Ambient pressure synthesis of zeolite films and their application as corrosion resistant coatings

a technology of zeolite and zeolite film, which is applied in the direction of liquid/solution decomposition chemical coating, chemical production of bulk materials, electric/magnetic/electromagnetic heating, etc., can solve the problems of chromate becoming more and more stringent, and affecting the synthesis process, so as to achieve the effect of drastically shortening the synthesis tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

AEL Coating Synthesis on Aluminum Alloys.

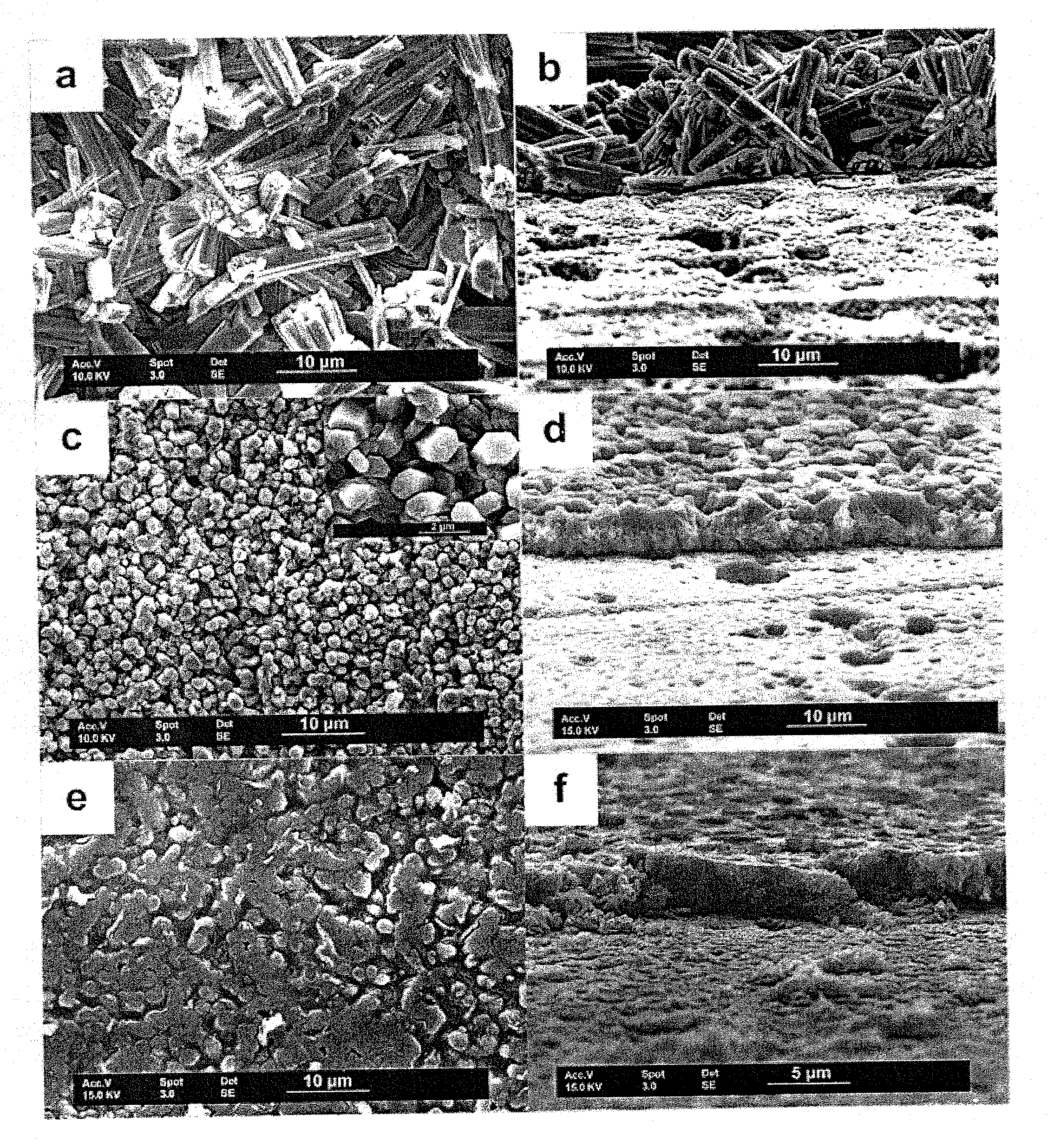

[0047]In accordance with an exemplary embodiment, both AIOPO-11 and SAPO-11 were synthesized on Al alloys. These alumino- and silicoalumino-phosphate zeolites have an AEL-type framework. A synthesis mixture with molar composition: 32[1-methyl-3-ethylimidazolium bromide ([emim]Br)]:1[Al(OC3H7)3]:3[H3PO4]:0.8[HF] was pre hours (approximately 240 minutes) at 100° C. For SAPO-11, tetraethyl orthosilicate (TEOS) was introduced to synthesis mixture with the molar ratio of 0.25Si:1AI. Metal substrates (i.e., AA 2024-T3 substrates) were pretreated by an Alconox detergent solution. The substrates were then fixed vertically inside the synthesis mixture in the Teflon vessel designed for MARS5 (CEM Co.) microwave reaction system. The unsealed vessel (with holes on the cover) was then quickly heated to 150° C. and held at the temperature for 2 hours (approximately 120 minutes) under microwave radiation. After the synthesis, the coated sample was thoroughl...

