Patents

Literature

652 results about "Cryogenic treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

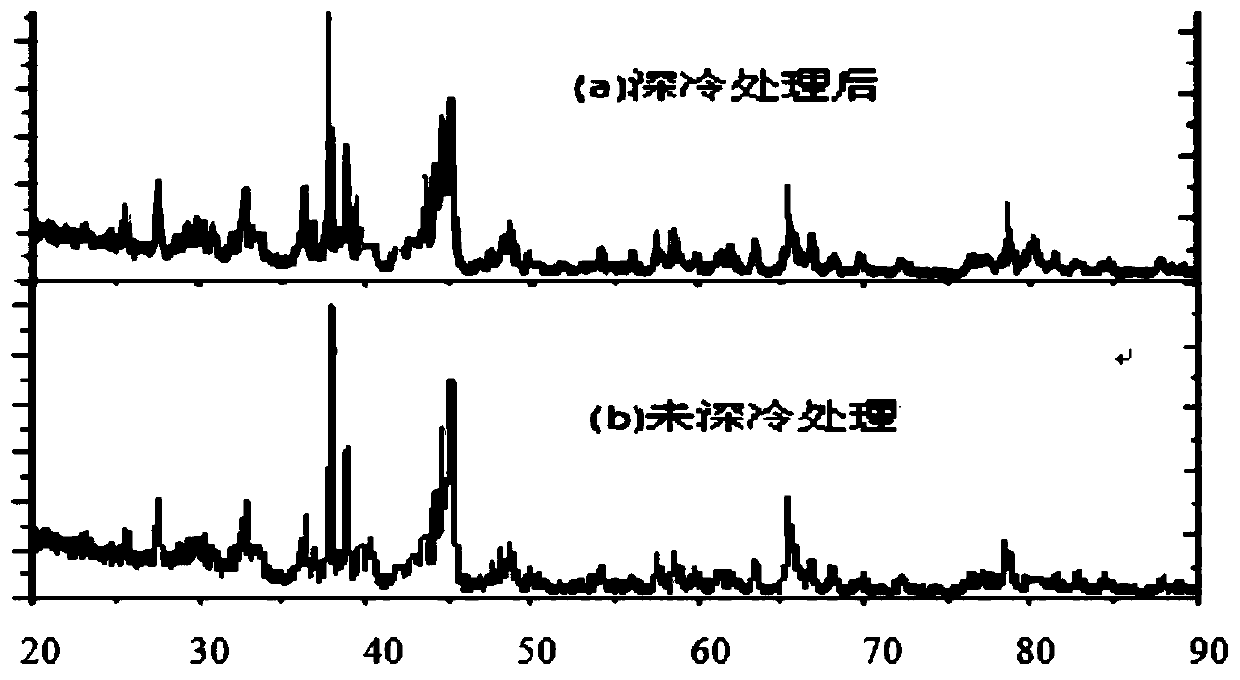

A cryogenic treatment is the process of treating workpieces to cryogenic temperatures (i.e. below −190 °C (−310 °F)) in order to remove residual stresses and improve wear resistance on steels and even composites. In addition to seeking enhanced stress relief and stabilization, or wear resistance, cryogenic treatment is also sought for its ability to improve corrosion resistance by precipitating micro-fine eta carbides, which can be measured before and after in a part using a quantimet.

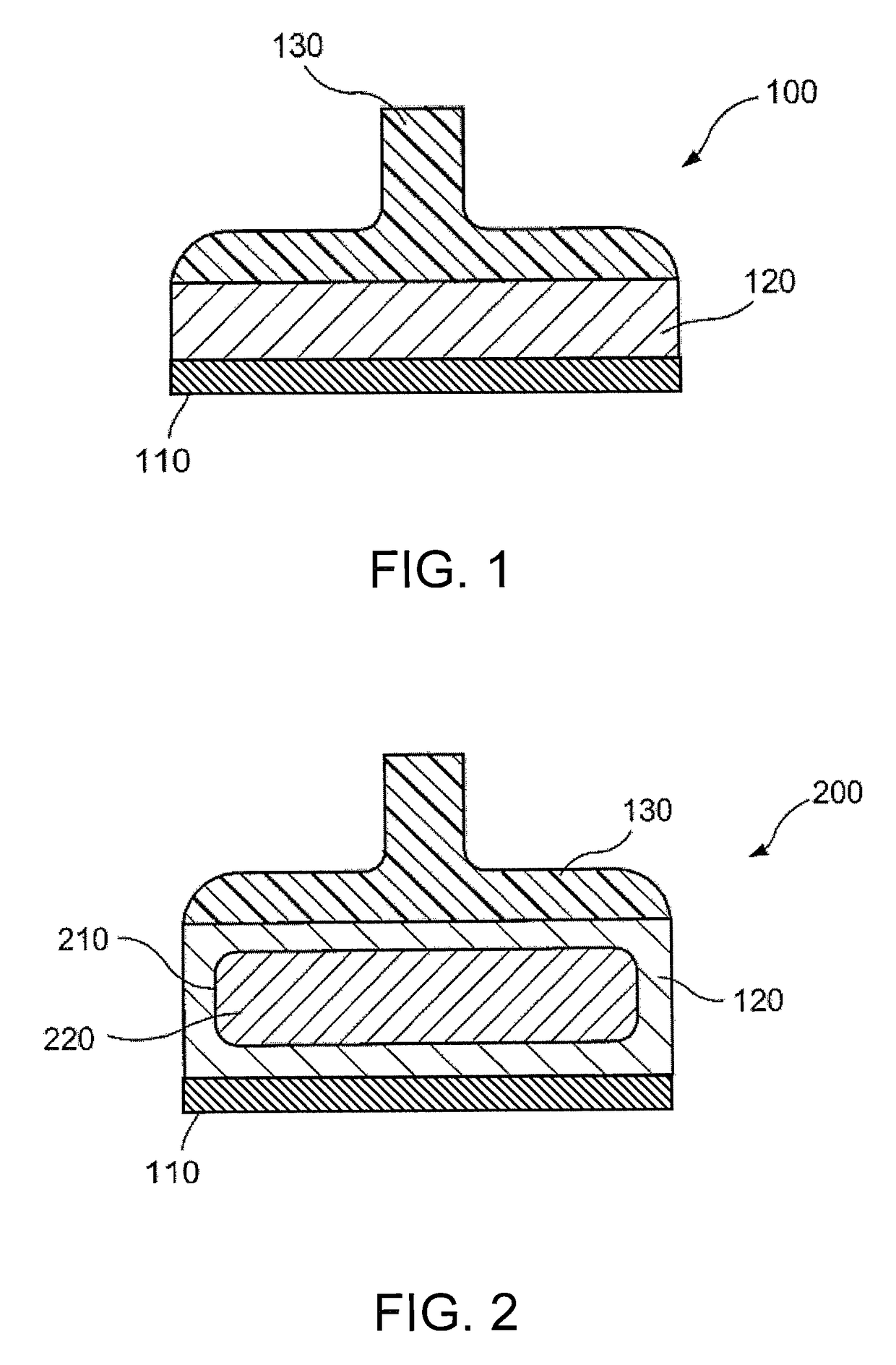

Method and apparatus for cryogenic treatment of skin tissue

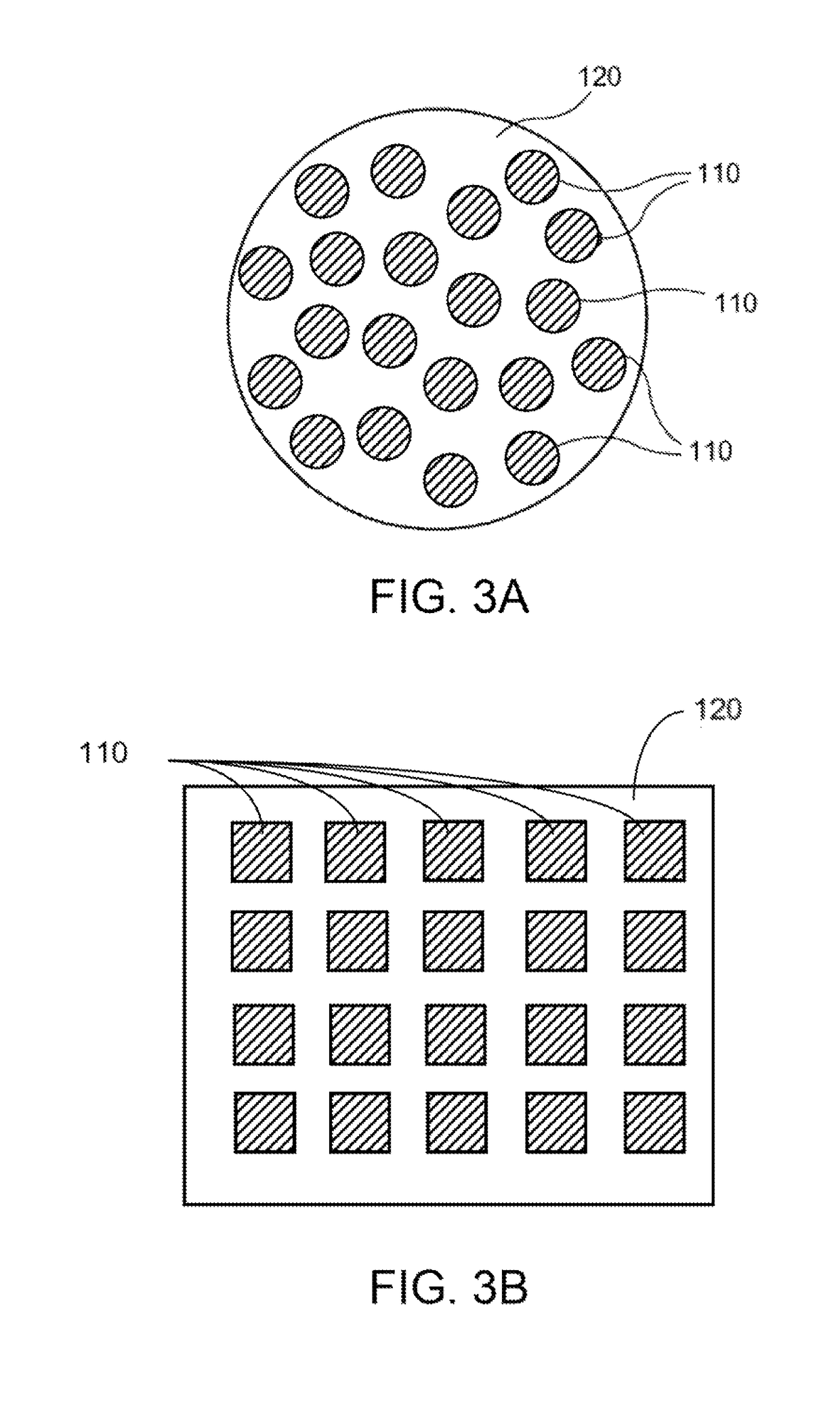

ActiveUS20140303697A1Reduce hyperpigmentationWhitening skinSurgical instruments for coolingTherapeutic coolingCelsius DegreeSkin surface

Cosmetic method and apparatus are provided that can provide cooling and / or freezing of skin tissue proximal to the skin surface to generate an appearance of lightening or reduced pigmentation in the skin. The skin can be cooled to a temperature of less than about −5 degrees Celsius for a duration of about one minute or less, using a plurality of cooled contact surfaces, each having a width between about 2 mm and about 20 mm. A cooling arrangement can be provided to provide controlled heat removal from the skin tissue being treated. A sensor can optionally be provided to detect freezing of tissue proximal to the cooled surfaces.

