Patents

Literature

36 results about "Experimental proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sichuan fritillary bulb, and method for culture of the same

ActiveCN100998286AHas nitrogen fixationStandards compliantComponent separationHorticulture methodsExperimental proofEcological environment

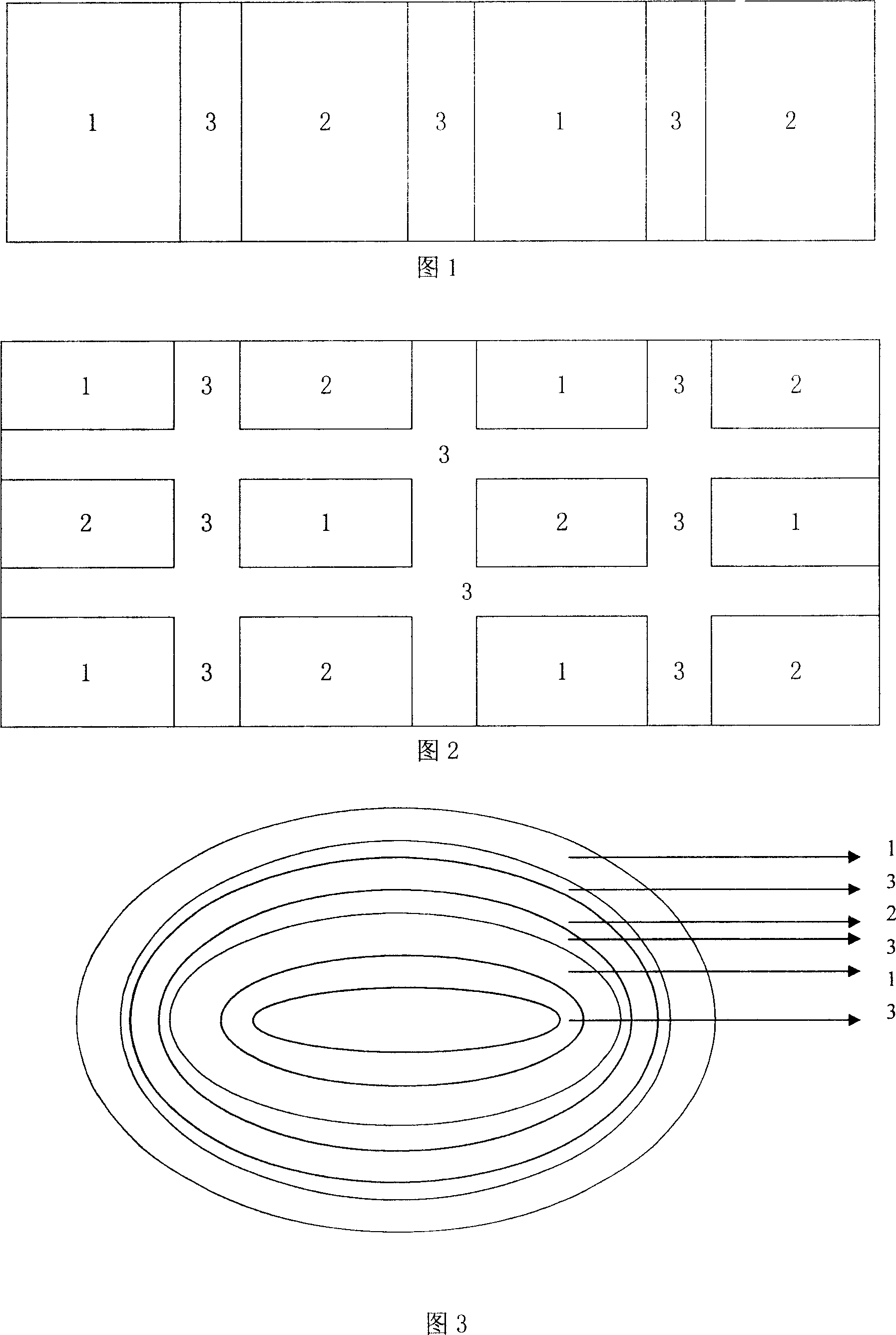

An artificial culture method for tendrilled fritillary bulb features that its original ecologic environment is simulated and the intercroping and croping rotation are used for high yield and quality.

Owner:四川国青川贝母生物科技股份有限公司

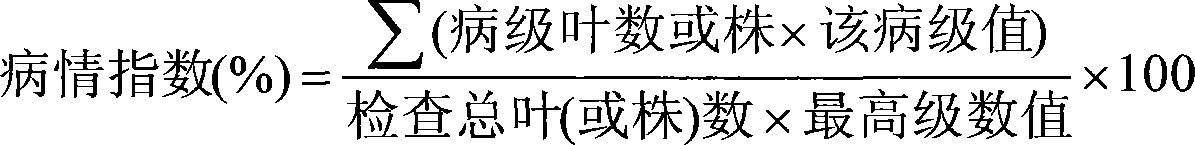

Agricultural chemical composition containing carbendazim and kasugamycin

InactiveCN101248794AOvercome the disadvantage of easy resistanceLong durationBiocideFungicidesAdditive ingredientAntibacterial activity

The invention belongs to the pesticide field, in particular to a pesticide composition with an active ingredient to be the combination of carbendazim and kasugamycin or carbendazim and kasugamycin hydrochloride, wherein, the kasugamycin can be sourced from Actinomycetes microaurous or Streptomyces kasugaensis. The main agent thereof is the composition comprising the following components by the weight percentages as follows: carbendazim 10%-70%, kasugamycin 0.1%-20%, and the rest is an accessory ingredient. The mixed pesticide can be widely used for preventing and curing the plant diseases of vegetables, paddies, fruit trees and so on, so as to protect and cure crop plants with strong antibiotic activity. Based on the experimental proof, the pesticide composition provided by the invention is characterized in that the bactericidal spectrum is wide, the use-cost is low, the application is safe to crop plants and environment, etc.

Owner:JIANGMEN PLANT PROTECTION

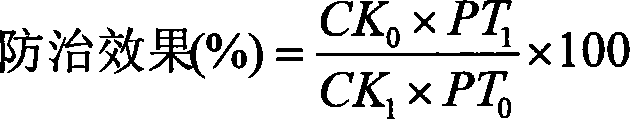

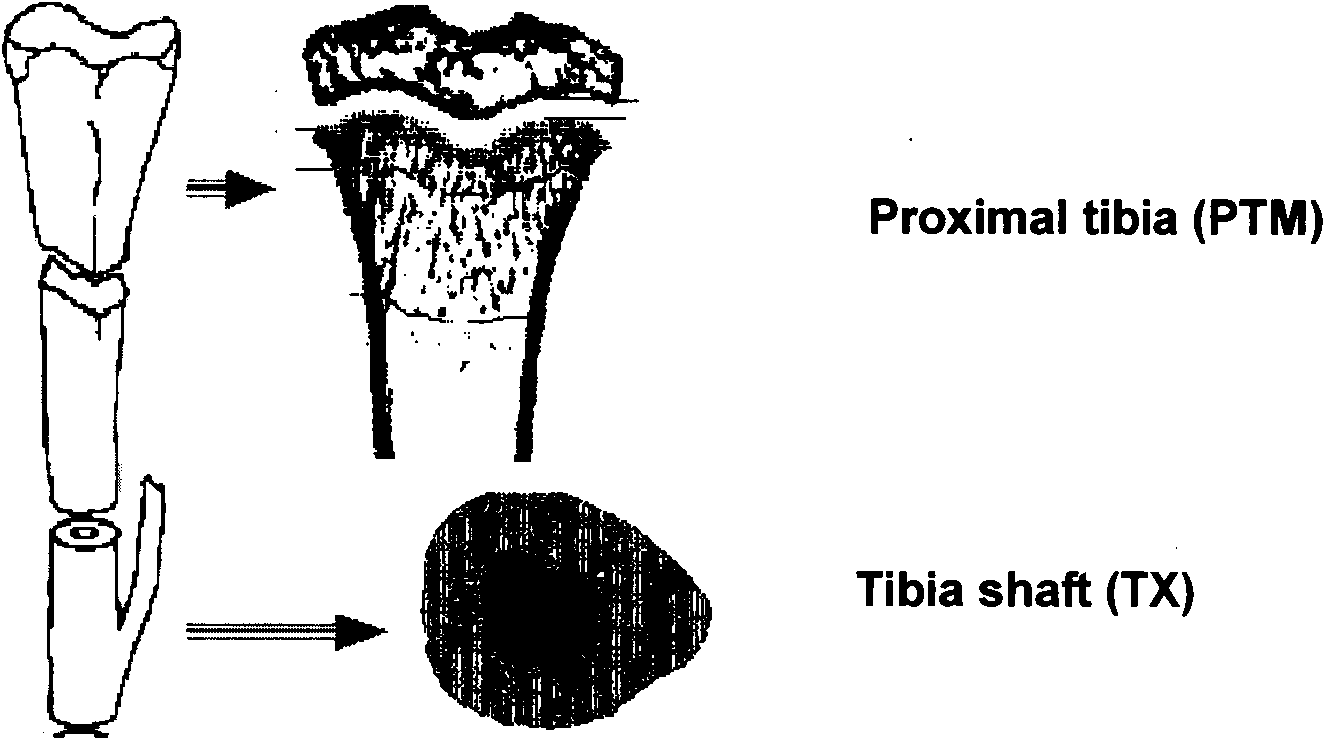

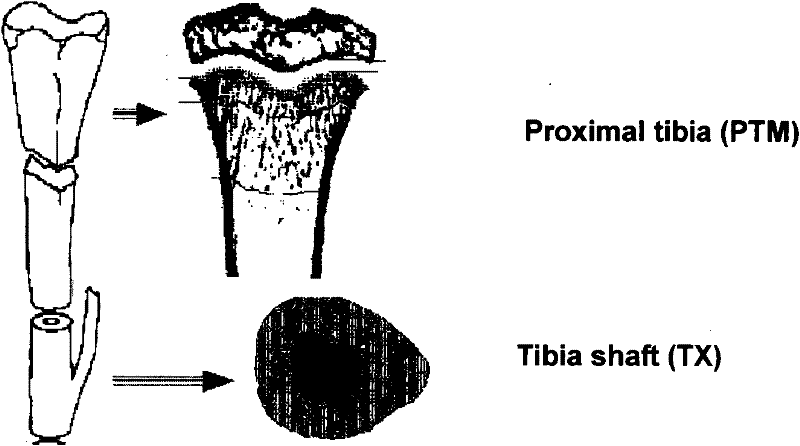

New application of HuGu capsule in preventing glucocorticoid-induced osteoporosis

ActiveCN101890127ANo change in biomechanical propertiesGood effectSkeletal disorderUnknown materialsExperimental proofMedicine

The invention relates to a new application of a HuGu capsule (HG) in preventing glucocorticoid-induced osteoporosis (GIO), belonging to the technical field of traditional Chinese medicine application. The invention discusses HG prevention effect towards GIO induced by glucocorticoids (GCs) based on bone histomorphometry. The experimental result proves that the glucocorticoids (GCs) can induce cortical bone loss of a rat in short time, after HG intervention is carried out for 45d, the GCs is prevented from inducing the cortical bone loss of the rat, thereby providing experimental proof for the new application of the HG in preventing the GIO.

