Magnetic bioactive glass as well as preparation method and application thereof

A bioactive glass, magnetic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve the problems of the need to improve biological activity, expensive raw materials, lower calcination temperature, etc., to reduce synthesis cost, low cost, The effect of reducing the composition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] According to a typical embodiment of the present invention, a method for preparing magnetic bioactive glass is provided, the method comprising:

[0055] Step S1, preparing sodium metasilicate pentahydrate into sodium silicate transparent colloid sodium silicate transparent colloid;

[0056] As an optional implementation manner, the step S1 includes:

[0057] Add sodium metasilicate pentahydrate into pure water, and then add concentrated sulfuric acid dropwise until all solids disappear to form sodium silicate transparent glue; the concentration of the concentrated sulfuric acid is usually 25-35%; in other embodiments, Concentrated sulfuric acid is replaced by hydrochloric acid;

[0058] Step S2, adding iron ferric oxide and magnesium oxide to the sodium silicate transparent colloid, then adding concentrated sulfuric acid dropwise until the pH is 7-8, reacting at 50-70°C for 20-40 hours, and filtering to obtain black solid;

[0059] In the step S2, the concentration r...

Embodiment 1

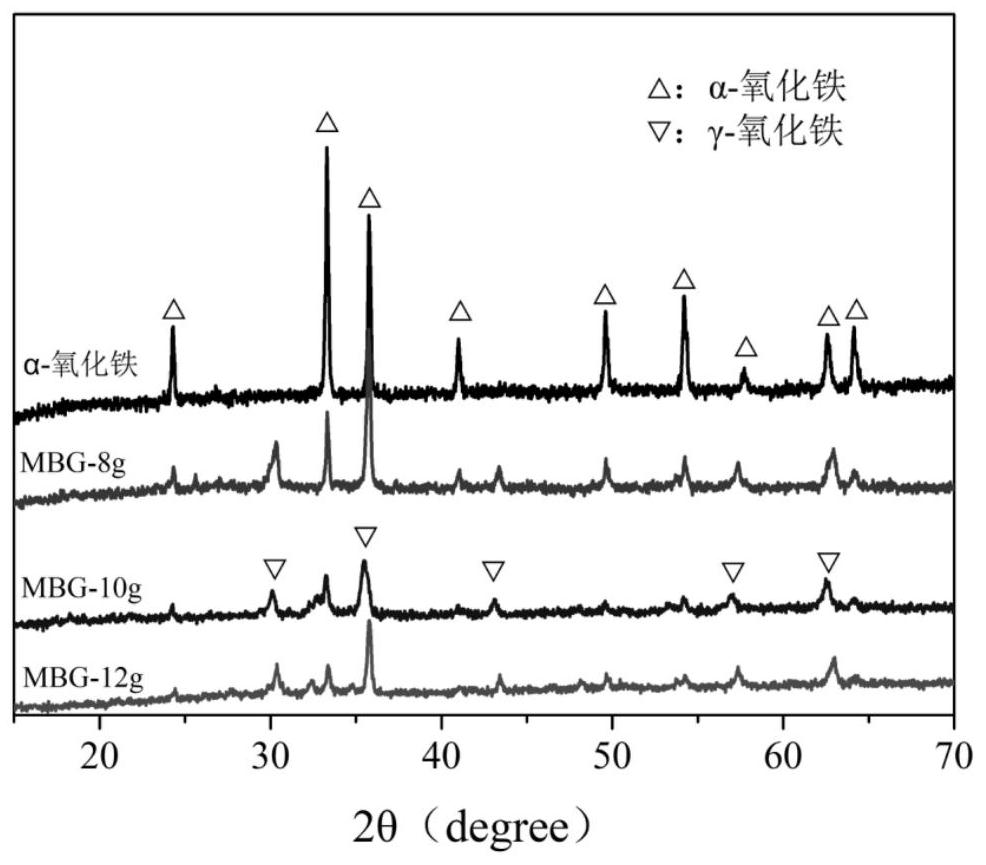

[0083] The embodiment of the present invention provides a magnetic bioactive glass, the preparation method of which is as follows:

[0084] Add 39g sodium metasilicate pentahydrate to 20mL purified water, add 30% concentrated sulfuric acid dropwise until all solids disappear and form a transparent colloid;

