Patents

Literature

937 results about "Surface cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

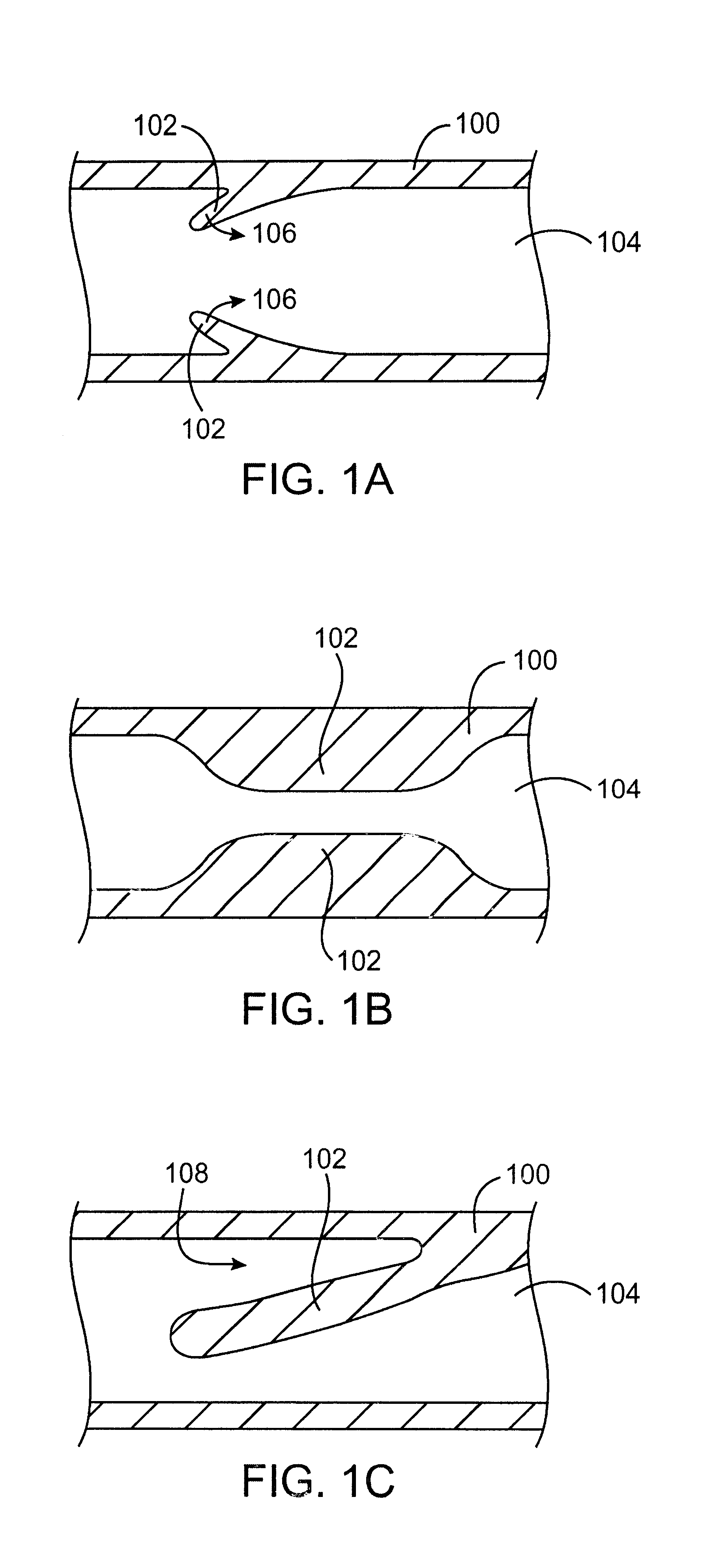

Cryotherapy methods for treating vessel dissections and side branch occlusion

The present invention provides cryotherapy treatment of dissections in a blood vessel of a patient. The present invention further provides cryotherapy treatment of side branch occlusion in a bifurcated blood vessel. One method for treating potential or existing dissections in a blood vessel comprises cooling the blood vessel to a temperature and for a time sufficient to remodel the blood vessel such that dissections of the blood vessel are reduced. Another method for treating side branch occlusion in a bifurcated blood vessel, the bifurcated blood vessel having a side branch and a main branch, the main branch having plaque disposed thereon, comprises cooling an inner surface of the main branch to a temperature and for a time sufficient to inhibit plaque shift from the main branch into the side branch.

Owner:BOSTON SCI SCIMED INC

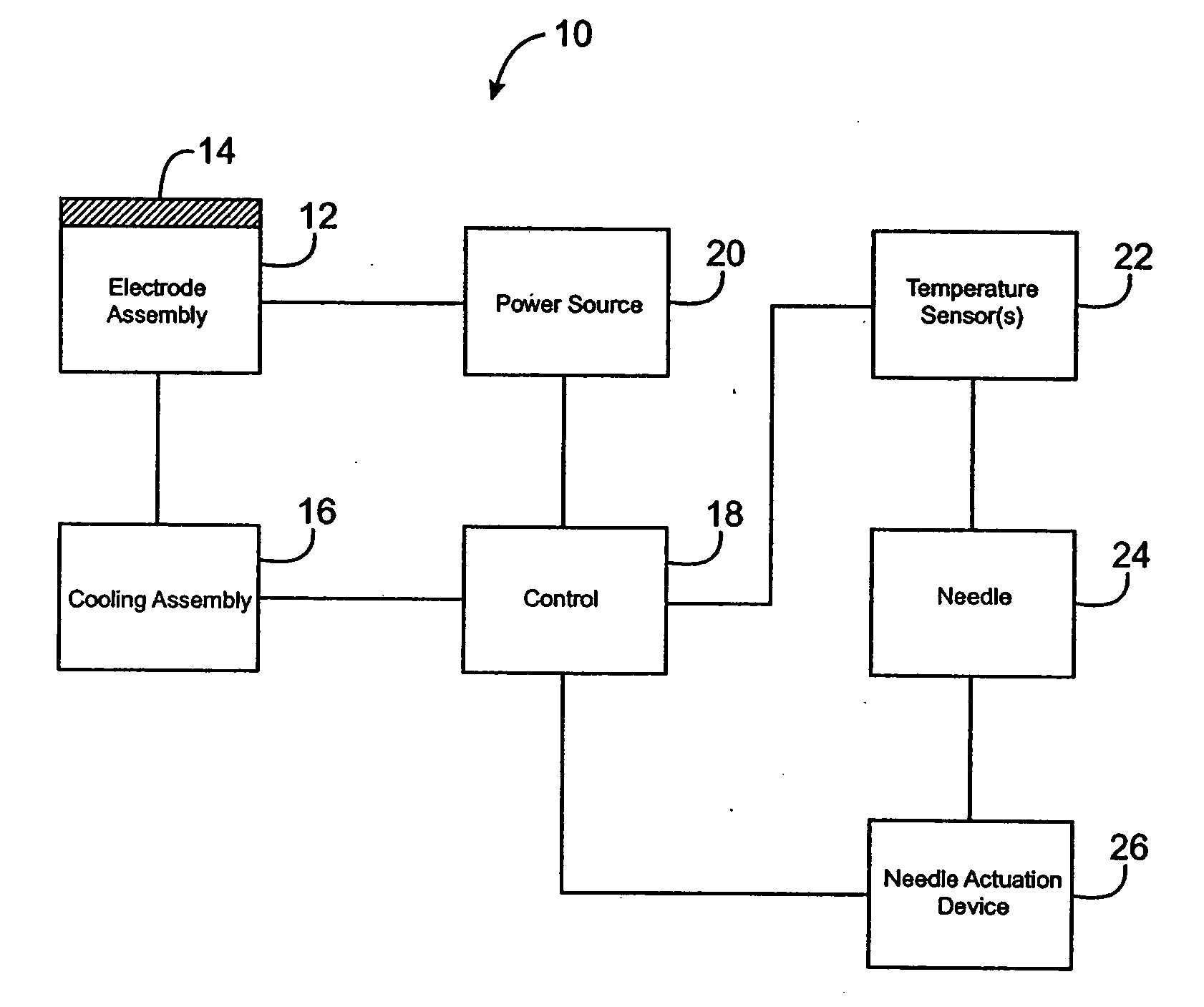

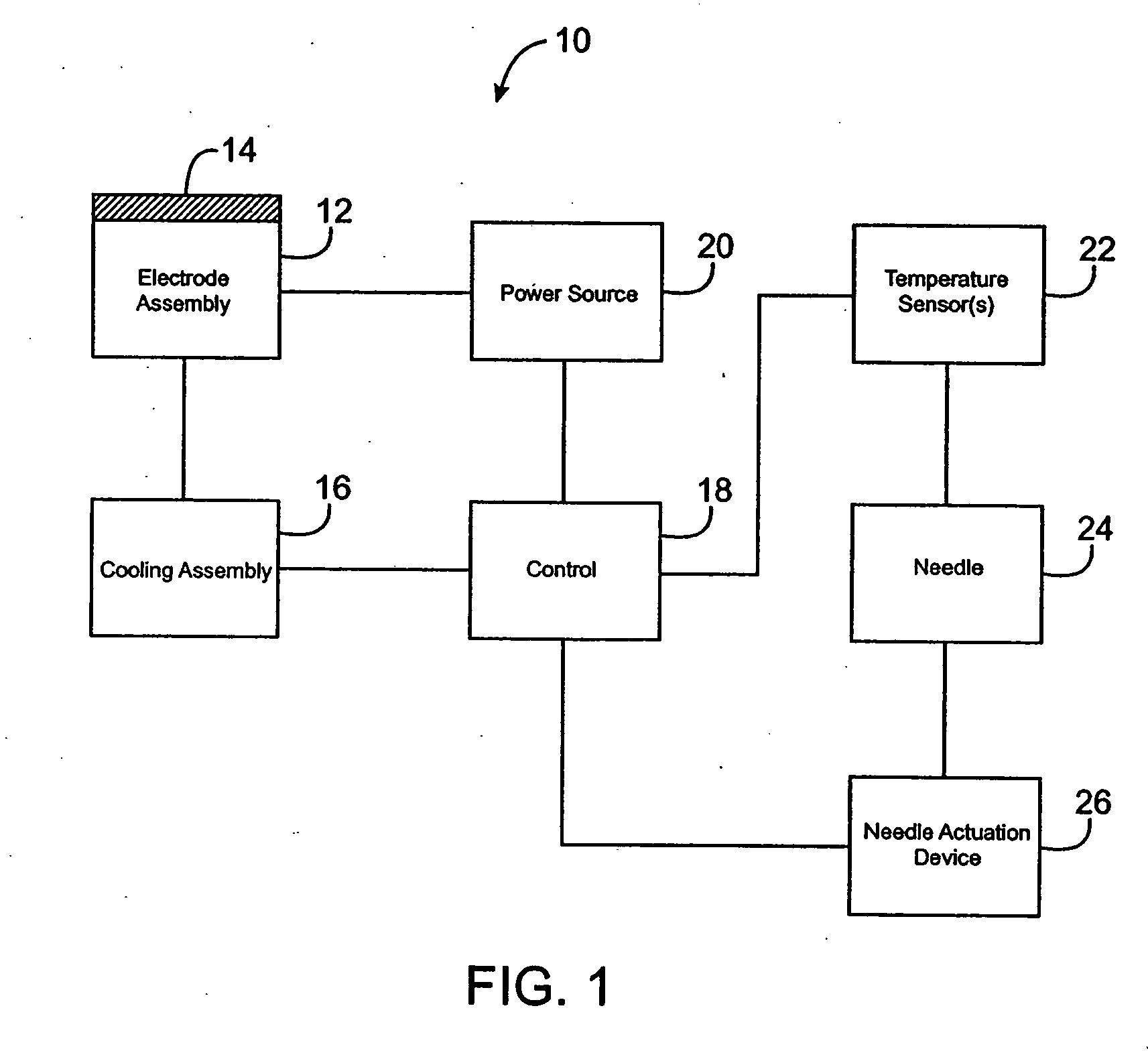

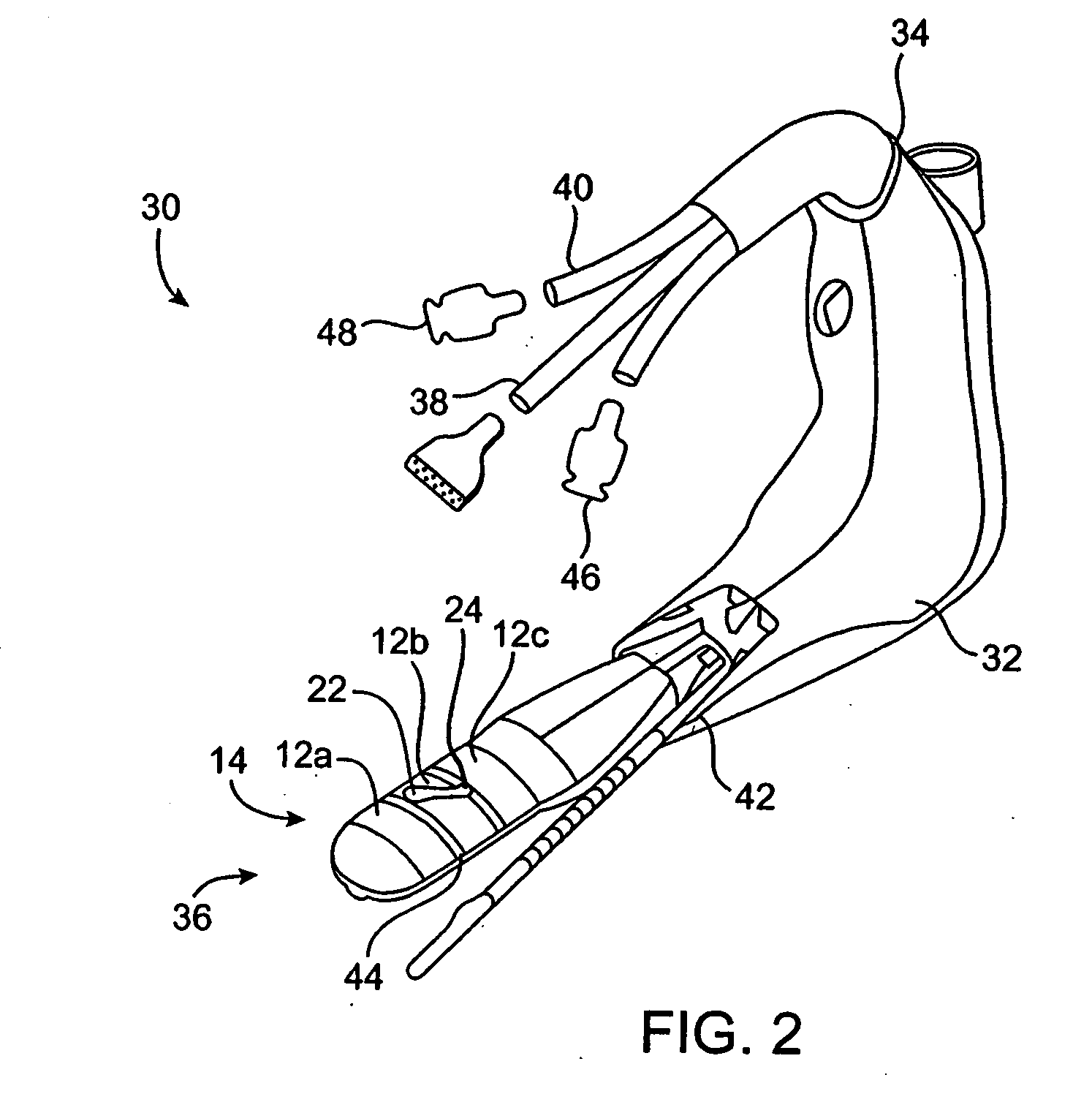

Electrically heated/phase change probe temperature control

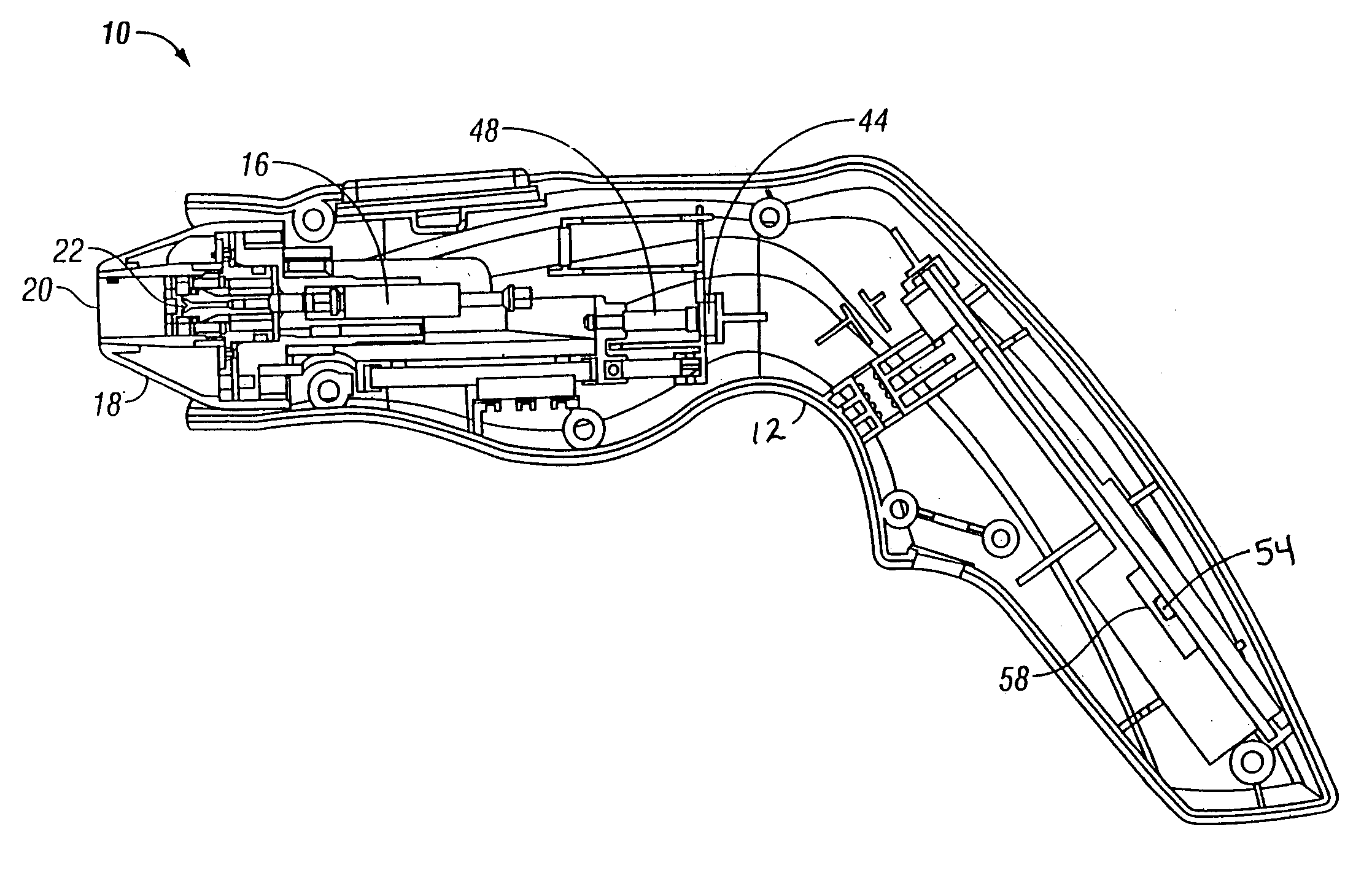

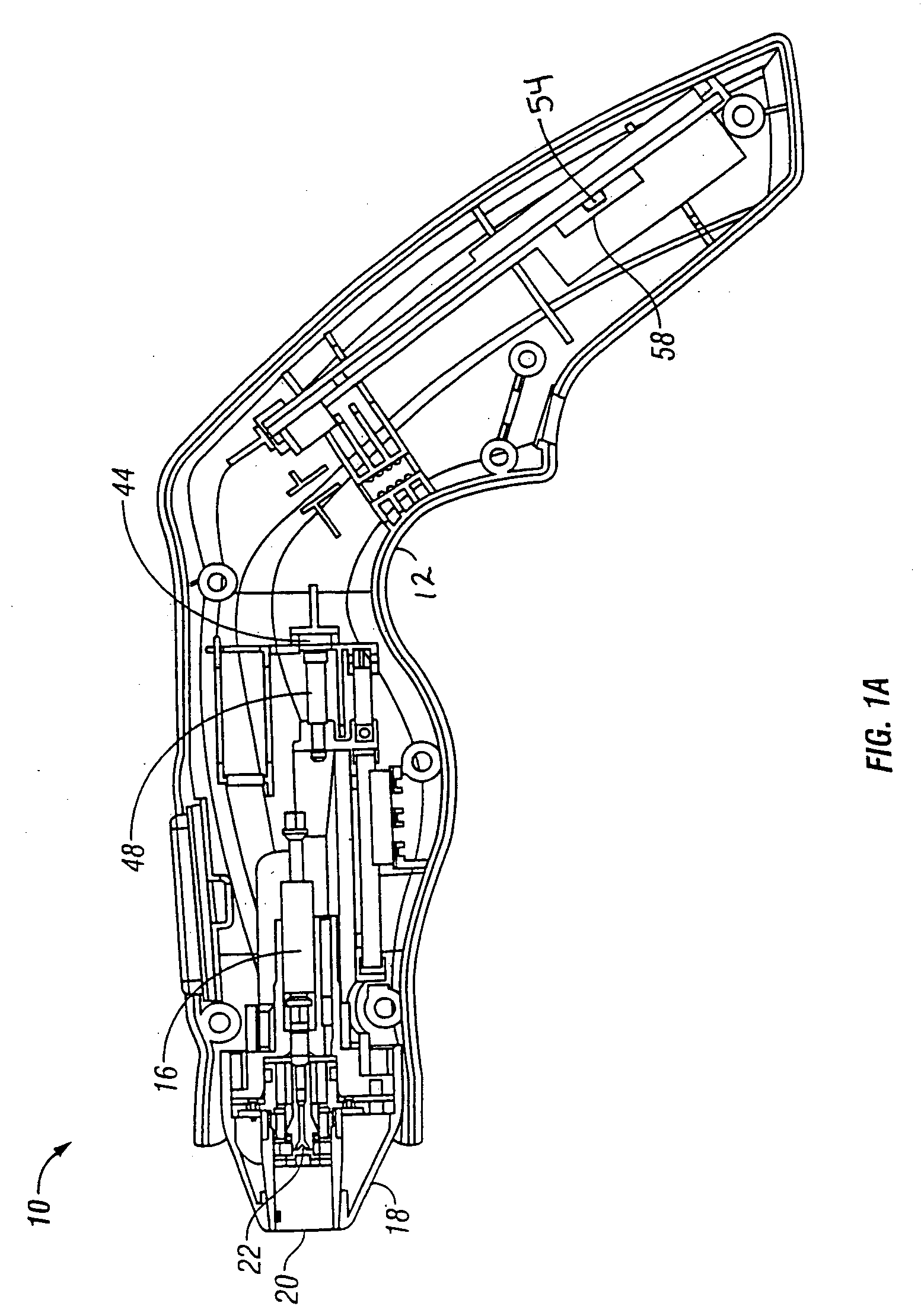

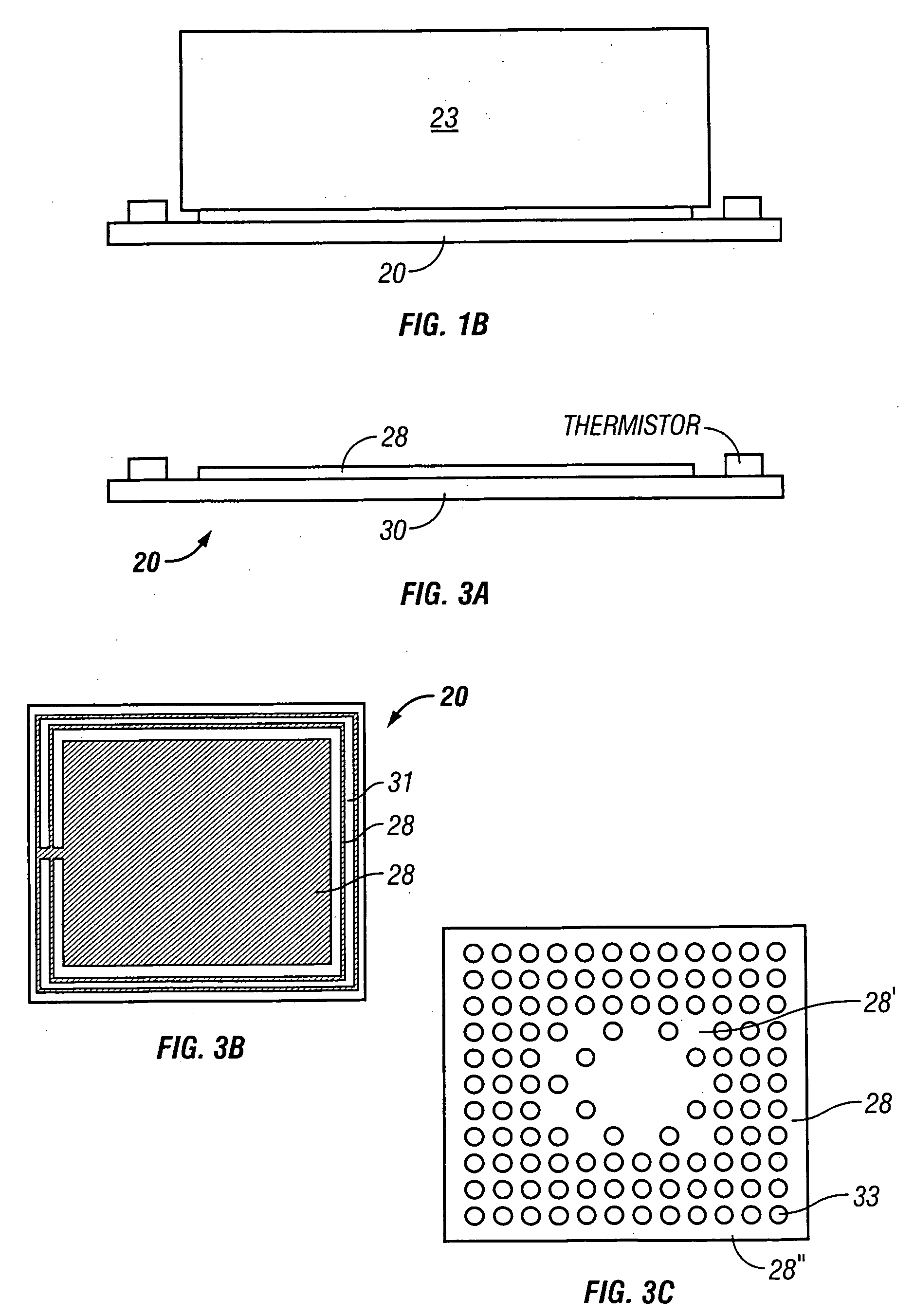

ActiveUS20050171582A1Reduce temperature differenceSurgical instruments for heatingTherapeutic coolingTemperature controlSurface cooling

The present invention provides devices and methods for treating tissue. In one embodiment the present invention provides a method of controlling a temperature of an applicator body, the method comprising providing an applicator body that comprises at least one contact surface A coolant is delivered through at least a portion of the applicator body at a substantially constant rate. Energy is delivered to the coolant through a heating element so that the contact surface of the applicator body is cooled to a desired temperature.

Owner:ASTORA WOMENS HEALTH

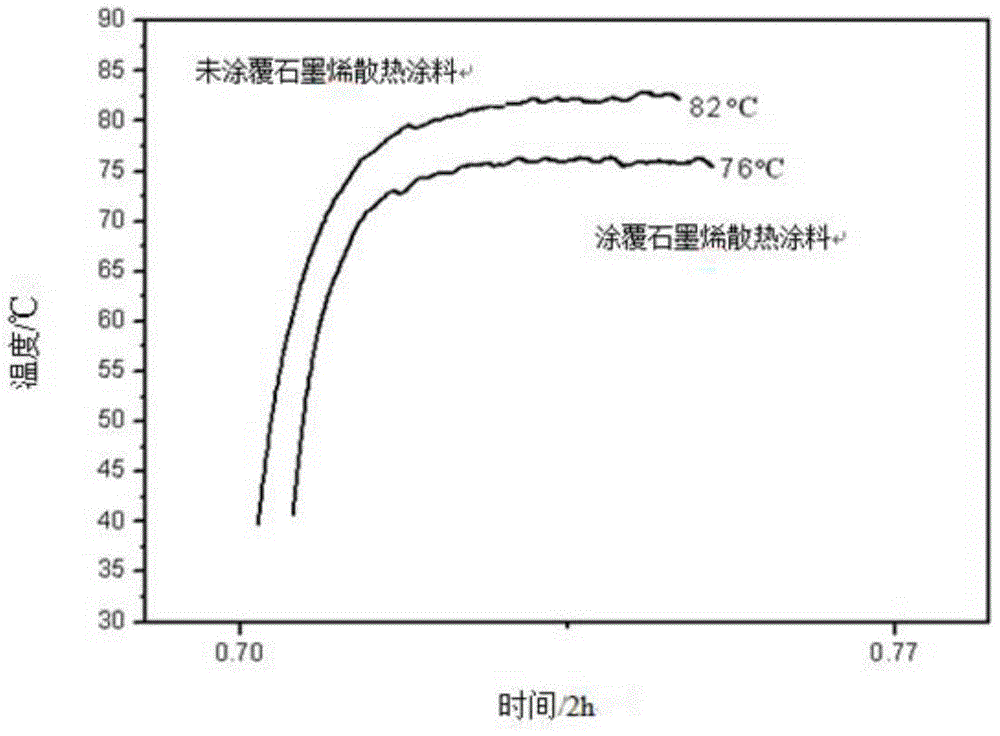

Efficient graphene-based cooling coating as well as preparation method and application thereof

InactiveCN104559424AEasy to stackGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsSurface coolingThin layer

The invention discloses an efficient graphene-based cooling coating as well as a preparation method and application thereof. The coating mainly consists of graphene composite powder, a filler, a high-molecular binder and a solvent, wherein the graphene composite powder mainly consists of thin-layer graphene and carbon black; the carbon black is mainly dispersed among the thin-layer graphene. Further, the graphene composite powder is formed by ultrasonically dispersing and mixing the thin-layer graphene powder and the carbon blank and then drying. When the coating is coated on the surfaces of devices, the surface cooling efficiency of the devices can be remarkably improved and the cooling ability of the cooling devices is greatly enhanced; the coating is antiseptic, waterproof, antifouling, stable in cooling property and free of being influenced by surrounding medium, and has wide application prospect and practical value in the electronic cooling field; meanwhile, the coating preparation process is simple, low in cost and suitable for large-scale production.

