Patents

Literature

70results about How to "Shorten the compositing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

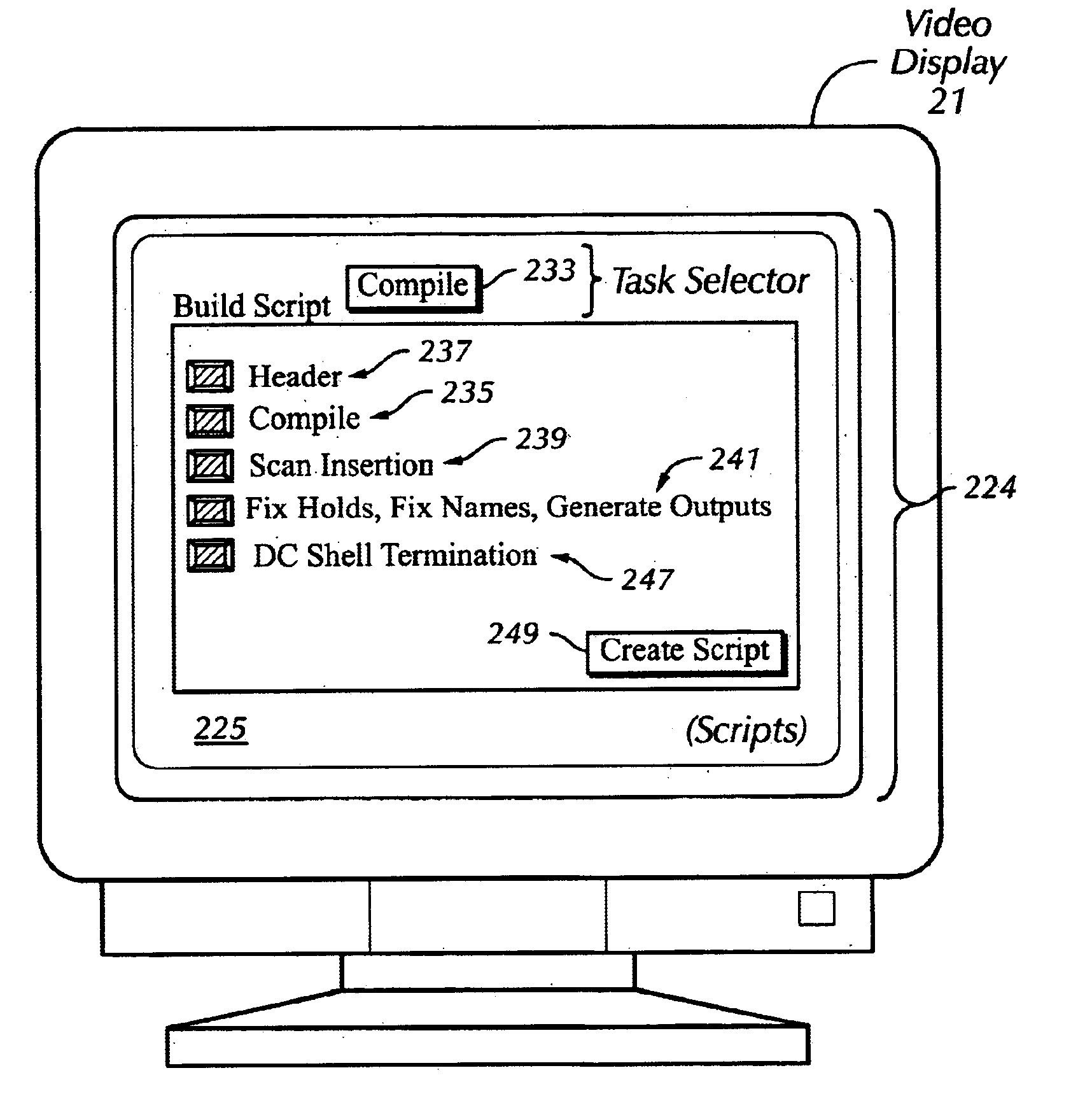

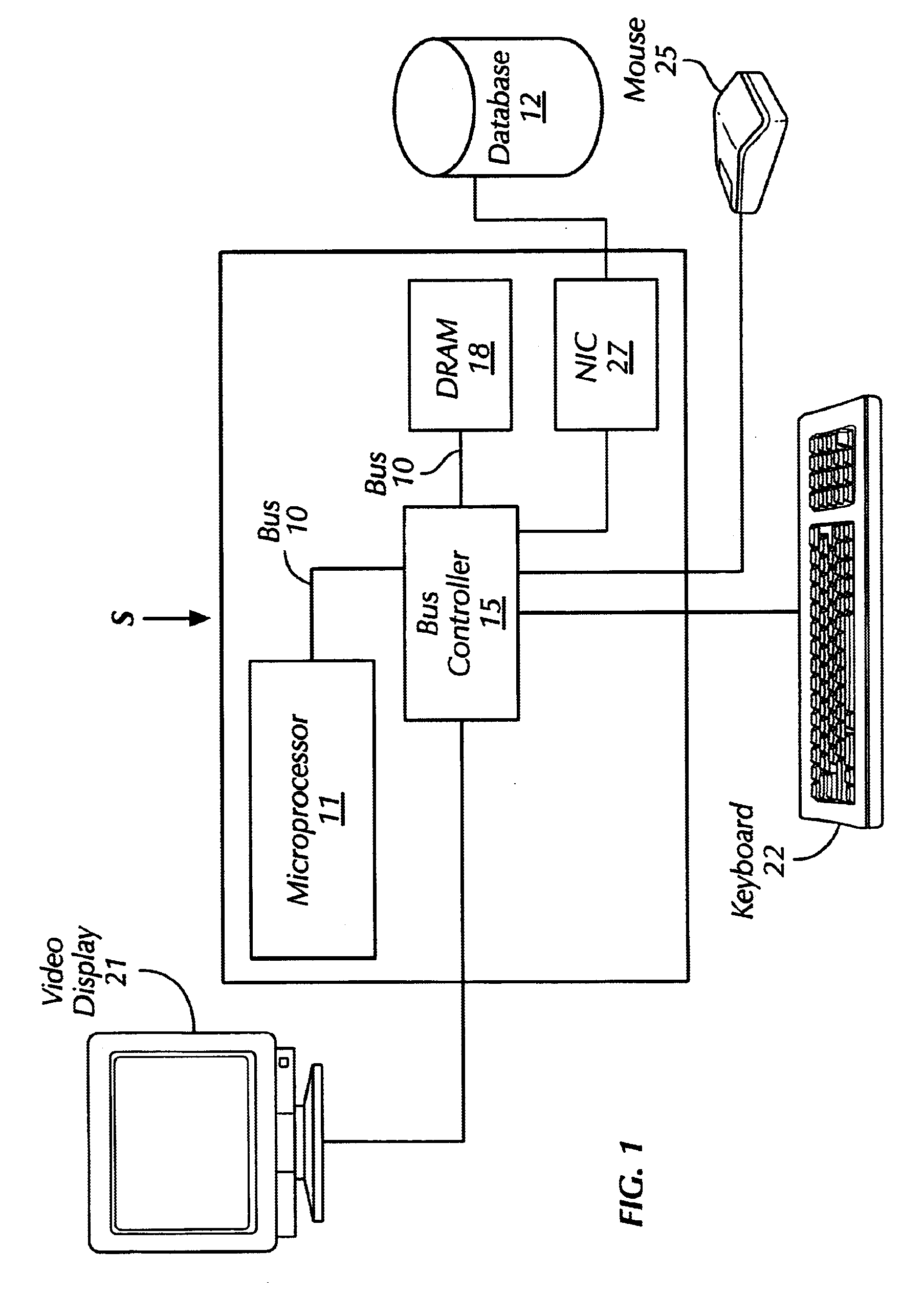

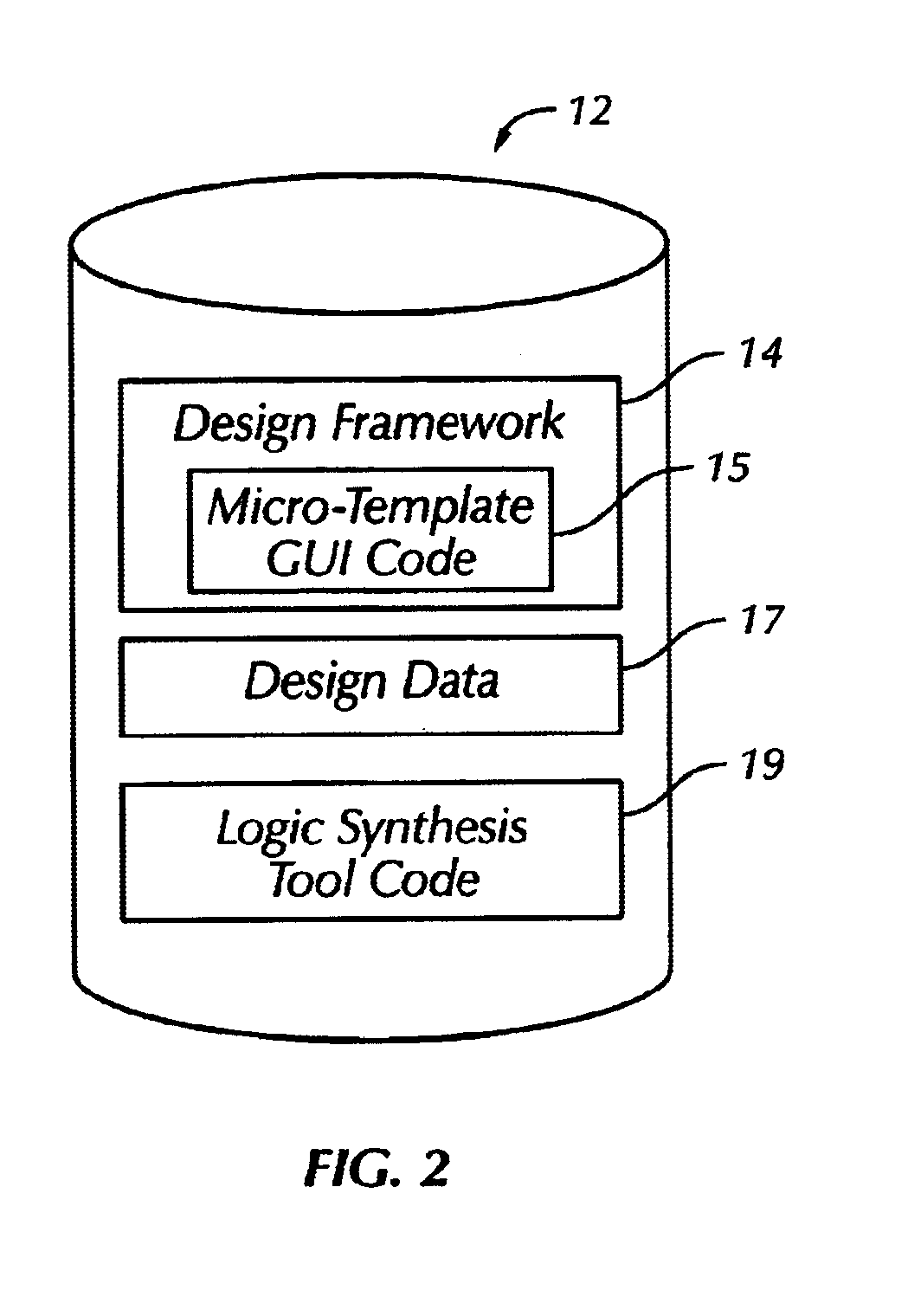

Methodology and graphical user interface for building logic synthesis command scripts using micro-templates

InactiveUS6697880B1Shorten the compositing timeSoftware engineeringSpecific program execution arrangementsGraphicsGraphical user interface

A template for a logic synthesis command script is broken into smaller and functionally independent templates termed "micro-templates." Using micro-templates, logic synthesis time may be significantly reduced. Each micro-template may correspond to a particular synthesis operation and may be enabled or disabled. Where synthesis of a particular set of synthesis operations is desired, the micro-templates corresponding to those synthesis operations are enabled.

Owner:GLOBALFOUNDRIES INC

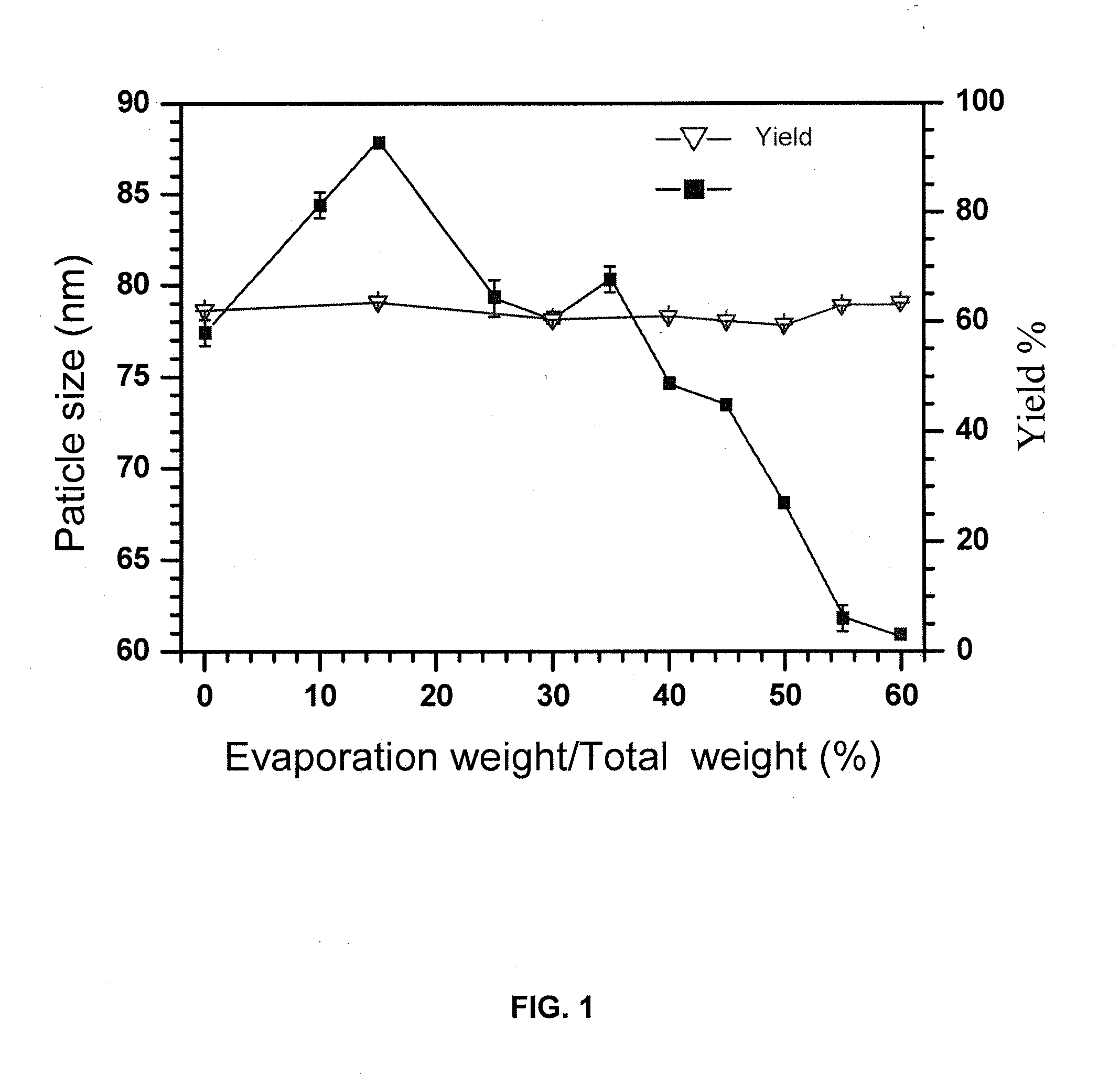

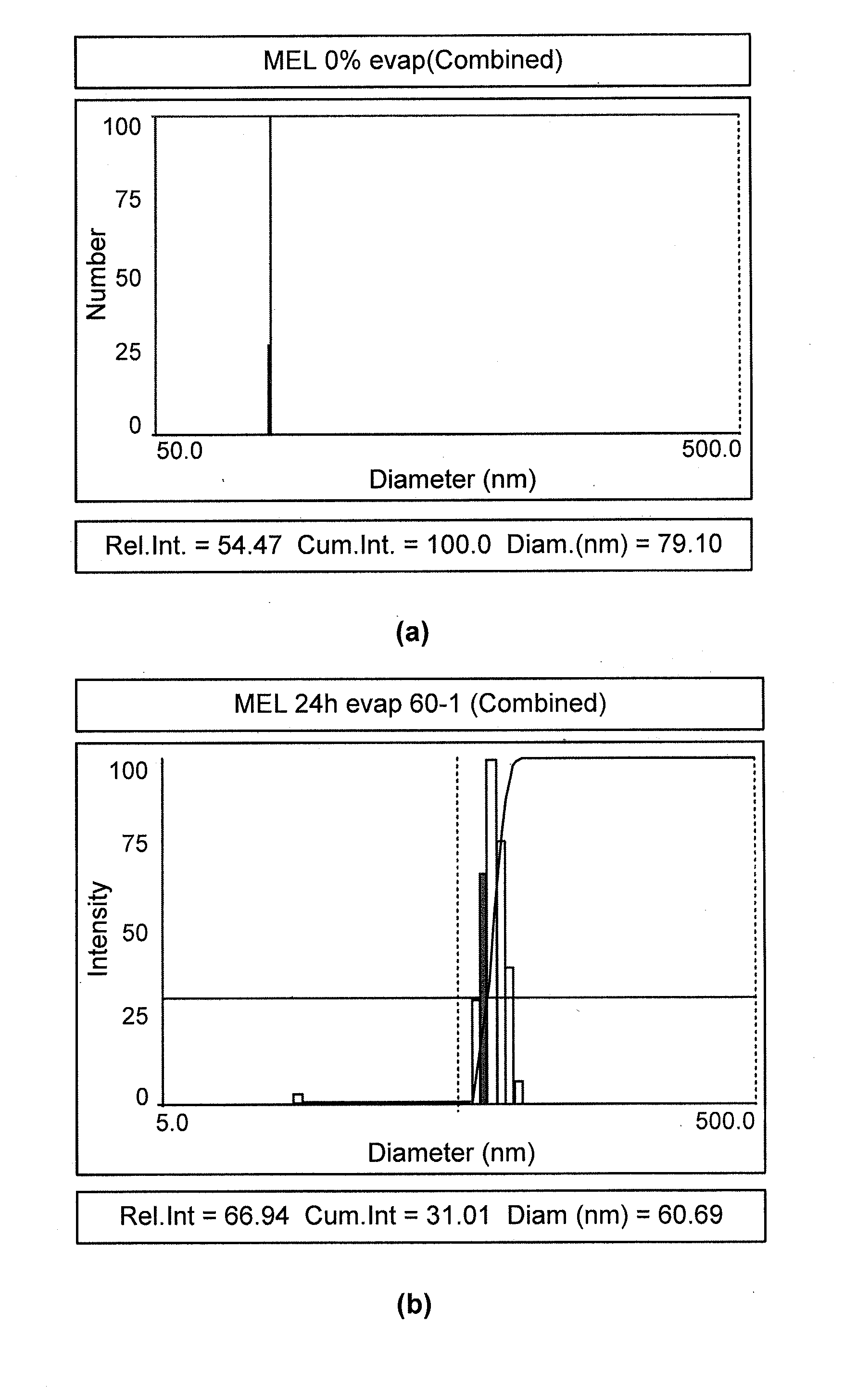

Ambient pressure synthesis of zeolite films and their application as corrosion resistant coatings

InactiveUS20100119736A1Shorten the compositing timeAccelerates synthesis processAluminium compoundsVacuum evaporation coatingAmbient pressureSolvent

A method for producing zeolite films or membranes at essentially ambient pressure, which includes preparing a synthesis mixture comprising an ionic liquid solvent and an aluminum and / or silicon and / or phosphate source and converting the synthesis mixture to form a continuous zeolite layer. In addition, a method of synthesizing zeolite nanocrystals, which includes preparing a synthesis mixture, the synthesis mixture having a silica or a silica and alumina source, and a template; and synthesizing the synthesis mixture to form zeolite nanocrystals.