Owner:GUANGDONG ANNOL PHARM CO LTD

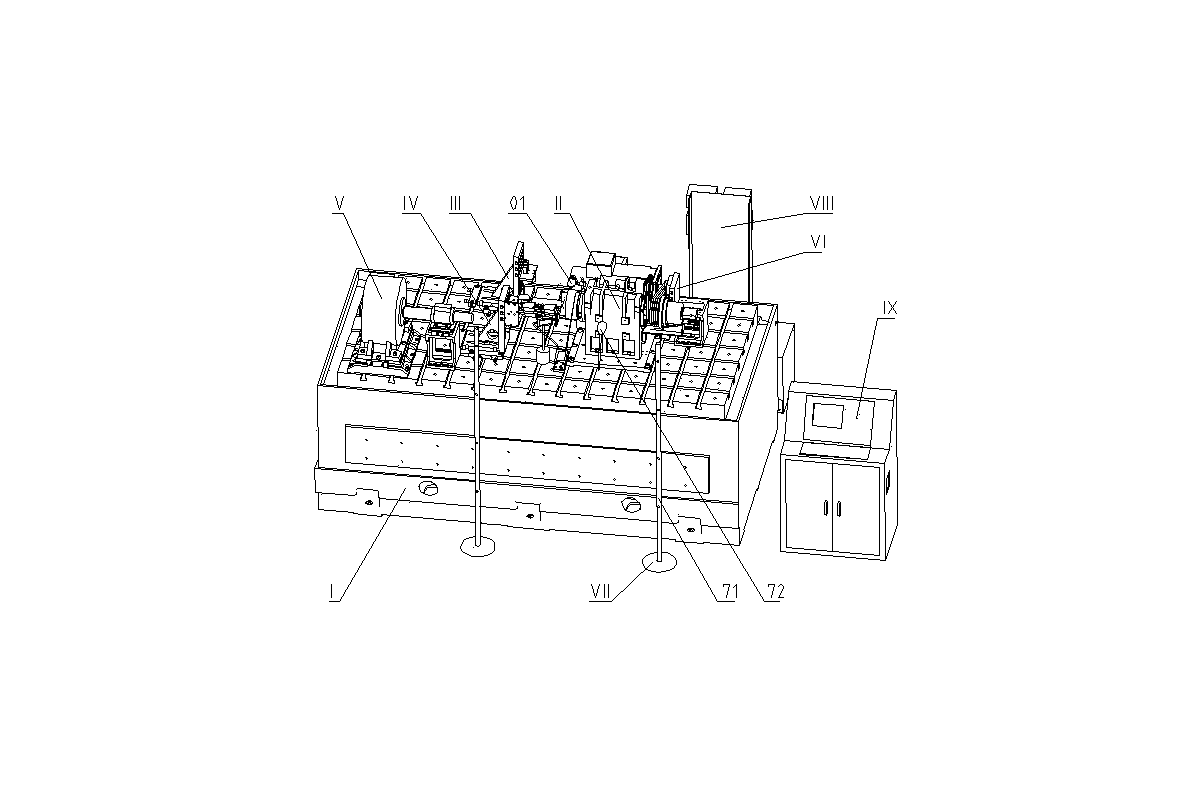

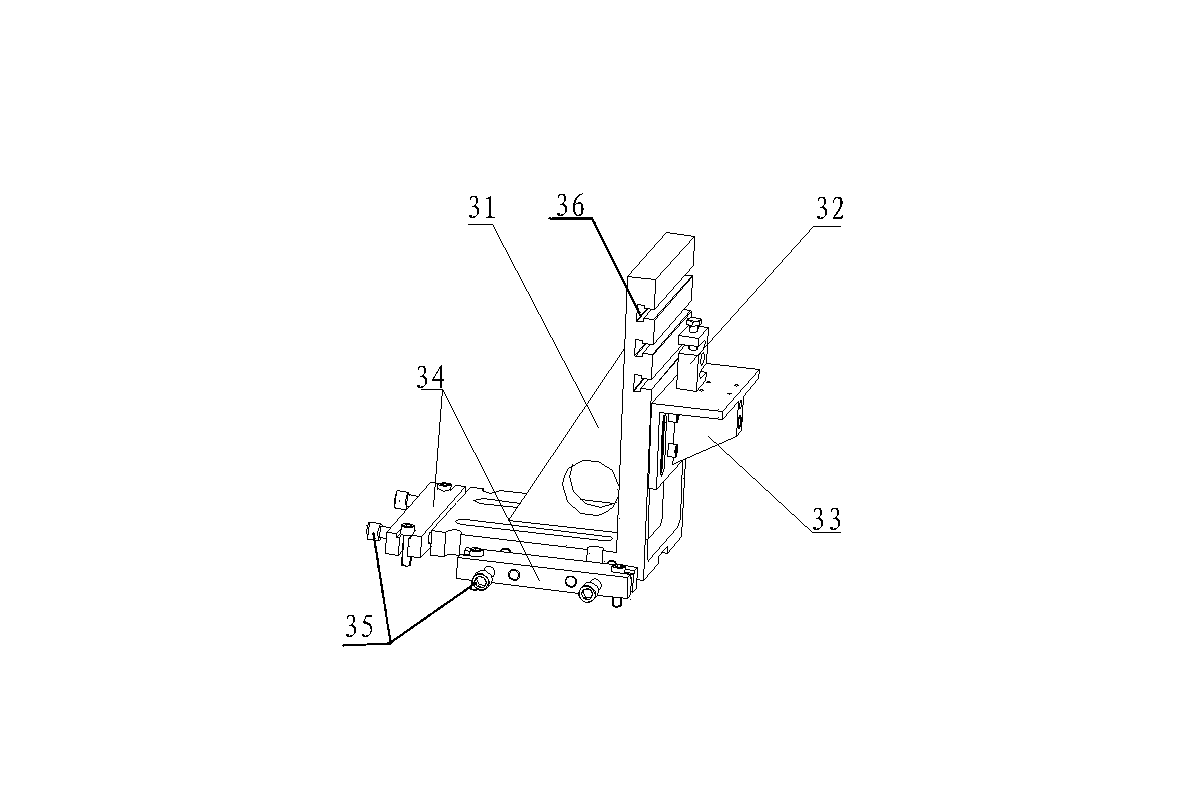

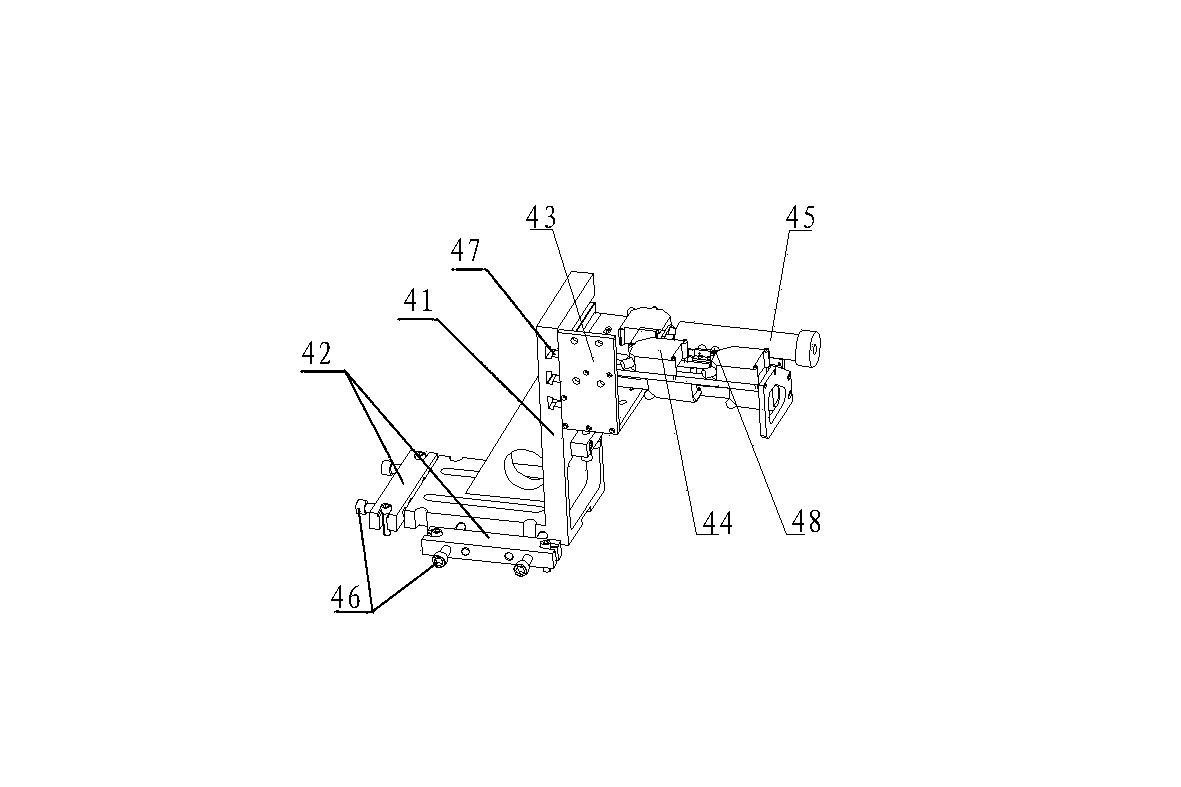

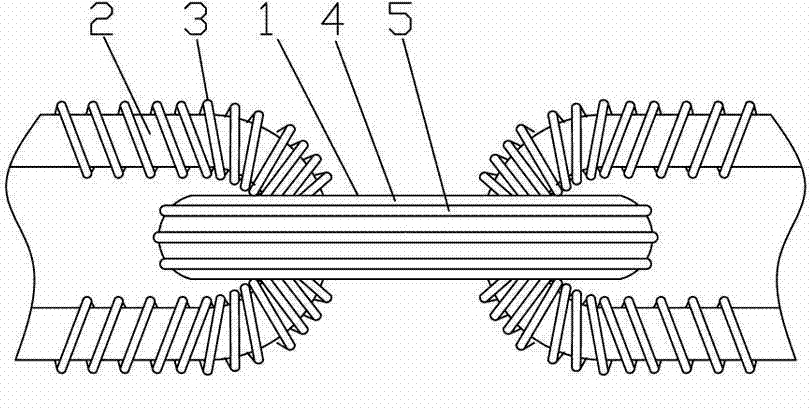

Main shaft performance testing platform

ActiveCN103674504AGuaranteed accuracyFull range of performanceMachine part testingExperimental proofDynamic balance

The invention discloses a main shaft performance testing platform, and relates to a main shaft performance detecting device of a machine tool. The structure of the main shaft performance testing platform is as follows: a main shaft rigidity measuring module, a main shaft heating thermal deformation measuring module, an output torque measuring module and a belt tension measuring module are respectively arranged on a platform base; a tested main shaft box is mounted on the platform base through a main shaft box mat. The testing platform not only can accurately test such indexes of the main shaft as precision, rigidity, force, dynamic balance and overall performance, but also can simulate the influence on all performances of the main shaft under different assembly conditions to finger out reasonable assembly relationship so as to provide a certain experimental proof to the real production and assembly of the main shaft.

Owner:通用技术集团沈阳机床有限责任公司

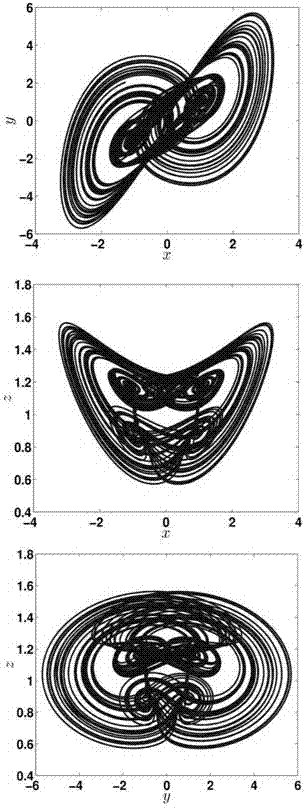

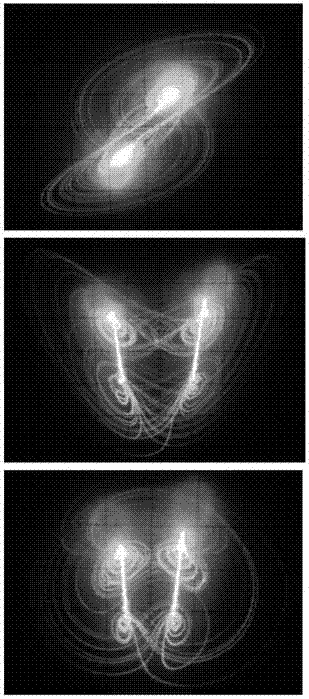

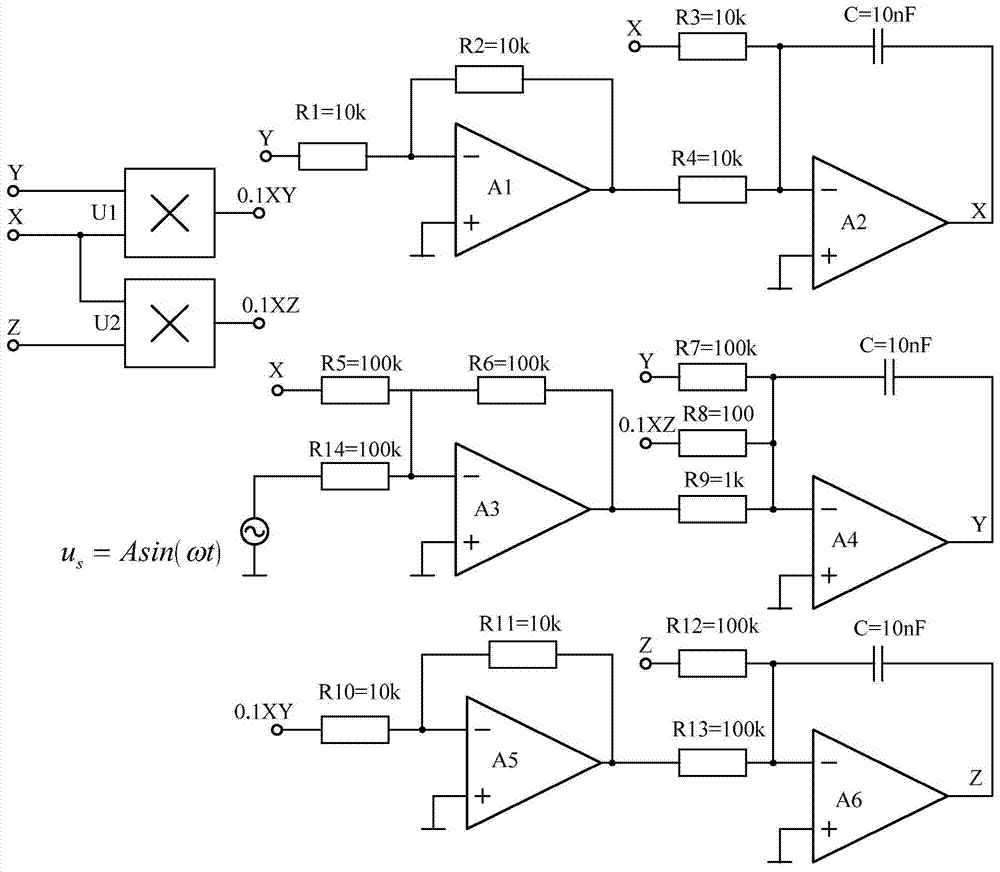

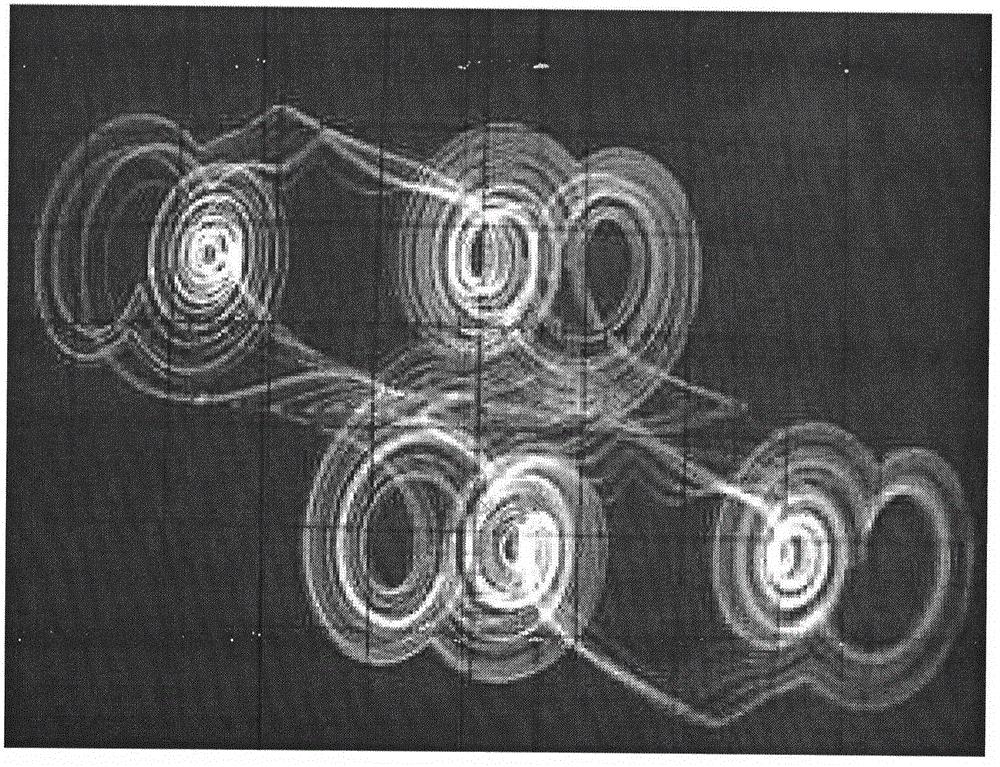

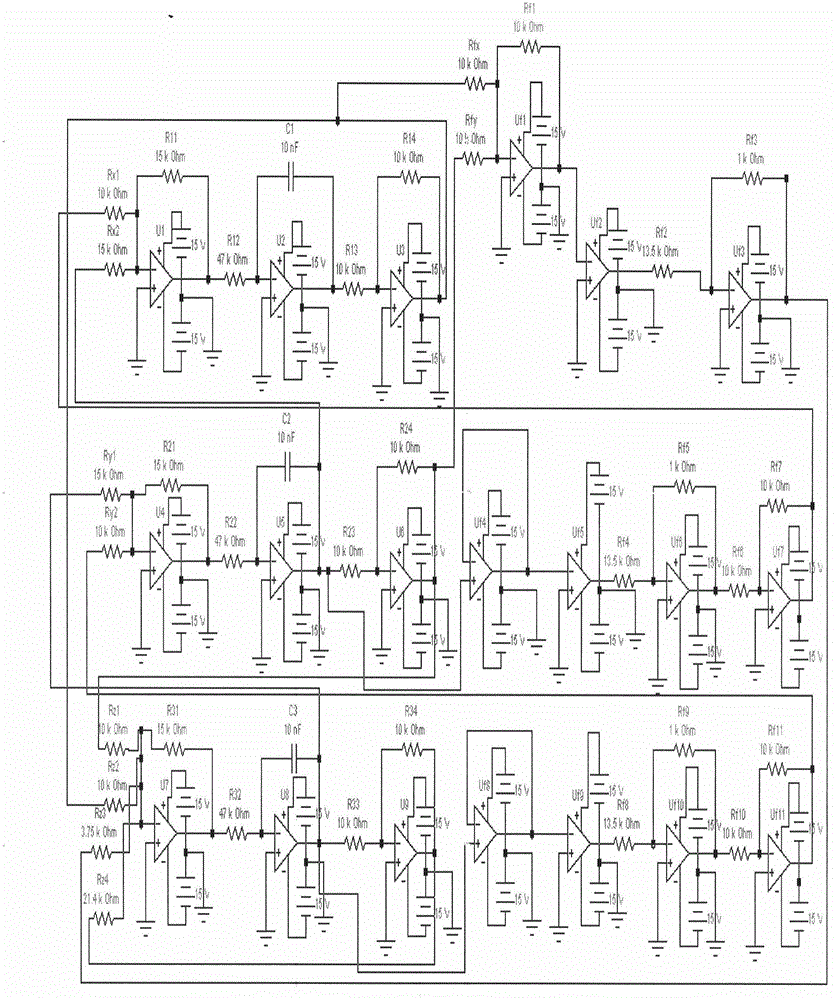

Double-layered butterfly attractor chaotic generator and circuit

InactiveCN103684747ASecuring communicationPulse generation with predetermined statistical distributionCapacitanceExperimental proof

The invention provides a double-layered butterfly attractor chaotic generator and a circuit. An operational amplifier U1, an operational amplifier U2, resistors and capacitors are utilized to form an inverse-phase adder and an inverse-phase integrator, a multiplier U3 and a multiplier U4 are utilized to carry out multiplication, a function signal generator U5 is utilized to generate a sinusoidal signal, LF347Ds are adopted as the operational amplifier U1 and the operational amplifier U2, AD633JNs are adopted as the multiplier U3 and the multiplier U4, a YB1638 is adopted as the function signal generator U5, the operational amplifier U1 is connected with the multiplier U3 and the multiplier U4, the operational amplifier U2 is connected with the multiplier U4, the multiplier U3 is connected with the operational amplifier U1, the multiplier U4 is connected with the operational amplifier U2, and the function signal generator U5 is connected with the operational amplifier U1. The invention has the advantage that the invention provides the chaotic system with double layers of butterfly attractors and uses the simulation circuit to carry out experimental proof, thus providing a new choice for the application of chaotic systems in engineering practice.

