A bipolar plate for fuel cell with proton exchange membrane and preparation method thereof

A technology of proton exchange membranes and fuel cells, which is applied to fuel cell components, battery electrodes, circuits, etc., can solve the problems of difficult precise control of pore size and pore size distribution, and poor operability, so as to reduce production costs, The effect of increasing integration and simplifying the stack system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

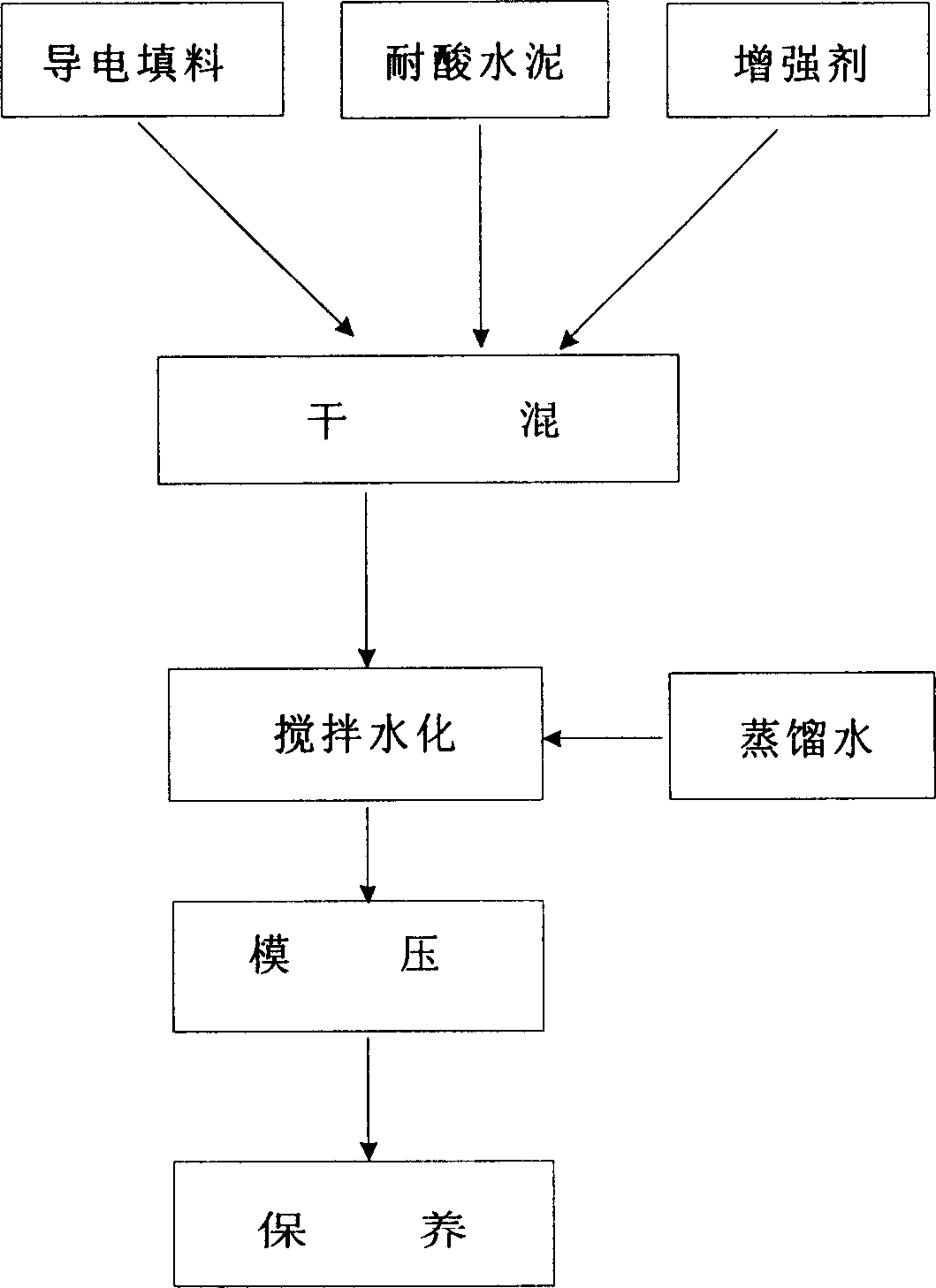

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: to Ti 3 SiC 2 Grind and sieve to obtain a powder less than 30um, sieve the sulfoaluminate cement to obtain a powder less than 30um, the silica is nano-scale, dry mix the above mixture in a ball mill for 1-2 hours, add distilled water and stir to let The cement is hydrated for 30 minutes, the weight ratio of cement and water is 1:0.2-0.4, and the sheet is obtained by mold compression molding on a flat vulcanizer. The compression molding conditions are: pressure 15Mpa, compression time 12 hours. Boil in distilled water at 80°C for 2 hours, and maintain for 1 day under 90% relative humidity. Its performance test results are shown in Table 1.

[0023] Ti 3 SiC 2 volume

[0024] Table 1Ti 3 SiC 2 , cement and nano-silica conductive microporous composites performance test results.

Embodiment 2

[0025] Embodiment 2: the preparation method is the same as embodiment 1, the conductive filler Ti 3 SiC 2 Replaced with graphite, the graphite fineness is less than 20um, and its performance test results are shown in Table 2.

[0026] Graphite volume

[0027] Table 2 Performance test results of graphite, cement and nano-silica conductive microporous composites.

Embodiment 3

[0028] Embodiment 3: the preparation method is the same as embodiment 1, the conductive filler Ti 3 SiC 2 Replacement to Graphite and Ti 3 SiC 2 A mixture of graphite fineness less than 20um, Ti 3 SiC 2 The fineness is less than 30um, and the performance test results are shown in Table 3.

[0029] Graphite volume

[0030] Table 3 Graphite, Ti 3 SiC 2 , cement and nano-silica conductive microporous composites performance test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com