Owner:RGT UNIV OF CALIFORNIA +1

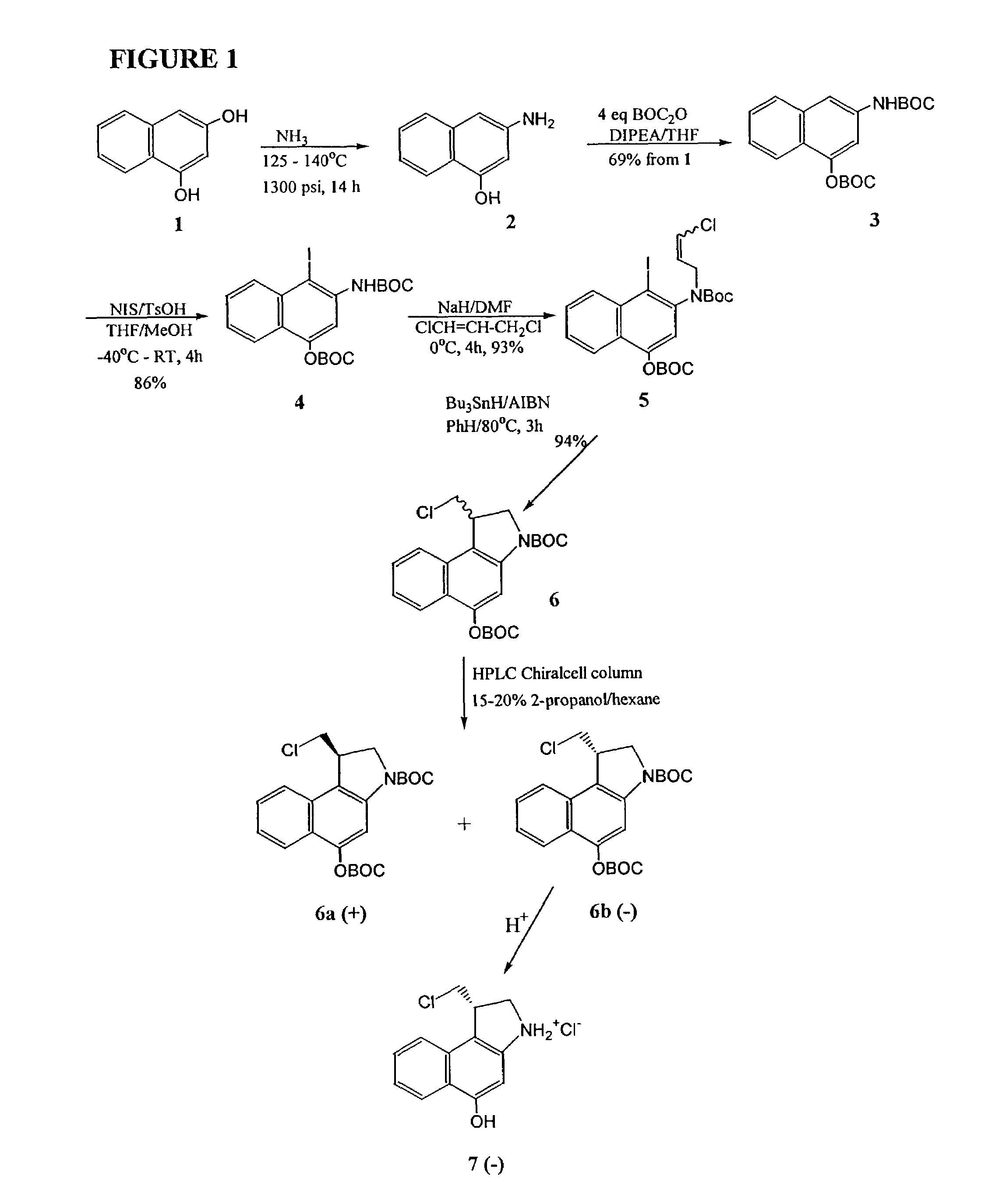

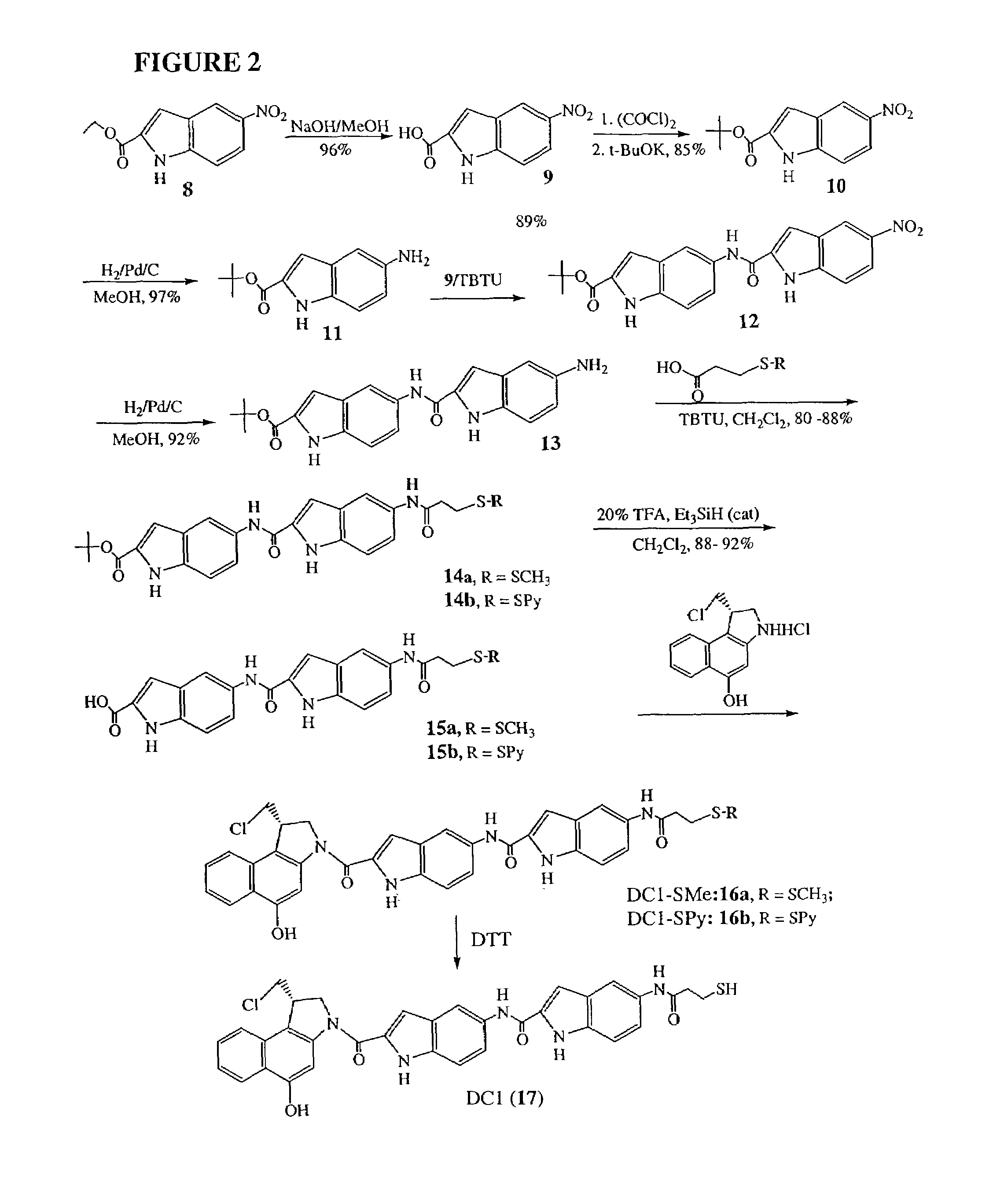

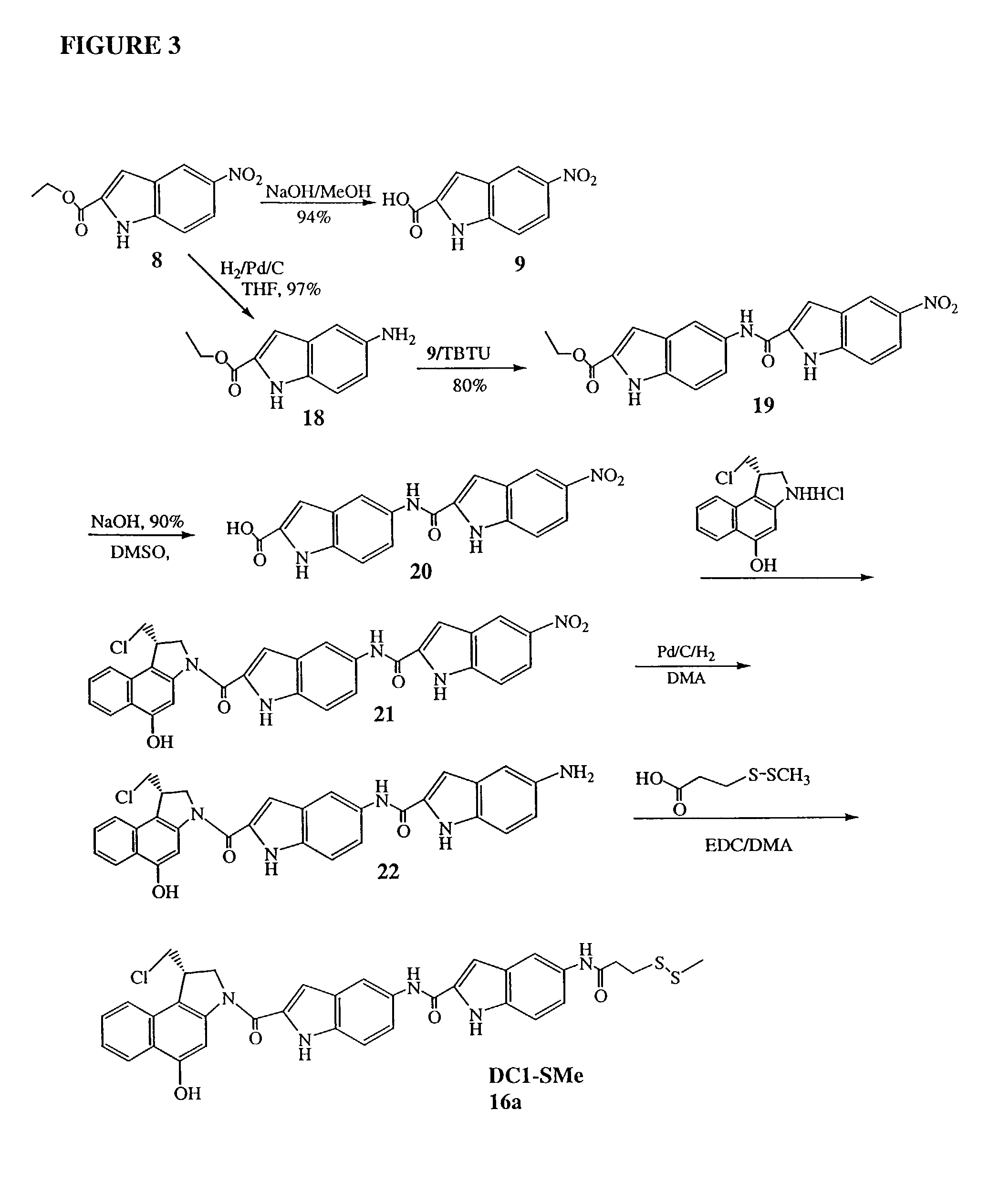

CC-1065 analog synthesis

InactiveUS7329760B2Shorten the compositing timeImprove production yieldAntibacterial agentsOrganic active ingredientsAnalog synthesisMedicinal chemistry

Improved synthesis of seco(−)CBI (5-hydroxy-3-amino-1-[S]-(chloromethyl)-1,2-dihydro-3H-benz(e)indole):and improved syntheses therefrom of a wide variety of CC-1065 analogs that comprise a cyclopropabenzidole (CBI) alkylating moiety, and which are collectively DC1 and its derivatives, for the synthesis of cell-targeted therapeutic agents.