Owner:BINZHOU UNIV +2

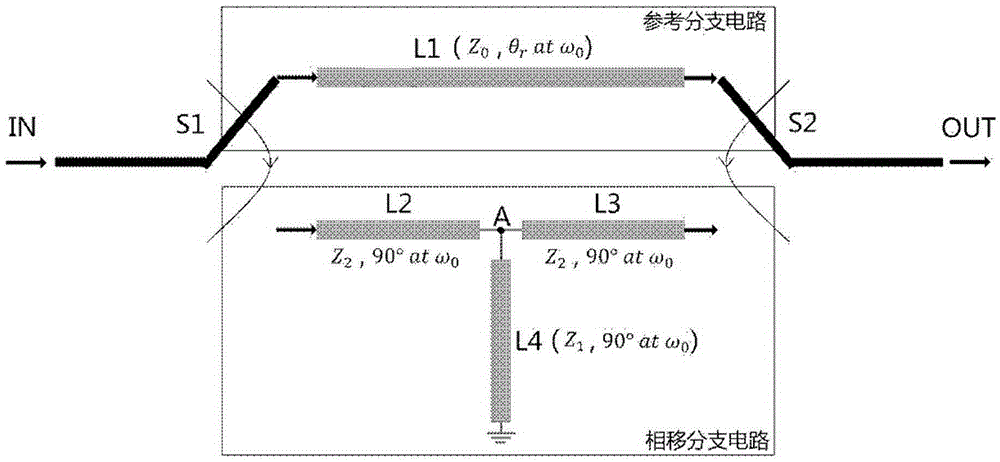

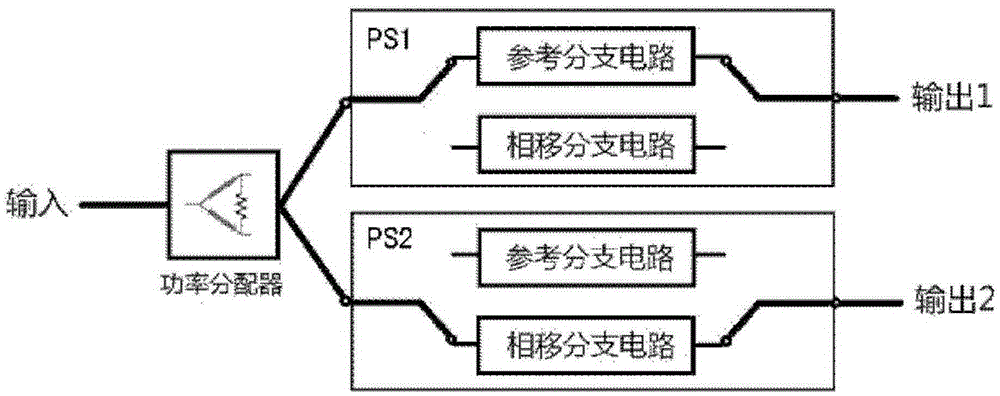

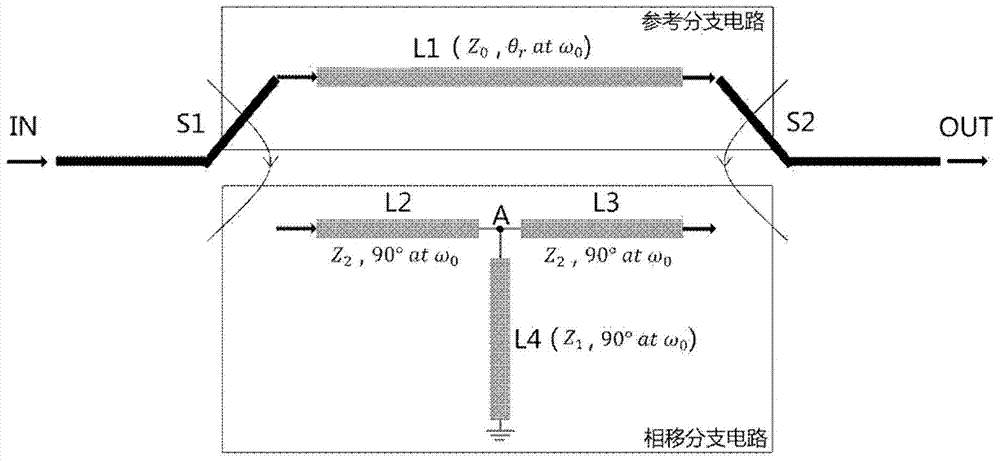

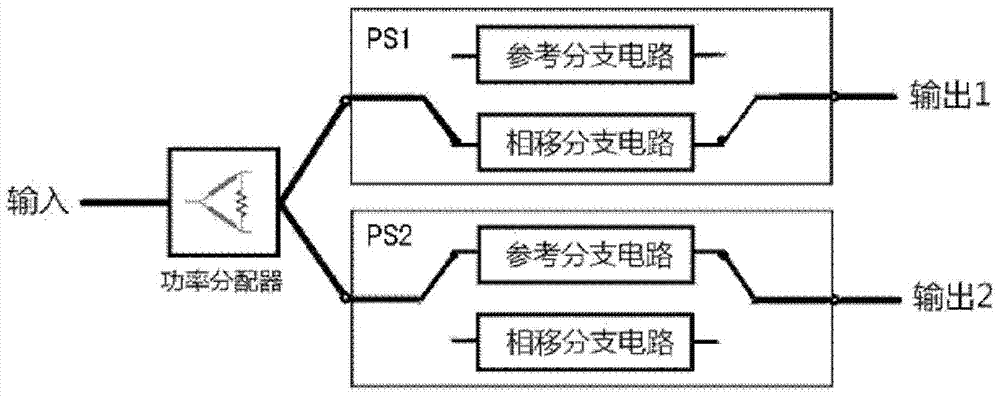

Microstrip switch type phase shifter and phase shifting module using same

ActiveCN105356014AReduce parasitic parametersFlat Phase Shift CharacteristicsWaveguide type devicesExperimental proofPhase shift module

The invention provides a microstrip switch type phase shifter and a phase shifting module using the same. The microstrip switch type phase shifter comprises a reference branch circuit, a phase shifting branch circuit, a first path selection switch and a second path selection switch, wherein the reference branch circuit comprises a first microstrip transmission line; the phase shifting branch circuit comprises a second microstrip transmission line and a third microstrip transmission line which are connected in series, and a fourth microstrip transmission line connected between a node between the second and third microstrip transmission lines and the ground level; the front end of the first path selection switch is connected to a signal input end, the rear end of the second path selection switch is connected to a signal output end, and the first and second path selection switches are simultaneously connected to the reference branch circuit and the phase shifting branch circuit under control. By adopting continuous microstrip lines and a simple topological structure, the phase shifter and the phase shifting module reduce parasitical parameters caused by discontinuous microstrip lines, can be applied to high-frequency scenarios, meanwhile, have very flat phase shifting characteristic nearby center frequency by simulation and experimental proof, and have high phase shifting precision.

Owner:SOI MICRO CO LTD

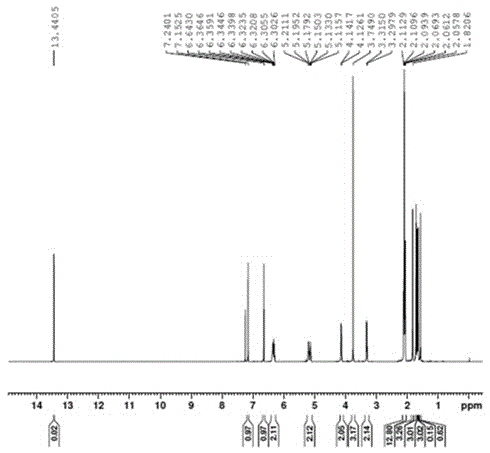

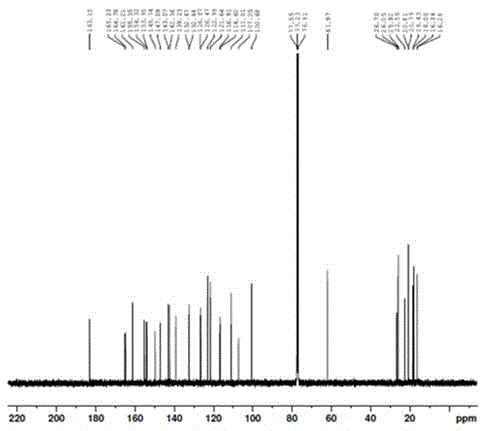

Alpha-mangostin derivative and application thereof in preparation of metabolic syndrome resistant medicine

InactiveCN105481819AClear efficacyPrevent and/or treat high blood pressureOrganic active ingredientsOrganic chemistryTherapeutic effectMetabolic disorder

The invention provides an alpha-mangostin derivative and application thereof in preparation of a metabolic syndrome preventing and / or treating medicine. Through experimental proof, the alpha-mangostin derivative can simultaneously improve multiple metabolic disorders factors, and can obviously improve abnormal lipids metabolism, increase insulin sensitivity and reduce blood pressure. The compound provided by the invention has obvious treatment effect for the metabolic syndromes caused by gathering of the factors such as the abnormal lipids metabolism, blood pressure abnormity, blood glucose metabolic disorder and obesity and can be used as a metabolic syndrome clinic treatment medicine for use.

Owner:成都普瑞法科技开发有限公司

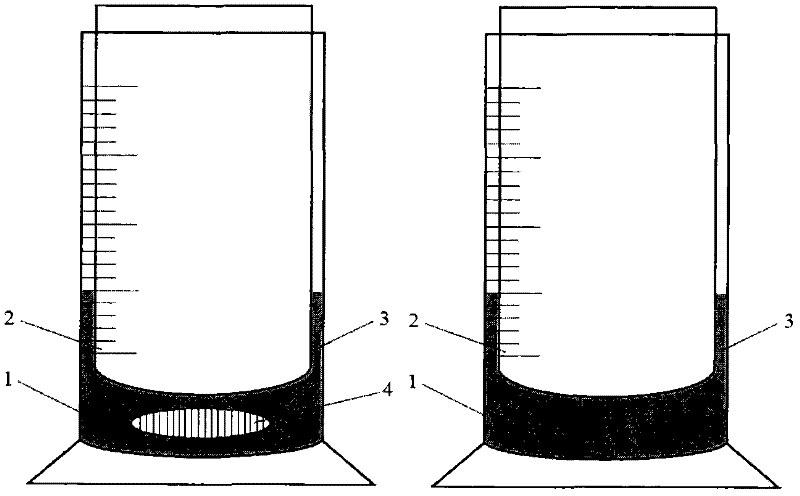

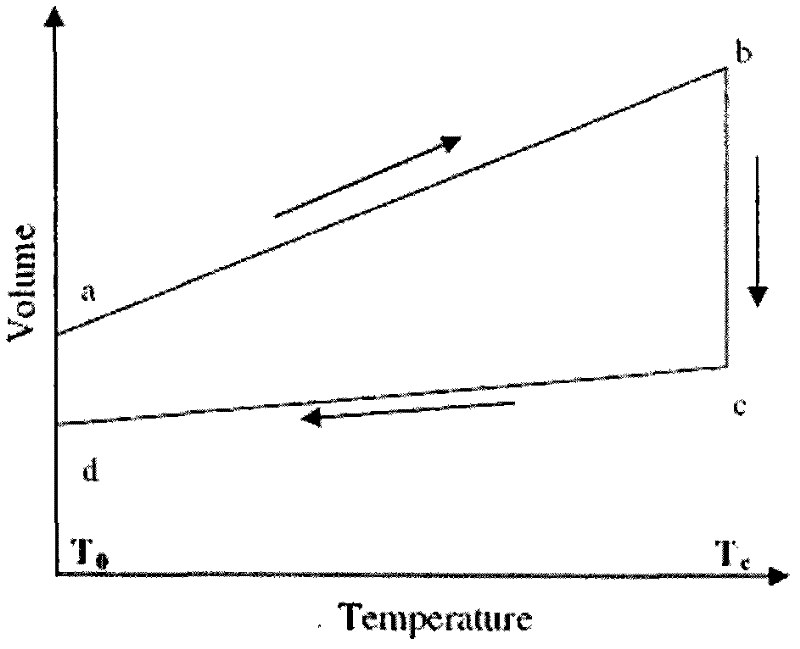

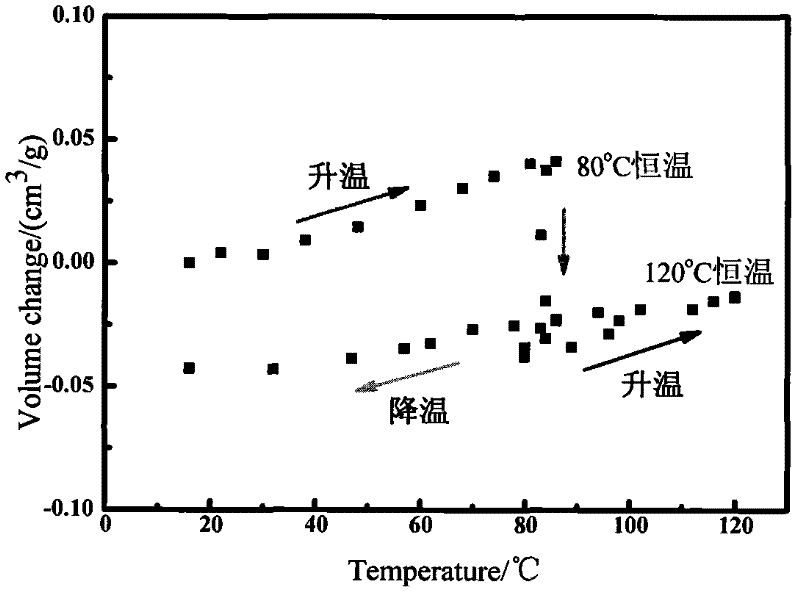

Test method for solidification volume change of thermosetting resin

ActiveCN102520004AOvercome volumeOvercome errorMaterial thermal coefficient of expansionExperimental proofVolume variation

The invention belongs to the research of solidification volume change feature of thermosetting resin and relates to a test method for researching the solidification volume change of the thermosetting resin. According to the test method, a high temperature resistant liquid medium which cannot carry out chemical reaction under high temperature is adopted as the volume transfer reagent, and the volume change original position of the thermosetting resin under full process temperature is recorded in the online and real-time manners. By researching the solidification volume change behavior of the typical thermosetting resin system, people can understand the volume change rules of different resin substrates in the solidification process, the solidification contraction of the thermosetting resin can be controlled by physical and chemical measures, so that the experimental proof is provided for improving the overall quality of composite material workpiece manufacturing.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Process for extracting protohemin by using surfactant

This invention is the extraction of chlorhematin with a kind of surface activator. In this invention, water, acid and non-ionic surface active agent or cationic surfactant is added in to hemoglobin from demostic animal's blood to form a blend. Stir it while heat gradually. Stop heat until crystal appear, but continue stiring, cool and centrifuge to isolate the chlorhematin crystal. Then, wash the crystal with water, dry to obtain the product chlorhematin. This method is advantageous in stable reaction, easy manipulation, safe process, low-level cost and good repeatability with plenty of experimental proof.