Owner:THE GENERAL HOSPITAL CORP

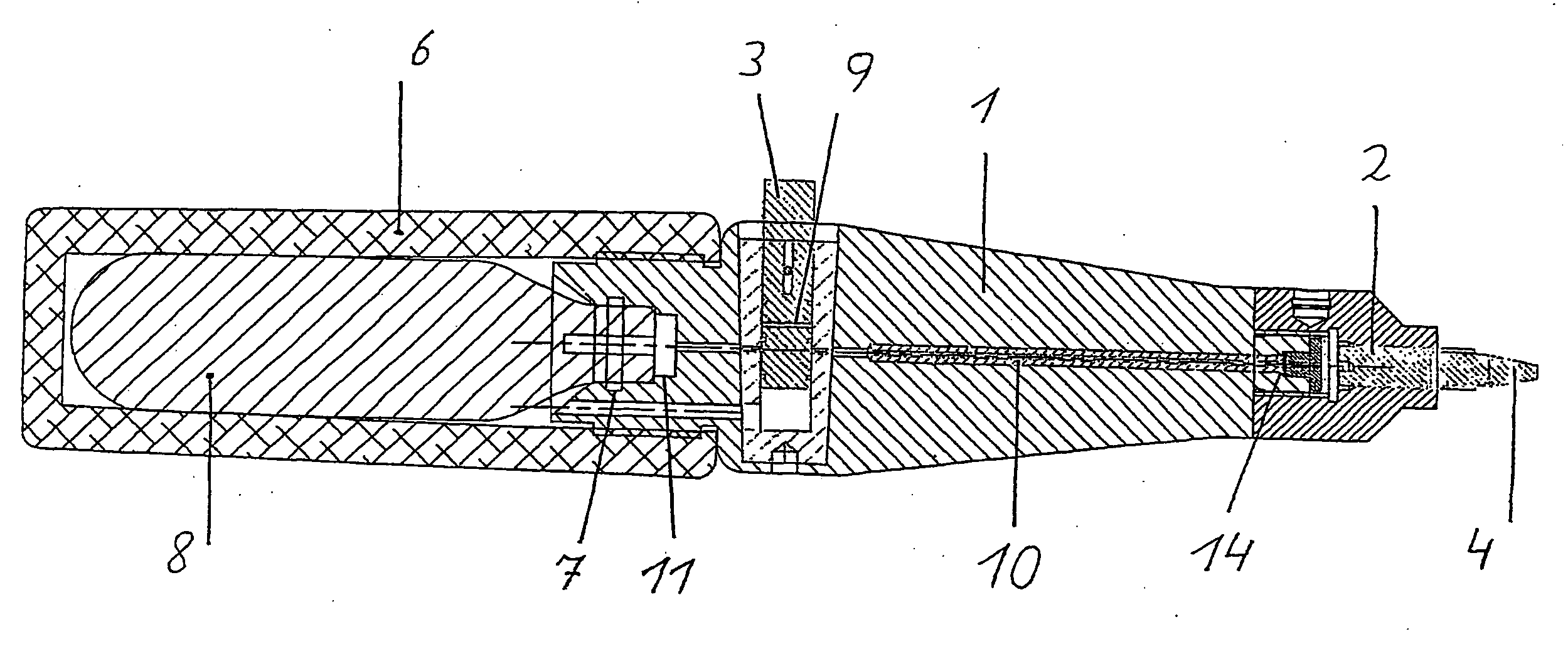

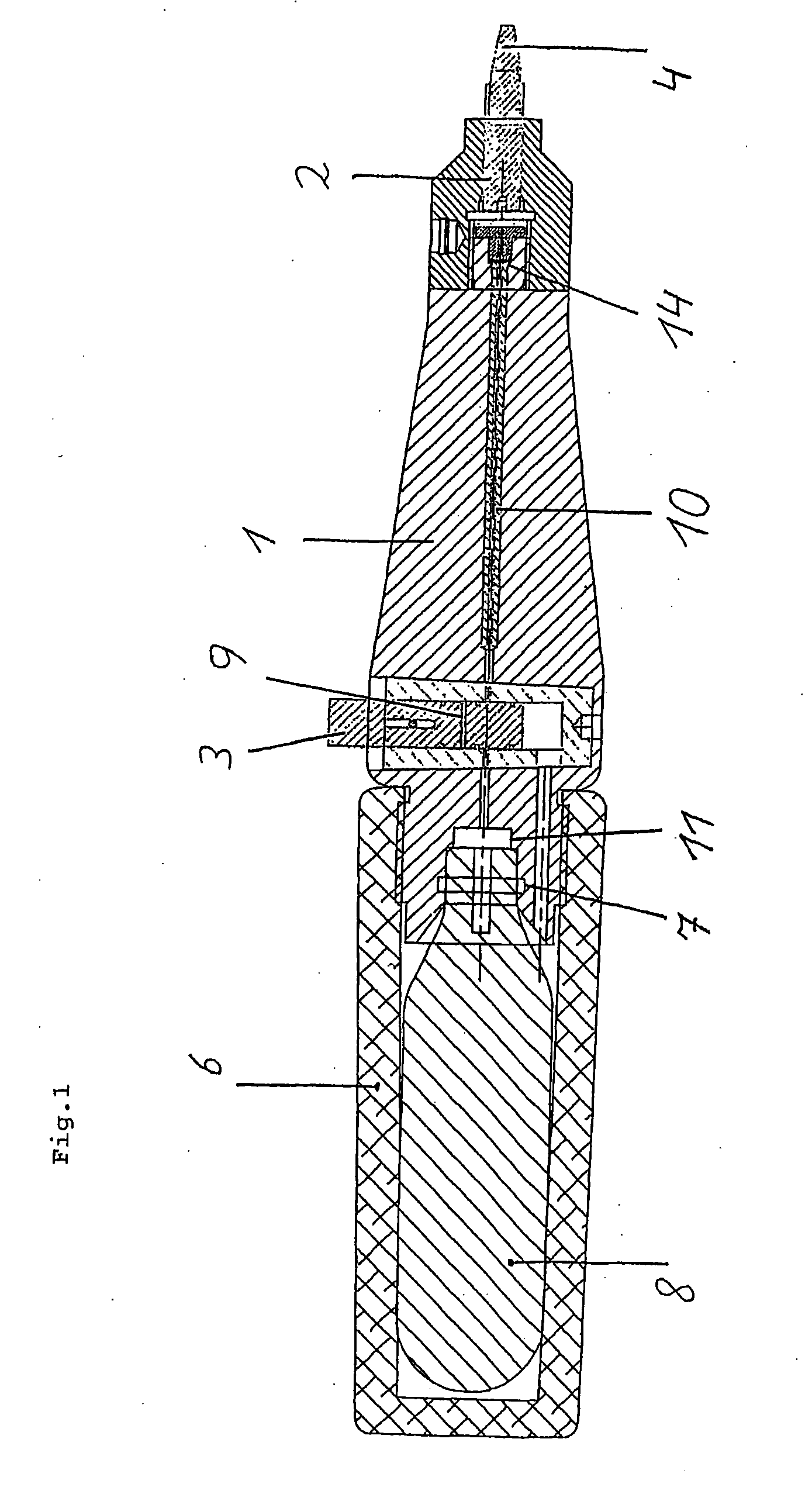

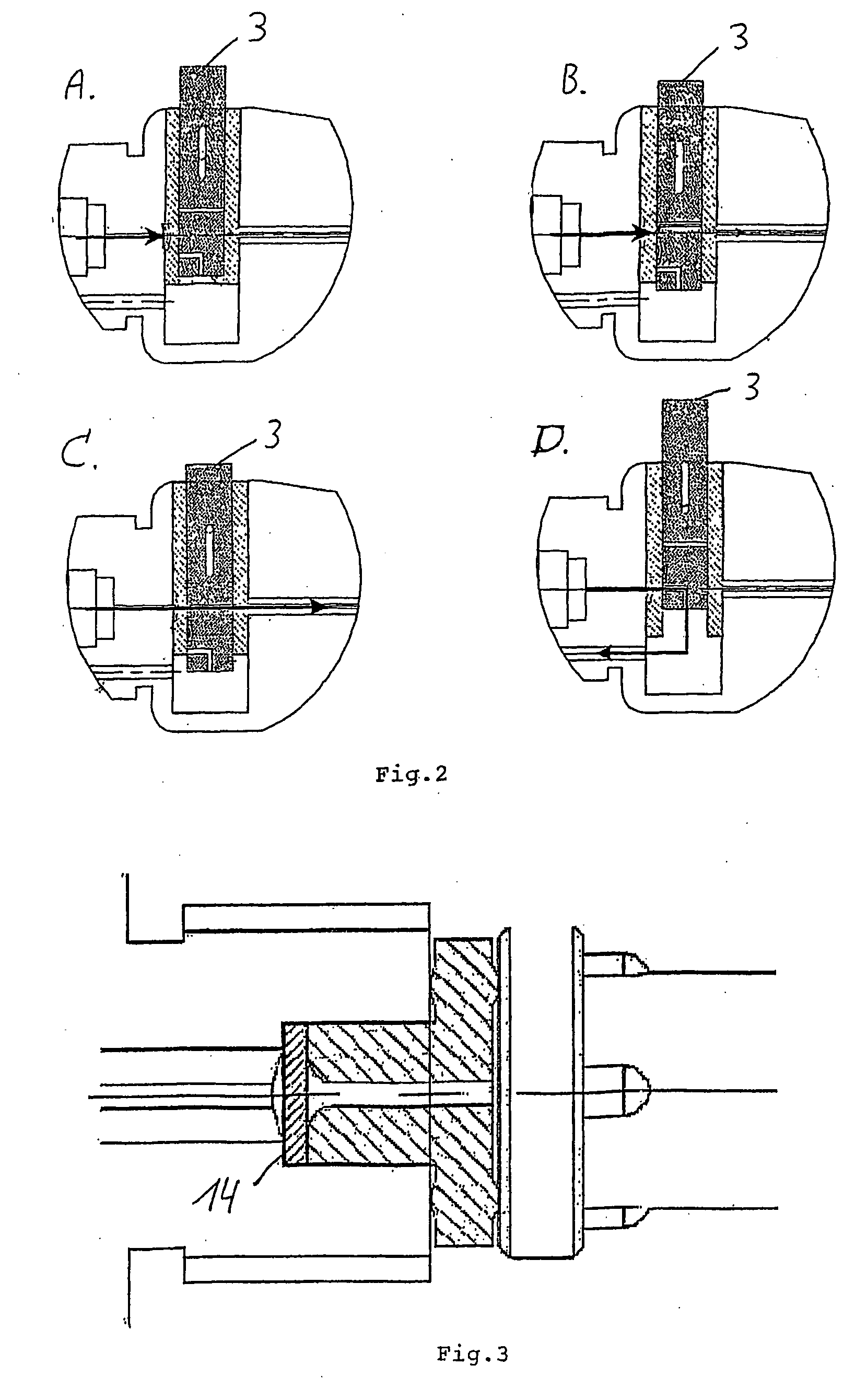

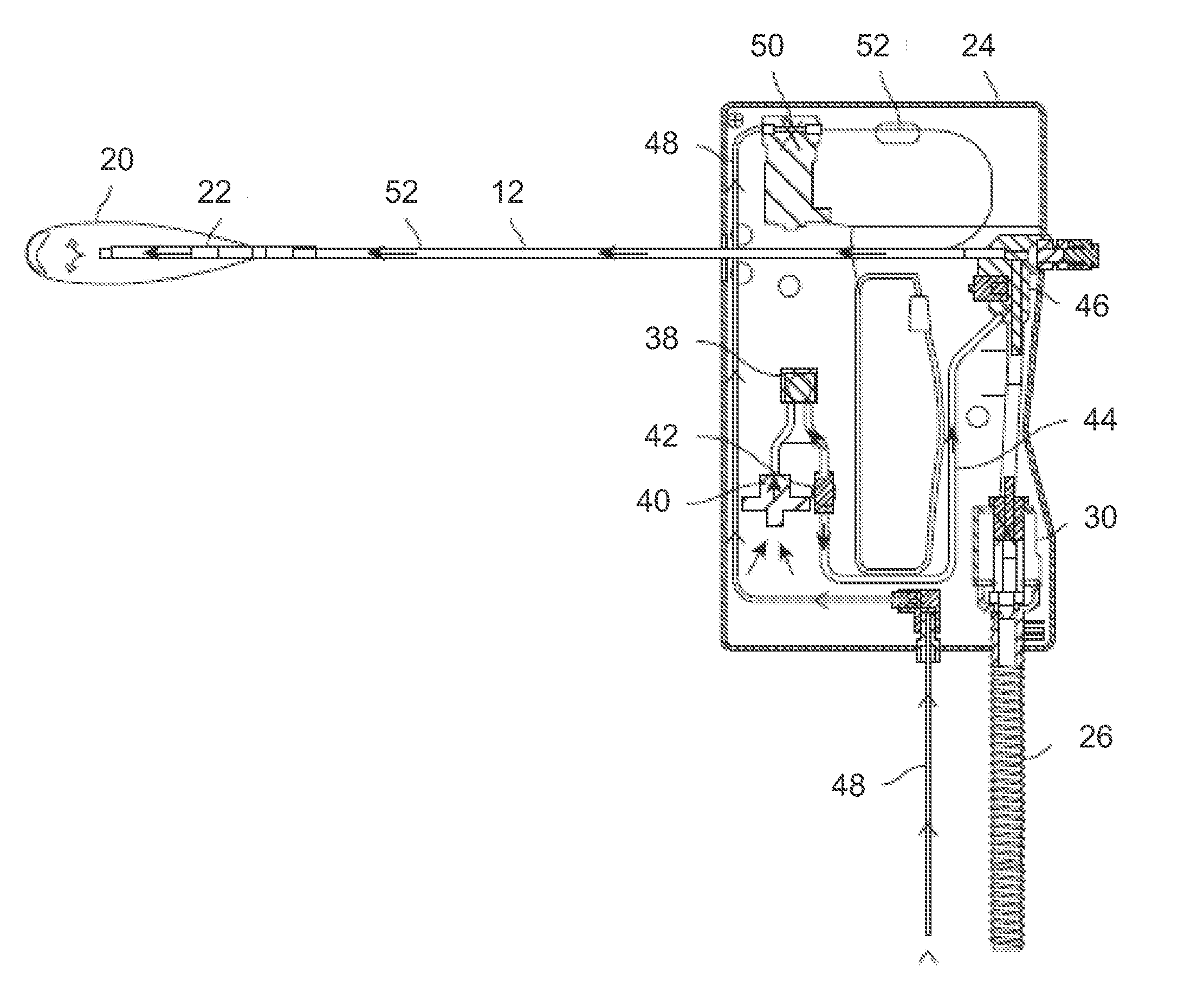

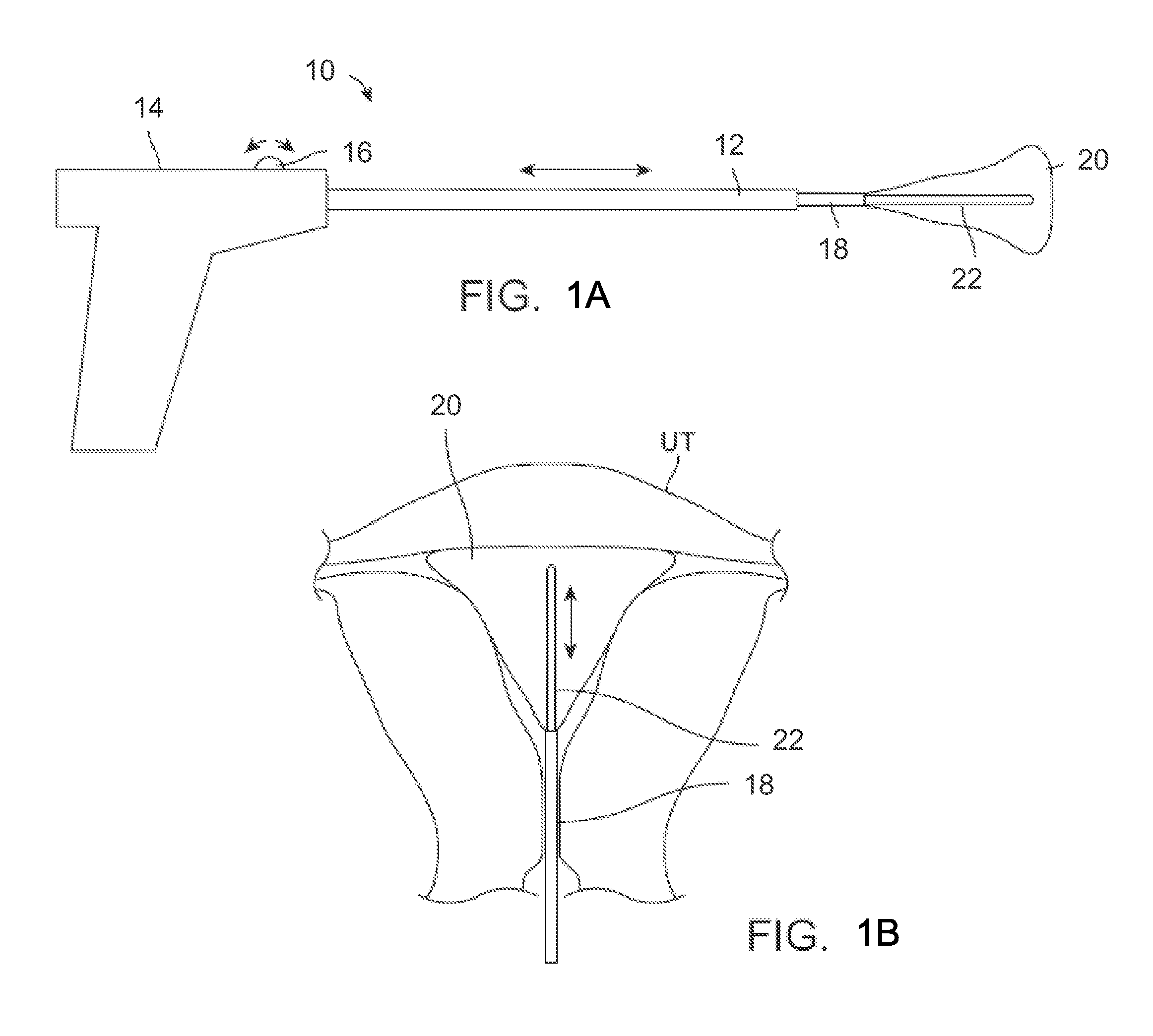

Method And Device For Combined Treatment

InactiveUS20080140061A1Efficient deliveryShort timeInfusion needlesSurgical instruments for coolingActive agentCryogenic treatment

A cryoprobe supports administration of an active agent to a location of cryogenic treatment. The cryoprobe may optionally be combined with a syringe to form a cryoprobe system; alternatively and optionally, the syringe may be external to the cryoprobe.

Owner:ICECURE MEDICAL

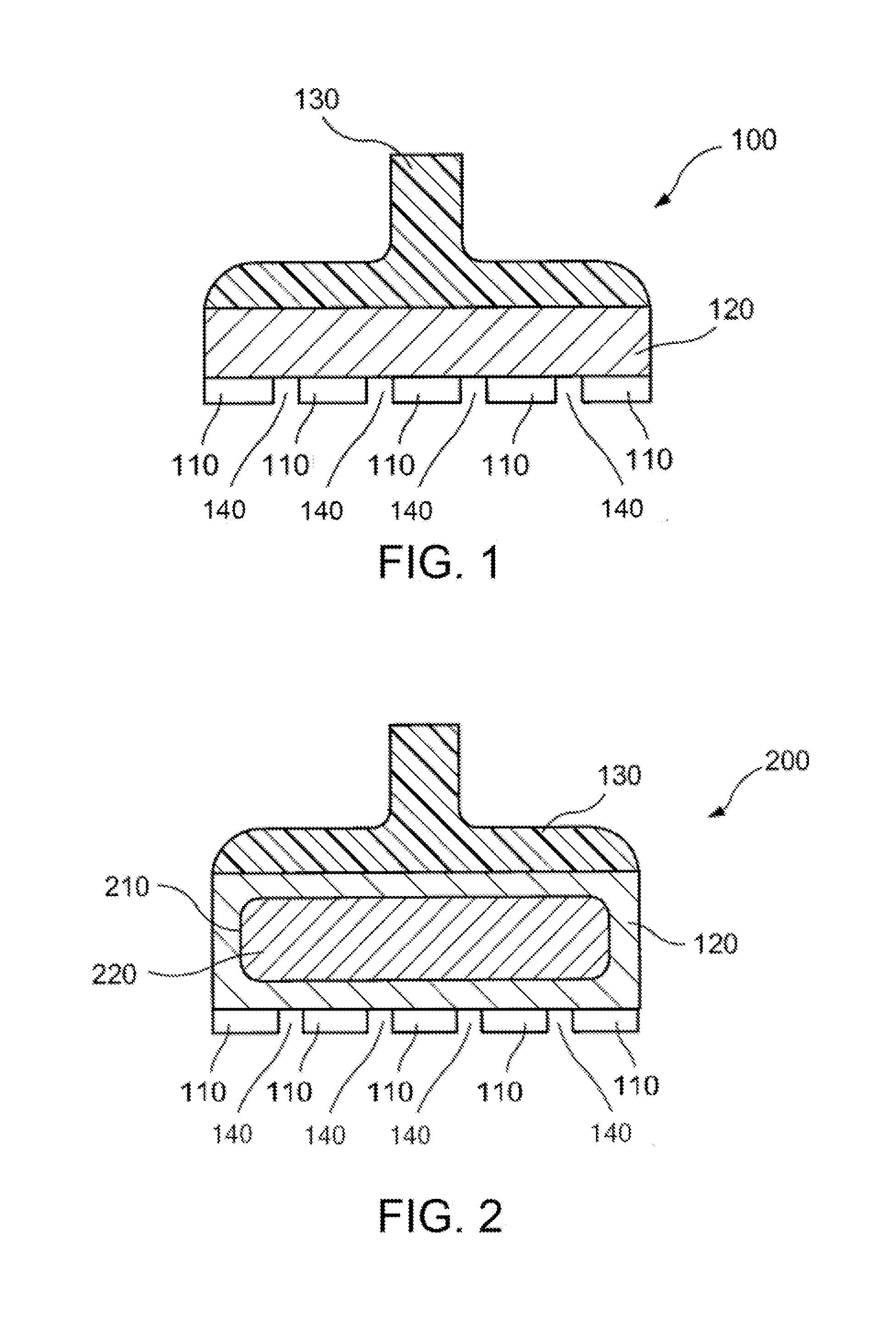

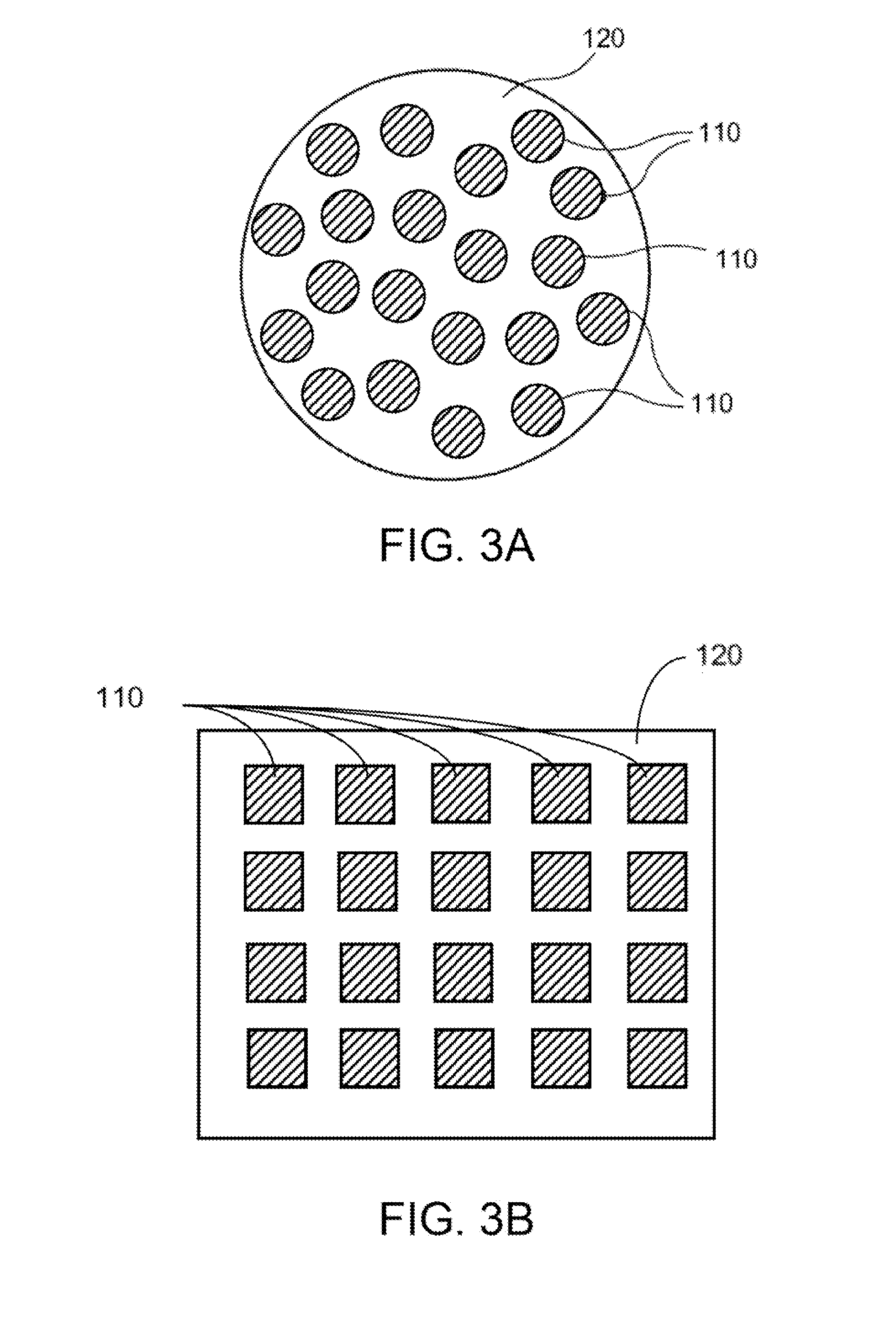

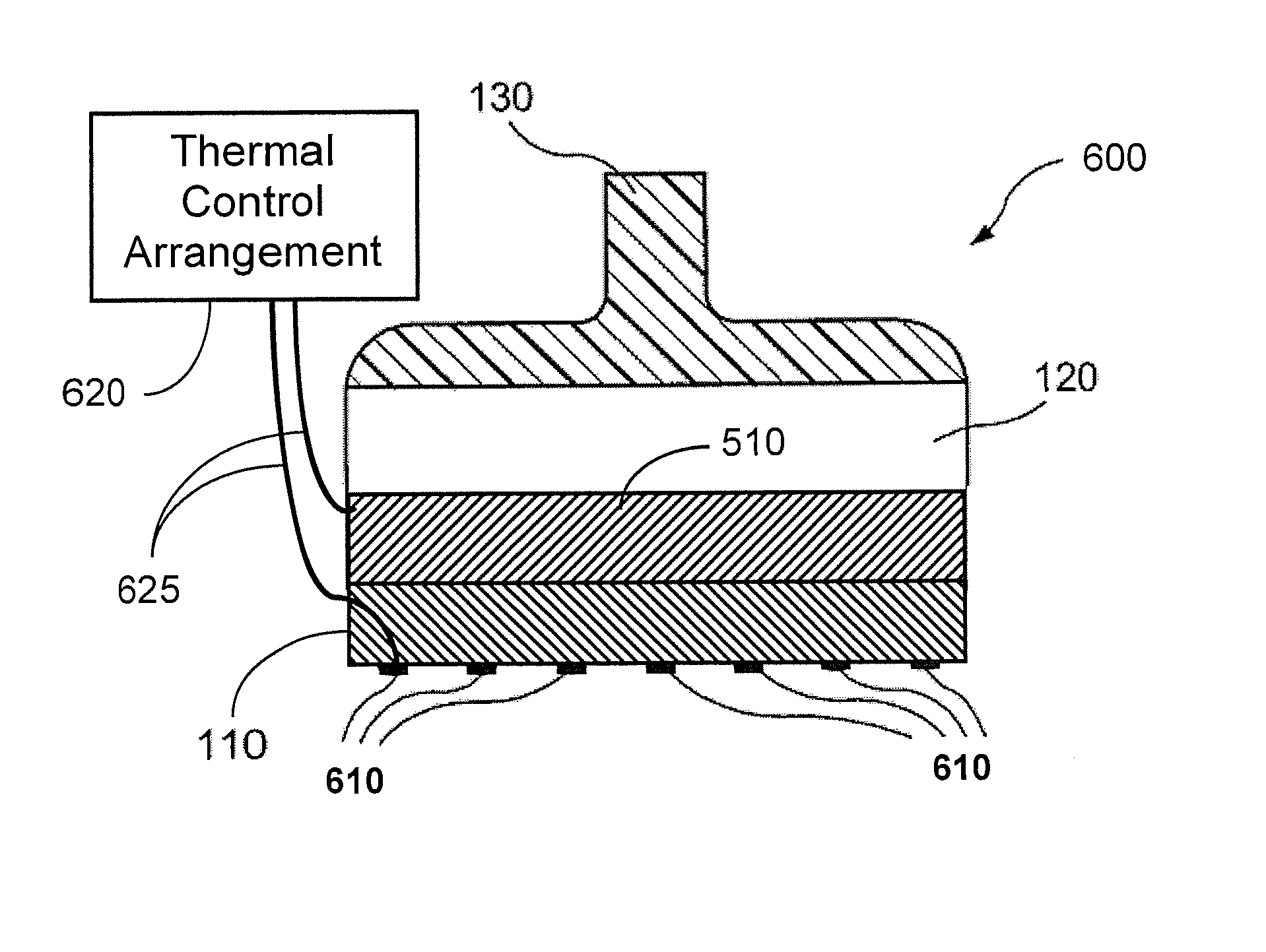

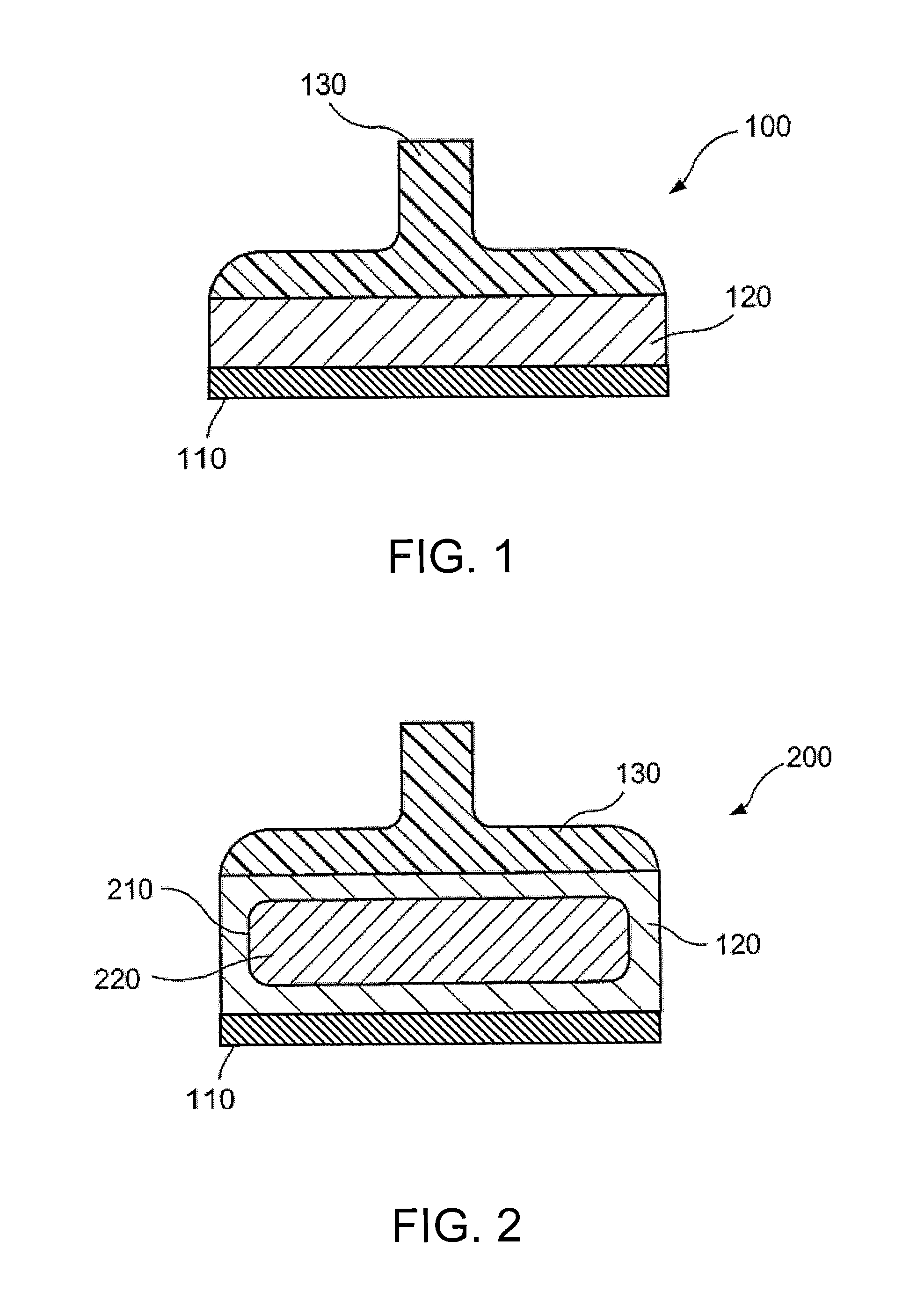

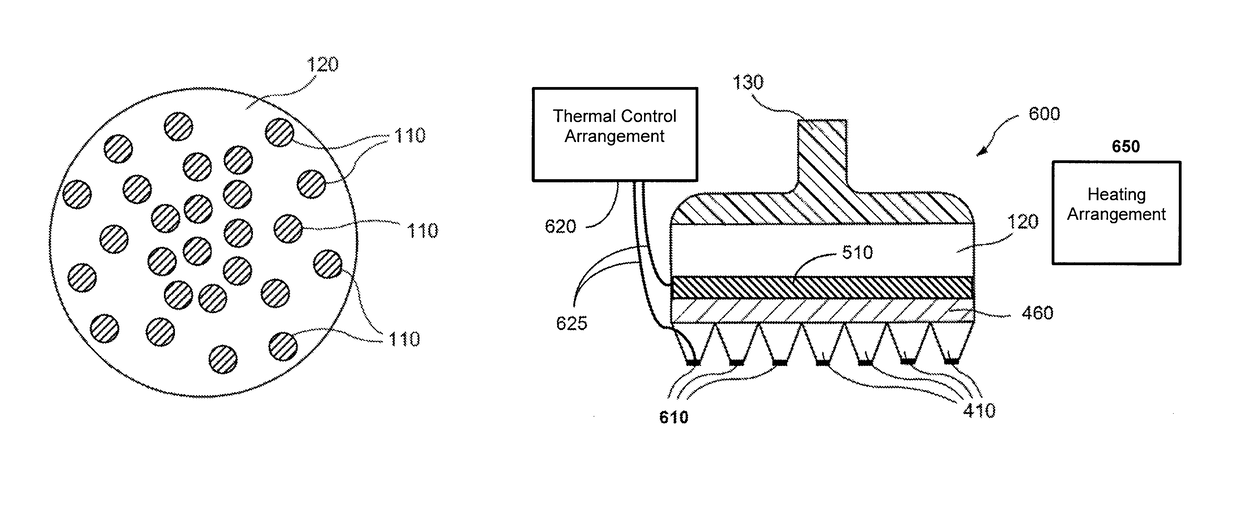

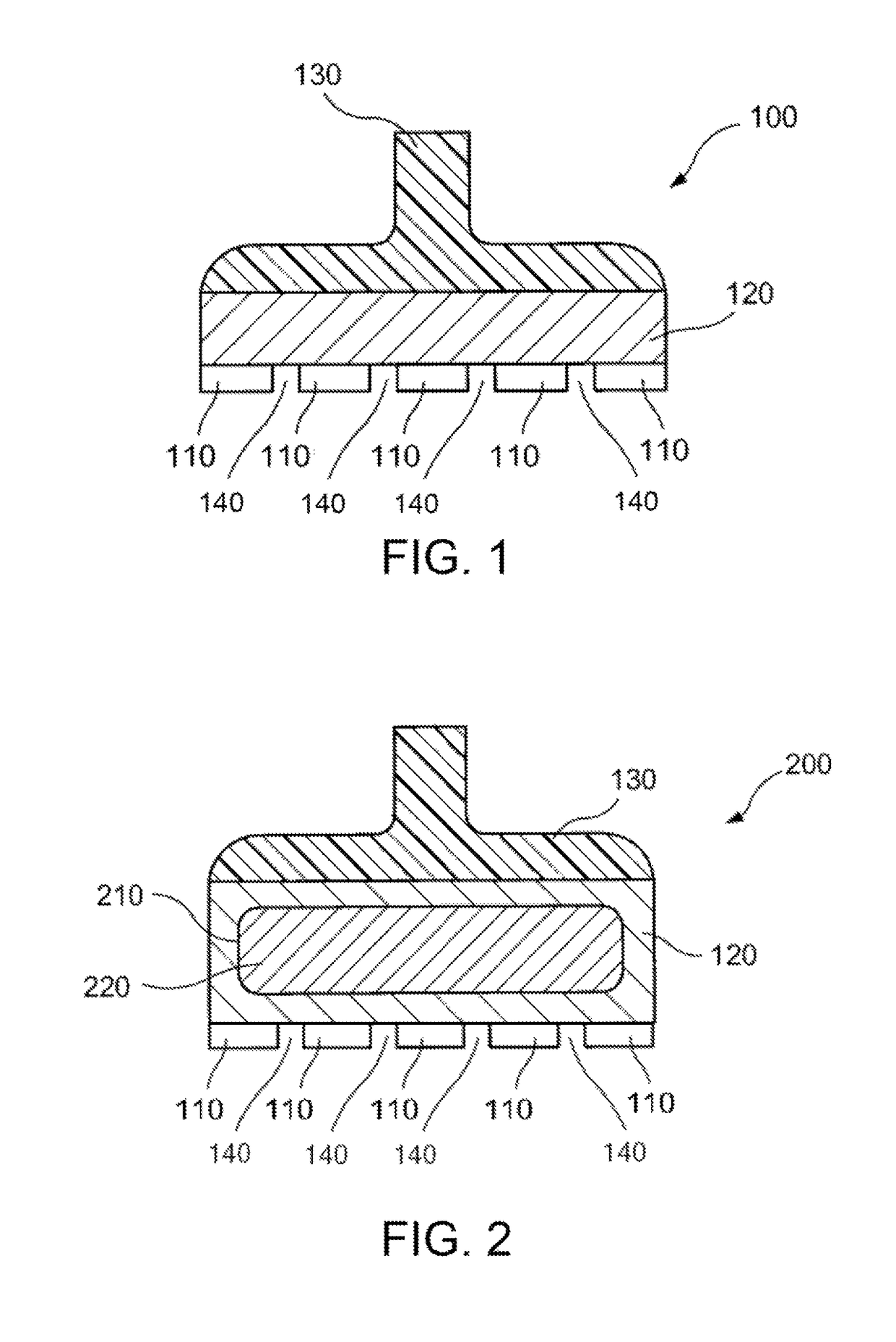

Method and apparatus for cryogenic treatment of skin tissue

ActiveUS20140303696A1Reduce hyperpigmentationWhitening skinDiagnostic recording/measuringSensorsCelsius DegreeSkin surface

Cosmetic method and apparatus are provided that can provide cooling and / or freezing of skin tissue proximal to the skin surface to generate an appearance of lightening or reduced pigmentation in the skin. The skin can be cooled to a temperature of less than about −5 degrees Celsius for a duration of about one minute or less, using a cooled surface that is at least 3 cm in width. A cooling arrangement can be provided to provide controlled heat removal from the skin tissue being treated. A sensor can optionally be provided to detect freezing of tissue proximal to the cooled surface.

