Patents

Literature

207results about How to "Solve the sticking problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

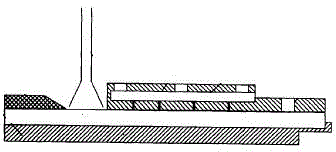

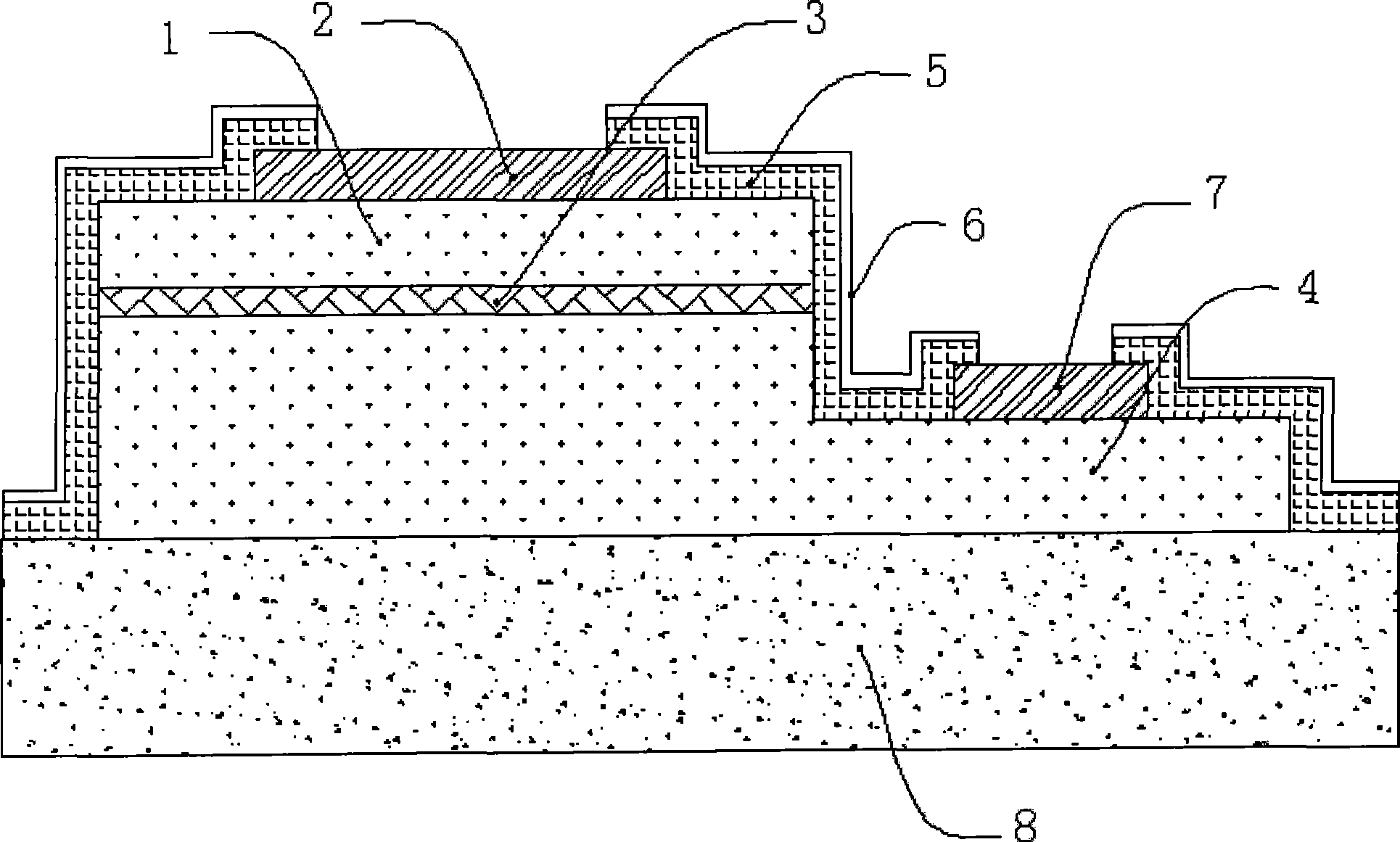

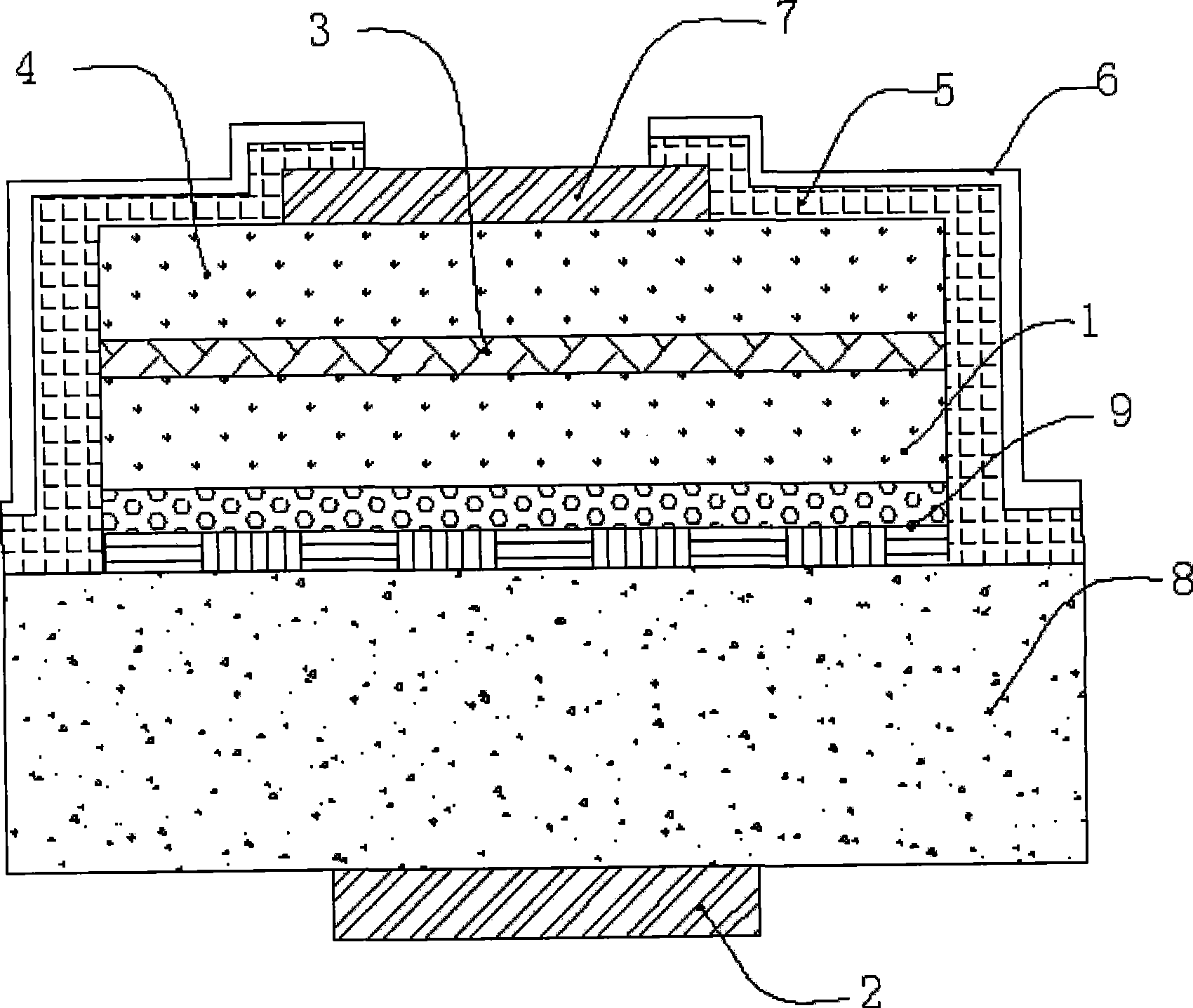

Manufacturing method for floating type micro-silicon electrostatic gyro/accelerometer sensitive structure

InactiveCN101279713AInhibit sheddingThickness loss is negligibleAcceleration measurement using interia forcesDecorative surface effectsLevitationAccelerometer

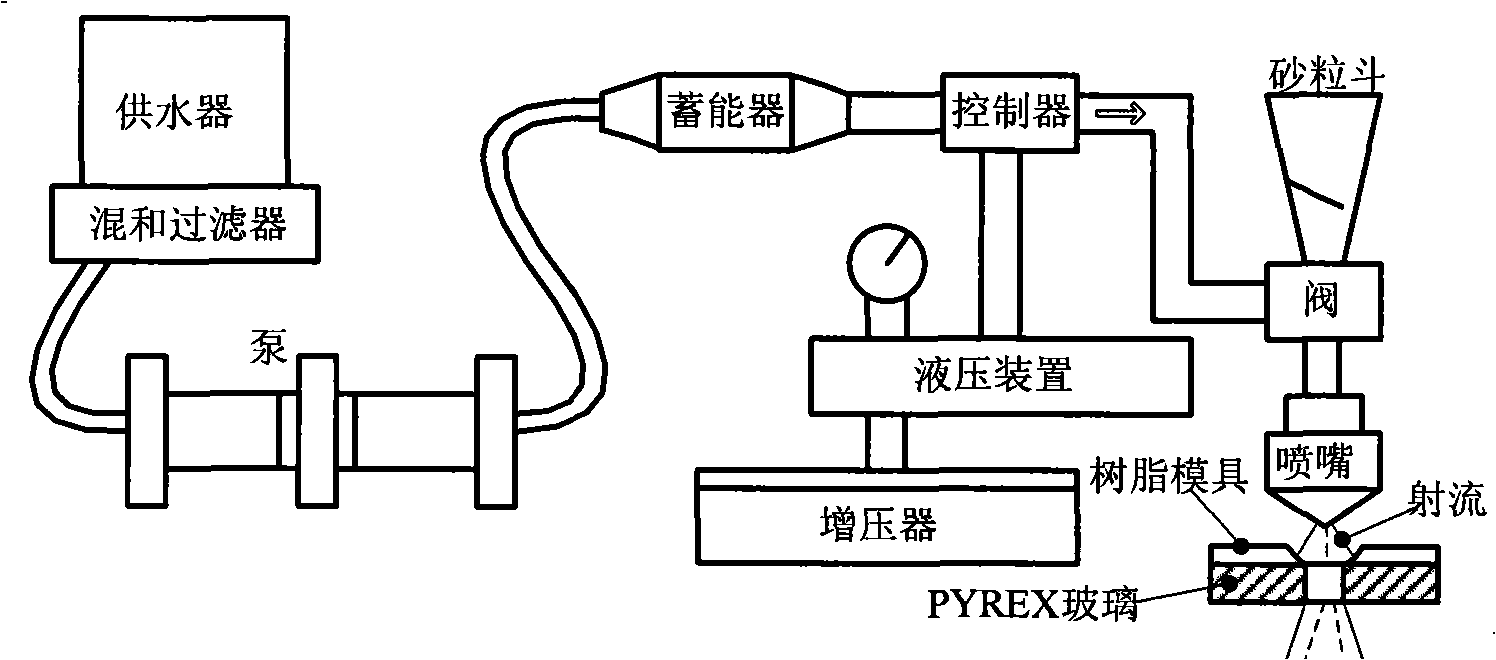

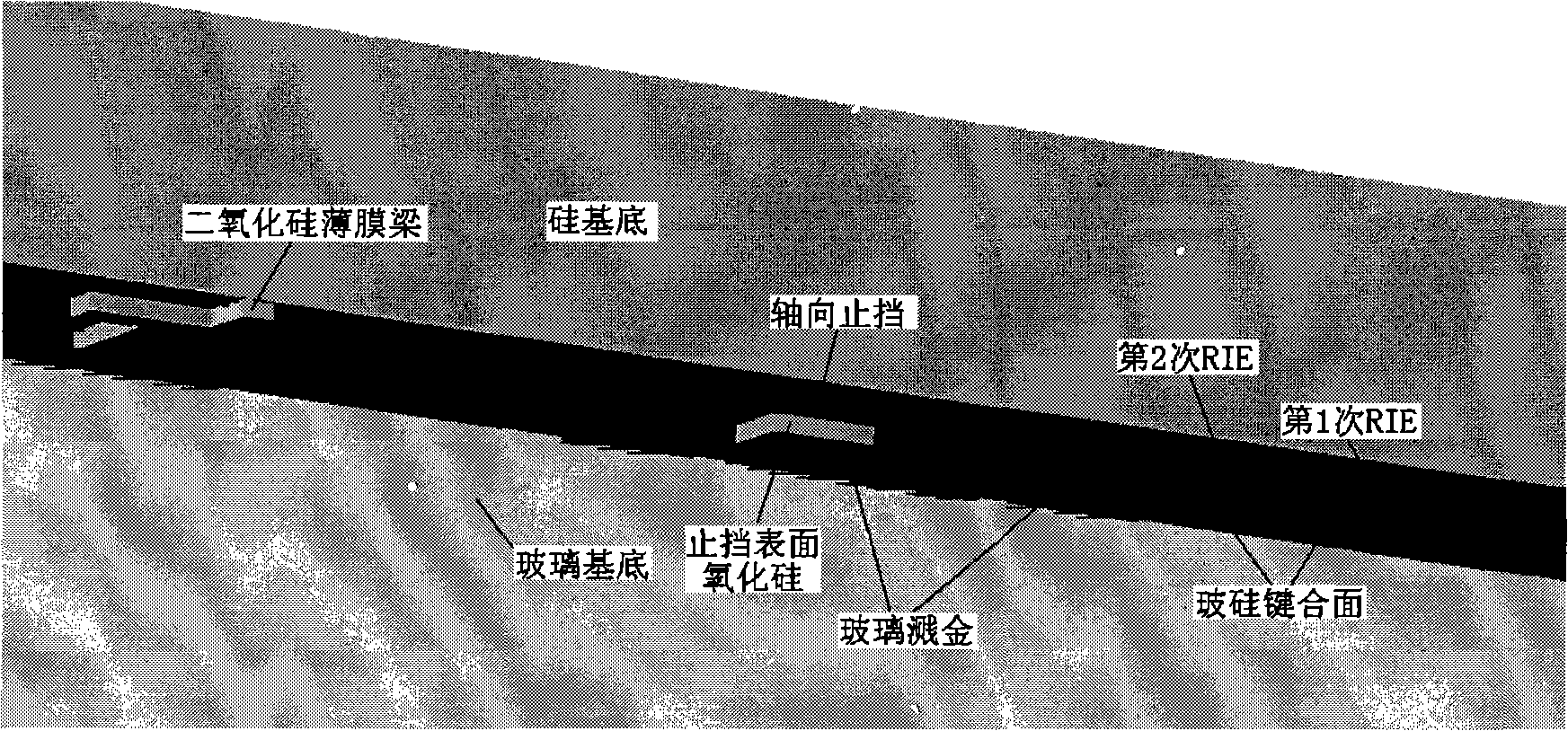

The invention relates to a method for preparing a levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure, which belongs to the technical field of silicon structure processing. The method comprises the steps: glass etching; glass gold splashing: a metal layer raising 400-600 tenthmeters higher than a glass surface; perforating the glass; a first and a second RIE etching for the silicon slice; film beam process: high-temperature dry oxidation and surface corrosion; a first electrostatic bonding for glass and silicon; thinning and polishing to the silicon slice; ICP etching for the silicon slice; a third RIE etching for the silicon slice; a fourth RIE etching for the silicon slice; a second electrostatic bonding for glass and silicon; ICP removal for film beam to prepare the levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure. The method adopts the proposal of sandblasting perforating for perforating the glass, introduces the silicon dioxide film beam as a sacrificial layer and adopts the ICP film beam removal process; the method can effectively solve the problem of adherence of a sandwich microstructure in the second electrostatic bonding and does not need post treatment so that the method has higher efficiency and better compatibility with the MEMS process.

