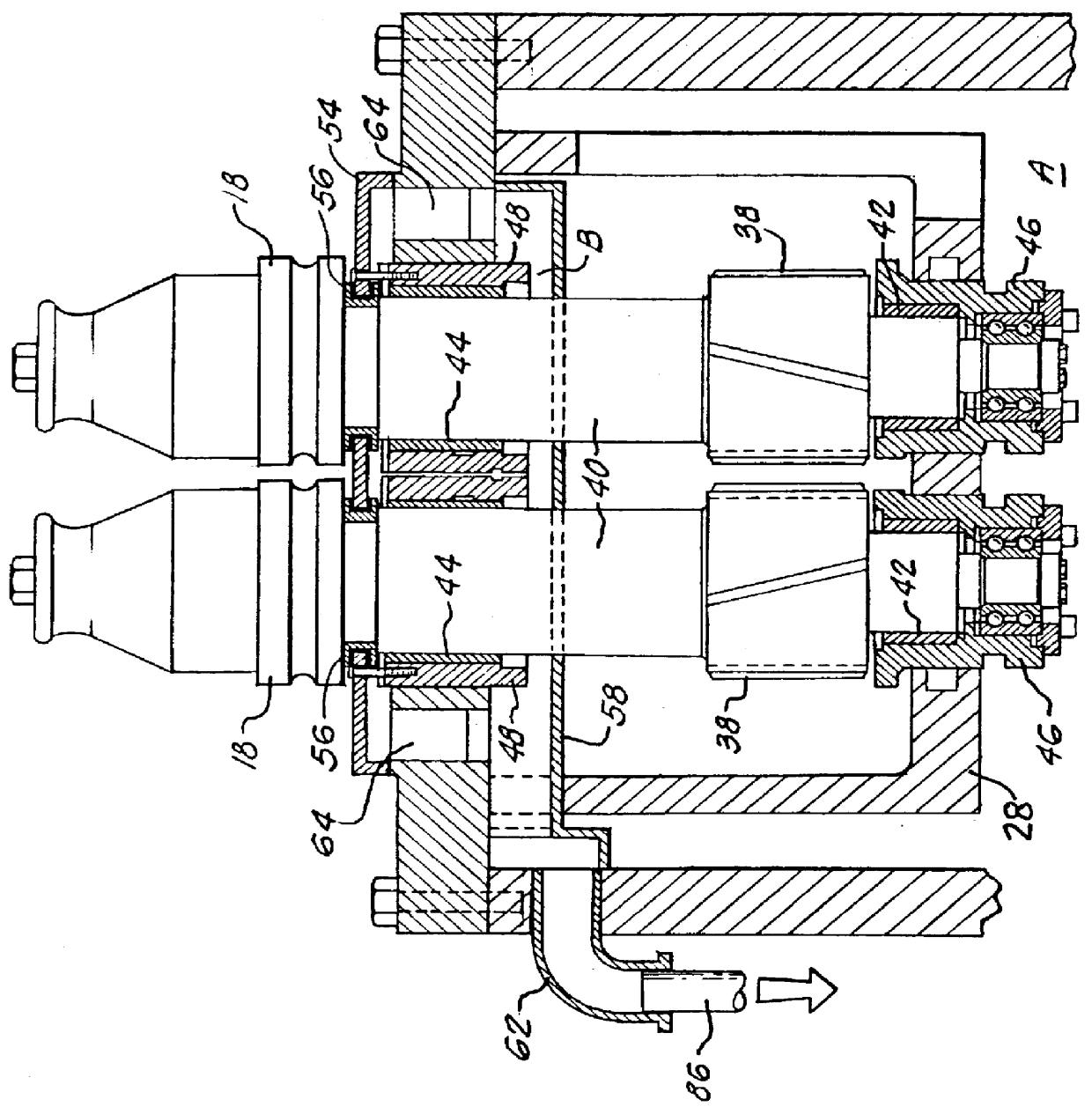

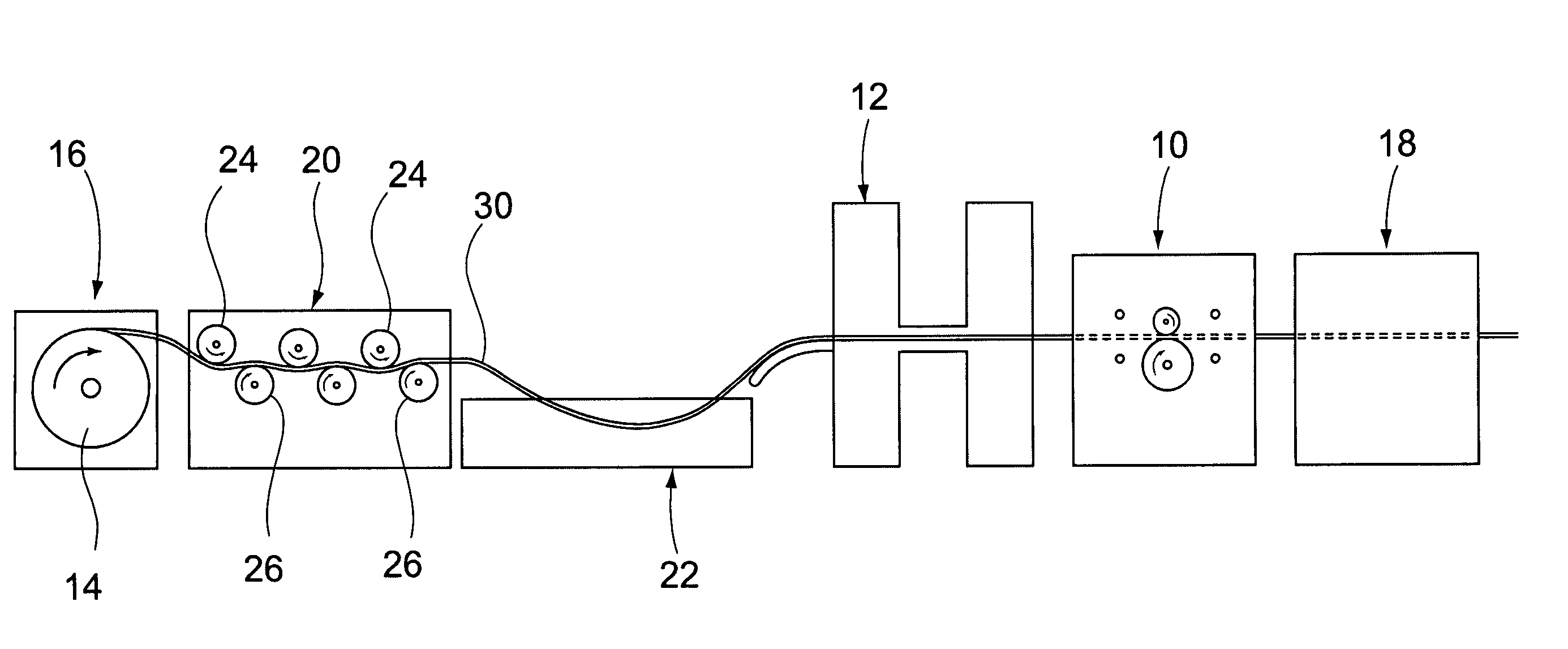

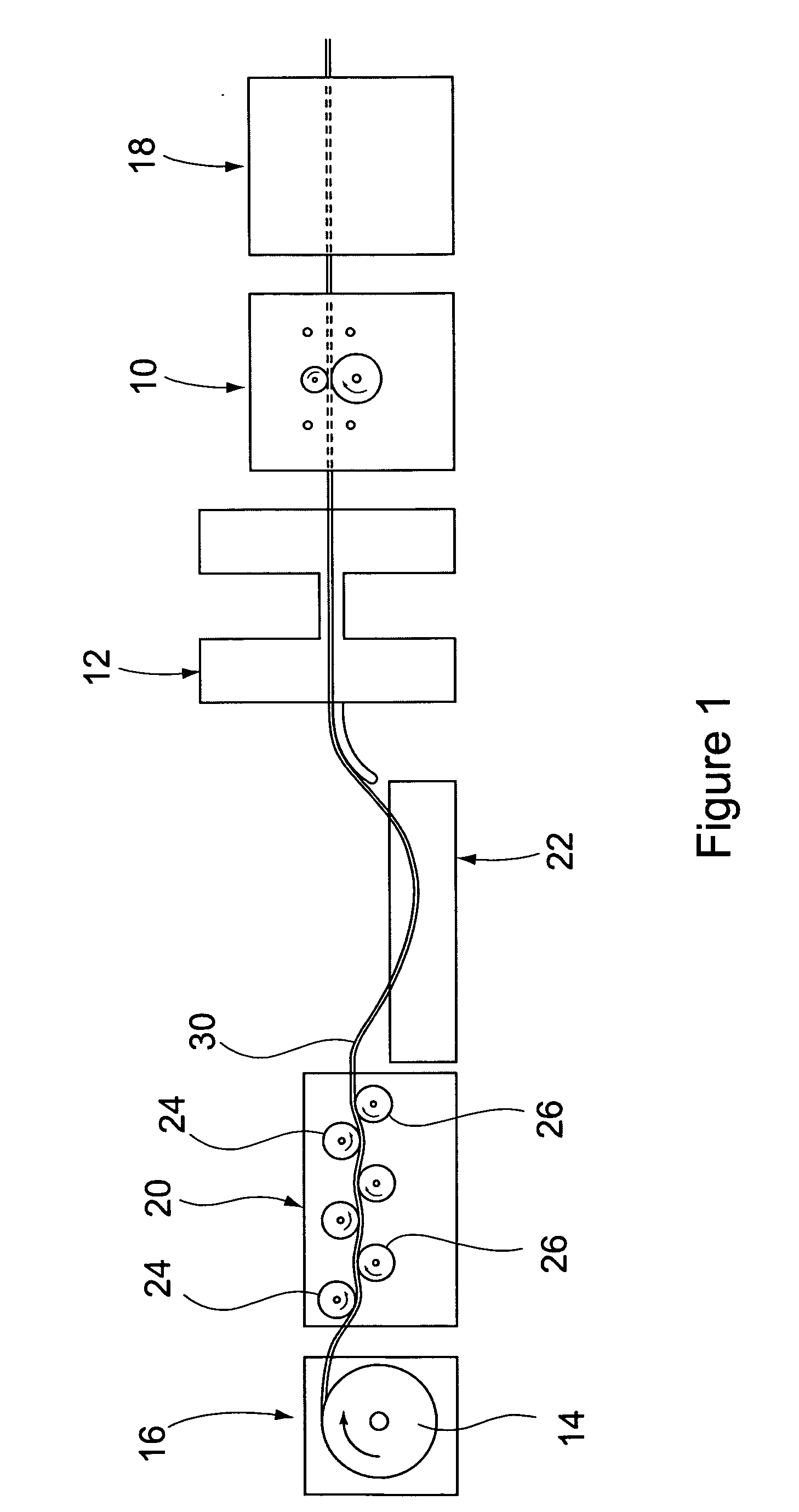

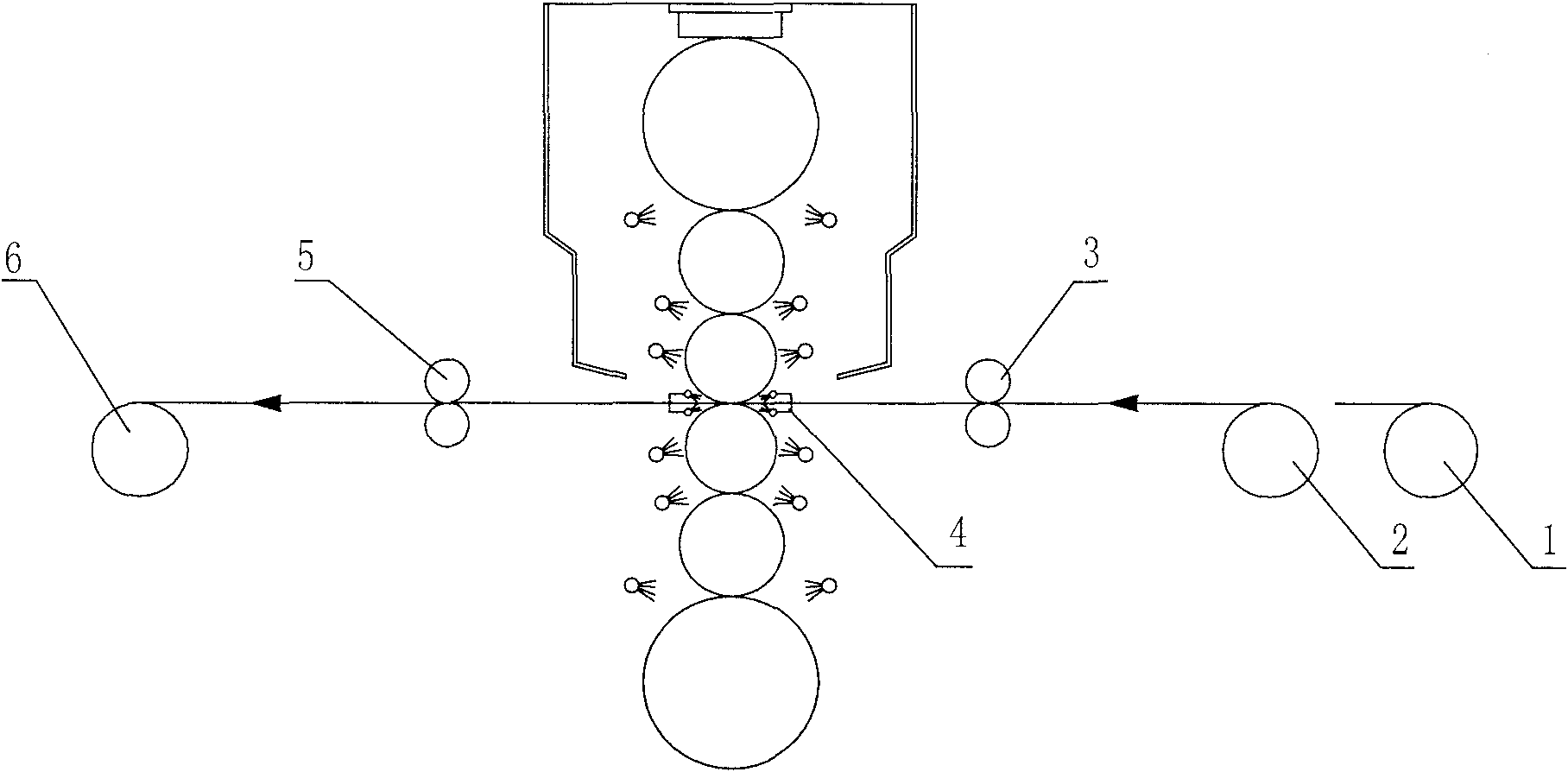

Method of removing scale and inhibiting oxidation and galvanizing sheet metal

InactiveUS20050136184A1Prevent oxidationLess-expensive and troublesomePretreated surfacesCleaning using toolsSurface conditionsZinc

A method of removing iron oxide scale and galvanizing sheet metal bonds galvanizing zinc to a wustite layer of the sheet metal. The iron oxide scale on the sheet metal generally comprises three layers prior to surface conditioning: a wustite layer, a magnetite layer, and a hematite layer. The wustite layer is bonded to a base metal substrate of the sheet metal. The magnetite layer is bonded to the wustite layer, and the hematite layer is bonded to the magnetite layer. Conditioning the surface of the sheet metal includes bringing a surface conditioning member into engagement with the surface of the sheet metal in a manner to remove substantially all of the hematite and magnetite layers from the surface, and in a manner to remove some but not all of the wustite layer from the surface. The portion of the wustite layer that remains bonded to the base metal substrate of the sheet metal protects the surface from oxidation until the surface is galvanized.

Owner:THE MATERIAL WORKS

8B cold-rolling precision steel belt and manufacturing method thereof

ActiveCN105195510AReduce lossImprove post-spot welding workabilityFurnace typesWork cleaning devicesAcid washingManganese

The invention belongs to the technical field of manufacturing of strip steel and discloses a manufacturing method of an 8B cold-rolling precision steel belt. The manufacturing method comprises the following steps: carrying out sizing vertical shearing on a raw material steel coil; carrying out cold rolling on the vertically-sheared steel coil; degreasing the coldly-rolled steel coil, and carrying out bright whole-soft-cover type annealing; carrying out small-ductility flattening on the annealed steel coil and carrying out large-ductility oil flattening and tempering; splitting the flattened steel coil to obtain the cold-rolling precision steel belt, wherein the raw material steel coil is a hot-rolling acid washing coil, and is prepared from the following components in mass percent: 0.02 to 0.055 percent of carbon, 0.002 to 0.30 percent of silicon, 0.0120 to 0.20 percent of manganese, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.09 percent of aluminum and the balance of iron and unavoidable impurities, and the equivalent weight of the carbon of the acid washing coil is not more than 0.30 percent, the thickness range is 2.5mm to 3.5mm, and the width range is 1250mm to 1280mm. According to the manufacturing method provided by the invention, a technical process from material selection to cold rolling is optimized, the quality is improved and the performance requirements of products are adapted.