Owner:IMMUNOGEN INC

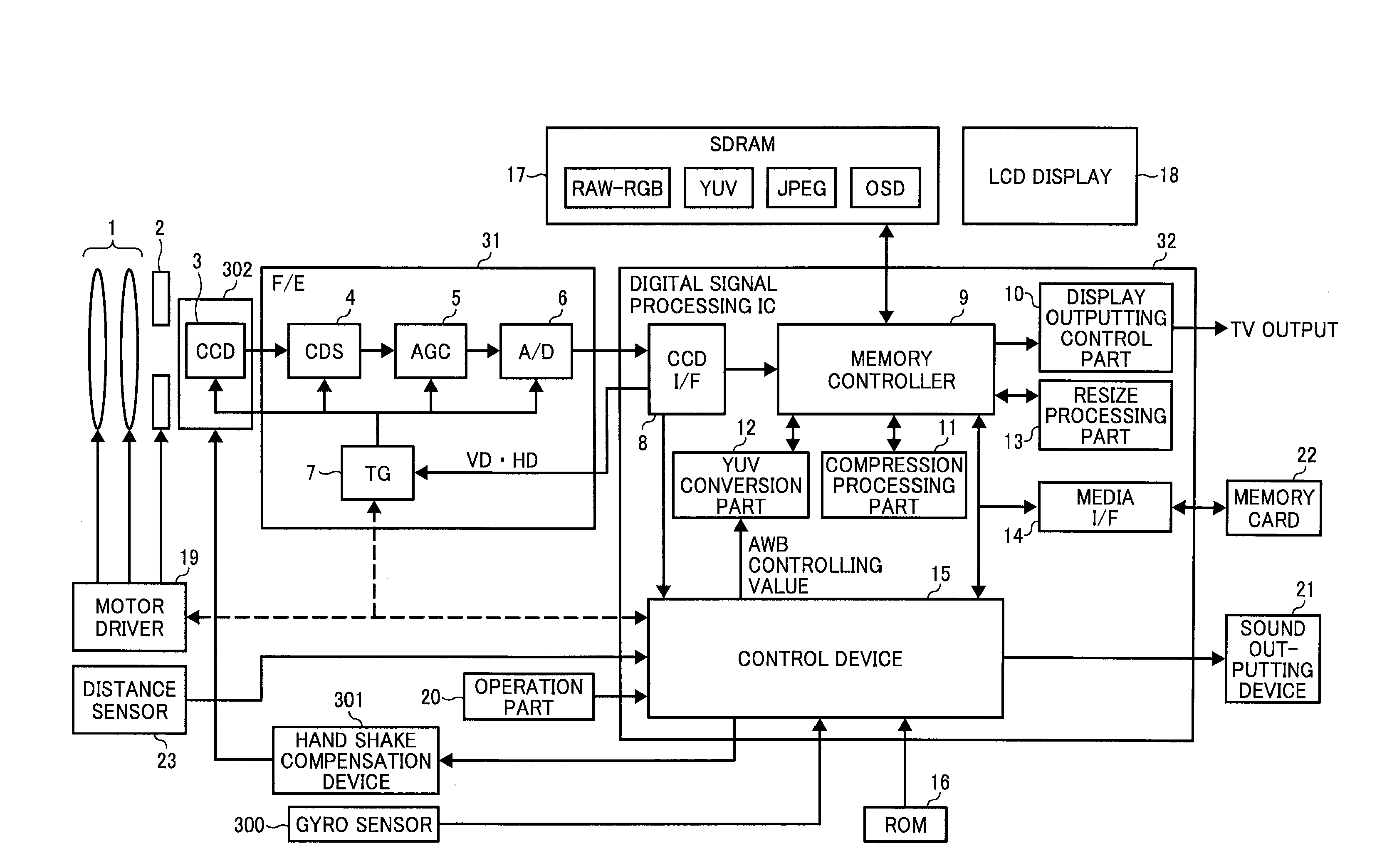

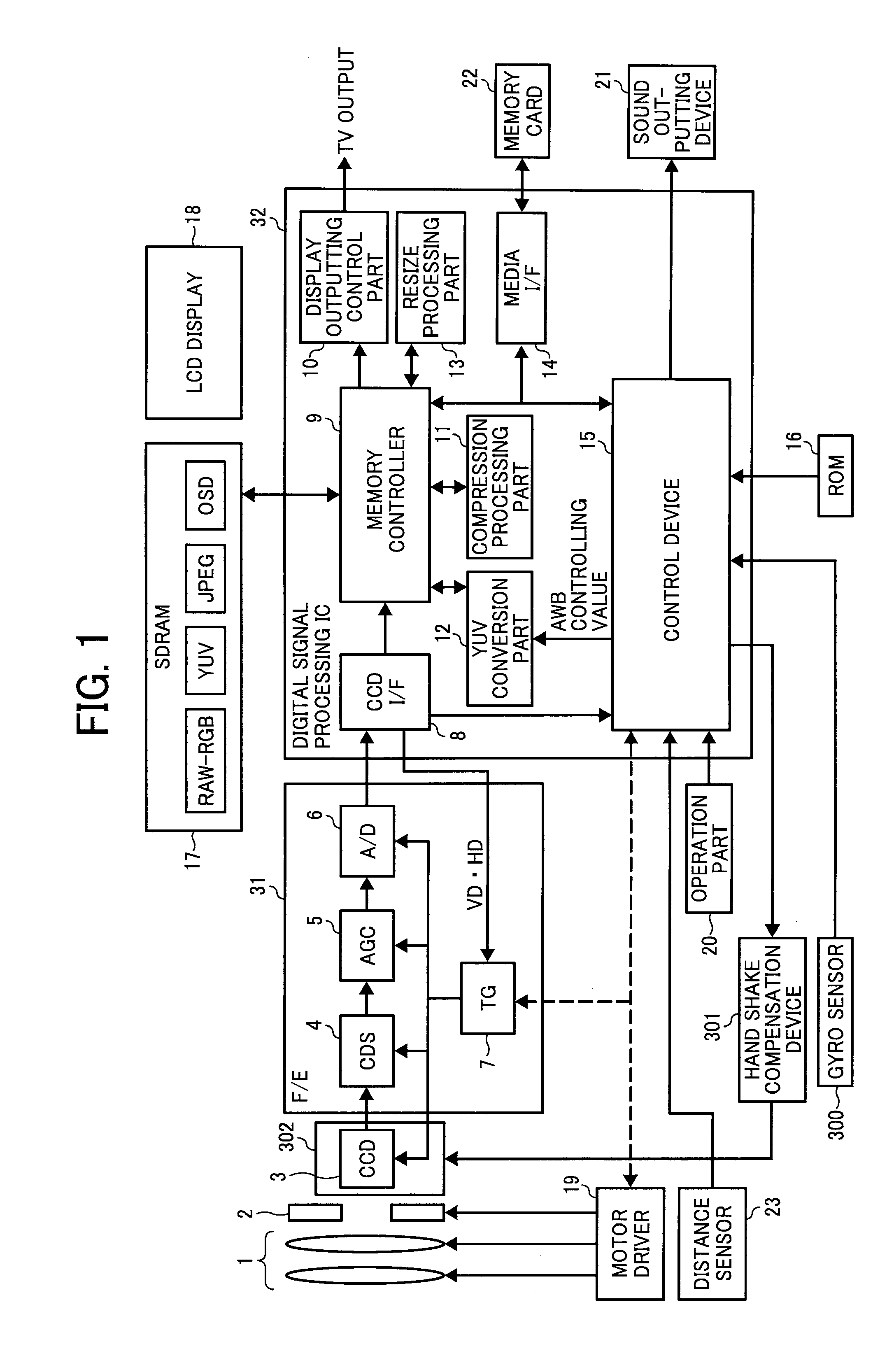

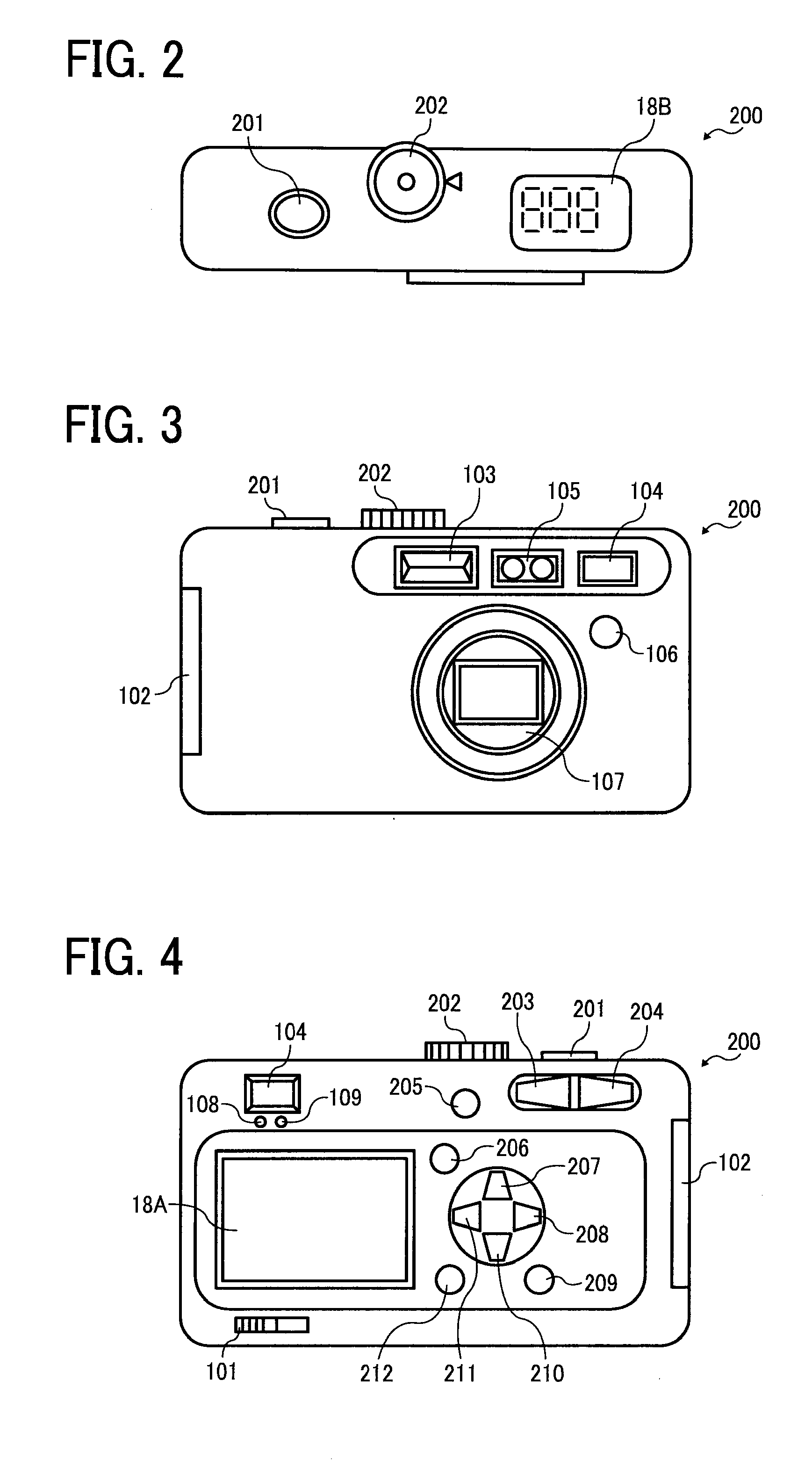

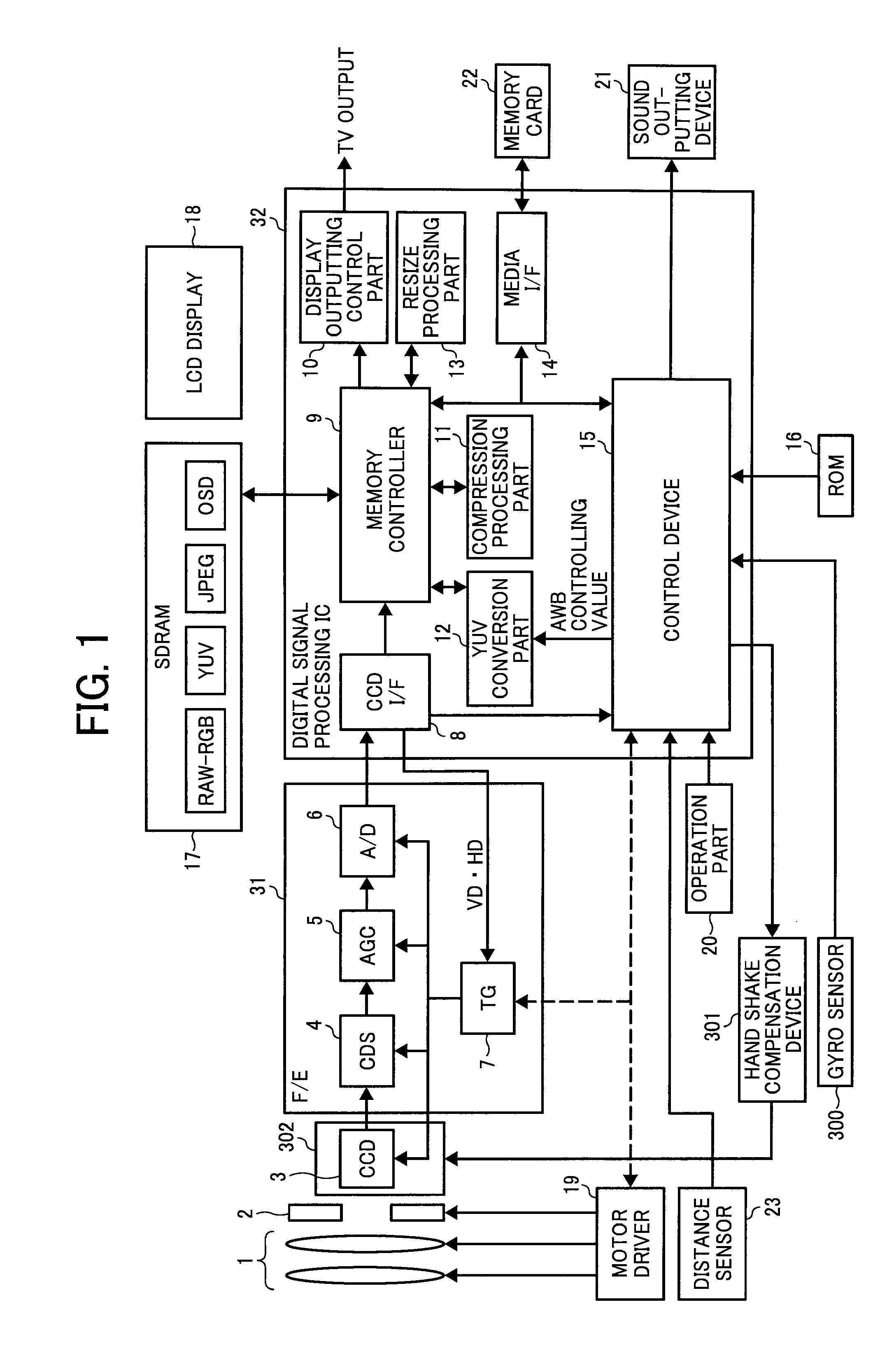

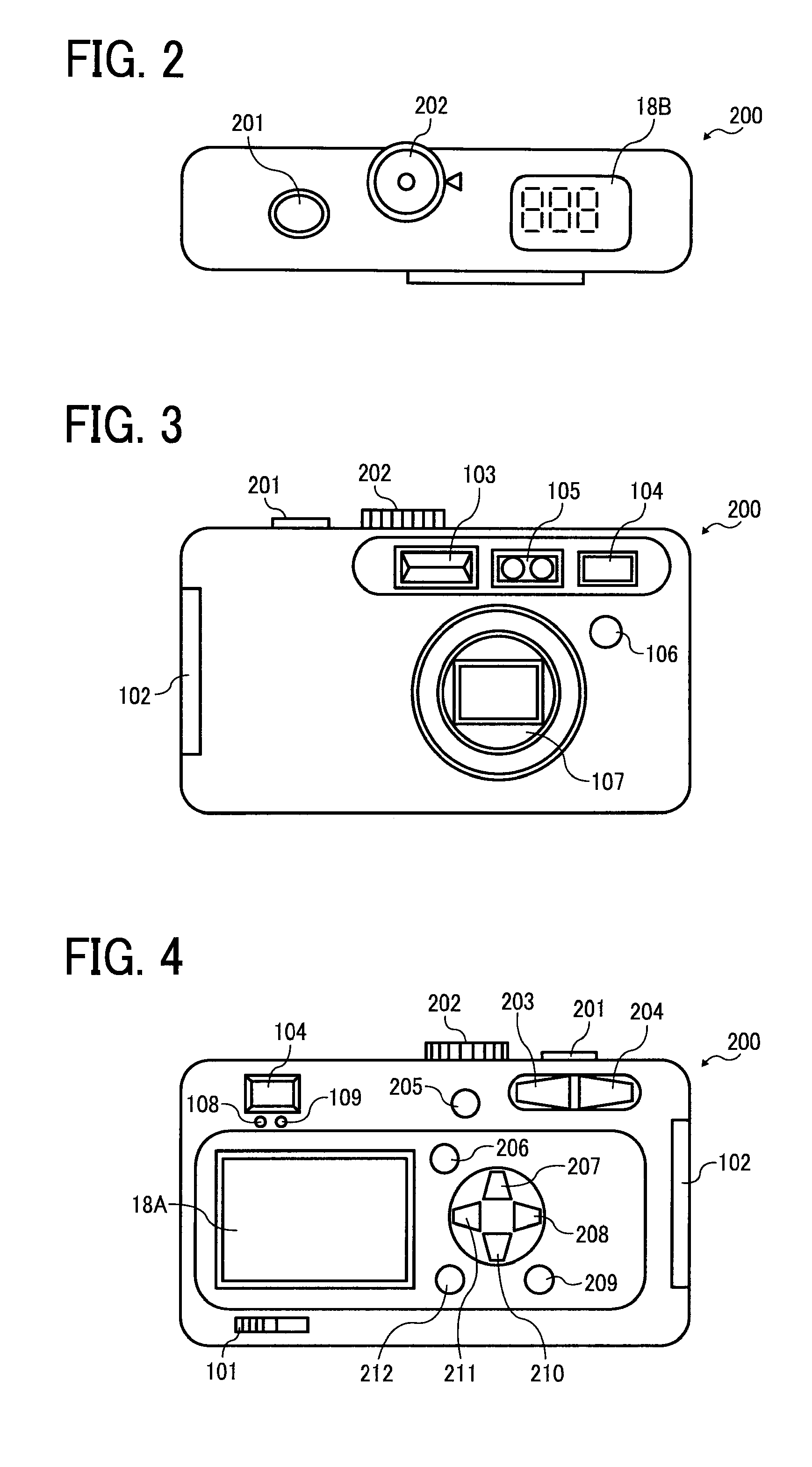

Imaging apparatus

ActiveUS20090231445A1Wide dynamic rangeReduce the impactTelevision system detailsTelevision system scanning detailsImaging equipmentComputer science

An imaging apparatus, includes: an imaging optical system; an image pickup device; and a control device which is configured to control the image pickup device, wherein the control device is configured to preliminarily decide an exposure order of a relatively short time exposure in a prescribed image size; an exposure with almost the same exposure time as the relatively short time in a smaller image size than the prescribed image size, and a relatively long time exposure in the prescribed image size, and to perform an imaging operation once by exposing the image pickup device by the decided exposure order.

Owner:RICOH KK

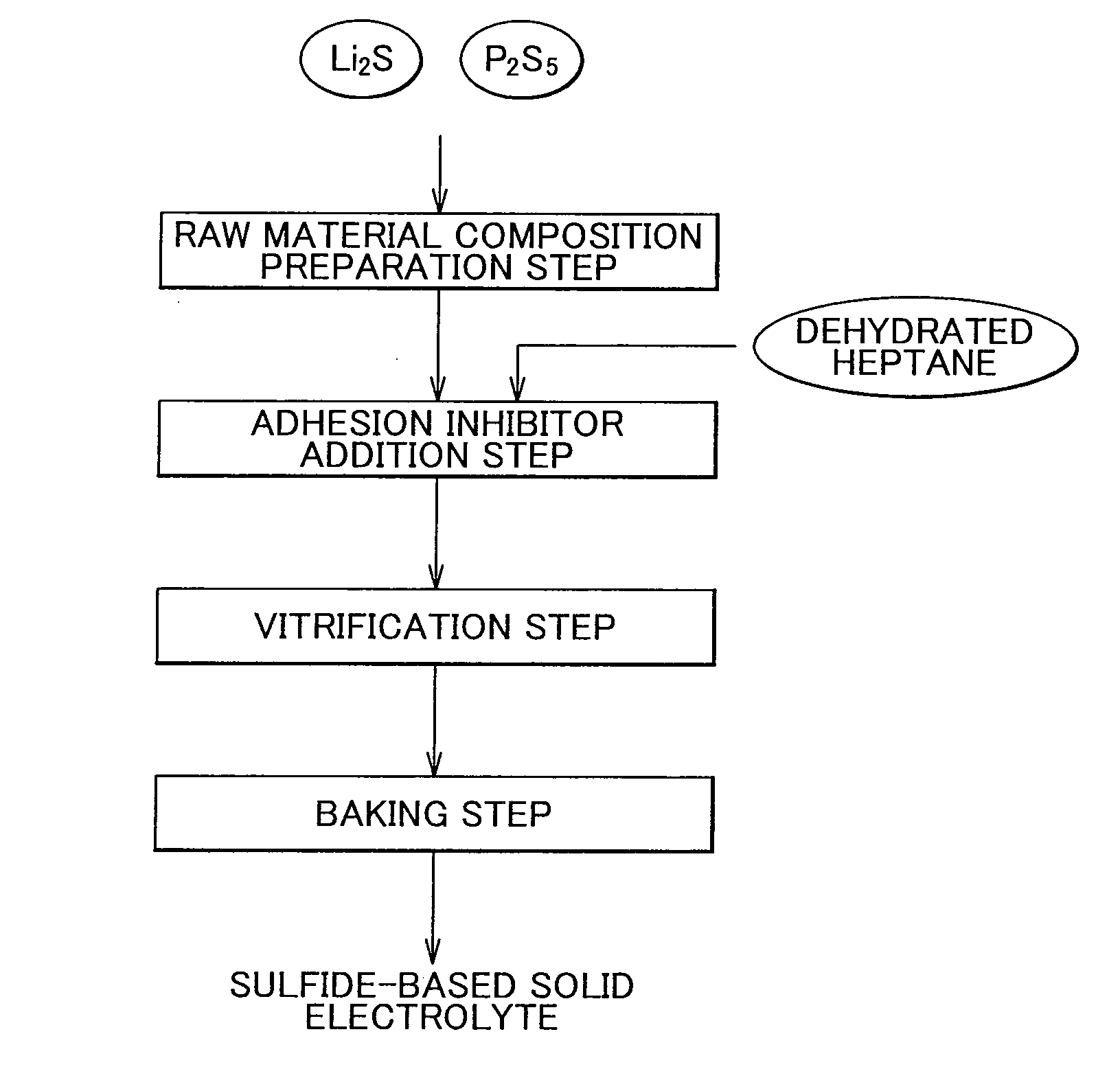

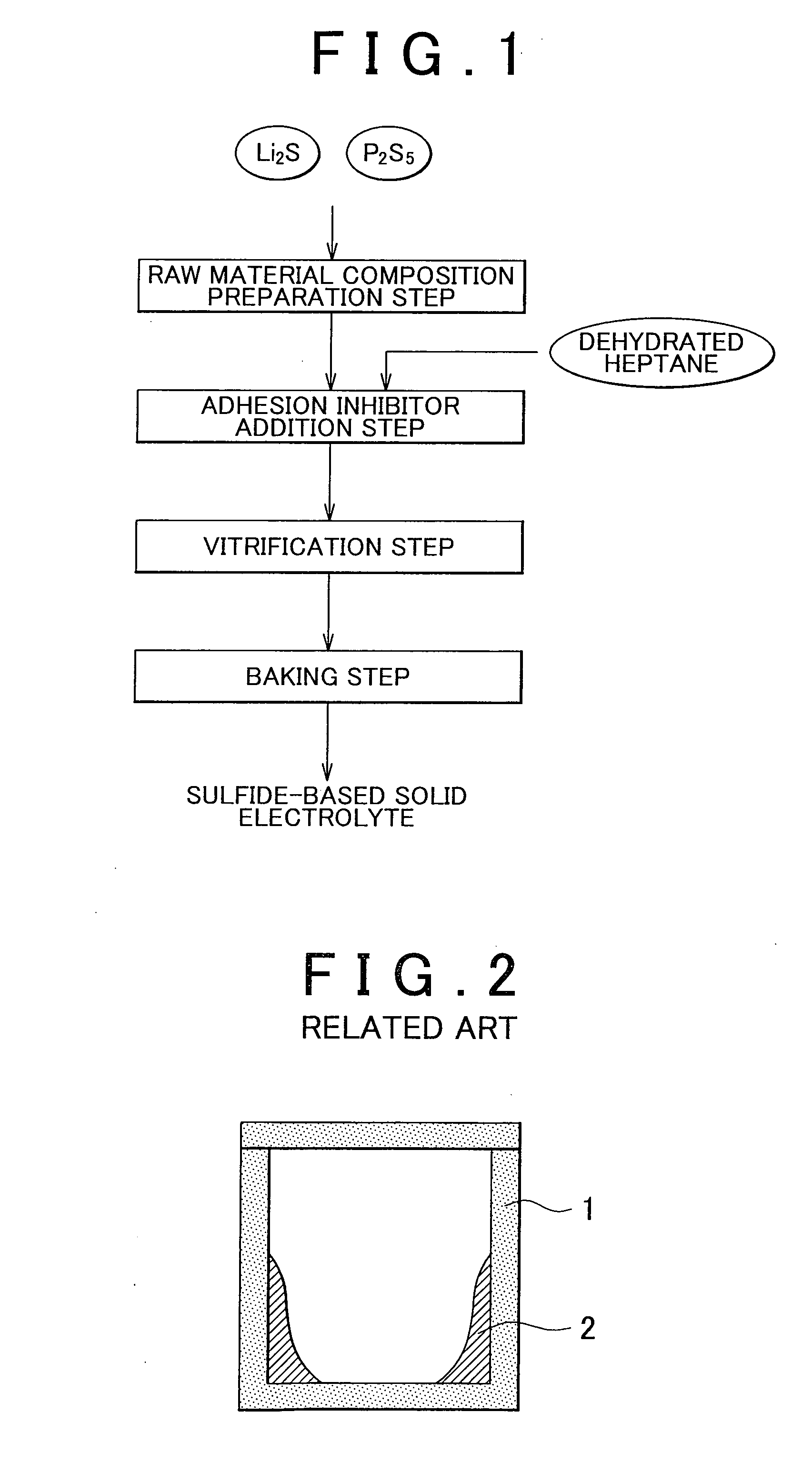

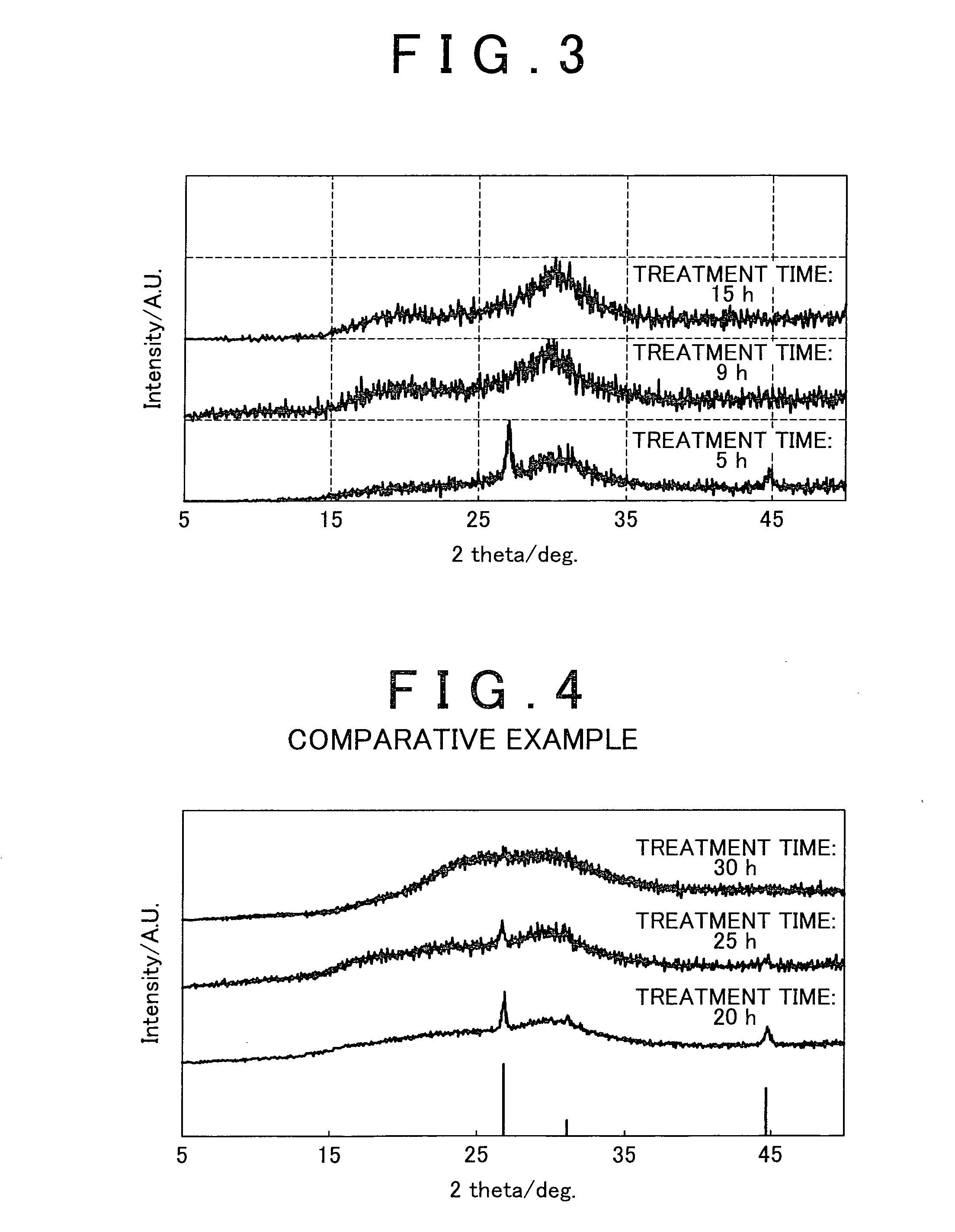

Process for producing sulfide-based solid electrolyte

ActiveUS20110108642A1Shorten the compositing timeImprove production efficiencyLi-accumulatorsCentrifugesVitrificationMechanical milling

The invention provides a process for producing a sulfide-based solid electrolyte, the process having: a raw material composition preparation step for preparing a raw material composition containing at least sulfur (S), an adhesion inhibitor addition step for adding to the raw material composition an adhesion inhibitor that inhibits formation of adhered substances including the unreacted raw material composition, on the inner surface of a milling pot during mechanical milling, and a vitrification step for synthesizing sulfide-based glass by carrying out mechanical milling on the raw material composition to which the adhesion inhibitor has been added.

Owner:TOYOTA JIDOSHA KK

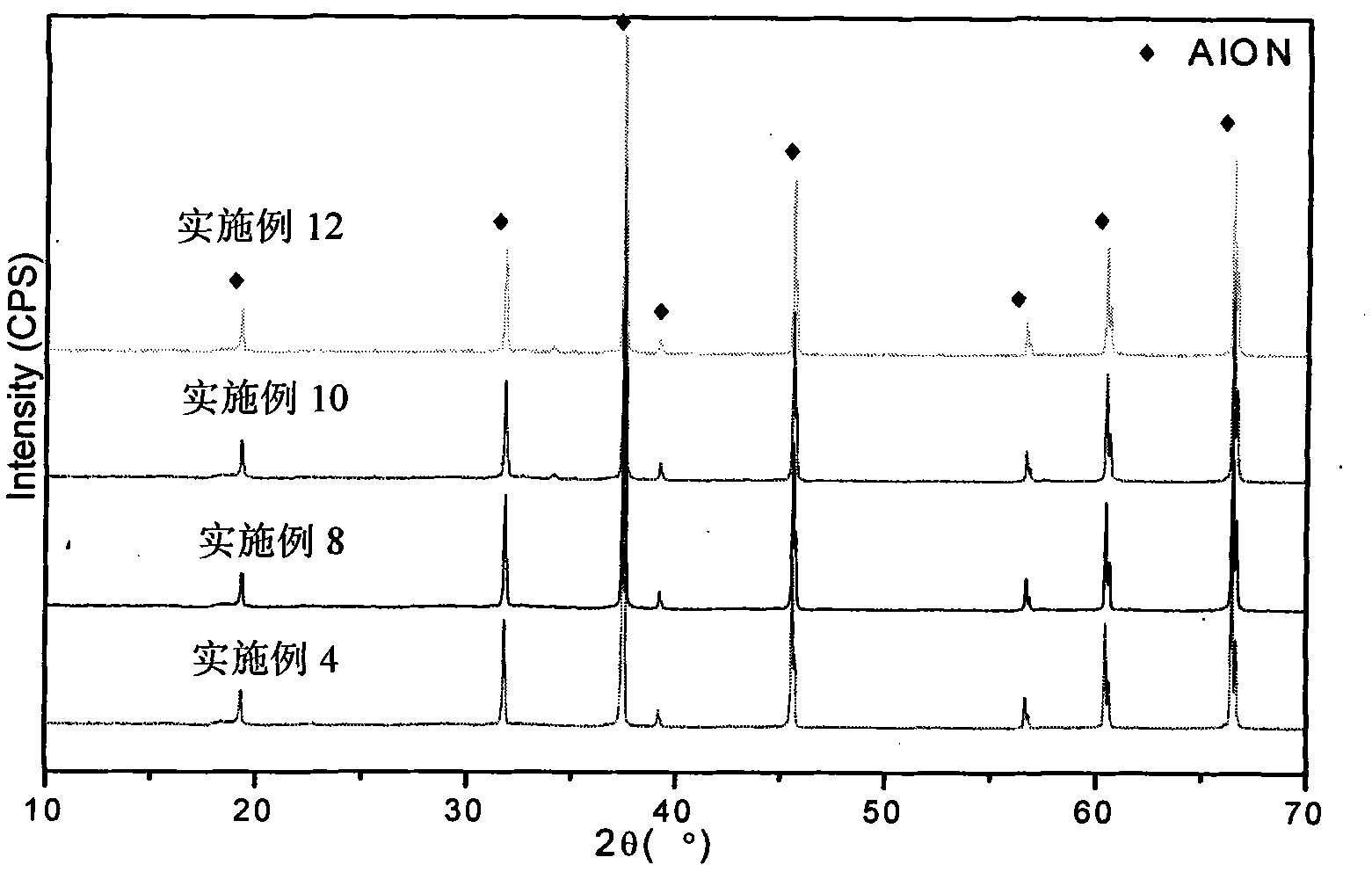

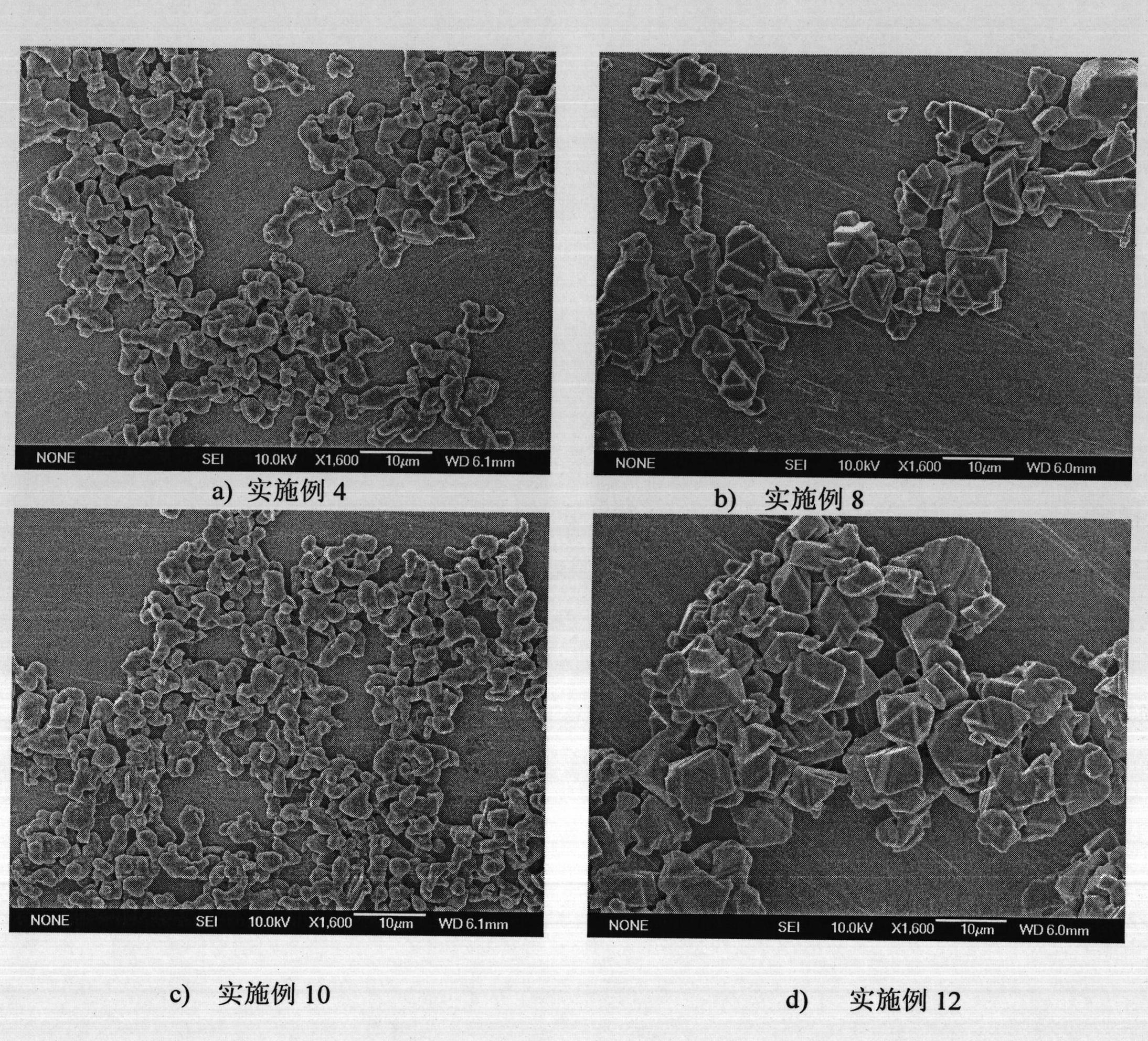

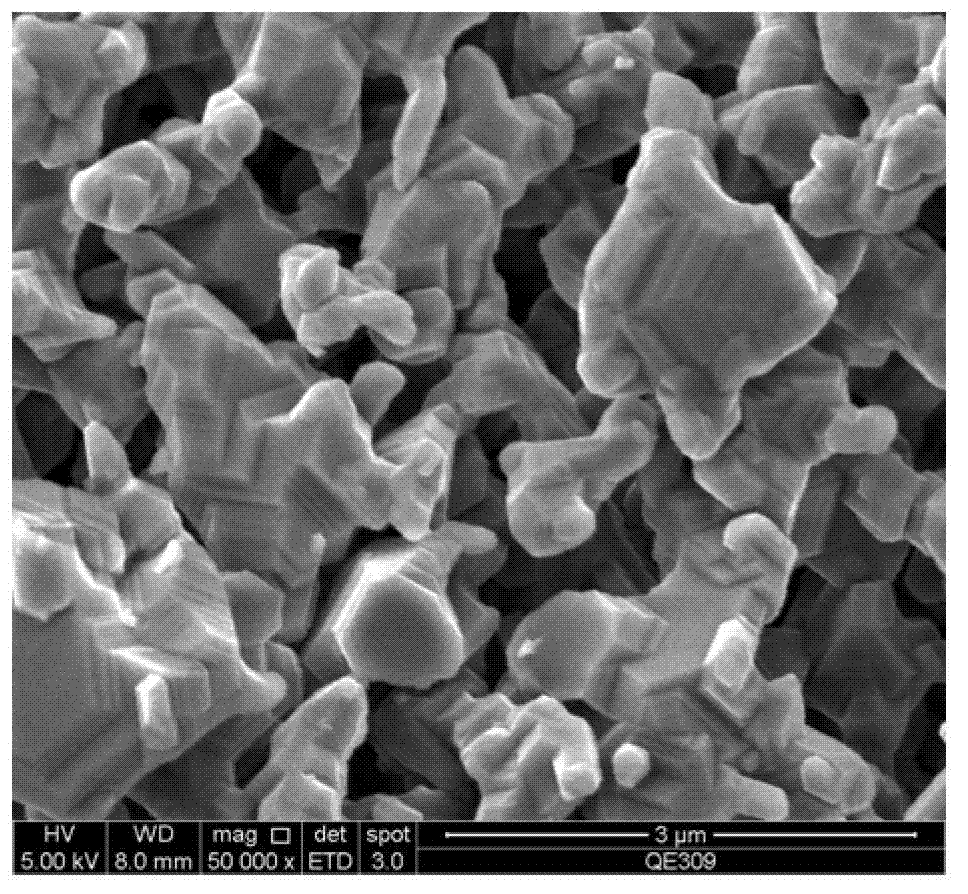

Preparation method of superfine and high-purity gamma-ALON transparent ceramics powder

