Patents

Literature

110results about How to "Overcome conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

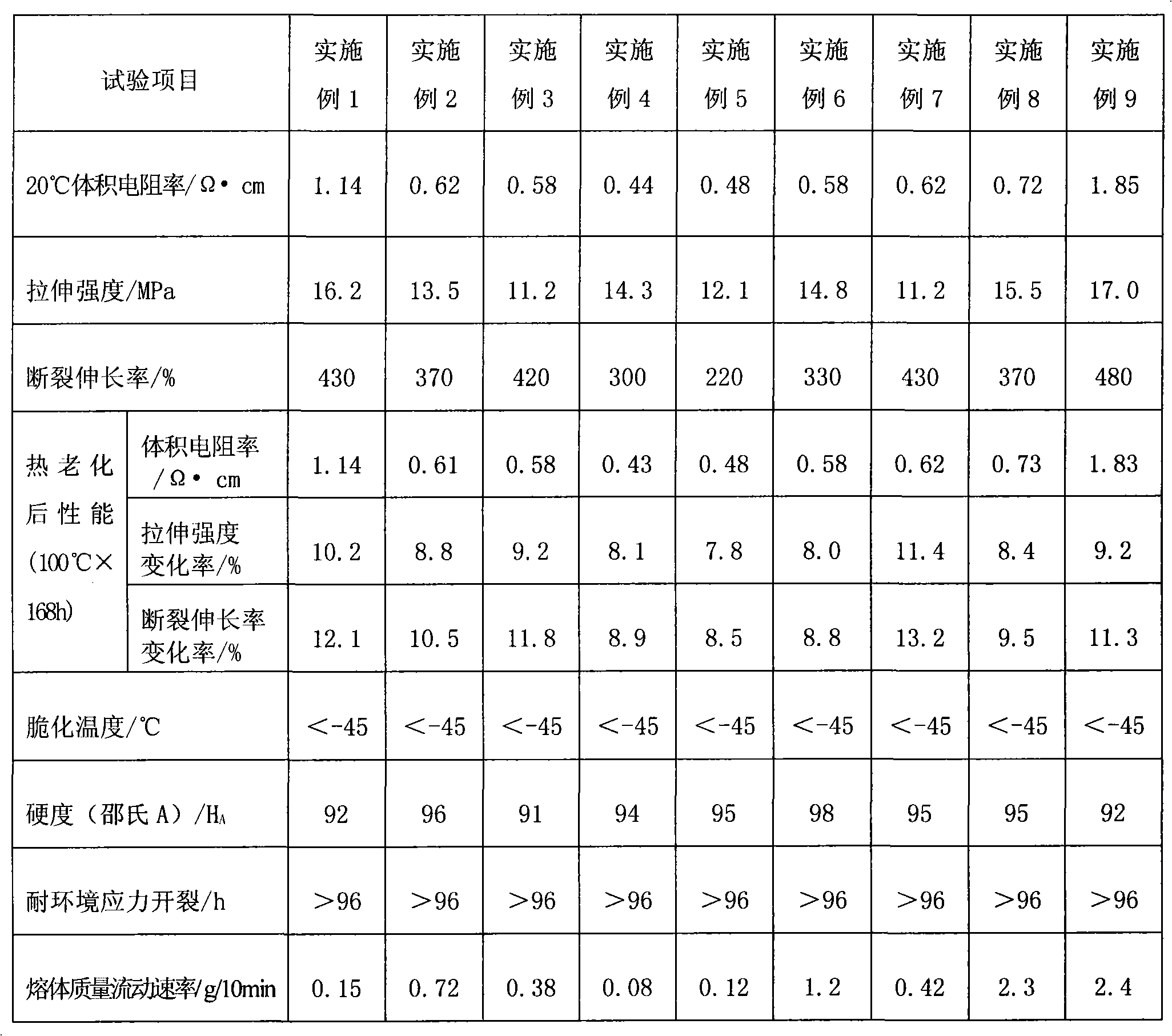

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Composite aerogel of graphene/Prussian-blue complexes, and preparation method and application thereof

InactiveCN102824883ALarge specific surface areaLow densityPhysical/chemical process catalystsOther chemical processesVolumetric Mass DensityElectrochromism

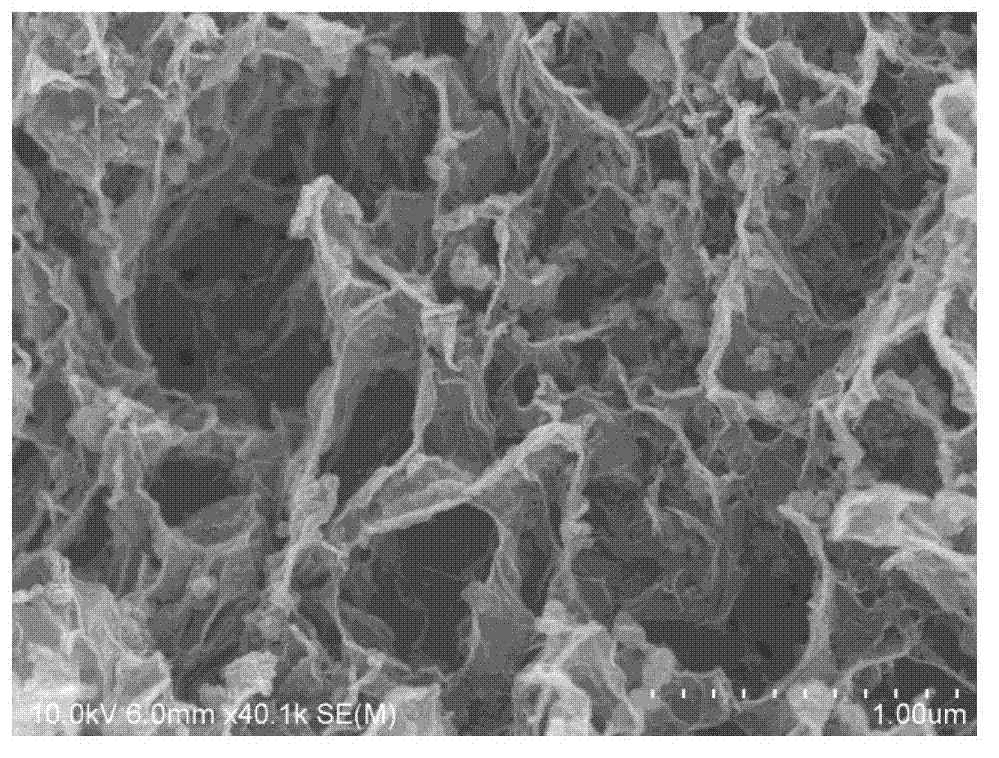

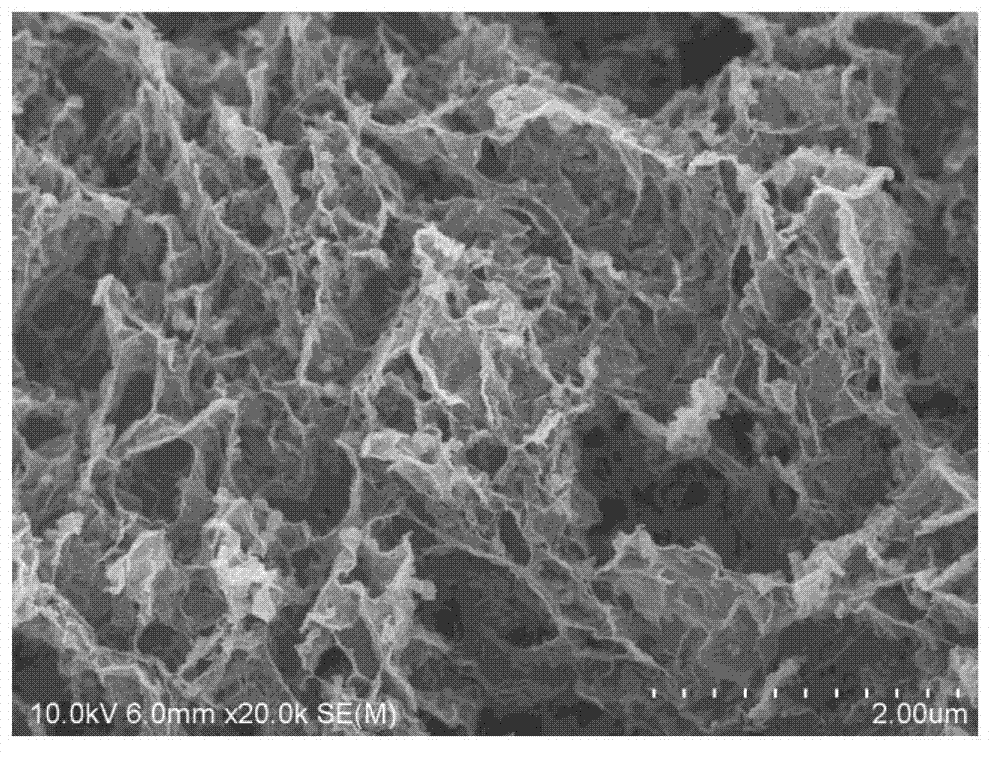

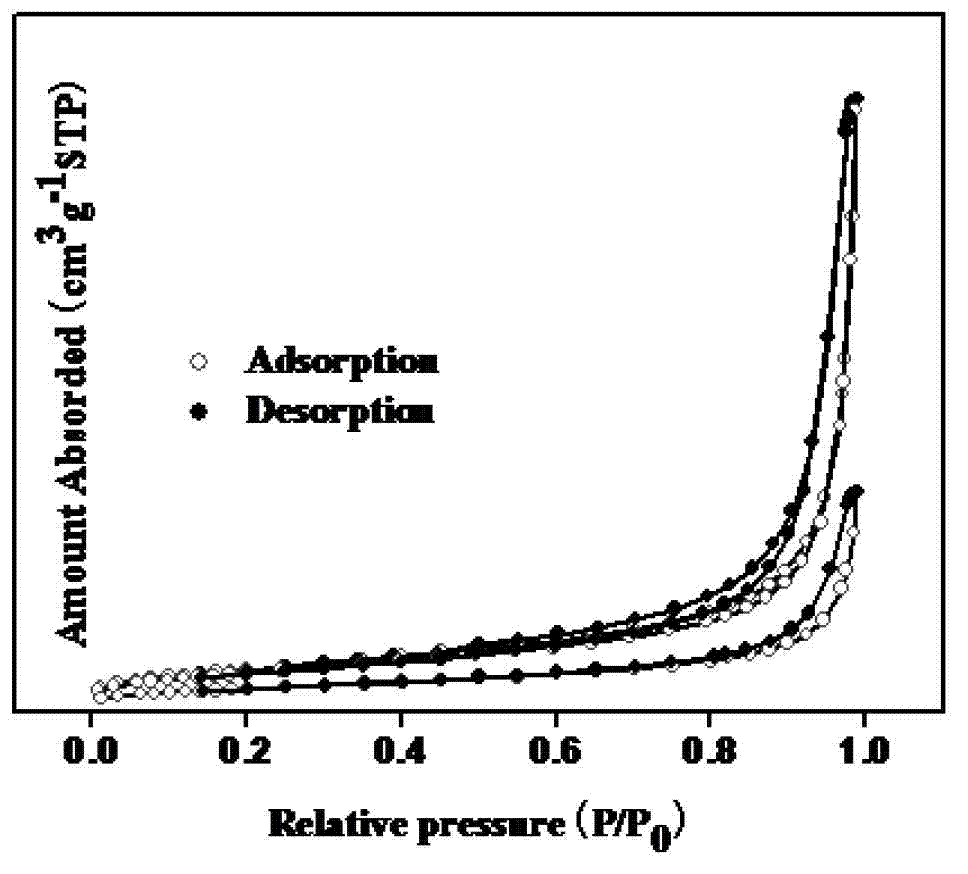

The invention relates to composite aerogel of graphene / Prussian-blue complexes, and a preparation method and application thereof. The composite aerogel is in a three-dimensional network structure formed by graphene sheets. Particles of the Prussian-blue complexes are nano-scaled and attach to the graphene sheets. The preparation method of the composite aerogel includes adding metallic cyanide in graphene oxide suspension, allowing for dispersion to obtain suspension A, dissolving metal salt in aqueous solution containing reductant to obtain solution B, ultrasonically mixing the suspension A and the solution B, allowing for standing, and drying to obtain the composite aerogel. The composite aerogel is large in specific surface area and low in density and is highly conductive. The preparation method of the composite aerogel is simple to operate, low in cost and applicable to large-scale industrial production. The composite aerogel has excellent hydrogen storage performance, hydrogen peroxide catalytic reduction and electrochromic property.