Owner:TSINGHUA UNIV +1

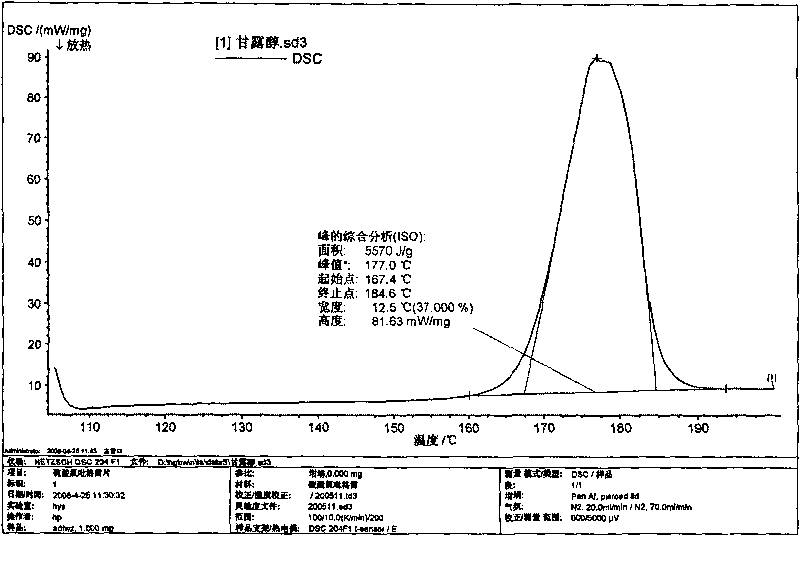

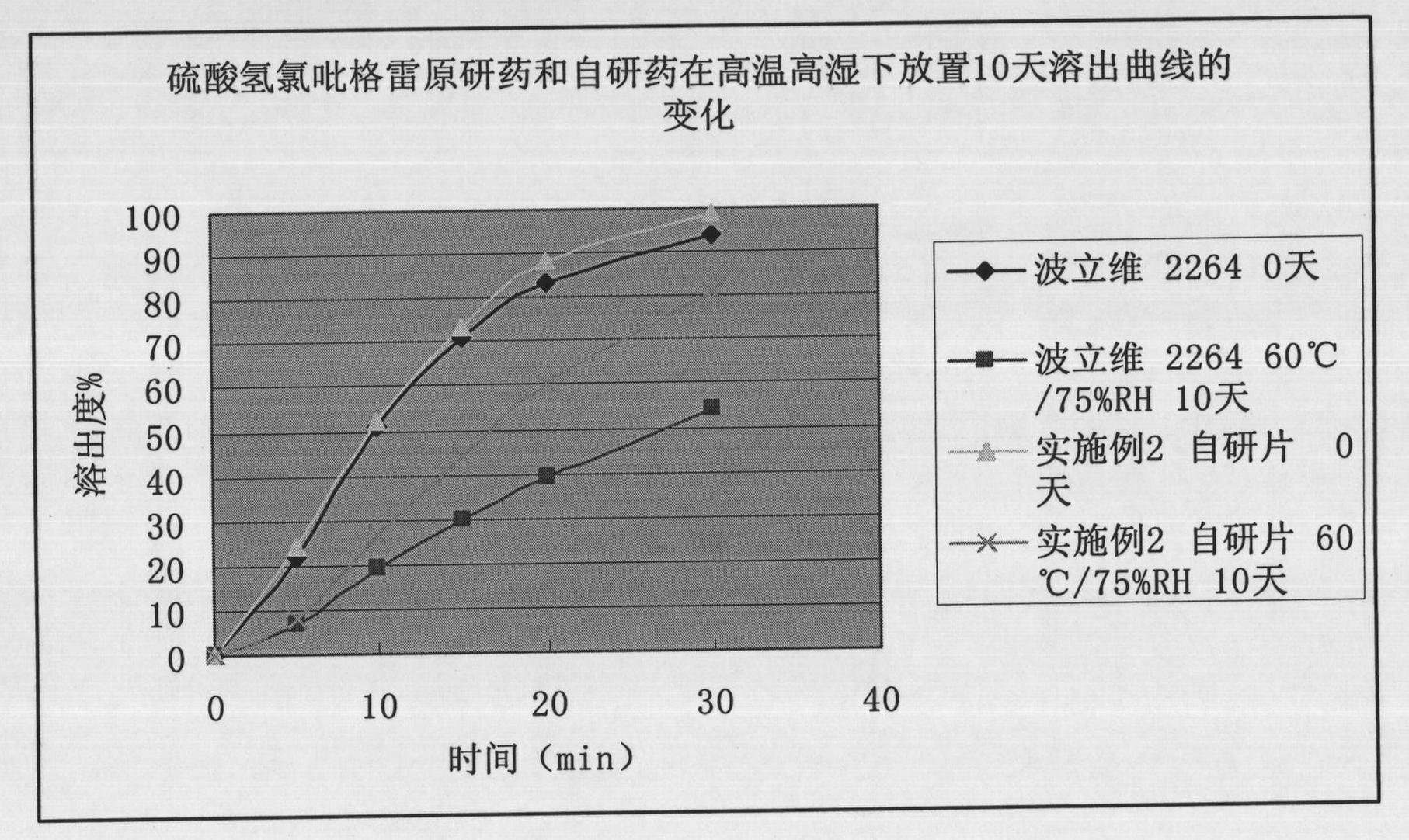

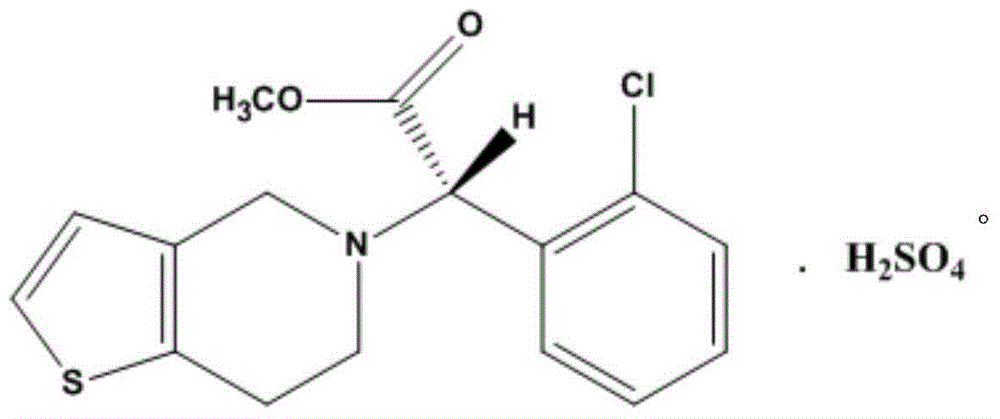

Solid medicinal composition of clopidogrel hydrogen sulfate

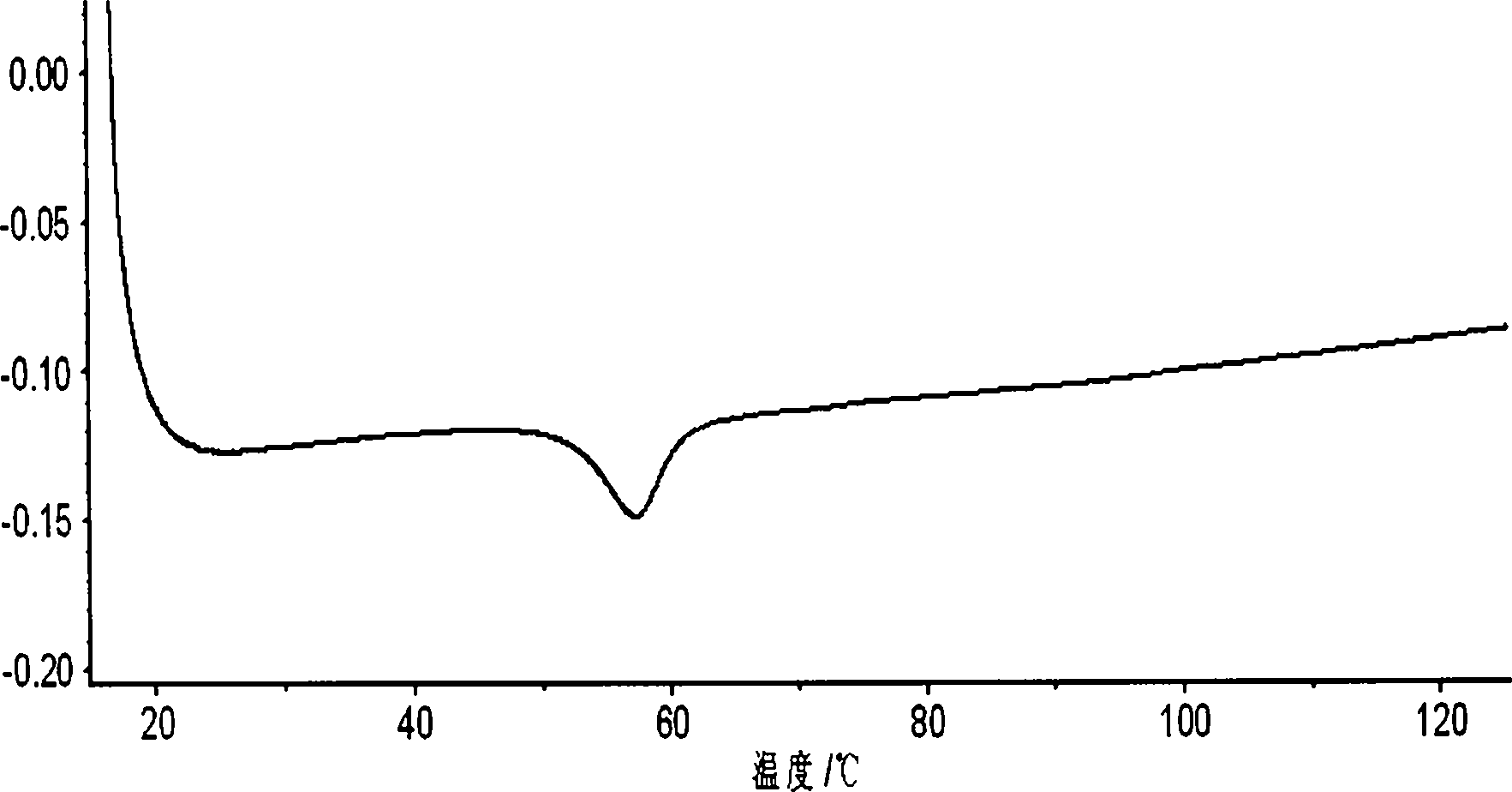

ActiveCN101721410AFast and efficient disintegrationFast and efficient dissolutionOrganic active ingredientsPharmaceutical non-active ingredientsMedicineFiller Excipient

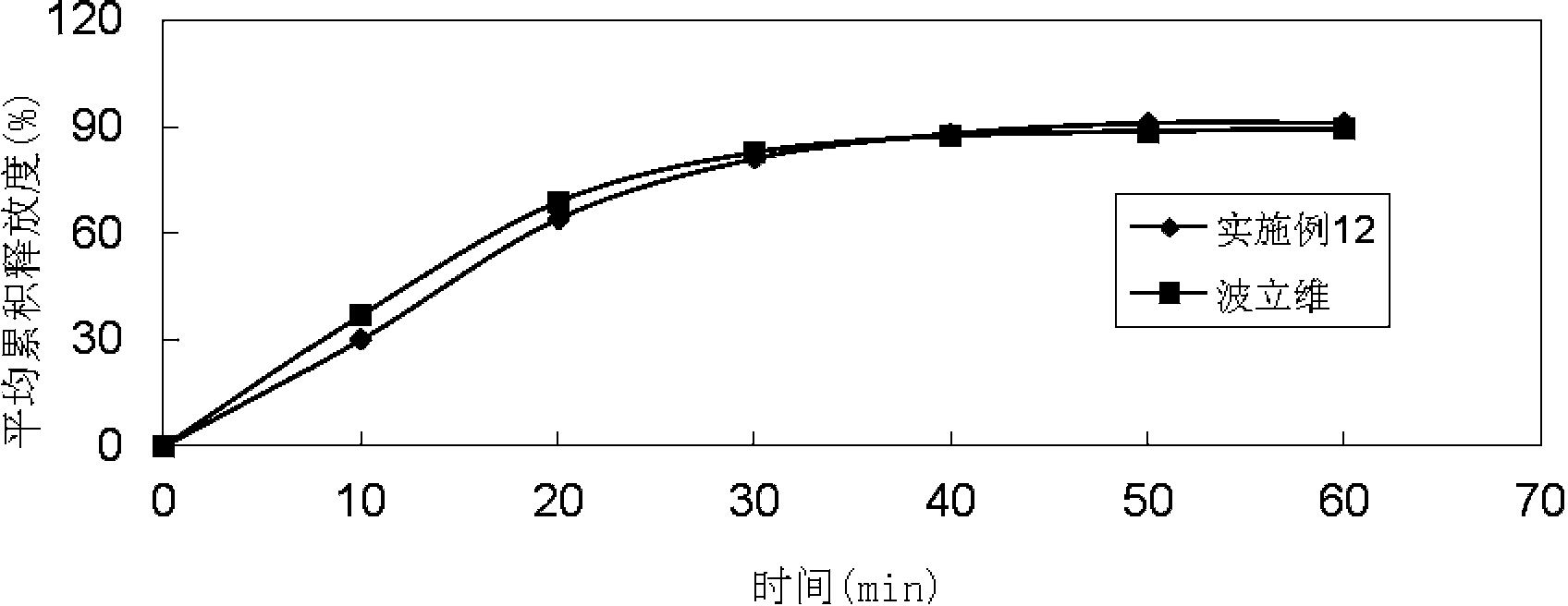

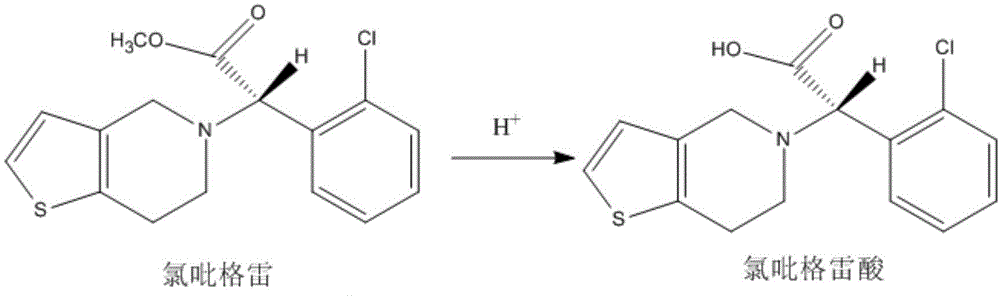

The invention relates to an oral medicinal composition containing I crystal-form clopidogrel hydrogen sulfate, polyethylene glycol and micro-powder silica gel, proper disintegrating agent and filling agent. The auxiliary materials of the composition are low in price and can be obtained easily; the preparation process is simple; the requirement for equipment and environment is not high; and the prepared tablet is stable in quality and good in reproducibility, and is applied to industrialized production. The prepared tablet has good stability in long-term storage and can be maintained stable after being placed for 6 months at the temperature of 40 DEG C, without appearance change and obvious degradation or crystal-form inversion phenomenon; the dissolution rate of the tablet is not reduced after the tablet is placed for a long time; and the dissolution rate of the tablet in 10 minutes can still reach more than 95 percent after the tablet is placed for 6 months at the temperature of 40 DEG C.

Owner:NANJING CHIA TAI TIANQING PHARMA

Production method of rabbit hair, cashmere and silk three-in-one face fabric

InactiveCN101225568ASoft and smoothNatural elegant lusterHeating/cooling textile fabricsLiquid/gas/vapor removalYarnEngineering

The invention relates to a triad producing method of clothing face fabric with rabbit hair, cashmere and silk, which is characterized in that: the raw material comprises 14% of the silk, 39% of the rabbit hair, 44% of the wool and 3% of the cashmere, the clothing face fabric with rabbit hair, cashmere and silk is made by the processes of dyeing, garneting, spun yarn, warping, weaving and after-finishing. The triad producing method of clothing face fabric with rabbit hair, cashmere and silk has the advantages of gathering the elasticity and heat retention of the wool, and the excellent properties of the rabbit hair and the silk, soft and satiny hand feeling, natural and elegant luster, excellent heat retention, and suitable for the demand of higher consumption level stratum.

Owner:江阴市天鹅制呢厂有限公司

Effervesce pieces of tea beverage, preparing method

ActiveCN101049121AEasy to operateSolve the sticking problemTea extractionBiotechnologyEffervescent tablet

An effervescent tablet of tea beverage with health-care function is proportionally prepared from the extract of tea leaf, alkaline substance, edible organic acid, food-class polyethene glycol 6000 (PEG 6000), edible defoaming agent, superfine silica gel powder, excipient, and flavouring. Its preparing process is also disclosed.