Owner:THE GENERAL HOSPITAL CORP

Instrument for cryogenic treatments in the medical, paramedical and cosmetic field

The invention concerns an instrument suited for cryogenic treatments, for the medical or paramedical field as well as for the cosmetic field, comprising a microapplicator having a bore on the order of 20 to 120 μm supplied with a gas stream wherein all the foreign particles above 3 μm and preferably above 1 μm are eliminated. The invention also concerns a microapplicator designed to be used in such an instrument provided with a filter housed in or on said microapplicator, so that each time the latter is replaced, the filter is also replaced.

Owner:N V H & O EQUIP

Method and apparatus for cryogenic treatment of skin tissue

ActiveUS9855166B2Reduce hyperpigmentationWhitening skinDiagnostic recording/measuringSensorsSkin coolingCelsius Degree

Cosmetic method and apparatus are provided that can provide cooling and / or freezing of skin tissue proximal to the skin surface to generate an appearance of lightening or reduced pigmentation in the skin. The skin can be cooled to a temperature of less than about −5 degrees Celsius for a duration of about one minute or less, using a cooled surface that is at least 3 cm in width. A cooling arrangement can be provided to provide controlled heat removal from the skin tissue being treated. A sensor can optionally be provided to detect freezing of tissue proximal to the cooled surface.

Owner:THE GENERAL HOSPITAL CORP

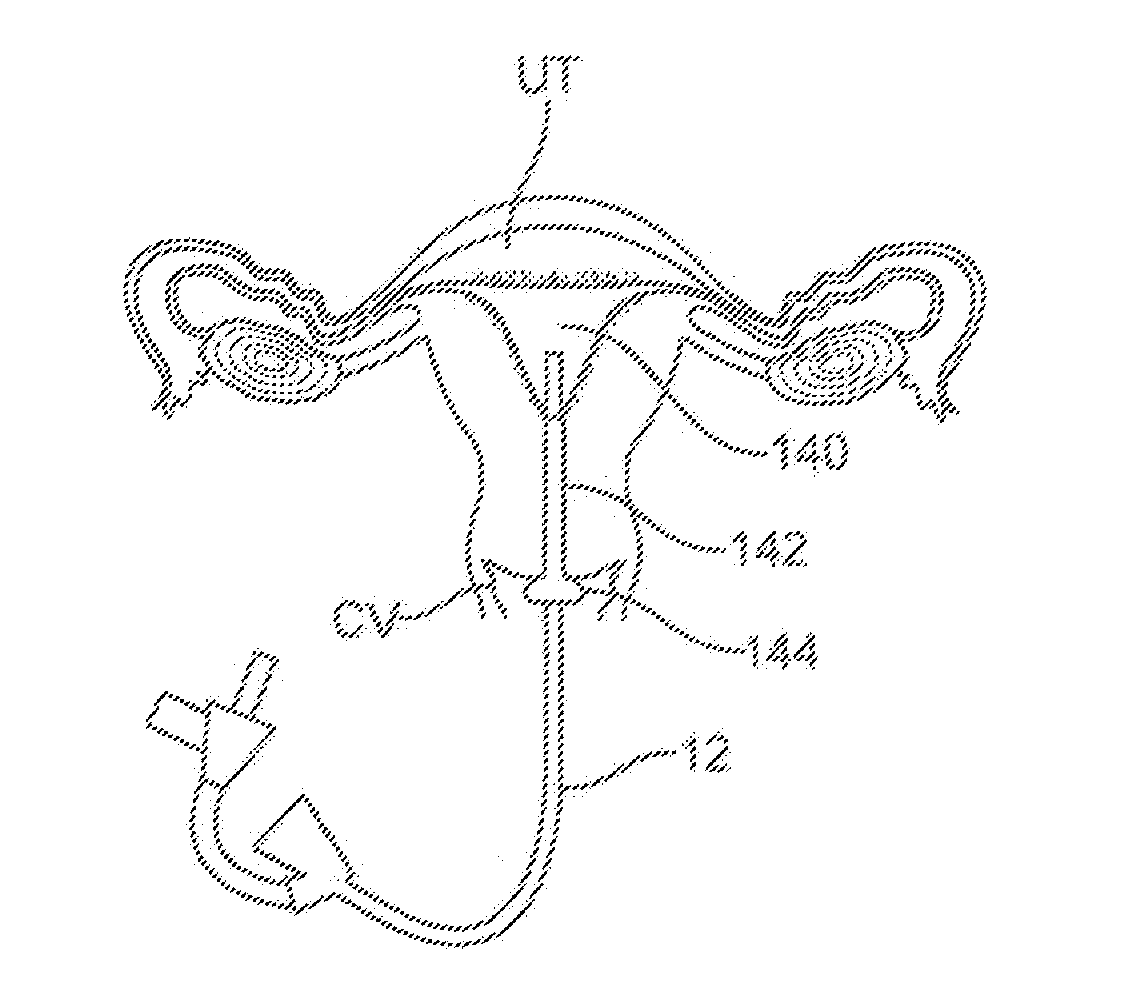

Cyrogenic treatment systems

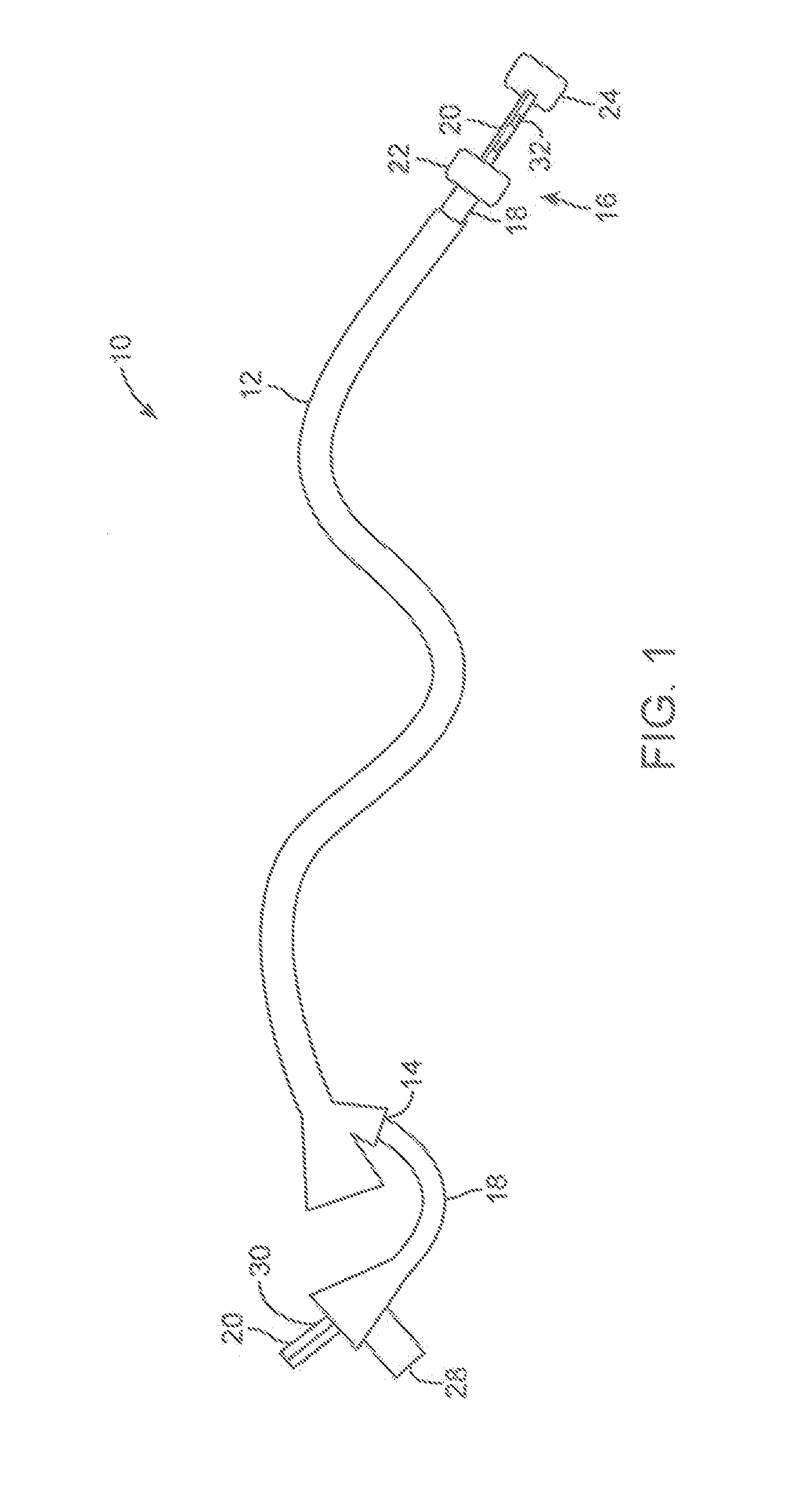

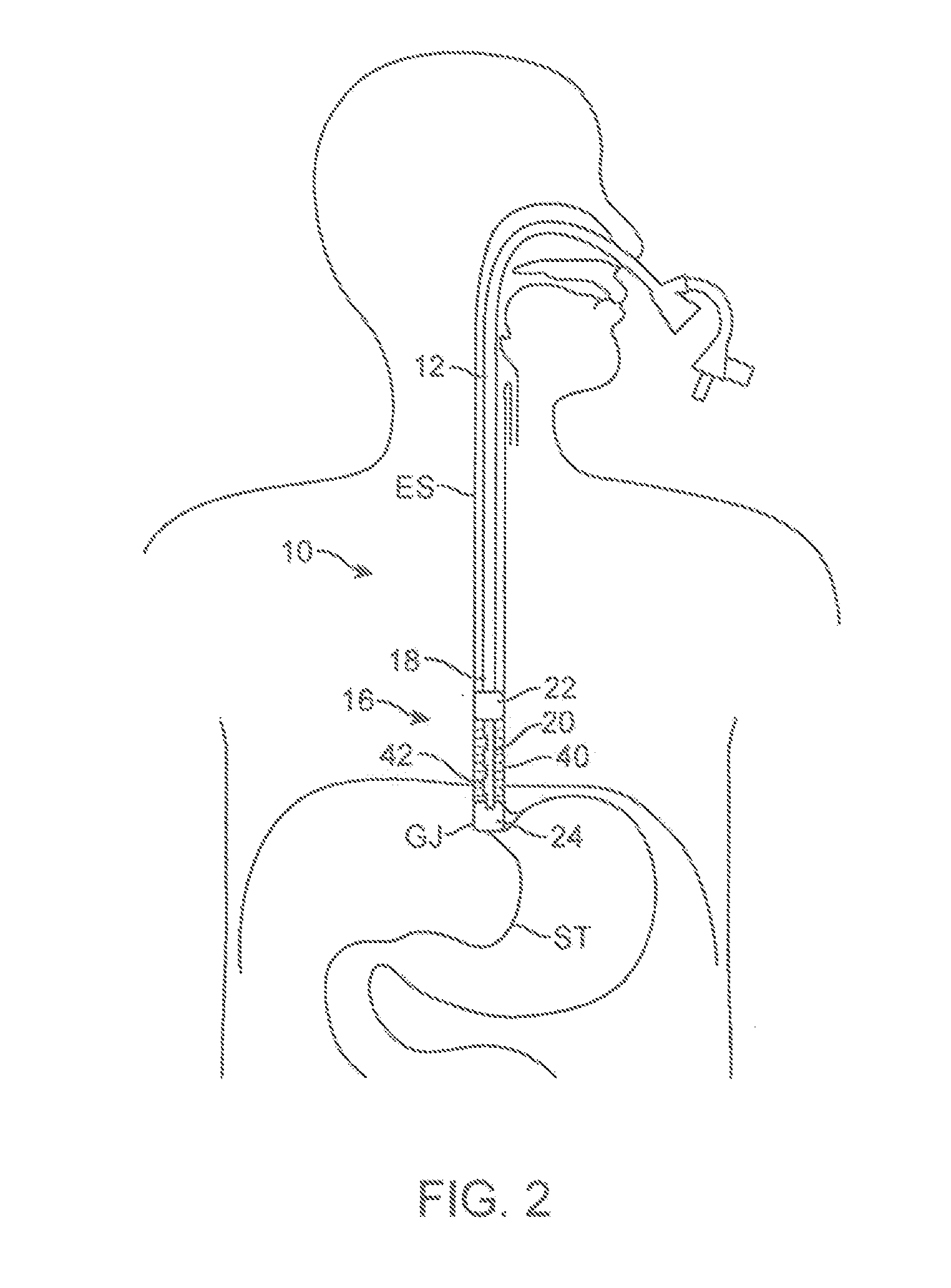

ActiveUS20130296837A1Preventing unwanted exposureEasy to controlEndoscopesCatheterRoom temperatureReady to use

Methods and apparatus for the treatment of a body cavity or lumen are described where a heated fluid and / or gas may be introduced through a catheter and into treatment area within the body contained between one or more inflatable / expandable members. The catheter may also have optional pressure and temperature sensing elements which may allow for control of the pressure and temperature within the treatment zone and also prevent the pressure from exceeding a pressure of the inflatable / expandable members to thereby contain the treatment area between these inflatable / expandable members. Optionally, a chilled, room temperature, or warmed fluid such as water may then be used to rapidly terminate the treatment session.

Owner:CHANNEL MEDSYST

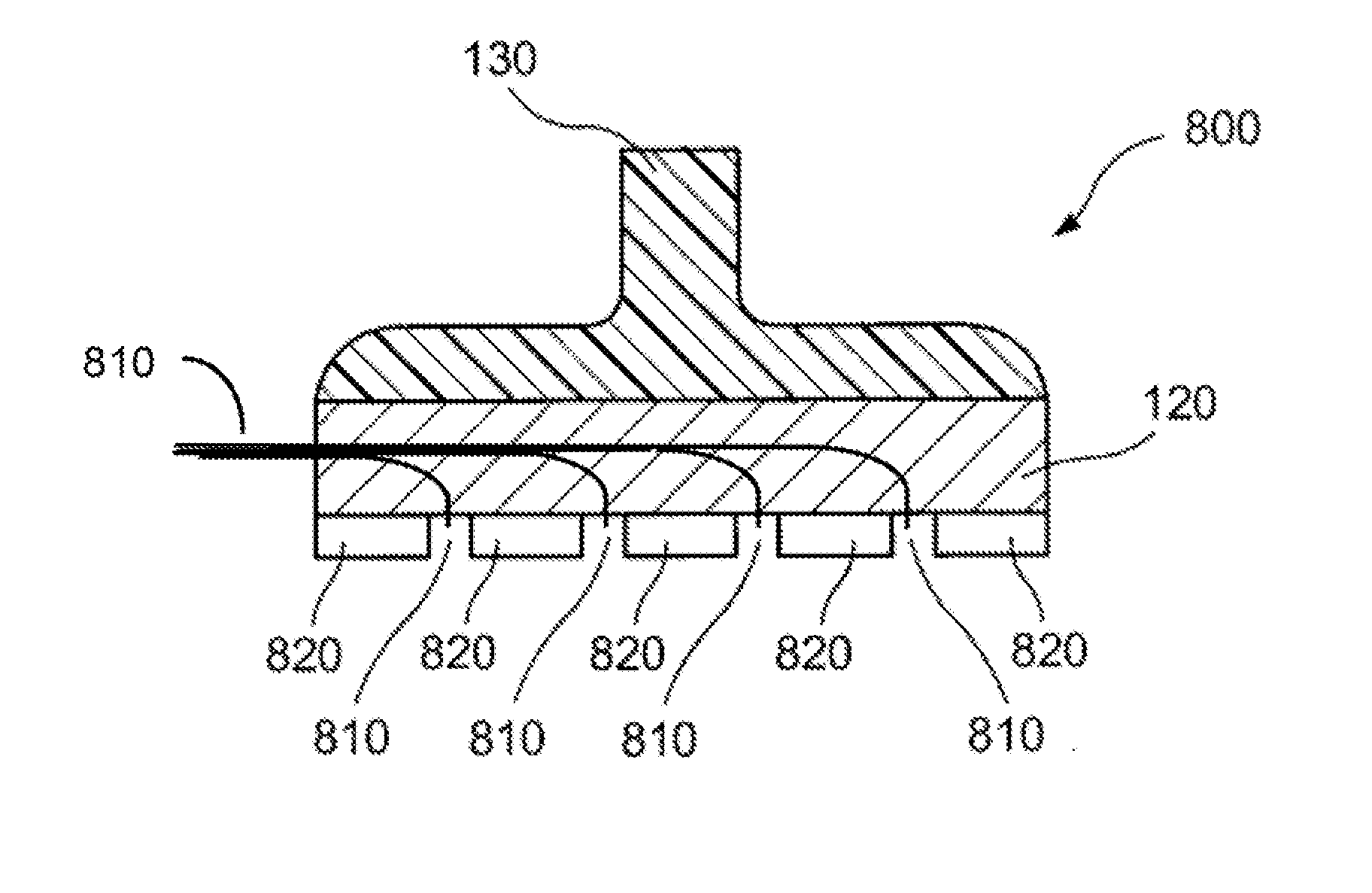

Method and apparatus for cryogenic treatment of skin tissue

ActiveUS9974684B2Reduce hyperpigmentationWhitening skinSurgical instruments for coolingTherapeutic coolingSkin coolingCelsius Degree

Cosmetic method and apparatus are provided that can provide cooling and / or freezing of skin tissue proximal to the skin surface to generate an appearance of lightening or reduced pigmentation in the skin. The skin can be cooled to a temperature of less than about −5 degrees Celsius for a duration of about one minute or less, using a plurality of cooled contact surfaces, each having a width between about 2 mm and about 20 mm. A cooling arrangement can be provided to provide controlled heat removal from the skin tissue being treated. A sensor can optionally be provided to detect freezing of tissue proximal to the cooled surfaces.

Owner:THE GENERAL HOSPITAL CORP

High melting point soldering layer and fabrication method for the same, and semiconductor device

