Cooling device, manufacturing method, and manufacturing line for hot rolled steel band

A technology of cooling device and manufacturing method, which is applied in the direction of workpiece cooling device, quenching device, metal rolling, etc., and can solve the problems of large flow rate attenuation, insufficient increase of cooling water, and inability to cool the upper and lower surfaces of steel strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

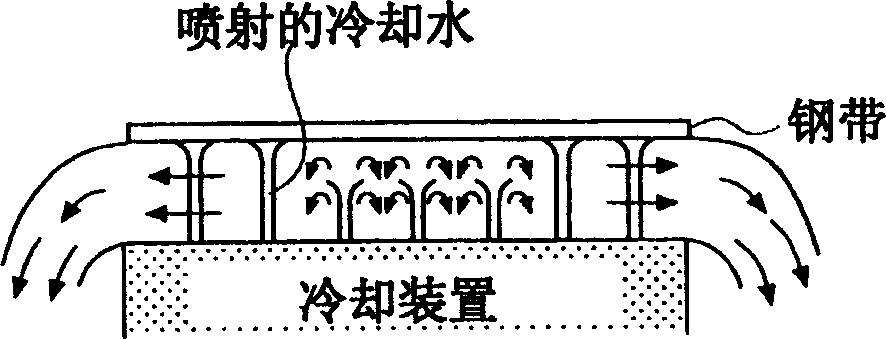

[0076] Use settings like Figure 13 The cooling device of the hot-rolled strip of the present invention shown is as Figure 14 In the production line of hot-rolled steel strip shown, the rough profile of carbon steel with a plate thickness of 30mm and a plate width of 1000m is rolled through a finishing mill consisting of 7 rolling stands at a conveying speed of 700mpm and a finishing temperature of 850°C. After forming a steel strip with a thickness of 3mm, the steel strip was cooled to 550°C at a cooling rate of about 700°C / s, and then cooled using the existing cooling device 8 so that the coiling temperature was 500°C. And, the water density when the cooling rate is about 700°C / s is 7500L / min·m 2 .