Owner:苏州格瑞丰纳米科技有限公司

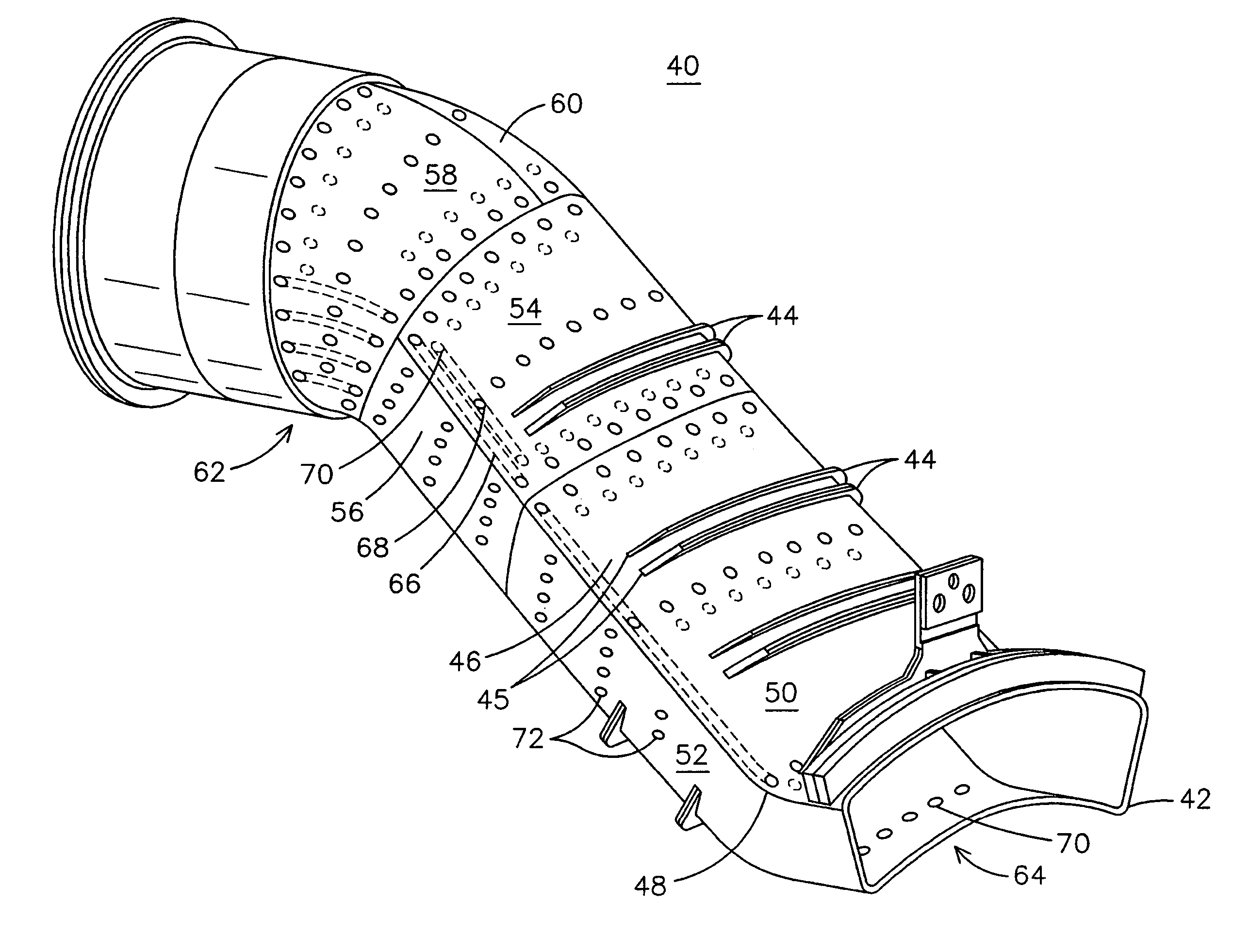

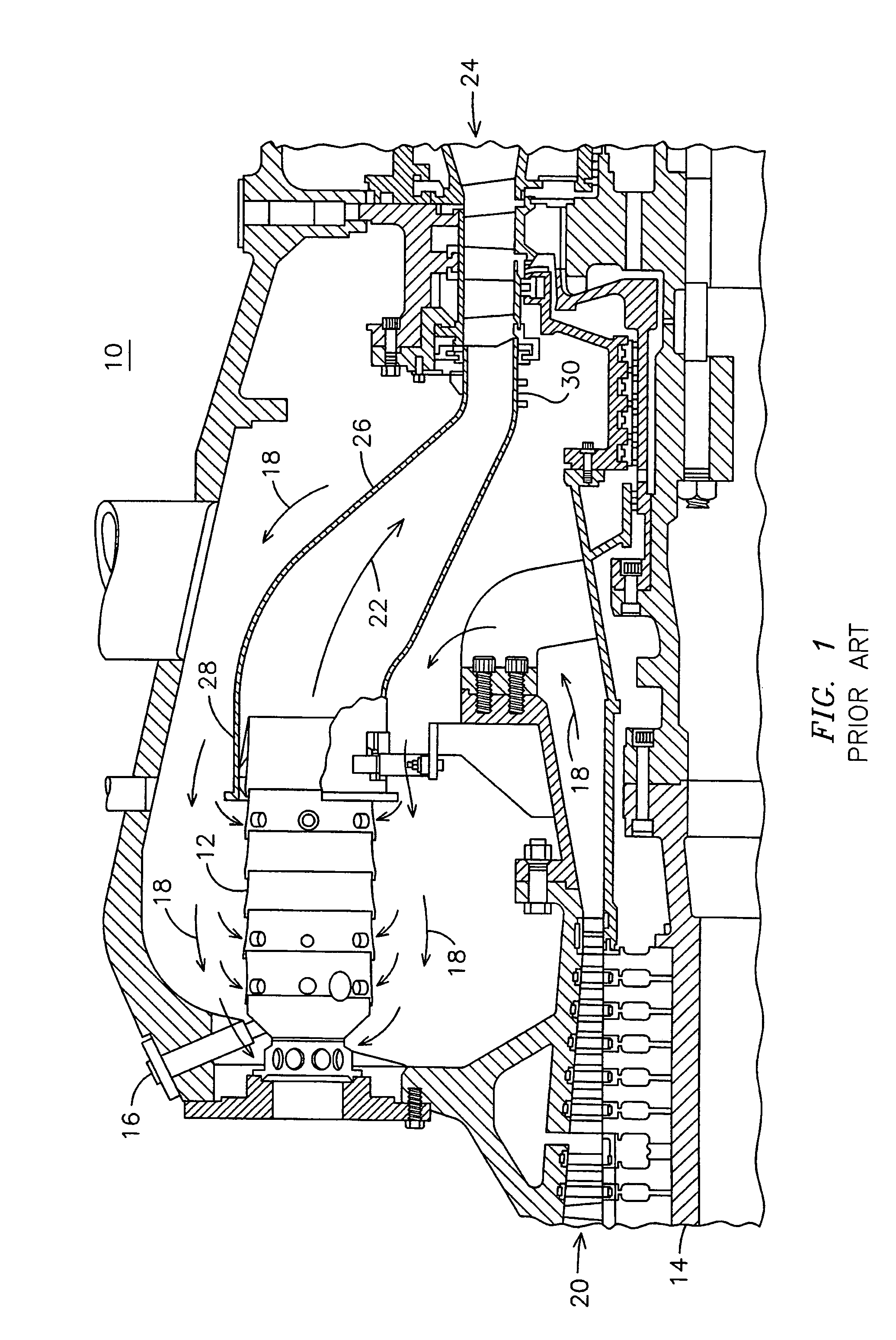

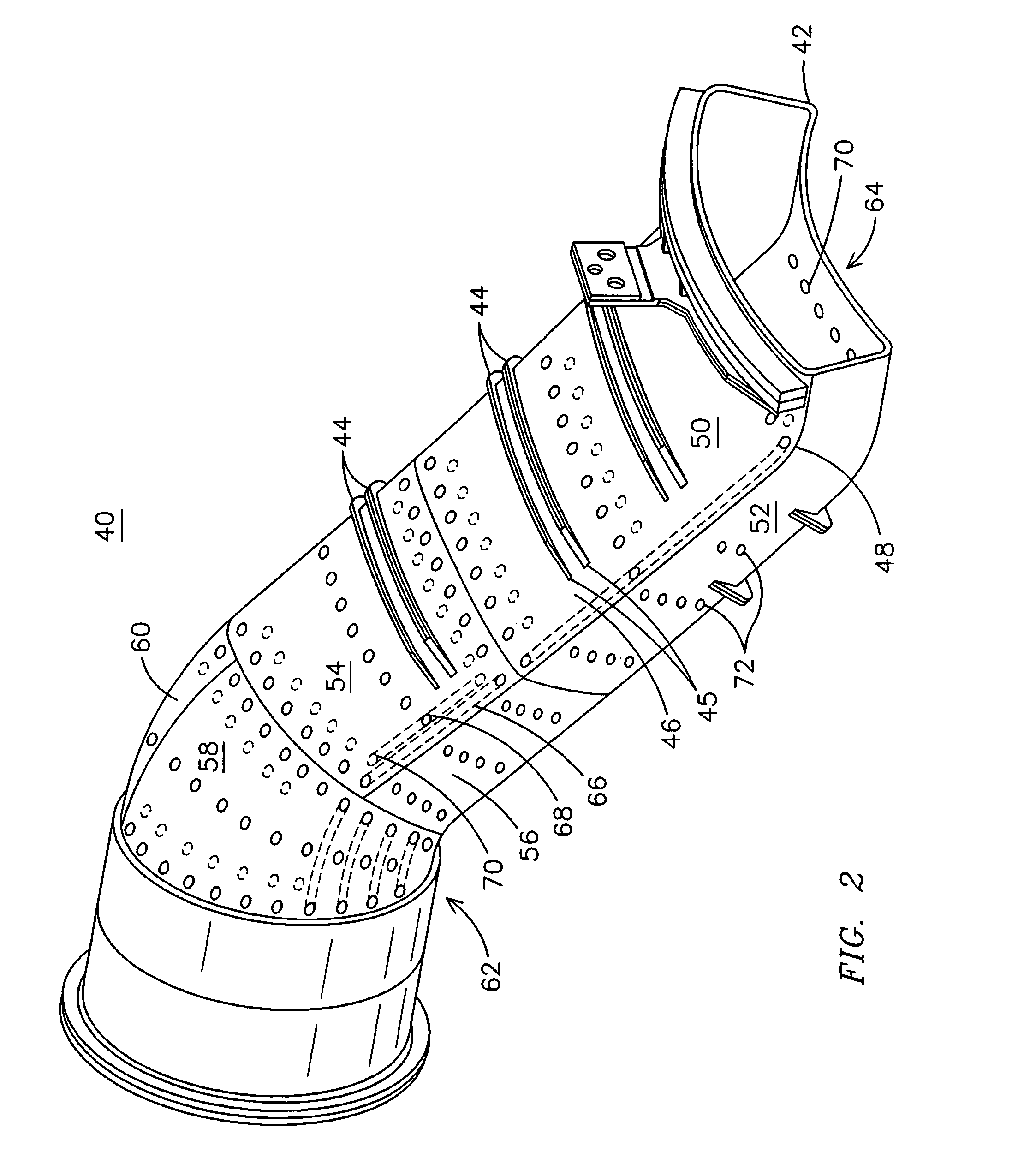

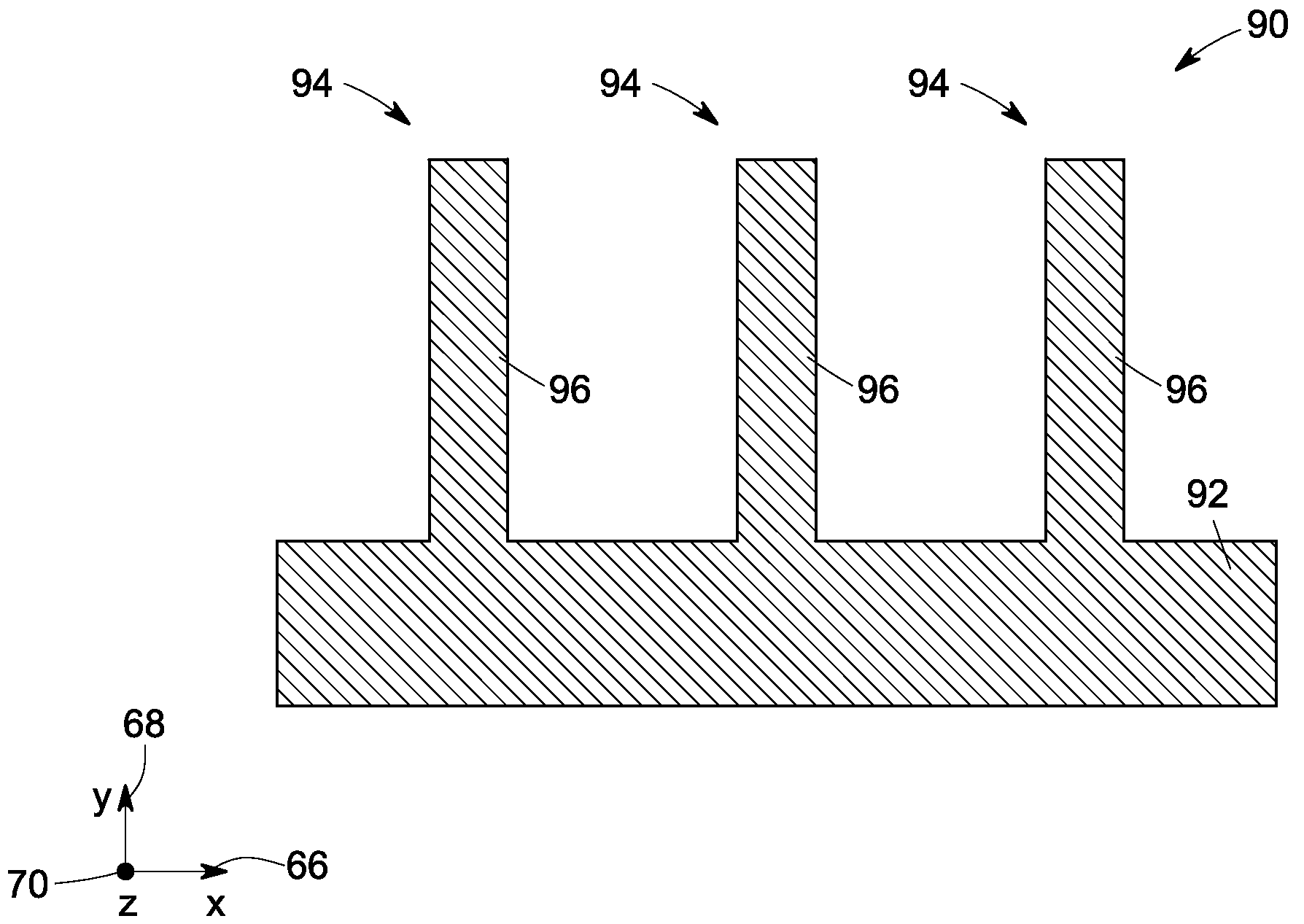

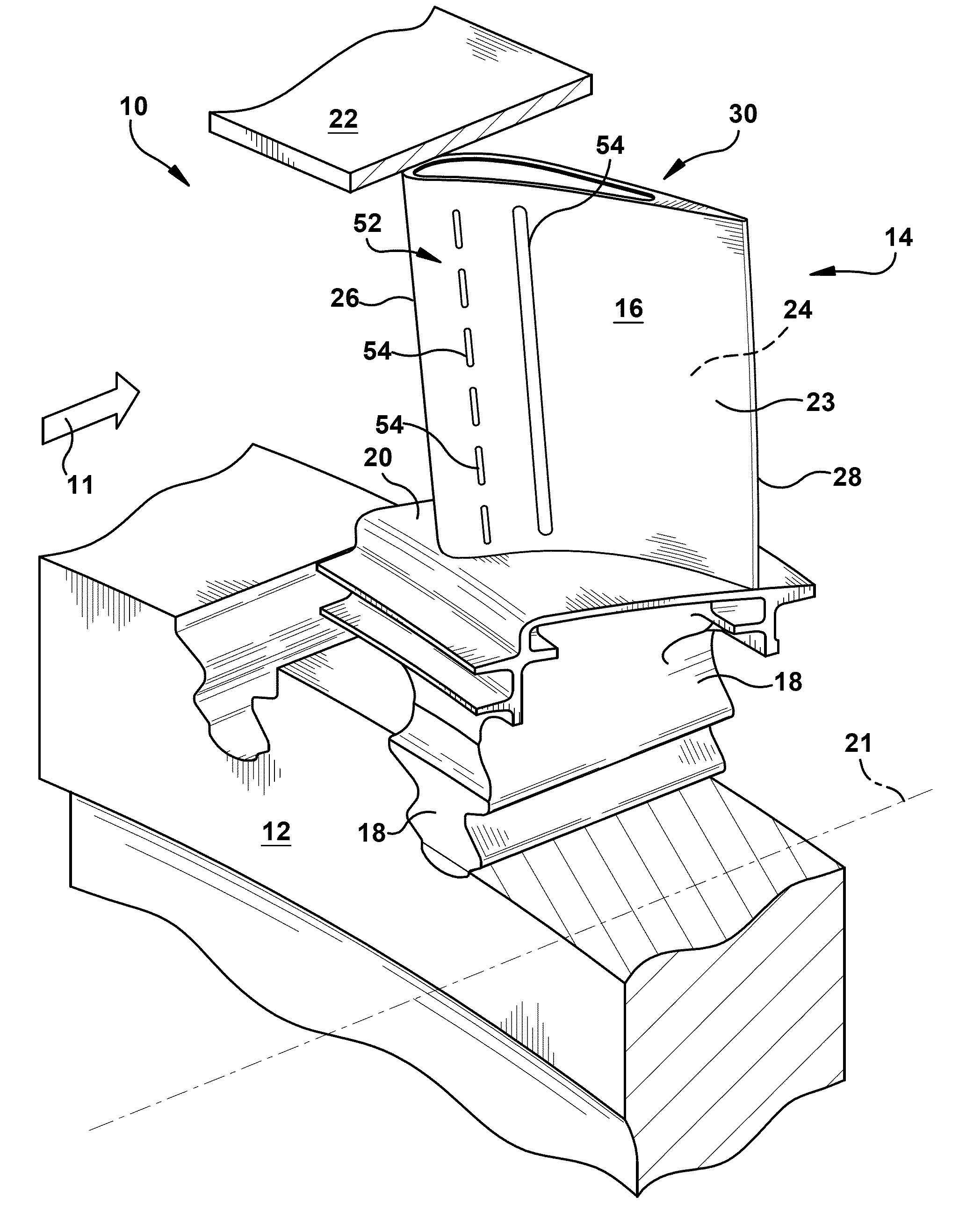

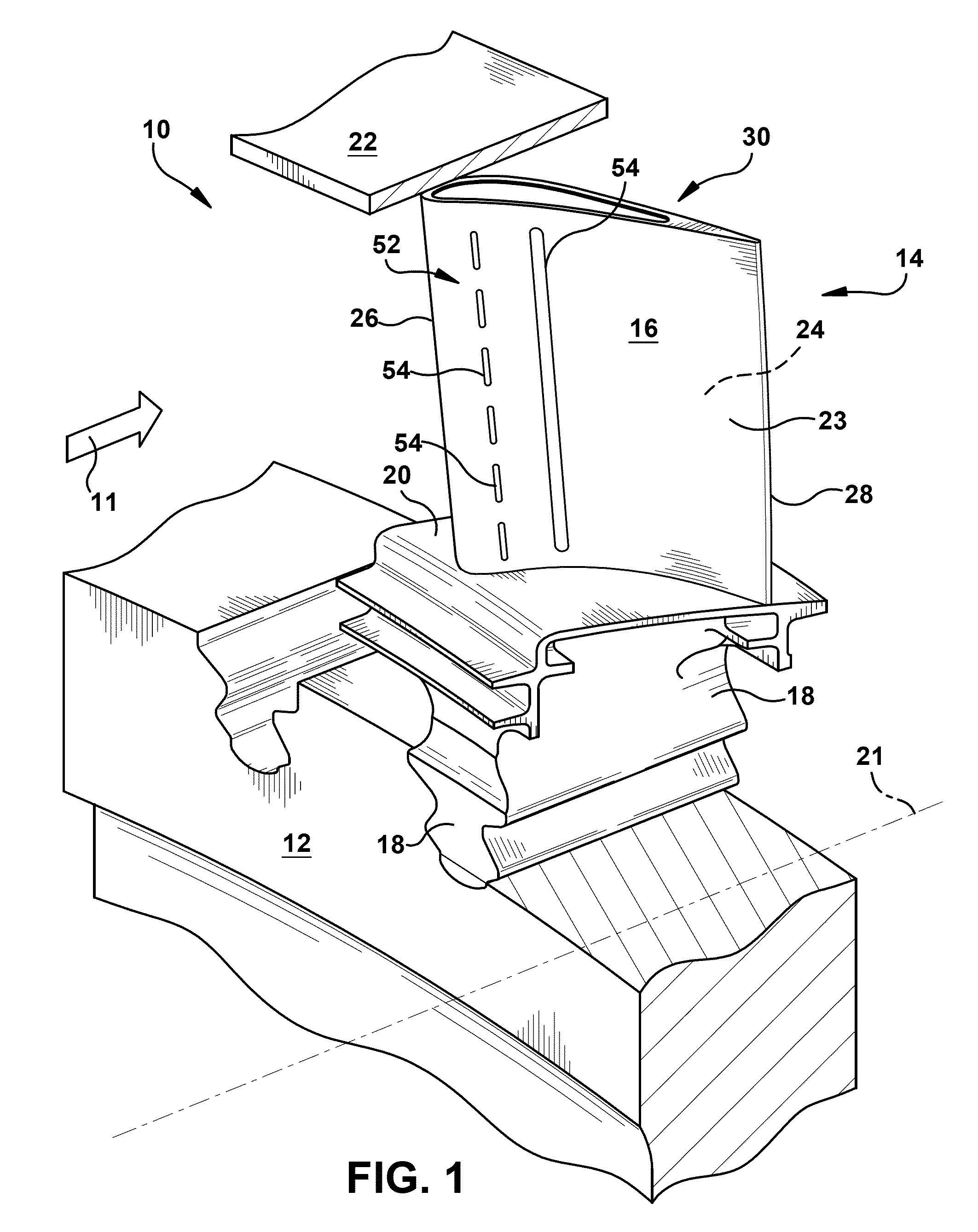

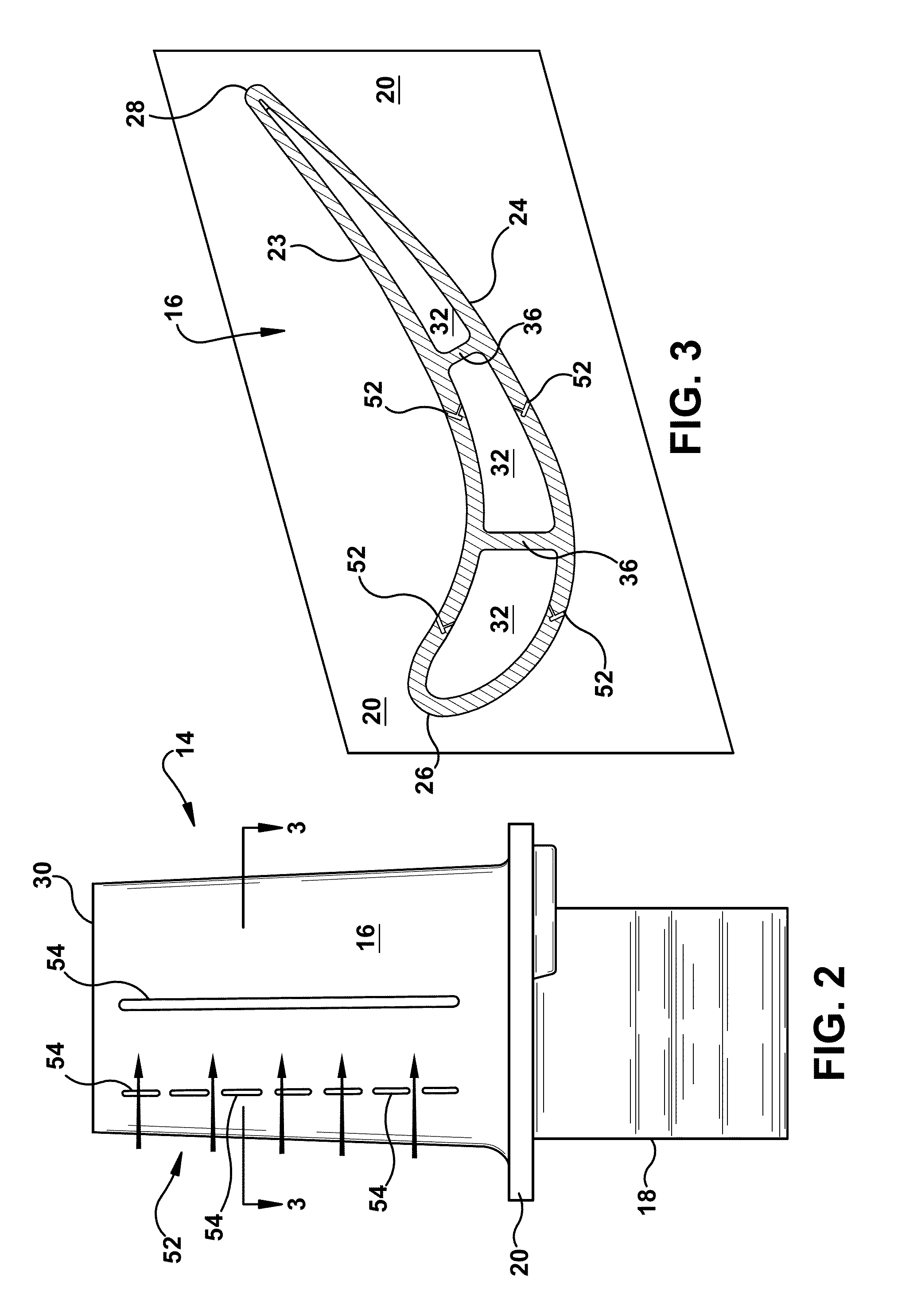

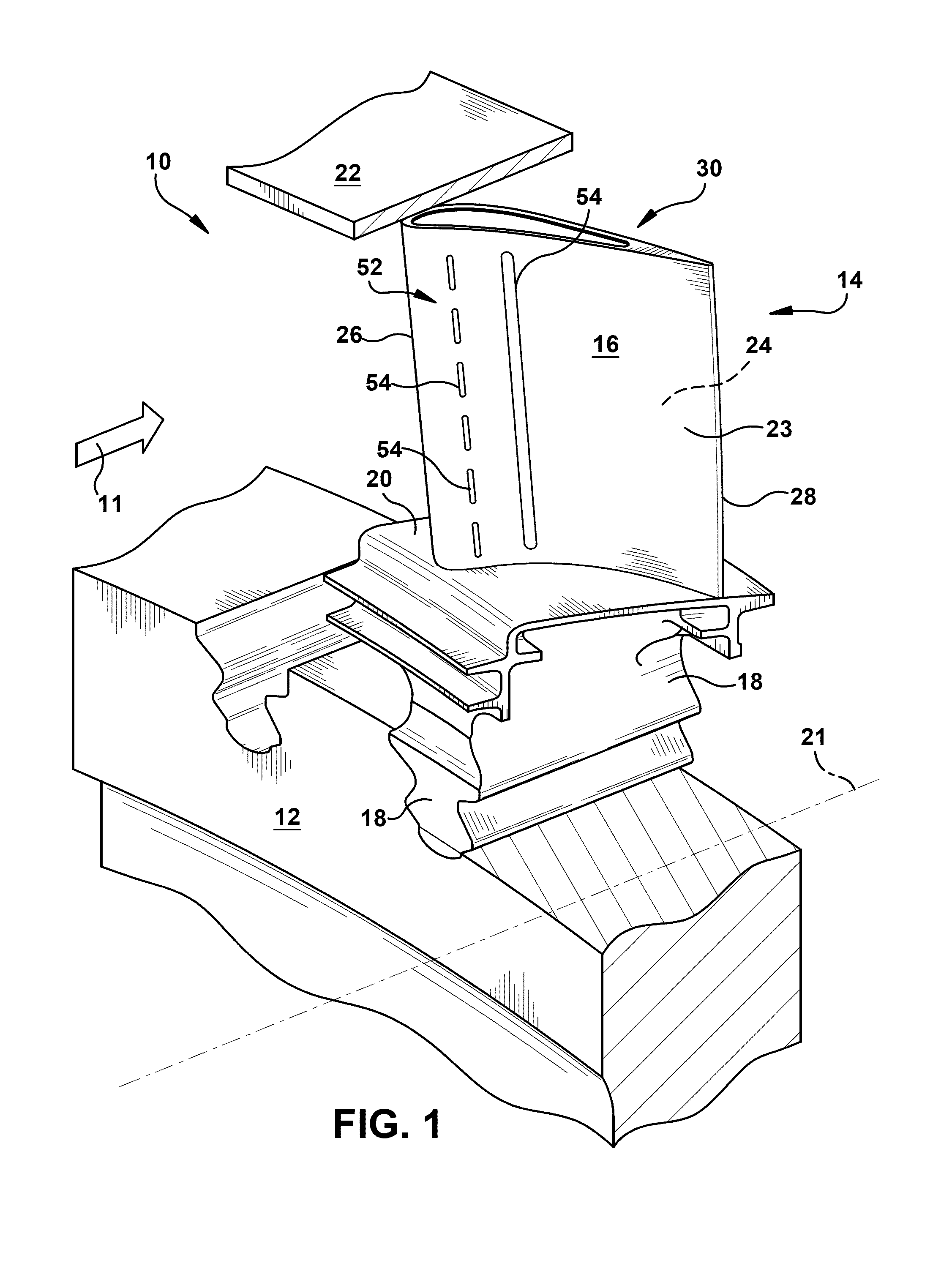

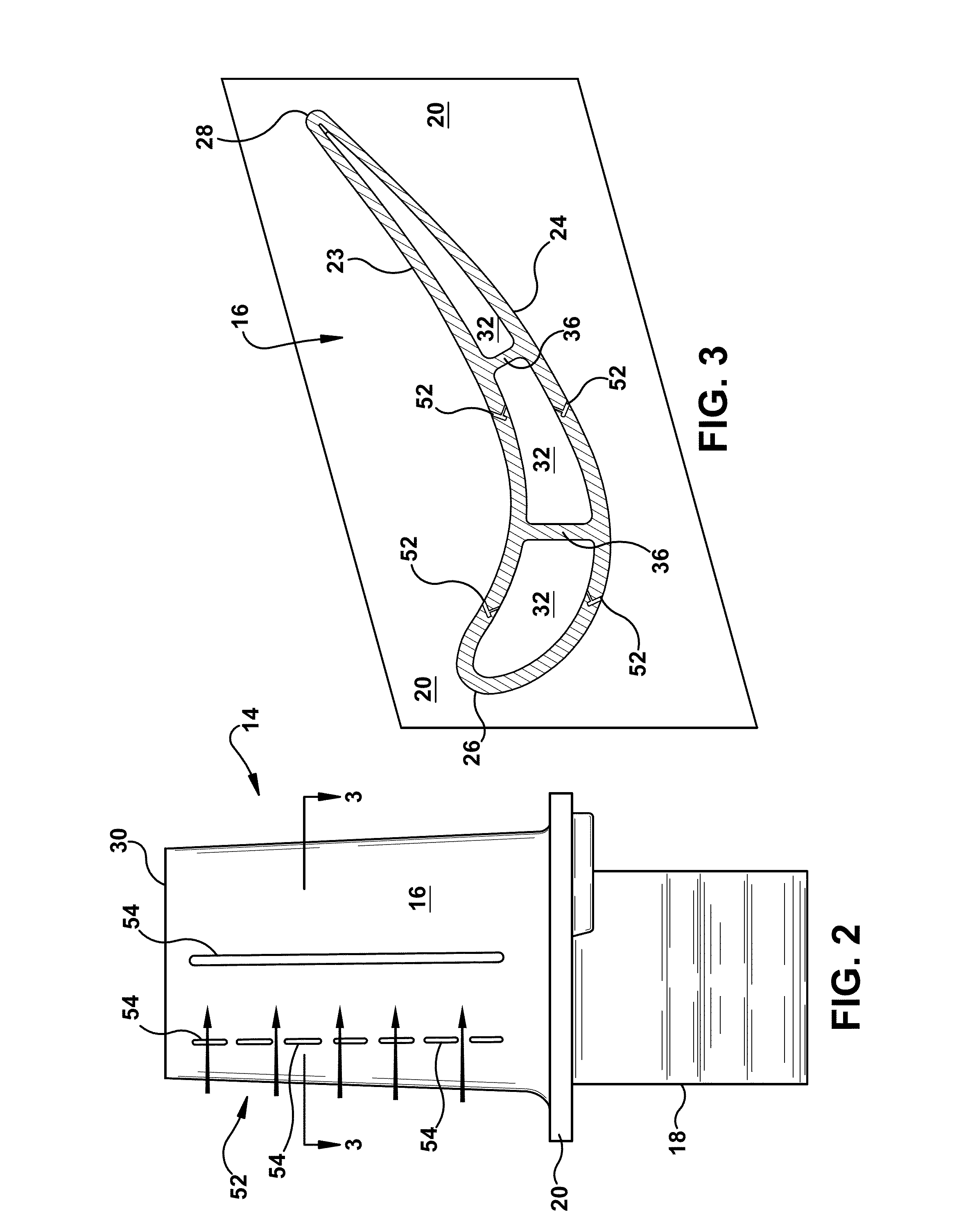

Cooled gas turbine transition duct

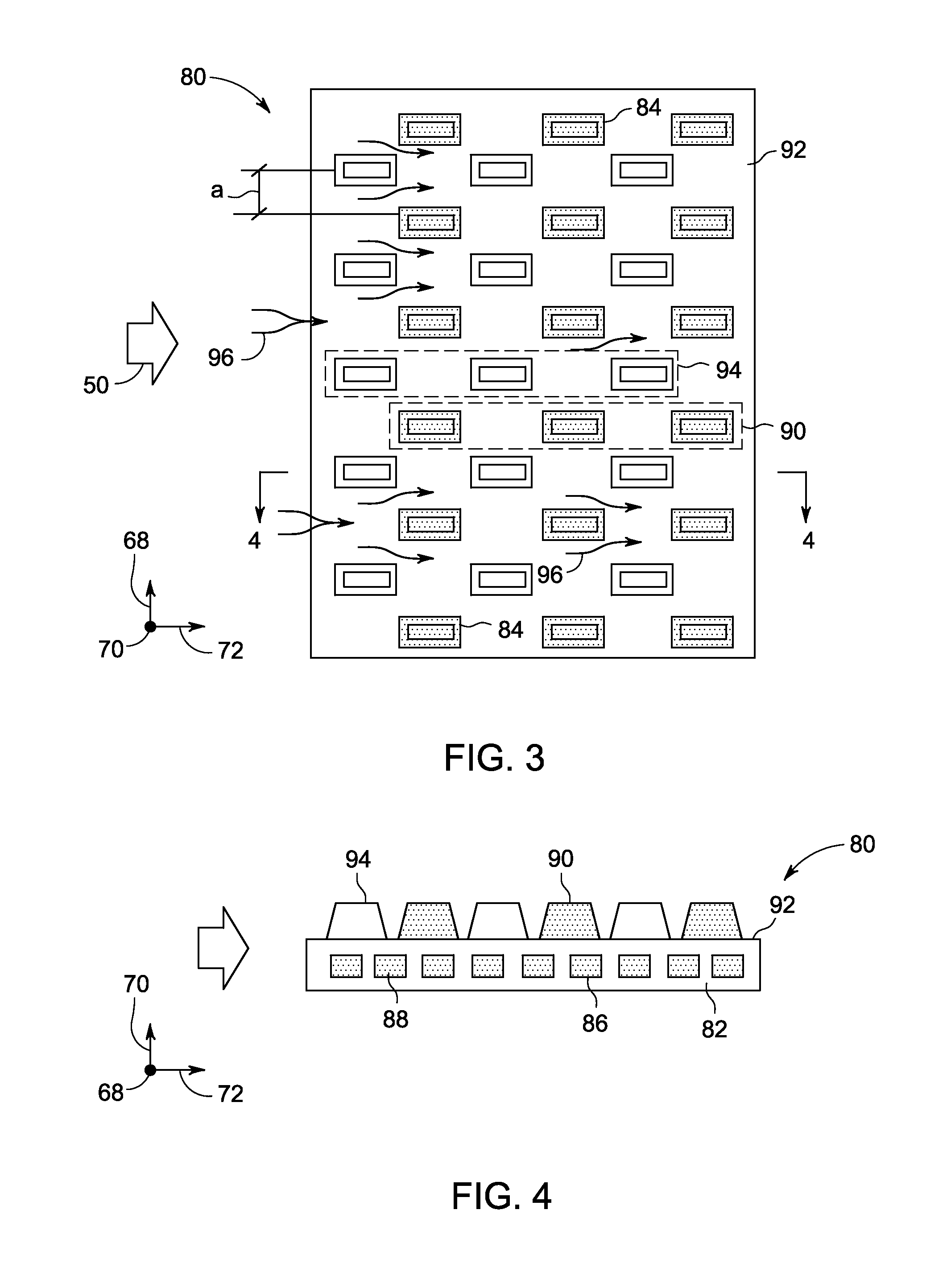

ActiveUS7310938B2Increase working temperatureSimple materialContinuous combustion chamberEngine fuctionsSurface coolingActive cooling

A transition duct (40) for a gas turbine engine (10) incorporating a combination of cooling structures that provide active cooling in selected regions of the duct while avoiding cooling of highly stressed regions of the duct. In one embodiment, a panel (74) formed as part of the transition duct includes some subsurface cooling holes (92) that extend under a central portion of a stiffening rib (90) attached to the panel and some subsurface cooling holes (94) that have a truncated length so as to avoid extending under a rib end (45). Effusion cooling holes (88) used to cool a side subpanel (48) of the panel may have a distribution that reduces to zero approaching a double bend region (48) of the panel. An upstream subpanel (76) of the panel may be actively cooled only when the panel is located on an extrados of the transition duct.

Owner:SIEMENS ENERGY INC

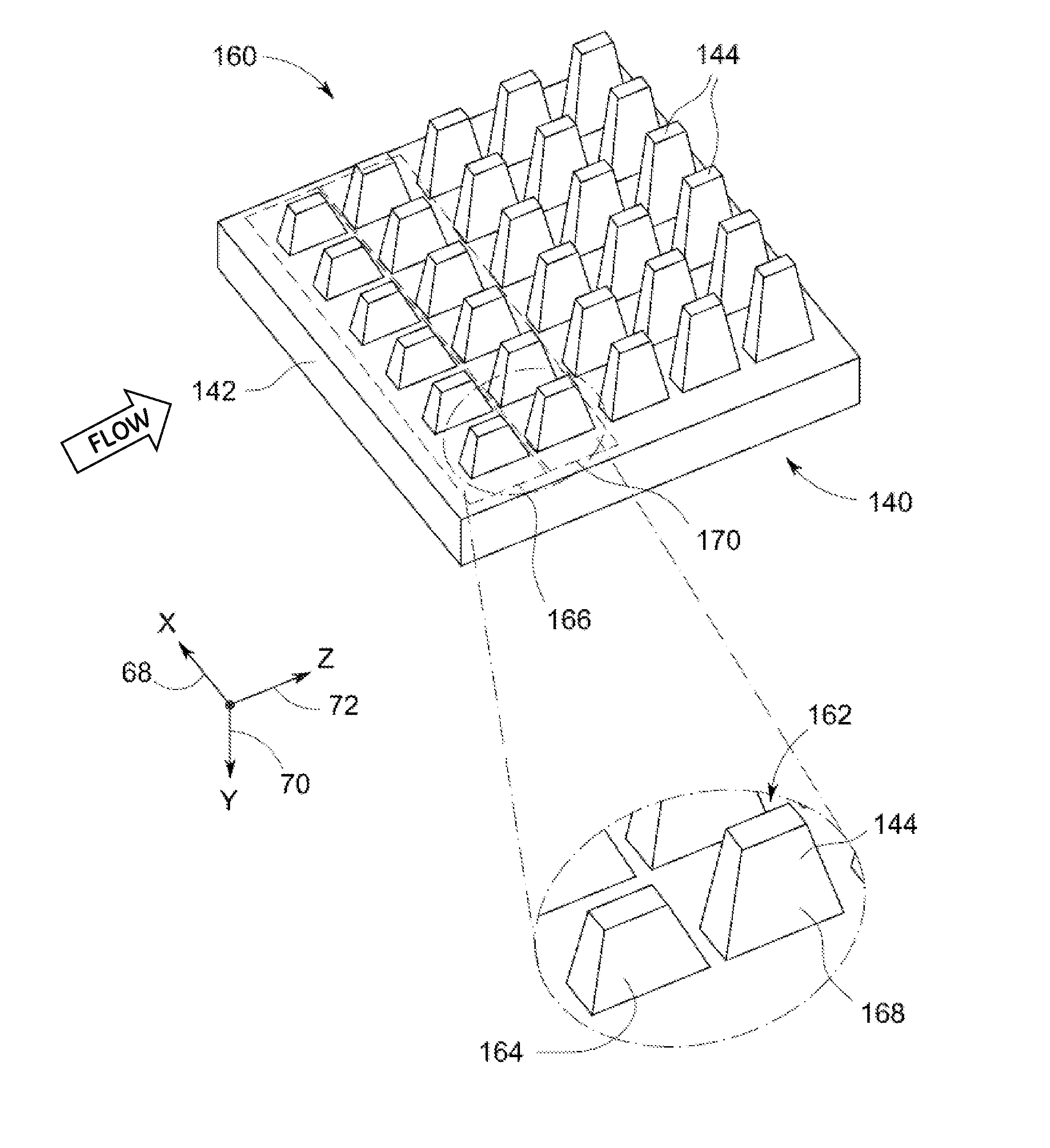

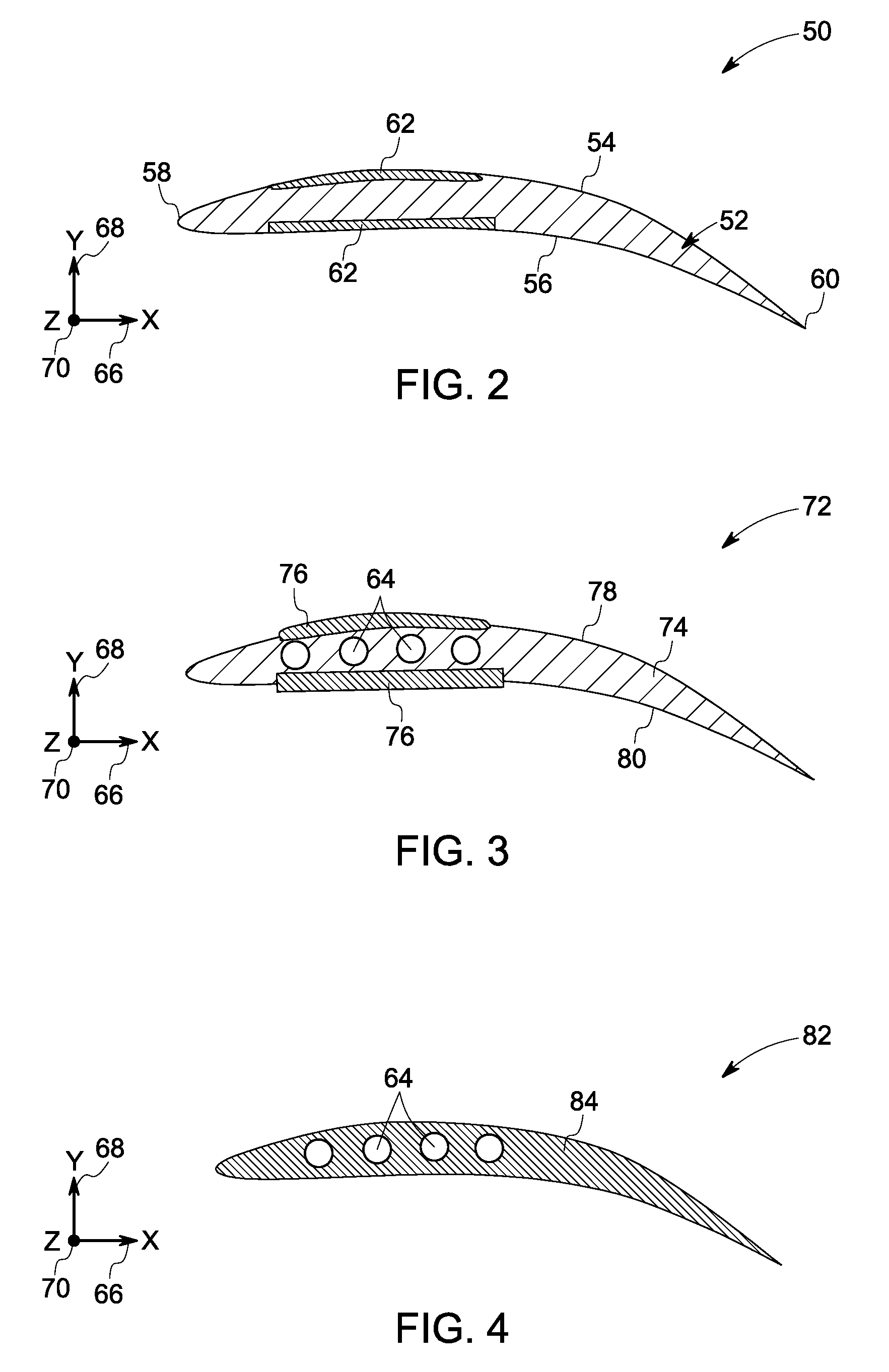

Air-cooled engine surface cooler

ActiveUS20140027102A1Improve heat transfer performanceIncreasing turbulence levelEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