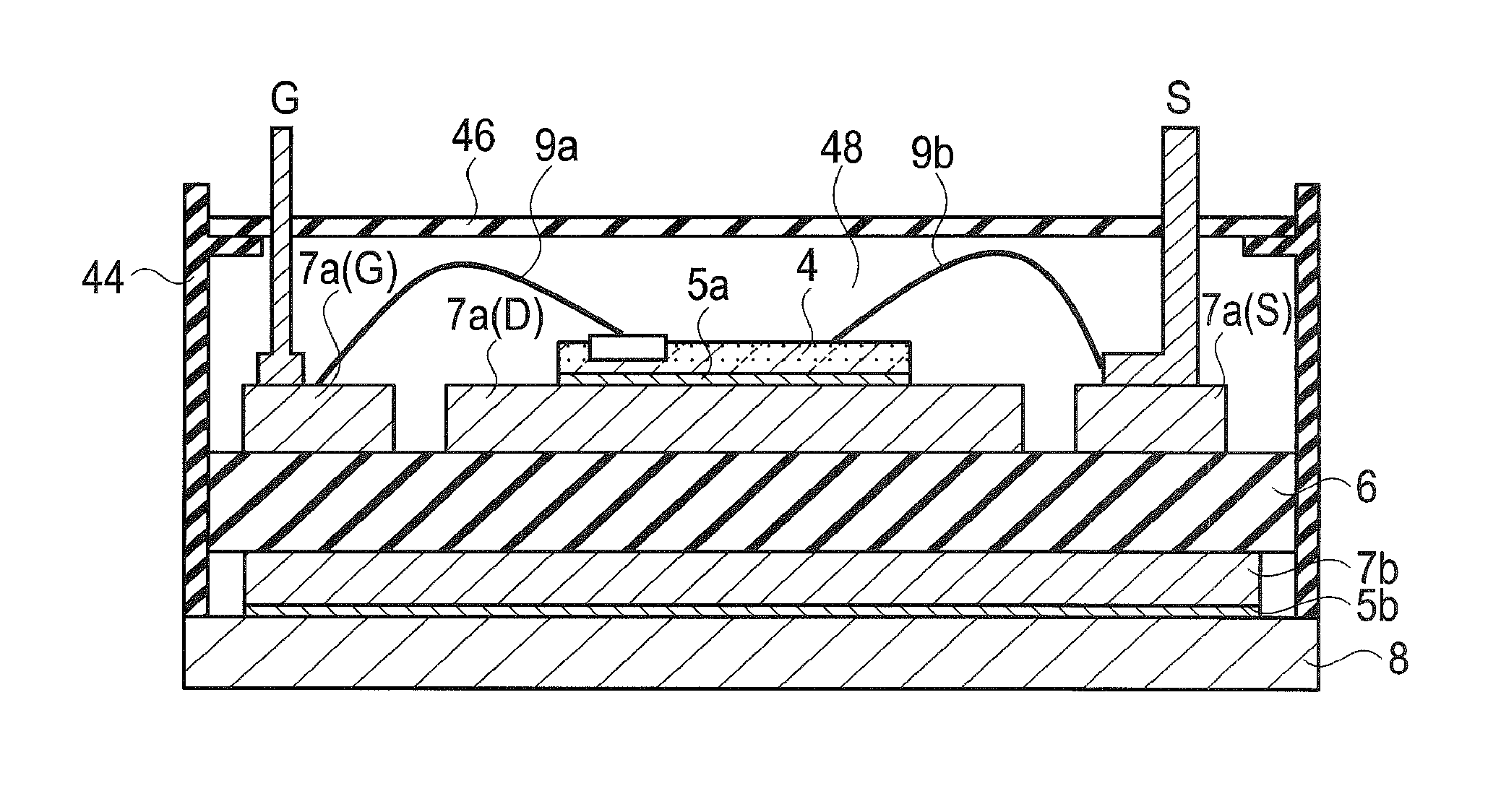

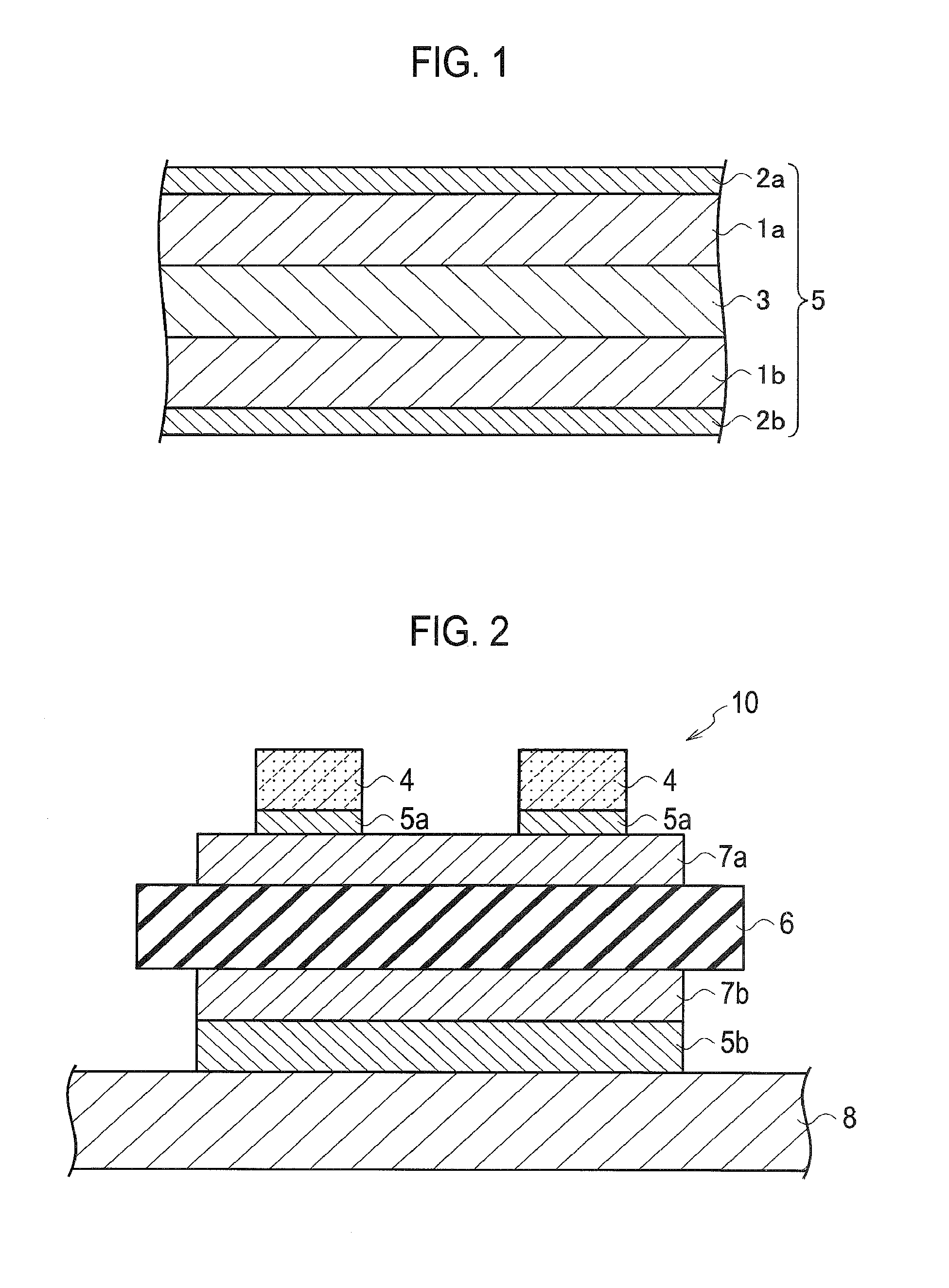

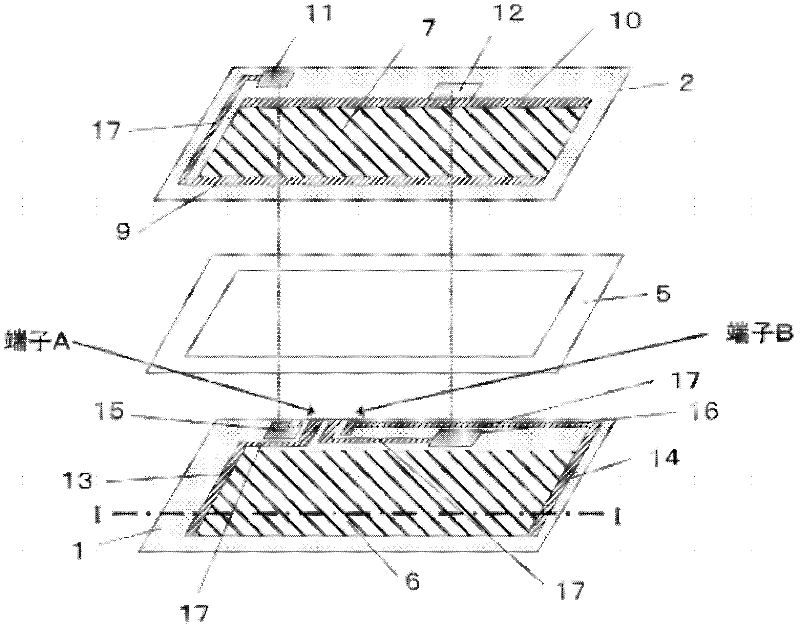

ActiveUS20120112201A1High melting pointSemiconductor/solid-state device detailsSolid-state devicesAlloyMaterials science

A high melting point soldering layer includes a low melting point metal layer, a first high melting point metal layer disposed on a surface of the low melting point metal layer, and a second high melting point metal layer disposed at a back side of the low melting point metal layer. The low melting point metal layer, the first high melting point metal layer, and the second high melting point metal layer are mutually alloyed by transient liquid phase bonding, by annealing not less than a melting temperature of the low melting point metal layer, diffusing the metal of the low melting point metal layer into an alloy of the first high melting point metal layer and the second high melting point metal layer. The high melting point soldering layer has a higher melting point temperature than that of the low melting point metal layer. It is provided a binary based high melting point soldering layer having TLP bonding of a high melting point according to a low temperature processing, a fabrication method for the high melting point soldering layer and a semiconductor device to which the high melting point soldering layer is applied.

Owner:ROHM CO LTD +1

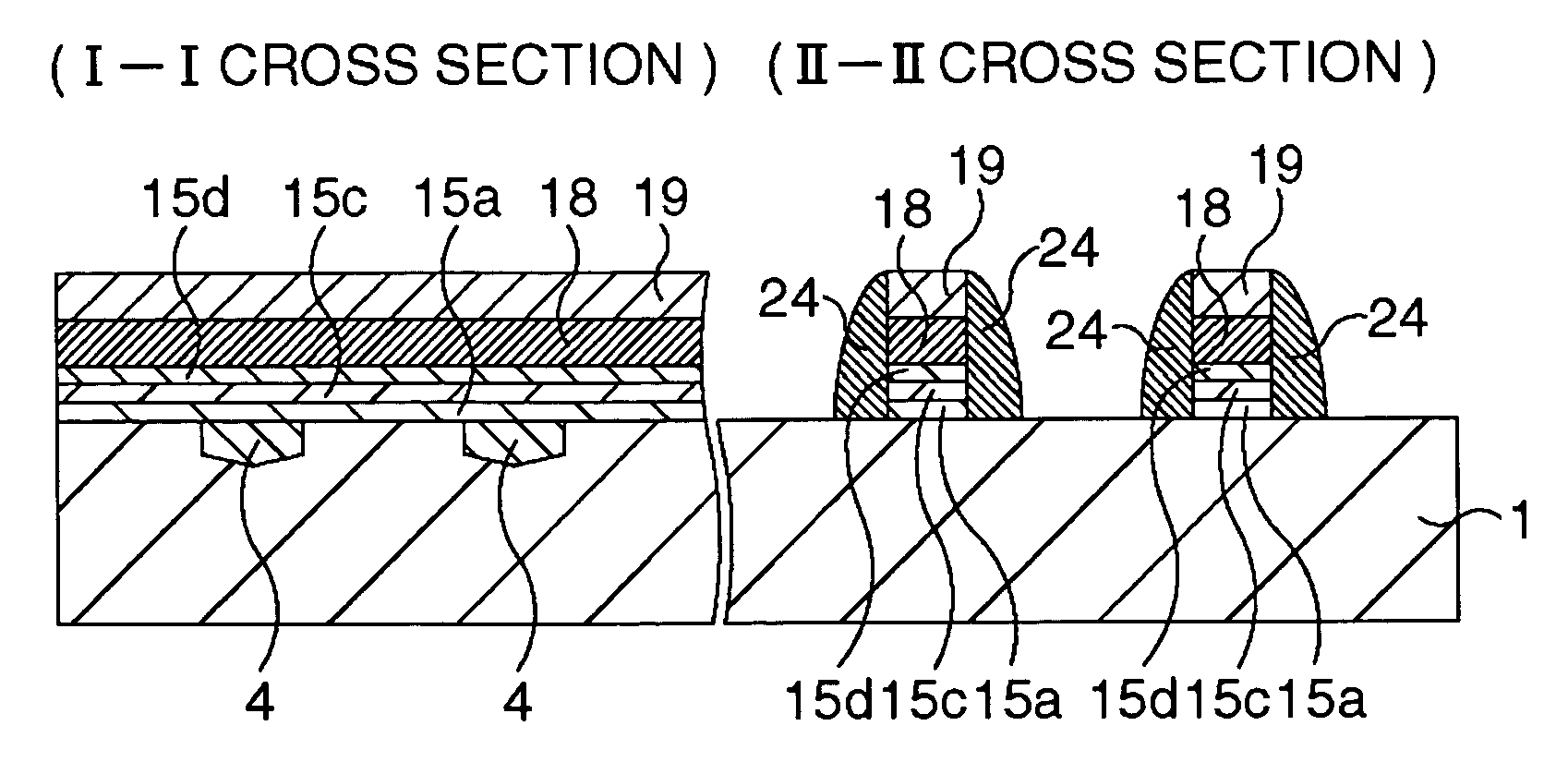

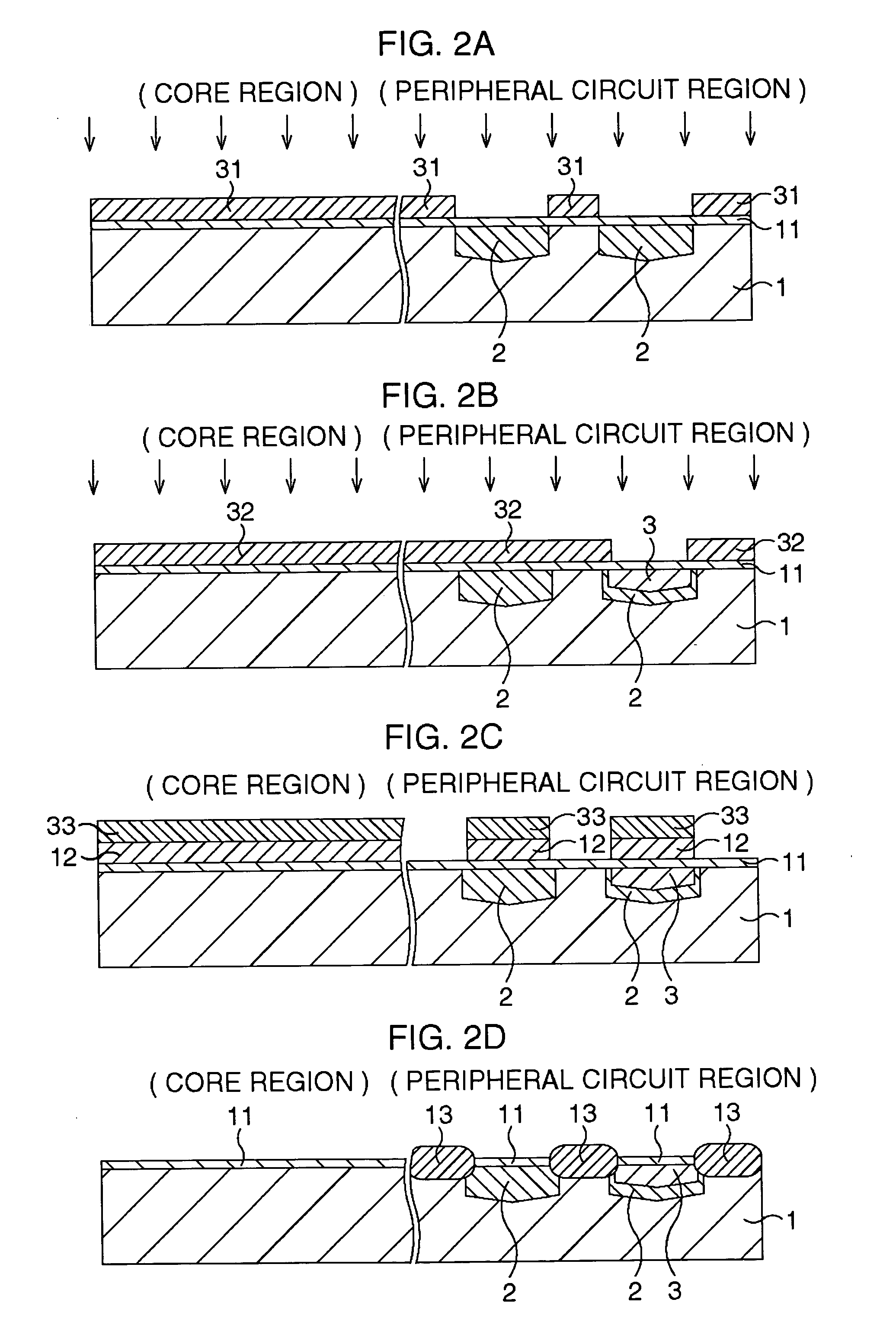

Method of manufacturing semiconductor device

A chemical oxide film formed on a semiconductor substrate is formed by wet cleaning using a strongly acidic solution so that the adhesion of impurities to the chemical oxide film can be reduced between a wet cleaning process and an insulation film forming process. This makes it possible to prevent insulation degradation of a gate insulation film when the gate insulation film embracing the chemical oxide film is formed in the insulation film forming process in which low-temperature processing is conducted.

Owner:SPANSION LLC

Cryogenic process for prolonging service life of jet-moulded high-speed steel milling cutter

ActiveCN103352112AImprove wear resistanceHigh hardnessFurnace typesHeat treatment furnacesAfter treatmentMilling cutter

The invention relates to the technical field of cryogenic processes, in particular to a cryogenic process for prolonging the service life of a jet-moulded high-speed steel milling cutter. The cryogenic process for prolonging the service life of the jet-moulded high-speed steel milling cutter is characterized by comprising the following specific steps: preheating; quenching in vacuum; cooling; tempering primarily; performing cryogenic treatment; and tempering secondarily. Compared with the prior art, a new technology for combining vacuum quenching, tempering and cryogenic treatment is performed on a material of the jet-moulded high-speed steel milling cutter, so that after treatment of the cryogenic process, the wear resistance and the hardness of the material of the jet-moulded high-speed steel milling cutter are obviously improved, the comprehensive mechanical property of the milling cutter is improved and the service life of the milling cutter is prolonged.

Owner:上海汇众汽车车桥系统有限公司

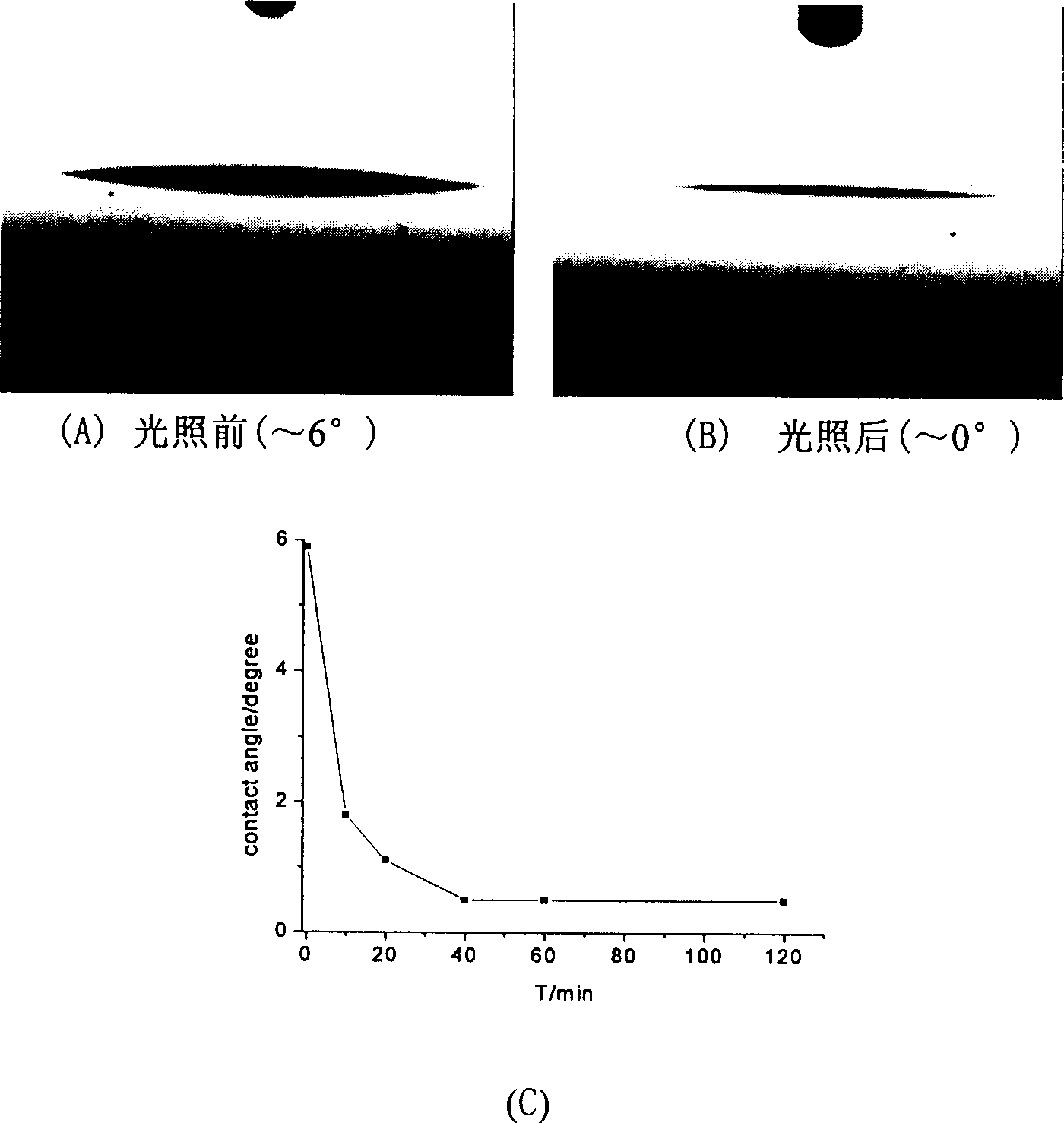

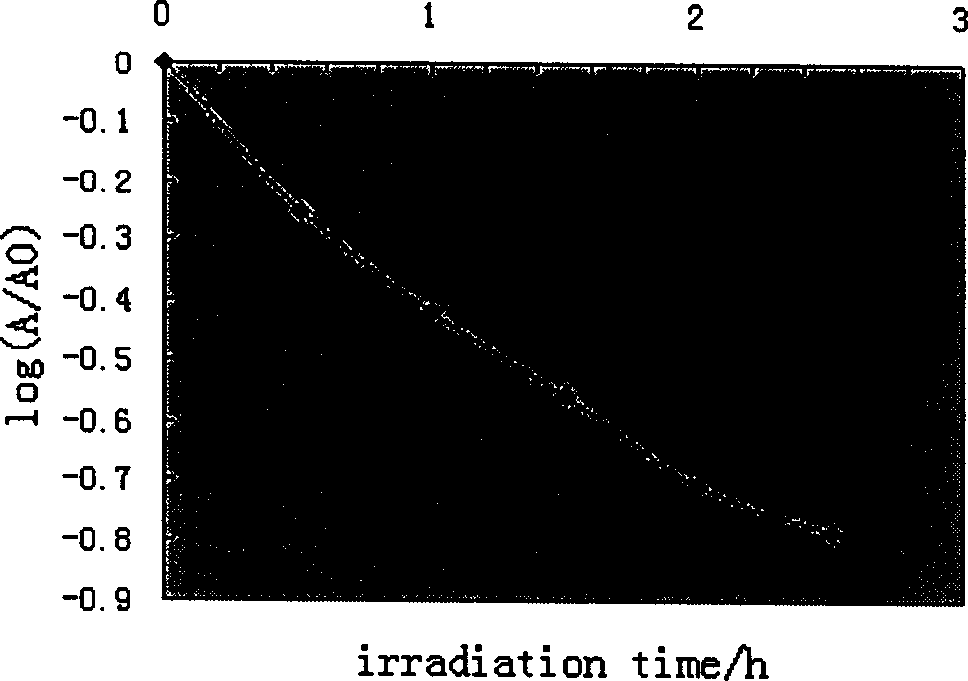

Low-temperature prepn process of self-cleaning nano Tio2 glass

InactiveCN1417147AImprove superhydrophilicityImprove photocatalytic performanceRoom temperatureFree cooling

The present invention relates to a low temperature treating process of self-cleaning TiO2 nanoglass. By using silica and anatase type nanosol as basic components and through pulling process, film is formed on the surface of glass plate. The film is dried at room temperature and cured or treated at temperature below 300 deg.c and cooled naturally. The prepared self-cleaned glass has excellent photocatalytic property, superhydrophilic property, high and homogeneous transparency. The said process is simple, low in cost and suitable for industrial production.

Owner:FUDAN UNIV

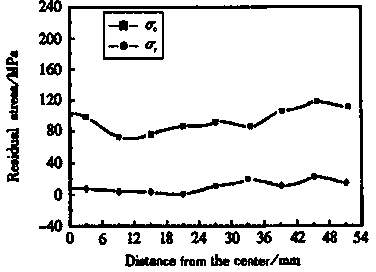

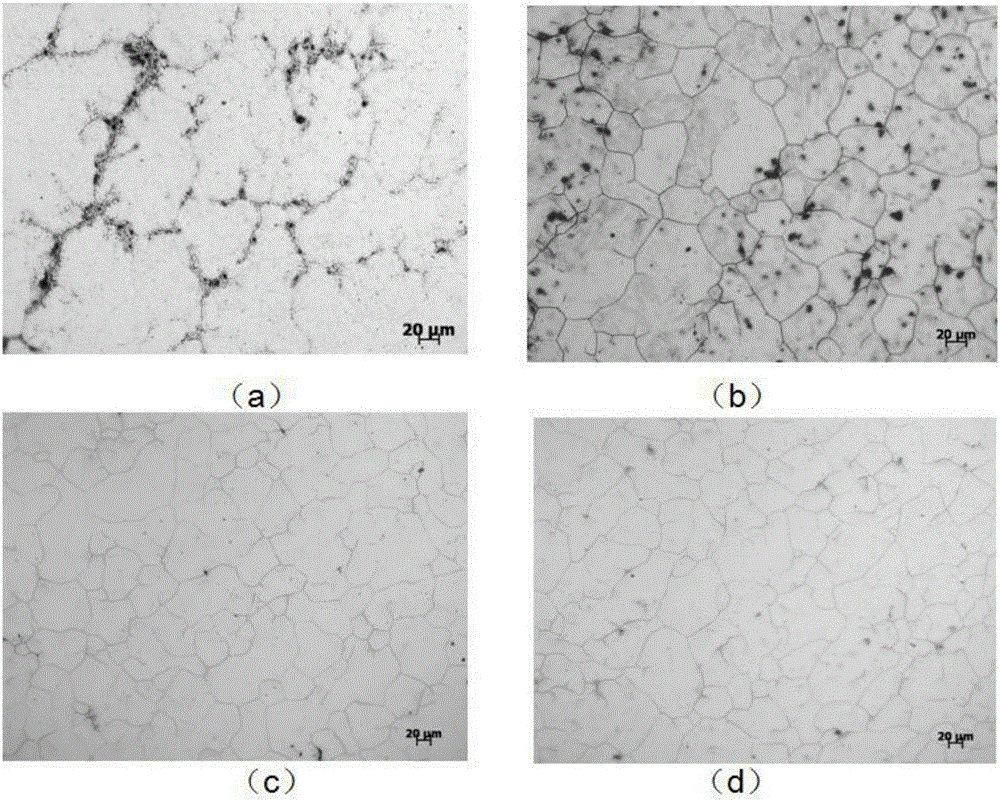

New method for eliminating aluminium alloy workpiece residual stress

The invention provides a new method for eliminating aluminium alloy workpiece residual stress, mainly aims at defects existing in a conventional residual stress eliminating method that the cost is high, the operation is complex, the requirement is high, the workpiece mechanical property is reduced, the workpiece surface is damaged, and the use is limited, and achieves double effects of eliminating residual stress and refining crystal grains through the organic combination of subzero treatment, the uphill quenching technology and conventional heat treatment. The new method has the specific operating steps of solution treatment, subzero treatment, uphill quenching and aging treatment, and has the characteristics that the technology method is simple, the environment is protected, the operation cost is low, the effect is superior to that of the conventional residual stress eliminating method, the residual stress is eliminated, meanwhile, the workpiece comprehensive mechanical property can be improved, and industrialized scale production can be realized.

