Patents

Literature

227 results about "CO2 content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CO₂ content (also known as "Total CO₂") is a blood test that usually appears on a "Chem 19" or an electrolyte panel. The value measures the total dissolved Carbon dioxide (CO₂) in blood. It is determined by combining the Bicarbonate (HCO⁻₃) and the partial pressure of CO₂ multiplied by a factor which estimates the amount of pure CO₂ that is dissolved in its natural form (usually 0.03).

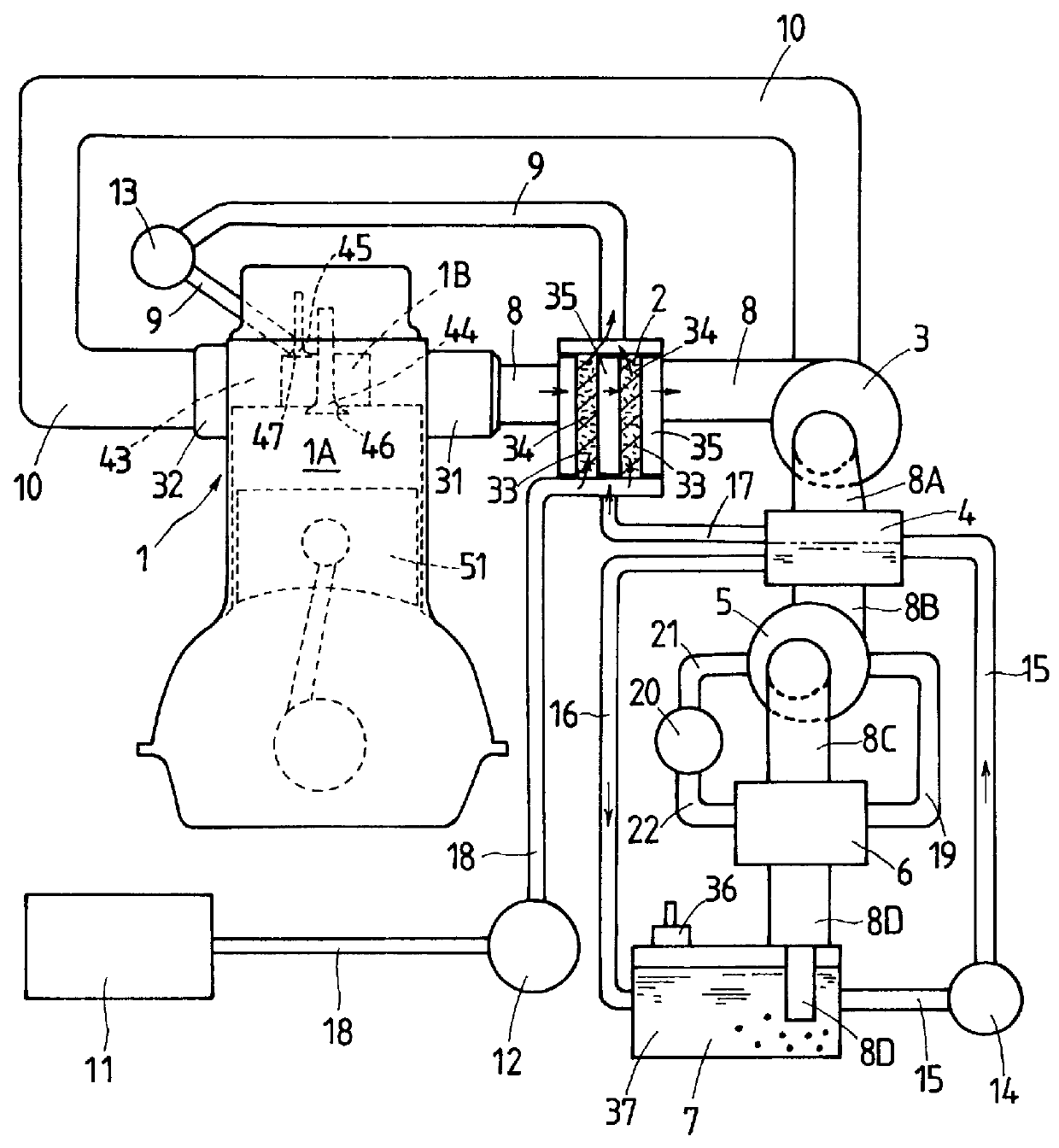

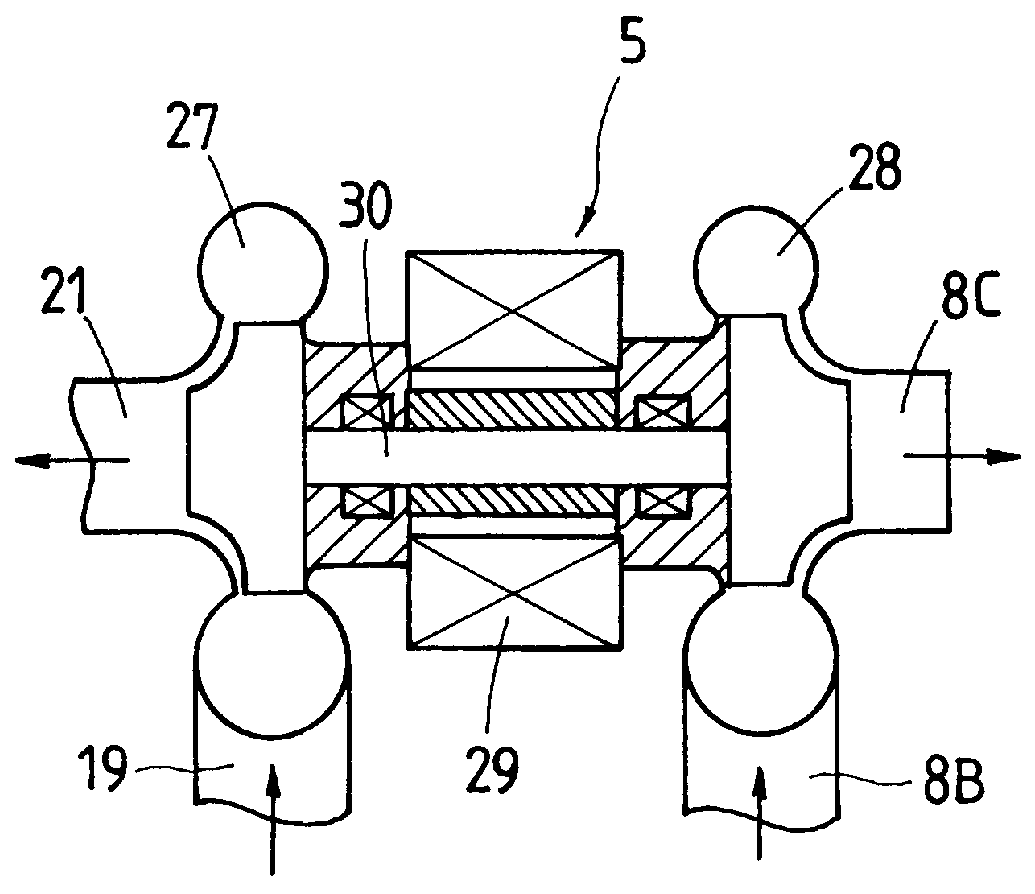

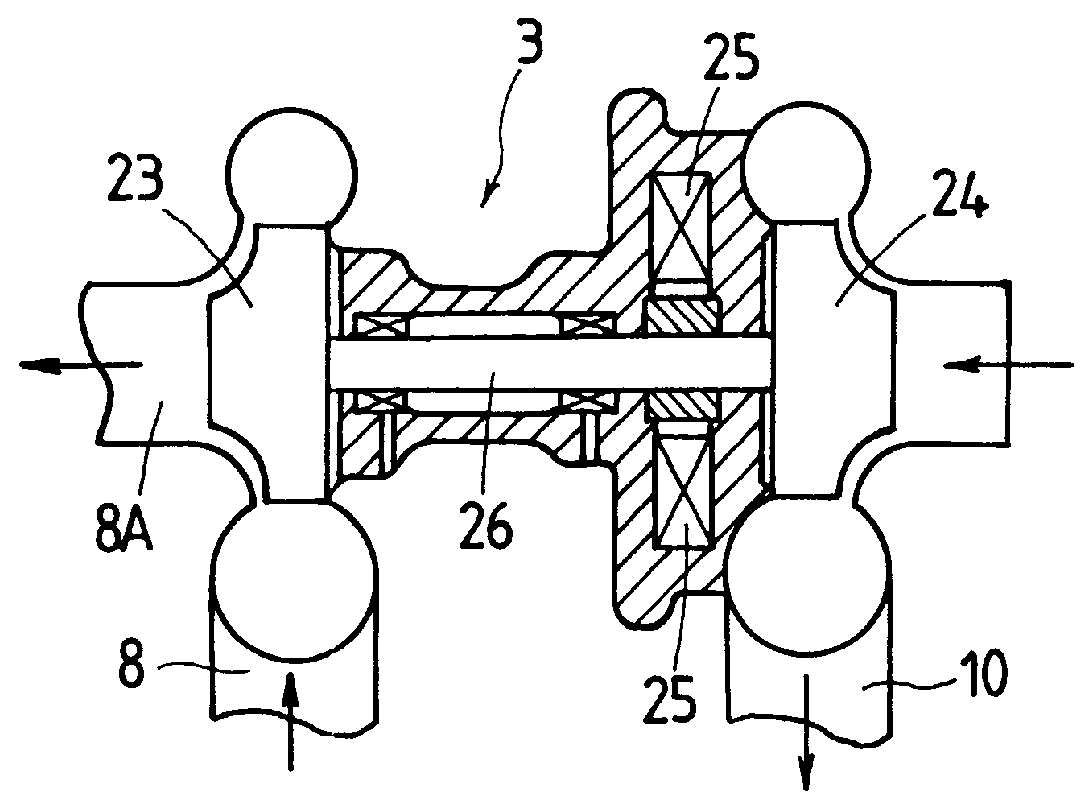

Gas engine with a gas fuel reforming device

InactiveUS6079373AReduce air pollutionMinimize formationInternal combustion piston enginesExhaust apparatusThermal energyCO2 content

The gas engine with a gas fuel reforming device thermally decomposes CH4, a major component of natural gas, into a reformed fuel of CO and H2 to increase the heat produced and thereby reduce the CO2 content in the exhaust gas and prevent the formation of NOx. The gas engine mixes CH4 with CO2 and sends the gas mixture to the catalyst reactor installed in the exhaust passage where the gas mixture is thermally decomposed into a reformed fuel by using the thermal energy of the exhaust gas. CO2 is extracted from the exhaust gas by the CO2 supply device which in turn sends the CO2 to the catalyst reactor. The CO2 supply device comprises a CO2 dissolving device that accommodates a solution to dissolve CO2 of low-temperature exhaust gas and a CO2 delivery device installed in the exhaust passage through which high-temperature exhaust gas flows and adapted to release CO2 from the solution supplied from the CO2 dissolving device. The CO2 supply device can be formed of a CO2 separation membrane that separates CO2 from the exhaust gas.

Owner:ISUZU MOTORS LTD

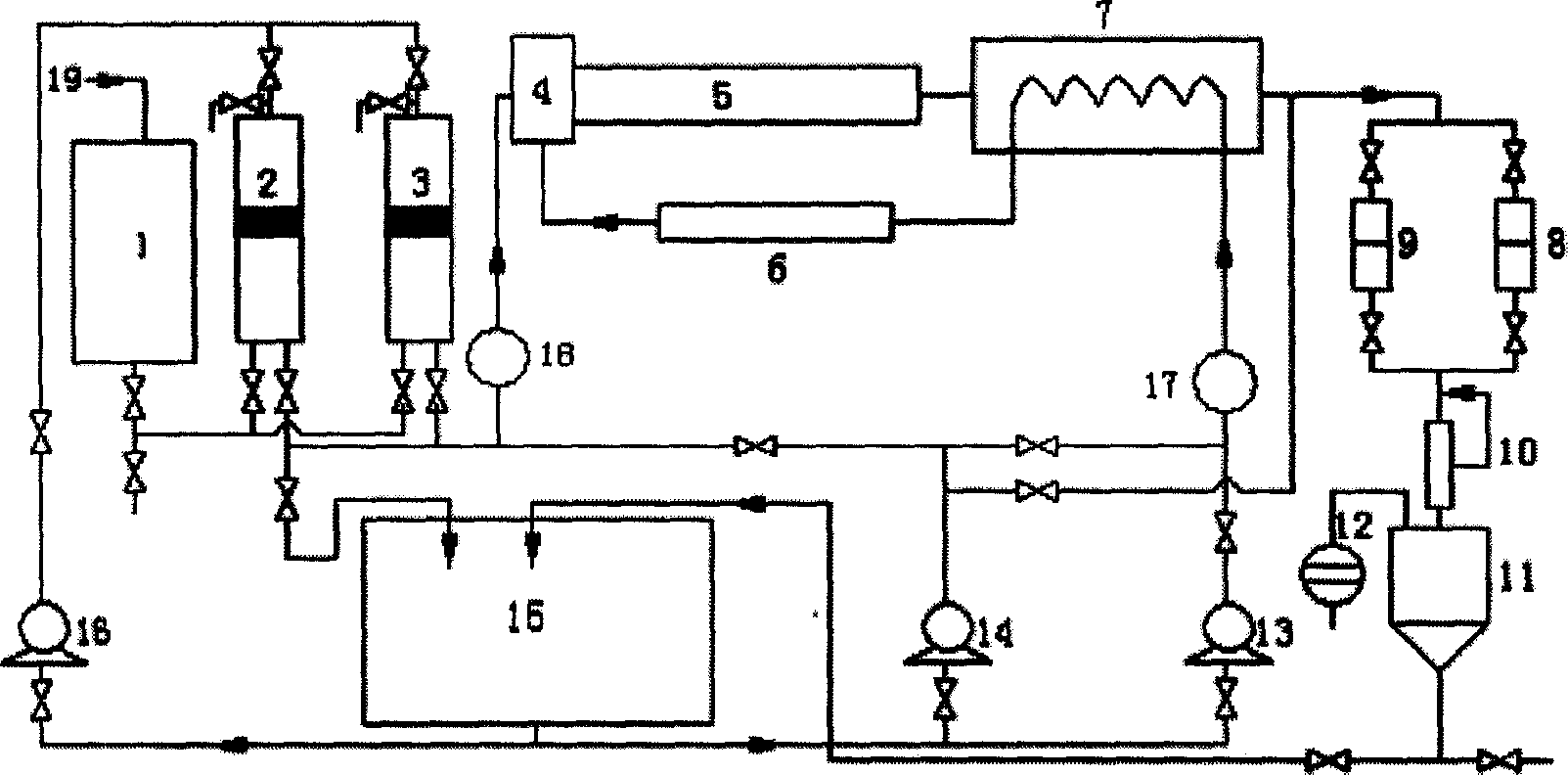

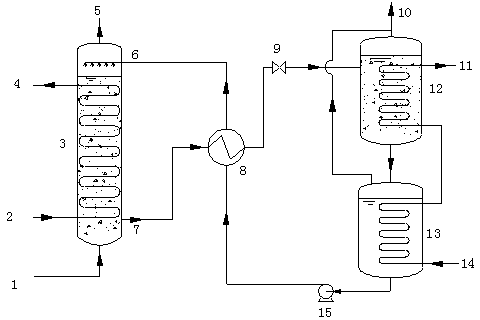

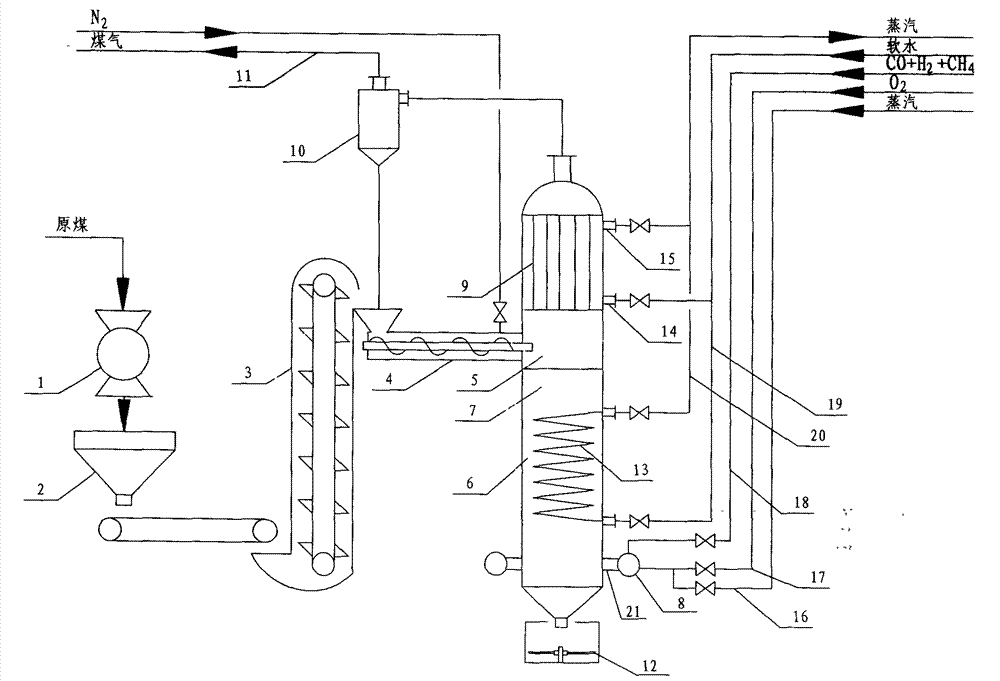

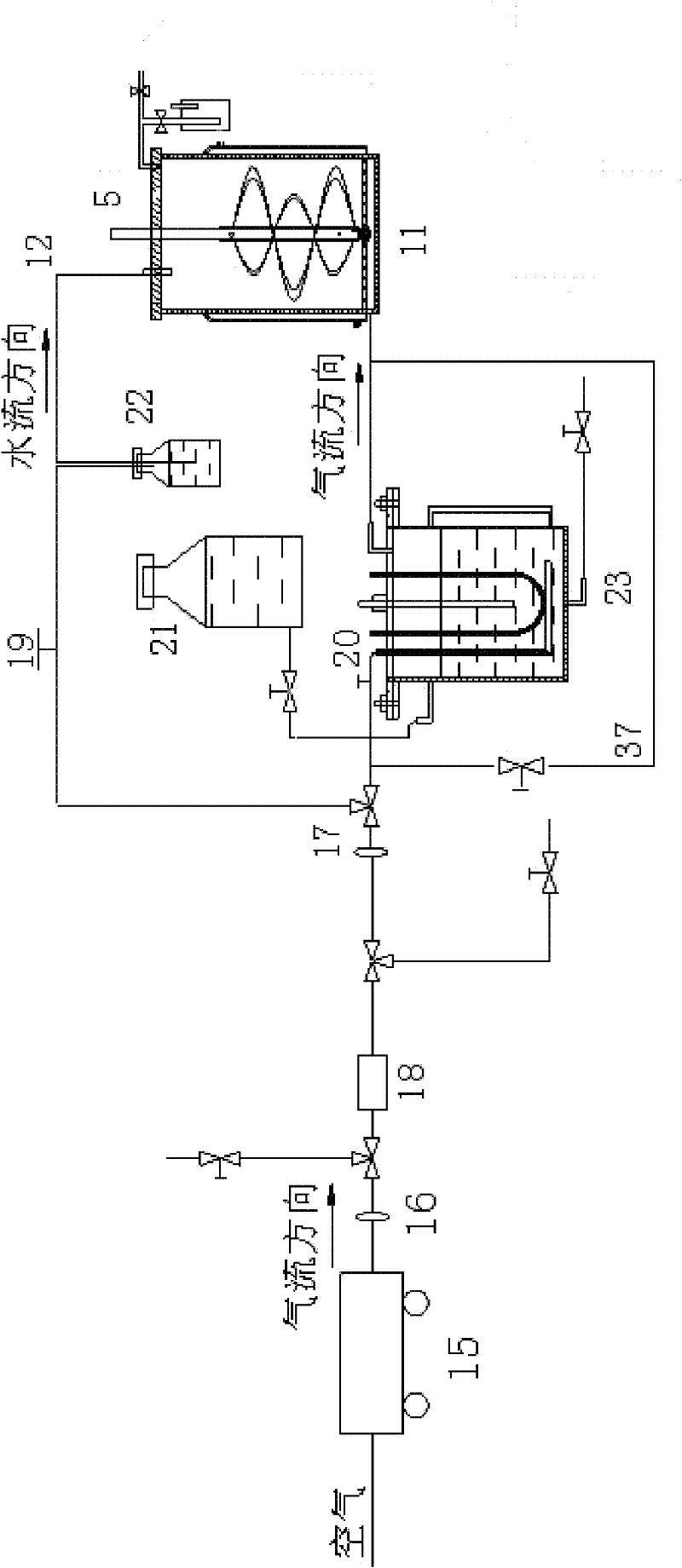

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

ActiveCN1654313AMild reaction conditionsEasy to controlHydrogen productionBulk chemical productionCO2 contentHydrogen content