The invention relates to a preparation method of superfine and high-purity gamma-ALON transparent ceramics powder, belonging to the filed of transparent ceramics material preparation. In the invention, the gamma-ALON transparent ceramics powder is prepared by combining a high energy ball mill with a carbothermic reduction nitriding method. The method of the invention is characterized by comprising the following steps: taking the gamma-Al2O3 powder with high specific surface area and carbon source, i.e. carbon black or nanometer powdered carbon as raw materials, mixing evenly by a wet process high energy ball mill and then drying; placing into a combined crucible of alumina and graphite to carry out the carbothermic reduction nitriding reaction; decarburizing by low-temperature process; and finally obtaining superfine and high-purity gamma-ALON transparent ceramics powder after being crushed by the high energy ball mill. The invention can synthesize pure phase alumina powder under the lower resultant temperature, has simple and feasible process, saves cost, and is suitable for industry production.

Owner:SHANGHAI FRP RES INST

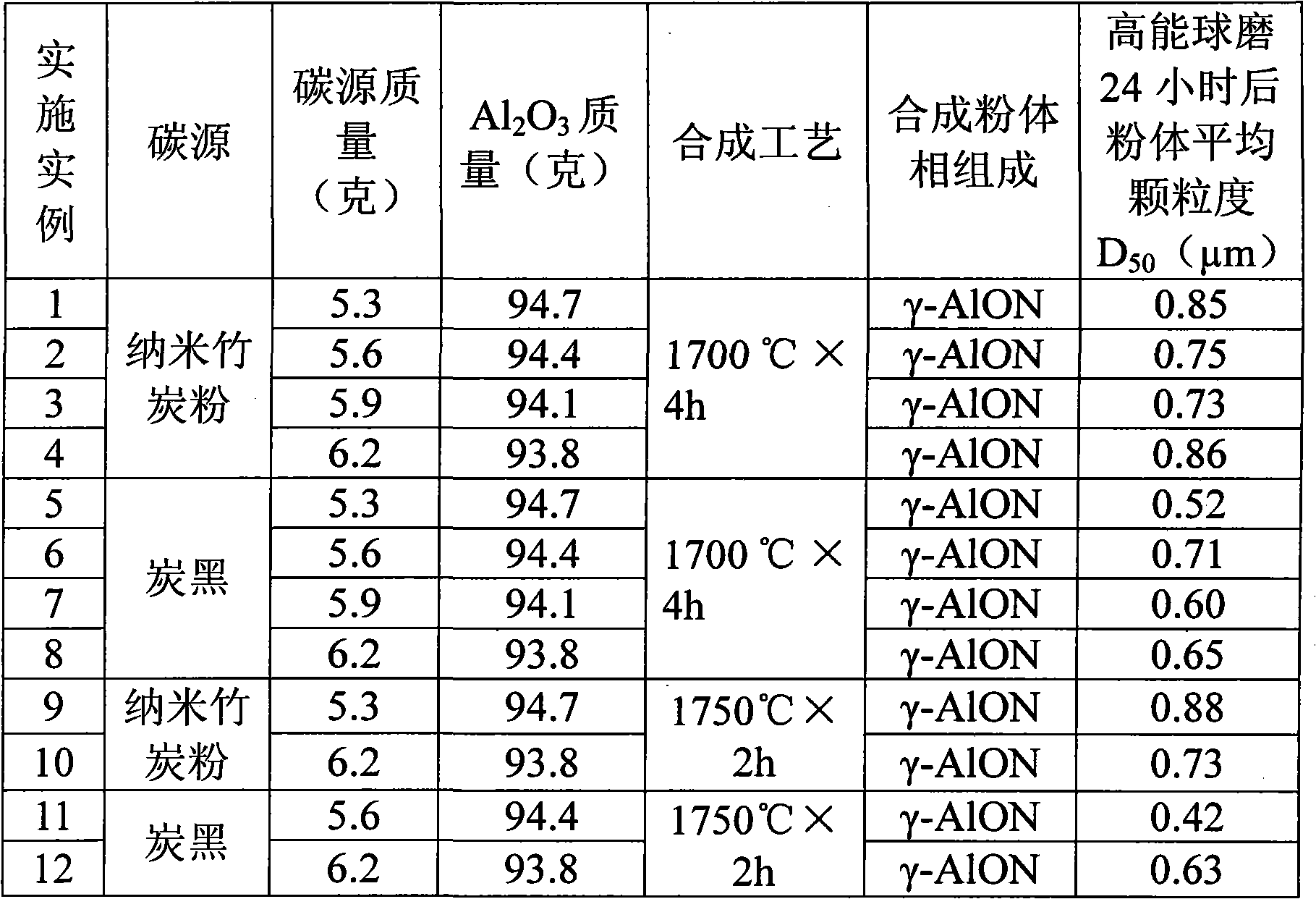

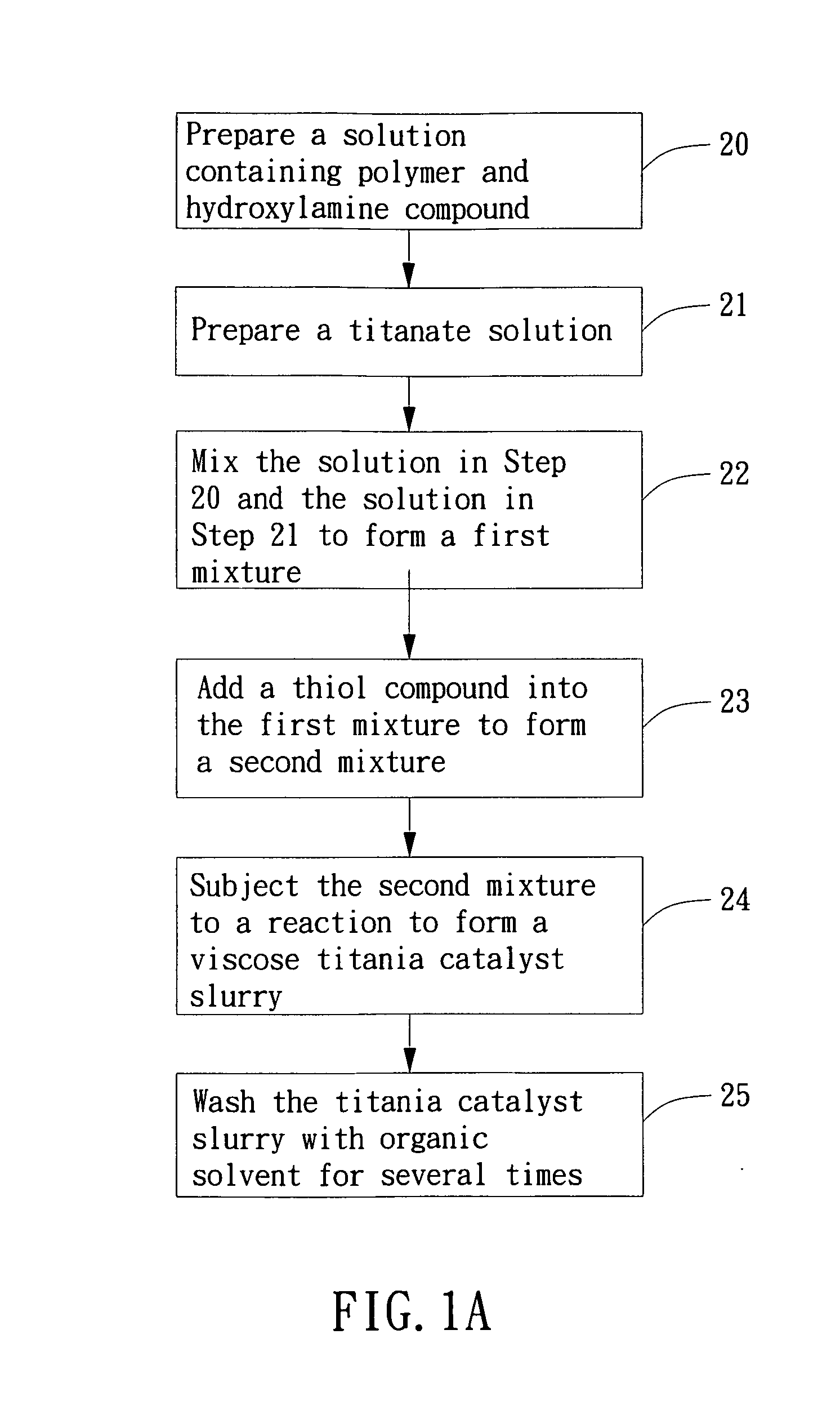

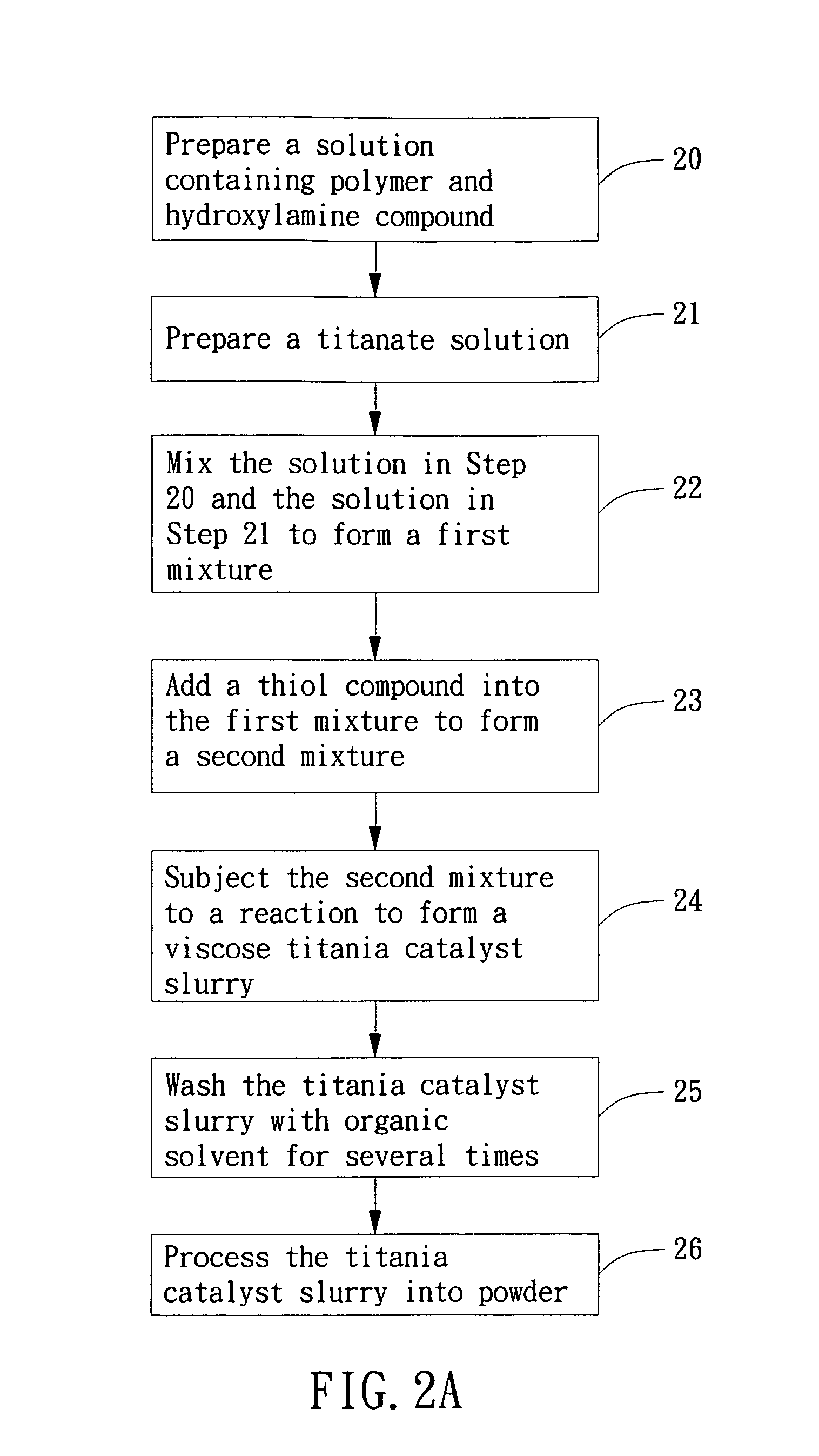

Method for producing catalyst for wastewater treatment

InactiveUS20090263314A1Shorten the compositing timeHigh porosityMaterial nanotechnologyWater/sewage treatment by irradiationSlurryHydrolysis

The present invention provides a method for producing catalyst for wastewater treatment, which comprising mixing polymers and additives, reacting with a titanate precursor, and then subjecting the resultant product to hydrolysis and condensation to form catalyst slurry. Due to using the titanate as a source of metal ions and the polymer compound as a dispersant and stabilizer, the aggregation between particles can be habited, and due to using additives as chelating agent and catalyst, it can improve solution stability and inhibit the oxidation of the metal, thereby facilitate the condensation and hydrolysis and shorten the reaction time. The catalyst slurry prepared by the method of the present invention exhibits excellent dispersibility to effectively contact with and decompose organics, such as those containing in wastewater and thus is suitable for wastewater treatment. In addition, the resultant catalyst slurry can be processed in the form of powder or film for using in industrial wastewater treatment.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Method for preparing norbornene and substituted derivatives of norbornene

InactiveUS6294706B1Improve responseTime of synthesis is minimizedHydrocarbon by isomerisationOrganic compound preparationHigh concentrationNorbornene

Disclosed is a method for the preparation of norbornene and substituted norbornene compounds via a Diels-Alder reaction, in which a cyclic diene is reacted with an olefinic compound in order to prepare a norbornene compound. According to the invention a cyclic diene is gradually added to react with an olefinic compound, in order to keep the concentration of the cyclic diene in the reaction mixture as low as possible during the reaction. It is possible to obtain a very pure product, high yield, short reaction time and high concentrations of the exo diastereomer with the method of the invention.

Owner:OPTATECH CORP

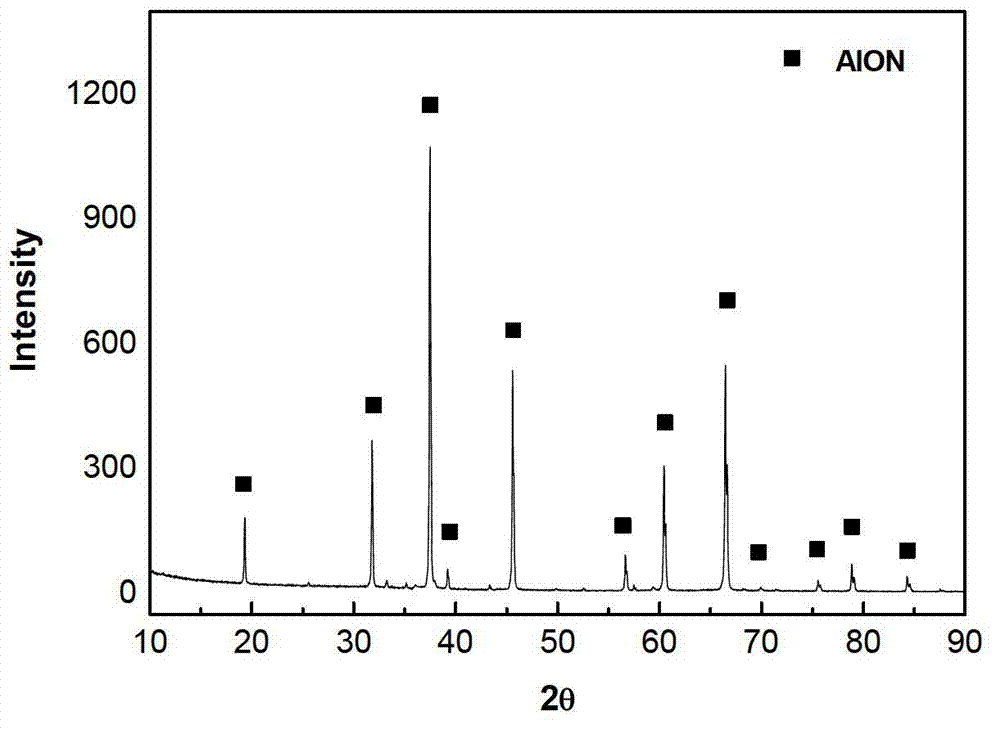

Method for rapidly preparing AlON ceramic powder by means of carbon thermal reduction

The invention provides a method for rapidly preparing AlON ceramic powder by means of carbon thermal reduction. The method takes low-cost gamma-Al2O3 powder and a carbon source, uniformly mixing the raw materials by means of wet-process ball milling, then drying and putting the raw materials in a zirconium oxide crucible, conducting a high-temperature carbon thermal reduction nitridation reaction at the high-pressure nitrogen atmosphere of 0.1-1MPa, quickly synthesizing the AlON powder, and then removing carbon at the low temperature of 500-900 DEG C to obtain the superfine, high-purity and uniformly dispersed single-phase AlON powder. Compared with the prior art, rapid sintering and carbon thermal reduction are combined under the condition of high nitrogen pressure, so that the activity of the AlON powder is improved, the preparation process is simplified, the preparation cost is lowered, and the method has an excellent industrialized application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Process for synthesizing mesic-porous molecular sieve SBA15

InactiveCN1724364AReduce dosageShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveHeteropoly acid

A process for synthesizing the meso-porous molecular sieve SBA-15 features that the tri-block copolymer 'polyepoxyethene-polyepoxypropane-polyepoxyethene' is used as template, the non-fluorine anionic salt as inducing agent, and the heteropoly acid as promoter and acidity regulator. Its advantages are short time and low environmental pollution and cost.

Owner:ZHEJIANG UNIV

Preparation process of resin with starch base high water absorbency

InactiveCN1560099AShorten the synthesis processShorten the compositing timeAcrylonitrileSaponification

The invention is a starch-based high water absorptivity resin preparing method, using starch, acrylic nitricle (AN), and 2-acrylamide-2-methyl prophyl sulfonic acid (AMPS) as raw materials, adopting [Mn(H2P2O7)3]3- as initiator, making graft polymerization and saponification, and fast synthesizing starch-based high water absorptivity resin. It makes graft copolymerization on starch and two kinds of monomer raw materials, making them form multielement compound, the initiator is cheap and the modified process can omit medium washing step and AMPS group is added to be able to obviously shorten the synthesis process and time of the final product, reduce production cost and simultaneously also be able to improve the water-absorbing performance of the final product.

Owner:JIANGNAN UNIV

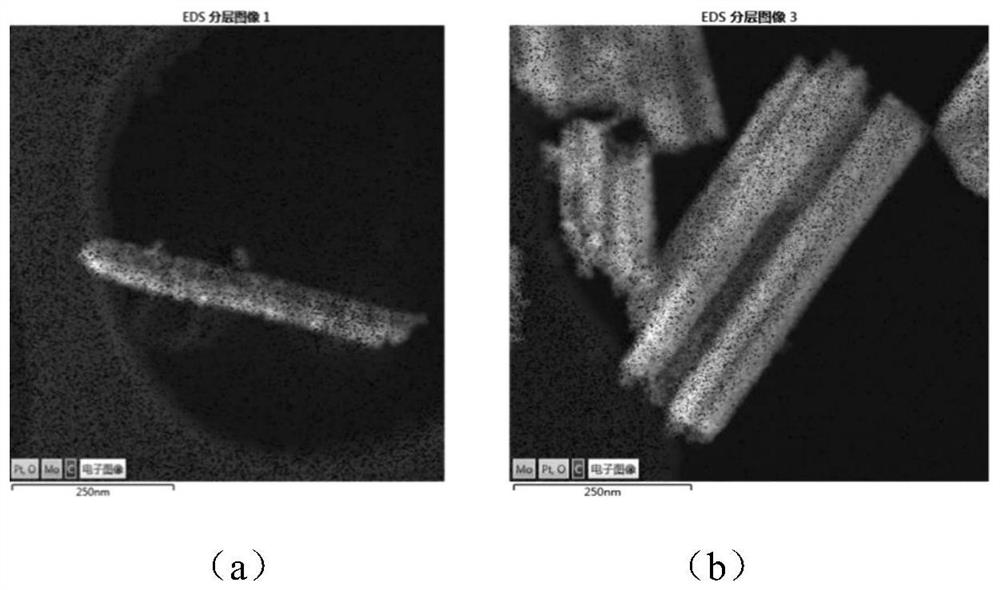

Monodisperse platinum-based two-dimensional metal hydroxide, and in situ synthesis method and application thereof in purification of volatile oxygen-containing hydrocarbons

ActiveCN110090640AStable complexationRich in surface hydroxyl functional groupsGas treatmentDispersed particle separationIonChemistry

The invention discloses a monodisperse platinum-based two-dimensional metal hydroxide, and an in situ synthesis method and an application thereof in the purification of volatile oxygen-containing hydrocarbons. A triblock copolymer poly(ethylene oxide)-polypropylene oxide-poly(ethylene oxide) is dissolved into deionized water, so taht a transparent and clear solution can be formed through stirring;hexamethylene tetramine is added, and then cerium or cobalt salts are added after uniform stirring; glycol is added after uniform stirring; a chloroplatinic acid hexahydrate-glycol solution is addedafter uniform stirring, so that a mixed solution can be obtained after uniform stirring; and heating reflux reaction is performed on the mixed solution in a microwave generator, and centrifugation androasting are performed after complete reaction, so that the monodisperse platinum-based two-dimensional metal hydroxide can be obtained. The prepared catalytic material has atomic-scale dispersed platinum active sites and shows excellent low temperature purifying capabilities of volatile oxygen-containing hydrocarbons; and the related catalyst synthetic method is simple and low in raw material price, and has good industrial application prospects.