Owner:葛鹏

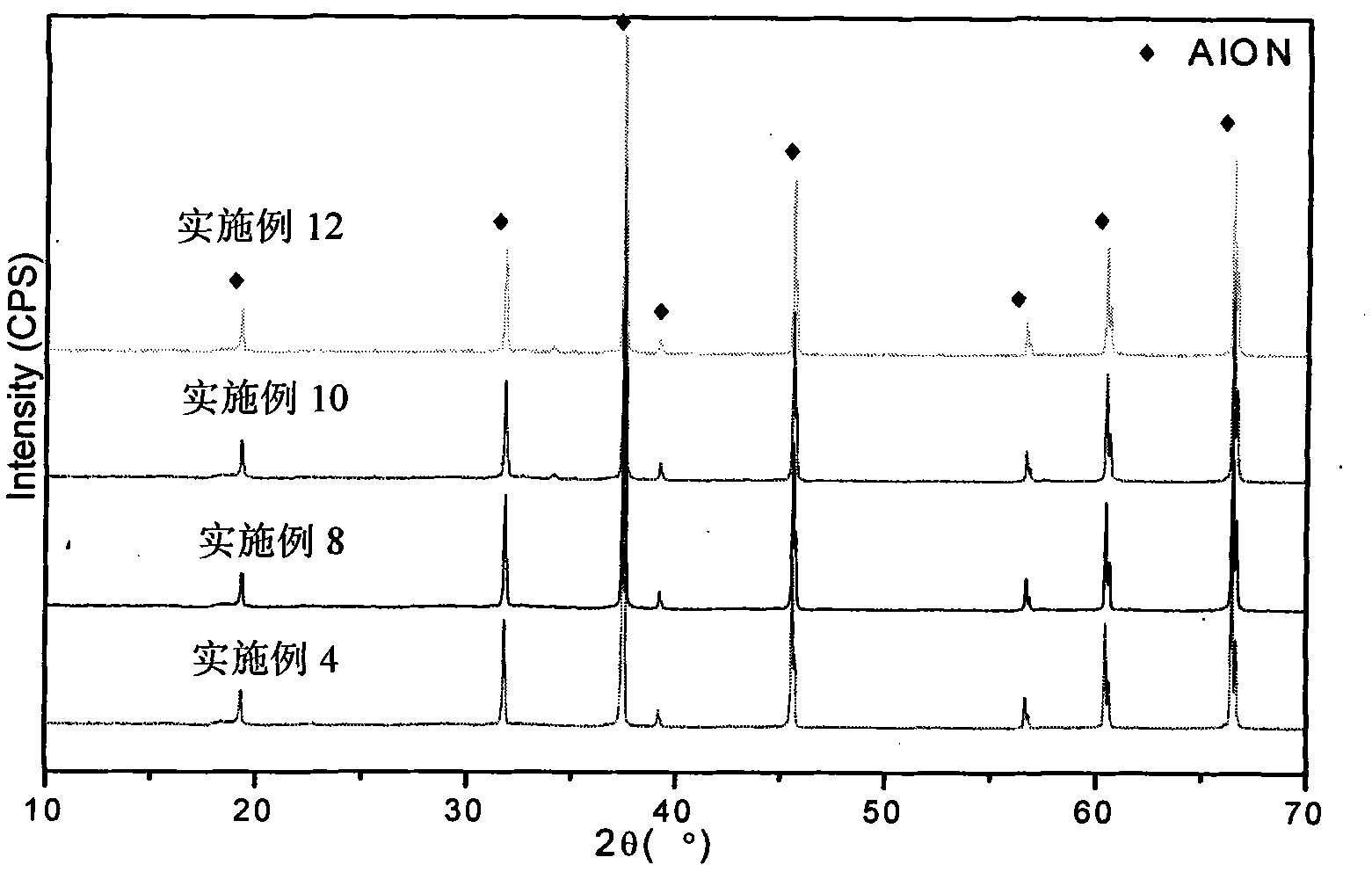

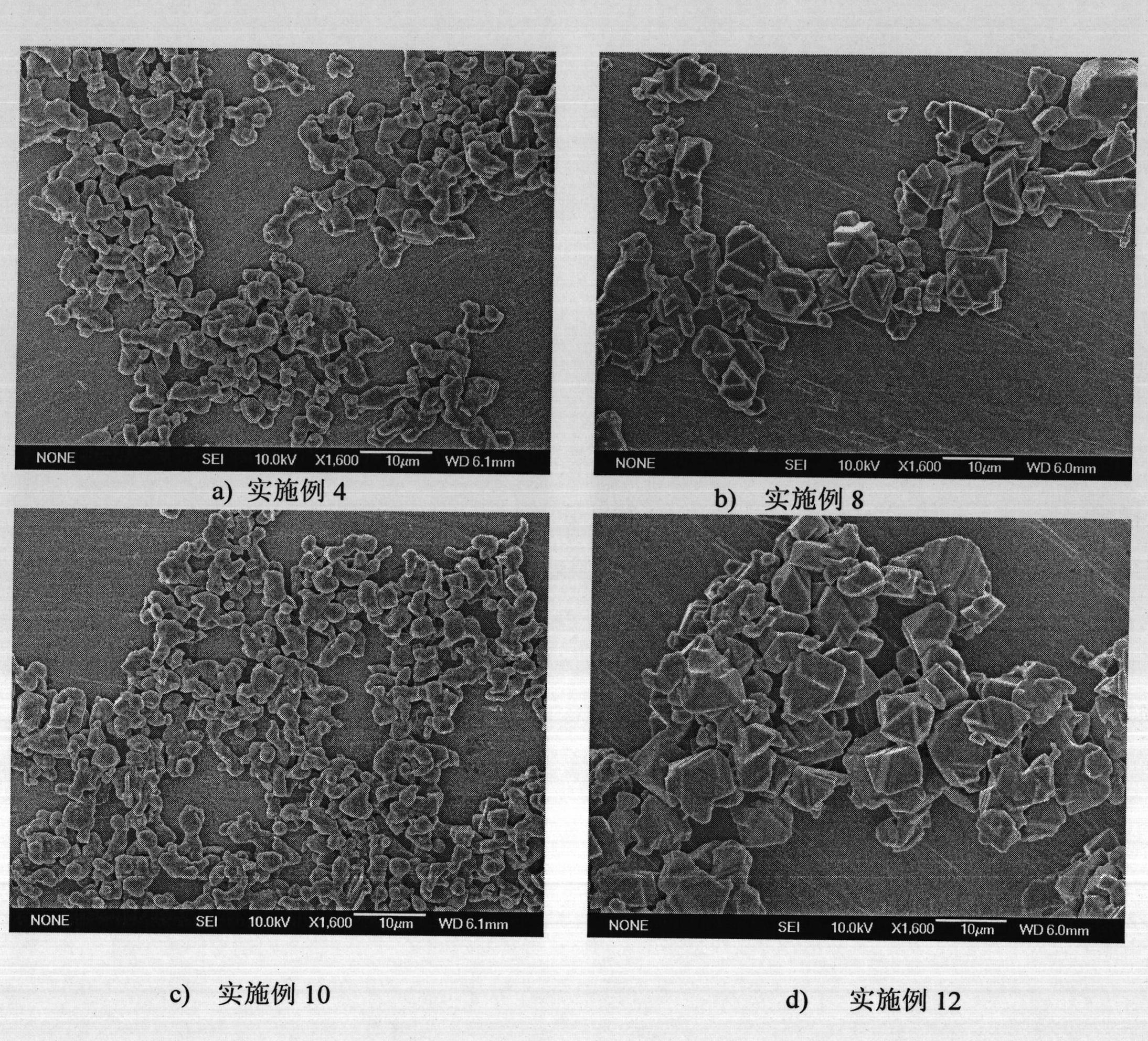

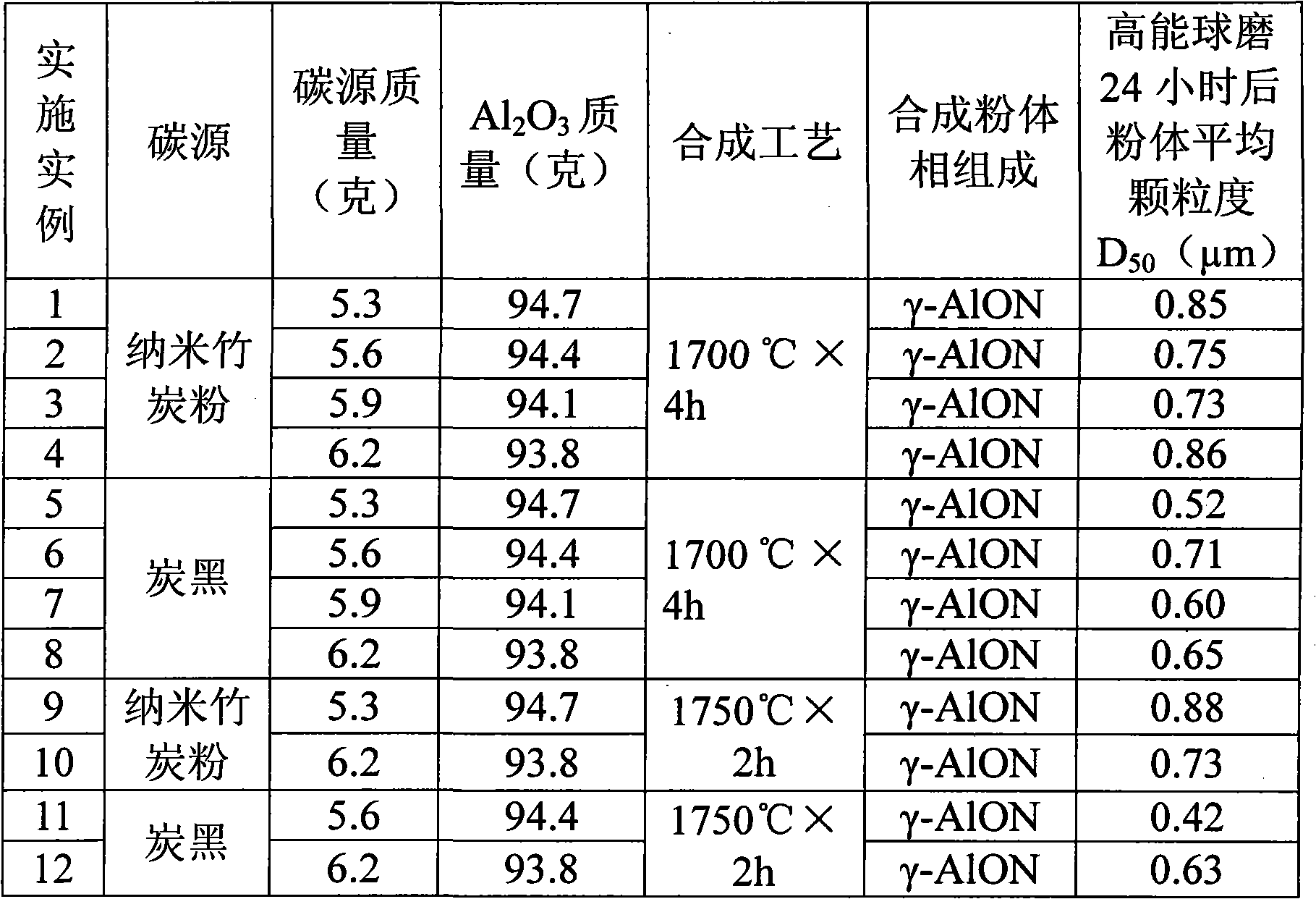

Preparation method of superfine and high-purity gamma-ALON transparent ceramics powder

The invention relates to a preparation method of superfine and high-purity gamma-ALON transparent ceramics powder, belonging to the filed of transparent ceramics material preparation. In the invention, the gamma-ALON transparent ceramics powder is prepared by combining a high energy ball mill with a carbothermic reduction nitriding method. The method of the invention is characterized by comprising the following steps: taking the gamma-Al2O3 powder with high specific surface area and carbon source, i.e. carbon black or nanometer powdered carbon as raw materials, mixing evenly by a wet process high energy ball mill and then drying; placing into a combined crucible of alumina and graphite to carry out the carbothermic reduction nitriding reaction; decarburizing by low-temperature process; and finally obtaining superfine and high-purity gamma-ALON transparent ceramics powder after being crushed by the high energy ball mill. The invention can synthesize pure phase alumina powder under the lower resultant temperature, has simple and feasible process, saves cost, and is suitable for industry production.

Owner:SHANGHAI FRP RES INST

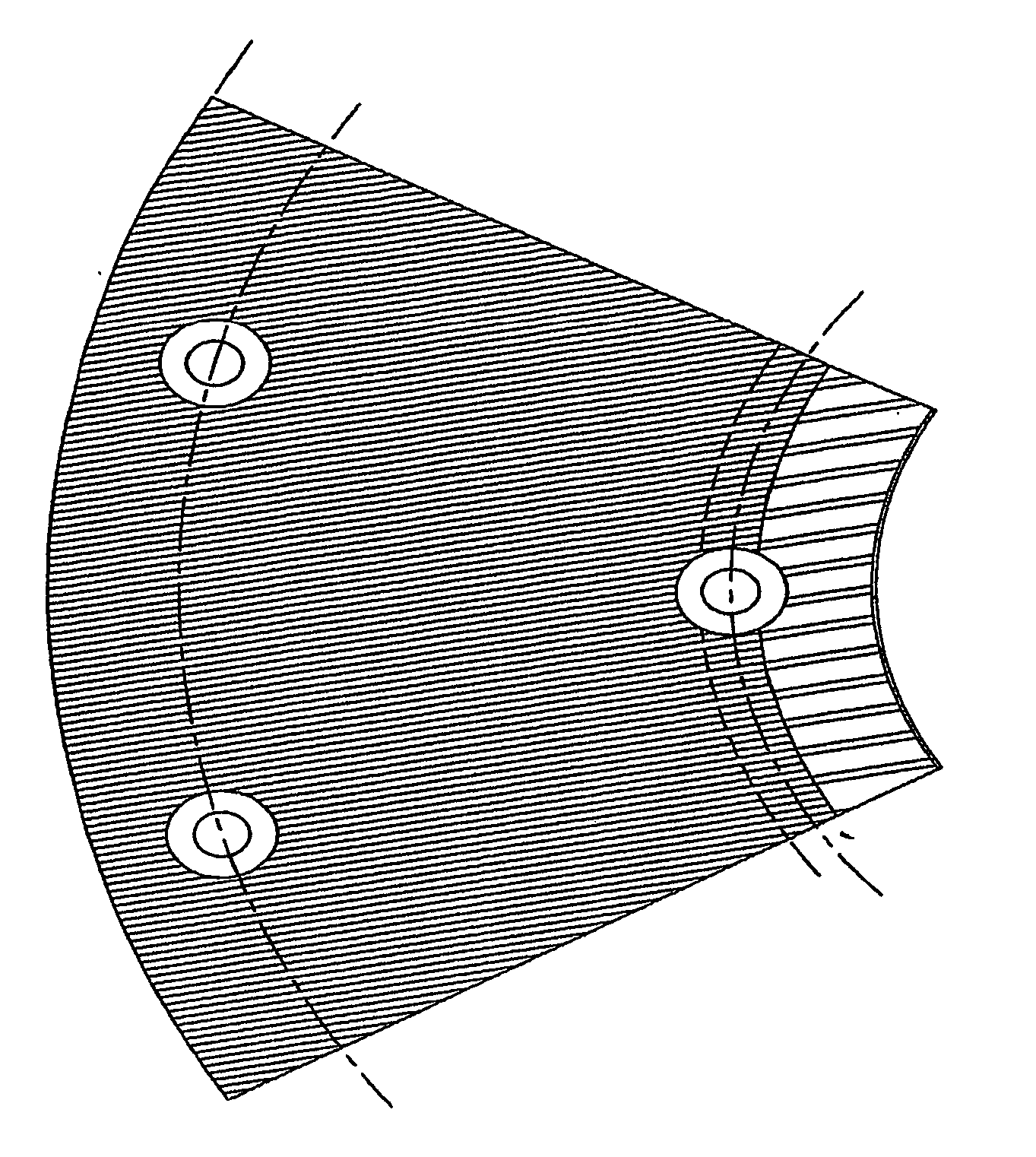

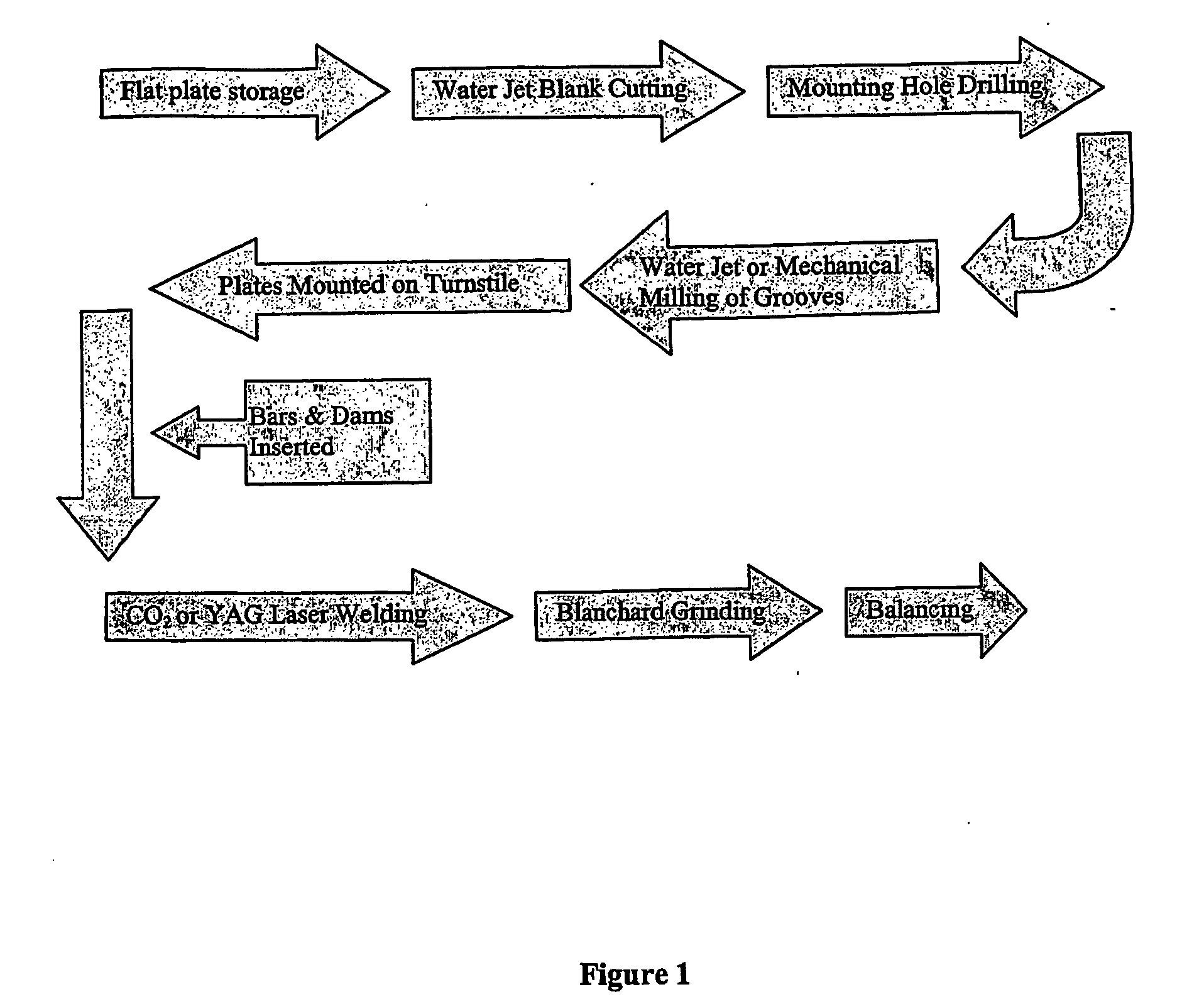

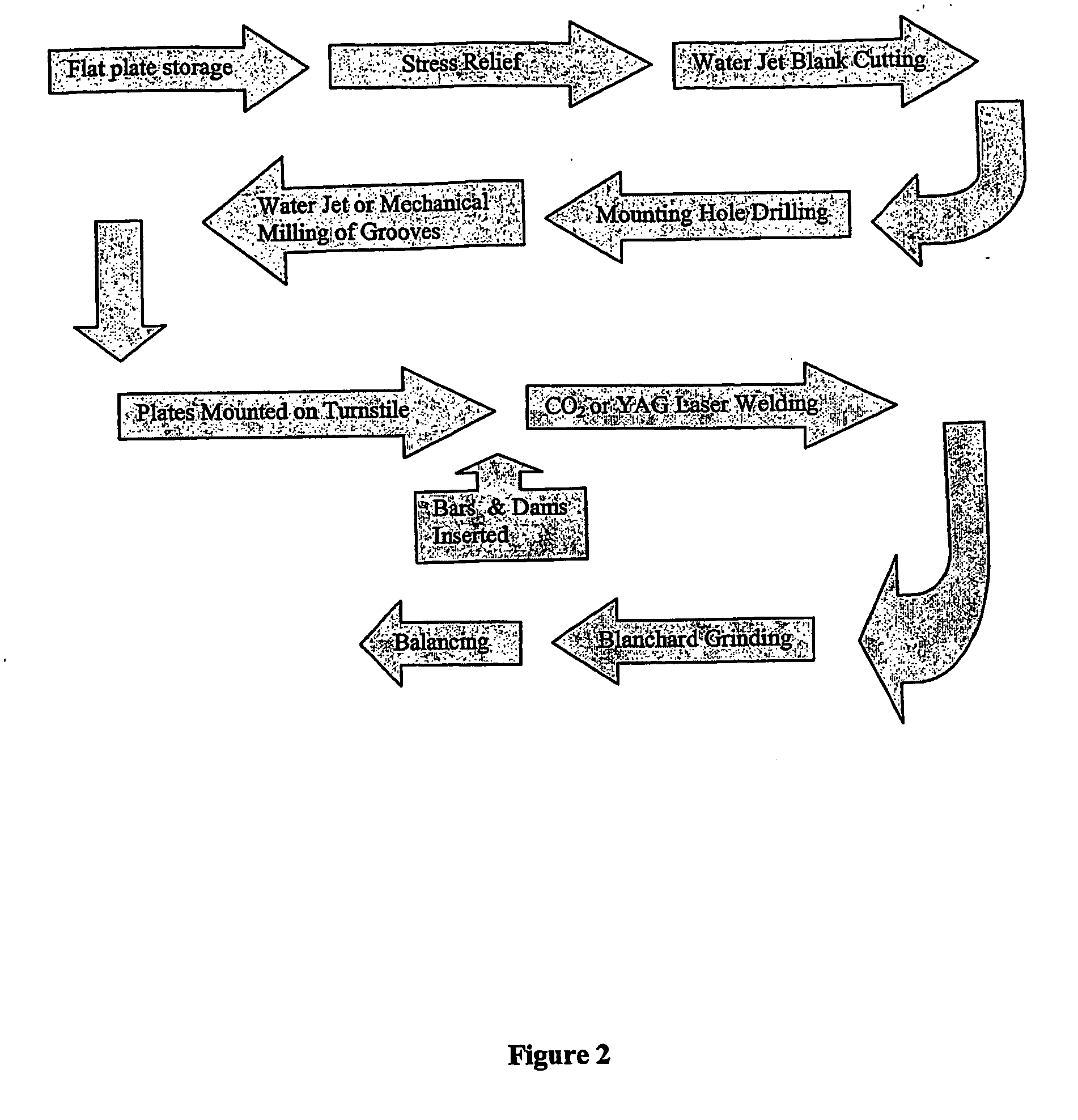

Method of manufacturing refiner elements

InactiveUS20050161542A1Life of element can be lengthenedMaximizes developmentCocoaWelding/soldering/cutting articlesEngineeringCryogenic treatment

An improved method for the manufacture of a solid disc rotor and / or rotor segment for a single disk refiner, double disk refiner, multi-disk refiner, single cone refiner, or a double cone refiner. The invention comprises a plurality of blades spaced apart by recessed locations of a base plate. Either a water jet milling machine or a horizontal gang mill or both may be used. The blades comprise appropriately dimensioned cold rolled and cryogenically stabilized stainless steel or other appropriate stock of the appropriate hardness required by the application. The blades fit into respective locations in the base. The invention is further characterized by a continuous laser weld (85) along either side of each respective blade at its junction with the base, a variety of possible blade and base materials, and the use of one or more of cryogenic treatment, water cut jetting and water jet milling technologies.