The present invention discloses one kind of supercritical water catalytic coal and biomass gasifying process and apparatus for producing hydrogen. The apparatus has material feeder with one inlet connected to the outlet of the material pump and the other inlet connected to the outlet of feeding tank, pre-heater with outlet connected to the preheated water inlet and inlet connected to the outlet of inner pipe outlet of the cooler, cooler with inlet connected to the inlet of water pump, water pump with outlet connected to the water tank, cooler jacket with outlet connected to the inlet of the first filter and the inlet of the second filter, and back pressure valve with inlet connected to the outlets of the first filter and the second filter. The present invention has special heating mode for fast heating of the reaction material, raised hydrogen content in the gas product, raised CO2 content in the gas product, and easy separation of CO2 and feeding of CO2 to the processing terminal. The present invention is simple, effective and feasible.

Owner:陕西中核交大超洁能源技术有限公司

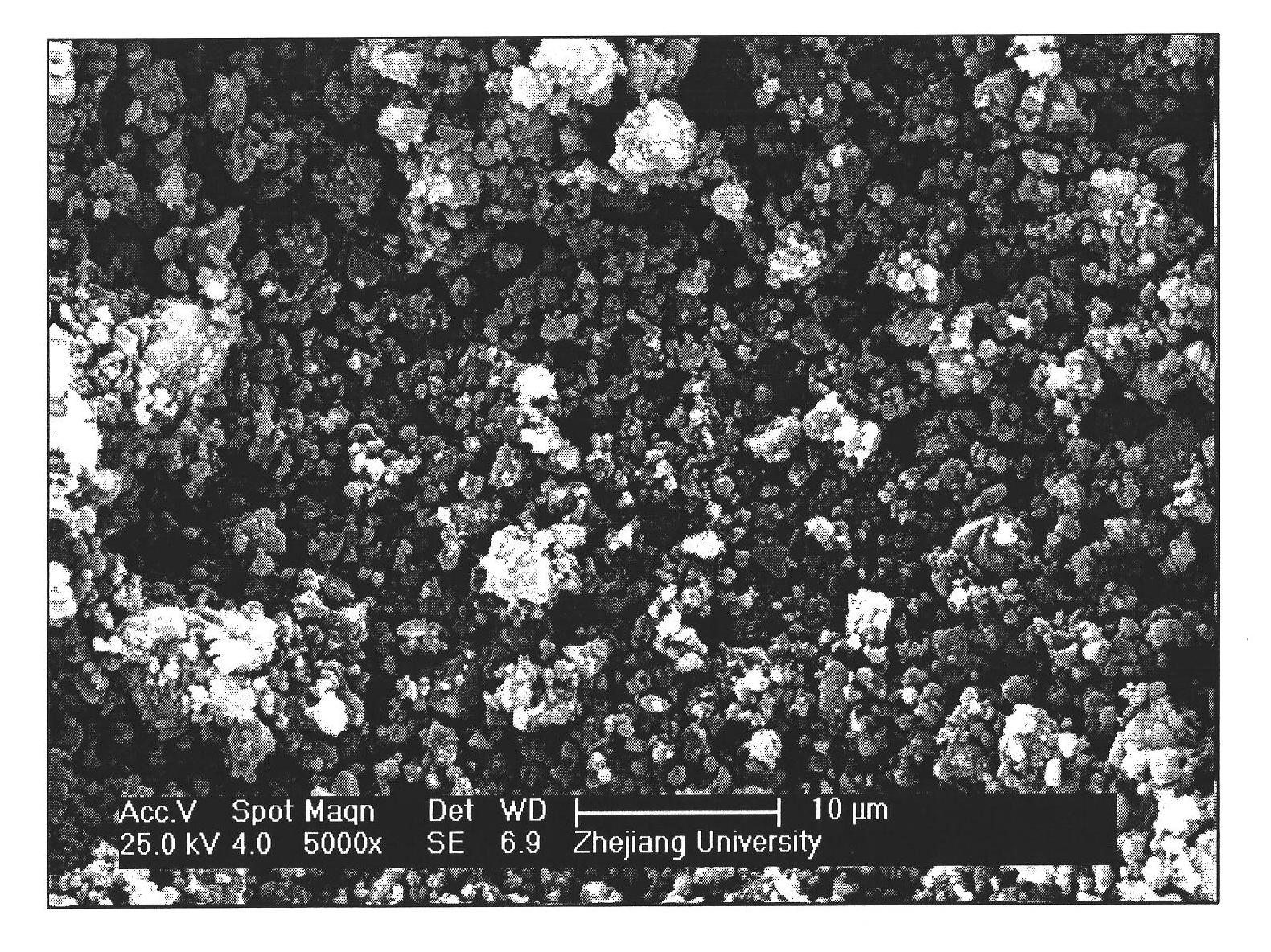

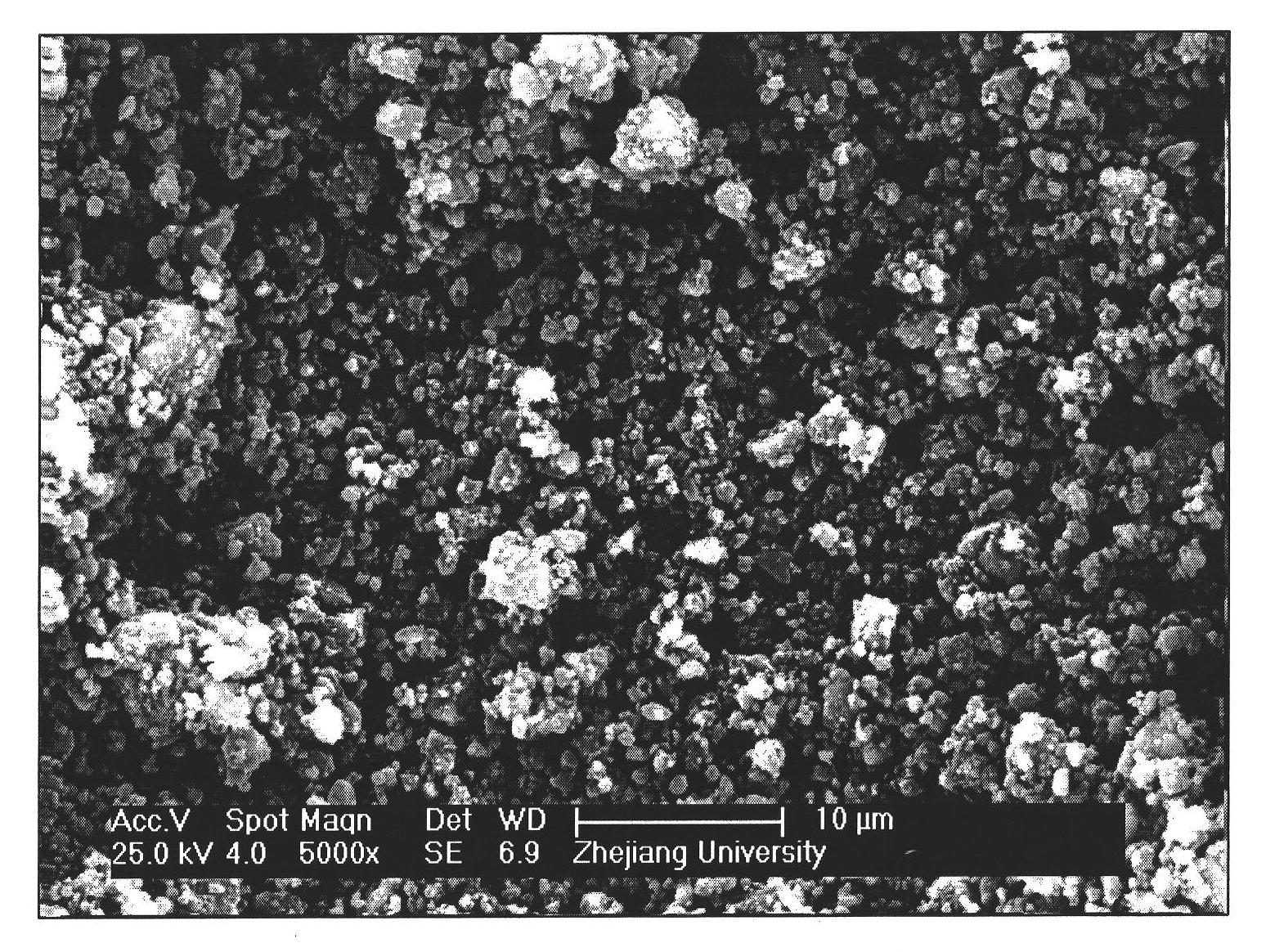

Methanol synthesizing catalyst and its prepn

InactiveCN1810357AEasy to makeEasy to industrializeOrganic compound preparationHydroxy compound preparationSyngasNitrate

The methanol synthesizing catalyst has the molar ratio of Cu to Zn to Al to Li equal to 6:3:1:0.5, and is prepared through coprecipitation process. The preparation process includes the following steps: 1. dropping mixed solution of nitrate of Cu, Zn, Al and Li in certain molar ratio and Na2CO3 solution into small amount of deionized water while stirring and maintaining the solution pH in 7-8; and 2. ageing for 2 hr after finishing dropping, suction filtering, washing and stoving to obtain the catalyst precursor, and stoving and roasting to obtain the catalyst product. The preparation process is simple and easy to use in industrial production, and the catalyst has activity higher than traditional Cu-Zn-Al catalyst and wide application range for traditional synthetic gas and synthetic gas with relatively high CO and CO2 content.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

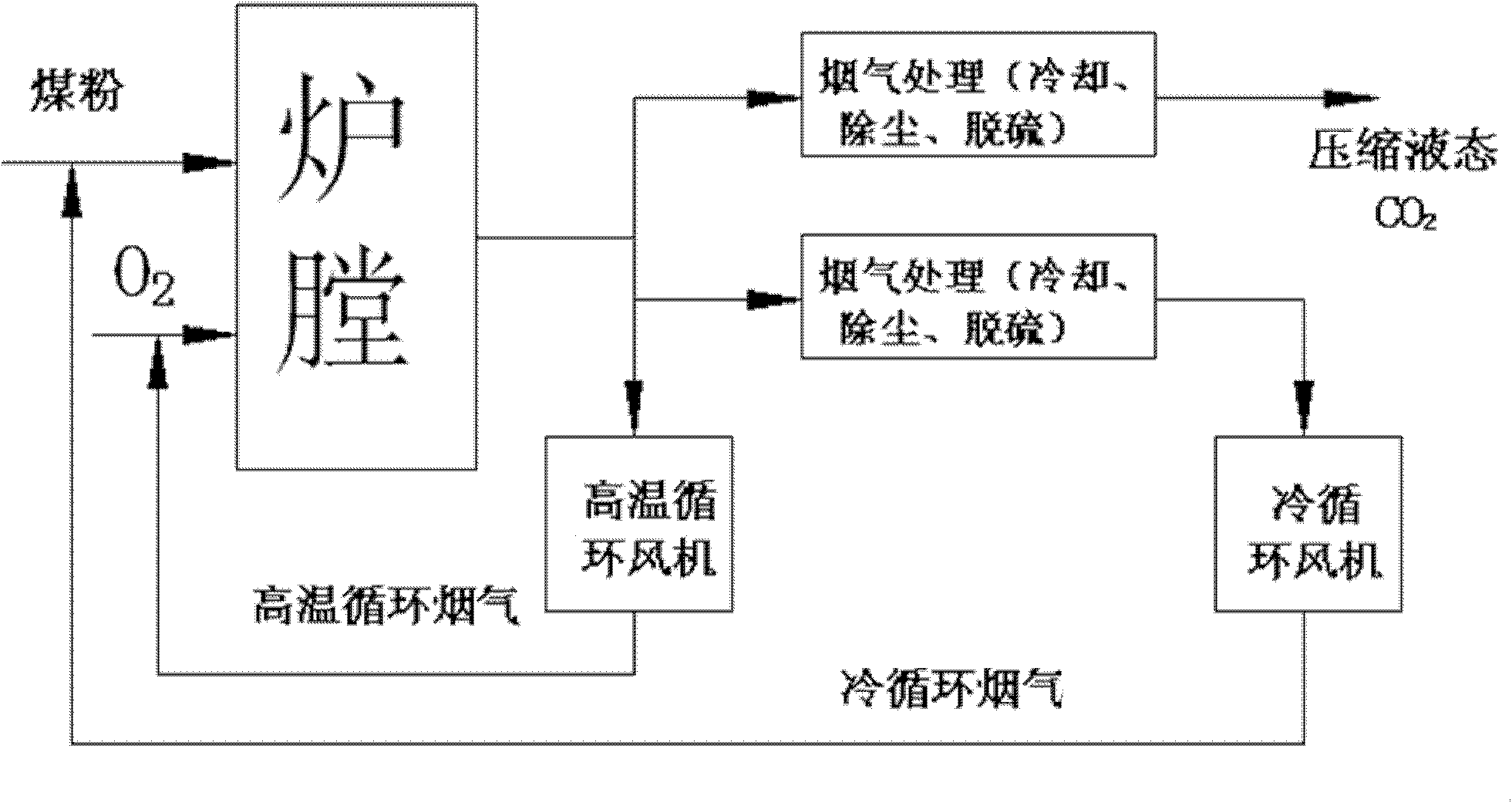

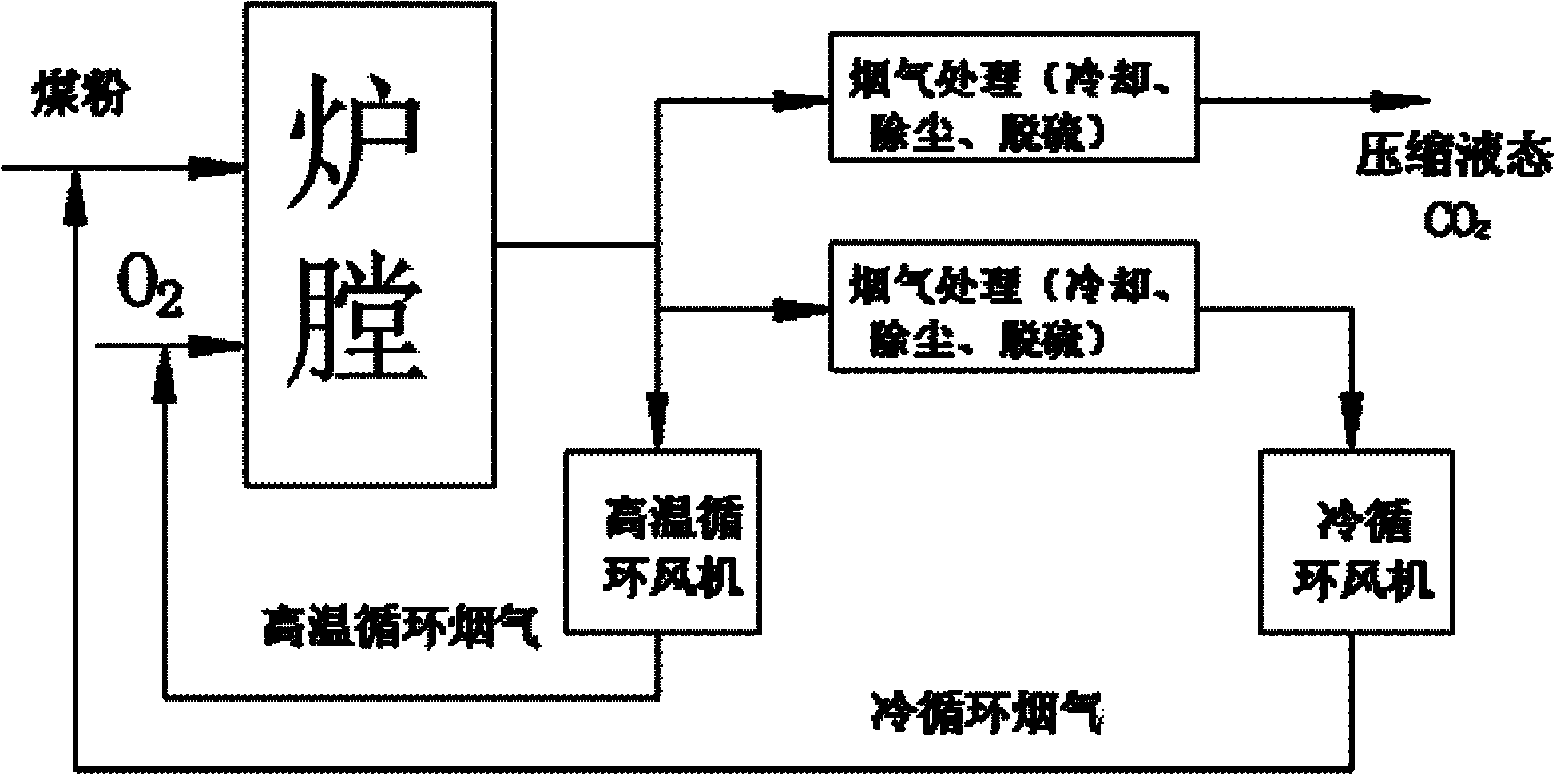

Method for re-circulating combustion of flue gas of pulverized coal fired boiler

InactiveCN101839474ASteam temperature increasedHigh thermal efficiencyFluidized bed combustionCarbon compoundsCO2 contentHearth