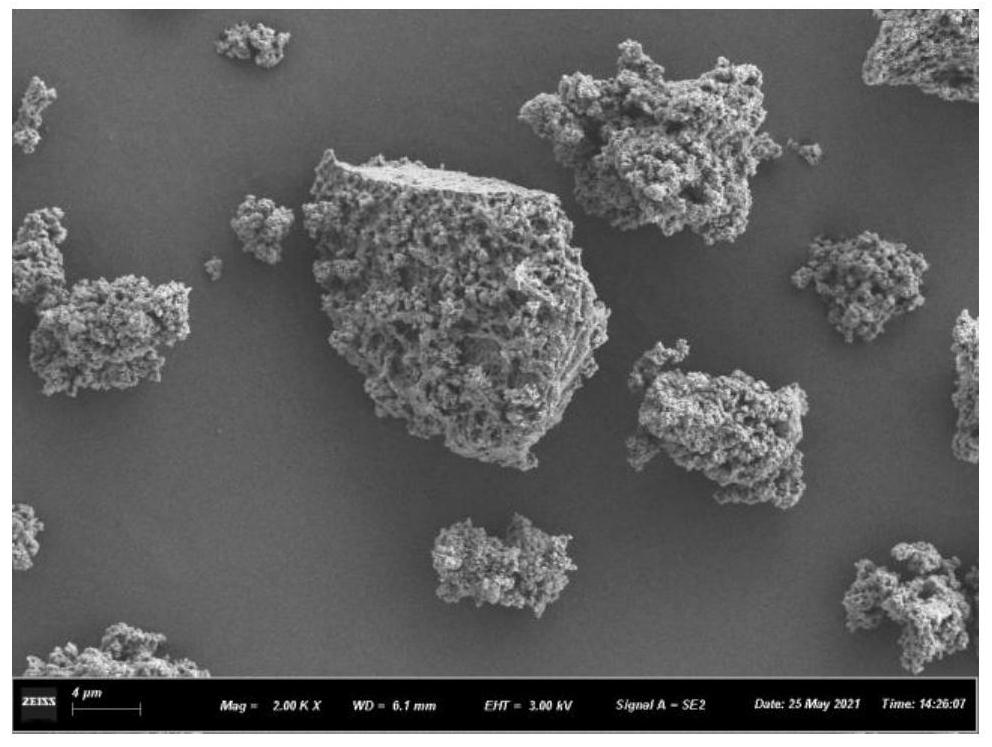

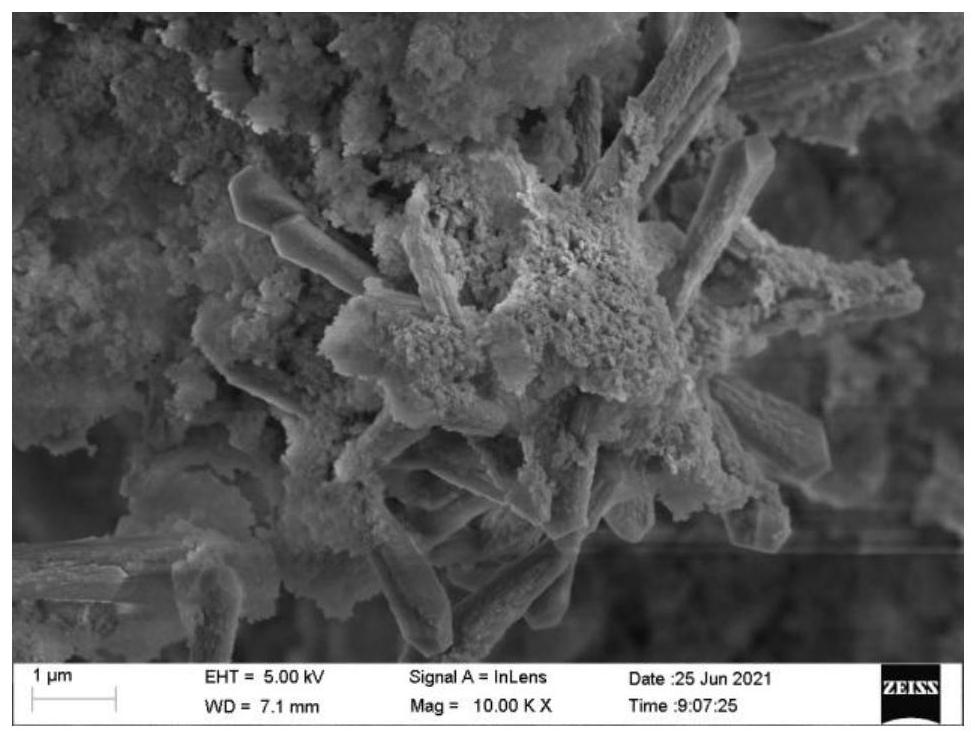

[0085] Add 5g of ferric oxide and 1g of magnesium oxide to the transparent colloid, continue to slowly add 30% concentrated sulfuric acid dropwise until it is neutral, then treat it at 60°C for 30h, filter, wash and filter with purified water for 3 times, and then Dry to constant weight at 105°C to obtain a black solid powder;

[0086] Weigh 20g of calcium nitrate tetrahydrate to prepare a saturated solution, add black solid powder to the saturated solution, heat-treat at 120°C for 15 hours, and then place it in a muffle furnace for high-temperature calcination. The heating curve is: 8°C / min from 30°C Raise the temperature to 150°C, keep it for 1 hour, then raise the temp...

Embodiment 2

[0088] The embodiment of the present invention provides a magnetic bioactive glass, the preparation method of which is as follows:

[0089] Add 40g sodium metasilicate pentahydrate to 20mL purified water, add 30% concentrated sulfuric acid dropwise until all solids disappear and form a transparent colloid;

[0090] Add 8g ferric oxide and 1g magnesium oxide to the transparent colloid, continue to slowly add 30% concentrated sulfuric acid dropwise until the pH is neutral, then treat at 70°C for 20h, filter, wash and filter with purified water 3 times, Then dry to constant weight at 110°C to obtain a black solid powder;

[0091] Weigh 20g of calcium nitrate tetrahydrate to prepare a saturated solution, add black solid powder to the saturated solution, heat-treat at 130°C for 12 hours, and then place it in a muffle furnace for high-temperature calcination. The heating curve is: 5°C / min from 30°C Raise the temperature to 160°C, keep it for 1 hour, then raise it to 500°C at 10°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com