Patents

Literature

261results about How to "Make full use of waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous casting blank hot charging and hot conveying process for preventing surface crack of steel plate

InactiveCN102059331AAvoid Surface Crack DefectsMake full use of waste heatMetallic materialsMaterials processing

The invention relates to a continuous casting blank hot charging and hot conveying process for preventing a surface crack of a steel plate under the condition of raising temperature of continuous casting blank hot charging, belonging to the technical field of metal material processing. The process comprises the following steps of: cutting a continuous casting blank on a cutting roller way, then introducing the cut continuous casting blank into a conveying roller way located between a continuous casting machine and a rolling mill, and spraying water and cooling the continuous casting blank quickly; reducing the temperature of the surface of the continuous casting blank to about 600 DEG C; controlling the cooling rate of the surface of the continuous casting blank to be 20-50 DEG C / s; controlling the cooling time of the surface of the continuous casting blank to be 15-60s; and cooling the continuous casting blank, and then introducing the cooled continuous casting blank to a heating furnace within 15min and heating. The process has the advantages that the temperature inside the continuous casting blank is ensured to be higher than 800 DEG C under the condition of ensuring the surface temperature of the continuous casting blank introduced into the heating furnace to be lower than 600 DEG C, therefore, the surface crack defect of the rolled steel plate is prevented, the waste heat of the continuous casting blank can be fully utilized, and the favorable energy saving effect is achieved.

Owner:SHOUGANG CORPORATION

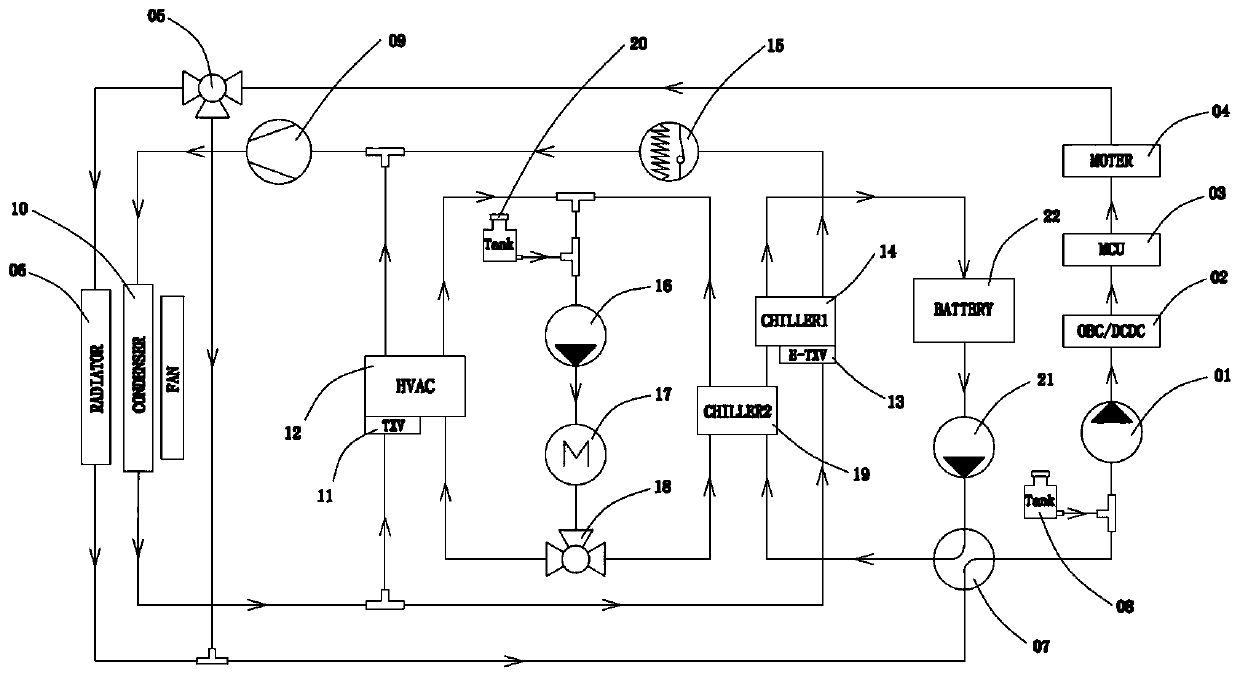

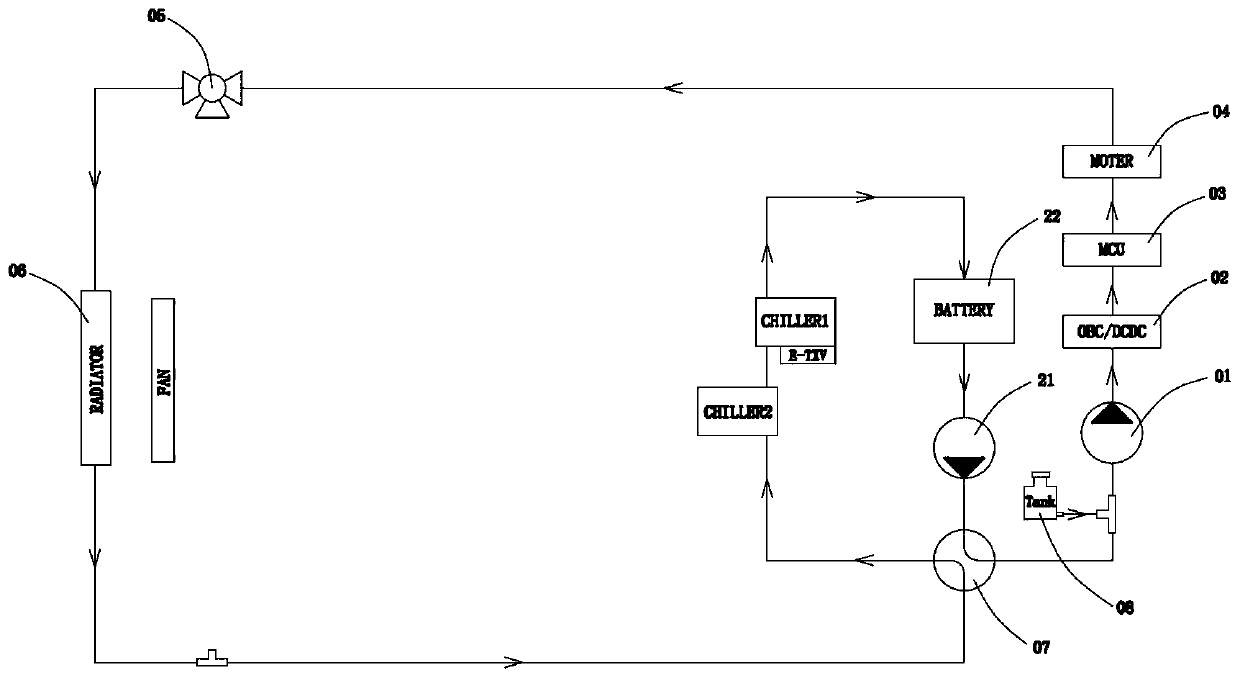

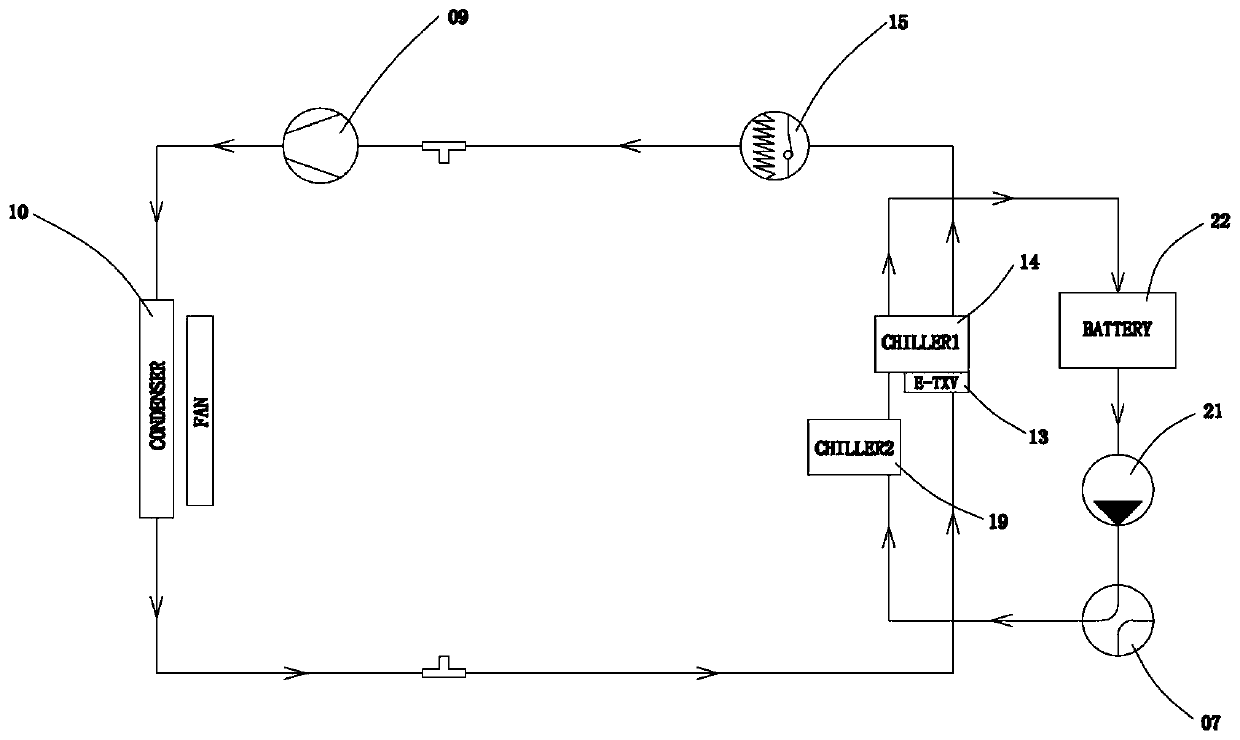

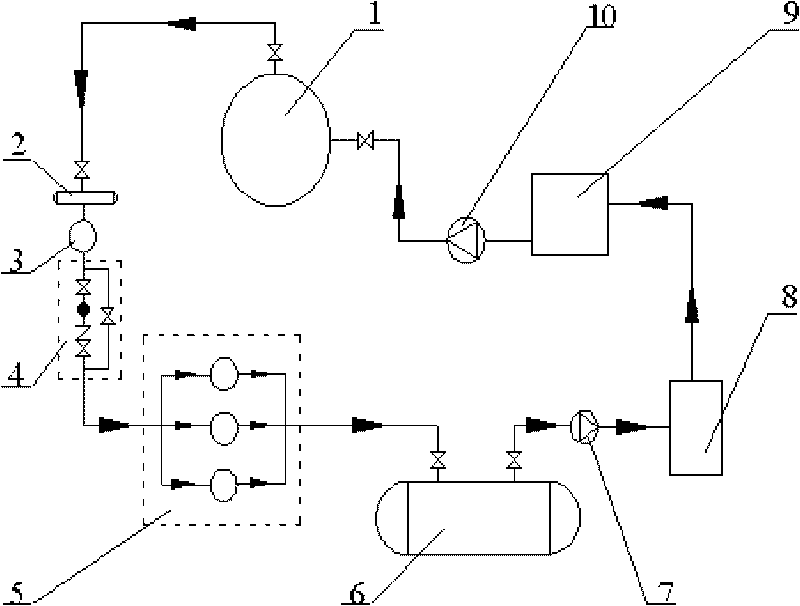

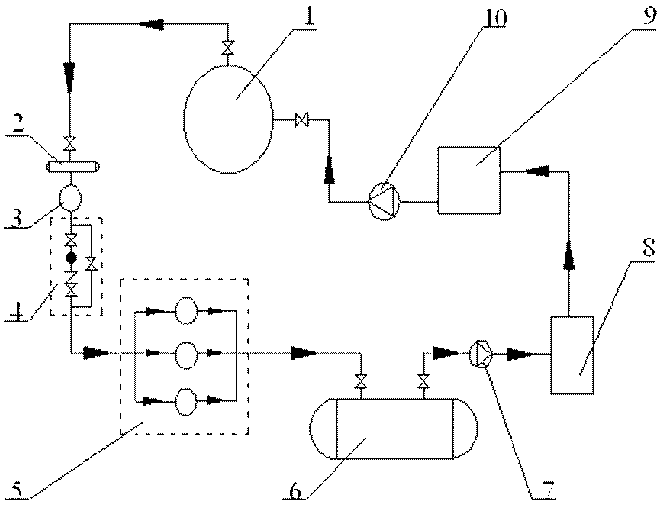

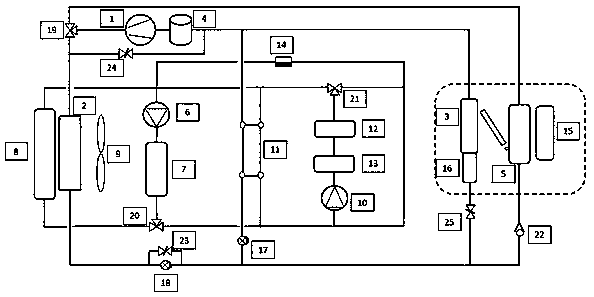

Electric vehicle heat management system and method

InactiveCN110356195AReduce power consumptionReduce wasteAir-treating devicesVehicle heating/cooling devicesElectricityHeat management

The invention discloses an electric vehicle heat management system and method. The electric vehicle heat management system comprises an electric drive assembly cooling loop, an air conditioning loop and a battery cooling and heating loop, wherein the battery cooling and heating loop communicates with the electric drive assembly cooling loop through a valve; and the battery cooling and heating loopcommunicates with the air conditioning loop through a heat exchanger. The electric vehicle heat management system has the advantages that the electric drive assembly cooling loop, the air conditioning loop and the battery cooling and heating loop of a vehicle system communicate with each other; and according to an actual vehicle state, the electric drive assembly cooling loop is controlled to radiate heat of a battery loop by using a low temperature heat radiator or to heat a battery at a low temperature by using heating after heat of an electric drive assembly; and therefore, the capacity utilization ratio is increased, and energy waste is reduced.

Owner:YIBIN COWIN AUTO CO LTD

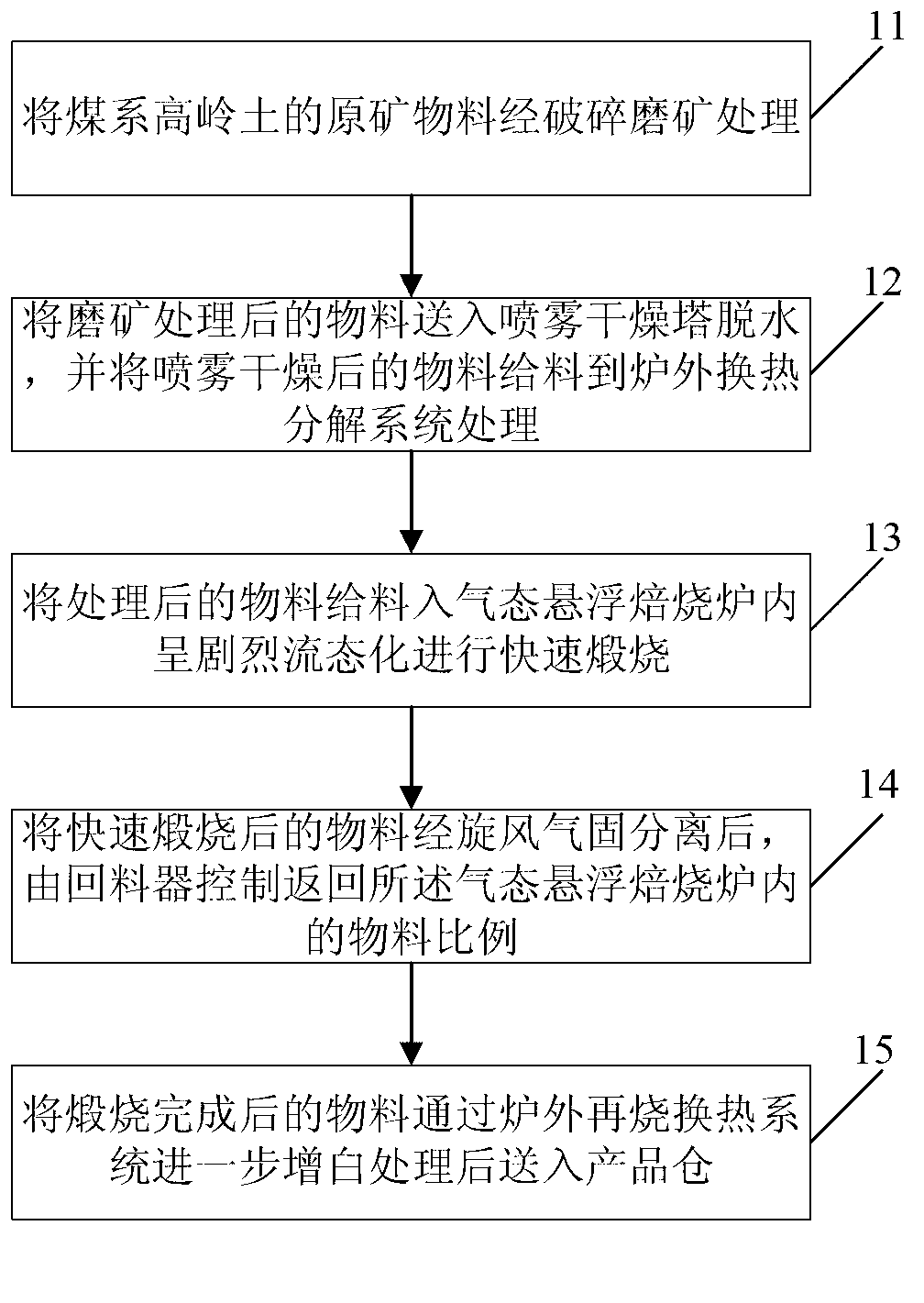

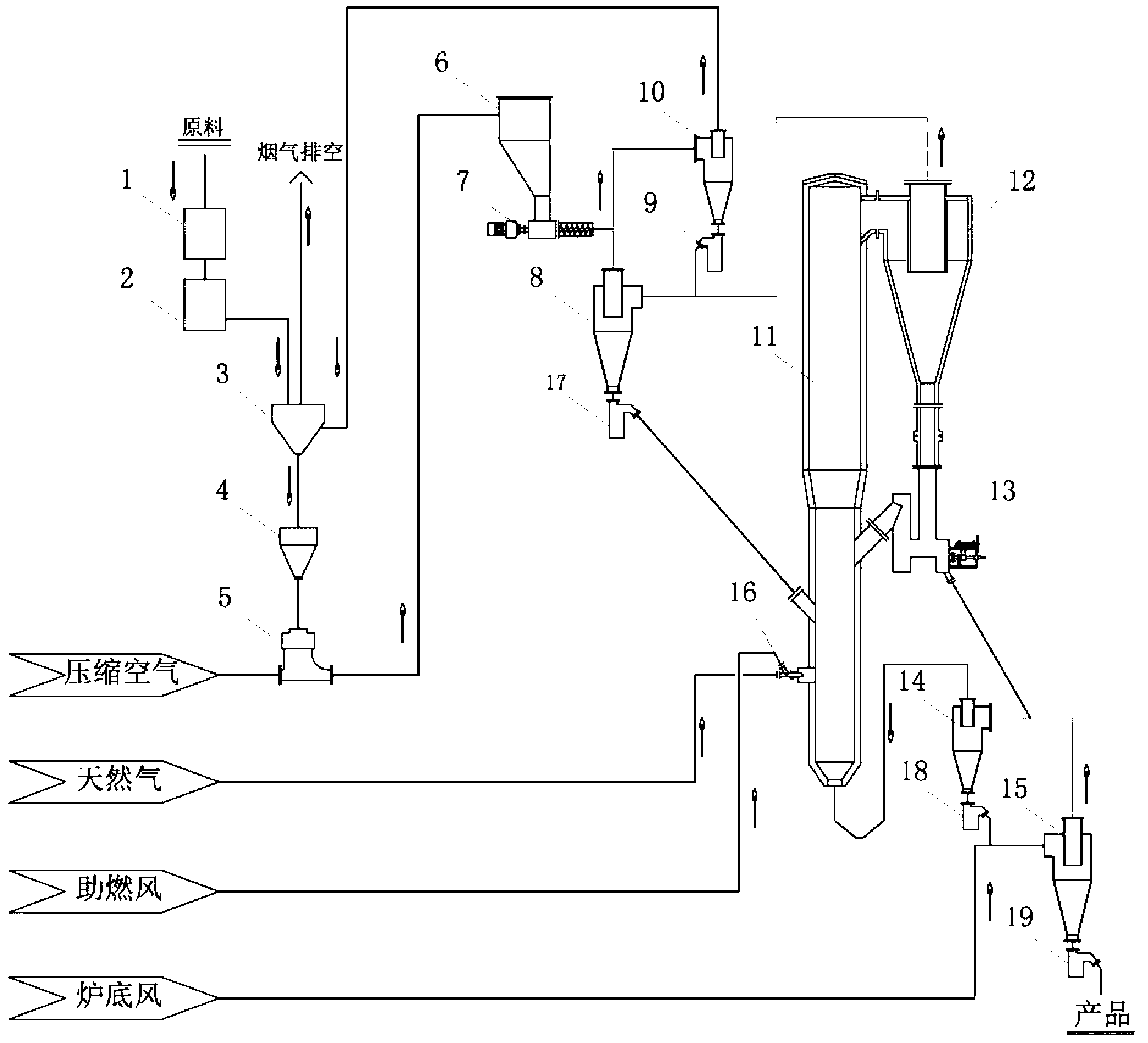

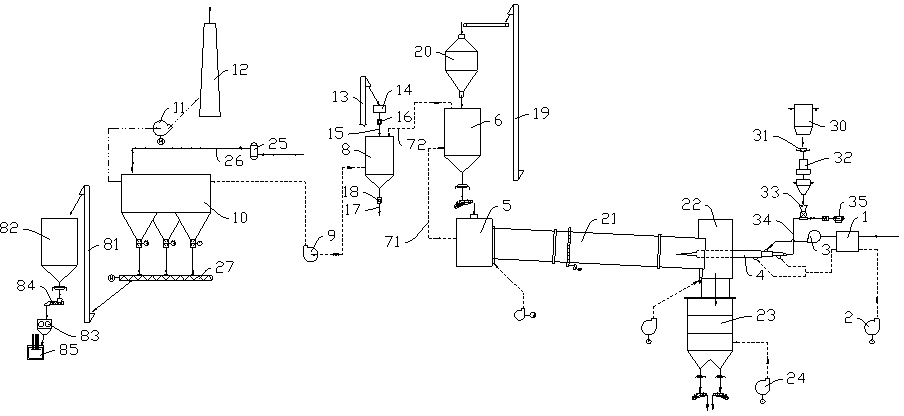

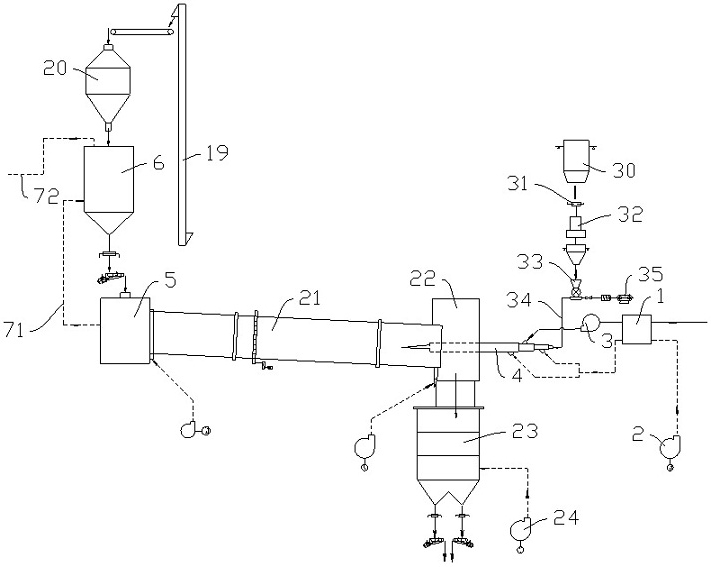

Coal-series kaolin gas suspension calcination method

InactiveCN102795633AEasy to removeImprove thermal efficiencyEnergy inputSilicon compoundsStructural waterDecomposition