The invention provides a method for re-circulating combustion of flue gas of a pulverized coal fired boiler, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of pulverized coal, and aims to solve the problems of low heat efficiency and poor burn-out property existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan, and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan. The method has the advantages of adjusting the steam temperature of the boiler by using the high-temperature flue gas, enhancing convective heat transfer, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

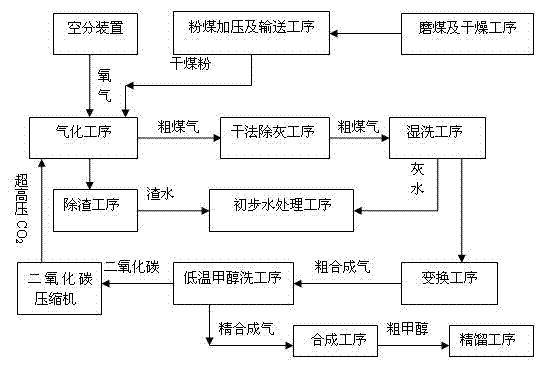

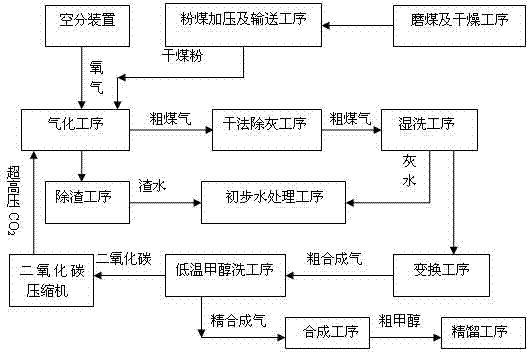

Method for using carbon dioxide as delivery gas and back flushing gas of coal powder instead of nitrogen in coal gasification methanol preparation process

InactiveCN102517086AIncrease productionEasy dischargeOrganic compound preparationBiofuelsAmmoniacal nitrogenSyngas

The invention relates to a method for performing gas delivery and ultrahigh pressure back flushing in a Shell coal gasification methanol preparation process. According to the method, when a methanol synthesis system runs, a low temperature methanol washing working section begins to absorb and concentrate CO2 in the synthesis gas, the absorbed CO2 is released through methanol regeneration, the CO2 is recovered and then sent to a compressor so as to be mixed with the N2 obtained through air separation, the mixed gas is pressurized to be used as the delivery gas and back flushing gas of coal powder, the delivery gas and back flushing gas and the coal powder are sent to a gasification furnace; and along with the increase of the CO2 content of the gasification furnace, the CO2 separated in the low temperature methanol washing working section increases gradually, and the amount of N2 in the compressor mixed gas is reduced gradually until CO2 completely replaces N2 to be used as the delivery gas and back flushing gas of coal powder. By adopting the method, the methanol yield can be increased in the methanol process, the CO2 gas emission can be reduced, simultaneously the problems that as a lot of N2 is involved in the reaction to generate ammonia nitrogen, the sewage treatment difficulty is increased and the environment is influenced can be solved, and the aims of reducing pollution and increasing the productivity and the production efficiency can be realized.

Owner:HENAN LONGYU COAL CHEM

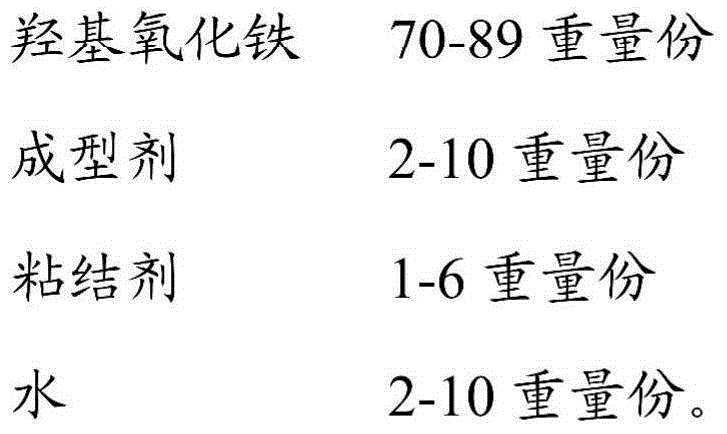

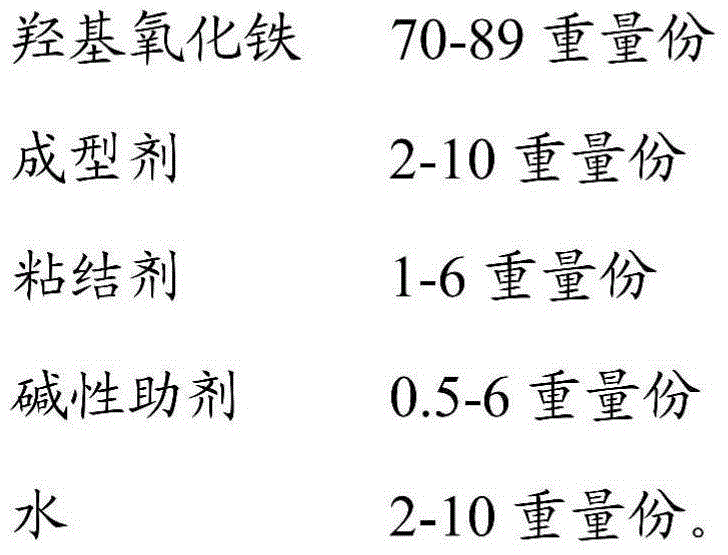

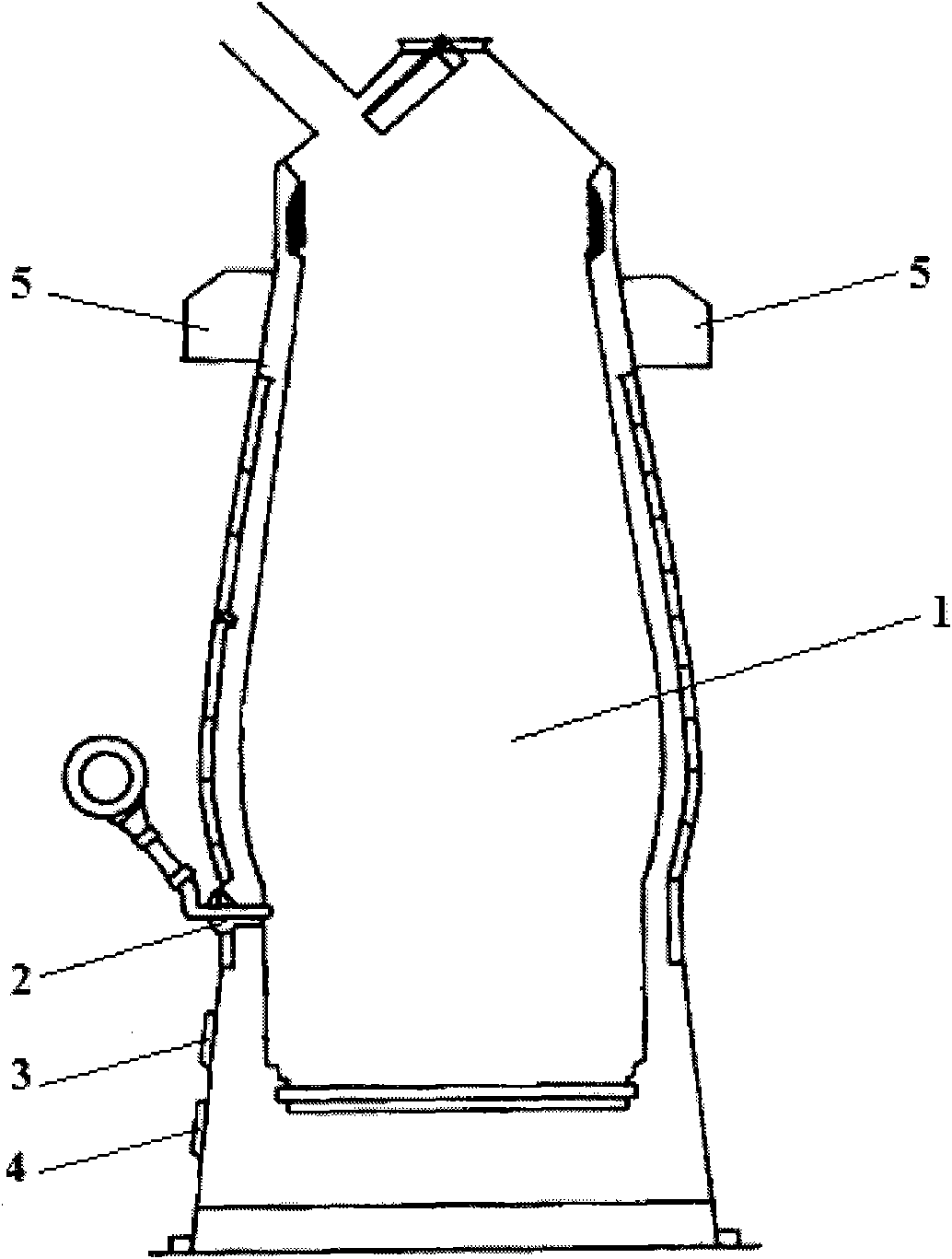

Preparation method of FeOOH low-temperature desulfurizer and desulfurizer prepared through same

ActiveCN105056719APromote generationIncrease oxidation rateDispersed particle separationIndustrial gasAdhesive

The invention provides a preparation method of a FeOOH low-temperature desulfurizer and a desulfurized prepared through the same. The preparation method comprises the following steps: sequentially adding a water soluble ligand, a precipitating agent, and a surfactant into a ferrous salt solution under continuous stirring, performing aging and centrifugation, adding a forming agent and an adhesive, mixing, kneading, and moulding so as to obtain the desulfurizer. For the first time, the directional orientation effect, template effect and dispersing effect of the surfactant have been utilized so as to form abundant point defects and surface hydroxy groups on the surface of FeOOH, thus the specific surface area and active crystal face of the desulfurizer are enlarged, the desulfurizing activity is strengthened and the sulfur capacity is increased. The preparation conditions are middle, the production cost is low, and the preparation method is very suitable for industrial massive production. Furthermore, the provided desulfurizer has a very good low-temperature desulfurizing performance, the low-temperature sulfur capacity can reach 70% at a temperature of 0 to 120 DEG C, the desulfurization precision can reach 2 ppm, and the provided desulfurizer can be used to remove hydrogen sulfide in industrial gas with a high CO2 content and is widely used.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

