Preparation method for high-viscosity metal cold extrusion forming mold

A forming die and cold extrusion technology, applied in the direction of metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of tool wear, poor symmetry, unstable penetrating body forming process, etc. The effect of good mold wear resistance and high mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a high-viscosity metal cold extrusion forming die, which specifically comprises the following steps:

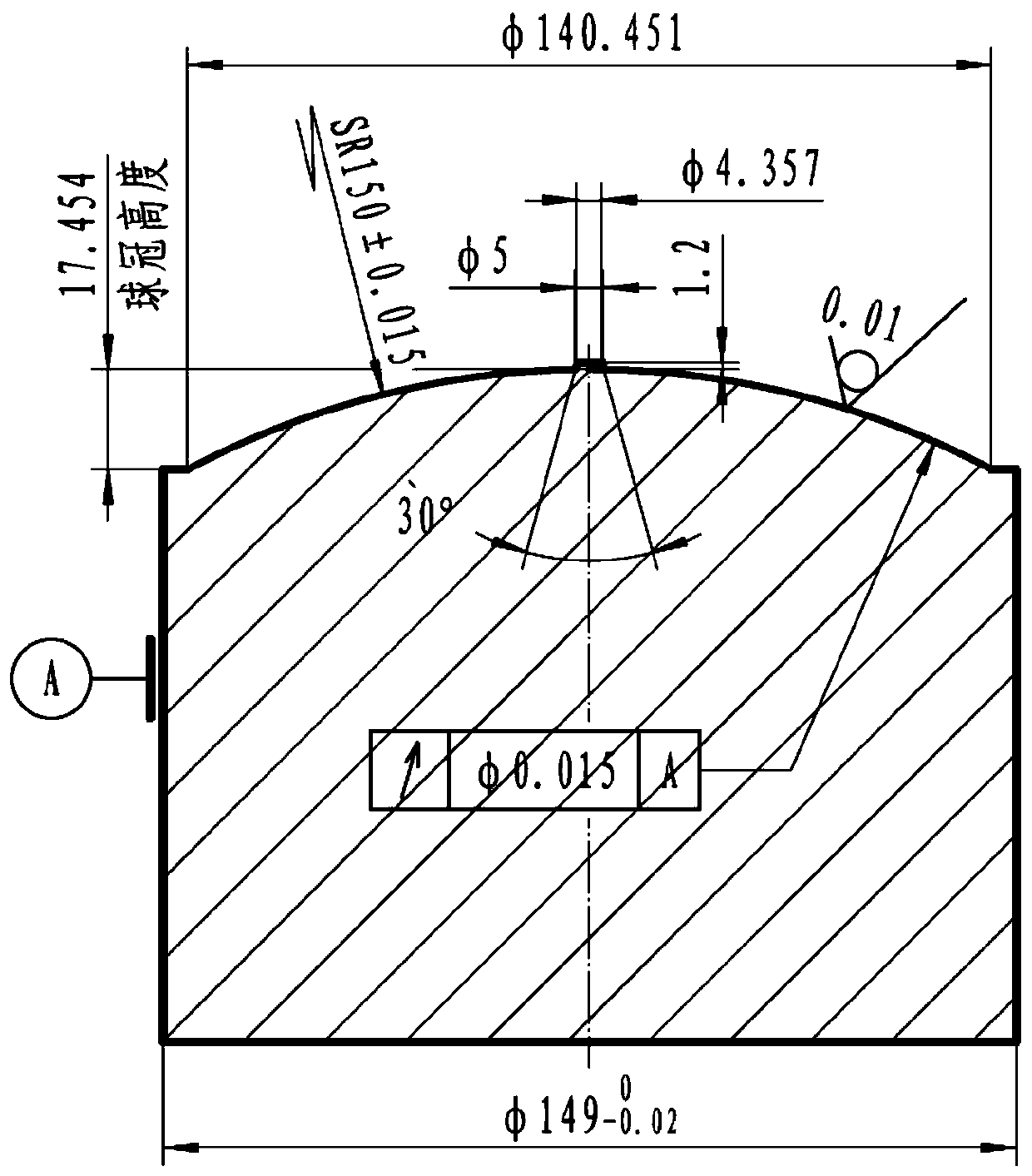

[0029] (1) The cold extrusion molding die designed according to the product drawing of the drug-type cover ( figure 1 ), according to the drawing size and technical requirements, the mold material is selected as LD steel (7Cr7Mo2v2Si), and the size specification is φ160×100mm.

[0030] (2) First, multi-directional forging is carried out on the mold material, the forging ratio is 6, and the carbide segregation is 1 grade.

[0031] (3) According to figure 1 Dimensions and technical requirements are rough turned, and (1~3)mm heat treatment decarburization layer and finishing allowance are reserved on the surface, and the overall size is φ154×95mm.

[0032] (4) Quenching and tempering heat treatment is carried out on the semi-finished product after rough machining. The process is 1 high-temperature quenching + 3 tempering + 1 cryogenic treatment. ...

Embodiment 2

[0041] A preparation method of a high-viscosity metal cold extrusion forming die, which specifically comprises the following steps:

[0042] (1) The cold extrusion molding die designed according to the product drawing of the drug-type cover ( figure 1 ), according to the drawing size and technical requirements, the mold material is selected as M2 steel (6W6Mo5Cr4V), and the size specification is φ160×100mm.

[0043] (2) First, multi-directional forging is carried out on the mold material, the forging ratio is 8, and the carbide segregation is 1 grade.

[0044] (3) According to figure 1 Dimensions and technical requirements are rough turned, and (1~3)mm heat treatment decarburization layer and finishing allowance are reserved on the surface, and the overall size is φ154×95mm.

[0045] (4) Quenching and tempering heat treatment is carried out on the semi-finished product after rough machining. The process is 1 high-temperature quenching + 3 tempering + 1 cryogenic treatment. ...

Embodiment 3

[0054] A preparation method of a high-viscosity metal cold extrusion forming die, which specifically comprises the following steps:

[0055] (1) The cold extrusion molding die designed according to the product drawing of the drug-type cover ( figure 1 ), according to the drawing size and technical requirements, the mold material is Cr12MoV1, and the size specification is φ160×100mm.

[0056] (2) First, multi-directional forging is carried out on the mold material, the forging ratio is 6, and the carbide is segregated to level 1.

[0057] (3) According to figure 1 Dimensions and technical requirements carry out rough turning, reserve (1~3) mm heat treatment decarburization layer and finishing allowance on the surface, and the overall size is φ153×94mm.

[0058] (4) Quenching and tempering heat treatment is carried out on the semi-finished product after rough machining. The process is 1 high-temperature quenching + 3 tempering + 1 cryogenic treatment. High temperature quenchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com