Owner:XI AN JIAOTONG UNIV

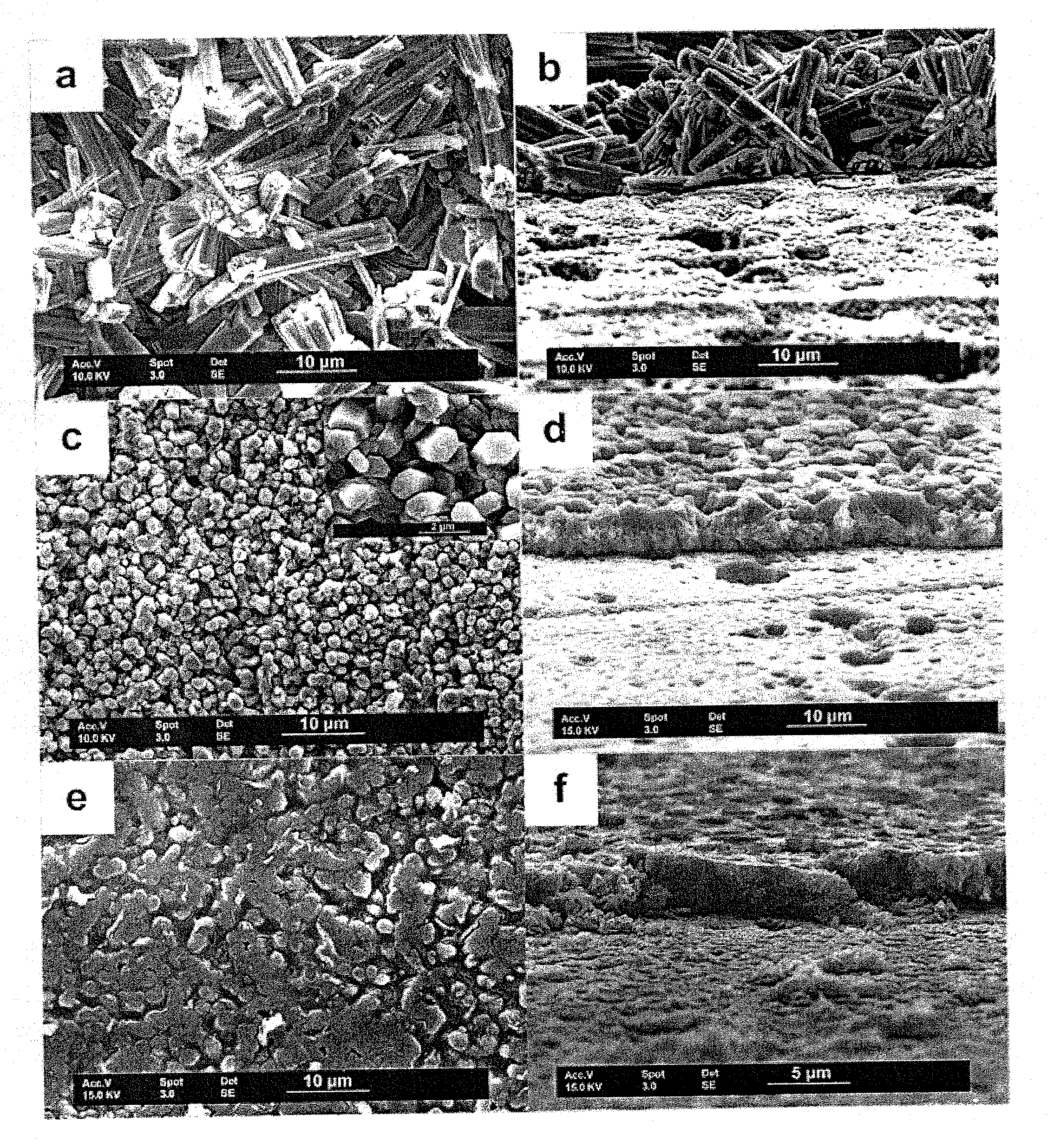

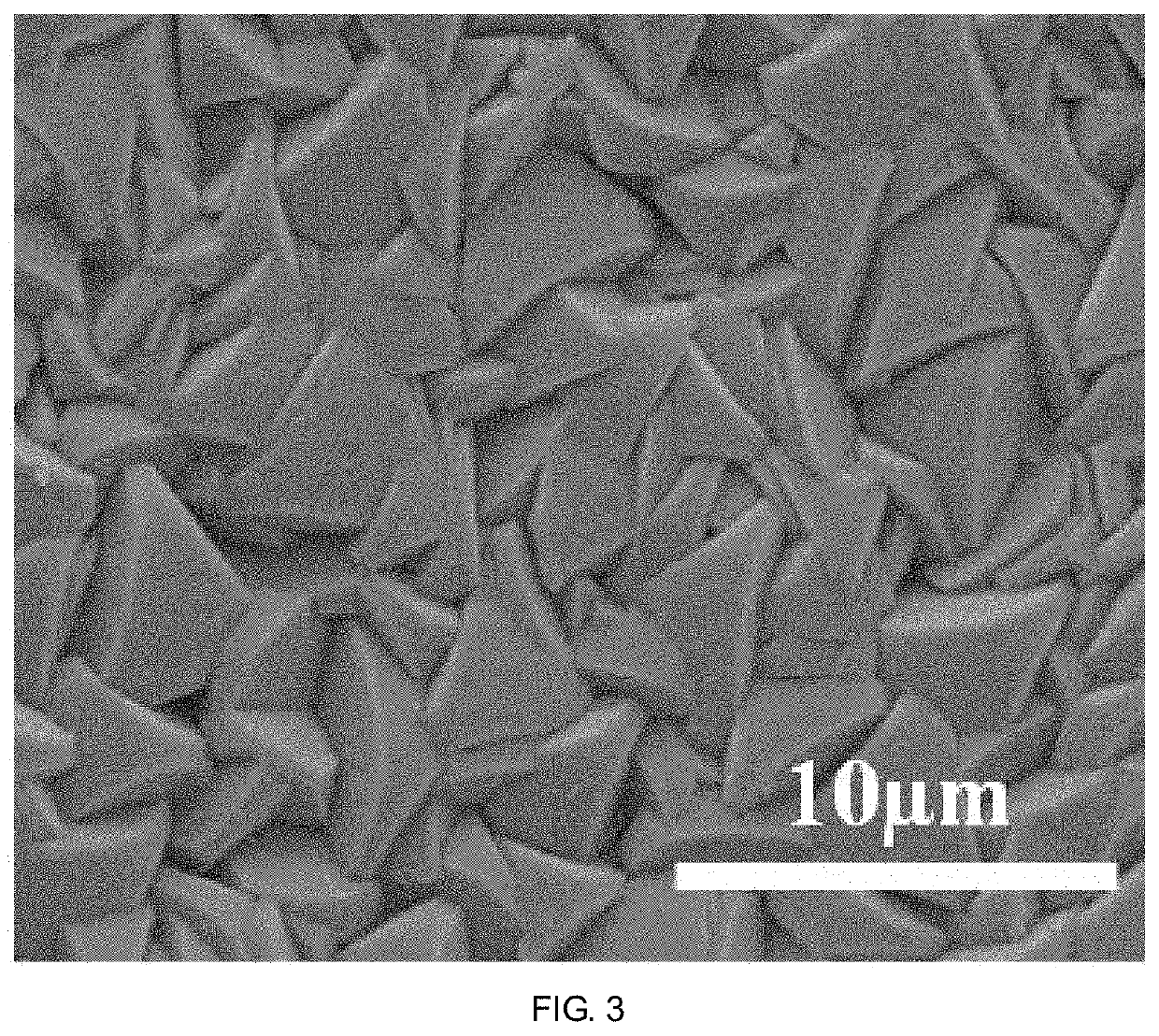

Method for preparing defect-free DDR molecular sieve membrane

ActiveUS20190366274A1Shorten the compositing timeImprove film qualityMembranesSemi-permeable membranesMolecular sieveGreek letter sigma

Provided is a method for preparing a defect-free DDR molecular sieve membrane. Sigma-1 molecular sieve is used as an inducing seed crystal to prepare and obtain a continuous and compact DDR molecular sieve membrane on the surface of a porous ceramic support. An ozone atmosphere or an external field assisted technology is used to remove a template in the pores of the molecular sieve membrane at a low temperature. The invention avoids the formation of intercrystal defects and cracks, an activated DDR molecular sieve membrane has a good selectivity for separating CO2, and the membrane preparation time is significantly reduced.