A surface cooler comprises a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

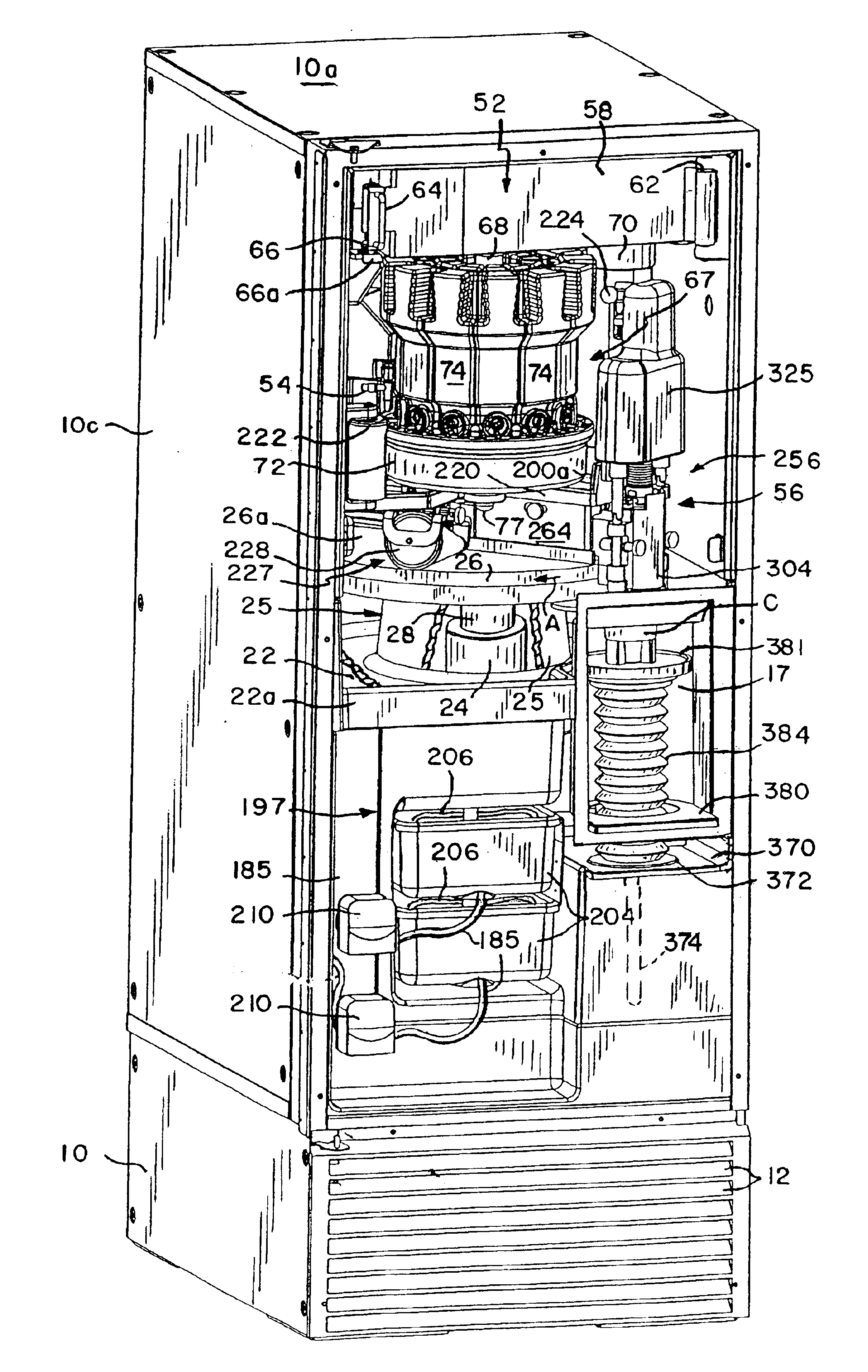

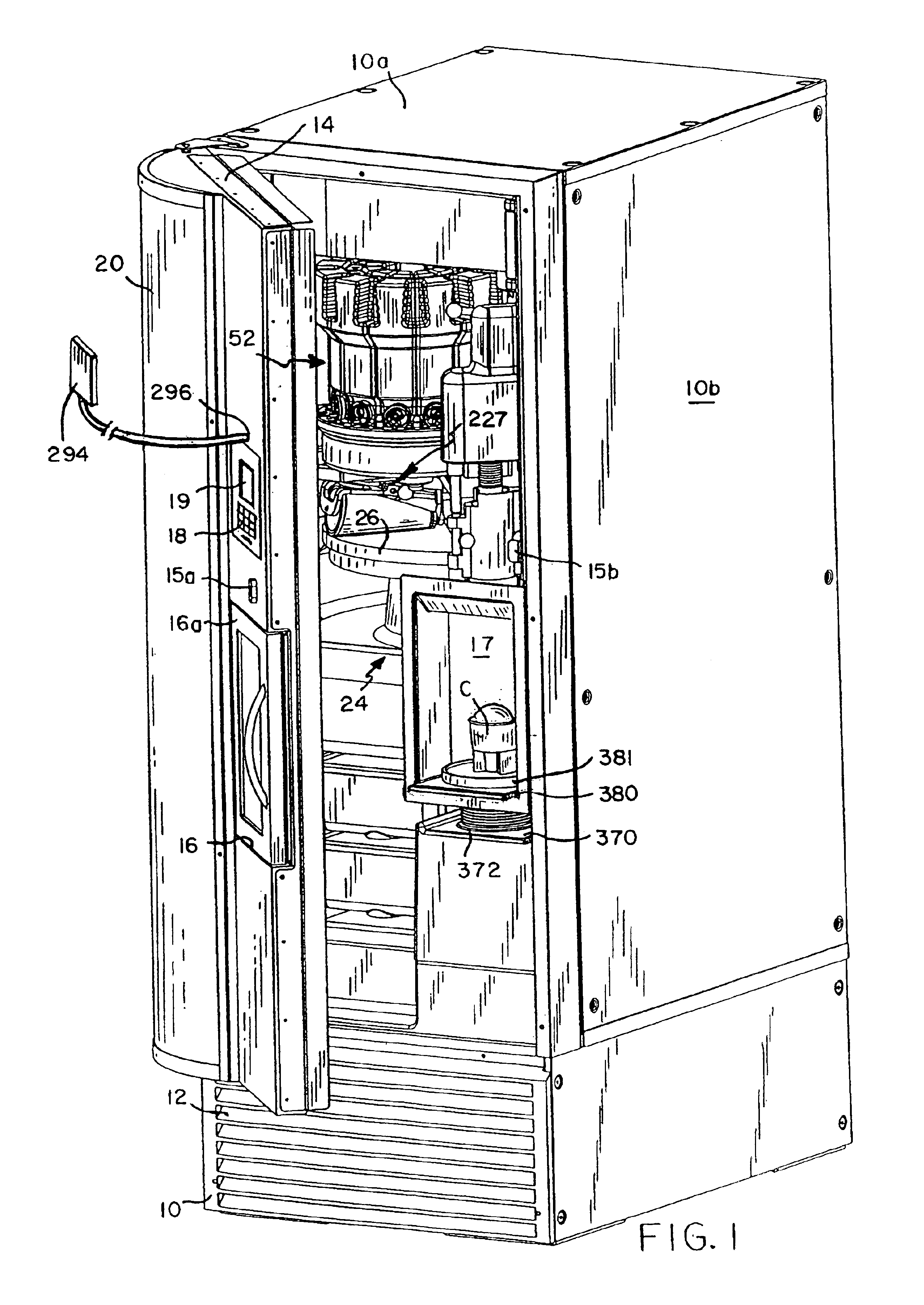

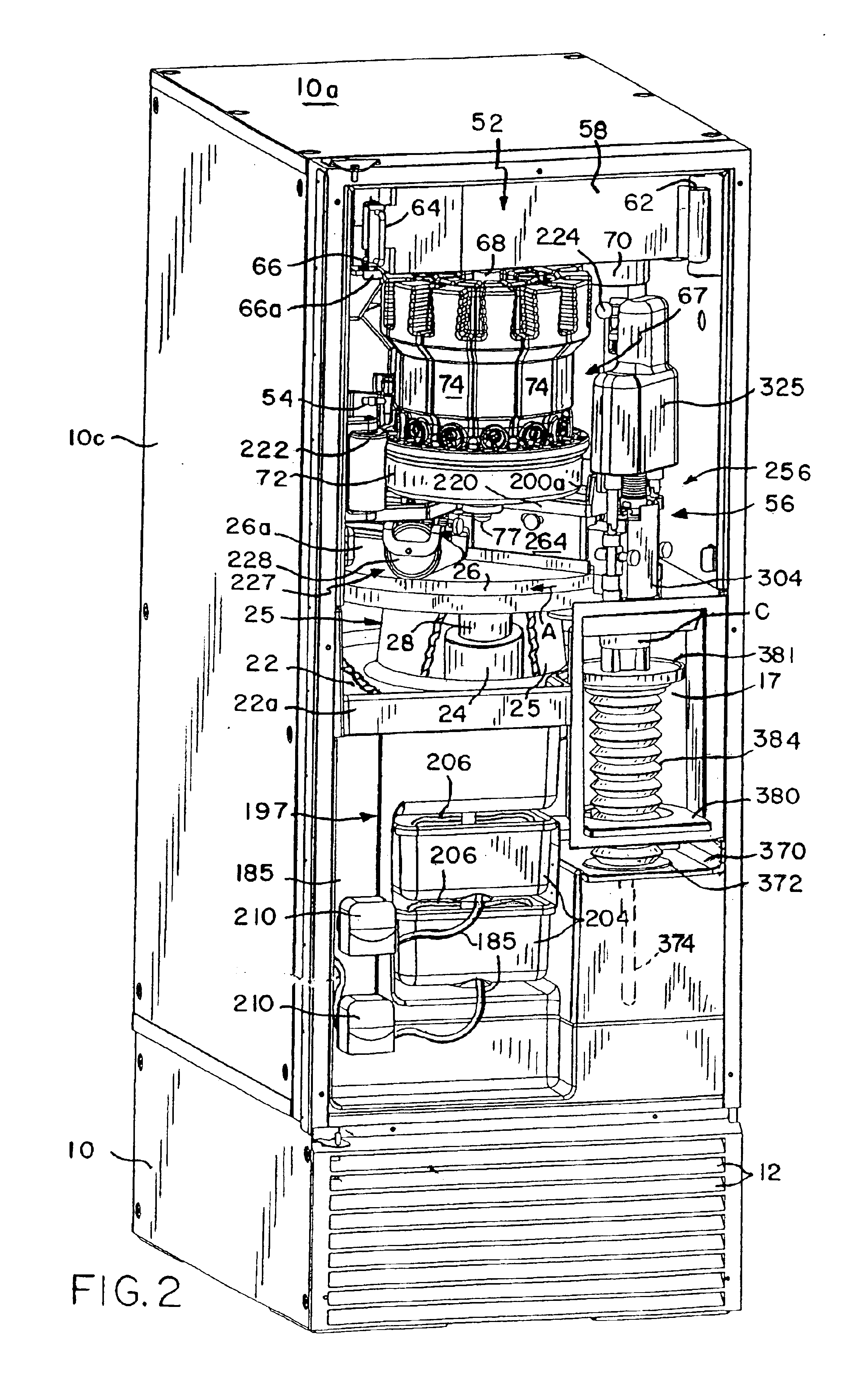

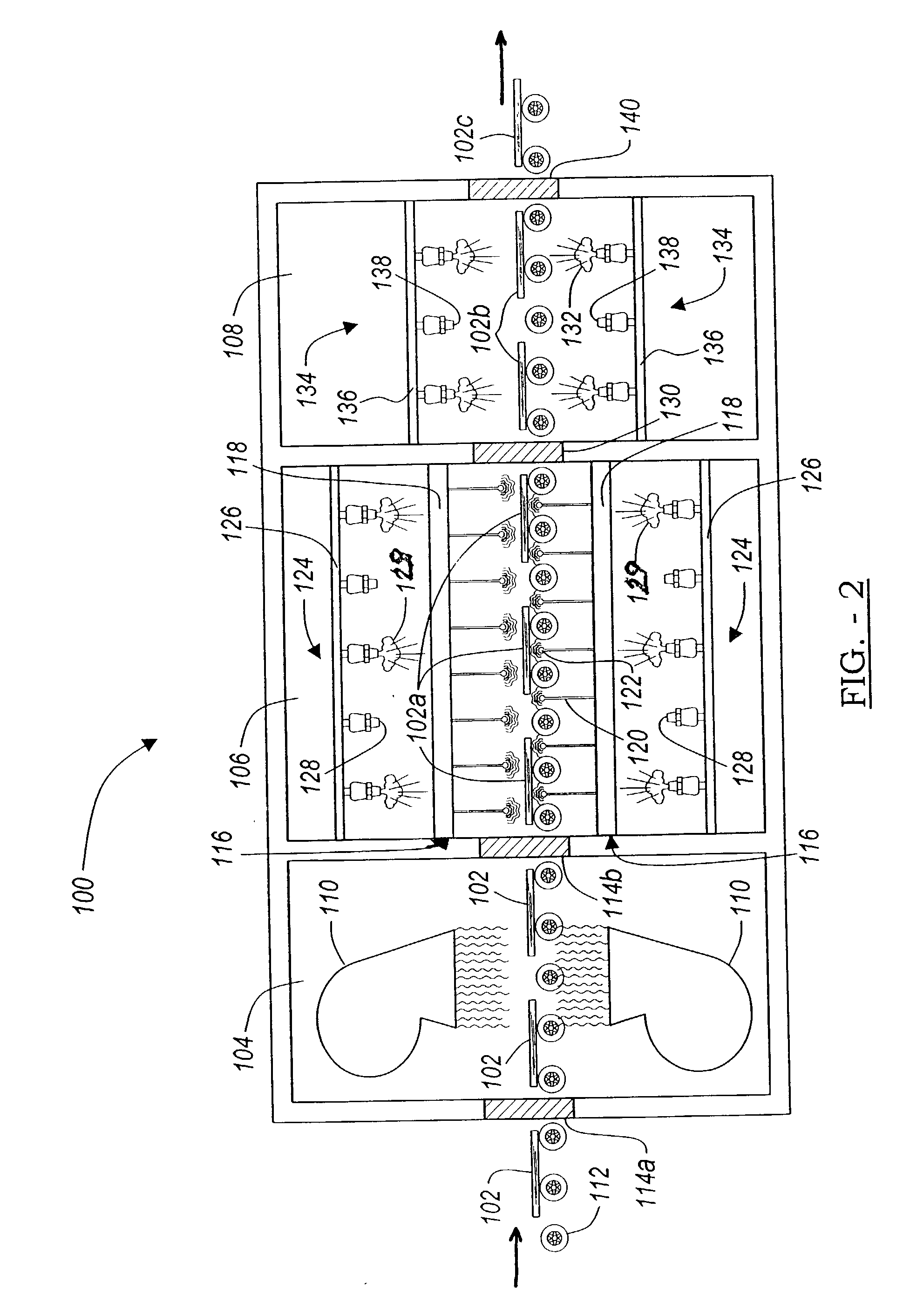

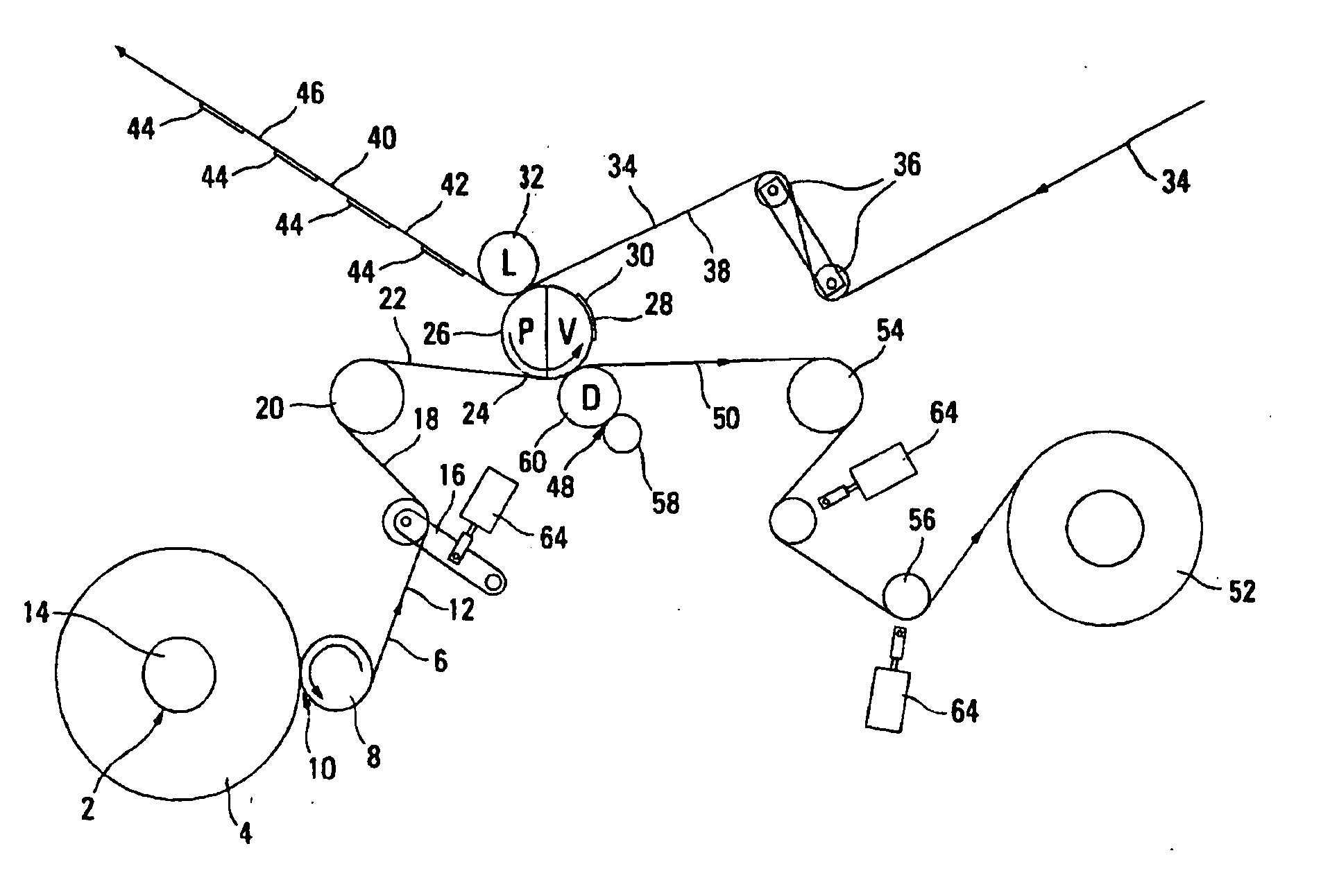

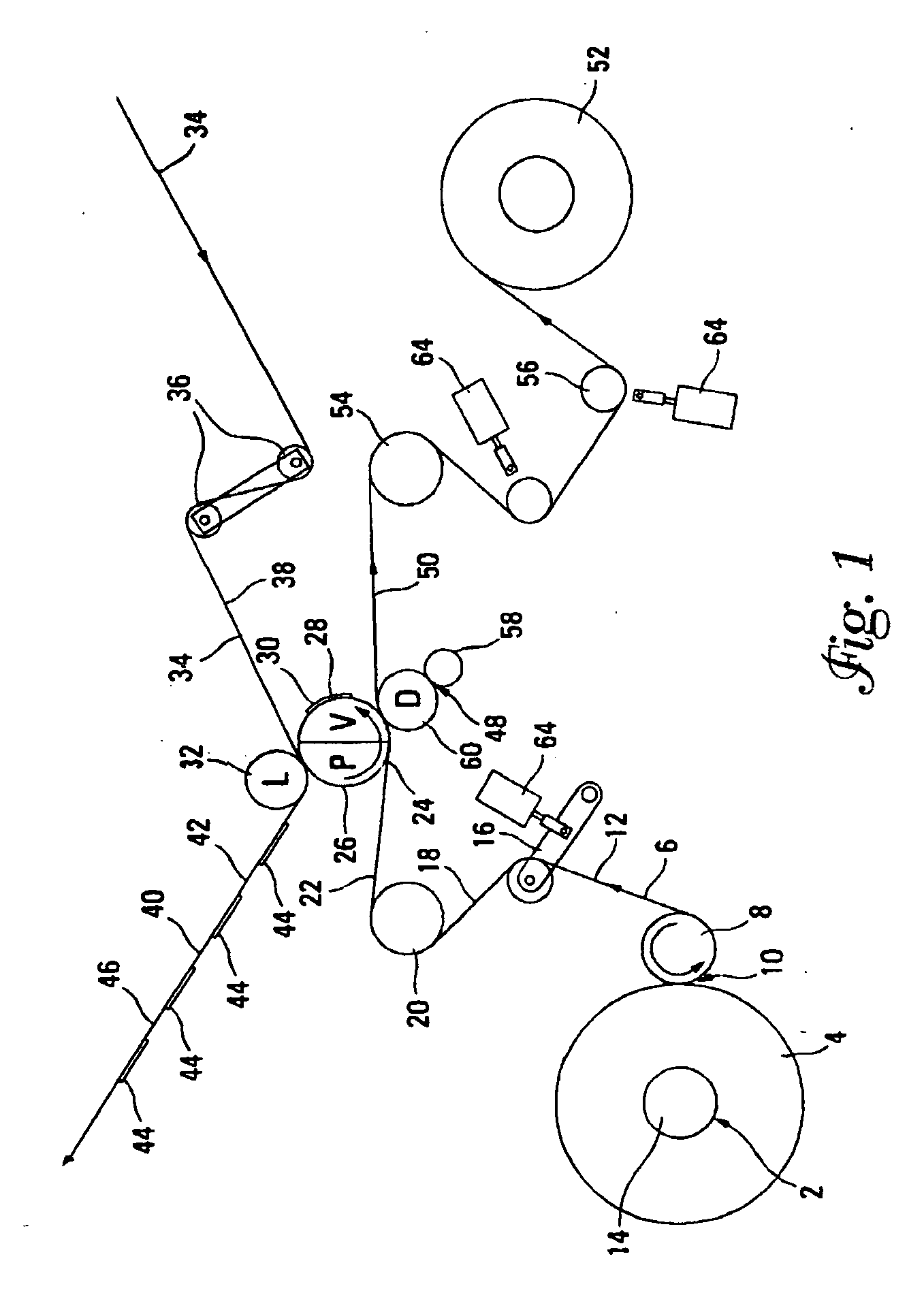

Method for producing and dispensing an aerated and/or blended food product

A method of dispensing a food product composed of a plurality of ingredients which are mixed to form the food product, includes the steps of providing a rotary surface having a rotary axis and a periphery, mixing together first and second fluid ingredients to form a liquid product mix, depositing the liquid product mix onto the surface while rotating the surface so that the liquid product mix spreads out on the surface in a layer, cooling the surface to a temperature low enough to at least partially freeze said layer to form a frozen product body, removing the product body from the surface as product body scrapings, and collecting and compacting the scrapings to form the food product.

Owner:KATEMAN PAUL R +1

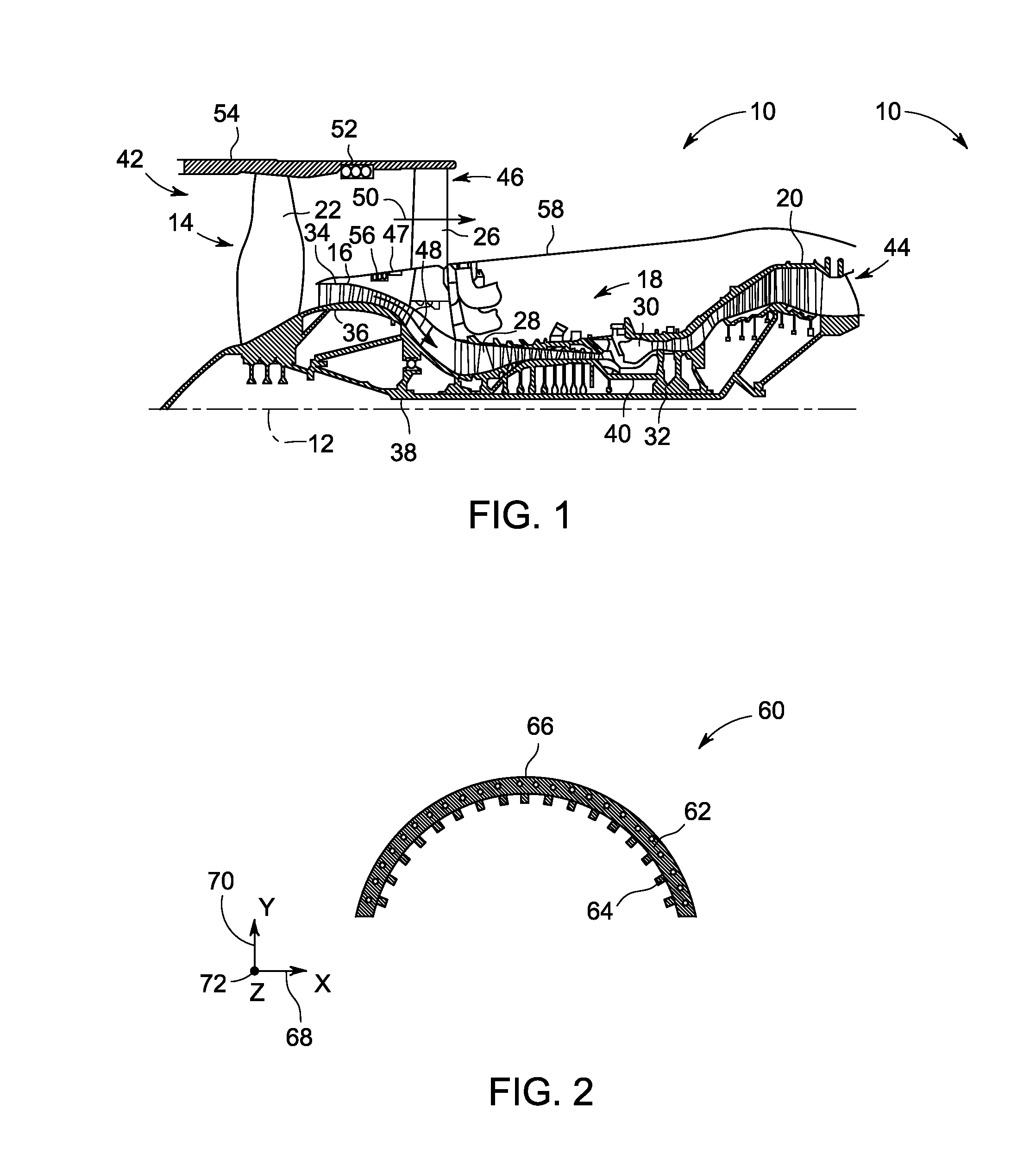

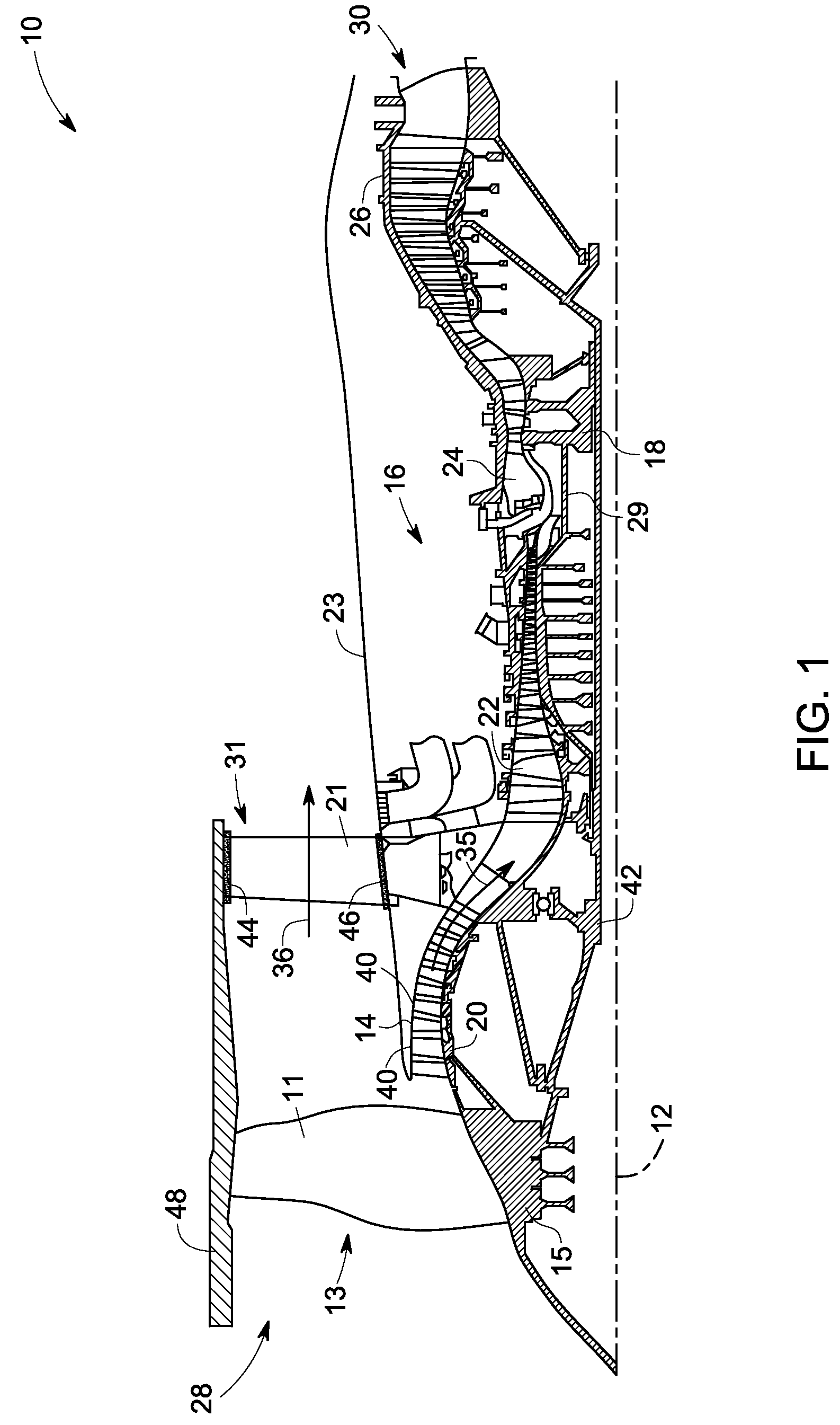

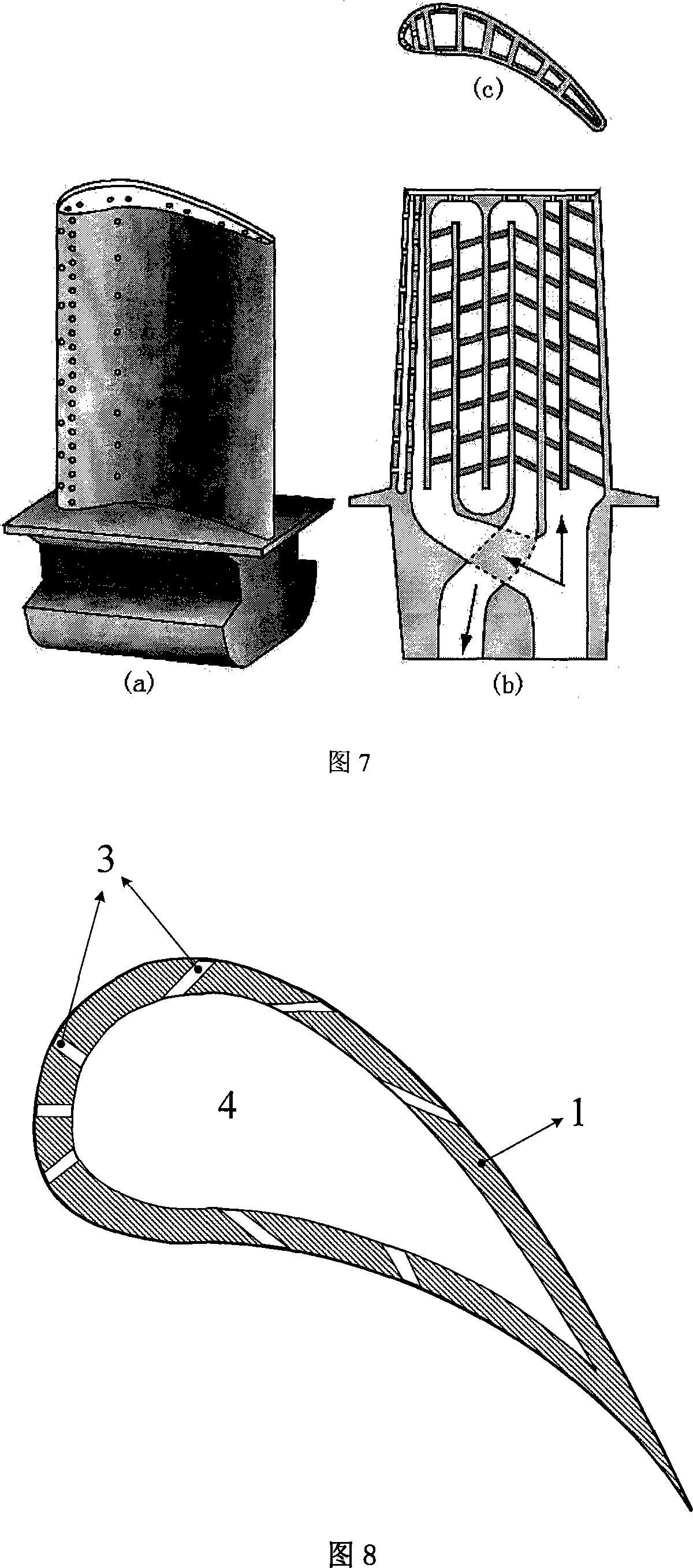

Combined acoustic absorber and heat exchanging outlet guide vanes

ActiveUS20090317238A1Improve heat transfer performanceImprove sound absorptionPump componentsEngine fuctionsSurface coolingAcoustic absorption

An outlet guide vane assembly for turbomachines is provided. The outlet guide vane assembly comprises one or more outlet guide vanes, wherein each of the one or more outlet guide vanes comprises a first surface and a second surface, and wherein the one or more outlet guide vanes are disposed between an inner wall and an outer wall of an engine and a surface cooler layer disposed on at least a portion of the first surface, the second surface, or both of the one or more outlet guide vanes, wherein the surface cooler layer comprises a metal foam, a carbon foam, or a combination thereof, wherein the metal foam, the carbon foam or the combination thereof is configured to augment heat transfer and enhance acoustic absorption.