Owner:YUNNAN LONGRUN PHARMA

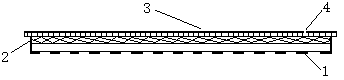

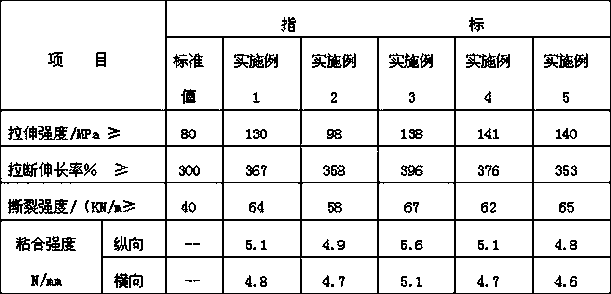

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

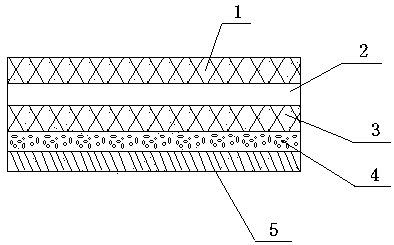

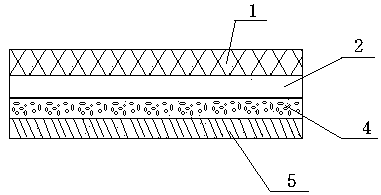

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

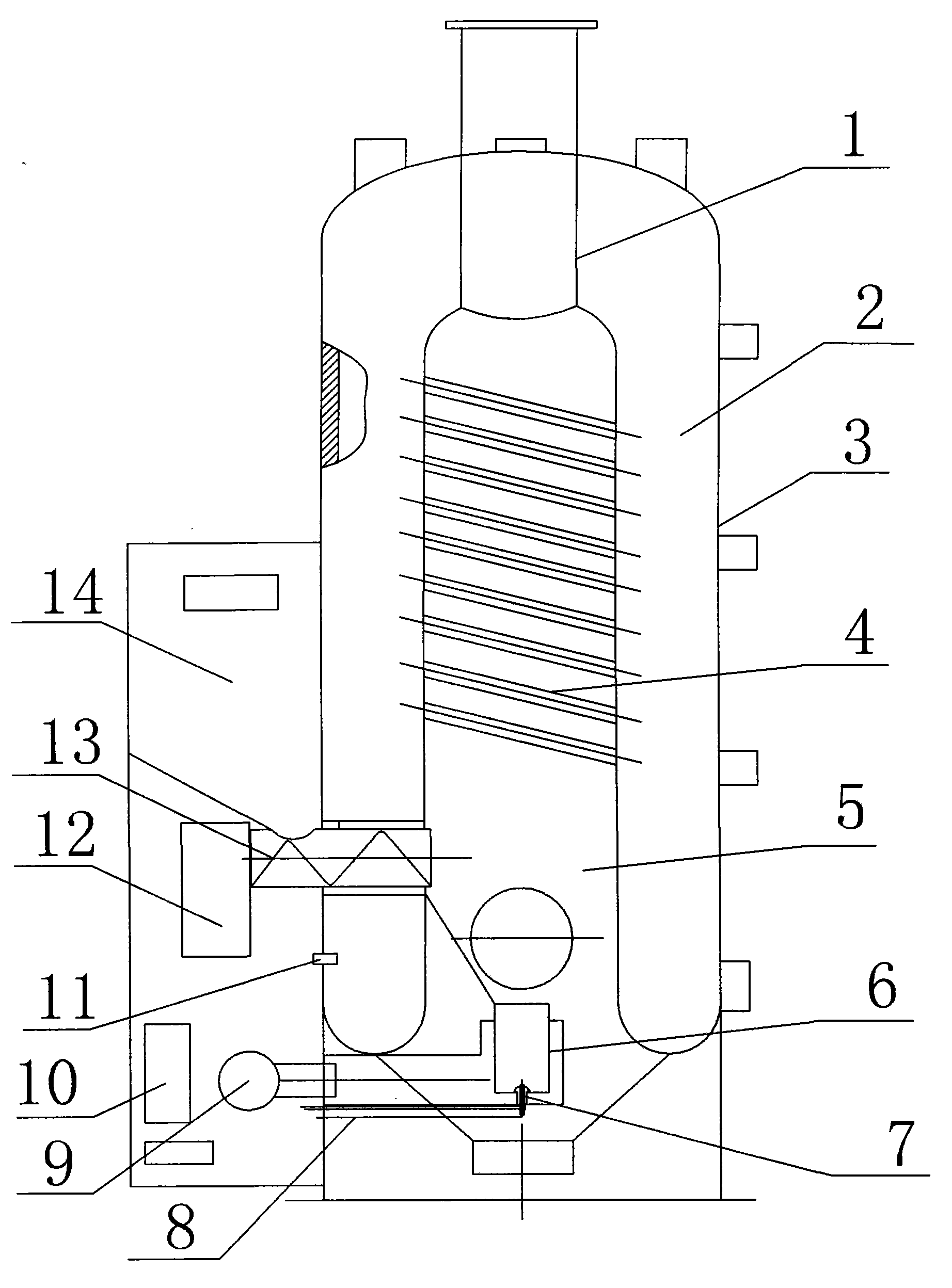

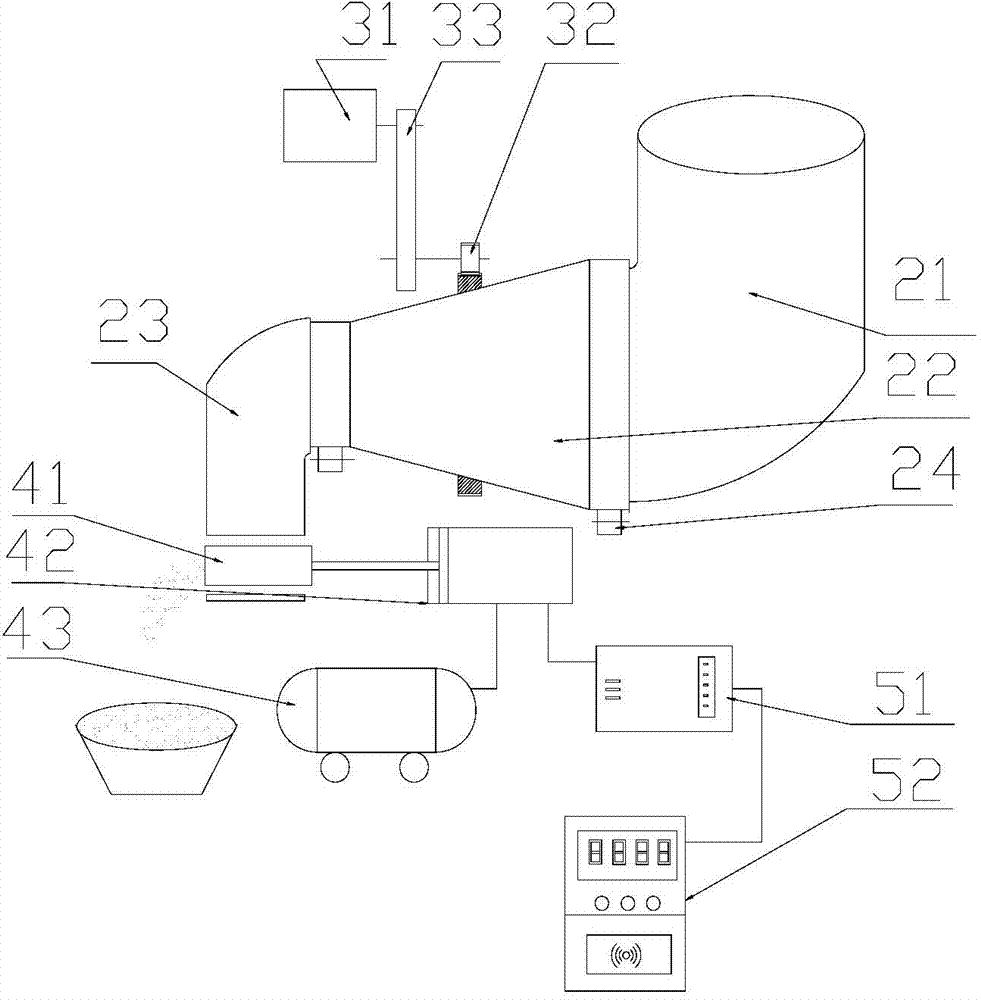

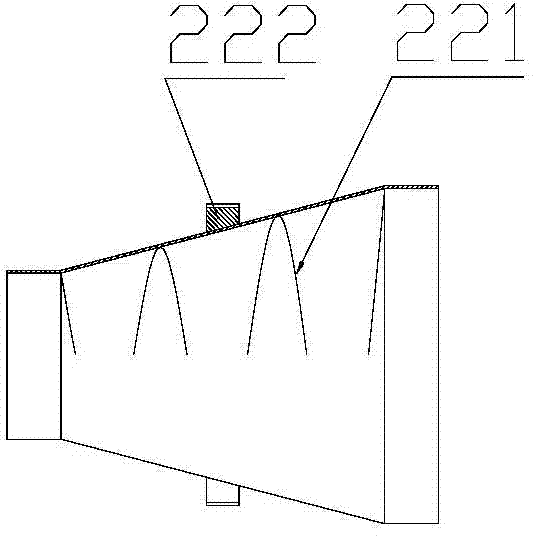

Biomass fuel boiler

InactiveCN101846386ABurn fullySolve the problem of stickingSteam generation plantsWater heatersCombustion chamberCombustor

The invention discloses a biomass fuel boiler which is equipped with an outer shell and an inner combustion chamber, wherein, a water storage room is arranged between a barrel and the combustion chamber, and a burner is arranged at the lower part of the combustion chamber. The biomass fuel boiler is characterized in that the burner is of a double-layer sleeve structure, wherein, the inner layer thereof is a cylinder with an open on the upper surface, and an ignition device is arranged in the middle of the bottom; an outer layer is a closed body which is communicated with a fan and is used for enclosing the inner-layer cylinder besides an open mouth; and air intakes are arranged at the middle part and the upper part of the bottom and the side of the inner-layer cylinder; and a particle fuel tank is arranged at the side of the shell, and particle fuel is connected to the burner through a twisting cage. In the invention, three types of combustion air such as upper straight air, middle spiral air and bottom raising air are formed in the burner by changing the mode of air supply, wherein, the bottom raising air enables biomass particles to suspend in the burner; the middle spiral air enables biomass fuel more dispersed and more fully burned; and the upper straight air performs secondary oxygen supply to achieve more thorough combustion and improve thermal efficiency.

Owner:范家文

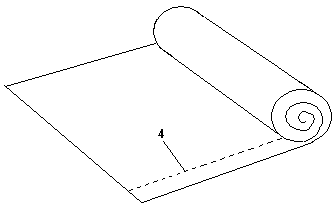

Production method of ethylene propylene diene monomer self-adhesion water-resistant coiled material

ActiveCN104059552ASolve the sticking problemGood value for moneyMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEthylene-propylene-diene-monomerHot melt

The invention relates to a production method of an ethylene propylene diene monomer self-adhesion water-resistant coiled material. The technical scheme is as follows: the method comprises the following steps: fully coating a composite modified butyl pressure-sensitive self-adhesion adhesive on a ethylene propylene diene monomer vulcanized water-resistant coiled material main body layer by using a hot-melt pressure-sensitive adhesive coating machine to form a composite modified butyl pressure-sensitive self-adhesion layer, coating an anti-adhesion barrier film on the composite modified butyl pressure-sensitive self-adhesion layer, and cutting the side of the anti-adhesion barrier film with a cutting device to arrange intermittent tear slots, thereby preparing the coiled material product. By arranging the ethylene propylene diene monomer vulcanized coiled material main body layer and the composite modified butyl pressure-sensitive self-adhesion layer, the product has dual water-resistant characteristic, and thus, has obviously higher water resistance; the product has the water-resistant function of full skin adhesion, implements the effective fusion and maximum permanent seal between the coiled material and base layer; and besides, the coiled material has high chemical corrosion resistance.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Inactivated lactobacillus effervescent tablets and preparation method thereof

ActiveCN103211143AFix existing technical deficienciesAvoid defectsFood shapingFood preparationEffervescent tabletDigestion

The invention discloses effervescent tablets with inactivated lactobacillus cells as an effective component, and a preparation method thereof. The inactivated lactobacillus effervescent tablets are prepared from the raw materials of, by weight, 5-15% of inactivated lactobacillus powder, 20-30% of oligosaccharide, 23-33% of an acid source, 25-35% of an alkali source, 2-5% of a disintegrant, and 2-5% of a lubricant. According to the invention, the lactobacillus cells are inactivated through a heat inactivation method. The effervescent tablets comprise lactobacillus cells, and have the functions of digestion promoting, intestinal micro-ecological balance maintaining, and human immunity improving. Also, the tablets comprise oligosaccharide bifidus factors, and can promote probiotic growth in bodies, such that a dual health-care effect is achieved. The effervescent tablets are convenient to carry and to eat. When the effervescent tablet is dissolved in proper amount of drinking water, an instant beverage can be obtained. The tablets are solid health-care beverages for various populations. The effervescent tablet preparation method provided by the invention is simple and feasible, and has important actual application and popularization values.

Owner:胡文锋

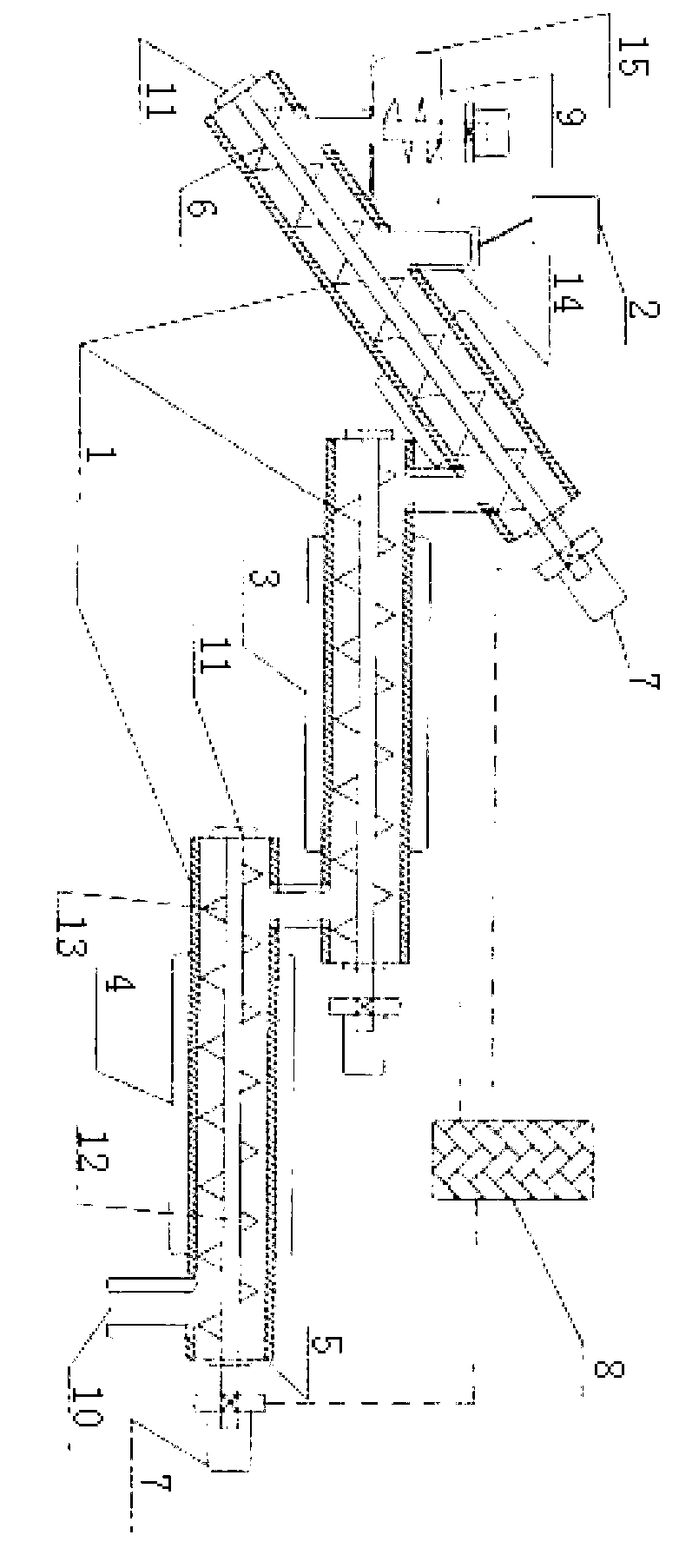

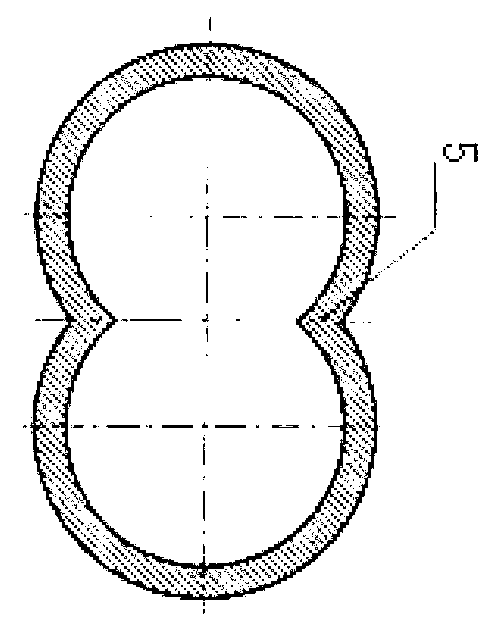

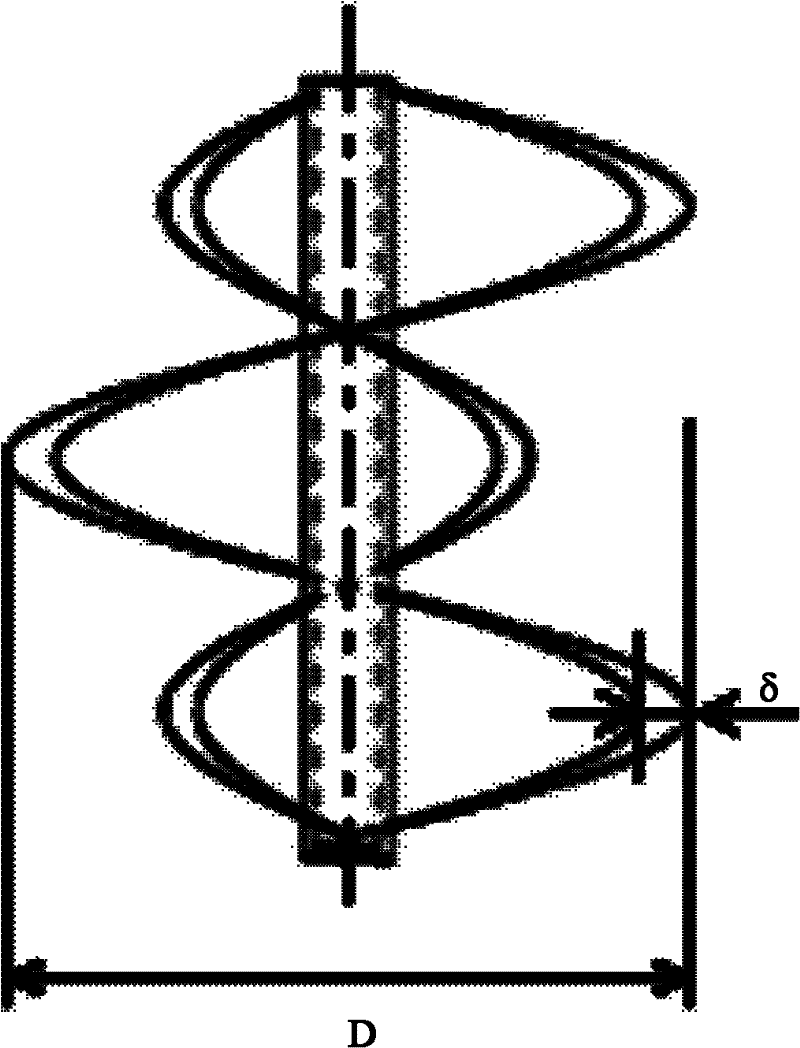

Continuous double-helix asynchronous rubber powder plasticization device

InactiveCN103341921ARealize automatic continuous plasticizing productionSolve the sticking problemTransport systemHelical blade

The invention belongs to the technical field of recovery processing of waste rubber, and relates to a continuous double-helix asynchronous rubber powder plasticization device. A helix cylinder is cut and closed by two cylinders along an outer wall to be connected to form an involutory 8-shaped double-cylinder structure, wherein a material inlet is fixedly formed in the upper side of one end of the structure, a material outlet is fixedly formed in the lower side of the other end of the structure, and bearings are respectively and fixedly arranged outside seal openings in two ends of the helix cylinder; helical blades are fixedly arranged on a threaded rod, a helix-shaped helix wing is coiled on the outer side face of the threaded rod, and two helical blade support type supports are arranged on the bearings; output power of a driving motor is respectively in butt joint with the corresponding helical blades; a control system measures and controls the rotation speed of the driving motor; a fuel spray nozzle in a fuel spray system penetrates through the outer wall of the helix cylinder of a first group of double-helix transport system; a first group of double-helix asynchronous transport system is provided with a heating system; the final group of double-helix asynchronous transport system is provided with a cooling system; the device is simple in structure, and convenient to operate, so that the automatic and continuous plasticization production of the rubber powder can be completely realized.