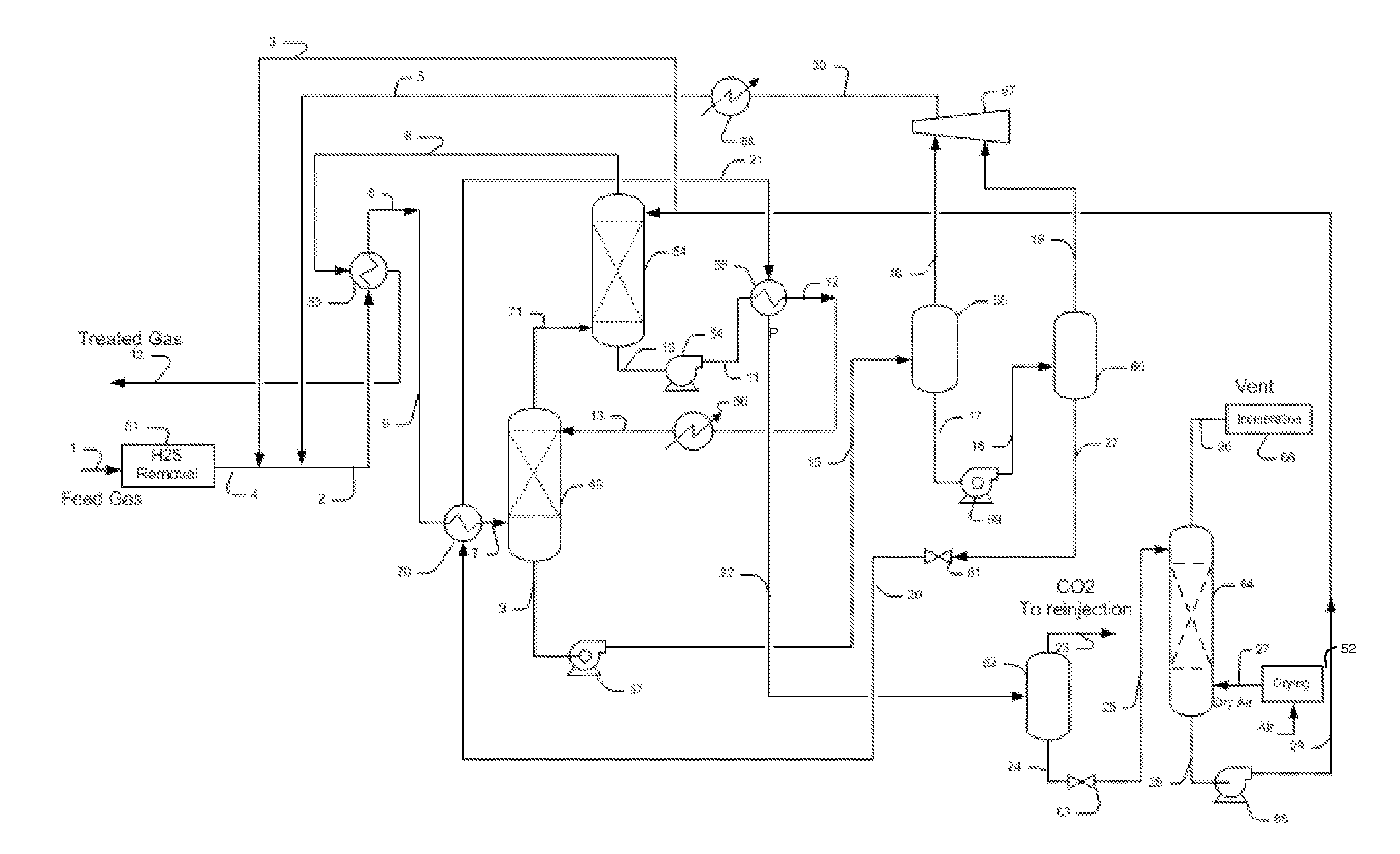

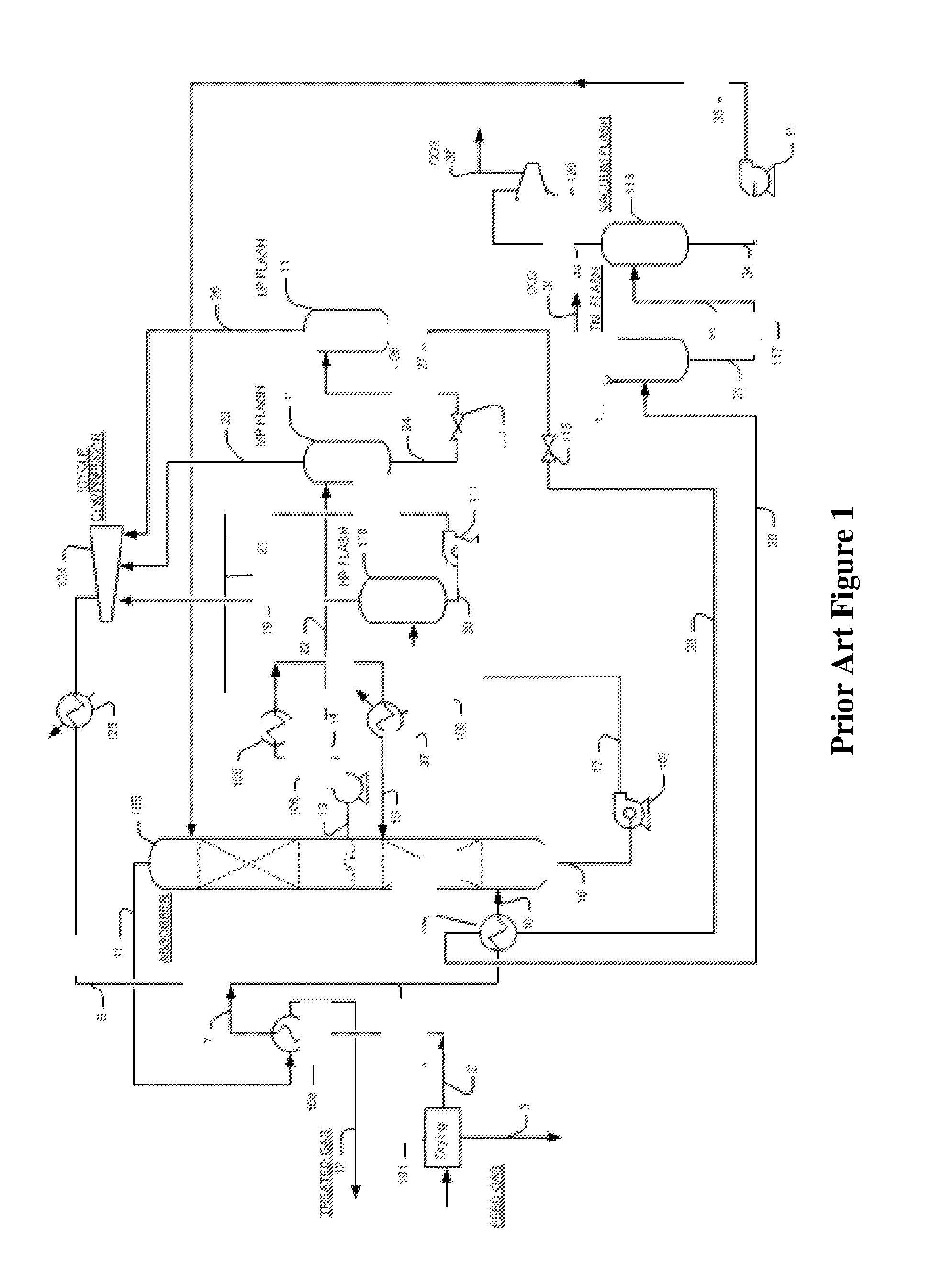

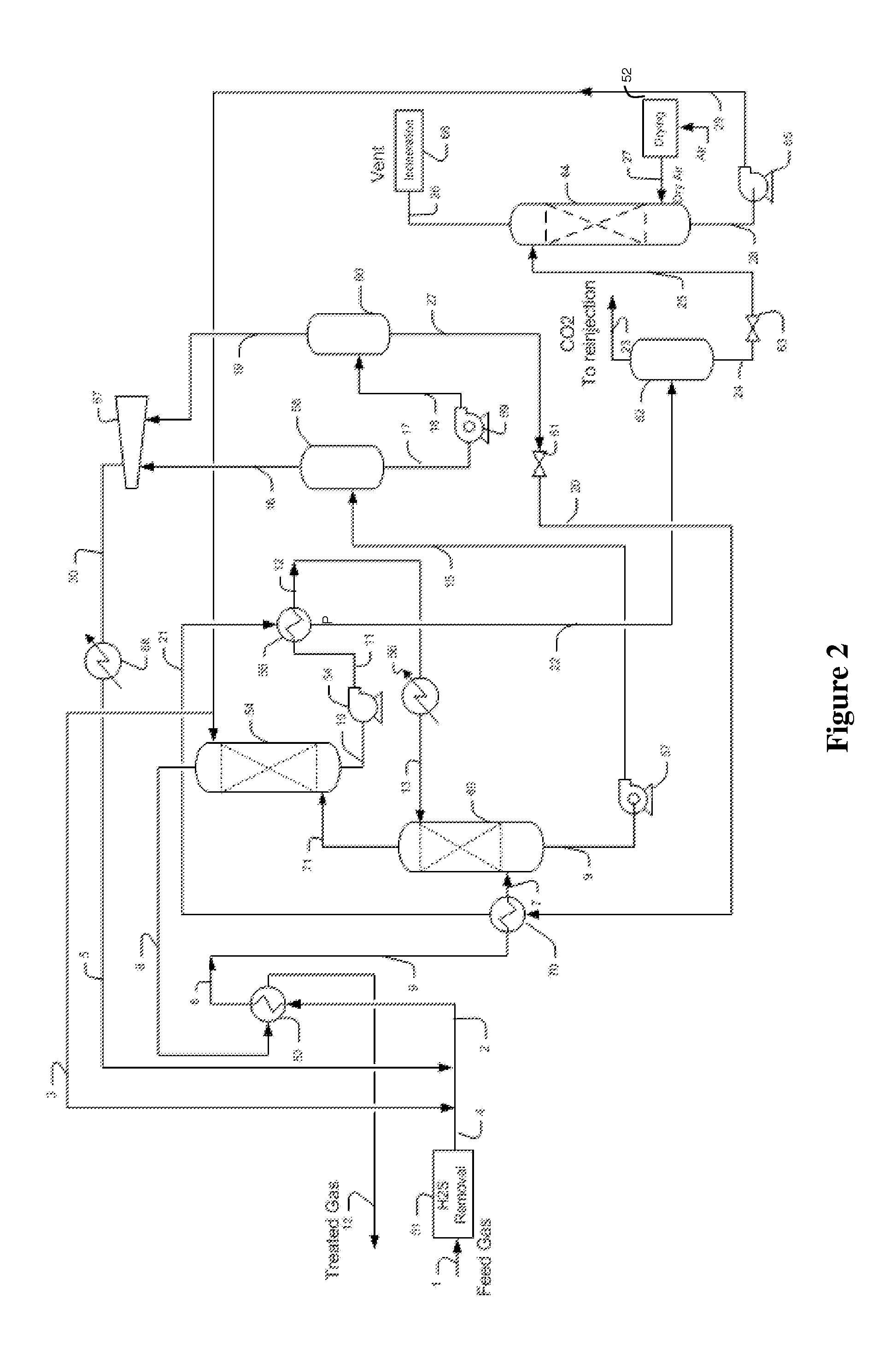

Configurations and methods of flexible co2 removal

A plant includes a pretreatment unit for H2S removal and air dehydration, and at least two absorbers that receive a feed gas at a pressure of at least 300 psig with variable CO2 content (e.g., between 5 to 60 mol %), wherein the feed gas is scrubbed in the absorbers with an ultralean and a semi-lean physical solvent, respectively, at low temperatures to at least partially remove the CO2 from the feed gas. Such configurations produces a low CO2 dry treated gas and a H2S-free CO2 for sequestration while advantageously providing cooling by expansion of the rich solvent that cools the semi-lean solvent and the feed gas, wherein an ultralean solvent is produced by stripping using dry air.

Owner:FLUOR TECH CORP

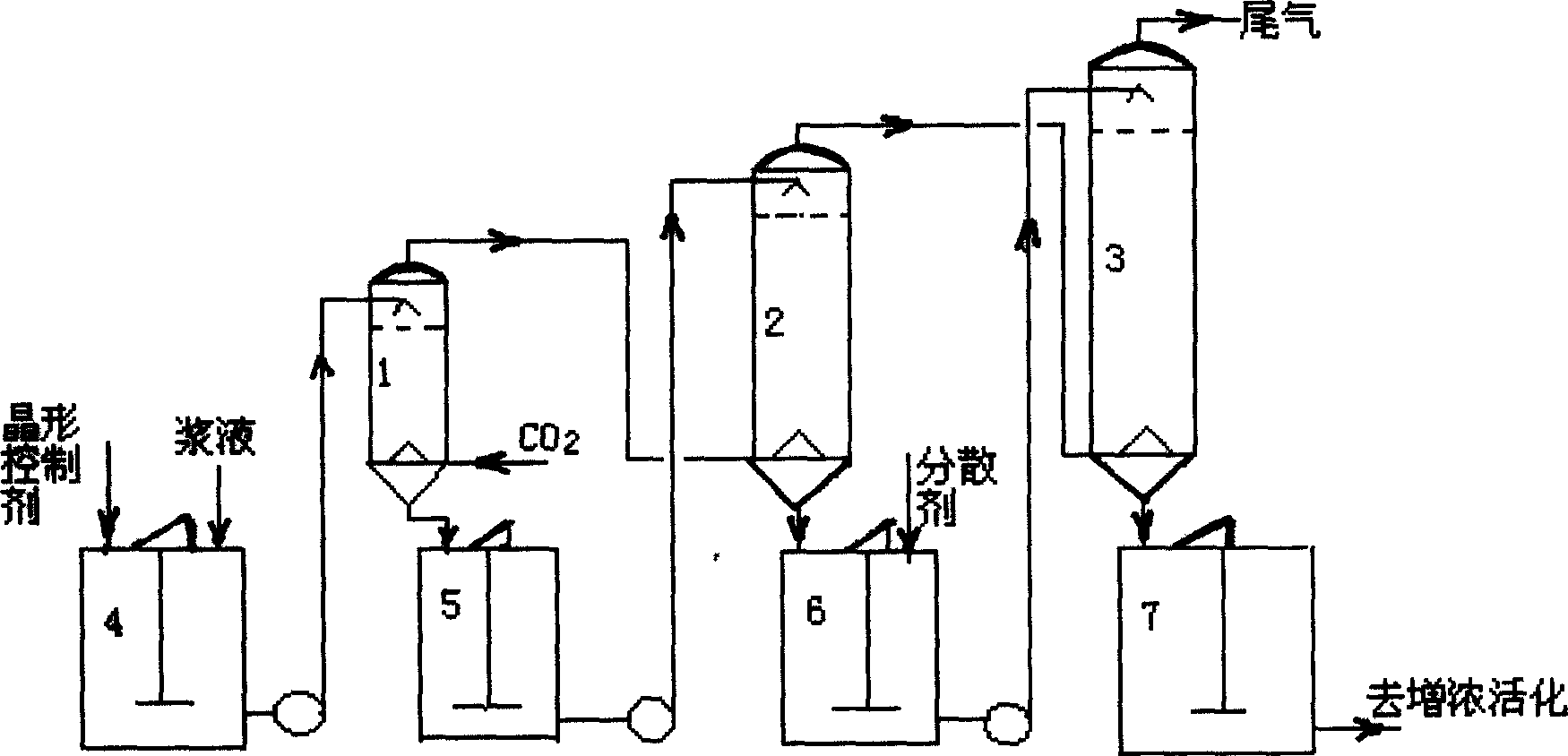

Continuous bubbling carbonizing new process for producing super fine active calcium carbonate

InactiveCN1749168AIncrease the nucleation rateIncrease production intensityCalcium/strontium/barium carbonatesHigh concentrationCO2 content

The present invention discloses continuous bubbling carbonizing process for producing superfine active calcium carbonate in the installation with pre-carbonizing tower with high concentration carbonizing gas with CO2 content of 50-99 %, No. 1 carbonizing tower and No. 2 carbonizing tower connected serially. Calcium other slurry passes successively through fine slurry trough, pre-carbonizing tower, No. 1 slurry trough, No. 1 carbonizing tower, No. 2 slurry trough, No. 2 carbonizing tower and chamotte trough; while carbonizing gas passes successively through pre-carbonizing tower, No. 1 carbonizing tower and No. 2 carbonizing tower before being exhausted to air. There are crystal form controlling agent added into the fine slurry trough and dispersant added into the No. 2 slurry trough, and the calcium carbonate slurry in the chamotte trough is prepared into the superfine active calcium carbonate through thickening, activating, dewatering, drying and crushing.

Owner:颜鑫

Method for blowing out blast furnace

The invention relates to a method for blowing out a blast furnace. The method comprises the following steps of: continuously adding iron ore and a solid carbonaceous substance into a blast furnace before blown out so that the height from a stock level to the horizontal plane of an iron notch is 86-93 percent of total eight of the blast furnace; when the adding volume of mixed materials is 65-75 percent of the total volume in the blast furnace, stopping adding the mixed materials; then leading the height from the stock level to the horizontal plane of the iron notch to be 45-65 percent of the total eight of the blast furnace by an empty stock level, spraying water into the blast furnace and predamping down; then continuously spraying water into the blast furnace and blowing air the blast furnace so that the stock level is reduced; when at least one of the following three conditions is met, opening the iron notch for tapping and then opening a residual iron notch for discharging slag iron; (1) calculating that the stock level depth reaches the horizontal plane of an air opening by the air blowing amount; (2) generating a second peak value of CO2 content in a change curve of the CO2 content; and (3) turning the combustion flame of the air opening to be yellow green. By adopting the method for blowing out a blast furnace, the probability for reducing the stock level in the blast furnace below the horizontal plane of the air opening after blowing out is as high as more than 90 percent.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

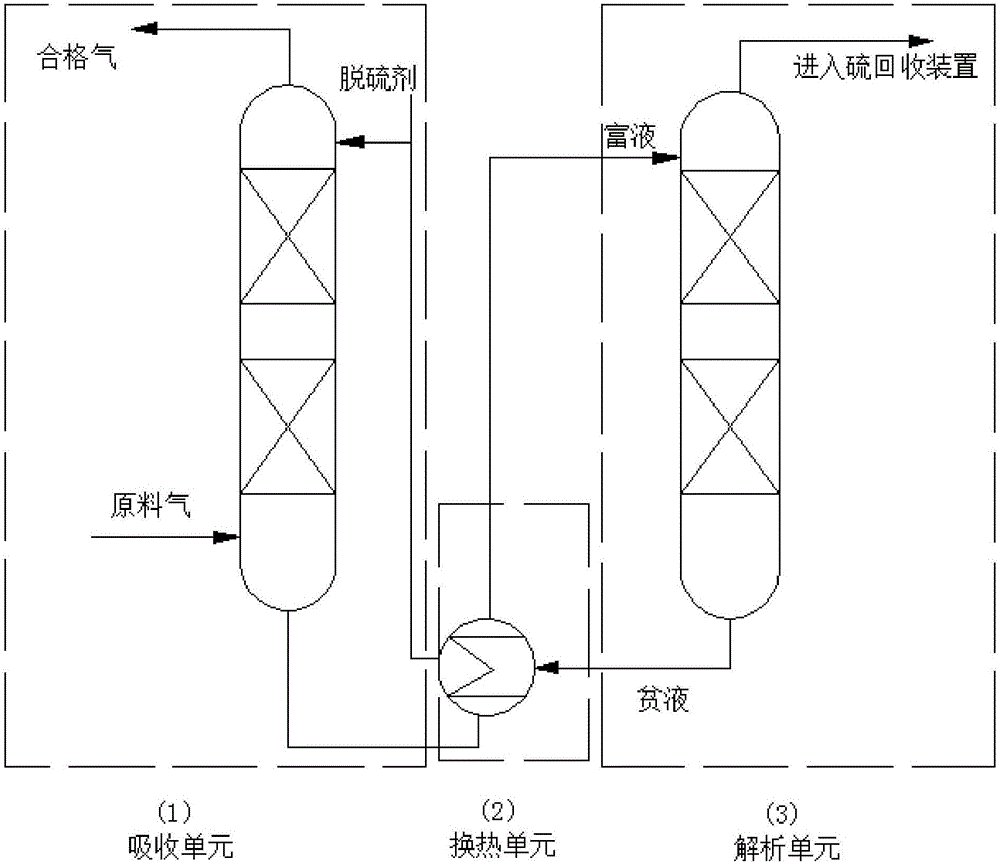

High-selectivity desulfurization system and compounding method of desulfurization agent of high-selectivity desulfurization system

InactiveCN106823744AImprove the degree of purificationLarge absorption capacityGas treatmentDispersed particle separationChemical industryAbsorption capacity

The present invention provides a high-selectivity eutectic compounding desulfurization agent, and relates to high selectivity removal of sulfides from acid gases during chemical industry production. The system comprises an absorption unit, a rich and poor liquid heat exchange unit and a desorption unit. The desulfurization absorber is a high-selectivity desulfurization compounding solvent, and is formed by compounding 40-50 wt% of N-methyldiethanolamine (MDEA), 1-5 wt% of an eutectic solvent (DES), and 45-59 wt% of water. According to the present invention, the eutectic solvent is firstly used for the removal of industrial gas H2S, wherein the H2S content after desulfurization is less than 10 ppm (the H2S recovery rate of the sulfur recovery apparatus is more than 80% and the CO2 content is less than 20 ppm); the desulfurization system has advantages of high purification degree, large absorption capacity, low regenerative energy consumption, and the like; and the eutectic desulfurization agent is non-toxic, green, and environmentally friendly, and high economic and social benefits are provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

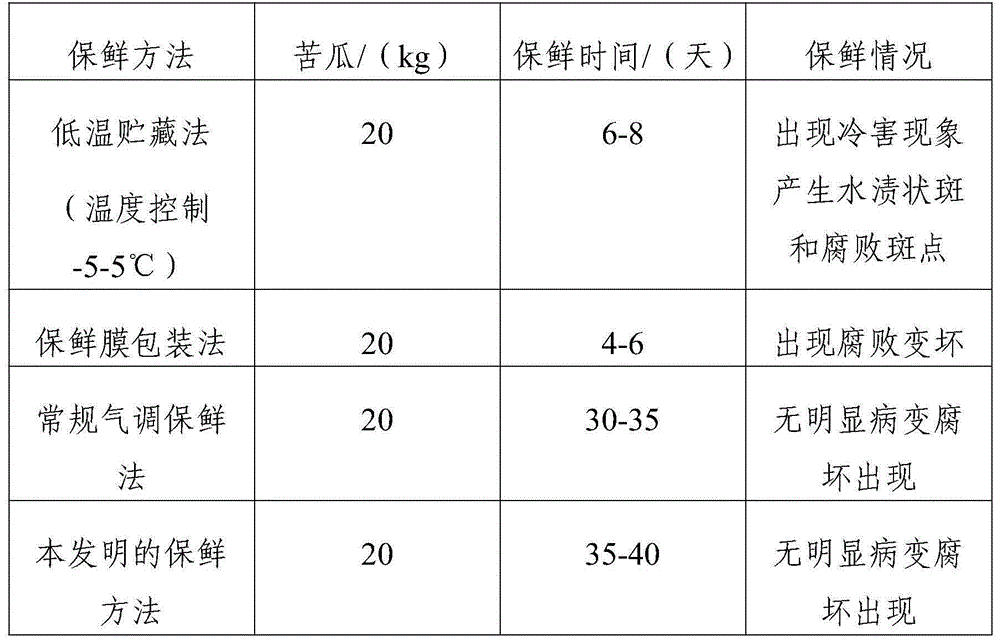

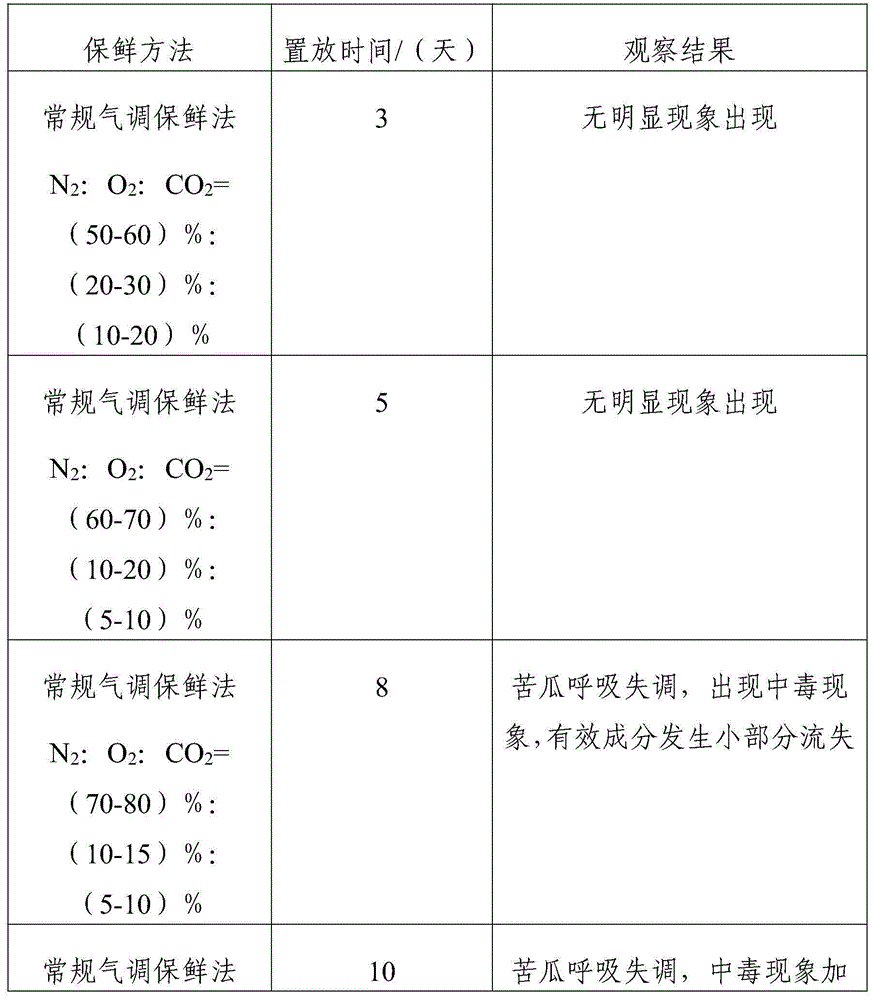

Modified-atmosphere preservation method for bitter gourds

InactiveCN105028619AInhibition of respirationInhibit biosynthesisFruit and vegetables preservationGas compositionCO2 content

The invention discloses a modified-atmosphere preservation method for bitter gourds. The method includes the following steps of raw material pretreatment, bagging, gas-filled packaging, sterilization and storage and transportation. By adopting a modified-atmosphere packaging technology and adjusting gas compositions in a packaging storage environment, growth and metabolism of microorganisms can be effectively restrained; meanwhile, by controlling temperature and improving a pretreatment and packaging process, cold damage, ethylene ripening and decaying of the bitter gourds are avoided. According to the modified-atmosphere packaging technology, the non-poisonous, non-harmful and no-residual effects are achieved, non-harmful treatment is adopted in the whole preservation process, the usage of poisonous chemical agents is avoided, and therefore no harmful influence on the bitter gourds exists. By means of the method, the defects of the prior art are overcome, the original freshness, color and luster and flavor of the bitter gourds can be kept, the shelf life of the bitter gourds can be prolonged, and the easily appearing problems that due to extremely low O2 concentration and extremely high CO2 content, the bitter gourds suffer oxygen deficit, and breathing disorders are caused in the modified-atmosphere preservation process of the bitter gourds can be solved.

