Preparation method of superfine and high-purity gamma-ALON transparent ceramics powder

A transparent ceramic and high-purity technology, which is applied in the field of preparation of γ-AlON transparent ceramic powder, can solve the problems that γ-AlON powder is not conducive to the promotion of engineering production, and achieves easy post-milling treatment, fine particle size, and reduced The effect of composition temperature and composition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

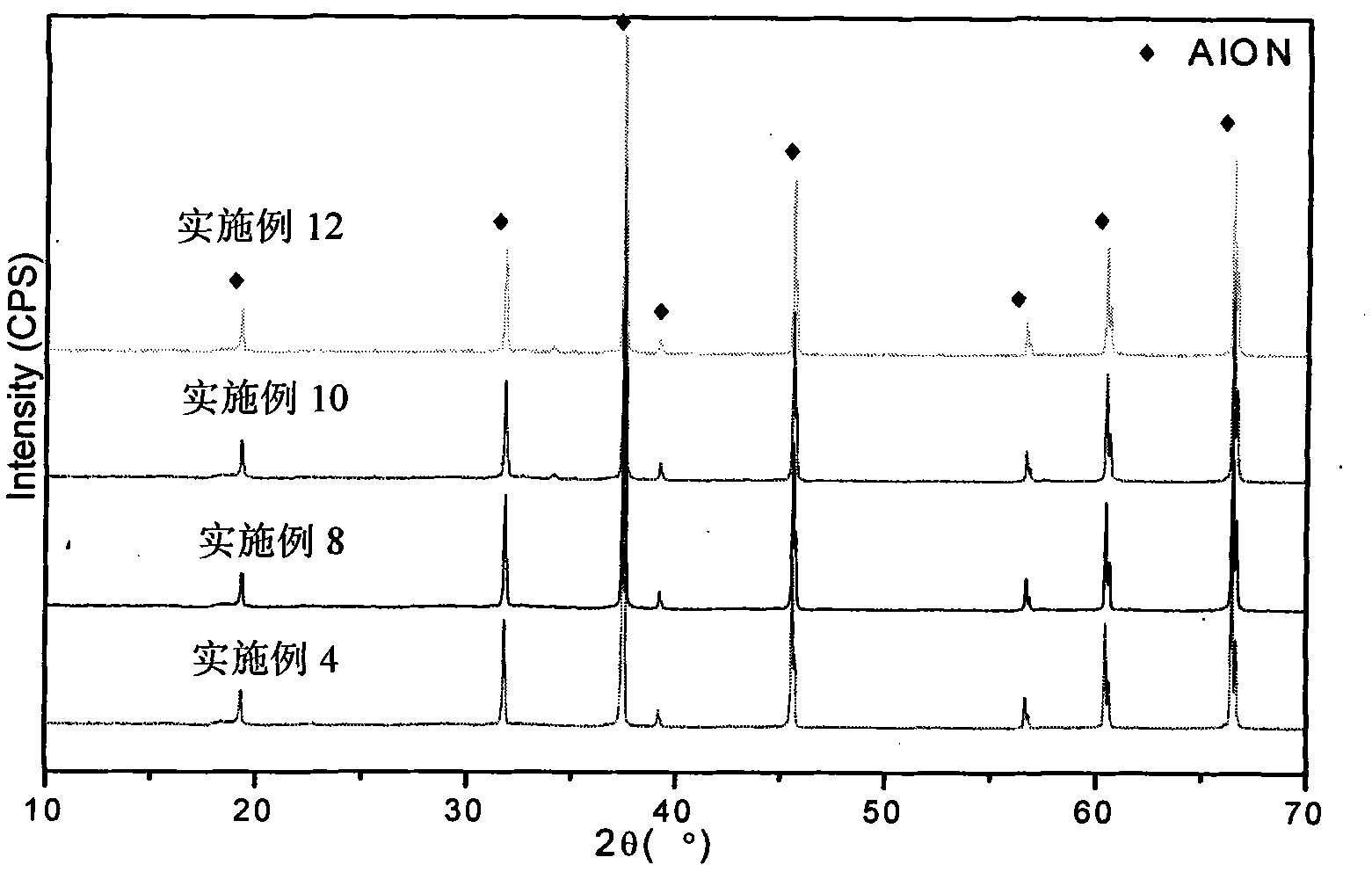

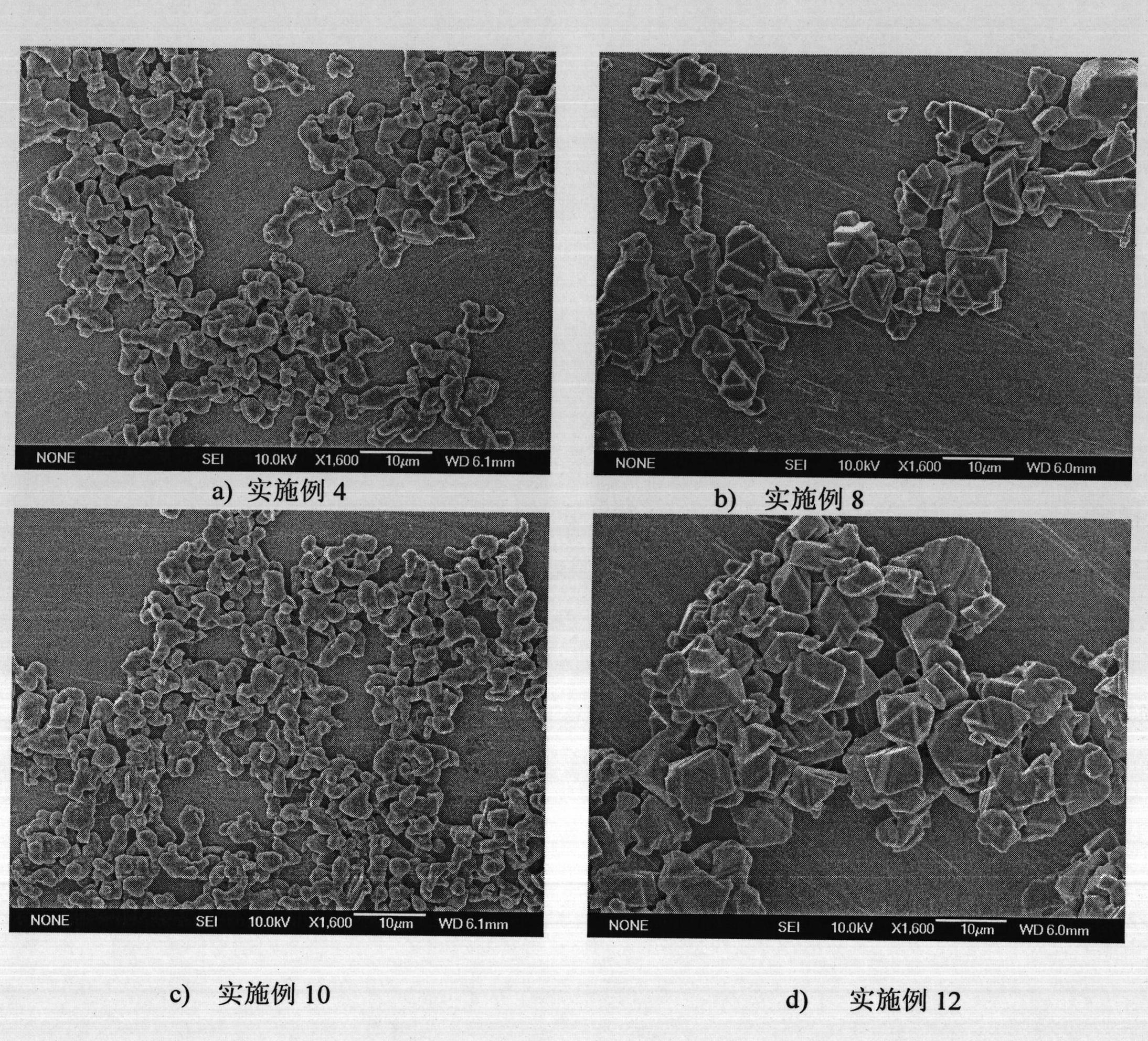

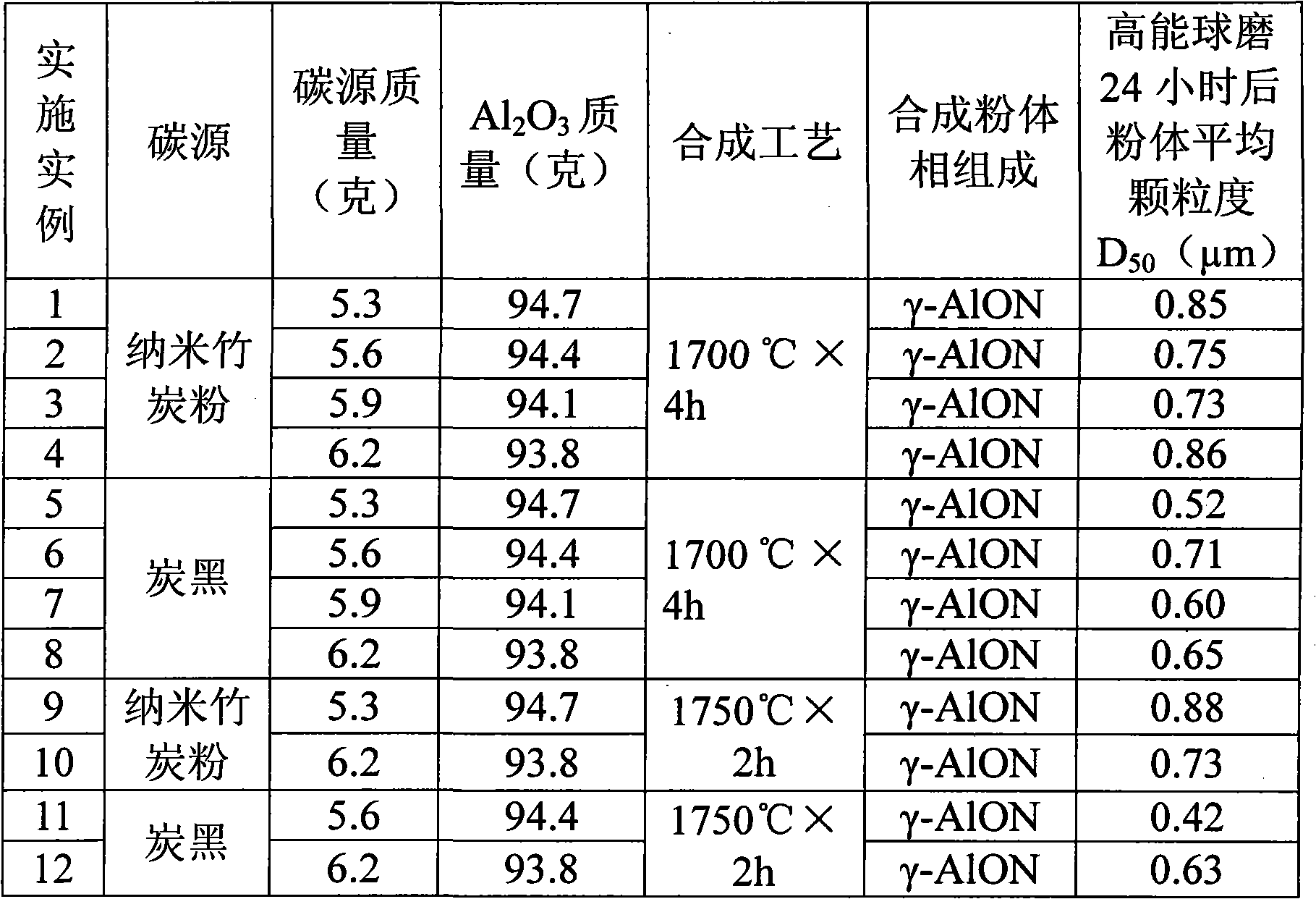

Embodiment 1~4

[0030] Select high-purity γ-Al 2 o 3 Powder (average particle size is 0.4μm, specific surface area is 90-110m 2 / g) and nano-bamboo charcoal