Test method for solidification volume change of thermosetting resin

A technology of volume change and resin curing, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of small amount of resin, large dispersion of experimental results, large error of capillary method, etc., to reduce curing shrinkage, improve overall quality, and eliminate curing residual stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

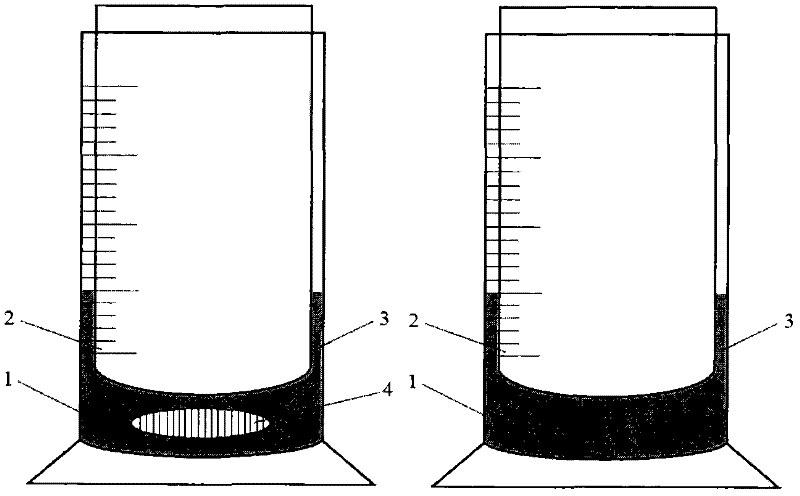

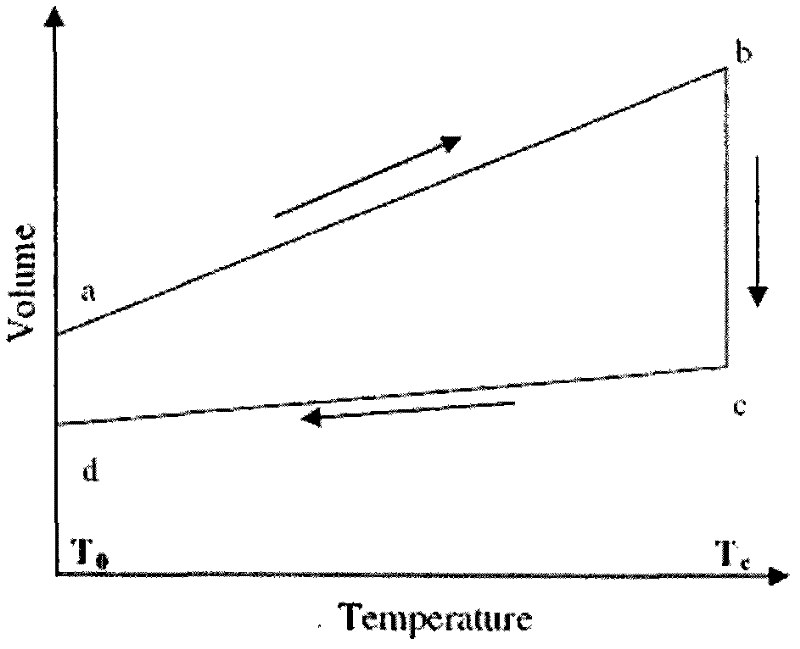

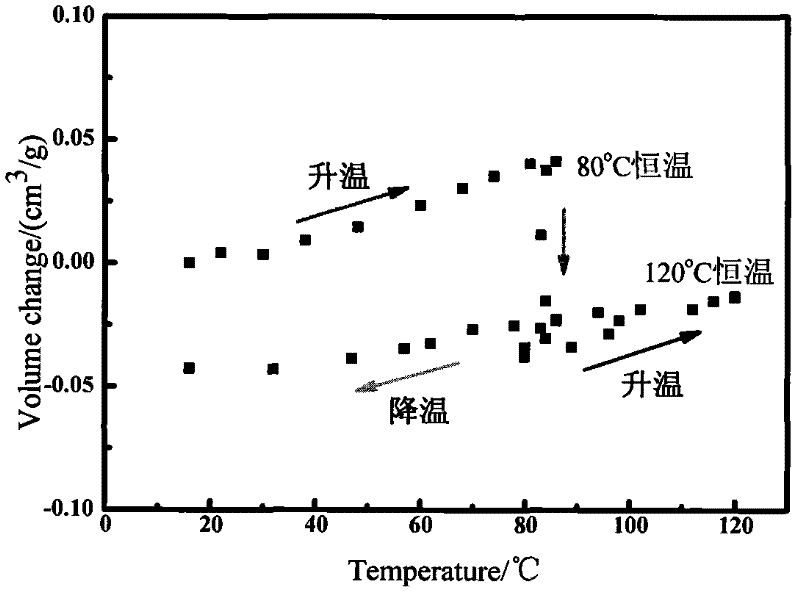

[0035] Add 30ml of volume transfer agent to two identical glass measuring cylinders 1 with precise graduations; then add 5g of medium temperature curing epoxy resin 4 to volume transfer agent 3 in one of the measuring cylinders; The cylindrical glass cylinder 2 of size and weight is put into the glass measuring cylinder without added resin to be tested and the glass measuring cylinder added with the measured resin respectively, and the distance between the outer wall of the glass cylinder and the inner wall of the glass measuring cylinder is kept at 1 mm; At the same time, put it into a vacuum oven, evacuate for 30 minutes to remove the air in the volume transfer agent and the measured resin, and read the volume transfer agent without the measured resin and with the measured resin through the scale of the glass measuring cylinder after vacuum degassing. Initial volume; heat up to 80°C at a heating rate of 2°C / min, hold for 4 hours, heat up to 120°C at a heating rate of 2°C / min,...

Embodiment 2

[0037]Add 50ml of volume transfer agent to two identical glass measuring cylinders with precise scales; then add 10g of high-temperature curing epoxy resin to the volume transfer agent in one of the measuring cylinders; Put the cylindrical glass cylinders into the glass measuring cylinders without the measured resin and the glass measuring cylinders with the measured resin respectively, keep the distance between the outer wall of the glass cylinder and the inner wall of the glass measuring cylinder at 1 mm; complete the assembly of the experimental device, put the two sets of experimental devices into the vacuum at the same time Oven, vacuumize for 30 minutes to remove the air in the volume transfer agent and the measured resin, after vacuum degassing, read the initial volume of the volume transfer agent without the measured resin and after adding the measured resin through the scale of the glass measuring cylinder respectively; Raise the temperature to 180°C at a heating rate ...

Embodiment 3

[0039] Add 40ml of volume transfer agent to two identical glass measuring cylinders with precise graduations; then add 8g of bismaleimide resin to the volume transfer agent in one of the measuring cylinders; and the weight of the cylindrical glass cylinder were placed into the glass measuring cylinder without the measured resin and the glass measuring cylinder with the measured resin, and the distance between the outer wall of the glass cylinder and the inner wall of the glass measuring cylinder was kept at 1 mm; Put it into a vacuum oven, evacuate for 30 minutes to remove the air in the volume transfer agent and the measured resin, and read the initial volume of the volume transfer agent without the measured resin and with the measured resin through the scale of the glass measuring cylinder after vacuum degassing ;Heat up to 150°C at a heating rate of 2°C / min, hold for 1 hour, then raise the temperature to 160°C at a heating rate of 2°C / min, hold for 1 hour, then raise the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com