Owner:宝武轻材(武汉)有限公司

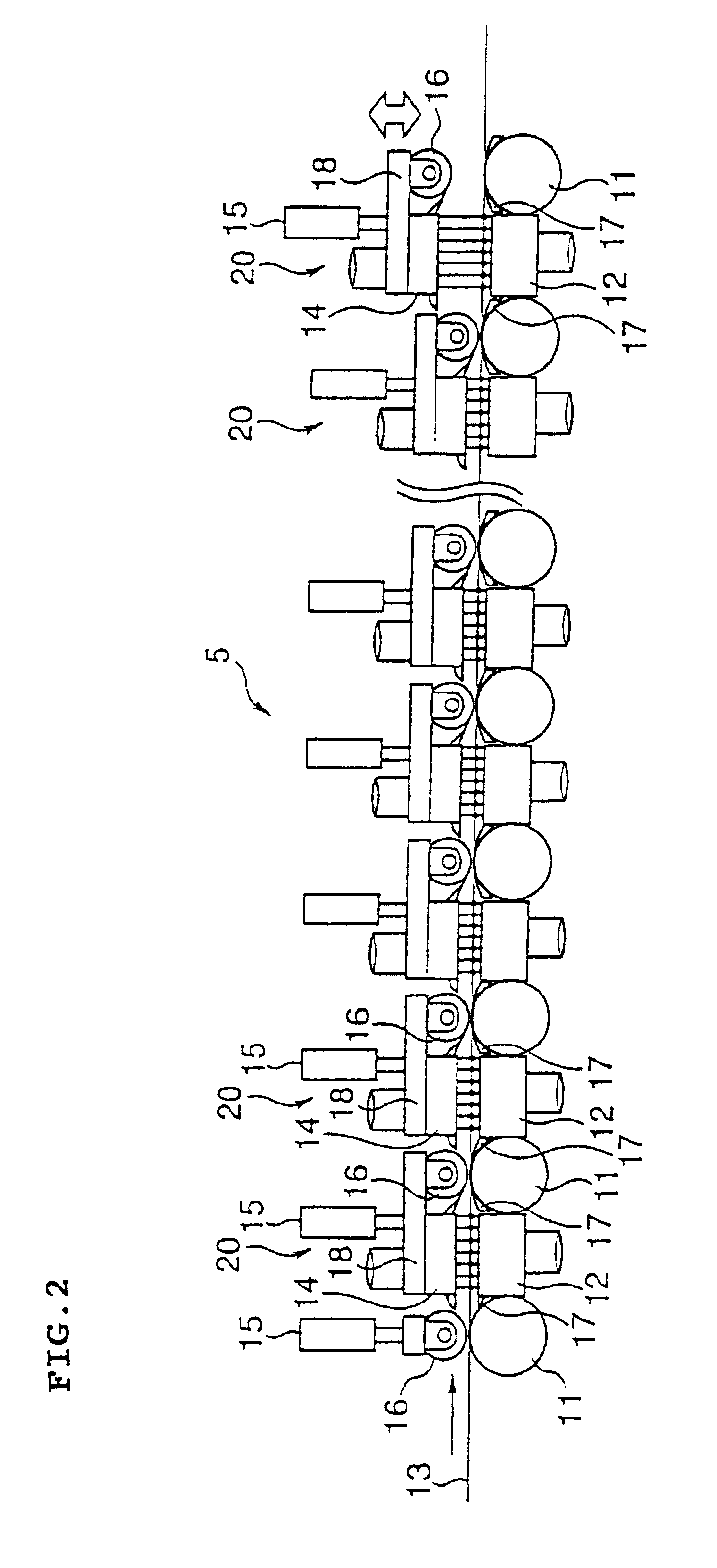

Cooling device, manufacturing method, and manufacturing line for hot rolled steel band

A cooling apparatus for a hot rolled steel strip comprising: top surface cooling means provided above a hot rolled steel strip which is transferred with transfer rollers; and a bottom surface cooling means provided below the hot rolled steel strip, each of the top surface cooling means and the bottom surface cooling means comprising: a protective member having at least one cooling water passage hole; at least one cooling water header opposing the hot rolled steel strip separated by the protective member; and cooling water jetting nozzles protruding from the cooling water header, wherein the tips of the cooling water jetting nozzles are disposed farther from the hot rolled steel strip than the surface, opposing the hot rolled steel strip, of the protective member.

Owner:JFE STEEL CORP

Production method for ultra-thin cold-rolled enamelled steel strips

ActiveCN105689392AMeet quality requirementsImprove deep drawing performanceWork cleaning devicesMetal rolling arrangementsBlack spotHydrogen

The invention discloses a production method for ultra-thin cold-rolled enamelled steel strips. The production method is characterized in that the ultra-thin cold-rolled enamelled steel strips have thicknesses of 0.18-0.20mm, and are obtained through the steps of carrying out hot-rolling production for cold-rolled materials, chlorohydric acid pickling, primary cold-rolling, primary intermediate annealing, and secondary cold-rolling to prepare ultra-thin cold and hard steel strips, and then carrying out smoothing and texturing, rewinding and tension losing, secondary intermediate annealing, and strip shape straightening. According to the method, the products have excellent deep drawing properties, and have no fish-scaling phenomenon, and moreover, with the adoption of a 950mm single-stand six-roll reversible cold-rolling mill, single-stand smoothing and texturing, severe-convection full-hydrogen bright bell-type annealing furnace annealing, the equipment is simplified, and the products achieve high-accuracy and ultra-thin requirements; the surfaces are smooth, and free from bonding, chromatic aberration, black spots, dots, oil stain and other defects; and the production method achieves the quality requirements of ultra-thin deep-drawn cold-rolled enamelled steel strips, is suitable for the fields of kitchen sanitary ware and ovens, water heater liners, decoration panels and the like, and has a broad market prospect.

Owner:山东泰山轧钢有限公司

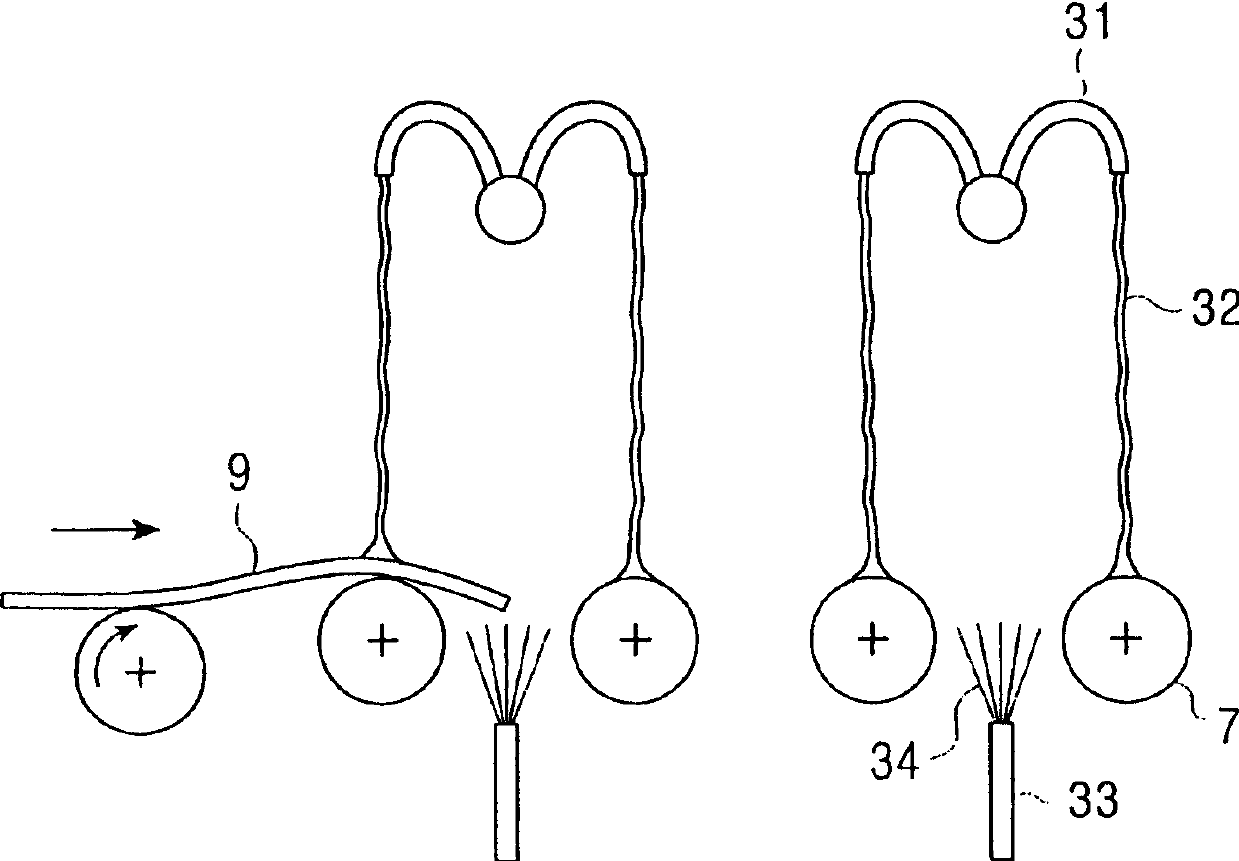

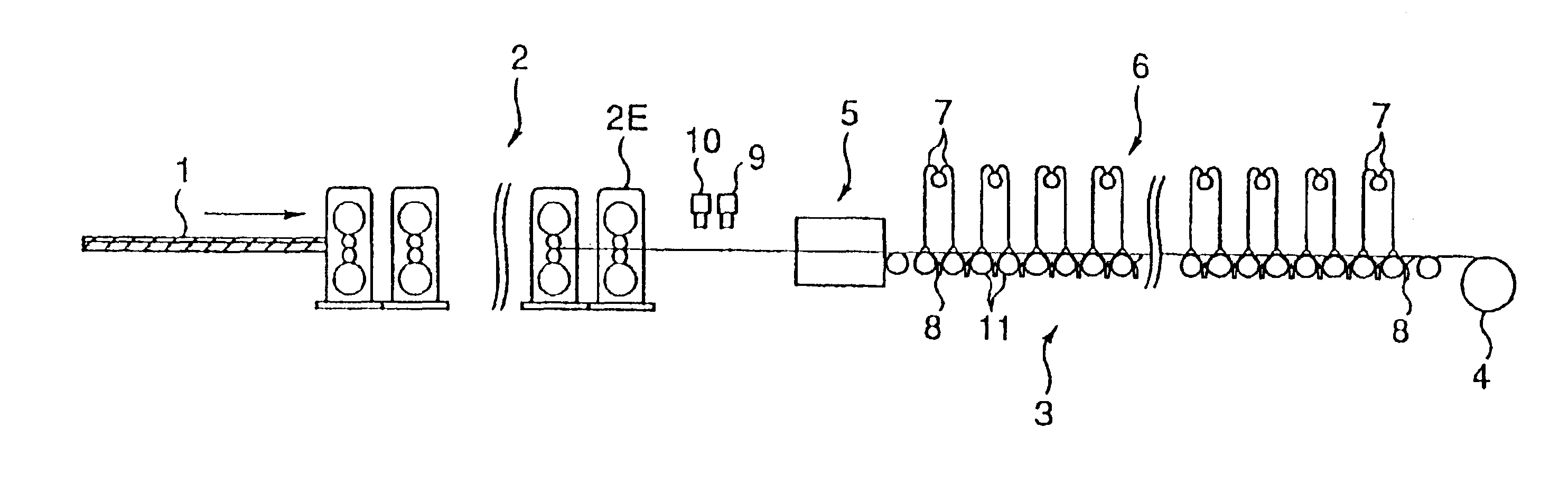

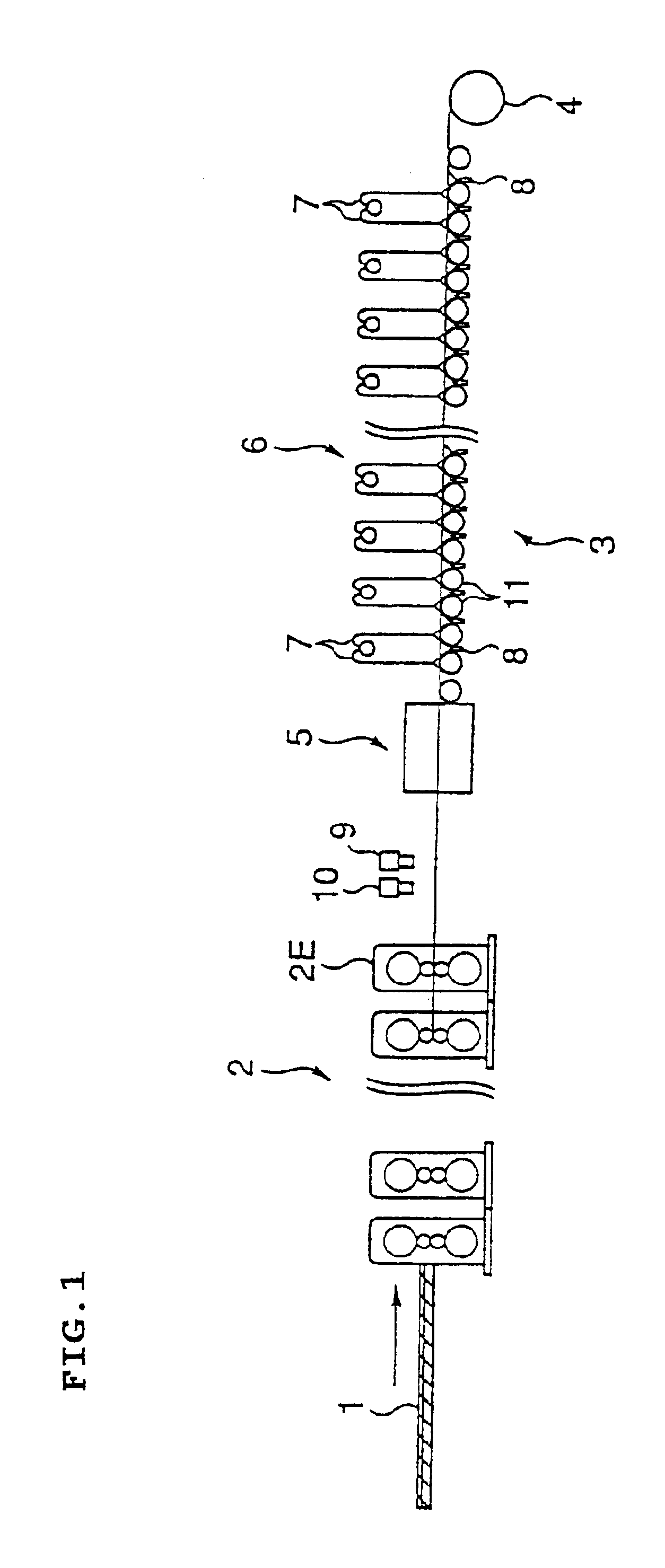

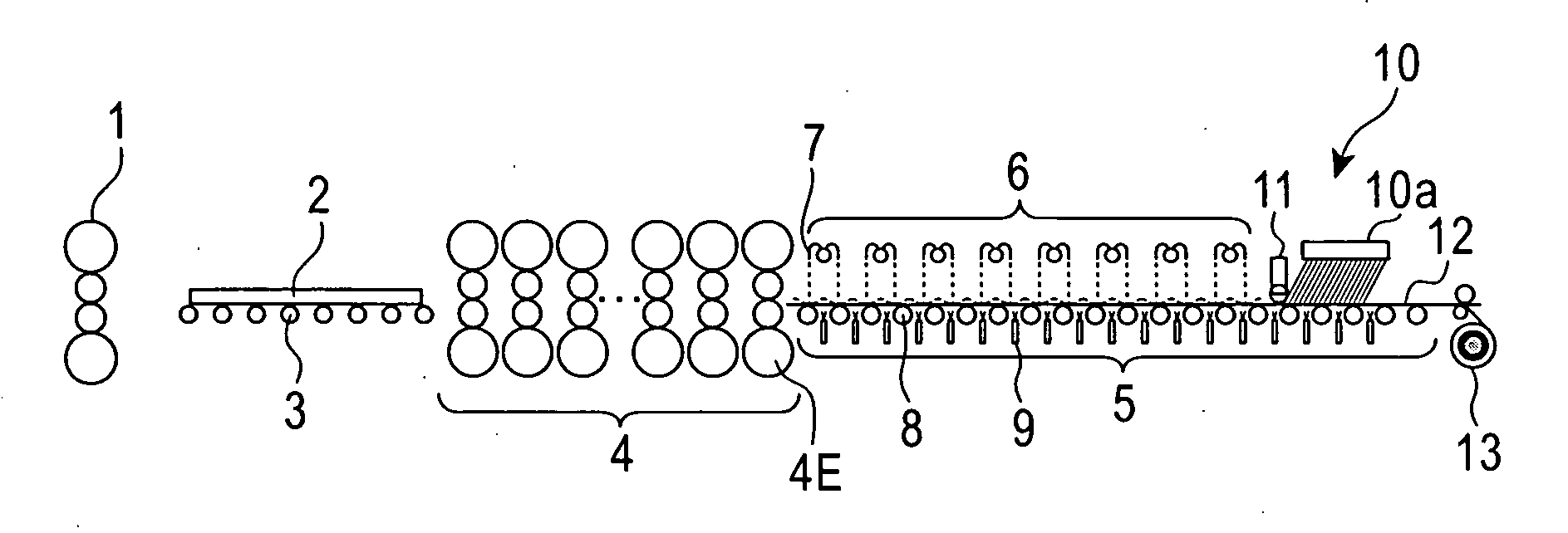

Method and apparatus for cooling hot rolled steel strip, and method for manufacturing hot rolled steel strip

InactiveUS6733720B2Efficient dischargeFine granularityBlast furnace detailsCooling devicesSurface coolingSteel belt

A lower surface cooling box 12 is arranged between transfer rolls 11 on a runout table 3 and an upper cooling box 14 moving freely is arranged at a position corresponding to the cooling box 12 to eject cooling water to the steel strip symmetrically in the vertical direction. The steel strip passes the center of converge of cooling water from upper and lower surfaces of the steel strip. A water breaking roll 16 is provided elevating freely at least at the outlet side rotating at the same peripheral speed as the transfer rolls and is rotated to lower concurrently with passing of the steel strip top at the cooling apparatus. The upper cooling box is also lowered concurrently to cool the steel strip.

Owner:JFE STEEL CORP

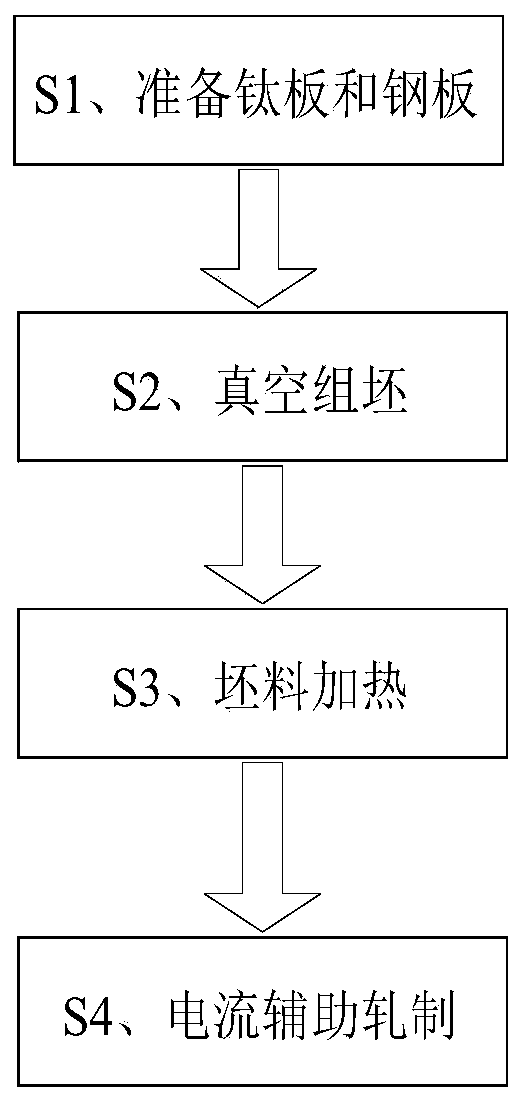

Method for preparing titanium steel composite plate through auxiliary hot rolling of pulse current

InactiveCN110788136AImprove plastic deformationFacilitated DiffusionRoll force/gap control deviceWork cleaning devicesTitaniumComposite plate

The invention provides a method for preparing a titanium steel composite plate through auxiliary hot rolling of pulse current. The method comprises the following steps that S1, a titanium plate, a steel plate and a middle layer material are prepared, and to-be-composited surfaces of the titanium plate, the steel plate and the middle layer material are subjected to treatment and cleaning thoroughly; S2, the titanium plate and the steel plate are subjected to vacuum assembling; S3, a heating device is heated to the designated temperature, a blank is put in the device, and vacuum heat preservation treatment is carried out for a certain time; S4, a roller gap and a rolling speed of a rolling mill are set in advance, the blank obtained after heat treatment is taken out to be put into a rollingmill inlet connected with a pulse power source device, an insulation push plate is used for pushing the blank into the rolling mill, and according to the certain rolling reduction and the rolling speed, rolling is carried out to obtain the titanium steel composite plate. According to the method for preparing the titanium steel composite plate through auxiliary hot rolling of the pulse current, theelectroplastic effect and the tip end effect of the pulse current are used, the two kinds of materials of titanium and steel achieve metallurgical bonding under the small reduction amount, and the titanium steel composite plate good in plate shape and high in combination strength can be obtained.

