Patents

Literature

38results about How to "Excellent electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-modified lithium iron phosphate positive electrode active material, preparation of the same and lithium-ion secondary cell

InactiveUS20120315550A1Excellent electrical conductivityGood lithium ion conductivityMaterial nanotechnologySolid waste disposalCell basedCyclic stability

The invention relates to a graphene-modified lithium iron phosphate positive electrode active material and a method for preparing the same, as well as a lithium-ion secondary cell based on this positive electrode active material. The positive electrode active material is prepared by a method in which graphene or graphene oxide and lithium iron phosphate are dispersed in an aqueous solution, agitated and ultrasonicated to mix homogeneously and for a mixture, dried to obtain a lithium iron phosphate material compounded with graphene or graphene oxide, and annealed at high temperature to obtain finally a graphene-modified lithium iron phosphate positive electrode active material. When compared with conventional modified lithium cells coated with carbon or doped with conductive polymers, the lithium-ion secondary cell based on this positive electrode active material features high cell capacity, good cycling performance of charge and discharge, long life and high cycle stability, and has great utility value.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

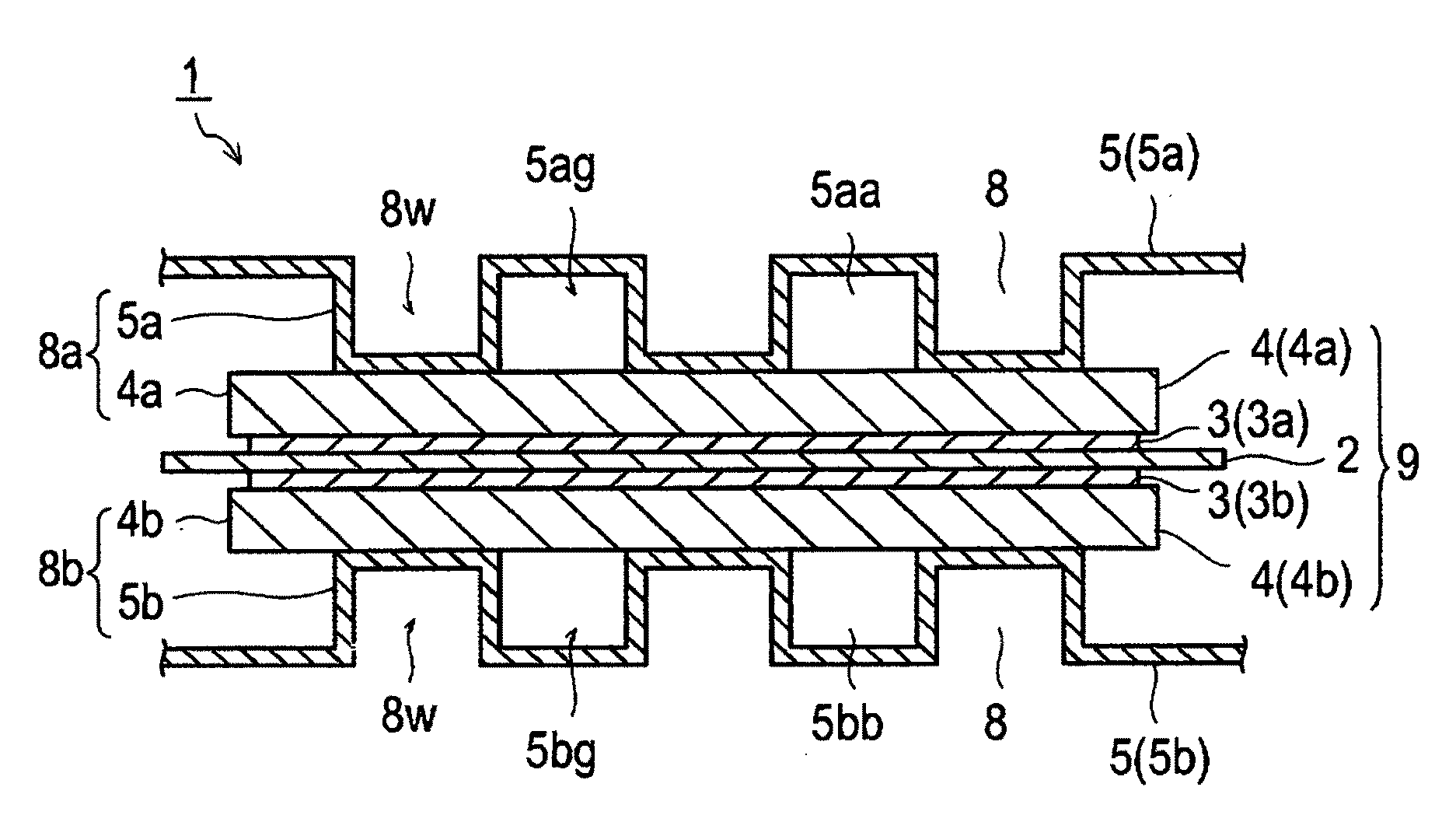

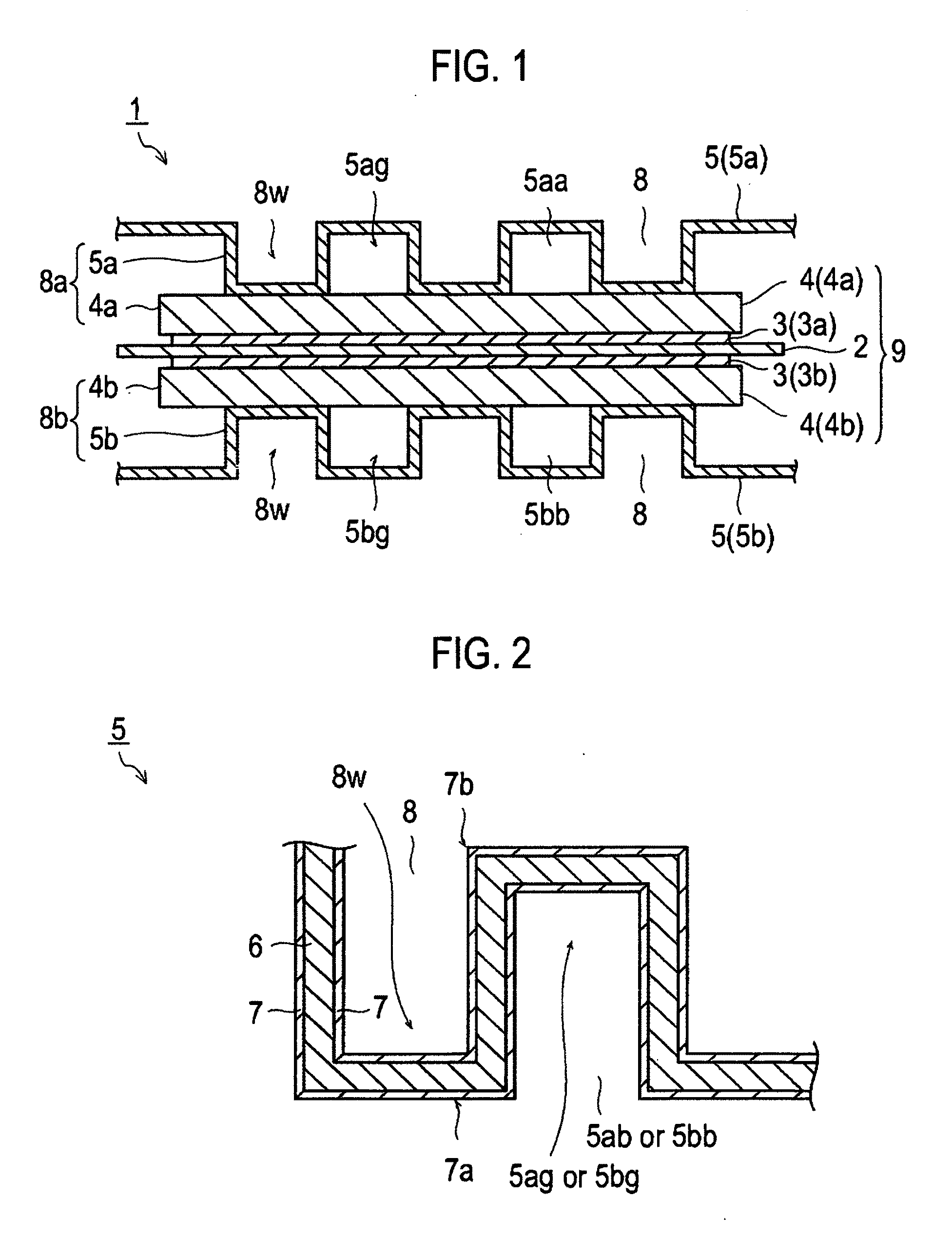

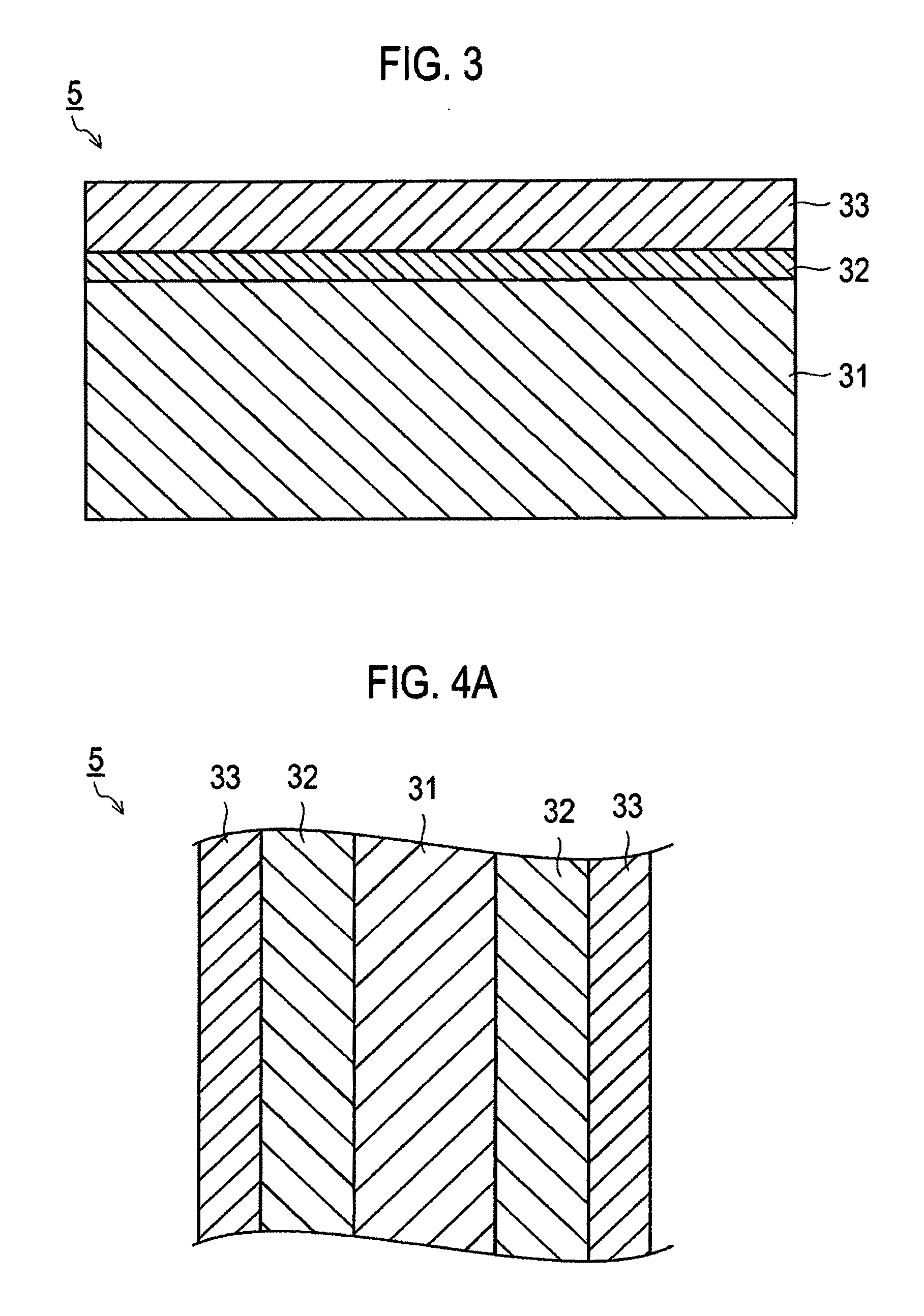

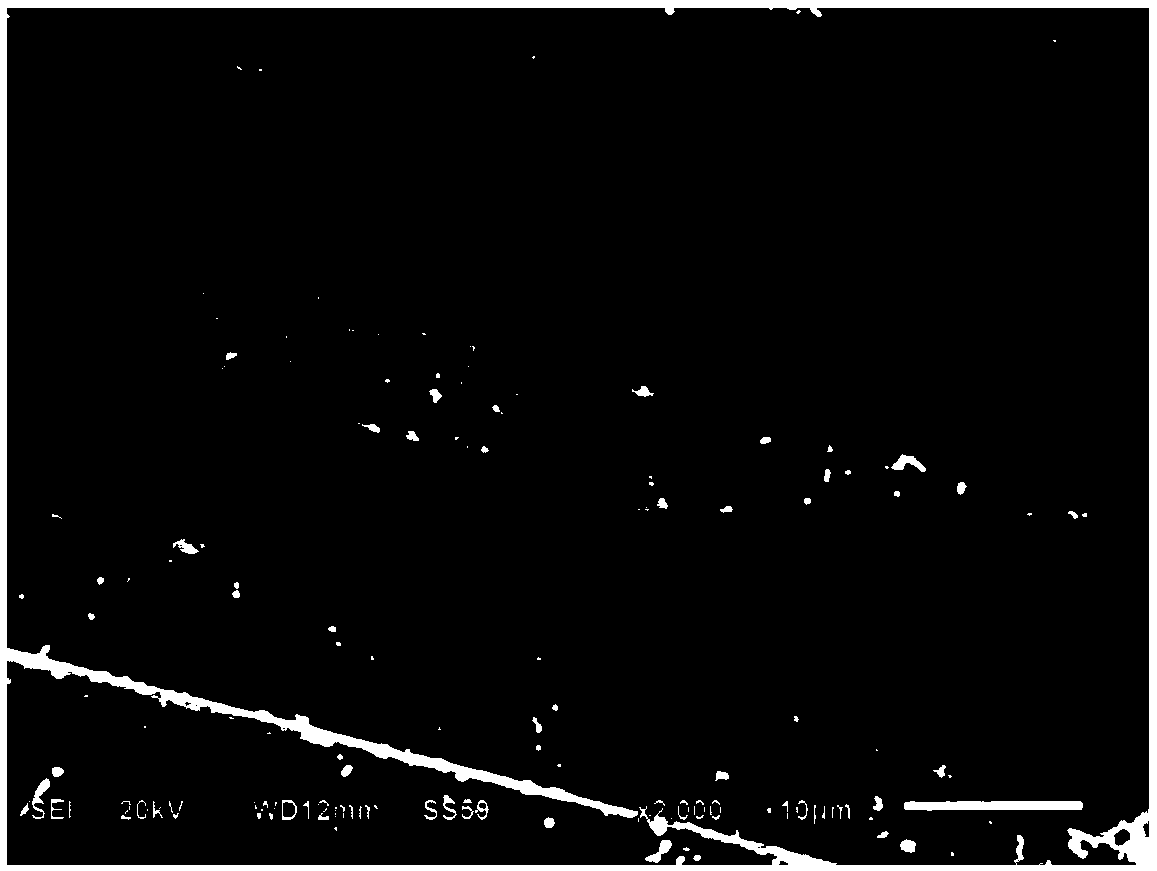

Electrical conductive member and polymer electrolyte fuel cell using the same

InactiveUS20110287336A1Improve resistanceExcellent electrical conductivitySingle bars/rods/wires/strips conductorsElectrode carriers/collectorsRaman scatteringOptoelectronics

An electrical conductive member includes: an electrical conductive structure including: a substrate (31, 152, 252, 352, 452); an electrical conductive carbon layer (33, 155, 254, 354, 454) provided on at least one surface of the substrate and containing electrical conductive carbon; and a middle layer (32, 154, 256, 356, 456) interposed between the substrate and the electrical conductive carbon layer. An intensity ratio R (ID / IG) of a D-band peak intensity (ID) to a G-band peak intensity (IG) measured by a Raman scattering spectroscopic analysis in the electrical conductive carbon layer is 1.3 or more.