Owner:GENERAL ELECTRIC CO

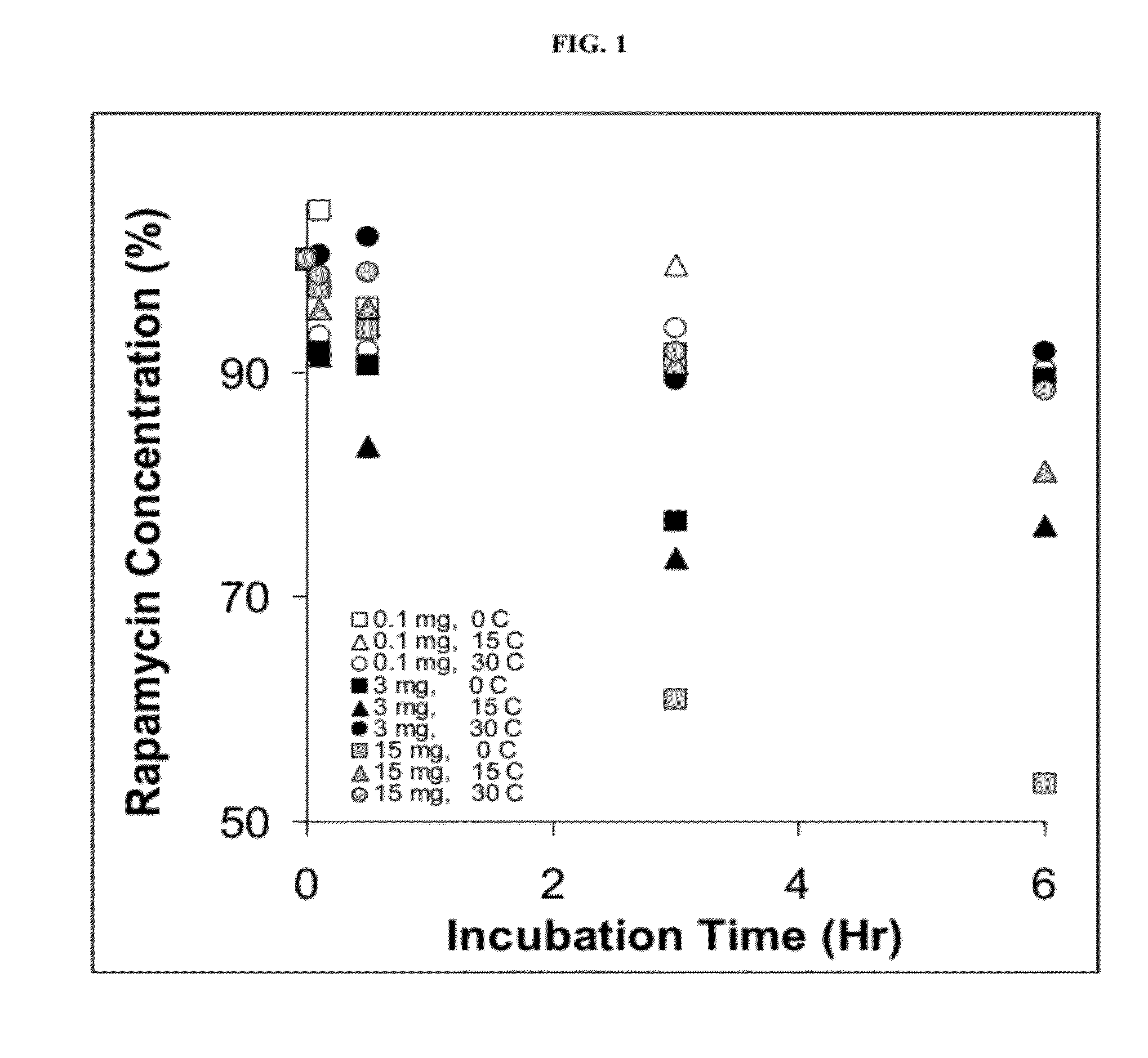

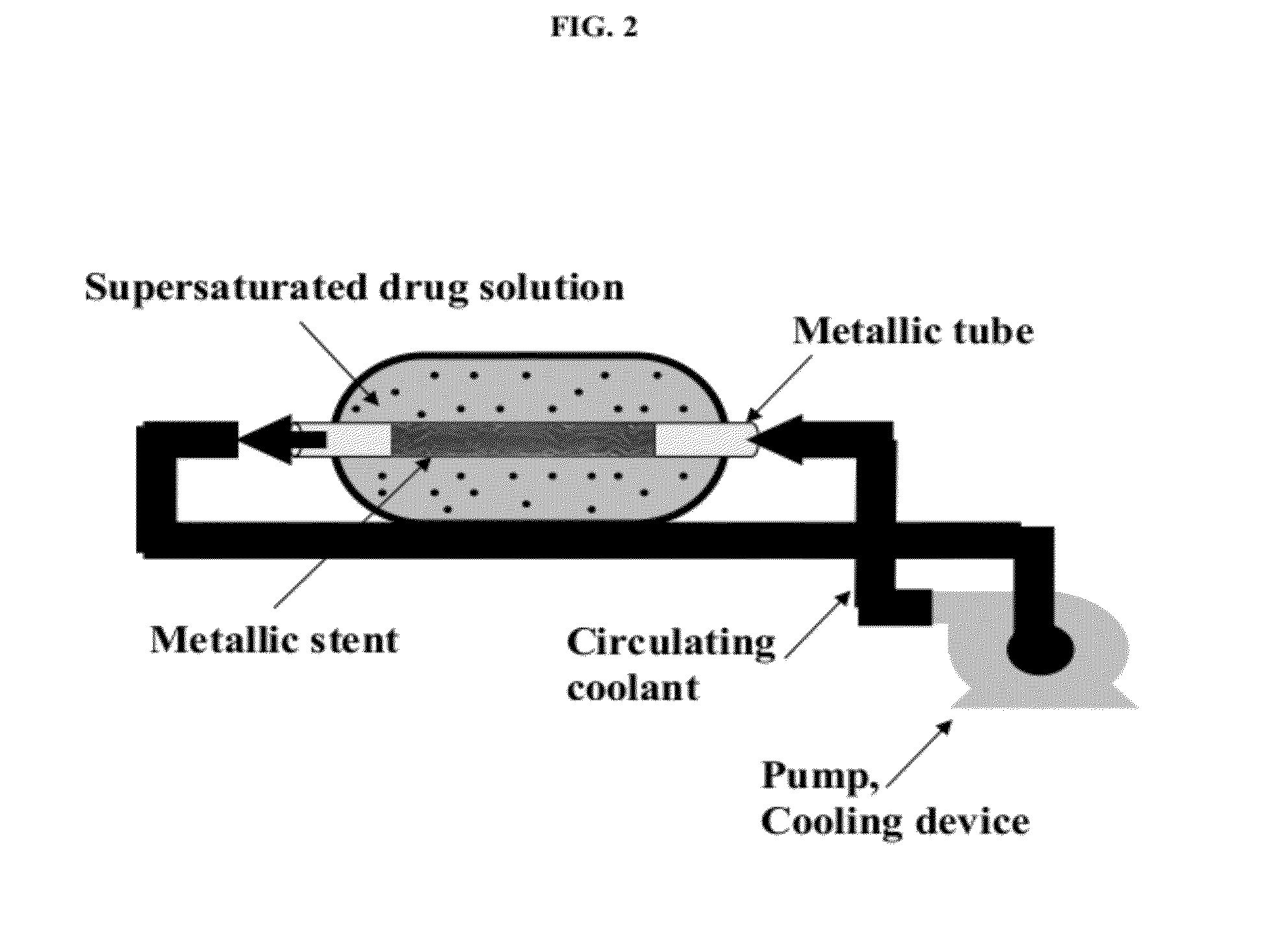

Crystalline drug-containing coatings

Articles-of-manufacturing comprising an object having a surface and a therapeutically active agent being deposited onto at least a portion of the surface, while at least a portion of said therapeutically active agent being in a crystalline form thereof are disclosed. Methods utilizing such articles-of-manufacturing for treating medical conditions are also disclosed. Processes of preparing the articles-of-manufacturing by contacting a surface of the object with a solution containing the therapeutically active agent; and cooling the surface to a temperature below a temperature of the solution, and apparatus for performing these processes, are also disclosed.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