Owner:NANJING UNIV OF TECH

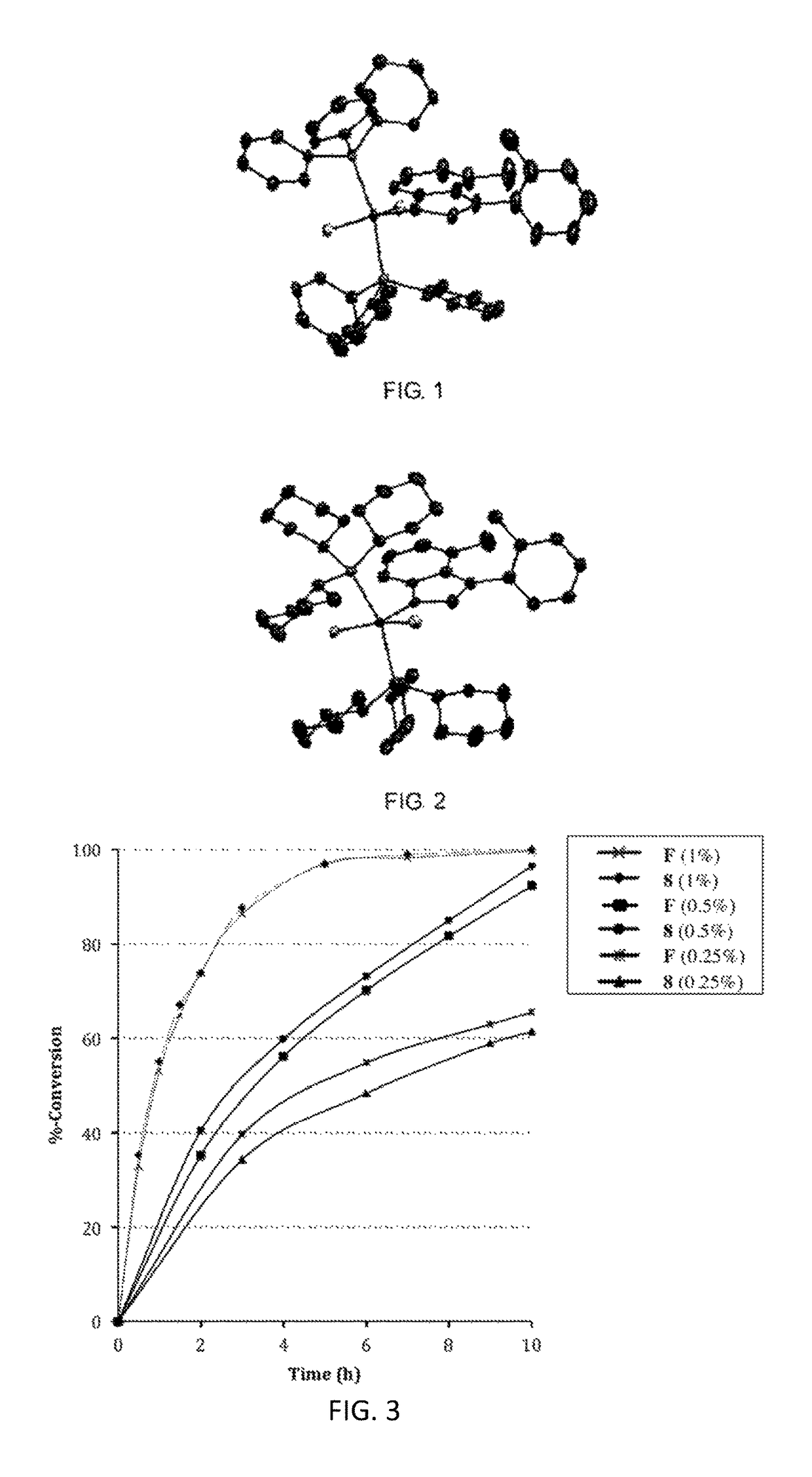

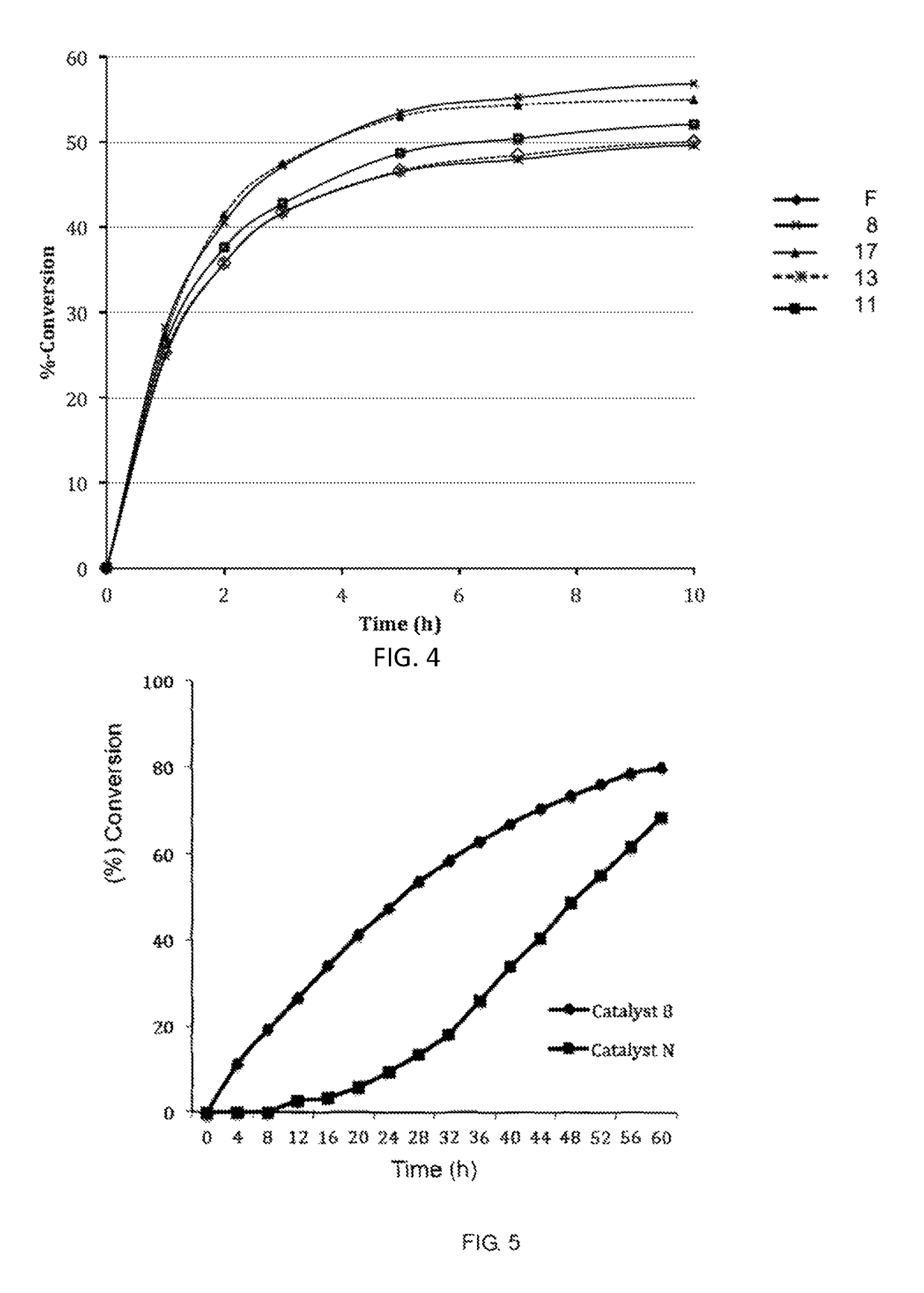

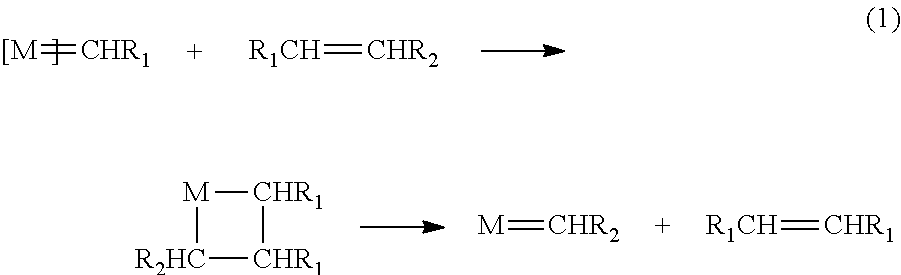

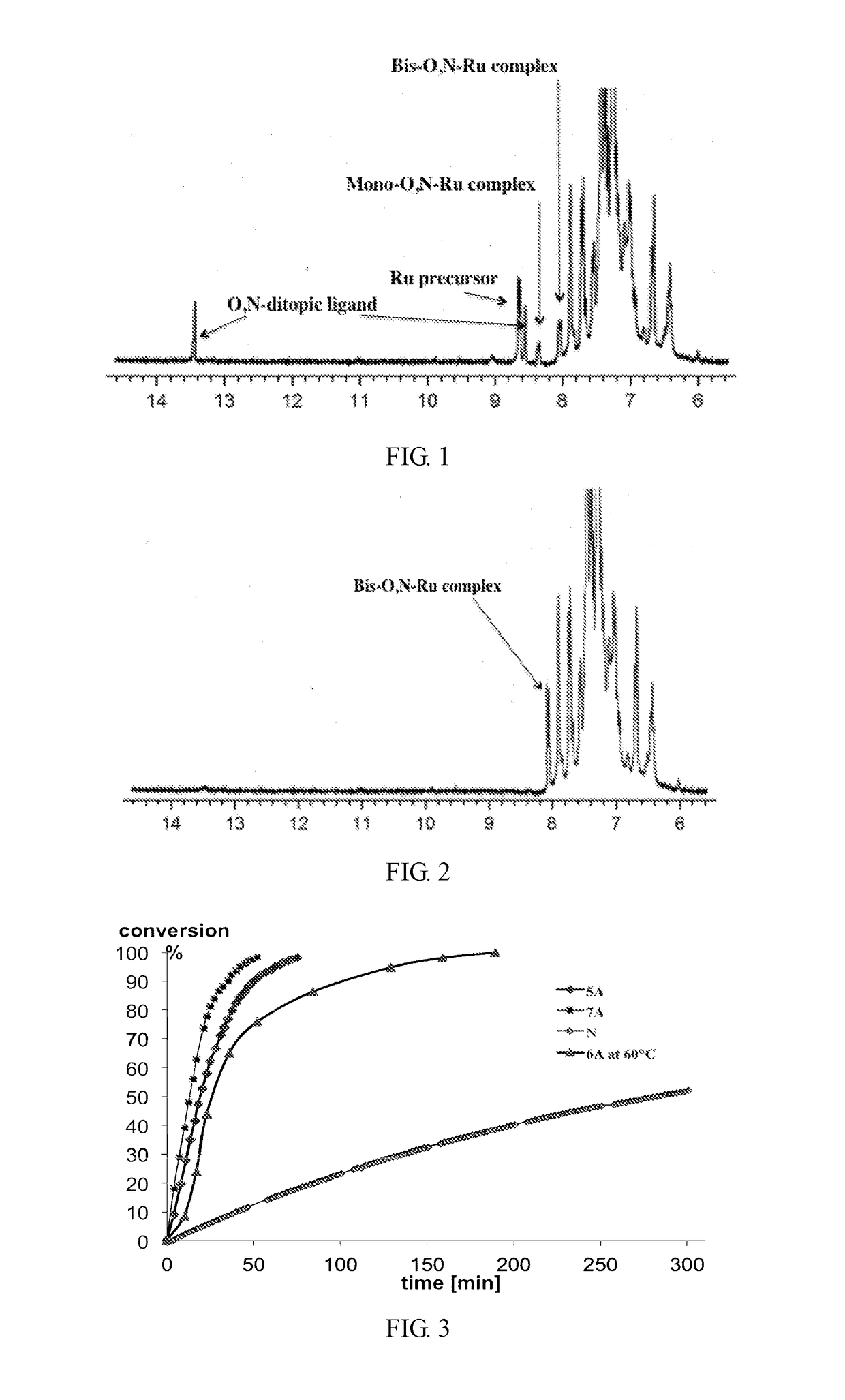

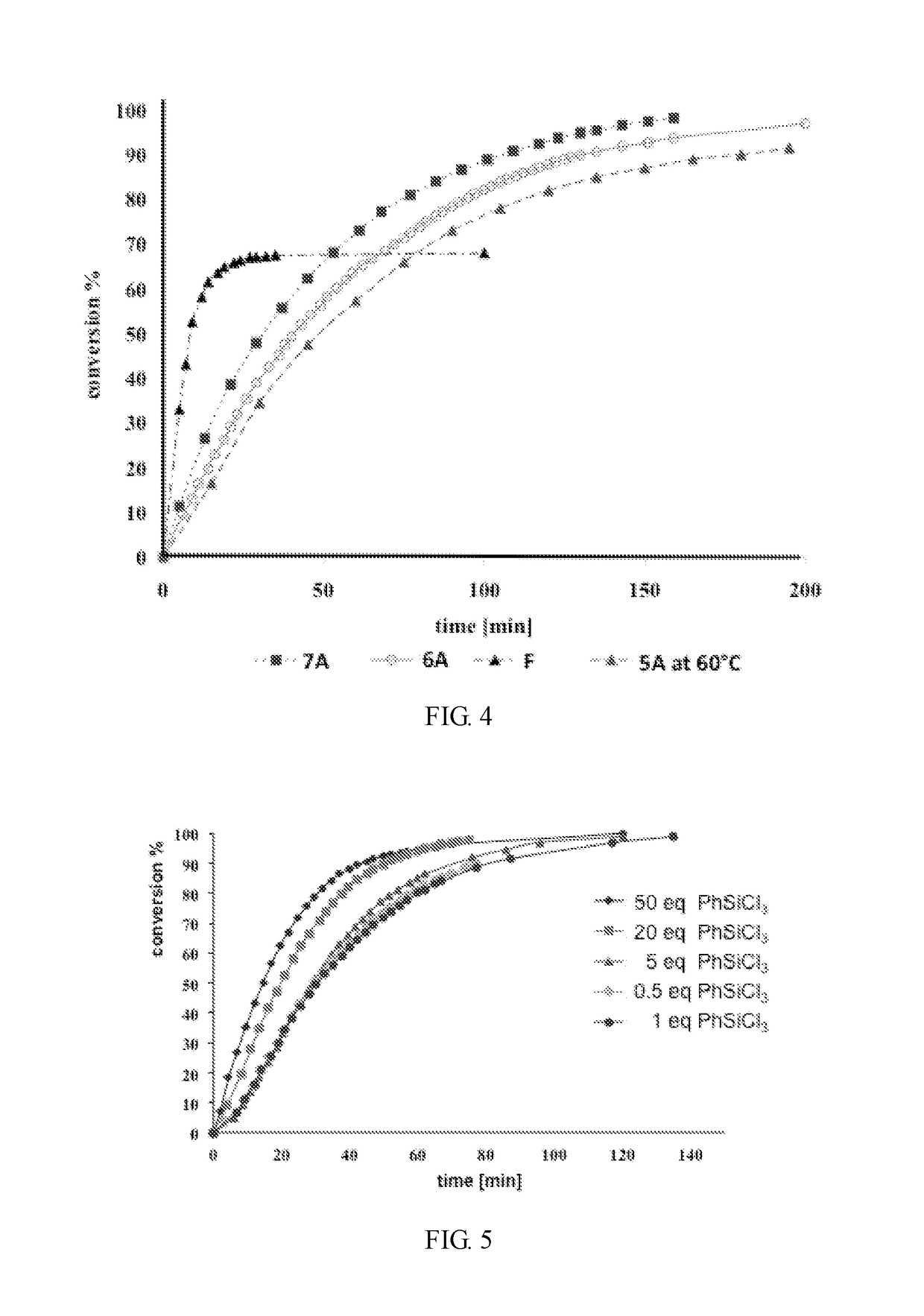

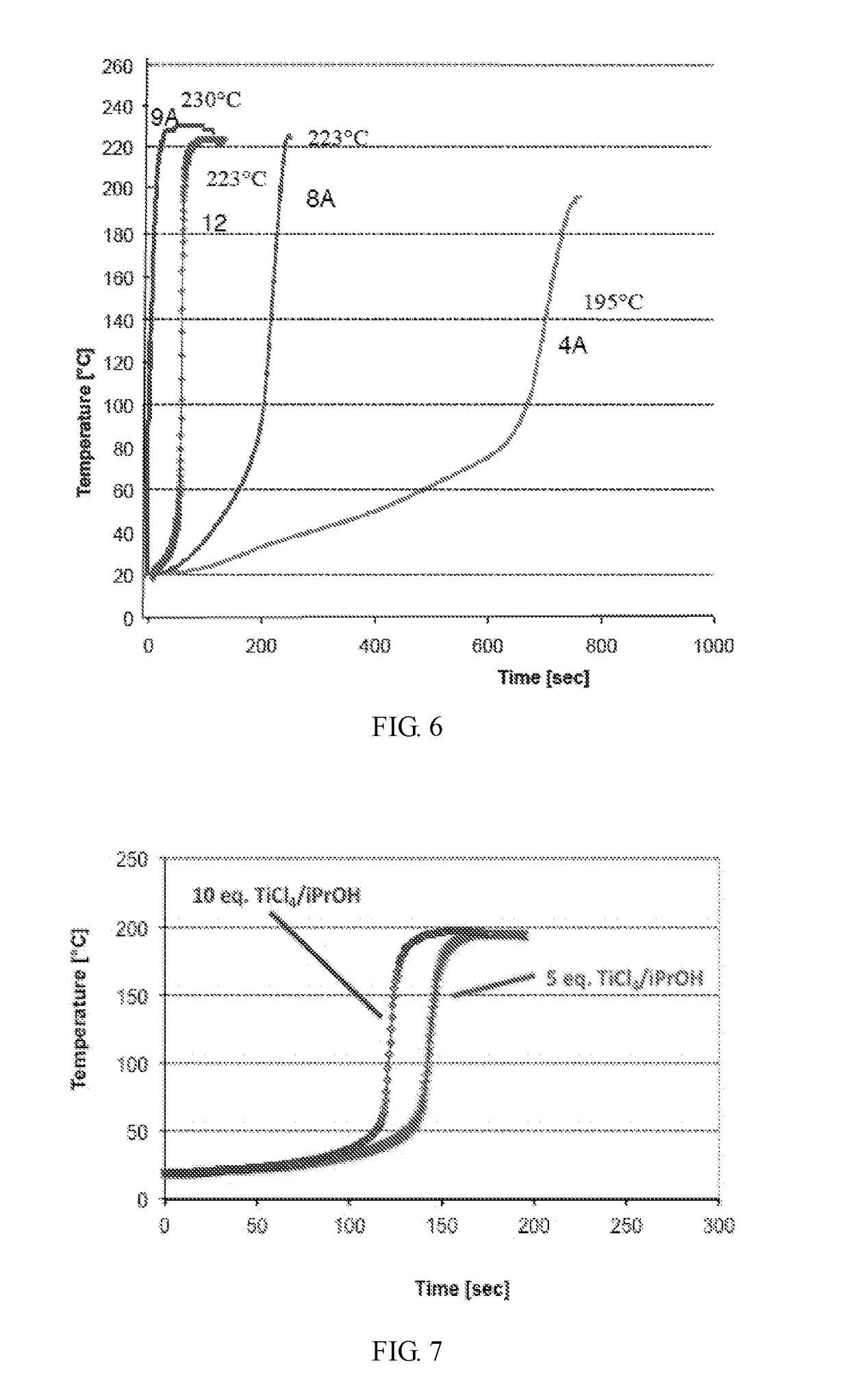

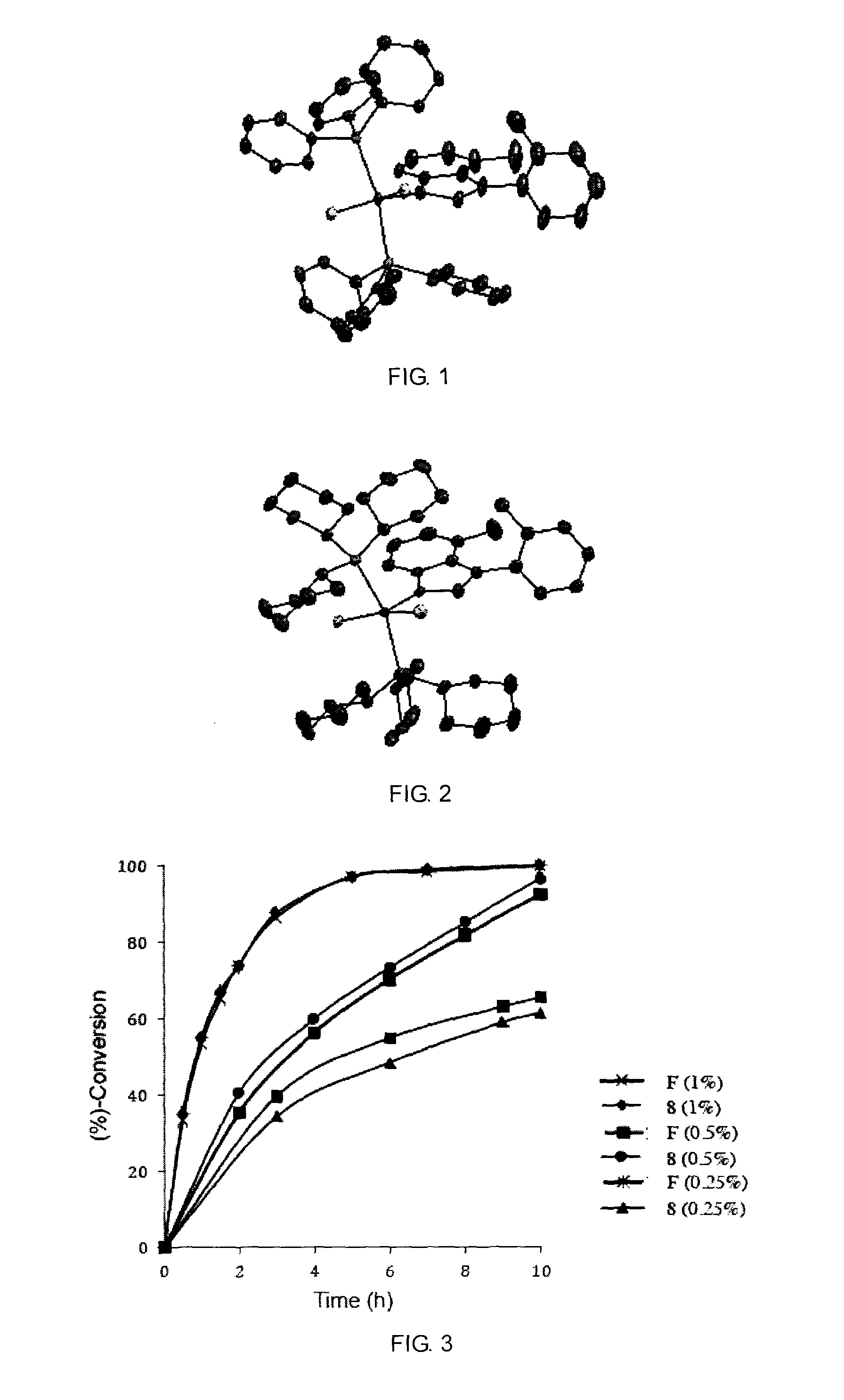

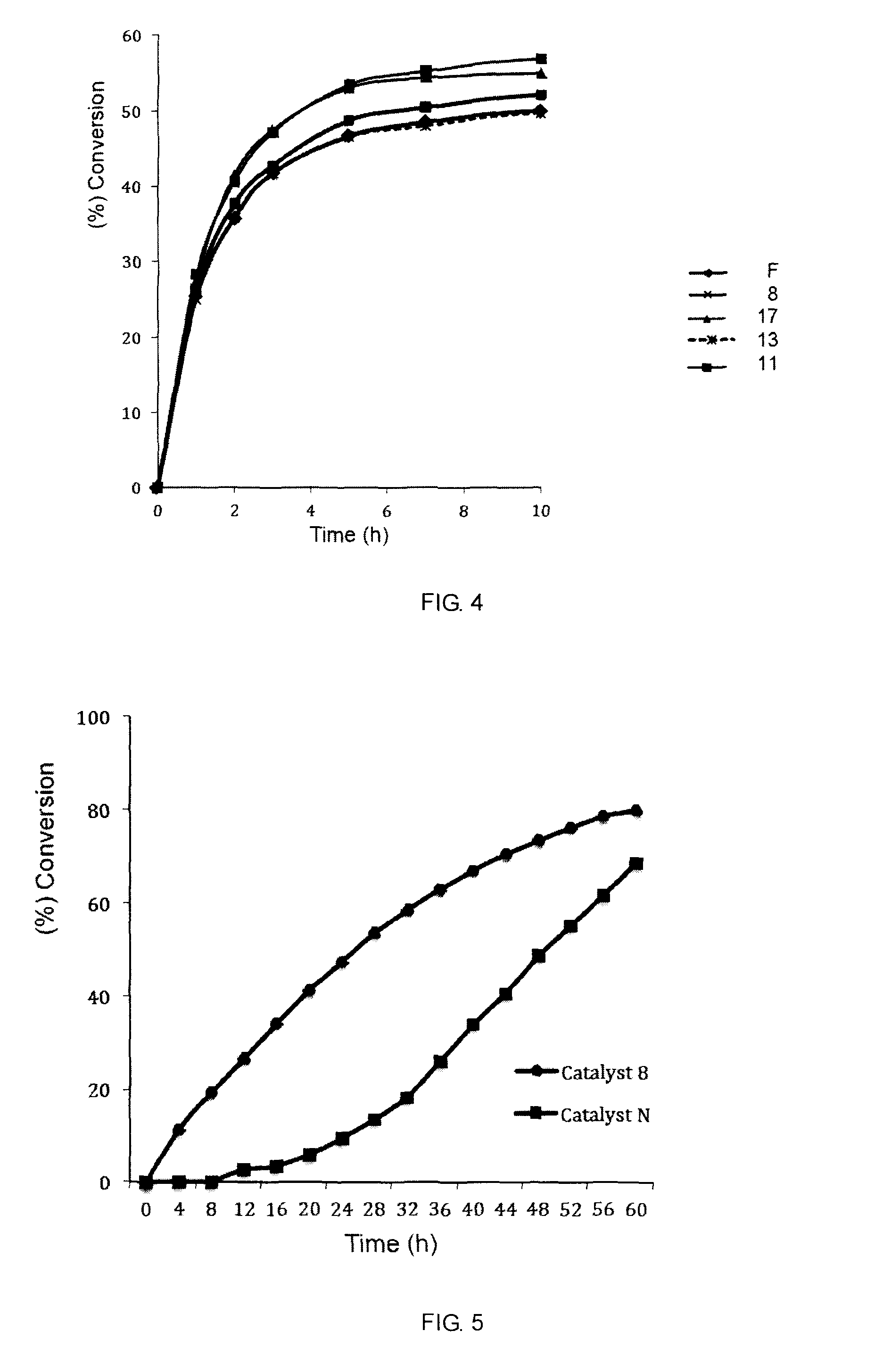

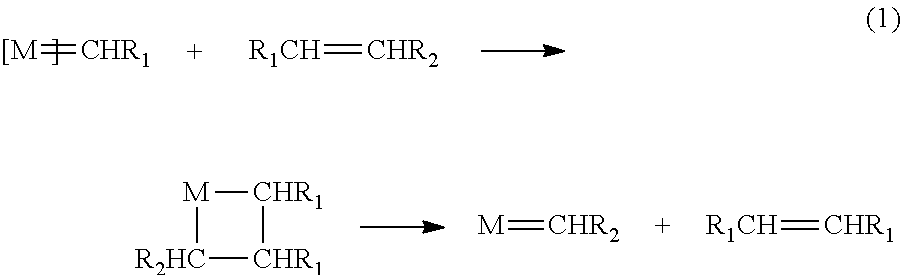

Group 8 transition metal catalysts and method for making same and process for use of same in metathesis reaction

ActiveUS20170145152A1Easily and efficiently activatedHigh yieldRuthenium organic compoundsOrganic compound preparationElectron donorRotational molding

Metal catalyst compounds are disclosed. The catalyst compound are represented by the formula (I-II and VII): wherein M is a Group 8 metal; X is an anionic ligand; L is a neutral two electron donor ligand; K 2 (A-E) is a ditopic or multitopic ligand. Also disclosed is an easy applicable catalyst synthesis and the application in different olefin metathesis processes, e.g. Reaction Injection Molding (RIM), rotational molding, vacuum infusion, vacuum forming, process for conversion of fatty acids and fatty acid esters or mixtures thereof, in -olefins, dicarboxylic acids or dicarboxylic esters, etc.

Owner:GUANGMING CHUANGXIN WUHAN CO LTD

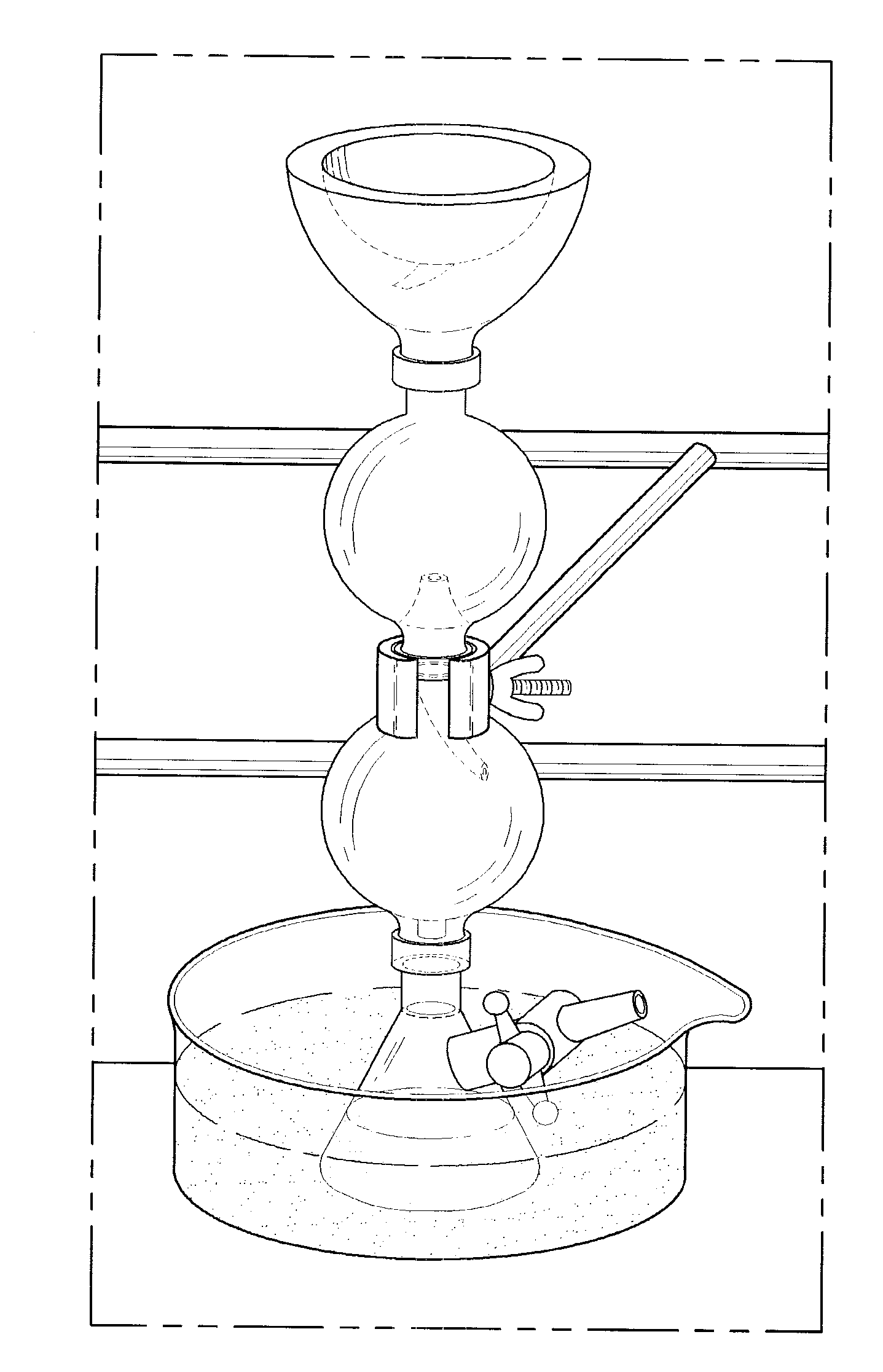

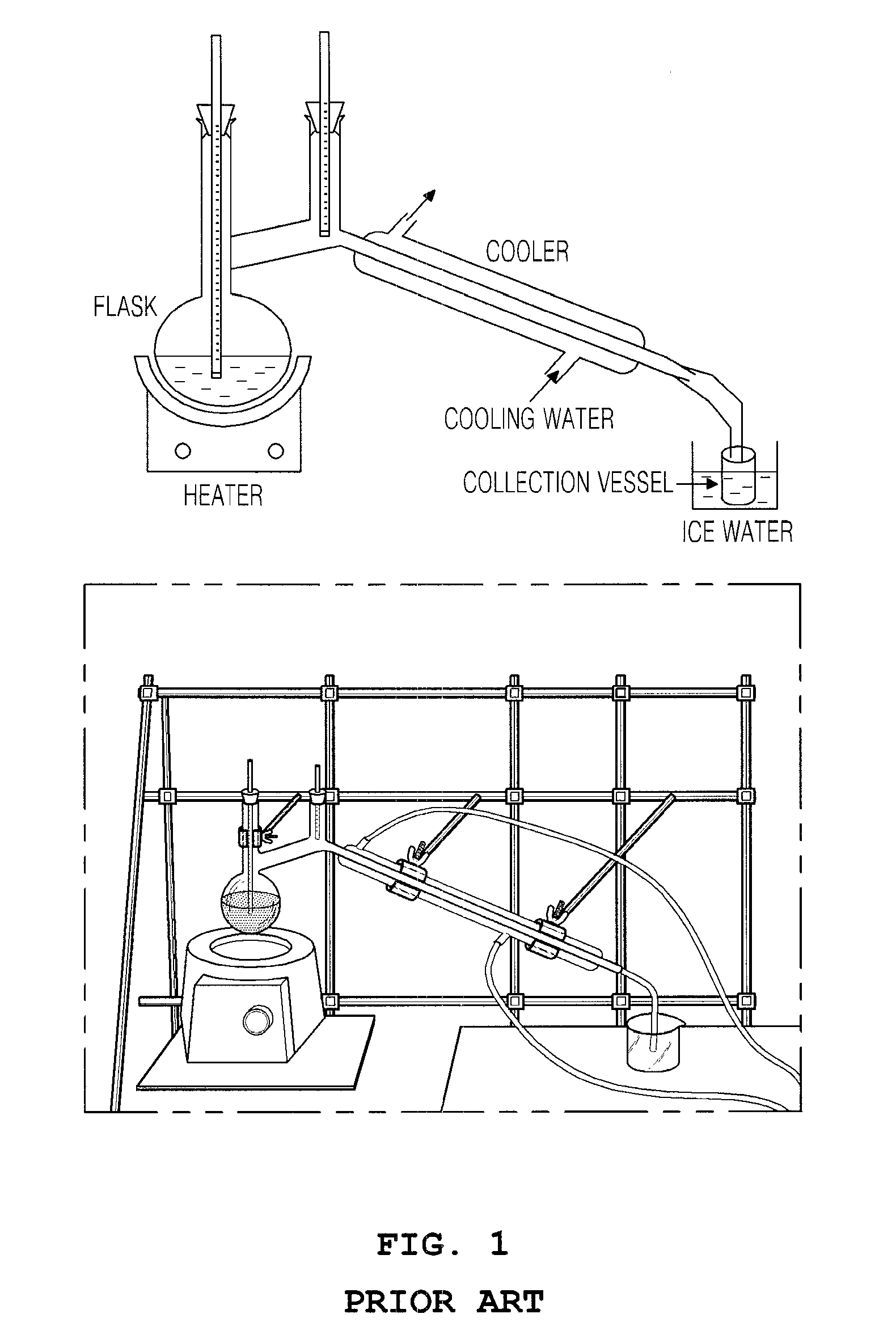

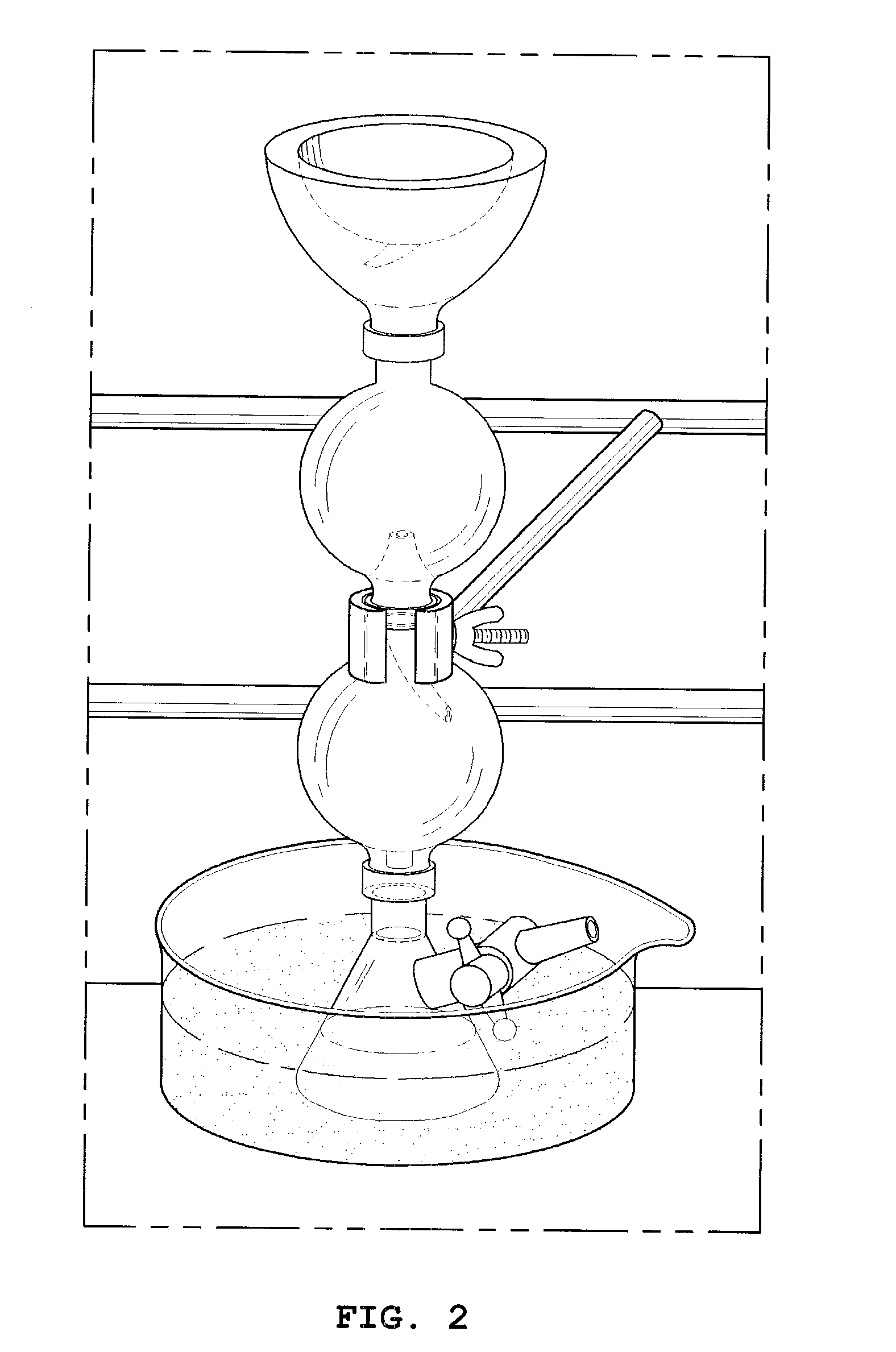

Method and device for synthesizing radioactive methyl iodine tracer

ActiveUS20120209035A1Minimizes probabilityShorten the compositing timePreparation by halogen replacementDistillation in boilers/stillsNuclear gradeActivated carbon