Owner:CHENGDU ACAD OF AGRI & FORESTRY SCI

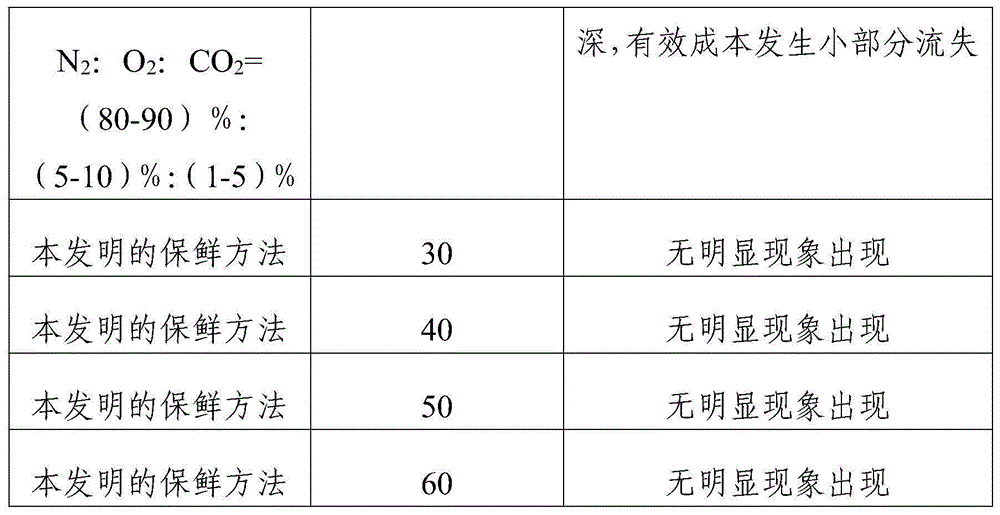

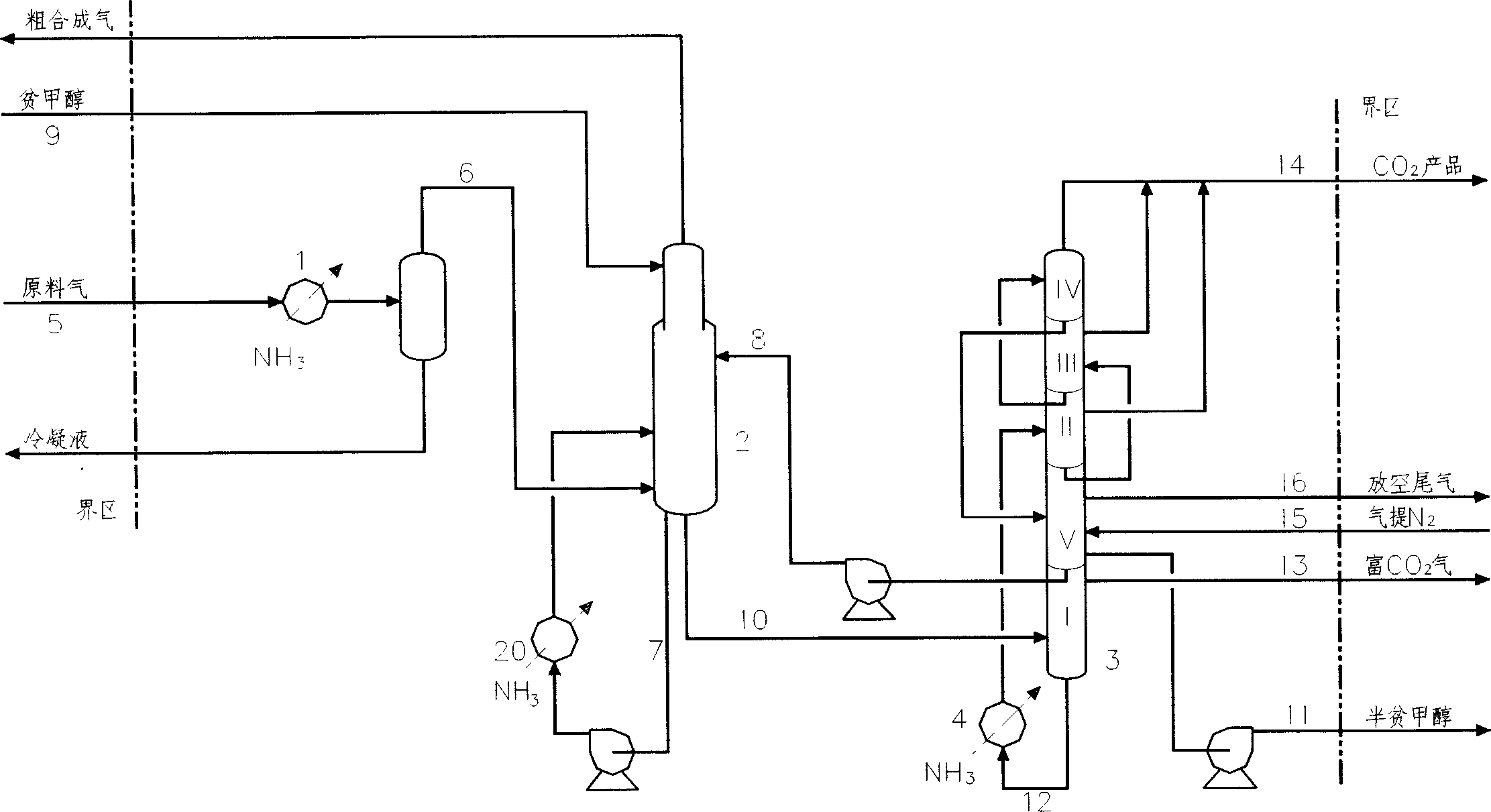

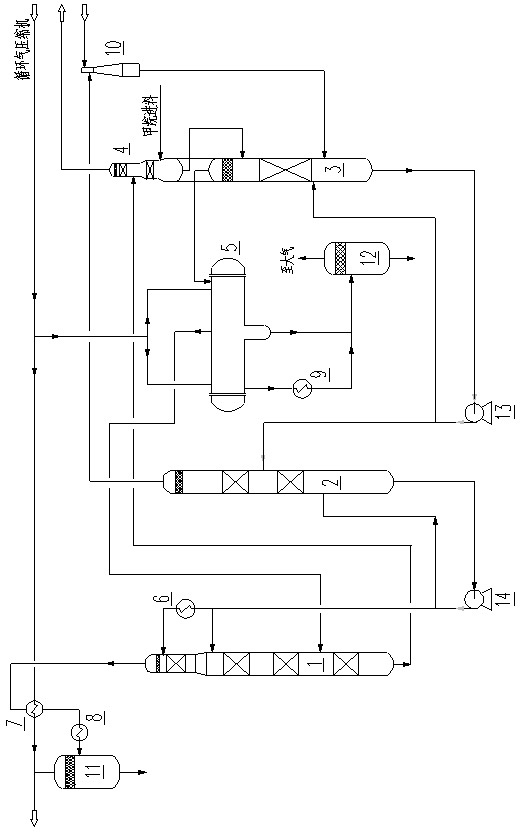

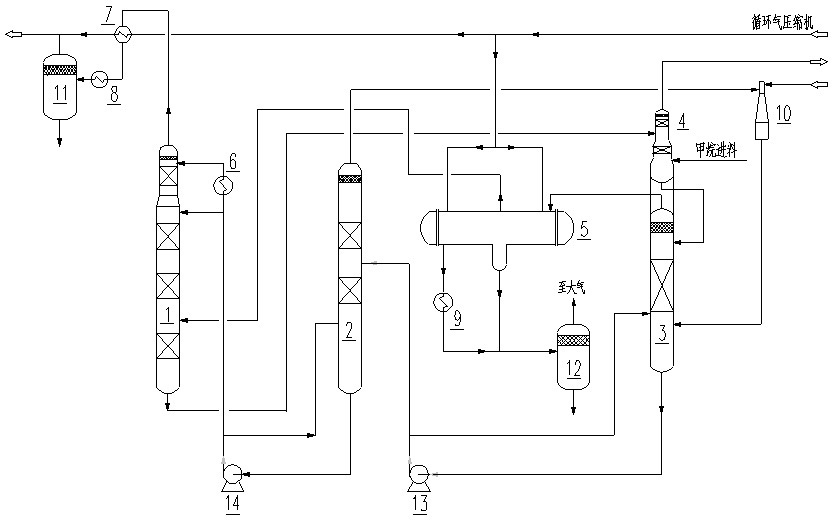

Low temperature methanol cleaning process

The process of absorbing and recovering acid gas, especially CO2 or CO2 and H2S, in gas mixture with methane includes methane absorption of acid gas, desorption of rich-methane solution, gas stripping, heating to separate acid gas. The process features that propylene chiller or vacuum ammonia chiller is increased before the system ammonia cooler to increase cold replenishing amount to the system so as to solve the problem of lowered methane cooling effect and system temperature raise during desorption caused by decreased CO2 content. The said low temperature methanol washing process is suitable for gas purifying device with light material and / or heavy material.

Owner:CHINA PETROCHEMICAL CORP

Coal gasification method using oxygen-rich air, CO2 flue gas and steam as gasifying agents

InactiveCN101381628AImprove thermal efficiencyIncrease gas calorific valueCombustible gas productionWater vaporCO2 content

The invention relates to a coal gasification method, in particular to a coal gasification method in which oxygen enriched air, CO2 smoke and steam are used as gasification agents. In the method, the CO2 smoke is led out from a combustion gas kiln furnace and pressurized and evenly mixed with the oxygen enriched air according to certain ratio to form the mixed gas richly containing O2 and CO2, wherein the O2 content reaches 30 to 50 percent, and the CO2 content reaches 5 to 25 percent; the mixed gas is mixed with vapor to be used as a coal gasification device; and in the coal gasification device, the gasification agents and coal are subjected to oxidation reduction reaction to generate coal gas in which CO and H2 are main combustible components. In the invention, the coal gasification reaction process is completed, and CO2 in the smoke exhausted by the kiln furnace is used as a reactive substance and is reduced to CO, thereby increasing the CO content in the coal gas, improving the calorific power of the coal gas, lowering the consumption of the gasified coal, reducing the emission of CO2 in the smoke exhausted by the combustion gas kiln furnace and achieving the effective composition of energy conservation and emission reduction.

Owner:唐山科源环保技术装备有限公司

Method for reducing dust of steel mill by using CO2

ActiveCN101250606AReduce evaporationReduce iron lossManufacturing convertersElectric furnaceSteelmakingElectric arc furnace

The invention belongs to the ferrous metallurgy and environmental protection field, relating to a treatment for offscum, which comprises a converter steelmaking and electric furnace steelmaking technology. The traditional treatment process in current offscum is recycled after dust removal and dust collection, which is a post treatment process. The invention aims to provide a novel process which can reduce dust generation in steelmaking process, and reduces the burning loss of iron and other melt elements in the smelting process. The process comprises mixing a little amount of CO2 gas into oxygen jet flow, reducing the temperature of the flash points region of a molten pool when the mixed gas jet flow is sprayed on the molten pool, controlling the evaporation of iron when the temperature of flash points region is decreased under 2750 DEG C, and reducing dust discharge in steelmaking smelting process, wherein the CO2 content in the mixed gas is controlled within 1-9%, and the content of oxygen is 99-91%. The process is suitable to the technology for the converter steelmaking of 30-300 ton and electric furnace steelmaking of 30-200 ton. The evaporation amount of iron is reduced about 30-70% through adopting the process, and the iron loss which is caused by dust is reduced 5-10kg / t.

Owner:UNIV OF SCI & TECH BEIJING

Austenitic stainless steel continuous pipe and manufacturing method thereof

The invention discloses an austenitic stainless steel continuous pipe and a manufacturing method of the austenitic stainless steel continuous pipe. The austenitic stainless steel continuous pipe comprises, by mass percent, 0.03% or below of C, 5-10% of Mn, 13-19% of Cr, 1.5-3.0% of Ni, 0.15-0.5% of N, 0.04% or below of P, 0.01% or below of S, and the balance Fe and unavoidable impurities. A plate for the continuous pipe is manufactured through the processes of refining, controlled rolling, acid pickling and the like; pipe manufacturing is conducted by the adoption of cage-roll forming and the high frequency induction welding (HFW) technology; the austenitic stainless steel continuous pipe is manufactured through follow-up heat treatment. The austenitic stainless steel continuous pipe is good in mechanical performance and corrosion resistance, applicable to environments where the austenitic stainless steel continuous pipe makes direct contact with CO2, and capable of being used under gas wells with high CO2 content in Sichuan province, Tarim and the like, and the corrosion resistance of the austenitic stainless steel continuous pipe is improved by over 3 times compared with a common low-carbon micro-alloyed steel continuous pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Coking composite leaning agent and preparation method thereof

The invention discloses a coking composite leaning agent and a preparation method thereof. The coking composite leaning agent comprises the following raw materials in percentage by mass: 5 to 15 percent of anthracite, 10 to 30 percent of coke powder, 3 to 10 percent of coal tar pitch and the balance of magnesite. The preparation method of the coking composite leaning agent mainly comprises the following steps of: mixing the magnesite, the anthracite and the coke powder in the atmosphere of hydrogen, performing ball milling on the mixture, adding the coal tar pitch into the mixture, and then performing ball milling on the mixture. The coking composite leaning agent of the invention has the advantages of reducing coke sulphur content, improving the mechanical strength of cokes and increasing CO content and CO2 content of the gas, along with low cost of the raw materials, simple preparation method and the like.

Owner:SHANDONG UNIV OF SCI & TECH

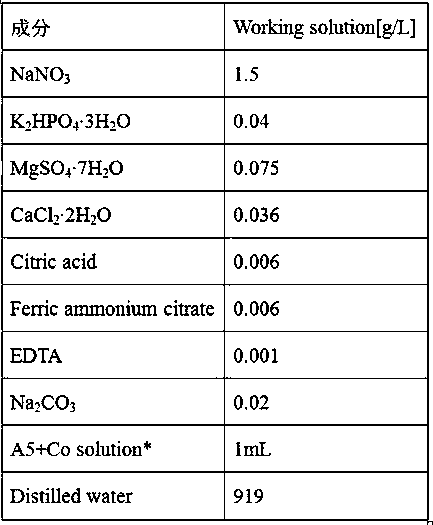

Method for producing microalgae grease by using flue gas

ActiveCN109576315AGrowth inhibitionImprove solubilityMicroorganism based processesFermentationSolubilityHigh concentration

The invention relates to a method for producing microalgae grease by using flue gas. The method for the producing microalgae grease by using the flue gas comprises the following steps that firstly, amicroalgae culture medium and parachlorella kessleri FSH-Y3 or / and a scenedesmus obliquus FSH-Y2 seed solution are added into a photobioreactor, the pH value is adjusted to 10-12, the flue gas with CO2 content of 1v-5v% is introduced, and culture is carried out for a certain time; and then the pH value is adjusted to 8-10, a chlorella SF-B1 seed solution is introduced, at least one of a scenedesmus MH-04 seed solution a monoraphidium SS-B1 seed solution is introduced, mixed culture is carried out, the flue gas with CO2 content of 5v%-45v% is introduced, and the mixture is cultured to a stableperiod under the condition of continuous illumination, so that microalgae cells are obtained. The method for producing the microalgae grease by using the flue gas improves the tolerance and solubilityof a microalgae culture system to high-concentration CO2, improves the carbon fixation efficiency, obviously improves the harvest amount of the microalgae grease, simultaneously improves the tolerance to SOx and NOx in the flue gas, and can purify the flue gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