The invention discloses a coal-series kaolin gas suspension calcination method comprising the following steps of: firstly, crushing and grinding mineral raw materials of coal-series kaolin, feeding the mineral raw materials into a spray drying tower for dehydration, and feeding the materials subjected to spray drying into a furnace external heat exchange decomposition system for treatment; feeding the treated materials into a gas suspension calciner for rapid calcination in an intensive fluidization condition, wherein the fluidizing velocity is 8-40m / s, and the calcination temperature is controlled within 600-1400 DEG C according to the requirements of products; carrying out gas-solid separation on the rapidly calcined materials under the action of whirlwind, then, controlling the proportions of materials returned to the gas suspension calciner through a loop seal, and adjusting the total standing time of the materials in the gas suspension calciner to control the calcination quality of a product; and further carrying out whitening treatment on the calcined materials through a furnace-external reburning heat exchange system, and then, feeding the materials into a product cabin. The method is simple in process, high in heat efficiency, good gas-solid heat and mass transfer and narrow in calcination temperature fluctuation range; and the product is stable and uniform in quality, smoke waste heat can be sufficiently utilized, high handling capacity is realized, and carbon impurities and structural water in the coal-series kaolin can be rapidly removed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for recovering condensation water in production process of gas concrete and recovery system thereof

InactiveCN101700675AScientific and reasonable way of using energyMake full use of waste heatCeramic shaping apparatusRecovery methodUser device

The invention discloses a method for recovering condensation water in the production process of gas concrete. The method comprises the following steps of: firstly, sending the saturated steam produced by a boiler to a still kettle in which gas concrete slabs or blocks are placed, and heating the gas concrete product, wherein the saturated steam is cooled to form the condensation water through the heat exchange; secondly, sending the condensation water drained from the still kettle to a plurality of secondary heating user devices filled with materials, and pre-heating the materials by using the afterheat of the condensation water, wherein the saturated steam is cooled to form the secondary condensation water through the heat exchange; and thirdly, after the secondary condensation water drained from the secondary heating user device satisfies the requirement of boiler water feeding through the purification treatment, sending the secondary condensation water to the boiler of the first step for recycle. By adopting the method, the afterheat resources and water resources discharged from the production process are sufficiently, reasonably and gradually utilized, and the energy and resource consumptions and the production cost of product per unit are reduced.

Owner:TIANJIN UNIV

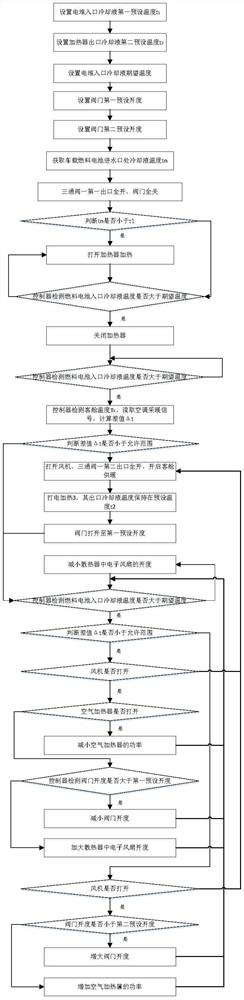

Hydrogen fuel cell automobile hydrothermal management system and control method thereof

ActiveCN112208392AImprove heating effectOptimizing Flow PathsAir-treating devicesVehicle heating/cooling devicesHydrogen fuel cellEngineering

The invention relates to a hydrogen fuel cell automobile hydrothermal management system which comprises a fuel cell, a main water pump and a heater which are sequentially communicated through a pipeline to form a circulation loop, and further comprises a first three-way valve, an inlet of the three-way valve I is communicated with an outlet of the fuel cell through a pipeline, and one outlet is communicated with the main water pump through a pipeline, the other outlet is communicated with an inlet of heating equipment in an automobile passenger cabin through a pipeline, and an outlet of the heating equipment is communicated with a pipeline between the three-way valve I and the main water pump through a pipeline; a pipeline between the fuel cell and the heater is communicated with a pipeline between the three-way valve I and the heating equipment through a heating loop, and a valve is mounted on the heating loop; the invention further provides a control method of the hydrogen fuel cellautomobile hydrothermal management system. The system has the beneficial effects that the flowing path of cooling liquid is optimized when the automobile passenger cabin does not need to be heated, the heating capacity in the automobile passenger cabin is improved while normal operation of the system is guaranteed, and energy consumption is reduced.

Owner:武汉海亿新能源科技有限公司

Safety energy-saving stove

InactiveCN103017206AReduce burns to usersNo risk of burstingStove/ranges for heating waterSteam generation plantsEngineeringWater tanks

The invention relates to a cooking stove, in particular to a safety energy-saving stove. The safety energy-saving stove comprises a hearth, a pot ring seat arranged at the upper part of the hearth, and a water tank arranged outside the hearth; the pot ring seat is slantingly arranged at the upper part of the hearth; a plurality of backfire pipes are further arranged outside the hearth; the backfire pipes are arranged perpendicular to the bottom surface of the hearth; the backfire pipes are communicated with the pot ring seat; and the water tank is arranged outside the backfire pipes. The safety energy-saving stove provided by the invention is safer and is more energy-saving.

Owner:贵州省贵阳白云锅炉厂

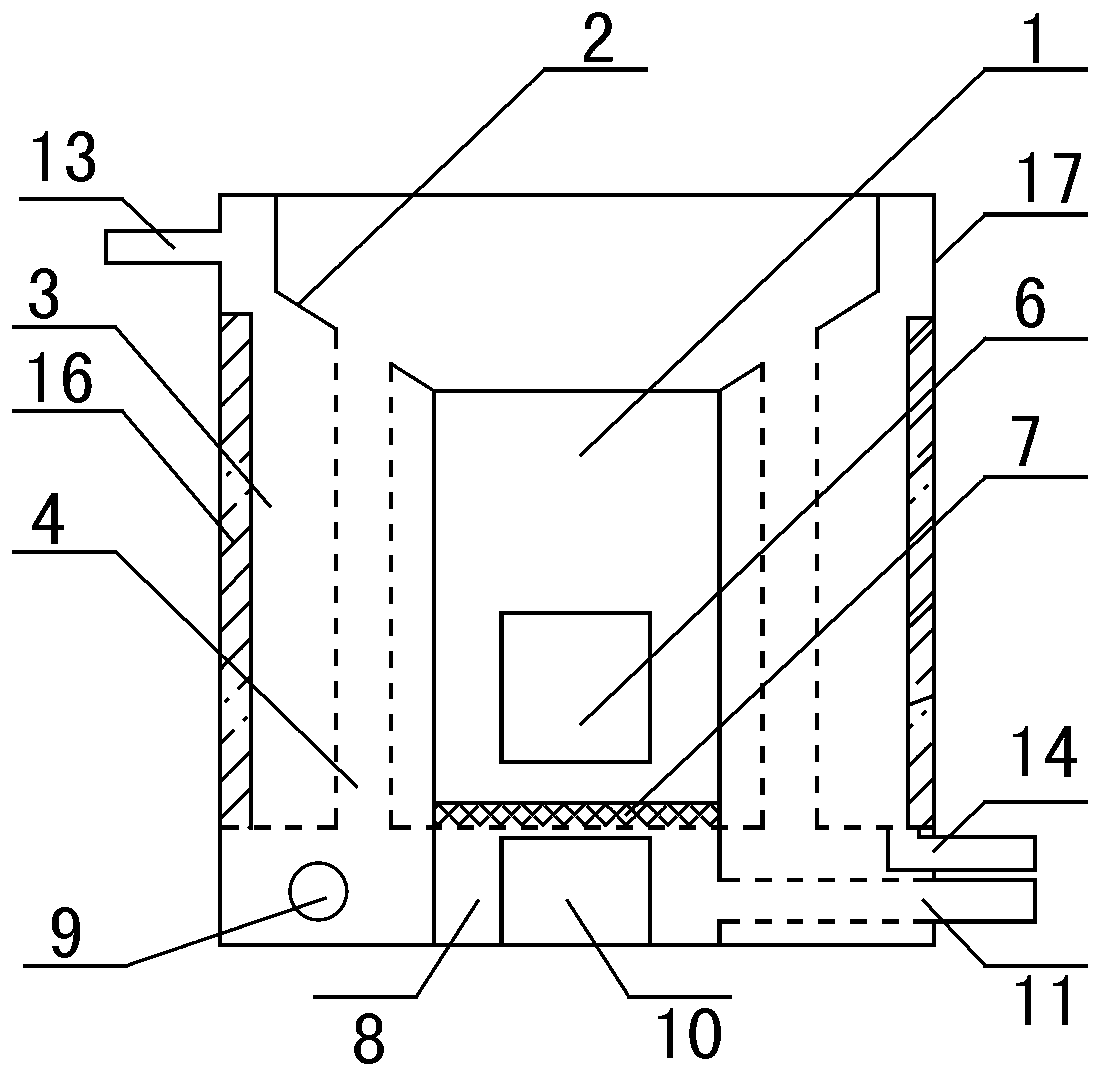

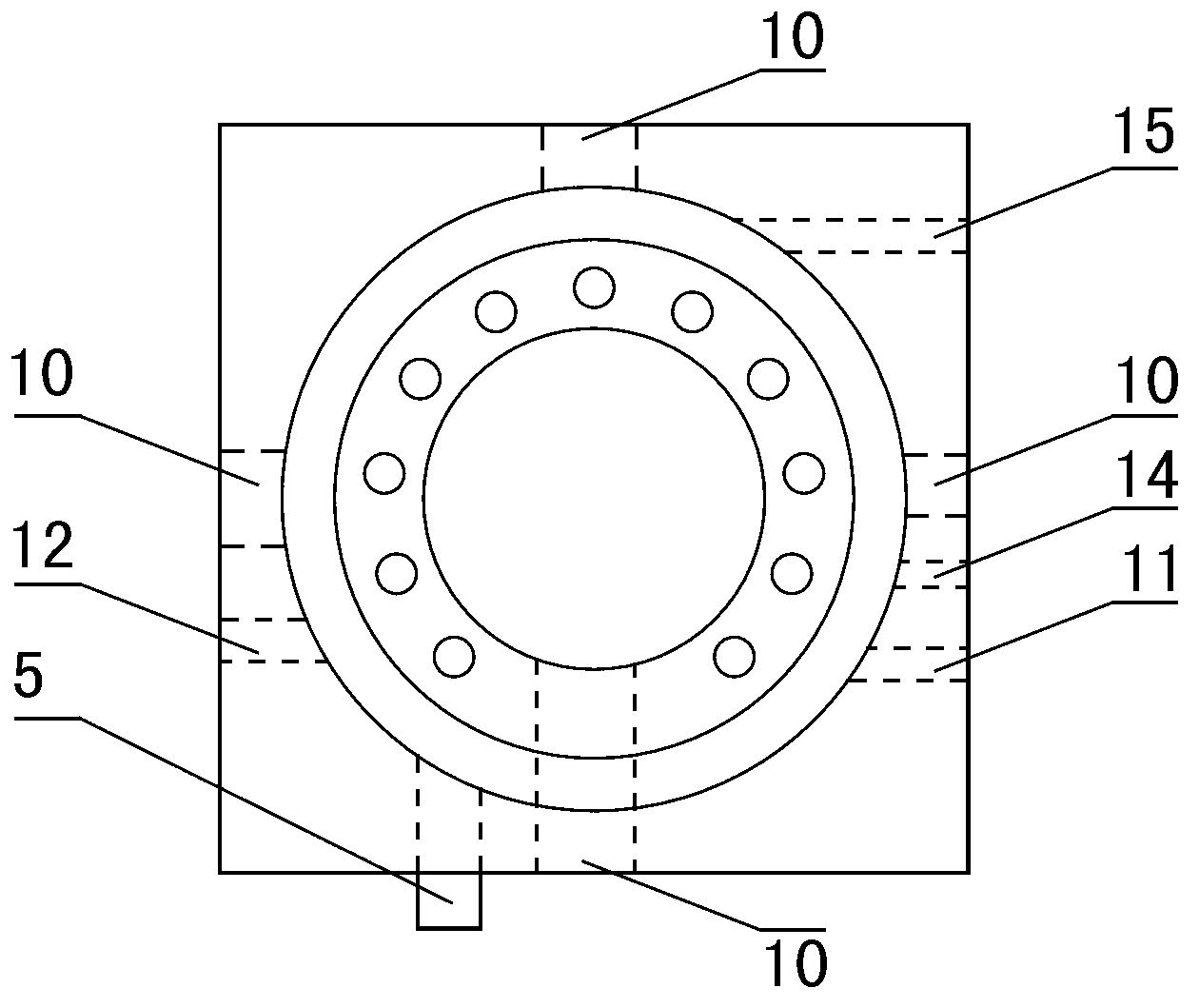

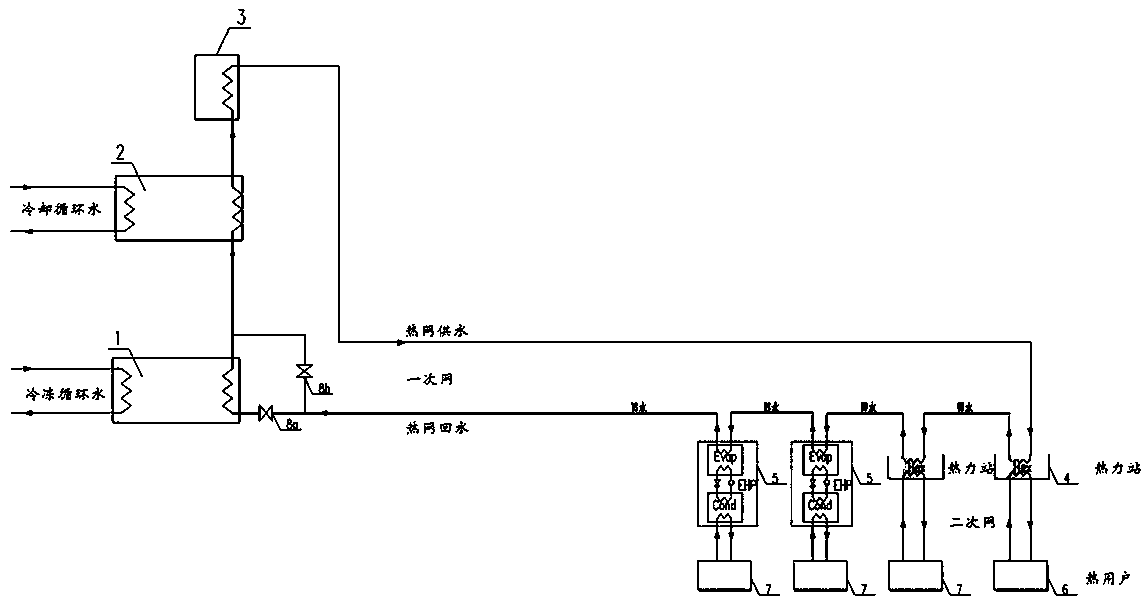

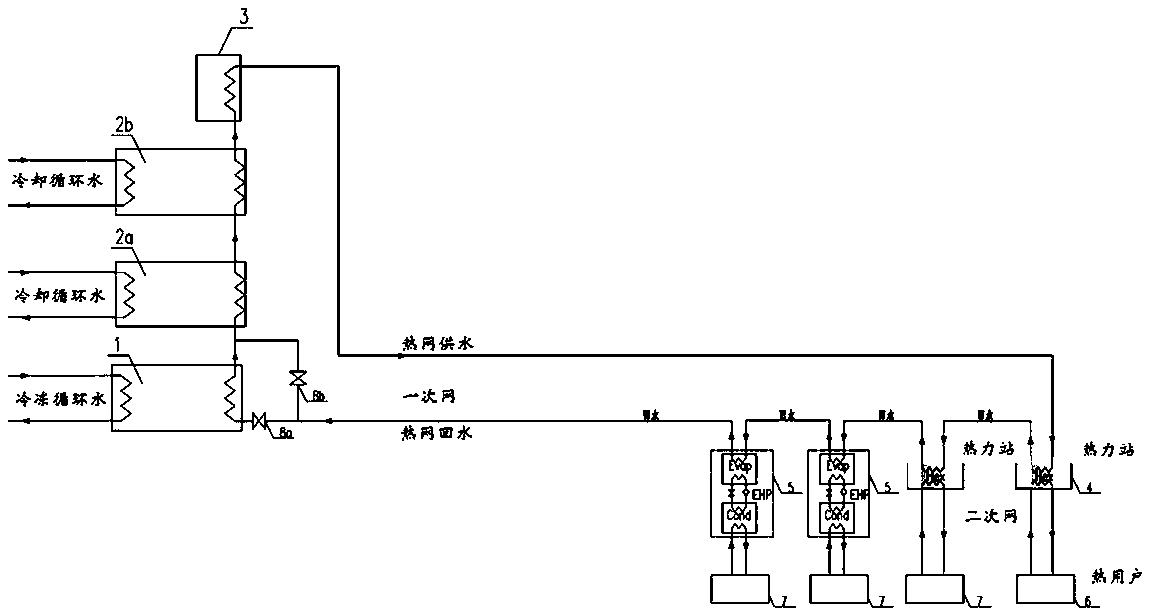

Data center cold and heat combined supply waste heat large-temperature-difference central heating system

PendingCN108317582AImprove utilization efficiencyLow running costLighting and heating apparatusHot-water central heatingCooling towerData center

The invention provides a data center cold and heat combined supply waste heat large-temperature-difference central heating system which comprises a conventional water cooling unit, compression heat pumps, a peak adjusting heat source, a water-water heat exchanger, electricity-driven compression heat pumps, a connecting pipeline and an accessory. Data center waste heat is extracted through frozen circulating water on the evaporator side, heat release is conducted in two ways on the evaporator side, heat of one of the two ways heats a primary heating network return water, heat of the other way is connected into all stages of compression heat pump evaporators to serve as low-level heat sources of the heat pumps, and surplus heat is discharged into the environment through a cooling tower. Thecompression heat pumps conduct heat release in a condenser to heat the primary heating network return water stage by stage. The peak adjusting heat source heats the heating network return water to theheating temperature finally, and then the heating network return water is sent out of the data center through a heating pipeline. The heating network supplied water passes through the water-water heat exchanger to heat a terminal radiator user firstly and then flows into the electricity-driven compression heat pumps in series to heat the tail end of a radiation floor. According to the central heating system, cold and heat combined supply and cascaded heating are adopted, the primary heating network temperature difference is large, and only electricity is needed to serve as driving energy of the heat pumps.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