Disclosed is a method and device for simply and safely preparing, using a direct synthesis process at room temperature, a radioactive methyl iodine (CH3131I) tracer for use in evaluating the ability of impregnated activated carbon to adsorb radioactive organic iodine according to ASTM D 3803 (Standard Test Method for Nuclear-Grade Activated Carbon), in which the tracer can be directly synthesized by mixing radioactive sodium iodide (Na131I) with methyl iodine (CH3I) at room temperature under reduced pressure, thus shortening excessive synthesis time and decreasing the probability of radiation exposure due to leakage of volatile material during the distillation.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

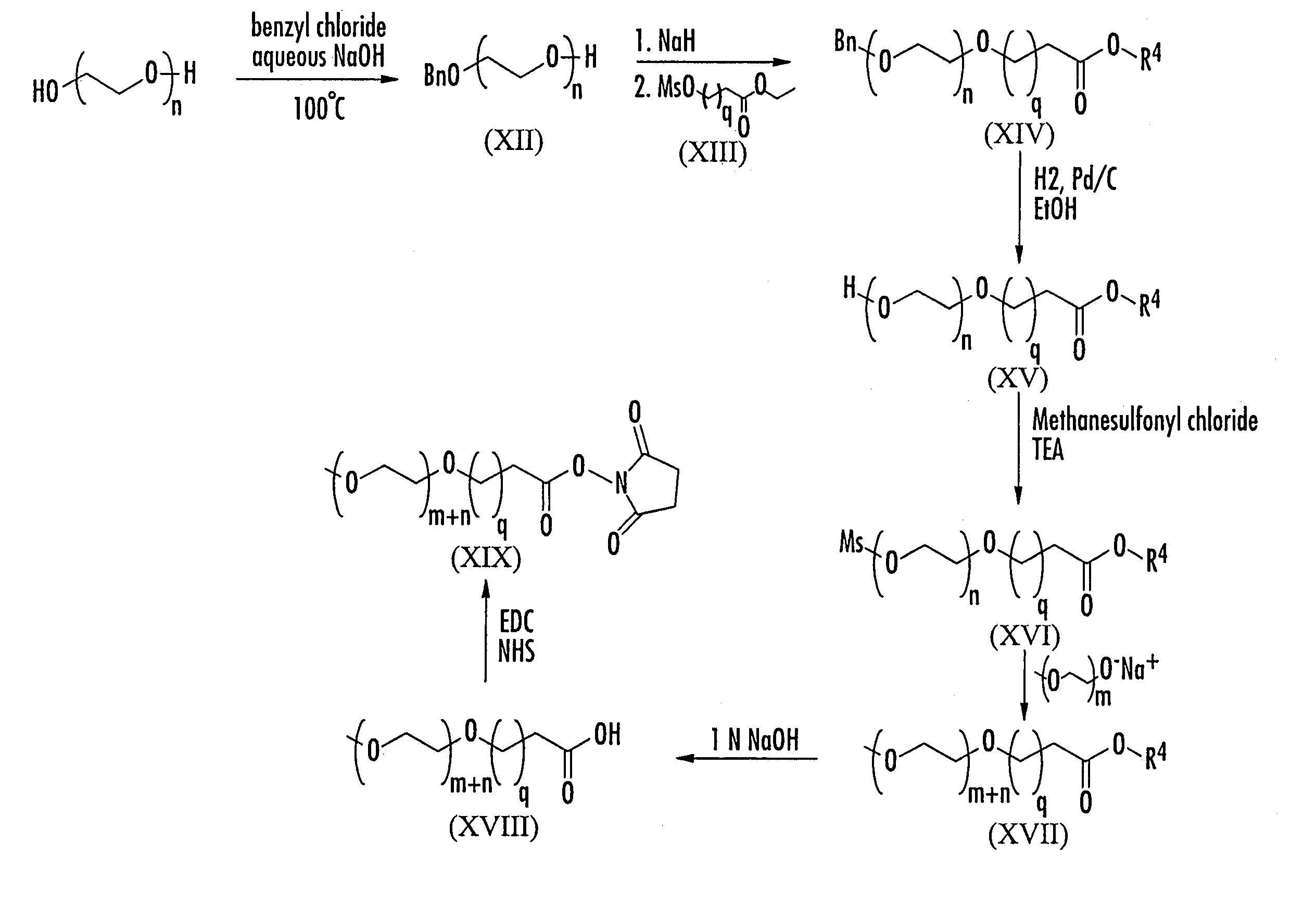

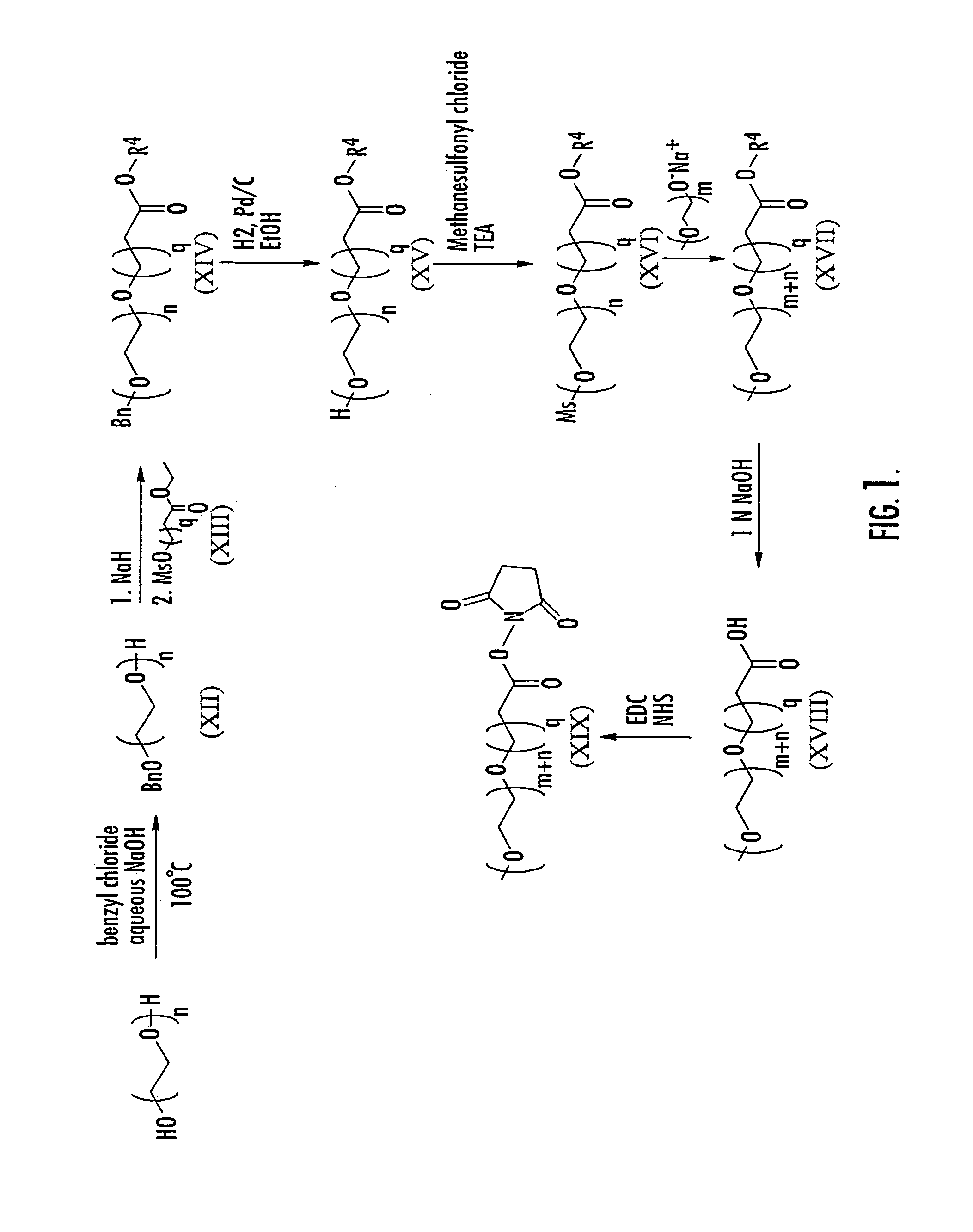

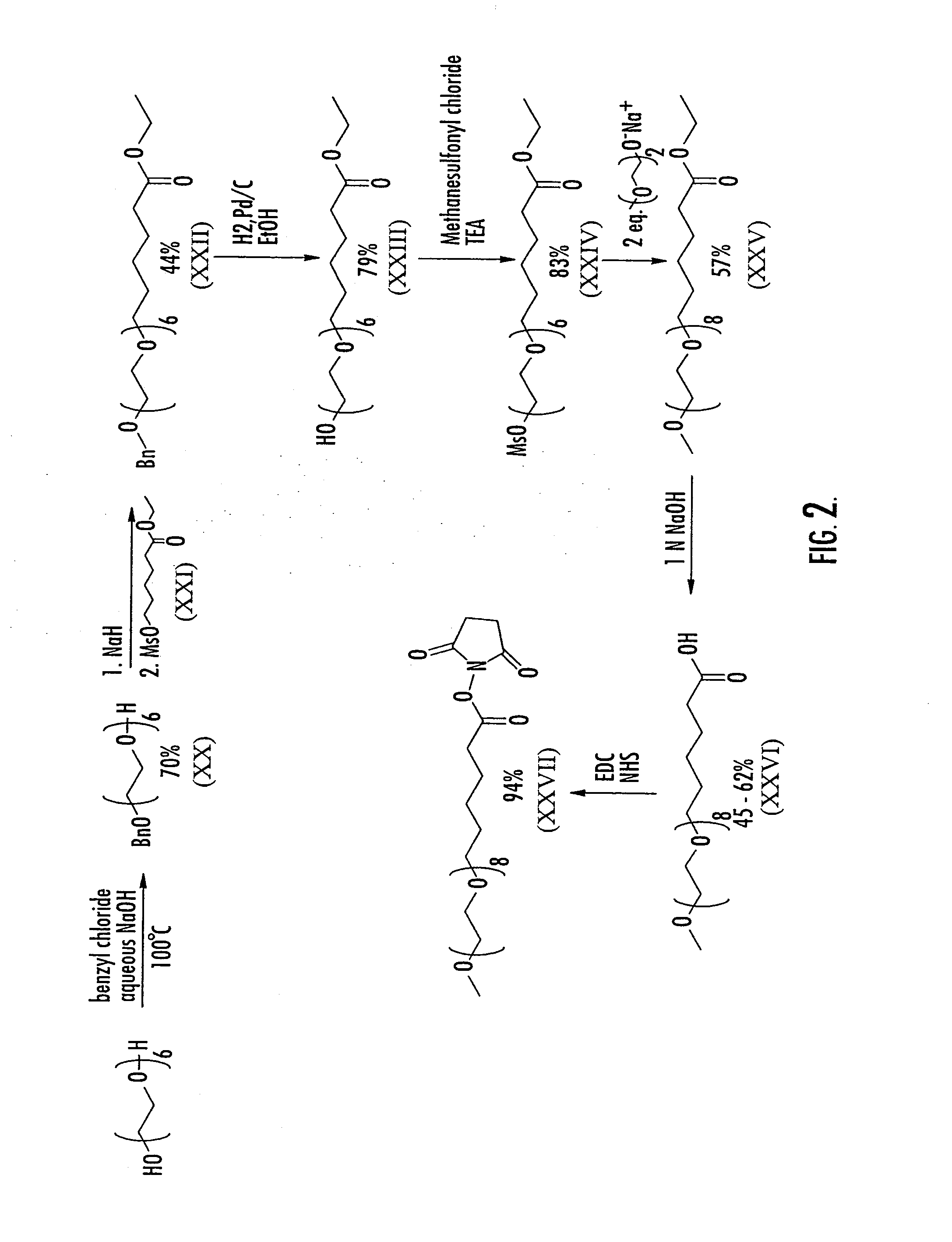

Substantially monodispersed mixtures of polymers having polyethylene glycol moieties

InactiveUS7119162B2Reduce and prevent formationFew stepsEther preparation by ester reactionsPolymer sciencePolyethylene glycol

Methods of synthesizing a substantially monodispersed mixture of polymers comprising polyethylene glycol moieties include:reacting a substantially monodispersed mixture of compounds having the structure of Formula I:R1(OC2H4)n—O−X+ (I)wherein R1 is H or a lipophilic moiety; n is from 1 to 25; and X+ is a positive ion,with a substantially monodispersed mixture of compounds having the structure of Formula II:R2(OC2H4)m—OMs (II)wherein R2 is H or a lipophilic moiety; and m is from 1 to 25, under conditions sufficient to provide a substantially monodispersed mixture of polymers comprising polyethylene glycol moieties and having the structure of Formula III:R2(OC2H4)m+n—OR1 . (III)Substantially monodispersed mixtures of polymers comprising polyethylene glycol moieties are also disclosed.

Owner:BIOCON LTD

Catalyst complexes with carbene ligand and method for making same and use in metathesis reaction

ActiveUS20150367338A1High to excellent yieldShorten the compositing timeRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

This invention relates to catalyst compounds and the synthesis and applications useful in olefin metathesis reactions. The catalyst compounds of the invention are represented by the formula (I): wherein M is a Group 8 metal; X1 and X2 are anionic ligands; L1 and L2 are neutral two electron donor ligands. The present invention also relates to an easy applicable catalyst synthesis and the application in different olefin metathesis processes, e.g. Reaction Injection Molding (RIM), process to make α-olefins from fatty acid ester, e.g. methyl oleate.

Owner:GUANGMING CHUANGXIN WUHAN CO LTD

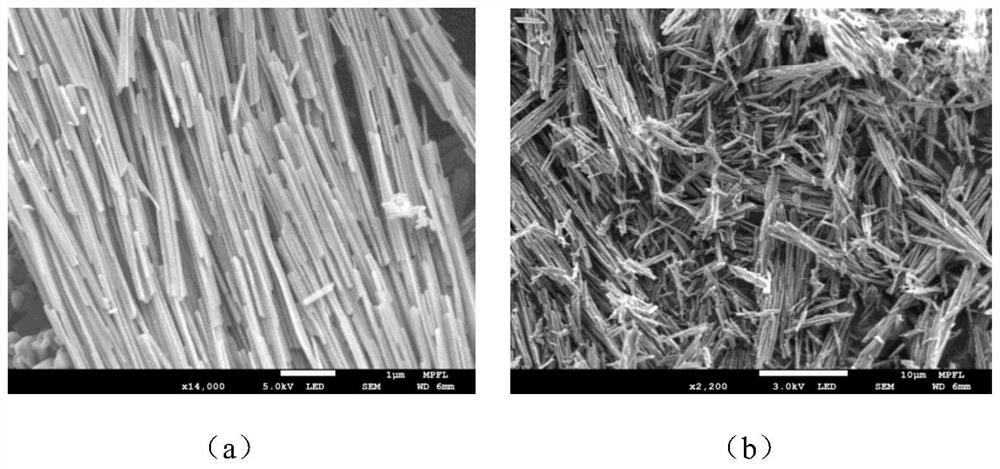

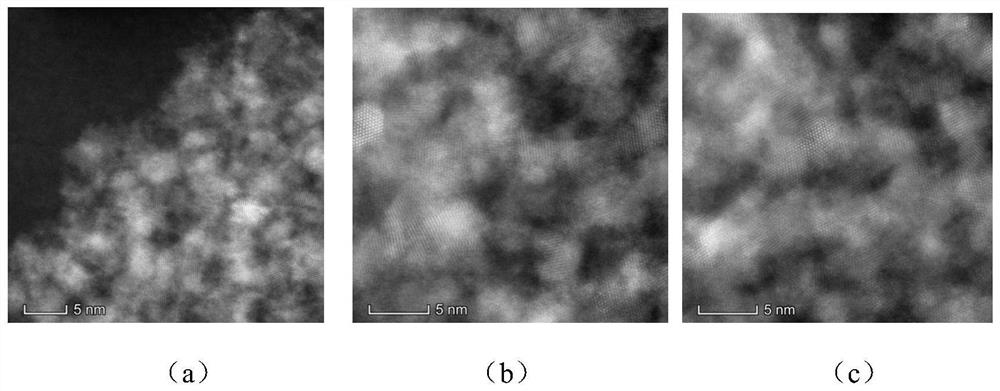

High-stability monatomic platinum-based catalytic material, preparation method and application thereof in oxygen-containing volatile hydrocarbon purification

ActiveCN111686774AHigh degree of complexationImprove efficiencyDispersed particle separationCatalyst activation/preparationPlatinumPhysical chemistry

The invention relates to a high-stability monatomic platinum-based catalytic material, a preparation method and application thereof in oxygen-containing volatile hydrocarbon purification. High-stability molybdenum carbide is used as a carrier, and abundant surface hydroxyl groups are constructed on the surface of the carrier through a hydrothermal alkaline leaching method; and the monatomic platinum active phase is stably dispersed on the surface of the molybdenum carbide carrier through strong interaction with surface hydroxyl. The prepared monatomic platinum-based catalytic material has excellent low-temperature catalytic activity and stability, and deep purification of volatile oxygen-containing hydrocarbons discharged by an industrial source can be achieved under the conditions that the temperature is 100-135 DEG C, the reaction space velocity is 36000-45000 h<-1> and the oxygen concentration is 10-20 vol.%. The low-temperature catalytic efficiency of the monatomic catalytic material is greatly improved. The problem of high cost of the supported noble metal is solved to a certain extent, and the catalytic material has good application universality.

Owner:XI AN JIAOTONG UNIV

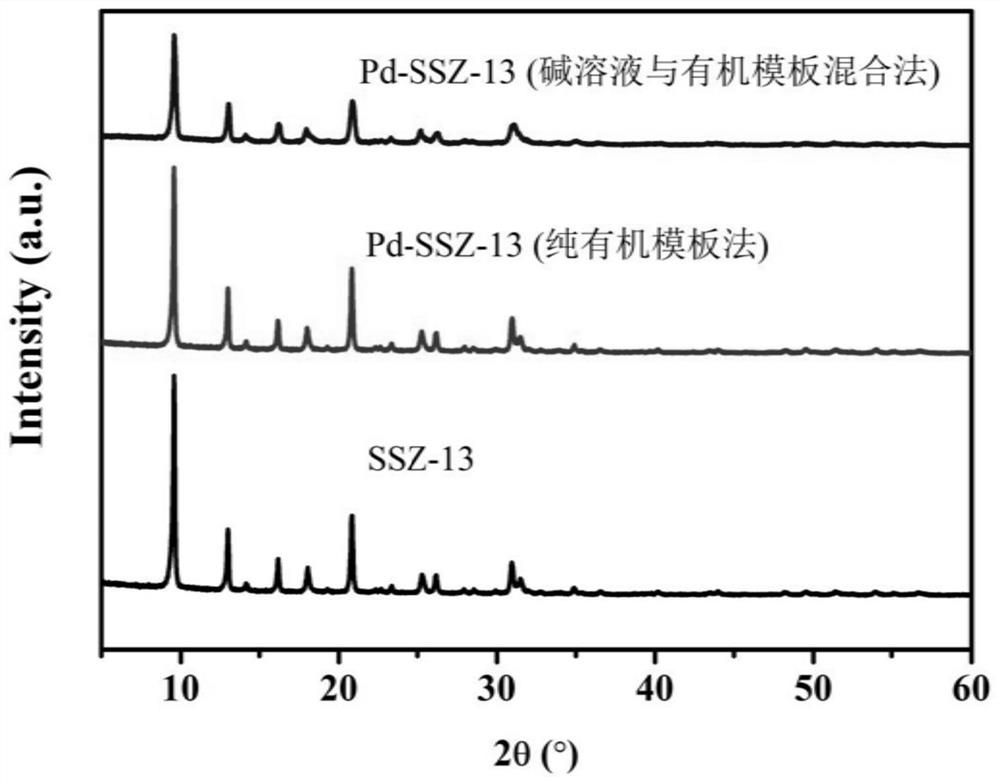

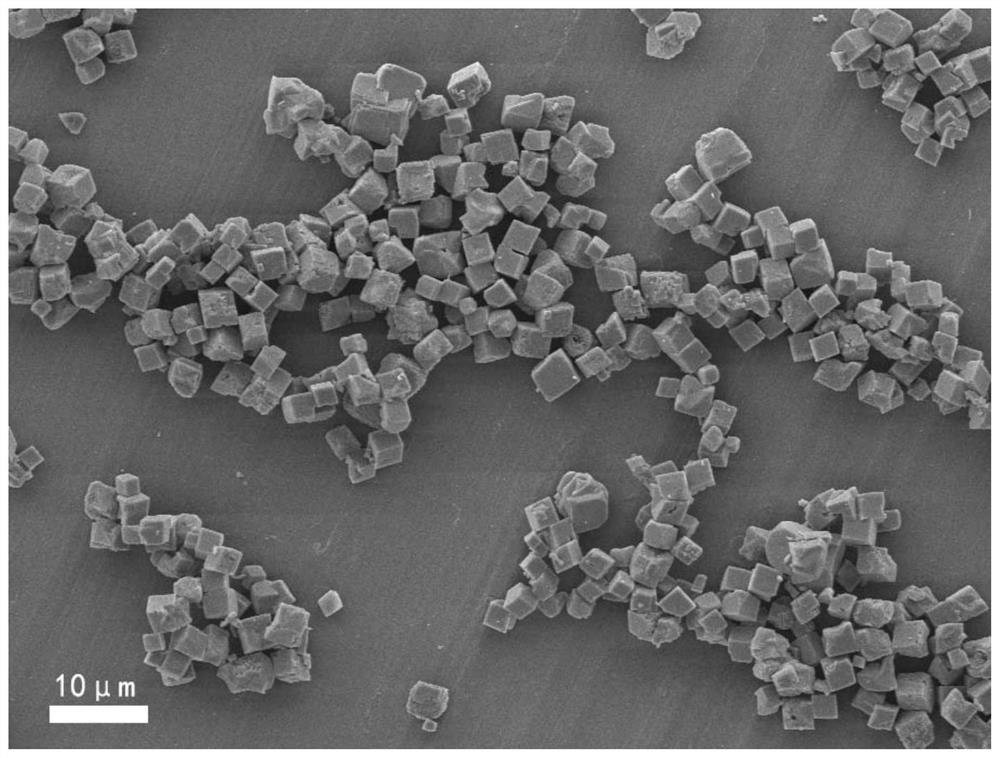

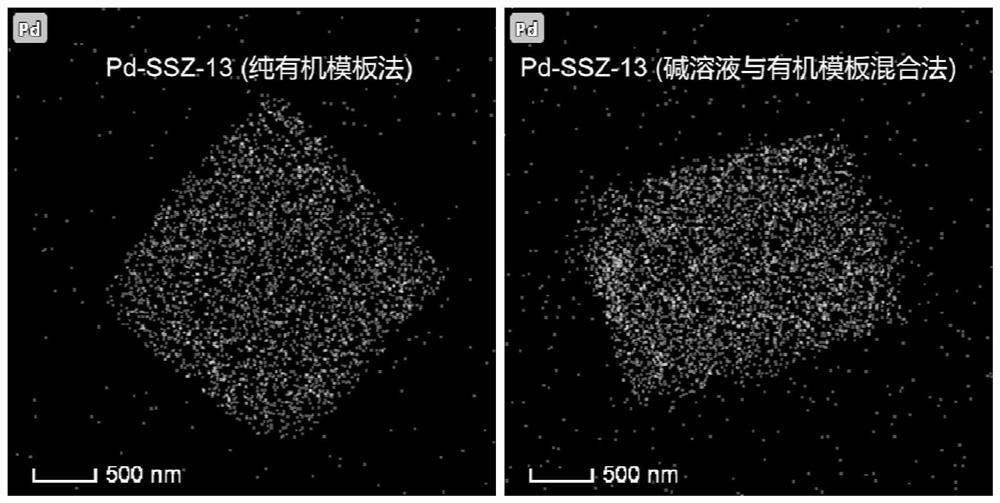

Preparation method and application of small-pore molecular sieve-loading noble metal material prepared by one-pot reaction