Owner:陶丽

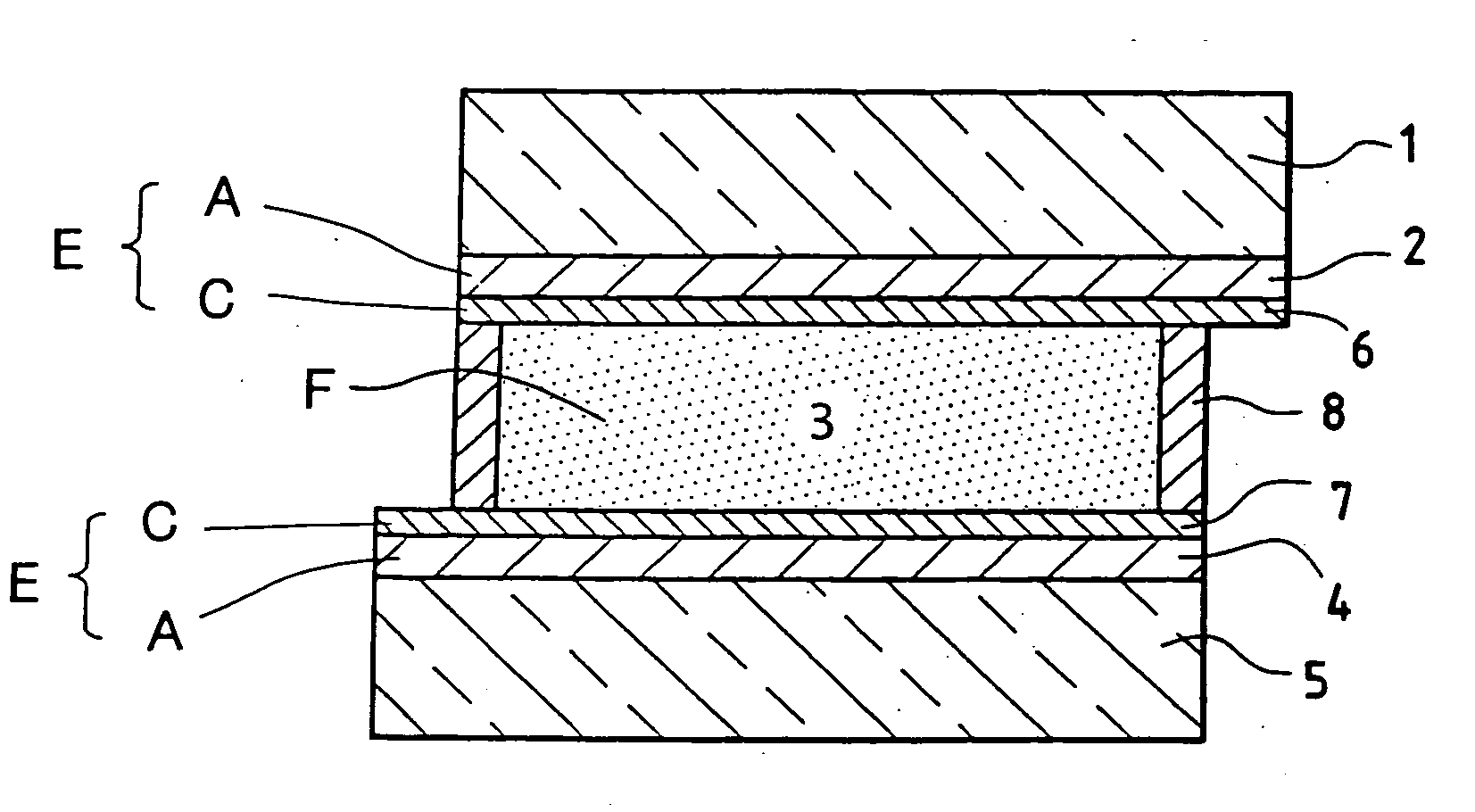

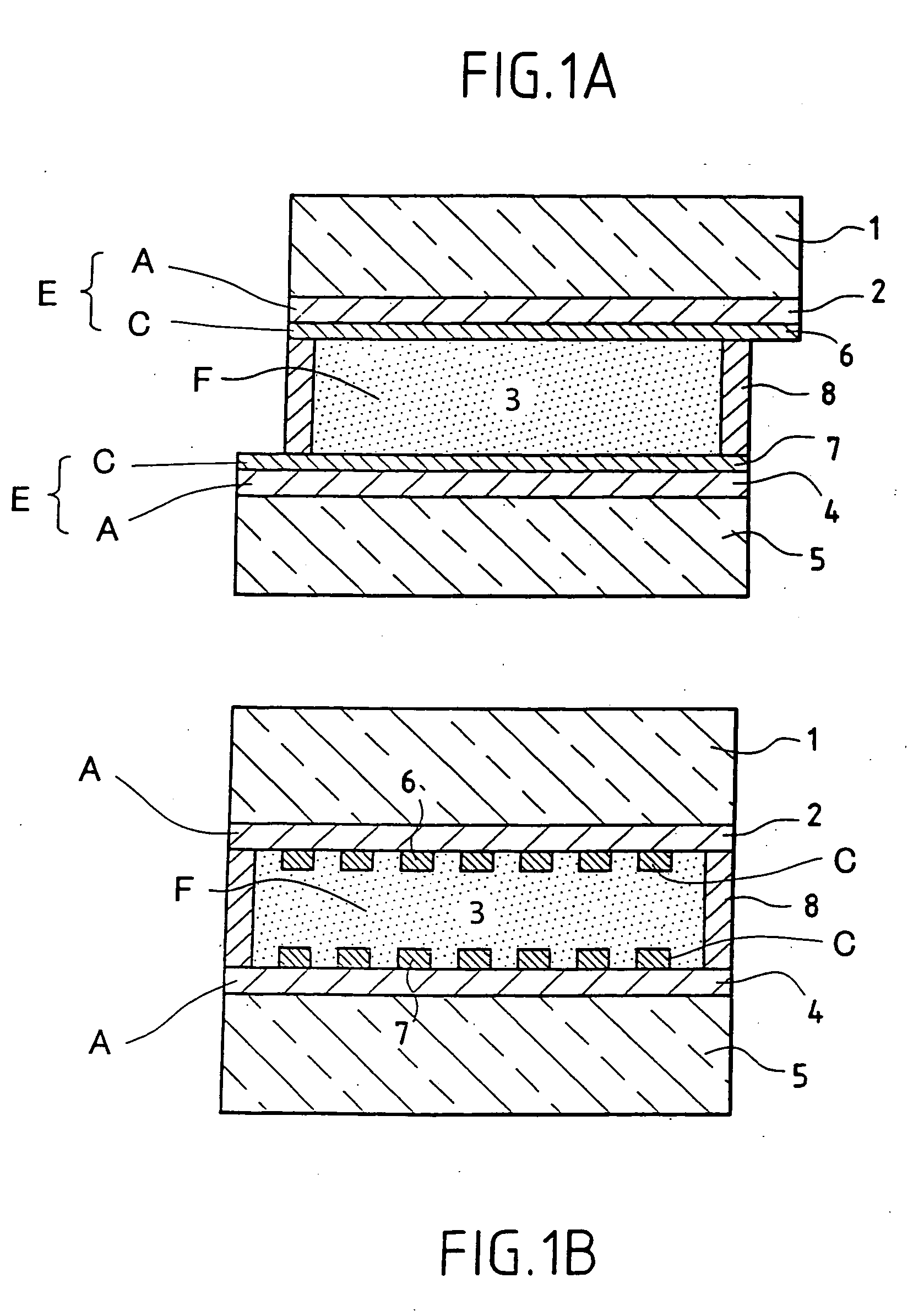

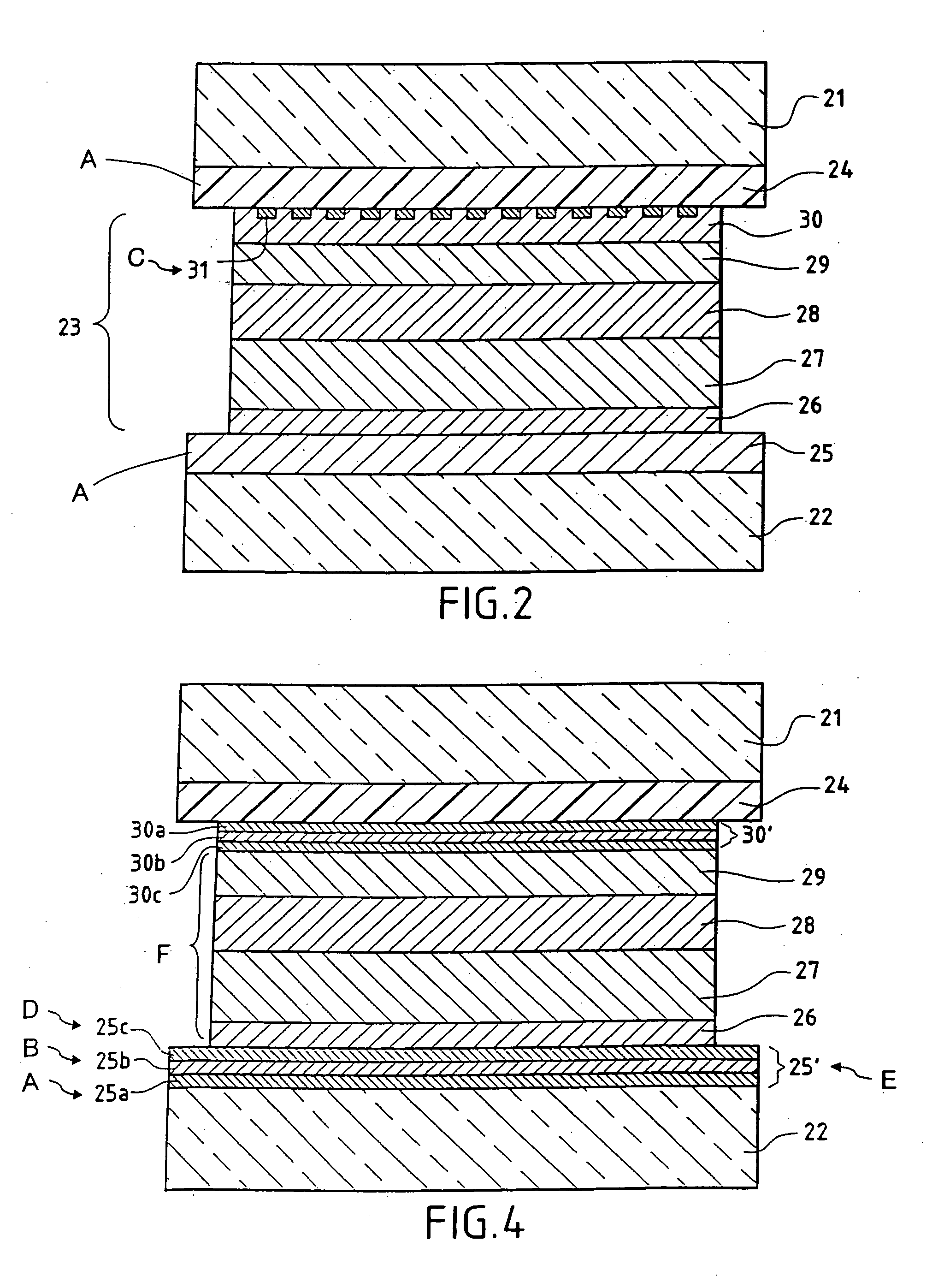

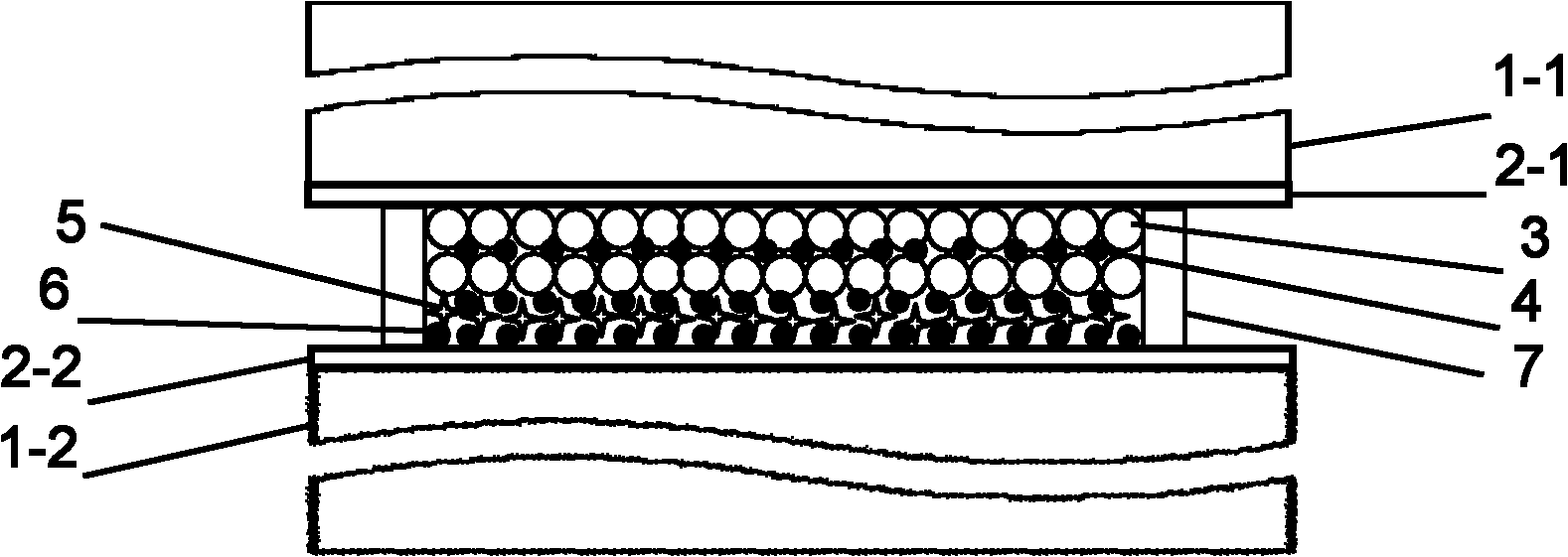

Electrochemical device, such as an electrically controlled system with variable optical and/or energy properties

InactiveUS20060033978A1Improve conductivityNot possible to discernElectrode carriers/collectorsElectric lighting sourcesElectrical resistance and conductanceGlasses type

An electrochemical device includes at least one carrier substrate, and a stack of functional layers including at least one electrically conducting layer that includes metal oxide(s), and a multicomponent electrode including at least one electrochemically active layer, at least one higher-conductivity material and at least one network of one of conducting wires and conducting strips. The higher-conductivity material has a surface resistance that is lower than a surface resistance of the electrically conducting layer. The stack of functional layers is arranged between two substrates, and each may be rigid, of glass type or rigid polymer or semi-rigid or flexible of PET type.

Owner:SAINT-GOBAIN GLASS FRANCE

Copper alloy materials with high-strength and conducting performances and production thereof

InactiveCN1818109AHigh temperature strengthImprove plasticityHigh intensityUltimate tensile strength

The invention opened a high strength and conductance aldary material which includes: Cr 0.05%-0.10wt%; Zr 0.05%-0.50%; Mg 0.05-0.20wt%; (Ce+Y)<=0.20%; The residue is Cu. The process is : water quench for 1h in 900-960DEG C->30%-45% of cold-drawing deformation->aging treatment for 0.5-4h in 440-520 ->formed by cold-drawing. The strength can reach above 550-600MPa and the specific conductivity can keep above 80% IACS, and the life is improved to 3-5 times, the sintering can reach 550DEG C; the slip is less than 10% in the 300DEG C, the elongation percentage is above 5%, also the alloy has the performance of resistance to elevated temperatures and stand wear and tear.

Owner:HENAN UNIV OF SCI & TECH

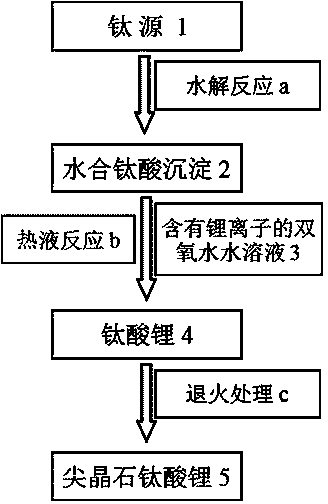

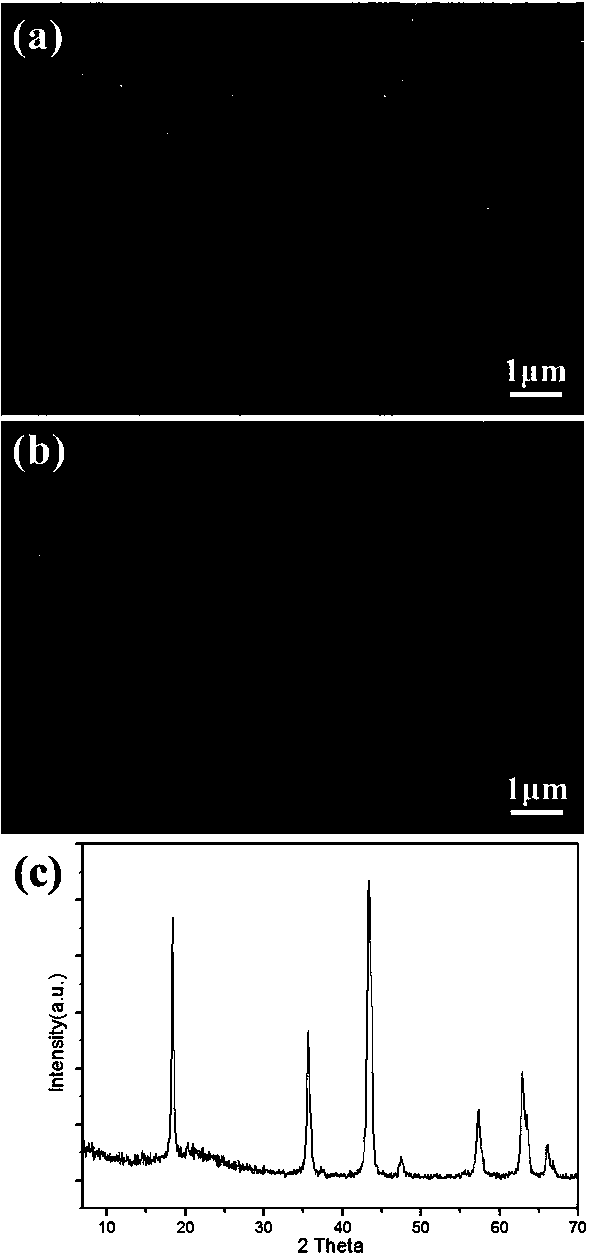

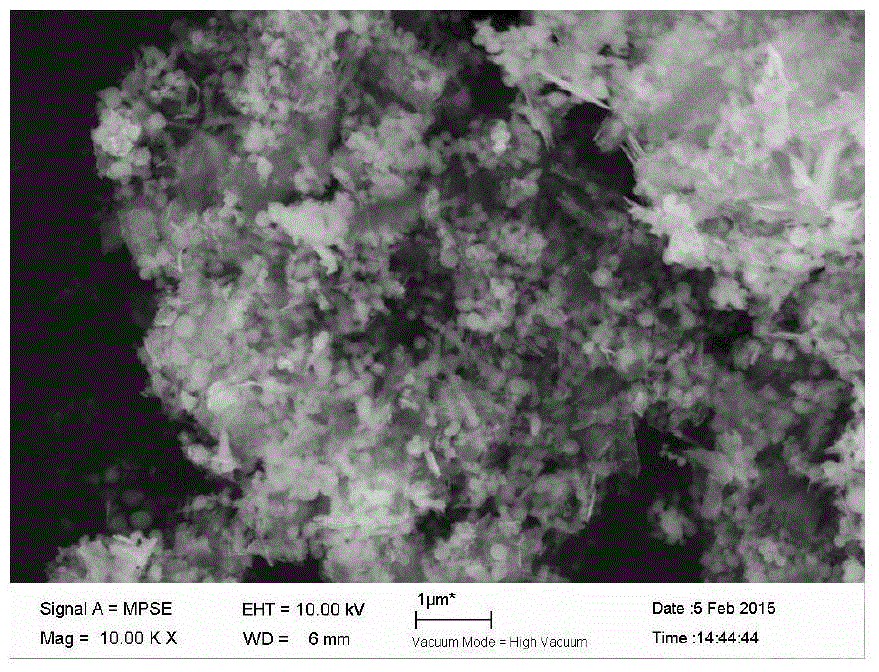

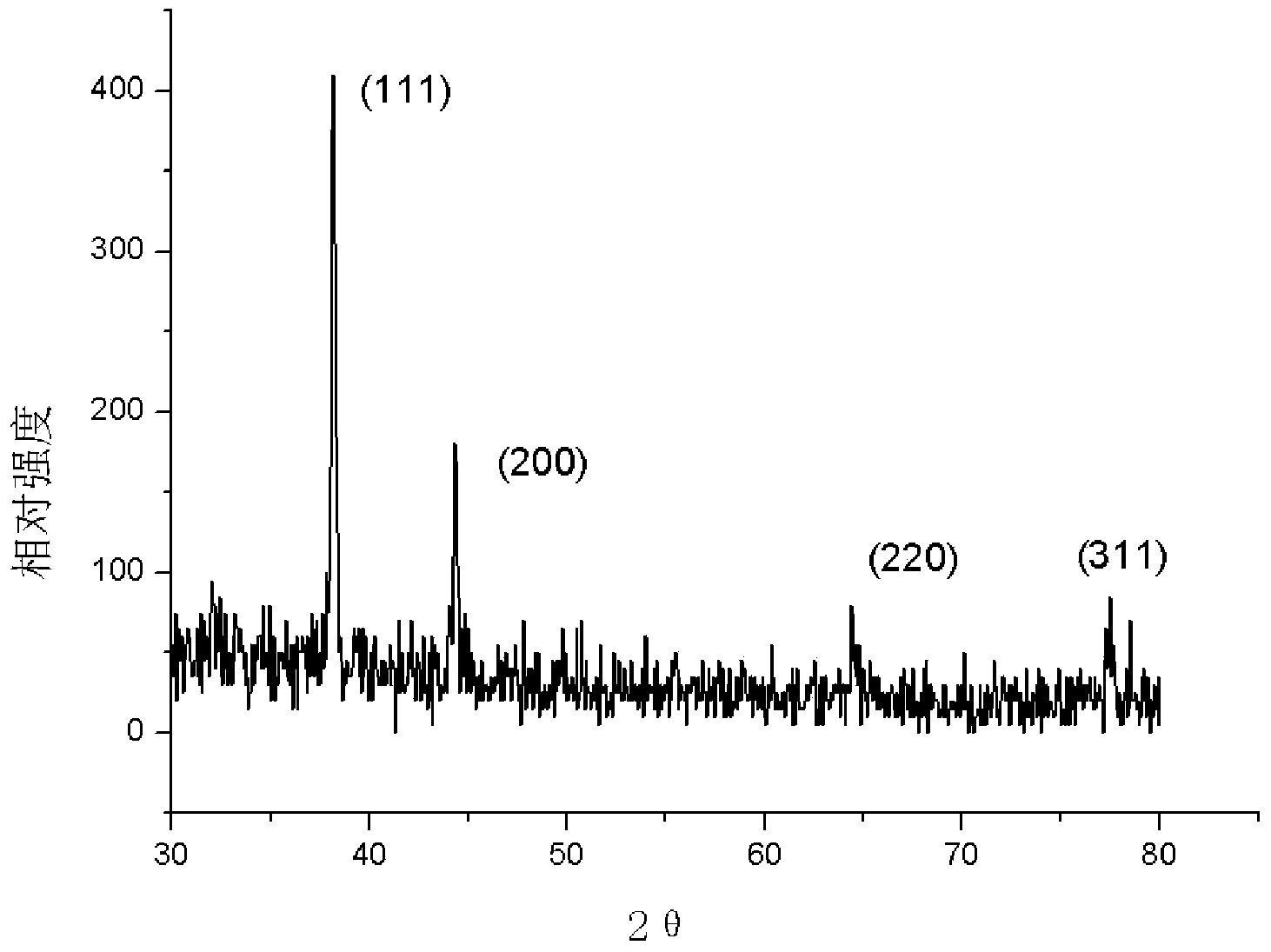

Method for preparing spinel lithium titanate

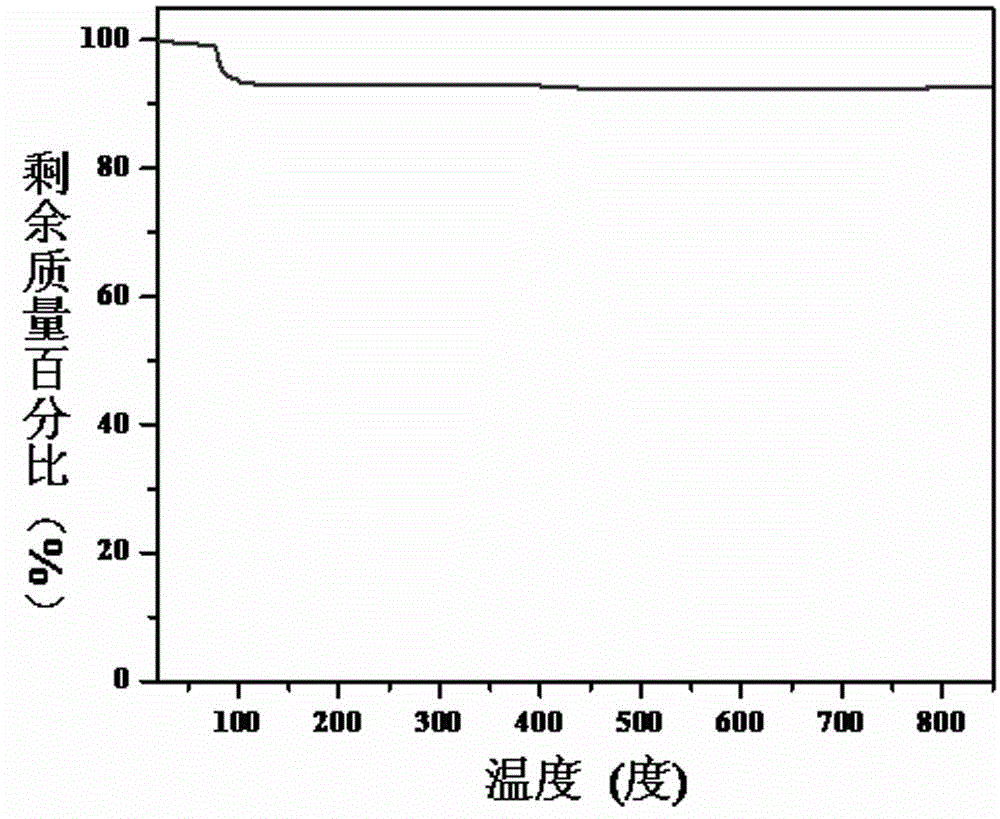

InactiveCN104201364AOvercome conductivityLow priceMaterial nanotechnologyAlkali titanatesLithiumNanowire

