Modularized differential temperature forming hot punching mold

A hot stamping die and differential temperature forming technology, applied in the field of hot stamping, can solve rare problems and achieve the effects of convenient operation, reasonable structure and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

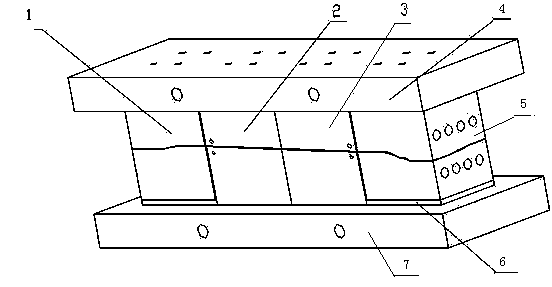

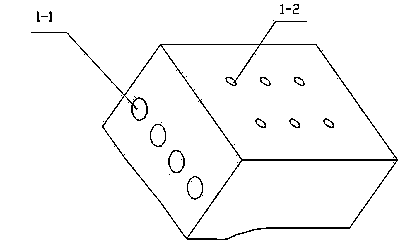

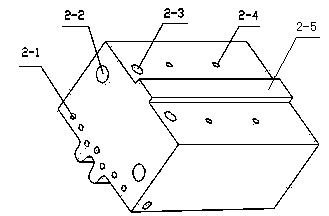

[0016] From figure 1 It can be seen that a modular differential temperature forming hot stamping die includes an upper template 4, a lower template 7, a heating module and a cooling module. The mold adopts a block structure, and four heating modules are respectively fixed on both sides of the upper and lower formworks by bolts, and at least two cooling modules are respectively fixed in the middle of the upper and lower formworks by bolts. The heating module 1, the cooling module in the middle, the heating module 5 and the upper template 4 together constitute the upper die of the stamping die. Other heating modules, cooling modules and the lower template form the lower mold of the stamping die. Since the combination of the heating module, the cooling module and the upper mold plate or the lower mold plate is the same, only the structure of the upper mold formed by the heating module, the cooling module and the upper mold plate will be described below.

[0017] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com