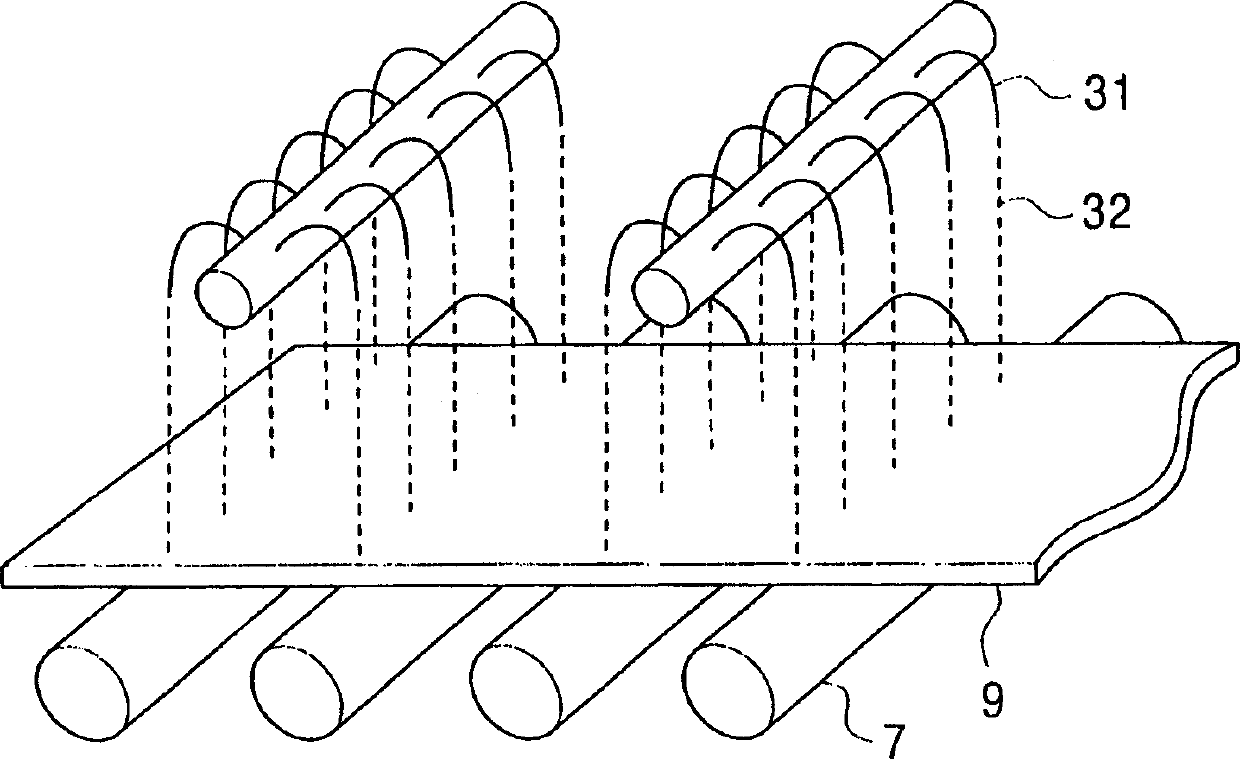

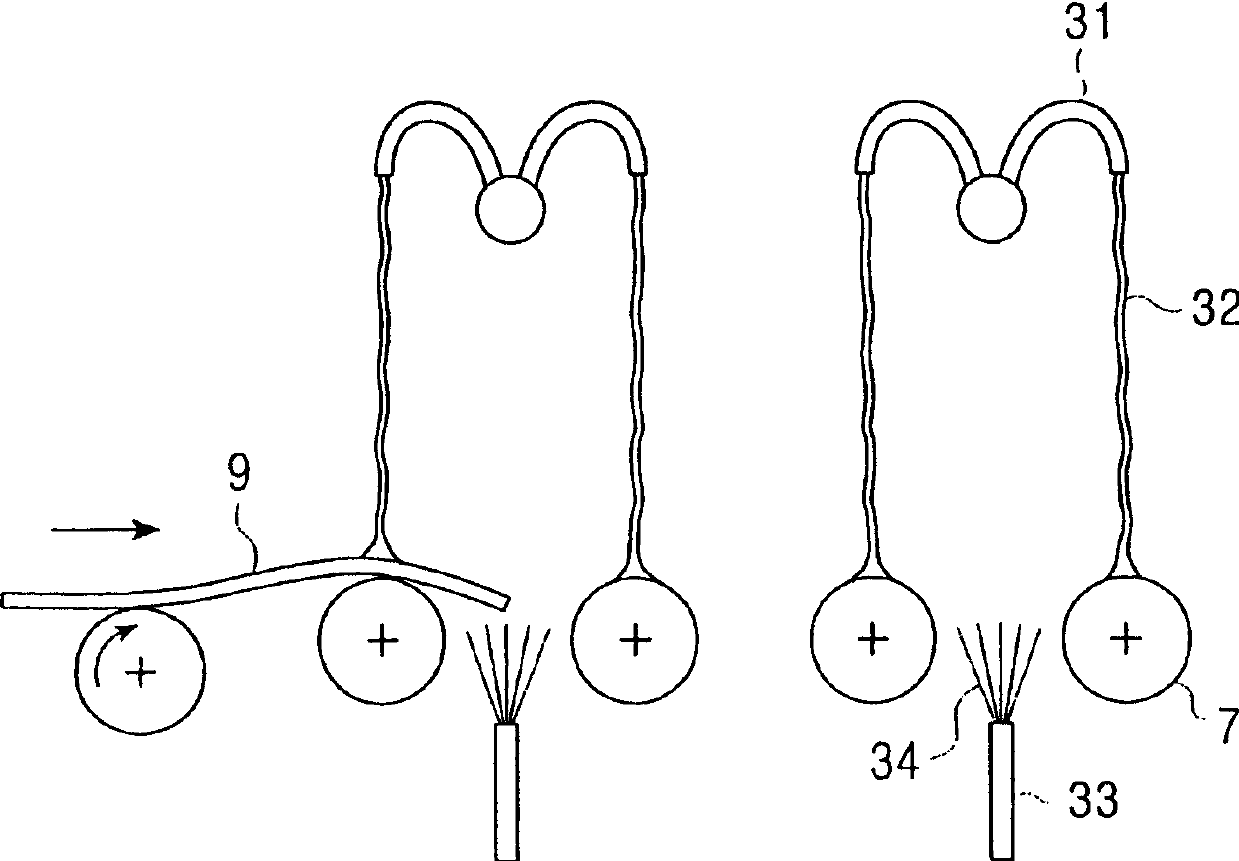

[0077] Such as Figure 13 As shown, the lower surface cooling device 4a has a plurality of conveying rollers 7 with a diameter of 300mm arranged at a pitch of 500mm in the longitudinal direction. The lower surface protection member 10a of the plate thickness 25mm flat plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com