The invention discloses a method for preparing spinel lithium titanate. The method is characterized by comprising the steps of S1, performing hydrolysis reaction on a titanium source to obtain hydrated titanium acid sediments; S2, dispersing the hydrated titanium acid sediments into lithium ion-containing hydrogen peroxide aqueous solution to obtain a mixture; S3, performing hydrothermal reaction on the mixture to obtain nanowire type lithium titanate and / or lithium titanate with a nano differential level structure; S4, annealing the nanowire type lithium titanate and / or the lithium titanate with the nano differential level structure to obtain nanowire type spinel lithium titanate and / or the spinel lithium titanate with the nano differential level structure. According to the method, both spinel lithium titanate nanowires and the spinel lithium titanate with the nano differential level structure can be prepared.

Owner:李建明

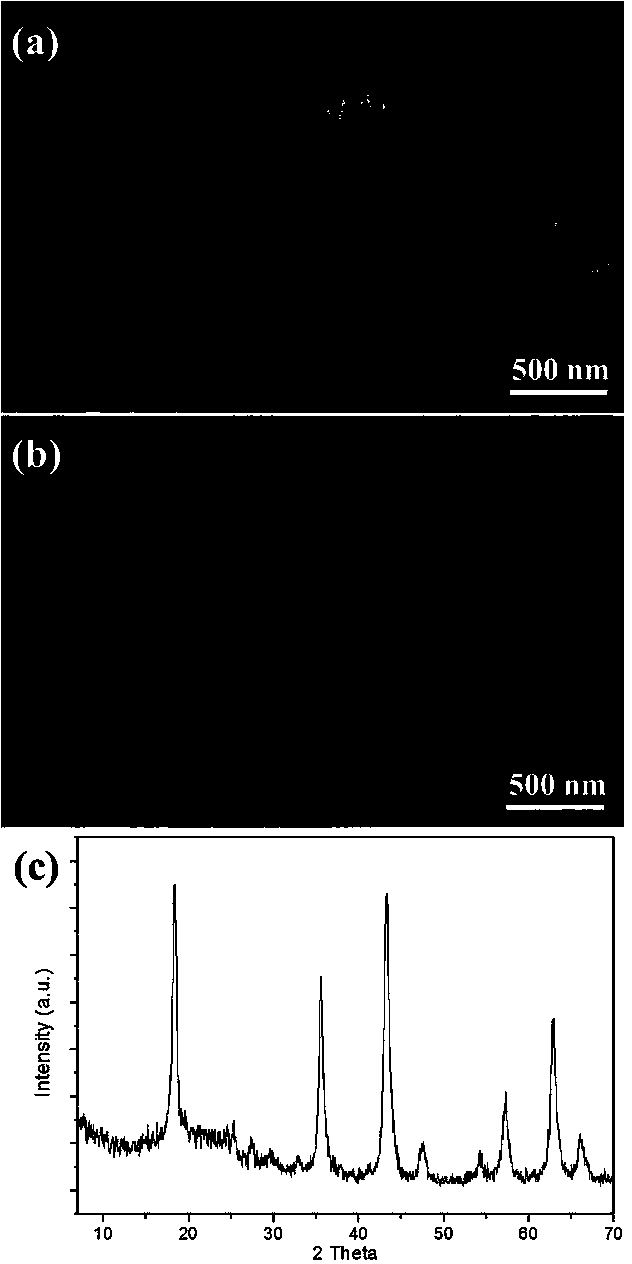

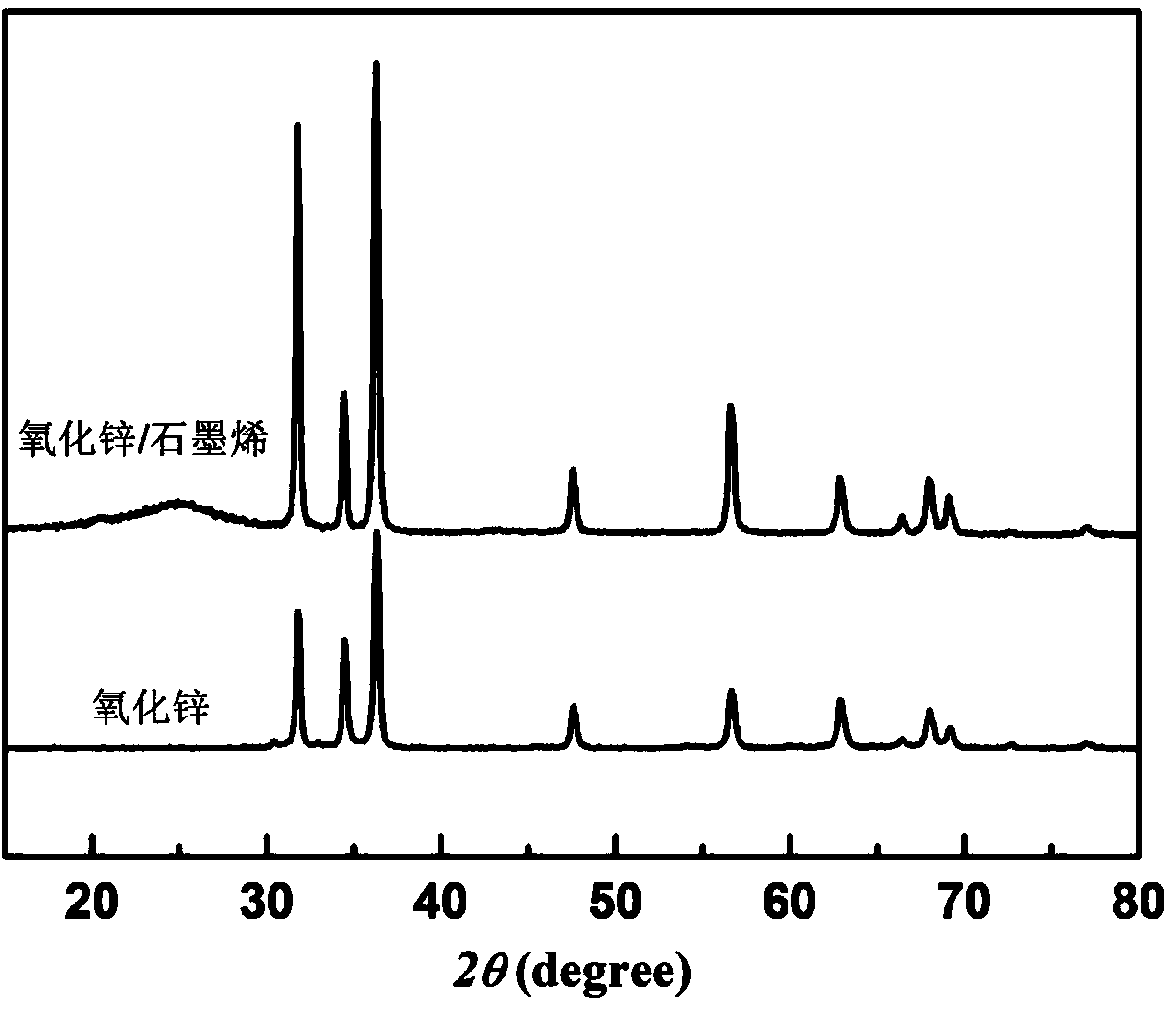

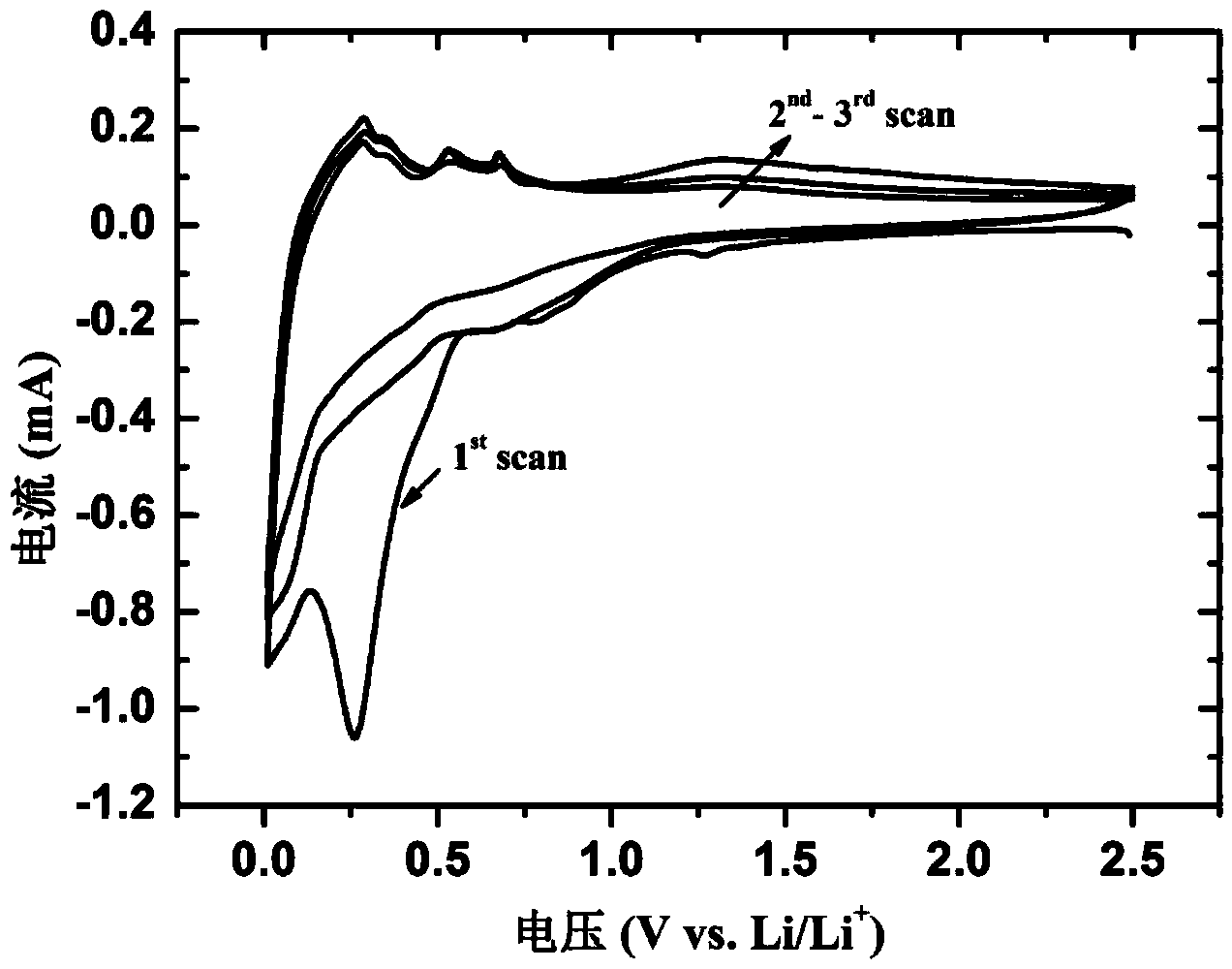

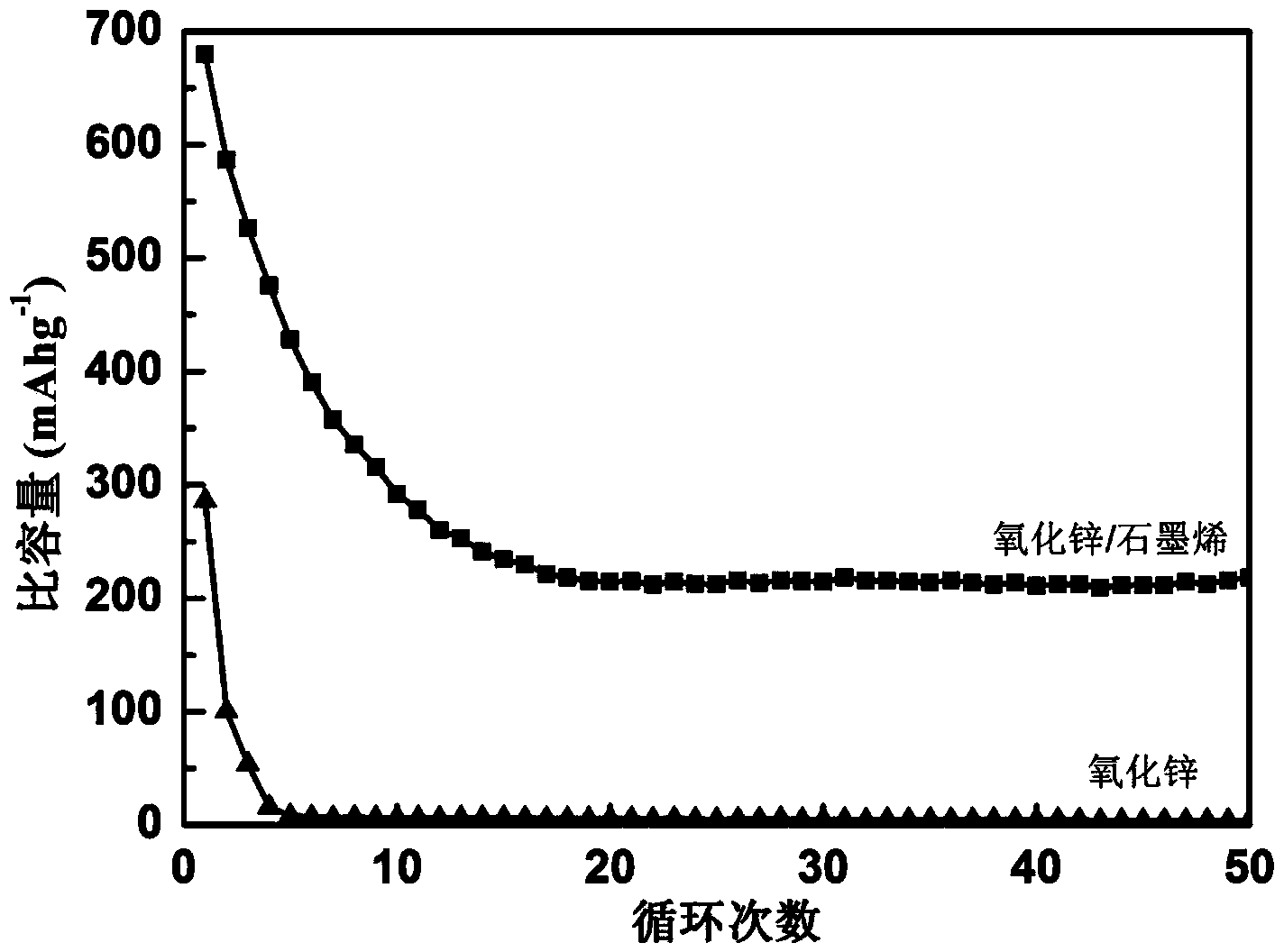

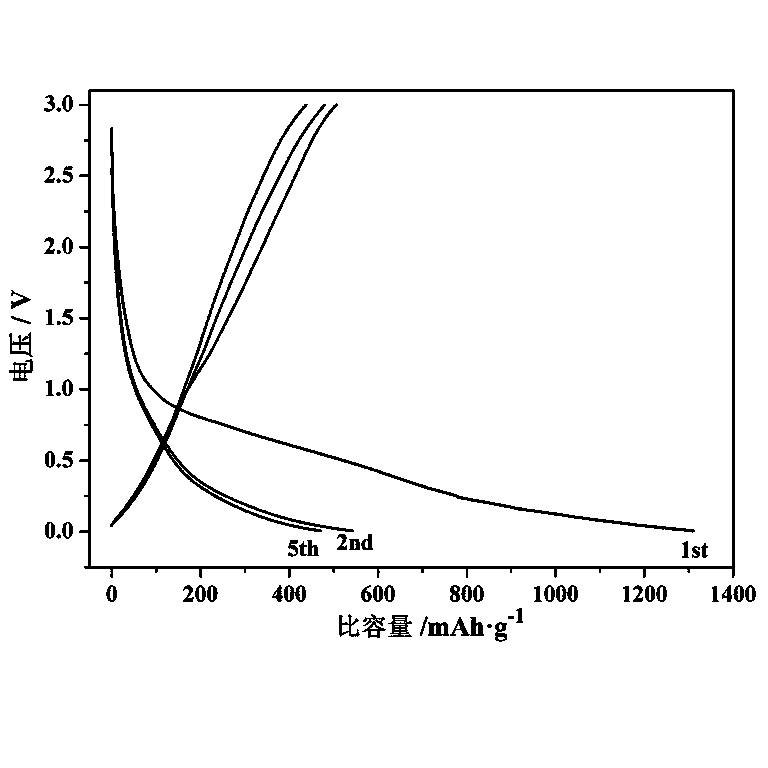

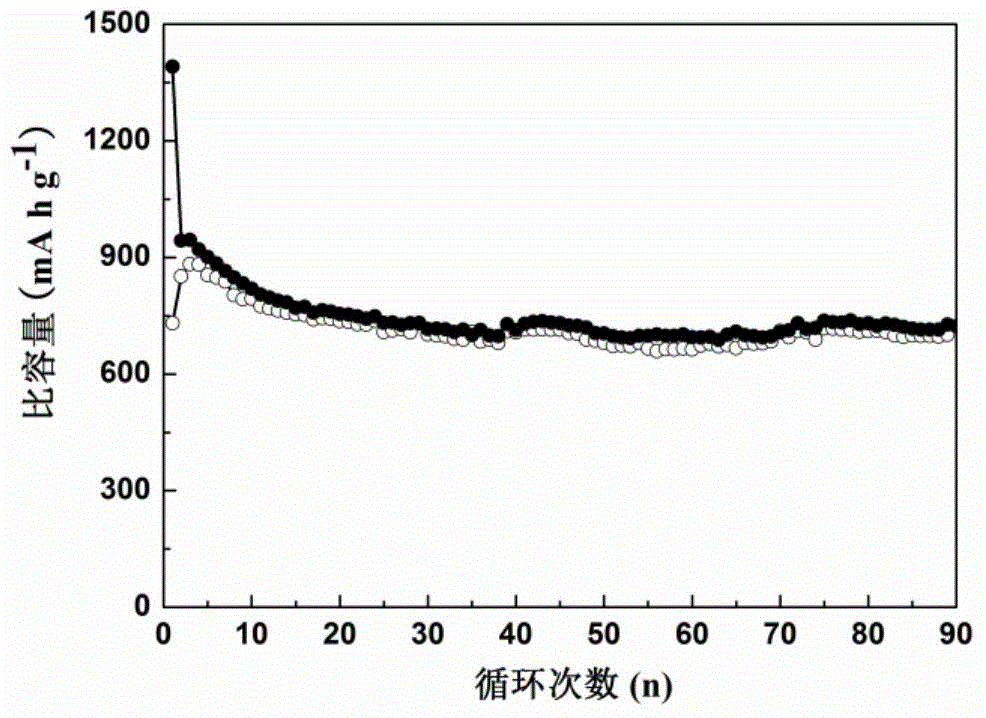

Preparation method of zinc oxide /graphene composite material for lithium ion battery

InactiveCN104022268ANo pollution in the processOvercome conductivityCell electrodesSecondary cellsOxide compositeSolvent

A preparation method of a zinc oxide / graphene composite material for a lithium ion battery is as follows: first, taking graphite oxide to add into a solvent for ultrasonic treatment to obtain a graphene oxide dispersion liquid; then taking a zinc salt to add into the graphene oxide dispersion liquid, performing pH adjustment to make the mixed solution alkaline; then transferring the mixed solution to a hydrothermal reactor for reaction, cooling to room temperature when the reaction is finished, respectively washing for 3 times with water and ethanol, performing vacuum drying treatment to obtain a partly reduced graphene-zinc oxide composite material; finally, calcining the partly reduced graphene-zinc oxide composite material under inert atmosphere, cooling to room temperature when the calcining is finished to obtain the zinc oxide / graphene composite material. The zinc oxide / graphene composite material prepared by the method can be used as a negative electrode material for lithium ion batteries, can overcome the problems of poor conductivity and serious volume expansion effect of zinc oxide, has the characteristics of strong cyclic stability and strong conductivity; and the method has characteristics of simple operation, high repeatability and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

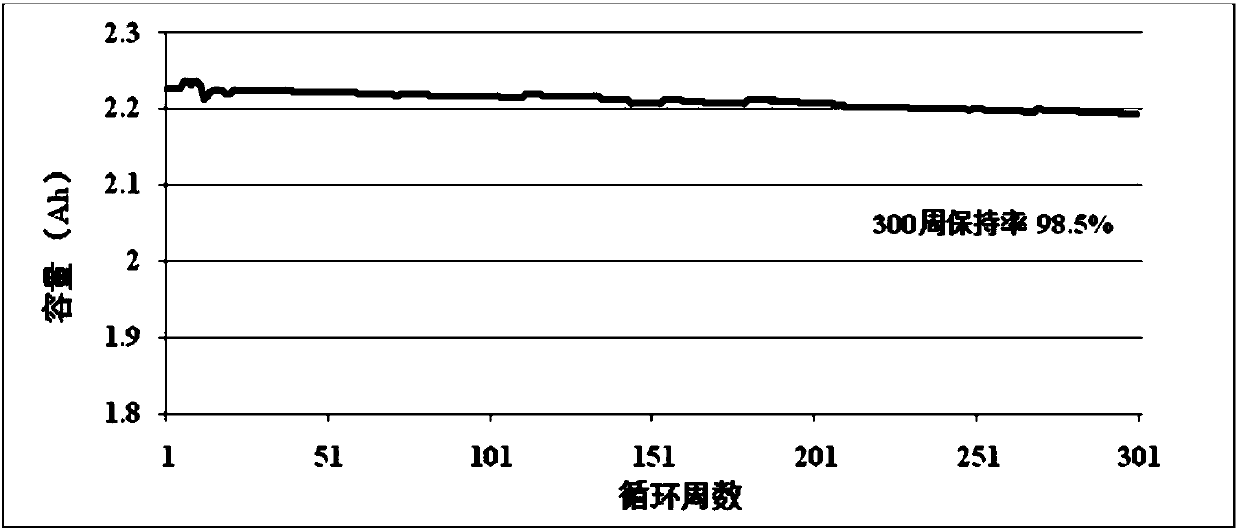

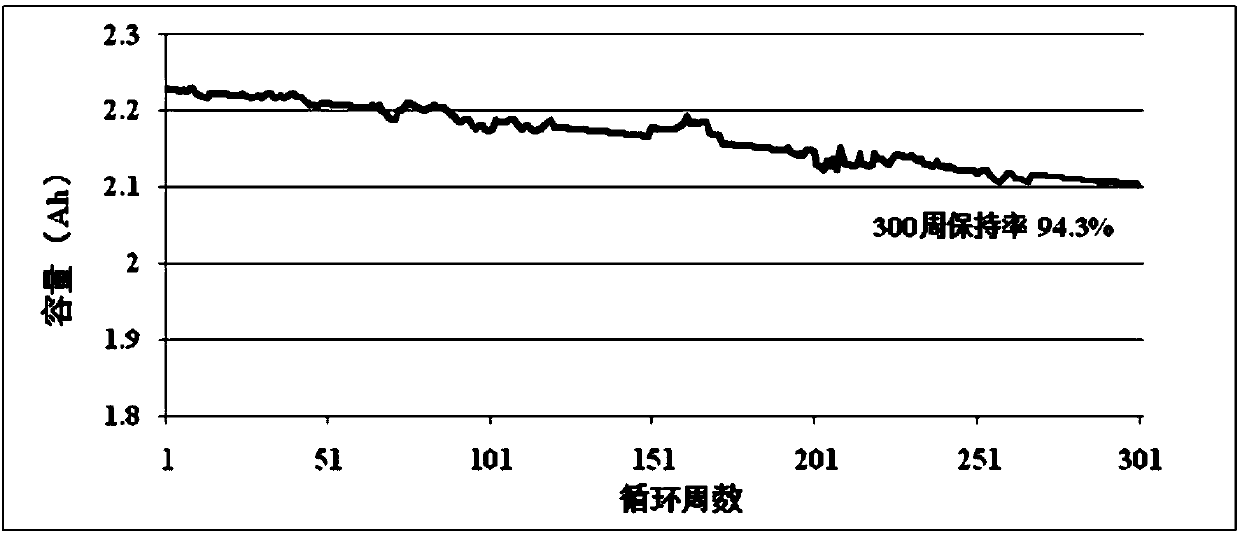

Positive plate, preparation method and lithium-ion battery comprising positive plate

InactiveCN107706351AGood lithium supplement functionWith lithium supplement functionCell electrodesSecondary cellsEngineeringLithium-ion battery

The invention discloses a positive plate, a preparation method and a lithium-ion battery comprising the positive plate. The positive plate comprises a current collector, an active layer formed on thecurrent collector and a conducting layer, wherein the conducting layer is formed on the active layer and the surface of the conducting layer is coated with an inert material which 0.1-30nm in thickness, wherein the active layer contains a positive active material and a lithium supplement component. The positive plate is simple in structure, stable, good in security and good in compatibility with an existing manufacturing process and has a lithium supplement function; the problems of poor solubleness and conductivity of the lithium supplement component are solved; the energy density and the rate capability of the lithium-ion battery are improved; and the cycle life of the lithium-ion battery is prolonged.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Rare earth copper alloy and its preparation method

The invention discloses a rare earth copper alloy and its preparation method, which comprises charging electrolytic copper by weight percentage, smelting 20-30 minutes, then charging 0.03-0.1% of zirconium, 0.02-0.16% of silver, 0.02-0.155 of rare-earth elements, smelting 1-3 minutes and casting, subjecting the cast alloy to heat preservation 1-4 hours at 800-850 deg C, forming bar stock through processing, the forging deformation amount is 50-80%, loading the bar stock into heat treatment furnace, thermally insulating 30-60 minutes at 800-950 deg C, then carrying out quenching treatment, subjecting the quenched alloy to 30-80% deformation treatment, cold drawing the alloy, thermally insulating 1-8 hours at 440-520 deg C, carrying out 50-70% deformation treatment to the alloy undergone ageing treatment. The invention can achieve high-strength and high conductivity.

Owner:HENAN UNIV OF SCI & TECH

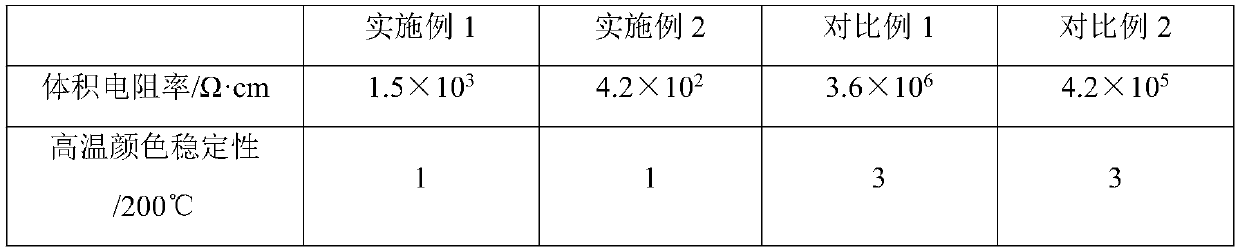

High-conductivity polyetheretherketone composite material and preparation method thereof