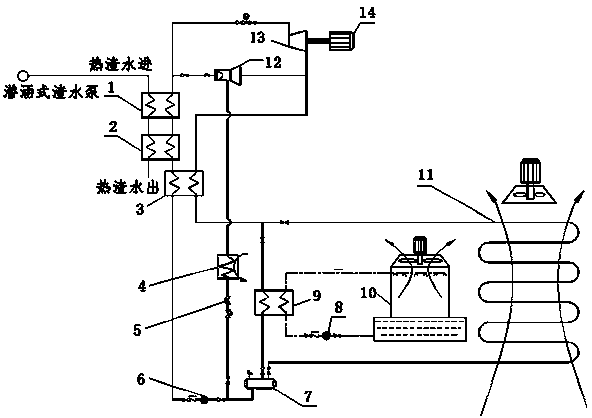

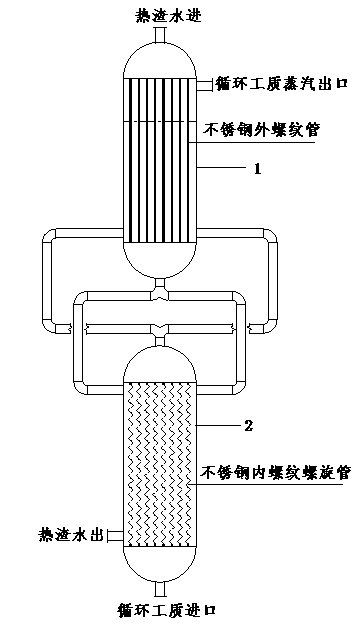

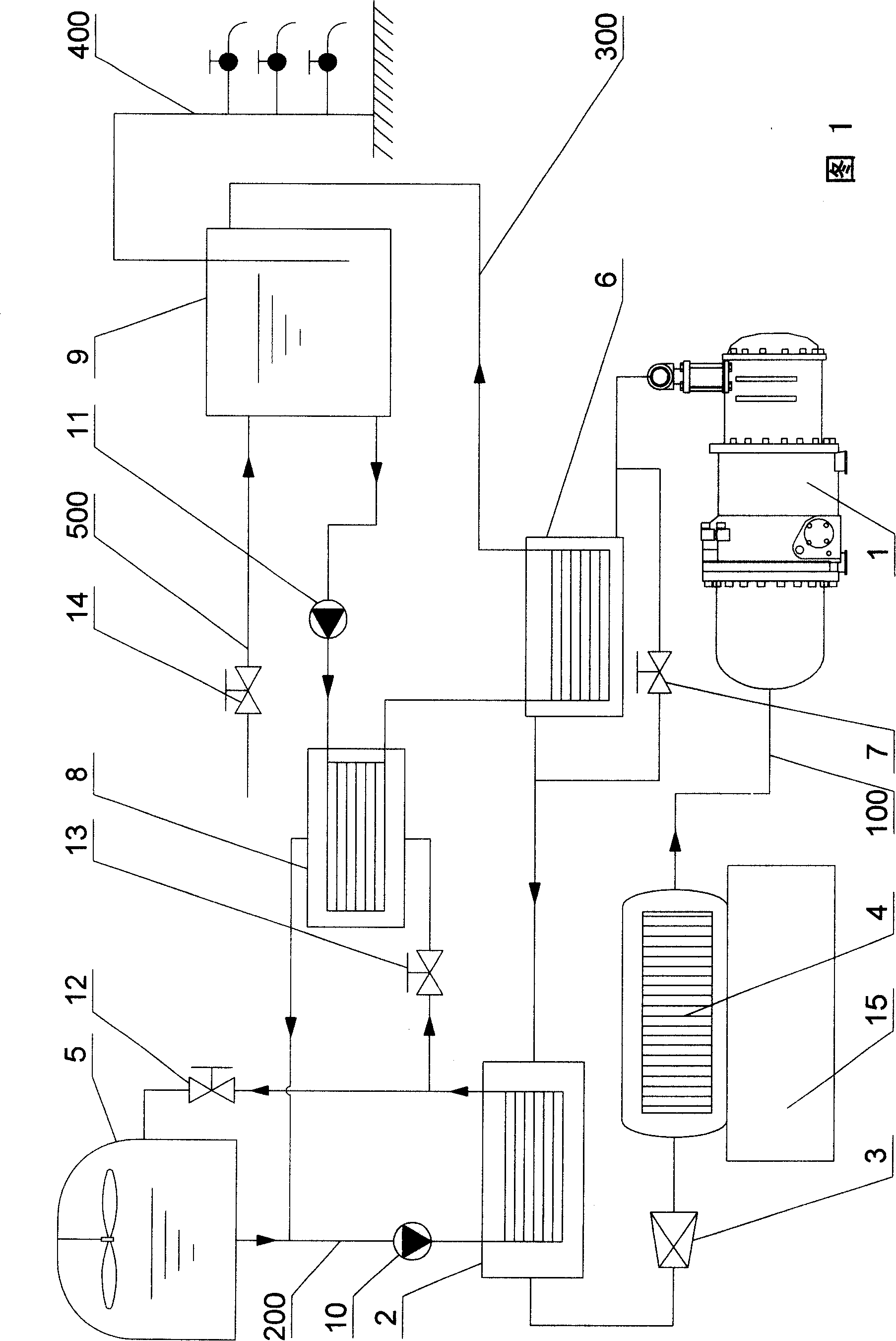

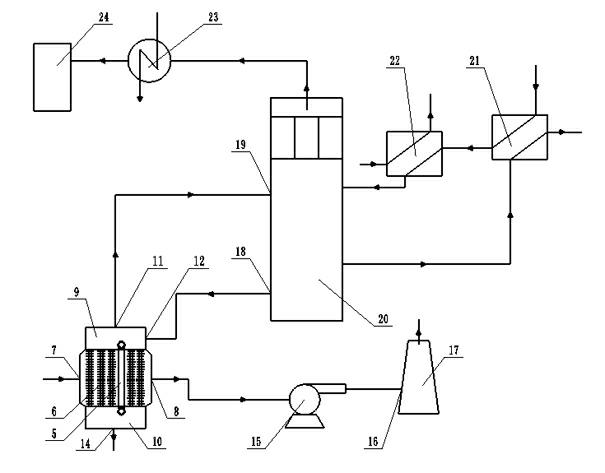

System capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water

ActiveCN104196584AEnhanced boiling heat transferAvoid pollutionClimate change adaptationEnergy industryElectricityVapor–liquid separator

The invention relates to a system capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water, and belongs to the technical field of energy and environment. The system comprises a slag flushing water heat recovery and heat exchange system, an organic Rankine cycle, a steam injection type cooling system and a cooling water circulation system. An internal-thread stainless steel spiral tube shell-and-tube heat exchanger is used as a pre-heater, an external-thread stainless steel tube shell-and-tube heat exchanger is used as a steam generator, and the steam generator is also used as a gas-liquid separator. The system has the advantages of being simple in structure, easy to machine and manufacture, low in manufacturing cost, capable of preventing blockage, capable of realizing countercurrent flow heat exchange, high in heat exchange efficiency, capable of effectively utilizing waste heat of the slag flushing water and the like; the system can be independently used for generating electricity or providing prime power, can also be independently used for cooling and can further provide electric power and chilled water required by a cooling air conditioner at the same time.

Owner:KUNMING UNIV OF SCI & TECH

Utilization method and system for tail gas of calcium carbide furnace

InactiveCN102620573AEliminate potential safety hazardsLess investmentWaste heat treatmentHigh concentrationCombustor

The invention provides a utilization system for the tail gas of a calcium carbide furnace. By the system, without purification treatment, the tail gas of the calcium carbide furnace is directly conveyed into a burner and then burnt, investment to the purification treatment of the tail gas of the calcium carbide furnace is eliminated, and hidden danger in the purification treatment of the tail gas of the calcium carbide furnace, which contains high-concentration carbon oxide (CO), is eliminated. The utilization system for the tail gas of the calcium carbide furnace comprises a heat exchanger, a pressurizing conveying fan and a lime rotary kiln, wherein the heat exchanger cools the tail gas of the calcium carbide furnace; the lime rotary kiln is provided with the burner; and a calcium carbide furnace tail gas discharge pipe, the heat exchanger, the pressurizing conveying fan and the burner are sequentially connected in series. The invention also provides a utilization method for the tail gas of the calcium carbide furnace. The method comprises the following steps of: reducing the temperature of the tail gas of the calcium carbide furnace to 200 to 400 DEG C; pressurizing the tail gas of the calcium carbide furnace to be over 3,000 Pa by using the pressurizing conveying fan; conveying the tail gas of the calcium carbide furnace into the burner of the lime rotary kiln; and burning the tail gas of the calcium carbide furnace.

Owner:NANJING SUYE CALCIUM IND TECH

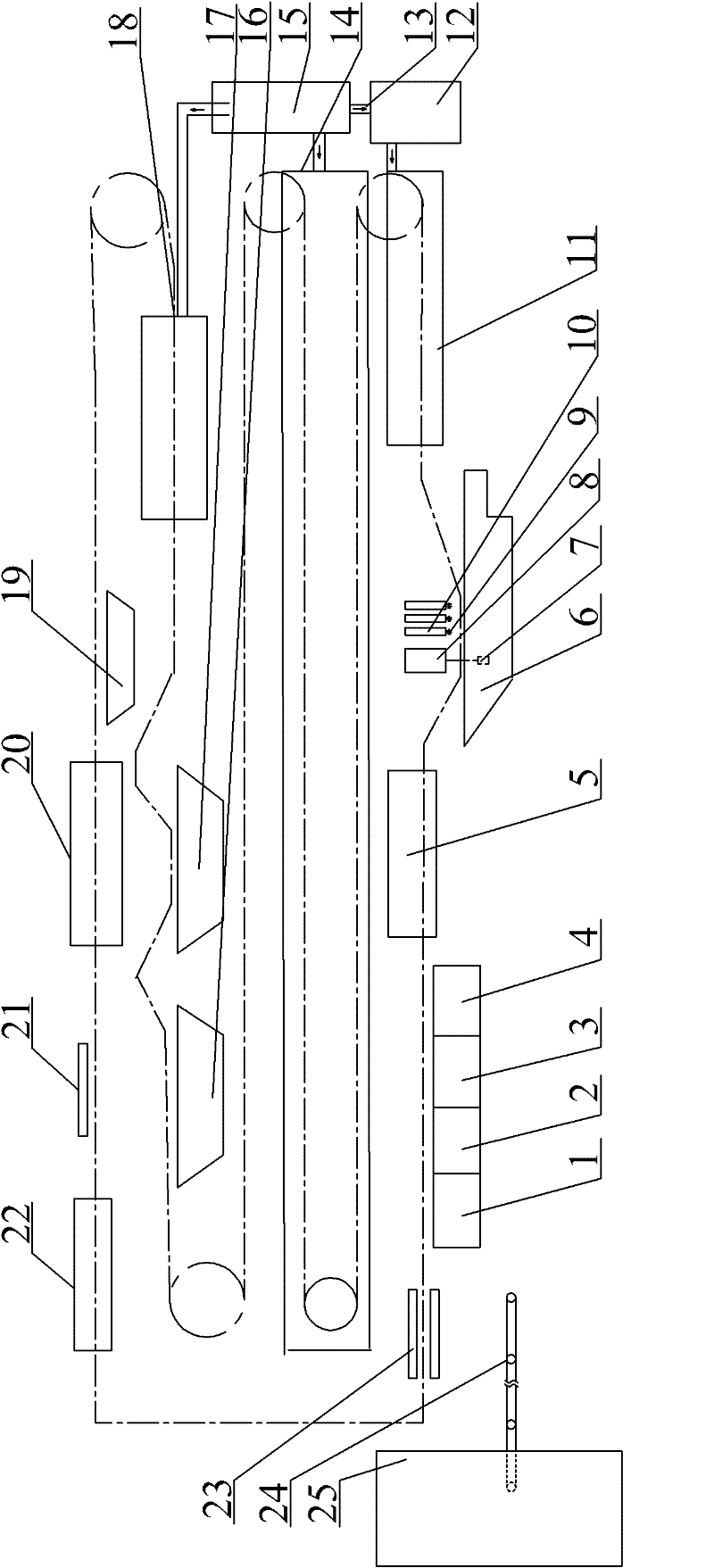

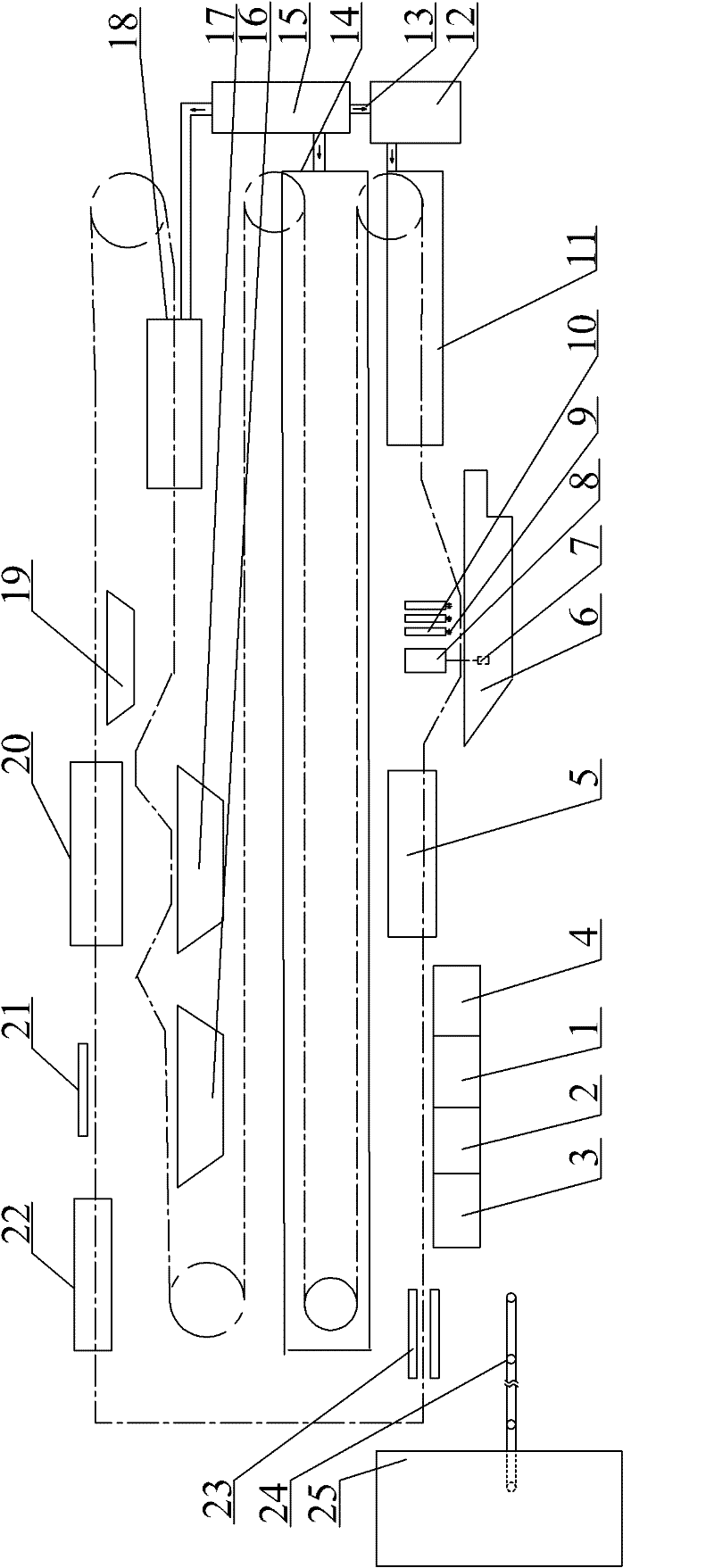

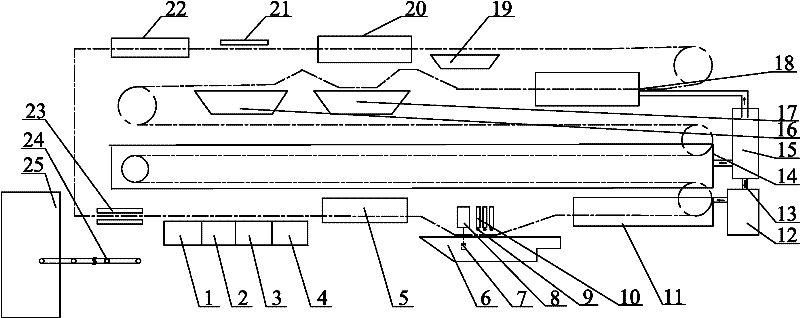

Polyvinyl chloride (PVC) glove production device

ActiveCN102173017ARapid coolingGood release effectDomestic articlesCoatingsPolyvinyl chlorideEngineering

The invention belongs to the field of polyvinyl chloride (PVC) glove production and relates to a PVC glove production device. The device comprises a hand mold rail line and a glove production device, wherein the hand mold rail line is positioned above the glove production device; the glove production device comprises a PVC material groove, a PVC material dripping section, a PVC plasticizing forming device, a polyurethane (PU) material groove, a PU drying device, a PVC glove hemming device and a demolding device in turn; and the PVC plasticizing forming device and the PU drying device are connected with a heat supply boiler. The device is characterized in that: a hand mold cleaning device and a hand mold drying device are arranged in turn between the demolding device and the PVC material groove; the PVC material groove is provided with a viscosity detection adjusting device; and a PU washing device and a washing drying device are arranged in turn between the PU drying device and the PVC glove hemming device. The device has high automation degree and good effect of forming PVC gloves; moreover, the product is easy to demold, and stickness or damage hardly appears in the demolding process, so that the glove quality is ensured.

Owner:SHANDONG INTCO MEDICAL SUPPLY CO LTD

High-concentration malodorous gas catalytic oxidation deodorizing equipment and deodorizing method thereof

InactiveCN106247355ARealize the heating effectImprove responseStationary tubular conduit assembliesIncinerator apparatusCatalytic oxidationCatalytic combustion

The invention discloses high-concentration malodorous gas catalytic oxidation deodorizing equipment and a deodorizing method thereof. A shell is internally divided into an upper-layer area, a middle-layer area and a lower-layer area; a gas inlet pipeline is used for collecting malodorous gas to be treated and pre-mixing the malodorous gas and air so as to achieve preset malodorous gas concentration; the mixed gas enters a heat exchange area on the lower part of an airtight shell and enters a multi-way heat exchange pipeline so as to be preheated; the preheated gas to be treated is heated through a heating area so as to meet the conditions of catalytic combustion reaction temperature; the heated gas to be treated enters a catalytic reaction area so as to be subjected to catalytic combustion reaction, and malodorous gas molecules in the gas to be treated are combusted; and the reacted purified gas enters the zigzag heat exchange area, and is heat-exchanged with the untreated gas to be treated located in the heat exchange pipeline so as to be discharged out of the airtight shell through a gas outlet pipeline. The high concentration malodorous gas catalytic oxidation deodorizing equipment provided by the invention is of an integral structure, can be used for realizing preheating, heating and catalytic combustion reaction of the gas to be treated, and is compact in structure; the heat energy of the gas after being catalytic combusted is effectively utilized, so that the energy consumption is reduced; and the cleanness treatment of the malodorous gas is realized through catalytic combustion.

Owner:ENVIRONMENTAL HYGIENE DESIGN INST ACAD BEIJING

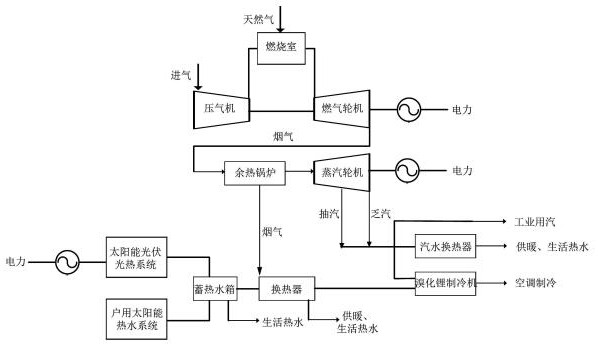

Distributed fuel gas type complementary solar energy utilization combined cooling heating and power system

ActiveCN111928219AStrong Use ProspectsImprove efficiencySolar heating energyCombustion technology mitigationLithium bromideEnvironmental geology

The invention relates to a distributed fuel gas type complementary solar energy utilization combined cooling heating and power system. The system comprises a distributed fuel gas system, a solar photovoltaic photo-thermal system, a household solar water heating system and a lithium bromide absorption type refrigerating system, wherein the solar photovoltaic photo-thermal system and the household solar water heating system are connected with inlet water of a heat storage water tank, the heat storage water tank is connected with a cold water inlet of a heat exchanger, a hot water outlet of the heat exchanger is connected with a lithium bromide refrigerator, and a hot air inlet of the heat exchanger is connected with a fume exhaust pipeline of a waste heat boiler in the distributed fuel gas system. Hot water generated by a photo-thermal system in the solar photovoltaic photo-thermal system and the household solar water heating system flows into the heat storage water tank and is stored inthe heat storage water tank, and the hot water flows into the heat exchanger and is heated by exhaust fume of the distributed fuel gas waste heat boiler to reach the heat source temperature of the lithium bromide refrigerator, so that refrigeration is realized; and the system makes full use of heat generated by the system, the electric quantity generated by the system can be used by the system orconnected to a grid, efficient gradient utilization of clean energy is truly realized, and the system has a very strong utilization prospect.

