Silver conductive ink and method for manufacturing printed circuit with same

A silver conductive ink, printed circuit technology, applied in conductive pattern formation, ink, application and other directions, can solve the problems of inability to remove high temperature impurities, wire morphology characteristics, affecting circuit electrical performance, poor stability of conductive ink, etc. Excellent performance, overcoming poor electrical conductivity and surface flatness, and uniform circuit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 5.19 g of silver nitrate into 10 mL of water, and stir at a constant speed at room temperature to completely dissolve the silver nitrate. Then add ammonia water with a mass percentage concentration of 33%, dropwise until saturated, then add 10 mL of triethanolamine aqueous solution with a concentration of 3 mol / L, and then add 1 mL of dilute nitric acid with a molar concentration of 0.8 mol / L, and Stir at a constant speed at room temperature until uniform, to obtain silver conductive ink.

[0026] Printed circuit board production: spray-print the silver conductive ink obtained in this embodiment on a PI (polyimide) substrate, and cure it at 60°C and a vacuum of 4.5Pa for 22 hours; take out the cured circuit board , and then heat it at 280°C and a vacuum of 4.5Pa for 7 minutes; after naturally cooling to room temperature, wash with water and air-dry to obtain a printed circuit board with a resistivity of 19.1μΩ·cm.

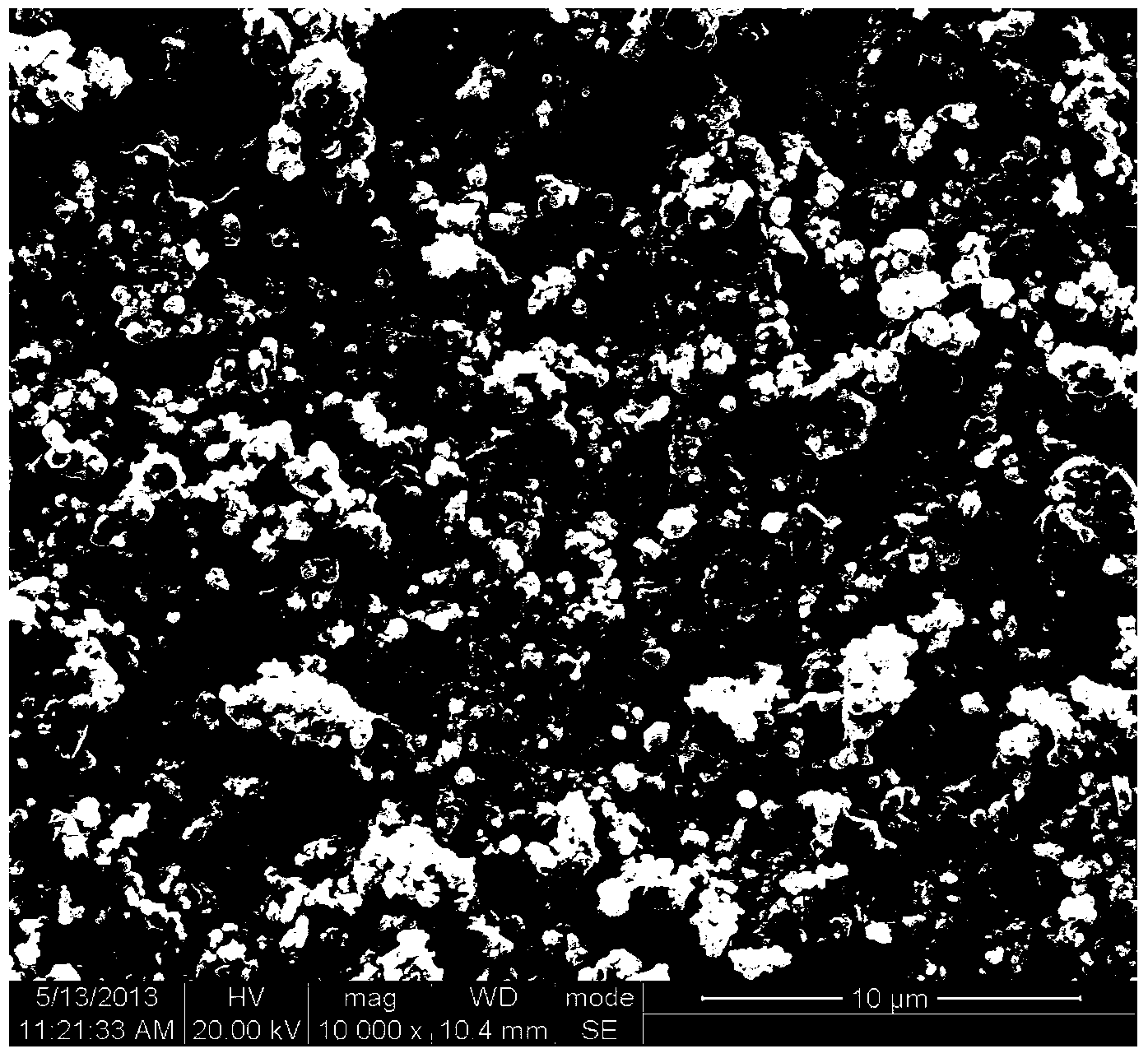

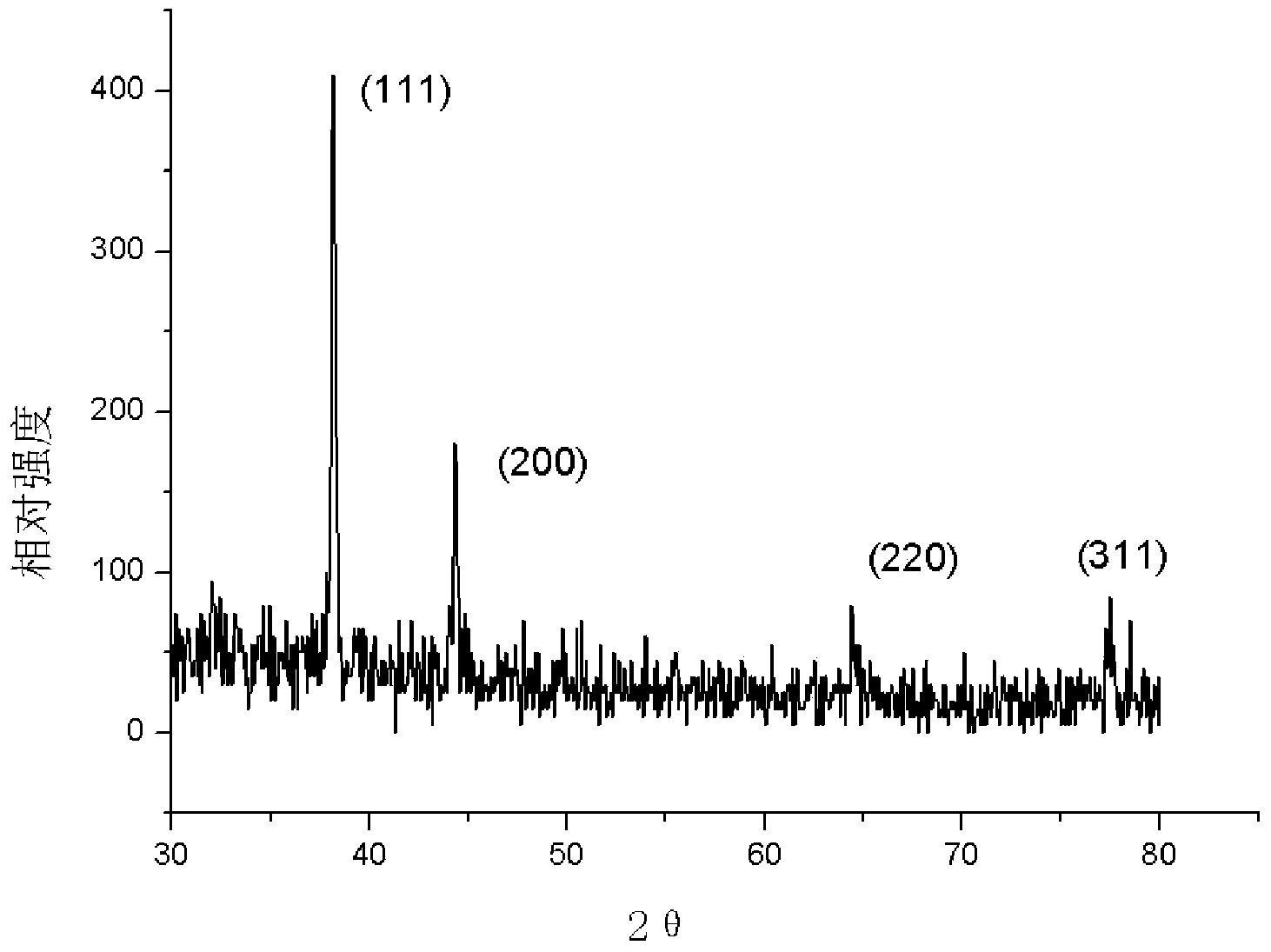

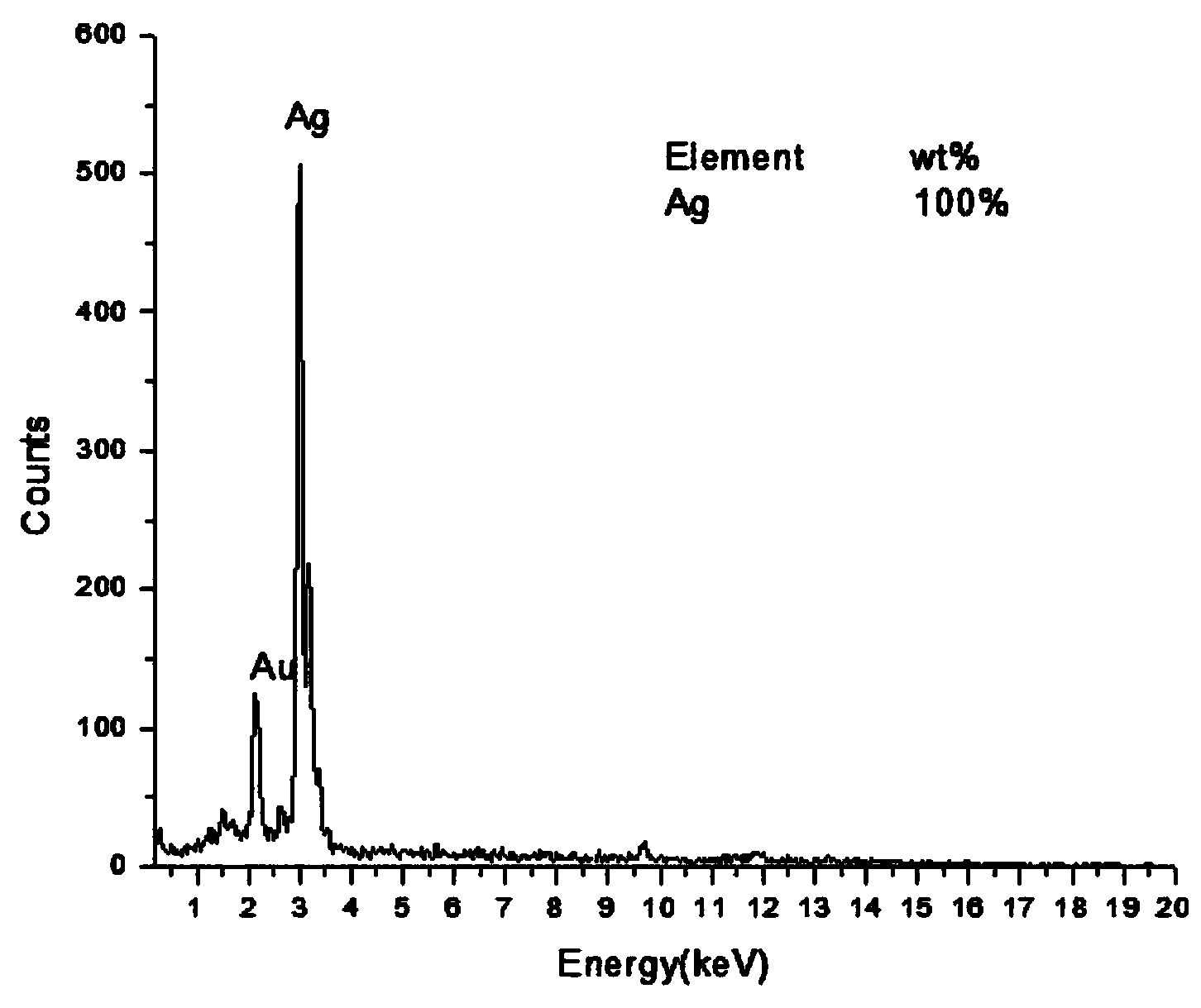

[0027] attached figure 1 It is the scanning elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com