The invention provides a high-conductivity polyetheretherketone composite material and a preparation method thereof, and belongs to the field of conductive polymer materials. The high-conductivity polyetheretherketone composite material comprises, by weight, the following raw materials: 80-100 parts of PEEK, 10-20 parts of a reinforced fiber, 10-15 parts of grafted modified carbon nanotube, 3-8 parts of a wear-resistant agent, 2-5 parts of a coupling agent, 0.5-1 part of an antioxidant and 1-2 parts of a lubricant. According to the material, PEEK is used as a base material, and the reinforcingfiber, the carbon nanotube, the wear-resistant agent and the like are added, so that the prepared composite material not only has excellent mechanical properties, high temperature resistance and wearresistance, but also is chemically grafted and modified from the carbon nanotube, so that the composite material has high electrical conductivity and high-temperature appearance color stability.

Owner:苏州聚泰新材料有限公司

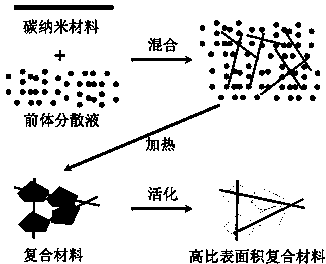

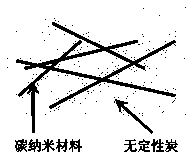

Carbon composite material, and preparation method and application thereof

InactiveCN104176721ATo achieve an organic combinationRaw materials are easy to getMaterial nanotechnologyOther chemical processesFiberCarbon composites

The invention discloses a carbon composite material. The carbon composite material comprises 0.1-35wt% of a carbon nanomaterial and 99.9-65wt% of amorphous carbon with a high surface area; the carbon nanometer is one or a mixture of more of carbon nanotubes, carbon fibers, graphene oxide and graphene; and the specific surface area, the pore volume and the conductivity of the composite material are not lower than 800m<2> / g, not lower than 0.3cm<3> and not lower than 4S / cm respectively, and the aperture of the composite material is 0.5-10nm. The carbon composite material has the respective characteristics of the carbon nanomaterial and the amorphous carbon, realizes the organic combination of the carbon nanomaterial and the amorphous carbon in functions, has high surface area and high conductivity, and can provide superior capacity and rate performance as an excellent electrode and conductive material of super capacitors, lithium ion capacitors, fuel batteries and lead carbon battery electrodes. The carbon composite material can remove impurities in water as an electrode material in water treatment devices.

Owner:JIANGSU JF ADVANCED TECH

Graphene dye sensitized solar cell and production method thereof

InactiveCN102148099AMaterials are readily availableLow costLight-sensitive devicesFinal product manufactureSputteringSolar cell

The invention discloses a graphene dye sensitized solar cell and a production method thereof. The solar cell comprises a light anode comprising transparent upper base material and graphene conducting layer, a porous nano semiconductor film and a dye sensitizer, oxidation reduction electrolyte solution, a counter electrode comprising a lower base and graphene conducting layer and a composite catalytic layer as well as a film shell. The production method comprises the steps of preparing the light anode, preparing the counter electrode, encapsulating and injecting the electrolyte solution. In the invention, graphene with an available raw material, low cost, good conductive performance, extremely high flexibility and good ductibility is adopted as the conducting layer, the flexible transparent material is adopted as a substrate, and platinum metal particles are embedded on the graphene conducting layer of the counter electrode by adopting adsorption instead of magnetron sputtering to form the composite catalytic layer. Thus, the invention has the characteristics that the raw material is available, the production cost is low, the production process is simple and reliable, the flexible solar cell can be produced and applied to the flexible field, and the application range is effectively expanded.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Dispersed copper composite material and preparation method thereof

The invention discloses a dispersed copper composite material and a preparation method thereof, belonging to the technical field of dispersed copper processing. The dispersed copper composite material is composed of the following components in percentage by mass: 0.24-3.74% of Al2O3, 0.03-1.27% of Y2O3 and the balance of Cu and unavoidable impurities. The dispersed copper composite material is prepared from Cu2O powder and Cu-Al-Y alloy powder through the steps of mixing, pressing, sintering and internal oxidation, extruding and forging; the composite material has the high strength of 500Pa or above and the high conductivity of 80% IACS or above and overcomes the defect that the high strength and high conductivity of other composite materials cannot simultaneously exist; and meanwhile the composite material is favorable in softening resistance, high in high-temperature strength and good in plasticity, and the softening temperature is 800 DEG C or higher.