Owner:国网(天津)综合能源服务有限公司 +5

Dynamic ice-storage type cold-hot water energy-saving set

InactiveCN101165418AAvoid pollutionNo pollution in the processLighting and heating apparatusAir conditioning systemsCooling towerWater cycling

This invention discloses a dynamic ice collecting type cold and hot water energy saving machine set which fully uses heat energy. It includes compressor, condenser, evaporator, cooling tower, I heat exchanger, by-pass valve, II heat exchanger, hot water tank, cooling water pump, hot water circulating pump, cooling water valve, cooling water circulating valve and ice collecting groove. The medium side of I heat exchanger and the by-pass valve are paralleled connected into the refrigerating medium pipeline between the compressor outlet and condenser. The I heat exchanger, hot water tank, hot water circulating pump and the hot water side of II heat exchanger are connected successively to form water heating circulating loop. The cooling water side inlet of II heat exchanger is connected into the refrigerating water circulating pipe between condenser and cooling water valve. Its outlet connects to the water inlet of cooling water pump. This invention can be used widely in the air conditioner energy saving field.

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

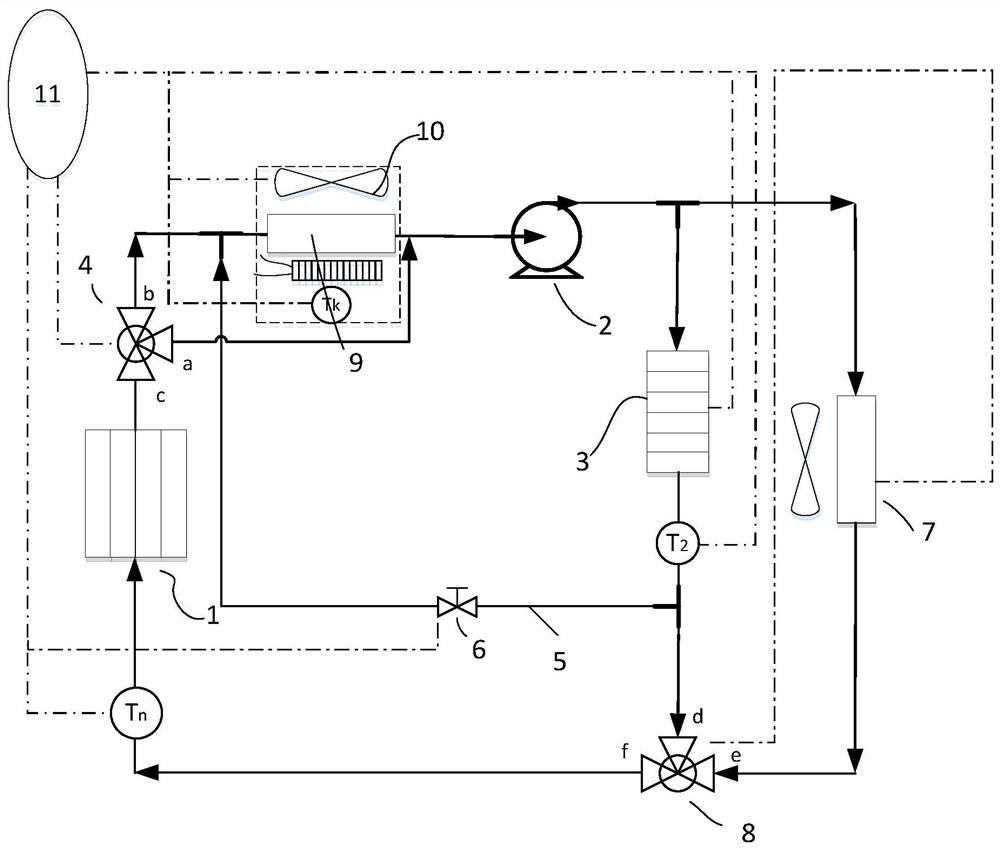

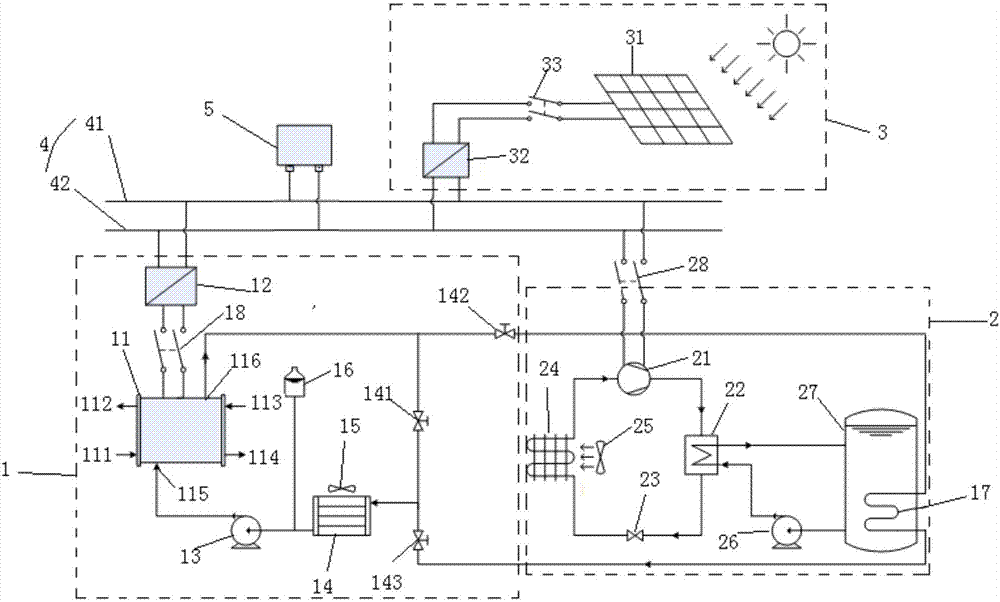

Hydrogen energy and solar energy complementary type heat and power combined supply system and working method thereof

PendingCN107888126AMake full use of electric energyMake full use of waste heatHeat pumpsPV power plantsAutomotive engineeringPower grid

The invention discloses a hydrogen energy and solar energy complementary type heat and power combined supply system. The system comprises a proton exchange membrane fuel battery power generation system, a steam compression type heat pump system, a solar photovoltaic power generation system, a direct-current bus and a storage battery pack. The proton exchange membrane fuel battery power generationsystem, the steam compression type heat pump system, the solar photovoltaic power generation system and the storage battery pack are connected with the direct-current bus. The current generated by theproton exchange membrane fuel battery power generation system and the current generated by the solar photovoltaic power generation system are stored in the storage battery pack through the direct-current bus or are used for driving the steam compression type heat pump system to heat. Meanwhile, the waste heat of the proton exchange membrane fuel battery power generation system is recycled for heat supply. The system can run in the off-grid mode, and can be used in places without a power grid. Moreover, the supply of electric energy and the supply of heat energy can be taken into considerationat the same time. The system is good in flexibility, high in heating efficiency and high in comprehensive energy utilization rate. The electric energy and the waste heat of fuel batteries are fully utilized. The temperature of the prepared hot water is high (above 60 DEG C).

Owner:WUHAN IND TECH RES INST OF GEO RESOURES ENVIRONMENT CO LTD

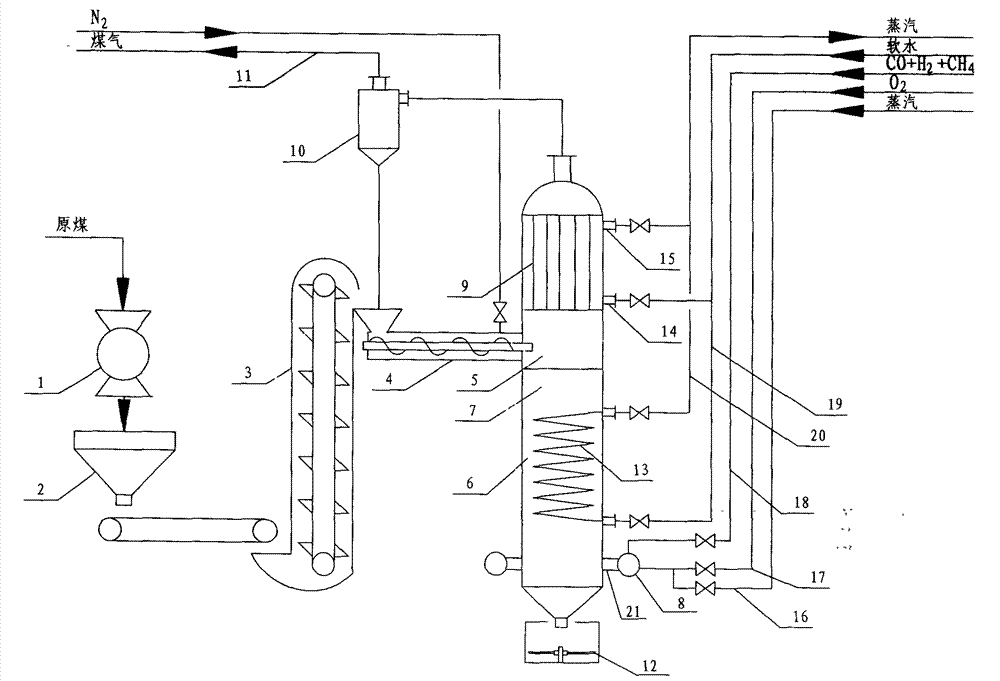

Four-segment spray coal oxygen-enriched gasification method

InactiveCN103113923AIncrease contentReduce pollutionGranular/pulverulent flues gasificationCO2 contentSlag

The invention discloses a four-segment spray coal oxygen-enriched gasification method. A four-segment spray coal oxygen-enriched gasification process is adopted; the spray coal with small particle (0.1-0.5mm) and an oxygen-rich gasification agent (the oxygen content is 96%) are boiled and gasified; the gasification reaction is complete; the carbon conversion rate is more than 90%; the coal utilization rate can be up to 86% and is improved by 26% compared with a traditional fixed bed intermittent gasification process; CO2 in high-temperature coal gas and cracked C are subjected to reduction reaction to generate CO at the reduction period; the CO2 content in the coal gas is reduced; the content of effective gas of the coal gas is improved; the effective gas achieves 89% and is close to the coal gas mass of the spray coal gasification technology; the high-temperature coal gas preheats the spray coal through a preheating cracking section and then passes through an afterheat recovery segment to generate steam, so as to achieve the target of fully utilizing afterheat; the thermal efficiency is improved to 79%; a water-sealing disc-type slag eliminator is adopted to remove sludge; and the pollution on the environment is reduced, so as to achieve the aim of clean production.

Owner:SHANDONG RUNYIN BIOCHEM

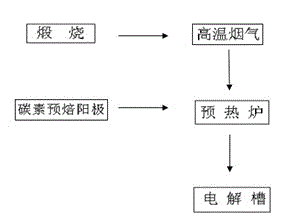

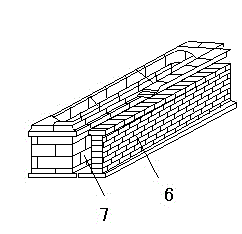

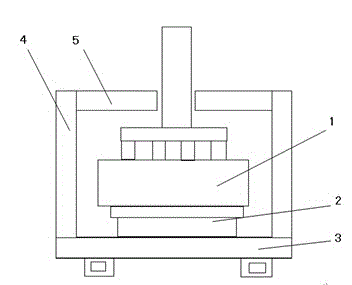

Aluminum electrolysis carbon pre-baking anode pre-heating method

The present invention discloses an aluminum electrolysis carbon pre-baking anode pre-heating method. According to the method, aluminum carbon calcination rotary kiln high temperature flue gas is adopted as a heat source, and the loaded carbon pre-baking anode is pre-heated in a pre-heating furnace, such that the average temperature of the anode can achieve more than or equal to 300 DEG C within 24 h; according to the requirement of the electrolysis bath electrode replacing period, the heated anode is taken out from the pre-heating furnace, is loaded into a special thermal insulation device for conveying the pre-heated anode, is conveyed to an electrolysis workshop, and is loaded into the electrolysis bath to replace the old anode so as to be used; and with the pre-heating, the thermal shock influence on the anode can be reduced, the carbon consumption of the anode is reduced, the fluctuation of the stability and the thermal balance of the electrolysis bath can be reduced, the current efficiency is increased, the current conduction time of the anode is shortened, the furnace bottom precipitate is reduced, the anode effect and the noise generated during the electrode replacing are reduced, and the disordered and harsh conditions of the anode current distribution are reduced so as to provide great benefits for the normal operation of the electrolysis bath.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

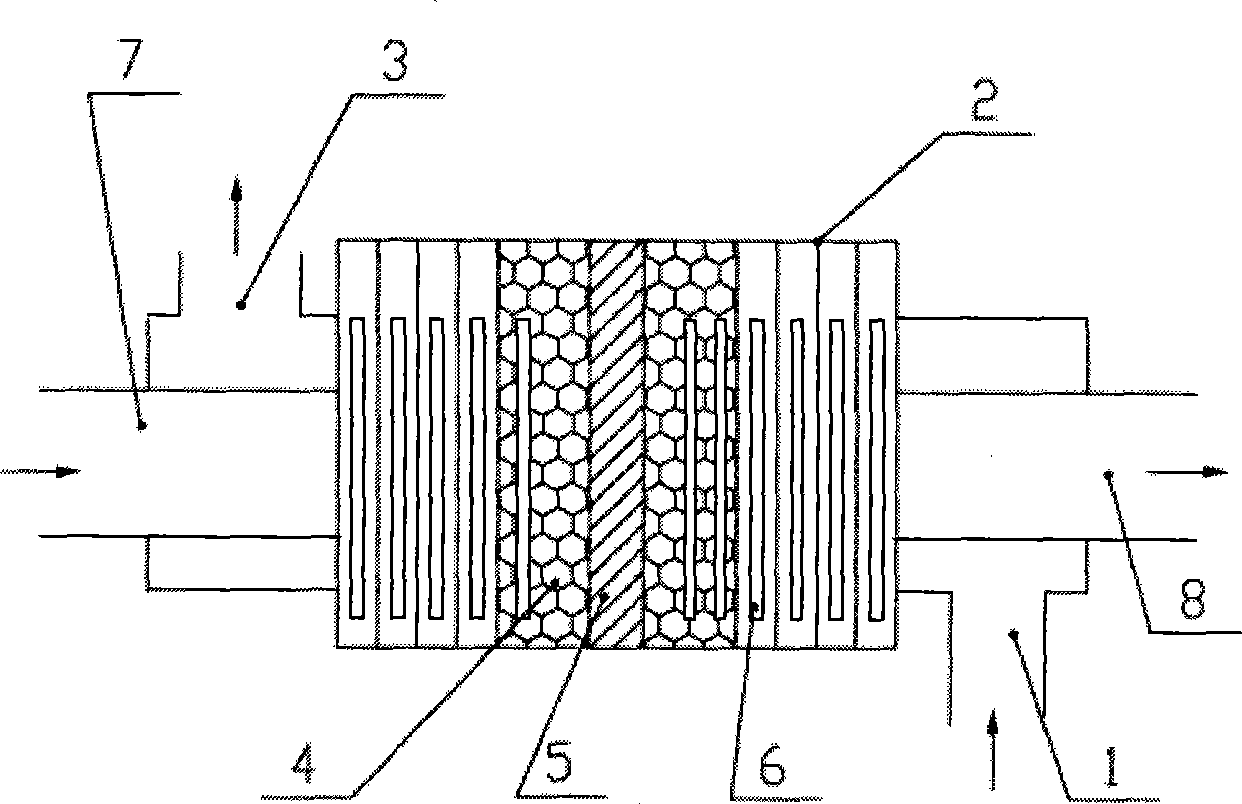

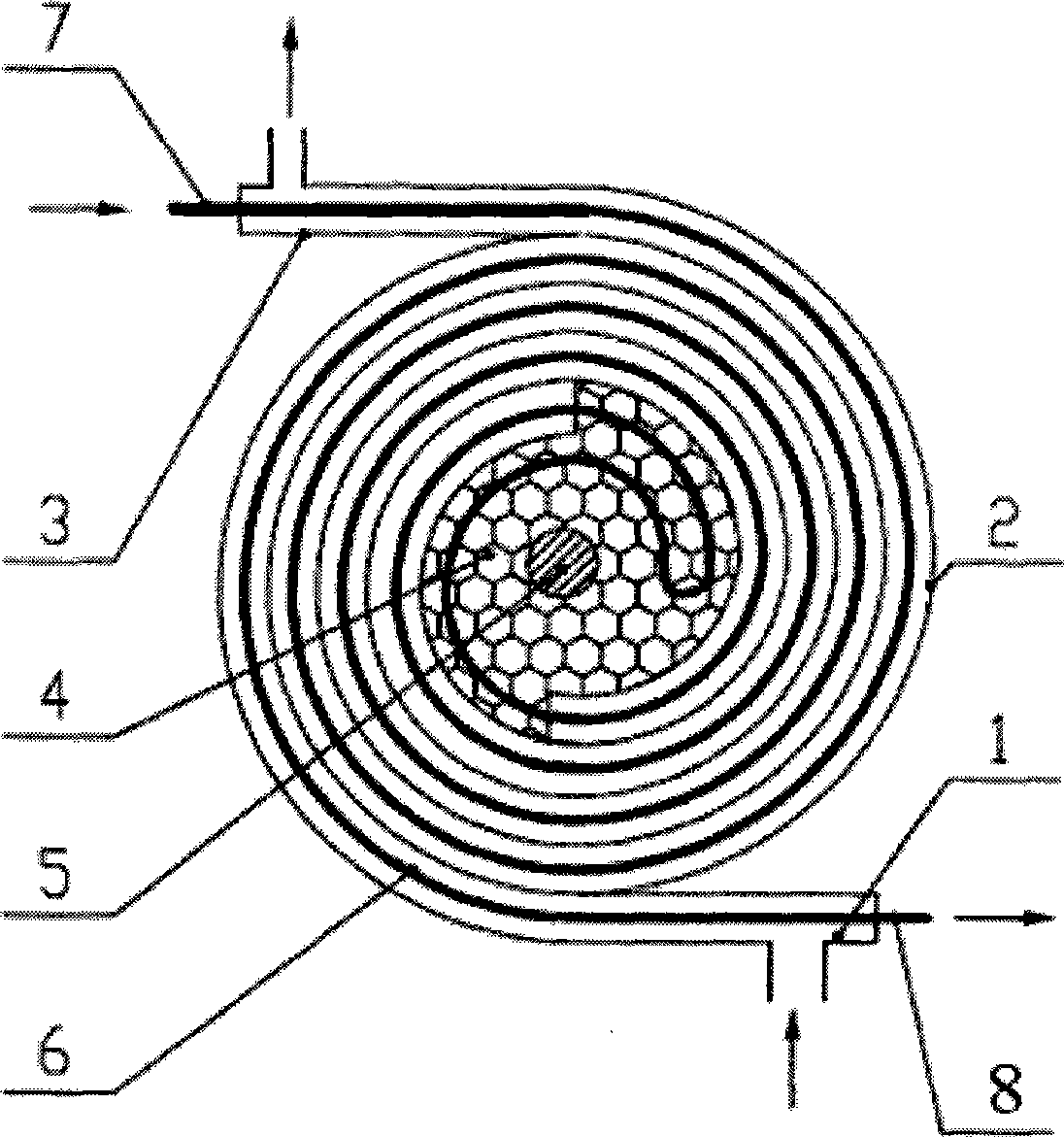

Natural gas hydrogen production plant and method

The invention belongs to the technical field of hydrogen production, and particularly relates to a hydrogen on-spot production device by natural gas and a method thereof. The device mainly comprises a tangential inlet, a reverse heat exchanger, a tangential outlet, a porous medium, an electrically heated silicon carbide rod and a reaction coil, and is characterized in that the external reverse heat exchanger can realize cooling the products and preheating the reacting substances; the effective heat storage of the porous medium arranged in the center of the reverse heat exchanger and the heat preservation of the external reverse heat exchanger can provide a beneficial hot environment for producing pure hydrogen by the schizolysis of the natural gas in the reaction coil; and the electrically heated silicon carbide rod is arranged in the center to preheat the porous medium and start ignition, with convenient operation and high ignition reliability. The hydrogen on-spot production device by natural gas and the method have the advantages of self preheating, self heat preservation, self cooling, simple structure, low energy consumption, stabilization and the like, and can realize pure hydrogen production.