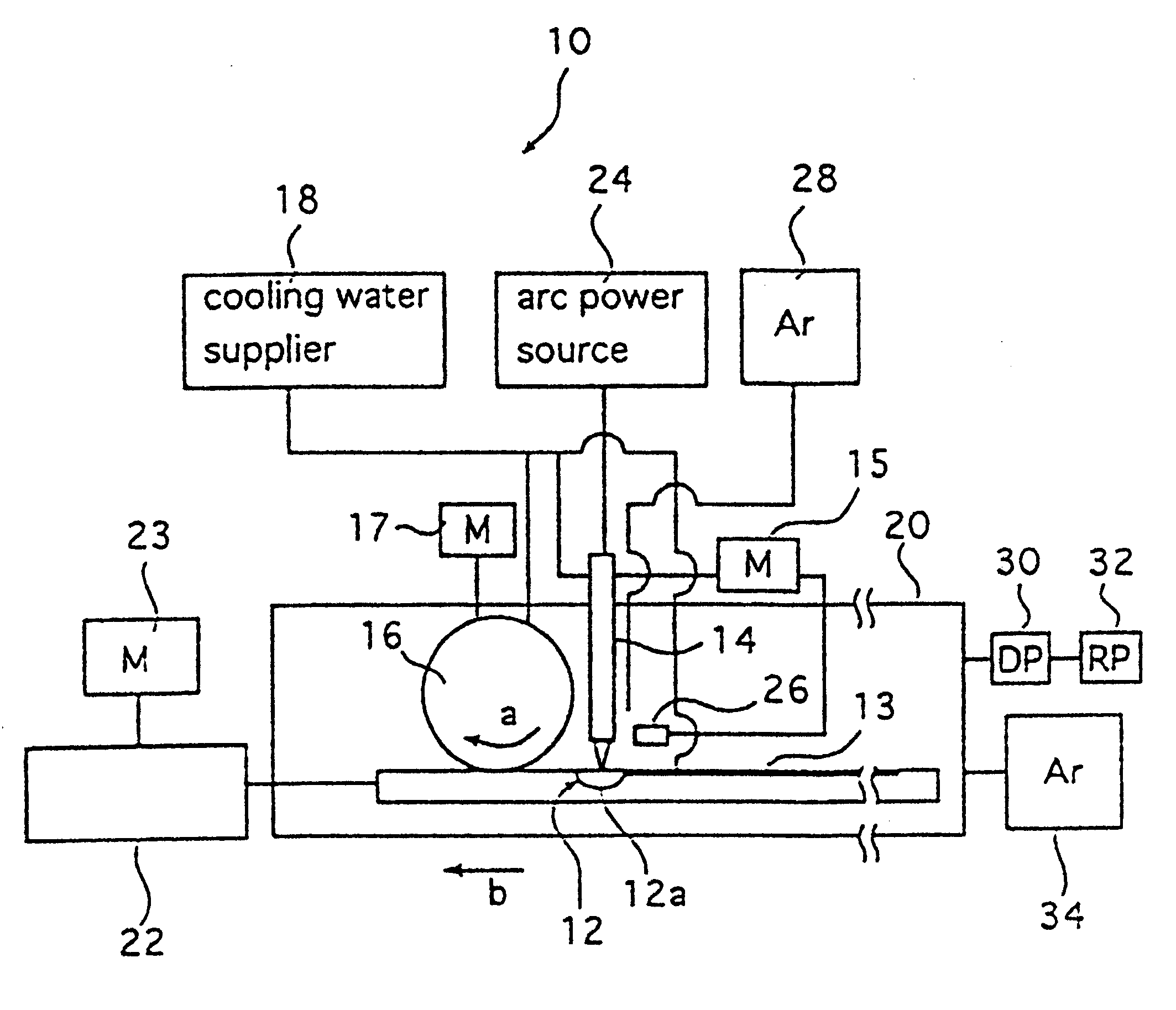

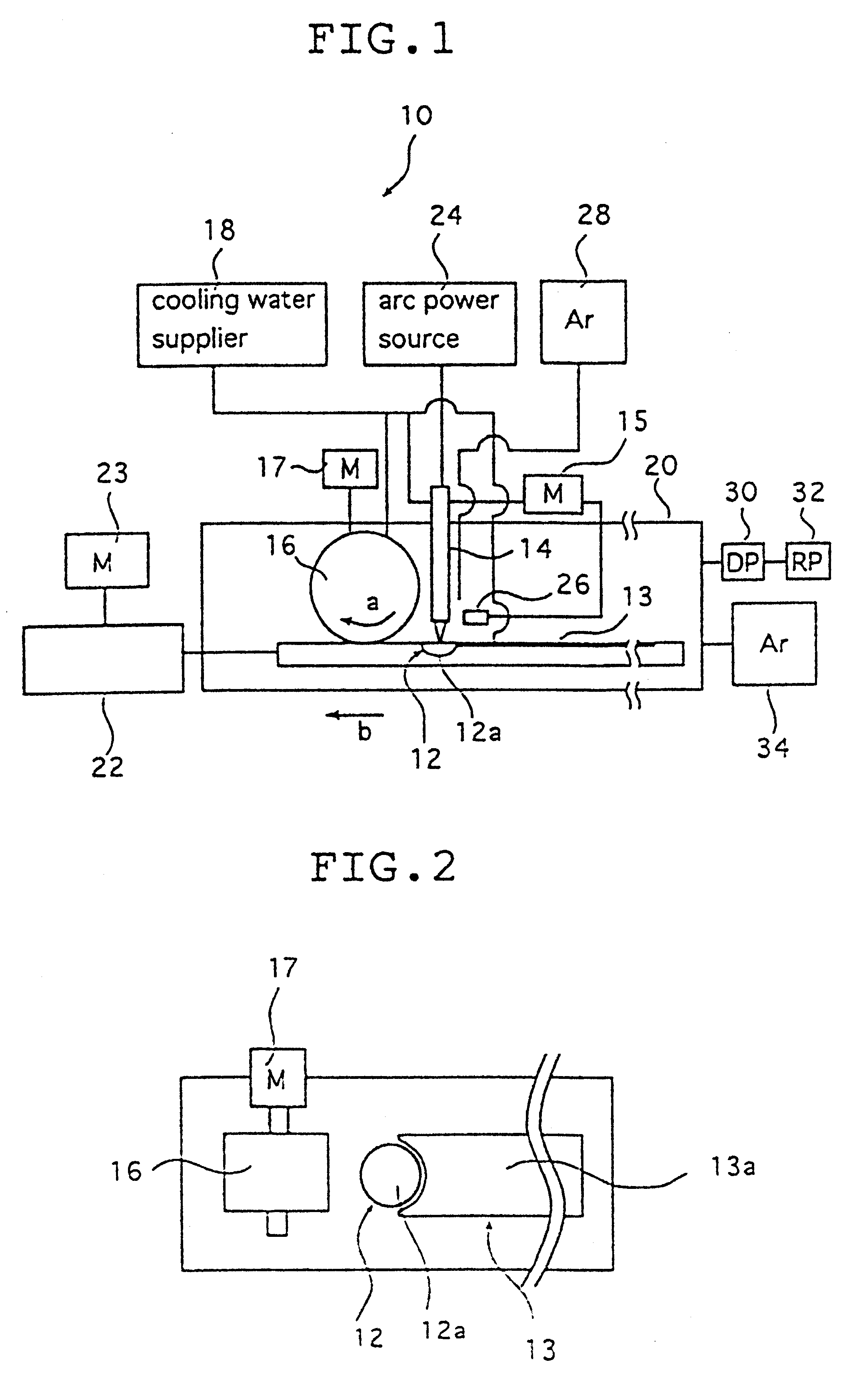

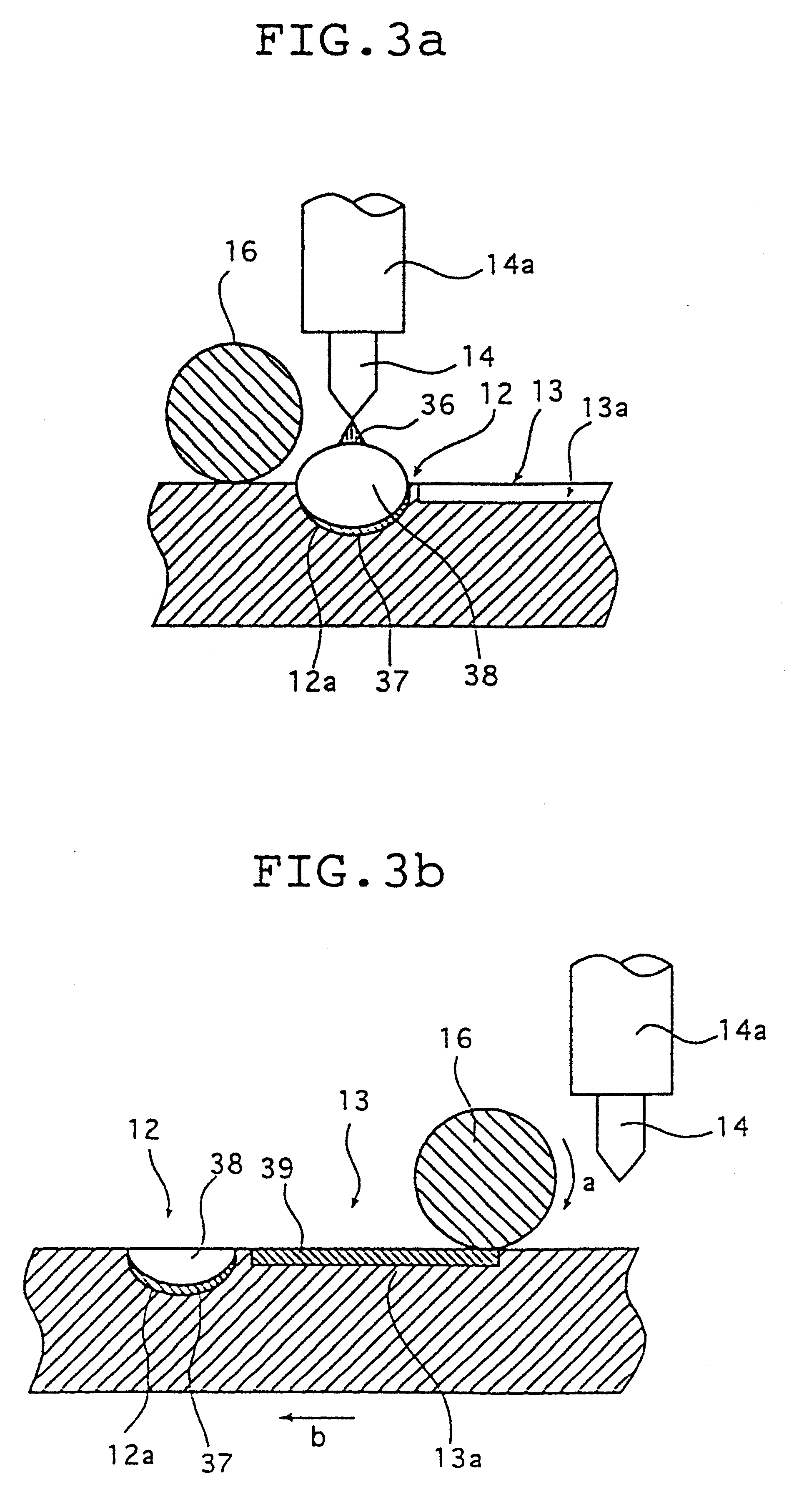

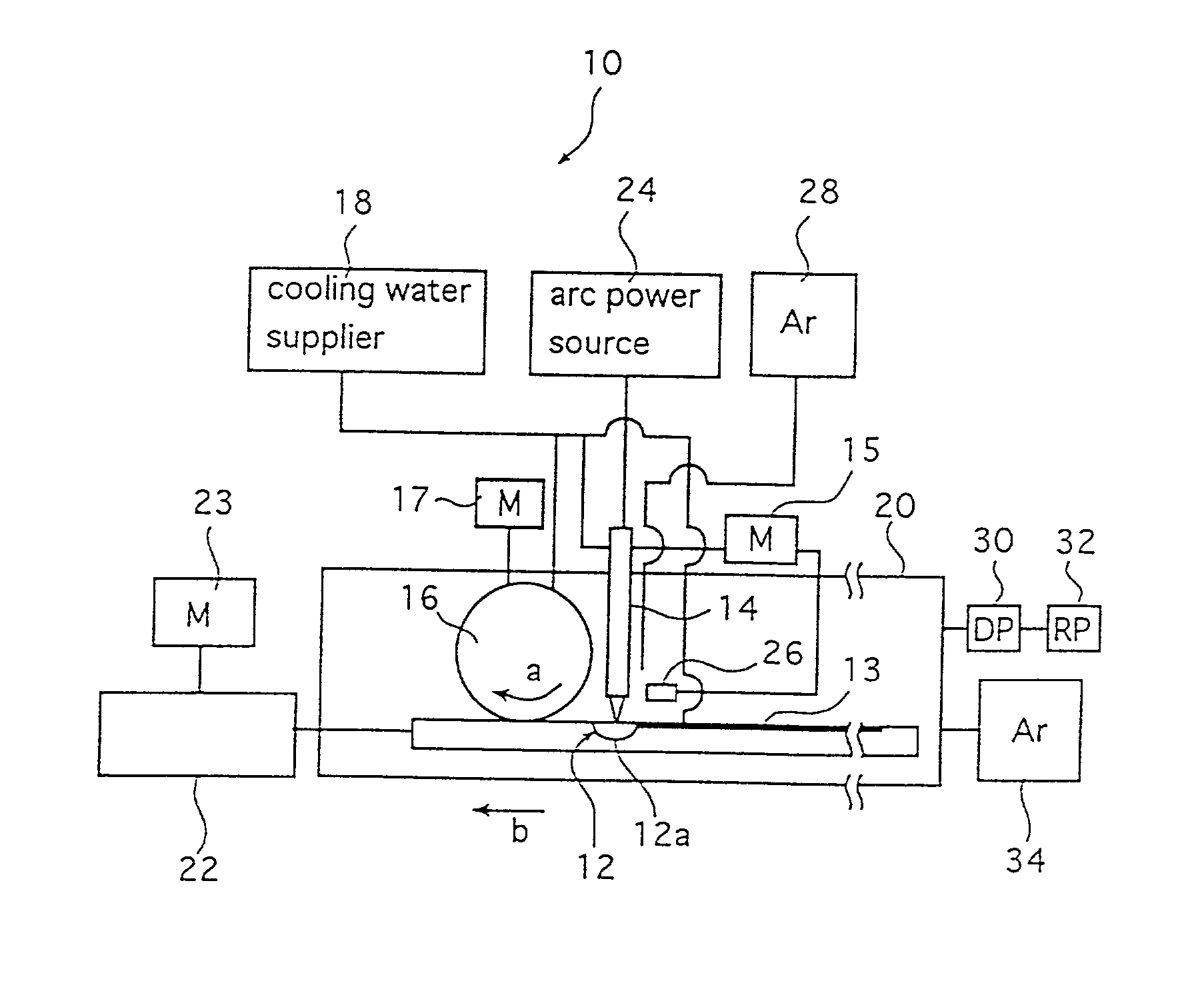

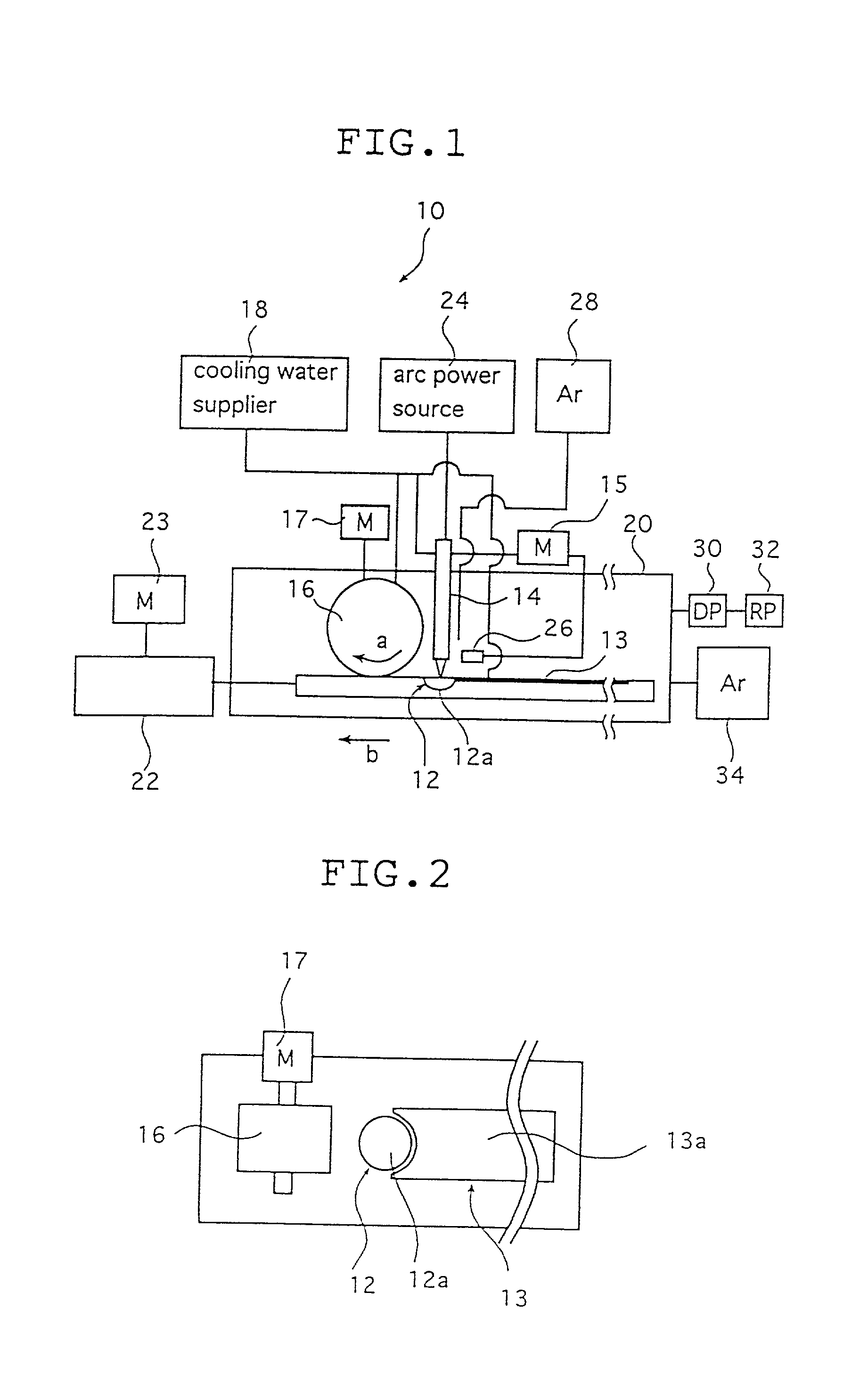

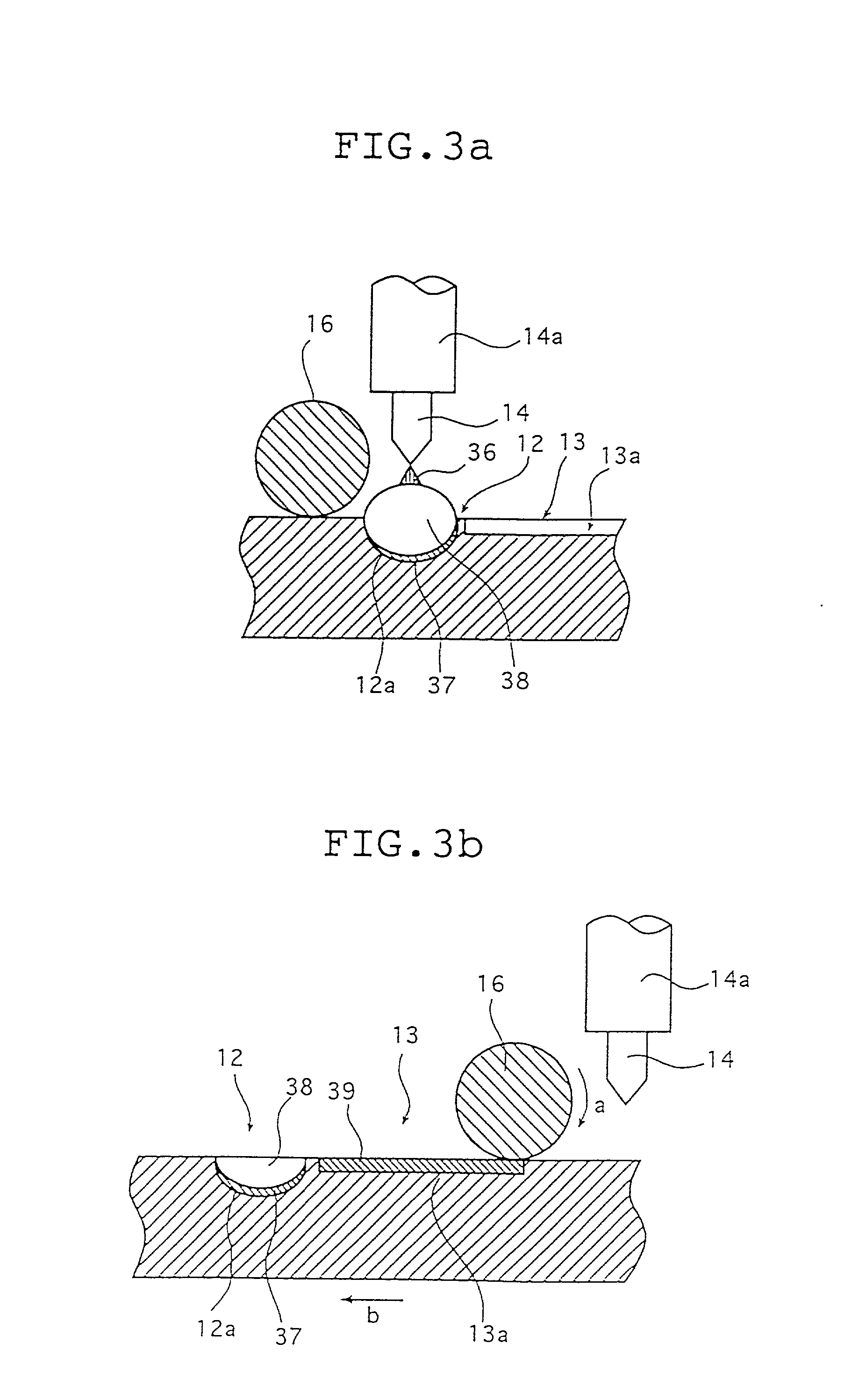

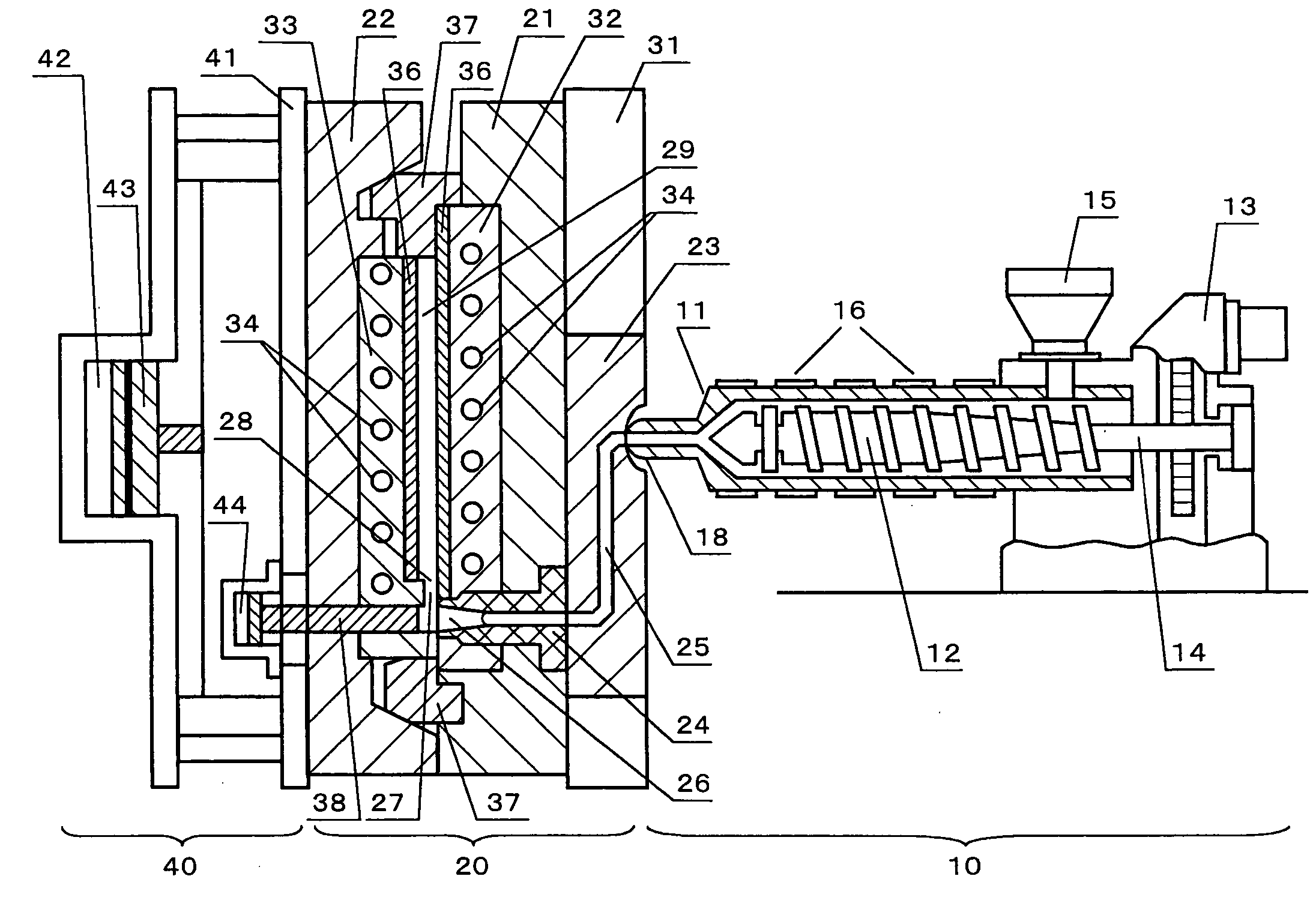

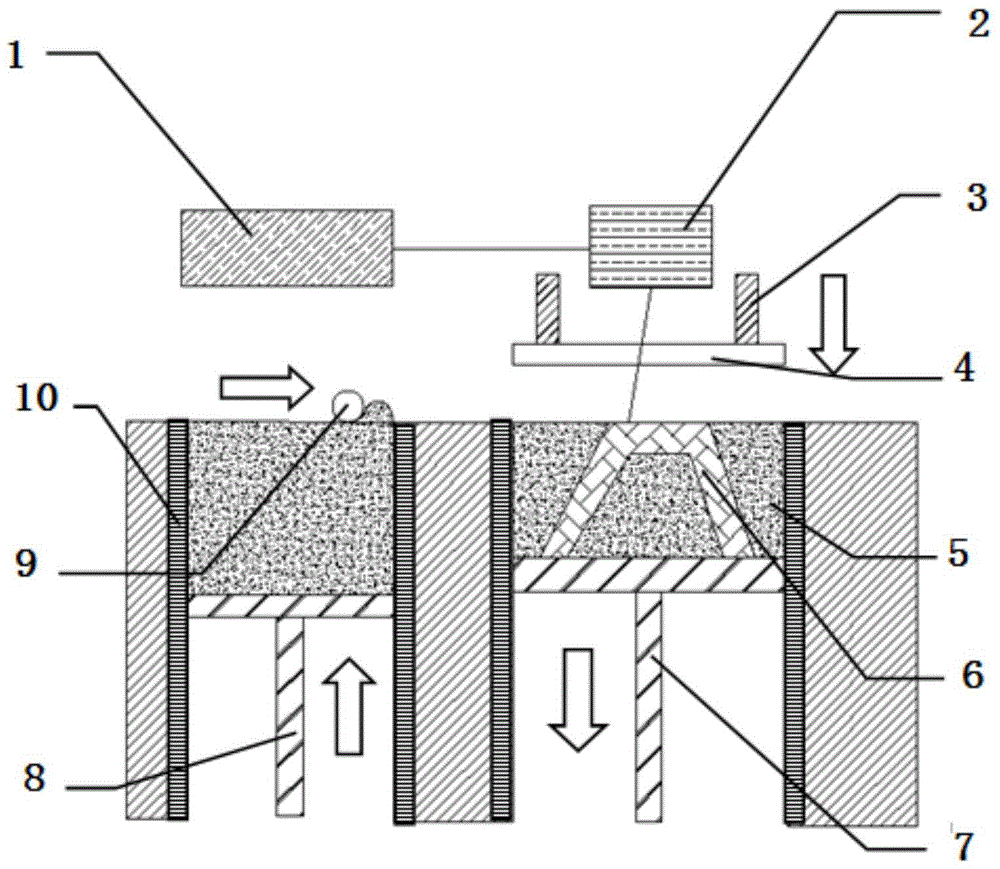

Process and apparatus for producing metallic glass

InactiveUS6427753B1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyHearth

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

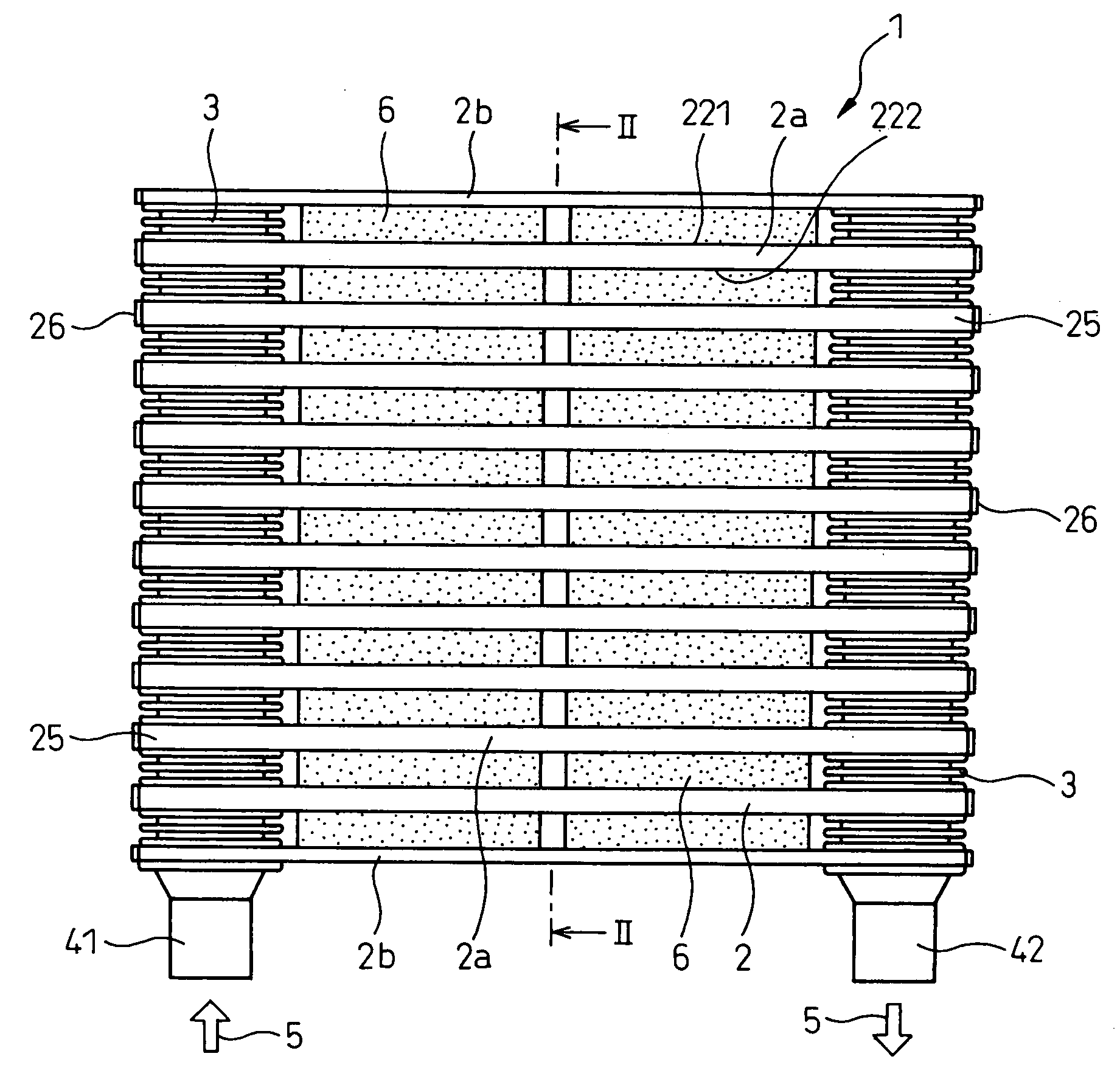

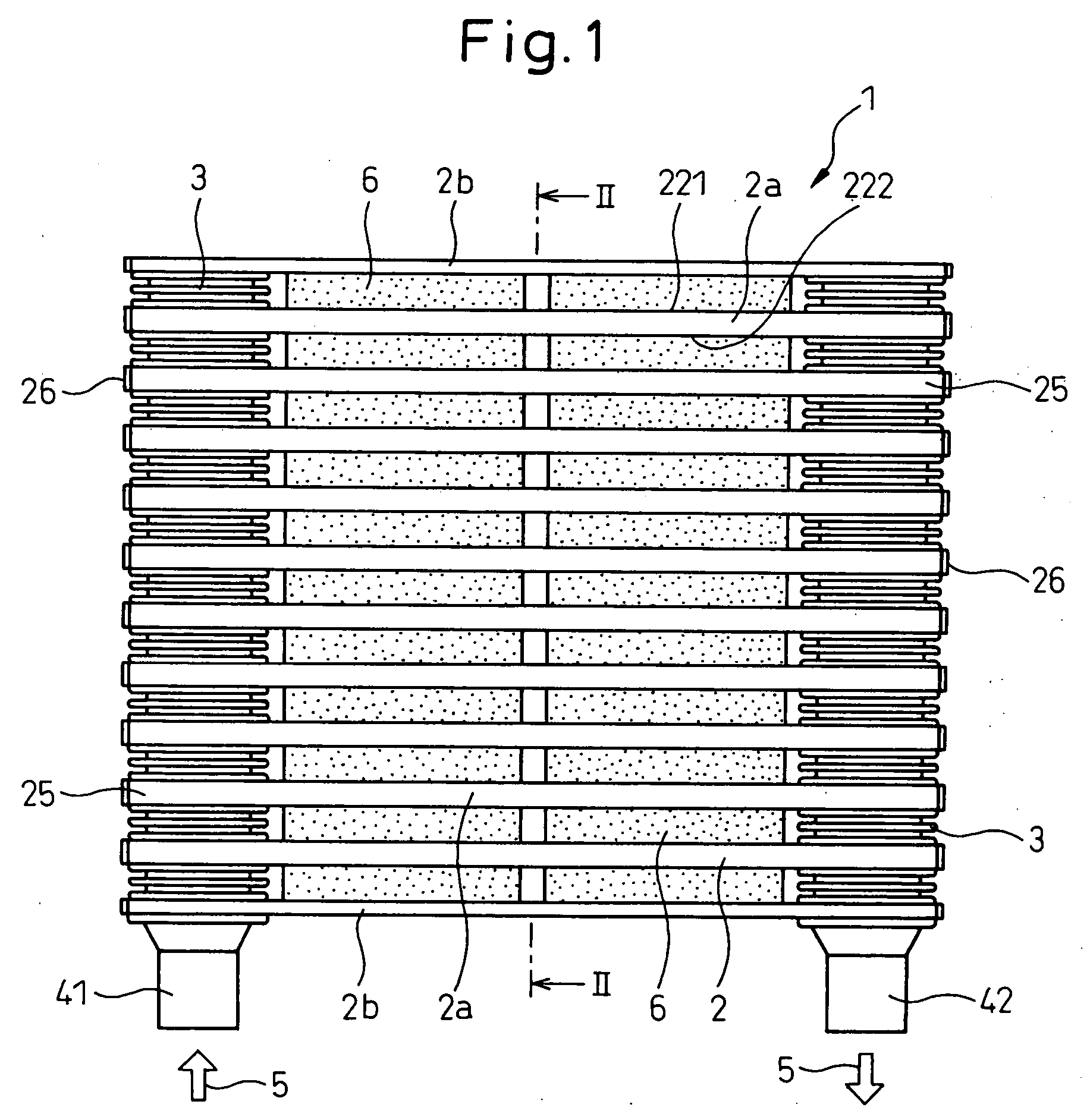

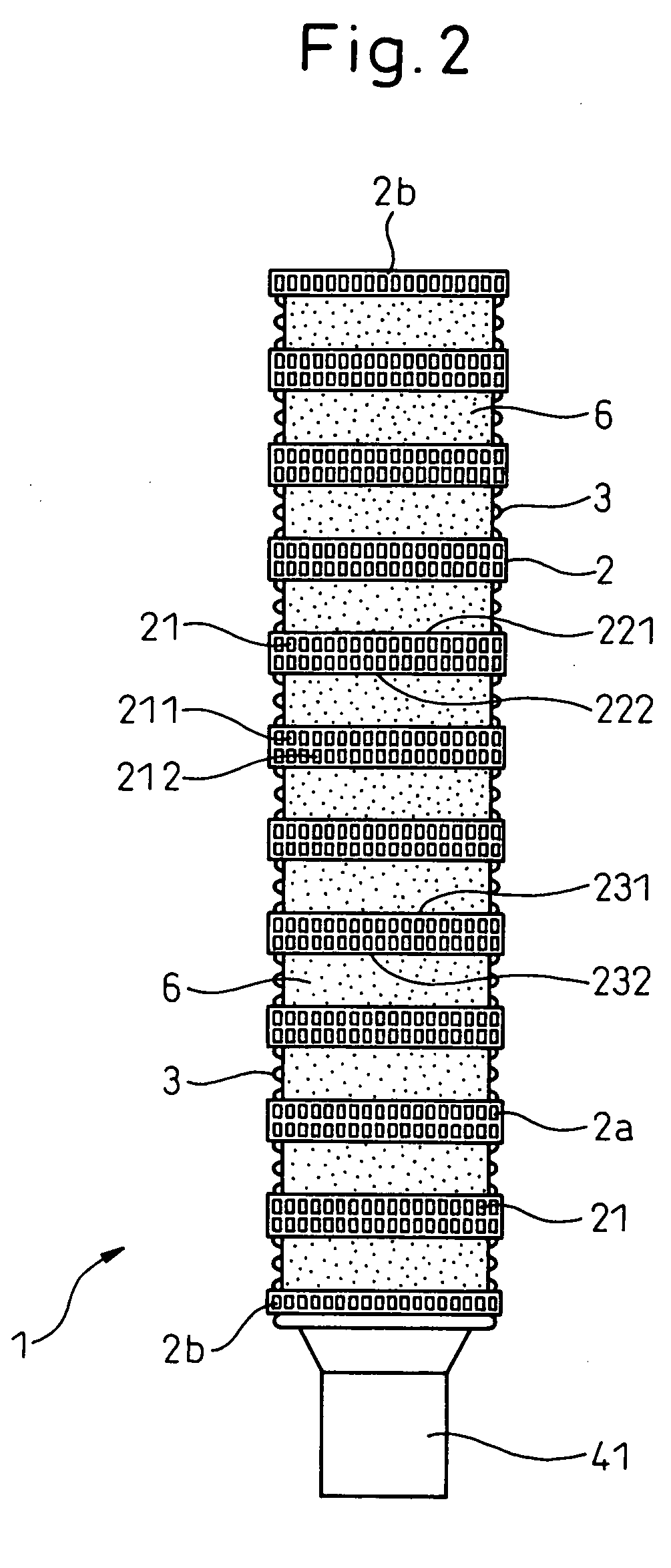

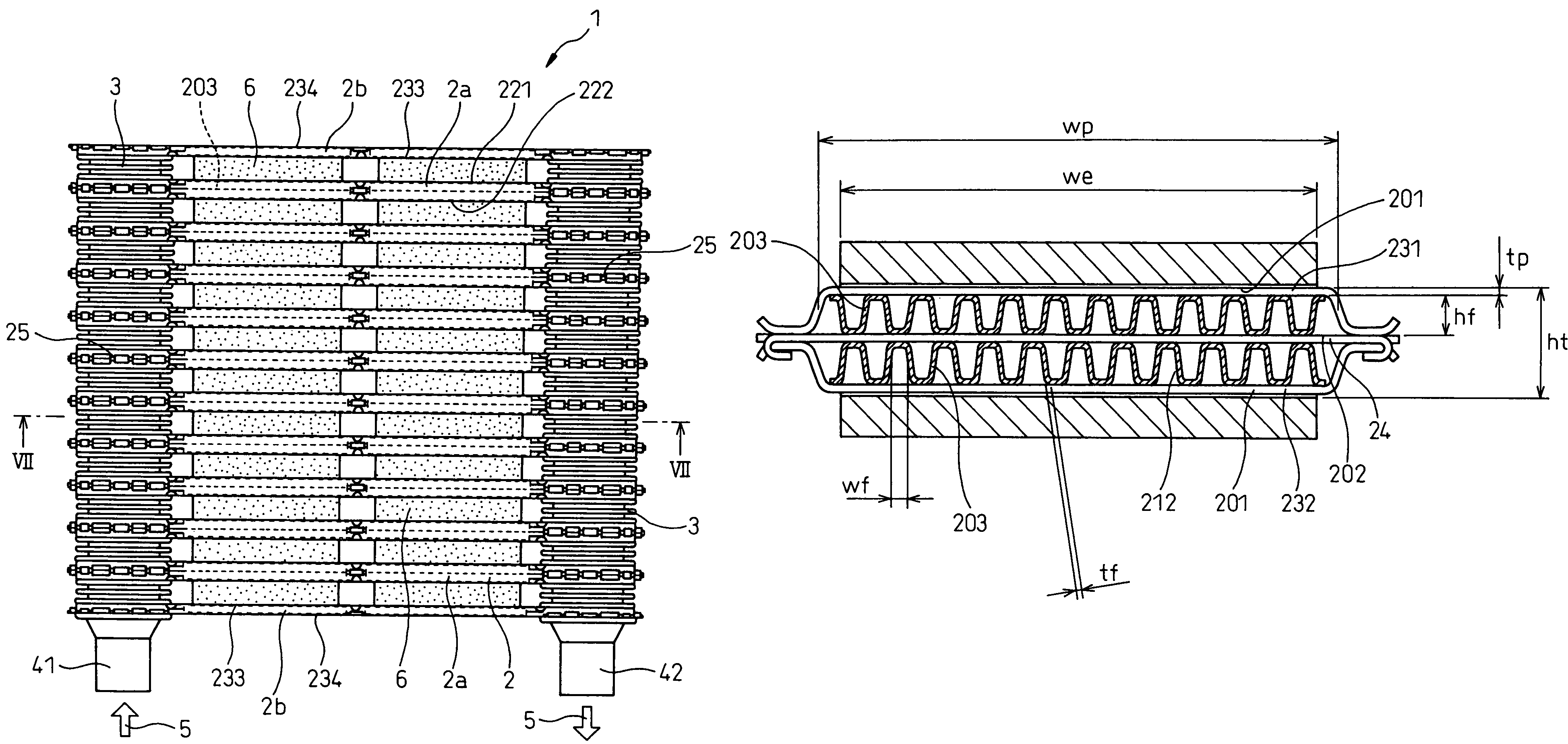

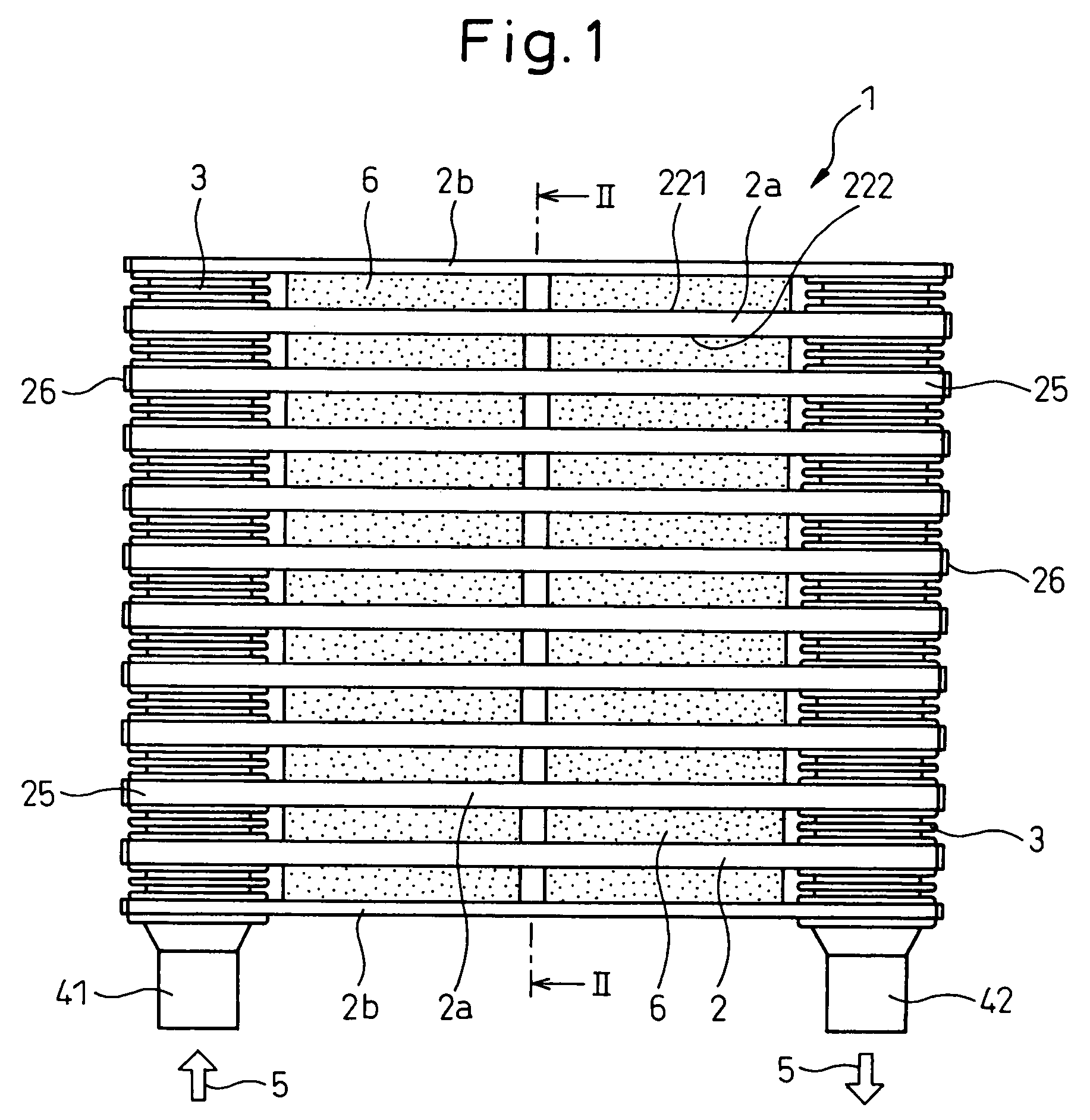

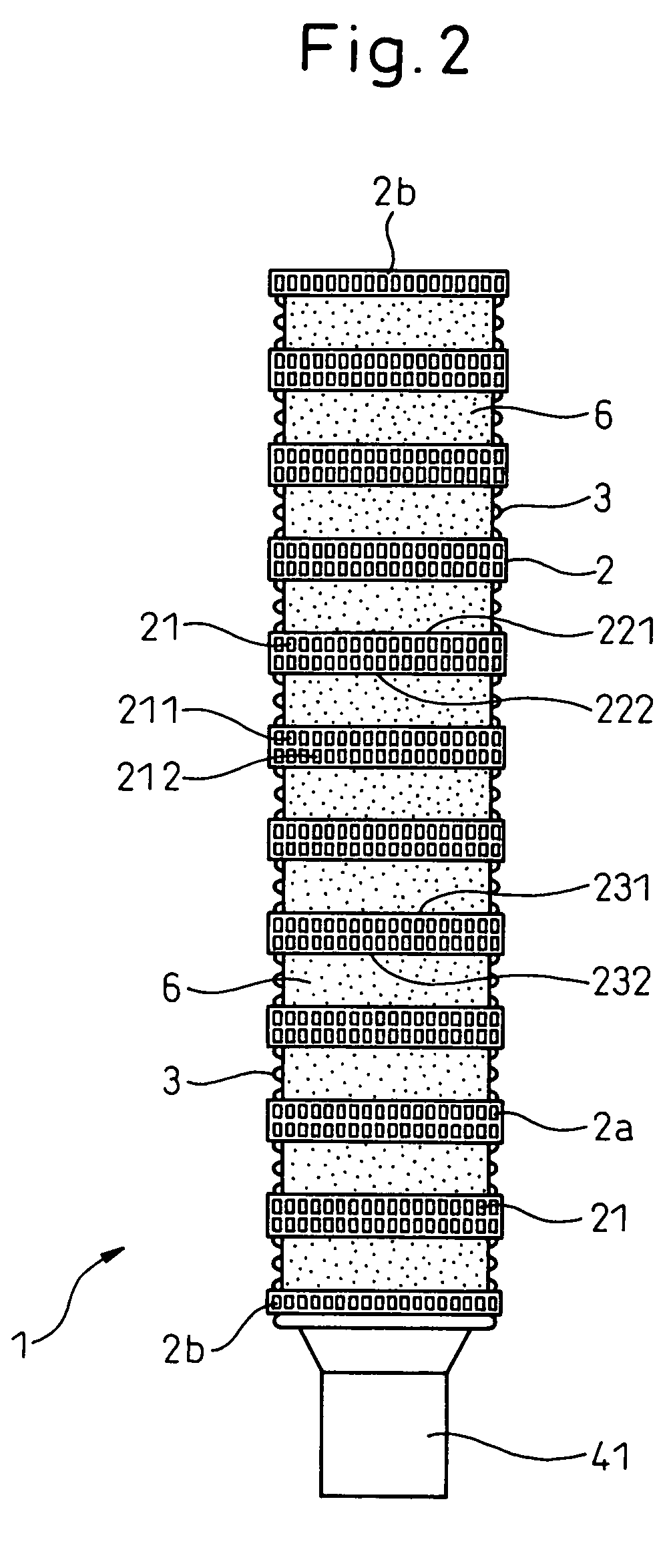

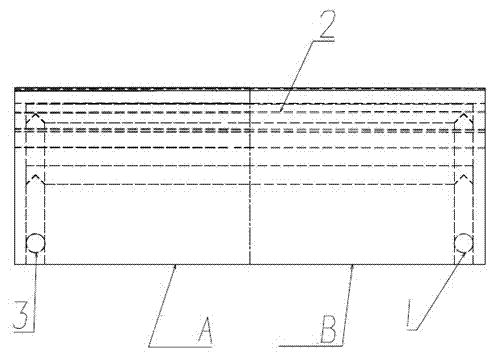

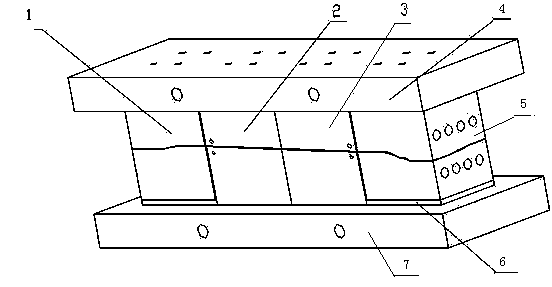

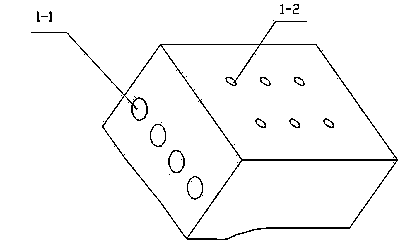

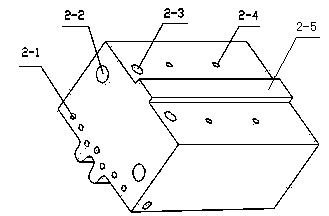

Stacked type cooler

ActiveUS20050121173A1Avoid temperature riseHeat transfer areaSemiconductor/solid-state device detailsSolid-state devicesSurface coolingCoolant flow

A stacked type cooler 1 for cooling a plurality of electronic components 6 from two surfaces of each component includes a plurality of cooling tubes 2 having a flat shape and coolant flow passage 21 for allowing a coolant to flow, and a connecting pipe 3 for communicating these cooling tubes 2. The plurality of cooling tubes 2 is arranged and stacked in such a fashion as to interpose the electronic components 6 between the cooling tubes. The plurality of cooling tubes 2 includes an outside cooling tube 2b and an inside cooling tube 2a. The inside cooling tube 2a includes at least a first coolant flow passage 211 facing a first tube wall 231 constituting a first main surface 221 of the inside cooling tube 2a and a second coolant flow passage 212 facing a second tube wall 232 constituting a second main surface 222 on the opposite side to the first main surface 221. The coolant flow passage 21 is formed into two or more stages in a direction of thickness of the inside cooling tube 2a.

Owner:DENSO CORP

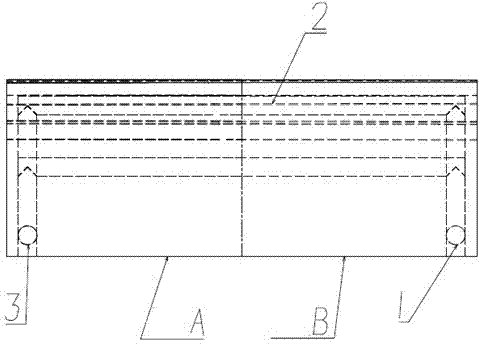

Stacked type cooler

ActiveUS7571759B2Avoid temperature riseImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSurface coolingCoolant flow

Owner:DENSO CORP

Process and apparatus for producing metallic glass

InactiveUS20020100573A1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyAlloy

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

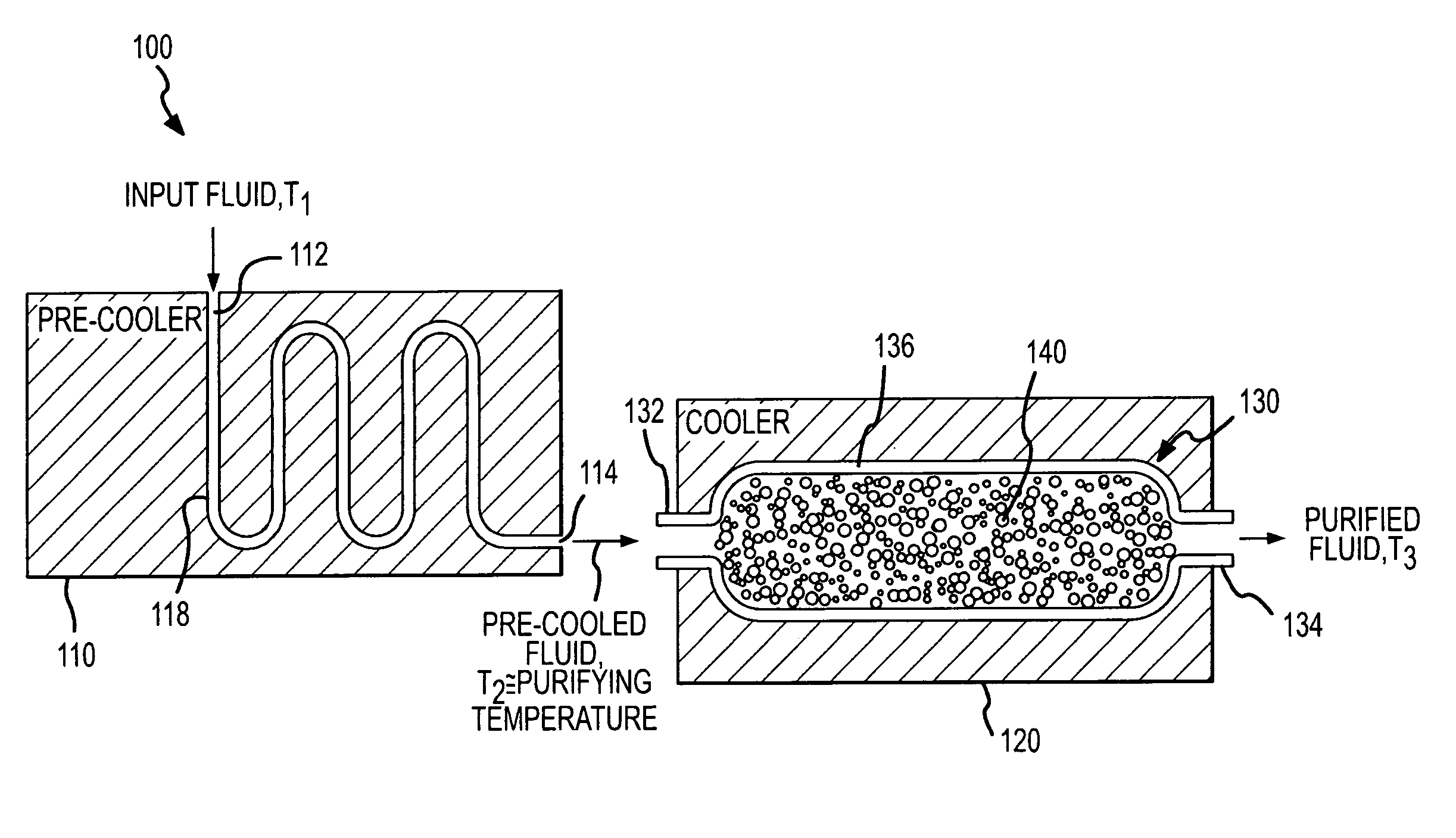

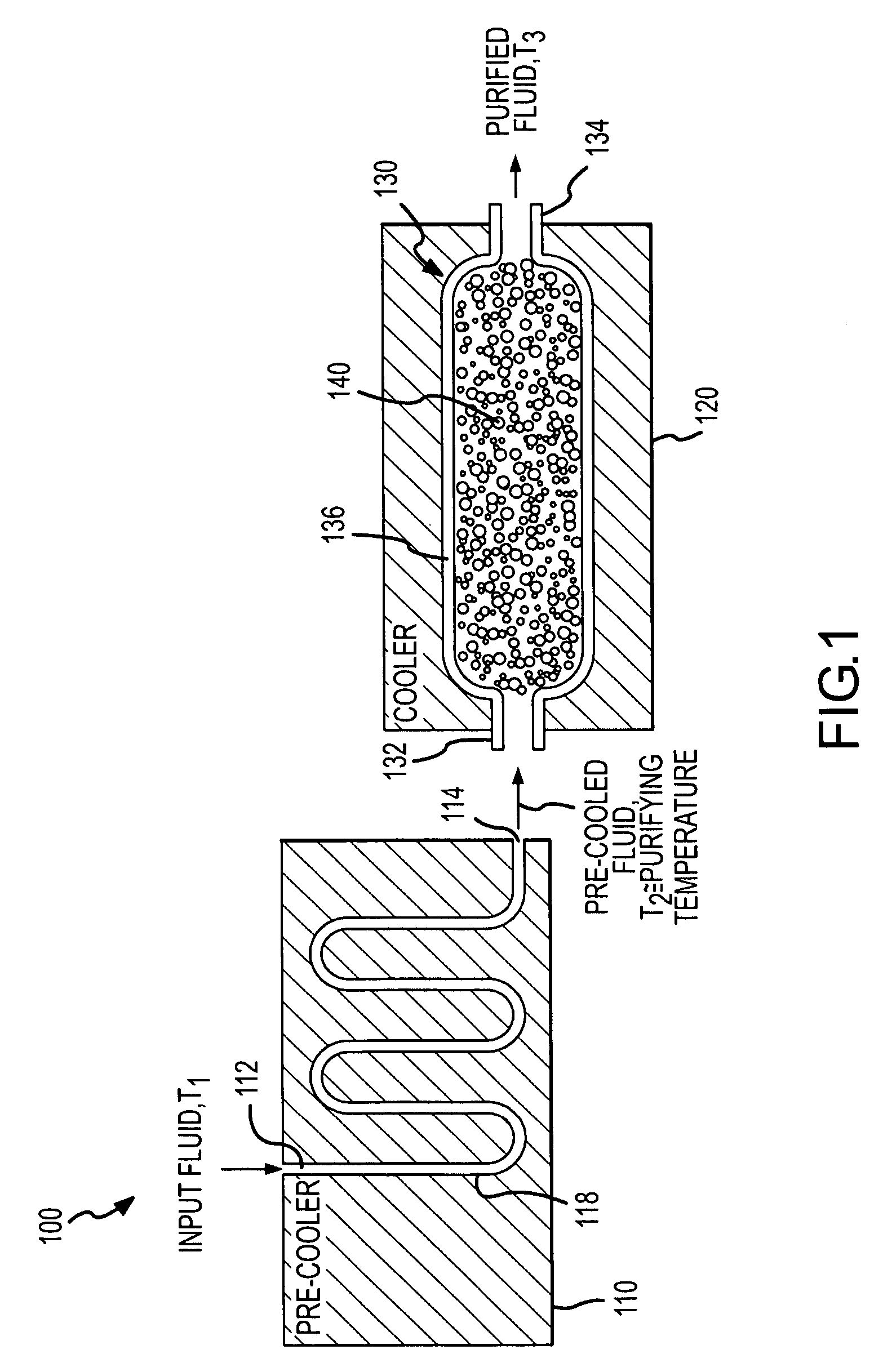

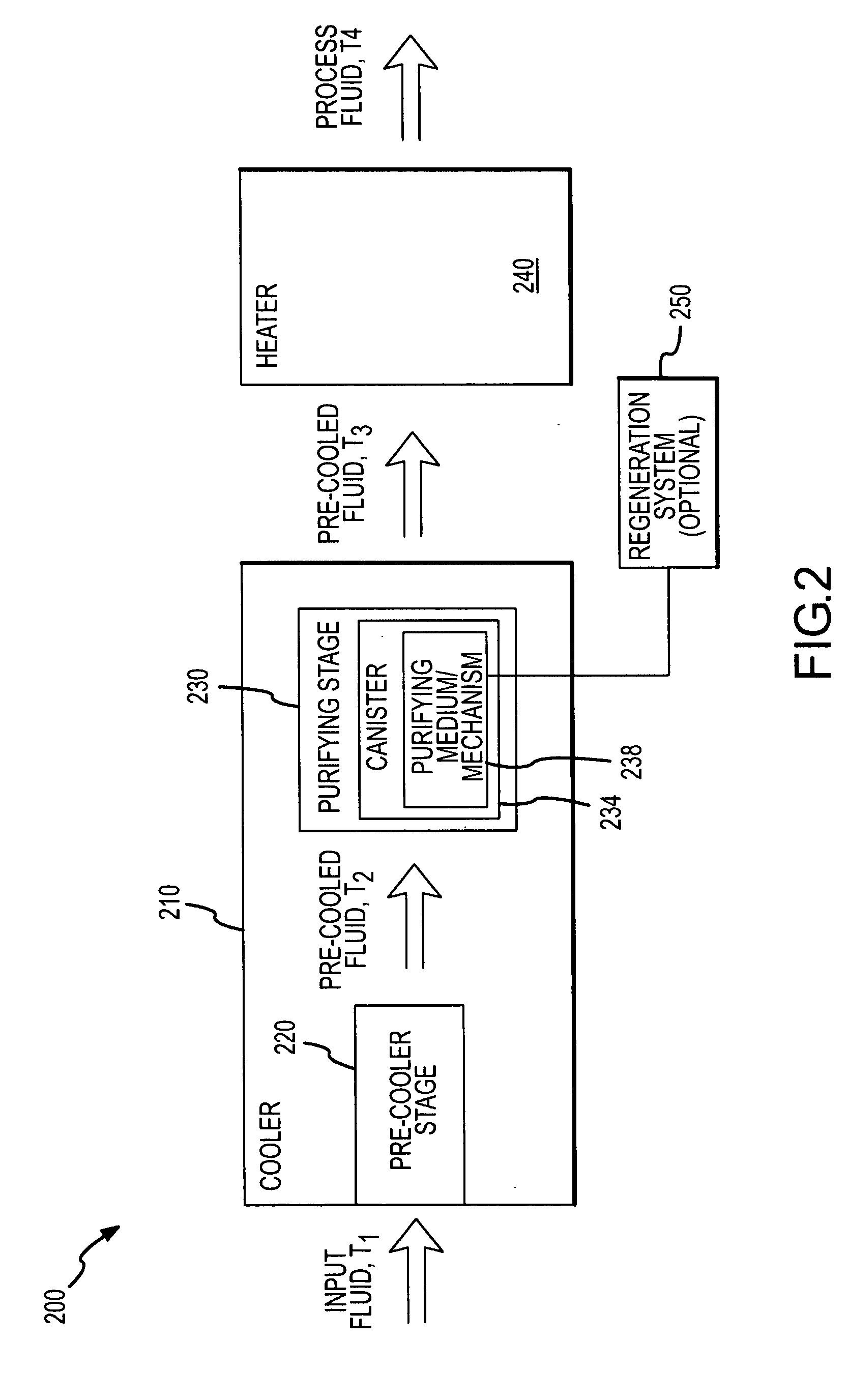

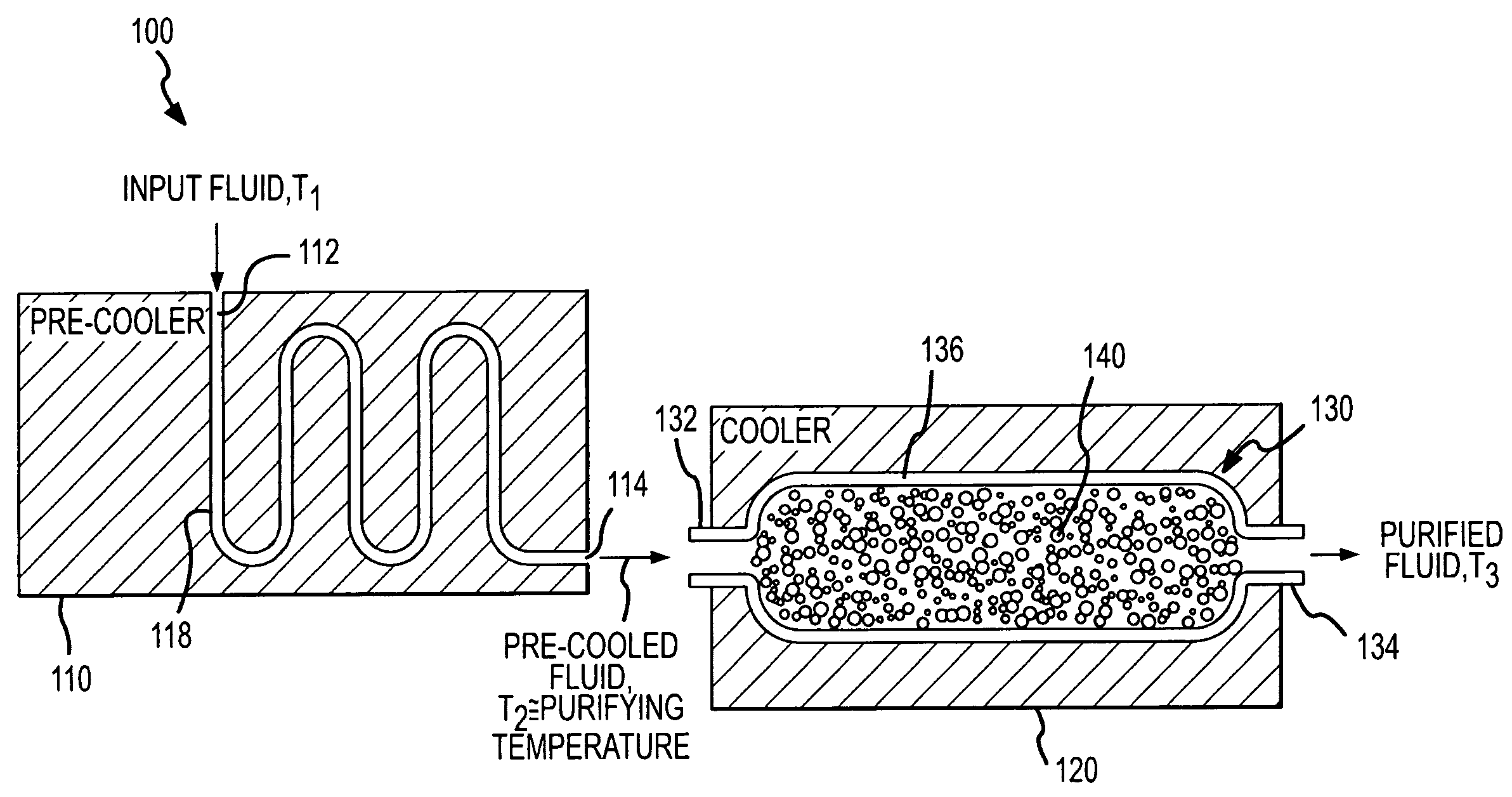

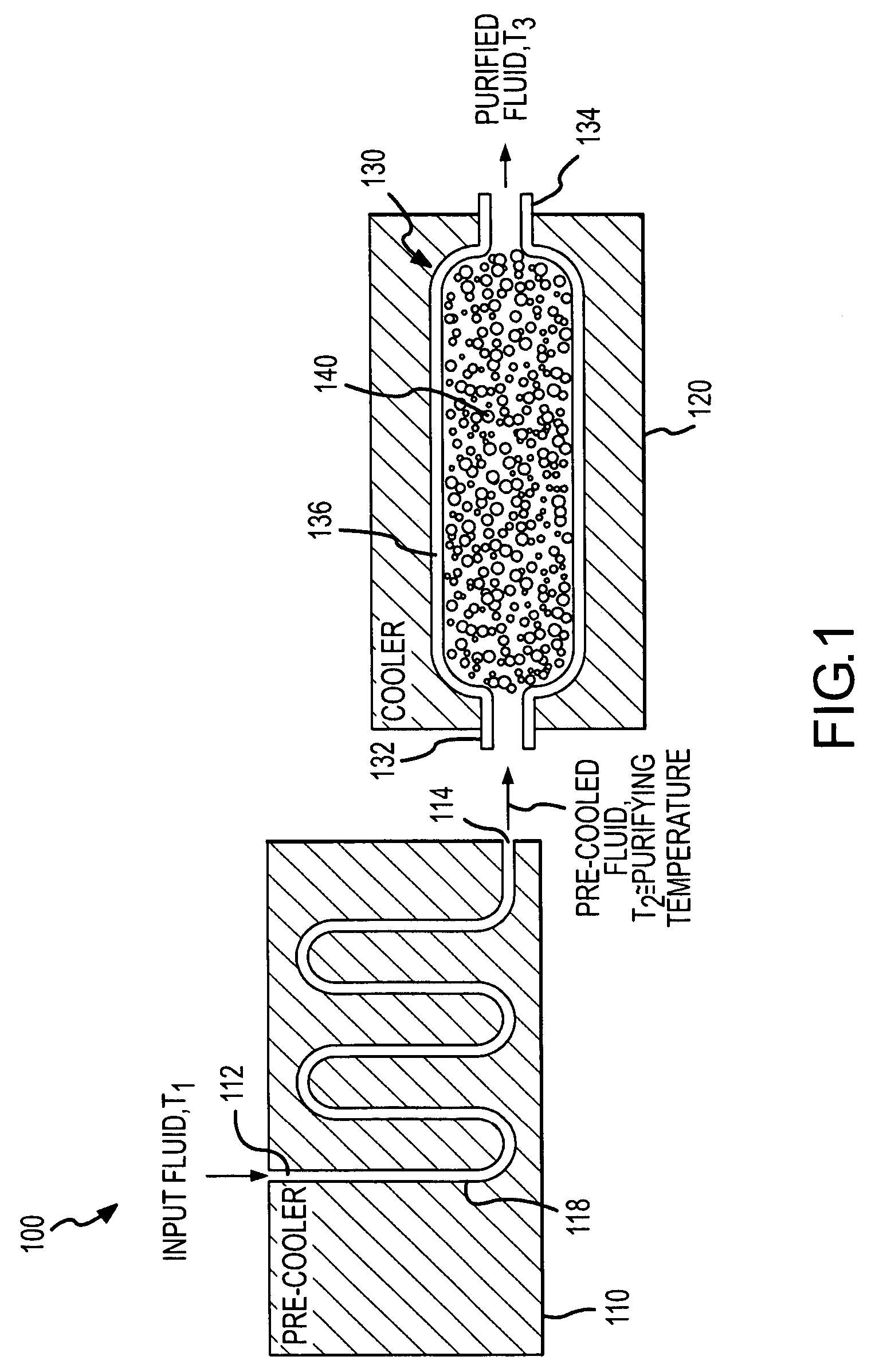

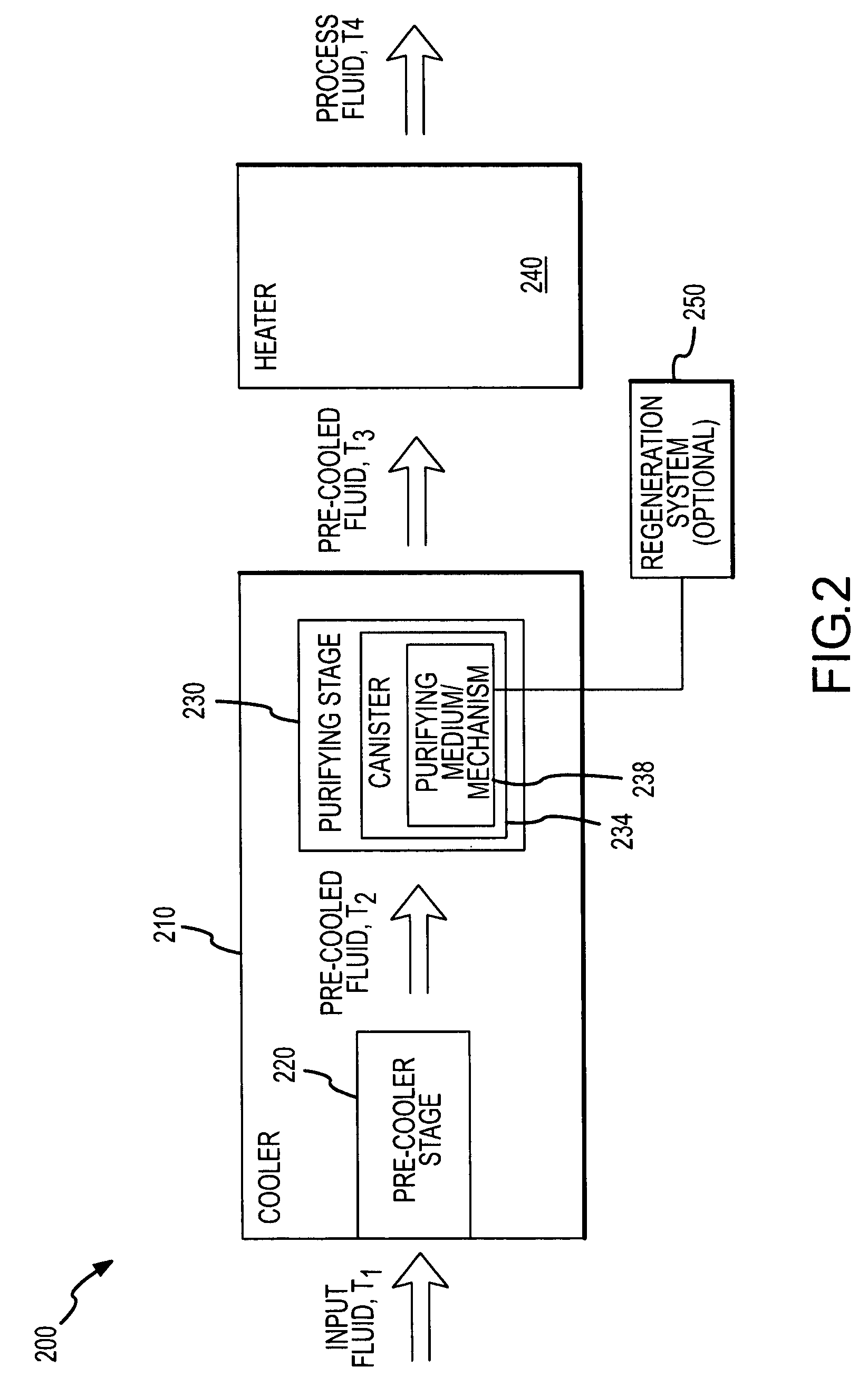

Fluid purification system with low temperature purifier

ActiveUS20060086247A1Good removal effectNitrous oxide captureIsotope separationSurface coolingEngineering