Owner:NISSAN MOTOR CO LTD

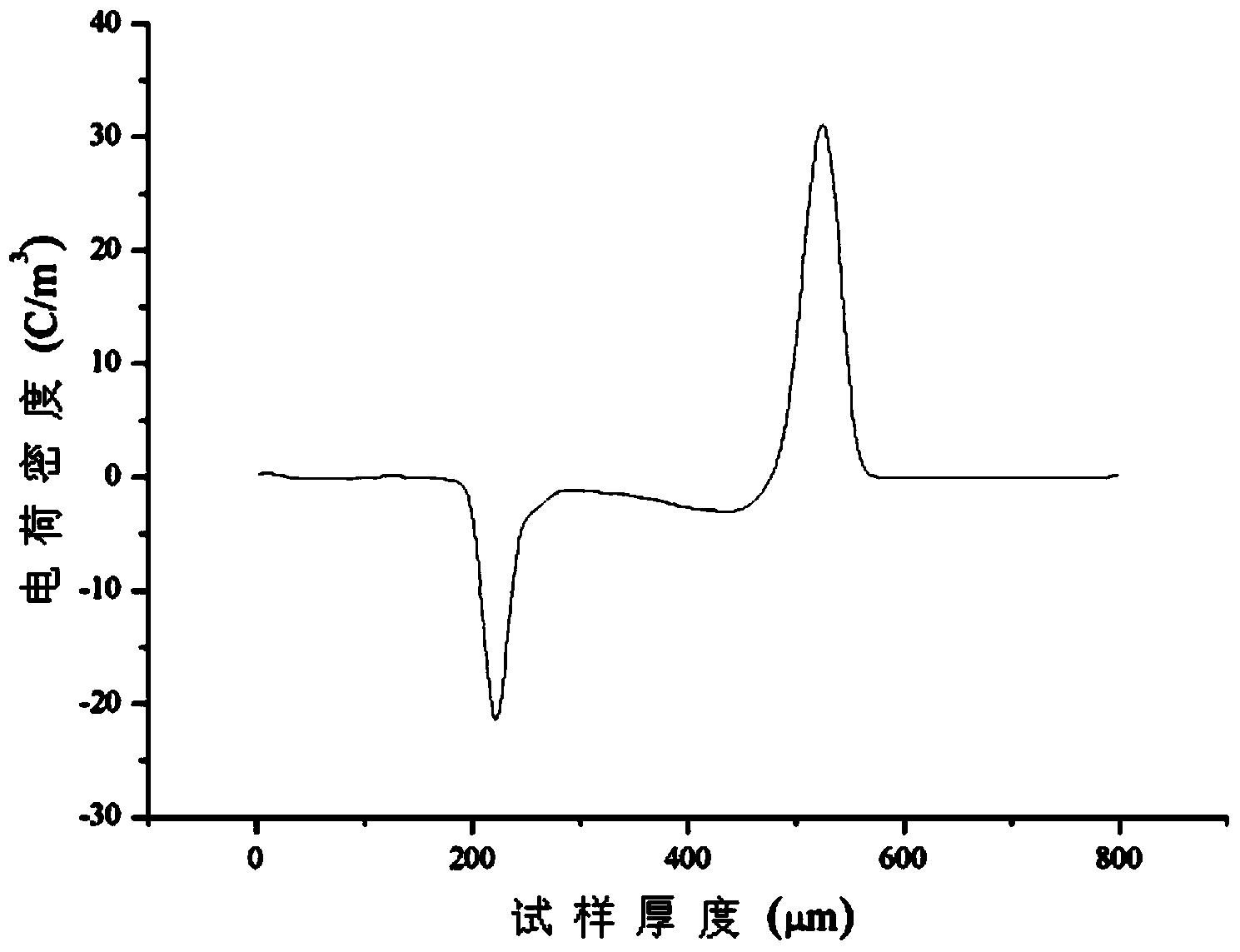

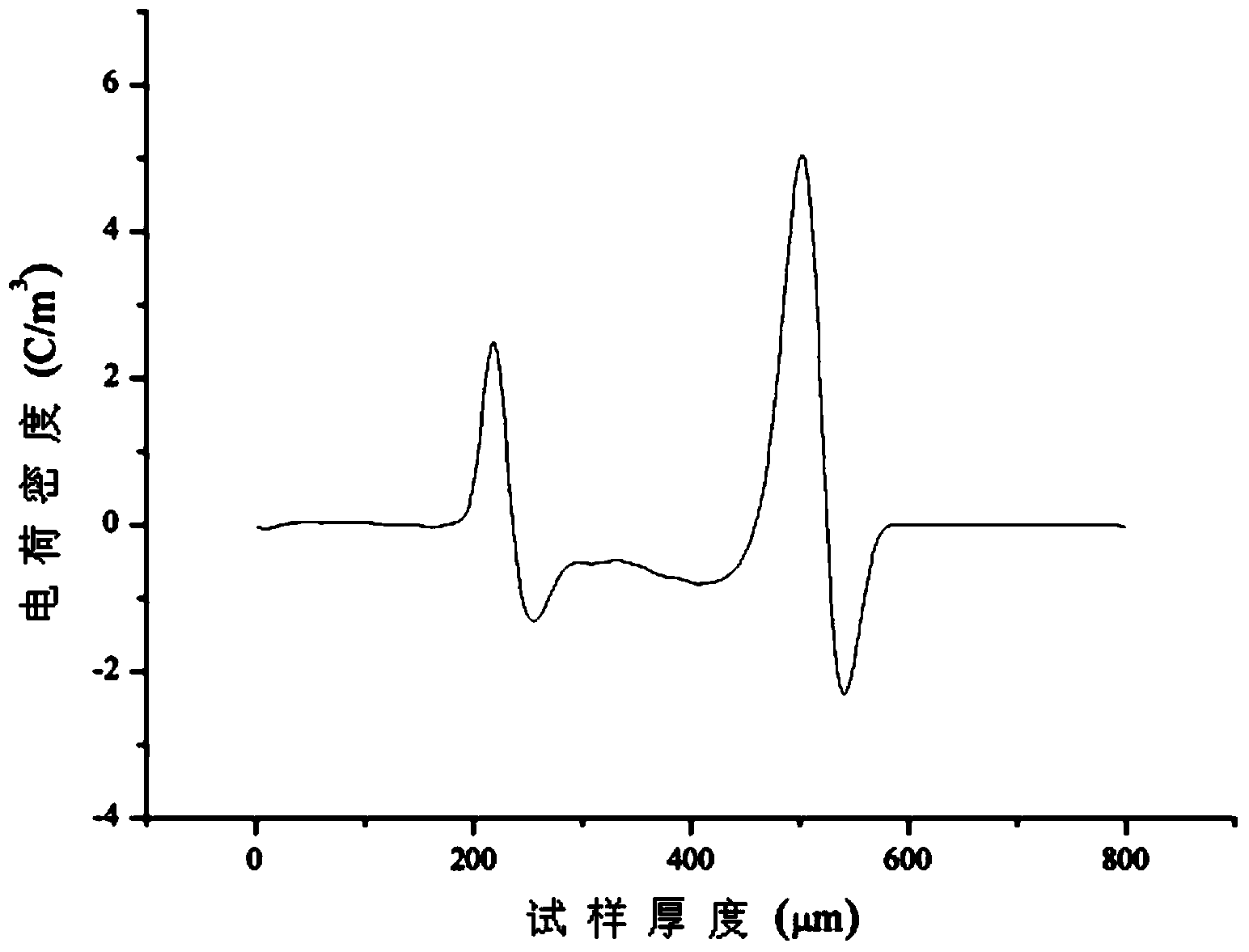

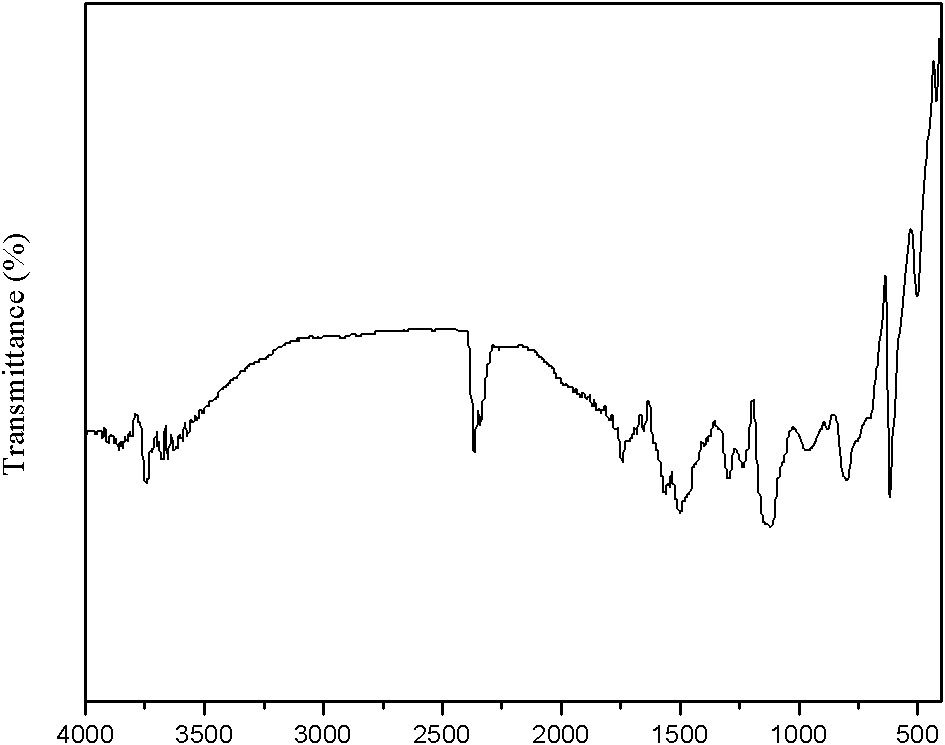

Crosslinkable polyethylene insulation material for high-voltage direct-current cable

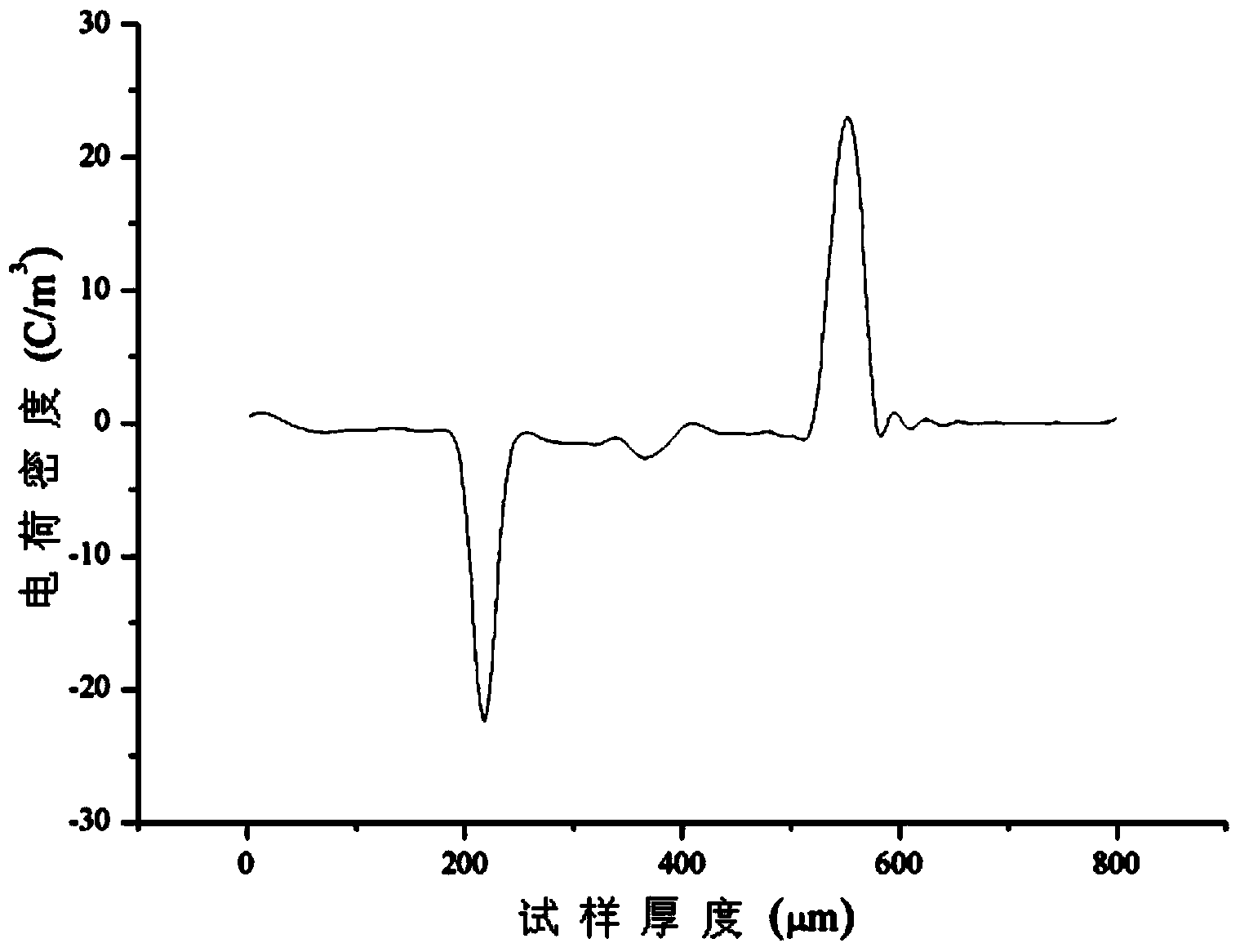

InactiveCN103965543AExcellent electrical conductivityAbility to suppress space chargePlastic/resin/waxes insulatorsCross-linked polyethyleneElectric field

The invention discloses a crosslinkable polyethylene insulation material for a high-voltage direct-current cable, relating to a crosslinkable polyethylene insulation material. The crosslinkable polyethylene insulation material is used for solving the technical problems that existing common crosslinked polyethylene is easy to generate space charge accumulation and has poor electrical conductivity characteristics under the effect of a direct-current electric field. The crosslinkable polyethylene insulation material for the high-voltage direct-current cable is prepared from the following components in parts by weight: 100 parts of low-density polyethylene, 1.5-2.2 parts of crosslinking agent, 0.2-0.5 part of antioxidant and 0.5-1.2 parts of nano-carbon material. Crosslinked polyethylene prepared by using the crosslinkable polyethylene insulation material has excellent electrical conductivity characteristics and space charge inhibiting capacities, and can be used for manufacturing the high-voltage direct-current cable to replace imported products. The crosslinkable polyethylene insulation material for the high-voltage direct-current cable, disclosed by the invention, can be applied to the field of preparation of the crosslinkable polyethylene insulation material.