Owner:QINGDAO YUSHENGYUAN RUBBER

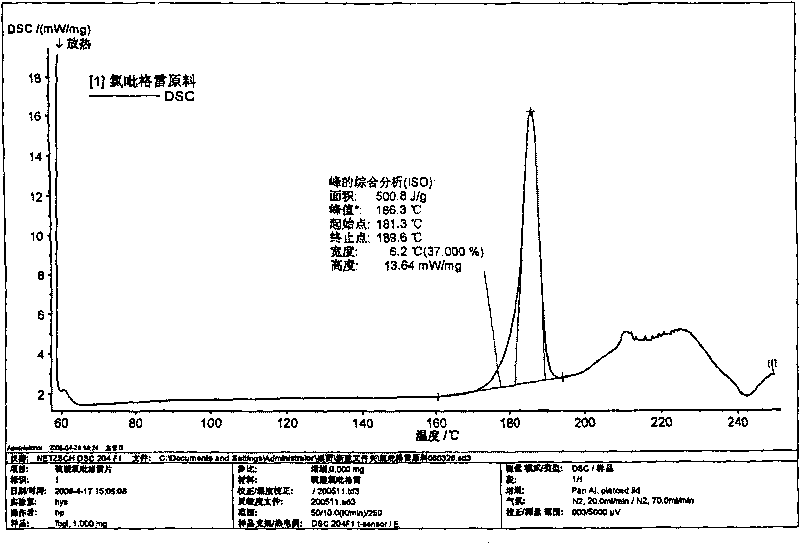

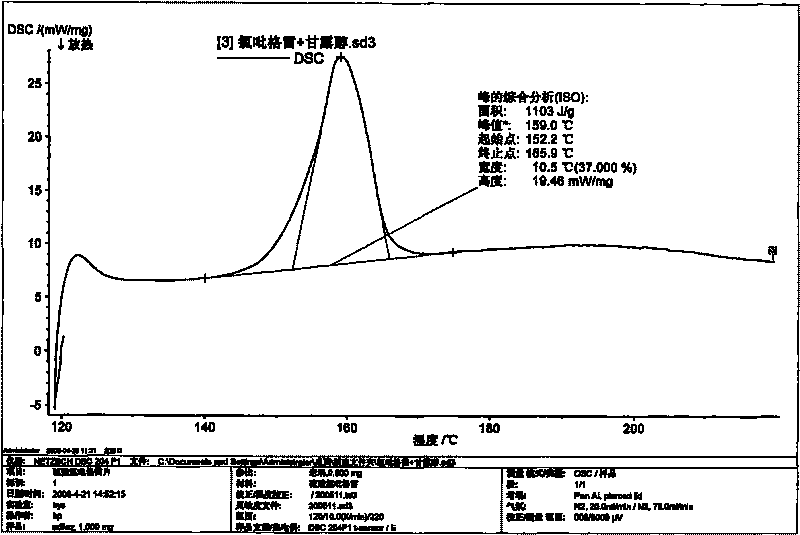

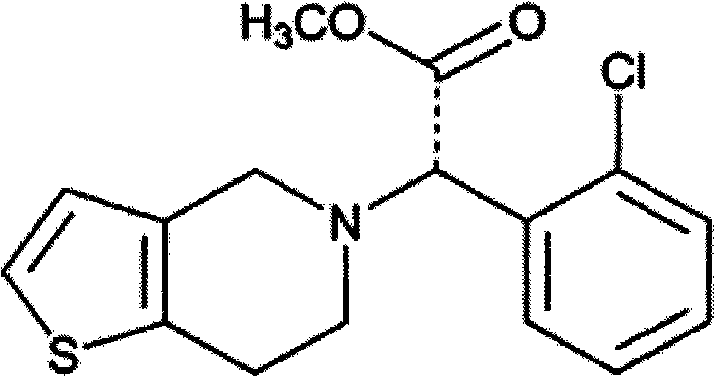

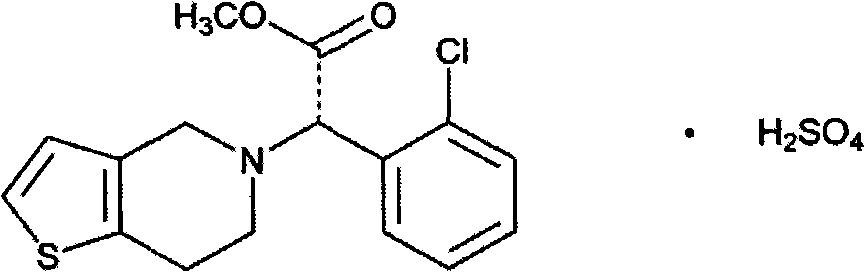

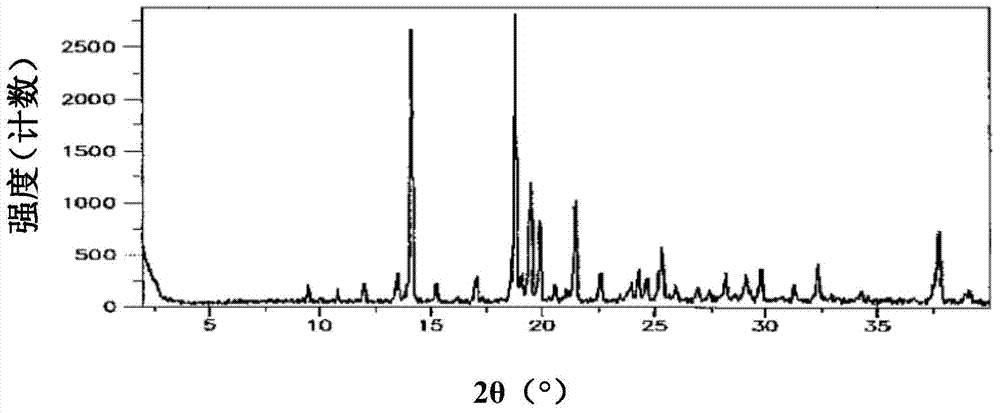

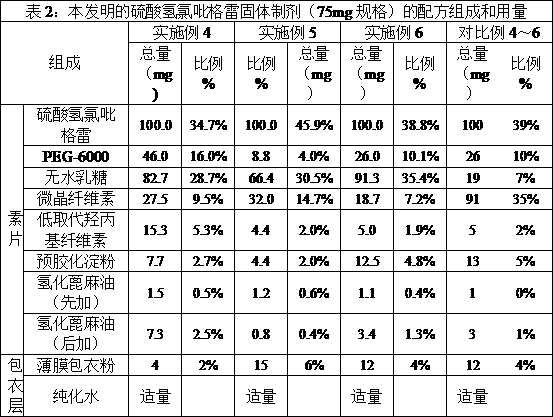

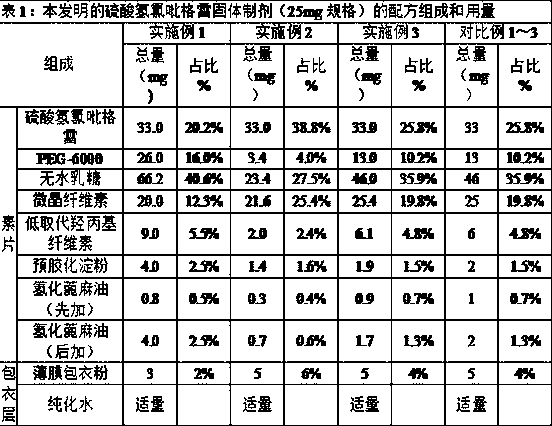

Composition containing clopidogrel bisulfate crystal particles

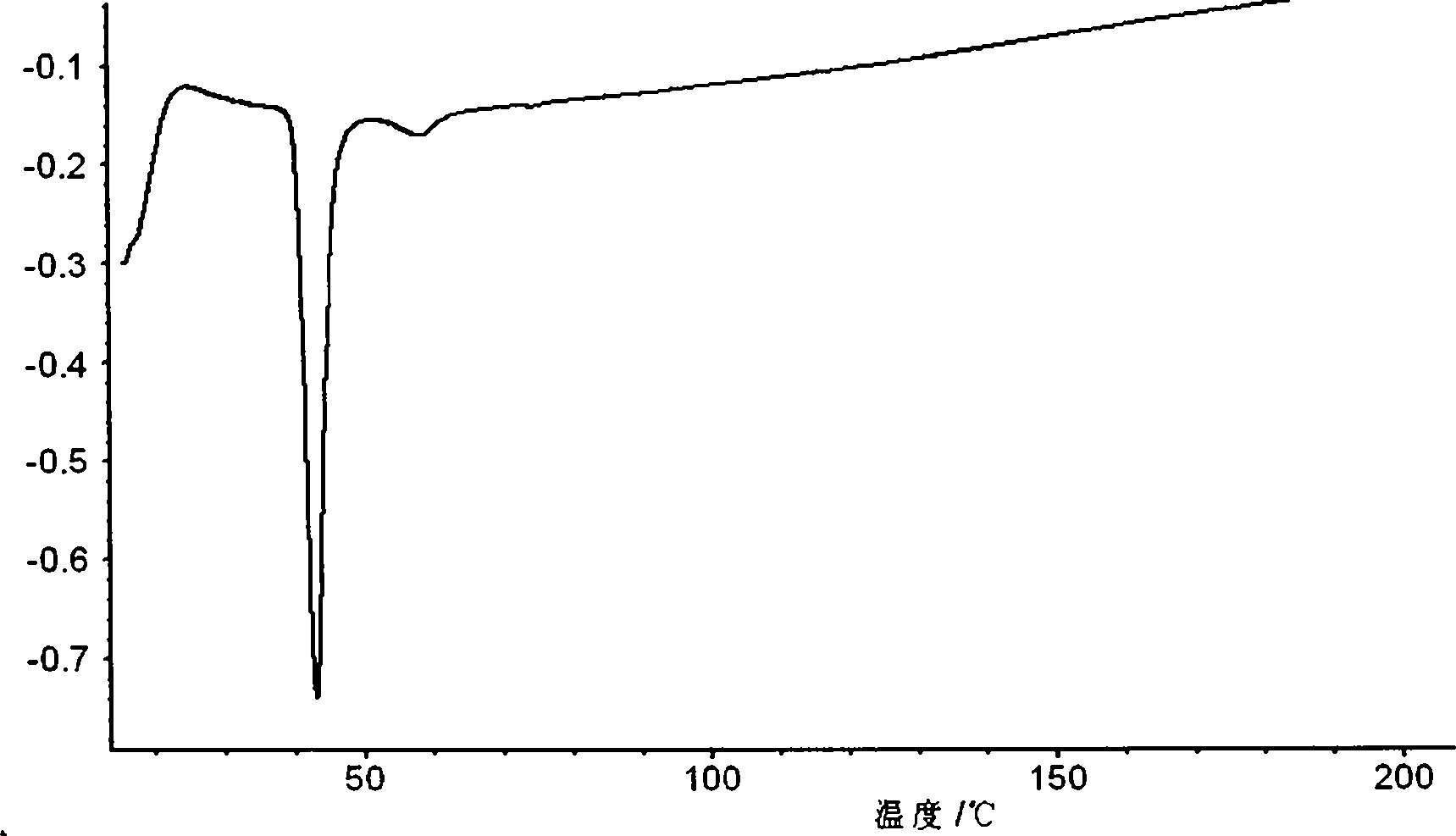

ActiveCN101851247ASolve the sticking problemAvoid mass generationOrganic active ingredientsOrganic chemistryCrystalline particleClopidogrel Bisulfate

The invention discloses clopidogrel bisulfate crystal particles with the median particle diameter of at least 120 microns. The invention also discloses a method for preparing the crystal particles, a pharmaceutical composition containing the crystal particles and a preparation method of the pharmaceutical composition.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

Tablet and preparation method

InactiveCN103099793AMeet the requirementsOvercoming technical problems of sticking and punchingInorganic non-active ingredientsPill deliveryDrugFriability

