Method for preparation of graphene/nano-silicon lithium ion battery cathode material by liquid phase physical technique

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering performance, easy stacking and re-agglomeration, application field limitations, etc., to overcome poor conductivity, simple process, overcome silicon The effect of large volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

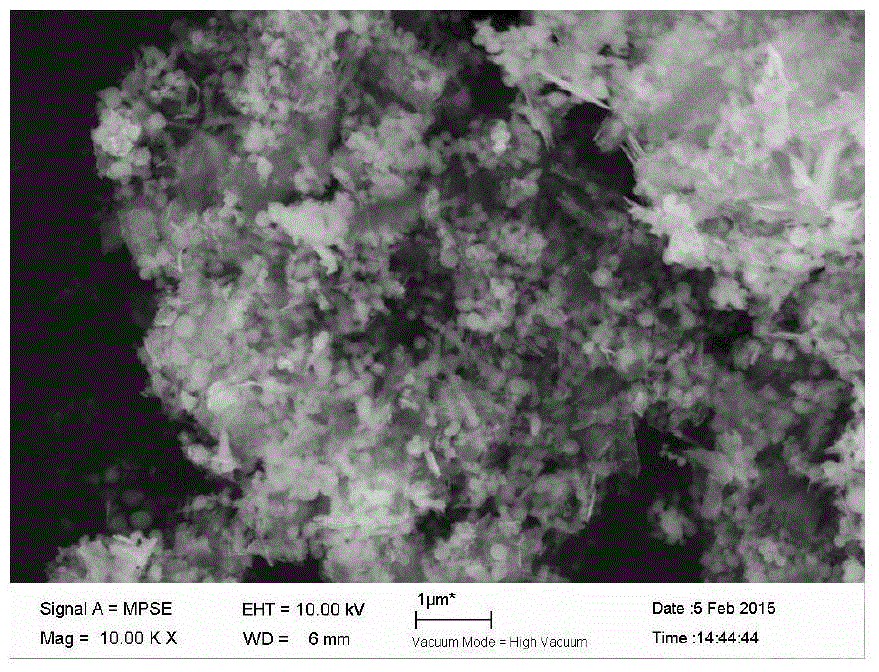

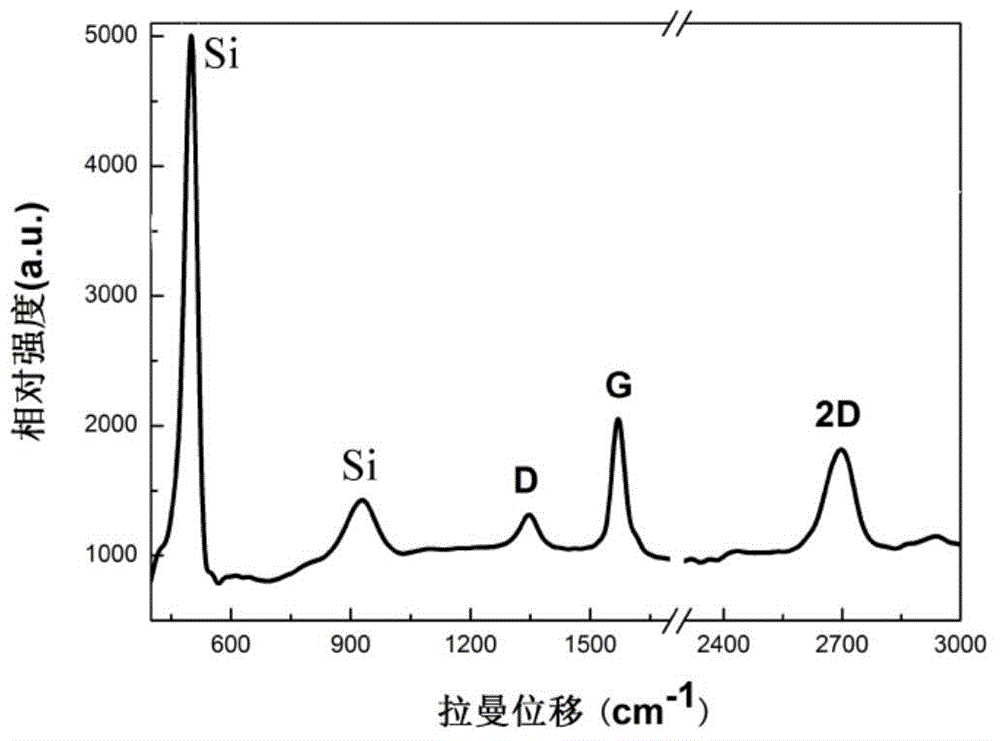

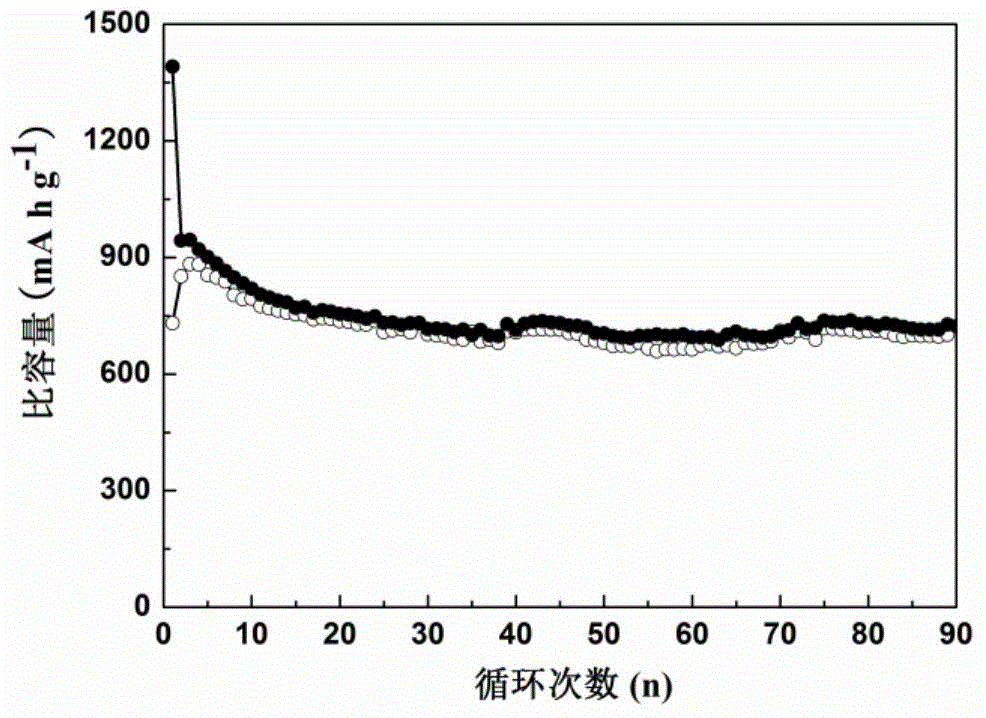

[0034] Embodiment 1 Graphene and nano-silicon composite material preparation and electrochemical performance test

[0035] Preparation of graphene and nano-silicon composites

[0036] Step 1: take by weighing 40mg surface modifier CTAB, add 40mL deionized water, vigorously stir 12h, make surface modifier fully dissolve in water, obtain the solution (CTAB mass ratio for preparing graphene and nano-silicon composite material is 0.1%);

[0037] Step 2: Weigh 200mg of graphite powder (particle size less than 325 mesh) and 15mg of nano-silicon powder and add it to the prepared solution, stir until it is uniformly dispersed, and obtain a mixed dispersion of graphite powder and nano-silicon powder (the mass ratio of graphite powder is 0.5%, Nano silicon powder mass ratio 0.0375%), and it is packed in the screw-top glass bottle with lid;

[0038] Step 3: soak the screw-top glass bottle containing the graphite dispersion in the container of the ultrasonic cavitation generator (pre-fi...

Embodiment 2

[0049] Embodiment 2 Graphene and nano-silicon composite material preparation and electrochemical performance test

[0050] Preparation of graphene and nano-silicon composites

[0051] Step 1: Weigh 40 mg of surface modifier CTAB, add 40 mL of deionized water, and stir vigorously for 12 hours to fully dissolve the surface modifier in water to obtain a solution for preparing graphene and silicon composites (CTAB mass ratio is 0.1 %);

[0052] Step 2: Add 15 mg of nano-silica powder to the prepared solution, stir and ultrasonically disperse for 4 hours until it is uniformly dispersed, put it into a centrifuge for centrifugal separation, take the upper liquid to obtain a dispersion of nano-silica powder; the centrifugal speed is 2000rpm, and the centrifugal The time is 0.5h; then 200mg of graphite powder (particle size less than 325 mesh) is added to the nano-silicon powder dispersion (graphite powder mass ratio 0.5%), stirred until it is uniformly dispersed to obtain a mixed dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com