Owner:TAIYUAN UNIV OF TECH

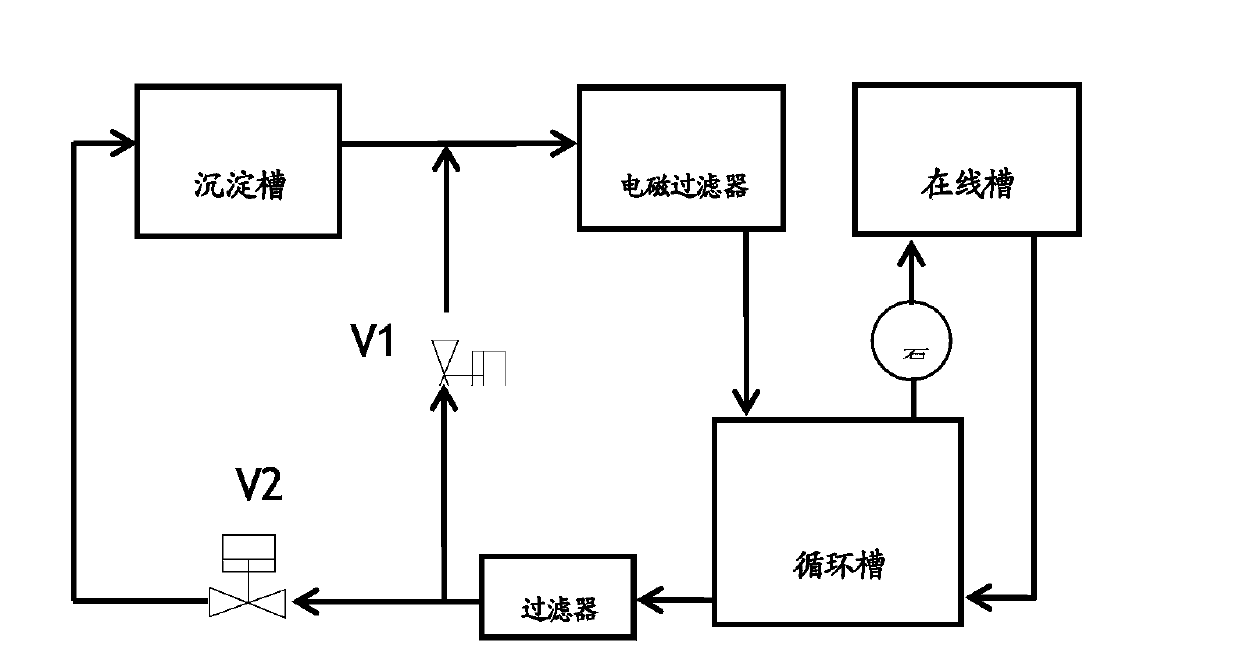

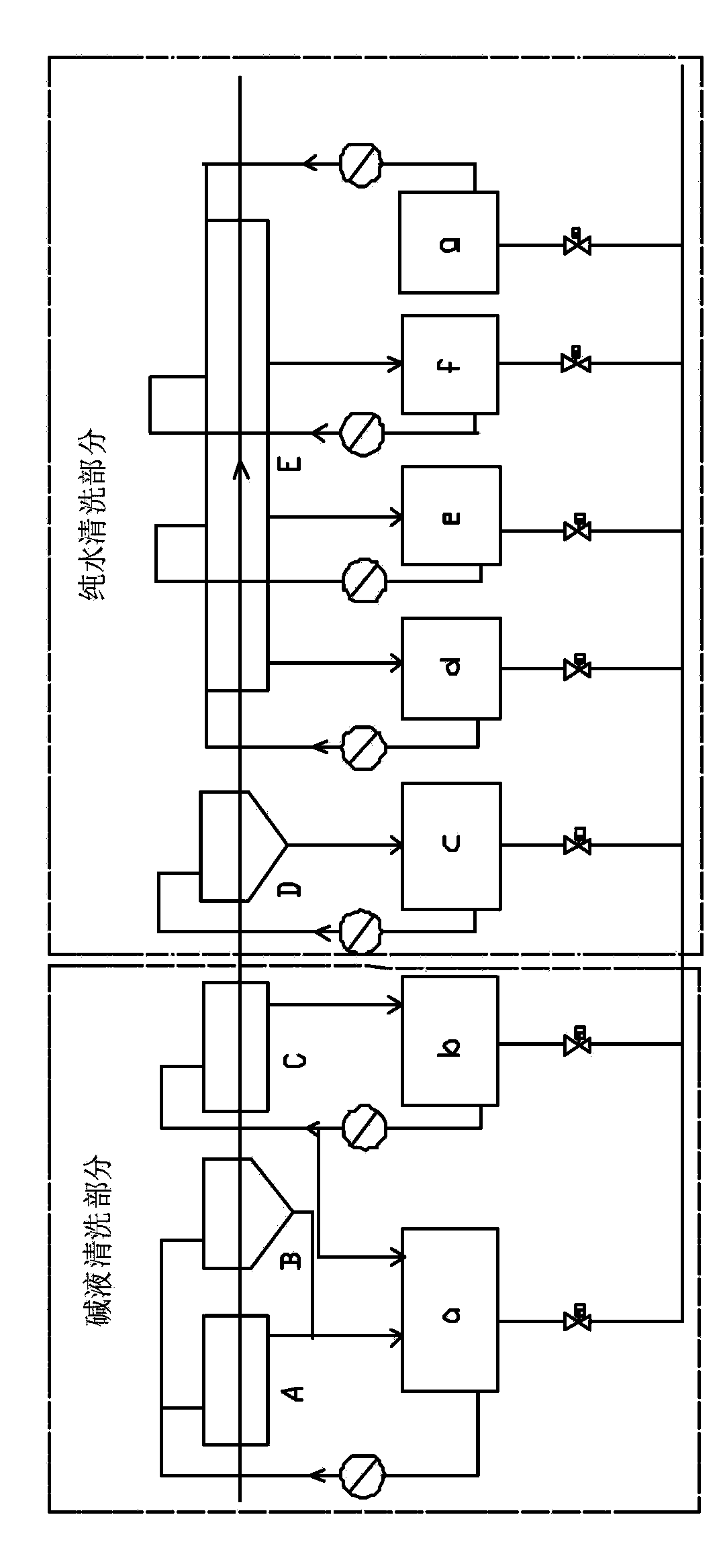

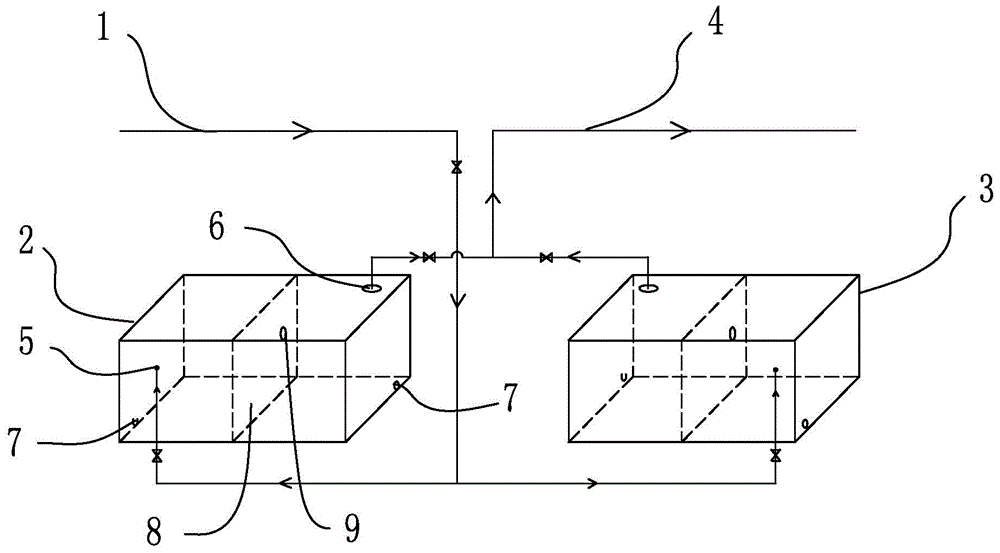

Device and method for cleaning surface of silicon steel

ActiveCN104117510AThoroughly remove residueEliminate residueWork cleaning devicesCleaning processes and apparatusElectrolysisHigh pressure water

The invention provides a device for cleaning the surface of silicon steel. The device comprises online grooves including the alkali liquor immersion groove, the alkali liquor brushing groove, the electrolysis cleaning groove, the high-pressure-water spraying groove, the water brushing groove, the hot-water rinsing groove, the hot-water spraying groove and the like and corresponding circulation grooves connected with the online grooves, wherein the online grooves are sequentially connected. The circulation grooves are provided with high-low liquid level water supplementing control devices respectively. The high-pressure-water spraying groove and the hot-water spraying groove are internally provided with vertically-arranged spraying nozzles respectively. The invention further provides a method for cleaning the surface of the silicon steel. The silicon steel is effectively cleaned by setting parameters such as the alkali liquor concentration, the alkali liquor temperature and the pure water temperature through the device. By means of the device and the method, the cleaning quality of the surface of rolled hard roll strip steel is improved in an electrical steel unit, it is guaranteed that the surface of furnace-entered strip steel is clean, inner-furnace dross is easily reduced, the quality of the surface of the strip steel is improved, and meanwhile pure water consumption is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing ultra-thin metal lithium strip

InactiveCN107052047ARealize automatic roll productionIncrease productivityWork cleaning devicesMetal rolling arrangementsThin metalLithium–sulfur battery

The invention discloses a method for producing an ultra-thin metal lithium strip. The method includes the following steps that (1) the surface of a base material is coated with a lubricating agent; (2) rolling is conducted; (3) edge cutting is performed; (4) oil stains on the surface of the lithium strip are cleaned; and (5) the lithium strip is subjected to air drying, and surface impurities are removed. By the adoption of the method, the rolling technology is adopted, the base material is subjected to surface treatment before rolling, cleaning and air drying are carried out after rolling, the thickness of the obtained ultra-thin metal lithium battery strip can reach 0.02mm or below, and the lithium strip is mainly applied to high-capacity secondary batteries like a lithium-sulfur battery, a lithium air battery, a lithium negative electrode full-solid-state battery, a lithium polymer battery and other secondary batteries using lithium as the negative electrode; and automatic coiling production can be achieved, small-batch slicing production can also be conducted, production efficiency can be greatly improved, product quality is well guaranteed, and a foundation is laid for research, development and follow-up production of the high-capacity lithium ion secondary batteries.