Owner:HENAN UNIV OF SCI & TECH

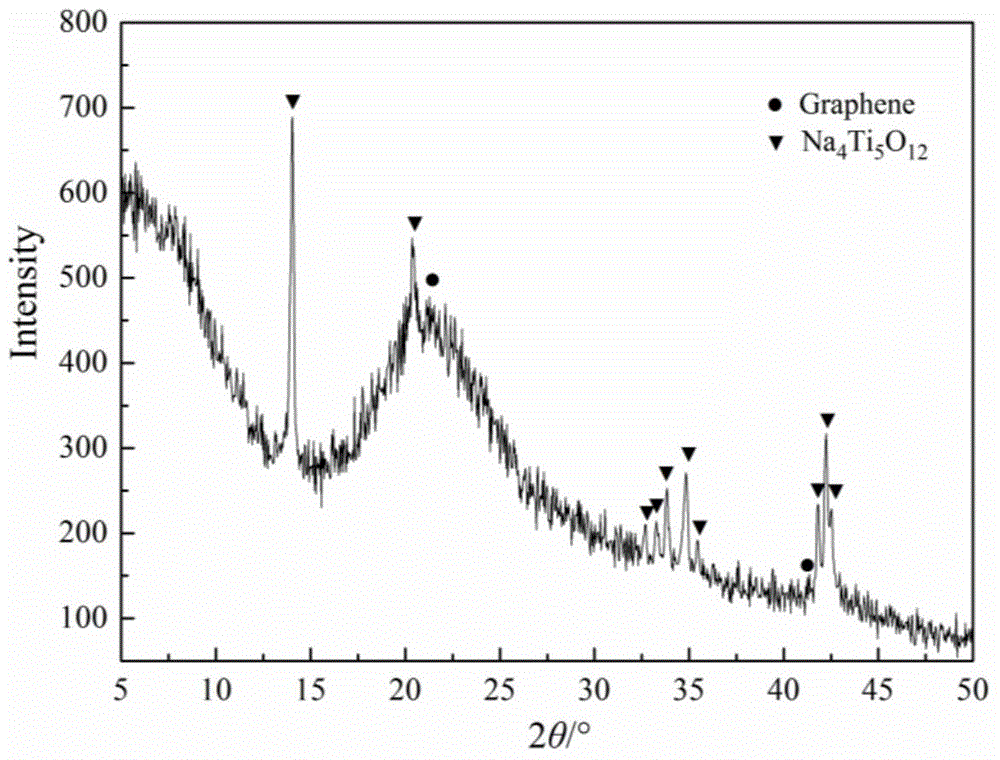

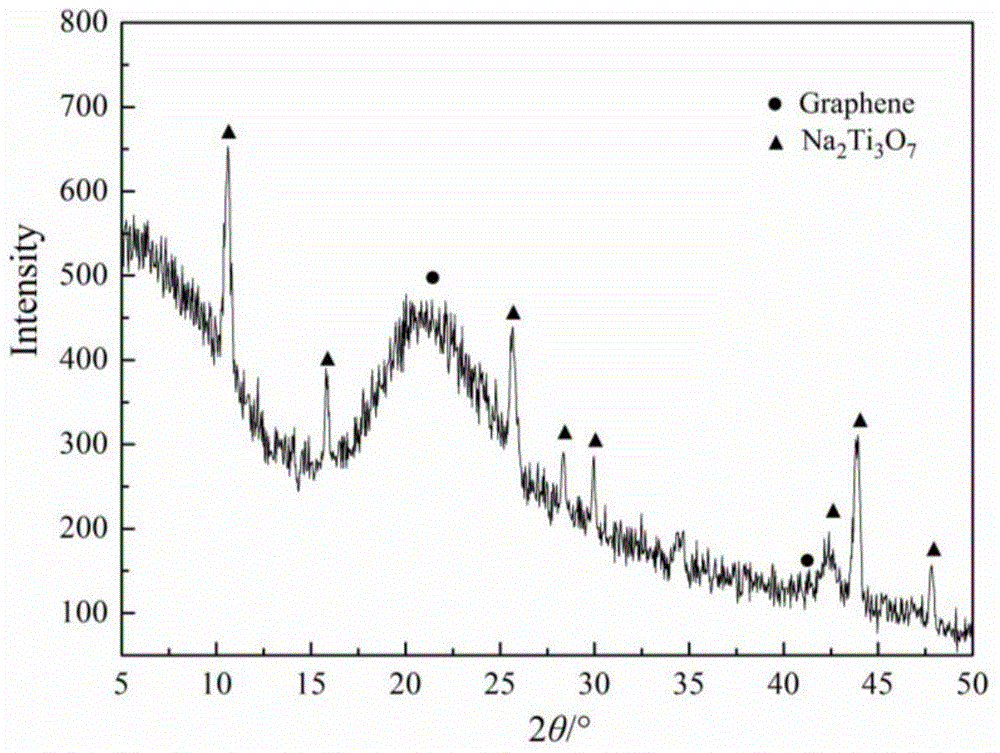

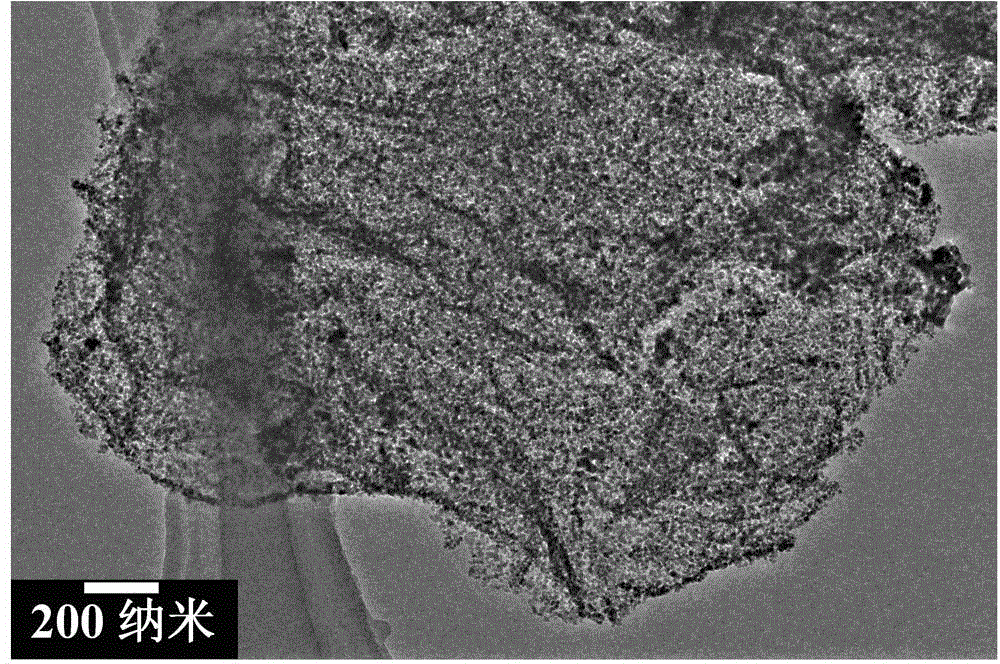

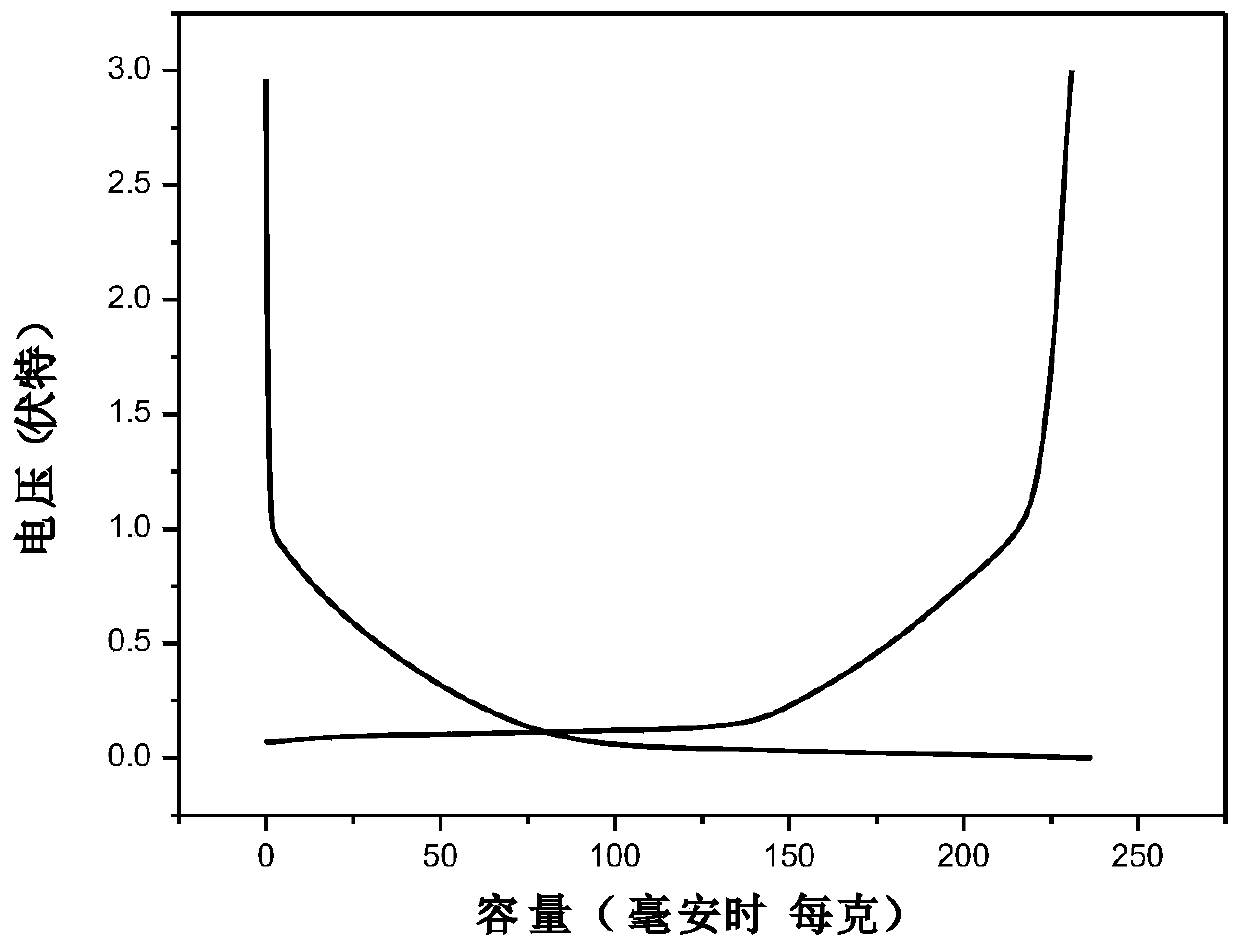

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

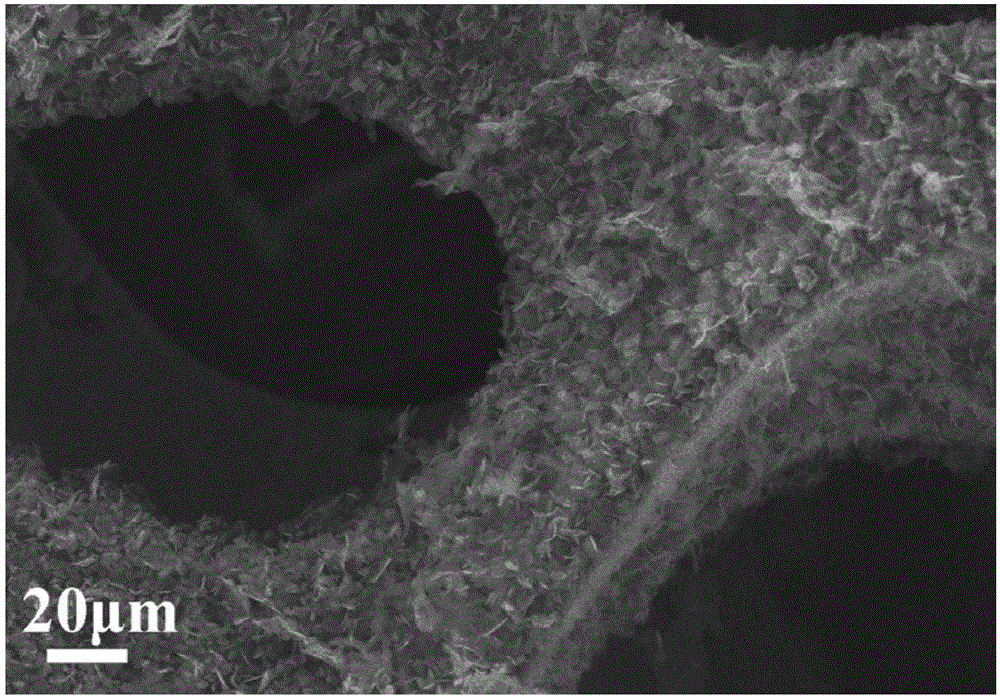

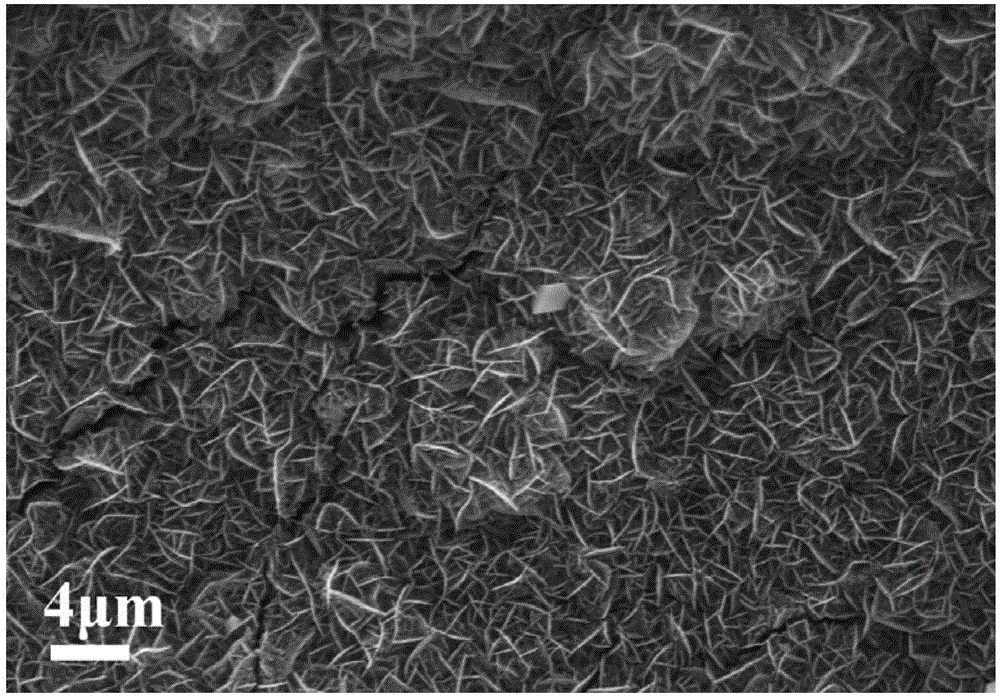

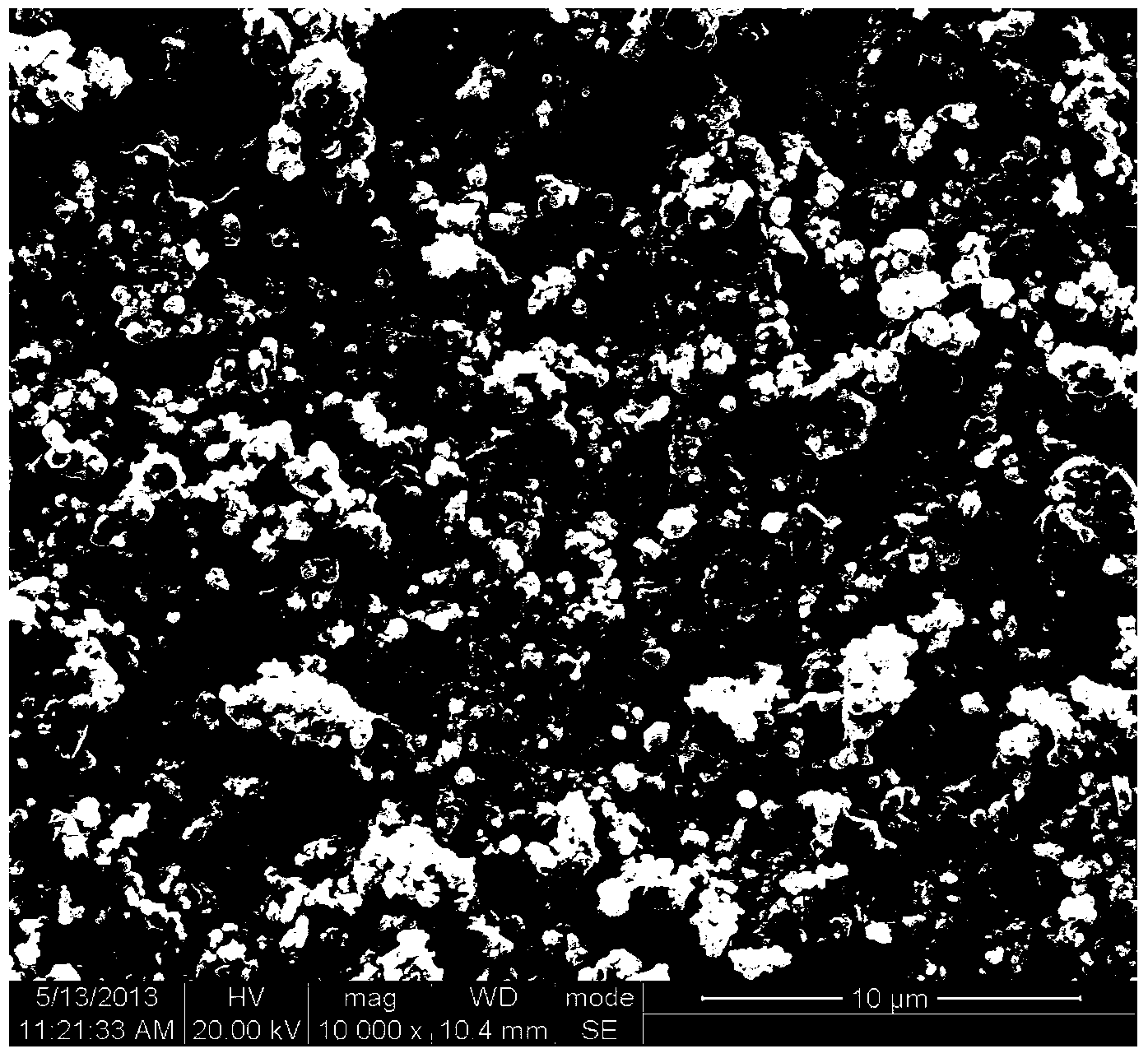

Preparation method of ultra-high density cobaltosic oxide/porous graphene nano-composite anode material for lithium ion battery

InactiveCN104934574ASolve the technical bottleneck that is difficult to grow high-density cobalt trioxide nanoparticlesImprove electronic conductivityMaterial nanotechnologyCell electrodesPorous grapheneGraphene nanocomposites

The invention relates to a preparation method of an ultra-high density cobaltosic oxide / porous graphene nano-composite anode material for a lithium ion battery and brings forward a novel low-cost in-situ growth method. According to the method, evenly distributed in plane defect sites are manufactured on the surface of oxidized graphene by means of strong oxidization of a chemical reagent; and then through a low-temperature hydrothermal reaction, in-situ growth of ultra-high density cobaltosic oxide nano-particles happens on porous graphene with the defect active sites. Cobaltosic oxide accounts for more than 92% of the compound, and adverse effects such as the drop in first coulombic efficiency and tilt of a charging / discharging platform due to addition of overmuch graphene can remarkably be improved. In the cobaltosic oxide / porous graphene nano-composite material, graphene can effectively improve conductivity insufficiency of cobaltosic oxide; and volume effect of cobaltosic oxide during the cyclic process can be well overcome due to the particle size of 5-10 nm. Thus, the material has ultra-high electrochemical performance. According to the invention, the principle is simple, and the material is easy to produce.

Owner:SUZHOU GREEN POWER TECH CO LTD

Preparation method of porous graphene and applications of finished product thereof

InactiveCN103490050AEvenly distributedLarge specific surface areaCell electrodesSecondary cellsPorous grapheneTubing types

The invention relates to a preparation method of porous graphene and applications of finished product thereof. The preparation method comprises following steps: (1) ultrasonically dispersing graphene oxide in deionized water; (2) dissolving a certain amount of water-soluble transition metal salts in deionized water, dropwise adding the solution into the graphene oxide solution, and stirring at the same time; (3) subjecting the mixed solution to treatments of centrifugation and washing to extract products, drying the products for 1 to 20 hours; (4) putting the obtained materials into a tube-type furnace, heating, burning the materials at a constant temperature of 500 to 1050 DEG C for 1 to 20 hours, while controlling the flow speed of inert gas in the range of 10 to 300 mL / min, cooling, and collecting the solid products; (5) processing the solid products with dilute hydrochloric acid to remove the transition metal oxides in the solid products so as to obtain the porous graphene material. The porous graphene material prepared by the method has the advantages of few layers and controllable hole size, and solves the problems of non-conductivity of electrons in the vertical direction to the horizontal surface of the graphite material multi-layer graphene and obstructed route of Li. Furthermore, the construction of nano micro-hole structure is beneficial for storage, diffusion, and transportation of charges.