Owner:新疆科丽生物技术有限公司

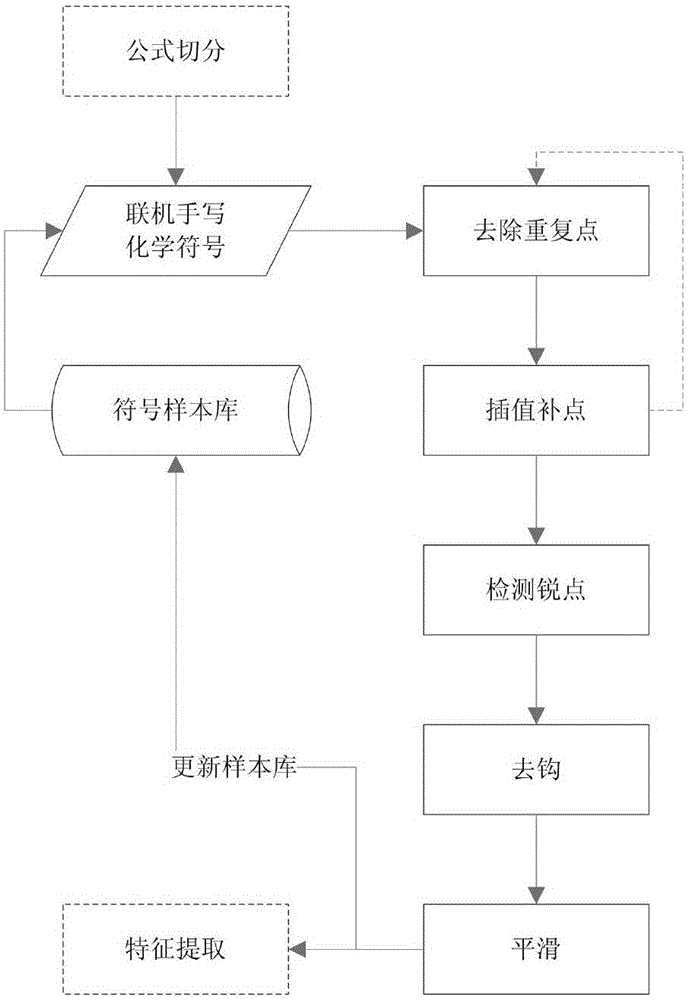

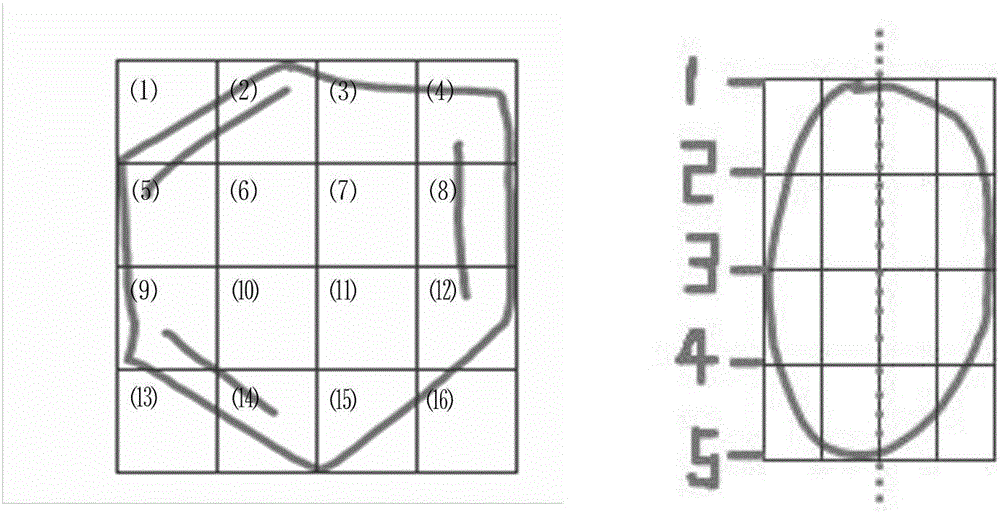

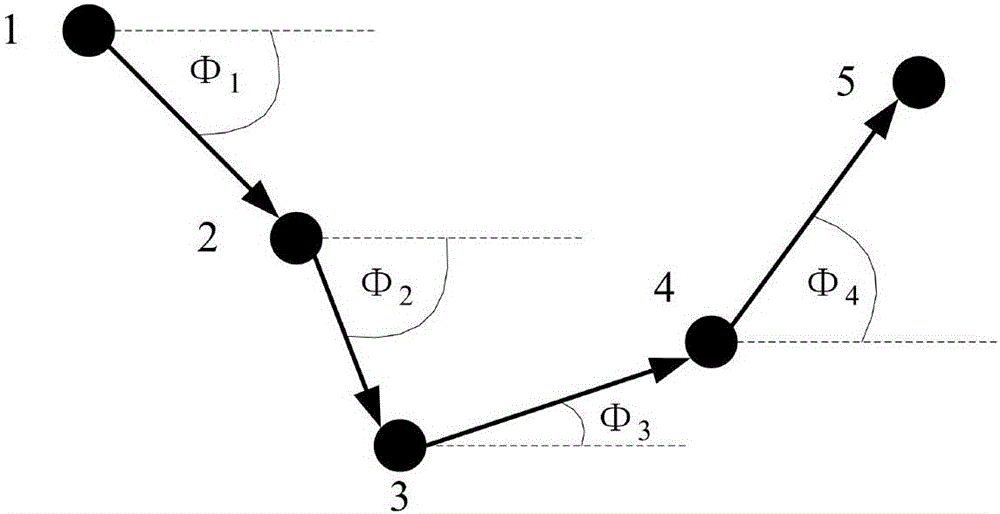

Online hand-written chemical symbol identification method based on Hidden Markov model

InactiveCN106650686AReduce performance consumptionImprove usabilityCharacter and pattern recognitionExperimental proofSupport vector machine

An online hand-written chemical symbol identification method based on the Hidden Markov model solves the problem of the online identification of chemical symbol written by any one writer on any one device. The method constructs a processing framework of identification of the online written chemical symbol, and employs a hierachical processing and step-by-step optimization strategy. The method based on a support vector machine selects grid features and peripheral contour features to distinguish organic ring symbols and non-ring symbols, and the classification error rate is controlled under 0.2%. The method based on the Hidden Markov model to identify concrete symbols, and the accuracy is more than 90%. In order to improve the precision design, a set of preprocessing flow is designed, and the post-processing measures such as candidate result reliability, chemical symbol adjacent matrixes and the atom element conservation detection are employed. The method has the universal meaning, systematicness and completeness through the experimental proof of the data source such as the input of a Tablet PC, a digital panel and a mouse simulation pen, and can be used for the online hand-written chemical symbol identification field.

Owner:NANKAI UNIV

Serum-free medium for vitro amplification culture of immune cells and application thereof

InactiveCN105713873AStable traitsGood lot-to-lot varianceCulture processBlood/immune system cellsCvd riskCell therapy

The invention discloses a serum-free medium suitable for immune cells and a preparation method thereof. According to experimental proof, the immune cells cultured by the serum-free medium for immune cells have more stable characters, and the cell growth and proliferation effects are better. The serum-free medium for immune cells has the advantages of clear chemical components, little batch-to-batch difference and stable quality and can guarantee the consistency among the medium batches; without animal origin or human origin, the serum-free medium has high safety, overcomes potential risk caused by human or animal serum and is conducive to studying the action mechanisms of various immune cells, promoting the safety standardization of domestic cell therapy and reducing the risk of accidental infection of patients and is of great significance in the promotion and application of immunotherapy.

Owner:GUANGDONG XTEM BIOTECH CO LTD

Application of transcription factor Fo x O3 in preparing cerebral ischemia reperfusion nerve injury drug

InactiveCN105920617ANervous disorderPeptide/protein ingredientsReperfusion injuryBiological activation

The invention relates to the technical field of medicine, in particular to application of a transcription factor Fo x O3 in preparing cerebral ischemia reperfusion nerve injury drug. The application of the transcription factor Fo x O3 in preparing the cerebral ischemia reperfusion nerve injury drug constructs two kinds of overexpression Fo x O3 plasmid, packs the overexpression Fo x O3 into the expression that adenovirus Ad-WT-Fo x O3 and Ad-TM-Fo x O3 regulates Fo x O3 and discusses the influence of Fo x O3 in OGD / R and MCAO / R damage on the expression of autophagy gap-associated protein LC3 and Beclin-1. According to experimental proof, Fo x O3 overexpression can promote the activation of autophagy gap-associated protein and has protective effect for the cerebral ischemia-reperfusion injury. The application of the transcription factor Fo x O3 in preparing the cerebral ischemia reperfusion nerve injury drug provides a new thought and a new path for the prevention of cerebral ischemic injury and a new target spot for the study of neuroprotective agents.

Owner:NANTONG UNIVERSITY

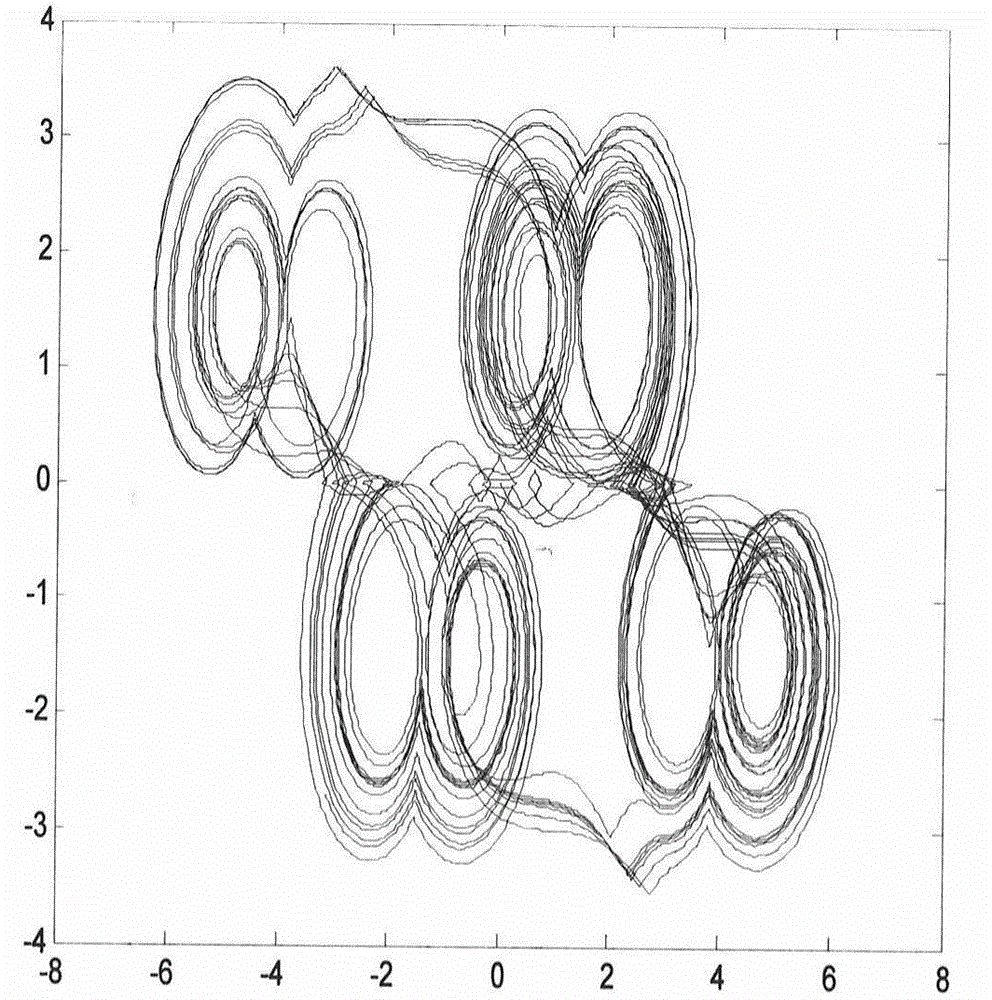

Grid multi-scroll chaotic system and circuit

The invention provides a 4 times 2 grid multi-scroll chaotic attraction subsystem and circuit, which consists of a first channel circuit, a second channel circuit, a third channel circuit and three paths of symbol function circuits. The first channel circuit consists of an invert adder U1, an integrator U2, an inverter U3 and resistors R11, R12, R13, R14 and Rx1 and Rx2. The second channel circuit consists of an invert adder U4, an integrator U5, an inverter U6 and resistors R21, R22, R23, R24 and Ry1 and Ry2. The third channel circuit consists of an invert adder U7, an integrator U8, an inverter U9 and resistors R31, R32, R33, R34 and Rz1, Rz2, Rz3, and Rz4. The invention provides one 4 times 2 grid multi-scroll chaotic attraction subsystem, which is subject to experimental proof with a simulation circuit, and has wide application prospect and important application value in the fields such as secret communication.