Owner:CHINA ENERGY LITHIUM

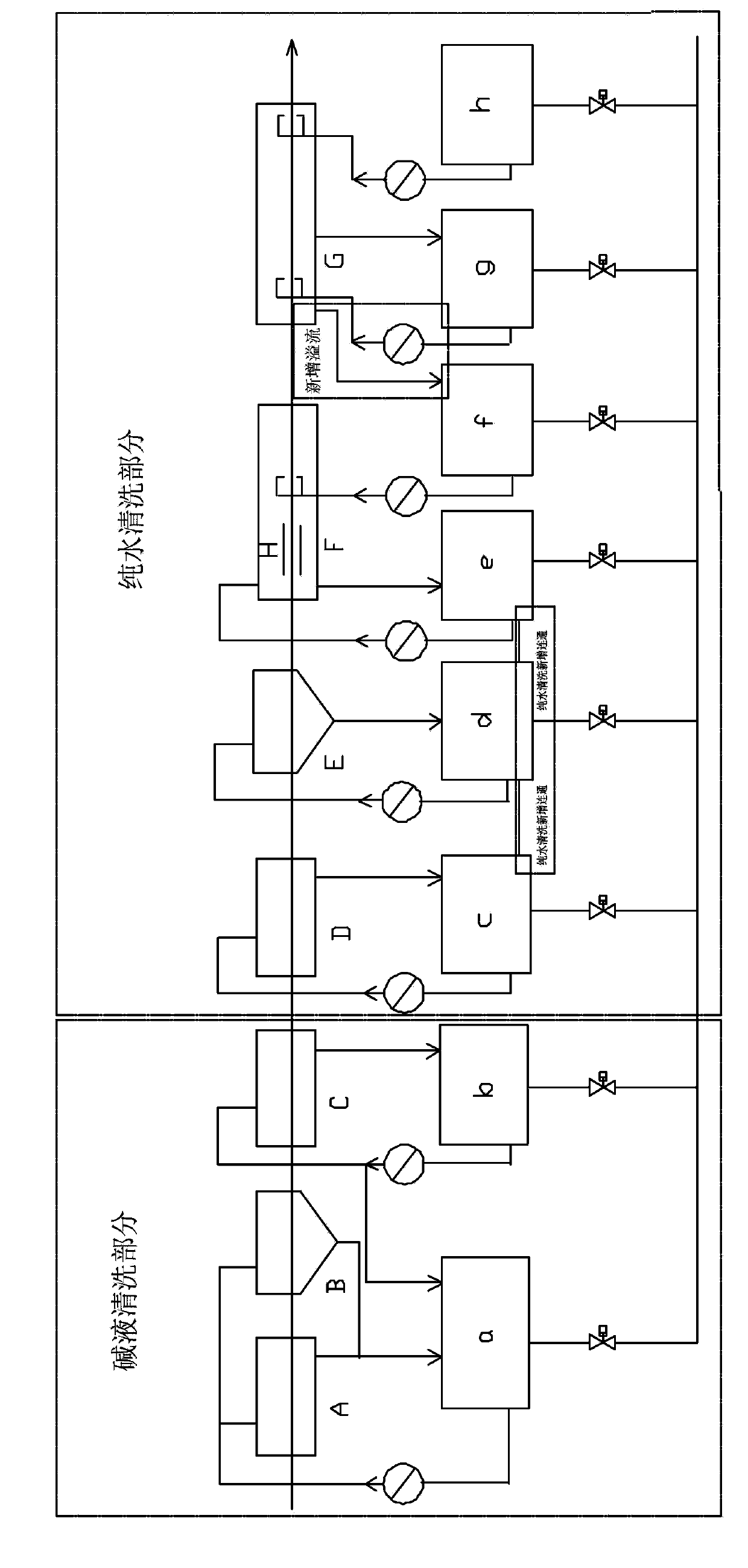

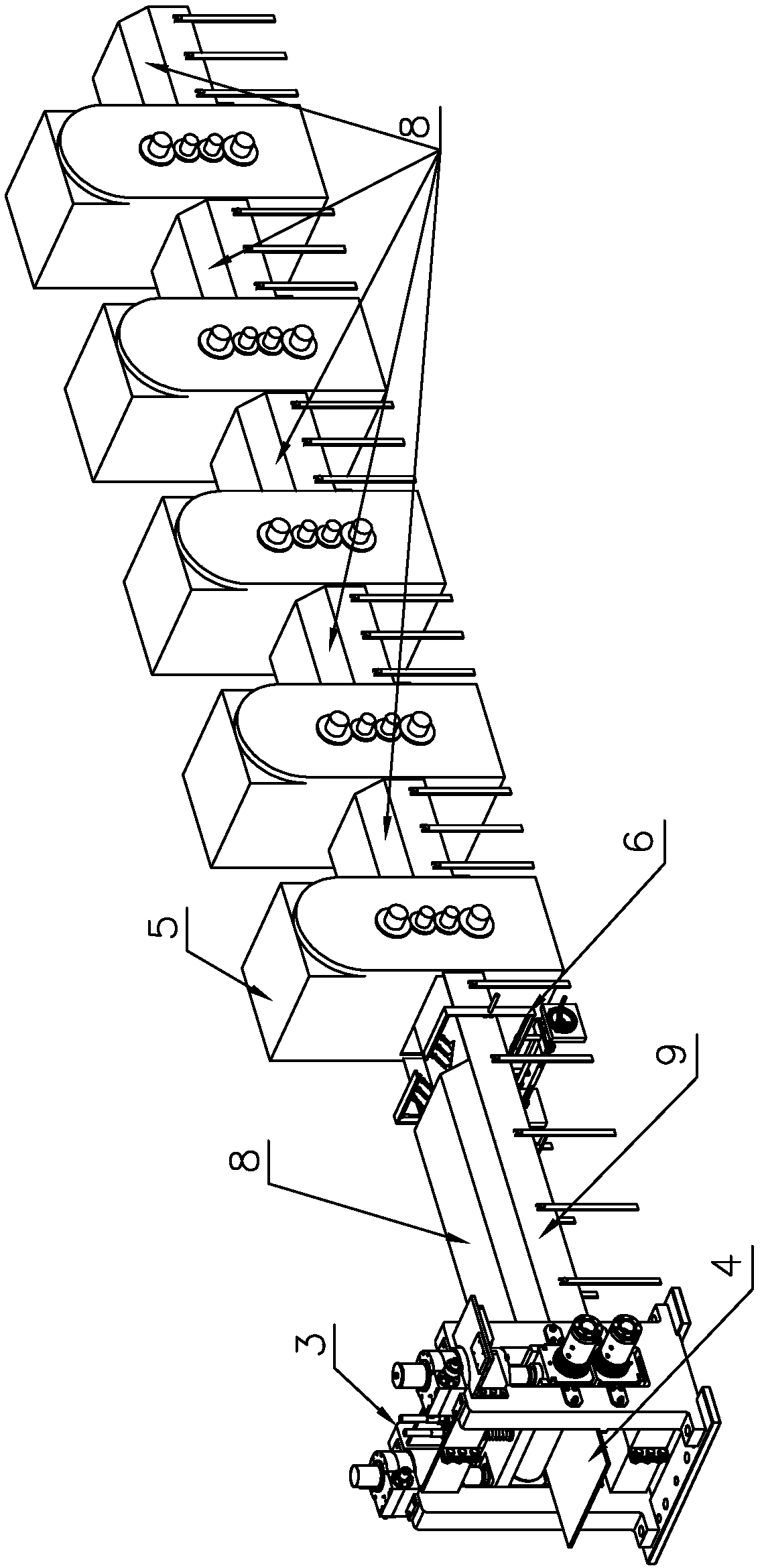

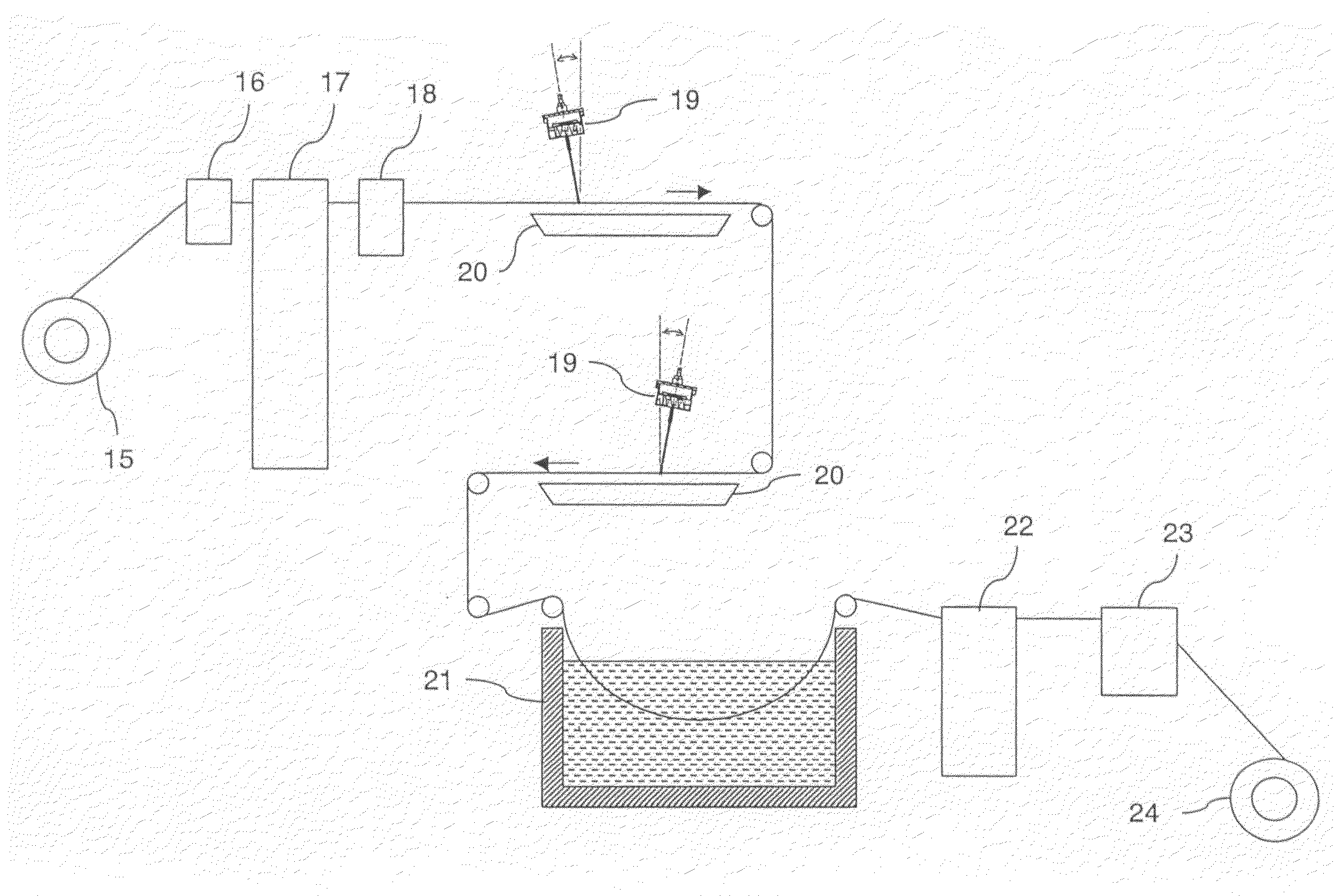

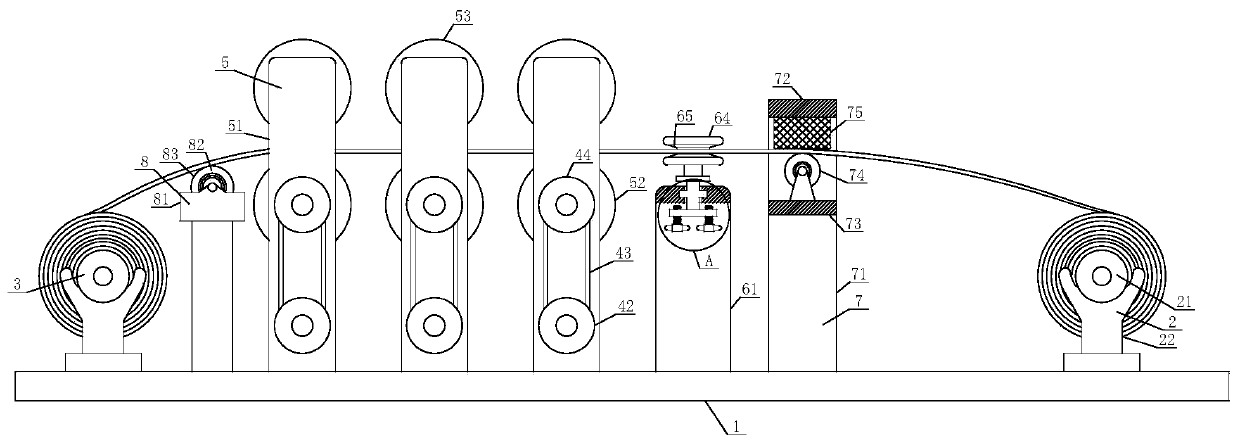

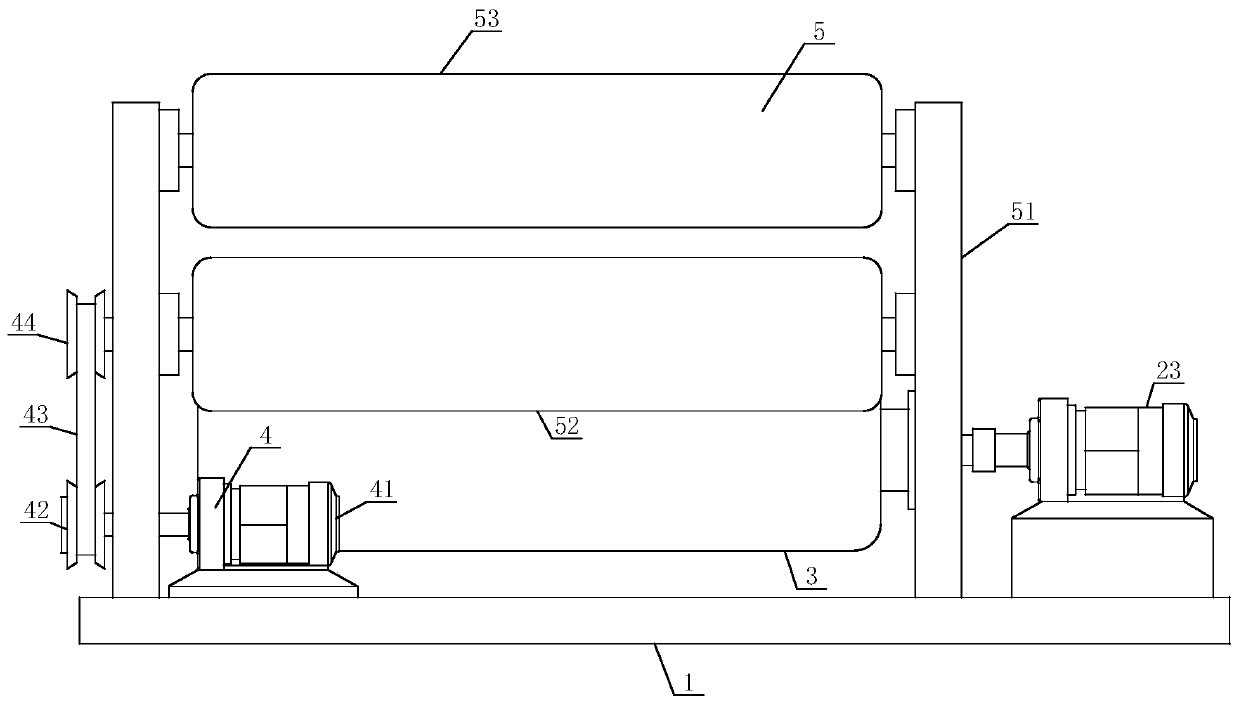

Ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and method

PendingCN107309272AImprove deformationFulfil requirementsWork cleaning devicesMetal rolling arrangementsTinningEmulsion

The invention provides ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and a method. By arranging a leveling liquid system taking a low-concentration emulsion as a medium in a two-stand leveling unit, the wet leveling elongation percentage of strip steel is raised substantially; by reasonably arranging a splashing prevention device, the splashing of leveling liquid is effectively prevented; equipped with an alkali liquor washing system and a strip steel cleaning system, the surface of the strip steel is subjected to alkali liquor washing and soft water cleaning, so that the leveling liquid remained on the surface of the strip steel is cleaned, and spots of the leveling liquid are effectively controlled; by adopting a curtain wall air knife type air knife blowing system, high-output and low-noise efficient blowing is realized; and equipped with a hot air drying system, surface cleanness and dryness of the strip steel are guaranteed. By adopting the leveling liquid system taking the low-concentration emulsion with the concentration being 0.5-1.5% as the medium, the elongation percentage and the antirust capability of the strip steel are raised and improved significantly, steel plate deformation is improved substantially and the elongation percentage can reach 5-10%, the high elongation percentage wet leveling can repair and cover a part of surface defects, and thus the plate surface quality and the product overall quality are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Preparation method of high-precision rolled copper foil for lithium battery

ActiveCN106513438APrevent oxidation and discolorationSimple processRoll force/gap control deviceRolling mill drivesRoll formingCopper foil

The invention discloses a preparation method of a high-precision rolled copper foil for a lithium battery. The preparation method is characterized in that I, technological steps and technological parameters of rolling of a copper foil rolling machine are improved according to a copper foil rolling theory, a 0.15-mm copper foil parent material is prepared into a 0.0097-mm rolled copper foil through five passes of rolling, the rolled copper foil is tested through a bending resistance testing machine and resists 784 times of bending on average, and the bending resistance requirement (the bending resistance time is larger than 600) of the rolled copper foil for the lithium battery is met; and II, chromium plating and zinc plating surface treatment is added after rolling forming is carried out and before the rolled copper foil is applied to the lithium battery, and the technological steps and technological parameters of chromium plating and zinc plating are optimized, so that the rolled copper foil subjected to rolling forming is prevented from oxidizing and discoloring, the corrosion resistance is improved, and the rolled copper foil does not oxidize and discolor when the rolled copper foil is stored for a long time at the normal temperature and is placed at the high temperature of 180 DEG C for 30 minutes.

Owner:中色正锐(山东)铜业有限公司

Titanium plate hot continuous rolling large-scale manufacturing method

ActiveCN109317518AReduce drum distortionGuaranteed temperatureCleaning using toolsWork heating devicesMetallurgyIngot

The invention discloses a titanium plate hot continuous rolling large-scale manufacturing method. The titanium plate hot continuous rolling large-scale manufacturing method comprises the following steps of: step (1) heating; (2) carrying out rough rolling; step (3) carrying out finish rolling; step (4) crimping; step (5) welding; and step (6) pickling and annealing. According to the titanium platehot continuous rolling large-scale manufacturing method, the temperature required for rolling a titanium plate is ensured by arranging a heat preservation cover on a conveying roller; before an titanium ingot is heated, the edge of the titanium ingot is chamfered, and the chamfering reduces the drum type deformation of the edge of the titanium plate and ensures the shape of a plate formed by rolling the titanium plate.

Owner:山东盛阳金属科技股份有限公司

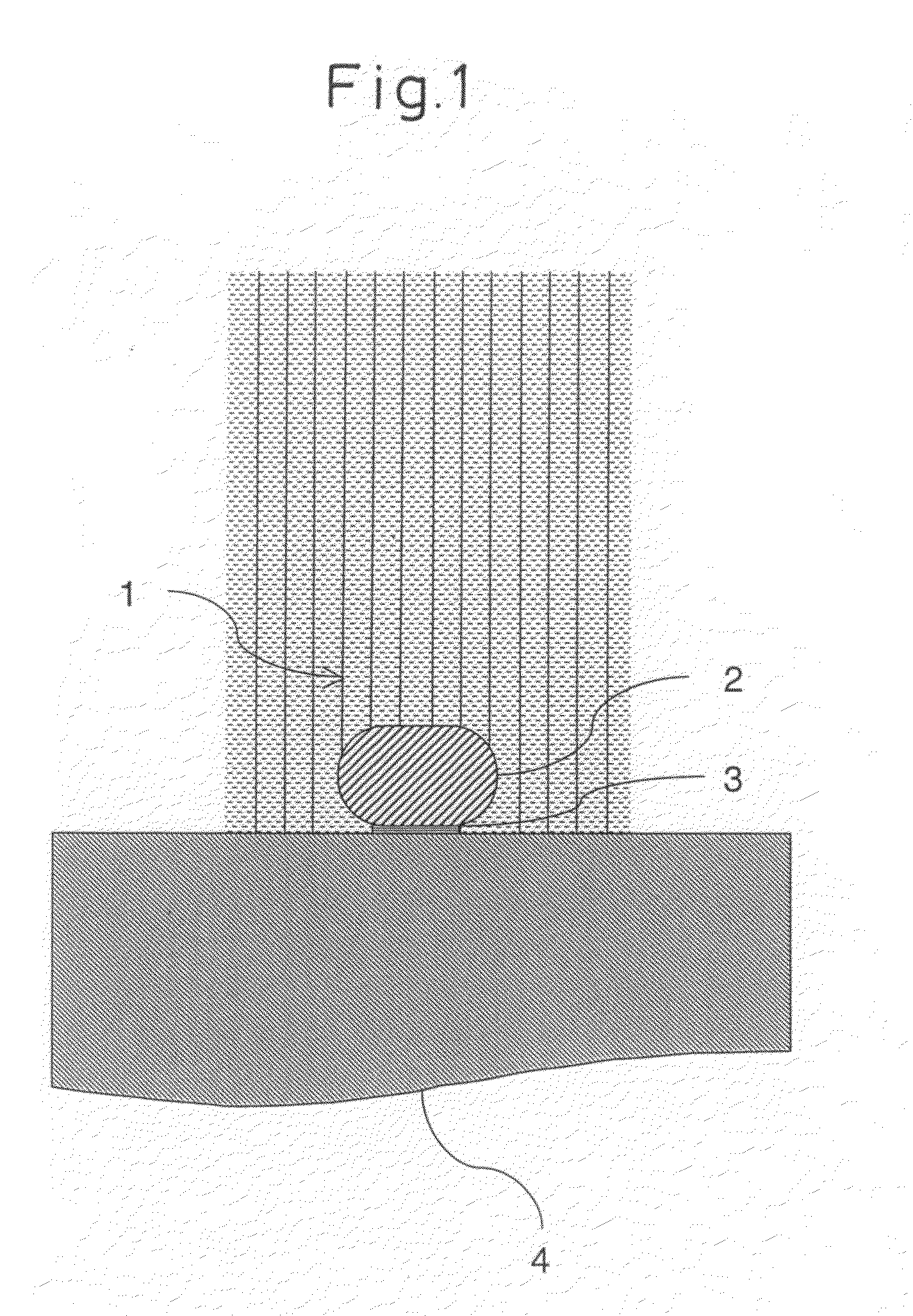

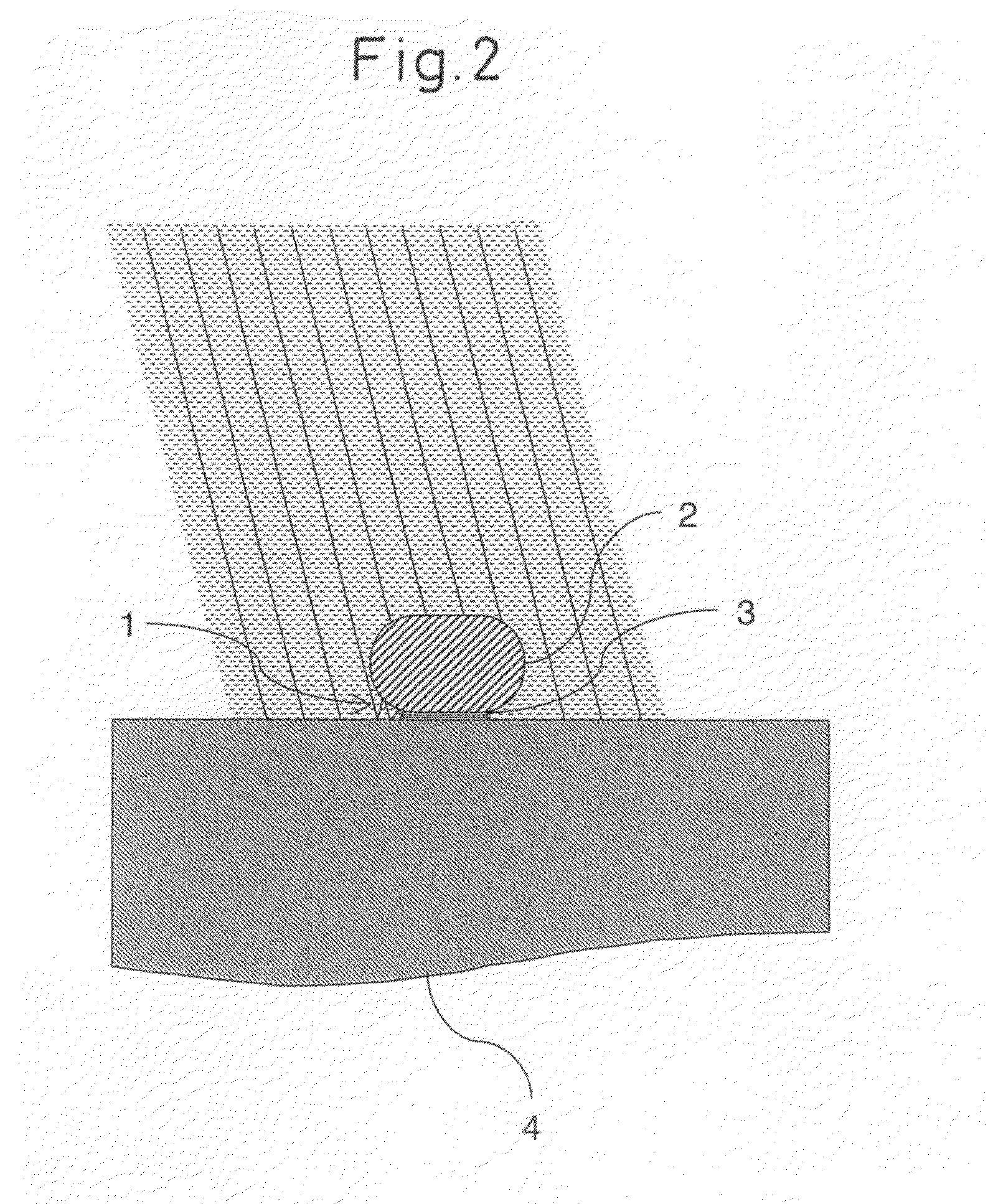

Method of cleaning steel sheet and continous cleaning system of steel sheet

ActiveUS20100095980A1Easy to cleanIncrease pickling speedLiquid processing with progressive mechanical movementCleaning using liquidsSheet steelEngineering

The present invention provides a method of cleaning steel sheet, said method of cleaning steel sheet feeding a cleaning solution activated by ultrasonic waves of a frequency of 0.8 MHz to 3 MHz to a surface of steel sheet at an angle inclined by 1 to 80° with respect to a line perpendicular to the surface of the steel sheet in a direction opposite to the running direction, thereby enabling megasonic waves to be applied to cleaning of running steel sheet and improving the cleaning effect and cleaning speed, and a continuous cleaning system of steel sheet.