Owner:上海一广新能源科技有限公司

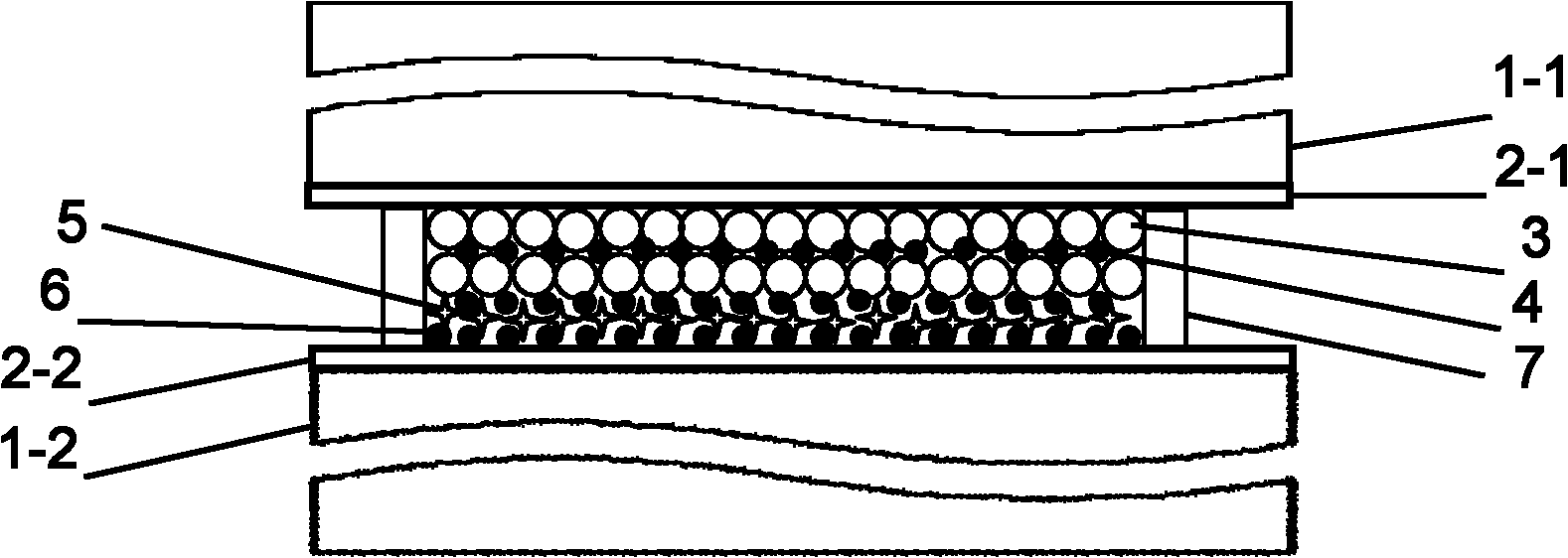

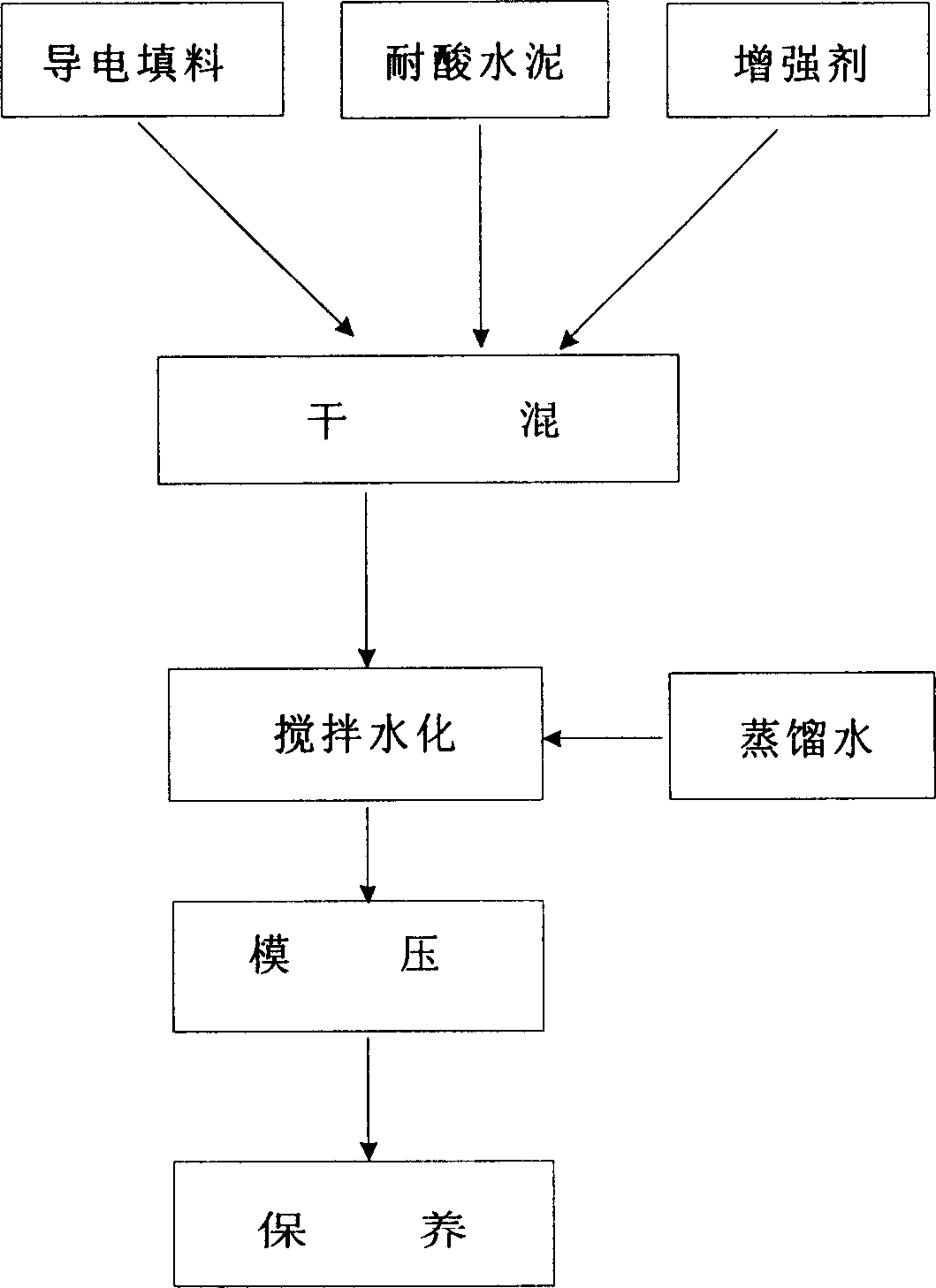

A bipolar plate for fuel cell with proton exchange membrane and preparation method thereof

InactiveCN1595697AOvercome conductivityOvercome mechanical propertiesFinal product manufactureCell electrodesSilicon dioxideMechanical property

The invention relates to a dual-pole plate having function of inner humidification for proton exchange membranes fuel cell and its manufacturing method, which uses Ti3SiC2, graphite powder as conductor filler, acid proof cement as agglomerant and thermoplastic resin polyvinylidene fluoride as reinforcing agent to make dual-pole plate with air flow field and cooled water channel by once one-off combined die pressing. By millimicron and micron sized micro-hole formed in conducting composite material in the hydration course acid proof cement agglomerant, the invention has realized protection to water created in negative electrode plate of fuel battery or cooled water channel and inner humidification to proton exchange membranes; by high conductibility and plasticity of conductor filler Ti3SiC2, it has made the dual-pole plate manufactured by die stamping method has high electric conductivity as well as excellent mechanical property.

Owner:WUHAN UNIV OF TECH

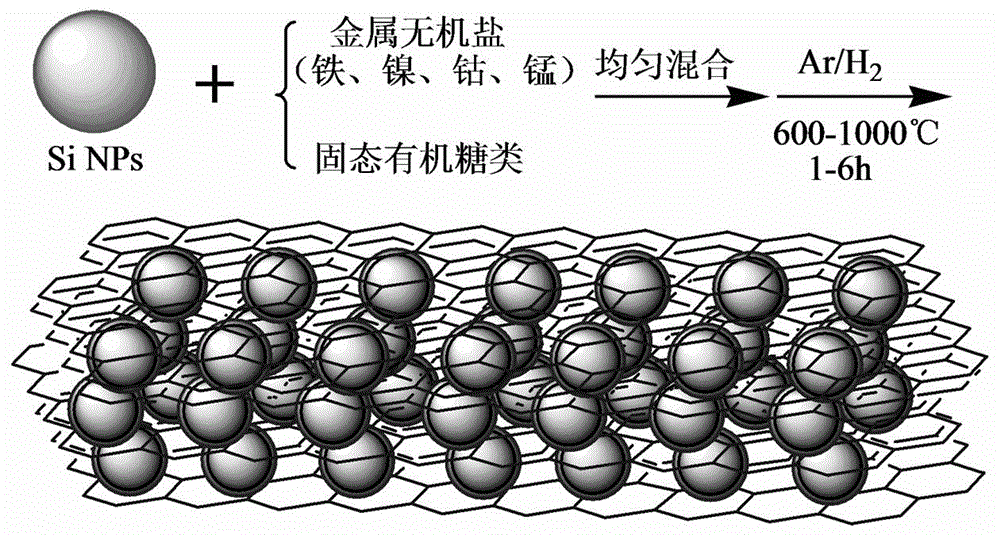

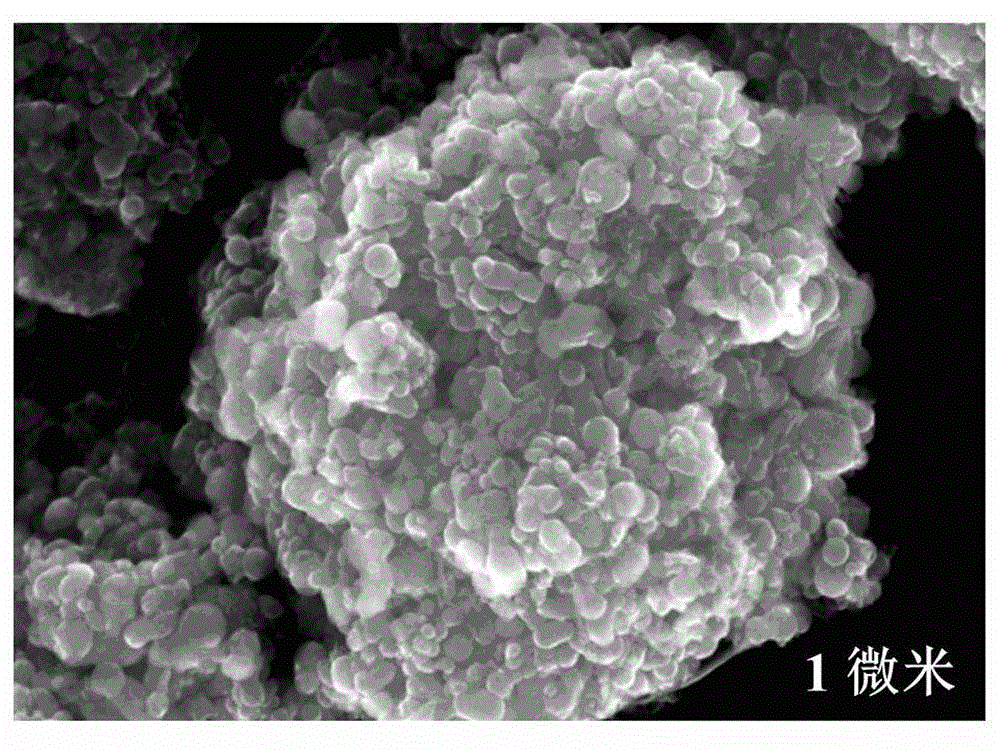

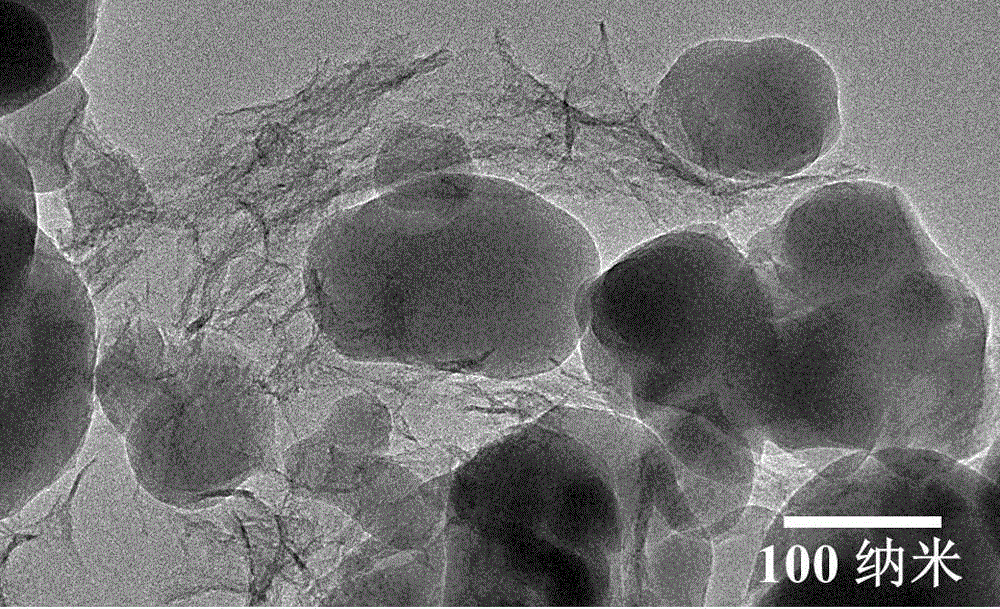

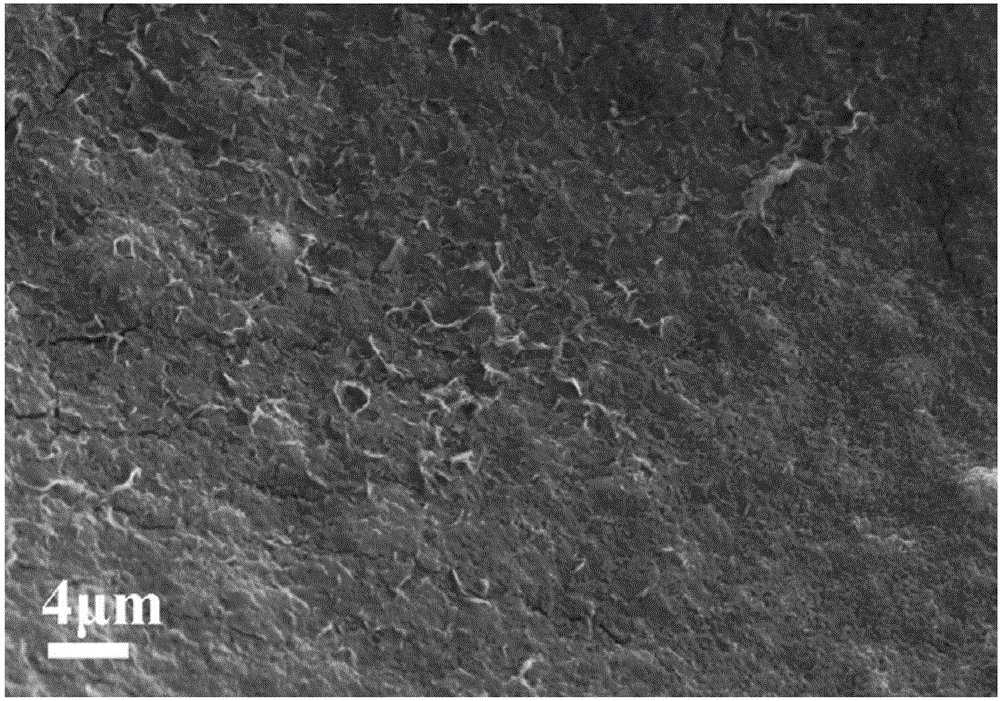

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

InactiveCN104934573AAvoid volume effectImprove electronic conductivityCell electrodesFinal product manufacturePtru catalystElectronic conductivity

The invention brings forward a novel low-cost in-situ solid-phase preparation method. By the method, a silicon-graphene spheroidal composite material with a multilevel structure can be synthesized by one step. The composite material can be used as a high specific energy anode material to be applied in a lithium ion battery. Low-cost organic carbohydrate and inorganic transition metal salt which are respectively used as a carbon source and a metal catalyst precursor are selected to be uniformly mixed with a silicon nano-material; by a tube furnace heating method, in-situ catalytic growth of a graphene coated network happens on the surface of silicon nano-particles; and through the bridging effect of the graphene network, spheroidal micro-scale particles with a nanometer fine structure is self-assembled. The silicon-graphene spheroidal composite anode material with the multilevel structure has an advantage of high specific capacity. In addition, two main bottleneck problems such as poor electronic conductivity of a silicon anode material and severe volume effect during the cyclic process can be overcome simultaneously, and multiplying power and cycle performance of silicon anode can be raised greatly.

Owner:SUZHOU GREEN POWER TECH CO LTD

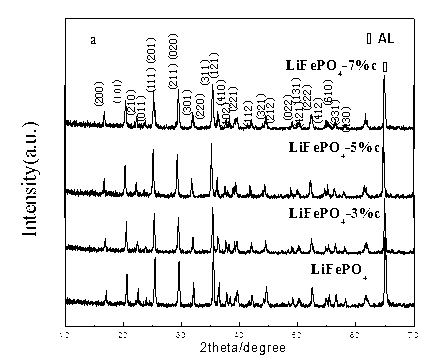

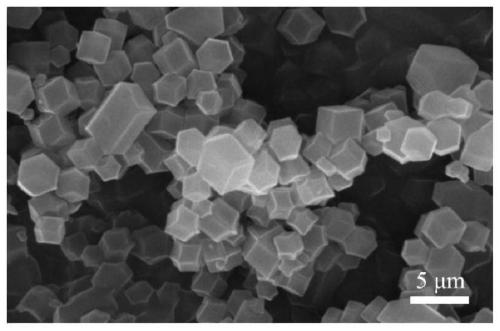

Preparation method of hydrothermal synthesis carbon coated lithium iron phosphate

The invention discloses a method of preparing lithium ion battery anode material, namely, carbon coated lithium iron phosphate by utilizing ascorbic acid as reducing agent and carbon source, and the method comprises: adding ascorbic acid in a reaction solution to prevent Fe2<+> from being oxidized to Fe3<+>, and hydrothermal synthesizing LiFePO4; adding the ascorbic acid in the LiFePO4 to serve as reducing agent and carbon source to prepare a LiFePO4 / C precursor; and roasting the LiFePO4 / C precursor at a high temperature under the shield of argon atmosphere to obtain lithium iron phosphate uniformly coated by carbon. The method disclosed by the invention wraps the carbon to control the morphology of the crystalline grain and improve the lithium-ion diffusion coefficient of lithium iron phosphate so as to obtain a lithium iron phosphate material with uniform dimension and excellent electrochemical performance. The preparation method disclosed by the invention is simple and economic and is suitable for industrial mass production.