Owner:HARBIN UNIV OF SCI & TECH

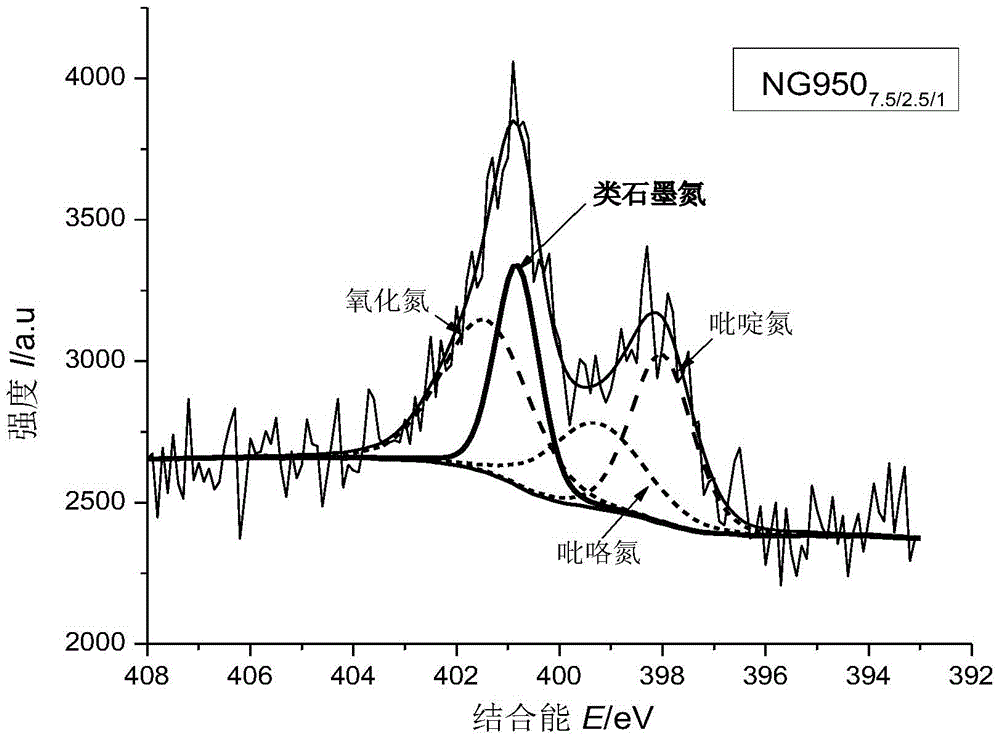

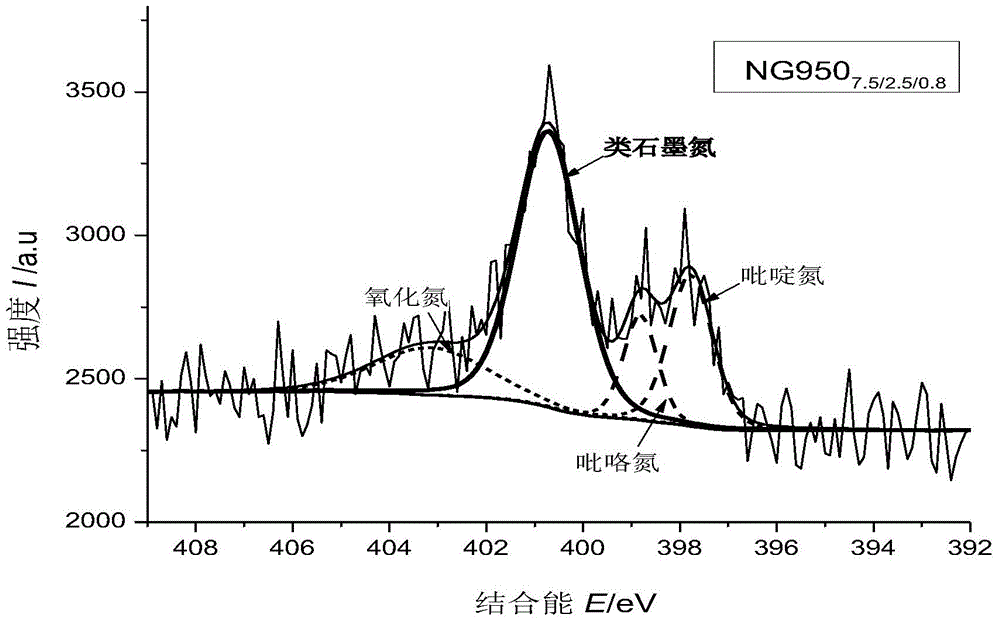

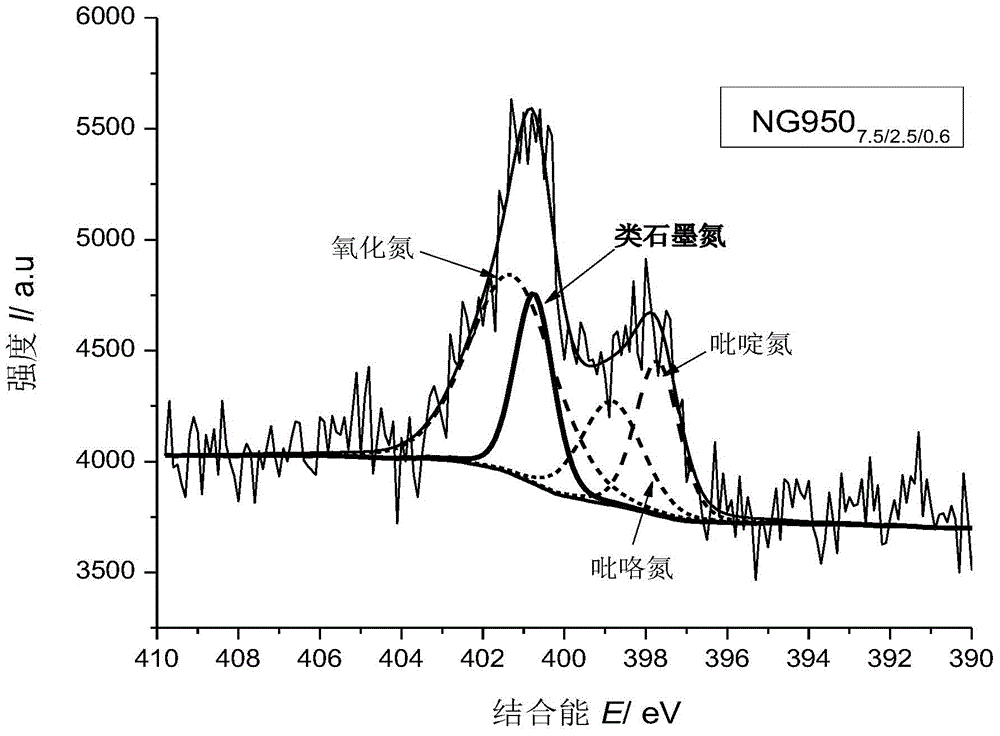

Nitrogen-doped graphene catalyst as well as preparation method and application thereof

InactiveCN104525235AIncrease inertiaImprove hydrophobicityPhysical/chemical process catalystsCell electrodesNitrogen doped grapheneNitrogen gas

The invention discloses a nitrogen-doped graphene catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: drying and dehydrating glucose and urea, and mixing with melamine, wherein the mass ratio of the urea to melamine is 2-4; uniformly grinding the mixture, and calcining the mixture into a muffle furnace at the temperature of 550 DEG C for 3 hours; cooling and grinding uniformly, adding the mixture into a tube furnace, introducing into nitrogen protection, calcining at the temperature of 850-1000 DEG C for an hour, thereby obtaining the nitrogen-doped graphene catalyst. According to the in-situ nitrogen-doped graphene disclosed by the invention, the used raw materials are low in price, the method is simple, the yield is high, and graphite-like nitrogen doped graphene with the highest ratio is obtained by changing the rate of the raw materials and the temperature, so that the catalyst has a good oxidation-reduction effect, and expensive Pt can be replaced to a certain degree.

Owner:SOUTH CHINA UNIV OF TECH

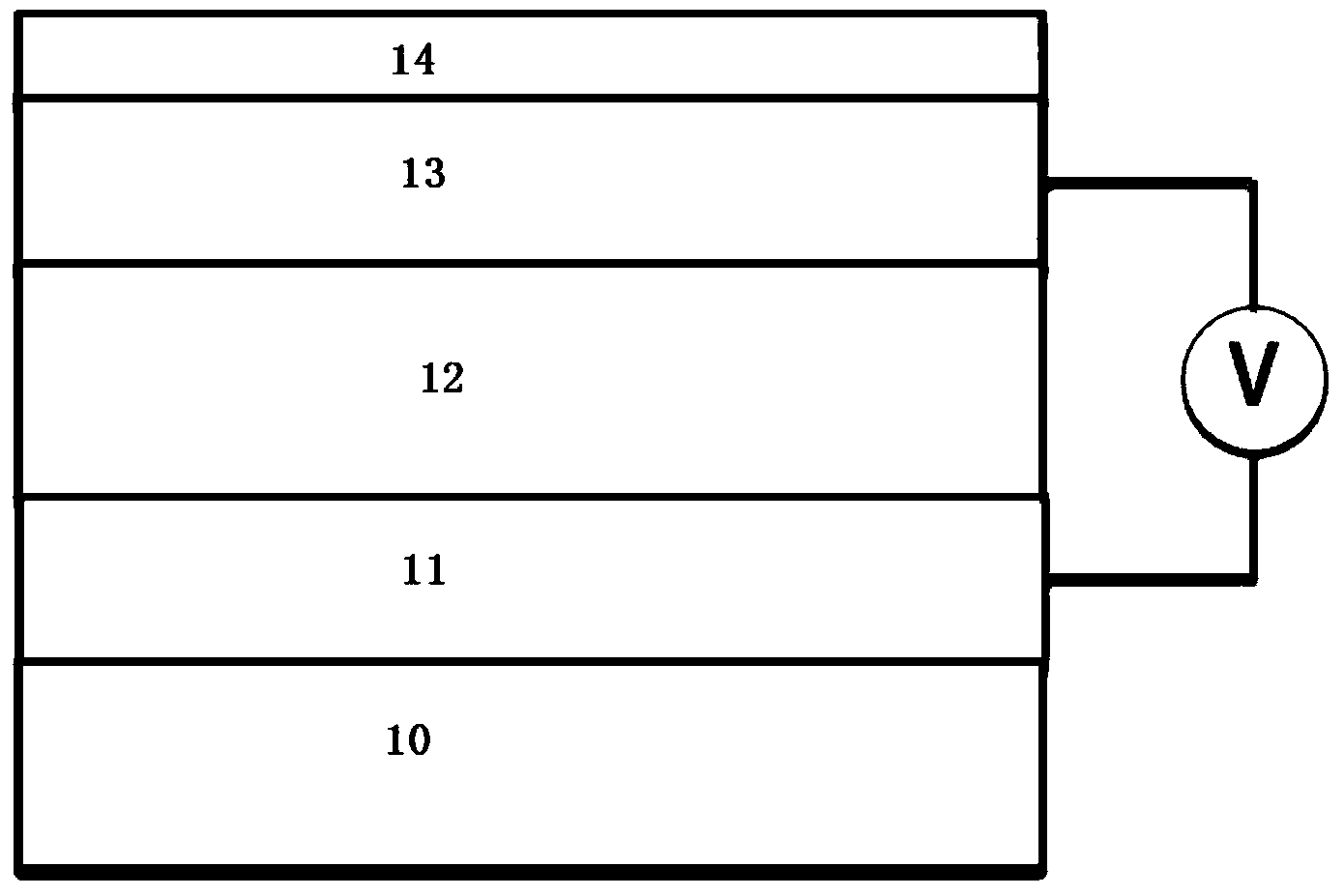

Solid-state polymer electrolyte and preparation method thereof

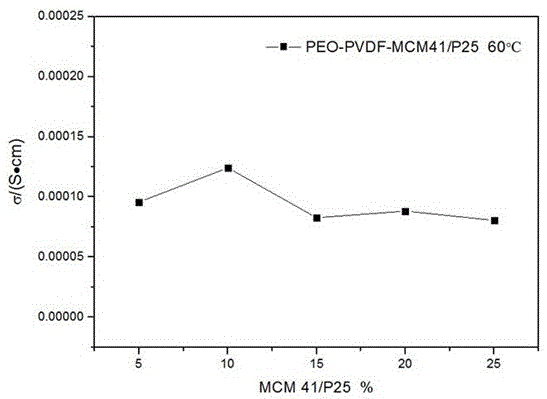

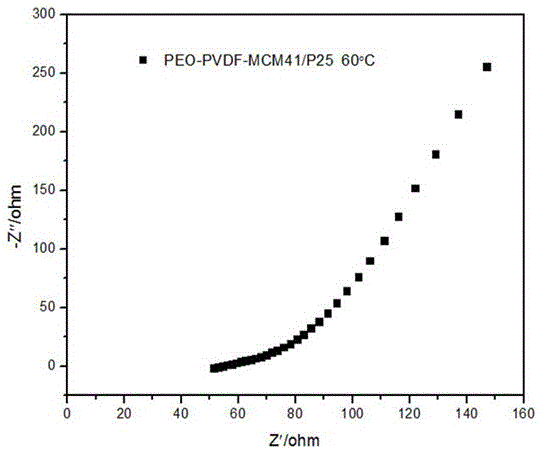

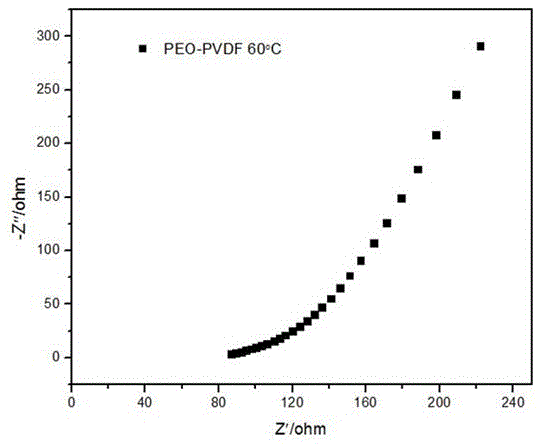

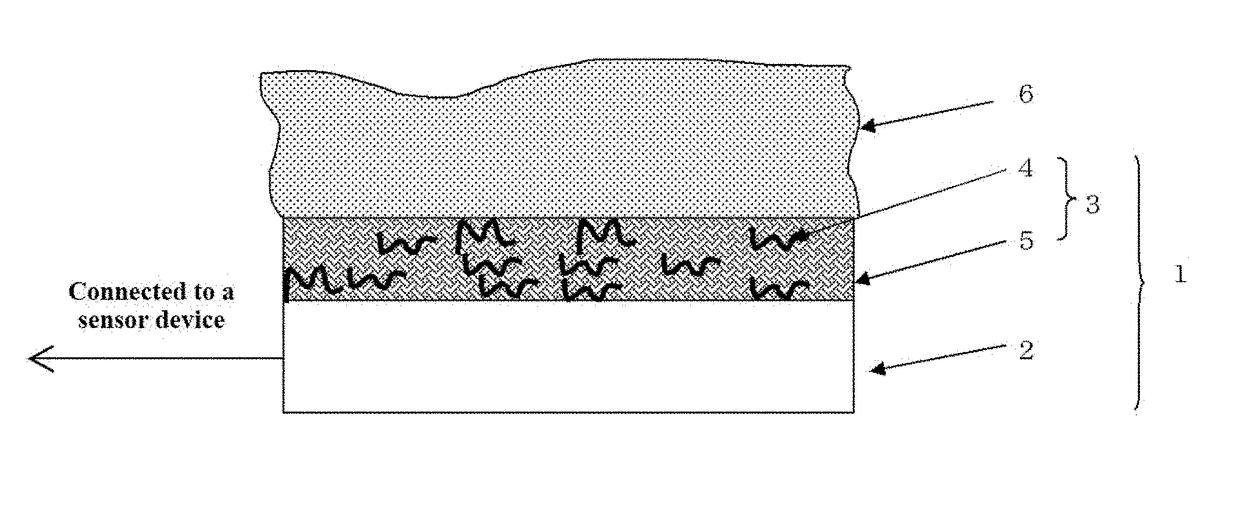

ActiveCN105680092AExcellent electrical conductivityLower internal resistanceFinal product manufactureElectrolyte accumulators manufactureSolventChemistry

The invention relates to a preparation method of a modified mesoporous silica-doped solid-state polymer electrolyte for a lithium-ion battery. The method comprises the following steps: dissolving polymer matrix into a solvent to prepare a polymer solution; with lithium perchlorate (LiClO4) as a lithium salt, dispersing the modified mesoporous silica into the obtained polymer solution; carrying out dispersing and casting to form a film; and after the solvent volatilizes, obtaining a composite polymer film, namely the composite polymer electrolyte for the lithium-ion battery. The method is simple to operate; the solid-state polymer electrolyte with high mechanical property and high ionic conductivity is easy to obtain; and the solid-state polymer electrolyte has a wide application prospect in the aspect of a power lithium-ion battery car.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