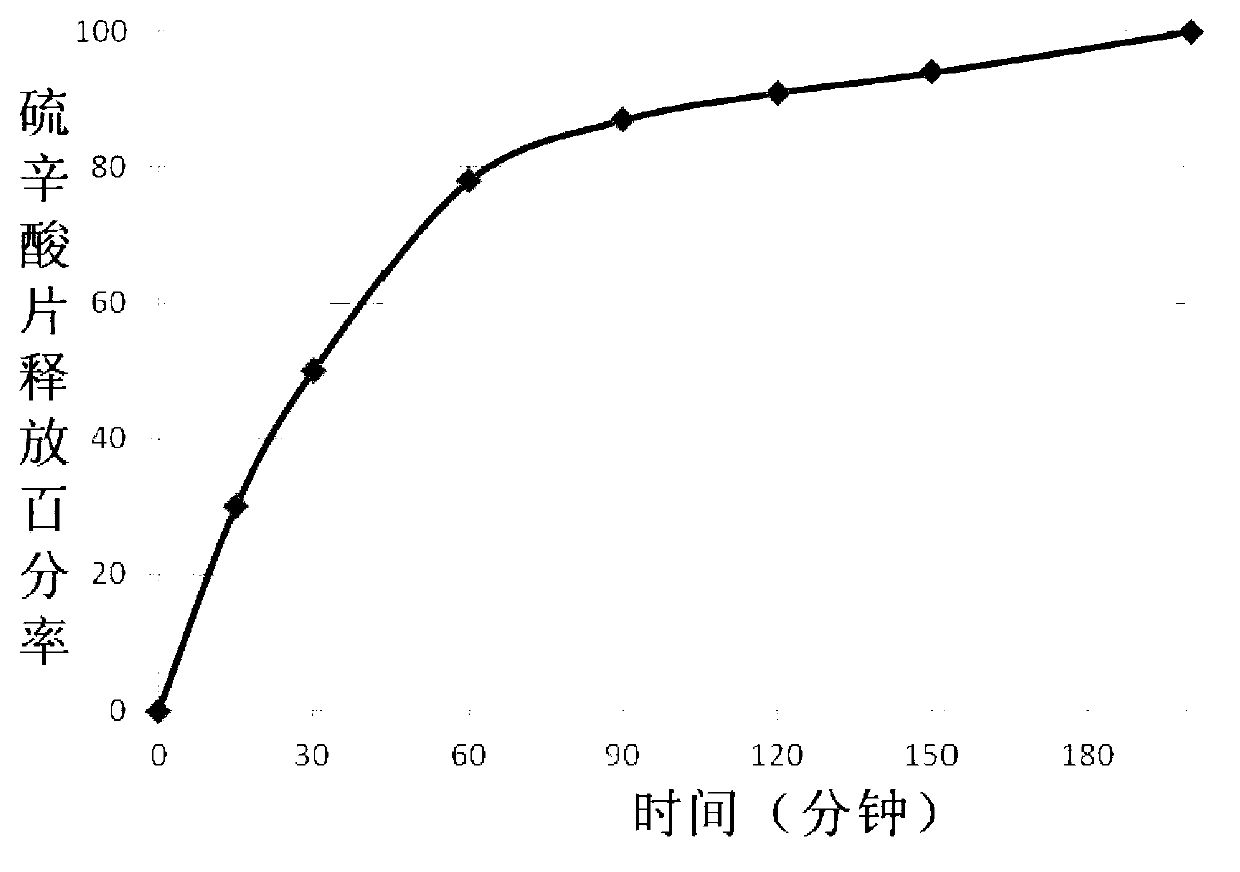

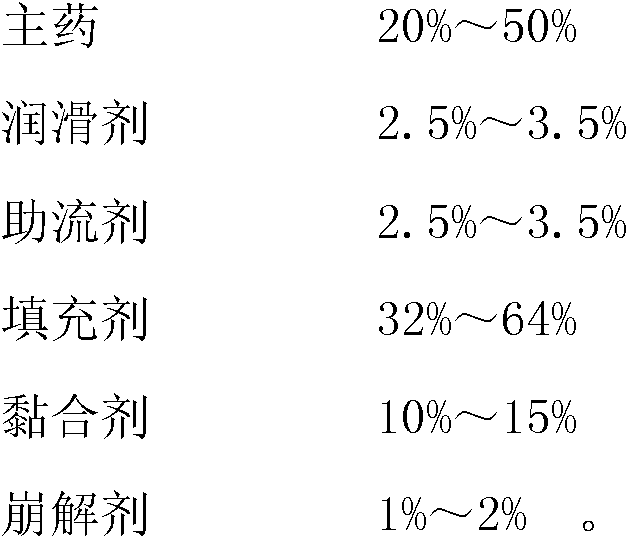

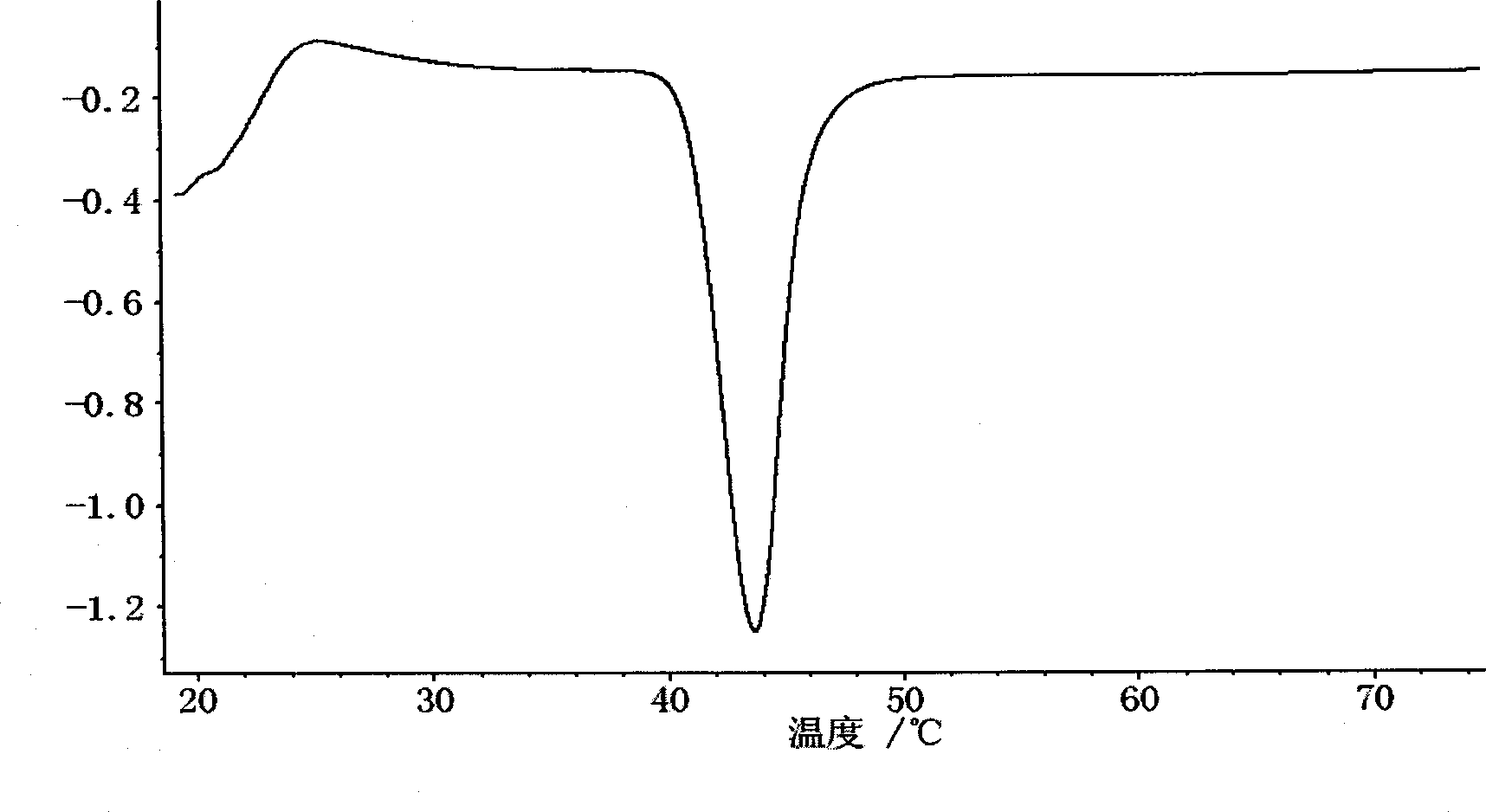

The invention discloses a tablet, which comprises a main drug, a lubricant, a flow aid, a filler, an adhesive and a disintegrating agent. The invention also discloses a preparation method of the tablet, which comprises the following steps: using a proper amount of lubricant and main drug, crushing and mixing, increasing the fluidity of the main drug; mixing the flow aid and the filler of the tablet to increase the fluidity of the filler; selecting the proper adhesive and mixing with the flow aid and the disintegrating agent, and uniformly mixing with a generated mixture and then sieving; and using a conventional rotation tablet press for tabletting under proper pressure and speed condition. The tablet and the preparation method can effectively solve the sticking problem during a straight press process of the tablet, and the hardness, the disintegration time, the friability and the dissolution rate of the obtained tablet accord with a national pharmacopeia standard.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Pure titanium seamless pipe cross rolling piercing method

ActiveCN104889163AEliminate stickingSolve the sticking problemMetal rolling arrangementsMicrometerSurface roughness

The invention discloses a pure titanium seamless pipe cross rolling piercing method which includes the steps: hot spraying a zirconium oxide coating with the thickness of 0.2-0.4mm on a working surface of a guide plate of a cross rolling piercing machine by the aid of plasma; grinding the zirconium oxide coating with surface roughness of 0.9-1.5 micrometers; smearing boron nitride lubricants on a working surface of a front guide plate of the cross rolling piercing machine; setting the ellipticity of a pure titanium seamless pipe cross rolling piercing hole pattern to be 1.09-1.2. By the method, piercing and sizing can be performed on a hot rolling mill comprising the cross rolling piercing machine, so that a high-precision pure titanium seamless pipe is directly produced on a production process line, and the problems of easiness in adhesion and low yield of guide plates of a cross rolling piercing machine in the prior art are solved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Orlistat oral preparation and preparation method thereof

InactiveCN103222964ASolve the problem of low dissolution rateWell mixedOrganic active ingredientsPowder deliveryAcrylic resinMedicine

The invention discloses an orlistat oral preparation and a preparation method thereof. The orlistat oral preparation is an orlistat tablet. The orlistat tablet comprises an orlistat acrylic resin solid dispersion, a disintegrating agent and pharmaceutically acceptable auxiliary materials. The orlistat acrylic resin solid dispersion is prepared by rapid expansion of supercritical solution and has D90 less than 10 microns. The raw materials of the orlistat oral preparation are micronized by a supercritical technology and an inert material layer is coated on the orlistat surface so that the problems of a low dissolution rate of the preparation obtained by the prior art, and sticking in tabletting are solved.

Owner:QINGDAO UNIV

Internally-reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof coiled material and production method thereof

ActiveCN108440848AReduced activityImprove composite qualityRoof covering using flexible materialsSynthetic resin layered productsFiberCompound a

The invention relates to an internally-reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof coiled material and a production method thereof. The internally-reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof coiled material is formed by sequentially and mutually overlapping and compounding a basic layer, a self-adhesive layer and a sticking prevention layer; the basic layer is prepared by compounding a surface layer and a foundation layer on two sides of a reinforcement layer or compounding the surface layer above the reinforcement layer; thesurface layer and the foundation layer are both ethylene-propylene rubber layers; the reinforcement layer is an expanded metal net or fiber grid cloth; the self-adhesive layer is a butyl self-adhesiverubber layer or a butyl hot melt adhesive; the sticking prevention layer is a PE isolating membrane. According to the internally-reinforced composite butyl self-adhesive ethylene-propylene rubber waterproof coiled material disclosed by the invention, node parts of thin parts are permanently sealed to a maximum extent, so that a waterproofing effect of an overall waterproof layer is greatly improved and the durability life of the overall waterproof layer is greatly prolonged, and the problem that the node parts of the thin parts of the waterproof layer cannot be handled well by adopting an existing ethylene-propylene-diene monomer rubber waterproof coiled material is solved.

Owner:解飞

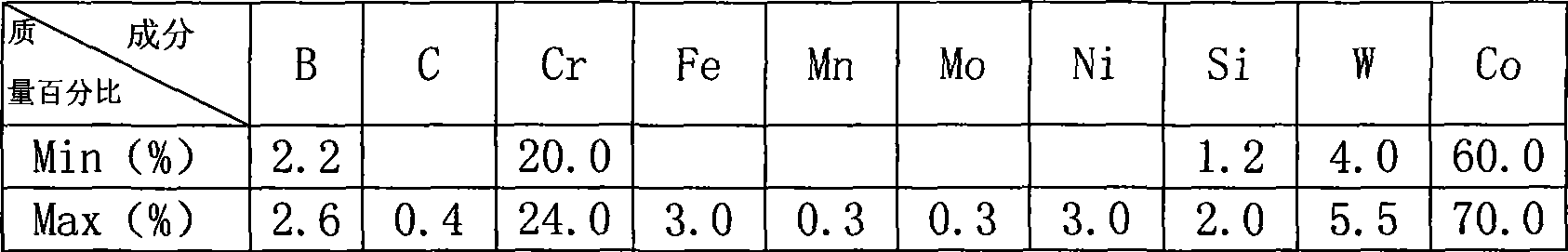

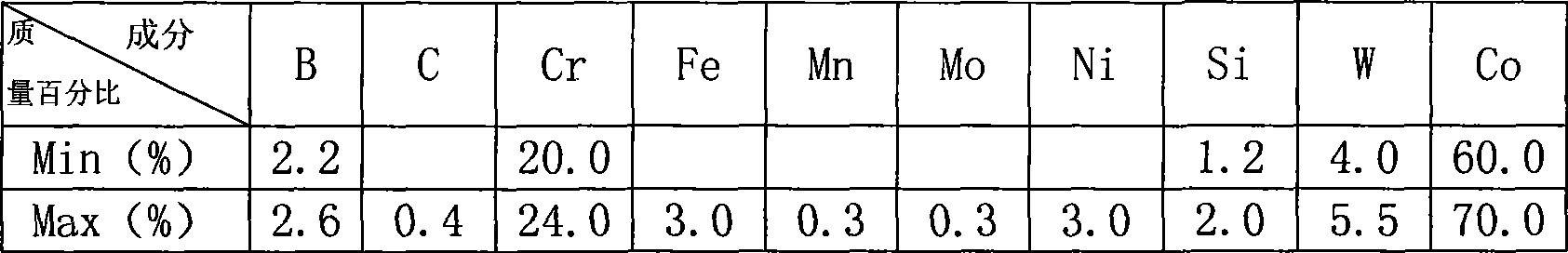

Plunger chip die for processing magnetic material and manufacture method thereof

ActiveCN101380828AHigh hardnessImprove adhesionWelding/cutting media/materialsSoldering mediaDlc coatingAlloy

The invention relates to a punch mould for processing magnetic materials, which comprises a parent body, a non-conducting magnet layer which is arranged on the parent body. The non-conducting layer uses alloy material; the surface of the non-conducting layer is provided with a DLC coat. The processing method of the mould comprises the steps: 1) the materials of the parent body carry out the quenching and tempering treatment; 2) according to the drawing paper of the mould and the design of the magnetic line of force, the materials of the parent body are made into the parent body with the needed shape and size; 3) the welding face of the parent body to be treated is removed with oil and oxidizing layers; 4) by adopting a spray welding technique, the non-conducting layer is processed; 5) according to the size of the mould, the machining is carried out; according to the drawing paper and the size of the mould cavity, the assembly manufacturing are carried out; 6) polishing treatment is carried out on the surface of the punch; 7) the non-conducting magnet layer of the punch adopts the DLC spray finishing treatment. The mould solves the problems that in the existing technology, the surface of the punch often has mold sticking; the punch is easily deformed; the magnet line of force is not clear and the service life of the punch is short.

Owner:德昌电机(南京)有限公司

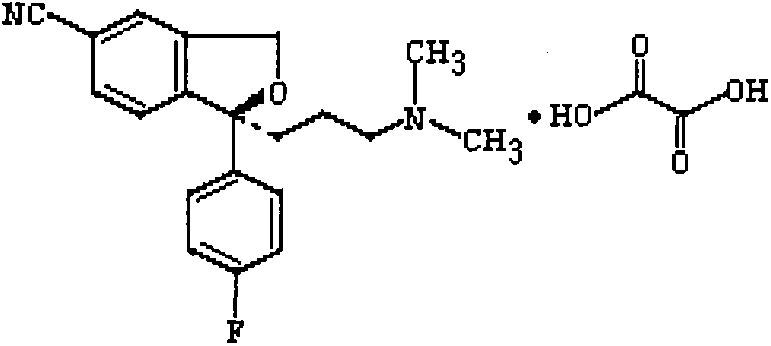

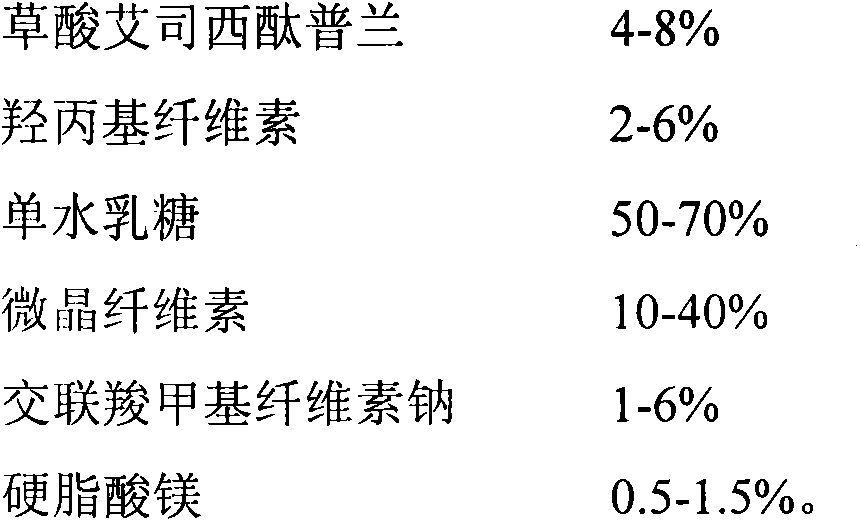

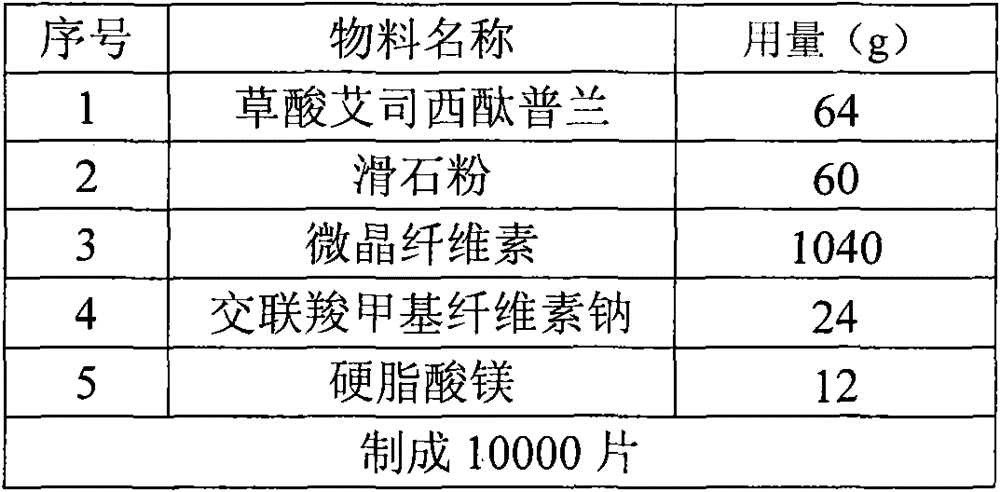

Tablet containing escitalopram oxalate and preparation method thereof

ActiveCN104523638ASolve Content Uniformity ProblemsSolve the sticking problemOrganic active ingredientsPharmaceutical non-active ingredientsAdhesiveChemistry

The invention discloses a tablet containing escitalopram oxalate and a preparation method thereof. According to the invention, the tablet containing escitalopram oxalate uses hydroxy propyl cellulose as an adhesive and uses escitalopram oxalate with median particle size less than or equal to 20mum, and the prepared tablet containing escitalopram oxalate has the advantages of beautiful appearance and stable quality. The invention also provides the preparation method of oral tablet, and has the advantages of simple process and adaptability of commercialized production.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