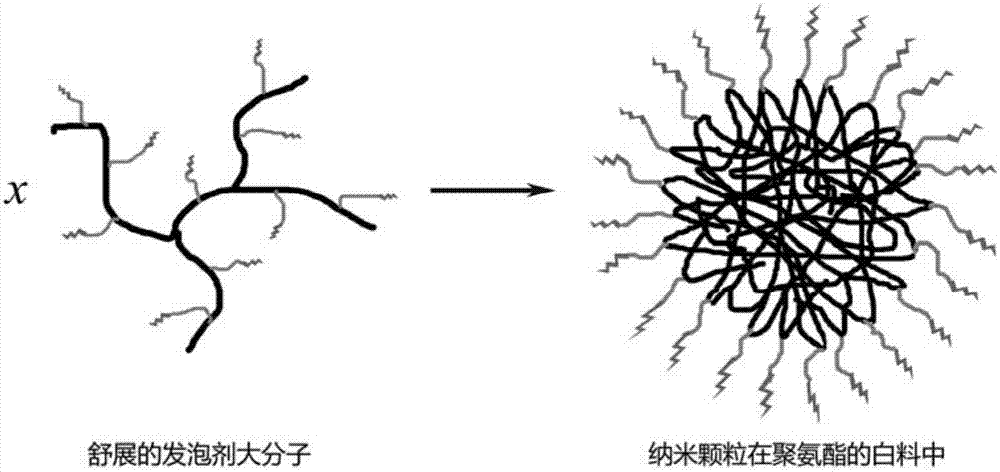

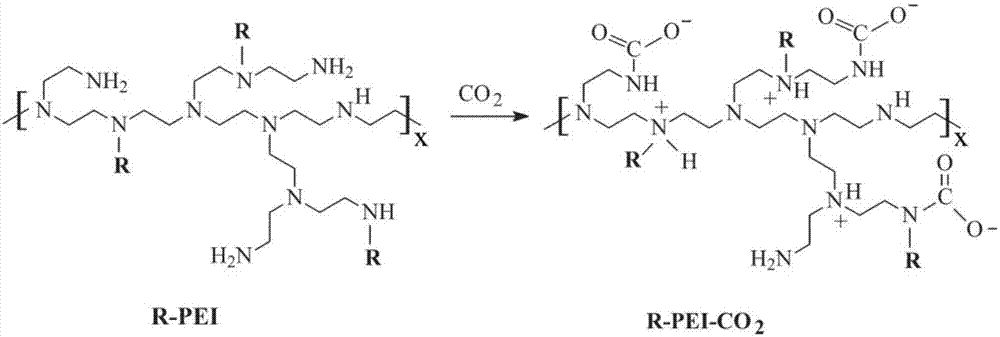

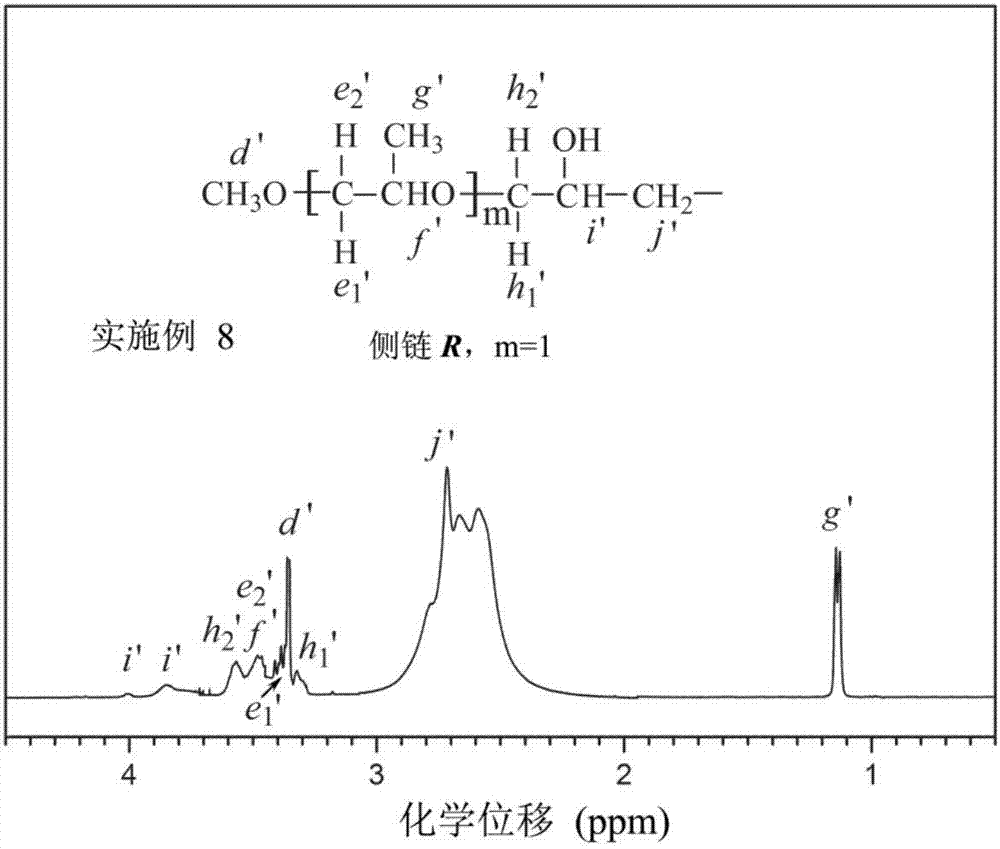

Hydrophobically modified polyethyleneimine foaming agent

The invention relates to preparation of a hydrophobic chain modified polyethyleneimine foaming agent capable of releasing carbon dioxide and an application of the foaming agent in polyurethane foam materials. The grafting degree of a hydrophobic chain of the hydrophobic chain grafted polyethyleneimine foaming agent capable of releasing carbon dioxide is 1%-45%, the hydrophobic chain contains 1-2 polypropylene oxide repetitive units, and the terminal of the hydrophobic chain is C1-C6 alkoxy. By constructing a novel foaming agent core-shell structure in which an outer layer is an alkoxy polypropylene oxide chain and an inner layer is a CO2 adduct of polyethyleneimine, the polymerization degree of an alkoxy polypropylene oxide side chain of a CO2 adduct foaming agent of hydrophobic chain modified polyethyleneimine is decreased to 1 and 2, so that the dispersity of the prepared foaming agent in a polyurethane white material is not decreased, the smooth foaming process is guaranteed, and compared with corresponding foaming agents with the polymerization degrees more than 2 under the same grafting conditions, the CO2 content of the prepared foaming agent is substantially increased.

Owner:SICHUAN UNIV

Method for removing carbon dioxide in recycle gas for synthesizing ethylene oxide/glycol

ActiveCN102675248AReduced regeneration heat consumptionReduce heat consumptionOrganic chemistryBulk chemical productionTemperature controlPtru catalyst

The invention belongs to the technical field of gas purification and provides a decarbonization solution and a decarbonization method due to the fact that CO2 content in recycle gas needs to be lowered when a novel high selective catalyst is adopted for synthesizing ethylene oxide / glycol. The solution is composed of potassium carbonate and an inorganic activating agent. Two-section absorption process of appropriate flow distribution and temperature control is adopted. Desorbing of the solution adopts novel transformation regeneration energy-saving technology, differential pressure is formed between two towers of a pressurization regeneration tower and a normal pressure regeneration tower by using a desorbing effect of an adjustable supersonic speed steam ejector on the normal pressure regeneration tower, mixed gas containing a large amount of water vapour is desorbed for gas stripping and regeneration for the pressurized regeneration tower. By means of the method, residue CO2 in the recycle gas after decarbonization is greatly reduced, and simultaneously solution reclaimed heat consumption is reduced by more than 30% compared with conventional potassium carbonate decarbonization process.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

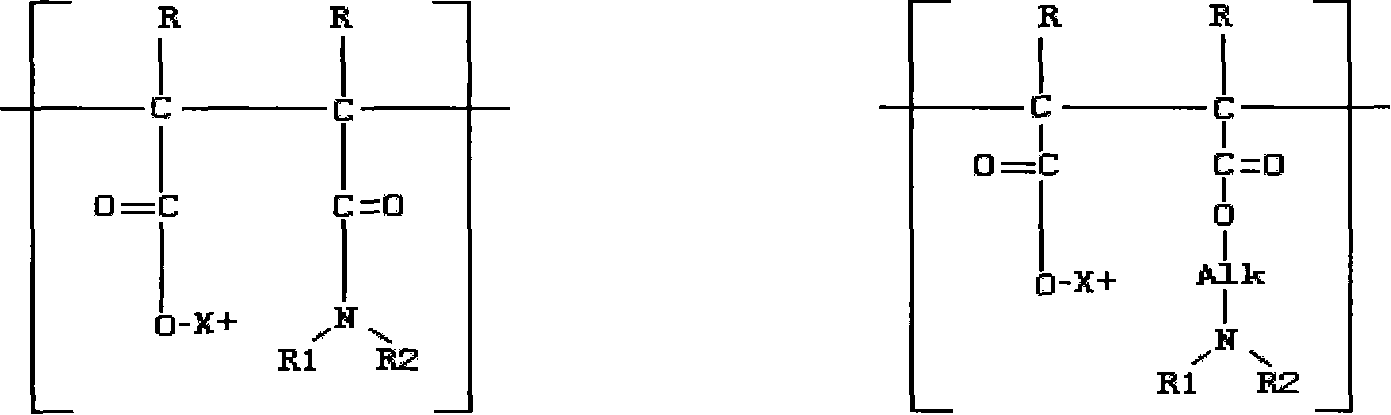

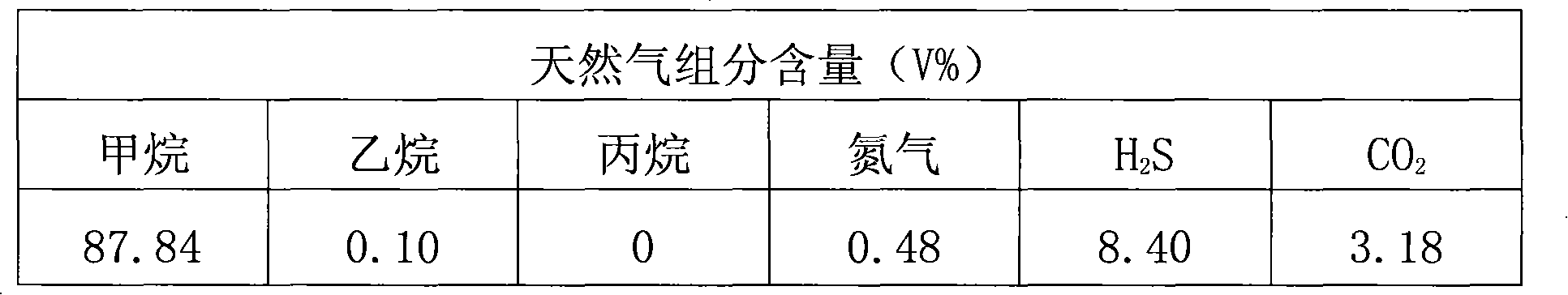

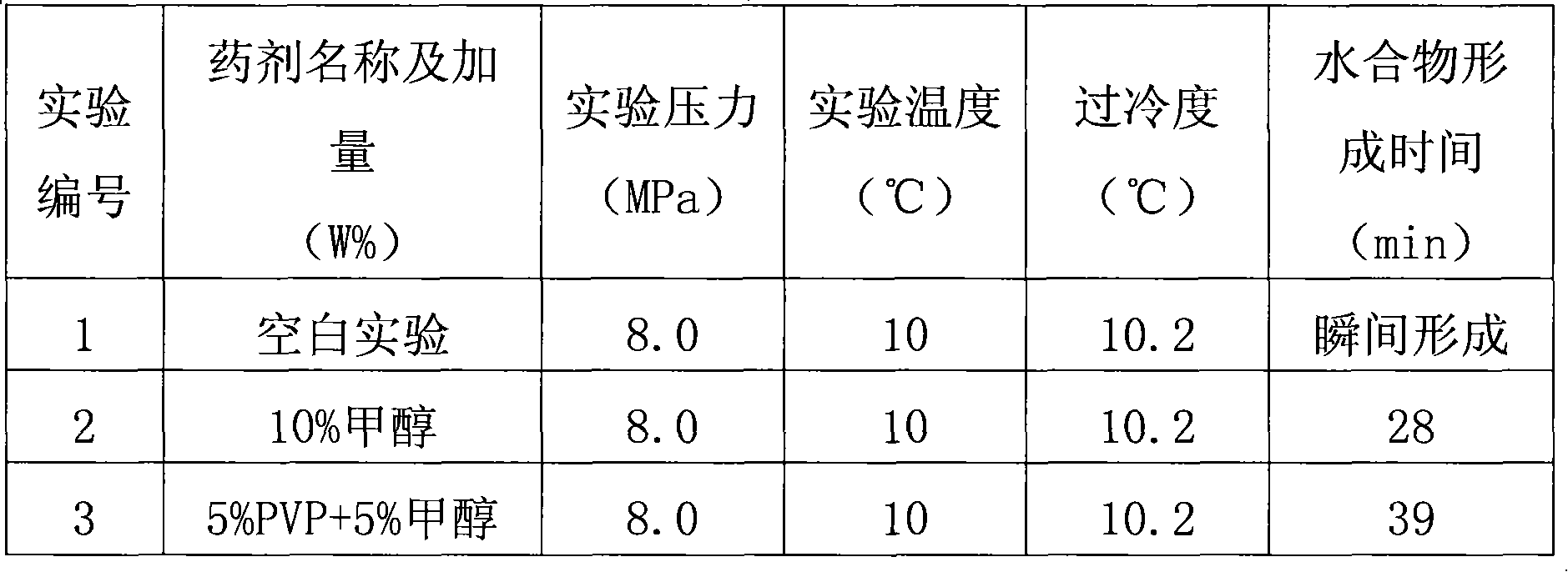

Inhibitor for preventing the formation of natural gas hydrates of high-sulfur acid gas fields

ActiveCN101608118APrevent anti-corrosion effectNot easy to aggregateGaseous fuelsFluid removalBiopolymerCO2 content

The invention relates to an inhibitor for preventing the formation of natural gas hydrate of high-sulfur acid gas fields, which comprises the following components in percentage by weight: 5 to 30 percent of biopolymer, which has the weight average molecular weight of between 3,000 and 10,000, of vinyl pyrrolidone and vinyl caprolactam or terpolymer, which has the weight average molecular weight of between 65,000 and 100,000,of the vinyl pyrrolidone, the vinyl caprolactam and N, N-(dimethylamino)ethyl methacrylate, 5 to 30 percent of amido group-containing and lipid group-containing polyesteramide or amidation product which is formed by polymerizing maleic anhydride, a derivative thereof and alkyl alcohol amine and has the number average molecular weight of between 1,000 and 15,000, 10 to 15 percent of surfactant and defoaming agent, and 50 to 70 percent of mixture of methanol or ethanol and glycol. The inhibitor has better inhibition effect on acid natural gas hydrate which has the H2S content between 0 and 8 percent, the CO2 content between 0 and 5 percent, and no hydrocarbon components above C2.

Owner:PETROCHINA CO LTD

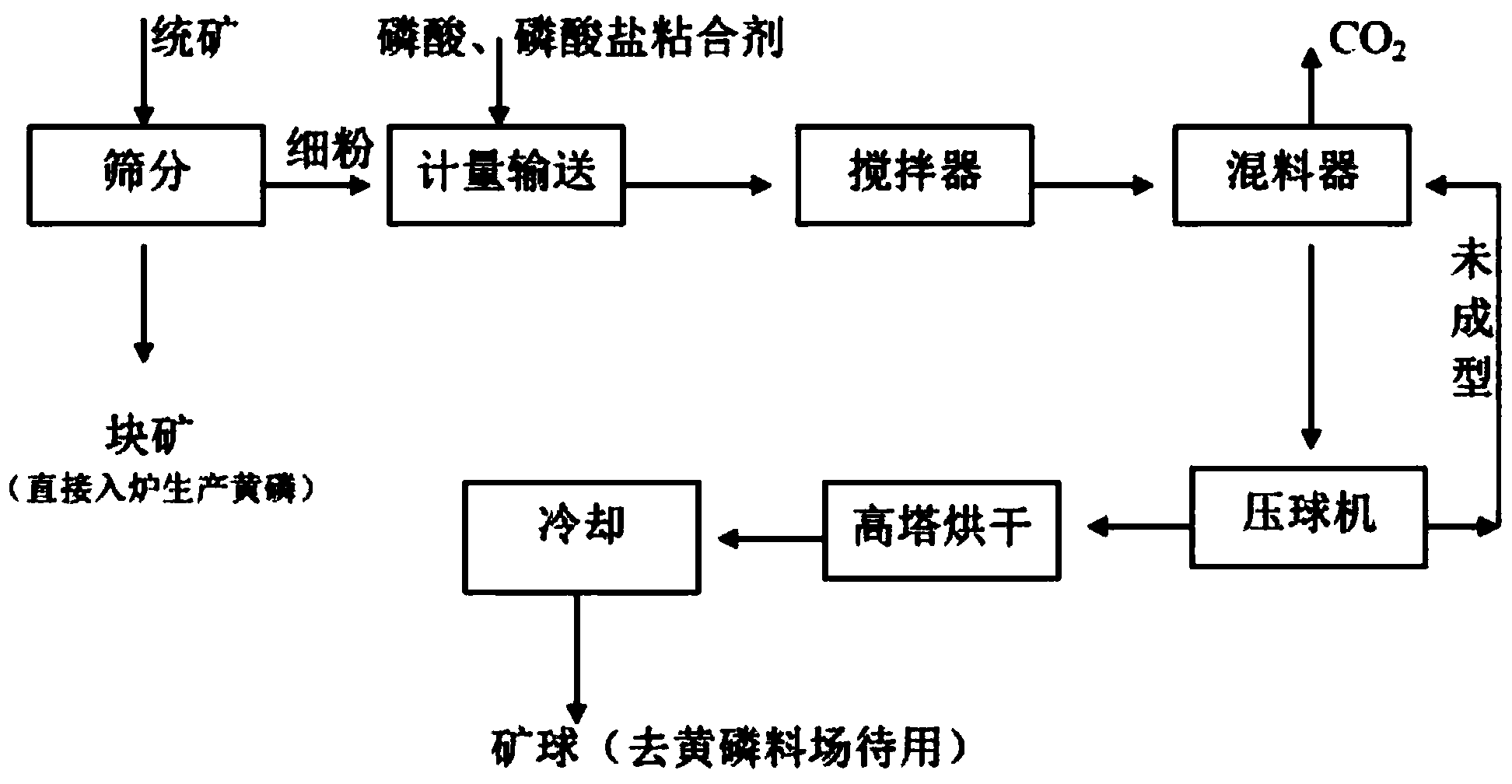

Method for producing powdered rock phosphate balls by using powdered rock phosphate

ActiveCN103964404AIncrease contentRaise the gradeRaw phosphate material treatmentCO2 contentCalcium Binder

The invention relates to the technical field of mineral processing, in particular to a method for producing powdered rock phosphate balls by using powdered rock phosphate screened out by enterprises or mineral powder left after mine production with low-concentration phosphoric acid. The method comprises the steps of screening, batching, mixing, ball pressing, drying and cooling; in the method, the content of P2O5 in phosphate rock is increased as a phosphate acid and phosphate binder is adopted and the P2O5 in the binder ultimately enters a furnace and participates the phosphorus producing reaction, and the quality of phosphate rock is improved; carbonate impurities in the added phosphoric acid and phosphate rock are subjected to chemical replacement reaction, and mixing is carried out by a double-roll mixer, so that carbon dioxide and organic matters harmful to the electric furnace during production can be fully released; in the production of yellow phosphor, the power consumption of the electric furnace can be reduced by 190 kilowatt hour as long as 1% of CO2 content is reduced, the consumption of coke can be reduced by 29 kilograms, and the production costs of the enterprises can be greatly reduced.