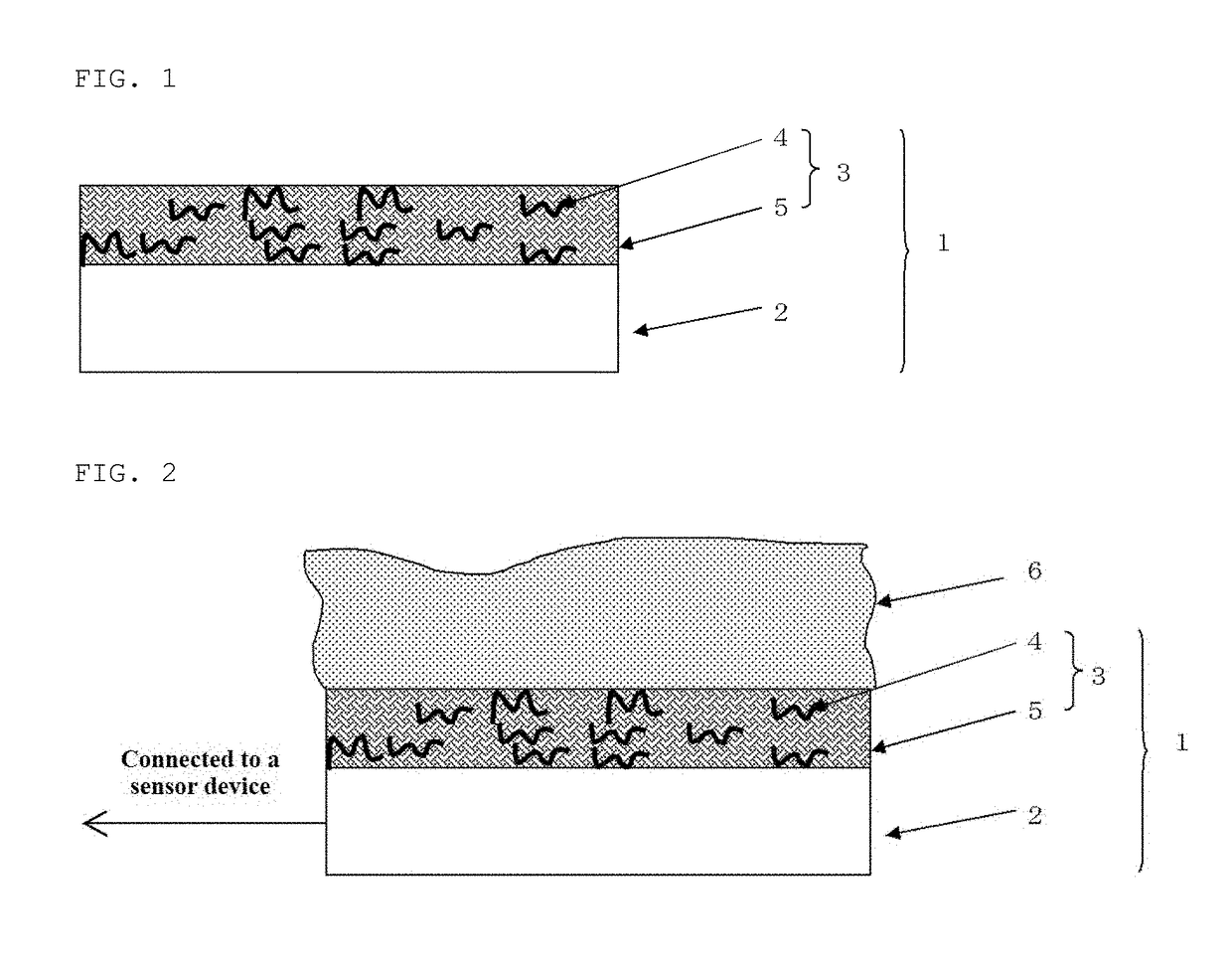

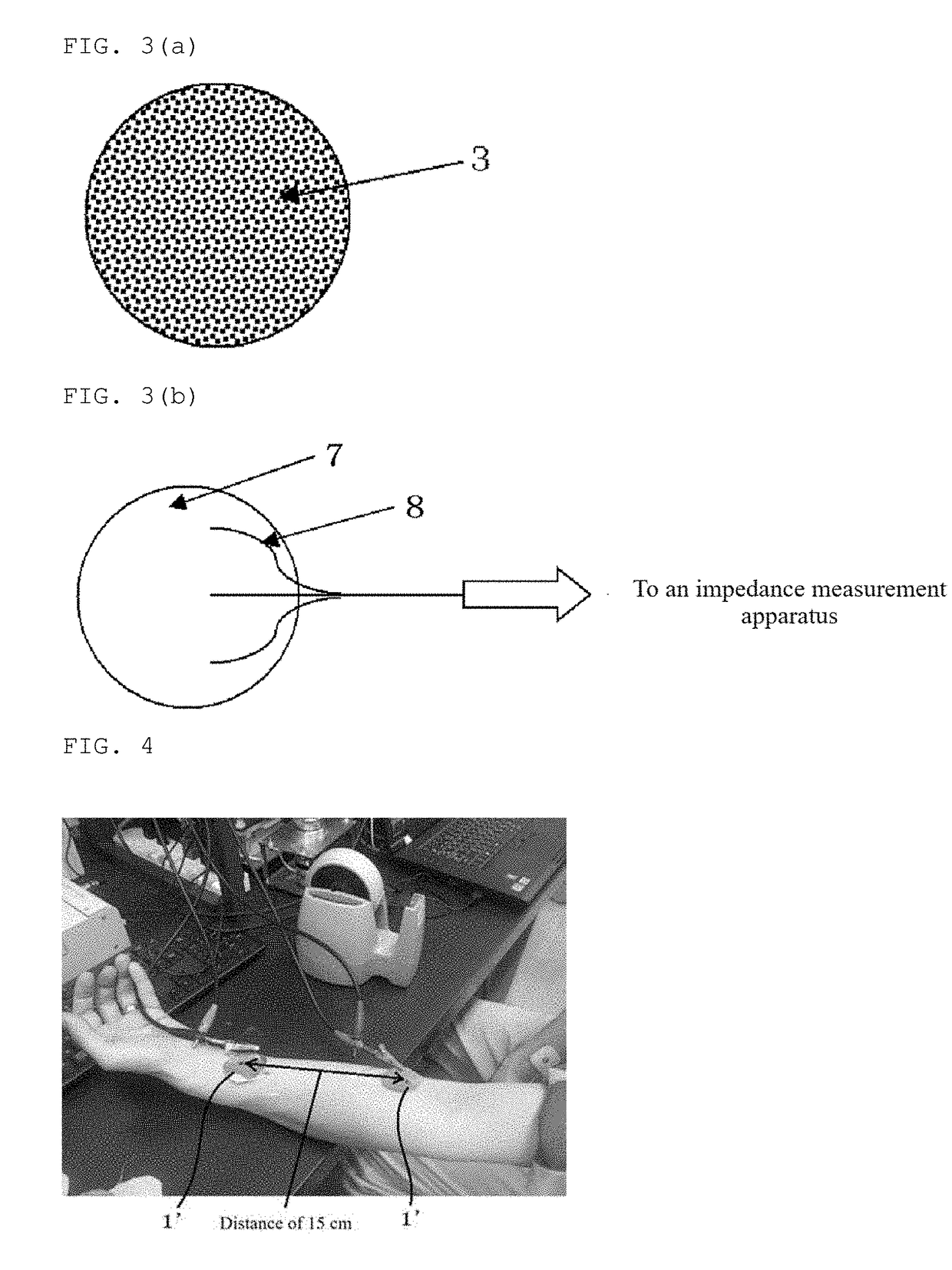

Bio-electrode composition, bio-electrode, and method for manufacturing bio-electrode

ActiveUS20180168470A1High tackiness and elasticityExcellent electrical conductivityCation exchanger materialsElectrocardiographyElectrically conductiveRepeat unit

The present invention provides a bio-electrode composition including a polymer compound having both an ionic repeating unit A and a (meth)acrylate repeating unit B, wherein the ionic repeating unit A is a repeating unit selected from the group consisting of sodium salt, potassium salt, and ammonium salt having either or both partial structures shown by the following general formulae (1-1) and (1-2), and the (meth)acrylate repeating unit B is a repeating unit shown by the following general formula (2).This can form a living body contact layer for a bio-electrode with excellent electric conductivity, biocompatibility, and light weight, which can be manufactured at low cost and does not cause large lowering of the electric conductivity even when it is wetted with water or dried.

Owner:SHIN ETSU CHEM CO LTD

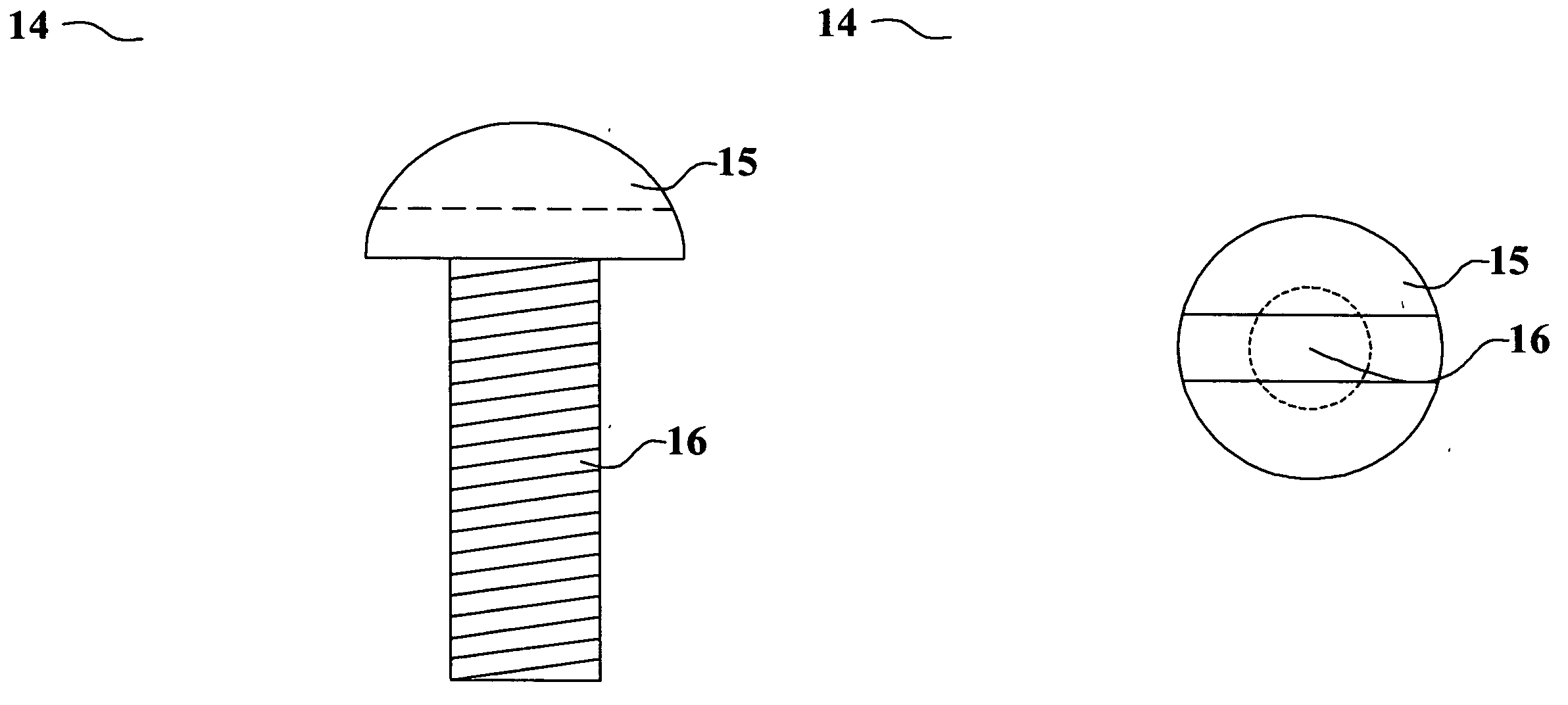

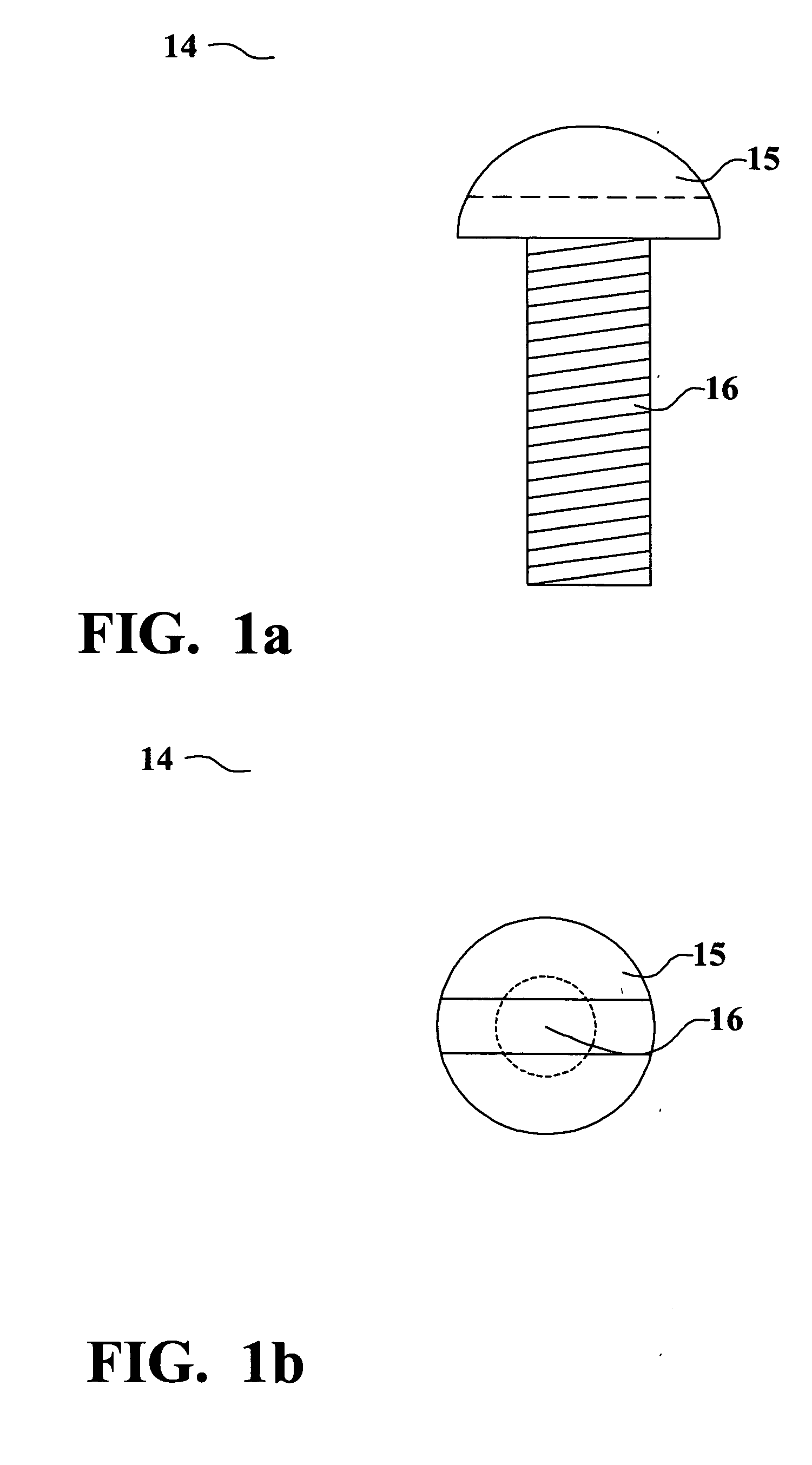

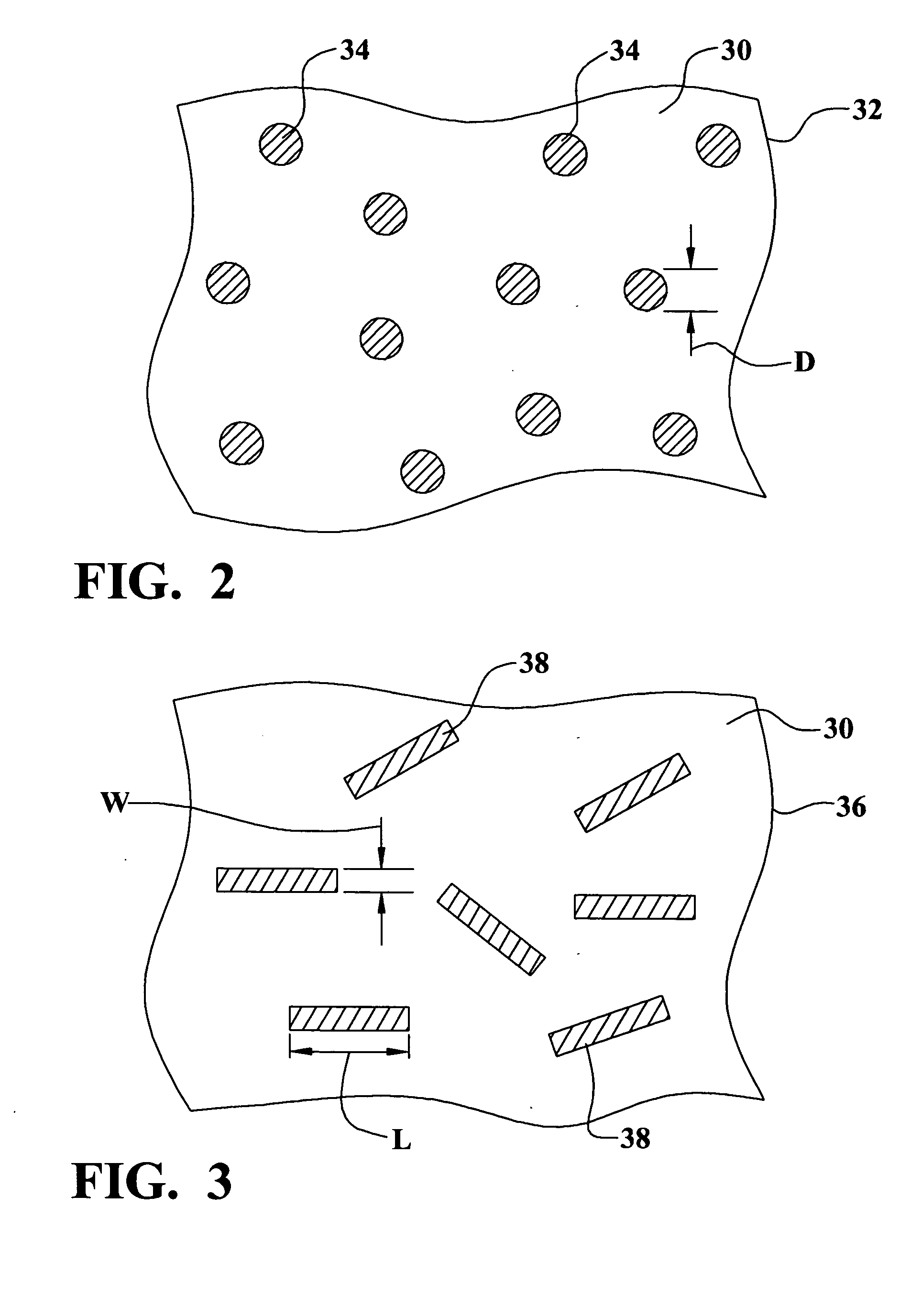

Low cost hardware manufactured from conductive loaded resin-based materials

InactiveUS20050200136A1Excellent electrical conductivityExcellent thermal conductivityAntenna arraysAntenna supports/mountingsFastenerNickel plate