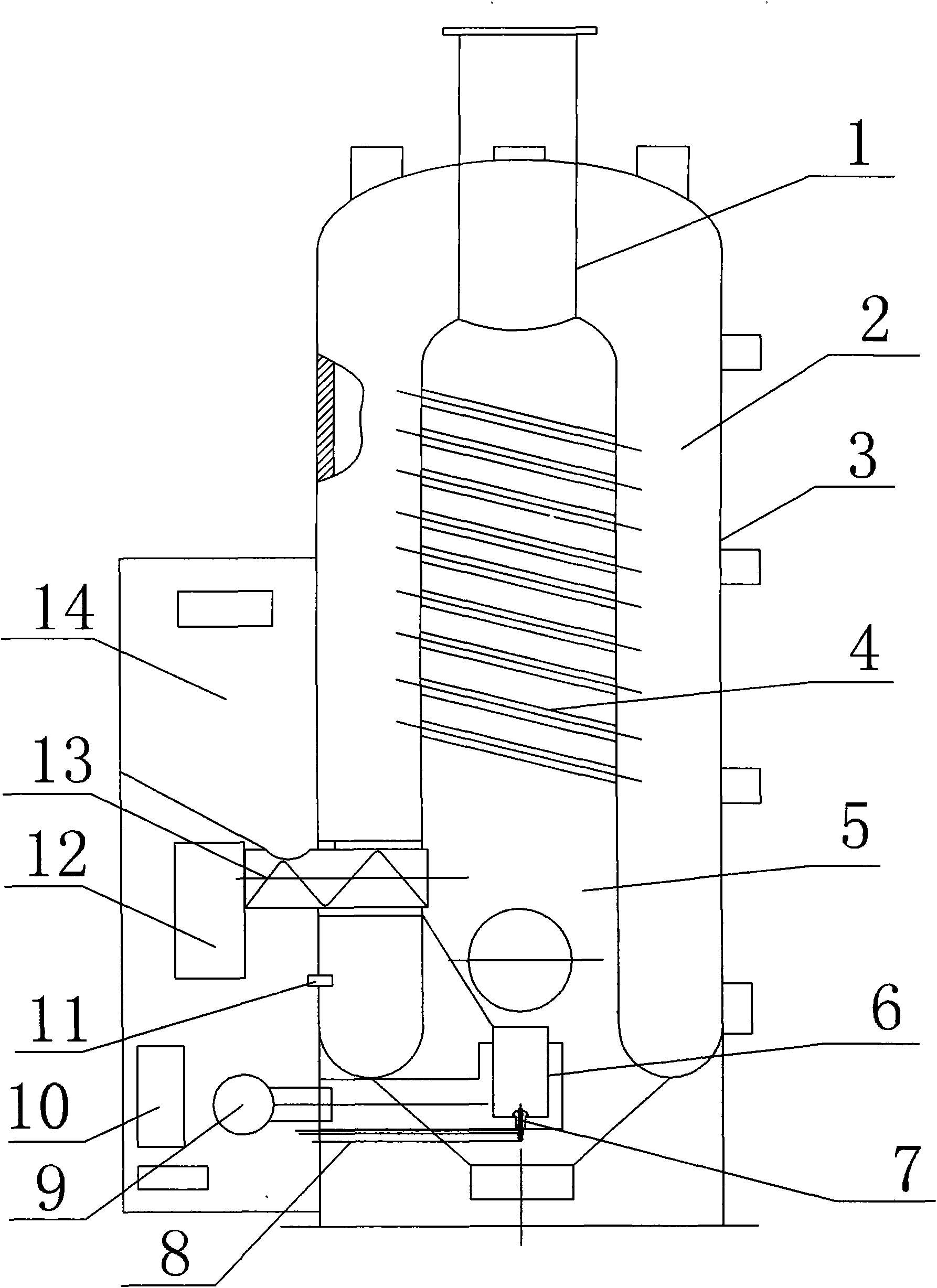

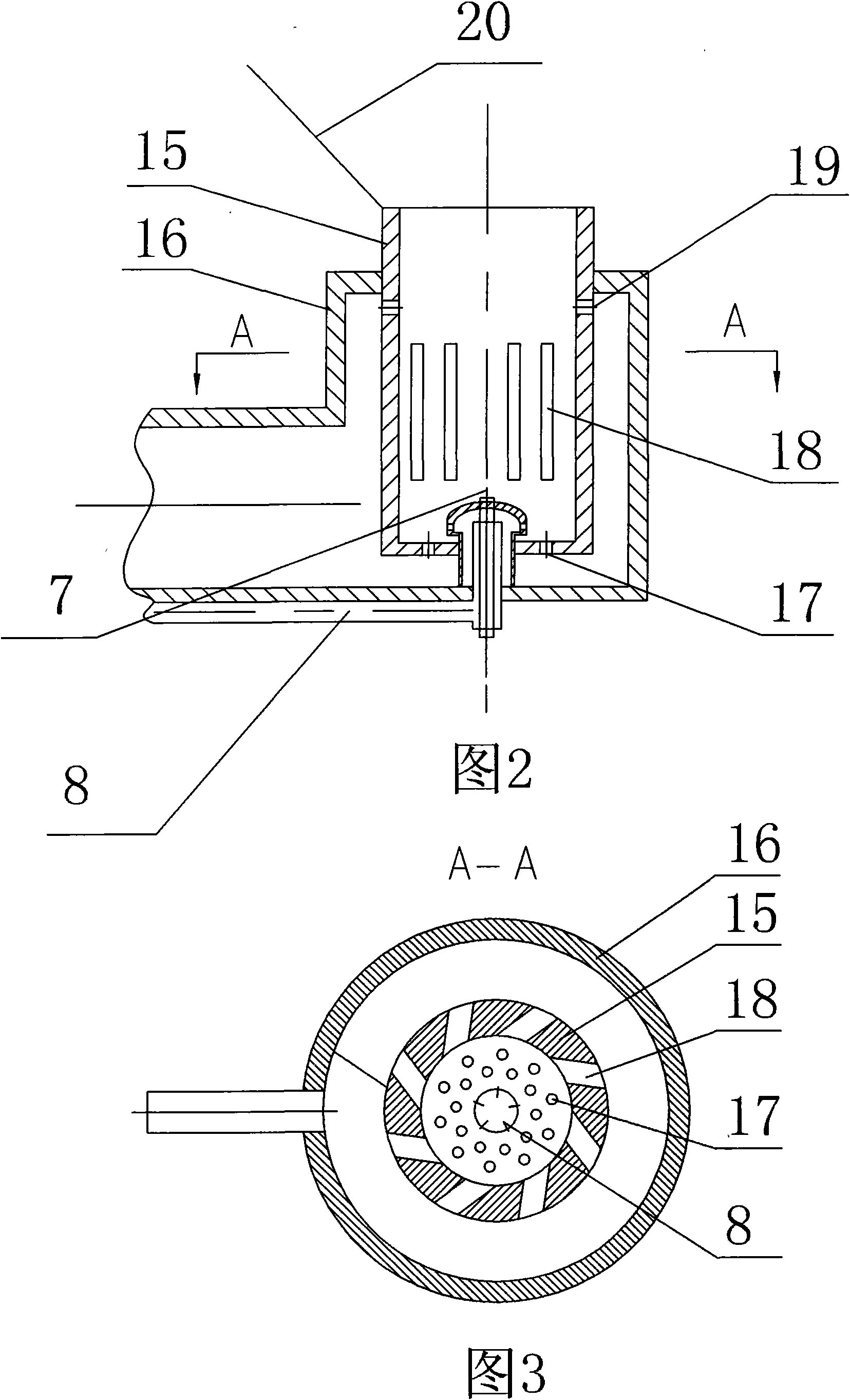

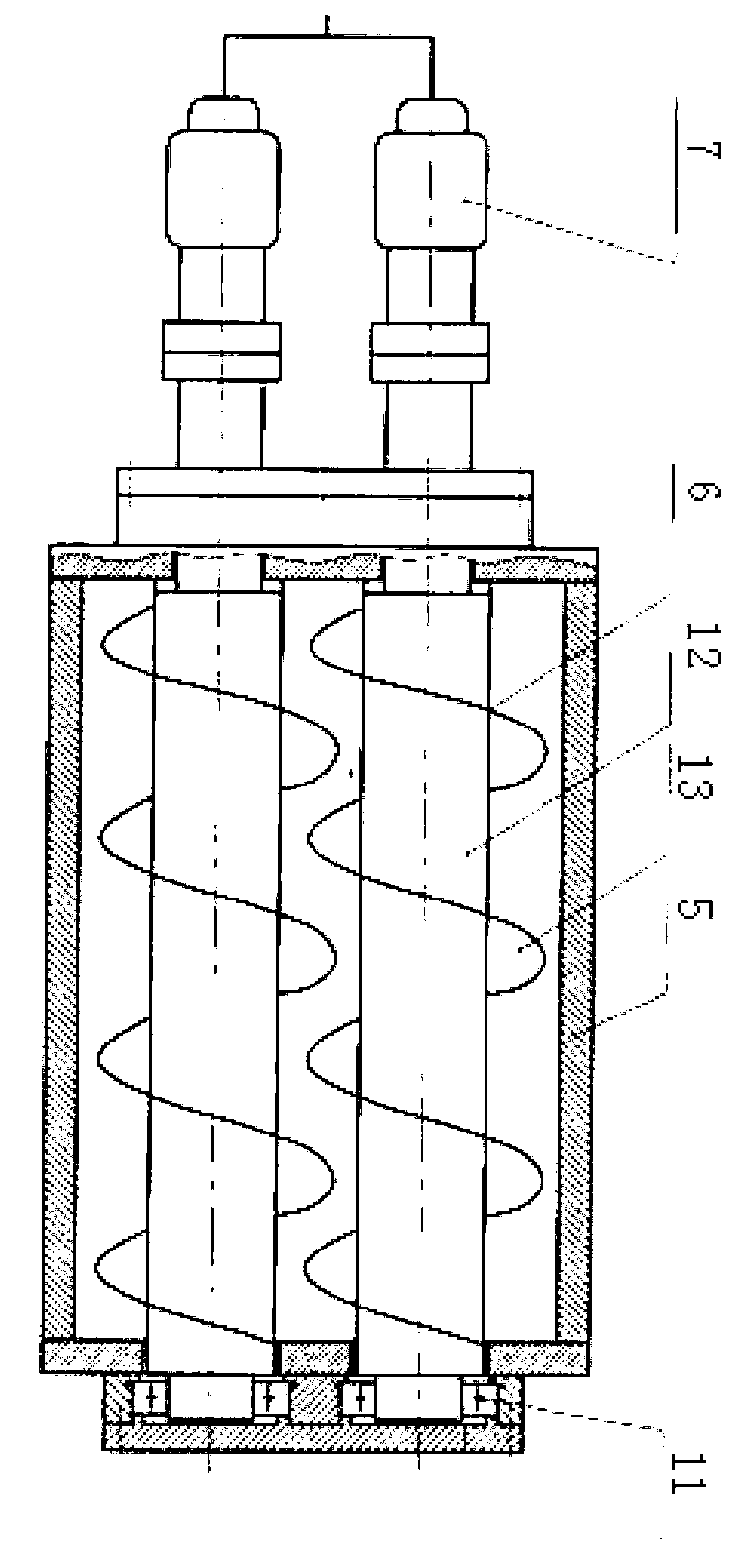

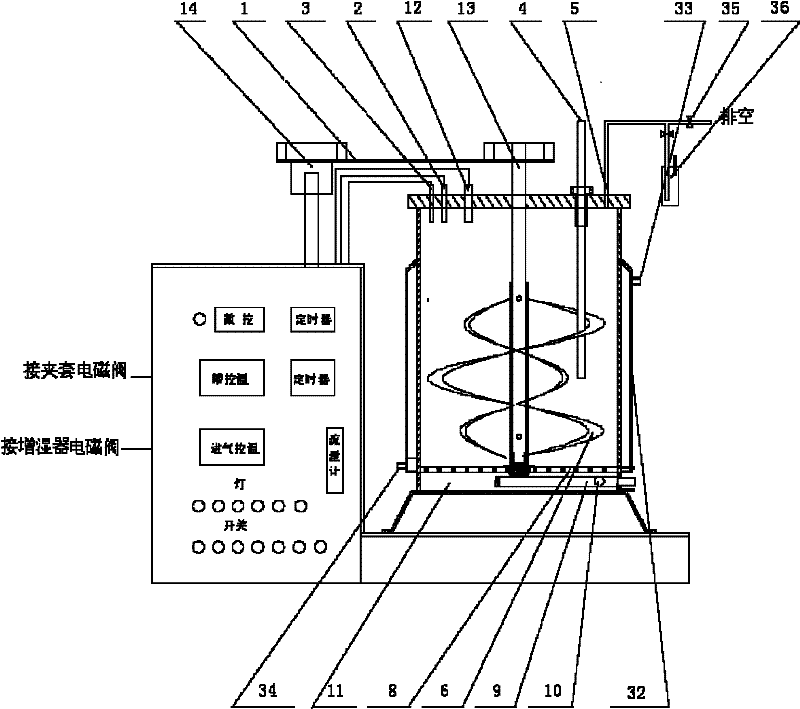

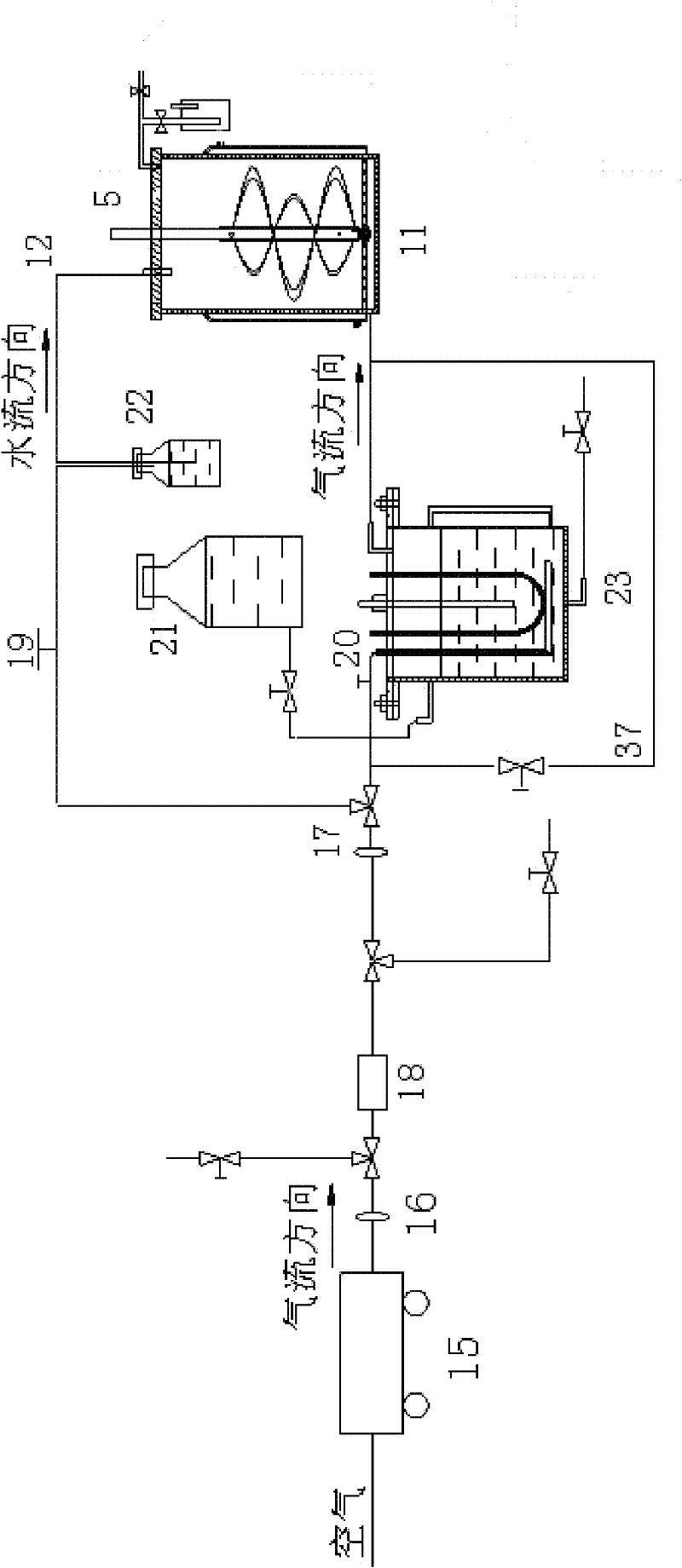

Enclosed solid state fermentation bioreactor

InactiveCN102199521ASolve the sticking problemSolve the problem of overheatingBioreactor/fermenter combinationsBiological substance pretreatmentsCollection systemSolenoid valve

The invention discloses an enclosed solid state fermentation bioreactor. The bioreactor comprises a solid state fermenter, an air inlet system, a humidification system and a tail gas detection and collection system. The solid state fermenter is a sealed container, and a central shaft of the fermenter is provided with a reverse double spiral stirring paddle which allows materials to carry out bidirectional movement, so an adhesion problem which appears in stirring solid materials can be solved and a mixing effect can be enhanced. A top tail gas outlet of the fermenter is connected with an evacuation tube and a CO2 collector, and a fermentation process and a fermentation state are displayed through detecting the CO2 content. A jacket is arranged on the outside the fermenter, a bypass is arranged on a humidifier, and the fermentation bed temperature can be automatically adjusted through feeding back information to a control system by a thermocouple which is on an upper part of the fermenter to adjust solenoid valves of jacket cooling water and the humidifier bypass. The humidifier temperature and periods and times of stirring and spraying can be preset according to material fermentation characteristics. A bed overtemperature problem, which appears in a fermentation peak period and is most difficult to solve in solid fermentation processes, can be solved by removing heat of fermentation through a plurality of modes such as jacket cooling water adjusting, cold air accessing, atomized water spraying, material stirring and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