InactiveCN111974444AFew synthetic stepsPrevent reunionGas treatmentMolecular sieve catalystsMolecular sieveMetallic materials

The invention relates to the technical field of thermocatalysis, in particular to a preparation method and application of a small-pore molecular sieve-loading noble metal material prepared by one-potreaction. The small-pore molecular sieve-loading noble metal material provided by the invention comprises a small-pore molecular sieve SSZ-13 and a noble metal Pd species dispersed in the small-pore molecular sieve. The one-pot reaction for preparing the small-pore molecular sieve-loading noble metal material can effectively reduce the synthesis steps and shorten the preparation time of a catalytic material. The method can uniformly disperse noble metal in the molecular sieve, prevent agglomeration of the noble metal species, and provide more NOx adsorption sites. The small-pore molecular sieve-loading noble metal material disclosed by the invention is applied to the field of low-temperature NOx adsorption and high-temperature NOx desorption, the adsorption efficiency of the small-pore molecular sieve-loading noble metal material prepared by the one-pot reaction on NOx under a low-temperature condition is remarkably improved, so that NOx removal at a low temperature can be effectivelyrealized, and the small-pore molecular sieve-loading noble metal material can be applied to the field of atmospheric pollution treatment.

Owner:SOUTH CHINA UNIV OF TECH

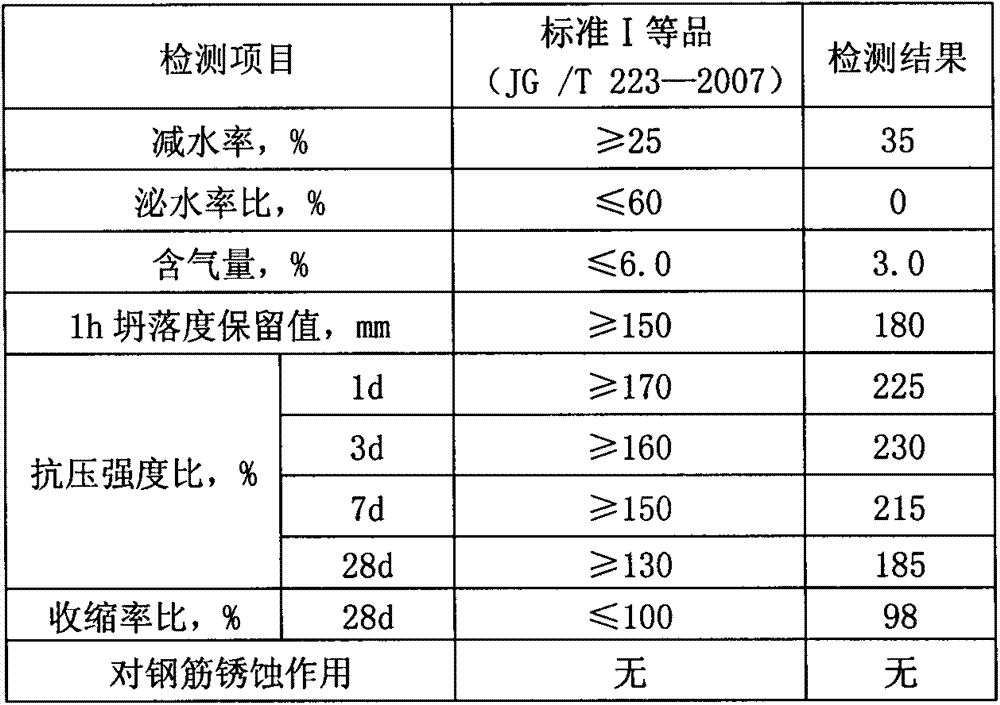

Polycarboxylate superplasticizer catalyzing production technology without high temperature

The invention relates to the field of building materials, and particularly discloses a polycarboxylate superplasticizer catalyzing production technology without high temperature. The polycarboxylate superplasticizer catalyzing production technology comprises the following steps: (1) sequentially adding tap water, methyl polyoxyethylene alkenyl ether, sodium persulfate and azo diisopropyl imidazoline hydrochloride into an agitation tank to be uniformly stirred; (2) adding 30-40 kg of sodium bisulfite and 150 kg of tap water into a measuring tank, fully stirring to enable the sodium bisulfite to be completely dissolved to prepare a sodium bisulfite aqueous solution; (3) sequentially adding 420 kg of water, 140 kg of acrylic acid and the sodium bisulfite aqueous solution into an overhead tank to be uniformly stirred to obtain a mixed solution; (4) opening a valve of the overhead tank to enable the mixed solution to be dropwise added into the agitation tank, performing dripping and stirring at the same time, allowing the dripping to be completed within 1 hour, and obtaining the polycarboxylate superplasticizer after discharging. The production technology has the benefits that the production efficiency is improved, the synthesis reaction temperature is reduced, the synthesis time is shortened, the production cost is greatly reduced, and environmental pollution is reduced.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

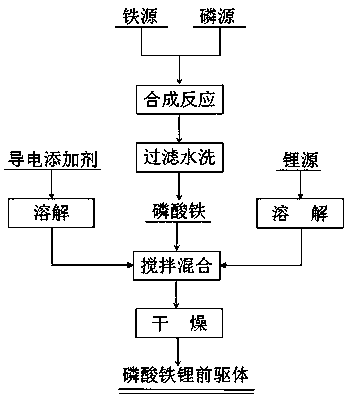

Preparation method of lithium iron phosphate positive electrode material precursor

InactiveCN108448112AShorten the compositing timeReduce energy consumptionCell electrodesSecondary cellsPhosphoric acidMolecular level

The invention relates to a preparation method of a lithium iron phosphate positive electrode material precursor and belongs to the technical field of preparation of positive electrode materials for lithium-ion batteries. The method comprises the steps of carrying out combination reaction and ageing on an iron source and a phosphorus source, obtaining iron phosphate precipitates, washing the iron phosphate precipitates until the pH value of filtered water is 7-8 and drying to obtain iron phosphate powder; preparing a lithium source solution from a lithium source according to the molar ratio ofLi to Fe to P in the lithium source, the iron source and the phosphorus source being (0.95-1.10):1:1; dissolving a conductive additive into an additive solution; and adding the lithium source solutionand the additive solution to the iron phosphate powder, stirring evenly and then drying to obtain the lithium iron phosphate positive electrode material precursor. According to the method, various raw materials are dissolved into the solution, so that mixing at the atomic or molecular level is achieved; ball-milling and ultrafine grinding are not needed, the used raw materials are primary raw materials and iron phosphate, and the procedures, such as drying and packaging are not needed, so that the production cost can be reduced.

Owner:KUNMING UNIV OF SCI & TECH

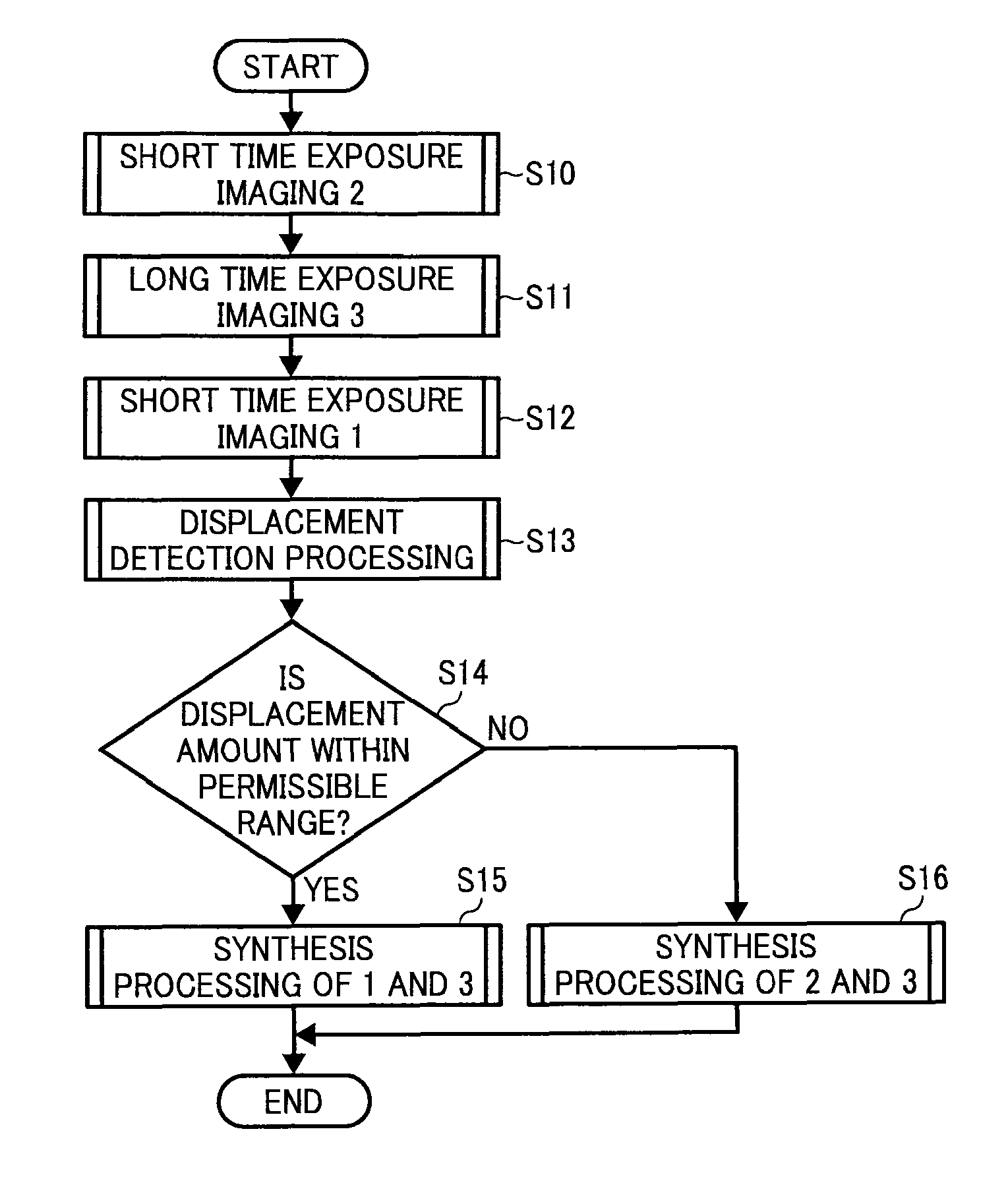

Imaging apparatus

ActiveUS8208034B2Shorten the compositing timeReduce impactTelevision system detailsTelevision system scanning detailsImaging equipmentComputer science

An imaging apparatus, includes: an imaging optical system; an image pickup device; and a control device which is configured to control the image pickup device, wherein the control device is configured to preliminarily decide an exposure order of a relatively short time exposure in a prescribed image size; an exposure with almost the same exposure time as the relatively short time in a smaller image size than the prescribed image size, and a relatively long time exposure in the prescribed image size, and to perform an imaging operation once by exposing the image pickup device by the decided exposure order.

Owner:RICOH KK

Method for synthesizing [18f]sfb using microsynthesis technique

InactiveUS20120029209A1Shorten the timeImprove reaction efficiencyIsotope introduction to heterocyclic compoundsIn-vivo radioactive preparationsMicroreactorInjection port

A method for synthesizing [18F]SFB is disclosed, which comprises using a microreactor including a substrate having one channel formed therein so as to have a cross-sectional width of 1 mm or less and a cross-sectional depth of 1 mm or less, the channel being connected to a raw material injection port and a first reagent injection port at one end thereof, and connected to a second reagent injection port at a position far from the one end thereof, and connected to a third reagent injection port at a position far from the second reagent injection port in a direction toward another end thereof, and connected to a liquid discharge port at the other end thereof; and continuously performing a three-step reaction by allowing a reaction solution to flow through the channel serving as a reaction channel from the one end to the other end thereof without taking out the reaction solution from anywhere between the one end and the other end of the channel.

Owner:SHIMADZU CORP +1

Process for synthesizing mesic-porous molecular sieve SBA-15

InactiveCN100335410CReduce dosageShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveHeteropoly acid

A process for synthesizing the meso-porous molecular sieve SBA-15 features that the tri-block copolymer 'polyepoxyethene-polyepoxypropane-polyepoxyethene' is used as template, the non-fluorine anionic salt as inducing agent, and the heteropoly acid as promoter and acidity regulator. Its advantages are short time and low environmental pollution and cost.

Owner:ZHEJIANG UNIV

Method for synthesizing pre-hydrolyzed polysilicate

PendingUS20210206923A1Shorten the compositing timeLow production costSilicon compoundsAlkoxy groupSilanes

A method for synthesizing a pre-hydrolyzed polysilicate, wherein a polysilicate is applied as a reactant when synthesizing the pre-hydrolyzed polysilicate, and the total amount of water added in the reaction system is specified. The method is capable of omitting a condensation reaction by applying a polysilicate as a reactant, thereby significantly shortening synthesis time and reducing production costs when compared with a typical synthesis method in which alkoxysilane-based monomer compound is used as a reactant. In addition, the gelation reaction time and the weight average molecular weight can be easily controlled, and a pre-hydrolyzed polysilicate excellent in storage stability and processability can be synthesized.

Owner:LG CHEM LTD

Magnetic bioactive glass as well as preparation method and application thereof

ActiveCN113429127APromote mineralizationImprove biological activityGlass shaping apparatusTissue regenerationCalcium nitrate tetrahydrateSilicon dioxide

The invention discloses magnetic bioactive glass as well as a preparation method and application thereof. The magnetic bioactive glass is obtained by carrying out high-temperature calcination on glass with a core-shell structure, the glass with the core-shell structure is of the core-shell structure which takes ferroferric oxide as a core layer and takes silicon dioxide and calcium oxide as a shell layer to be coated on the core layer, and after high-temperature calcination, the ferroferric oxide is oxidized into magnetic gamma-ferric oxide. The method comprises the steps of adding ferroferric oxide and magnesium oxide into sodium silicate transparent colloid, dropwise adding concentrated sulfuric acid until the pH value is 7-8, reacting at the temperature of 50-70 DEG C, filtering, cleaning, filtering and drying to obtain black solid powder; and adding into a calcium nitrate tetrahydrate saturated solution for heat treatment, and then calcining at high temperature to obtain the magnetic bioactive glass. The method is simple in process, low in cost and relatively low in calcination temperature, the surface of the material has a microporous structure, the specific surface area is larger, mineralization of the material is facilitated, and the biological activity of the material is improved.

Owner:ZHONGNAN HOSPITAL OF WUHAN UNIV

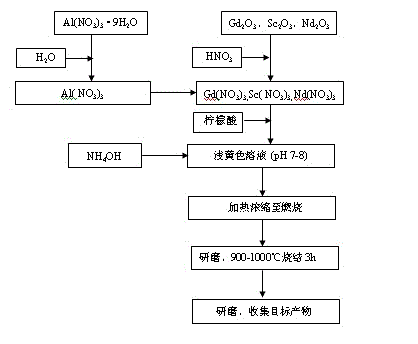

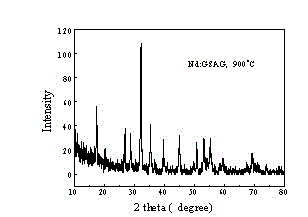

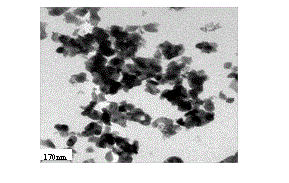

Method for preparing neodymium/gadolinium/scandium/aluminum garnet doped nanometer powder

InactiveCN102303891BGood dispersionSimple manufacturing equipmentMaterial nanotechnologyRare earth metal compoundsMuffle furnaceNuclear chemistry

The invention relates to a method for preparing neodymium / gadolinium / scandium / aluminum garnet (Nd:GSAG) doped nanometer powder. The method for preparing neodymium / gadolinium / scandium / aluminum garnet doped nanometer powder comprises the following steps of: preparing Gd(NO3)3 with the mol concentration of 0.12-0.12x mol / L, Nd(NO3)3 with the mol concentration of 0.12x mol / L, Sc(NO3)3 with the mol concentration of 0.08 mol / L and Al(NO3)3 with the mol concentration of 0.12 mol / L, wherein x is equal to 0.01, 0.015 and 0.02; weighing citric acid and adding the mixed nitrate solution until the molar concentration of citric acid is 0.48 mol / L in the mixed solution; controlling the temperature of the mixed solution to 70-80 DEG C; when adjusting the pH to 7-8, obtaining the pale yellow solution; heating and concentrating, and then forming a gel; continuously heating, and starting burning the gel; after the gel is burnt completely, obtaining precursor powder at the bottom of a container; collecting the precursor powder, grinding and then putting the powder into a muffle furnace for burning; keeping the constant temperature at 900 DEG C for 3 hours and then cooling along with the furnace, and obtaining the target powder. By combining a sol / gel method with a combustion method, the method provided by the invention is simple in preparation equipment, reduced in time of synthesis process, and capable of preparing the nanometer powder raw material with good dispersibility.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Catalyst complexes with carbene ligand and method for making same and use in metathesis reaction

ActiveUS10159966B2High yieldShorten the compositing timeRuthenium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

Owner:GUANGMING CHUANGXIN WUHAN CO LTD

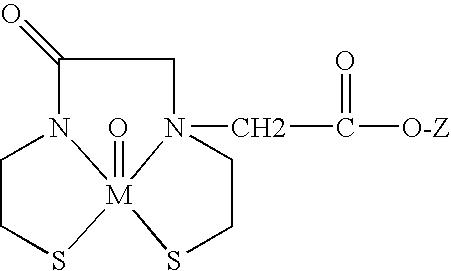

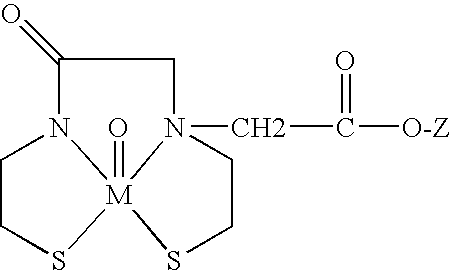

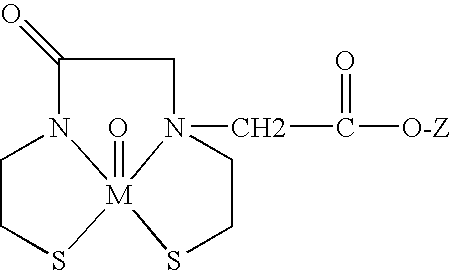

Radioactive material for inhibiting cancer and preparation method thereof

InactiveUS20090324496A1Shorten the compositing timeImprove yieldIn-vivo radioactive preparationsAntineoplastic agentsWAS PROTEINRadioactive agent

A radioactive material for inhibiting cancer and a preparation method thereof are disclosed. The radioactive material for inhibiting cancer is M-SOCTA-Z and M is a radioactive nuclide such as 188Re or 99mT while Z is protein or peptides having amino acid with NH or NH2 group. The preparation method of the radioactive material for inhibiting cancer includes steps of: reacting SOCTA with protein or peptide. Ester (—COOR) in SOCTA reacts with amines (—NH, —NH2) in protein or peptide to form peptide bond. Thus SOCTA-protein or SOCTA-peptide complex is produced. Then these SOCTA-protein complex reacts with radioactive nuclide M so as to generate M-SOCTA-protein or M-SOCTA-peptide. In an embodiment of the present invention, monoclonal antibody Herceptin is applied to bind with SOCTA and in combination with radiation-based therapy, effects of cancer treatment (such as breast cancer) are enhanced.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Nanometer material as well as preparation method and application thereof

ActiveCN109675061AGood dispersionEasy to manufactureEnergy modified materialsGeneral/multifunctional contrast agentsBiocompatibility TestingTherapeutic effect

The invention relates to the field of nanoscale biomedical materials, in particular to a nanometer material as well as a preparation method and application thereof. The nanometer material comprises BSA: RE1, an RE2 inner core, a PDA shell layer covering the surfaces of the BSA: RE1 and the RE2 inner core, and FA on the surface of PDA, where RE1 and RE2 are different. The nanometer material has good dispersibility, is easy to prepare, has excellent biocompatibility and safety, can accurately perform multimodal MRI / CT imaging on tumors, and has a good photothermal treatment effect on the tumors.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing [18f]sfb using microsynthesis technique Method for synthesizing [18f]sfb using microsynthesis technique](https://images-eureka.patsnap.com/patent_img/b5d540a1-7e92-44c0-a8c5-510c9bb0a0e4/US20120029209A1-20120202-D00001.png)

![Method for synthesizing [18f]sfb using microsynthesis technique Method for synthesizing [18f]sfb using microsynthesis technique](https://images-eureka.patsnap.com/patent_img/b5d540a1-7e92-44c0-a8c5-510c9bb0a0e4/US20120029209A1-20120202-D00002.png)

![Method for synthesizing [18f]sfb using microsynthesis technique Method for synthesizing [18f]sfb using microsynthesis technique](https://images-eureka.patsnap.com/patent_img/b5d540a1-7e92-44c0-a8c5-510c9bb0a0e4/US20120029209A1-20120202-D00003.png)