Hardware fastener devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

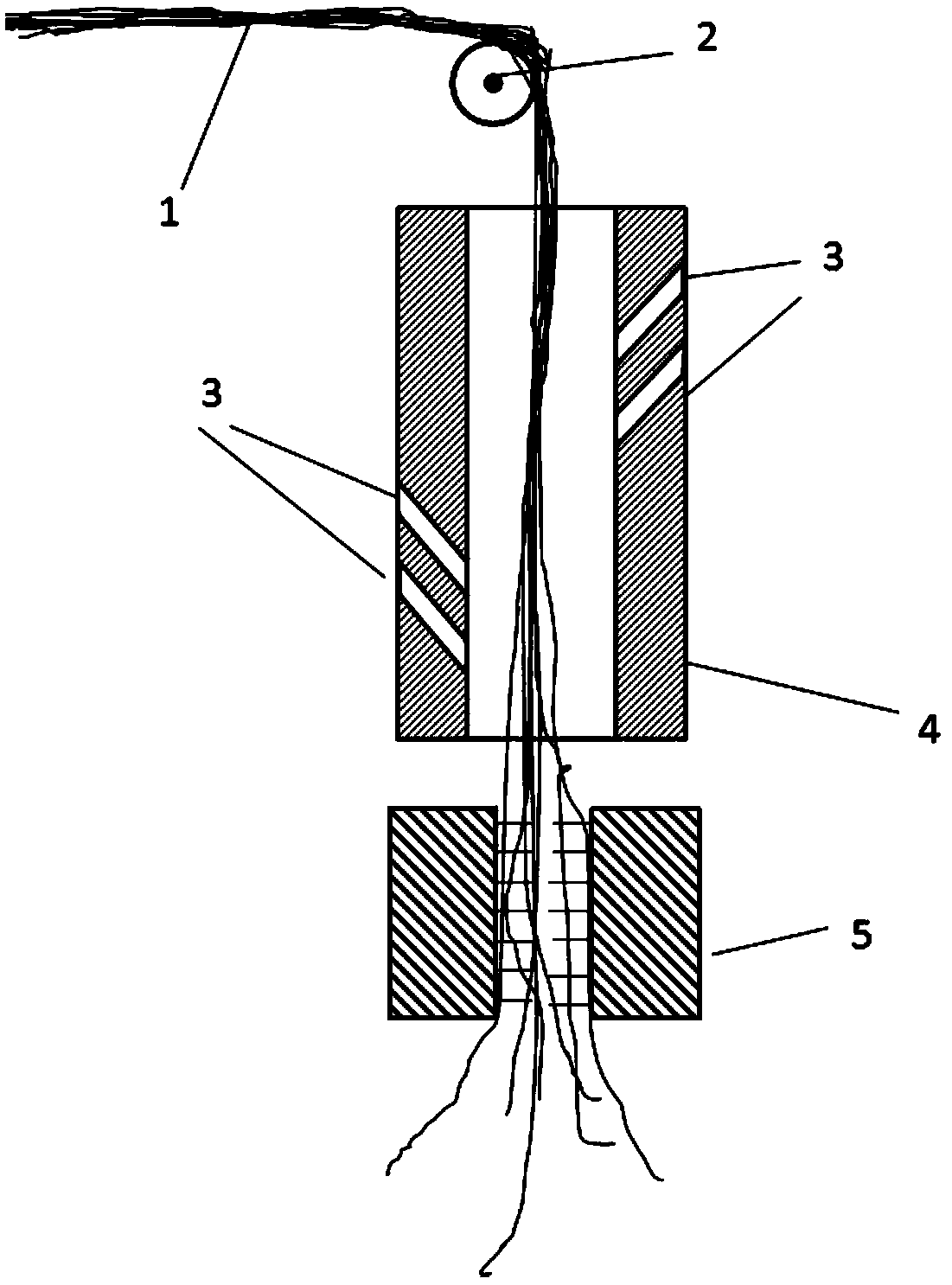

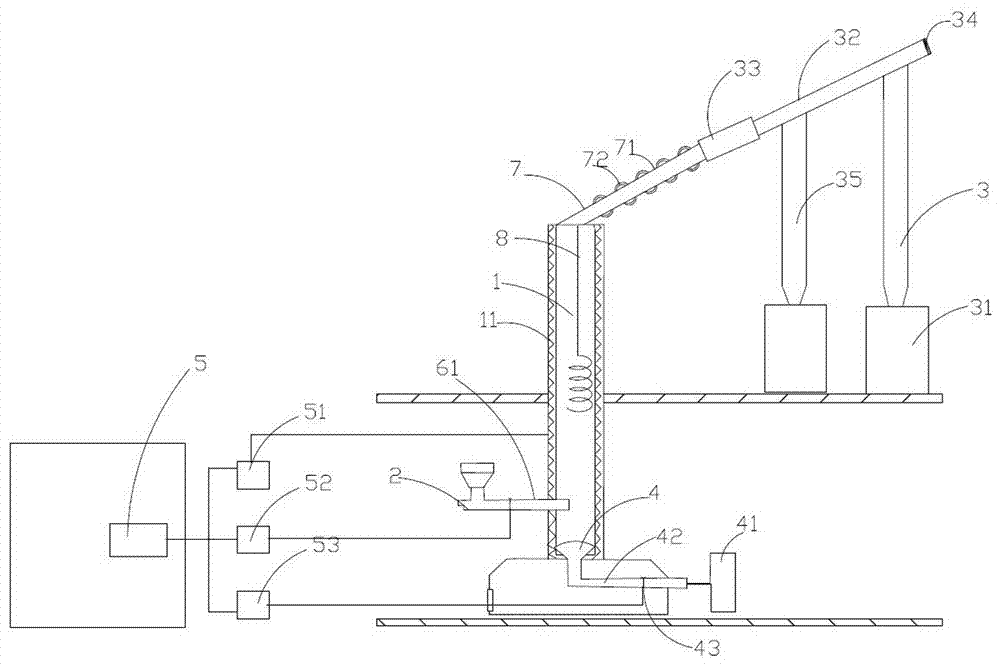

Preparation method of continuous carbon fiber reinforced aluminum-based composite material

The invention provides a preparation method of a continuous carbon fiber reinforced aluminum-based composite material. According to the preparation method provided by the invention, the thickness of an aluminum layer adhered to the surface of the carbon fiber can be controlled by adopting a method of adhering curing aluminum powder to the surface of continuous carbon fiber through organogel, so that the content and the spacing of the carbon fiber in a composite material after hot pressing sintering can be controlled, the carbon fiber can be parallelly distributed in an aluminum matrix, and analuminum-based composite material with high carbon fiber content can be prepared. The preparation method disclosed by the invention is low in cost and easy to operate and is capable of realizing industrialized production; the strength of the carbon fiber reinforced aluminum-based composite material obtained through the preparation method provided by the invention is obviously superior to that of the carbon fiber reinforced aluminum-based composite material prepared through an existing infiltration method, and a wide application prospect is obtained.

Owner:江苏戍卫新材料科技有限公司

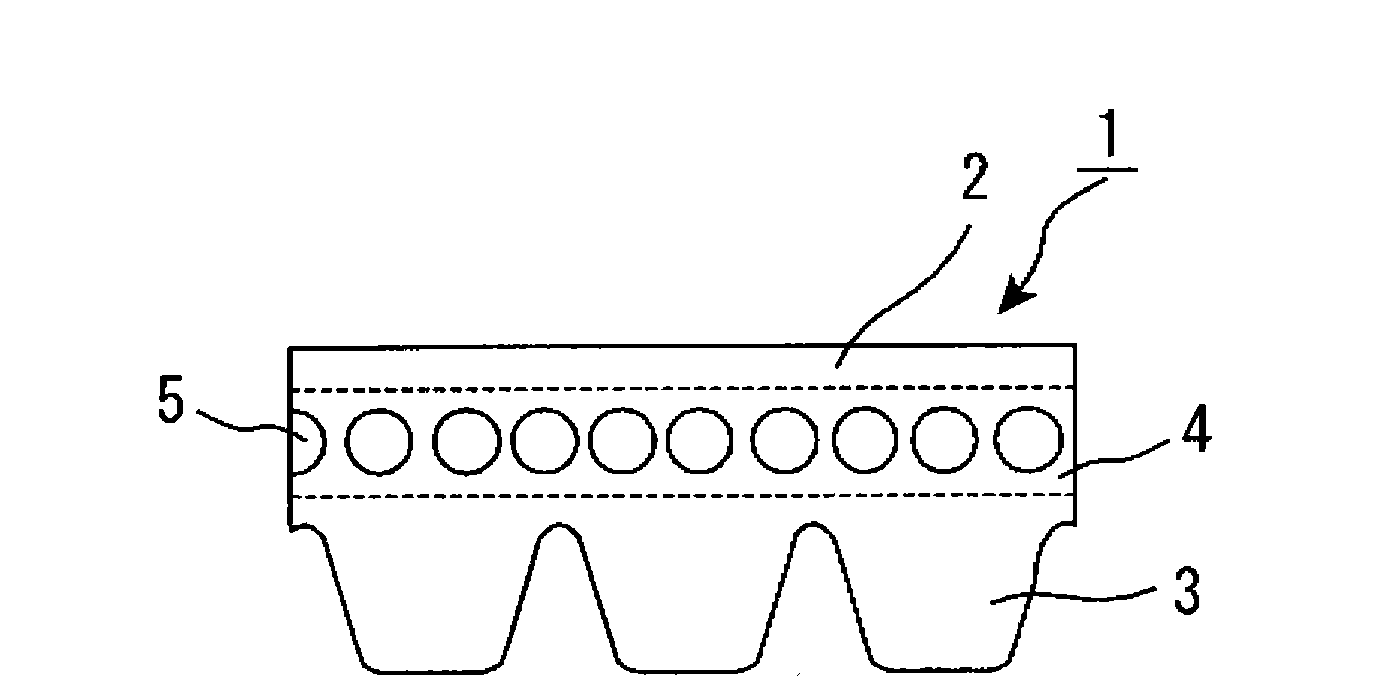

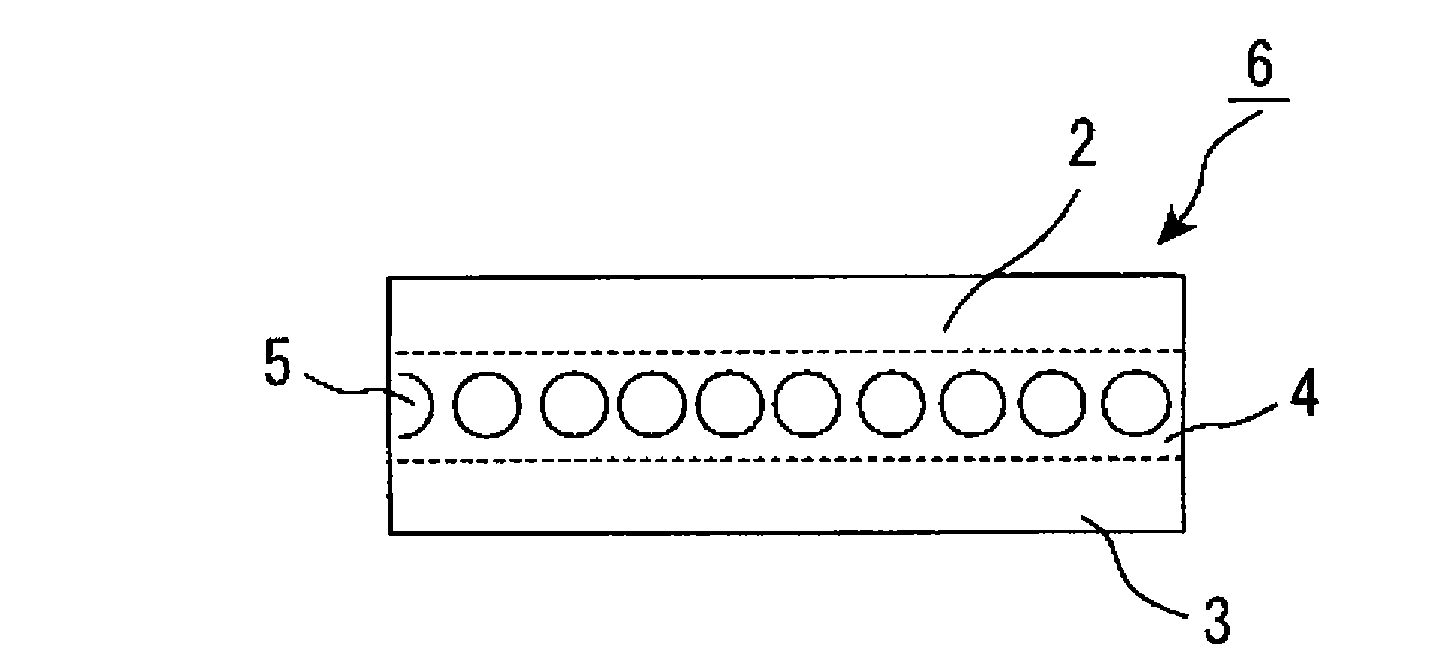

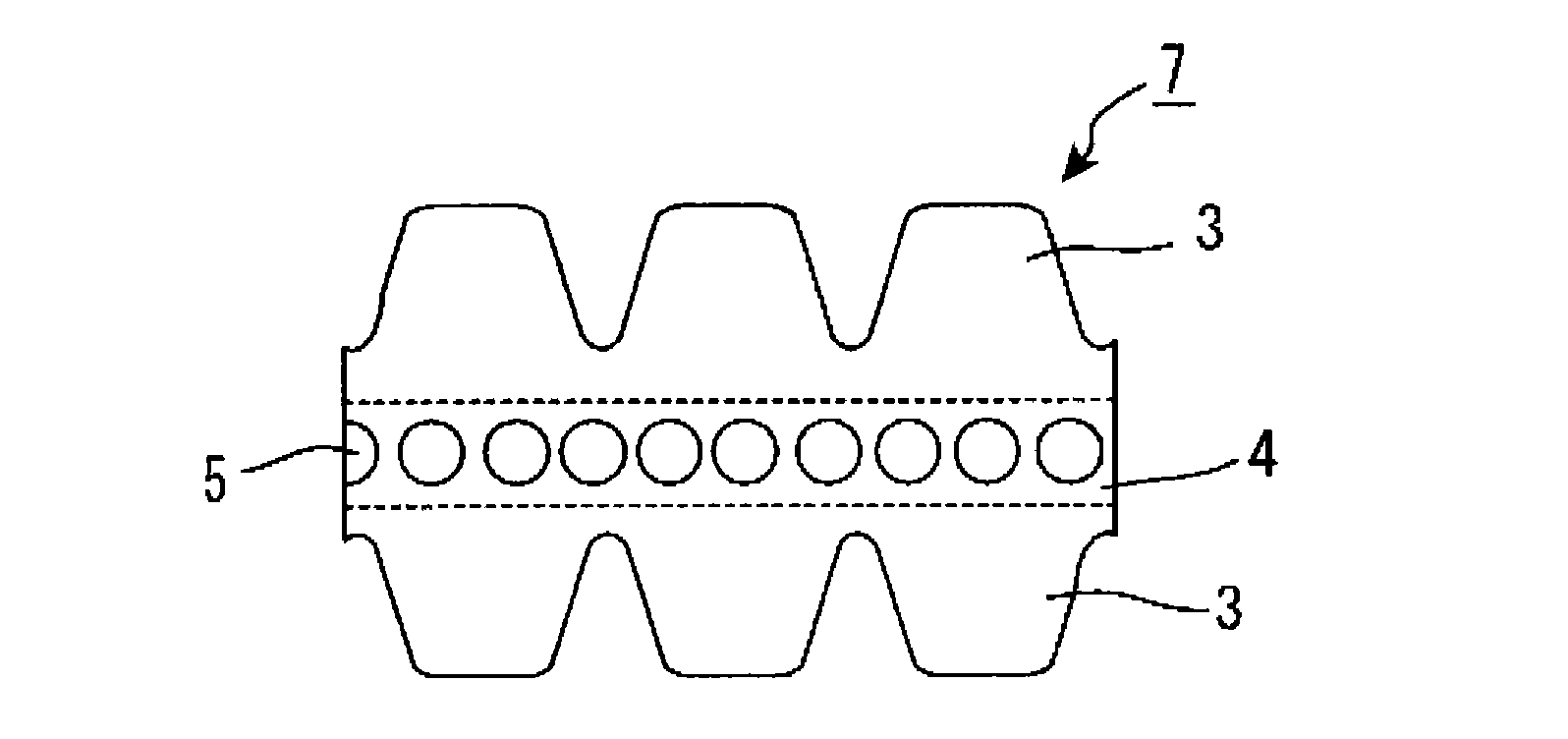

Rubber composition for transmission belt and transmission belt

InactiveCN101636447AImprove conductivityHigh bending fatigue resistanceV-beltsDriving beltsPolymer scienceTransmission belt

This invention provides a rubber composition for a transmission belt, which can realize the manufacture of a transmission belt excellent in electroconductivity as well as in electroconductivity retaining property after running and having excellent resistance to fatigue from flexing and abrasion resistance. The rubber composition contains rubber, furnace carbon black, zinc oxide, and stearic acid. The furnace carbon black has a nitrogen adsorption specific surface area of not less than 75 m<2> / g and a DBP absorption of not less than 100 cm<3> / 100g and is contained in an amount of 50 to 100 parts by mass based on 100 parts by mass of the rubber. The content of the zinc oxide is not less than 6 parts by mass based on 100 parts by mass of the rubber. The content of the stearic acid is not less than 1 part by mass based on 100 parts by mass of the rubber.