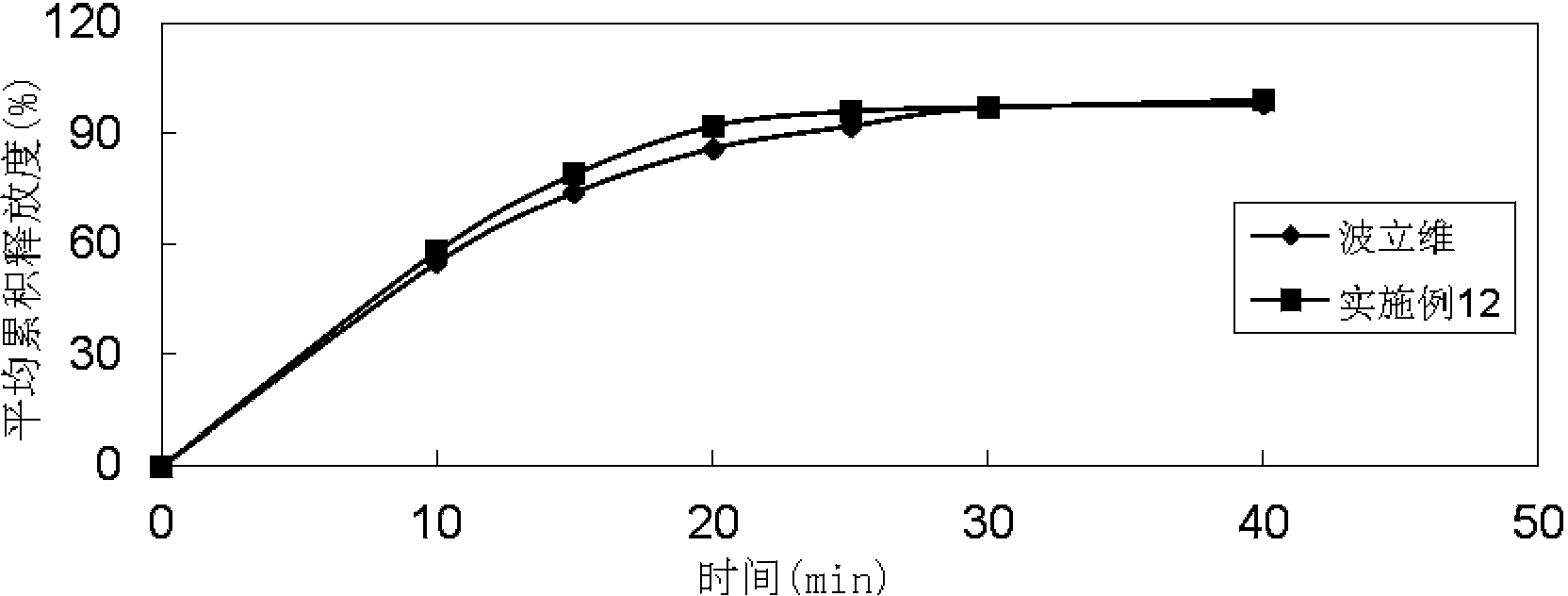

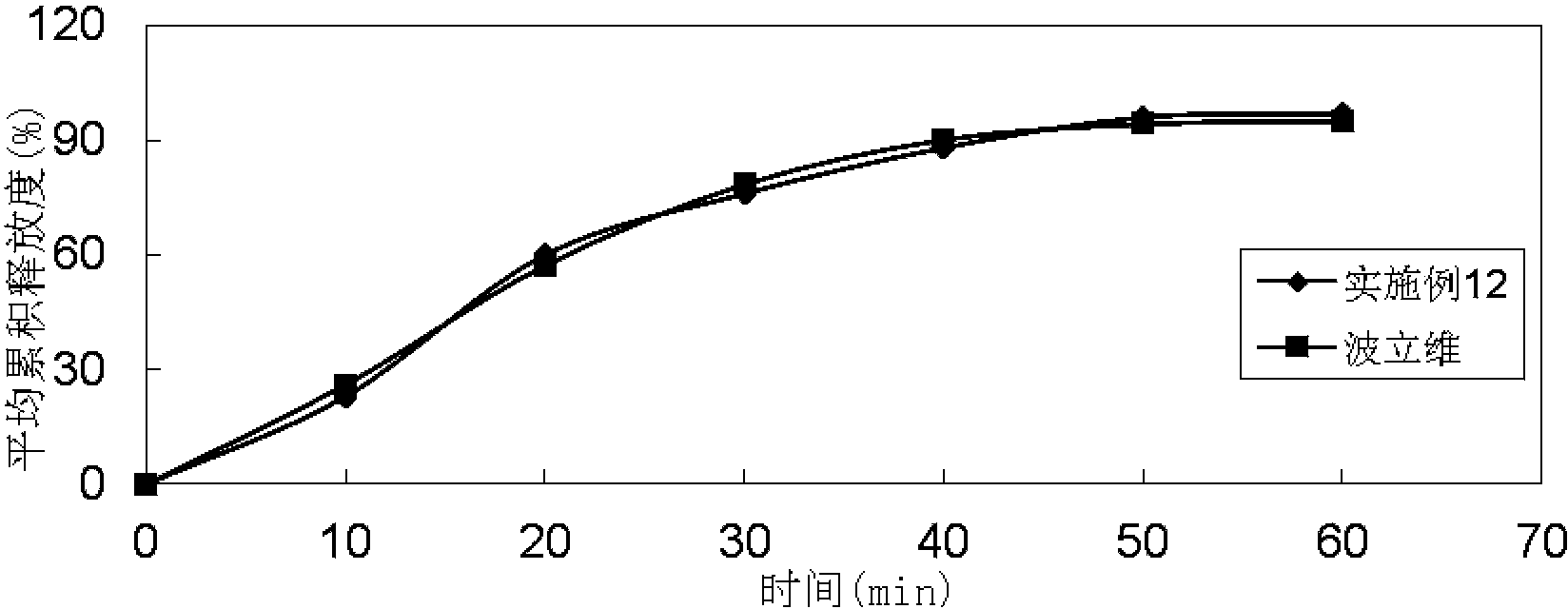

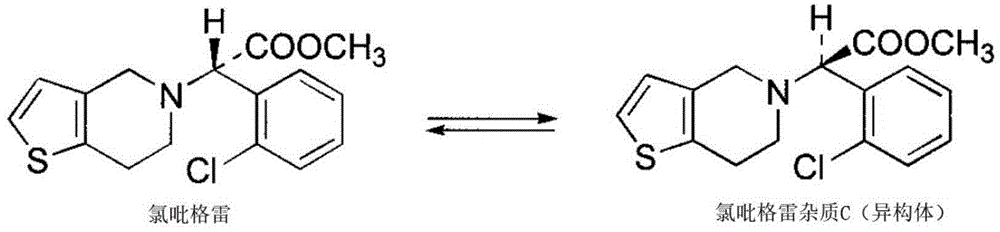

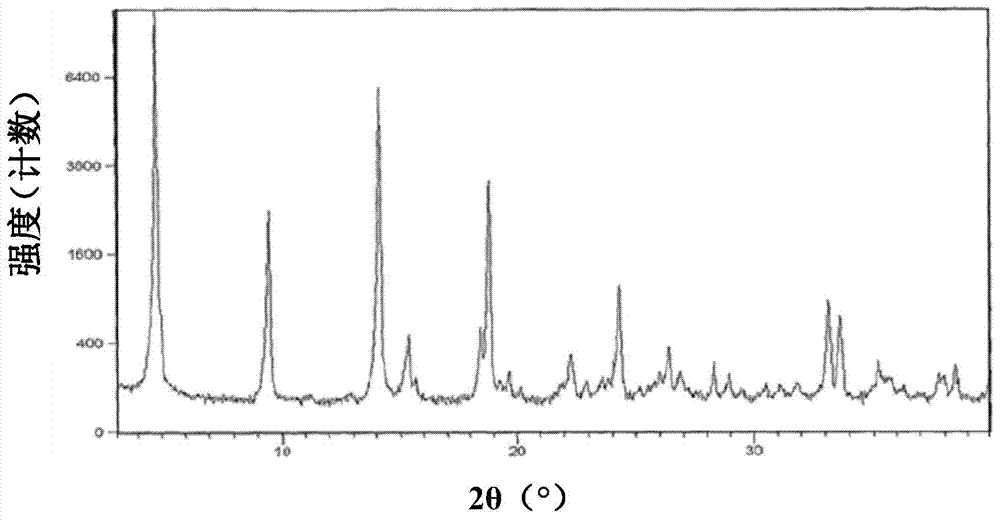

Clopidogrel tablet and preparation method thereof

InactiveCN103877056AAvoid the phenomenon of melting and aggravating stickingGood compatibilityOrganic active ingredientsInorganic non-active ingredientsCoated tabletsMANNITOL/SORBITOL

The invention discloses a clopidogrel tablet and a preparation method thereof. The clopidogrel tablet is a coated tablet which consists of a clopidogrel table body and a coating material, wherein the clopidogrel table body comprises the following ingredients in parts by weight of clopidogrel free alkali: 75 parts of pharmaceutically acceptable salt of clopidogrel, 6-9 parts of sodium stearyl fumarate, 3-6 parts of talcum powder, 90-135 parts of diluent, 2-6 parts of bonding agent and 7-17 parts of disintegrating agent, wherein the diluent is made of combined mannitol and microcrystalline cellulose in a weight ratio of (2:1)-(1:1); the weight of the coating material accounts for 2.7-3.3% of the weight of the clopidogrel tablet. By adopting the clopidogrel tablet, not only is the problem of sticking in the tabletting process solved, but also the mixed lubricant and clopidogrel have good compatibility, the phenomena that active ingredients are degraded or the configuration is inversed are avoided, and the clopidogrel tablet is high in stability, good in quality, and high in similarity in dissolving behavior to that of an original triturate plavix.

Owner:WUHAN SUNRISE BIO PHARMA SCI & TECH

Solid pharmaceutical composition with clopidogrel

ActiveCN104644595AInhibit productionQuality improvementOrganic active ingredientsPharmaceutical non-active ingredientsMedicineMutarotation

In order to overcome shortcomings of material sticking of a clopidogrel crude drug and hydrolysis of the crude drug in a preparation thereof in storage, the invention designs a solid pharmaceutical composition with clopidogrel and provides a prescription and a process for further preparing the solid pharmaceutical composition into a tablet. The tablet has good forming property and is capable of inhibiting hydrolysis of the crude drug in the process of existence; and unexpectedly, the tablet also inhibits mutarotation of the crude drug. The tablet of the invention is simple in preparation method and can be manufactured by conventional preparation methods without special devices, so that the tablet has the advantages of easy industrialization, high production efficiency, good stability and controllable quality. Thus the solid pharmaceutical composition has outstanding substantive features and obvious inventive steps.

Owner:吕霄芳

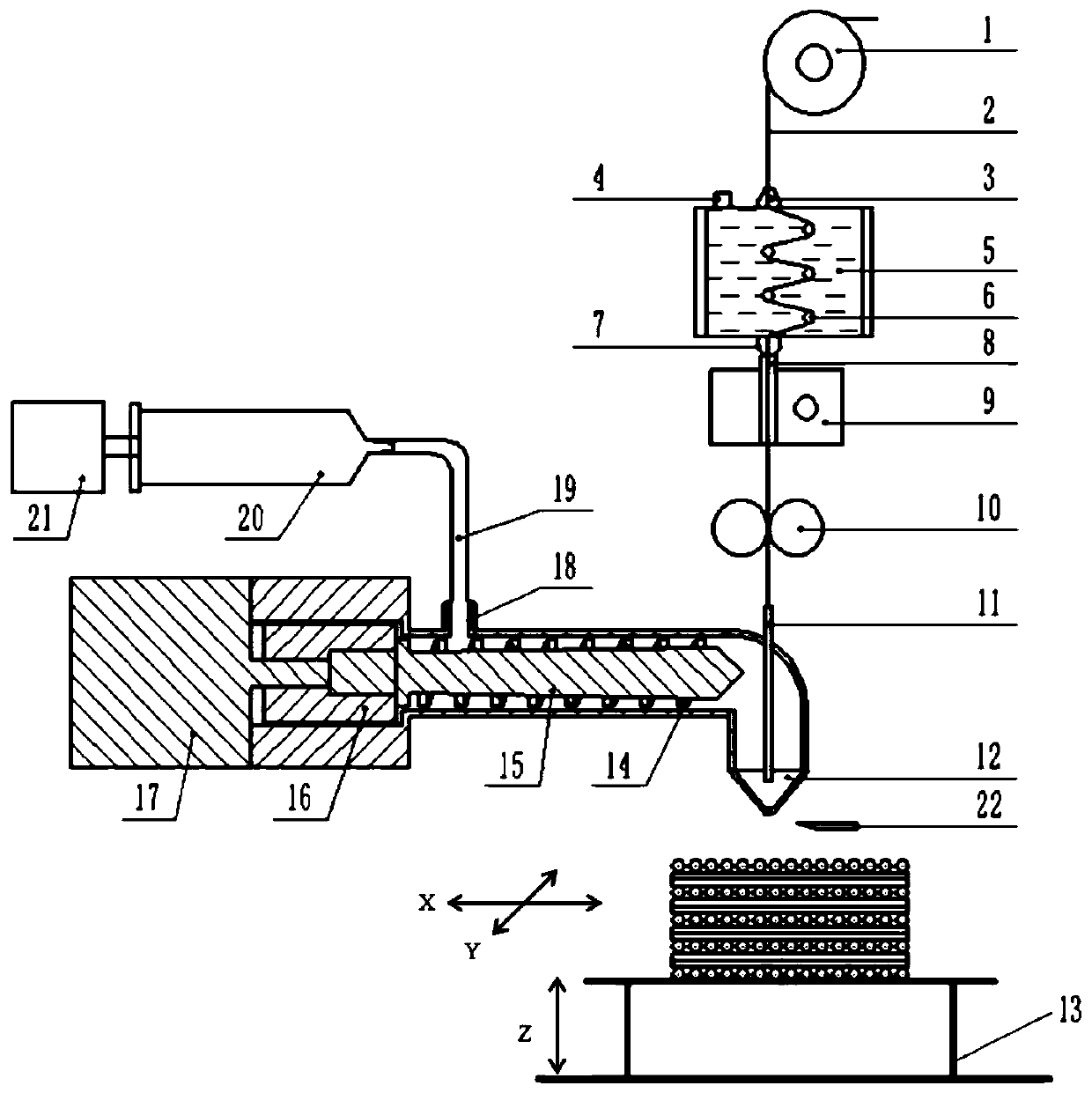

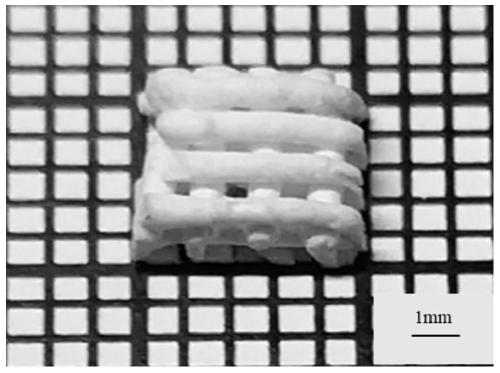

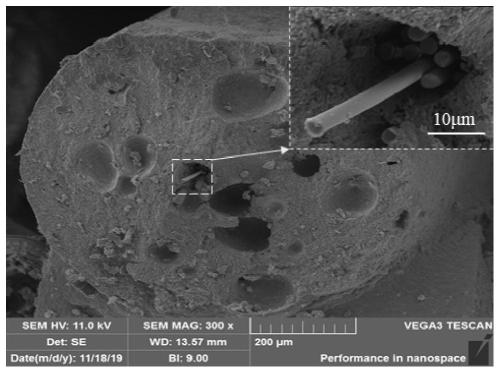

Three-dimensional (3D) printing device and method for bionic porous continuous carbon fiber reinforced ceramic bone scaffold

ActiveCN111168807ARealize integrated designAchieve extrusionAdditive manufacturing apparatusBathroom accessoriesCarbon fibersIntegrated design

The invention discloses a three-dimensional (3D) printing device and method for a bionic porous continuous carbon fiber reinforced ceramic bone scaffold. According to the device provided by the invention, a continuous fiber pretreatment device and a ceramic slurry extruding device are combined, so that the integrated design of the continuous fiber reinforced ceramic bone scaffold 3D printing device is realized. A fiber pretreatment material adopted by the method provided by the invention is a ceramic slurry which is the same as a base material but has lower solid content, and the ceramic slurry with lower solid content has better wettability and is not only capable of being adhered to the outer part of a carbon fiber multifilament and but also capable of permeating into the carbon fiber multifilament so as to realize adhesion, so that a biological performance of a composite material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Low-silicon high-thermal-conductivity die-casting aluminum alloy and preparation method thereof

ActiveCN112626391AImprove liquidityImproving Die Casting Process PerformanceSiliconThermal conductivity

The invention discloses a low-silicon high-thermal-conductivity die-casting aluminum alloy and a preparation method thereof. The low-silicon high-thermal-conductivity die-casting aluminum alloy is prepared from, by mass percentage, 1.5-3% of Si, 0.4-1.3% of Fe, 0-0.1% of Sr, 0-1% of RE, 0-0.15% of impurity elements, and the balance Al. According to the preparation method, the content of Si and the content of Fe are adjusted to be kept in a low-content state, and the adverse effect of Si and Fe on the thermal conductivity of the aluminum alloy is reduced; and meanwhile, the aluminum alloy remains high die-casting manufacturability, and die-casting can be conducted at the temperature of 670-720 DEG C.