Owner:NIPPON STEEL CORP +1

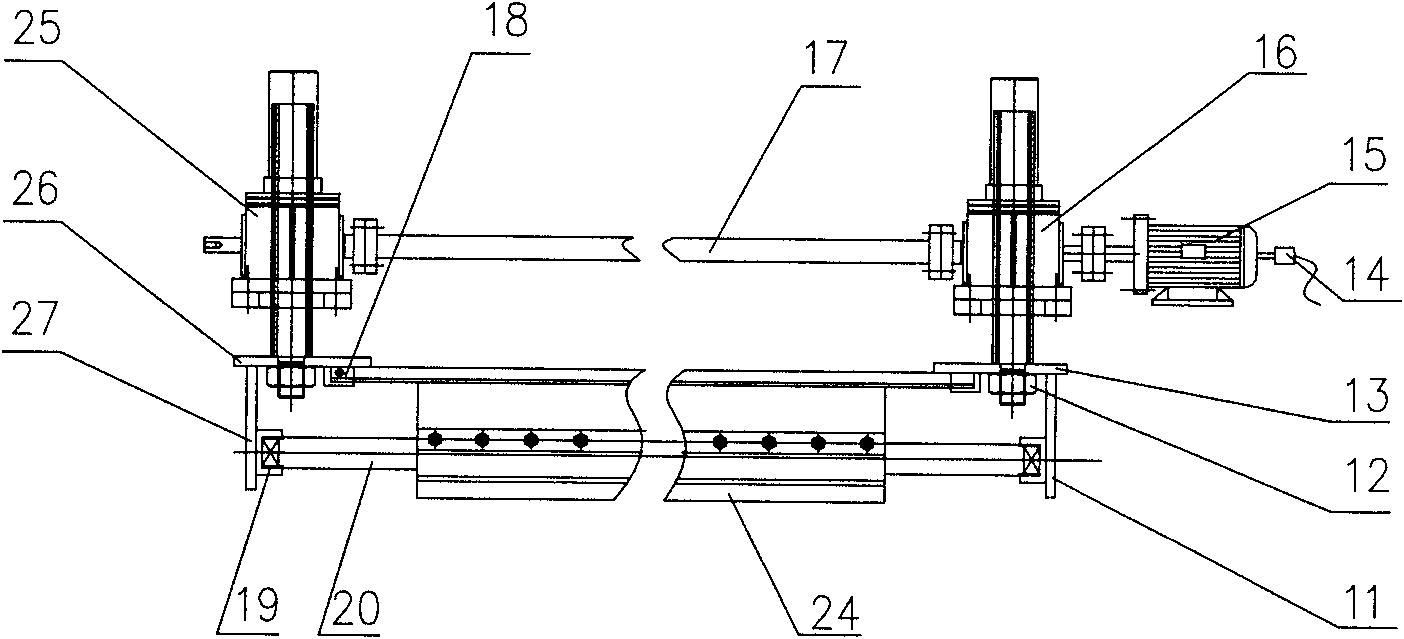

Method for blocking backflow of emulsified liquid with low inertia force

InactiveCN101829682APrevent backflowSimple methodRolling equipment maintainenceRollsLow speedStrip steel

The invention belongs to the technical field of cold-rolled emulsified spot processing, and in particular relates to a method for blocking backflow of emulsified liquid with low inertia force, which is applied to various cold mill trains. The method for blocking the backflow of the emulsified liquid with low inertia force is characterized by comprising the following steps of:1) arranging a rubber scraper on the inlet side of a cold mill, and arranging a rubber scraper on the outlet side of the cold mill, wherein the rubber scraper on the inlet side and the rubber scraper on the outlet side are all positioned above a steel strip passing line; and 2) after the mill completes switching rolling passes, putting down the rubber scraper on the inlet side to press against the upper surface of a steel strip so as to block the backflow of the emulsified liquid when the rolling speed of the cold mill is less than 4m / s, lifting the rubber scraper to leave the upper surface of the steel strip when the rolling speed of the cold mill is more than or equal to 4m / s, and in the process, always lifting the rubber scraper on the outlet side. The method has the characteristic of simpleness, and can prevent the backflow of the emulsified liquid during low-speed rolling of the mill.

Owner:WISDRI ENG & RES INC LTD

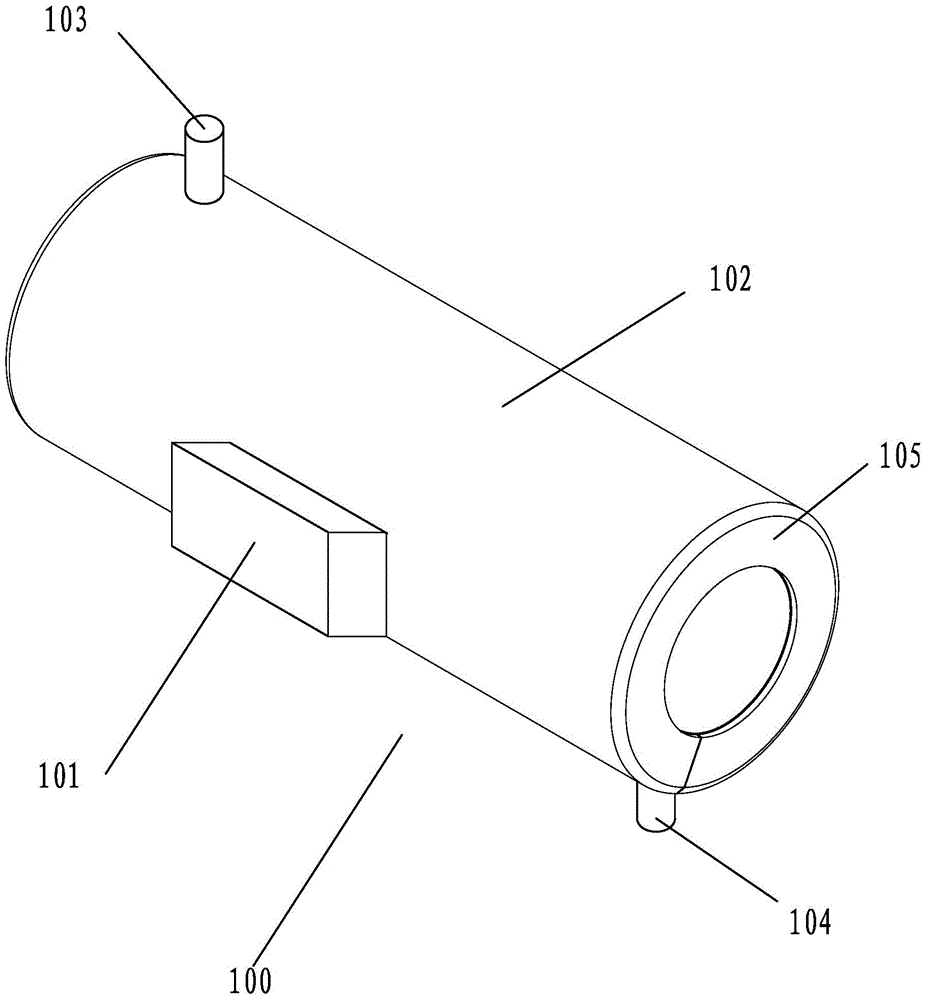

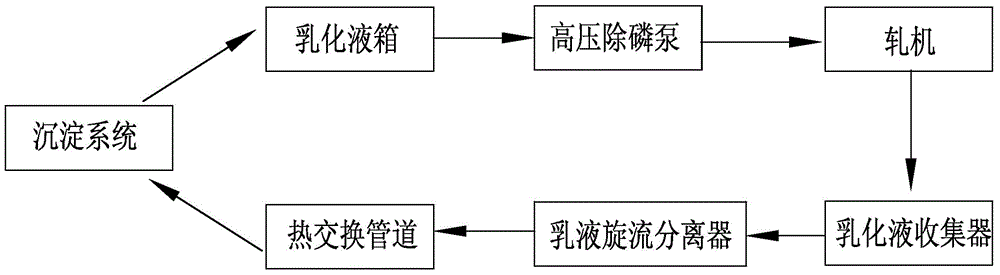

Method for reducing cost of producing copper rod via continuous casting and continuous rolling

InactiveCN104646420AQuality improvementReduce manufacturing costWork cooling devicesWork cleaning devicesEmulsionWater cycling

The invention discloses a method for reducing cost of producing a copper rod via continuous casting and continuous rolling. The method is improved on the basis of the prior art, and a water circulating heat exchange device and an emulsion circulating system are additionally arranged; energy sources are reasonably utilized, and energy conservation and environment friendliness are realized; the production cost is effectively reduced and the quality of a product is improved to a certain extent. The method relates to the field of machining of metal copper.

Owner:XINXING PIPES ZHEJIANG COPPER

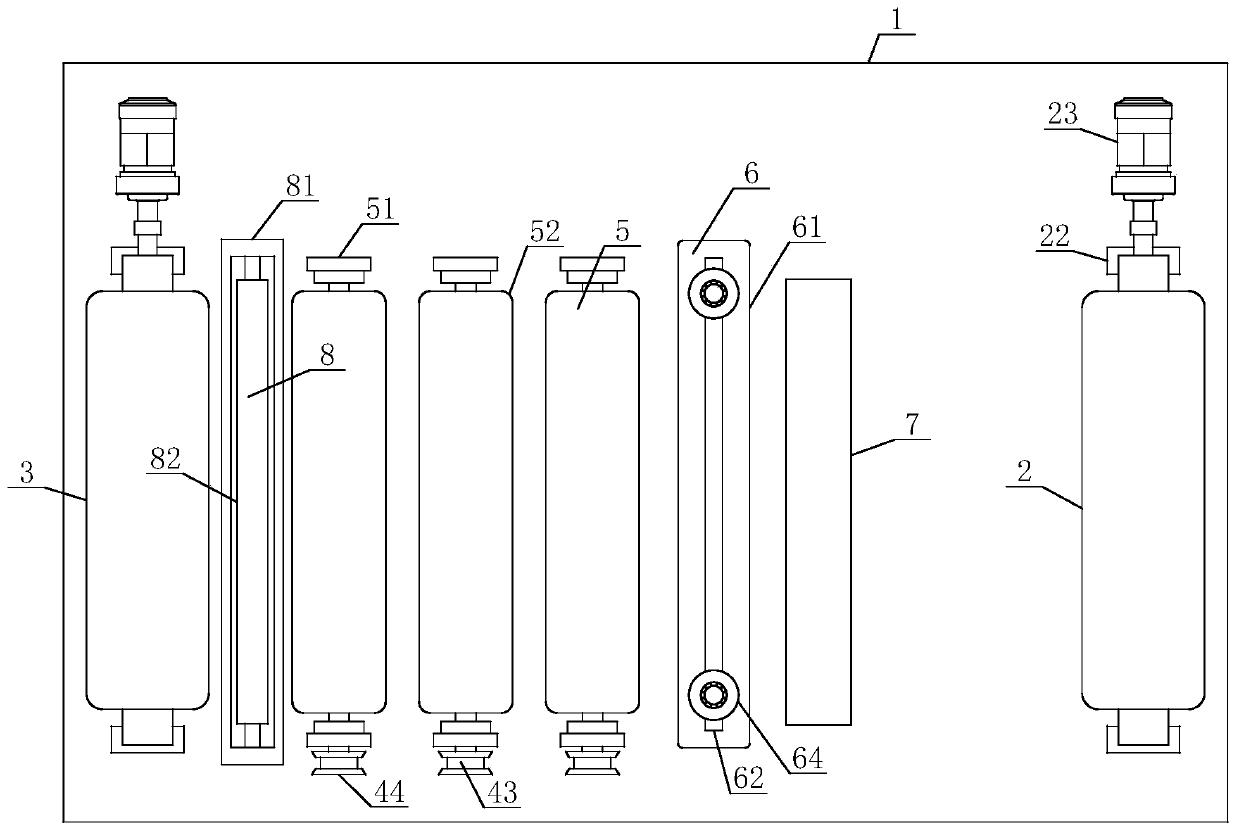

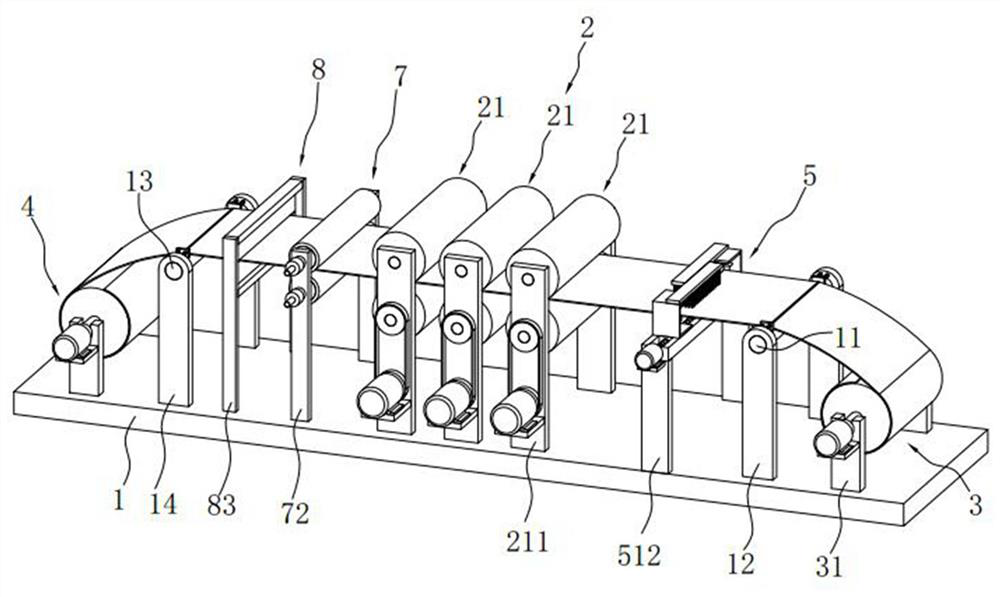

Stainless steel strip cold rolling device

ActiveCN110369508AAvoid offsetAvoid scratchesMetal rolling stand detailsGuiding/positioning/aligning arrangementsForeign matterSS - Stainless steel

The invention relates to the field of stainless steel strips, in particular to a stainless steel strip cold rolling device. The stainless steel strip cold rolling device comprises a base, a feeding coil, a collecting coil, a power mechanism, a cold rolling mechanism, a guide mechanism, a foreign matter removing mechanism and a cooling mechanism, wherein the feeding coil and the collecting coil arerespectively fixed on two sides of the upper end of the base; the cold rolling mechanism is fixed to the middle of the upper end of the base and driven by the power mechanism; the power mechanism isfixedly connected to the upper end of the base; and the guide mechanism and the foreign matter removing mechanism are arranged on the right side of the cold rolling mechanism. Due to the arrangement of the guide mechanism and the foreign matter removing mechanism, a steel strip to be processed can be positioned by utilizing a guide wheel and a wheel groove in the guide mechanism, the steel strip is prevented from deviating in the processing process, the foreign matter on the surface of the steel strip can be removed by utilizing a brush of the foreign matter removing mechanism when the steel strip passes through a bearing roller, and scratches and grooves on the surface of the steel strip due to the foreign matter are avoided when the steel strip is subjected to cold rolling.

Owner:东阳市和宇金属材料有限公司

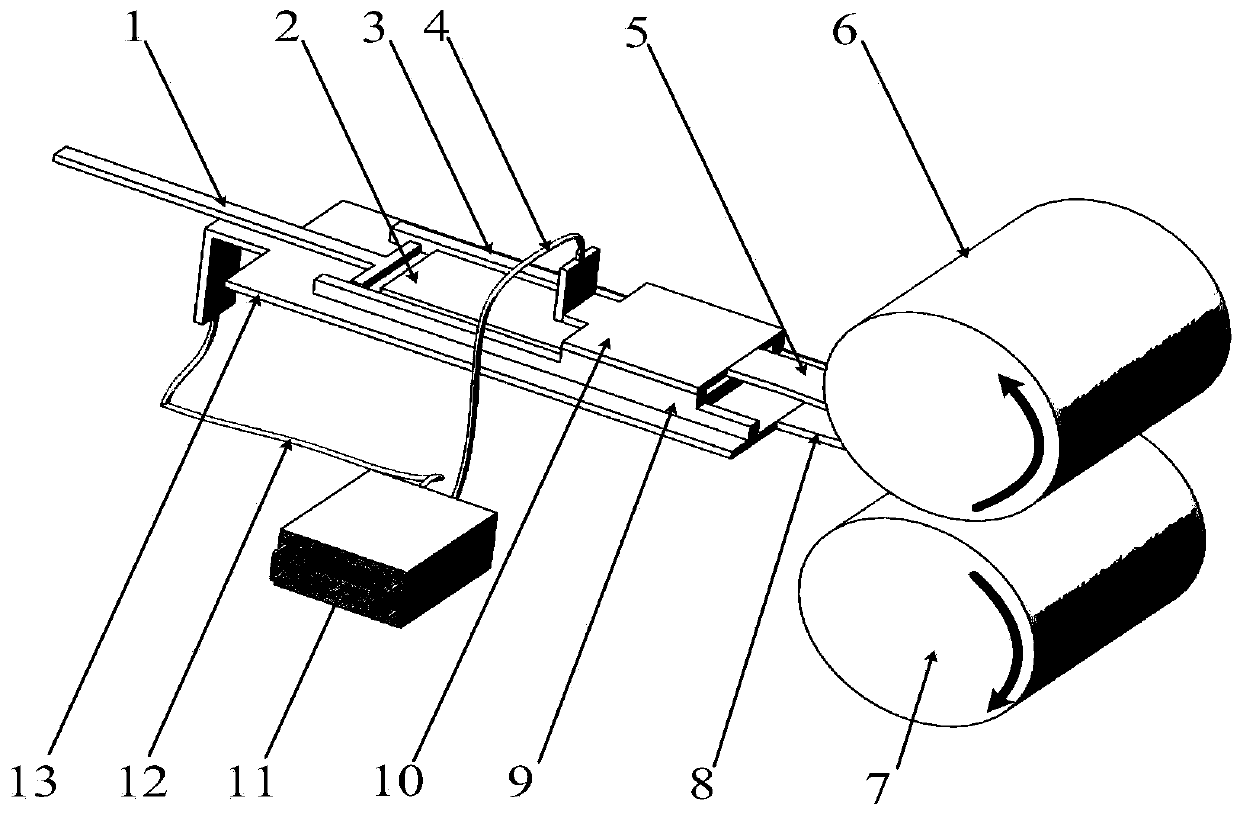

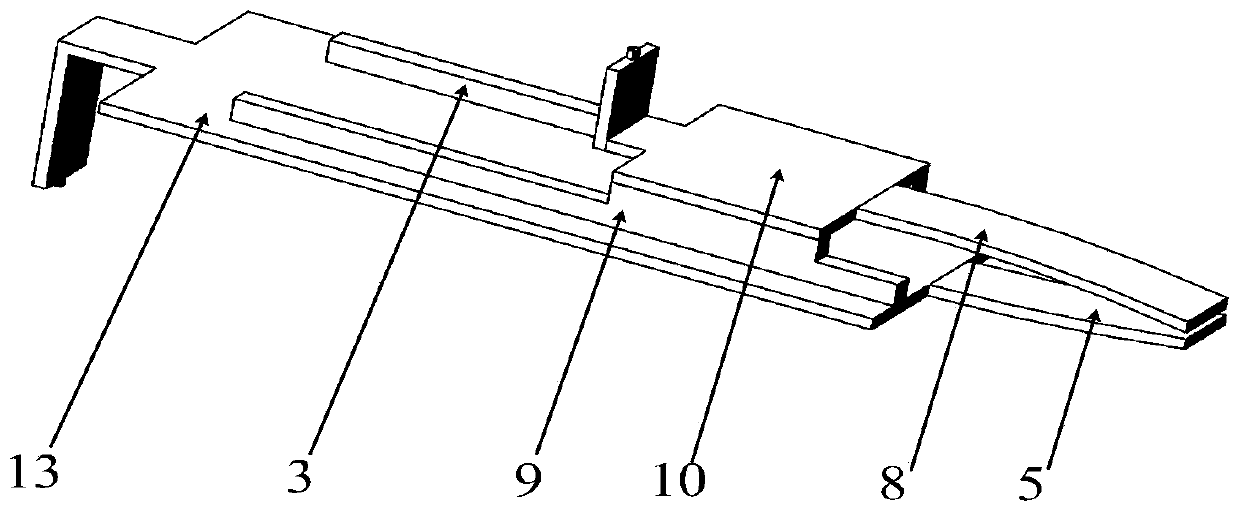

Current assisted vacuum rolling method for preparing metal composite plate

InactiveCN108273847APromote formationImprove distributionAuxillary arrangementsWork cleaning devicesSurface oxidationSuperalloy

The invention relates to a current assisted vacuum rolling method for preparing a metal composite plate. The current assisted vacuum rolling method for preparing the metal composite plate specificallycomprises the steps that firstly, surface oxide layer removing treatment, surface fresh metal exposing treatment and surface oil contamination removing treatment are carried out on each tailored plate; then, the plates which are sequentially overlapped are subjected to sealing welding treatment, and air between composite plate assemblies is pumped to guarantee that plate contact surfaces cannot be oxidized when the plate contact surfaces are subjected to the pulse current action; next, the composite plate assemblies are put into a rolling mill, a pulse current is input to segments to be machined of the composite plate assemblies through an electric contact device, electrical plastic rolling bonding is carried out, multi-pass rolling is carried out by controlling the pulse current parameters and the rolling reduction rate, and the total reduction rate is 58%-72%; and after rolling, the appropriate homogenizing annealing temperature is selected according to the differences of the platesto treat the composite plate 30 min to 3 h. The current assisted vacuum rolling method for preparing the metal composite plate has the beneficial effects of being low in cost and energy consumption,high in plate bonding strength and especially suitable for rolling a titanium alloy, a nickel-cobalt high-temperature alloy, high-strength steel and other refractory materials at a relatively low temperature to prepare the composite plate.