Owner:UNIV OF SCI & TECH OF CHINA

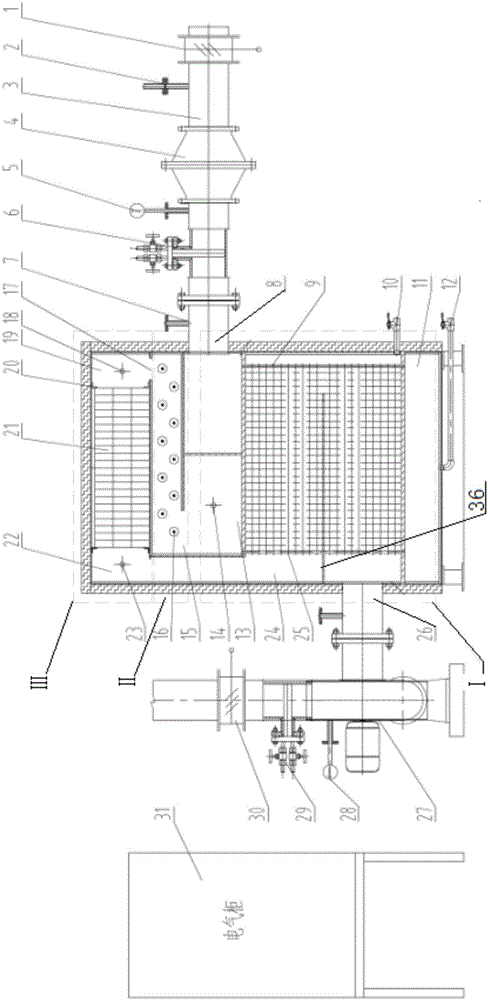

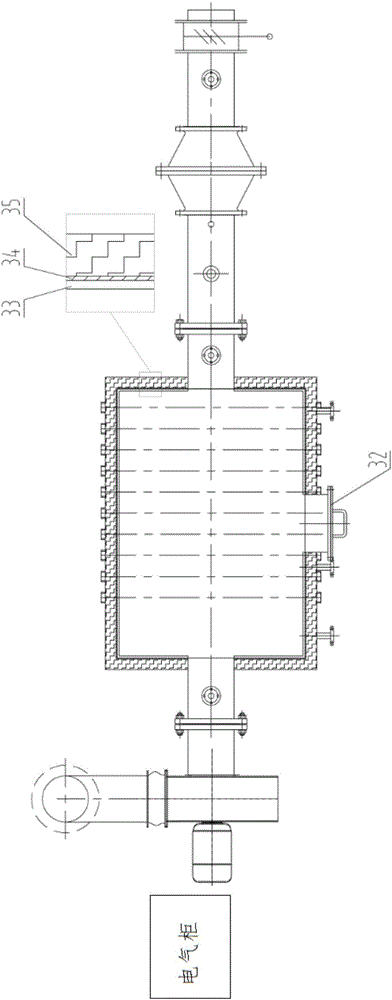

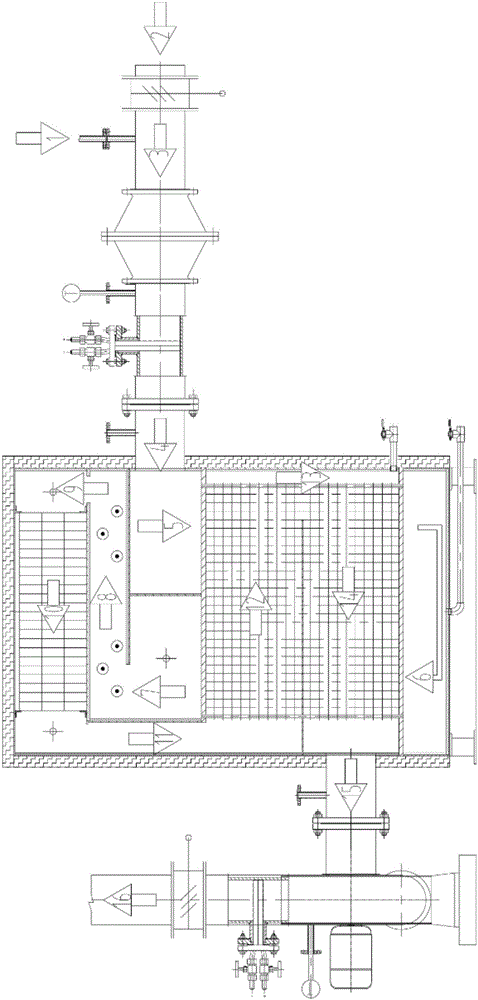

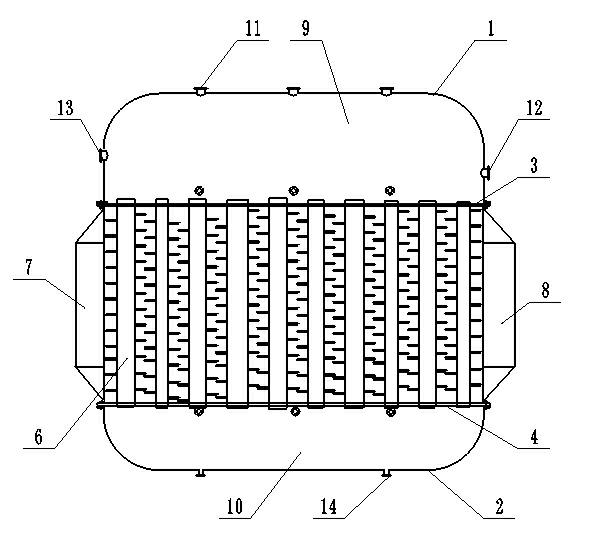

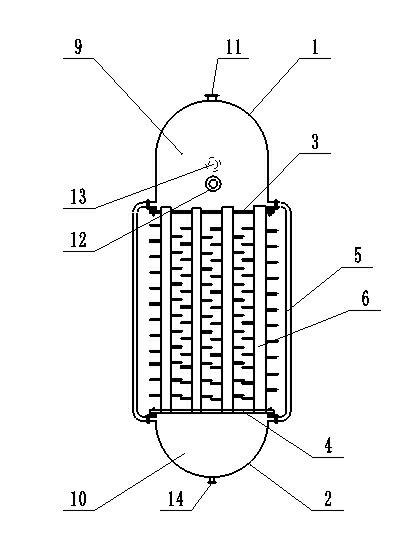

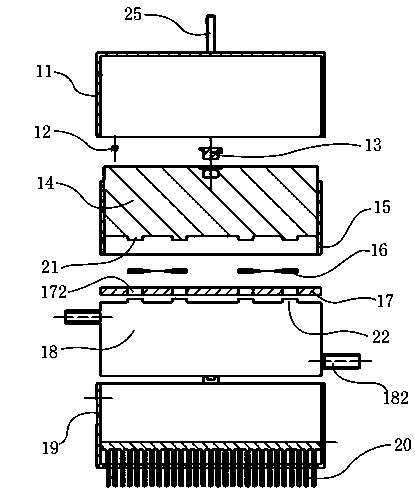

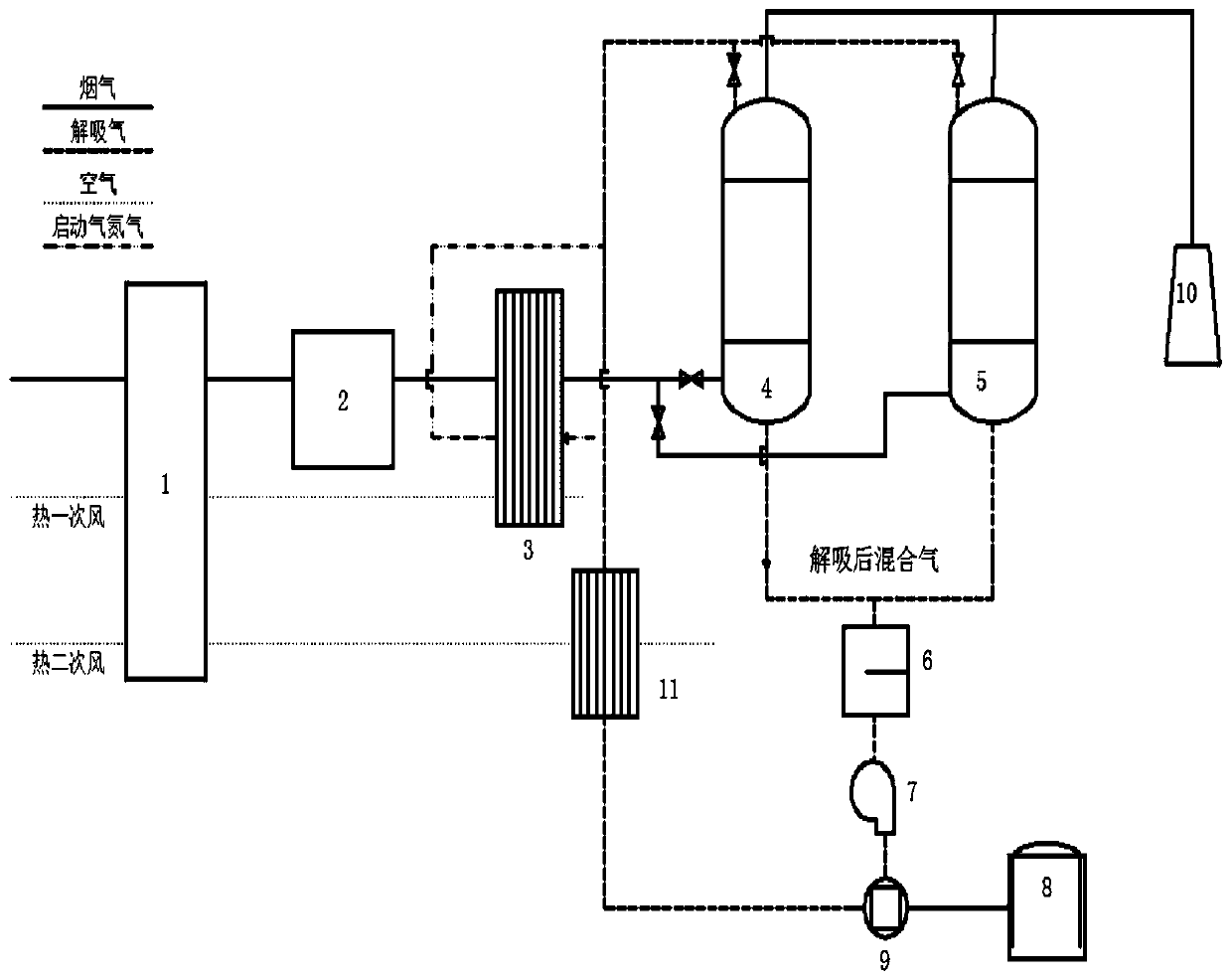

Ammonia distillation method for waste heat of coke-oven flue gas and equipment

ActiveCN102502703AEmission reductionReduce usageEnergy inputWater/sewage treatment by degassingThermodynamicsReboiler

The invention discloses an ammonia distillation method for waste heat of coke-oven flue gas and equipment, and belongs to the technical field of ammonia distillation process secondary heating methods and used devices; for solving technical problems, the invention provides the method and the equipment which can effectively use waste heat of coke oven flue gas and meanwhile can reduce waste water discharge amount during an ammonia distillation process; the invention adopts the technical scheme as follows: the ammonia distillation method for waste heat of coke-oven flue gas is carried out according to the following steps: firstly, injecting water, secondly, depositing solid impurities, thirdly, exchanging heat, fourthly, carrying out vapor-liquid separation, and then repeating the steps from the first to the fourth; a reboiler used in the ammonia distillation method for waste heat of coke-oven flue gas comprises an upper casing, a lower casing, an upper pipe plate, a lower pipe plate, a circulation downcomer and a plurality of evaporating pipes; and the upper pipe plate and the upper casing form a vapor-liquid separating chamber, and the lower pipe plate and the lower casing form a water settlement chamber. Due to the invention, amounts of soft water and energy are saved, and the quantity of wastewater discharge is reduced.

Owner:SHANXI POLARBEAR ENVIRONMENTAL TECH CO LTD

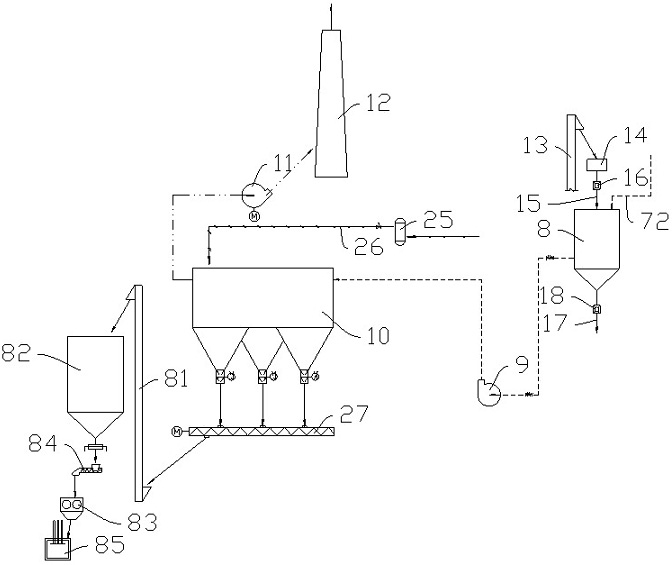

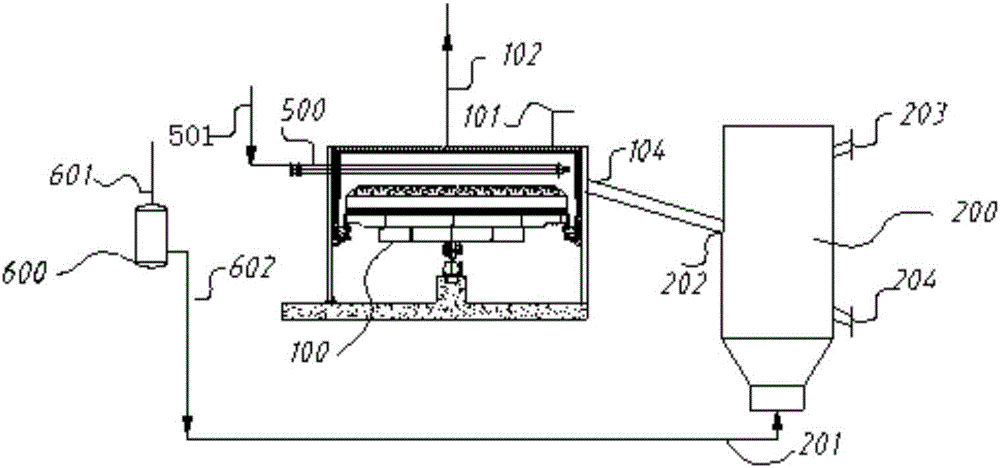

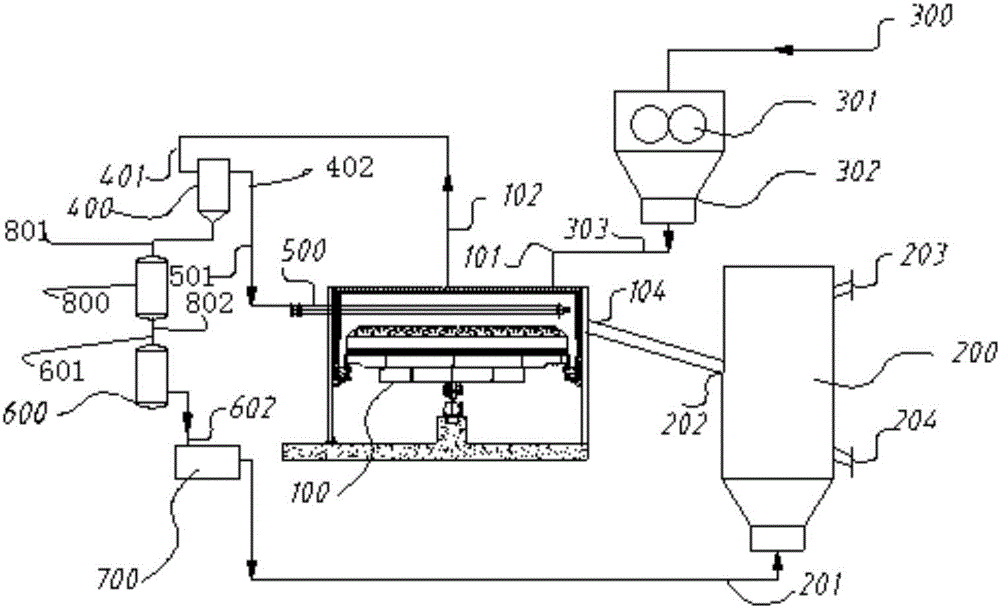

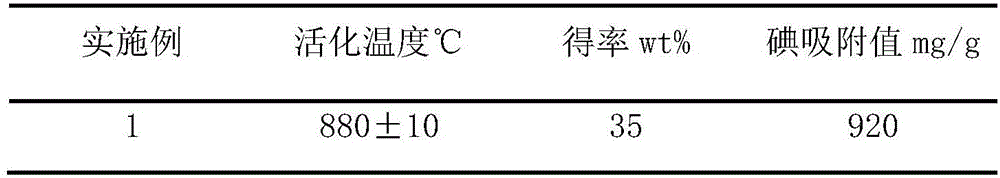

System and method for preparing active carbon by biomass

PendingCN106629715ASolve the blockageSolve heavy dustCarbon compoundsSpecial form destructive distillationCombustorWater vapor

The invention relates to a system and a method for preparing active carbon by biomass. The system comprises a pyrolyzing furnace, a combustor, a steam boiler and a fluidized bed, wherein the pyrolyzing furnace is used for pyrolyzing raw material biomass to generate pyrolyzed oil gas and carbon residue; the combustor is used for heating the raw material biomass to pyrolyze the raw material biomass; the steam boiler is used for heating water to obtain steam; and the fluidized bed is used for activating the carbon residue to generate active carbon. According to the system and the method, the existing fluidized bed does not need to be transformed, heat loss is reduced, energy consumption is reduced, the productivity of the pyrolyzing furnace is improved, and reduction, harmless treatment and resource utilization of the materials is realized.