Owner:马英杰 +6

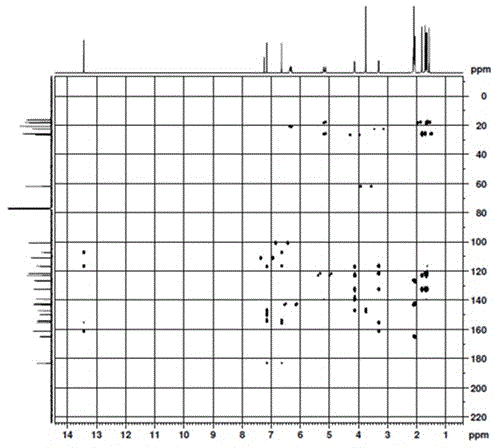

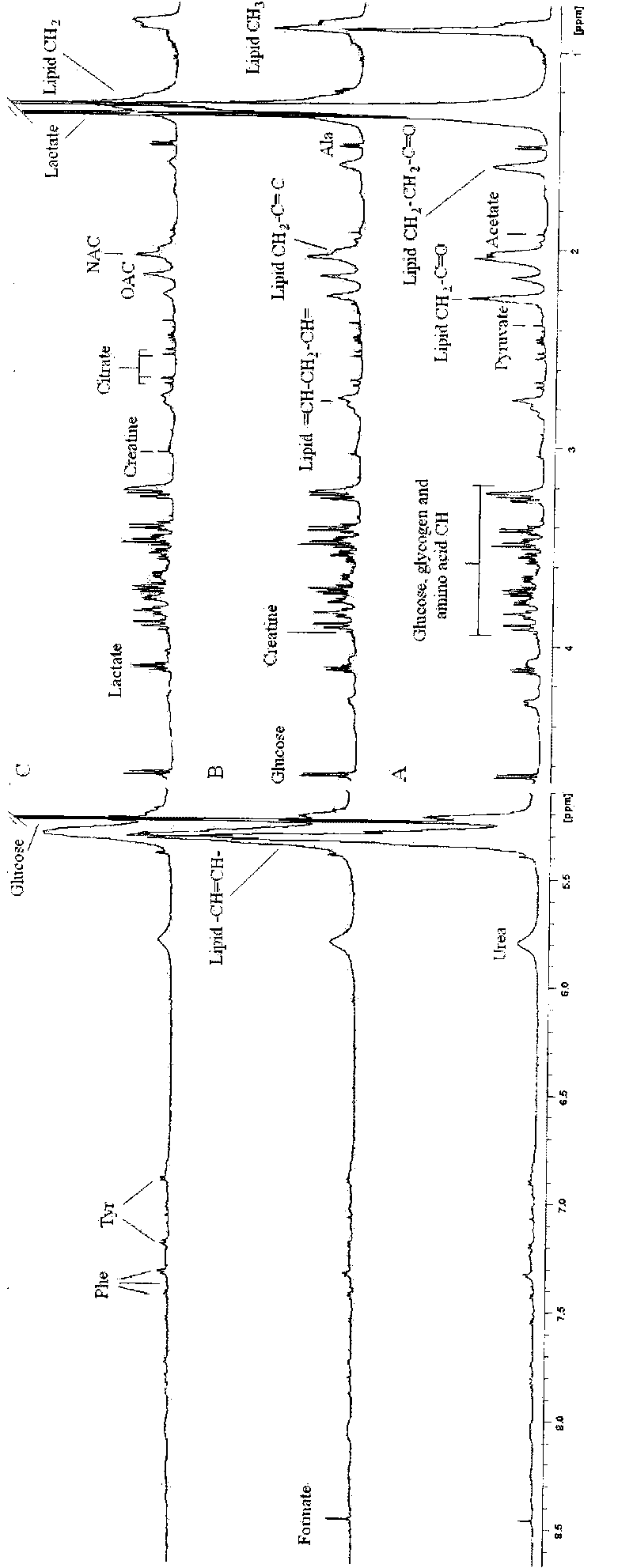

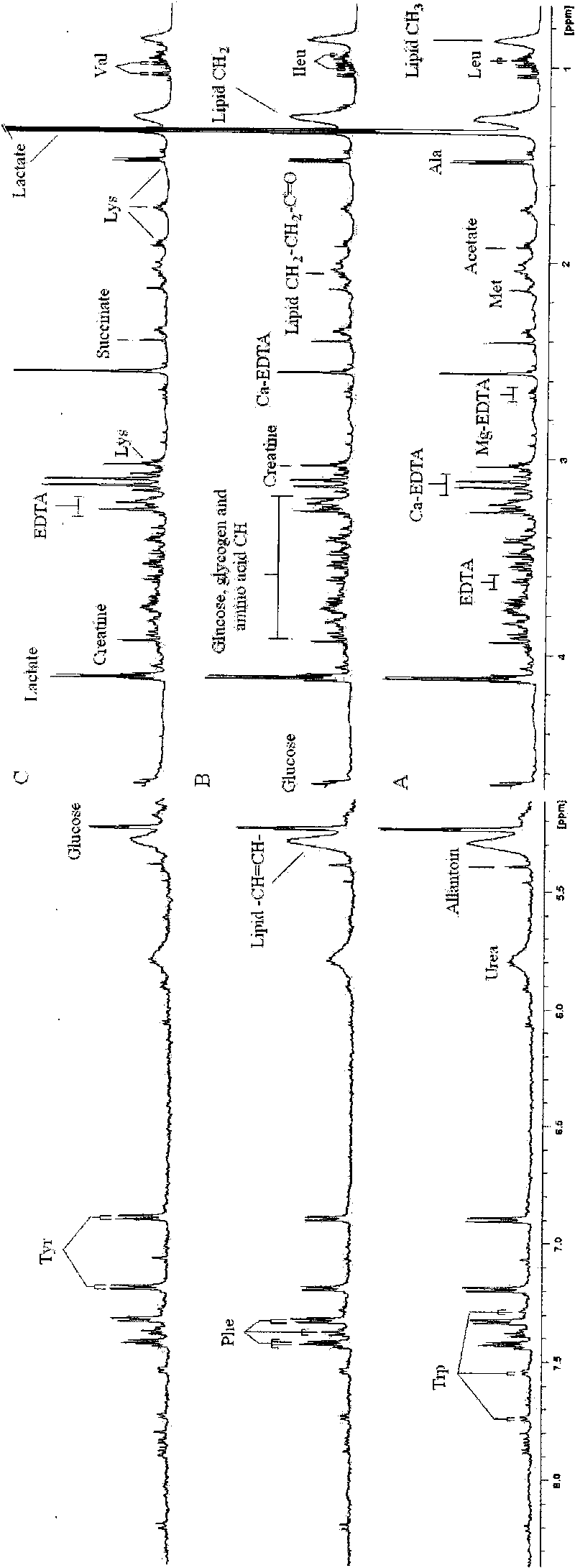

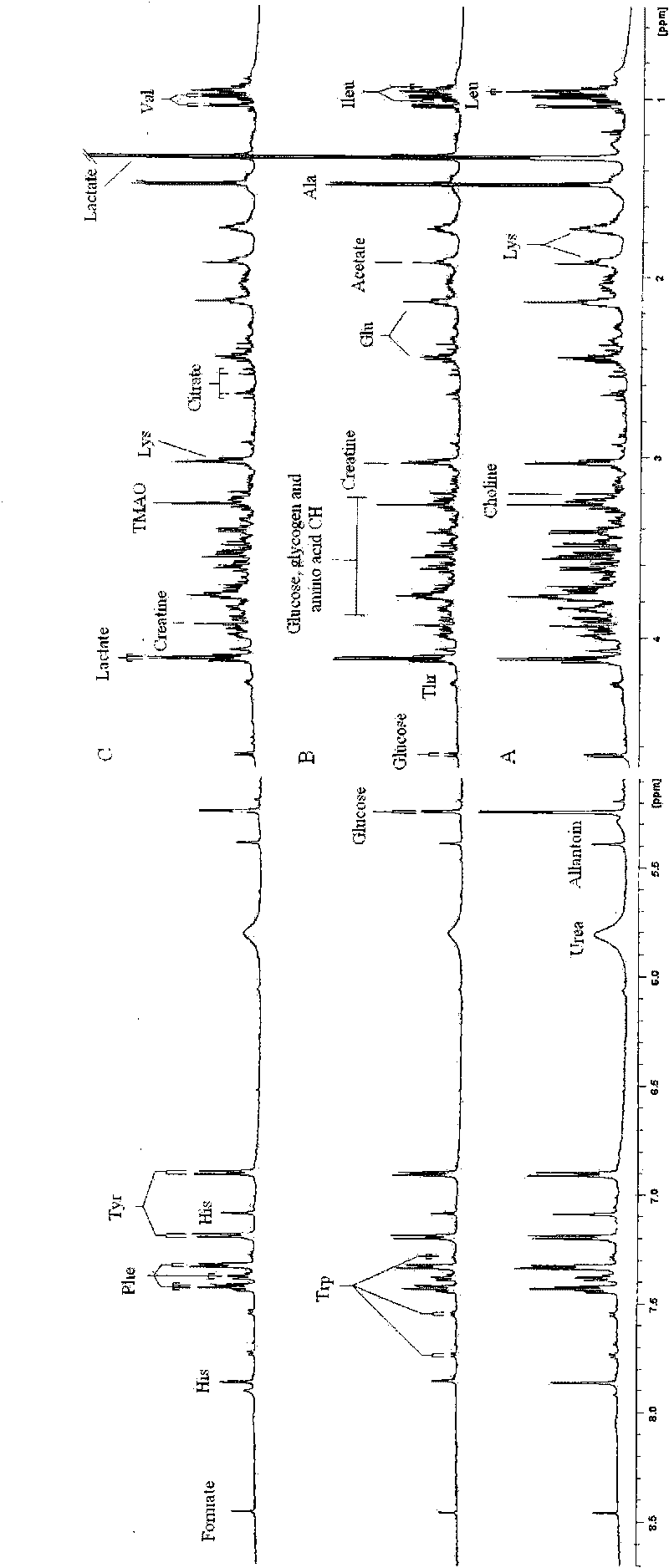

Application of metabonomic technology in intrauterine growth retardation

InactiveCN101713753AIncreased sensitivityAnalysis using nuclear magnetic resonanceBiological testingGenomicsAmniotic fluid

The invention relates to application of metabonomic technology in intrauterine growth retardation, which is mainly characterized by starting from the view of system biology (Cowley AW Jr.The elusive field of systems biology. Physiol Genomics.2004;16(3):285-286), and applying a magnetic resonance spectroscopy technology based metabonomic method to seek a nuclear magnetic resonance spectrogram capable of specifically reflecting the intrauterine growth retardation in the peripheral blood of an experimental pregnant animal or a pregnant woman so as to provide proofs for further diagnosing the intrauterine growth retardation. The application comprises the following steps: during analysis, detecting a biological sample (comprising parent blood, embryo blood and amniotic fluid) of the pregnant animal or the pregnant woman in normal pregnancy and intrauterine growth retardation experiment by using nuclear magnetic resonance technology, acquiring a metabonomic spectrogram, analyzing the metabonomic spectrogram by using a pattern identification method, determining the metabonomic change of the intrauterine growth retardation through analysis and comparison, and acquiring one or more (groups of) nuclear magnetic resonance spectrograms for reflecting the intrauterine growth retardation from the metabonomic change so as to provide theoretical and experimental proofs for the subsequent further determination of a biomarker and the application of the metabonomic technology in the intrauterine growth retardation. The application has the advantages of high sensitivity, good specificity, early stage, non-invasion or micro-invasion and the like.

Owner:WUHAN UNIV

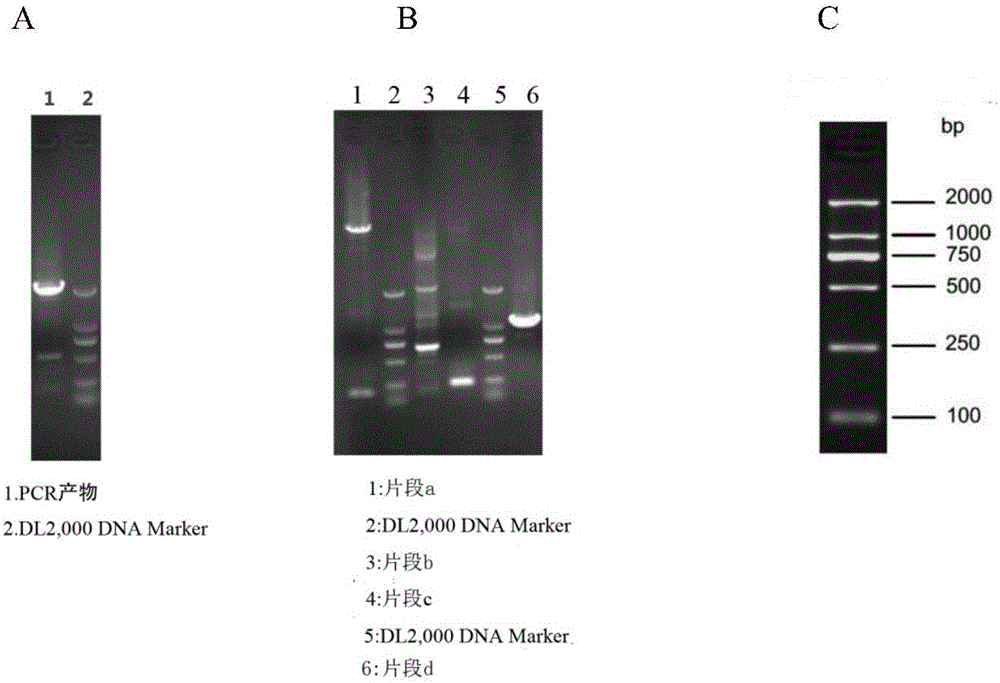

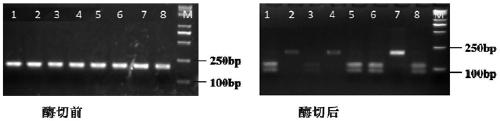

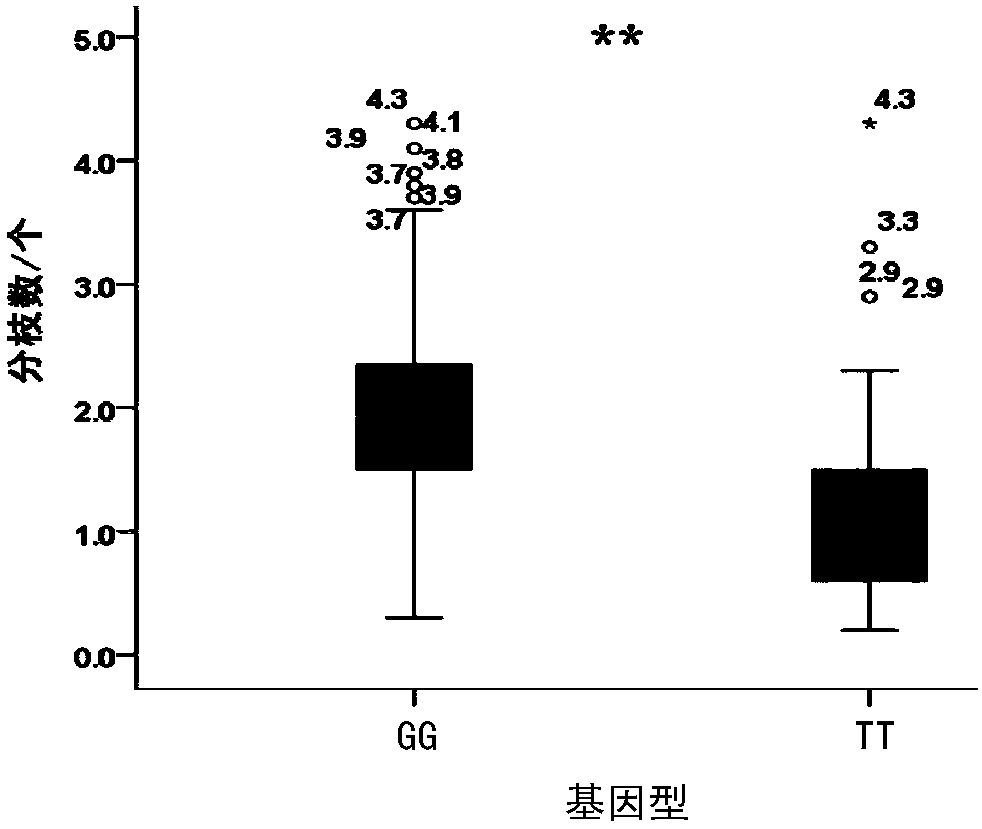

Application of molecular marker and its polymorphism in identification of branching number traits in soybean

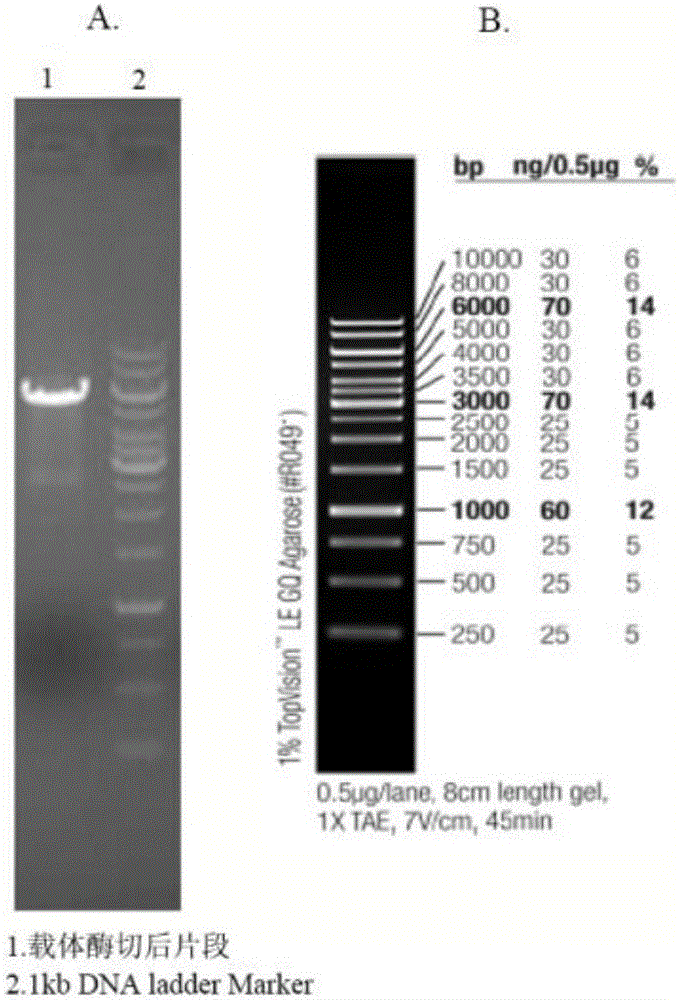

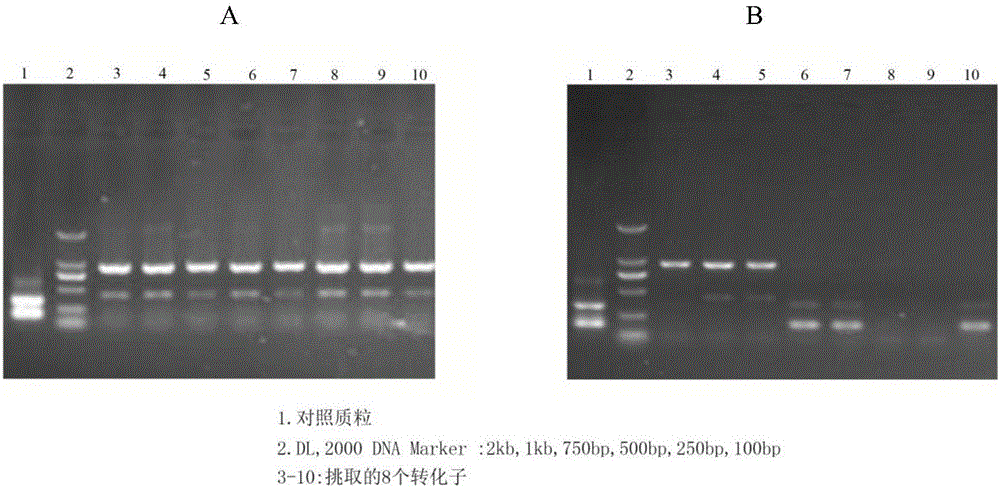

ActiveCN109234423AMicrobiological testing/measurementDNA/RNA fragmentationExperimental proofGenomic DNA

The present invention discloses the application of a soybean molecular marker and its polymorphism in the identification of branching number traits in soybean. The soybean molecular marker disclosed by the invention is a DNA molecule obtained by amplifying BRCH with a soybean genomic DNA as a template and a primer. BRCH consists of single-stranded DNA named BRCH_F and BRCH_R, BRCH_F is a single-stranded DNA that specifically binds to the 84th upstream of SEQ ID NO: 1 in soybean genomic DNA, and BRCH_R is a single-stranded DNA that specifically binds to the 84th downstream of SEQ ID NO: 1 in soybean genomic DNA. Experimental proof, Among the genotypes distinguished by the soybean molecular markers according to the present invention, the number of branches of the GG genotype soybean is significantly higher than that of the TT genotype soybean, indicating that the soybean molecular markers of the present invention are closely related to the number of branches of the soybean, can be used for identifying the number of branches of the soybean, and can also be used for soybean breeding according to the molecular markers of the soybean.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Environment-friendly battery conductive coating material

InactiveCN106009979APromote environmental protectionImprove sealingElectrically-conductive paintsConductive coatingExperimental proof

An environment-friendly battery conductive coating material is composed of the following raw materials in parts by weight: 40-60 parts of a base material, 15-25 parts of a conductive additive, 10-18 parts of an inorganic filler and 8-15 parts of a modification additive. The environmentally friendly battery conductive coating material provided by the present invention has good adhesion and low contact resistance through reasonable raw material ratio and a large number of experiments, which can effectively reduce the amount of adhesive and improve the environmental protection of battery manufacturing. property; the conductive coating of the present invention does not contain highly toxic toluene and xylene, and has better sealing effect.