Owner:YUNNAN MINZU UNIV

Special cleaning device for steel pipe surface cleaning machine

ActiveCN104889119AFix security issuesSolve environmental problemsHollow article cleaningWork cleaning devicesHydraulic cylinderSurface cleaning

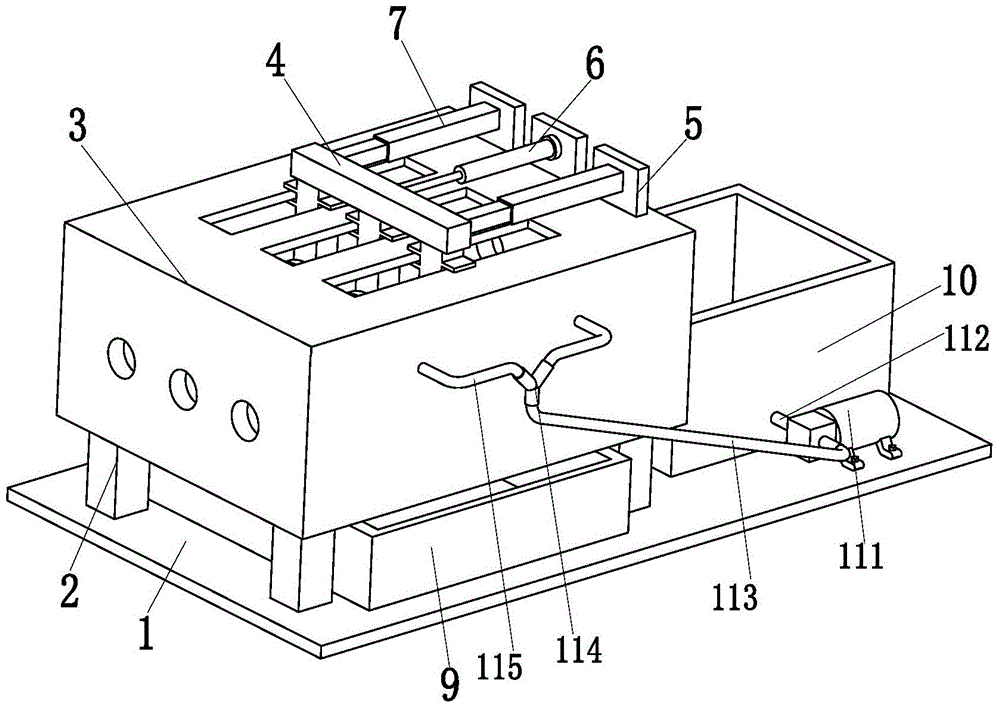

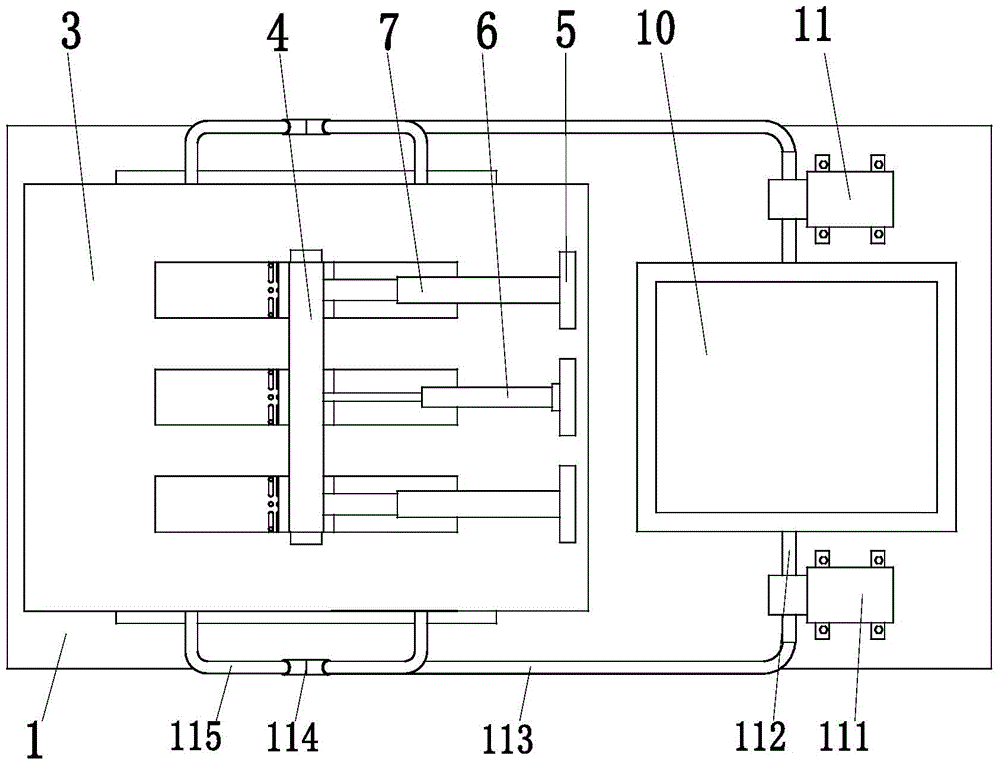

The invention relates to a special cleaning device for a steel pipe surface cleaning machine. The special cleaning device comprises a mounting plate; four supporting columns are symmetrically welded on the left side of the upper end face of the mounting plate; a cleaning wash rack is welded on the upper end face of the four supporting columns; three slides are evenly arranged in the middle of the upper end face of the wash rack; the three slides are mounted on a cleaning support chain in a sliding fit manner; three baffle plates are welded on the right side of the upper end face of the wash rack; a hydraulic cylinder is mounted on the middle baffle; the top end of the hydraulic cylinder is mounted on a pushing plate; two telescopic rods are mounted on the two baffle plates on the two sides of the hydraulic cylinder, respectively; the two ends of the two telescopic rods are mounted on the pushing plate, respectively; three pairs of through holes are correspondingly formed in the two sidewalls of the wash rack; two drain pipes are symmetrically arranged at the lower end of the wash rack. The special cleaning device for the steel pipe surface cleaning machine is capable of realizing the function of simultaneous and quick cleaning of a plurality of steel pipes, free from manual operation, and low in labor intensity; the personnel safety of people is protected; the special cleaning device has the advantages of high cleaning speed, low cost, good environmental protection property, high working efficiency and the like.

Owner:浙江益宏不锈钢有限公司

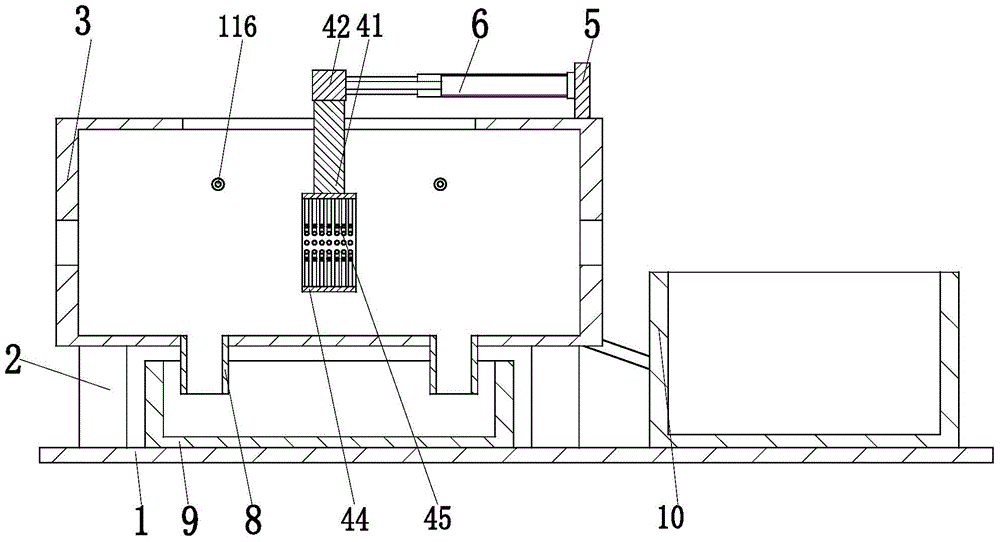

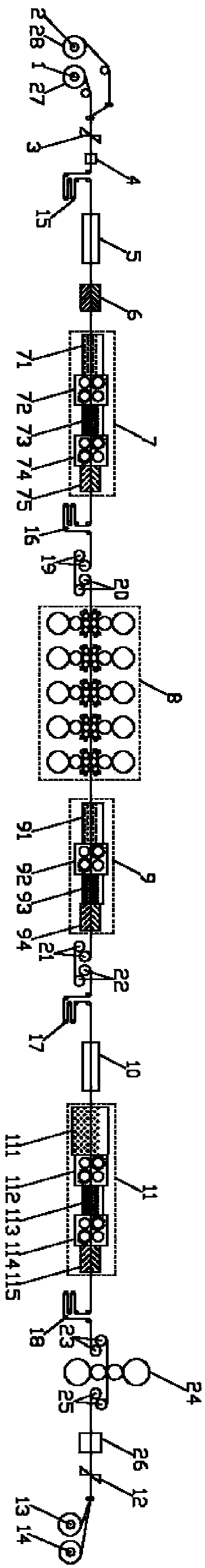

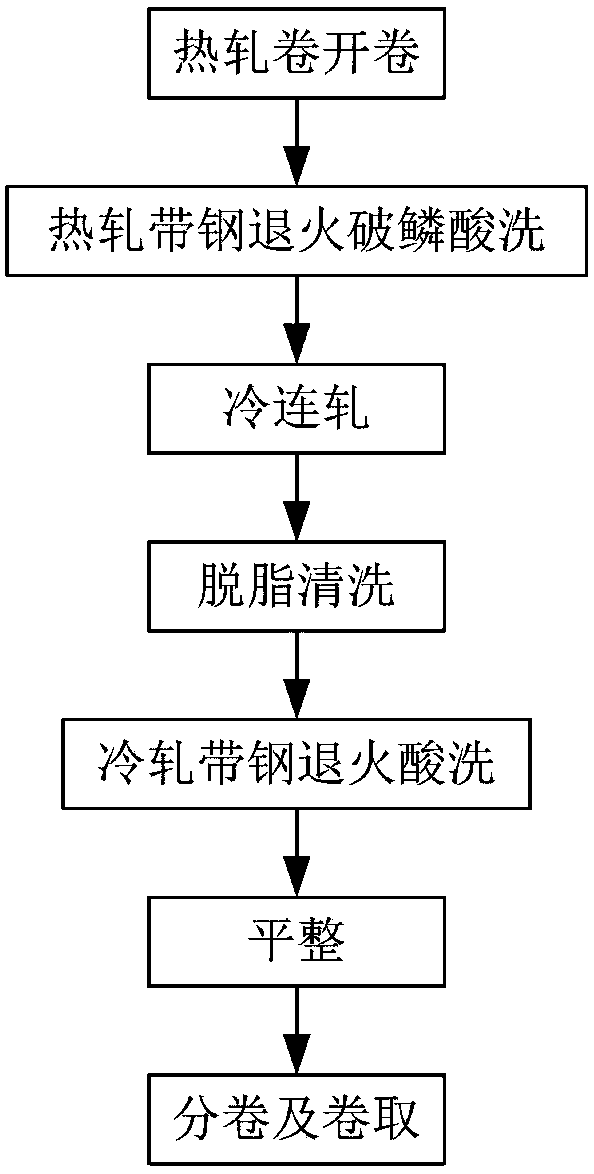

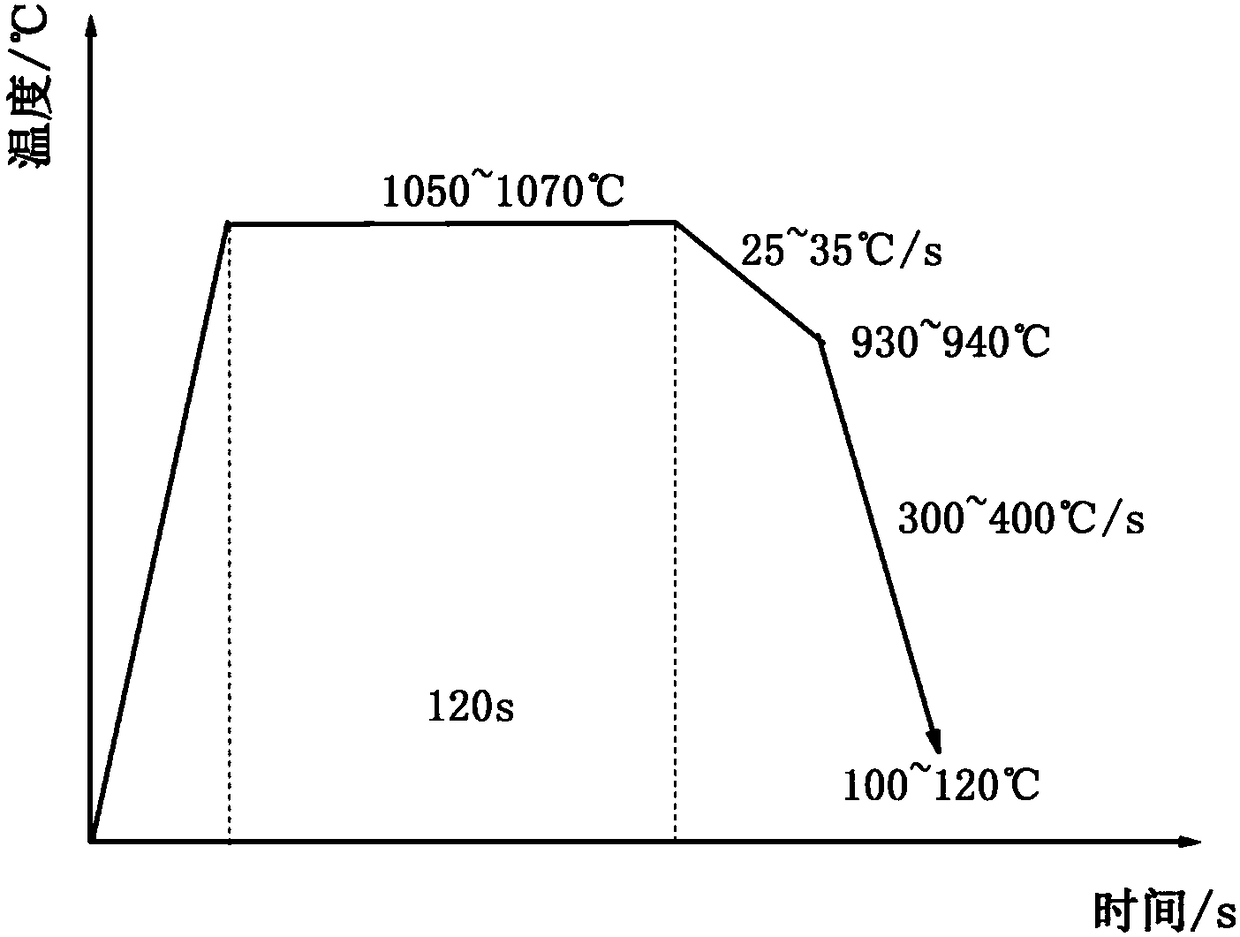

Stainless steel cold rolling production unit and production method thereof

InactiveCN108405608ARealize continuous mass productionShorten the production cycleWork cleaning devicesMetal rolling arrangementsHigh volume manufacturingContinuous rolling

The invention discloses a stainless steel cold rolling production unit comprising an uncoiling section, a first annealing and acid pickling section, a cold continuous rolling section, a second annealing and acid pickling section and a coiling section, wherein the uncoiling section, the first annealing and acid pickling section, the cold continuous rolling section, the second annealing and acid pickling section and the coiling section are sequentially arranged in the rolling section. The uncoiling section comprises a first uncoiling machine, a second uncoiling machine, a first shearing machineand a welding machine, wherein the first uncoiling machine, the second uncoiling machine, the first shearing machine and the welding machine are sequentially arranged. The first annealing and acid pickling section comprises a first annealing furnace, a shot blasting machine and a first acid pickling device, wherein the first annealing furnace, the shot blasting machine and the first acid picklingdevice are sequentially arranged. The cold continuous rolling section comprises a cold continuous rolling unit and a degreasing and washing device, wherein the cold continuous rolling unit and the degreasing and washing device are sequentially arranged. The second annealing and acid pickling section comprises a second annealing furnace and a second acid pickling device, wherein the second annealing furnace and the second acid pickling device are sequentially arranged. The coiling section comprises a second shearing machine, a first coiling machine and a second coiling machine, wherein the second shearing machine, the first coiling machine and the second coiling machine are sequentially arranged. The invention further discloses a method for producing stainless steel by means of the stainless steel cold rolling production unit. The stainless steel cold rolling production unit has the beneficial effects that a hot rolling annealing and acid pickling unit, a cold continuous rolling unit and a cold rolling annealing and acid pickling unit are integrated, a combined unit is formed, and continuous batch production from hot rolled black plate roll fed materials to cold rolled finished products is achieved.