Owner:贵州福泉川东化工有限公司

Physical honey peach storage method

ActiveCN103609666AReduce decay rateImprove sensory qualityFruits/vegetable preservation by freezing/coolingHeat shockCO2 content

The invention belongs to the technical field of fruit and vegetable fresh keeping and in particular relates to a physical honey peach storage method. The physical honey peach storage method mainly comprises the following steps: (1) selecting peaches and dissipating heat in a room at the temperature of 20 to 25 DEG C after the honey peaches are picked within 5 hours; (2) performing heat shock treatment on the selected honey peaches at the temperature of 53 to 55 DEG C for 8-12 minutes, and rapidly taking the honey peaches subjected to heat shock treatment out; (3) dissipating heat of the honey peaches subjected to the heat shock treatment in an indoor environment at the temperature of 20 to 25 DEG C; (4) performing unsealed package on the honey peaches by using polyamide film and polyethylene film composite bags; and (5) storing the packaged honey peaches in an air-conditioned cold store at the temperature of 8 to 10 DEG C, regulating the temperature of the air-conditioned cold store to be 2 to 4 DEG C after adapting to a low temperature, and continuously performing cold storage, wherein the volume rate of gas in the air-conditioned cold store is as follows: the N2 content is 86 percent, the O2 content is 4 percent and the CO2 content is10 percent, and the humidity is controlled to be 80-90 percent. The invention aims to provide the physical honey peach storage method which is convenient to operate, safe, high-efficiency, good in storage effect and long in storage time.

Owner:ZHEJIANG JIAXING AGRI SCI ACADEMY INST

Biomass carbon storage product preparation, metering, sealing and carbon trading method

ActiveCN104766232AEmission reductionRestoring the ecological environmentBuying/selling/leasing transactionsBulk storage containerBiomass carbonCarbon emission trading

The invention discloses a biomass carbon storage product preparation, metering, sealing and carbon trading method. The method comprises steps: (1) the biomass is smashed, dried, compressed and formed, and a carbon storage product is obtained; (2) the organic carbon content, the weight, the volume, the density, the mass moisture content and the like of the carbon storage product are detected; (3) the carbon storage product after being metered is sealed; and (4) the sealed carbon product participates in global carbon trading. A physical goods capable of being accurately metered is adopted for carbon trading, and a standard and a method of accurately metering the carbon trading are built. What is firstly pointed out is that the product participating in carbon trading needs to have stable quality, and the product is a static carbon product whose carbon is in a non-cyclical state, and a dynamic carbon product capable of releasing CO2 to the air does not participate in carbon trading. A new way of using plant photosynthesis and the energy transfer process to separate, store and control the CO2 content in the atmosphere circle, realizing negative growth of CO2 in the atmosphere and regulating greenhouse effects is established by people.

Owner:雷学军 +3

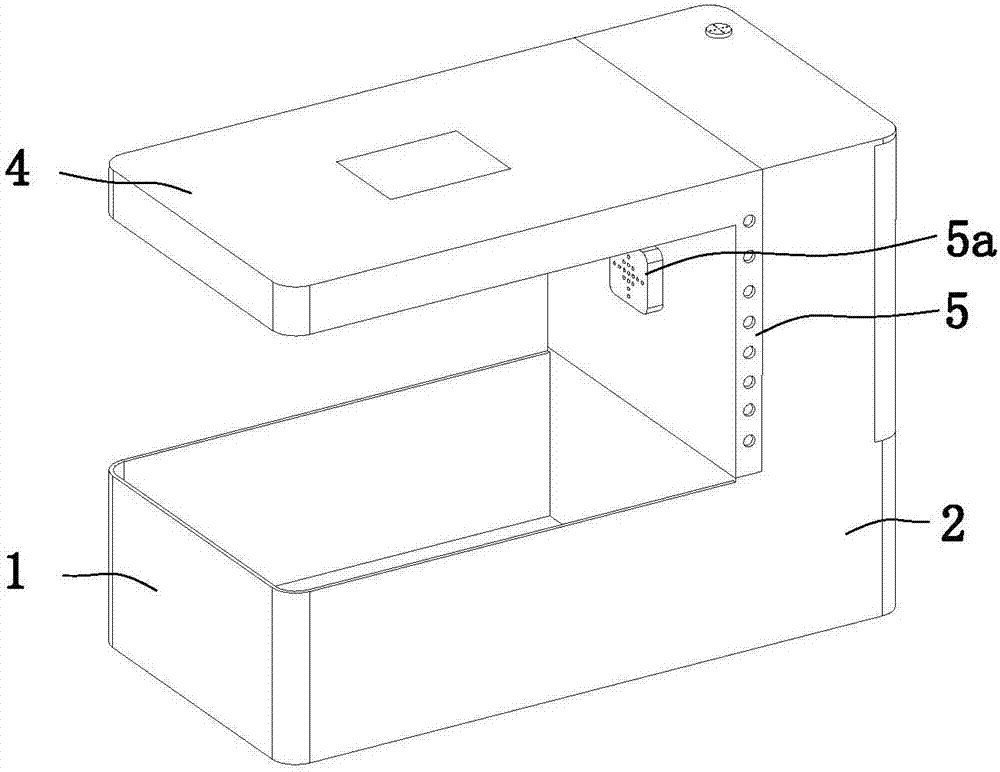

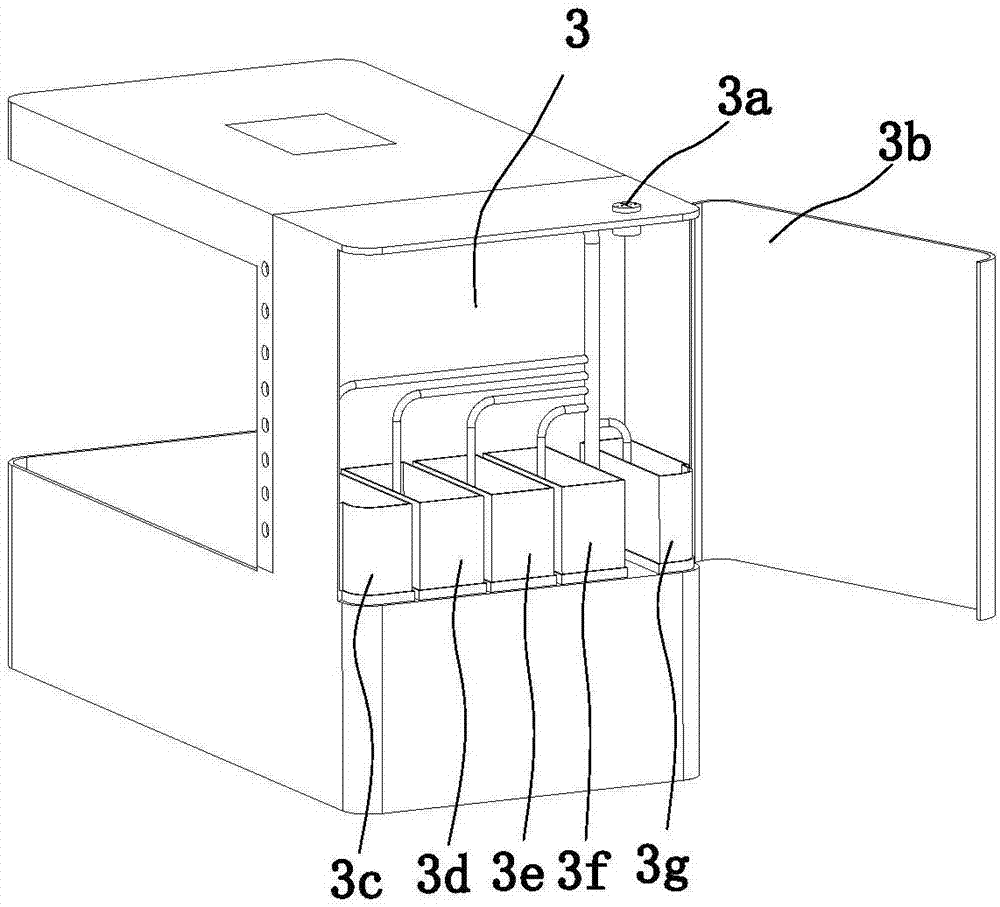

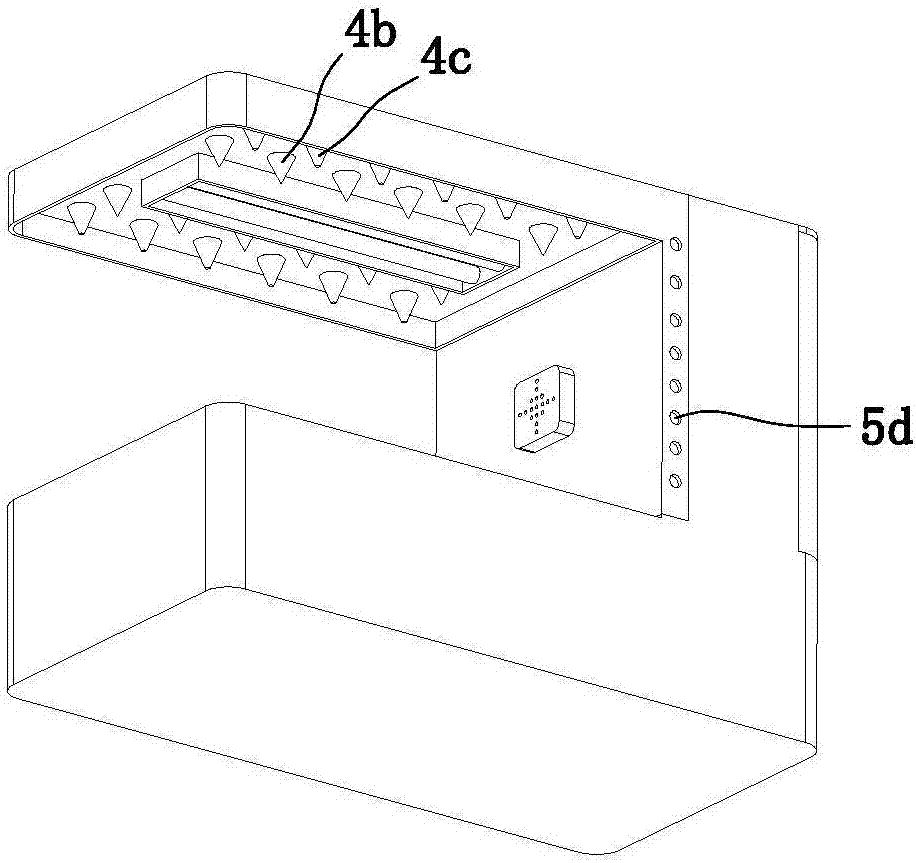

Intelligent internet of things flowerpot

InactiveCN107535223AEasy to viewLearn about cultivationSelf-acting watering devicesLiquid fertiliser distributionSiphonCO2 content

The invention relates to the field of potted plant equipment, in particular to an intelligent internet of things flowerpot. The flowerpot includes a planting basin, a control room, a fertilizer room,a siphon fertilization mechanism, a condensing water mechanism and a light compensation assembly, the condensing water mechanism comprises a first condensing plate and a second condensing plate, a temperature and humidity sensor, a moisture sensor, a conductivity sensor and a trace element detector, the fertilizer room is connected with an illumination sensor, a CO2 content sensor is arranged on the second condensing board, an IC main control board is arranged on the control box, and the IC main control board includes a controller and a communication module. According to the intelligent internet of things flowerpot, plants are automatically cultured, real-time environment data of the plants is sent to a user to facilitate the user to understand the cultivation situation of the plants, andthe user can set up suitable environment parameters according to plant variety in a mobile phone terminal to satisfy the cultivation of the plants with different species.

Owner:ANHUI WALTER MACHINERY TRADE

Carbon dioxide capturing method

InactiveCN104028079AAbsorptive Capacity LimitationImprove capture efficiencyDispersed particle separationBy absorptionAbsorption capacityLiquid water

The invention discloses a carbon dioxide capturing method. The carbon dioxide capturing method comprises the steps of absorbing CO2 by using an ion liquid water solution containing primary amine as a CO2 capturing working medium and forming a CO2 hydrate. According to the method, two CO2 capturing modes such as an ion liquid method and a hydrate method are integrated, dual-capturing effects on CO2 through the ion liquid water solution and a gas hydrate are achieved, and the CO2 capturing efficiency is greatly improved, so that the decarburization efficiency is improved. The limitation on an existing ion liquid method caused by ion liquid absorption capacity is overcome, and the stress caused by single hydrate decarburization and the limitation on high CO2 content requirement are eliminated; the method is good in industrial application value.

Owner:SUN YAT SEN UNIV

Cascade type natural gas pressurized liquefaction process with sublimation removal of CO2

InactiveCN102620524AImprove toleranceReduce unit energy consumptionSolidificationLiquefactionCO2 contentThree stage

The invention relates to a cascade type natural gas pressurized liquefaction process with sublimation removal of CO2. Natural gas is kept at a gas state and precooled in a precooler, and is fed into a crystallizer and kept on cooling, so that solid dry ice can be separated out by sublimation and the CO2 content is reduced to 0.5%; and then, natural gas is fed into a cryogenic compressor for pressurization, fed into a liquefier for liquefaction under a high pressure, and fed into a storage tank for storage. The cold quantity required by a liquefaction process is provided by an independent two-stage cascade refrigerating cycle. Compared with the prior art, the process provided by the utility model not only dispenses with CO2 pretreatment equipment which occupies a large area in the conventional natural gas liquefaction process, but also simplifies the traditional three-stage cascade refrigerating cycle to two-stage refrigerating cycle, so as to greatly reduce the cost of investment for natural gas liquefaction on an offshore platform which has high manufacturing cost. Meanwhile, the natural gas liquefaction at a high temperature also reduces the energy consumption of the refrigerating cycle.

Owner:SHANGHAI JIAO TONG UNIV

Four-segment spray coal oxygen-enriched gasification method

InactiveCN103113923AIncrease contentReduce pollutionGranular/pulverulent flues gasificationCO2 contentSlag

The invention discloses a four-segment spray coal oxygen-enriched gasification method. A four-segment spray coal oxygen-enriched gasification process is adopted; the spray coal with small particle (0.1-0.5mm) and an oxygen-rich gasification agent (the oxygen content is 96%) are boiled and gasified; the gasification reaction is complete; the carbon conversion rate is more than 90%; the coal utilization rate can be up to 86% and is improved by 26% compared with a traditional fixed bed intermittent gasification process; CO2 in high-temperature coal gas and cracked C are subjected to reduction reaction to generate CO at the reduction period; the CO2 content in the coal gas is reduced; the content of effective gas of the coal gas is improved; the effective gas achieves 89% and is close to the coal gas mass of the spray coal gasification technology; the high-temperature coal gas preheats the spray coal through a preheating cracking section and then passes through an afterheat recovery segment to generate steam, so as to achieve the target of fully utilizing afterheat; the thermal efficiency is improved to 79%; a water-sealing disc-type slag eliminator is adopted to remove sludge; and the pollution on the environment is reduced, so as to achieve the aim of clean production.

Owner:SHANDONG RUNYIN BIOCHEM

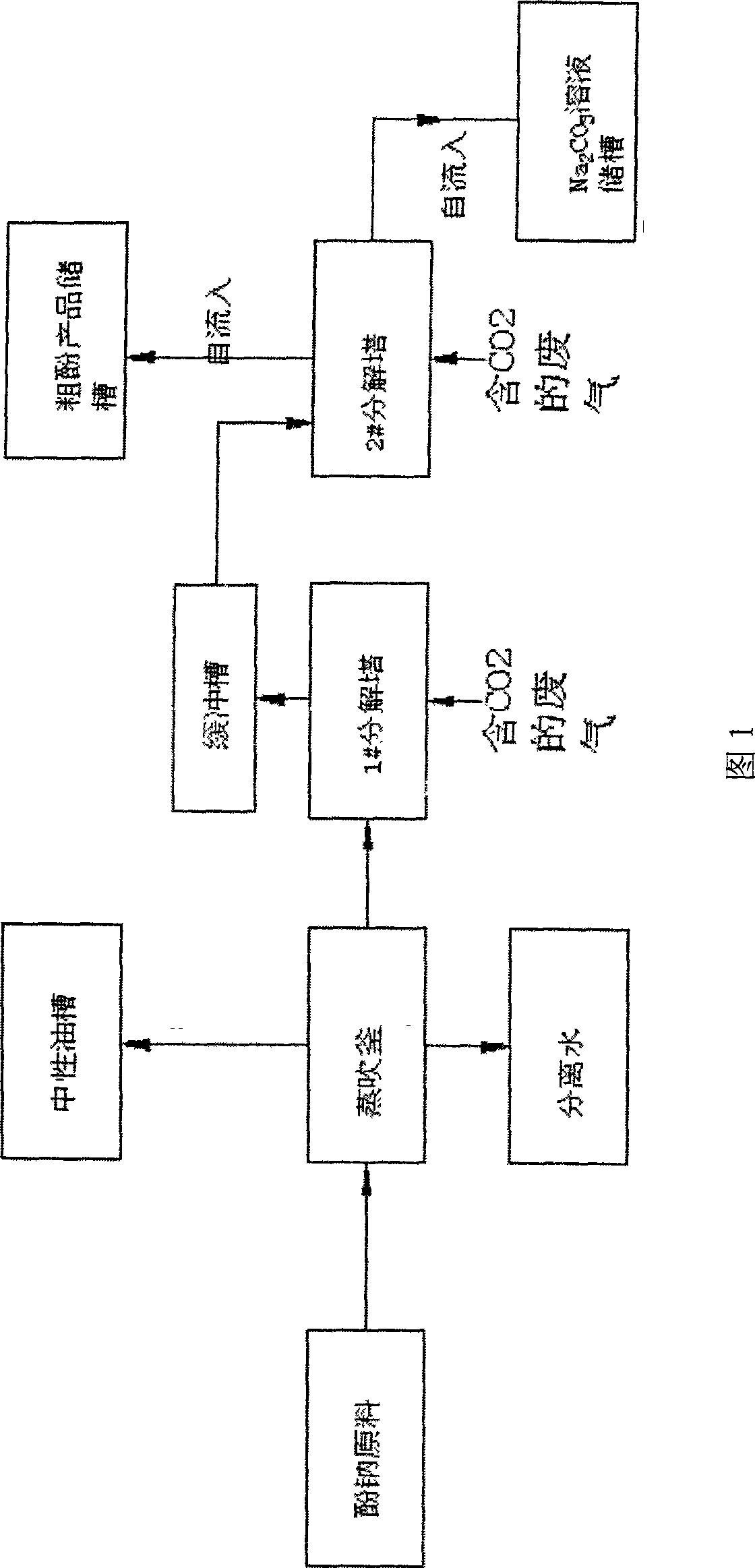

Method for decomposing sodium phenolate using low CO2-content exhaust gas

ActiveCN101381284AEmission reductionProtection advantageOrganic chemistryOrganic compound preparationForeign matterCO2 content