Owner:重庆慧鼎华创信息科技有限公司 +1

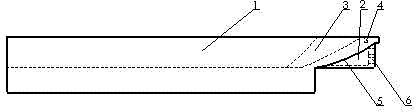

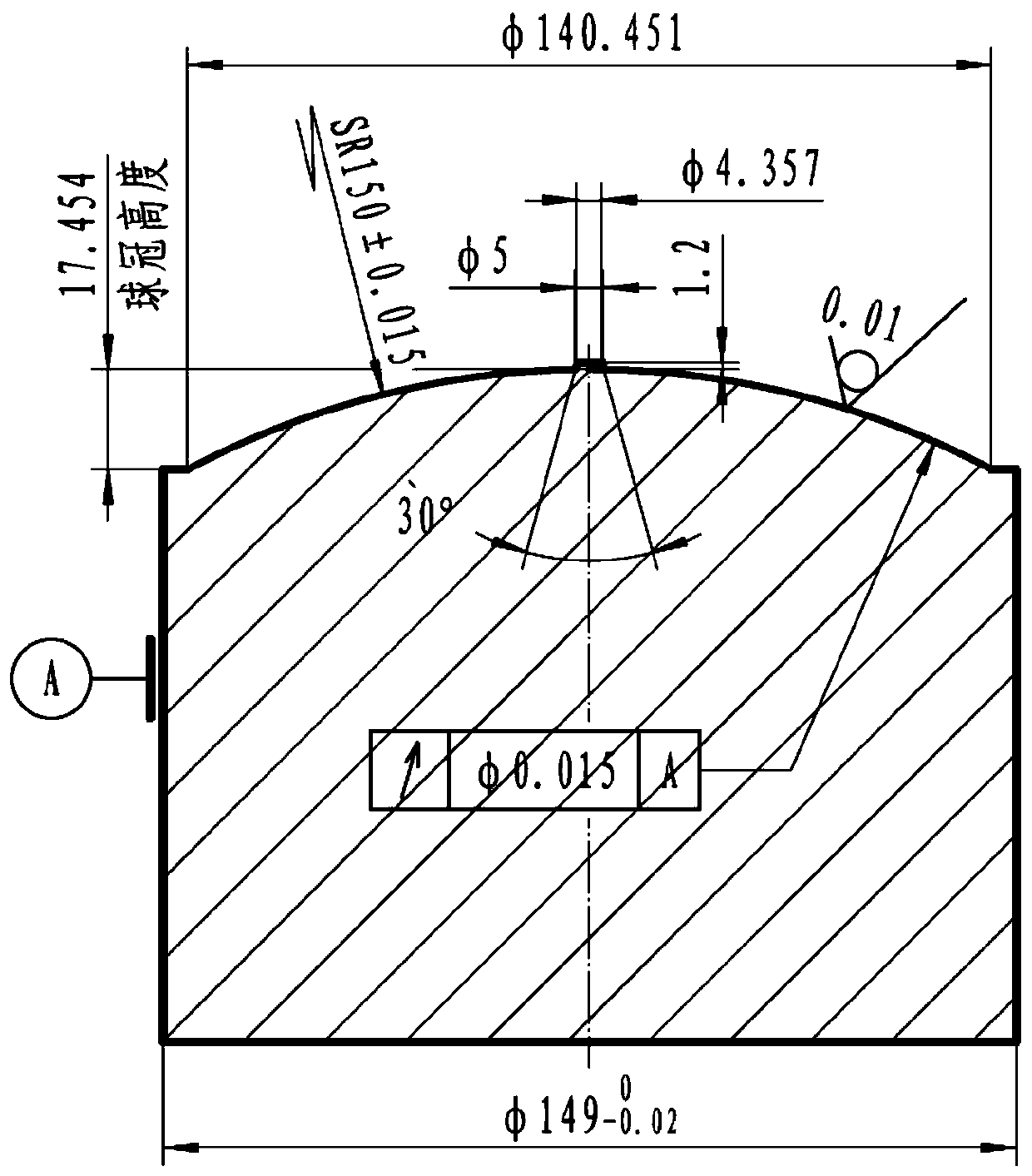

Integral optical glass forming mould

InactiveCN104817256ASolve the sticking problemSolving the Problem of Forming StreaksGlass pressing apparatusTemperature controlOptoelectronics

The invention discloses an integral optical glass forming mould, belongs to the field of an optical glass melting and forming technology, and mainly solves the problems that the glass metal sticky mold and moulded stripes can be easily caused when an optical glass strip is formed. The integral optical glass forming mould is characterized by mainly comprising a forming part and a cooling part, wherein the forming part is an integral forming groove, one end of the forming groove is opened, and an end working surface at another end of the forming groove is a concave working cambered surface; the bottom surface of the forming groove below the end working surface is a lower convex cooling cambered surface, the cooling part is a cooling cavity closely adhered to the cooling cambered surface, and a cooling hole is formed in the cooling cavity; a temperature control thermocouple is arranged above the forming part. The integral optical glass forming mould provided by the invention has the characteristics of the optical glass strip of stable production, high forming temperature and low forming viscosity, thereby being mainly used for the forming of lanthanide series optical glass.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Self-service food buying machine

ActiveCN103810791AAvoid burnsPlay the role of overload protectionCoin-freed apparatus detailsApparatus for dispensing discrete articlesControl systemAgricultural engineering

The invention discloses a self-service food buying machine. The self-service food buying machine comprises a machine frame, wherein a rice guiding mechanism, a roller drive mechanism, a rice pushing mechanism and a control system are sequentially arranged in the machine frame from top to bottom, and the rice pushing mechanism is controlled by the control system. The rice guiding mechanism comprises a rice storage box, a roller and a discharging pipe, wherein the rice storage box is arranged on the machine frame, the inlet of the roller is connected with the outlet of the rice storage box, and the outlet of the roller is connected with the inlet of the discharging pipe. The roller drive mechanism comprises an alternating-current motor, a belt wheel, a gear and a straight gear, wherein the roller is driven by the alternating-current motor, the belt wheel, the gear and the straight gear, the two ends of the belt wheel are arranged on a rotating shaft of the alternating-current motor and the gear respectively in a sleeved mode, the gear is meshed with the straight gear, and the straight gear is arranged on the roller. The self-service food buying machine is fully automatic; customers just need to select buttons corresponding to required food on a control panel and swipe cards, and therefore the self-service food buying machine is convenient and easy to operate.

Owner:ZHEJIANG UNIV OF TECH

Method for improving quality of inner surface of titanium alloy seamless steel tube

ActiveCN106363022ASolve the sticking problemReduced incidence of wartsWork lubrication devicesMetal rolling arrangementsAluminum foilTitanium alloy

The invention provides a method for improving the quality of the inner surface of a titanium alloy seamless steel tube. The method comprises the following steps that a glass powder lubricating agent is prepared and wrapped into a cylinder with the height being 70 mm and the bottom area diameter being 50 mm through aluminum foil paper, and the outer surface of the cylinder is wrapped with asbestos cloth; a centering hole is punched; piercing is conducted; the glass powder lubricating agent prepared in the first step is injected into the centering hole of a titanium alloy seamless steel tube blank after the blank is discharged out of a circular furnace, and a cross-rolling piercing unit is started for piercing rolling of the titanium alloy seamless steel tube; and after piercing is completed, the high-temperature titanium alloy tube is subjected to continuous rolling, sizing and straightening, and the final finished titanium alloy seamless steel tube is formed. The method for improving the quality of the inner surface of the titanium alloy seamless steel tube has the beneficial effects that the problem that the top of a cross-rolling piercer for hot-rolling piercing of the titanium alloy seamless steel tube is prone to adhesion and caking, and consequentially defects on the inner surfaces of the oil tube are increased is solved, the warping rate of the inner surface of the finished oil tube is decreased to 10%, the inward folding defect rate is decreased by 50%, the production cost is reduced, and the delivery time of finished products is shortened by one time.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Preparation method of immediate release oral preparation containing sitagliptin or sitagliptin pharmaceutical salt

ActiveCN104771377AGood compressibilityGuaranteed therapeutic effectOrganic active ingredientsMetabolism disorderSitagliptinImmediate release

The invention belongs to the field of pharmaceutical preparations, and particularly relates to a preparation method of an immediate release oral preparation containing sitagliptin or sitagliptin pharmaceutical salt. The immediate release oral preparation is characterized in that in a preparation process of the immediate release oral preparation, when sitagliptin or sitagliptin pharmaceutical salt is in a hydrate crystal form, a wetting agent is water, and when sitagliptin or sitagliptin pharmaceutical salt is in an anhydrous crystal form, the wetting agent is ethanol. According to the preparation method, various technical features in the preparation method supplement each other, influence each other and synergistically act, and the crystal form of an active ingredient is not transformed before and after the preparation is prepared, so that the treatment effect is ensured; in addition, the compressibility of a material is improved significantly; the disintegration time is shortened obviously; and the problem of sticking is solved effectively.

Owner:华益泰康药业股份有限公司

Probiotic pressed candy and production method thereof

InactiveCN106359796ARaise the barrierAvoid damageConfectionerySweetmeatsAdditive ingredientMagnesium stearate

The invention discloses probiotic pressed candy and a production method thereof; the probiotic pressed candy is made from, by weight, 40-70 parts of starch, 10-30 parts of xylooligosaccharide, 20-40 parts of erythritol, 10-20 parts of glutamine, 5-15 parts of skim milk powder, 3-5 parts of probiotic powder, and 0.5-1.5 parts of magnesium stearate. The probiotic pressed candy is high in probiotic count and activity, and has the physiological functions of promoting intestinal digestive system functionality, maintaining gastric and intestinal mucosal health, enhancing human immunity and the like.

Owner:江苏阜丰生物科技有限公司

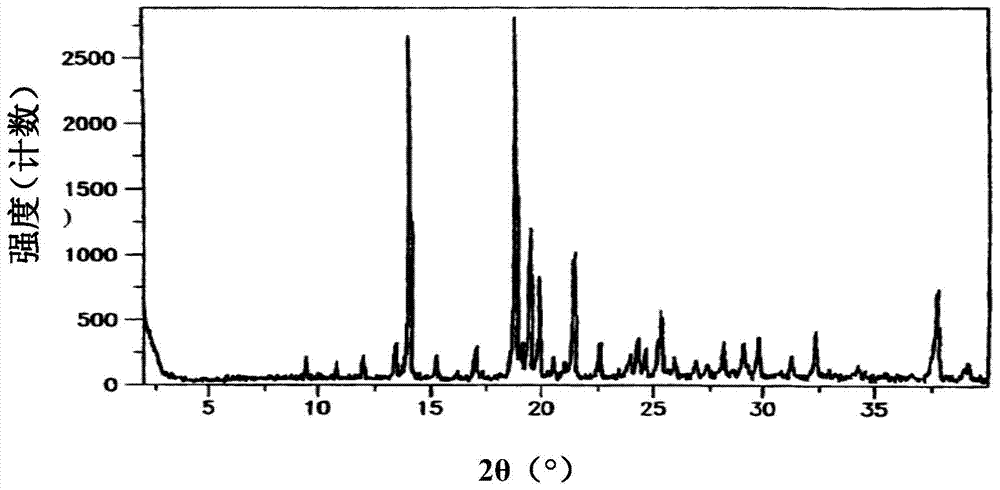

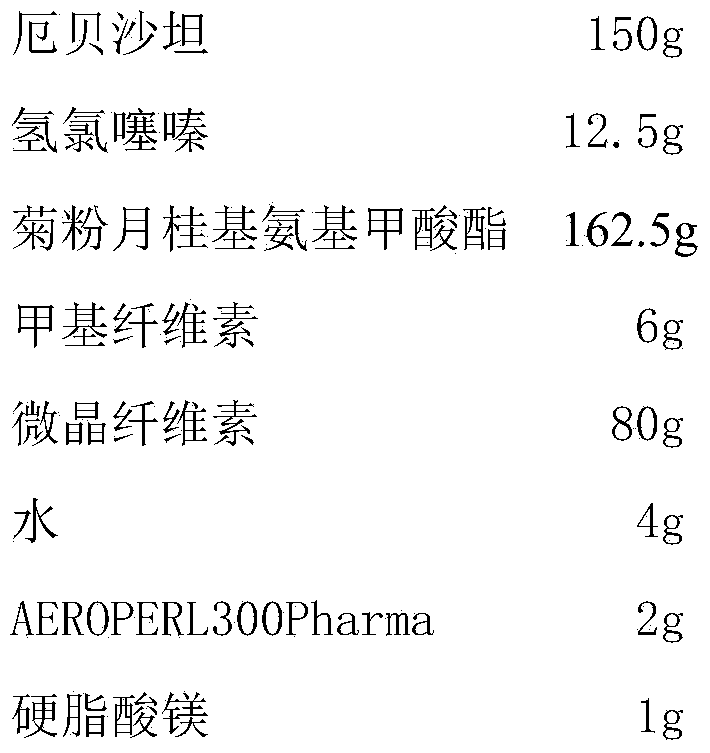

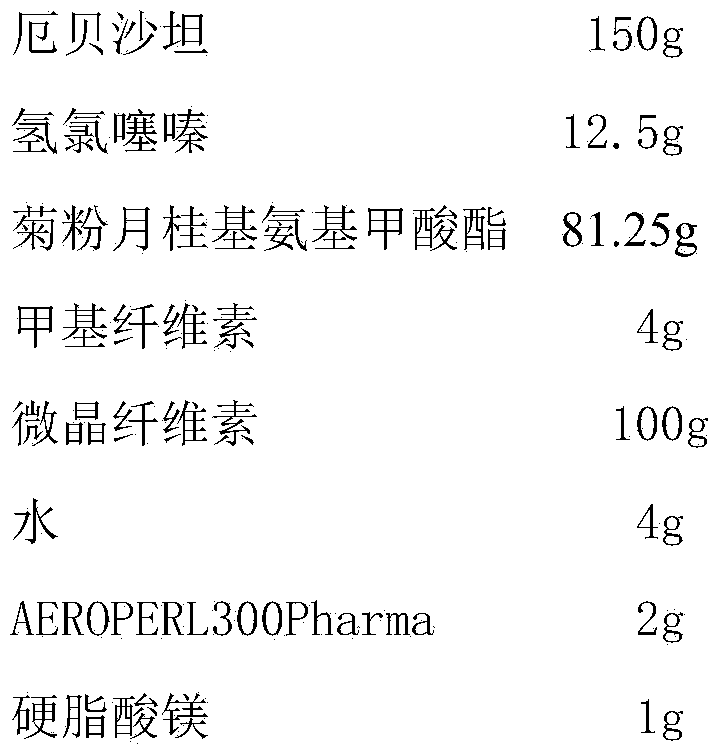

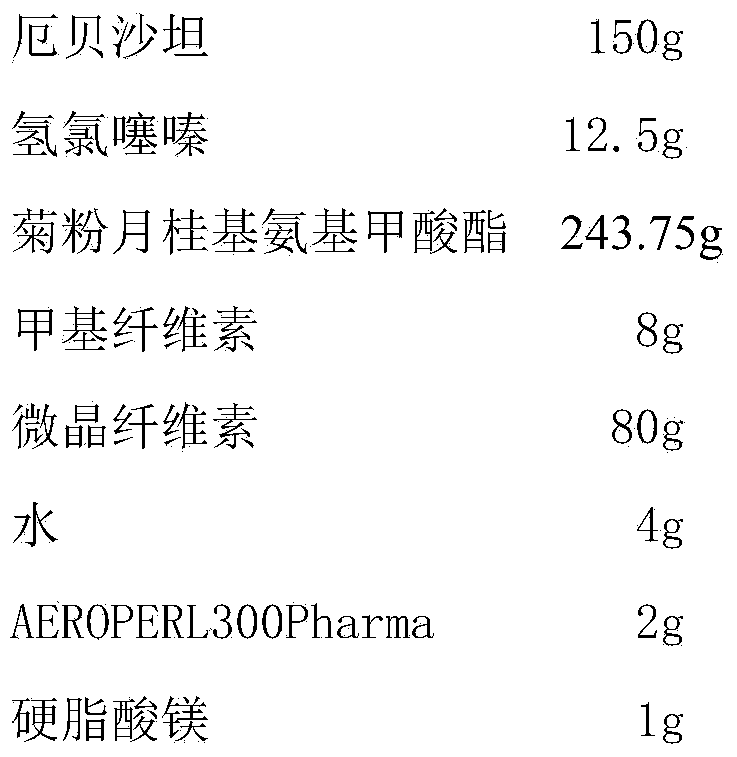

Irbesartan and hydrochlorothiazide tablet and preparation method thereof

ActiveCN103622970AAvoiding Substandard Content Uniformity IssuesImprove solubilityOrganic active ingredientsPill deliveryCarbamatePoor mobility

The invention relates to an irbesartan and hydrochlorothiazide tablet and a preparation method thereof, belonging to the technical field of drug preparations. The tablet contains an irbesartan and hydrochlorothiazide medicinal premix, wherein the irbesartan and hydrochlorothiazide medicinal premix is formed by irbesartan, hydrochlorothiazide and inulin lauryl carbamate, wherein the ratio of the total weight of irbesartan and hydrochlorothiazide to the weight of inulin lauryl carbamate is 1:(0.5-2), and the weight ratio of irbesartan to hydrochlorothiazide is 12:1. The tablet has the advantages of high dissolution rate and high uniformity. The preparation method of the tablet can be used for solving the problems of electrostatic adsorption, agglomeration, poor mobility and sticking of irbesartan and hydrochlorothiazide.

Owner:HEBEI LONGHAI PHARMA

Preparation method of clopidogrel bisulfate solid preparation

ActiveCN110339178AReduce the probability of stickingIncrease dissolution rateOrganic active ingredientsDrageesSulfateDissolution

The invention relates to a preparation method of a clopidogrel bisulfate solid preparation. The method discloses a two-step granulation process of melt-granulating and then dry-pressing granulating for clopidogrel bisulfate, and the obtained granules have good compressibility and fluidity, and are not easy to stick to a die, so that the problems of tablet sticking, easy revealing or splitting which are common in the preparation of oral tablets of clopidogrel bisulfate is solved. The preparation method can ensure the rapid dissolution of the drug in the preparation, and the long-term retentionof the sample does not increase the impurities. The preparation process of the present invention is highly practical and can be used for large-scale preparation of clopidogrel sulfate bulk drugs withdifferent physical properties.

Owner:GUANGZHOU BAIYUSN TIANXIN PHARMA

Silica gel protected LED chip and manufacturing method thereof

InactiveCN101488553AReduce viscositySolve the sticking problemSemiconductor devicesSemiconductor structureEngineering

The invention discloses a light emitting diode (LED) chip protected by silica gel and a manufacture method thereof. The LED chip can avoid or reduce the occurrence of dice bonding and blockage of suction nozzles during production, thus improving the production efficiency. The LED chip comprises a substrate and a multilayer semiconductor structure formed on the substrate, wherein, a silica gel layer is formed on the surface of the multilayer semiconductor structure and a thin film used for preventing the silica gel layer from sticking to other workpieces is formed on the surface of the silica gel layer. The method put forward by the invention comprises the following steps: forming the multilayer semiconductor structure on a silicon substrate, forming a covered silica gel layer on the surface of the multilayer semiconductor structure and forming a layer of thin film used for preventing the silica gel layer from sticking to other workpieces on the surface of the silica gel layer. The method can effectively solve the sticking problem of the chip during dicing, film turning and sorting and packaging, etc.

Owner:LATTICE POWER (JIANGXI) CORP

Preparation method for high-viscosity metal cold extrusion forming mold

InactiveCN110314954AImprove toughnessIncrease roughnessExtrusion profiling toolsNumerical controlGas phase

The invention provides a preparation method for a high-viscosity metal cold extrusion forming mold. A diamond-like film layer is prepared on the working face of the mold by adopting the processes of multi-directional forging, high-temperature quenching, tempering and cryogenic treatment and a plasma-enhanced chemical vapor deposition method through numerical control grinding and ultrasonic electrolytic polishing. Multiple control over the shape, the performance and the surface quality of a high-hardness curved-surface mold is achieved, and the technical problems such as mold sticking and pulling damaging in the high-viscosity metal cold extrusion process are effectively solved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com