Owner:WISDRI ENG & RES INC LTD

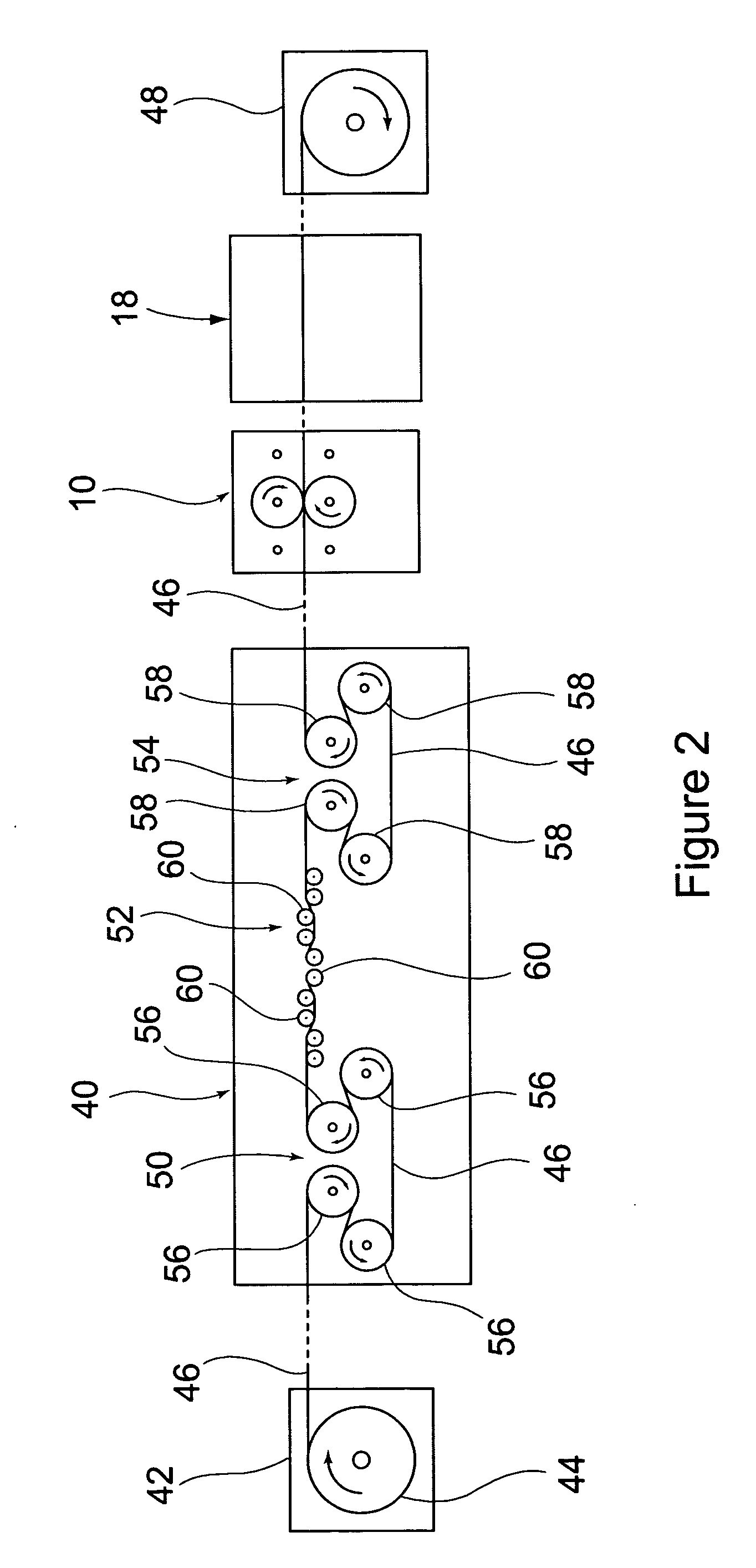

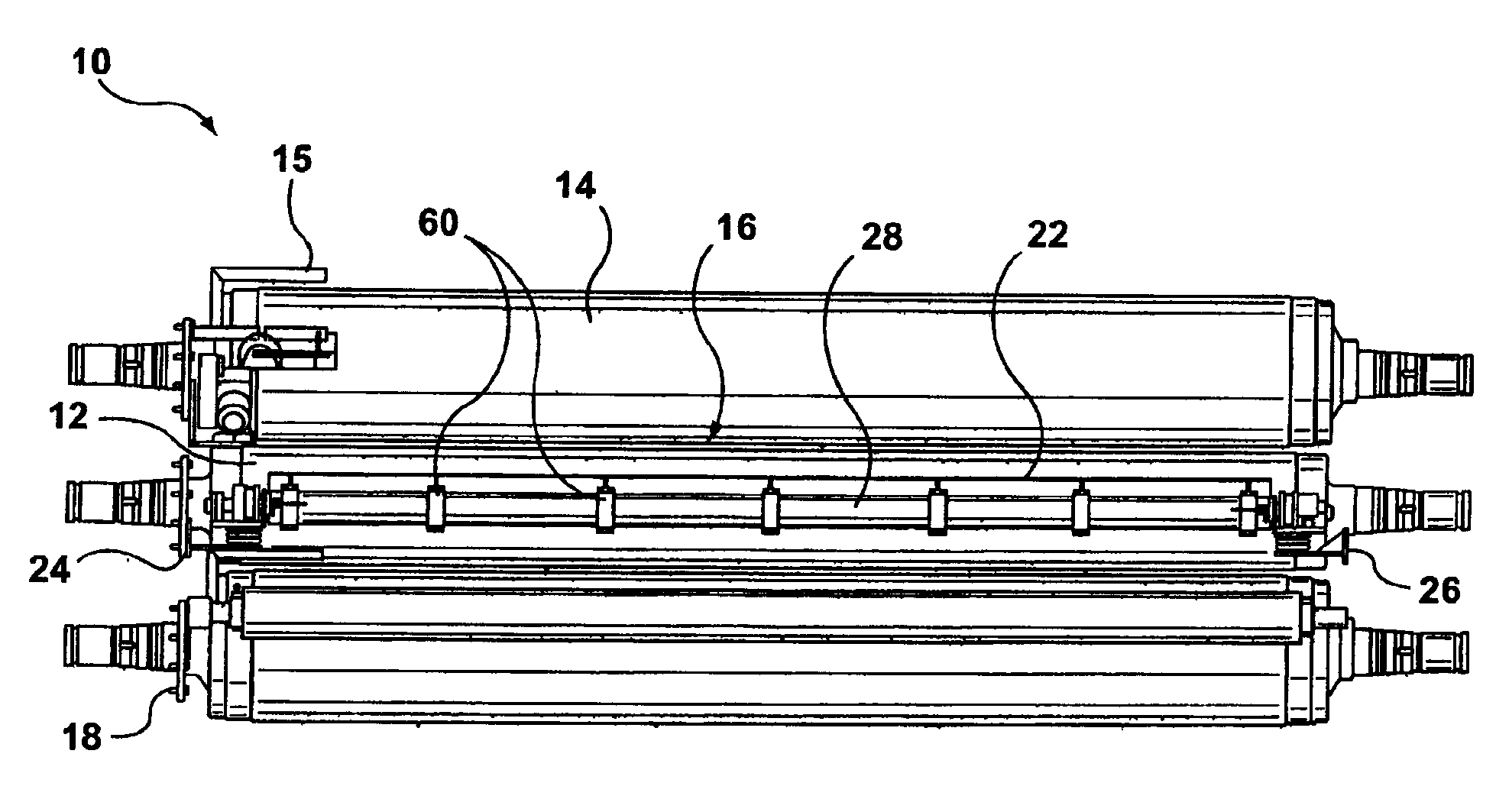

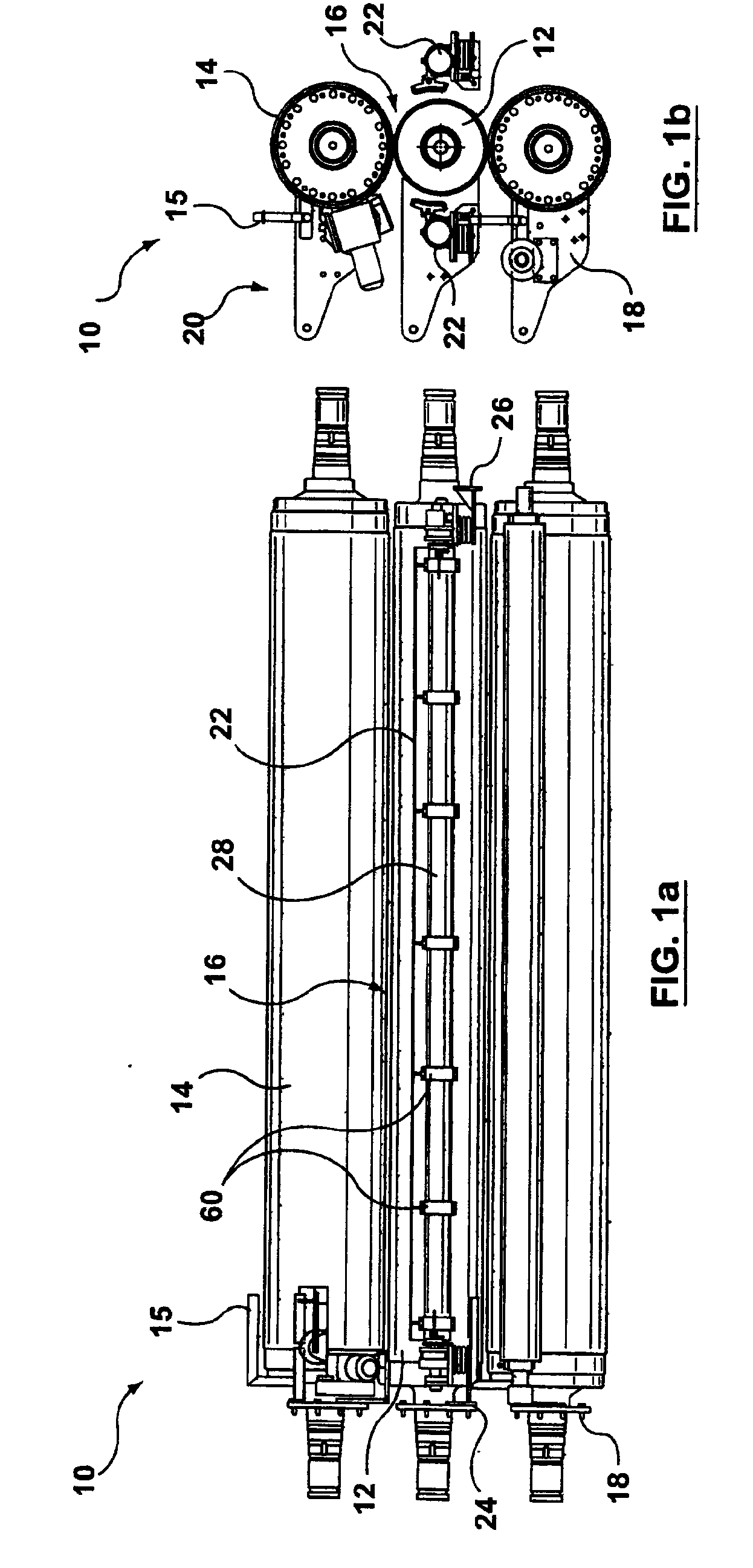

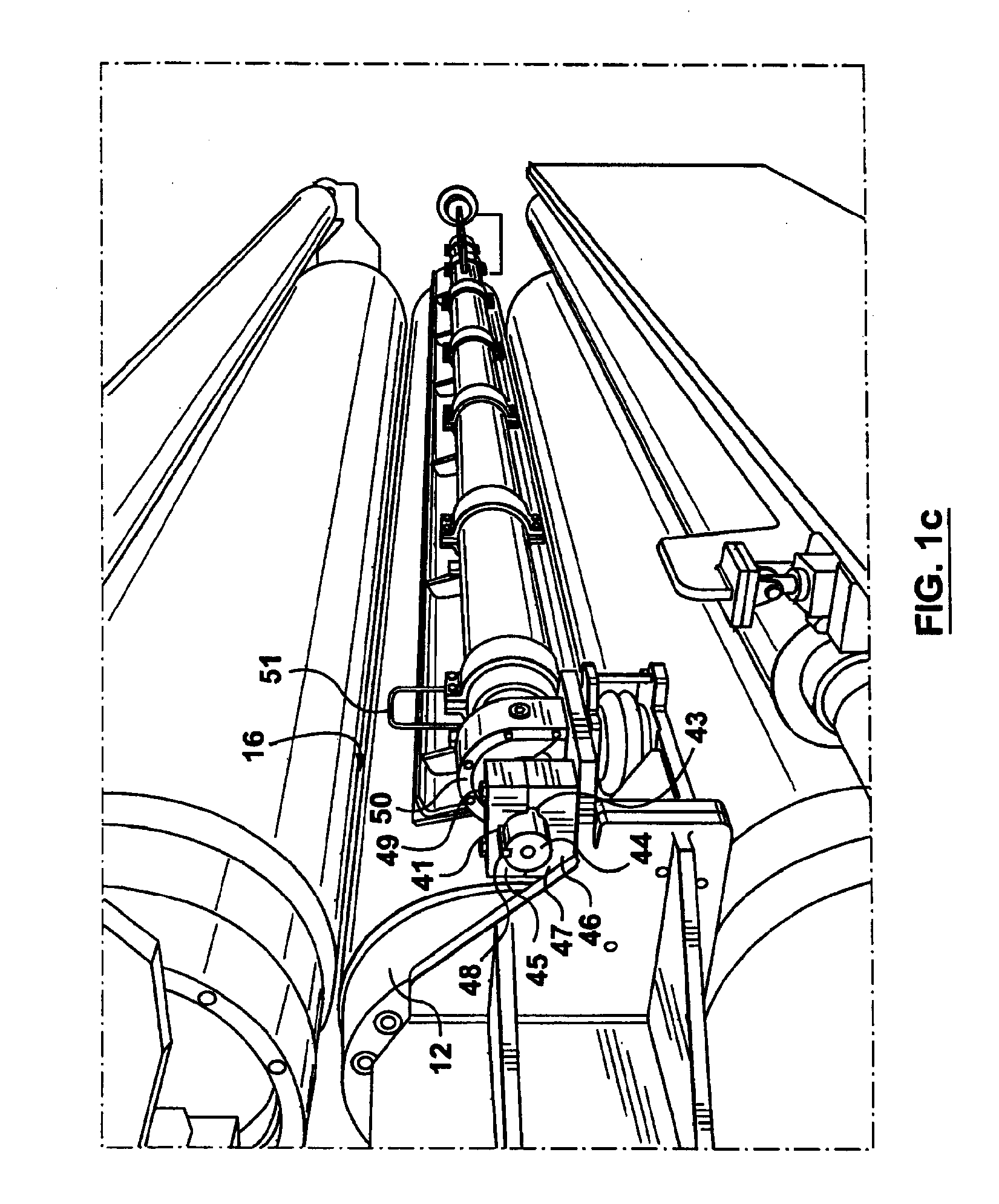

Roll cleaning apparatus and method

A roll cleaning apparatus having a cleaning member mounted to a support member that extends lengthwise relative to a first roller of the machine. The cleaning member has a brush having a substantial area to place against the surface of the roll. The cleaning member may be movable between an engaged position against the roll during operation, and a disengaged position spaced away from the roll in a non-operating condition, such as when replacement of the cleaning member is desired. The roll cleaning apparatus may include a drive connected to cause linear reciprocation of the cleaning member. The roll cleaning apparatus may have a drive or actuator mounted to move the cleaning member between the engaged and disengaged positions, and may be operable to bias the cleaning member against the roll in use. The roll cleaning member may have a contact head that includes an array of abrasive bristles.

Owner:SUPERIOR INDAL SERVICES

Cold rolling mill for steel belt machining and cold rolling process

ActiveCN114101326AReduce the possibility of driftImprove cleanlinessGuiding/positioning/aligning arrangementsWork cooling devicesClassical mechanicsSteel belt

The invention relates to a cold rolling mill for steel strip machining and a cold rolling process, and belongs to the technical field of steel strip machining, the cold rolling mill comprises a bottom plate and a cold rolling mechanism mounted on the bottom plate, one side of the cold rolling mechanism is provided with an unwinding mechanism mounted on the bottom plate, and the other side of the cold rolling mechanism is provided with a winding mechanism; a first guide roller is arranged between the cold rolling mechanism and the unwinding mechanism, and a second guide roller is arranged between the cold rolling mechanism and the winding mechanism; a guide mechanism is arranged between the cold rolling mechanism and the first guide roller, the guide mechanism comprises a supporting frame and two first mounting blocks, a sliding groove is formed in the upper surface of the supporting frame, sliding blocks slidably connected with the sliding groove are fixed to the bottom ends of the two first mounting blocks, and a driving assembly is arranged on the supporting frame; the two first mounting blocks are each provided with a first mounting groove, first guide wheels are arranged in the first mounting grooves, and the steel belt is located between the two first guide wheels. The device has the effects that the possibility of deviation of the steel belt is reduced, and the machining quality of the steel belt is improved.