A system and method for processing a matrix fluid to remove one or more impurities (such as moisture from a process gas). The purifier includes a pre-cooler that receives the matrix fluid and cools the matrix fluid to a second, lower temperature. A container is provided to contain a purifier element made up of a high surface area material. The container includes an inlet for receiving the matrix fluid from the pre-cooler and an outlet for outputting the matrix fluid after it is forced to flow through the purifier element. The purifier includes a cooler in thermal contact with an outer surface of the container to cool the outer surface of the container to a purifying temperature, which is selected to be below the ambient temperature and above a phase change point of the matrix fluid and is typically in the range of about 0 to −200° C.

Owner:MATHESON TRI GAS

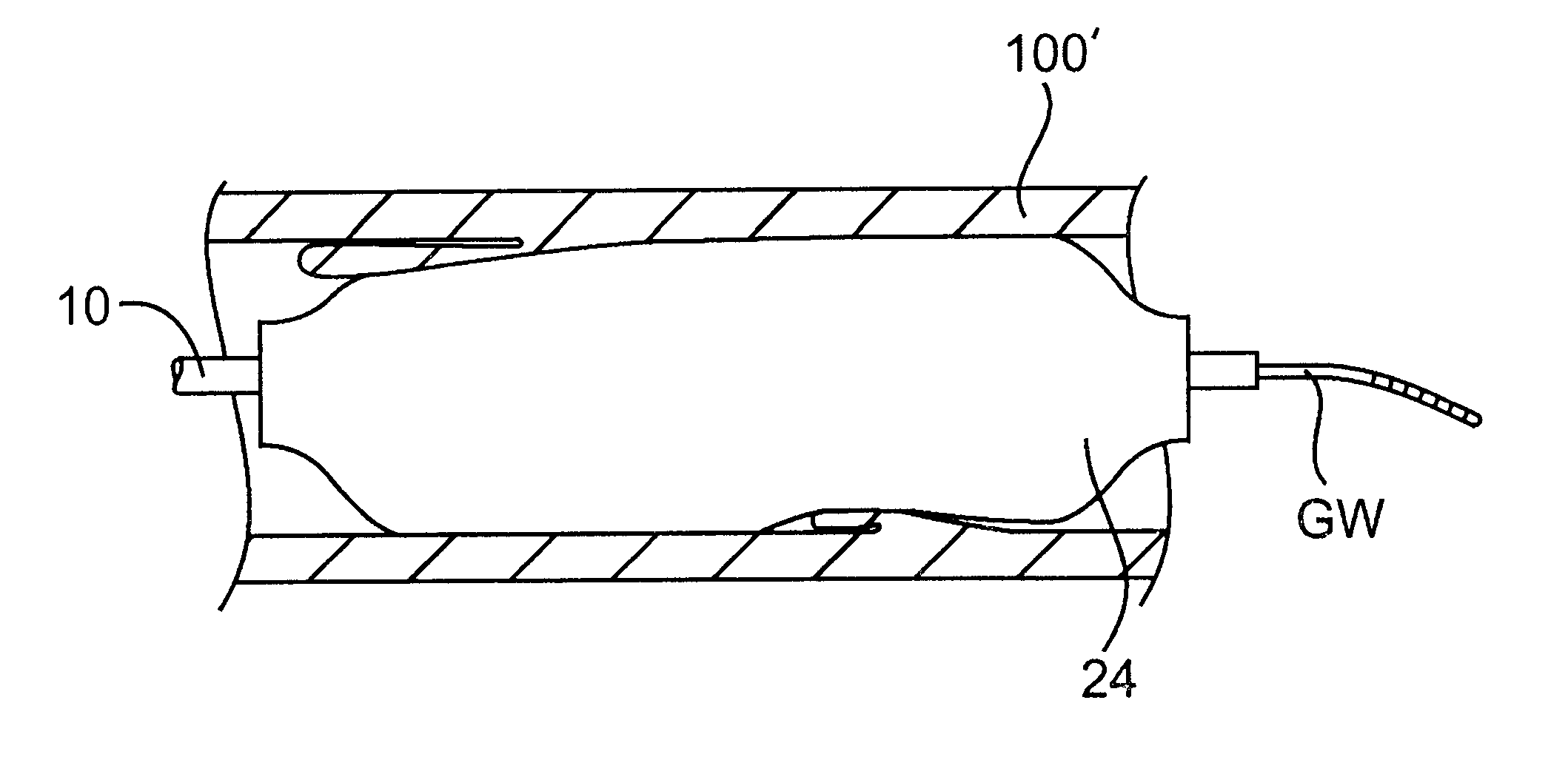

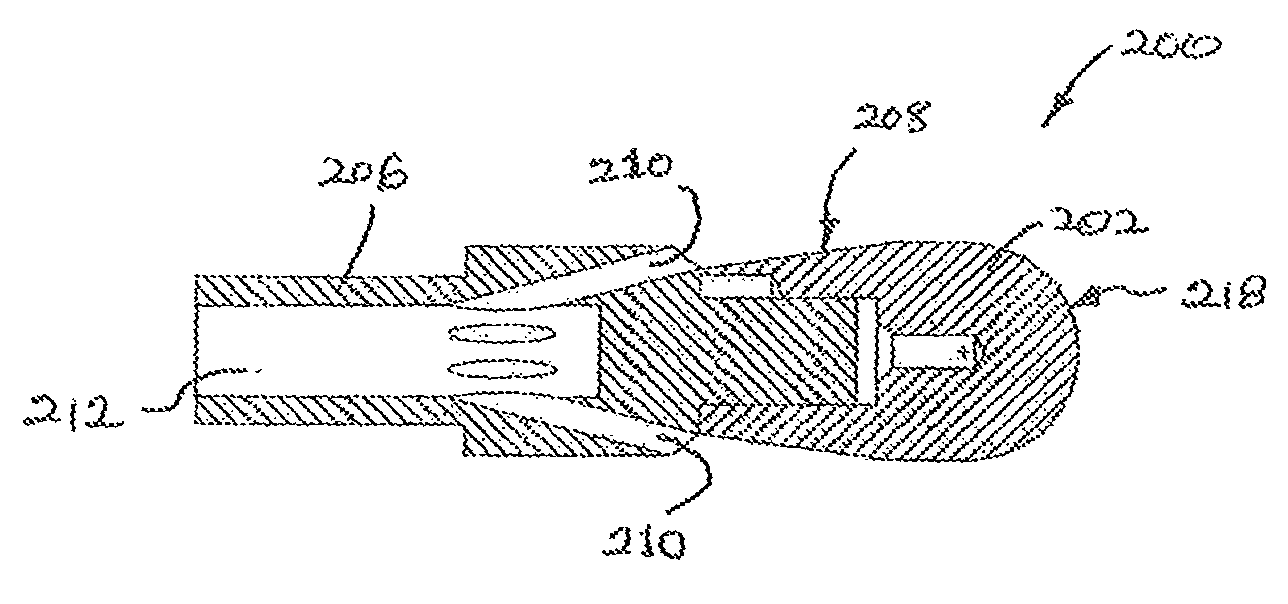

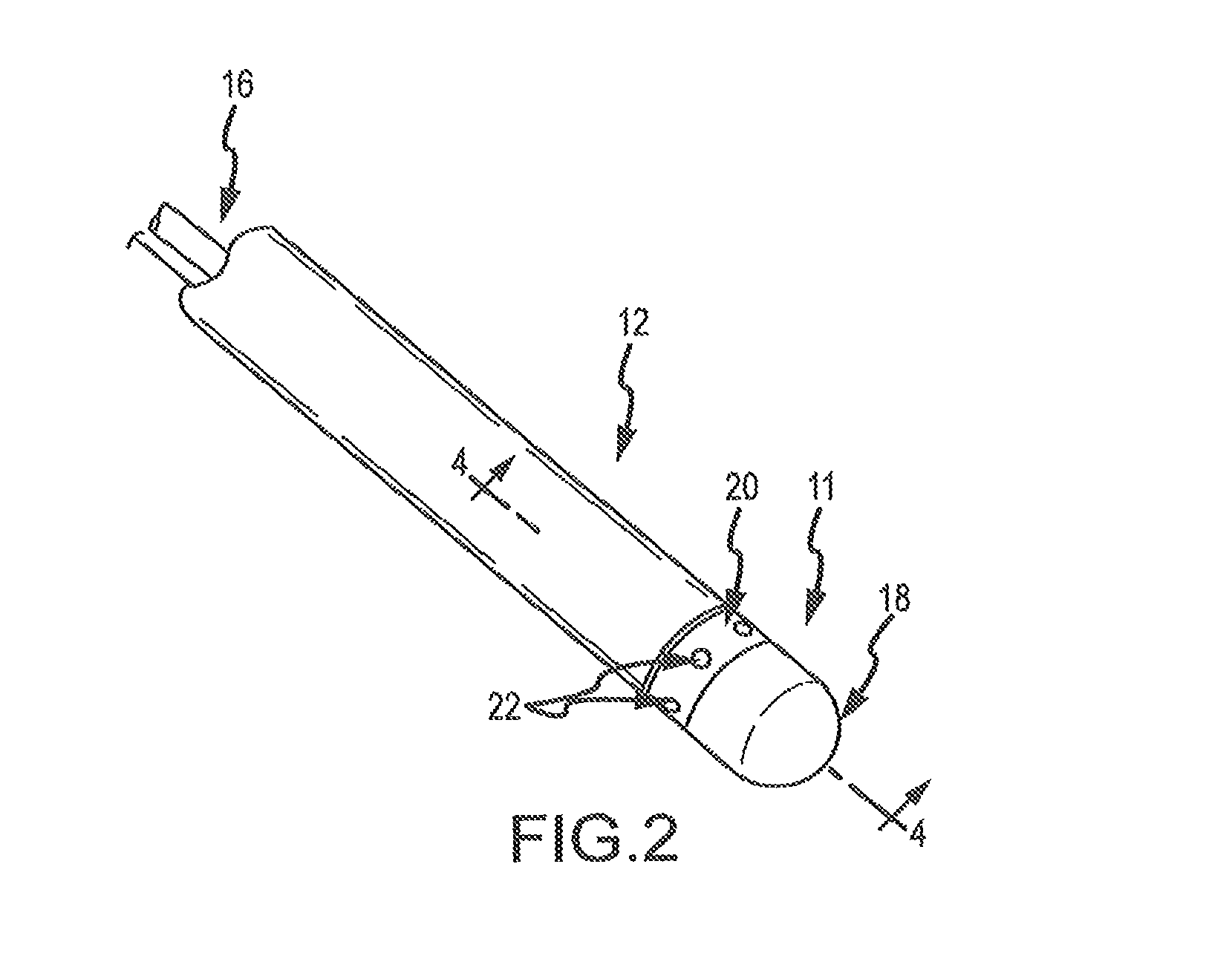

Irrigated ablation catheter having parallel external flow and proximally tapered electrode

Embodiments of the present invention provide an irrigated catheter having irrigation fluid directed at a taper angle generally in parallel with a proximally tapered portion of the tip electrode to provide improved electrode surface cooling. In one embodiment, an irrigated ablation electrode assembly for use with an irrigated catheter device comprises a proximal member having at least one passageway for a fluid with an outlet disposed at an external surface of the proximal member; and a distal member connected with the proximal member and having an external surface, the distal member including an electrode. The external surface of the distal member has a tapered proximal portion narrowing toward the proximal member at a taper angle with respect to a longitudinal axis of the distal member. The at least one passageway of the proximal member is configured to direct a fluid flow through the outlet in a distal direction at an angle substantially equal to the taper angle to produce an external flow that is generally parallel to the tapered proximal portion of the external surface of the distal member.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

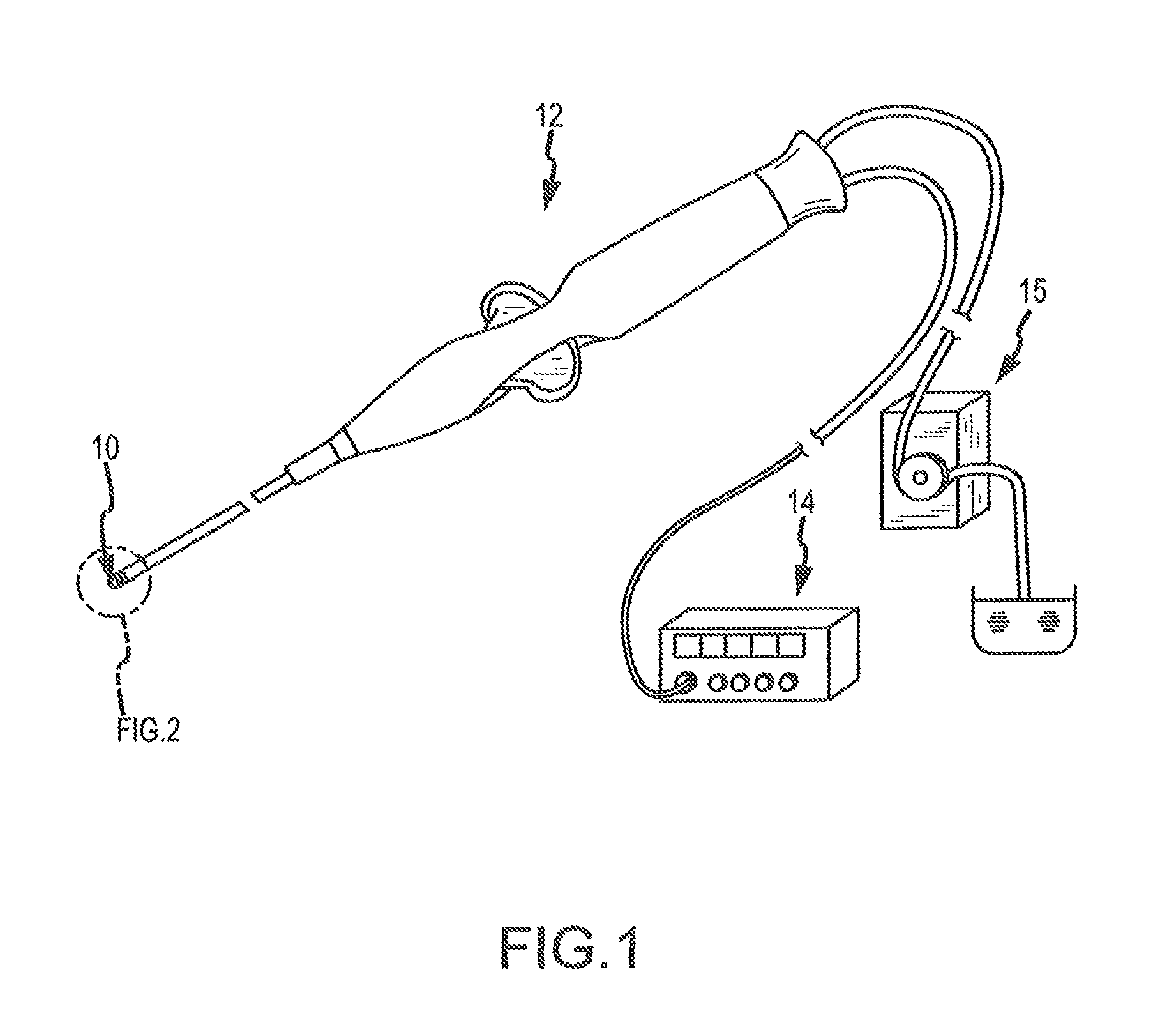

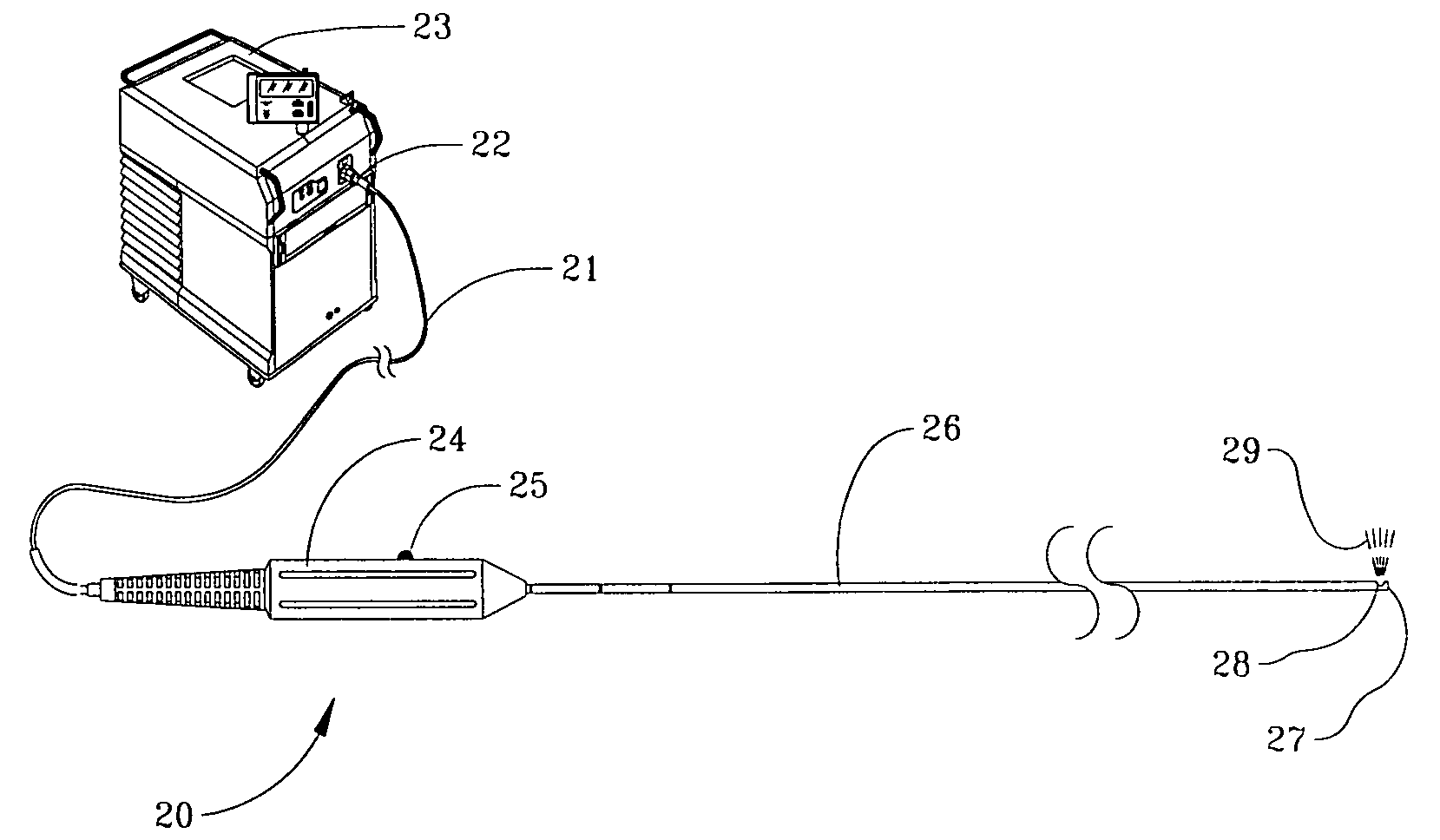

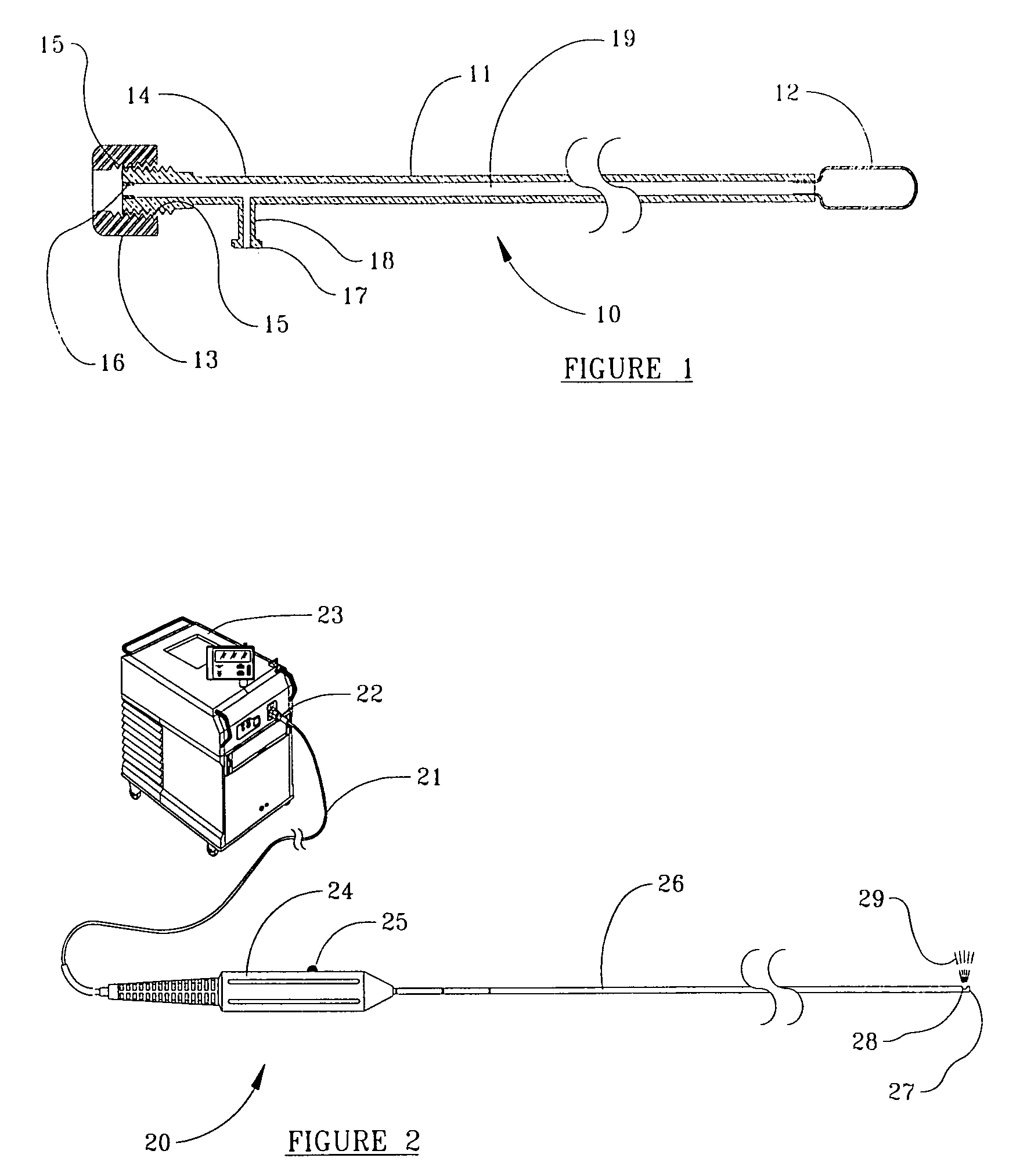

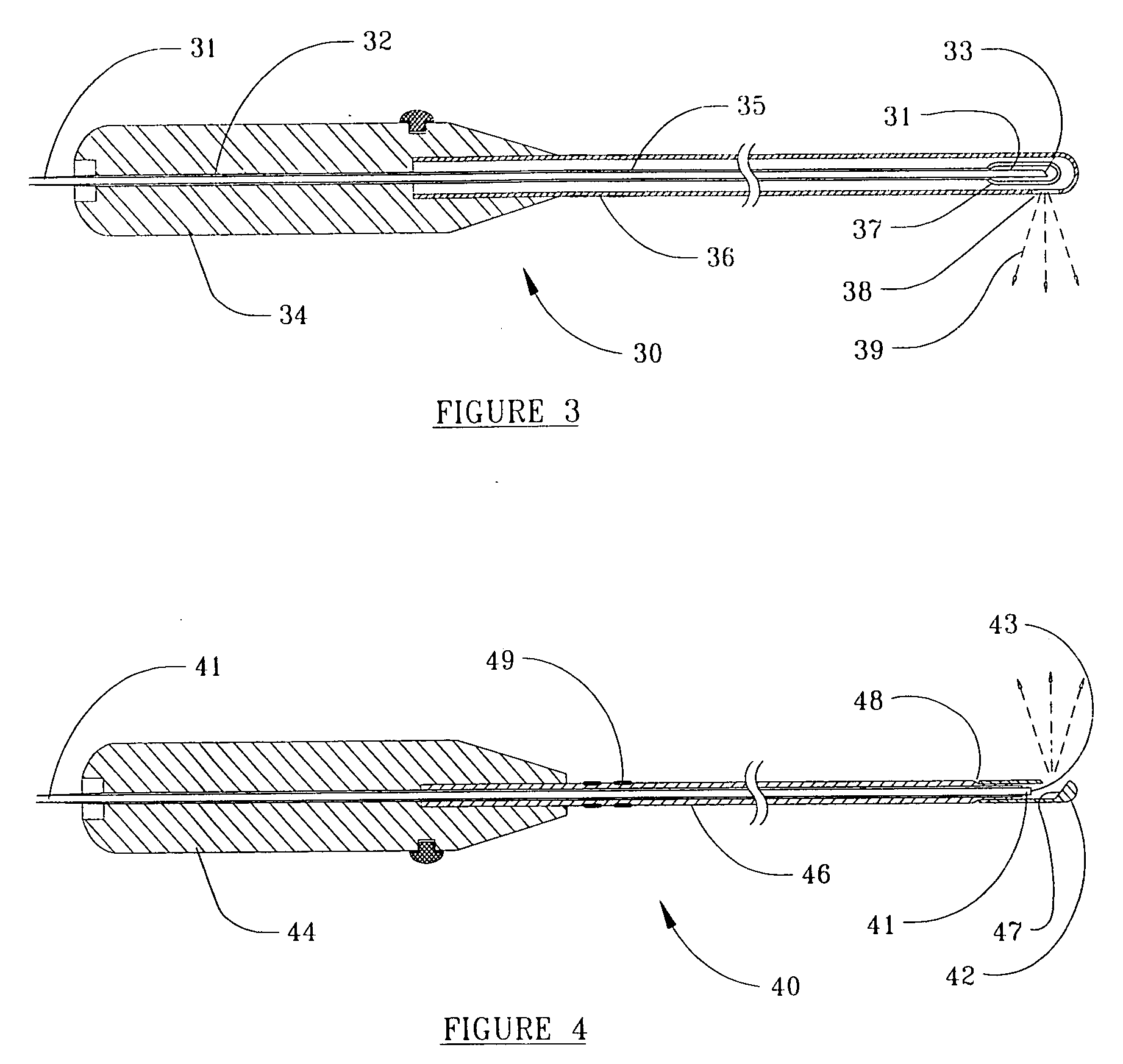

Economical, two component, thermal energy delivery and surface cooling apparatus and its method of use

InactiveUS20080195085A1Avoid cross-contaminationAvoid infectionCatheterSurgical instruments for heatingSurface coolingThermal energy

The present invention is embodied in a medical device which is comprised of a thermal energy delivery component, for example, including an elongate optical fiber terminating in a lateral laser energy emitter, and an outer coolant component, which includes a cannula for receiving the thermal energy delivery component, which terminates in an energy-transmissive balloon for surrounding the thermal energy emitter and providing a tissue-contacting coolant chamber. The cannula portion of the coolant component is moveably sealed around the laser energy delivery component. In one embodiment, a retaining means prevents the thermal energy delivery component from being detached from the coolant component. In an alternate embodiment, there is no retaining means, allowing the more costly thermal energy delivery component to be removed, sterilized and later reused, whereas the less costly outer coolant component, which contacts tissue, blood and body liquids, can be discarded after use.

Owner:LOEB MARVIN P

Fluid purification system with low temperature purifier

A system and method for processing a matrix fluid to remove one or more impurities (such as moisture from a process gas). The purifier includes a pre-cooler that receives the matrix fluid and cools the matrix fluid to a second, lower temperature. A container is provided to contain a purifier element made up of a high surface area material. The container includes an inlet for receiving the matrix fluid from the pre-cooler and an outlet for outputting the matrix fluid after it is forced to flow through the purifier element. The purifier includes a cooler in thermal contact with an outer surface of the container to cool the outer surface of the container to a purifying temperature, which is selected to be below the ambient temperature and above a phase change point of the matrix fluid and is typically in the range of about 0 to −200° C.

Owner:MATHESON TRI GAS INC

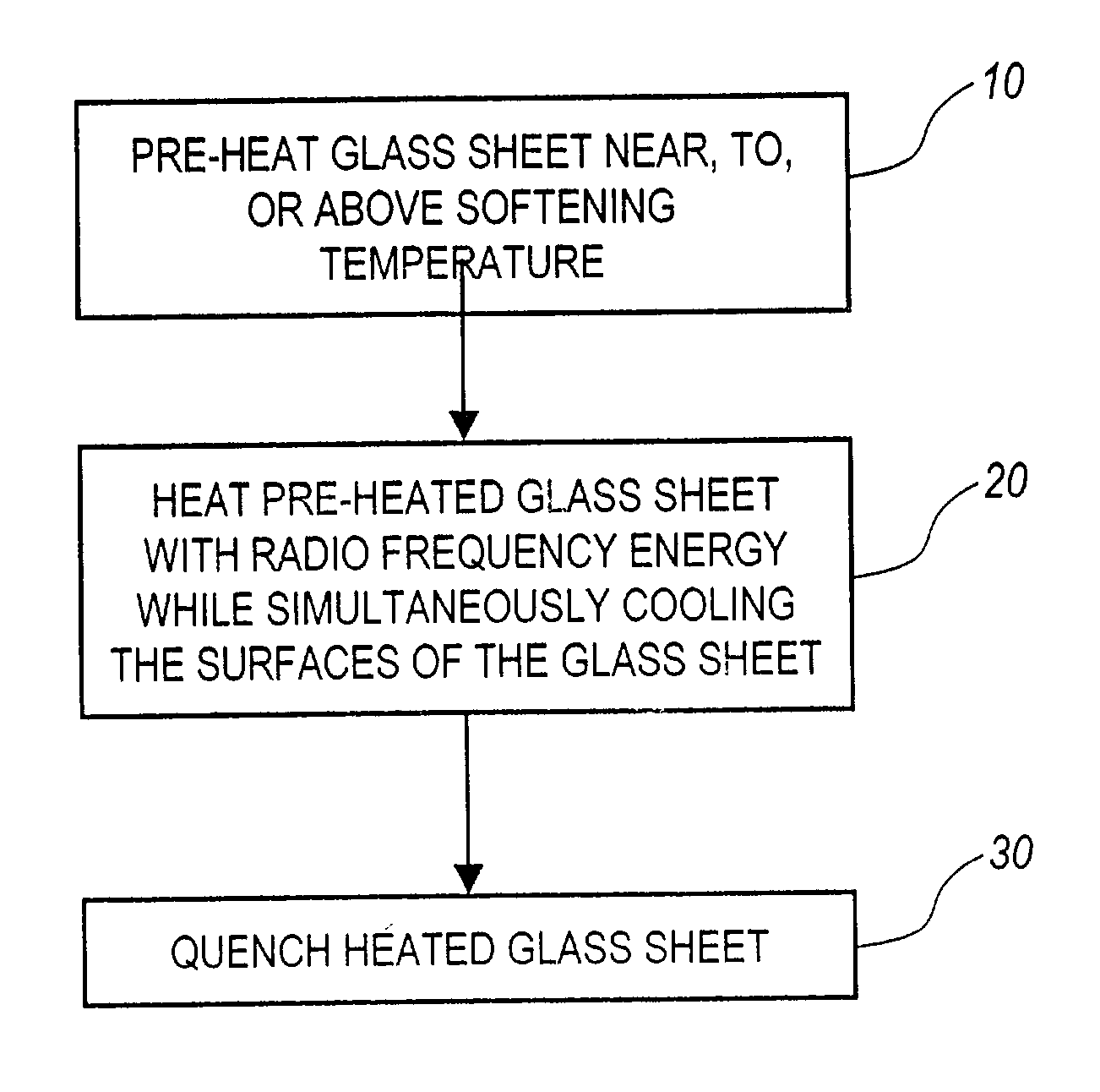

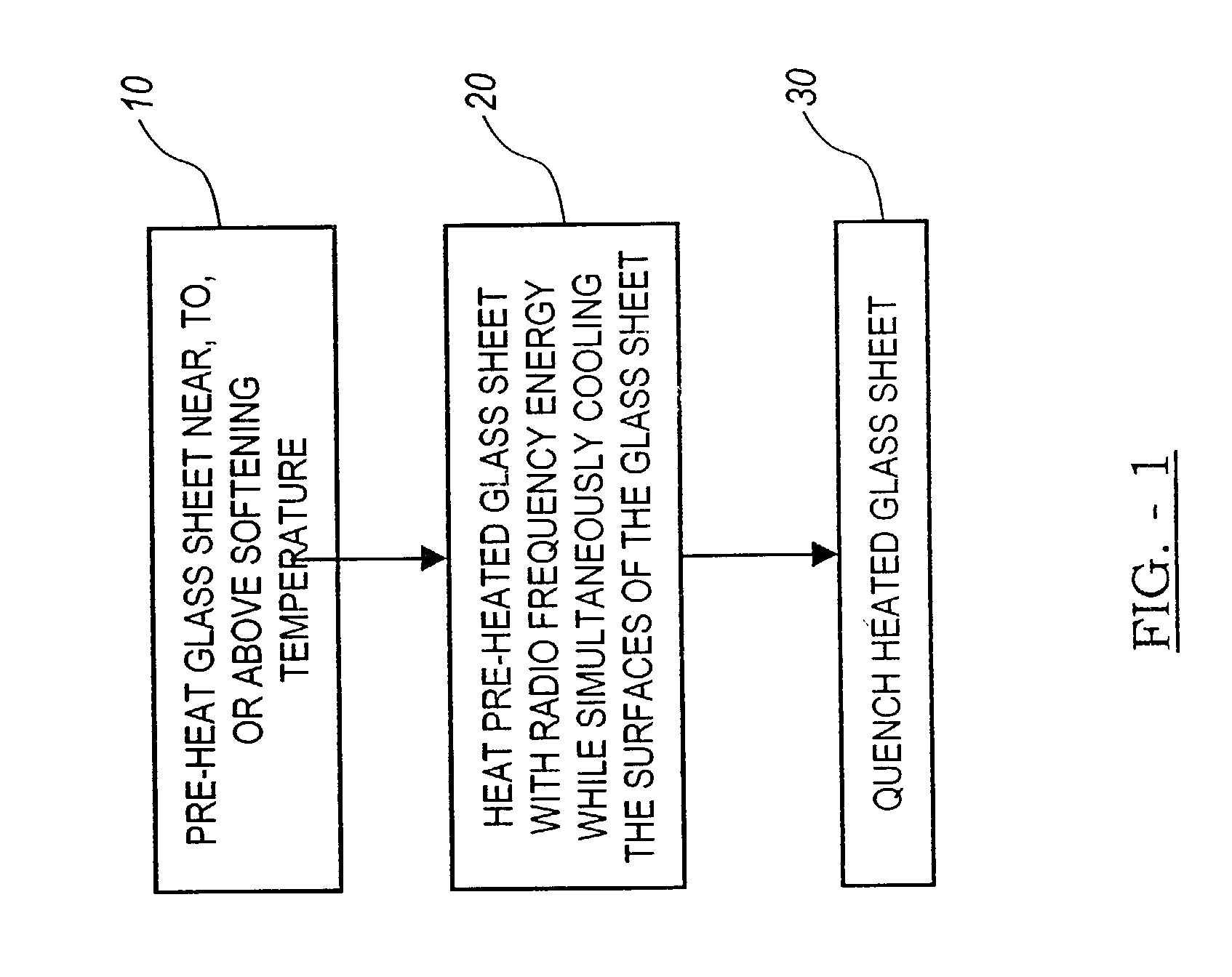

System and method for simultaneously heating and cooling glass to produce tempered glass

InactiveUS20030233846A1Rapidly and efficiently and inexpensively heatThin tempered glassGlass transportation apparatusGlass reforming apparatusSurface coolingRadio frequency energy

A system and method for heating, forming, and tempering a glass sheet includes pre-heating the glass sheet to at least a first predetermined temperature. The system and method includes also applying radio-frequency energy to the glass sheet to heat it to at least a second predetermined temperature and cooling at least one outer surface of the glass sheet to at least a third predetermined temperature to temper the glass sheet.