Owner:无锡市宝来电池有限公司

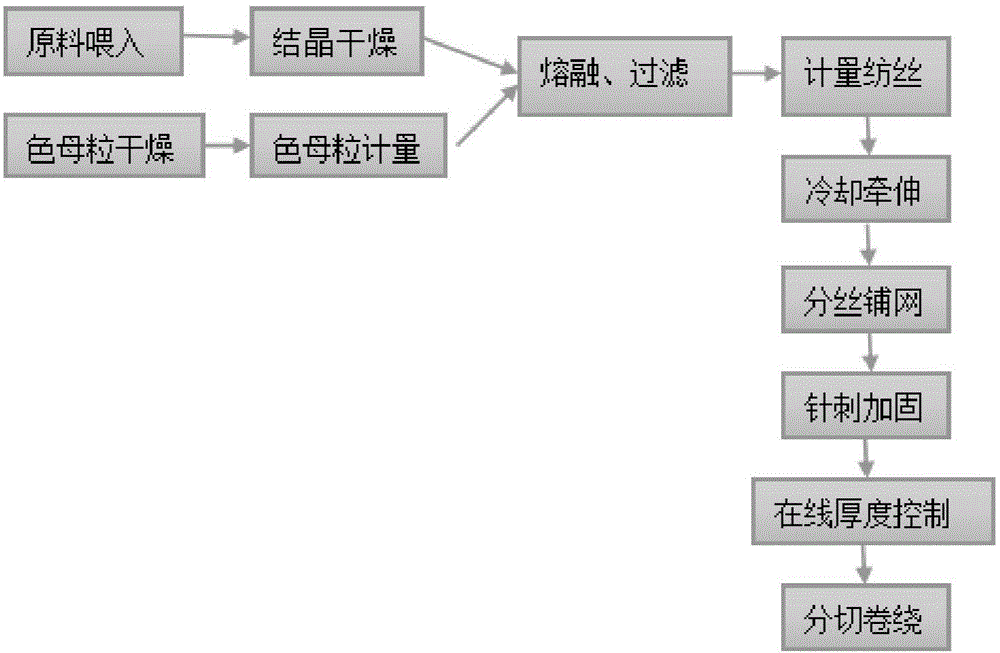

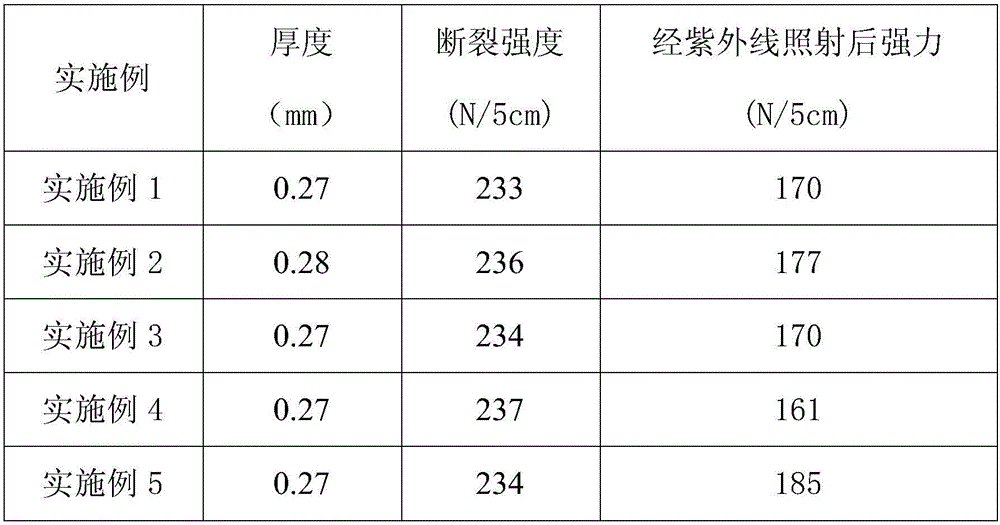

Preparing method for gray ultraviolet resistant non-woven

InactiveCN106436022AImproves UV resistancePlay a thermal insulation effectSpinning head liquid feederNon-woven fabricsPolyesterExperimental proof

Provided is a preparing method for gray ultraviolet resistant non-woven. The preparing method comprises the steps of adding a polyester chip into a main stock bin, conducting crystalization and drying at the temperature of 165-175 DEG C, and then conducting fusion in a screw; adding black master batch and ultraviolet resistant master batch into a small stock bin, wherein the adding proportion of the black master batch accounts for 0.5-2% of the dosage of the polyester chip and the adding proportion of the ultraviolet resistant non-woven accounts for 1.5-3% of the dosage of the polyester chip, conducting drying on the mixture for 3-5 hours at the temperature of 85-95 DEG C, adding a big screw into the mixture, and conducting melt mixing on the mixture; conducting screw extrusion after mixing the polyester chip, the black master batch and the ultraviolet resistant master batch, and conducting spinning, cooling, traction tube drafting and web forming to obtain a 80-150 g / m<2> product; conducting acupuncture reinforcing to reinforce and control the thickness of the product. The gray ultraviolet resistant non-woven product has an excellent ultraviolet resistant effect and is mainly used for being paved on the lawn to achieve an effect of partial heat retaining. According to experimental proof, after being exposed under an ultraviolet radiator for 500 hours, the gray ultraviolet resistant non-woven still has a mightiness retention rate of 79%.

Owner:TIANDINGFENG NONWOVENS CO LTD

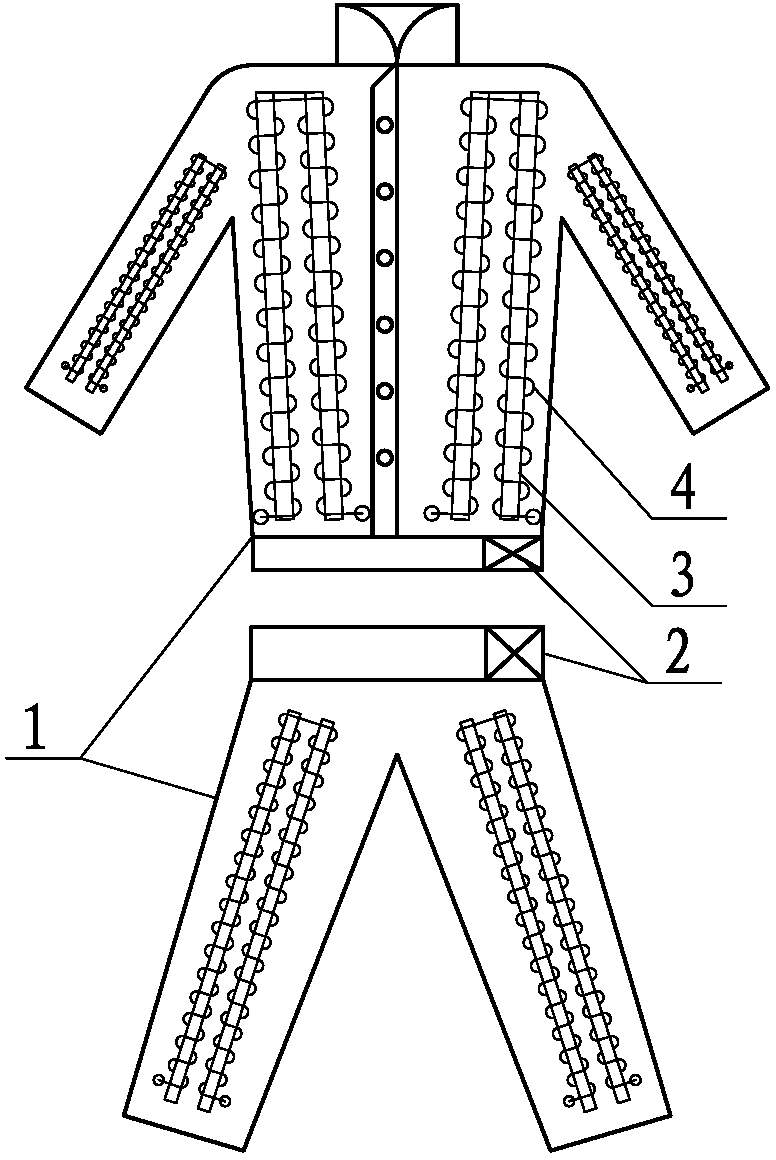

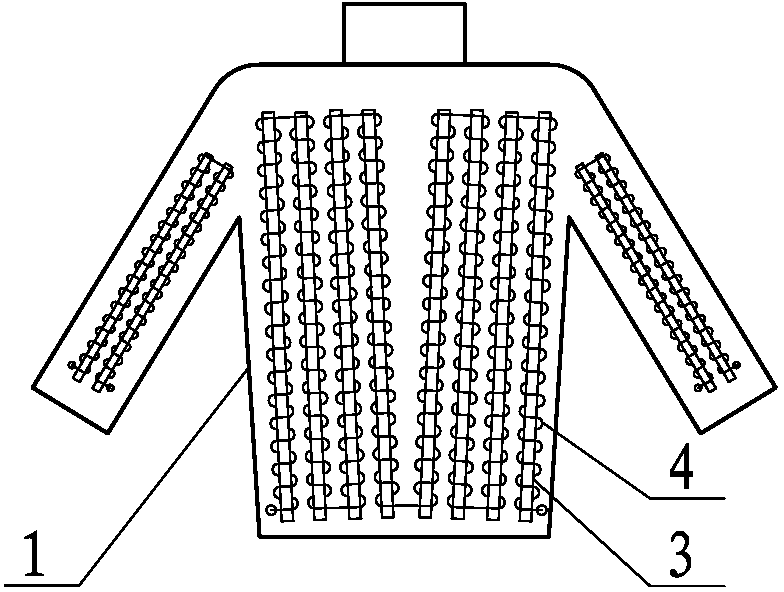

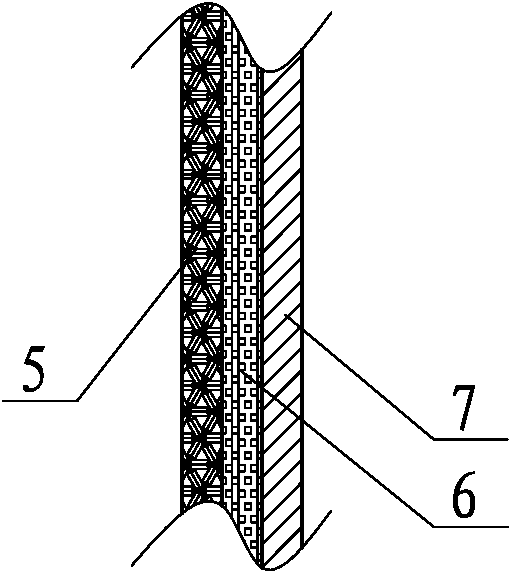

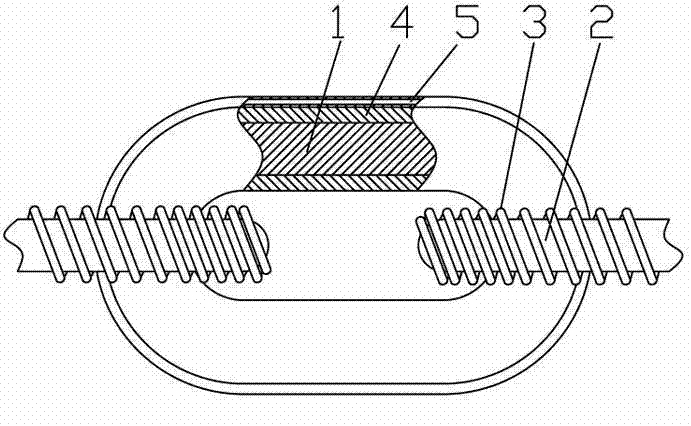

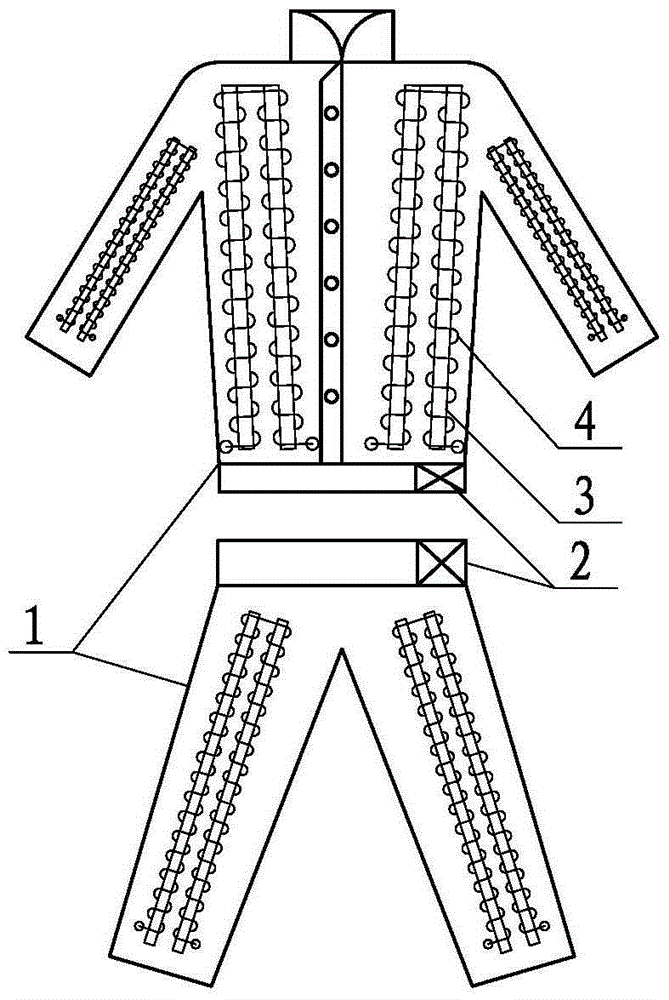

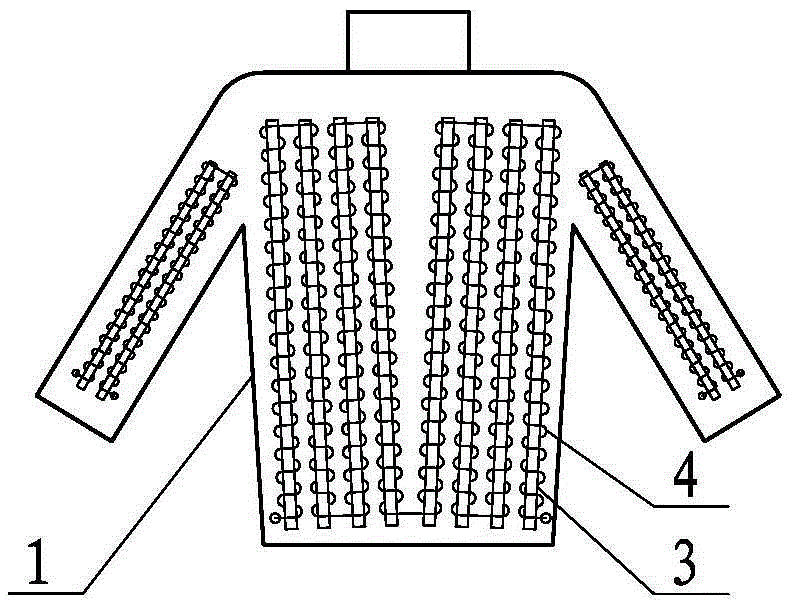

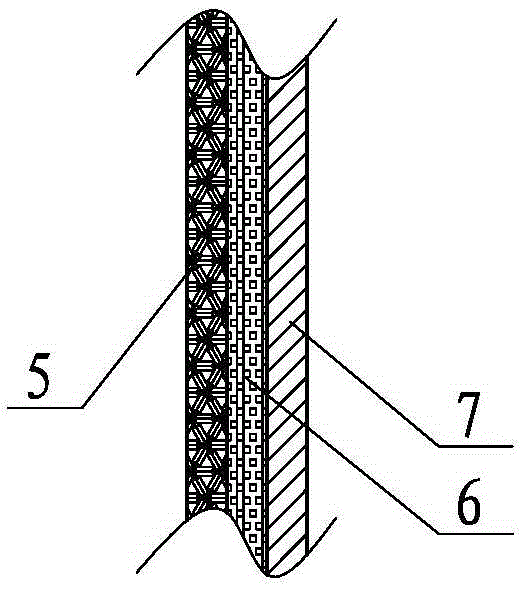

Electromagnetic thermal therapy suit and power source knapsack matched with same

ActiveCN103341233ABiomagnetic field enhancementImproved biomagnetic fieldElectrotherapyMagnetotherapyExperimental proofEngineering

The invention particularly relates to an electromagnetic thermal therapy suit and a power source knapsack matched with the electromagnetic thermal therapy suit and belongs to the field of electromagnetic thermal therapy instruments. The electromagnetic thermal therapy suit comprises a clothing body and is characterized in that a therapy interlayer is arranged in the clothing body, and 2n magnetic stripes are fixed in the therapy interlayer and arranged in pairs in a mutually parallel mode. Coils are wound on the magnetic stripes. The winding directions of the coils on the adjacent magnetic stripes are opposite. All the coils are connected with inverters together through wires in series, and power interfaces are arranged in the inverters. According to the electromagnetism theory and experimental proof, when the electromagnetic thermal therapy suit is close to the human body, a coupling circuit is formed. After the coupling circuit is formed, electric currents in the thermal therapy suit are induced to the biological circuit of the human body, so that the purposes that the human body currents are adjusted and intensified, and the biological magnetic field is improved are achieved. The thermal therapy suit also can enable the human body to continuously generate a sense of warmth and a temperature needed for maintaining physical health and is particularly suitable for being used by an outdoor worker in winter, a mountaineering enthusiast, a surfer and other activity persons in the low-temperature environment.