Owner:唐山国丰第一冷轧镀锌技术有限公司

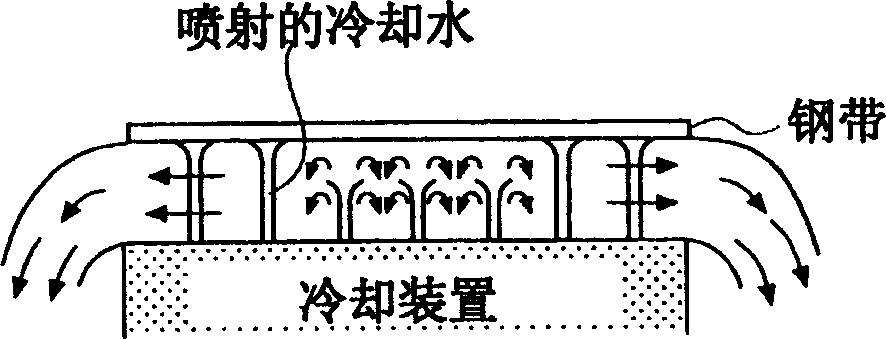

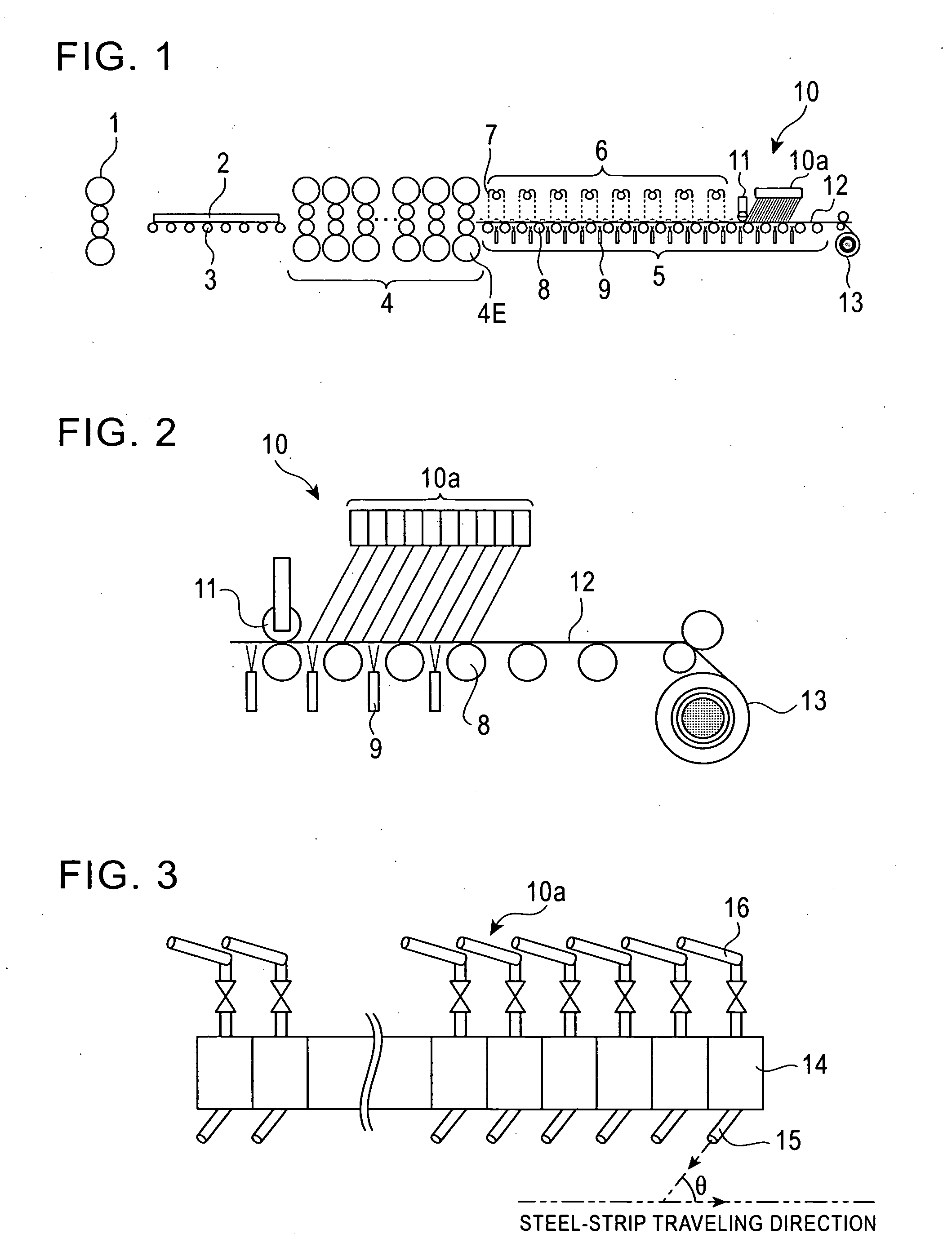

Hot-Strip Cooling Device and Cooling Method

ActiveUS20090019907A1Improve steel qualityHigh yieldBlast furnace detailsCooling devicesEngineeringSteel belt

A hot-strip cooling device and a cooling method are provided wherein uniform cooling of a hot-rolled steel strip using coolant is possible from the leading end to the trailing end of the steel strip. A cooling device (10) includes a plurality of round nozzles (15) disposed obliquely in such a manner as to eject rod-like flows of coolant at an ejection angle θ toward the upstream side in a direction in which a steel strip (12) travels, and a pinch roll (11) disposed on the upstream side with respect to the round nozzles (15) and configured to pinch the steel strip (12) in combination with a roller table (8).

Owner:JFE STEEL CORP

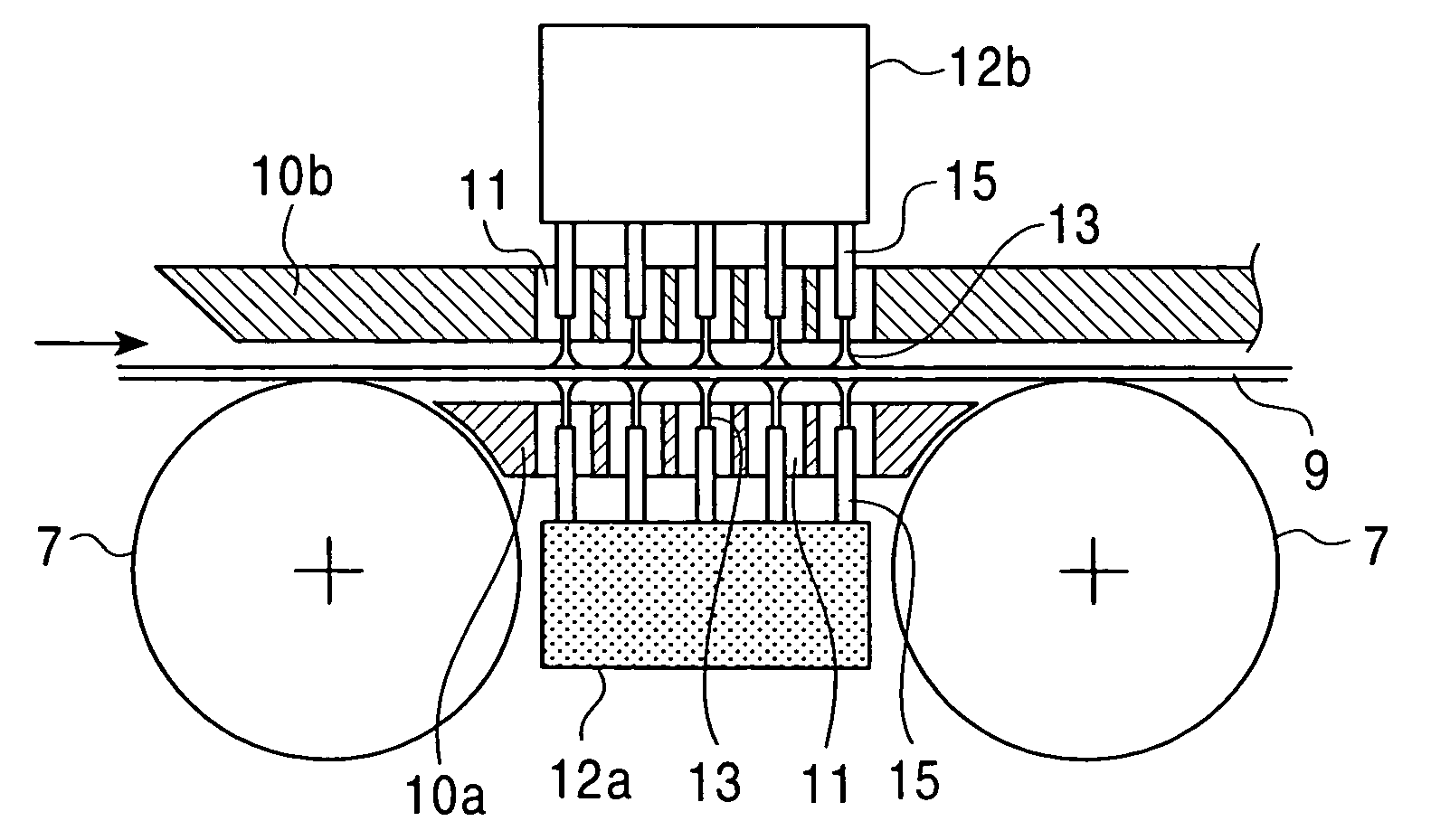

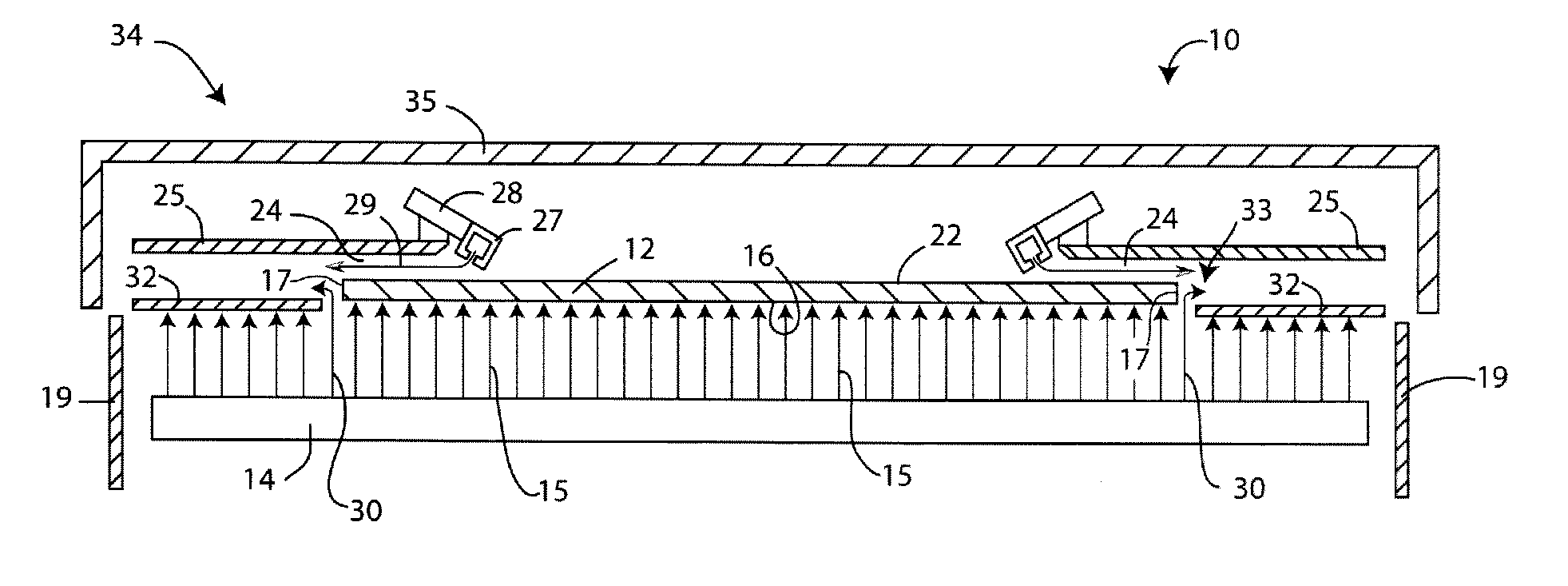

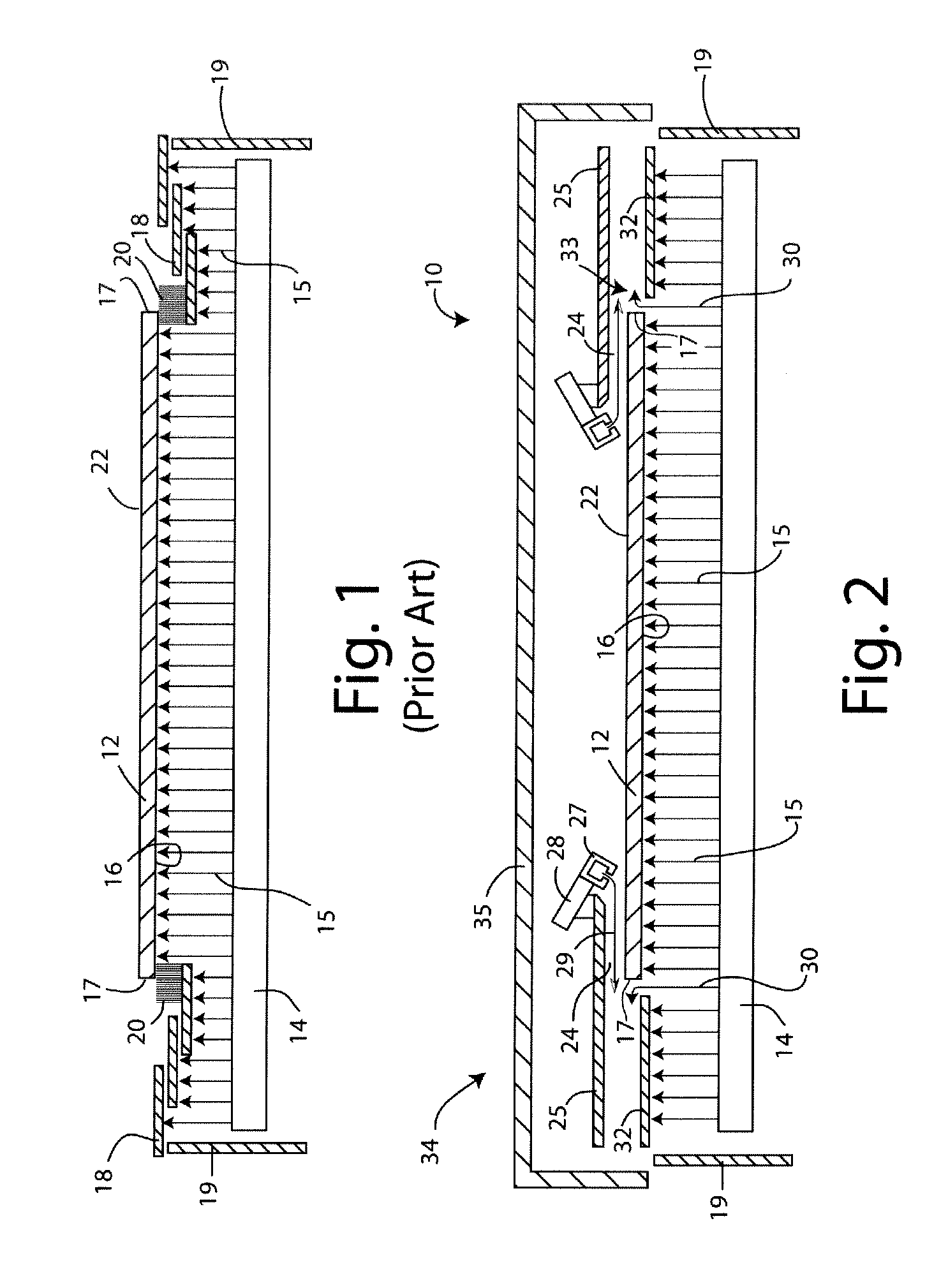

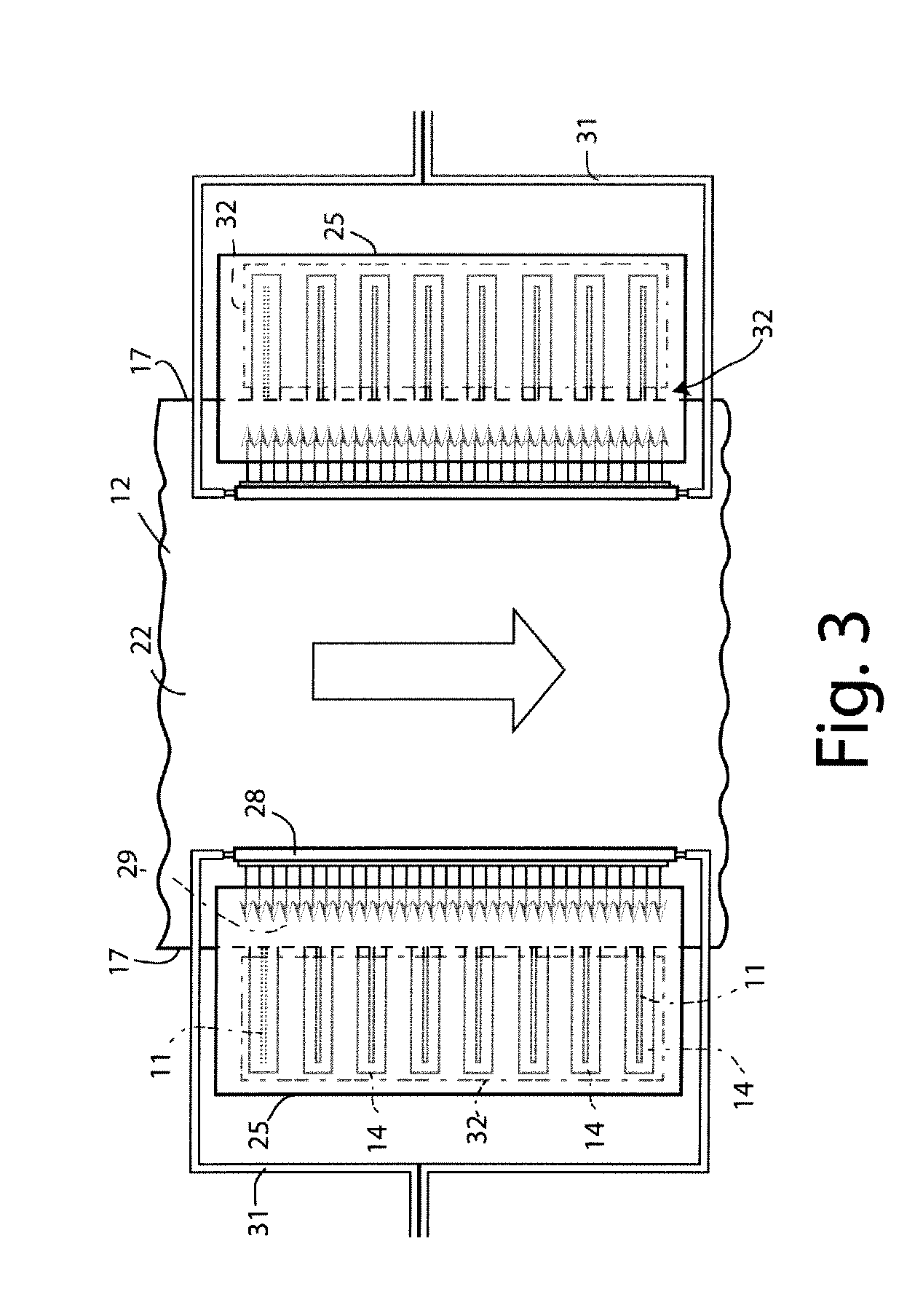

Method and apparatus for removing coolant liquid from moving metal strip

ActiveUS20120235331A1Avoid distractionAvoid contactTemperature control deviceFurnace typesEngineeringCooling fluid

Exemplary embodiments of the invention include a method and apparatus for cooling a metal strip that is being advanced in a generally horizontal fashion. The method involves delivering a coolant liquid onto a lower surface of the strip from below across the entire width of the strip, preventing the coolant liquid from contacting the upper surface of the strip, and optionally subsequently removing the coolant liquid from the lower surface. The coolant liquid is prevented from contacting the upper surface by forming a gas-directing channel immediately above the upper surface of the strip adjacent to one or preferably both lateral edges of the strip and forcing a gas through the channel in a direction generally away from a center of the strip towards the one or both lateral edges to deflect coolant liquid away from the upper surface of the strip. The apparatus provides means for carrying out these steps.

Owner:NOVELIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com