Owner:BOAZ PREMAKARAN T

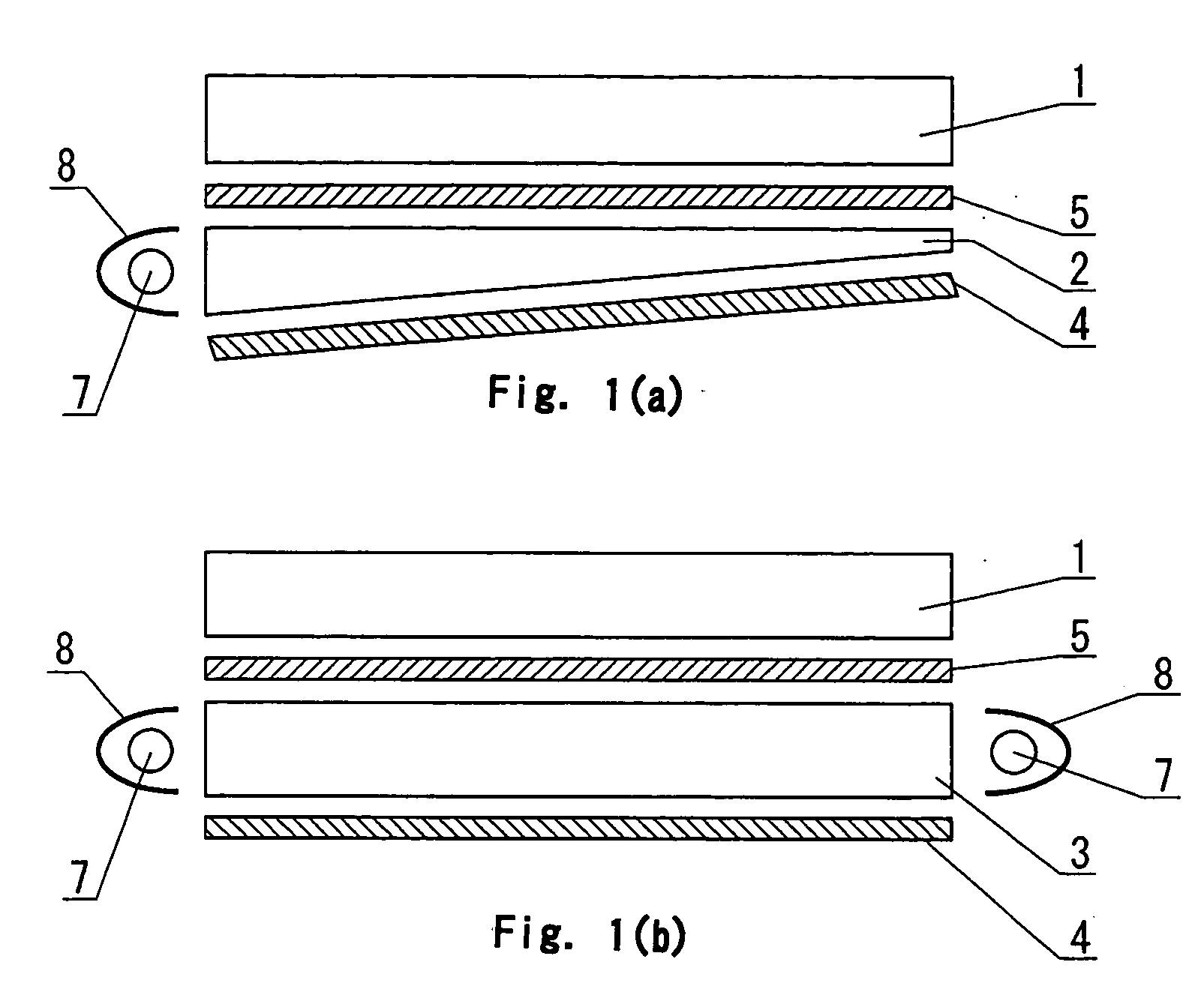

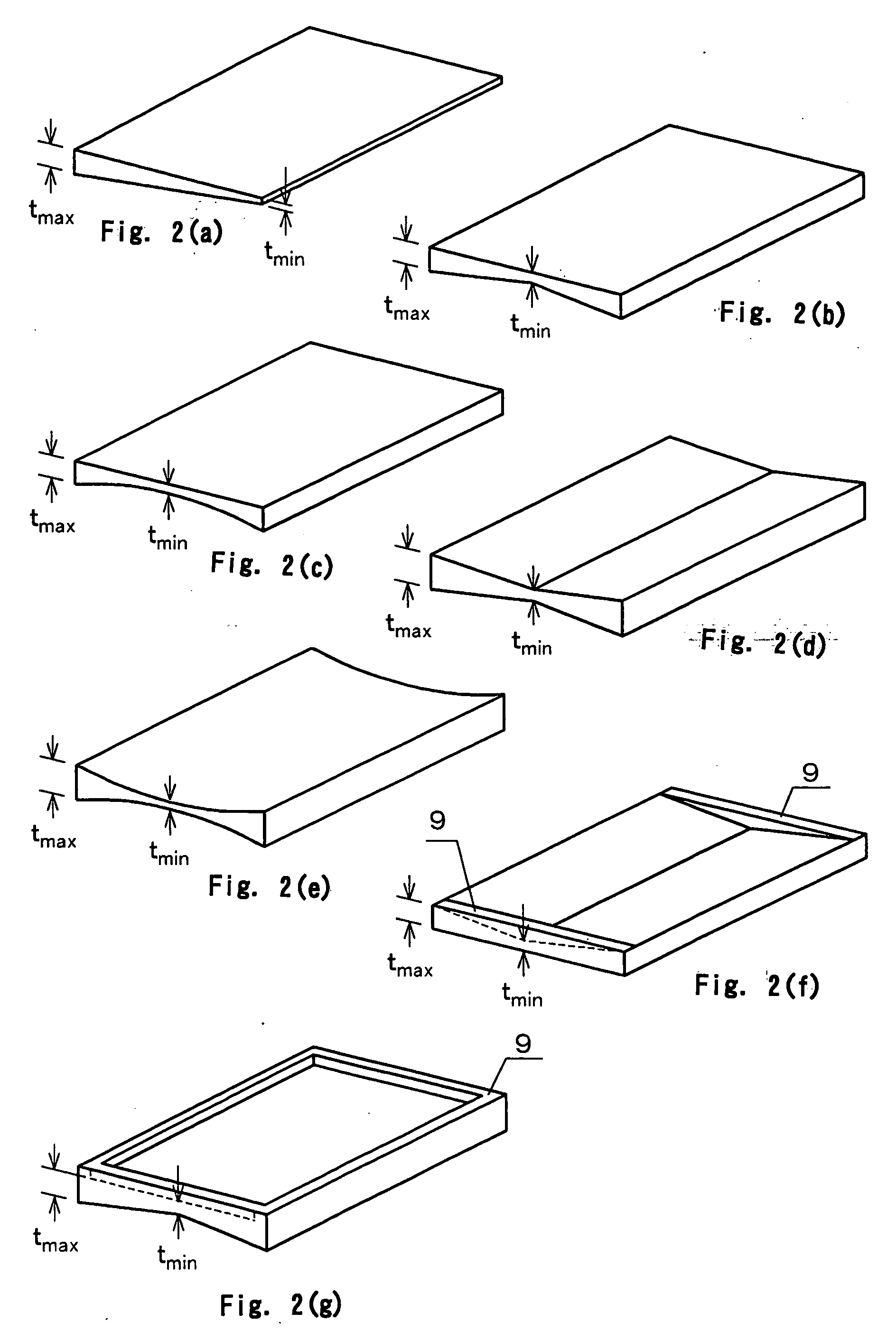

Method for producing light transmitting plate

InactiveUS20050189665A1Performance requirementNon-uniform thicknessOptical articlesFlat articlesSurface coolingEngineering

A method for producing a large-size light transmitting plate is provided. The method comprising (1) connecting a cylinder of an injection device with a cavity in a mold; the mold having a space with a non-uniform height and comprising a mold body and a cavity block, the cavity block having a fluid channel, the fluid channel being connected with a fluid switching means for changing a fluid medium and allowing a heating medium and a cooling medium, (2) passing the heating medium through the fluid channel; (3) supplying the resin to the cylinder; (4) filling the molten resin into the cavity; and (5) passing the cooling medium through the fluid channel after the filling of the cavity, to cool the cavity surface to a temperature lower than the glass transition temperature of the resin.

Owner:SUMITOMO CHEM CO LTD

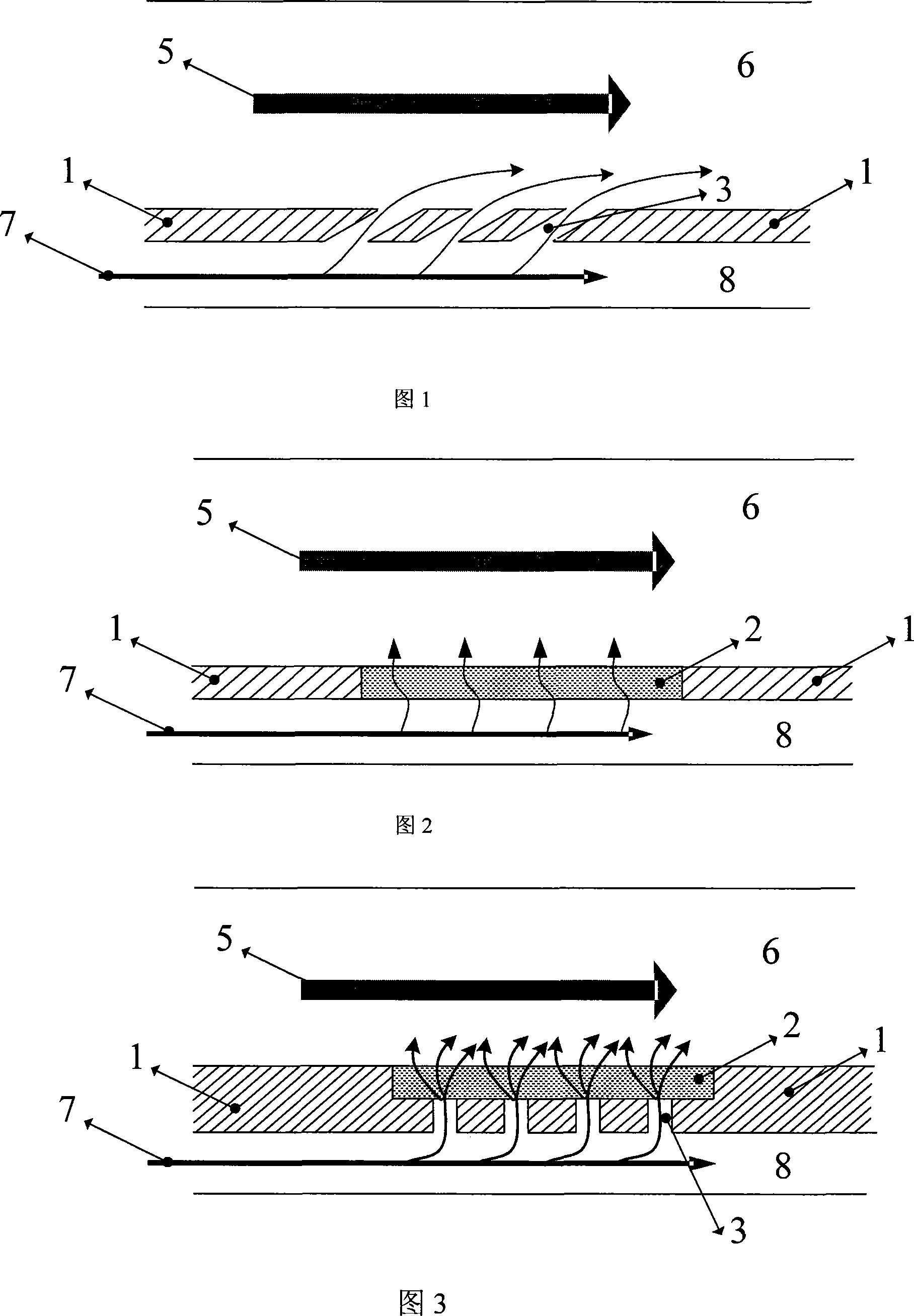

Heated wall surface cooling structure and gas turbine impeller vane with the same

ActiveCN101173610AEffective cooling efficiencyImprove thermal stressBlade accessoriesMachines/enginesPorous mediumEngineering

The invention relates to a cooling structure of the heated wall surface and a gas turbine blade of the cooling structure; wherein, the cooling structure comprises a compact wall surface layer, and a plurality of discrete through holes for the coolant to pass through are arranged on the compact wall surface layer; a porous coating is covered on the heated side of the compact wall surface layer to enable the porous coating and the compact wall surface layer with a plurality of discrete through holes to form a structure of double-layer superimposition, and the outlet of the discrete through hole is communicated with the porous coating. The porous coating can be continuously covered on the compact wall surface layer, and also can be covered on the local areas of the outlet of the discrete through holes. The invention has the advantages of synthesizing the characteristics of gas film cooling and transpiration cooling, fully combining the advantages of two cooling ways, effectively improving the cooling efficiency of the wall surface, reducing the geothermal gradient of the wall surface, and avoiding the continuous increase of the heat stress of materials. Simultaneously, the intensity of the cooling structure of the invention is enough to be used for common impeller machinery.

Owner:TSINGHUA UNIV

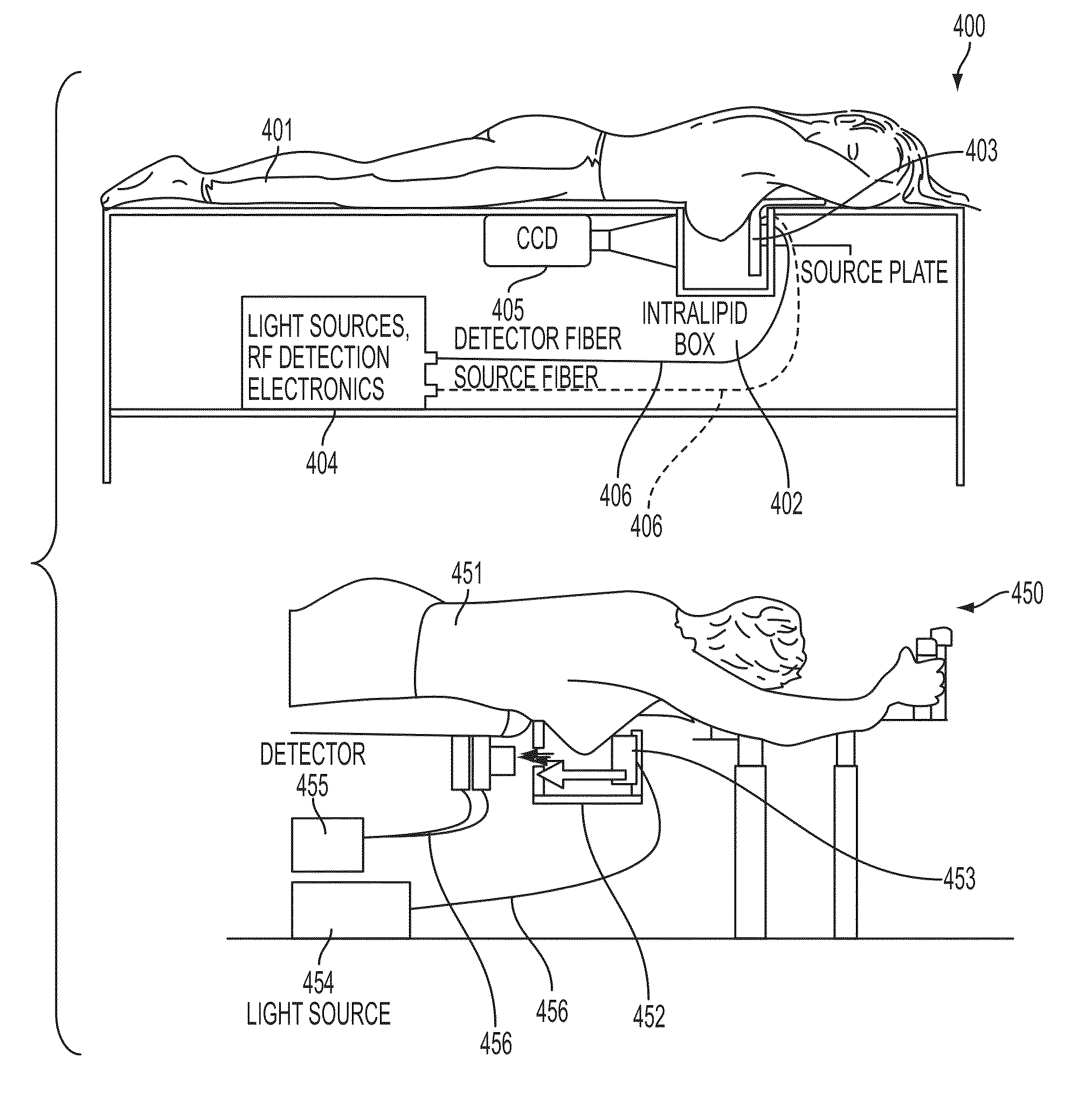

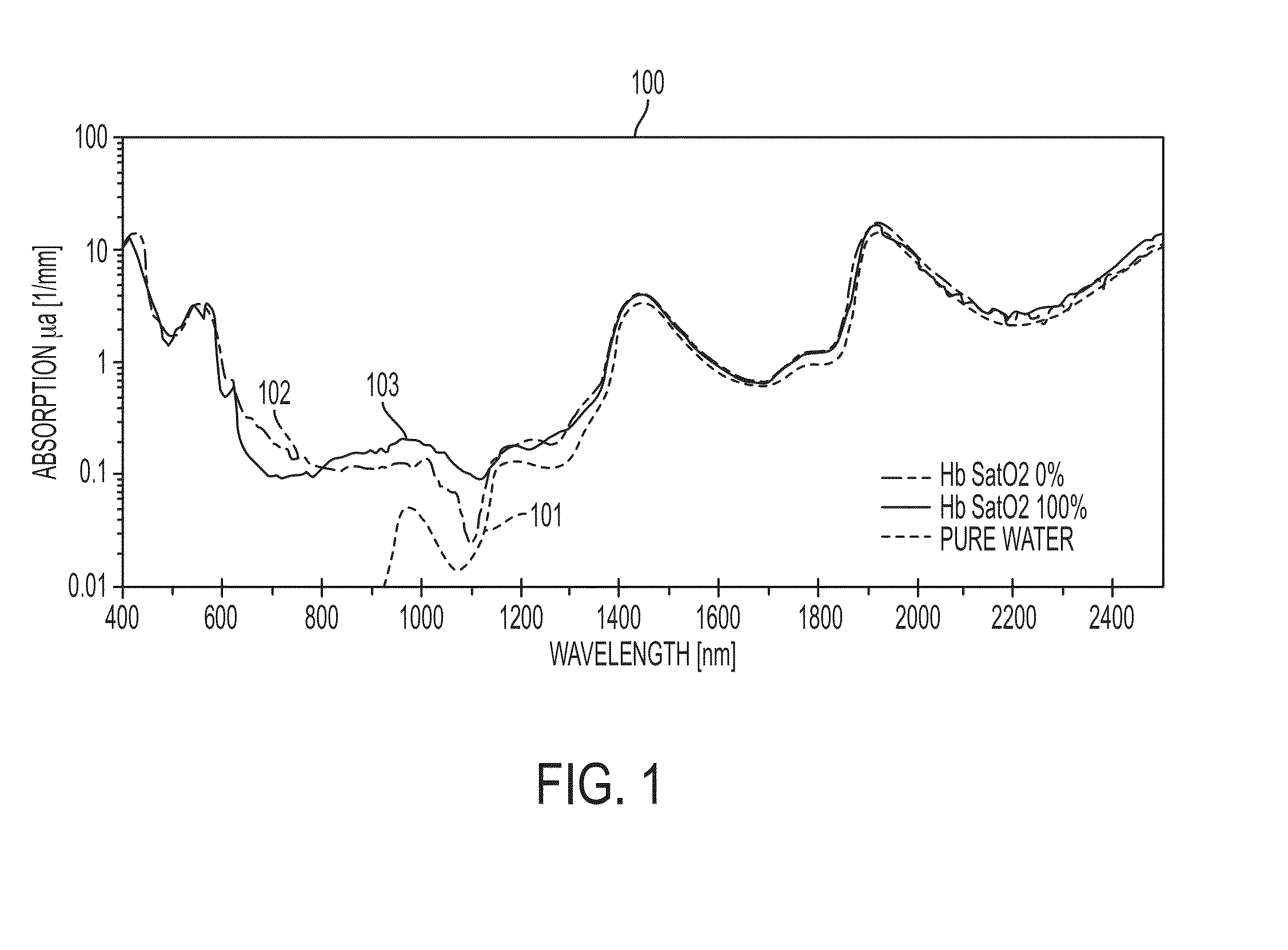

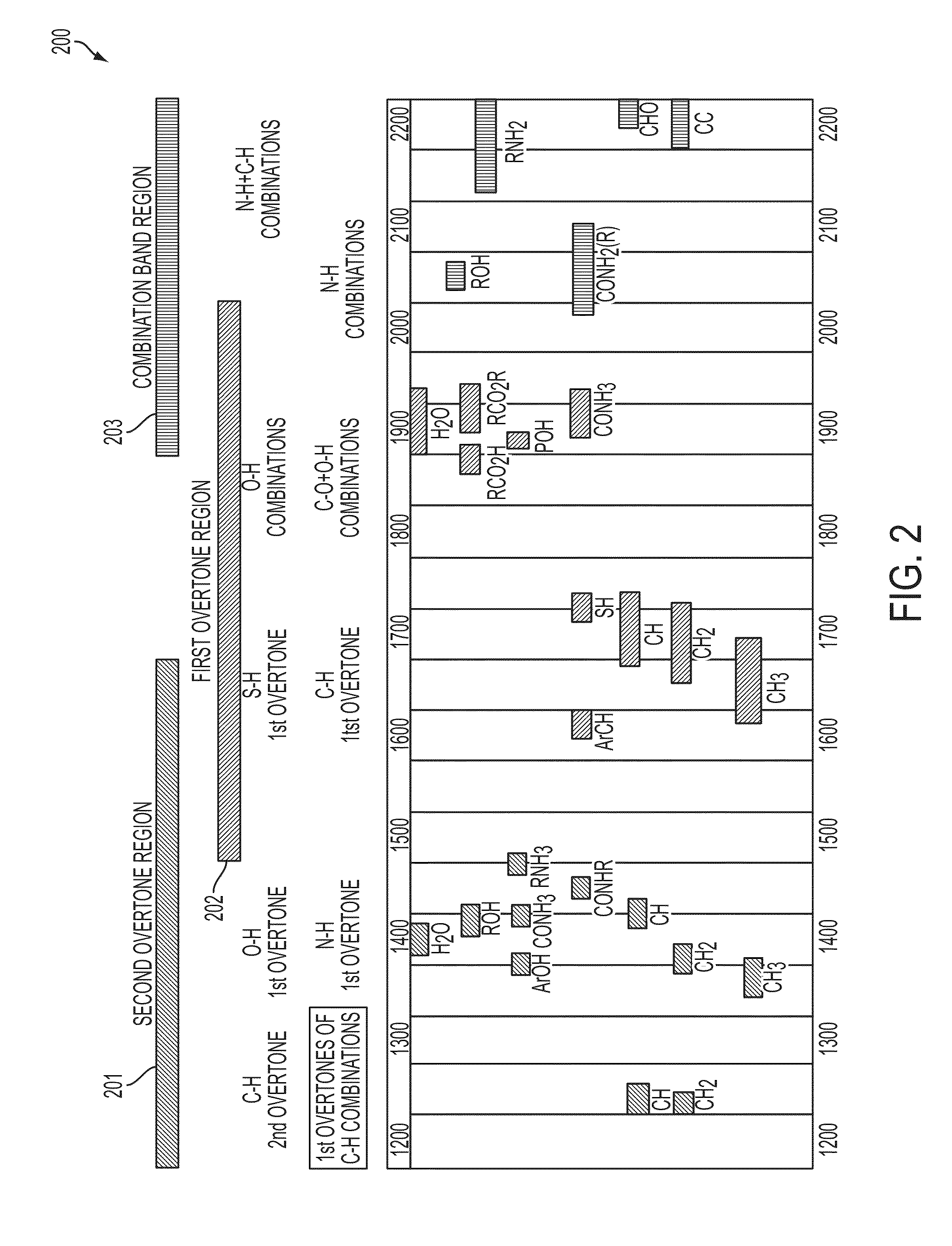

Near-infrared super-continuum lasers for early detection of breast and other cancers

InactiveUS20140236021A1Improve signal-to-noise ratioHigh in collagenDiagnostics using spectroscopyOptical sensorsConfocalScattering loss

A system and method for using near-infrared or short-wave infrared (SWIR) light sources for early detection and monitoring of breast cancer, as well as other kinds of cancers may detect decreases in lipid content and increases in collagen content, possibly with a shift in the collagen peak wavelengths and changes in spectral features associated with hemoglobin and water content as well. Wavelength ranges between 1000-1400 nm and 1600-1800 nm may permit relatively high penetration depths because they fall within local minima of water absorption, scattering loss decreases with increasing wavelength, and they have characteristic signatures corresponding to overtone and combination bands from chemical bonds of interest, such as hydrocarbons. Broadband light sources and detectors permit spectroscopy in transmission, reflection, and / or diffuse optical tomography. High signal-to-noise ratio may be achieved using a fiber-based super-continuum light source. Risk of pain or skin damage may be mitigated using surface cooling and focused infrared light.

Owner:OMNI MEDSCI INC

Device and method for improving strength of selective laser sintering 3D printing part

ActiveCN104785780AInfluence intensityImprove surface qualityAdditive manufacturing apparatusIncreasing energy efficiencySurface coolingSelective laser sintering

The invention discloses a device and method for improving the strength of a selective laser sintering 3D printing part. The device mainly comprises a laser unit, a powder spreading unit, a pressing unit and a powder heating unit. A quartz glass panel in the same shape as a forming cylinder piston is placed over the forming cylinder piston in parallel and moves vertically through a stepping motor and ball screws. The quartz glass panel moves upwards by a certain distance every time after sintering of one layer is completed so that a powder spreading roller can pass through smoothly to perform the next time of powder spreading. The optical quartz glass panel can transmit lasers and also can apply pressing force to press powder, so that the situation that because pores exist in the powder, holes are formed inside the product after the sintering process and influence the strength of the product is avoided, and the surface quality of the product is improved. The surface of the topmost layer of the formed product does not make contact with the quartz glass panel so that the formed product will not adhere to the quartz glass panel. Or, after the spread powder is sintered, the quartz glass panel performs pressing and is moved away till the surface of the formed product is cooled and solidified, and then the formed product is taken out.

Owner:BEIJING UNIV OF CHEM TECH

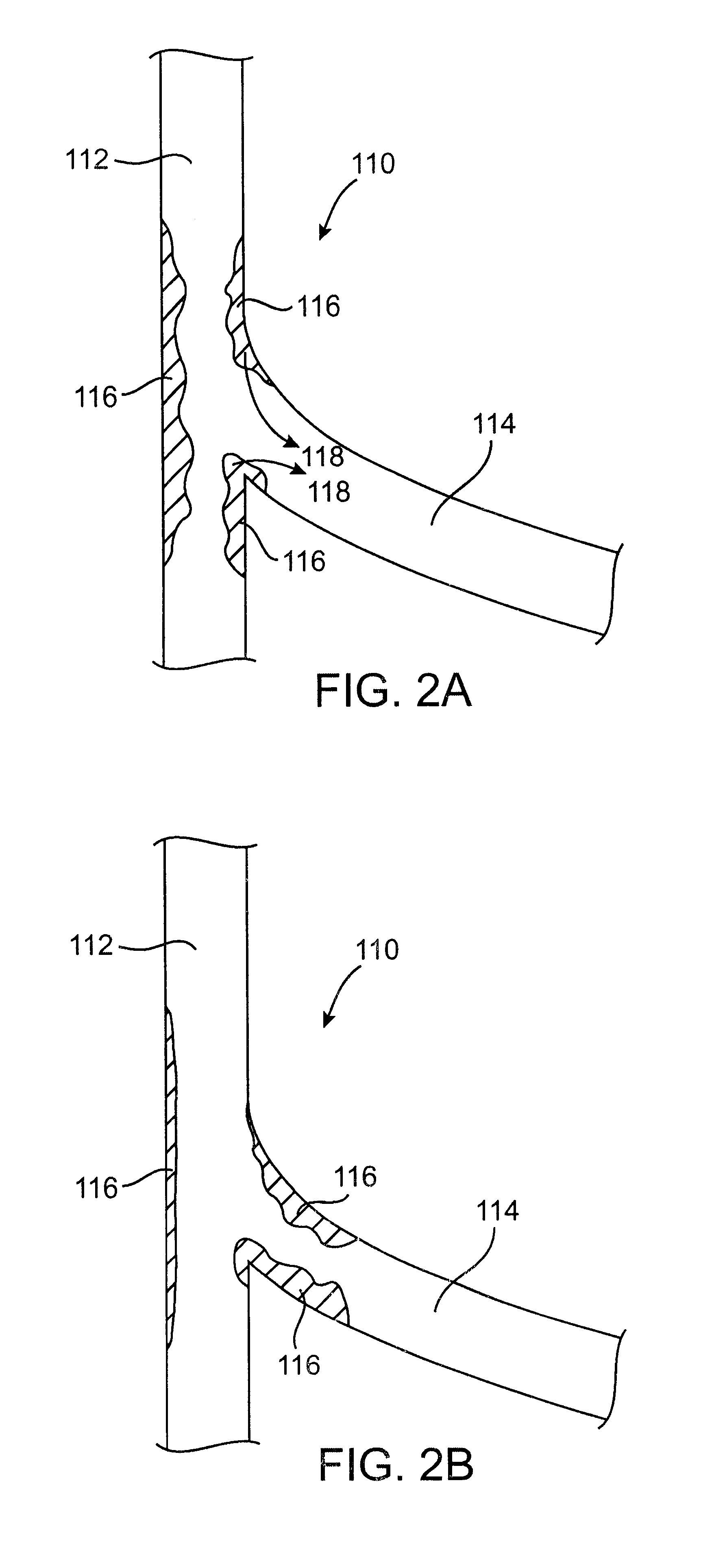

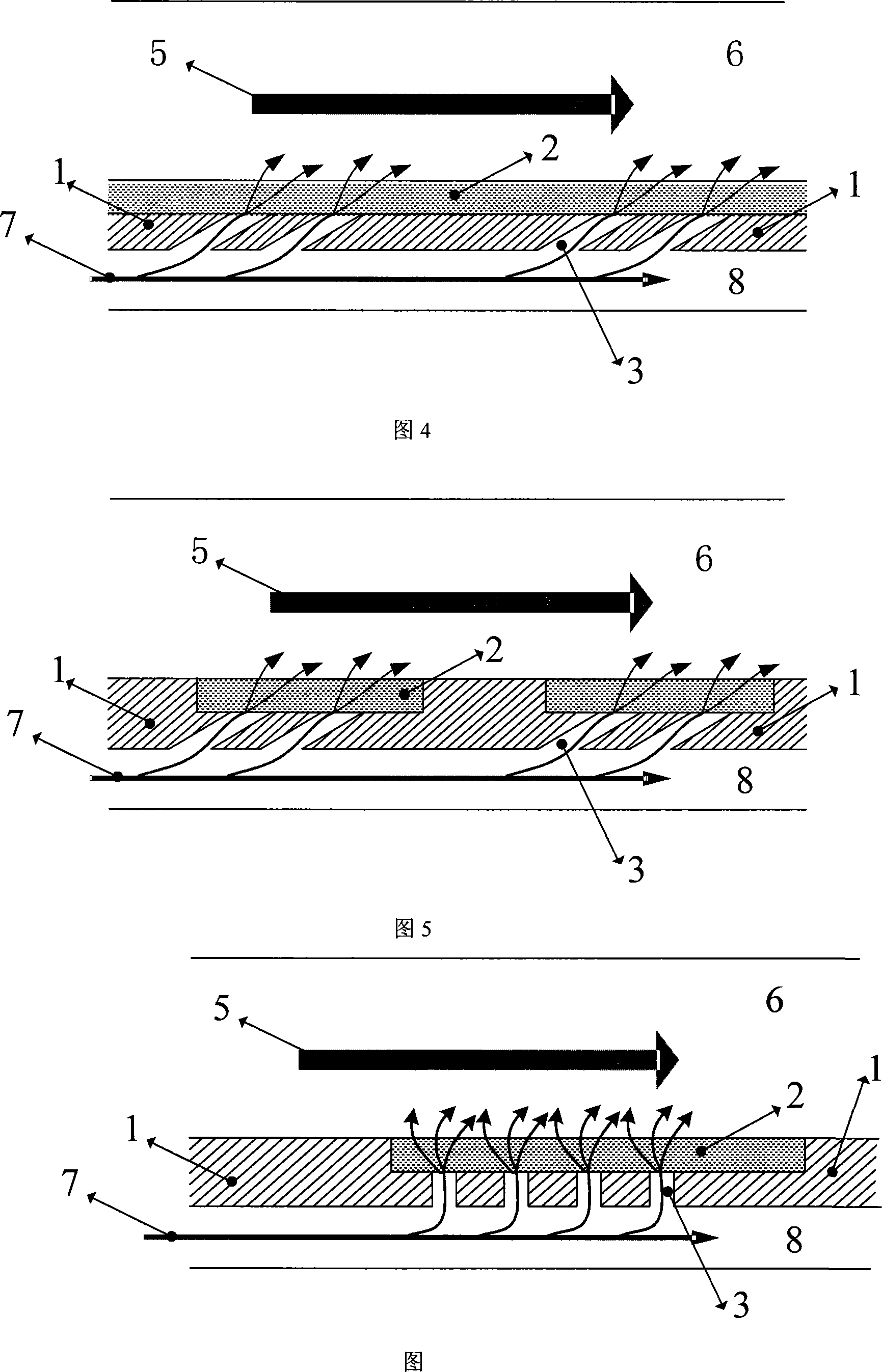

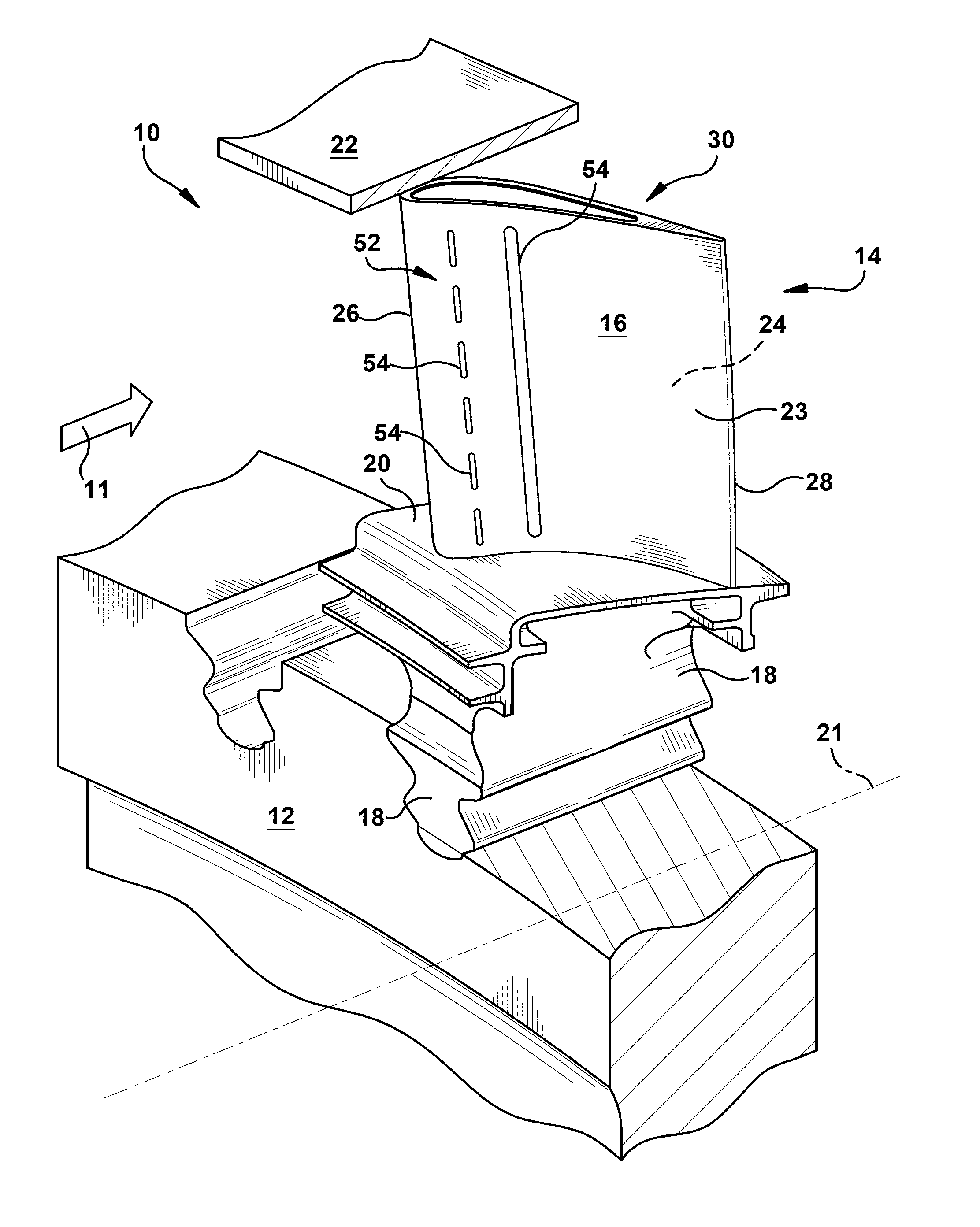

Metered cooling slots for turbine blades

A metered cooling slot disposed in a wall comprising an outer surface that is exposed to a hot gas stream and an inner surface that defines an internal coolant chamber through which a coolant passes, the metered cooling slot comprising: a slot formed within the outer surface elongated in a first direction, the slot comprising a pair of spaced apart, opposing, slot surfaces and a base, the slot surfaces intersecting the outer surface to form a slot outlet opposite the base; and two or more metering apertures formed within the wall, each metering aperture intersecting the inner surface of the wall to form a metering aperture inlet and intersecting one of the pair of slot surfaces to form a metering aperture outlet; wherein: D represents the approximate diameter of at least two of the metering apertures; P represents the approximate distance between the center lines of at least two neighboring metering apertures; and P / D comprises a value within the range of about 4 to 6.