Owner:THEUT PATRICK J

Treatment method for improving performance of 3D printing metal workpiece

The invention discloses a treatment method for improving the performance of a 3D printing metal workpiece. The treatment method comprises the following steps of sequentially carrying out primary cryogenic treatment and primary tempering treatment; carrying out secondary cryogenic treatment and secondary tempering treatment on a metal for 3D printing. The 3D printing metal workpiece treated by the treatment method disclosed by the invention has the micro-structural characteristic that when the 3D printing metal workpiece is subjected to cryogenic treatment, due to ultra-low temperature effect, the internal microstructure of the metal workpiece is shrunk, the gap is reduced, and thus the density of the product is increased; meanwhile, under cryogenic treatment conditions, ultrafine carbides are precipitated, the fine dispersed carbides can hinder the movement of dislocation in the plastic deformation of the material, and thus the wear resistance of the metal workpiece is enhanced; the lattice of martensite is promoted to be changed at an ultra-low temperature environment, the internal microstress of the metal workpiece is reduced, and the microstructure is strengthened, so that the hardness, impact toughness and wear resistance of the metal workpiece are significantly increased, and the microstructure and overall performances of the metal workpiece are finally improved, thereby enhancing the mechanical properties of the 3D printing metal workpiece.

Owner:NANTONG HUDA MASCH EQUIP CO LTD

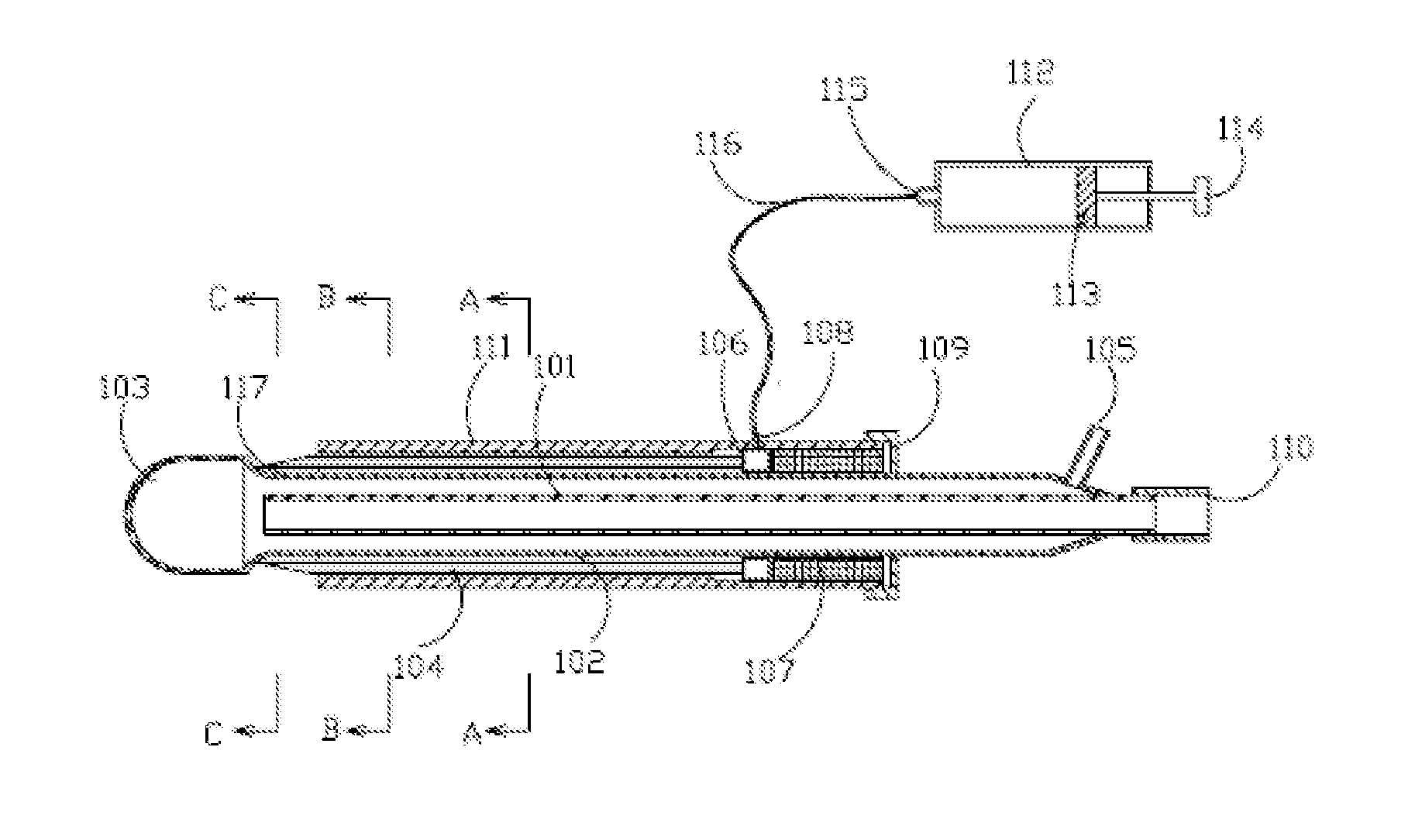

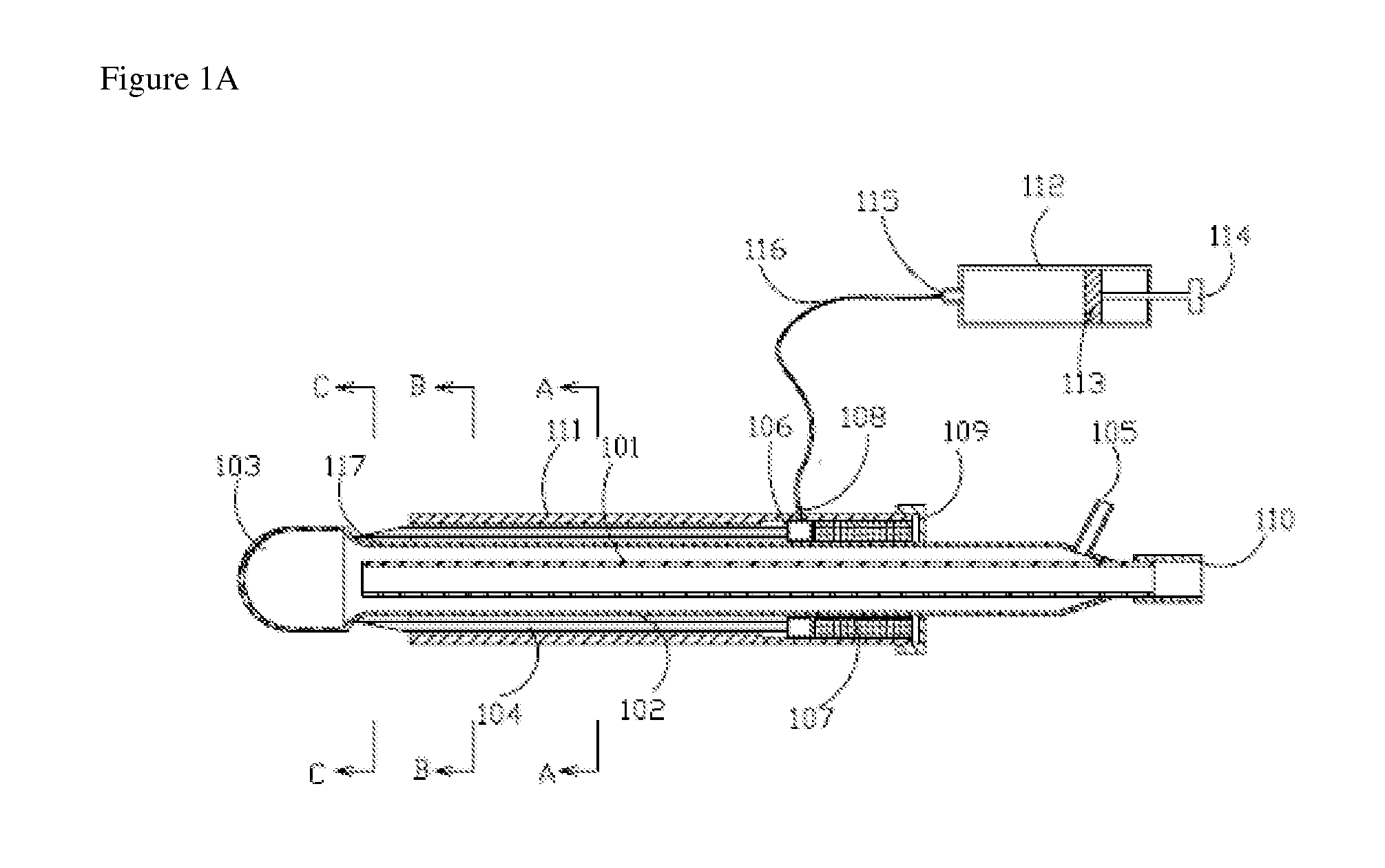

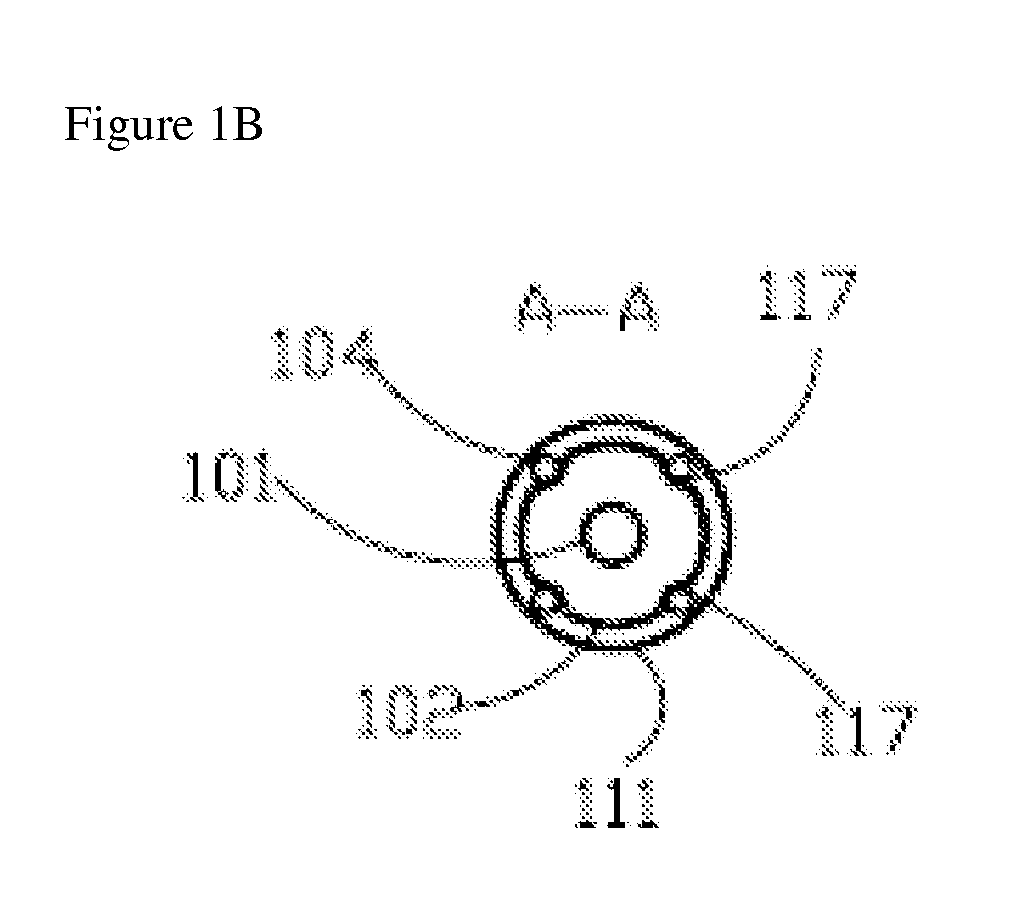

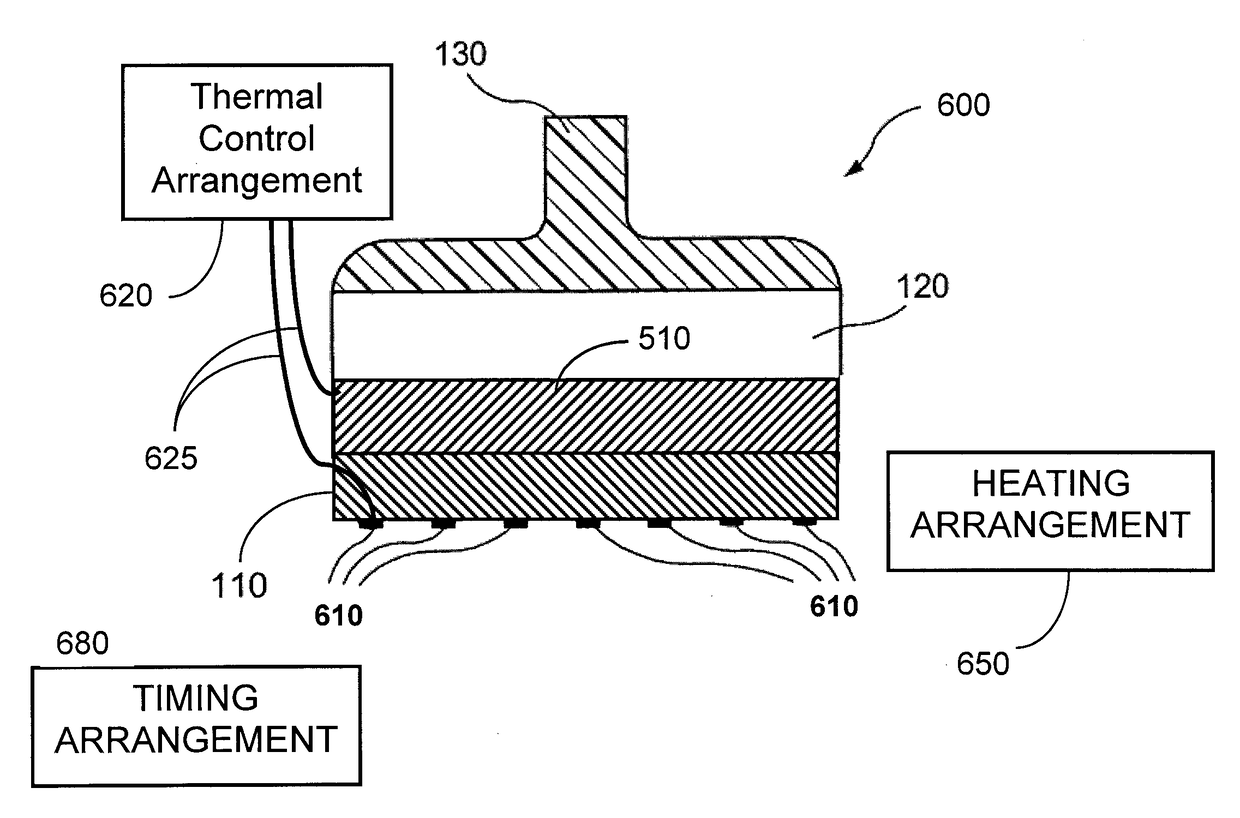

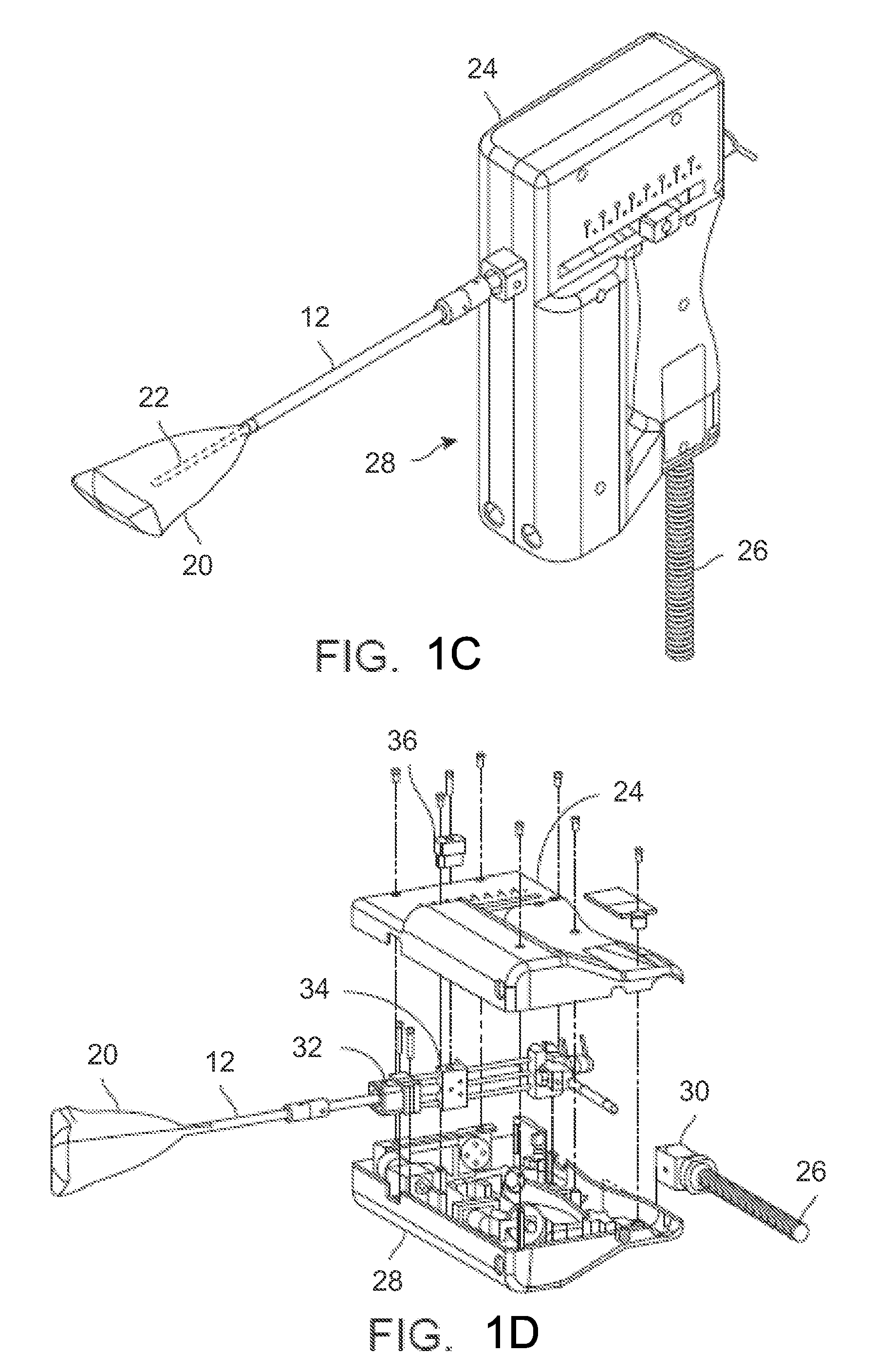

Apparatus and methods for regulating cryogenic treatment

ActiveUS20150289920A1Reduce cooling rateExtended availabilitySurgical instruments for coolingControl treatmentCryogenic treatment

Apparatus and methods for regulating cryogenic treatments are disclosed which comprise devices and methods for delivering controlled treatment of a cryoablative agent. In one variation, such devices may generally comprise an elongate probe having a distal tip and a flexible length, at least one infusion lumen positioned through or along the elongate probe, wherein the infusion lumen defines one or more openings along its length, and a liner expandably enclosing the probe. An inflow reservoir or canister valve may be fluidly coupled with a reservoir or canister containing the cryoablative agent and a modulation control unit may also be fluidly coupled with the inflow reservoir or canister valve and in fluid communication with the at least one infusion lumen. Additionally, a warming element may also be thermally coupled with the reservoir or canister.

Owner:CHANNEL MEDSYST

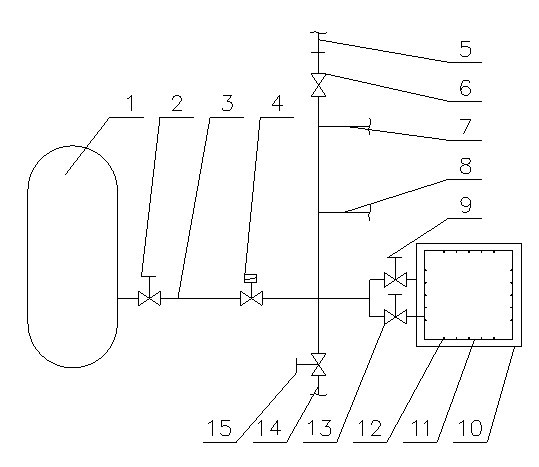

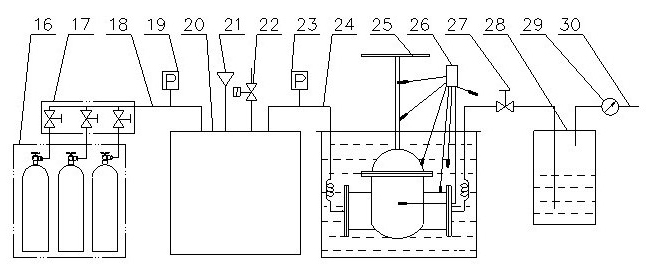

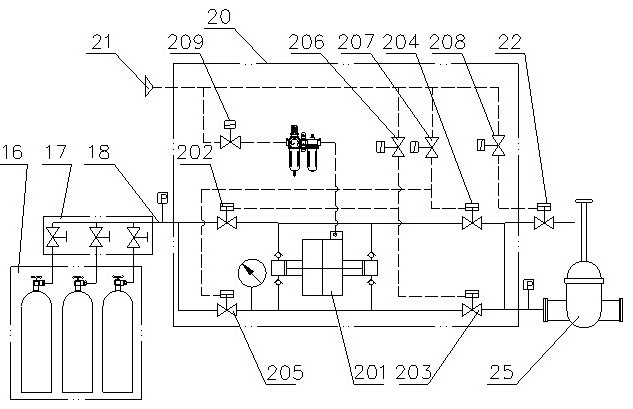

Saving type valve low temperature test system

ActiveCN101957294AGood insulation performanceReduce evaporationMeasurement of fluid loss/gain rateDomestic cooling apparatusProcess engineeringCryogenic treatment

The invention relates to a valve low temperature test system, in particular to a saving type valve low temperature test system capable of carrying out both cryogenic treatment on parts and valve low temperature test. The valve system comprises a low temperature environment unit and a test environment unit, wherein the low temperature environment unit is used for carrying out the cryogenic treatment on a valve to be tested, and the test environment unit provides gas for the valve to be tested; and the valve system further comprises a process monitoring unit for monitoring the test process. Theinvention can carry out both the cryogenic treatment on the parts and the valve low temperature test; in addition, the invention reduces the wastage of liquid nitrogen and helium and the accident risk of testers, and greatly reduces the manufacturing and testing costs of the system.

Owner:HEFEI GENERAL ENVIRONMENT CONTROL TECH

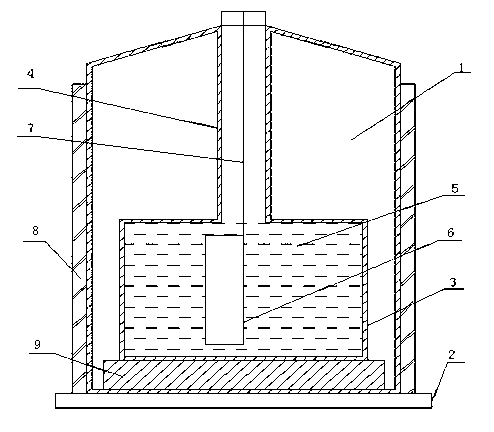

Heat treatment method for ultra-high-hardness nonferrous-metal cold roll

ActiveCN104032117AFully austenitizedIncrease the amount of solid solution carbonFurnace typesHeat treatment furnacesNonferrous metalCryogenic treatment

The invention discloses a heat treatment method for a ultra-high-hardness nonferrous-metal cold roll. The heat treatment method comprises the following steps: a, firstly putting the roll in a preheating furnace for preheating at a temperature of 220-250 DEG C; b, installing the roll on a quenching machine tool to performing rotation water-spraying quenching on the roll body, wherein the working parameters of the quenching machine tool comprise the quenching temperature of 900-950 DEG C, the quenching water temperature of 15-25 DEG C and the quenching water pressure of 0.15-0.30 MPa; c, after quenching, performing ultralow-temperature deep cryogenic treatment at -120 DEG C to -180 DEG C; d, after deep cryogenic treatment is finished, hanging the roll and sending to a heating furnace to quench at 100-120 DEG C, and controlling the quenching time to not less than 72 h; and e, performing hardness detection on the surface of the roll body subjected to quenching, so as to prepare the needed ultra-high-hardness nonferrous-metal cold roll is the surface hardness is qualified. The surface hardness of the prepared roll reaches 102-105 HSD, the hardness uniformity is 1 HSD or less, and the depth of a hardening layer reaches 20 mm or more.

