Integral optical glass forming mould

An optical glass and molding mold technology, applied in glass molding, glass pressing, glass manufacturing equipment and other directions, can solve the problems affecting the production yield, low molding yield, low molding viscosity, etc., to solve the problem of sticking and molding The problem of stripes, improving the production yield, and solving the effect of forming stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

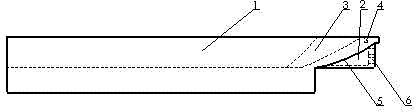

[0021] Such as image 3 , Figure 4 , Figure 5 shown. The integral optical glass forming mold of the present invention includes a forming part 1 and a cooling part 2 . Wherein, the forming part 1 is an integral forming groove, the width of the forming groove is 100-200 mm, and the depth is 40-60 mm. One end of the molding part 1 is open, and the working surface at the other end is a concave working arc surface 3, and the working arc surface 3 is an arc surface of 200°-300°. The bottom surface of the forming groove below the working arc surface 3 is a downwardly convex cooling arc surface 5, and the cooling arc surface 5 is an arc surface of 200°-300°. The thickness between the working arc surface 3 and the cooling arc surface 5 is 10-30mm. The cooling part 2 is a cooling cavity closely attached to the cooling arc surface 5 , and the cooling cavity is provided with cooling holes 6 . The length of the cooling cavity is 50-100mm, and the width is 50-100mm. A thermocouple ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com