Owner:GENERAL ELECTRIC CO

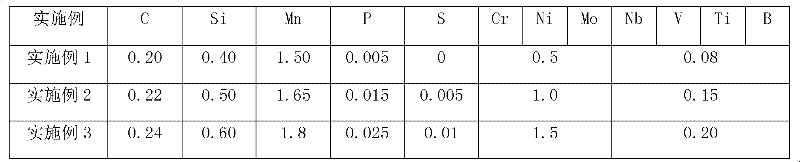

Hot-stamping automobile part with flexibly-distributed intensity and control method thereof

ActiveCN102212742AControl Surface Cooling RateImprove performanceVehicle componentsHot stampingSurface cooling

The invention discloses a manufacturing technology and process of a hot-stamping part with flexibly-distributed intensity. In the invention, by utilizing a flexible and controllable hot-stamping die with a cooling pipeline, the surface cooling speed of a die for forming a high-intensity part is controlled at more than 60-80 DEG C / s, the flow velocity of cooling water is 2.5-3m / s, the water flow pressure at an entrance is 7-8bar, and the water flow pressure at an exit is 5-7bar; and the surface cooling speed of a die for forming a medium-intensity part of the automobile parts is controlled at more than 10-30 DEG C / s, the water flow velocity in the die is 1-2m / s, the water flow pressure at the die entrance is 5-6bar, and the water flow pressure at the die exit is 3-5bar. By utilizing the process, diversified structures and flexible intensity distribution of the parts are realized so that different parts of the automobile parts have different intensity; and meanwhile plate structures with different intensity are transited gently and the performances of the plate structures are transited smoothly without abrupt changes, thus achieving more ideal performances, lowering the manufacturing cost and simplifying procedures.

Owner:东莞市豪斯特热冲压技术有限公司

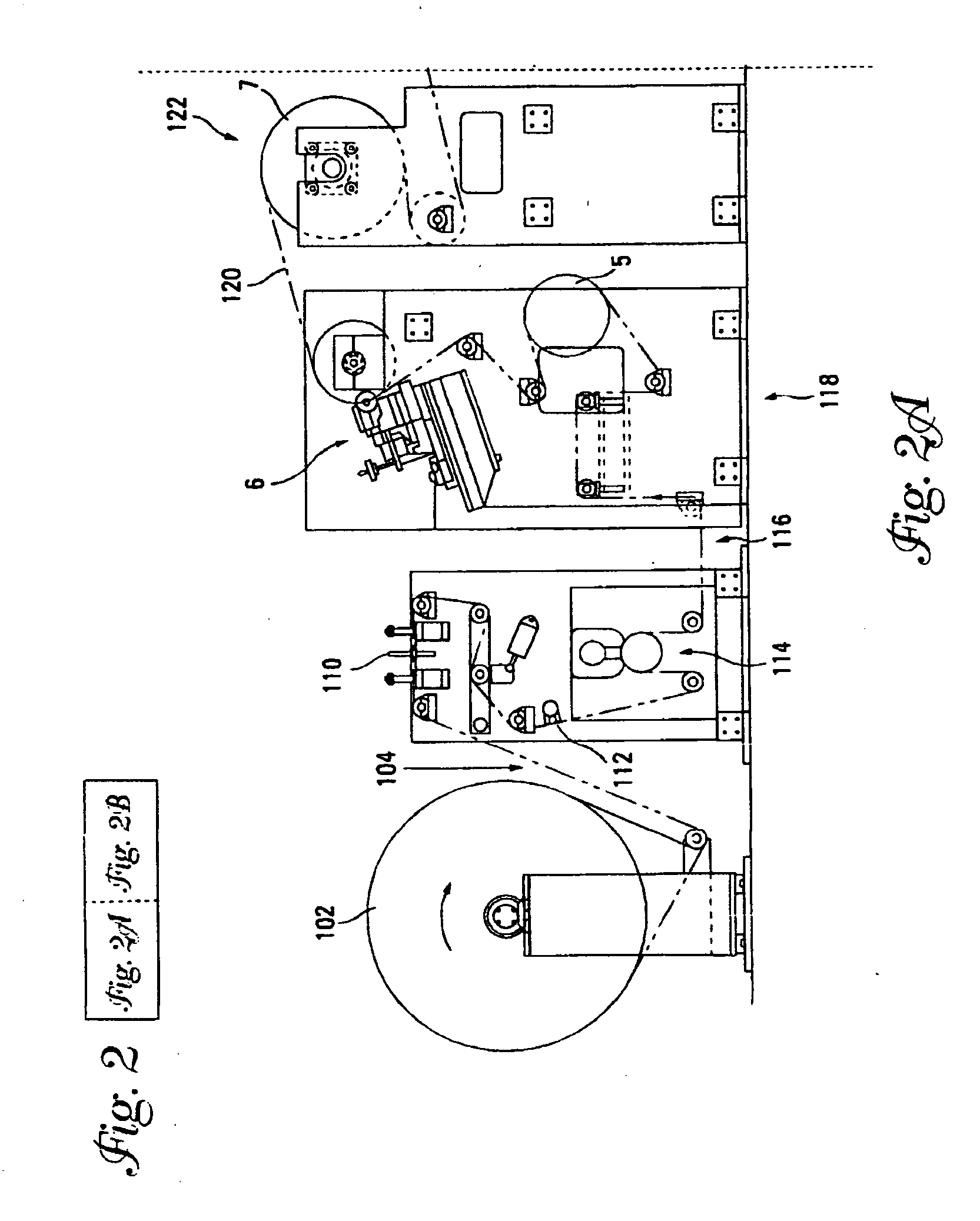

Apparatus and method for applying labels

InactiveUS20070074809A1Reduce workloadReduce cross contaminationStampsLamination ancillary operationsSurface coolingAdhesive

A method and apparatus enables linered label applicators to use labels on thin liners. Linered labels comprise a composite of an elongate sheet of thin or light-weight temporary liner having a precut label adhered to a low adhesion surface. The cut-out labels on the liner are fed into the linered label applicator. The use of support mechanisms other then vacuum application on rollers enables the use of thinner liner sheets on labels. A die head for cutting or perforating labels comprising adhesive on label stock comprising a die head having at least 80% of its outer surface comprising flat areas between cutting edges, multiple cutting edges on the outer surface, and an internal volume in the die head, the internal volume for carrying coolant liquid into and out of the volume so as to cool the outer surface of the die head when the coolant temperature is at least 10° C. cooler than the outer surface of the die head.

Owner:AVERY DENNISON CORP

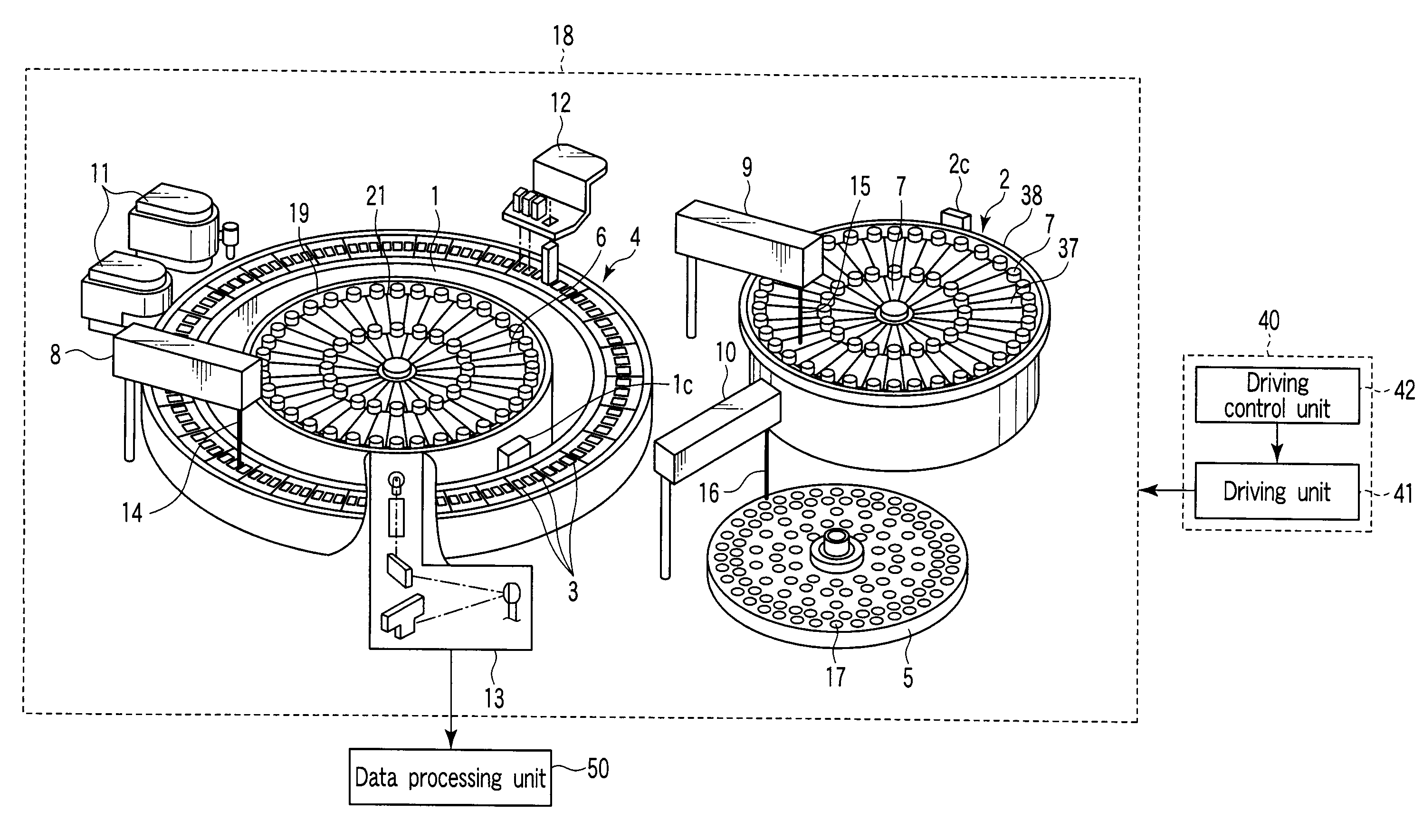

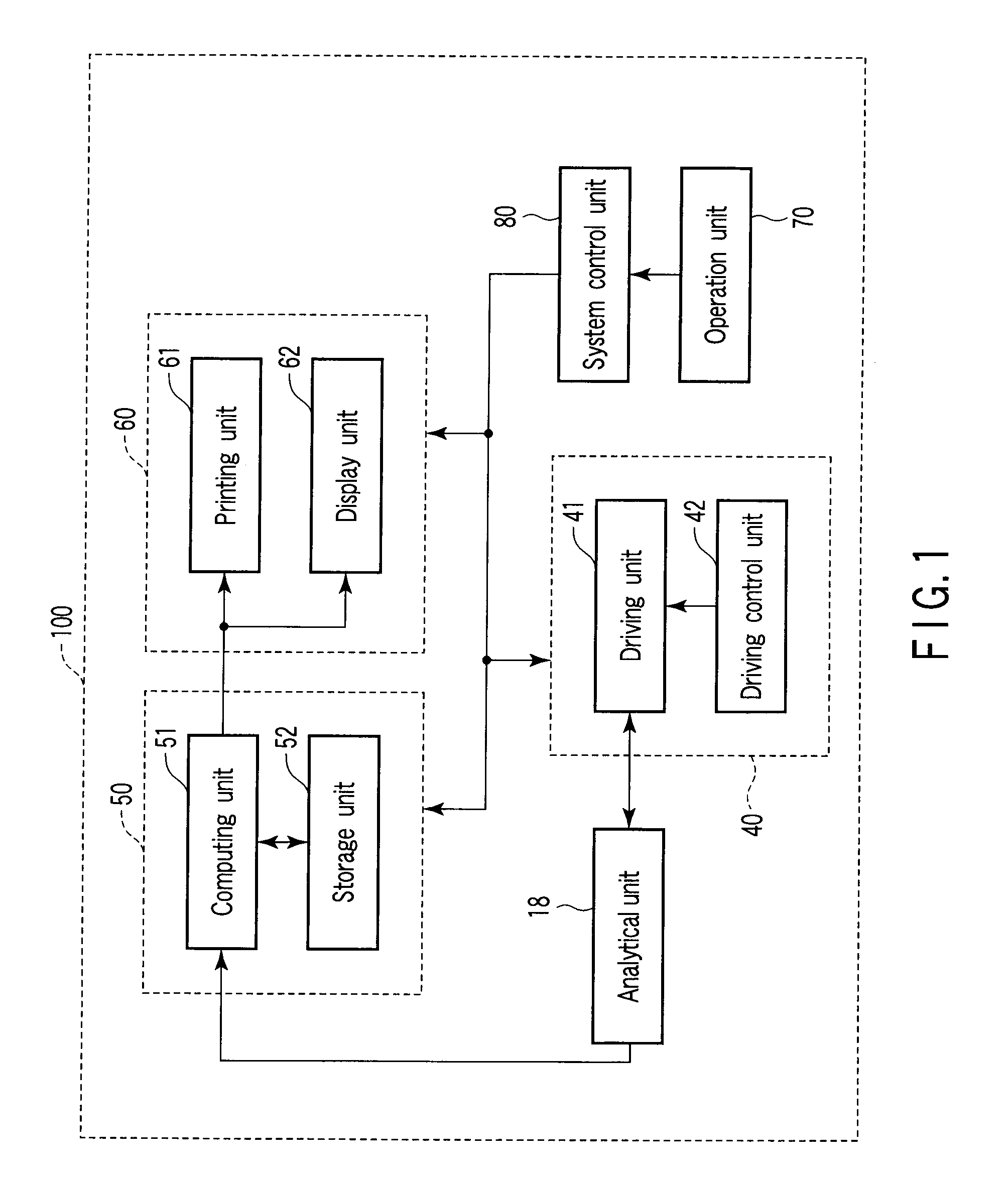

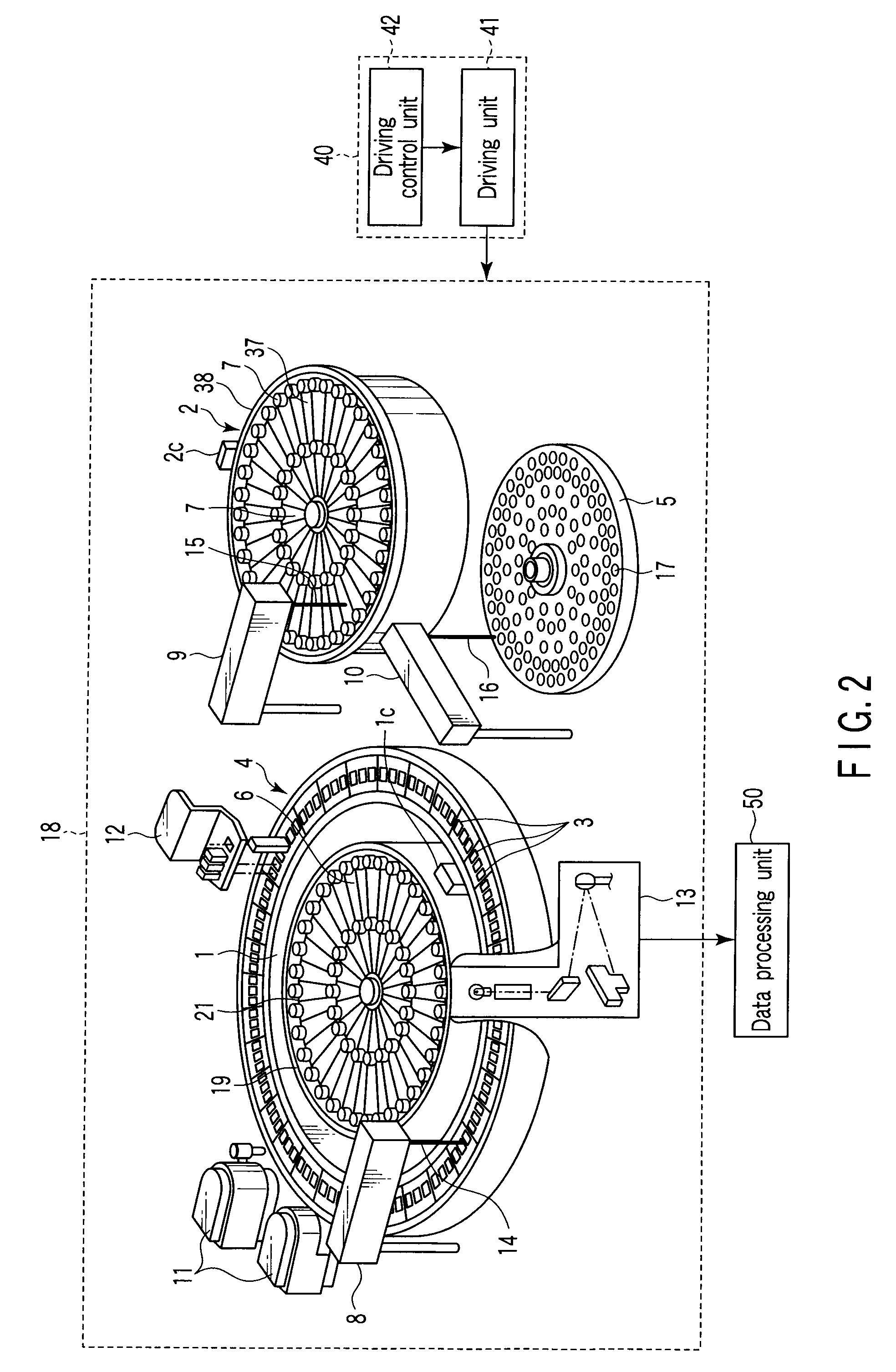

Automatic analyzer and reagent storage thereof

ActiveUS20090004057A1Stay efficientAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionSurface coolingEngineering

A holding unit pivotally holds a plurality of reagent bottles which store reagents. A reagent case houses the holding unit and has an edge higher than at least the housed holding unit. The reagent cover is a cover for closing the reagent case. A cooling unit is mounted on one outer surface of the reagent case and cools air in the reagent case closed by the reagent cover through one outer surface. A circulating unit is mounted on the holding portion and circulates the cooled air in the reagent case closed by the reagent cover.

Owner:TOSHIBA MEDICAL SYST CORP

Metered cooling slots for turbine blades

A metered cooling slot disposed in a wall comprising an outer surface that is exposed to a hot gas stream and an inner surface that defines an internal coolant chamber through which a coolant passes, the metered cooling slot comprising: a slot formed within the outer surface elongated in a first direction, the slot comprising a pair of spaced apart, opposing, slot surfaces and a base, the slot surfaces intersecting the outer surface to form a slot outlet opposite the base; and two or more metering apertures formed within the wall, each metering aperture intersecting the inner surface of the wall to form a metering aperture inlet and intersecting one of the pair of slot surfaces to form a metering aperture outlet; wherein: D represents the approximate diameter of at least two of the metering apertures; P represents the approximate distance between the center lines of at least two neighboring metering apertures; and P / D comprises a value within the range of about 4 to 6.

Owner:GE INFRASTRUCTURE TECH INT LLC

Modularized differential temperature forming hot punching mold

InactiveCN103464607APrevent transmission toRealize the purpose of partition coolingShaping toolsSurface coolingPunching

The invention relates to a modularized differential temperature forming hot punching mold, which comprises a template, heating modules and cooling modules, wherein the heating modules are respectively and fixedly arranged at the two sides of the template through screw bolts, the cooling modules are respectively and fixedly arranged in the middle of the template, heating rods are arranged in the heating modules, the uniform heating is carried out through the heating rods, water inlet and outlet holes are formed in the contact surfaces of the cooling modules and the template in a longitudinal direction, a plurality of surface cooling pipelines are arranged inside the cooling modules along the shape of the work surface, water inlet and outlet openings are correspondingly formed in the template, and the cooling modules are cooled through circulation water. A part of module is heated, and the other part of module is cooled, so the goal of regional cooling is reached, and the hot punching part with the performance gradient is obtained. The modularized differential temperature forming hot punching mold has the advantages that the structure is reasonable, the cooling speed of different positions is controlled, and the temperature gradient can be generated on the same hot punching part so that the hot punching part has good integral mechanical property.

Owner:HARBIN INST OF TECH AT WEIHAI

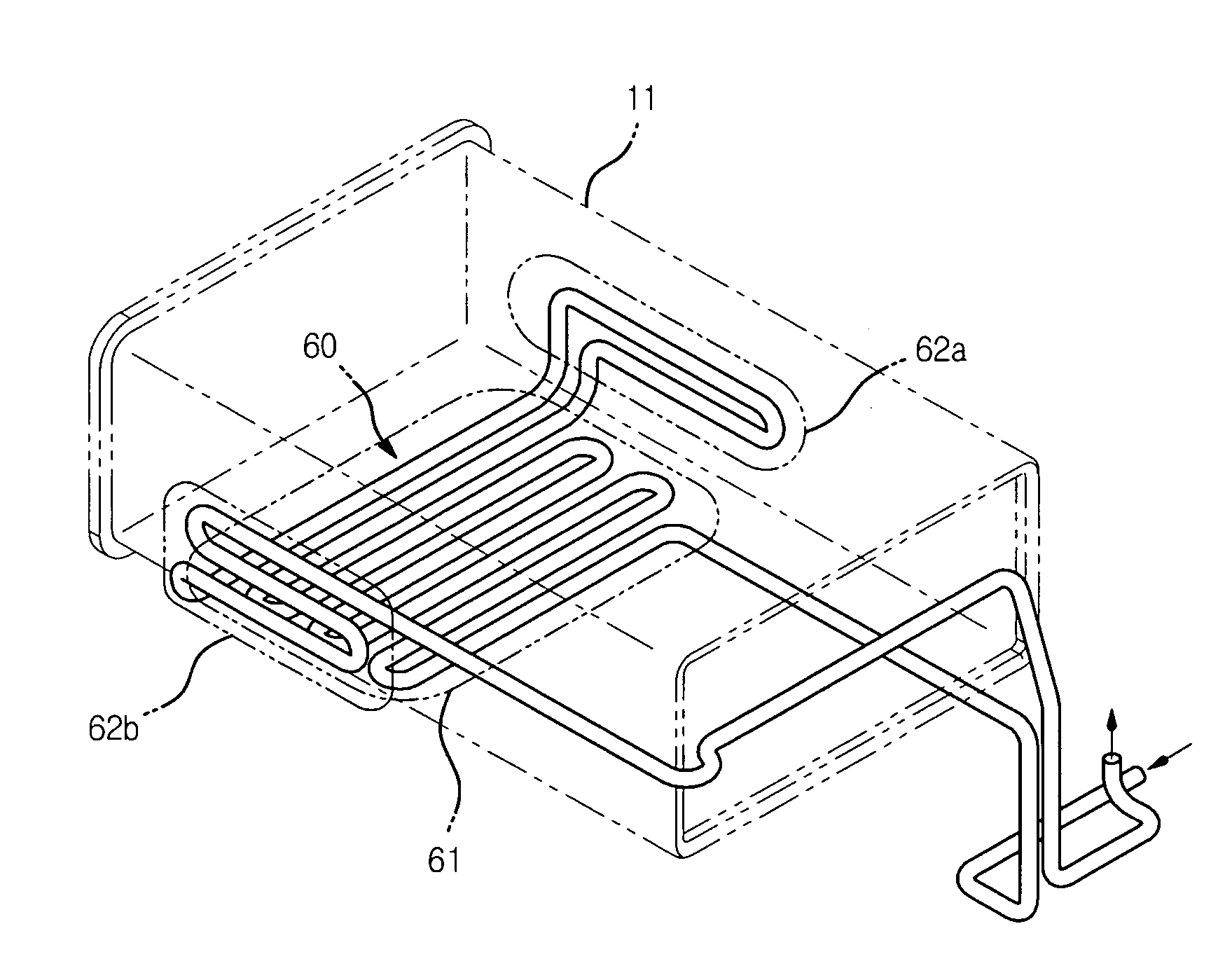

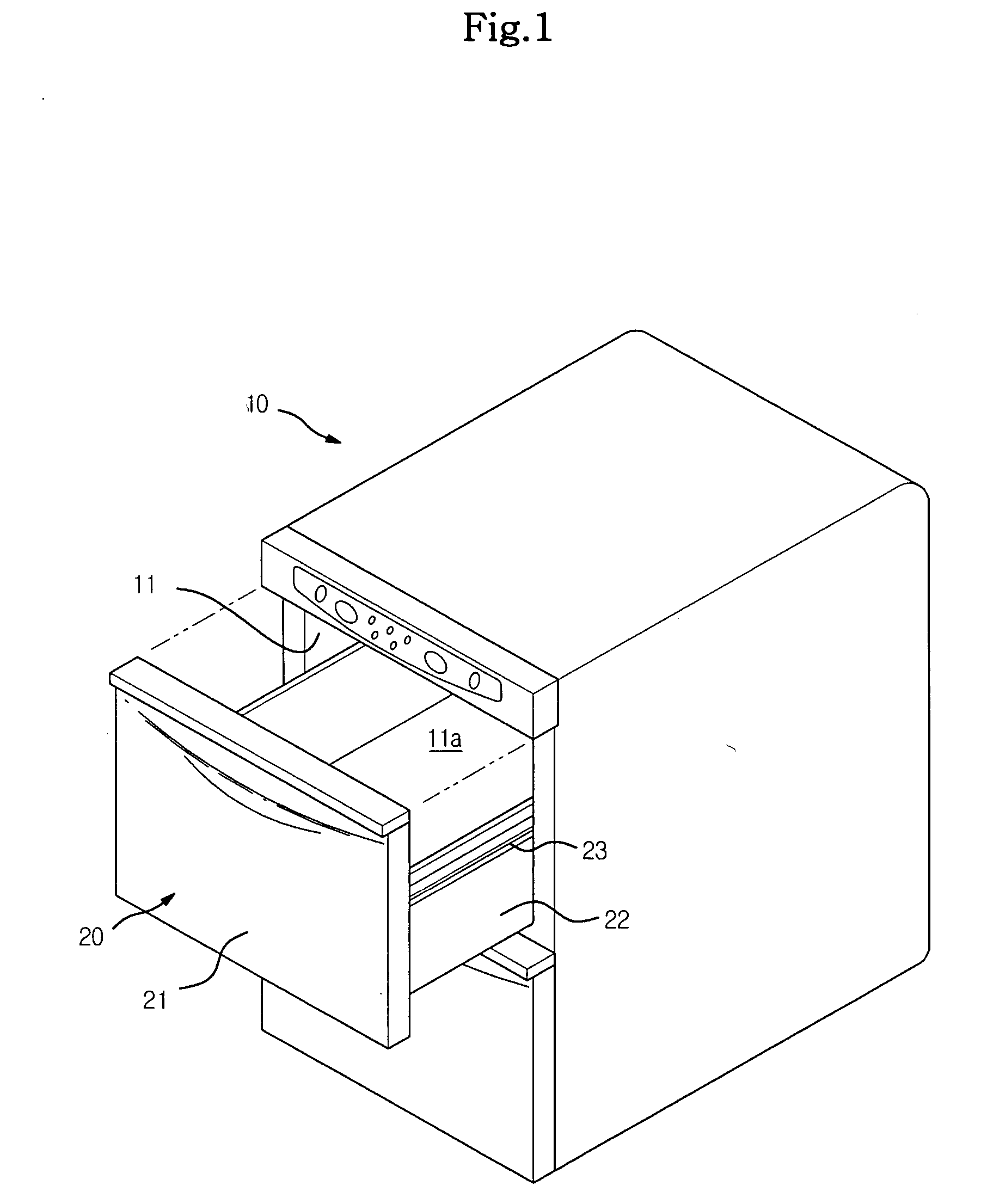

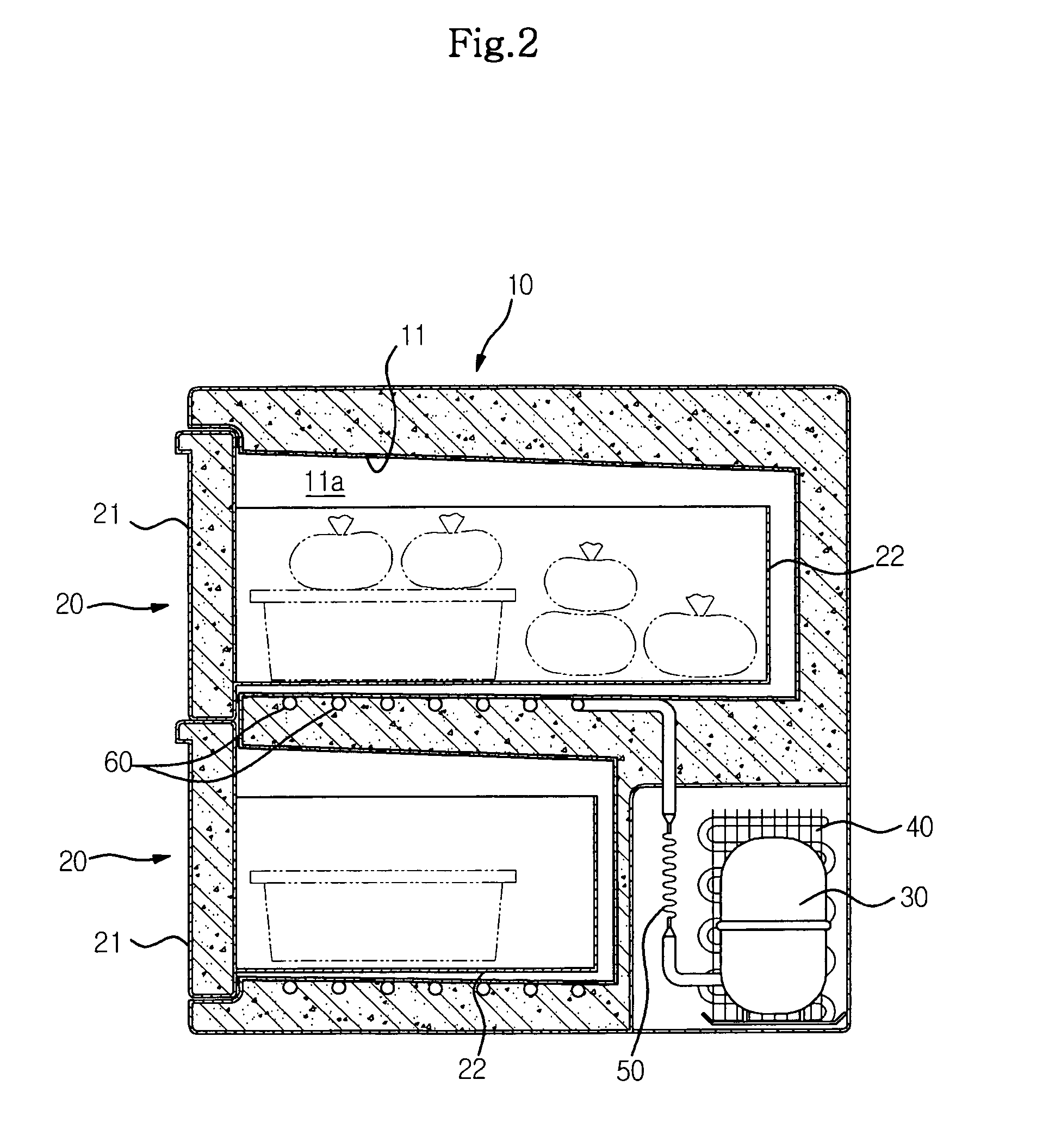

Refrigerator

InactiveUS20070017245A1More numberEvaporators/condensersDomestic refrigeratorsSurface coolingEngineering

An evaporator which enables respective side surfaces of an inner liner defining a storage compartment to be uniformly cooled to provide uniform distribution of temperature in the storage compartment. A refrigerator includes the evaporator positioned on an outer surface of the inner liner to absorb heat from the inner liner. The evaporator includes at least two side surface cooling portions respectively positioned on at least first and second side surfaces of the inner liner. The side surface cooling portion positioned at a downstream side to allow refrigerant of lower cooling capability to flow therethrough is longer than the side surface cooling portion positioned at an upstream side to allow refrigerant of higher cooling capability to flow therethrough. The refrigerant cools the inner liner while flowing through the side surface cooling portion positioned at the downstream side for a longer period, enabling a uniform distribution of temperature in the storage compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

Handpiece with RF electrode and non-volatile memory

InactiveUS20060025837A1Easy to operateControllable tissueElectrotherapyPneumatic massageElectricitySurface cooling

An RF device includes a support structure coupled to an RF electrode that has conductive and dielectric portions. A cooling member is coupled to the support structure and is configured to cool a back surface of the RF electrode. The cooling member is distanced from the back surface of the RF electrode. A memory is coupled to the RF electrode. The memory is configured to store information to facilitate operation of at least one of the RF electrode, the cooling member and an RF energy source.

Owner:THERMAGE INC

Continuous casting blank hot charging and hot conveying process for preventing surface crack of steel plate

InactiveCN102059331AAvoid Surface Crack DefectsMake full use of waste heatMetallic materialsMaterials processing

The invention relates to a continuous casting blank hot charging and hot conveying process for preventing a surface crack of a steel plate under the condition of raising temperature of continuous casting blank hot charging, belonging to the technical field of metal material processing. The process comprises the following steps of: cutting a continuous casting blank on a cutting roller way, then introducing the cut continuous casting blank into a conveying roller way located between a continuous casting machine and a rolling mill, and spraying water and cooling the continuous casting blank quickly; reducing the temperature of the surface of the continuous casting blank to about 600 DEG C; controlling the cooling rate of the surface of the continuous casting blank to be 20-50 DEG C / s; controlling the cooling time of the surface of the continuous casting blank to be 15-60s; and cooling the continuous casting blank, and then introducing the cooled continuous casting blank to a heating furnace within 15min and heating. The process has the advantages that the temperature inside the continuous casting blank is ensured to be higher than 800 DEG C under the condition of ensuring the surface temperature of the continuous casting blank introduced into the heating furnace to be lower than 600 DEG C, therefore, the surface crack defect of the rolled steel plate is prevented, the waste heat of the continuous casting blank can be fully utilized, and the favorable energy saving effect is achieved.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com