Owner:YIXING YONGCHANG ROLL

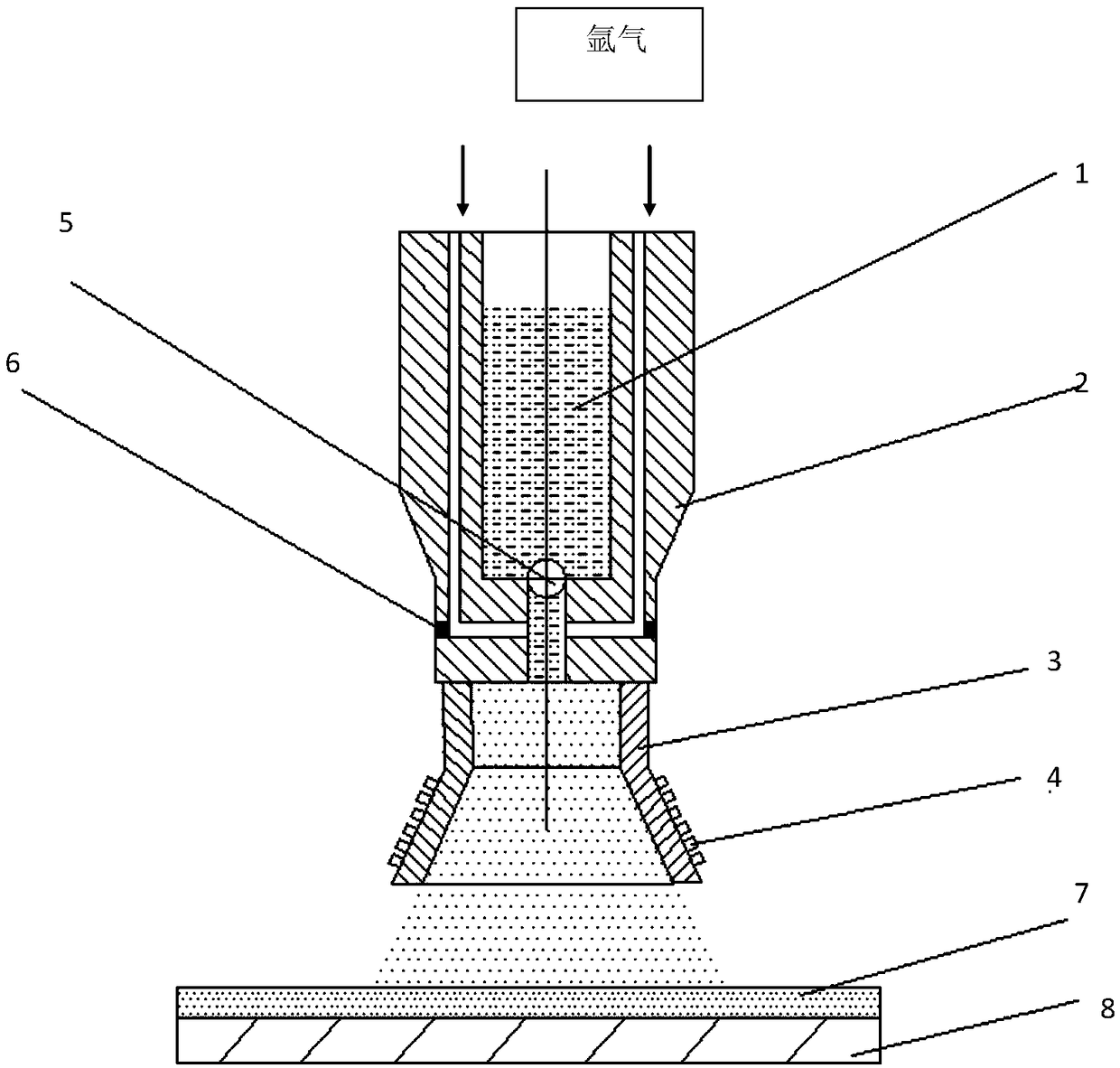

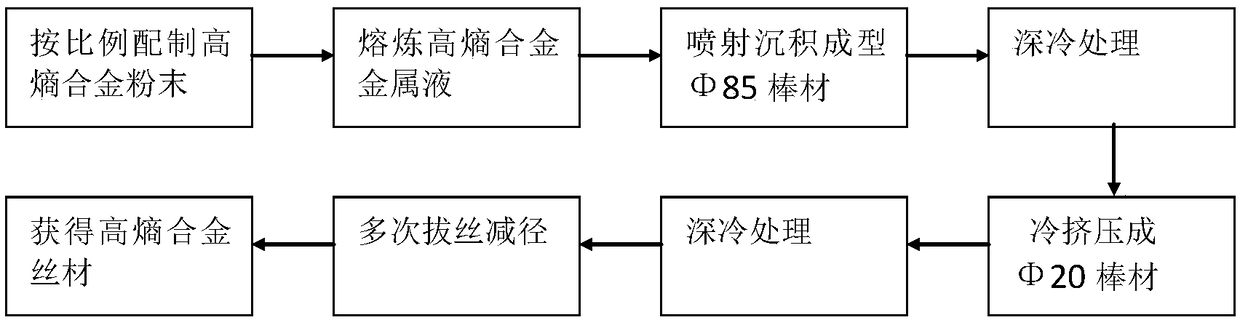

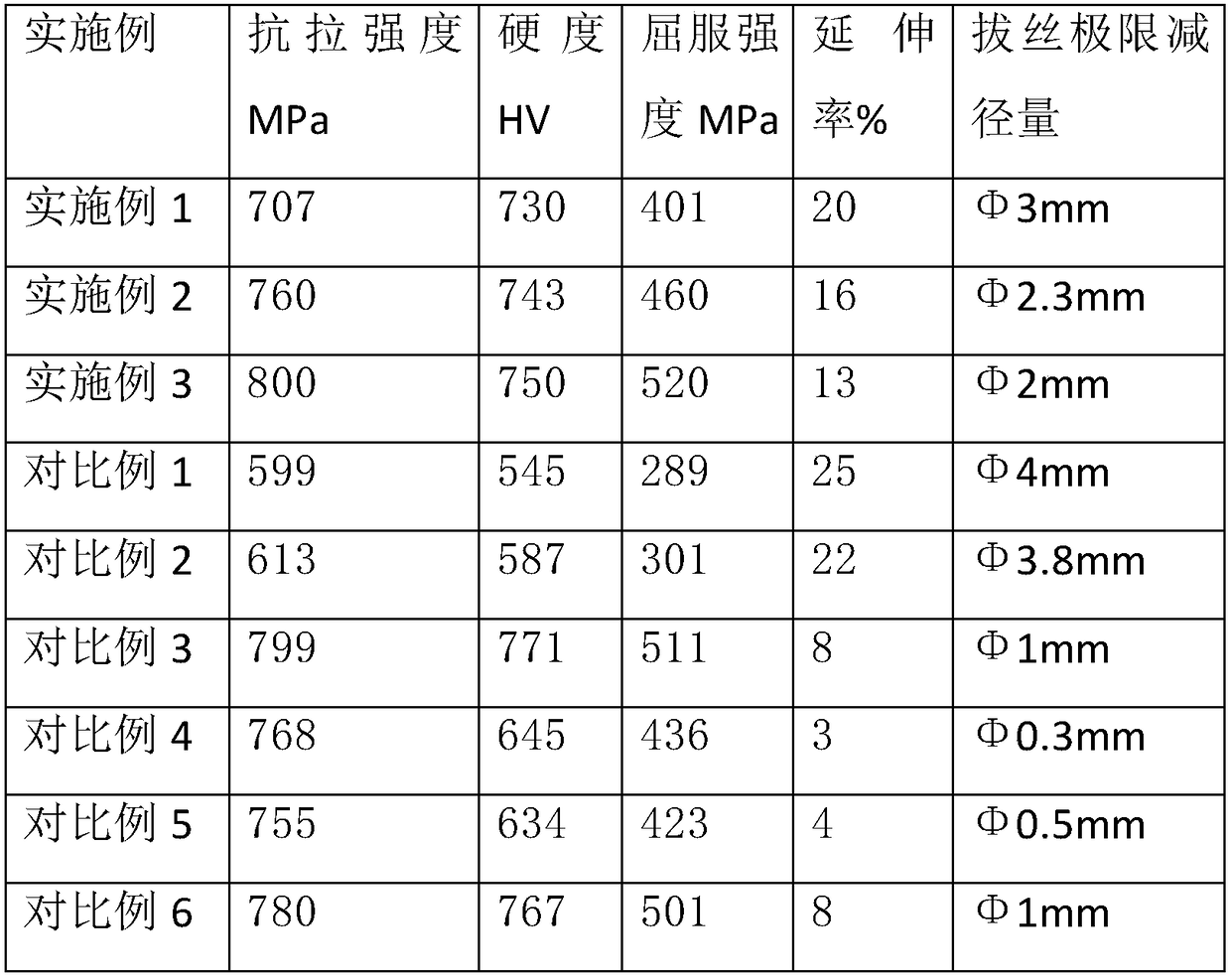

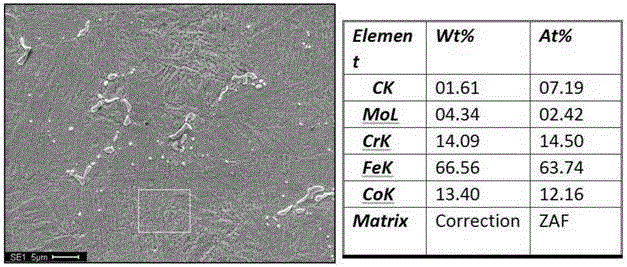

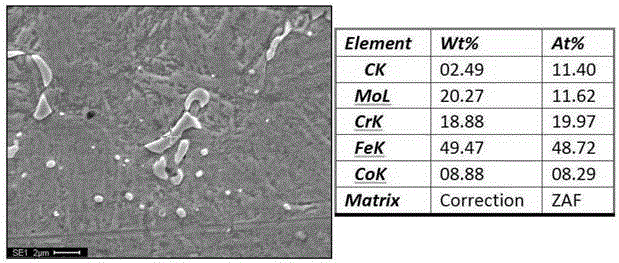

High-entropy alloy solid wire for arc cladding and preparation method thereof

ActiveCN109234601AImprove plasticityHigh strengthMetallic material coating processesHigh entropy alloysRoom temperature

The invention discloses a high-entropy alloy solid wire for arc cladding. The solid wire is a high-entropy alloy composed of 5 base elements: Co, Cr, Fe, Mn and Ni and a non-base element: Er. The preparation method comprises the following steps: (1) ball milling: weighing Co powder, Cr powder, Fe powder, Ni powder, Mn powder and Er powder according to molar fractions, and adding the powder into ahigh-energy ball mill for ball milling; (2) spray deposition molding: melting the high-entropy alloy powder, atomizing and depositing the solution into a cylindrical mold with high-pressure argon to obtain a high-entropy alloy bar; (3) cryogenic treatment: soaking the high-entropy alloy bar in liquid nitrogen at -196 DEG C for 48 h; (4) extrusion process: extruding the high-entropy alloy bar tilla diameter is phi 20 mm, and naturally heating the alloy bar to room temperature; (5) wire drawing process: soaking the extruded high-entropy alloy bar in the liquid nitrogen at -196 DEG C for 24 hours, performing wire drawing and reduction for multiple times, and finally obtaining the solid wire with the diameter of phi 2 mm.

Owner:JIANGSU UNIV OF TECH

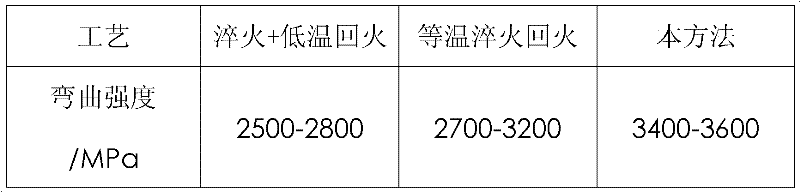

Heat treatment process for improving strength and toughness of 9SiCr die steel

The invention discloses a heat treatment process for improving the strength and toughness of 9SiCr die steel. The 9SiCr die steel is subjected to the final heat treatment after preheating treatment. The final heat treatment comprises the following steps of: heating to 880-920 DEG C for austenization, performing isothermal oil quenching at 230-260 DEG C, pre-tempering for 1 hour at 160-200 DEG C, then performing cryogenic treatment for at least 24 hours at a temperature between -130 DEG C and -190 DEG C, and finally tempering for 2 hours at 180-200 DEG C. With the process provided by the invention, the hardness value of a die is increased as compared with that of the isothermal quenching and tempering process and close to that of the quenching and tempering process; the impact toughness of the die is greatly increased as compared with those of the isothermal quenching and tempering process and the quenching and low-temperature tempering process and increased by 2 to 3 times as compared with that of the isothermal quenching and tempering process. Besides, both the wear-resistant property and the service life of the die are greatly improved.

Owner:SOUTHWEST JIAOTONG UNIV

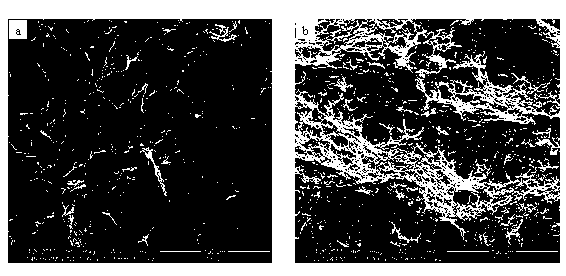

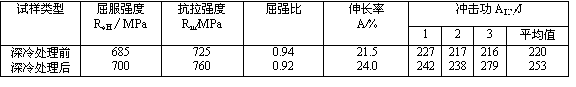

Quenching/subzero treatment method for heat treatment of low-temperature nickel steel

The invention relates to a quenching / subzero treatment method for heat treatment of low-temperature nickel steel, which comprises the following steps: based on characteristics and service conditions of low-temperature nickel steel, performing quenching, rapid cooling and liquid nitrogen subzero treatment on 9Ni low-temperature steel; and performing low-temperature tempering to relieve the internal stress, thus greatly enhancing the strength, toughness and hardness of the 9Ni low-temperature steel. After the treatment, the hardness can be up to HRC31-33, the yield strength is up to 695-705MPa, the tensile strength is up to 750-760MPa, and the low-temperature impact energy of the toughness is up to 250-260J. The technical method is advanced, full and accurate in data, favorable in treatment effect and high in stability, thus being a very ideal low-temperature nickel steel quenching / subzero treatment method. Other types of low-temperature steel can also be treated by using the method.

Owner:TAIYUAN UNIV OF TECH

Method for modification of glass fiber composite material by ultralow temperature treatment

Owner:DONGHUA UNIV

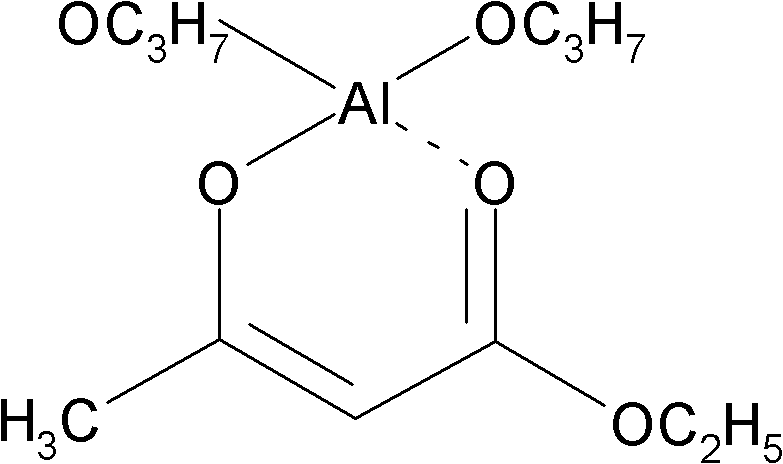

Electrically conductive ink, and laminate having electrically conductive pattern attached thereto and process for production thereof

ActiveCN102395634AExcellent resistance value stabilityGood effectConductive layers on insulating-supportsSynthetic resin layered productsScreen printingEpoxy

Disclosed are: a low-temperature-processing-type electrically conductive ink which enables the formation of an extremely fine electrically conductive pattern by screen printing, does not require any specialized process for production thereof, and has excellent resistance value stability; a laminate having an electrically conductive pattern attached thereto, which is produced using the electrically conductive ink; and a process for producing the laminate. The electrically conductive ink comprises electrically conductive particles each having a tap density of 1.0 to 10.0 (g / cm3), a D50 particle diameter of 0.3 to 5 [mu]m and a BET specific surface area of 0.3 to 5.0 m2 / g, an epoxy resin having a number average molecular weight (Mn) of 10,000 to 300,000 and a hydroxy value of 2 to 300 (mgKOH / g), and a metal chelate capable of achieving an alcohol interchange reaction with a hydroxy group in the epoxy resin and contained in an amount of 0.2 to 20 parts by weight relative to 100 parts by weight of the epoxy resin, and has a storage modulus (G') of 5,000 to 50,000 (Pa).