Owner:BANDO CHEM IND LTD

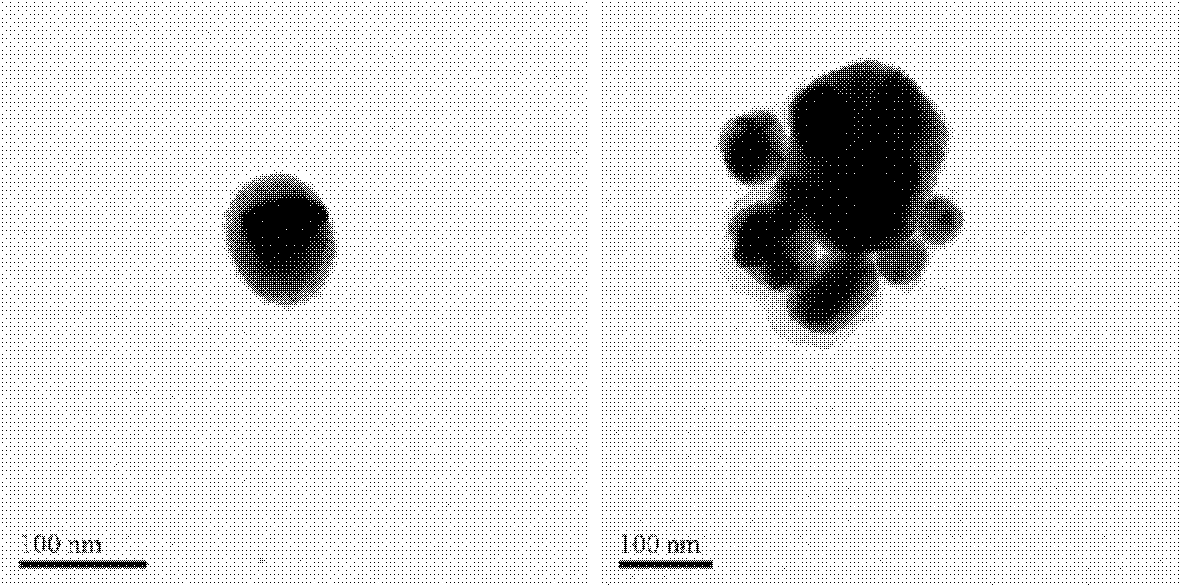

Method for preparing polyaniline/silver nanocomposite material

InactiveCN101838461AImprove conductivityGood dispersionElectrolytic capacitorsActive material electrodesMicroemulsionElectrochemistry

The invention provides a method for preparing a polyaniline / silver nanocomposite material, which belongs to the technical field of composite materials. The method comprises the following steps of: preparing nano-silver particles in microemulsion; and compounding polyaniline in situ to form a nanocomposite material. By using the method, the problem of the agglomeration of nano-silver particles in a composite material can be solved; an organic-inorganic nanocomposite material of a core-shell coating structure of which the nano-silver particles are inside and the polyaniline is outside is formed; and the organic-inorganic nanocomposite material has the characteristics of high electric conductivity, thermal property and electrochemical performance, and good application prospect. The method has the characteristics of simple process, low production cost, high production efficiency and good industrial production prospect.

Owner:CENT SOUTH UNIV

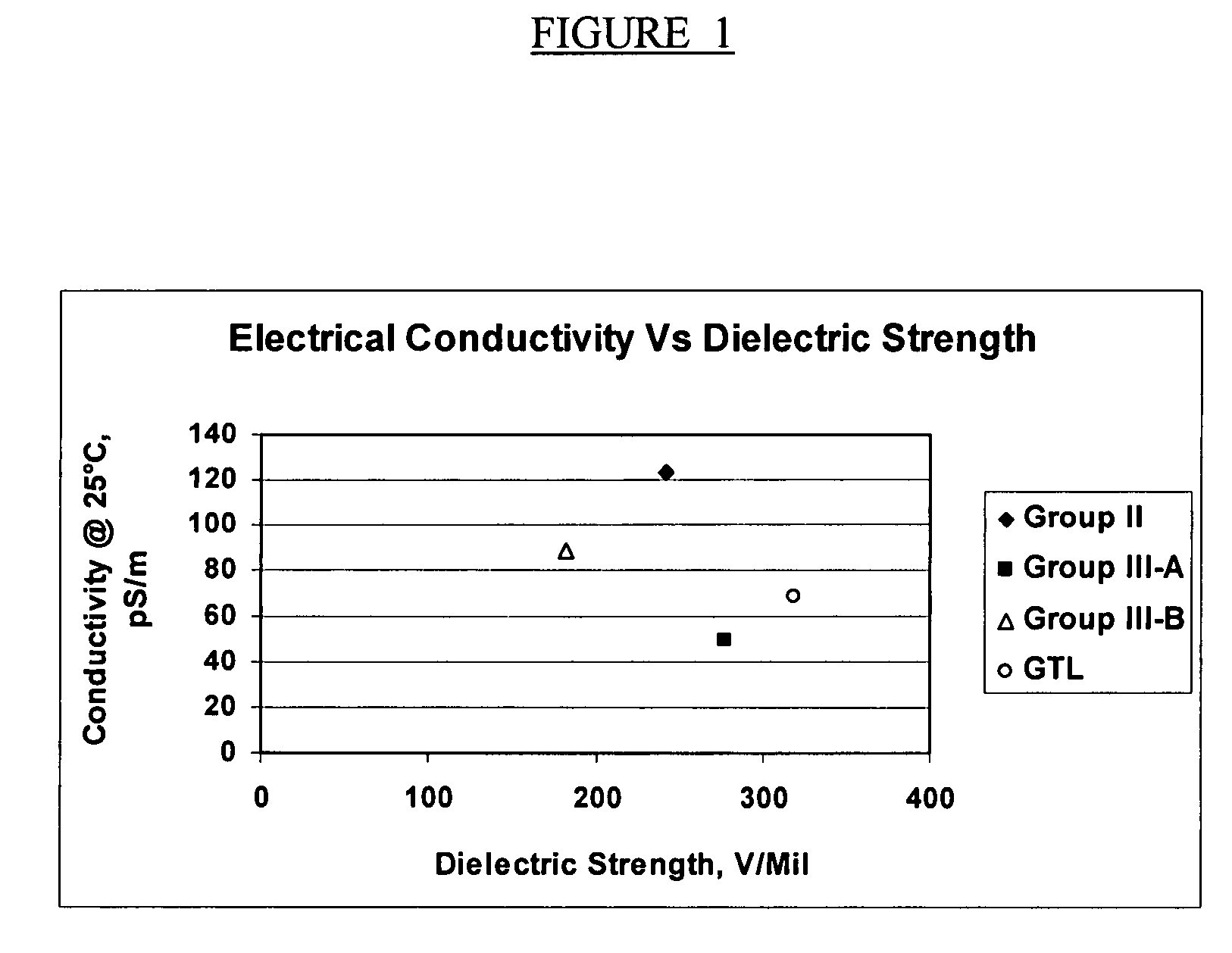

Lubricant composition with improved electrical properties

InactiveUS20080234155A1Improved electrical propertyExcellent electrical conductivityOrganic chemistryLubricant compositionVarnishElectrical resistivity and conductivity

A lubricant composition for improving electrical properties in lubricant systems to reduce the formation of sludge and varnish is disclosed. The lubricant composition comprises a base oil and an effective amount of antistatic additive to provide the composition with an electrical conductivity of at least about 50 pS / m at 25° C. and a dielectric strength of at least 300 V / mil.

Owner:EXXON RES & ENG CO

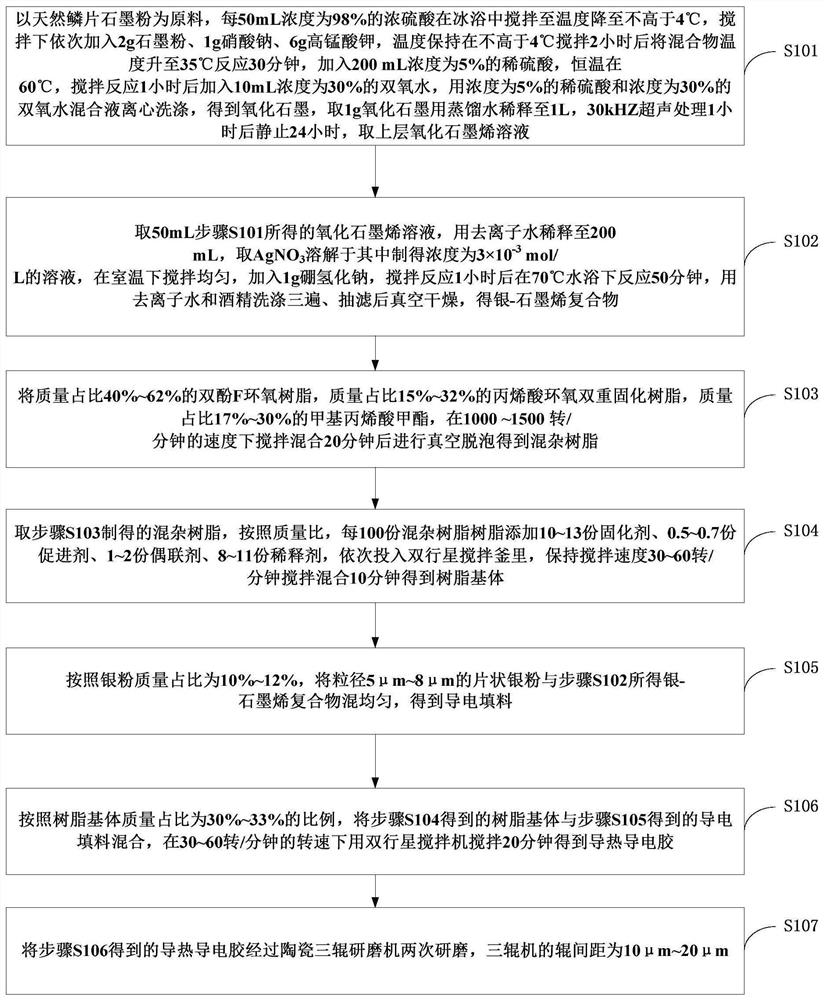

Thermosetting conductive adhesive and preparation method thereof

ActiveCN108753197AEasy to store and useExcellent electrical conductivityPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesVolatile organic compoundSilver particles

The invention discloses a thermosetting conductive adhesive. The thermosetting conductive adhesive comprises, by weight, 50-70% of a conductive filler, 1-20% of a thermosetting resin, 0-20% of volatile organic compound and 1-30% of a nano-silver cross-linking agent. The nano-silver cross-linking agent comprises nano-silver particles with the sizes of 1-100mm and oligomers are adsorbed onto the surfaces of the nano-silver particles. The group at one end of the oligomer is selected from a carboxyl group, a mercapto group and an amino group and the group at the other end of the oligomer is selected from a carboxyl group, a mercapto group and an amino group. Two ends of the thermosetting resin contain reactive epoxy groups. The invention also provides a preparation method of the thermosettingconductive adhesive. The conductive adhesive has a stable system at the normal temperature, is easy to store, resists aging and has excellent electrical conductivity.

Owner:佛山市瑞纳新材科技有限公司

PET/microcrystalline graphene composite heat-conducting film and preparation method thereof

InactiveCN107337804AUniform structureImprove permeabilityHeat-exchange elementsCoatingsProcess optimizationThermal diffusion coefficient

The invention relates to the field of preparation of graphene composites and discloses a PET / microcrystalline graphene composite heat-conducting film and a preparation method thereof. Expanded graphite is creatively prepared from microcrystalline graphite used as a raw material through secondary intercalation, a high-quality graphene product is obtained through ultrasonic treatment with a mechanical exfoliation method, and the PET / microcrystalline graphene composite heat-conducting film with high heat conductivity can be prepared in batches through process optimization of the graphene product. The prepared PET / microcrystalline graphene composite heat-conducting film has the graphene coating thickness of 3-9 mu m, the thermal diffusion coefficient of 8-12 cm<2> / S and the heat conductivity coefficient of 1,400-1,700 W / (m*k).

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

High-thermal-conductivity conductive adhesive and preparation method thereof

InactiveCN112239638AExcellent thermal conductivityExcellent electrical conductivityNon-macromolecular adhesive additivesModified epoxy resin adhesivesDual curePolymer science

The invention discloses a high-thermal-conductivity conductive adhesive and a preparation method thereof. The high-thermal-conductivity conductive adhesive comprises a resin matrix and a conductive filler, and the mass ratio of the resin matrix is 30%-33%; wherein the resin matrix comprises hybrid resin, the hybrid resin (100 parts by weight) comprises 10-13 parts by mass of a curing agent, 0.5-0.7 part by mass of an accelerant, 1-2 parts by mass of a coupling agent and 8-11 parts by mass of a diluent ; the hybrid resin comprises the following components in percentage by mass: 40%-62% of bisphenol F epoxy resin, 15%-32% of acrylic acid epoxy dual-cured resin and 17%-30% of methyl methacrylate; the conductive filler is a mixture of flake silver powder and a silver-graphene compound; test results show that the heat conduction and electric conduction effects of the high-thermal-conductivity conductive adhesive are superior to those of existing products on the market, the use performance of LED products is improved, and the service life of the LED products is prolonged.