Owner:SHENWU TECH GRP CO LTD

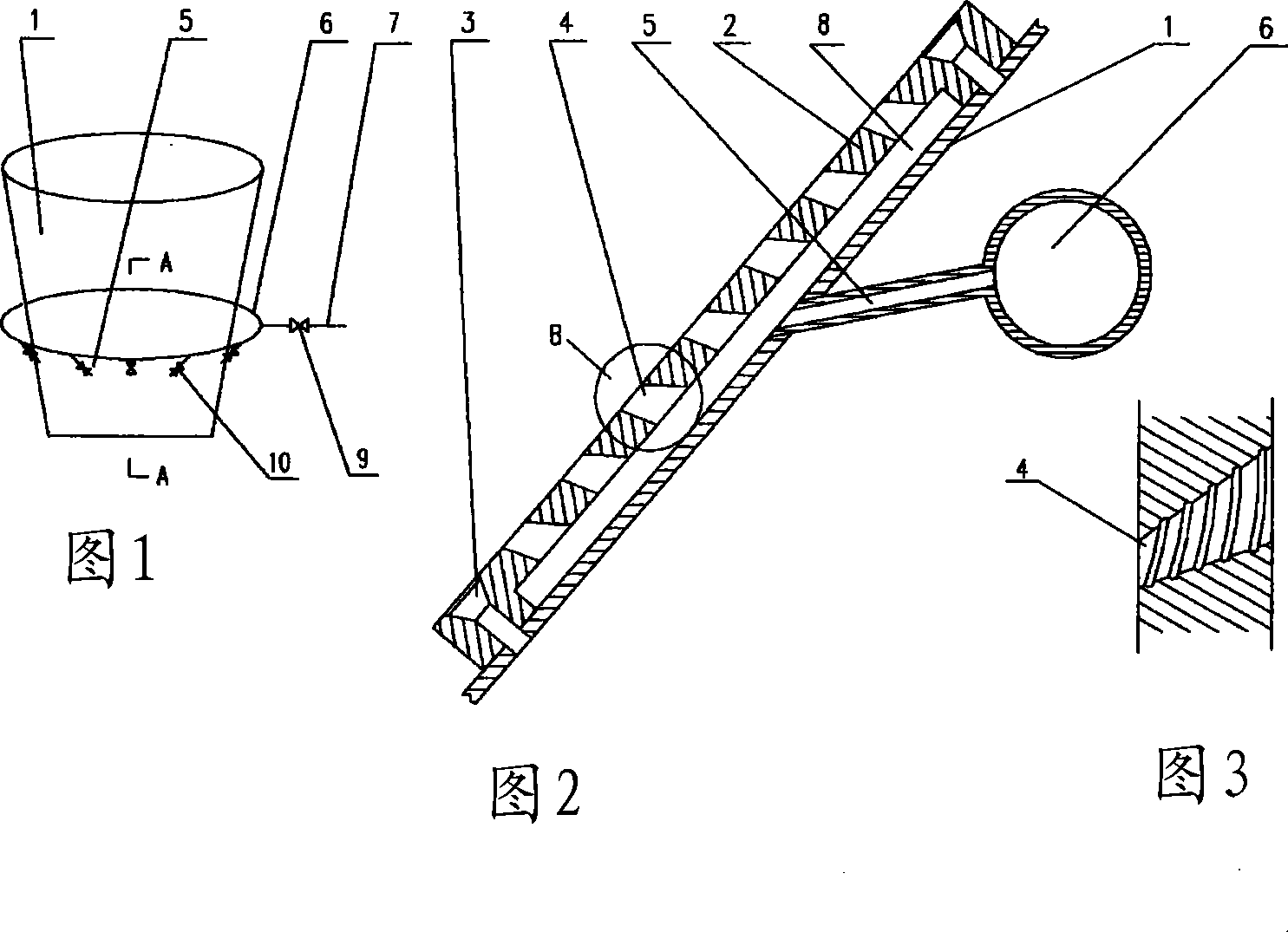

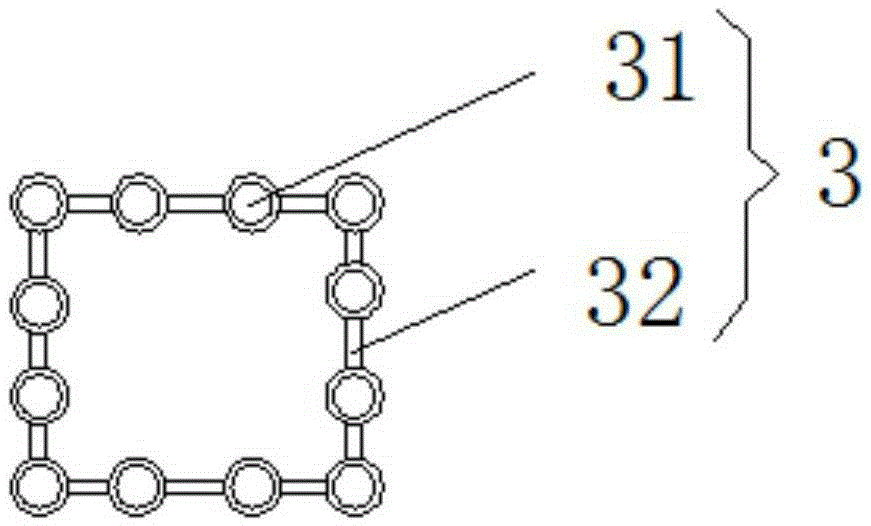

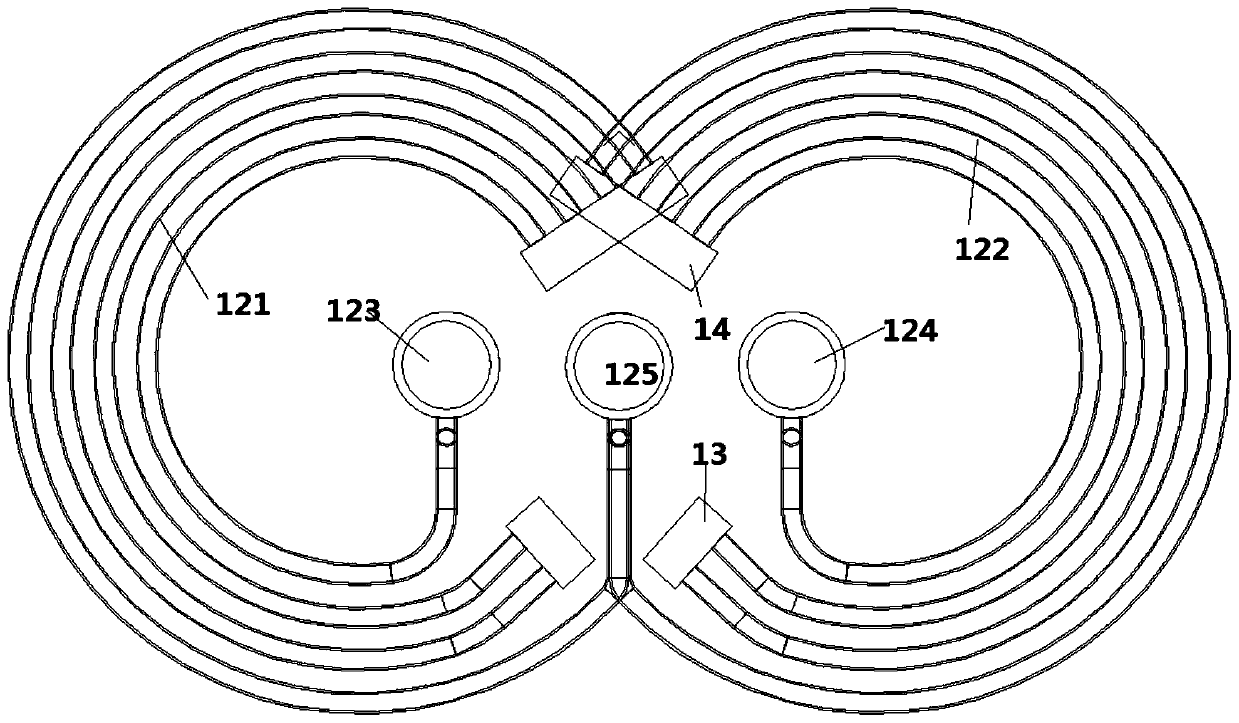

Preheating method and device for sintering mixture

The utility model discloses a steam preheating method for sinter mixtures and the device thereof, belongs to a sintering process in ferrous metallurgy, and helps to increase the heat exchange efficiency of steam preheating of sinter mixture, save the energy, increase the temperature of preheating the sinter mixture, reduce the energy consumption in sintering process, and increase the yield per machine hour. The technical proposal is that the superheated steam is produced by the waste heat from the sintering process and is introduced to a mixture bin; a steam chamber plate is fixed inside the bin and coupled with the inner wall of the bin, forming a steam chamber; the superheated steam is delivered to the steam chamber by using a branch pipe passing through the bin wall from a link ring pipe; all steam chamber plate are combined and encircled around the bin inner wall to form a ring-shaped preheating zone with heat exchange effect in double heat-conduction mode; and the mixture is pre-heated under the operational conditions (temperature rise up to 55-67 DEG C), thereby increasing the heat exchange efficiency. Compared with the prior art, the invention can increase the retreating temperature of mixture, reduce the solid fuel consumption for ore sintering by 3kg / t, and increase the yield per machine hour by 2 percent.

Owner:ANGANG STEEL CO LTD

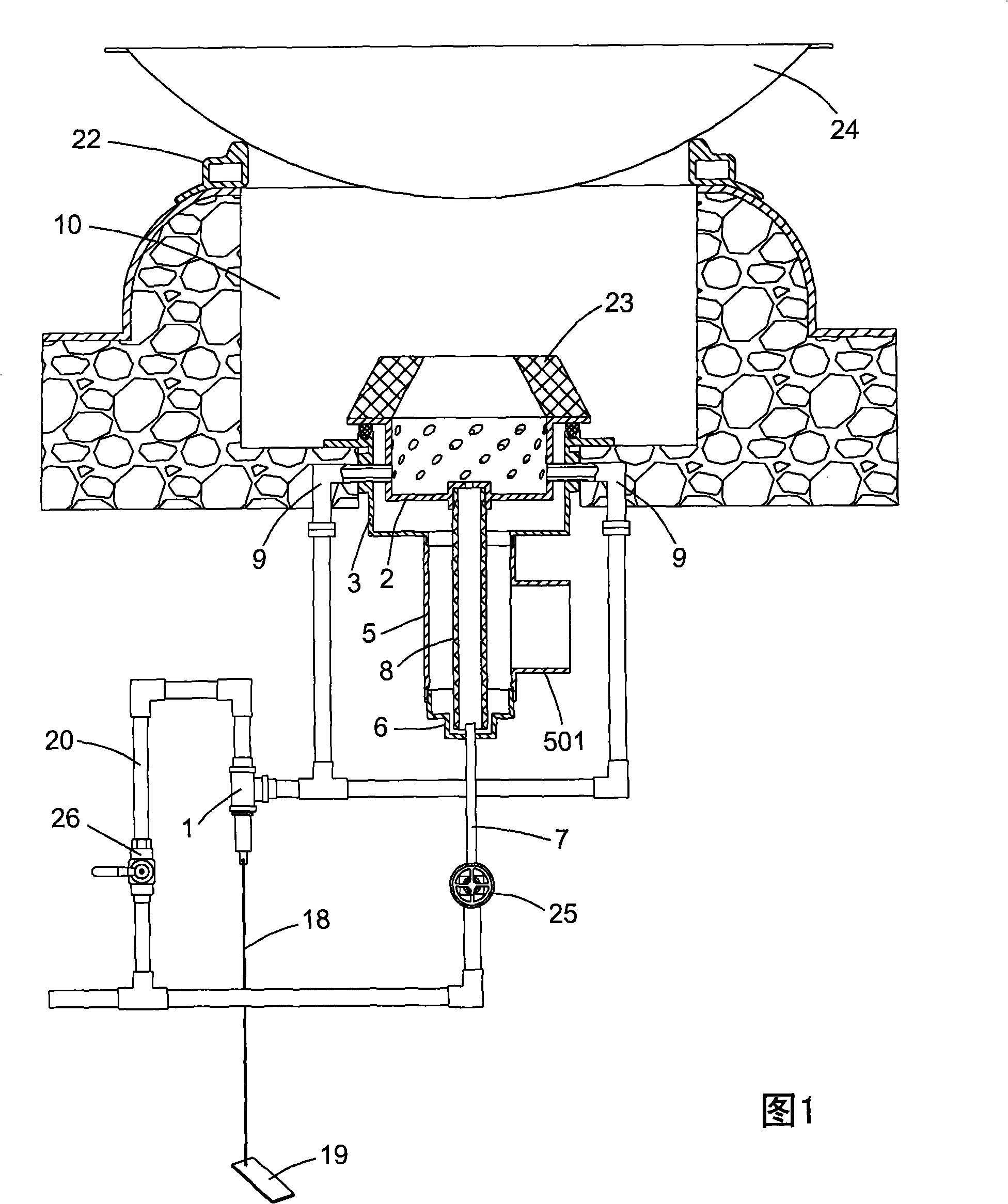

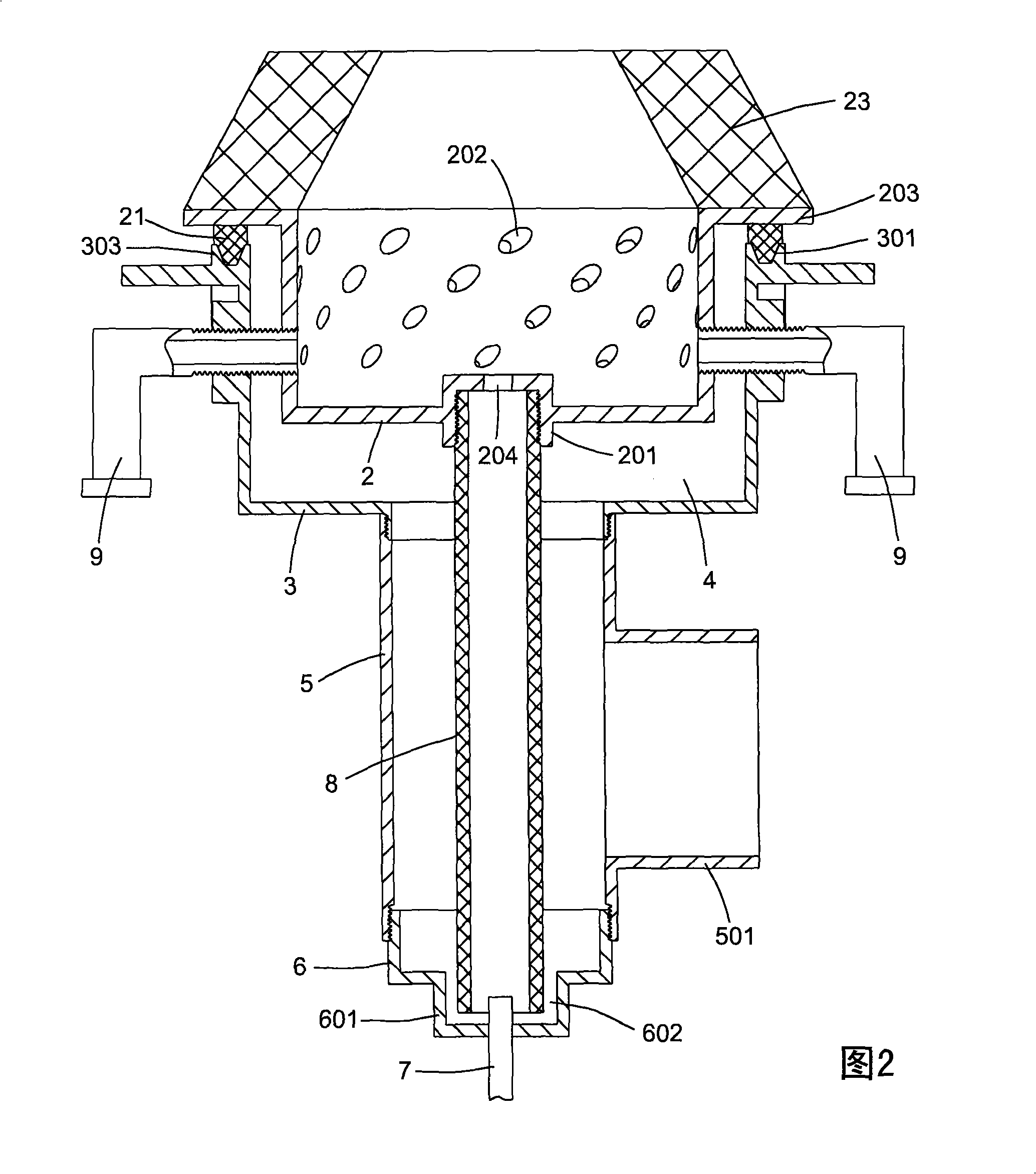

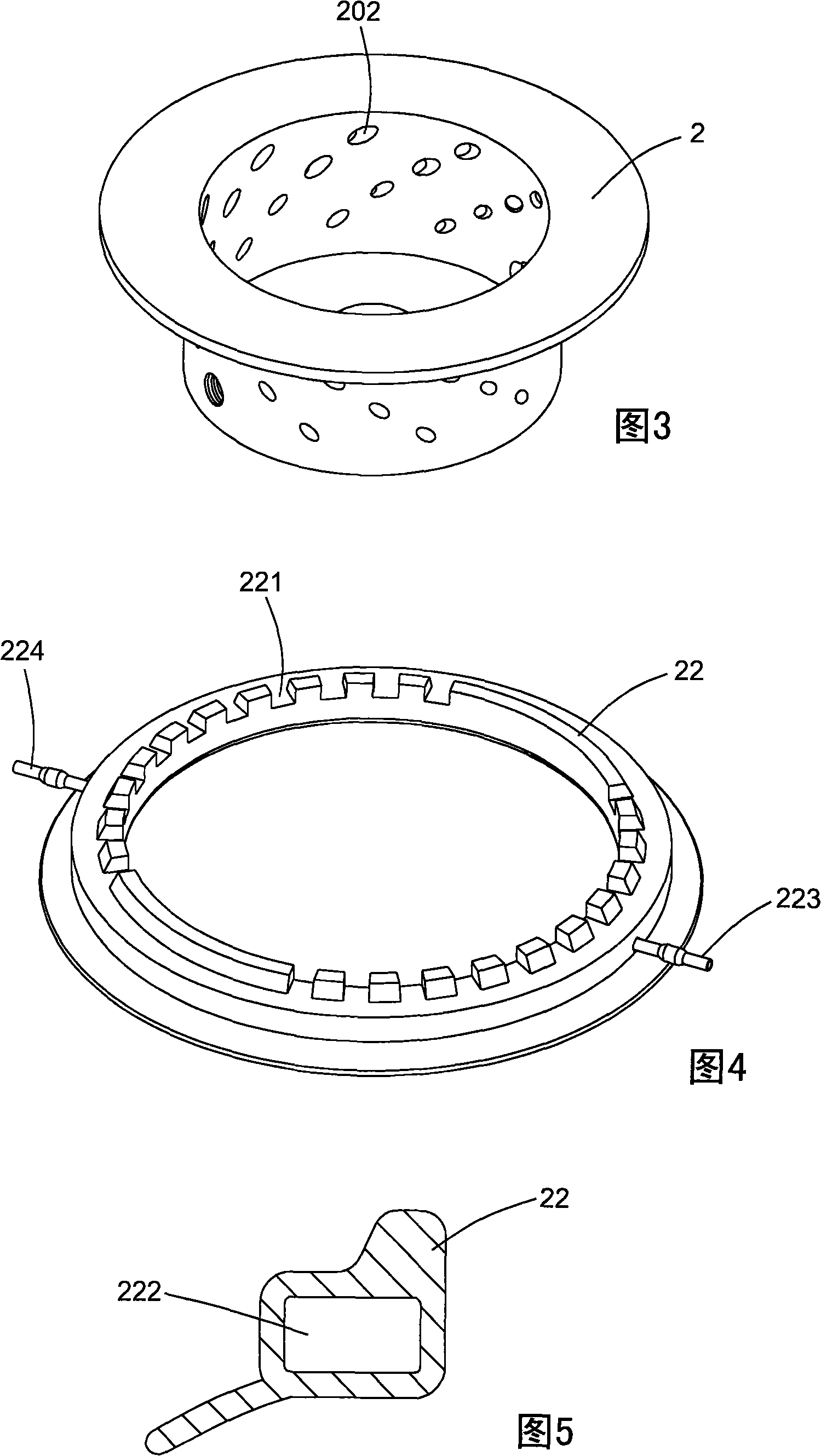

Water-saving, energy-saving and low noise oil gas dual-purpose air blast range

InactiveCN101275753ABurn fullyStrong firepowerLighting and heating apparatusWater heating stoves/rangesHearthLow noise

A water saving and energy saving low noise oil gas dual purpose blast hearth, wherein the burner is composed of an inner and an outer fire vessels, the top nozzle of the wind pipe is screwed on the bottom pot of the outer fire vessel, the bottom nozzle of the wind pipe is screwed with a pipe plug, the center of which is provided with a tubing head base, the central hole of the tubing head base is communicated with a fuel gas assistant burning supply pipe, the center of the inner fire vessel if provided with a tubing head cap seat, the center of which is provided with an air outlet. The center of the wind pipe is equipped with a sleeve, the upper end of which is screwed with the tubing head cap seat, while the lower end is in gap matched with the tubing head cap seat. The central nozzle of the wind pipe is connected with a fan, a heat insulating mattress is arranged between the flange on the inner fire vessel upper part and the circular flange of the outer fire vessel upper part, the side walls of the inner and the outer fire vessels are opened with screws, and the air inlet pipe traversely passes through the interlining chamber between the inner and the outer fire vessels to screw with the bolt hole. The invention is provided with conflagration and nagaaki fire, which controls the conflagration by the foot valve to save fuel gas; and provided hot water using the remaining heat, meanwhile reduces the temperature of the hearth, saves water with small fan and low noise.

Owner:高学廷

Waste heat recovery type heat pump heat management device for new energy automobile

PendingCN110254175AReduce power consumptionImprove heating efficiencyAir-treating devicesVehicle heating/cooling devicesNew energyEngineering

The invention discloses a waste heat recovery type heat pump heat management device for a new energy automobile, and relates to the technical field of heat management devices of new energy automobiles. The device comprises an electric compressor, one end of the electric compressor is connected with one end of a first three-way valve, the other end of the electric compressor is connected with a gas-liquid separator, the other end of the first three-way valve is connected with one end of an outdoor heat exchanger, an evaporator and a plate heat exchanger are arranged between the outdoor heat exchanger and the gas-liquid separator in parallel; the evaporator is connected with a thermal expansion valve and a third two-way valve in series, and the plate heat exchanger is connected with a first electronic expansion valve in series, and a second electronic expansion valve and a first two-way valve are arranged on a pipeline between the outdoor heat exchanger and the first electronic expansion valve in parallel. According to the waste heat recovery type heat pump heat management device, the waste heat of electric control of the motor is fully utilized, the electric control of the passenger compartment, the motor and the battery can be carried out at the same time, the working temperature lower limit of the heat pump is effectively reduced, the energy consumption of the battery is saved, and the cruising mileage of the whole vehicle is improved.