Owner:NANJING NORMAL UNIVERSITY

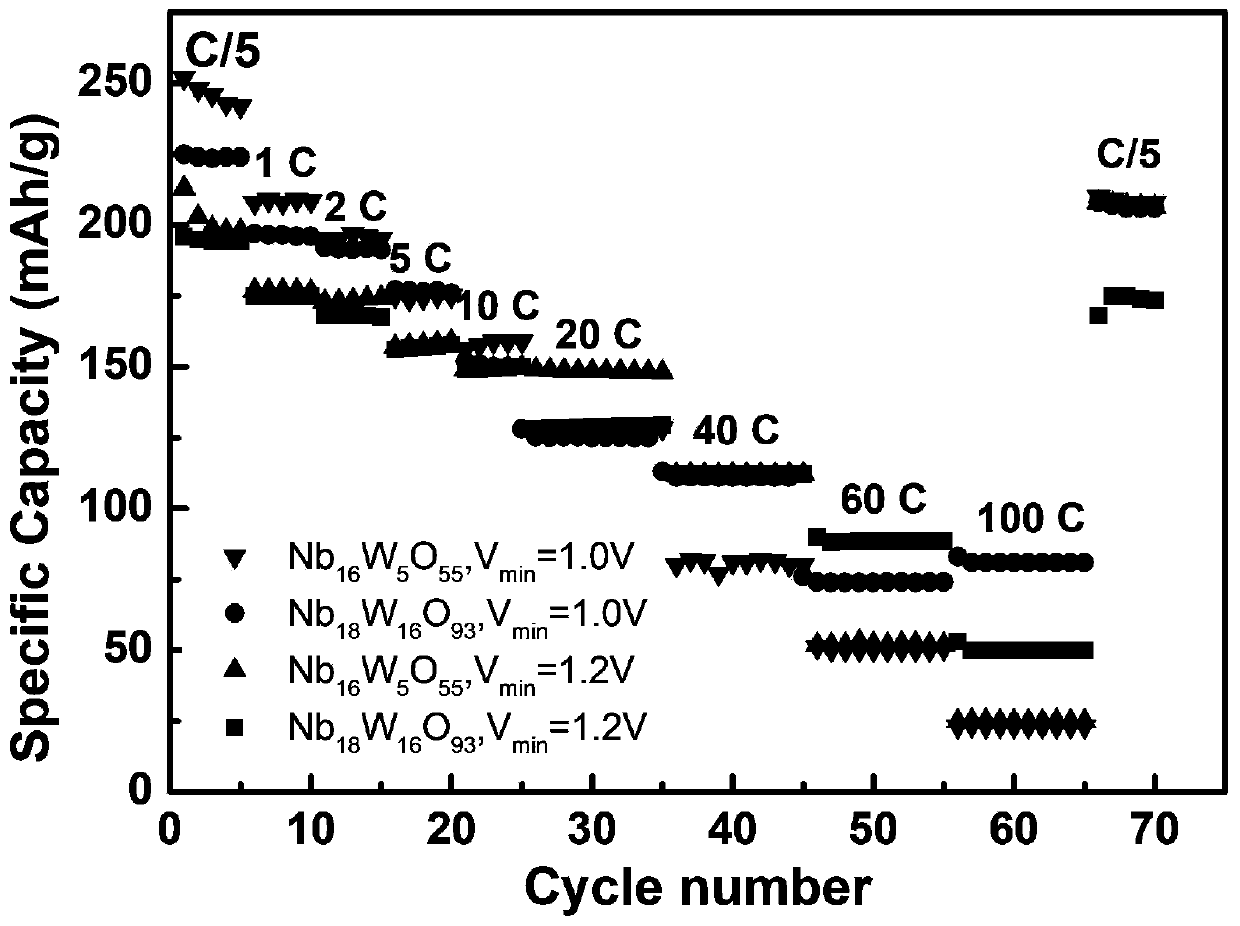

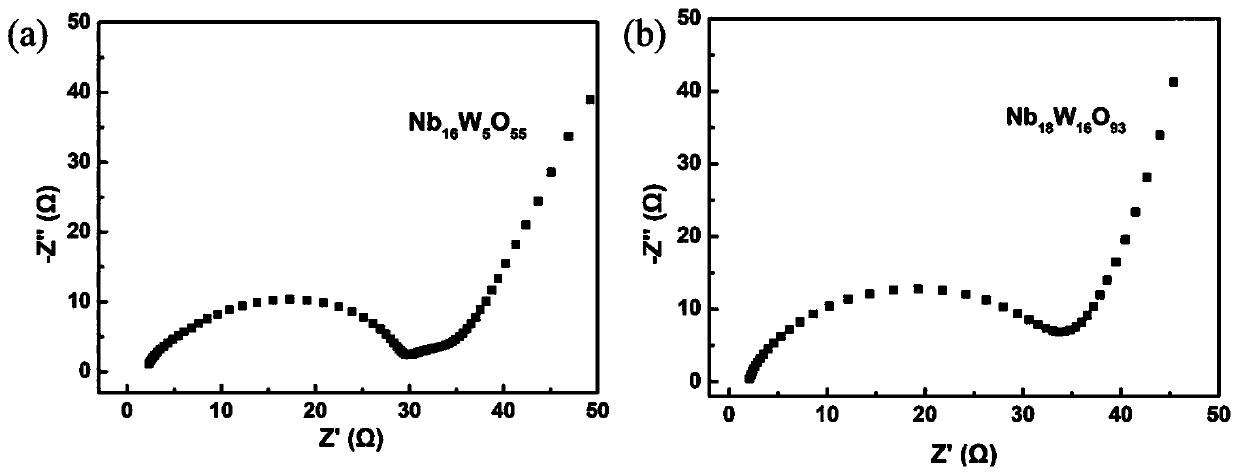

High-magnification niobium-tungsten oxide fast-charging electrode materials as well as preparation method and application thereof

InactiveCN109928750AIncrease volumetric energy densityOvercoming poor electronic conductivityCell electrodesSecondary cellsHigher PowerLithium electrode

The invention relates to high-magnification niobium-tungsten oxide fast-charging electrode materials as well as a preparation method and application thereof, and the preparation method comprises: mixing NbO2 and WO2, performing grinding and pressing into blocks, heating the blocks to 1200 DEG C from room temperature, and performing air-cooling to cool to room temperature. Two micron-sized Nb16W5O55 and Nb18W16O93 niobium-tungsten oxides are prepared to serve as lithium ion battery negative electrode materials by a high-temperature thermal oxidation method, the micron-sized active materials canundergo delithiation and lithium intercalation reactions in a few minutes, and have great significance for high-power fast-charging devices, the micron-scale structures can effectively improve the overall volume energy density of batteries, so that a traditional electrode material nano structure strategy is broken through, and the problem of poor ion diffusion and electron conductivity can be effectively overcome by virtue of a sub-stable crystal structure.

Owner:武汉瑞科美新能源有限责任公司

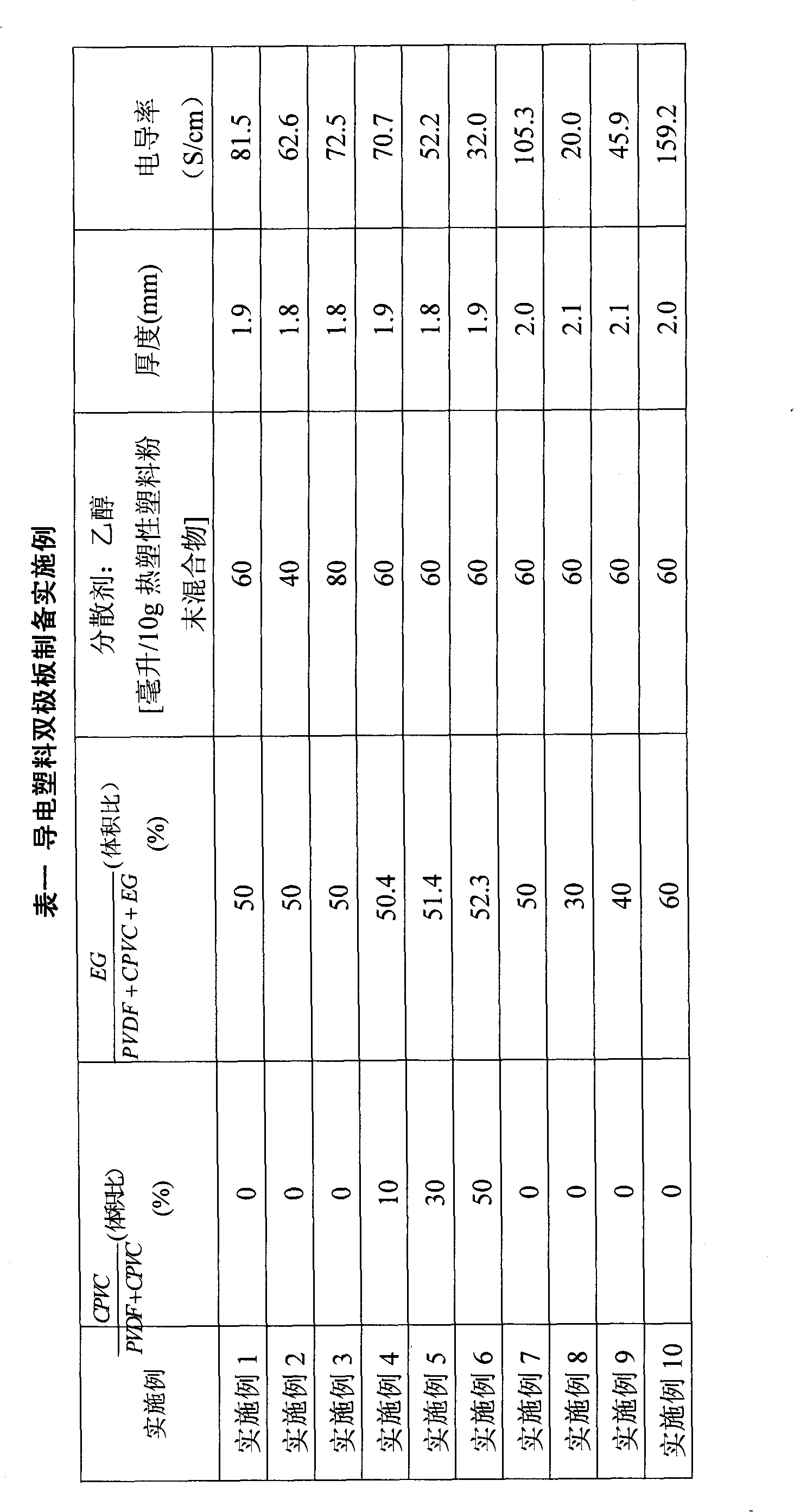

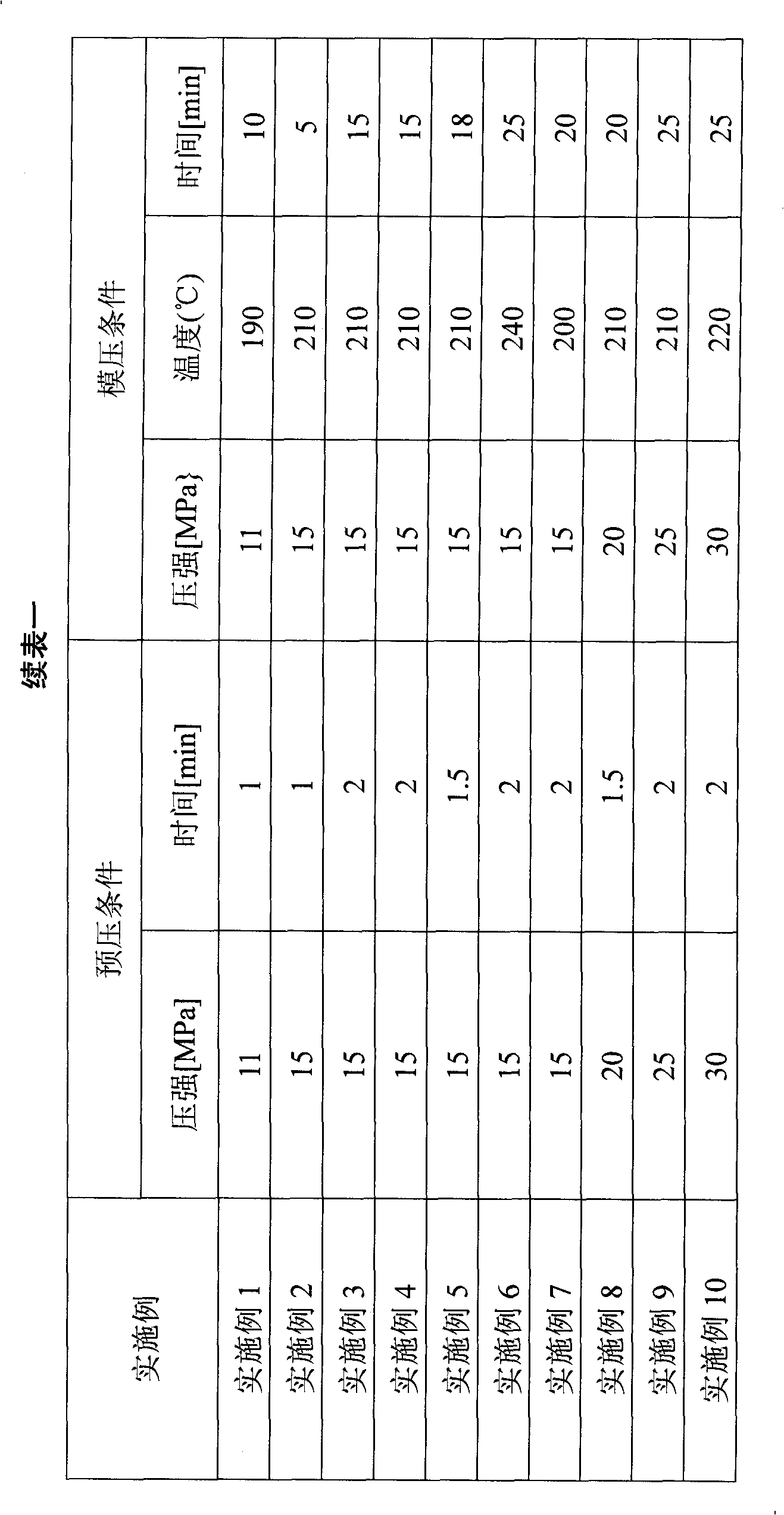

Preparation method of fluororesin-containing conductive plastic bi-polar plate

ActiveCN101814605AImprove conductivityGood chemical stabilityCell electrodesFuel cell detailsThermoplasticGram

The invention relates to a preparation method of a fluororesin-containing conductive plastic bi-polar plate, which belongs to the manufacturing technical field of the flow battery, and is characterized in that ethanol is used as a dispersing agent, polyvinylidene fluoride and polyvinyl chloride are used as thermoplastic plastics, graphite is used as a conductive filler, and the addition quantity of the dispersing agent ethanol is 40 to 80 ml per 10 grams; and the percent by volume of the thermoplastic plastics (polyvinyl chlorid / ( polyvinyl chlorid + polyvinylidene fluoride) is 0 to 5 percent; the percent by volume of the conductive filler (conductive filler / (conductive filler + thermoplastic plastics) is 30 to 60 percent; and the fluororesin-containing conductive plastic bi-polar plate is formed through the same stamping process. The conductivity of the prepared fluororesin-containing conductive plastic bi-polar plate is more than 20 Siemens per centimeter, the technological process is simple, the technical method is stable and reliable, and the mass industrialized production can be realized.

Owner:TSINGHUA UNIV +1

Preparation method and application of three-dimensional self-supporting nitrogen-doped carbon sodium ion negative electrode material

ActiveCN110416546ALarge and many holesPrevent precipitationSecondary cellsNegative electrodesElectrospinningGraphite

The invention discloses a preparation method and application of a three-dimensional self-supporting nitrogen-doped carbon sodium ion negative electrode material. The preparation method comprises the following steps: (1) preparation of ZIF-8; (2) electrostatic spinning preparation; (3) annealing and carbonizing. Reversible sodium intercalation and deintercalation can be realized, a slope type voltage behavior is presented, and the problems that a secondary battery anode material prepared by an existing method is low in improvement specific capacity, poor in stability and cycle performance, incapable of realizing sodium intercalation of graphite and the like are solved. The negative electrode material is a nitrogen-doped three-dimensional self-supporting carbon material, can be directly usedas an electrode, has no binder, is low in cost and simple in method, is suitable for large-scale production, and has application potential.

Owner:HUBEI UNIV

Carbon-coated CoAl-LDH@NF composite electrode material and preparation method thereof

InactiveCN106847541ARich sourcesLow reaction temperatureHybrid capacitor electrodesHybrid/EDL manufactureReaction temperatureCarbonization

The invention discloses a carbon-coated CoAl-LDH@NF composite electrode material and a preparation method thereof. The preparation method disclosed by the invention comprises the steps of firstly utilizing cobalt nitrate and aluminum nitrate as a cobalt source and an aluminum source and foamed nickel as a substrate and obtaining Co-Al LDH@NF after one-step hydrothermal; then utilizing glucose or cane sugar as a carbon source to coat the Co-Al LDH@NF and performing hydrothermal treatment to obtain Co-Al LDH@NF@C. According to the preparation method disclosed by the invention, a substep hydrothermal-drying method is utilized, a preparation technology and required equipment are simple, raw materials are rich in source, reaction temperature is lower, high-temperature carbonization is avoided, and large-scale production is easy to achieve. The Co-Al LDH@NF@C composition material obtained through the method disclosed by the invention has good thermal stability, high crystallization degree and large specific surface area, further has strong morphology controllability and is one of ideal energy materials.