powder (100~200nm) are mixed according to the ratio of Table 1 to prepare each 100 grams of precursor powders; add 250 grams of dehydrated alcohol after the powders are mixed, and use zirconia balls with a diameter of 10 mm as grinding balls, The quality of the balls is 500 grams, put them into a planetary high-energy ball mill, and mix them for 2 hours under the condition of working frequency 50Hz; bake the obtained slurry at 55°C for 24 hours, then dry it at 120°C for 5 hours, and then 80 mesh sieve; the precursor mixed powder obtained after sieving is put into an alumina crucible (99 porcelain) with a diameter of 30mm, and the loose packing height of the powder is controlled to be less than 15mm, covered with a lid, put into a large graphite crucible and added Cover, raise the temperature to 1100°C at a heating rate of 10°C / min, and ...

Embodiment 5~8

[0032] Carry out embodiment 5 according to the method for embodiment 1, difference is to adopt carbon black (average particle diameter is 18nm) as carbon source. The obtained aluminum oxynitride powder is subjected to high-energy ball milling to obtain submicron aluminum oxynitride powder with an average particle size of 0.7-0.9 μm.

Embodiment 9~10

[0034] Examples 9 and 10 were carried out according to the method of Example 1, except that the high temperature synthesis time was 2 hours. The obtained aluminum oxynitride powder is subjected to high-energy ball milling to obtain submicron aluminum oxynitride powder with an average particle size of 0.7-0.9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com