Owner:淄博思昂健康科技有限公司

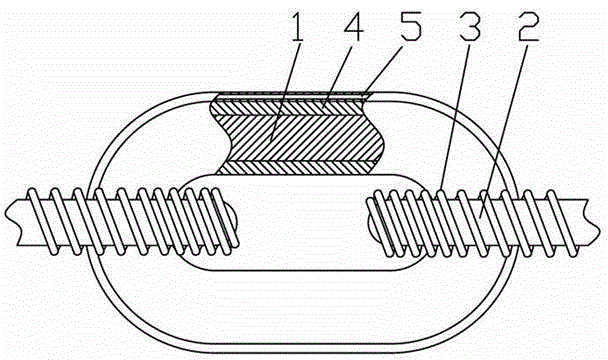

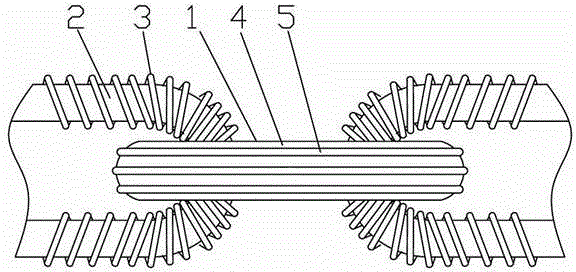

Connected metal link heat treatment process method

ActiveCN103114195AMeet processing requirementsMeet the process requirementsFurnace typesHeat treatment furnacesExperimental proofInsulation layer

The invention discloses a connected metal link heat treatment process method. The method comprises the following steps of: wrapping up an insulation layer on the outer surface of the connected link, and heating an inner metal through an outer induction coil so that the heat in the connected link is difficult to escape; and meanwhile, winding cooling pipes on other links close to the connected link, and rapidly taking away the heat generated in the connected link by the cooling pipe so that the other links are not affected. Through an experimental proof, the nearby links, particularly the connected links have the temperature lower than 150 DEG C in the heat treatment process, so that the requirement of classification society rule to chains processing is completely met.

Owner:FOSHAN MARINE ANCHOR CHAIN

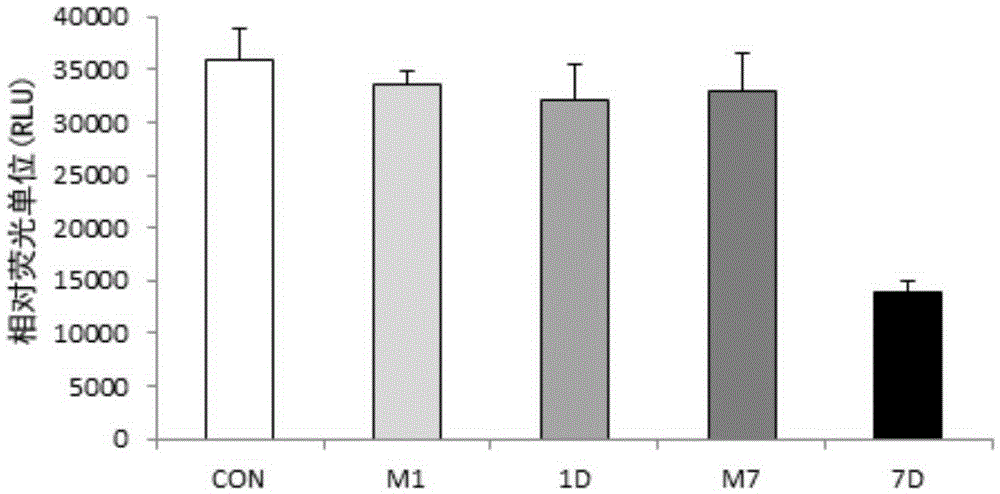

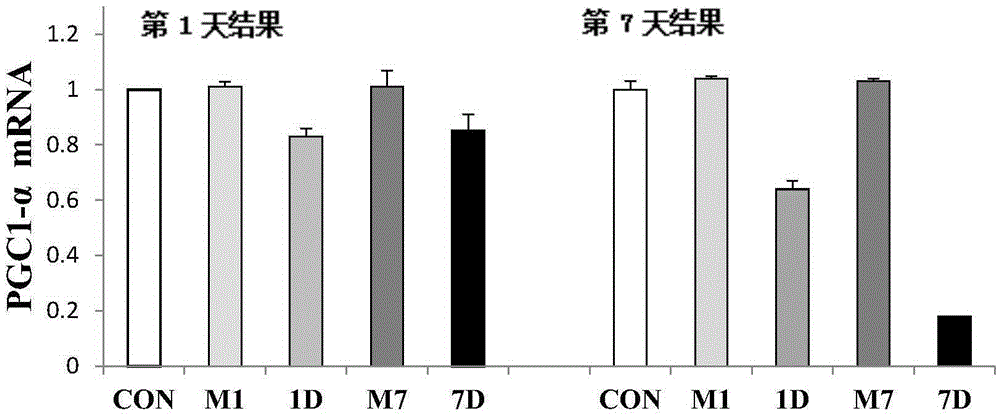

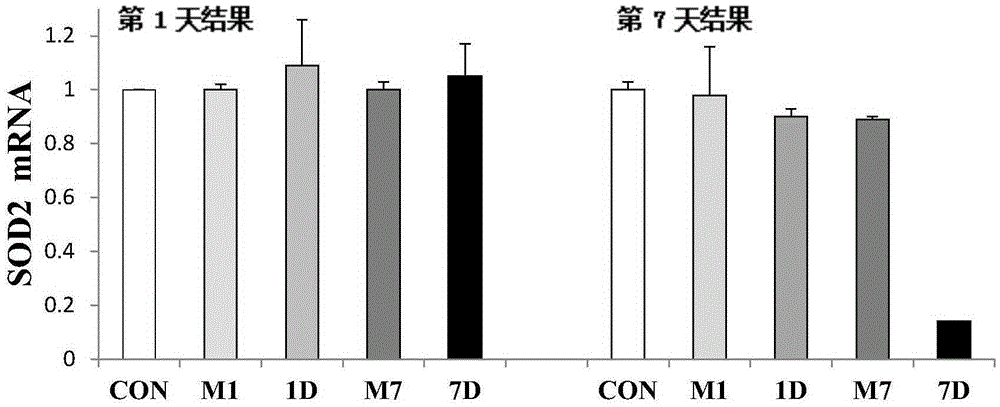

Diabetic retinopathy (DR) metabolic memory detection reagent and application thereof

InactiveCN104212908AEarly diagnosisRapid diagnosisMicrobiological testing/measurementExperimental proofDiabetes retinopathy

The invention belongs to the field of biotechnology and medical science and particularly relates to a diabetic retinopathy (DR) metabolic memory detection reagent and application thereof. According to experimental proof, methylation of locus (+214) in a peroxisome proliferator-activated receptor gamma coactivator 1 alpha (PGC1-alpha) gene is an early diagnosis mark of DR metabolic memory. On the basis of the study, the detection reagent is provided for detecting the diagnosis mark, and a corresponding detection kit is prepared. According to the provided methylation detection reagent, whether methylation of a detected object of the PGC1-alpha gene locus +214 occurs or not and methylation degree can be qualitatively or quantitatively detected, thereby, whether DR metabolic memory and illness risks of the detected object exist or not can be predicted, and the clinical application value is excellent.

Owner:陈有信

Medicine for curing ovulation failure and preparing method thereof

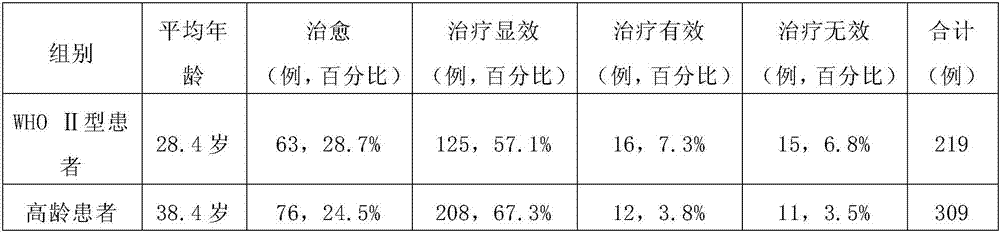

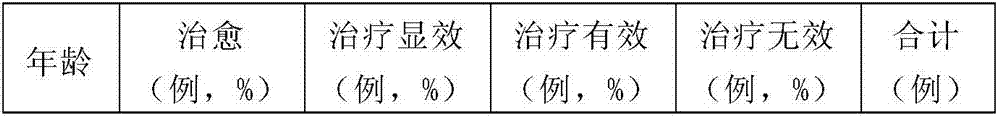

The invention discloses medicine for curing ovulation failure and a preparing method thereof. The medicine for curing ovulation failure is prepared from, by mass, 10 parts of lepidium meyenii, 2.4-15 parts of herba epimedii, 2.4-15 parts of fructus psoraleae, 4-20 parts of rhizoma polygonati, 3.6-20 parts of Chinese yam, 4-20 parts of prepared rehmannia root, 3.6-20 parts of bulbus fritillariae cirrhosae, 2-15 parts of spina gleditsiae, 1.2-15 parts of peach kernel and 3.6-20 parts of angelica sinensis. According to the experimental proof, by means of the medicine for curing the ovulation failure, WHOII type ovulation failure patients and elderly ovulation failure patients can be cured, patients with the curing effects can reaches 92.6% and 96.3%, and the medicine for curing ovulation failure has the advantages that the medicine aims to curing polycystic ovaries, the curing effects for hypoovarianism and elderly second child birth are remarkable, the pertinence is high, the curative effect is obvious, and the toxic and side effects do not exist.

Owner:许晋

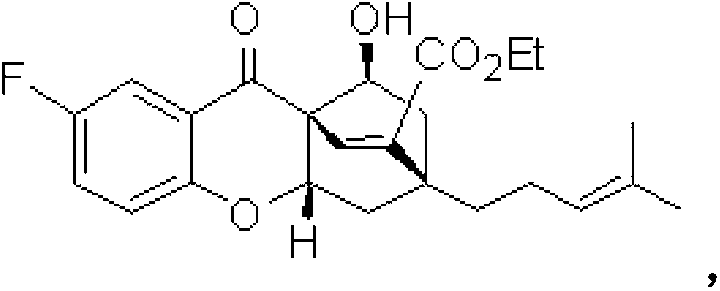

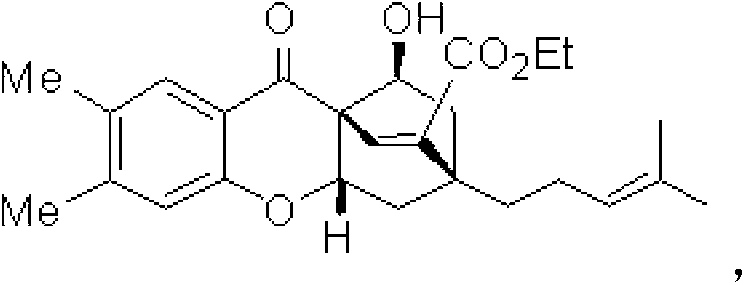

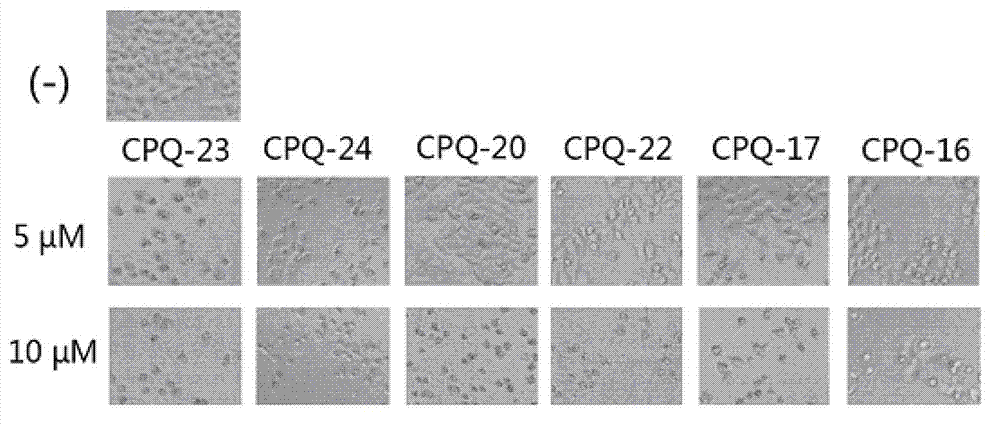

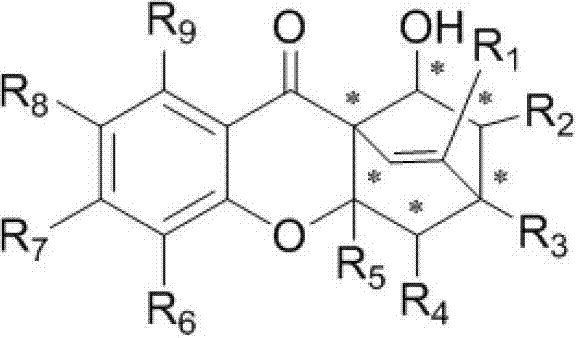

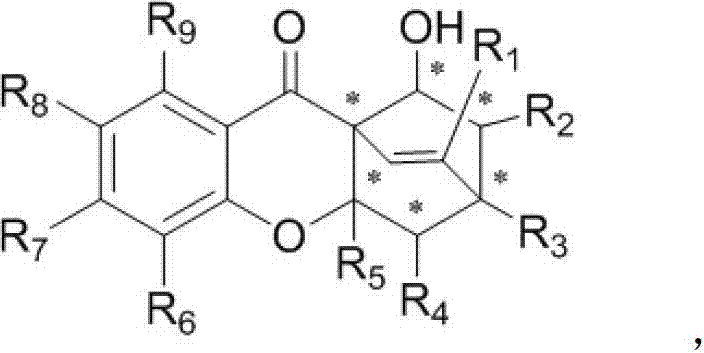

Applications of dihydro chromone framework compounds in preparing medicine for curing malignant tumor

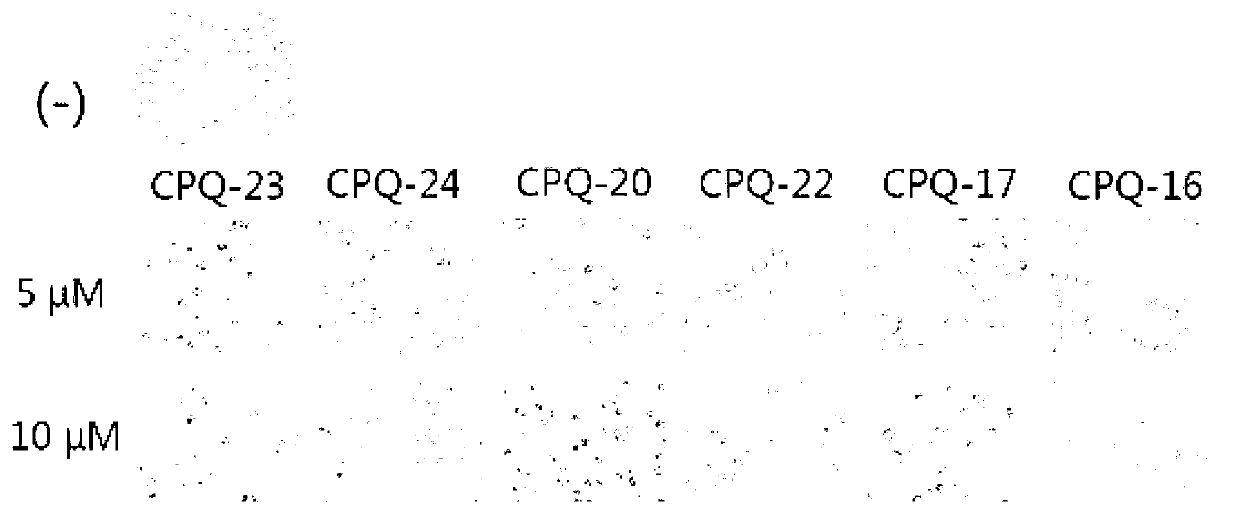

The invention discloses applications of dihydro chromone framework compounds of CPQ-16, CPQ-17, CPQ-20, CPQ-22, CPQ-23 and CPQ-24 in preparing medicine for curing malignant tumors. According to experimental proof, any kind of the six compounds can kill a plurality kinds of tumor cells of human bodies effectively, the tumor cells comprise cervical cancer cells, non-small cell lung cancer cells, breast cancer cells, ovarian carcinoma cells, hepatoma carcinoma cells, nasopharyngeal carcinoma cells, gastric carcinoma cells, laryngocarcinoma cells, pancreatic cancer cells, melanoma cells, bladder cancer cells and leukemia cells. Besides, with increase of dosages of the compounds, injured and killed cancers are increased with the increase of the dosages, and thus the new applications are proofed and discovered in the medicine for curing malignant tumors, and a new application range is exploited. Besides, new medicine is provided for the malignant tumors, and the difficulty in the chemical treatment of diseases that tumor cells are tolerant of chemotherapeutics is solved.