The invention relates to a production method for decomposing sodium phenolate by using low-content CO2 waste gas. The method comprises the following steps: the low-content CO2 waste gas is used, the temperature of the CO2 waste gas is reduced to between 40 and 60 DEG C through a cooling device, vapor and foreign matters in the CO2 waste gas are cleared away, and then the CO2 waste gas is pumped to a decomposing tower and an acidifying tower through a fan; the sodium phenolate is warmed up by steam and then is put into the decomposing tower to contact the low-content CO2 waste gas, and the temperature in the decomposing tower is between 40 and 60 DEG C; under the action of internal parts of the decomposing tower, thermal transfer and mass transfer are realized to decompose the sodium phenolate into crude carbolic acid and sodium carbonate; and the sodium phenolate is sprayed from the top of the decomposing tower to contact reverse current of the low-content CO2 waste gas so that the sodium phenolate is decomposed into the crude carbolic acid and the sodium carbonate which are separated to obtain a crude carbolic acid product and sodium carbonate solution after being kept stand, wherein the sodium carbonate solution is causticized into sodium hydroxide solution through calcium oxide, and the sodium hydroxide solution is used as a raw material for distillate washing to perform circulation. The production method makes full use of the characteristics of distillate processing and the prior resources of deep-processing enterprises to realize the standard emission of the waste gas to be emptied.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

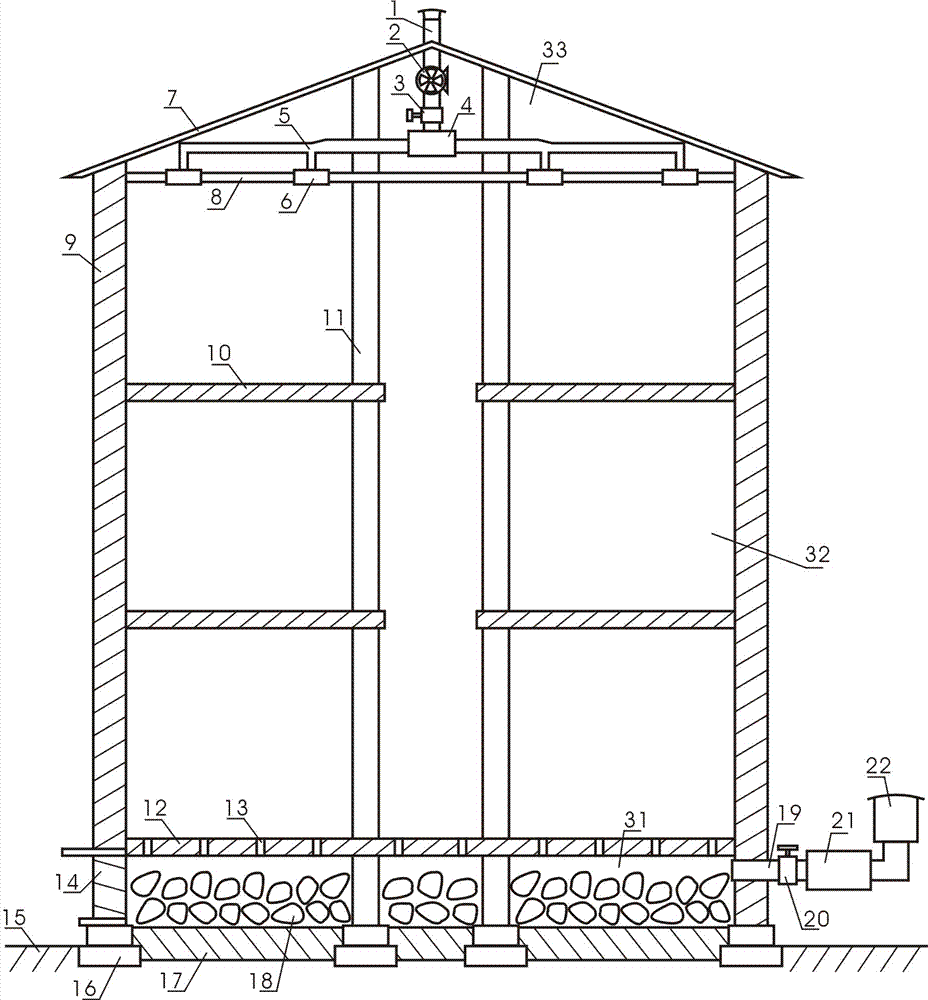

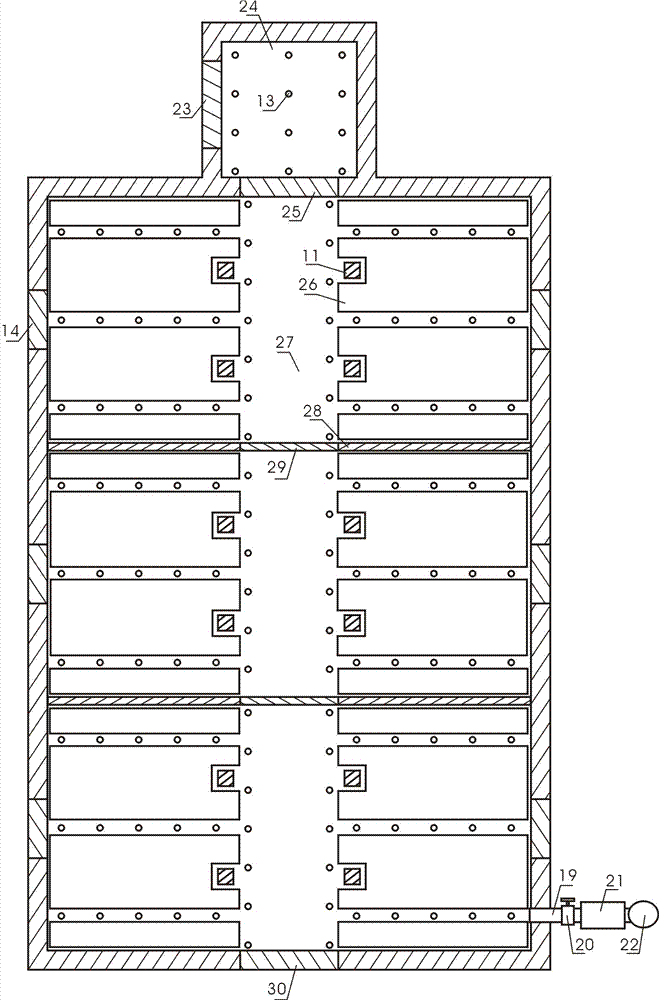

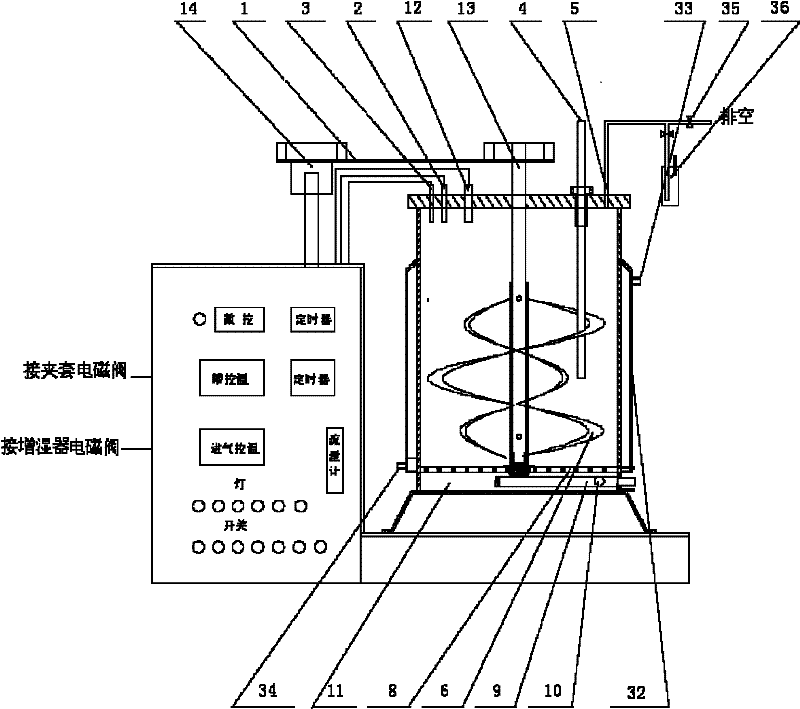

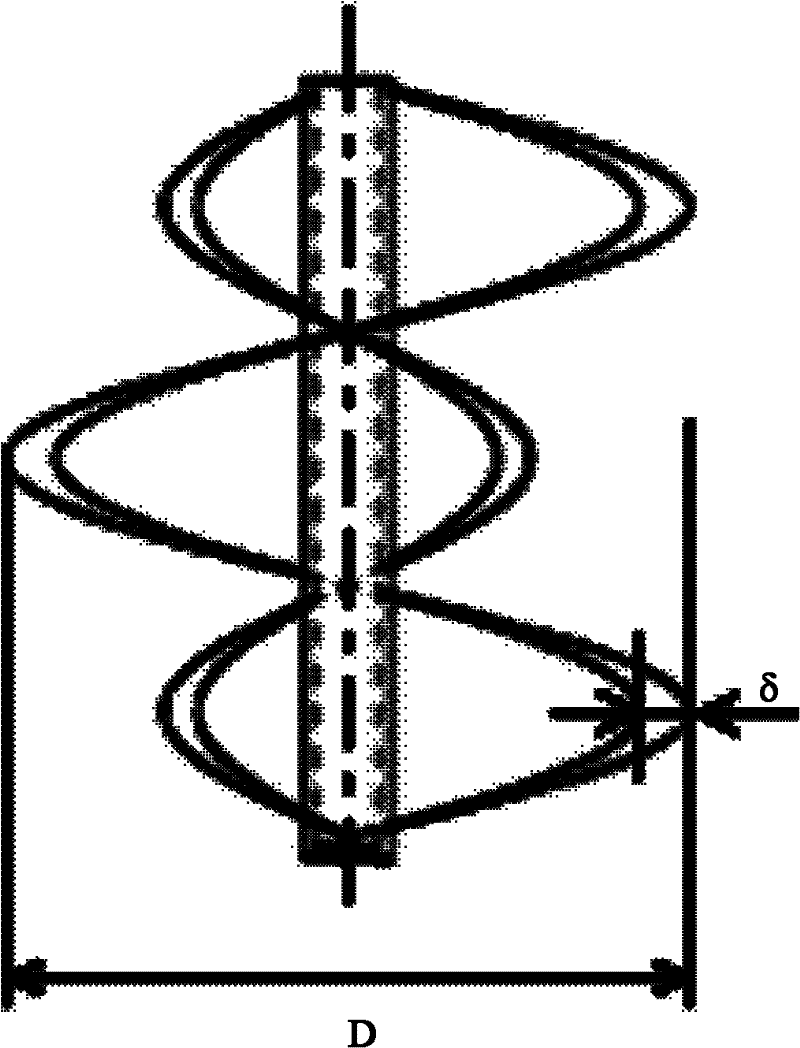

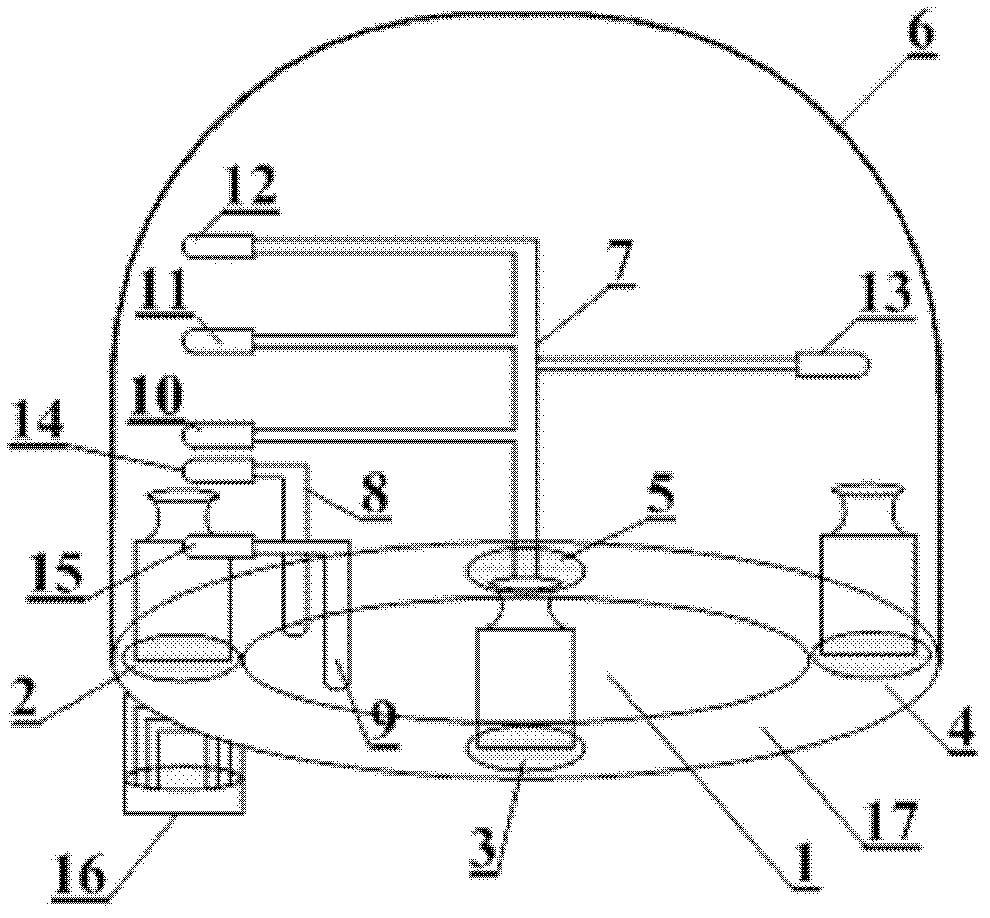

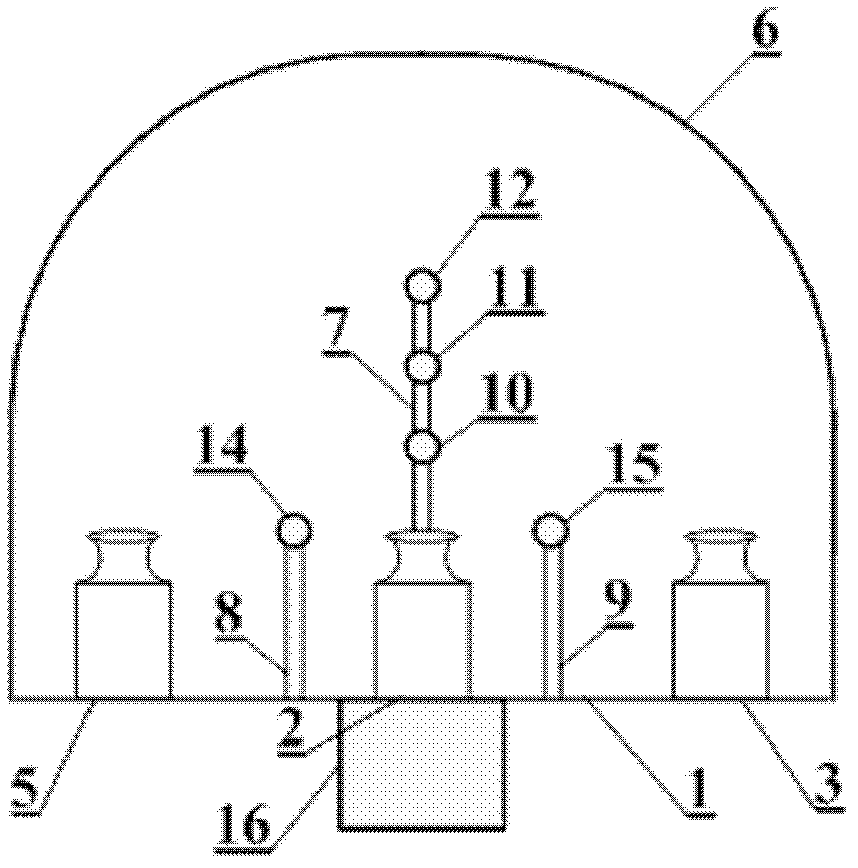

Enclosed solid state fermentation bioreactor

InactiveCN102199521ASolve the sticking problemSolve the problem of overheatingBioreactor/fermenter combinationsBiological substance pretreatmentsCollection systemSolenoid valve

The invention discloses an enclosed solid state fermentation bioreactor. The bioreactor comprises a solid state fermenter, an air inlet system, a humidification system and a tail gas detection and collection system. The solid state fermenter is a sealed container, and a central shaft of the fermenter is provided with a reverse double spiral stirring paddle which allows materials to carry out bidirectional movement, so an adhesion problem which appears in stirring solid materials can be solved and a mixing effect can be enhanced. A top tail gas outlet of the fermenter is connected with an evacuation tube and a CO2 collector, and a fermentation process and a fermentation state are displayed through detecting the CO2 content. A jacket is arranged on the outside the fermenter, a bypass is arranged on a humidifier, and the fermentation bed temperature can be automatically adjusted through feeding back information to a control system by a thermocouple which is on an upper part of the fermenter to adjust solenoid valves of jacket cooling water and the humidifier bypass. The humidifier temperature and periods and times of stirring and spraying can be preset according to material fermentation characteristics. A bed overtemperature problem, which appears in a fermentation peak period and is most difficult to solve in solid fermentation processes, can be solved by removing heat of fermentation through a plurality of modes such as jacket cooling water adjusting, cold air accessing, atomized water spraying, material stirring and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

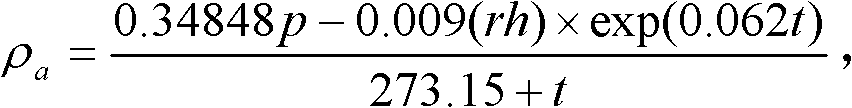

Method and device for measuring air density in weight mass measurement

InactiveCN102384882AAccurate temperatureAccurate Humidity ValueSpecific gravity measurementMeasurement deviceCO2 content

The invention provides a method for measuring an air density in weight mass measurement and a method for correcting a mass measurement result, which belong to the measurement field. The method comprises the following steps that: parameters of air surrounding a weight are firstly measured, then the air parameters are used for obtaining an air density, the air parameters include temperature, humidity and pressure and also include a content of carbon dioxide (CO2). By adopting a way that a plurality of temperature collecting points and at least two humidity collecting points are arranged inside a wind cap, the temperature and the humidity gradient parameters above a balance in the wind cap are obtained, so an accurate value of the air temperature and the accurate air humidity can be calculated to further obtain an accurate value of the air density; and the measurement of the CO2 content is further added in the method, and the influence factor of the CO2 is considered in the test result, so the test result is more accurate.

Owner:NAT INST OF METROLOGY CHINA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com