Owner:SHANGHAI INST OF TECH

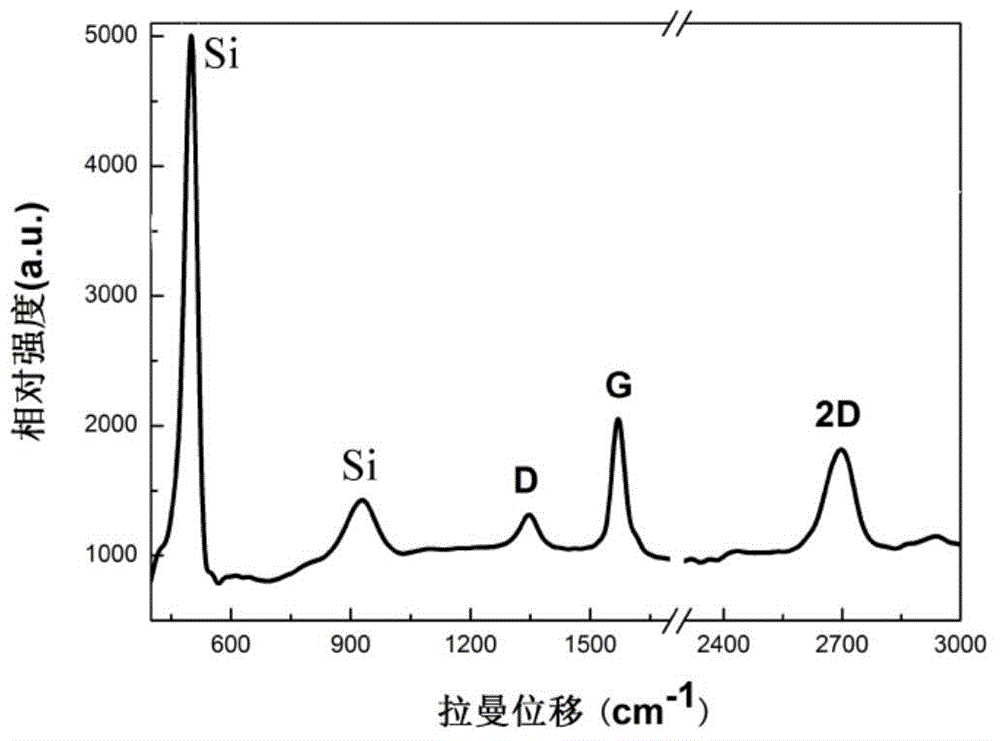

Method for preparation of graphene/nano-silicon lithium ion battery cathode material by liquid phase physical technique

ActiveCN104993109ASimple processEasy labCell electrodesSecondary cellsUltrasonic cavitationFiltration

The invention relates to a method for preparation of a graphene / nano-silicon lithium ion battery cathode material by liquid phase physical technique. The preparation steps include: 1. dissolving a surfactant in deionized water in proportion to obtain a solution; 2. dispersing graphite powder and nano-silicon powder uniformly in the solution; 3. conducting ultrasonic cavitation treatment on the graphite powder and nano-silicon powder mixed dispersion solution; 4. carrying out centrifugal separation treatment on the solution; 5. standing the solution for certain time and taking the upper solution; 6. subjecting the supernatant to vacuum pumping filtration and drying to obtain grey powder; and 7. calcining the grey powder to obtain the graphene / nano-silicon composite material. The preparation process involved in the invention is simple and practicable, graphene and nano-silicon particles have good dispersibility, thus avoiding agglomeration of liquid phase method prepared graphene, and omitting secondary dispersion of liquid phase physical method prepared grapheme. Constant current charging-discharging result shows that the grapheme / silicon composite material overcomes the disadvantages of large volume change and poor electrical conductivity of silicon, and improves the performance of lithium ion battery cathode materials.

Owner:BEIHANG UNIV

Preparation method for graphene-enhanced copper-niobium multi-core composite wire

ActiveCN106448799AHigh strengthImprove ductilityConductive materialMetal/alloy conductorsReduction treatmentAlcohol

The invention provides a preparation method for a graphene-enhanced copper-niobium multi-core composite wire. The preparation method comprises the following steps: firstly, uniformly mixing graphene powder, niobium powder and copper powder to obtain mixed powder; secondly, adding a tackifier and the mixed powder into alcohol ketone mixed solution, stirring uniformly, drying to obtain a powder material, and then performing thermal reduction treatment on the powder material to obtain graphene-enhanced copper-niobium composite powder; thirdly, filling a pipe with graphene-coated copper-niobium composite powder to obtain a piped composite body; fourthly, drawing to obtain a single-core composite wire; fifthly, performing primary compounding moulding to prepare a 19-core composite wire; sixthly, performing secondary compounding moulding to prepare a 192-core composite wire; seventhly, performing tertiary compounding moulding to obtain the graphene-enhanced copper-niobium multi-core composite wire. The wire prepared by the preparation method has the characteristics of high strength, high extensibility, high conductivity and the like of the graphene, and the obstacle that the performance of a Cu / Nb material prepared by a conventional process cannot be further improved is overcome.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

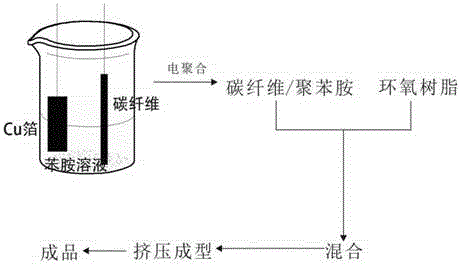

Preparing method of carbon fiber/polyaniline wave-absorbing electromagnetic shielding composite

The invention discloses a preparing method of a carbon fiber / polyaniline wave-absorbing electromagnetic shielding composite. The preparing method includes the following steps that 1, oiling agents and impurities on the surface of a fiber product are removed, and moisture on the surface is removed for use; 2, the carbon fibers obtained in the step 1 are taken and pasted on stainless steel foil with a conductive silver adhesive to serve as an anode, Cu foil serves as an cathode, an aqueous solution with aniline and a dopant mixed is selected as an electrolytic solution, a polyaniline film is electropolymerized on the surface of the carbon fibers through the electropolymerization method, and a carbon fiber / polyaniline composite is obtained; 3, the carbon fiber / polyaniline composite obtained in the step 2 is taken to serve as electromagnetic shielding bi-component functional filler, epoxy resin is selected as a resin matrix, and the carbon fiber / polyaniline wave-absorbing electromagnetic shielding composite is obtained through the extrusion forming technology. The carbon fiber / polyaniline composite prepared through the preparing method has the advantages of high electric conductivity of the carbon fibers, high electric conductivity of polyaniline and double-loss structure wave absorbing, and can be applied to the fields of electromagnetic shielding and the like.

Owner:HANGZHOU CHAOTAN NEW MATERIAL TECH

Preparation method of carbon nanotube/mesoporous carbon composite capacitive desalination electrode

ActiveCN102295325ASpecial hollow structureLarge specific surface areaWater/sewage treatment by electrochemical methodsCarbon compositesCapacitance

The invention relates to a preparation method of a carbon nano-tube / mesoporous-carbon composite capacitance-type desalting electrode, which belongs to the preparation field of capacitance-type desalting electrodes. The preparation method comprises the following steps of: adding a carbon nano-tube into a precursor of a mesoporous material, uniformly dispersing by utilizing ultrasonic and magnetic stirring, and forming a high-molecular compound with the mesoporous material around the carbon nano-tube through curing; carbonizing through inert-gas protection to obtain carbon nano-tube / mesoporous-carbon composite-mateiral powder with ordered height and large specific surface area; and finely grinding a sample, smearing the sample onto graphite paper after being mixed with a polytetrafluoroethylene emulsion, and drying to prepare the carbon nano-tube / mesoporous-carbon composite capacitance-type desalting electrode. The preparation method has a simple process and easily-controlled conditions. A carbon nano-tube electrode prepared by the method disclosed by the invention has good electrical conductivity and better desalting performance and has potential application prospects in the aspectof capacitance-type desalting.

Owner:SHANGHAI UNIV

Silver conductive ink and method for manufacturing printed circuit with same

InactiveCN103517569AFirmly attachedUniform circuitInksConductive pattern formationAmmonium hydroxidePrinted circuit board

The invention belongs to silver conductive ink and a method for manufacturing a printed circuit with the ink. The silver conductive ink comprises reducing agents, saturated [Ag(NH3)2]+ solutions and buffering agent dilute nitric acid. The method for manufacturing the printed circuit with the ink comprises circuit printing, solidification treatment and sintering. Firstly, silver nitrate and water are prepared into silver nitrate aqueous solutions, ammonium hydroxide is added to the silver nitrate aqueous solutions to prepare the saturated [Ag(NH3)2]+ solutions, and then the alkylol amine reducing agents and the buffering agent dilute nitric acid are added. When the printed circuit is manufactured, the solidification treatment is carried out under the condition of low-temperature heating, the silver conductive ink carries out silver mirror reaction-oxidizing reaction-silver mirror reaction repeatedly in the heat solidification process, and the printed circuit is manufactured through the high-temperature sintering. Therefore, the silver conductive ink and the method have the advantages that the silver conductive ink is short in production process procedure and low in cost, in the solidification treatment, reaction temperature is low, a manufactured silver wire is smooth in surface and good in compactness, silver purity is high, adhesive force to a substrate is strong, and the electric conduction and other performance of the circuit are good.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for preparing chopped carbon fiber reinforced carbon/carbon composite materials for pantograph slide plates

ActiveCN106631083AOvercome conductivityEasy to adjustPower current collectorsCarbon compositesCarbon fibers

The invention discloses a method for preparing chopped carbon fiber reinforced carbon / carbon composite materials for pantograph slide plates. The method includes placing chopped carbon fibers, mesophase asphalt powder and dispersing agents in water to obtain slurry; pouring the slurry into a metal container and carrying out freeze drying on the slurry in freeze drying equipment to obtain carbon fiber reinforcement; carrying out compression molding on the prepared carbon fiber reinforcement to obtain blanks; carrying out carbonization treatment on the prepared blanks; impregnating materials obtained after carbonization treatment is carried out in mesophase asphalt; carrying out carbonization treatment on materials obtained after materials are impregnated in the mesophase asphalt; repeatedly carrying out impregnation-carbonization by 4-6 times; carrying out graphitization treatment to obtain the target materials. The method has the advantages that the chopped carbon fiber reinforced carbon / carbon composite materials prepared by the aid of the method are excellent in electric conductivity and impact resistance, and the shortcoming of poor electric conductivity and impact resistance of existing pantograph slide plates made of carbon / carbon composite materials prepared in the prior art can be overcome.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Super high temperature molybdenum disilicide zirconia composite heating element and its preparation method

InactiveCN1865191AOvercoming low temperature resistance is too smallOvercome the disadvantage of large high temperature resistanceHydrogenAdhesive

This invention relates to a hyperthermal molybdenum disilicon zirconium oxide compound heater, belonging to the heating material technology. This heater uses molybdenum disilicon zirconium oxide two-phage reticulated structure compound material as matrix, concretely it uses (Mo1-x,Wx)Si2 as one phage of the two-phage compound material, where X=0-0.5, and uses yttrium oxide / calcium oxide stabilized zirconium oxide powder as the other phage, where the content of the zirconium oxide powder is 30-70vol% of the compound material. The process comprises: charging the above two-phage compound material and sintering aid, adding in adhesive for pugging, extrusion molding, drying, burning and filming treatment, so as to obtain the product, wherein: the bar produced by organic adhesive molding and drying needs degreasing process under 0.1MPa hydrogen gas pressure, at 300-600Deg C for 3-30 hours, where the burning temperature is 1500-1750Deg C. The invention can produce high efficient and long-life heater at more than 1850Deg C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

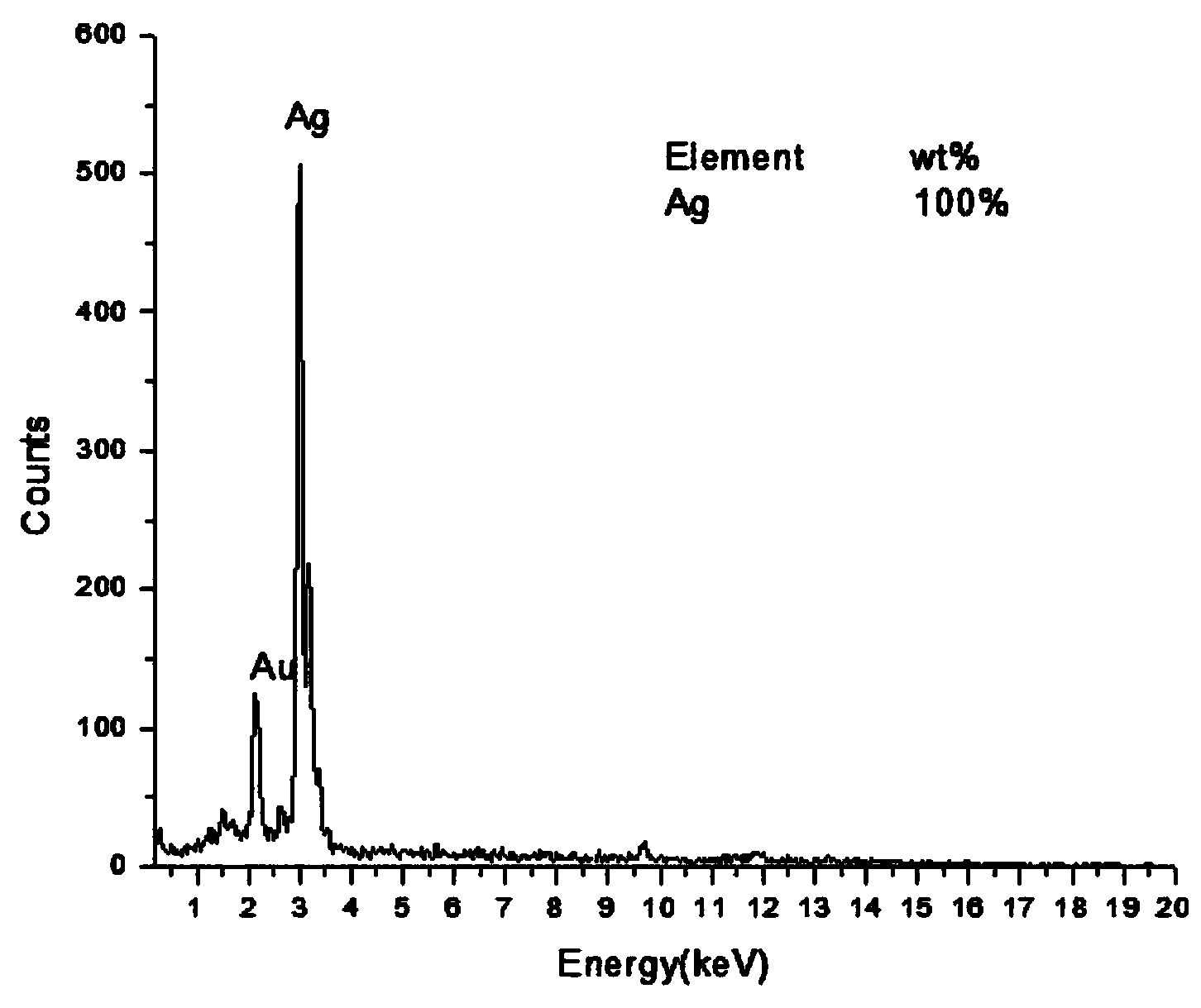

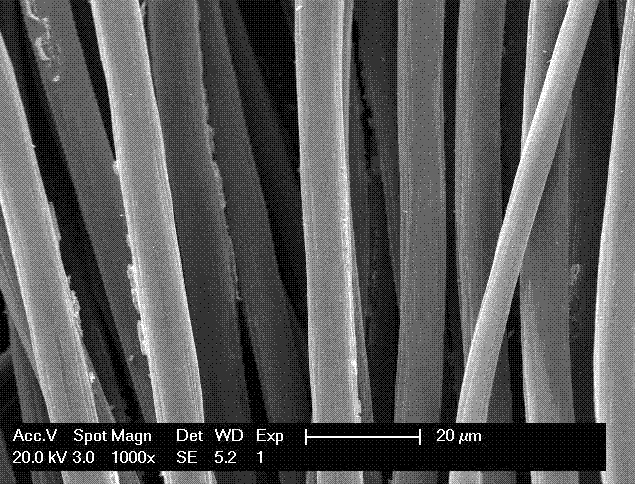

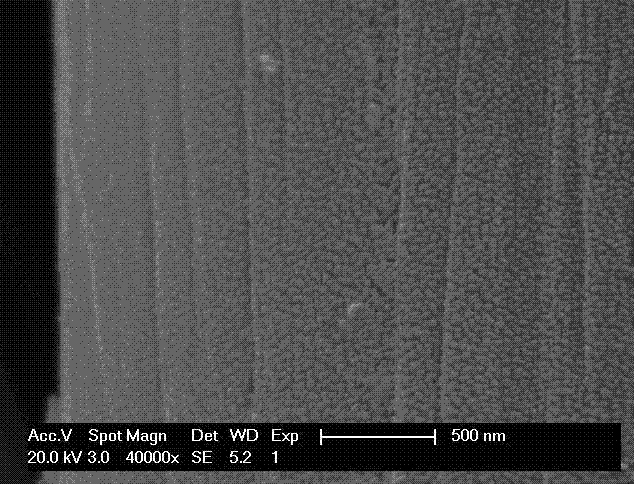

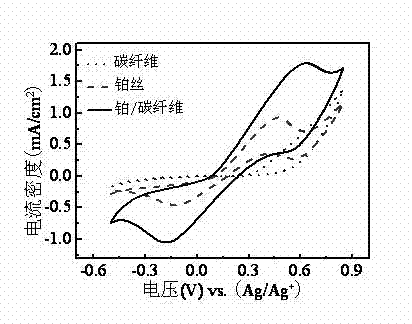

Method of preparing conductive carbon fiber/platinum nanometer material and application of conductive carbon fiber/platinum nanometer material

InactiveCN102832049AMaterials are readily availableLow costLight-sensitive devicesFinal product manufactureFiberCarbon fibers

The invention belongs to the technical field of a nanometer material, and in particular discloses a method of preparing a conductive carbon fiber / platinum nanometer material and an application of the conductive carbon fiber / platinum nanometer material. The conductive carbon fiber nanometer material loaded with platinum nanometer particles can be obtained by dipping the conductive carbon fiber after being preheated in an ethanol or isopropanol solution of chloroplatinic acid for overnight and sintering. The conductive carbon fiber / platinum nanometer material obtained by the preparation method acts as the electrodes of a dye-sensitized solar battery pair; and by taking the conductive carbon fiber with good electrical conductivity and high flexibility as a substrate, the shortcoming that the performance of the battery is reduced because of the deformation and resistance of a conductive film is solved. The electrode can be applied to a solid light absorption type battery; the use ratio of sunlight is improved, so that the dye-sensitized solar battery can be used in a narrow space; the preparation method of the electrode is simple; the cost is low; and the preparation method is in favor of commercial application of the dye-sensitized solar battery in a large area.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com