Owner:NANJING XIEZHONG AUTO AIRCONDITIONER CO CO LTD

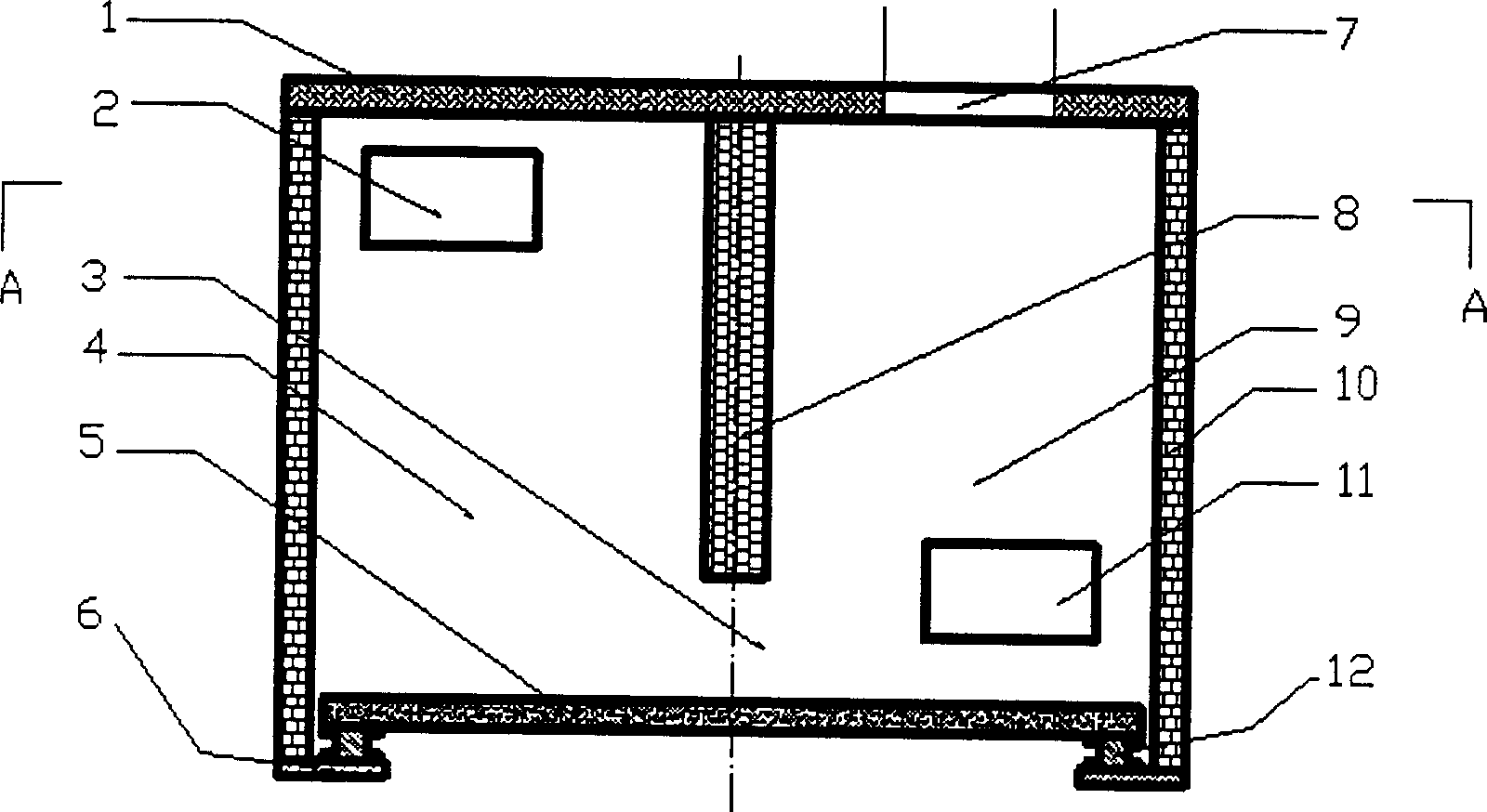

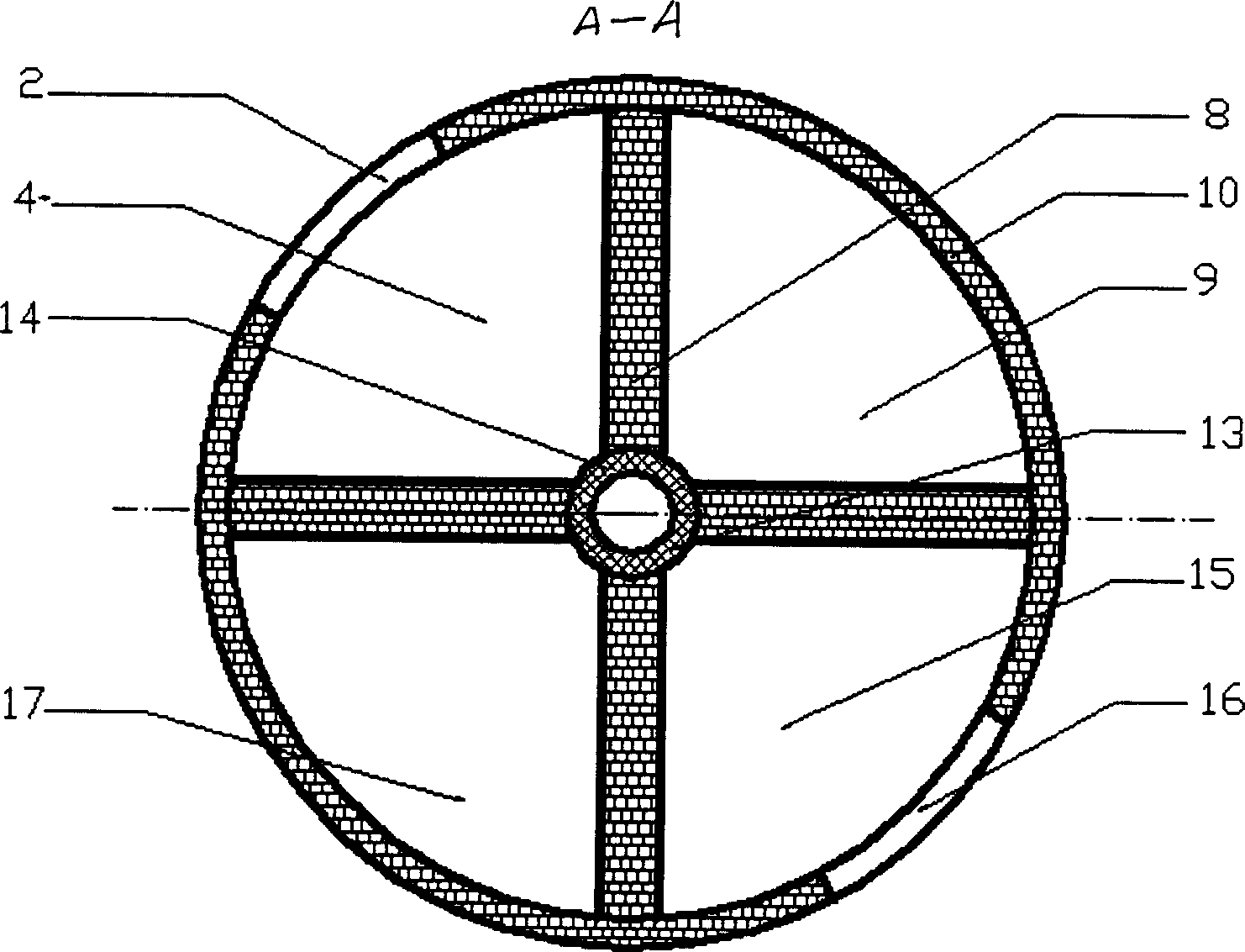

Multi-side stereo combustion boiler capable of realizing clean combustion of coal and combustion method thereof

InactiveCN1789806AEmission reductionSuppress sootSolid fuel combustionCombustion apparatusCombustion chamberNitrogen oxide

This invention relates to one multi-surface stand burst furnace and method to realize coke cleaning burst, wherein, the burst furnace comprises the following parts: column furnace with channel exit located on top cover and rotation row located on the bottom of the furnace; at least one gas chamber and one pair of burst stand symmetric cross isolation element and space burst mouth between the isolation parts down end and furnace row with gas room and burst room connected; each gas chamber top furnace wall is located with each coke adding mouth with smoke exit mouth and reside exit mouth downside as secondary mouth. The burst method is to cooperate with multiple gas rooms through rotation furnace row.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

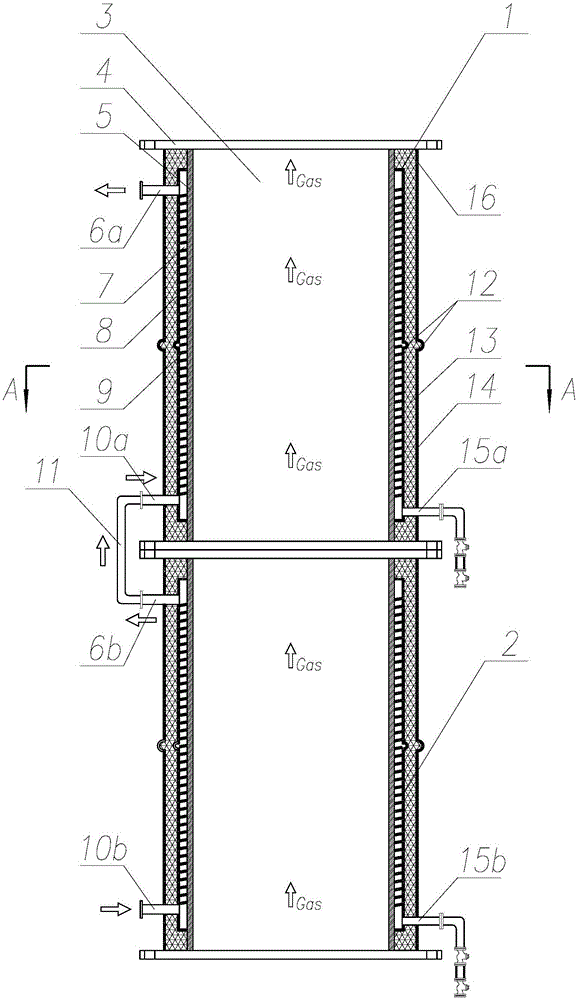

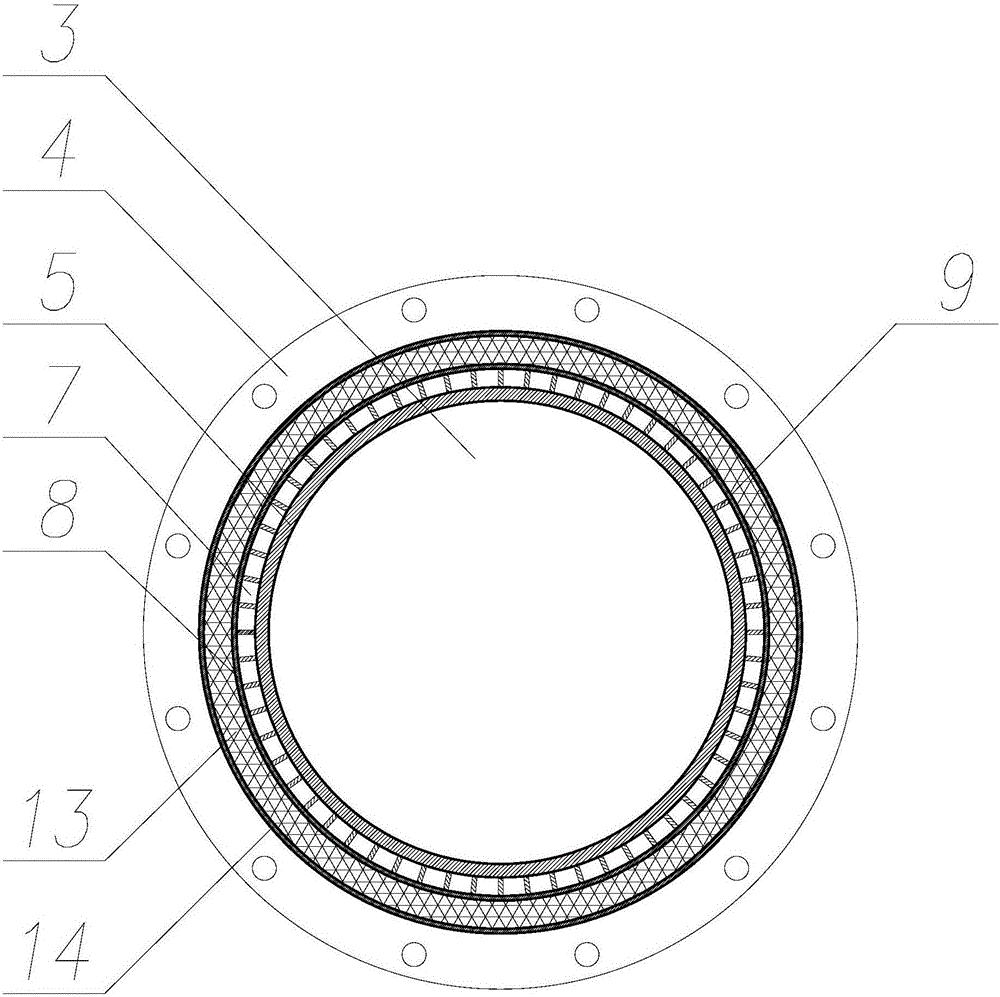

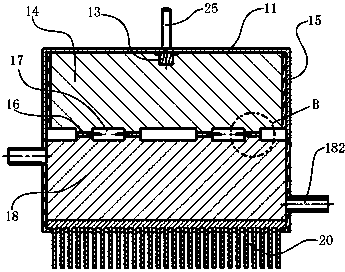

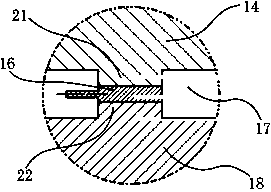

Waste heat recovery device for ascending pipe of coke oven

InactiveCN106398724AGuaranteed safe operationReduce dosageEnergy inputIncreasing energy efficiencyWaste heat recovery unitWater channel

The invention discloses a waste heat recovery device for an ascending pipe of a coke oven. The waste heat recovery device comprises two or more ascending pipe evaporators which are communicated sequentially, wherein the ascending pipe evaporators comprise inner pipes, inner sleeves, thermal insulation layers and outer jackets which are sequentially arranged from inside to outside, crude gas channels are arranged on the inner sides of the inner pipes, the top ends of the inner sleeves are in tight connection with the top ends of the inner pipes, the bottom ends of the inner sleeves are in tight connection with the bottom ends of the inner pipes, and gas-water channels are formed between the inner pipes and the inner sleeves; gas-water outlets are formed in the tops, corresponding to the gas-water channels, of the inner sleeves and penetrate through the thermal insulation layers and the outer jackets; gas-water inlets are formed in the bottoms, corresponding to the gas-water channels, of the inner sleeves and penetrate through the thermal insulation layers and the outer jackets; and the gas-water outlet of each ascending pipe evaporator is communicated with the gas-water inlet of the upper adjacent ascending pipe evaporator. According to the waste heat recovery device, the matching between the crude gas quantity and the waste heat recovery capacity of the device is realized.

Owner:HUATIAN ENG & TECH CORP MCC +1

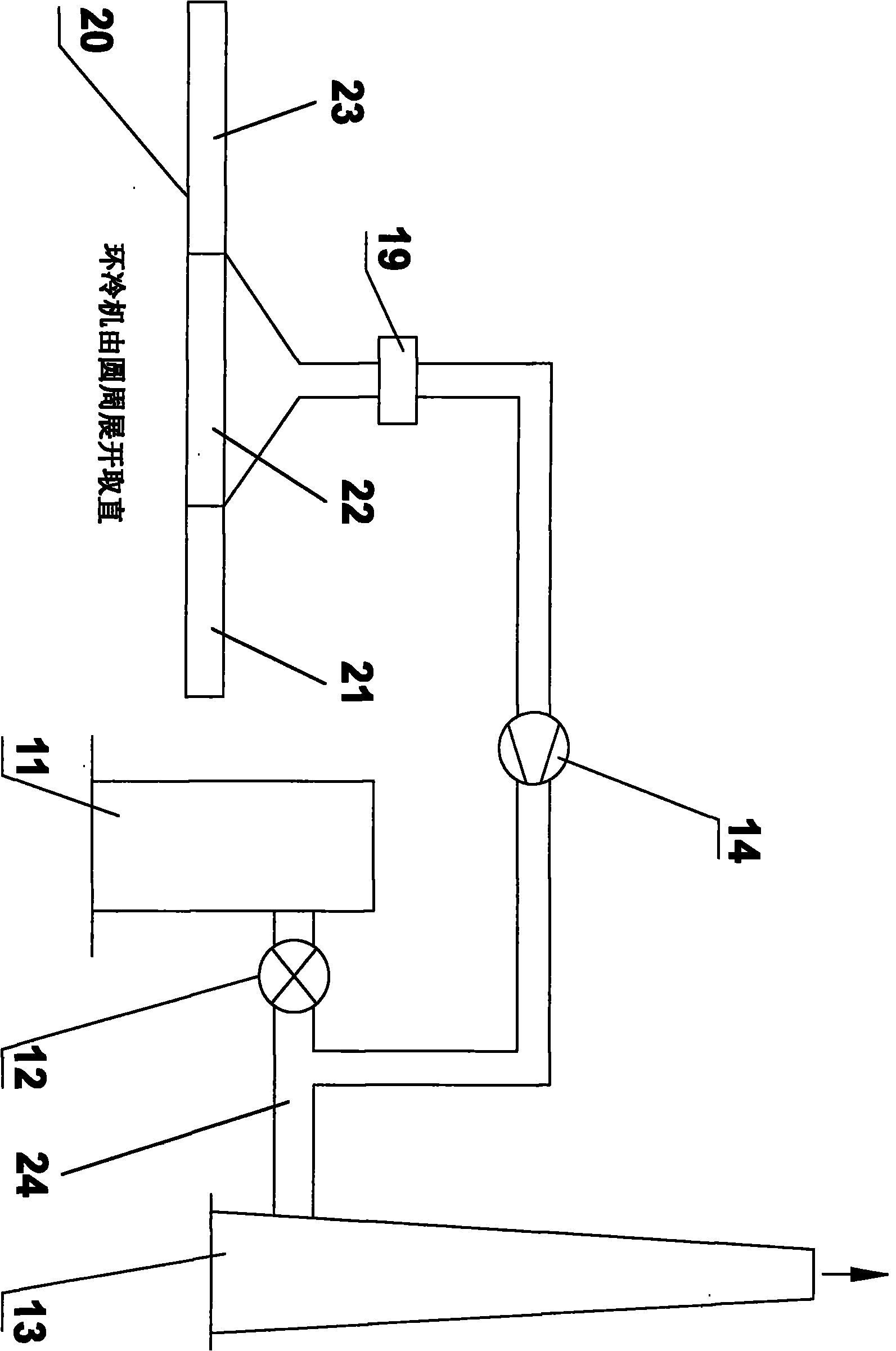

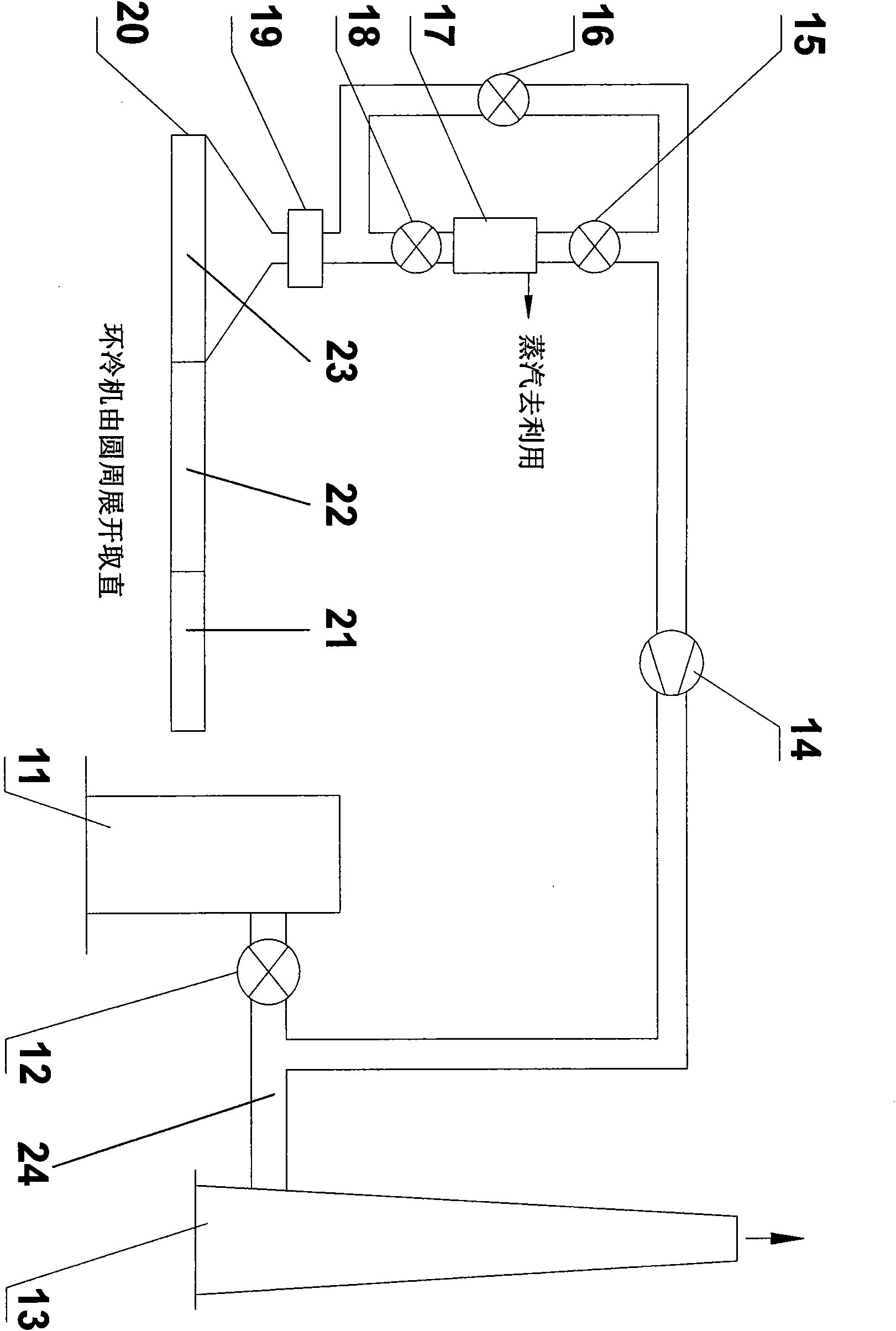

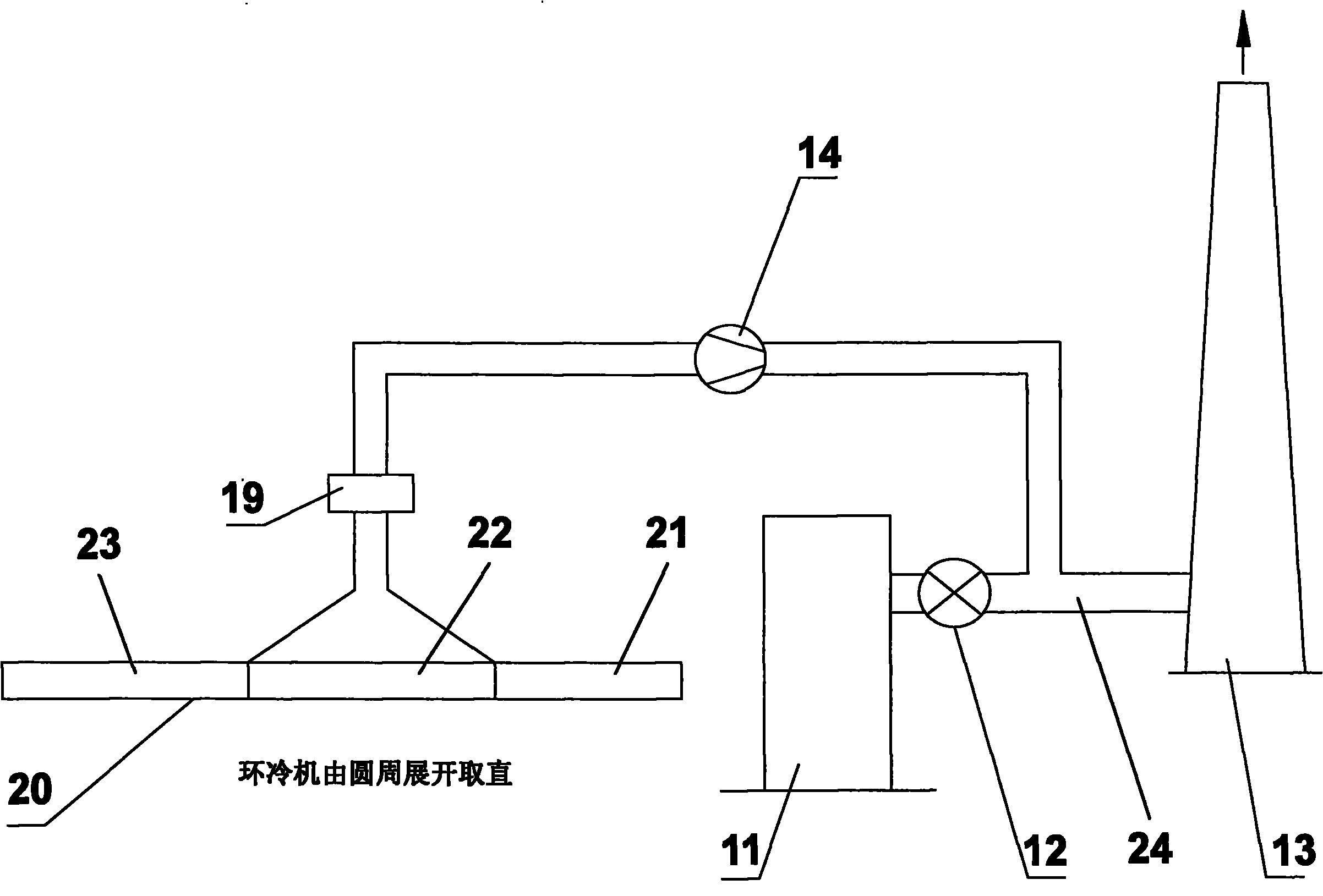

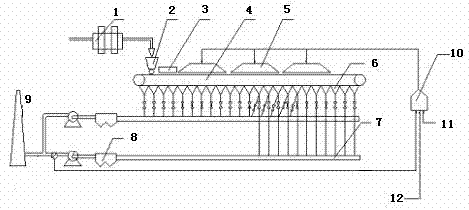

Corrosion decelerating system for wet desulphurization chimney of sintering machine

