Four-segment spray coal oxygen-enriched gasification method

A technology of fine coal and oxygen enrichment, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. The effect of improving thermal efficiency and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

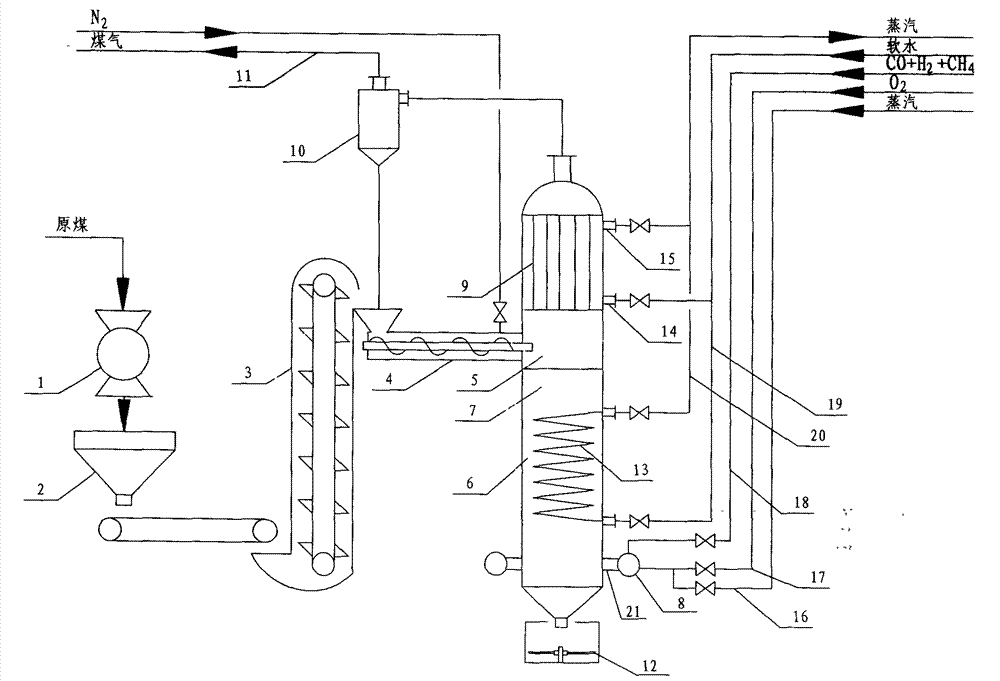

[0019] figure 1 It shows the process flow of the present invention and a schematic structural diagram of a four-stage oxygen-enriched oxidation furnace.

[0020] The raw coal purchased in the coal yard is pulverized by a raw coal crusher 1, sieved by a vibrating screen 2 to obtain fine coal with a particle size of 0.1-0.5mm, and then lifted into a coal hopper by a bucket elevator 3. The fine coal flows into the screw conveyor from the coal hopper, and driven by the screw conveyor, the fine coal conveyor 4 transports the fine coal to the preheating cracking section 5 of the four-stage oxygen-enriched oxidation furnace. A high-pressure nitrogen pipe is inserted on the fine coal conveyor 4, and the high pressure nitrogen gas is introduced to evenly distribute the fine coal in the preheating cracking section 5.

[0021] During the sinking process of the preheating cracking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com