Owner:SICHUAN UNIV

Application of dihydrochromone skeleton compound in preparation of medicine for treating malignant tumors

The invention discloses applications of dihydro chromone framework compounds of CPQ-16, CPQ-17, CPQ-20, CPQ-22, CPQ-23 and CPQ-24 in preparing medicine for curing malignant tumors. According to experimental proof, any kind of the six compounds can kill a plurality kinds of tumor cells of human bodies effectively, the tumor cells comprise cervical cancer cells, non-small cell lung cancer cells, breast cancer cells, ovarian carcinoma cells, hepatoma carcinoma cells, nasopharyngeal carcinoma cells, gastric carcinoma cells, laryngocarcinoma cells, pancreatic cancer cells, melanoma cells, bladder cancer cells and leukemia cells. Besides, with increase of dosages of the compounds, injured and killed cancers are increased with the increase of the dosages, and thus the new applications are proofed and discovered in the medicine for curing malignant tumors, and a new application range is exploited. Besides, new medicine is provided for the malignant tumors, and the difficulty in the chemical treatment of diseases that tumor cells are tolerant of chemotherapeutics is solved.

Owner:SICHUAN UNIV

Microstrip Switch Phase Shifter and Phase Shift Module Using It

ActiveCN105356014BReduce parasitic parametersFlat Phase Shift CharacteristicsWaveguide type devicesExperimental proofPhase shift module

The invention provides a microstrip switch type phase shifter and a phase shifting module using the same. The microstrip switch type phase shifter comprises a reference branch circuit, a phase shifting branch circuit, a first path selection switch and a second path selection switch, wherein the reference branch circuit comprises a first microstrip transmission line; the phase shifting branch circuit comprises a second microstrip transmission line and a third microstrip transmission line which are connected in series, and a fourth microstrip transmission line connected between a node between the second and third microstrip transmission lines and the ground level; the front end of the first path selection switch is connected to a signal input end, the rear end of the second path selection switch is connected to a signal output end, and the first and second path selection switches are simultaneously connected to the reference branch circuit and the phase shifting branch circuit under control. By adopting continuous microstrip lines and a simple topological structure, the phase shifter and the phase shifting module reduce parasitical parameters caused by discontinuous microstrip lines, can be applied to high-frequency scenarios, meanwhile, have very flat phase shifting characteristic nearby center frequency by simulation and experimental proof, and have high phase shifting precision.

Owner:SOI MICRO CO LTD

New application of HuGu capsule in preventing glucocorticoid-induced osteoporosis

ActiveCN101890127BNo change in biomechanical propertiesGood effectSkeletal disorderUnknown materialsExperimental proofGlucocorticoid

The invention relates to a new application of a HuGu capsule (HG) in preventing glucocorticoid-induced osteoporosis (GIO), belonging to the technical field of traditional Chinese medicine application. The invention discusses HG prevention effect towards GIO induced by glucocorticoids (GCs) based on bone histomorphometry. The experimental result proves that the glucocorticoids (GCs) can induce cortical bone loss of a rat in short time, after HG intervention is carried out for 45d, the GCs is prevented from inducing the cortical bone loss of the rat, thereby providing experimental proof for thenew application of the HG in preventing the GIO.

Owner:GUANGDONG ANNOL PHARM CO LTD

A kind of diabetic retinopathy metabolic memory detection reagent and its application

InactiveCN104212908BEarly diagnosisRapid diagnosisMicrobiological testing/measurementExperimental proofDiabetes retinopathy

The invention belongs to the field of biotechnology and medical science and particularly relates to a diabetic retinopathy (DR) metabolic memory detection reagent and application thereof. According to experimental proof, methylation of locus (+214) in a peroxisome proliferator-activated receptor gamma coactivator 1 alpha (PGC1-alpha) gene is an early diagnosis mark of DR metabolic memory. On the basis of the study, the detection reagent is provided for detecting the diagnosis mark, and a corresponding detection kit is prepared. According to the provided methylation detection reagent, whether methylation of a detected object of the PGC1-alpha gene locus +214 occurs or not and methylation degree can be qualitatively or quantitatively detected, thereby, whether DR metabolic memory and illness risks of the detected object exist or not can be predicted, and the clinical application value is excellent.

Owner:陈有信

Connected metal link heat treatment process method

ActiveCN103114195BMeet the process requirementsFurnace typesHeat treatment furnacesExperimental proofInsulation layer

The invention discloses a connected metal link heat treatment process method. The method comprises the following steps of: wrapping up an insulation layer on the outer surface of the connected link, and heating an inner metal through an outer induction coil so that the heat in the connected link is difficult to escape; and meanwhile, winding cooling pipes on other links close to the connected link, and rapidly taking away the heat generated in the connected link by the cooling pipe so that the other links are not affected. Through an experimental proof, the nearby links, particularly the connected links have the temperature lower than 150 DEG C in the heat treatment process, so that the requirement of classification society rule to chains processing is completely met.

Owner:FOSHAN MARINE ANCHOR CHAIN

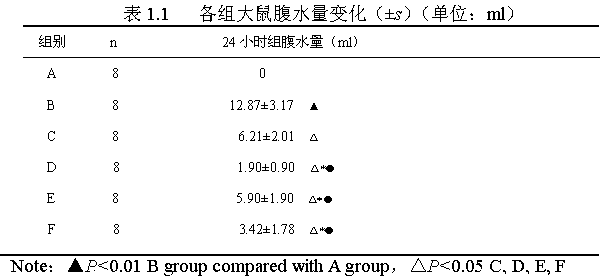

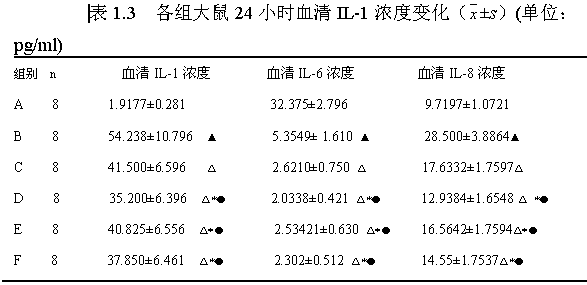

Aqueous extract of compound traditional Chinese medicine for treating acute pancreatitis and preparation method thereof

InactiveCN104887790BReduce bloatRelieve symptomsDigestive systemSulfur/selenium/tellurium inorganic active ingredientsSource materialMortality rate

The invention discloses a compound traditional Chinese medicinal water extract for treating acute pancreatitis. Calculated in parts by weight, 22-27 parts of gardenia, 22-27 parts of paeonol, 22-27 parts of woody fragrance and 22-27 parts of magnolia 22-27 parts of Yuanhu, 35-45 parts of Radix Paeoniae Rubra, 35-45 parts of Rhubarb and 12-17 parts of Glauber's Salt as raw materials for preparation. The present invention selects 8 kinds of traditional Chinese medicine compositions as raw materials for preparation, and applies the prepared water extract to the medicine for treating acute pancreatitis. According to experiments, the prepared medicine can obviously relieve abdominal distension and intestinal paralysis during SAP, Thus, the symptoms of SAP can be significantly relieved, complications can be reduced, and the mortality rate can be reduced. After more than 5,000 cases of acute pancreatitis and more than 1,000 cases of acute severe pancreatitis (SAP), the treatment and summary have received good curative effect. The cure rate of SAP can reach 85.4%, and the mortality rate has dropped to 10.1%. The material source of the invention is wide, easy to obtain, and low in cost, and the preparation method adopted is simple and easy to implement and easy to industrialize.

Owner:AFFILIATED HOSPITAL OF ZUNYI MEDICAL COLLEGE

An electromagnetic heat therapy suit and its matching power supply backpack

ActiveCN103341233BBiomagnetic field enhancementImproved biomagnetic fieldElectrotherapyMagnetotherapyHuman bodyOutdoor workers

The invention particularly relates to an electromagnetic thermal therapy suit and a power source knapsack matched with the electromagnetic thermal therapy suit and belongs to the field of electromagnetic thermal therapy instruments. The electromagnetic thermal therapy suit comprises a clothing body and is characterized in that a therapy interlayer is arranged in the clothing body, and 2n magnetic stripes are fixed in the therapy interlayer and arranged in pairs in a mutually parallel mode. Coils are wound on the magnetic stripes. The winding directions of the coils on the adjacent magnetic stripes are opposite. All the coils are connected with inverters together through wires in series, and power interfaces are arranged in the inverters. According to the electromagnetism theory and experimental proof, when the electromagnetic thermal therapy suit is close to the human body, a coupling circuit is formed. After the coupling circuit is formed, electric currents in the thermal therapy suit are induced to the biological circuit of the human body, so that the purposes that the human body currents are adjusted and intensified, and the biological magnetic field is improved are achieved. The thermal therapy suit also can enable the human body to continuously generate a sense of warmth and a temperature needed for maintaining physical health and is particularly suitable for being used by an outdoor worker in winter, a mountaineering enthusiast, a surfer and other activity persons in the low-temperature environment.

Owner:淄博思昂健康科技有限公司

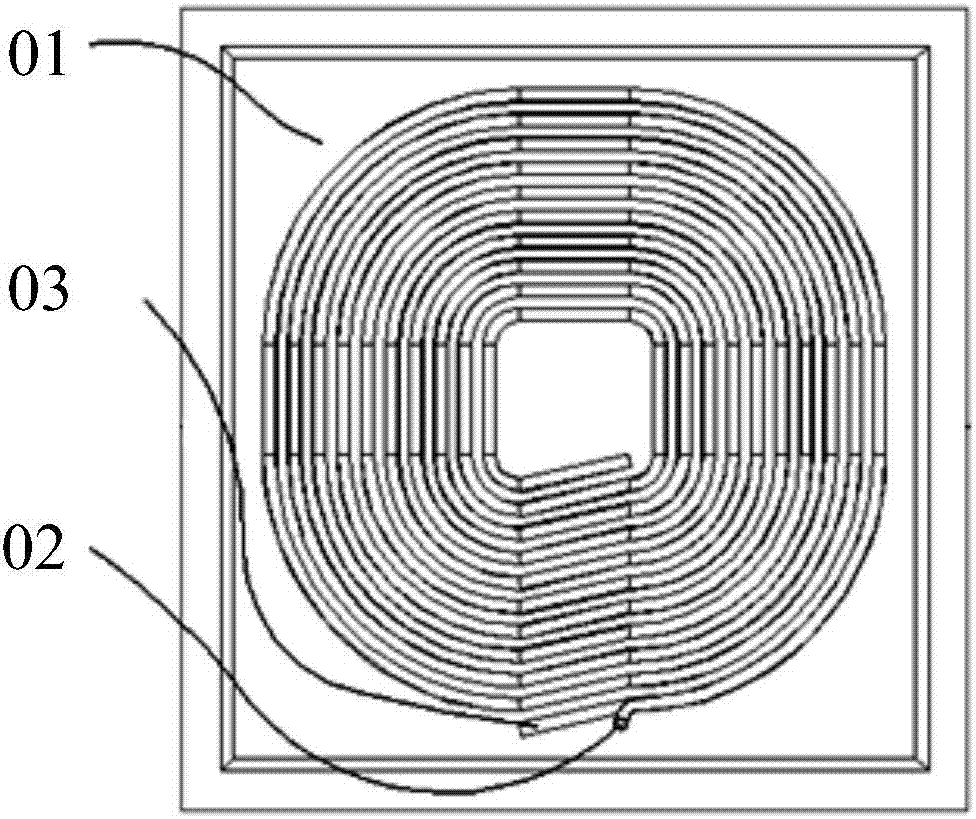

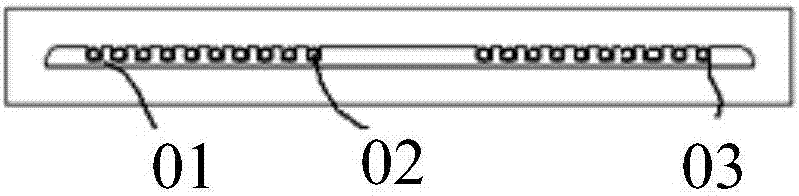

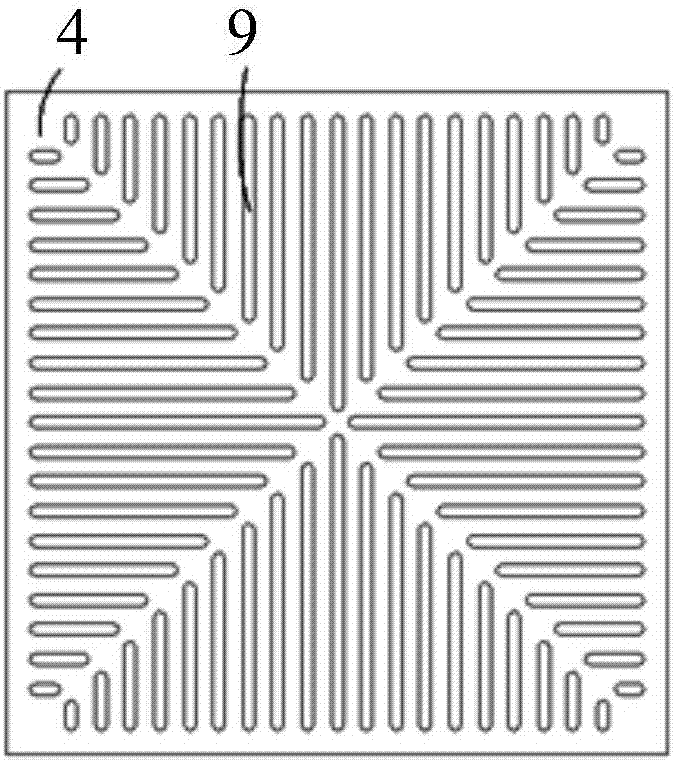

coil holder

ActiveCN106683860BFlexible installationEasy to operateBatteries circuit arrangementsTransformersGroove widthExperimental proof

The invention discloses a coil support which comprises a bottom plate and a plurality of basic blocks, wherein the bottom plate comprises a plurality of mounting positions arranged along preset direction, the basic blocks are detachably arranged on the mounting positions, and the two adjacent basic blocks are matched to form a clamping groove for clamping litz wires. According to the actual size of the litz wires, the mounting positions of the basic blocks on the bottom plate are selected and spliced into suitable coil supports, the coil support is simple to operate and good in use flexibility, cost is saved, the coil support can be disassembled and reassembled in a short time, coil supports of various groove widths can be spliced as mounting modes of the coil supports are flexible at the experimental development phase, and a lot of experimental proofing time can be saved.

Owner:ZONECHARGE (SHENZHEN) WIRELESS POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com