Owner:TOYO INK SC HOLD CO LTD +1

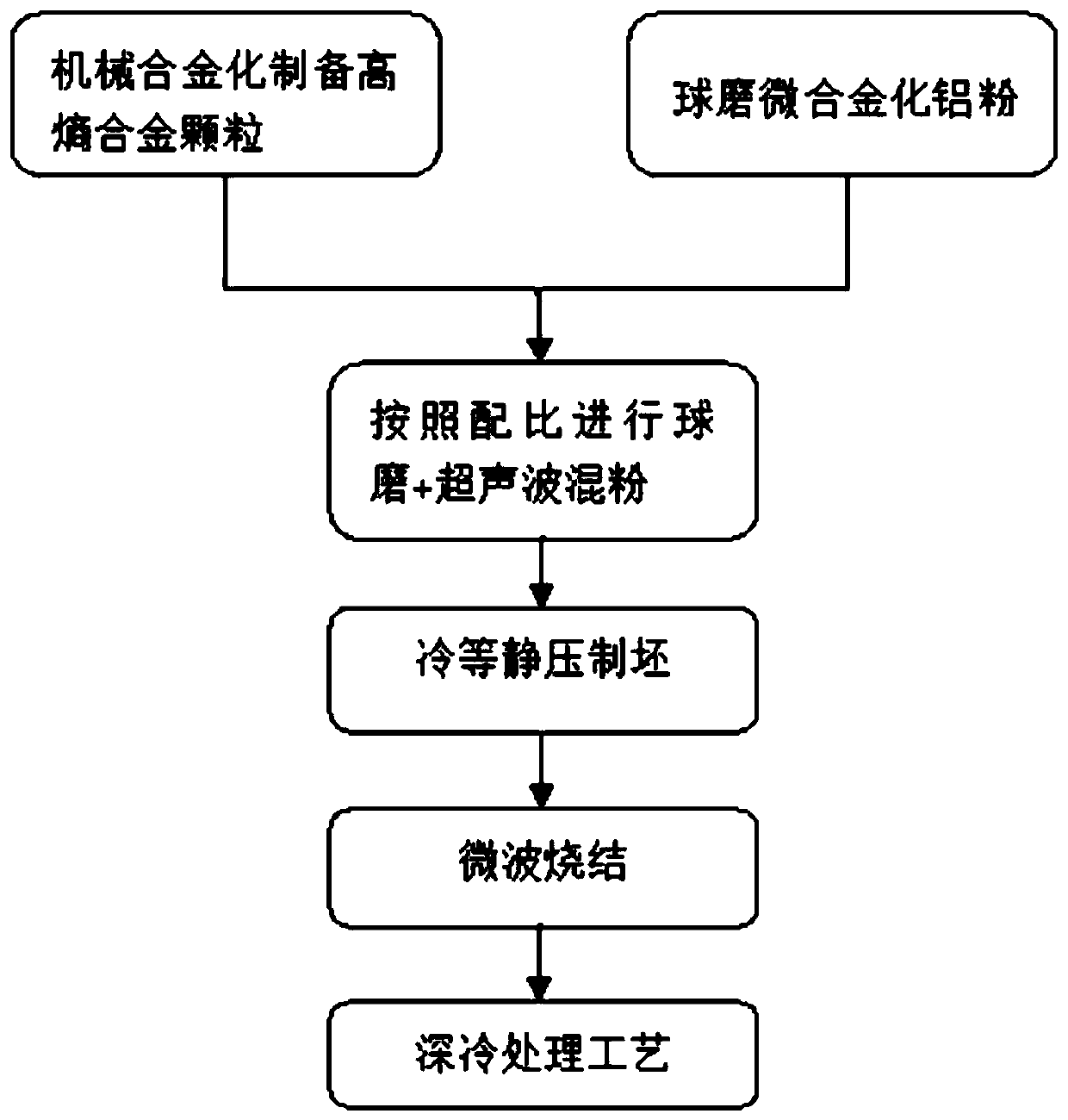

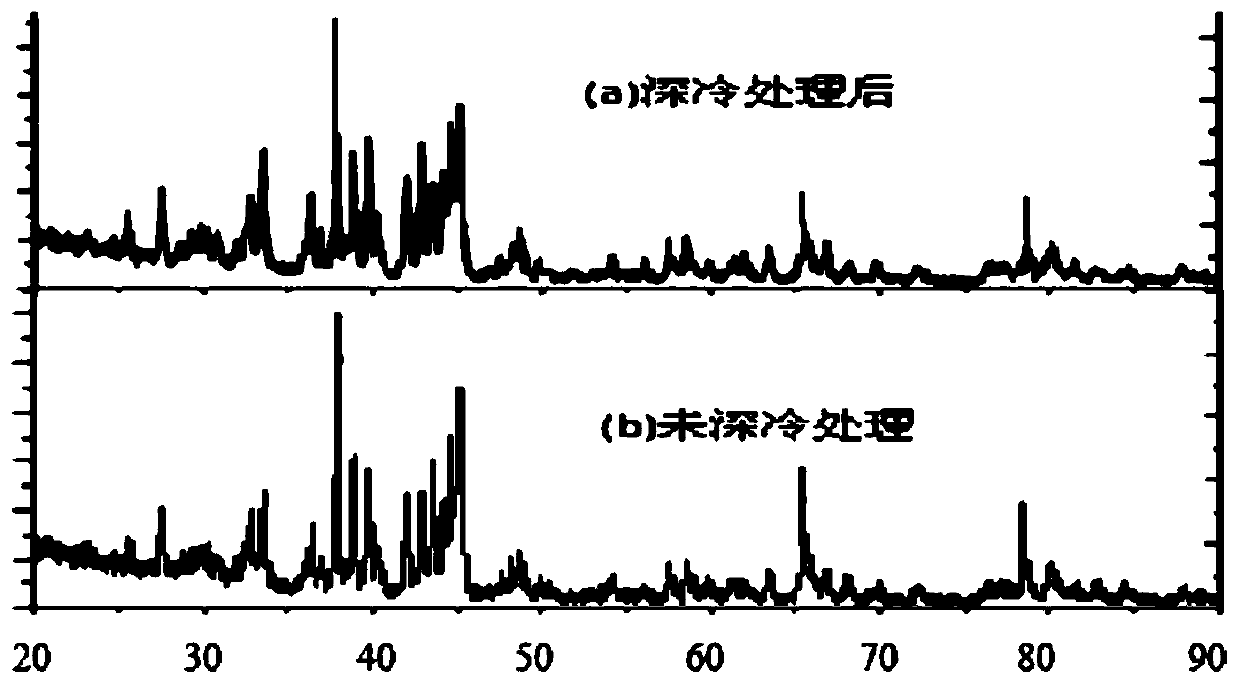

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

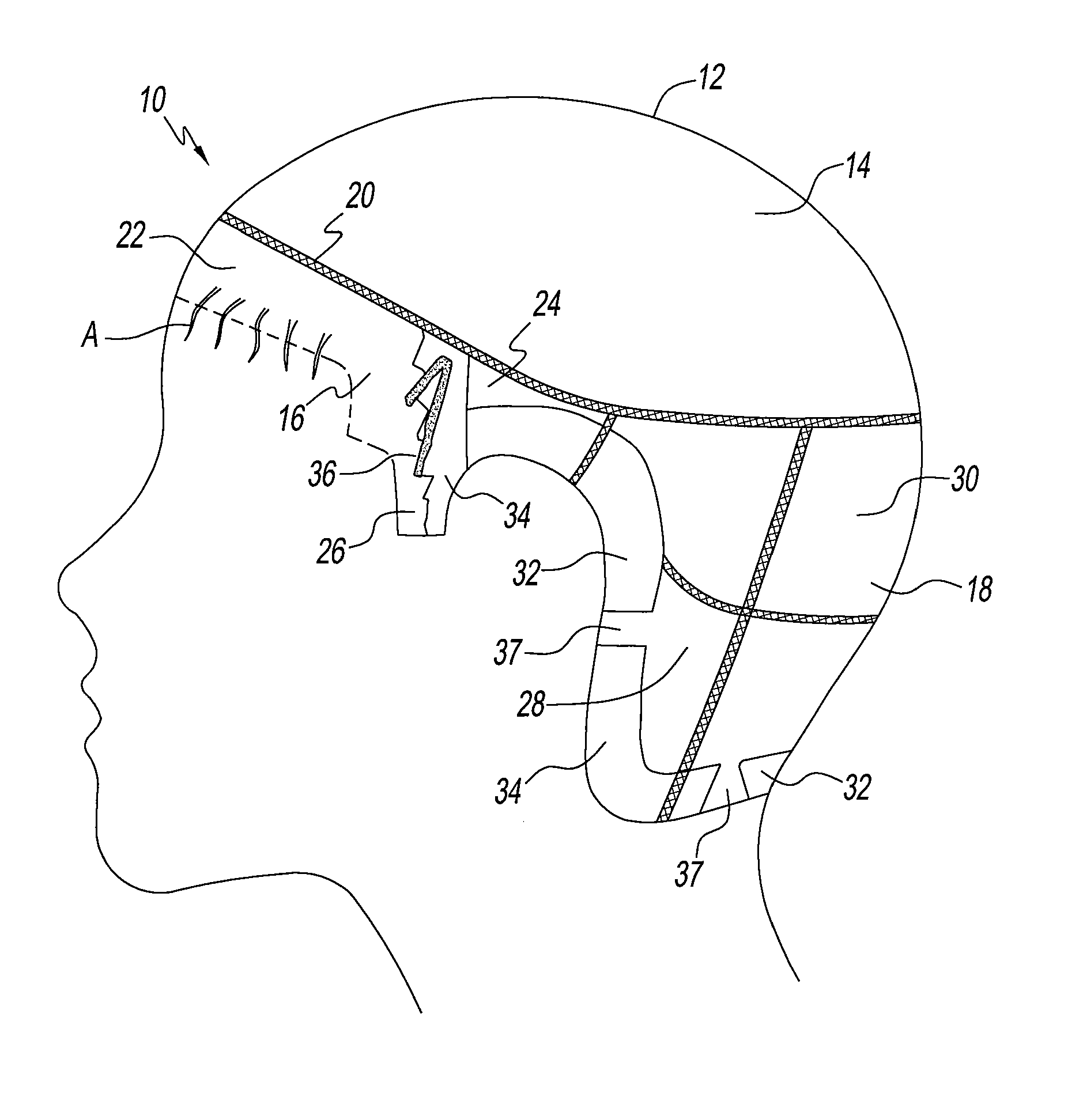

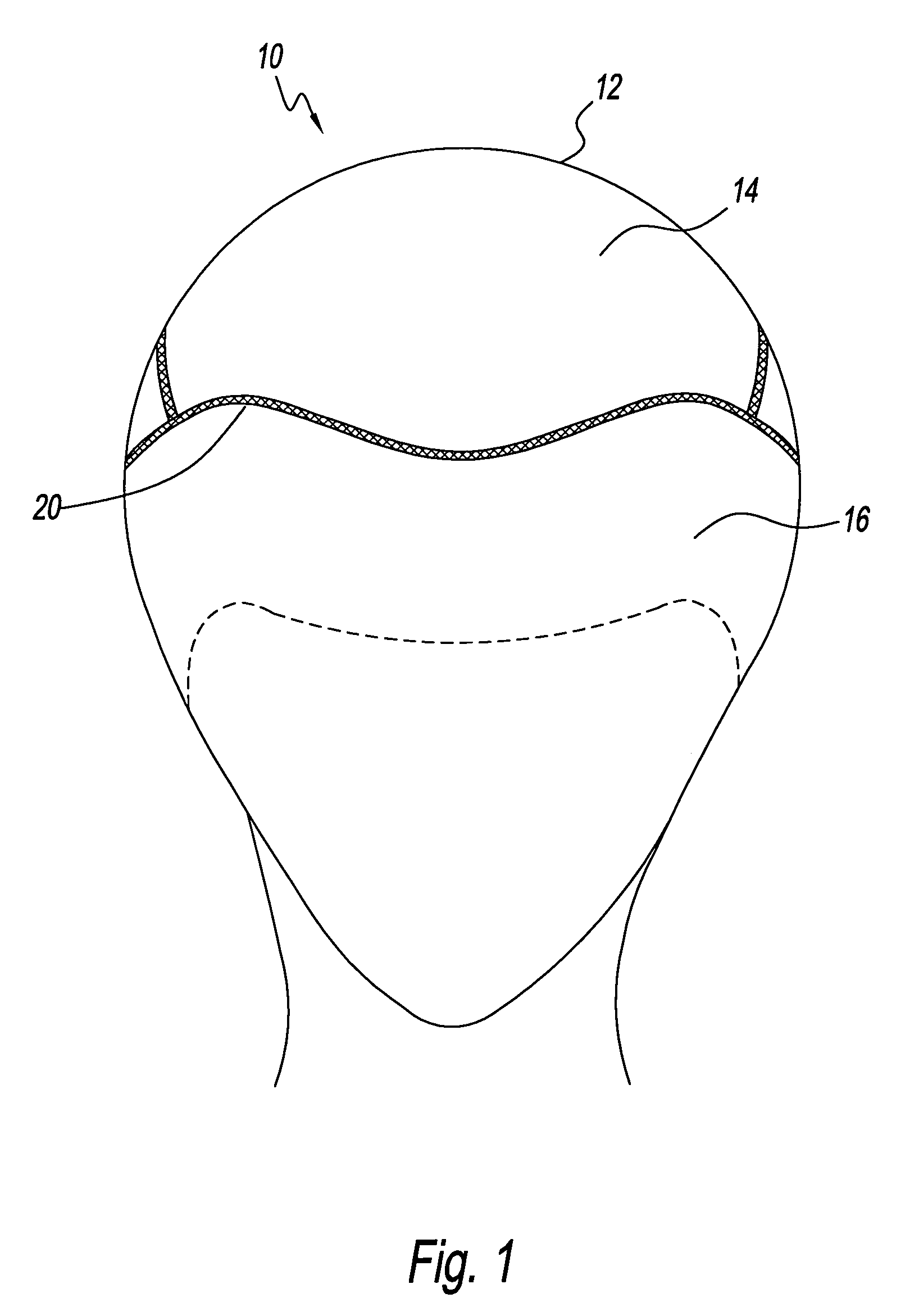

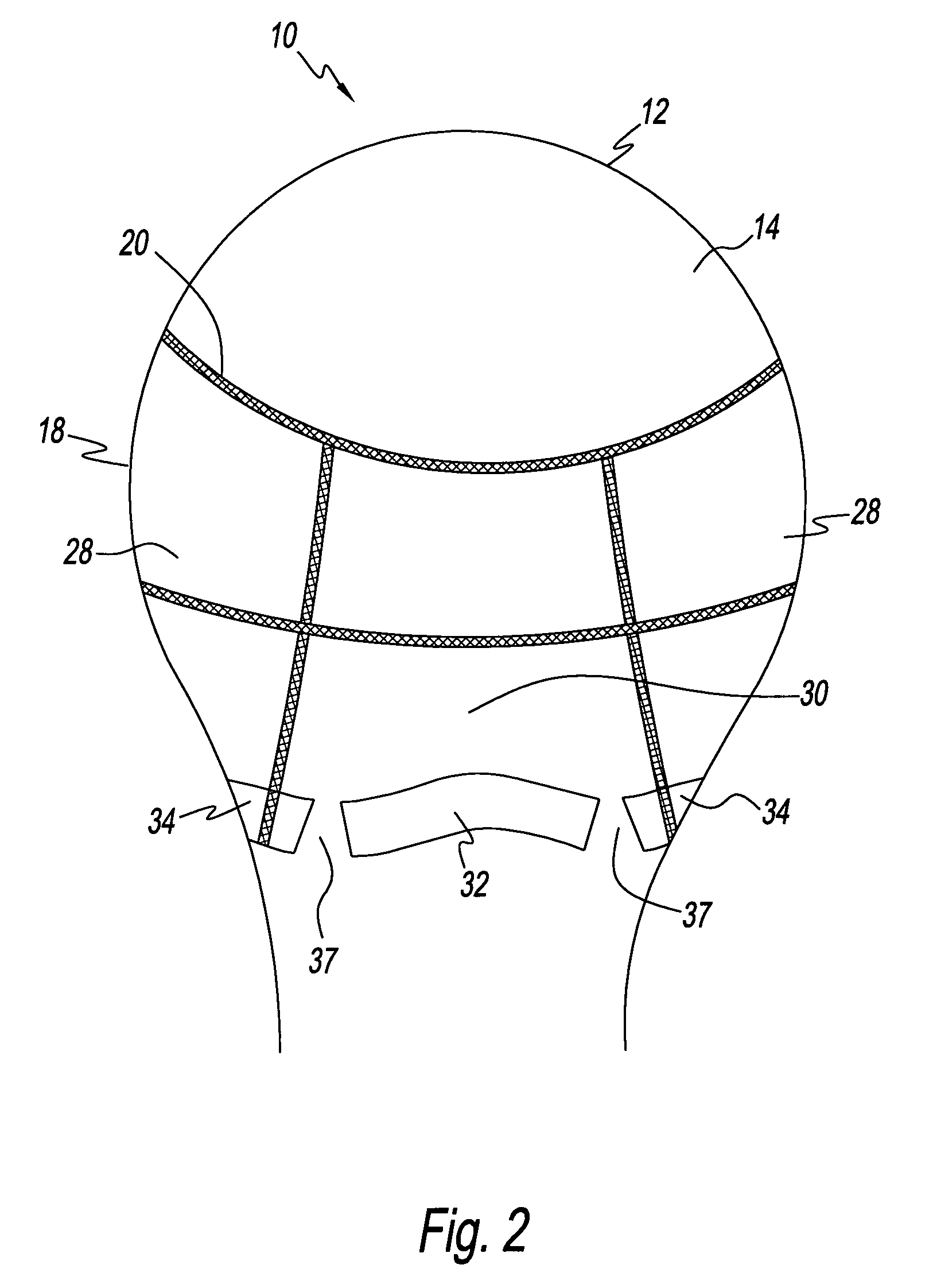

Medical hair prosthesis system

A medical hair prosthesis for use by a wearer that has had a pronounced loss of hair, where the foundation of the medical hair prosthesis is made of lace that has gone through a cryogenic treatment process to increase durability and comfort. The medical hair prosthesis is formed by a process of harvesting the wearer's own hair to incorporate into the front hairline of the hair prosthesis.

Owner:PARIS JOSEPH

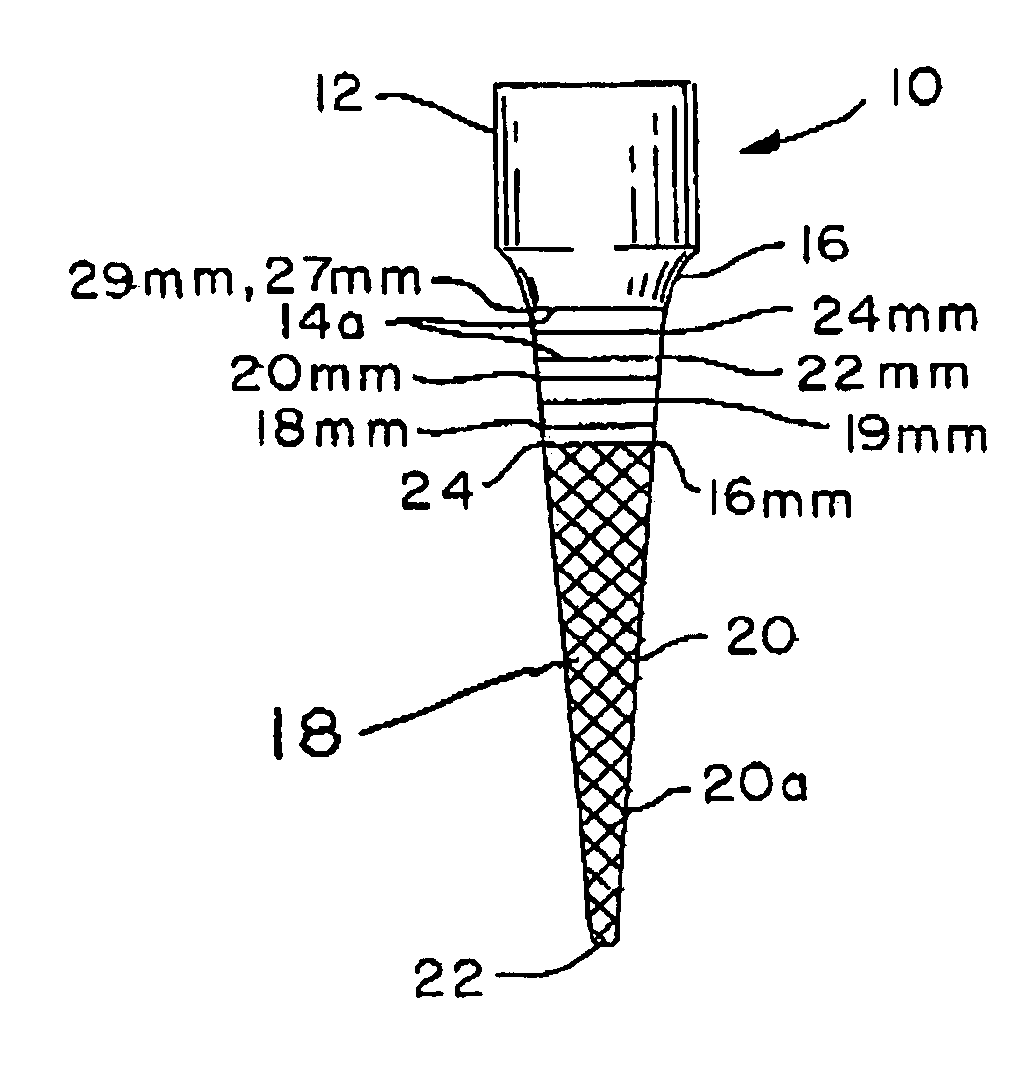

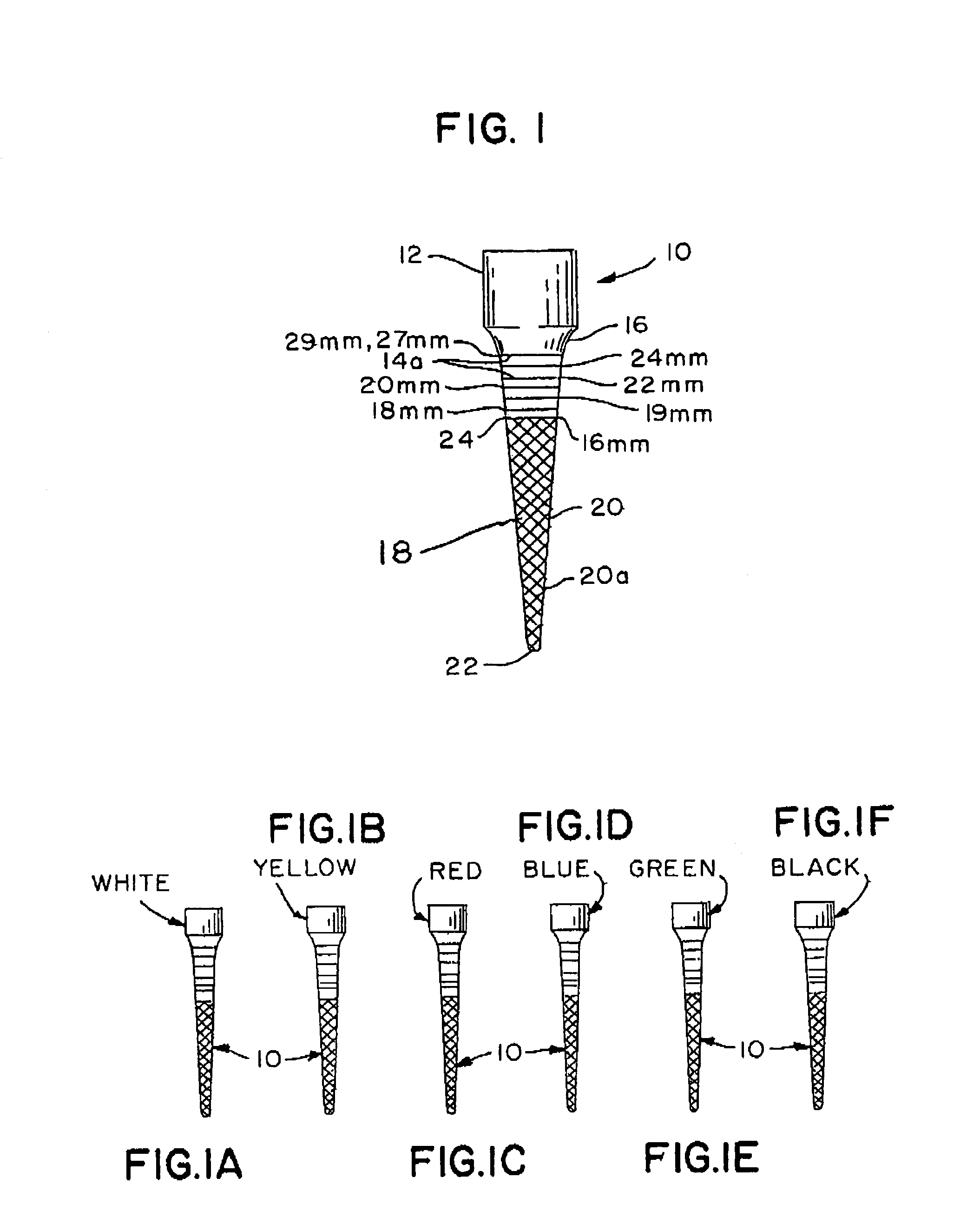

Integral gutta percha core/cone obturation technique

ActiveUS7021936B2Reduce leakageEasy to useImpression capsTeeth fillingGlass ionomersDelivery vehicle

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:ENDODONTIC EDUCATIONAL SEMINARS

Heat treatment method for maraging stainless steel

The invention aims at providing a heat treatment method for maraging stainless steel. The heat treatment method is characterized by comprising the following steps of performing solution treatment on the maraging stainless steel at the temperature of 1100 to 1250DEG C for 40 to 90 minutes, and performing water cooling; then performing cryogenic treatment; and finally, performing ageing treatment for two times at the temperature of 500 to 580DEG C, insulating for 1 to 2 hours each time, and performing air cooling to room temperature. For an alloy treated by adopting the method, the tensile strength reaches 1900Mpa, the impact toughness reaches ak60J / cm<2>, the hardness is HRC50, and the strength and the toughness are well matched.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Automotive transmission case and manufacturing method thereof

InactiveCN104561858AImprove wear resistanceHigh tensile strengthGearboxesTemperingCryogenic treatment

The invention relates to an automotive transmission case and a manufacturing method thereof. The automotive transmission case with high strength and high tenacity is obtained by preparing a mold for a specific component magnesium alloy; preparing materials, smelting, extruding and casting; quenching, carrying out cryogenic treatment, tempering and carrying out aging treatment.

Owner:邯郸市宝特铸造有限公司

Preparation method for cold rolls of super hardness wide width light gauge aluminum foils

ActiveCN103100829AExcellent hardening performanceExcellent hardenabilityFurnace typesHeat treatment furnacesNumerical controlTemperature control

The invention relates to the technical field of cold rolls, in particular to a preparation method for cold rolls of super hardness wide width double-zero aluminum foils. The method particularly comprises the following steps: firstly, carrying out anneal process on a blank roll which is made of high chromium alloy materials in a forged mode, then carrying out rough turning process, thermal refining, semi fine turning process and heat treatment, and finally carrying out fine turning process on the blank roll to repair a die until a finished product is obtained. According to the preparation method for the cold rolls of the super hardness wide width double-zero aluminum foils, the high chromium alloy materials and a four-pillar sunken downwards type double-power-frequency heat treatment technology are adopted, the cold rolls are manufactured through full numerical control four-area temperature-controlled liquid nitrogen processing cryogenic treatment, the hardness of roll bodies of the cold rolls can reach 102-104 HSD, the depth of a hardening layer is larger than or equal to 25mm, uniformity of the hardness is within HSD+ / -0.5, length of roll faces exceeds 2300mm, high-grade wide width aluminum foils with width of the finished aluminum foils reaching 2300mm and thickness of 0.0065mm or below 0.0065mm can be rolled, and the preparation method is widely applied to industries such as cigarettes, food, medicine, electrons, photographic apparatuses and chemicals for daily use.

Owner:CHANGZHOU ECCO ROLLER

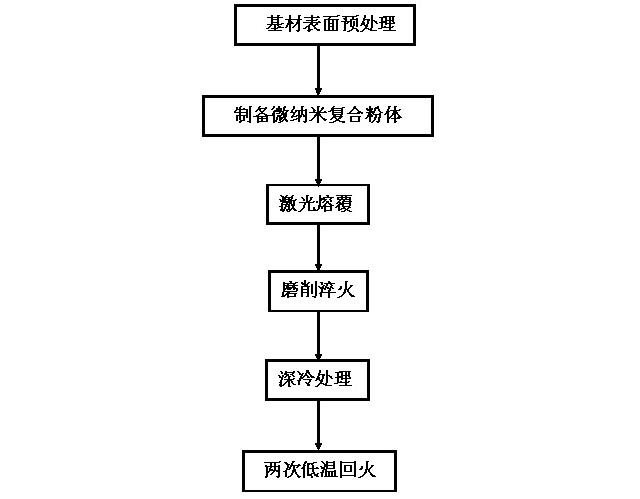

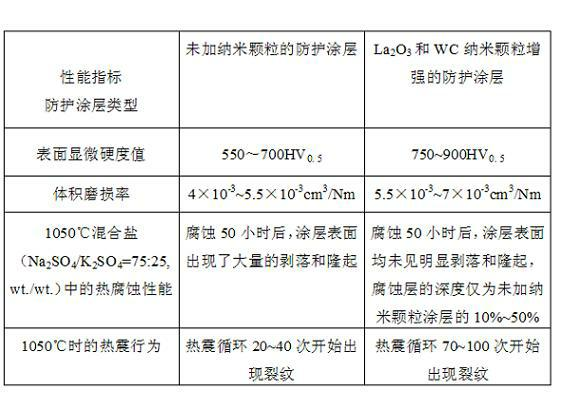

Bi-phase nano particle reinforced titanium alloy protective coating and preparation method of bi-phase nano particle reinforced titanium alloy protective coating

ActiveCN102605230AImprove performanceEasy to useMetallic material coating processesMicro nanoEtching

The invention relates to a bi-phase nano particle reinforced titanium alloy protective coating and a preparation method of the bi-phase nano particle reinforced titanium alloy protective coating, wherein the preparation method is characterized by comprising the steps of preparing nano La2O3 powders, WC powders and micron NiCoCrAlY into bi-phase nano particle reinforced metal base micron / nano composite powders according to a certain proportion; cladding the composite powders on the surface of titanium alloy through laser cladding; performing grinding and quenching on the titanium alloy coatingafter the cladding; placing the titanium alloy and the coating of the titanium alloy into liquid nitrogen for subzero treatment after the grinding and quenching; finally conducting twice low tempering on the titanium alloy coating after the subzero treatment. The titanium alloy protective coating has outstanding performances such as high hardness, high strength, wear resistance, thermal etching resistance and resistance to thermal shocks and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com