Owner:东莞市华卓电子科技有限公司

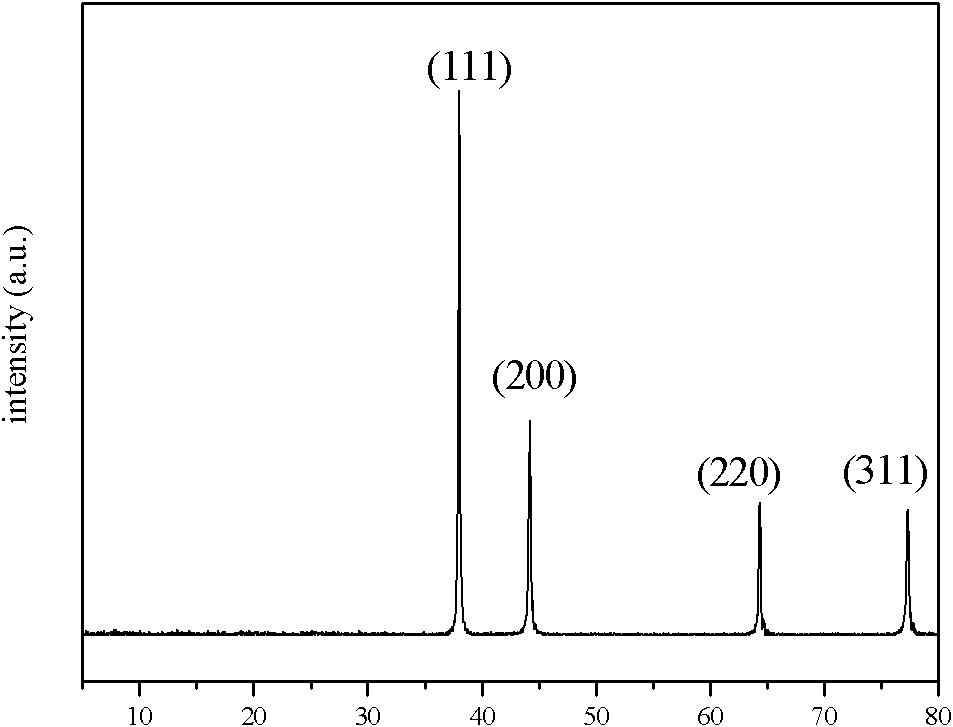

Nano-silver powder and, preparation of nano-silver powder and application of nano-silver powder in low-temperature curing conductive silver paste

ActiveCN109692971AExcellent electrical conductivityGuarantee application performanceTransportation and packagingMetal-working apparatusAmmonium hydroxideSilver paste

The invention provides a nano-silver powder, a preparation of the nano-silver powder and an application of the nano-silver powder in low-temperature curing conductive silver paste. A method for preparing the nano-silver powder adopts epoxy resin as a dispersing agent, hydrazine hydrate, ascorbic acid and one kind or several kinds of glucose as a reducing agent, and a silver-ammonia solution as a silver source, and the high-dispersity nano-silver powder with the particle size of 50 nm-700 nm is prepared through a reduction reaction. According to the method, the epoxy resin is used as the dispersing agent, the prepared nano-silver powder is applied to low-temperature curing conductive silver paste of the same resin system, the compatibility between the silver powder and the resin in the low-temperature curing conductive silver paste can be improved, so that the conductivity of the slurry is improved, by taking the nano-silver powder as a raw material, the low-temperature cured conductingsilver paste with square resistance which is reduced to 20 m Ohm / sq.

Owner:TAIYUAN HYPERION NEW MATERIAL CO LTD

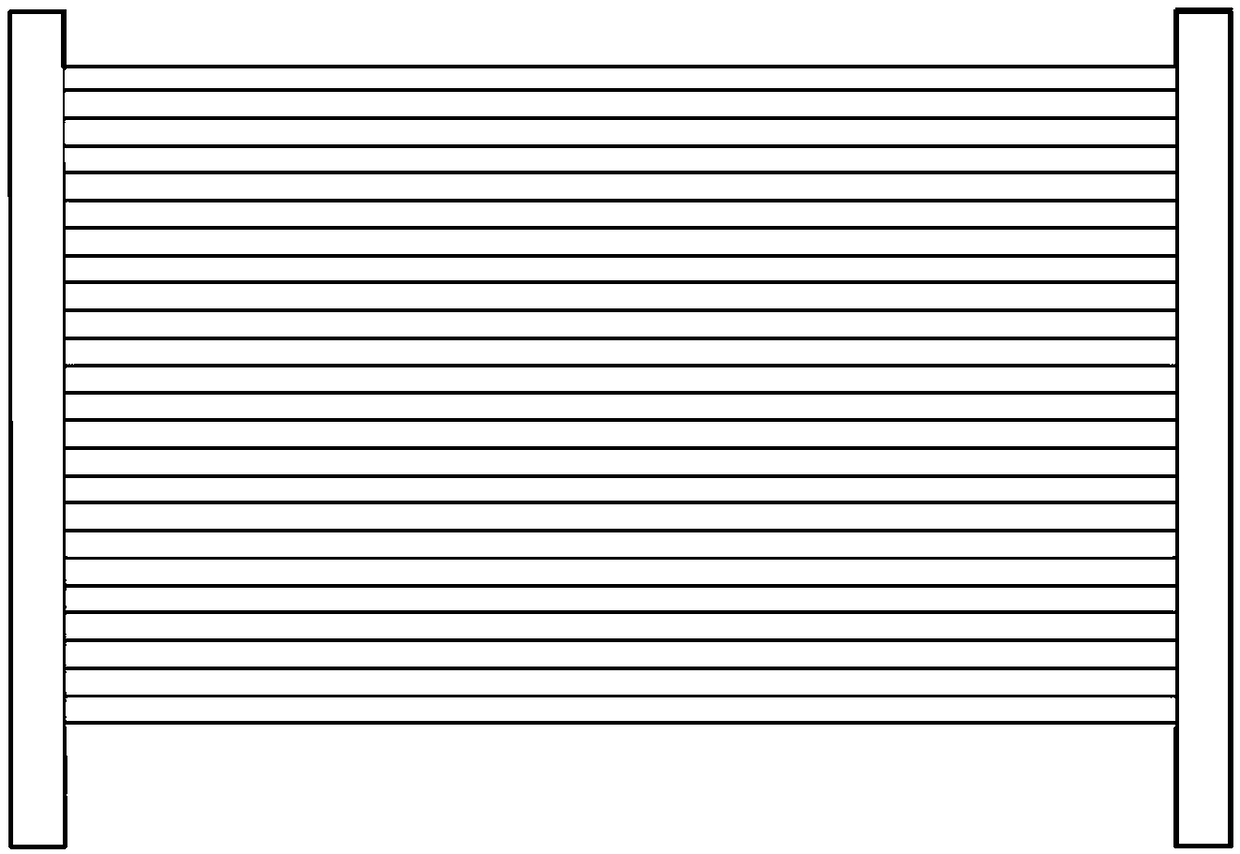

Preparation method of electric conduction polyimide film

InactiveCN107286654APrevent electrostatic dischargeExcellent electrical conductivitySteel platesSurface resistivity

The invention discloses a preparation method of an electric conduction polyimide film. The preparation method comprises: placing an aromatic diamine and an aromatic dianhydride in an aprotic polar solvent according to a molar ratio of 1:0.992-0.998, and carrying out a reaction to obtain a polyamic acid solution; adding carbon-based electric conduction particles to the polyamic acid solution, and uniformly dispersing by using a high shear dispersing machine to obtain a black mixing solution, wherein the carbon-based electric conduction particles account for 1-10 wt% of the total amount of the aromatic diamine and the aromatic dianhydride; coating a stainless steel plate with the mixing solution, drying, and stripping to obtain a gel film; and fixing the periphery of the gel film on a metal frame, placing in an imidization furnace, and carrying out imidization to obtain the electric conduction polyimide film. According to the present invention, the prepared electric conduction polyimide film has the volume resistivity of 10<3>-10<8>omega.cm, has the surface resistivity of 10<4>-10<8>omega.cm<2>, and further has performances of high strength, high modulus and the like.

Owner:ANHUI GUOFENG PLASTIC

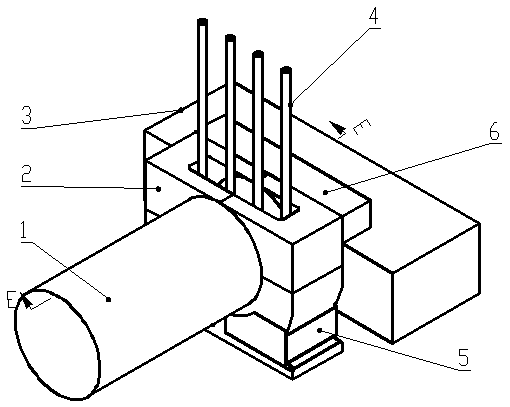

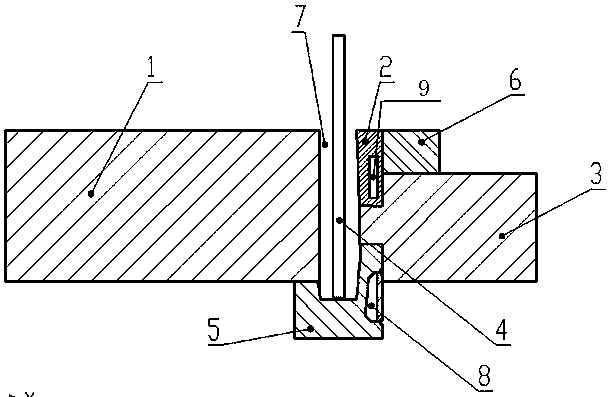

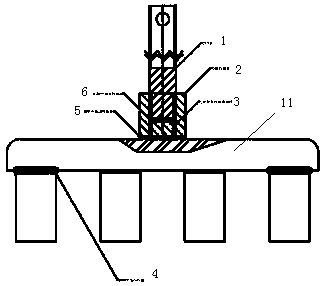

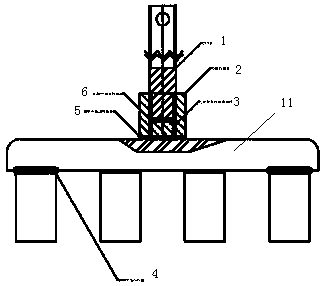

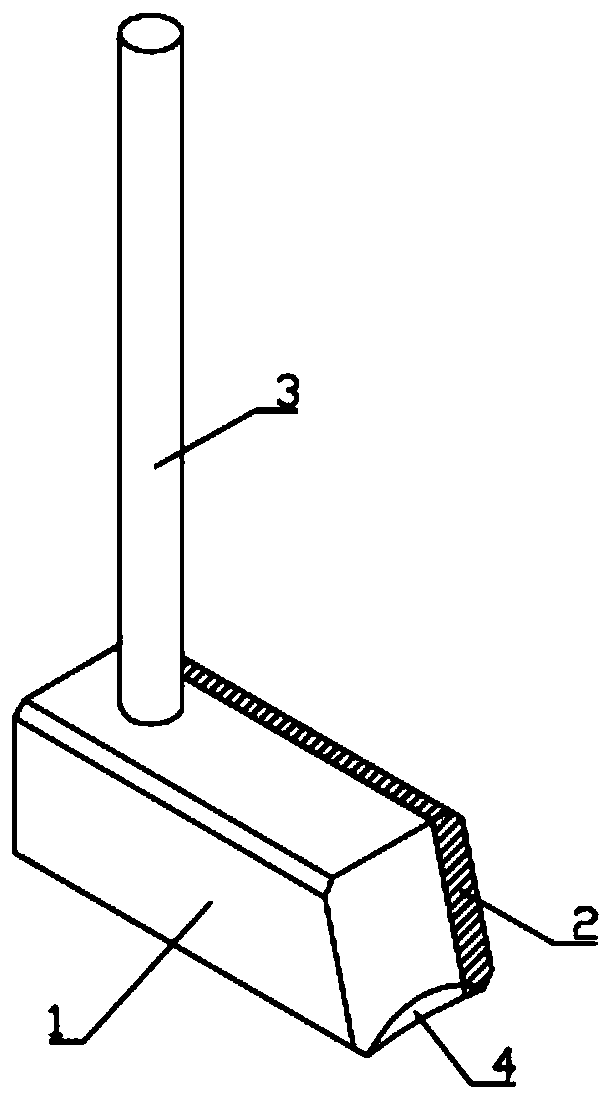

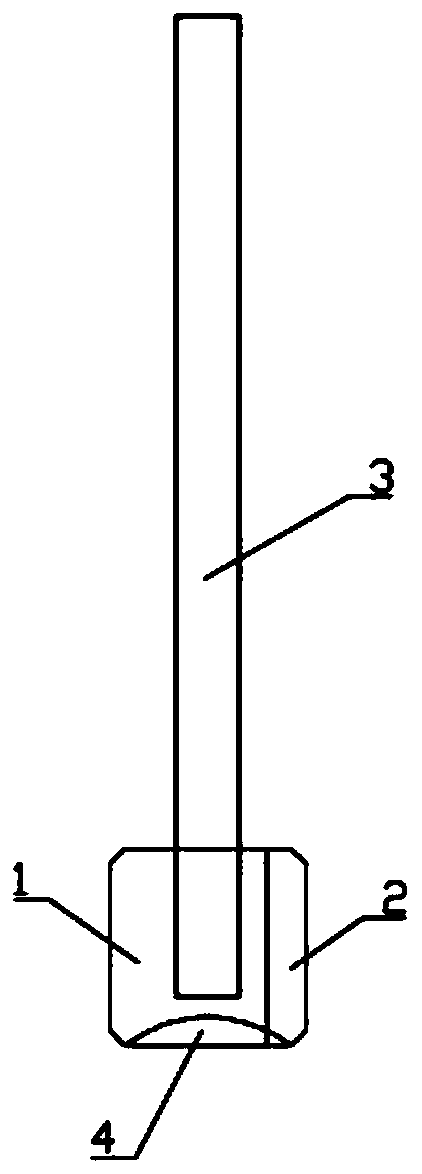

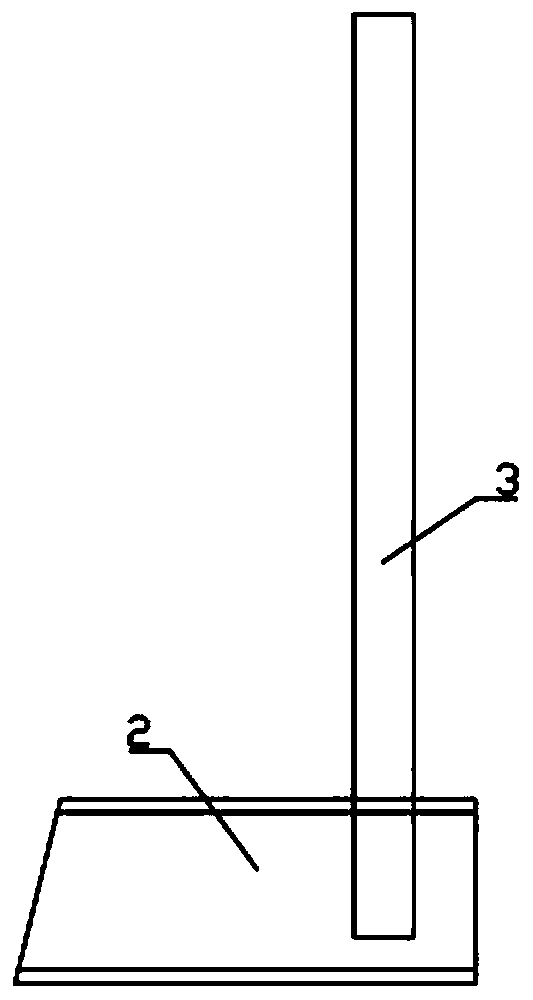

Anode steel claw welding tool and method

PendingCN109249126AAvoid high temperature oxidationHigh real-time monitoringShielded metal arc weldingElectroslag welding

The invention discloses an anode steel claw welding tool and method and aims to solve the technical problem that weld joint strength and conductivity are low in the prior art. The anode steel claw welding tool comprises a die formed by at least two combination modules and is characterized in that the die fixes a steel claw head welding end, is abutted against a to-be-welded crossbeam and allows asteel claw head to align with the rear of the crossbeam to form a weld joint weld pool with a top or lateral upper opening at a to-be-welded junction part; during welding, the steel claw head is placed in the combination modules of the welding die, the combination modules are combined to allow the crossbeam to align with the steel claw head welding end and be coordinated with the die to form a weld joint weld pool with a top or lateral upper opening at a to-be-welded junction part; a welding gun is used to perform electroslag welding through the opening of the weld joint weld pool until base metal on two sides is completely integrally fused. By the anode steel claw welding tool, anode steel claw welding cost can be lowered, service life can be prolonged, power consumption can be lowered, and the mechanical performance and conductivity of a steel claw welded by the tool are better than those of a steel claw welded by manual arc welding.