InactiveCN101963459ASave construction investmentNon-corrosiveWaste heat treatmentFlue gasEmission standard

The invention relates to a corrosion decelerating system for a wet desulphurization chimney of a sintering machine, which comprises a wet desulphurization device, a valve, a chimney, a blower, a circular cooler and a high temperature resistant duster, wherein the circular cooler is provided with temperature sections which comprise a low temperature section, a moderate temperature section and a high temperature section; the temperature sections are respectively connected with the wet desulphurization device and the chimney through pipelines; the blower is arranged on the pipelines; the wet desulphurization device is connected with the valve; and the high temperature resistant duster is arranged on the pipelines in a position near the temperature sections of the circular cooler. In the invention, a heat source for improving the temperature of wet flue gas in desulphurization can use the hot blast cooled in the moderate temperature section of the circular cooler, and also can use the flue gas exhausted from a waste heat boiler of the circular cooler. The system of the invention does not use GGH, the hot blast which achieves an emission standard after dust removal and recovery of waste heat by the circular cooler, or the hot blast in the moderate temperature section of the circular cooler without recovery of waste heat is mixed with wet flue gas after desulphurization for improving the temperature of the wet flue gas after desulphurization, so that the actual effect of decelerating corrosion of the wet desulphurization chimney is achieved, and the overall system is simple and practical.

Owner:BAOSTEEL ENG & TECH GRP

Slag waste heat recovery device

The invention discloses a slag waste heat recovery device comprising a base. A water pump and a furnace body are arranged on the base. An inner cavity of the furnace body is connected with a heat exchange pipeline through vertical supports and transverse supports. An upper port of the heat exchange pipeline is connected with a feed port. The feed port is connected with a slag outlet of a box body. A rotating shaft is arranged in an inner cavity of the box body in a penetrating manner. The tip of the rotating shaft is connected with a motor through a belt. Slag smashing blades are arranged on the rotating shaft. Counter blades corresponding to the slag smashing blades are arranged on the side faces of the box body. A lower port of the heat exchange pipeline penetrates the bottom of the furnace body. The heat exchange pipeline comprises water pipes and connection pieces. The water pipes are connected through the connection pieces. The two ends of each water pipe are connected with a water outlet pipe and a water inlet pipe correspondingly. The water outlet pipe penetrates the upper end of the side face of the furnace body. The water inlet pipe penetrates the lower end of the side face of the furnace body and is connected with the water pump. The slag waste heat recovery device is simple in structure and capable of sufficiently utilizing slag waste heat and improving the boiler efficiency.

Owner:CHONGQING QIANSHUN SCI & TECH CO LTD

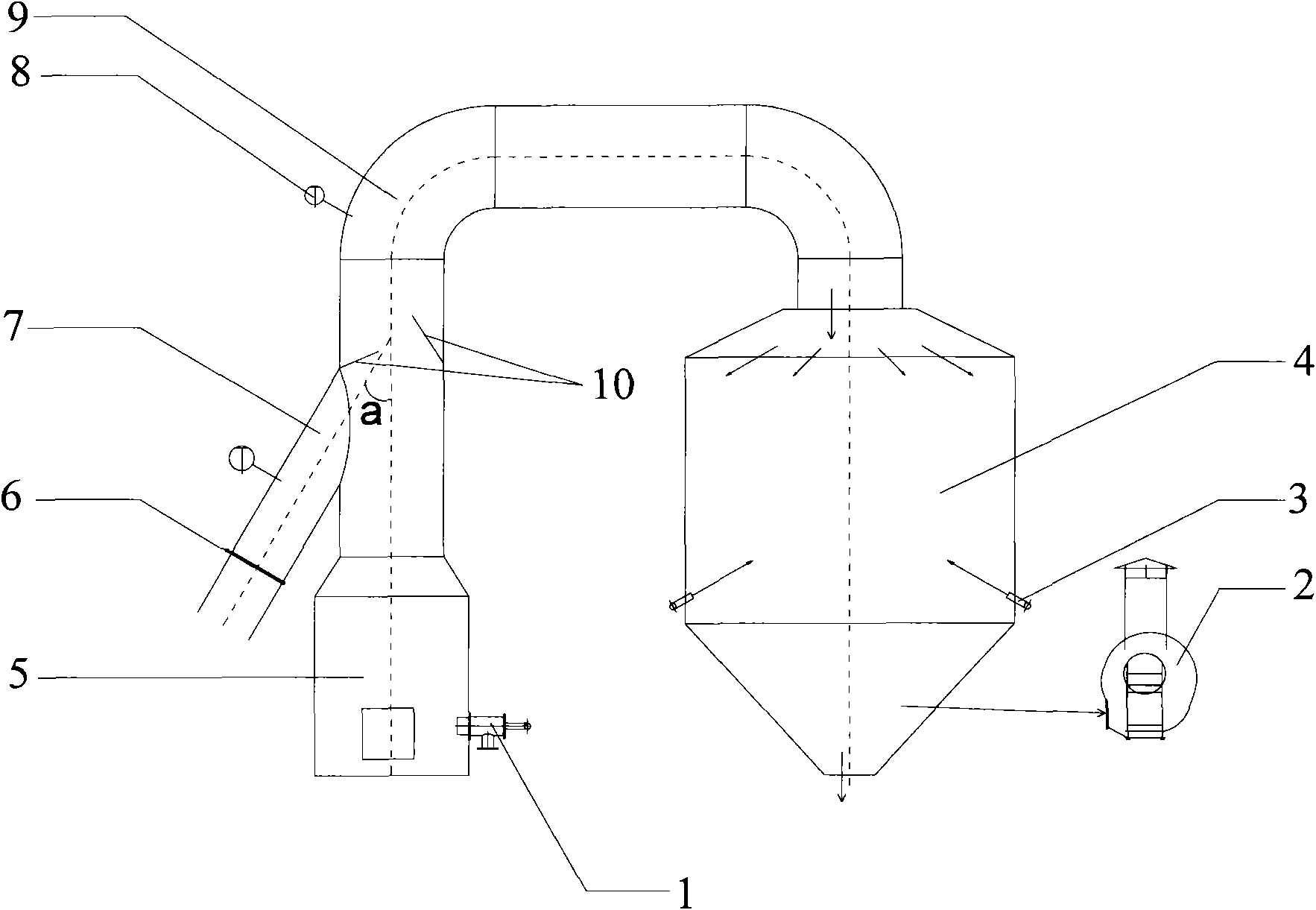

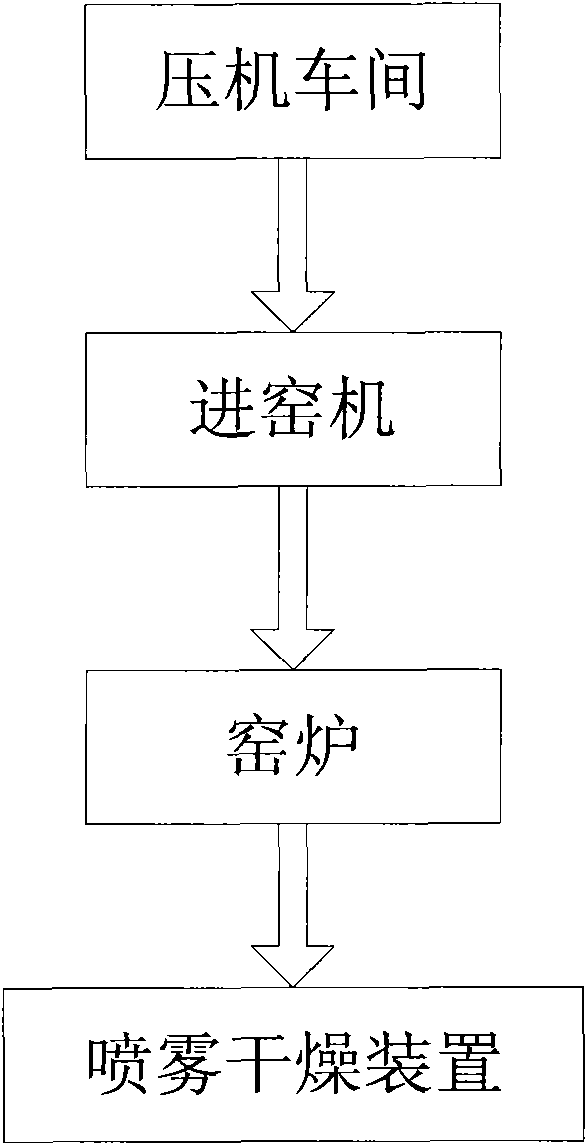

Spray drying device utilizing waste heat of kiln and ceramic production line

InactiveCN101598494AEfficient use ofEffective use of kiln waste heatDrying solid materials with heatDrying gas arrangementsProduction linePulp and paper industry

The invention discloses a spray drying device utilizing waste heat of a kiln, which comprises a spray drying tower, a hot air furnace and a waste heat pipe, wherein the spray drying tower is connected with the hot air furnace through a connecting pipeline; and the waste heat pipe is arranged on the connecting pipeline. The spray drying device utilizing the waste heat of the kiln can effectively utilize the waste heat of the kiln, and can solve the problem of the uniformity of hot air temperature in the spray drying tower. Based on the spray drying device, the invention also provides a ceramic production line, which comprises a press machine workshop, a kiln feeding machine, the kiln, and the spray drying device utilizing the waste heat of the kiln, wherein the press machine workshop, the kiln feeding machine, the kiln, and the spray drying device utilizing the waste heat of the kiln are orderly connected. The ceramic production line can reduce the transportation power of the waste heat of the kiln, and can effectively avoid the loss of the heat of the waste heat of the kiln.

Owner:霍镰泉 +1

Medium phase-change energy-storage thermoelectric power generating system

The invention discloses a medium phase-change energy-storage thermoelectric power generating system which comprises a fused salt energy-storage device, a machine hood holding the fused salt energy-storage device, a heat-preserving jacket arranged between the machine hood and the fused salt energy-storage device, a machine shell in butt joint with the machine hood to define a case in an enclosed mode, a heat exchange water tank located in the machine shell, a fin heat radiator which is located at the bottom of the machine shell and partially protrudes out of the machine shell, a heat insulating layer located between the fused salt energy-storage device and the heat exchange water tank and a thermoelectric power generation chip embedded in the heat insulating layer and located between the fused salt energy-storage device and the heat exchange water tank, wherein the heat-preserving jacket wraps the periphery of the fused salt energy-storage device, phase-change fused salt is stored in the fused salt energy-storage device, and the heat exchange water tank is in close contract with the fin heat radiator. The medium phase-change energy-storage thermoelectric power generating system is compact in structure, convenient to move, easy to popularize and use in different environments and situations and capable of improving energy utilization efficiency in the mode that the heat exchange water tank is combined with the fin heat radiator.

Owner:GUANGDONG UNIV OF TECH

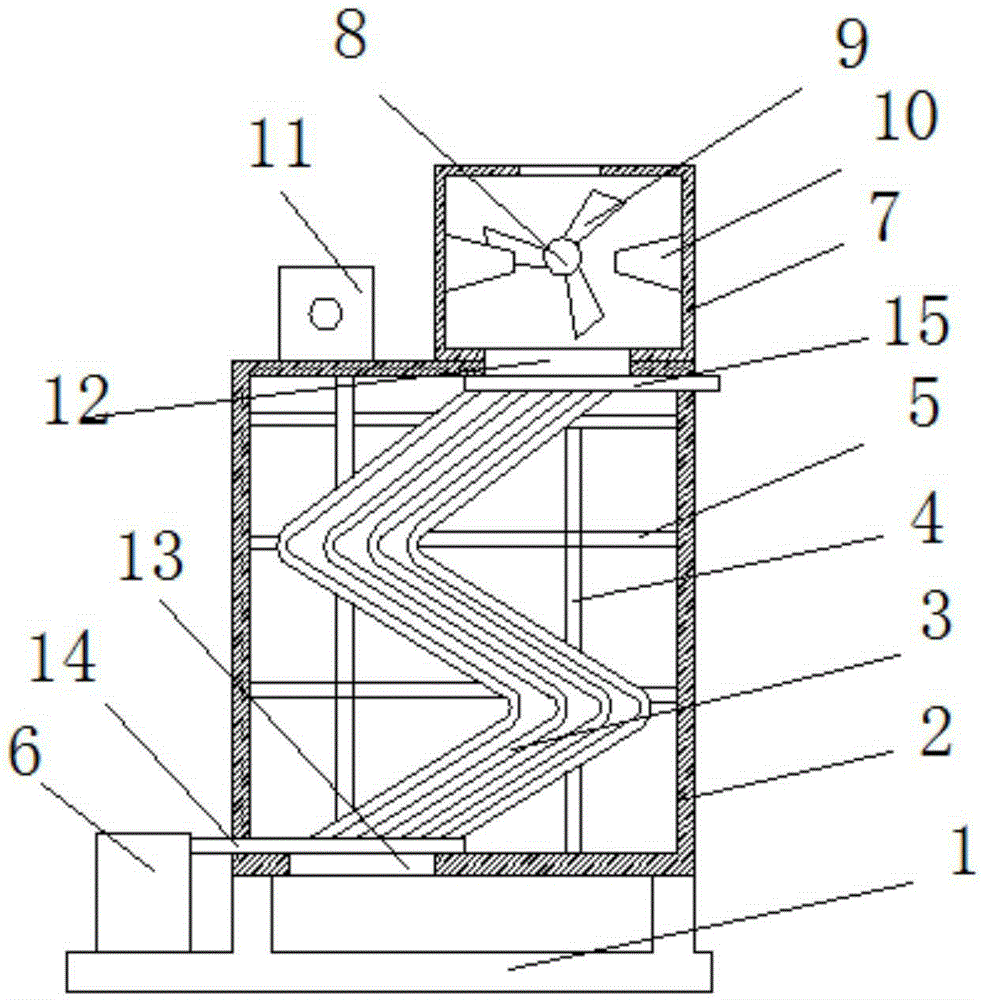

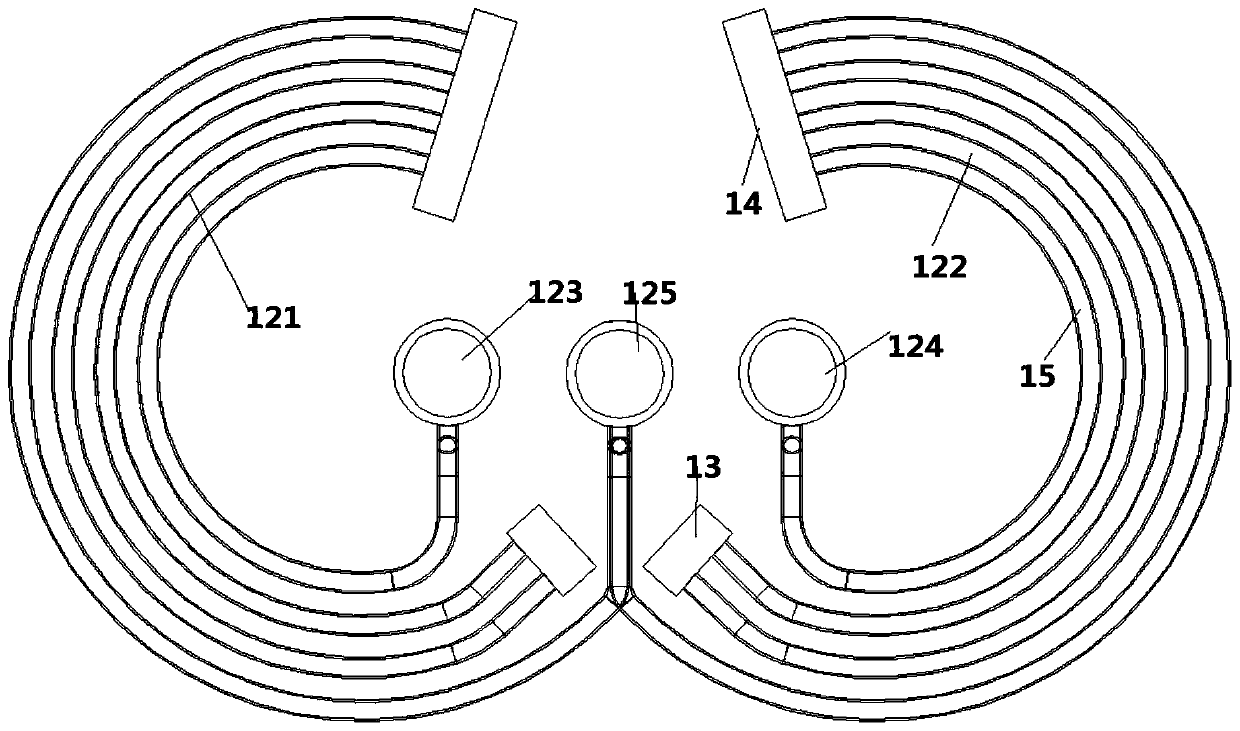

Asymmetrically-arranged heat exchanger

ActiveCN110174020AEnhanced heat transferStrengthen the dust removal effectEmission preventionIndirect heat exchangersEngineeringPlate heat exchanger

The invention provides an asymmetrically-arranged heat exchanger. The heat exchanger comprises a collecting pipe, left coil pipes and right coil pipes are distributed on the left side and the right side of the collecting pipe respectively; the heat exchanger is characterized in that the left coil pipes and the right coil pipes are arranged at intervals, one right coil pipe is arranged between every two adjacent left coil pipes, and one left coil pipe is arranged between every two adjacent right coil pipes. The heat exchanger can be used for carrying out reinforcing heat exchange and soot removal at different heights, and the effects of reinforcing heat exchange and removing accumulated dust are achieved.

Owner:SHANDONG UNIV

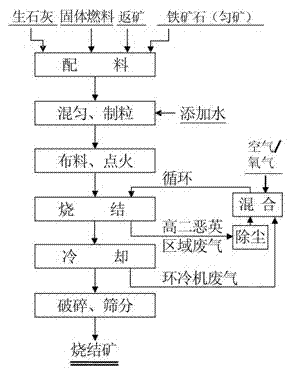

Low-energy-consumption method for reducing emission of dioxin in sintering waste gas

ActiveCN102901365AEmission reductionIncrease CaO contentEnergy industryWaste heat treatmentTemperature controlFlue gas

The invention discloses a low-energy-consumption method for reducing emission of dioxin in sintering waste gas. The low-energy-consumption method includes firstly, dividing air boxes from the machine head to the machine tail of a sintering machine into a low-dioxin containing area and a high-dioxin containing area; secondly, mixing dedusted hot waste gas at the temperature of 100-400 DEG C of the high-dioxin containing area of the sintering machine with hot waste gas at the temperature of 100-400 DEG C of a ring cooler, then adding air or oxygen in a certain quantity, keeping the oxygen content in the mixed gas higher than 14%, controlling the temperature within 100-250 DEG C, and conveying gas used for sintering to the surface of a material layer of the sintering machine; and thirdly, discharging low-temperature waste gas subjected to dedusting and desulfurizing in the low-dioxin containing area into the air from a chimney, wherein the high-dioxin containing area includes the 4th to the 10th air boxes from the machine tail to the machine head of the sintering machine, the low-dioxin containing area includes the rest air boxes and the length of the high-dioxin containing area is smaller than or equal to that of the low-dioxin containing area. By the low-energy-consumption method for reducing emission of the dioxin in the sintering waste gas, emission of the dioxin of the sintering process can be evidently reduced and waste heat in flue gas can be recovered.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com