example 2

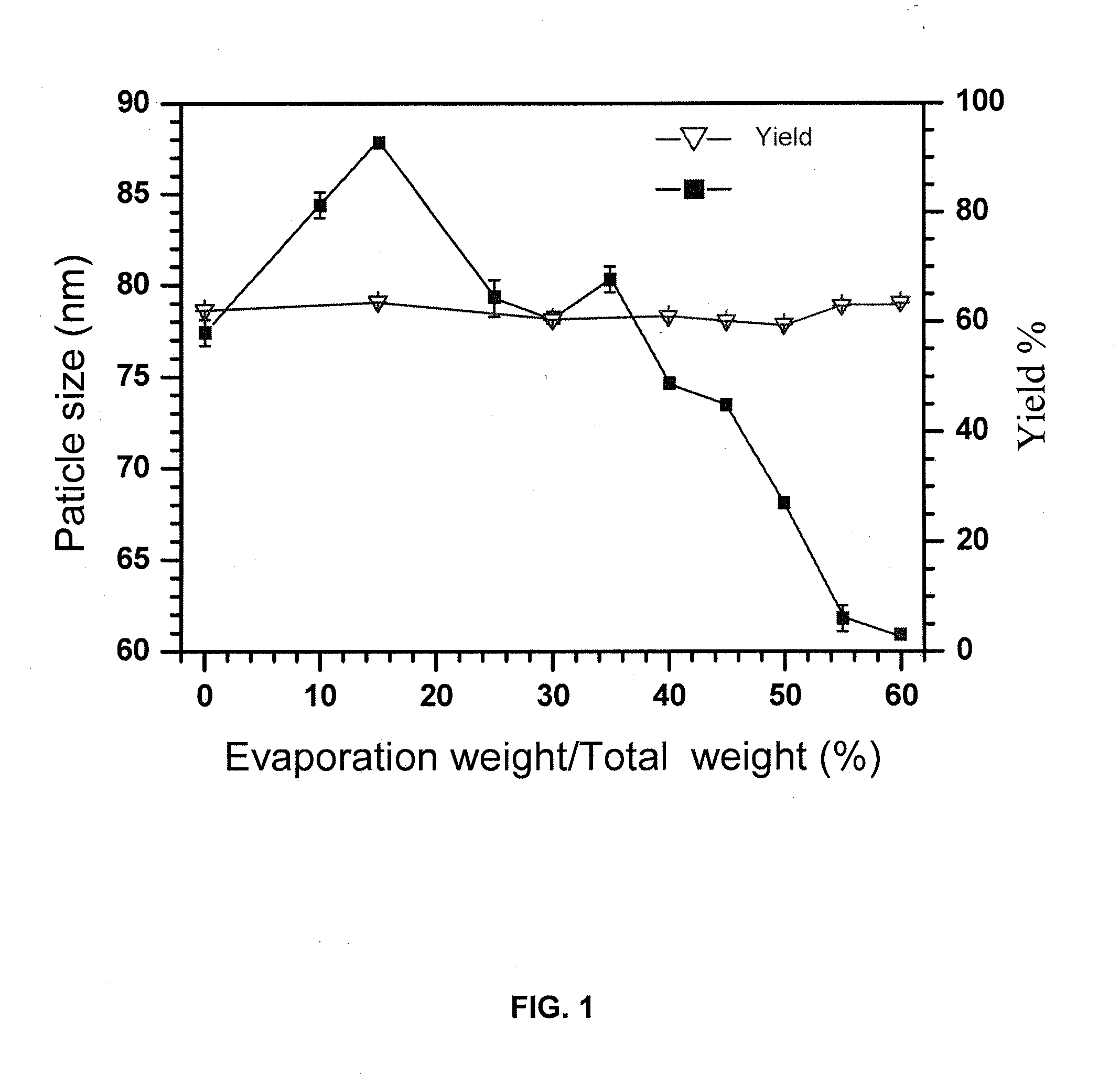

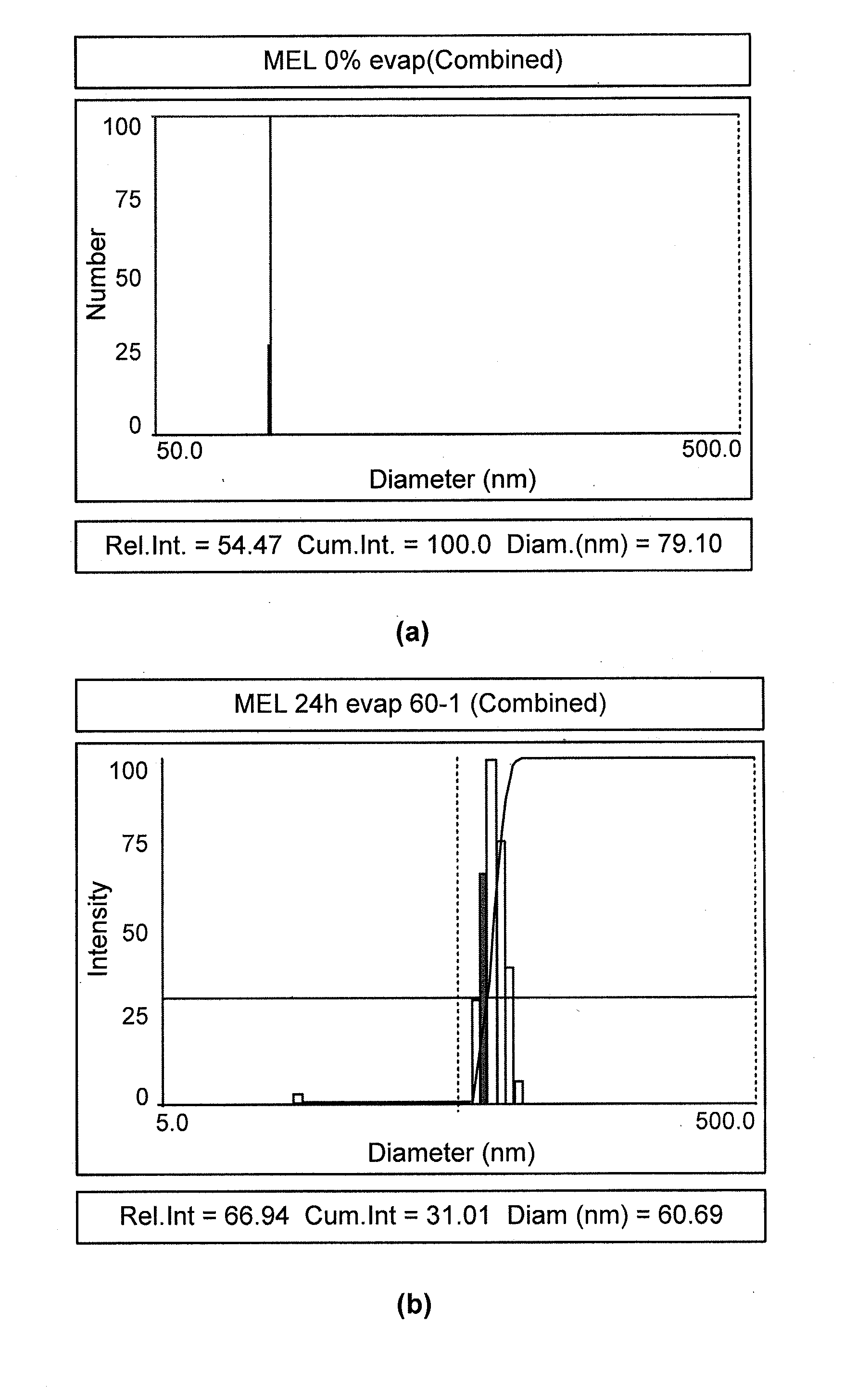

[0063]MEL PSZ nanocrystal suspension was synthesized in the following way: 9.15 g of tetrabutylammonium hydroxide (TBAOH, 40% aqueous solution, Sachem) and 4.67 g of double deionized (DDI) water were added into 10 g of tetraethylorthosilicate (TEOS, 98%, Aldrich). The mixture was stirred in a sealed plastic bottle for 24 hr at room temperature, and finally a clear homogeneous solution was formed with the molar composition of 0.3TBAOH:1SiO2:4EtOH:10H2O. The solution was then thermally treated at 80° C. for 2 days with constant stirring in an oil bath (noted as the first stage). Afterwards, a specific amount (varying from 10 wt % to 60 wt %) of solvent was evaporated out by house vacuum at room temperature with stirring. This solution was subsequently transferred to Teflon®-lined autoclaves and kept in a convection oven preheated at 114° C. for 24 hr (noted as the second stage). This synthesis approach is hereby referred to as an evaporation-assisted two-stage synthesis method. For co...

example 3

Silane-Zeolite Nanocrystal Coatings

[0067]In accordance with another exemplary embodiment, a 1,2-bis(triethoxysilyl)methane (BTSM) solution was prepared by adding silane to a DI water and ethanol mixture. The volume ratio of BTSM: DI water: Ethanol was approximately 1:1:20. Acetic acid was then added to adjust the pH of the solution in the range of approximately 4.5 to 5. The solution was then stirred at room temperature for aging at least 24 hours before a MEL suspension was added. MEL concentration in the solution was about 20 ppm (parts per million). Then the nanoparticle-silane mixture was spun on bare AI alloys or SAPO-11 coated AI Alloys at room temperature on a Laurell spin coater. Afterward, the sample was heated at 80° C. overnight and then 200° C. for 30 min (minutes).

Characterization

[0068]In accordance with another exemplary embodiment, the XRD patterns were obtained on Siemens D-500 diffractometer using Cu Kα radiation. SEM pictures were obtained on a Philips

[0069]XL30-FE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com