Owner:ZHENGZHOU JINGWEI TECH & IND

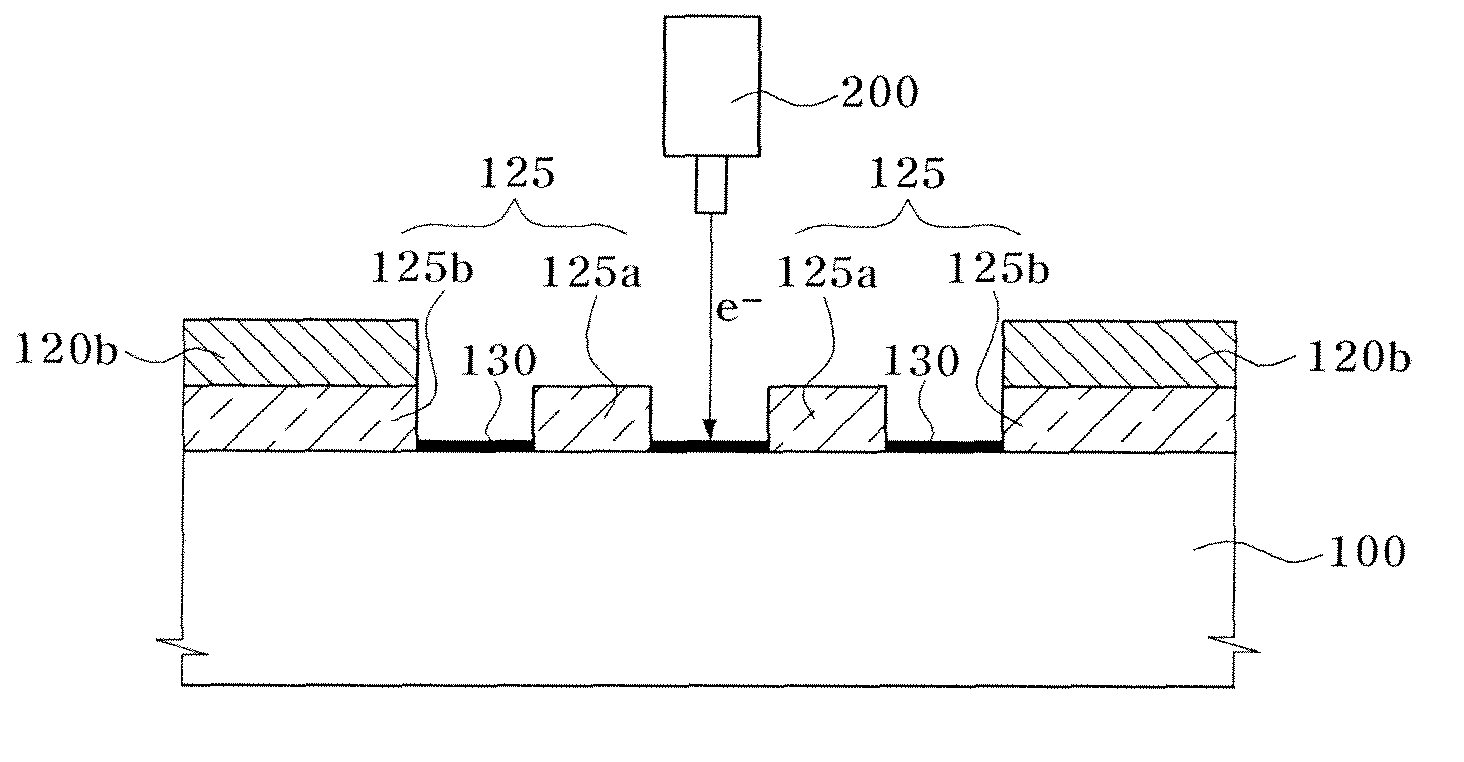

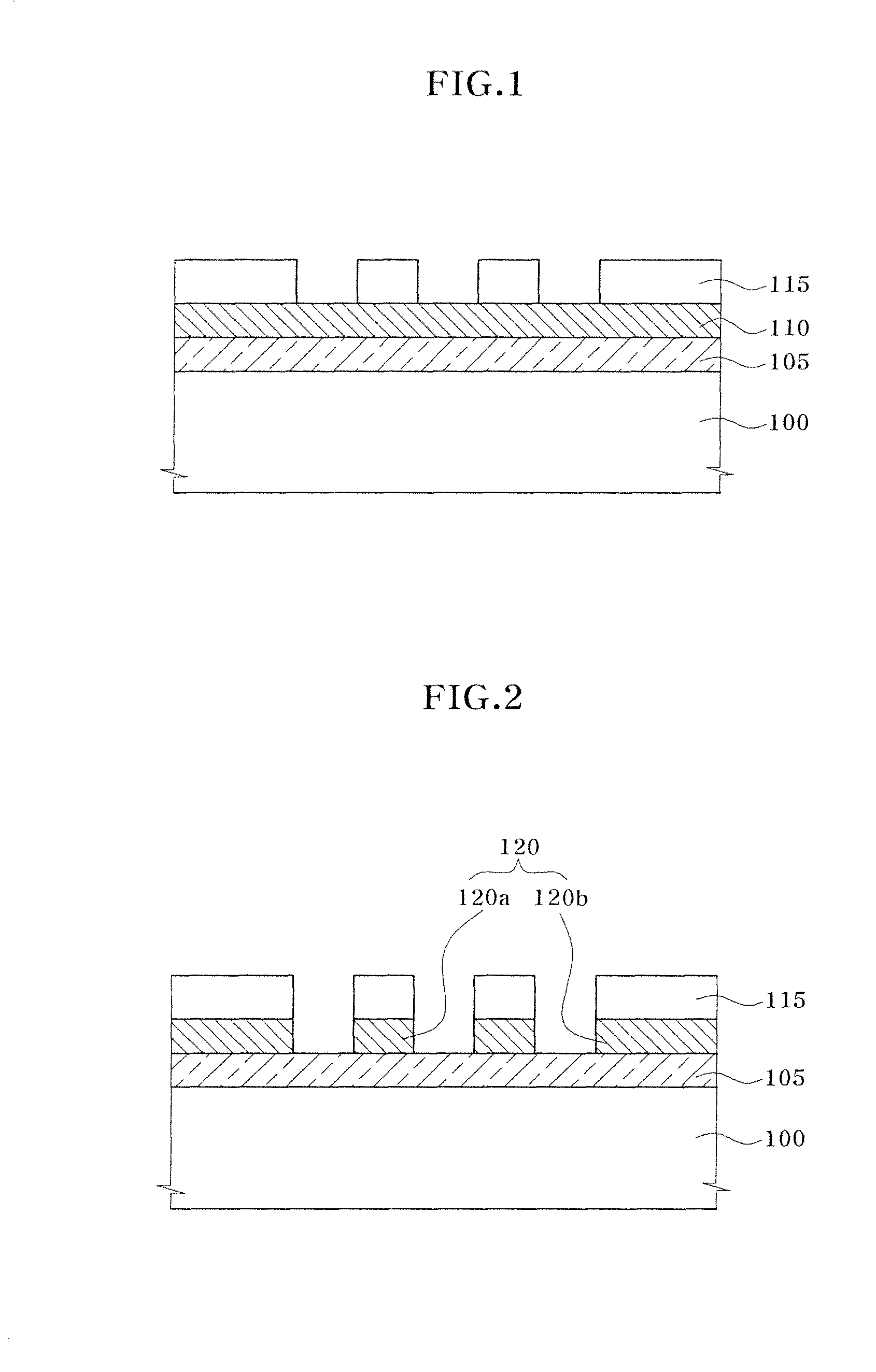

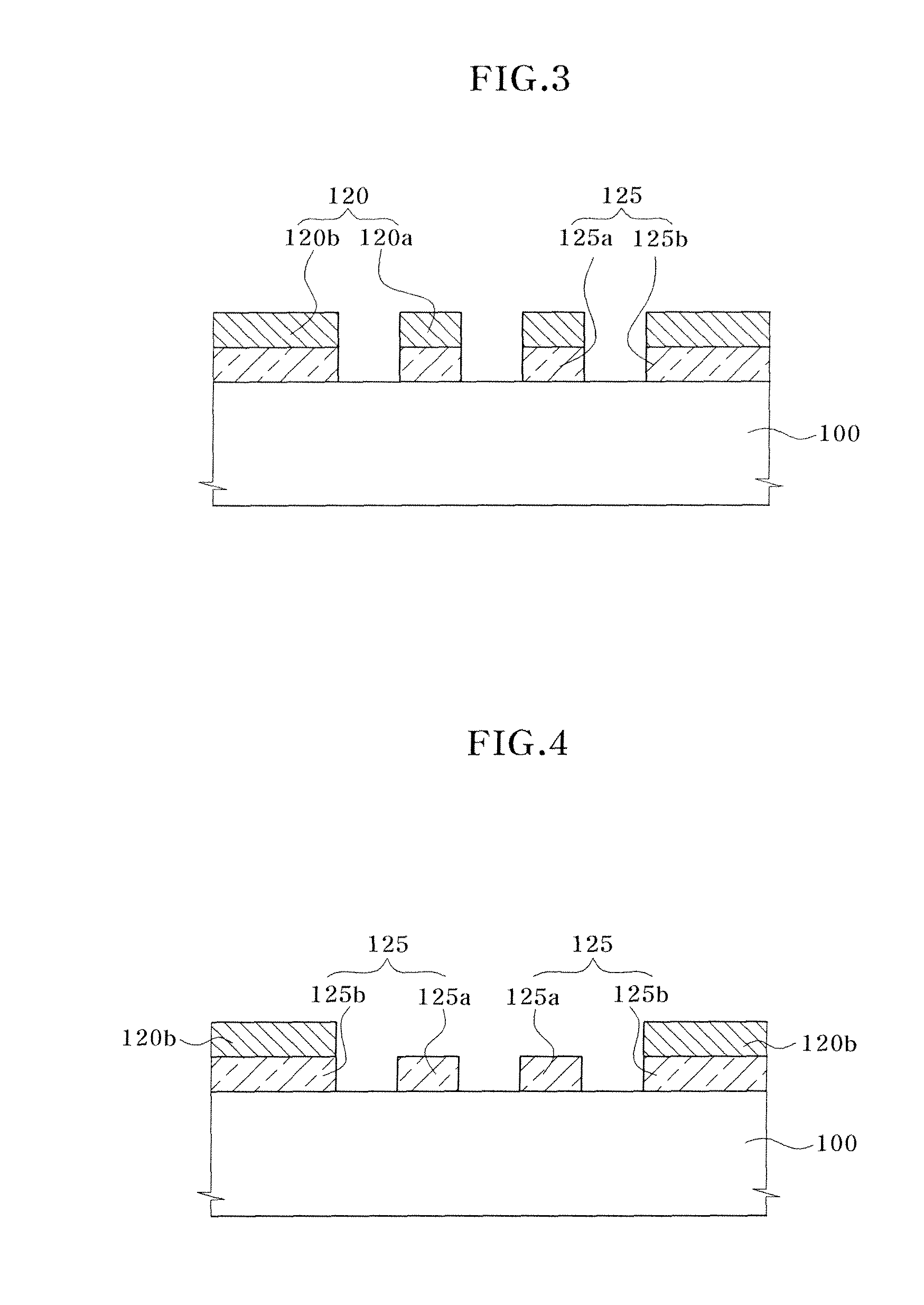

Method for Manufacturing Photomask Using Self-assembled Molecule Layer

InactiveUS20100233589A1Excellent electrical conductivityVacuum gauge using ionisation effectsElectrical testingPhase shiftedOptoelectronics

A method for fabricating a photomask using a self-assembled molecule layer, comprising: forming, on a transparent substrate, a stacked structure of a phase shift pattern and a light shielding pattern over the phase shift pattern, the stacked structure exposing a portion of a surface of the transparent substrate; exposing the phase shift pattern and a portion of the surface of the transparent substrate by removing a portion of the light shielding pattern; forming a self-assembled molecule layer allowing movement of electrons on the exposed surface of the transparent substrate; measuring a critical dimension of the phase shift pattern formed with the self-assembled molecule layer; neutralizing electrons applied during the measurement of the critical dimension with the self-assembled molecule layer allowing movement of electrons; and removing the self-assembled molecule layer.

Owner:SK HYNIX INC

Method for manufacturing a solid plating material and the solid plating material manufactured by the method

InactiveUS20090013904A1Excellent electrical conductivityImprove conductivityLiquid surface applicatorsMolten spray coatingElectroplatingMelting temperature

This invention provides a method for manufacturing a solid plating material which has excellent electrical conductivity and durability, and the solid plating materials manufactured by this method, whereina suspension liquid is made by mixing a fluid for coating that includes an organic binder, with a powder for plating having electrical conductivity and a metal powder to be used for binding, wherein thenlayers having the plating powder and the metal powder, and bound to the surfaces of core particles with the organic binder, are formed by means of injecting the suspension liquid on the surfaces of the core particles while the core particles are being agitated by centrifugal fluidization, and whereinthen the core particles are heated until their temperature is above the melting temperature of the metal powder to be used for binding so as to remove the organic binder and to form deposited layers of the plating powder by melting the metal powder to be used for binding.If a powder having excellent electrical conductivity is used as the plating powder, solid plating materials having excellent electrical conductivity and durability can be manufactured.

Owner:SINTO BRATOR CO LTD

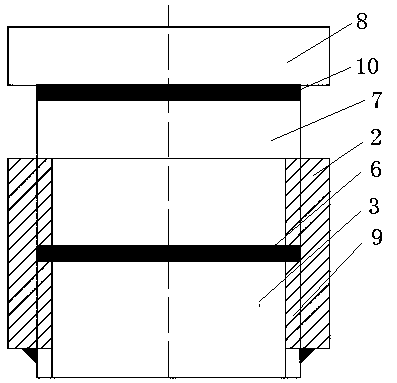

Aluminum electrolytic anode conductive device and preparation method thereof

The invention discloses an aluminum electrolytic anode conductive device and a preparation method of the aluminum electrolytic anode conductive device used in aluminum electrolysis. The preparation method of the aluminum electrolytic anode conductive device comprises the following steps of: carrying out whole section welding on an aluminum guide rod and a steel connecting block as a whole, and manufacturing an external thread on a part of outer edge of a welded joint of the aluminum guide rod and the connecting block and on the outer edge of the connecting block; and combining the external thread and an internal thread of a section of steel jacket, causing the lower end of the steel jacket to be flush with the outer end of the connecting block, and then carrying out whole section welding on the outer end of the connecting block, the lower end of the steel jacket and the upper surface of a steel claw transverse beam. The aluminum electrolytic anode conductive device has an electric conduction effect obviously superior to that of the prior art, can fully restrain an aluminum component of an aluminum-steel connecting surface from generating a thermal expansion amount larger than thatof a steel connecting piece during operation, and reduces the shearing force generated at a steel-aluminum bonding part, and therefore, the service life of the aluminum electrolytic anode conductive device is prolonged.

Owner:师建军

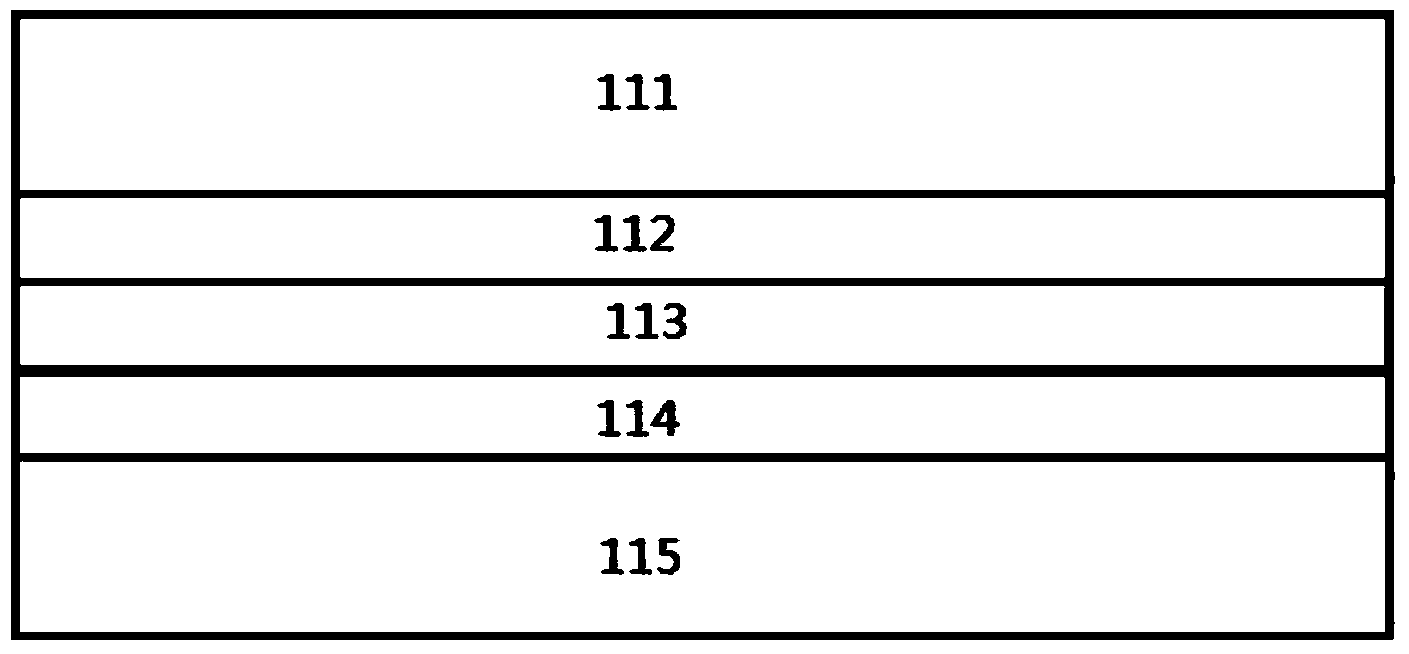

Transparent flexible silver nanowire-based conducting film and manufacturing method thereof

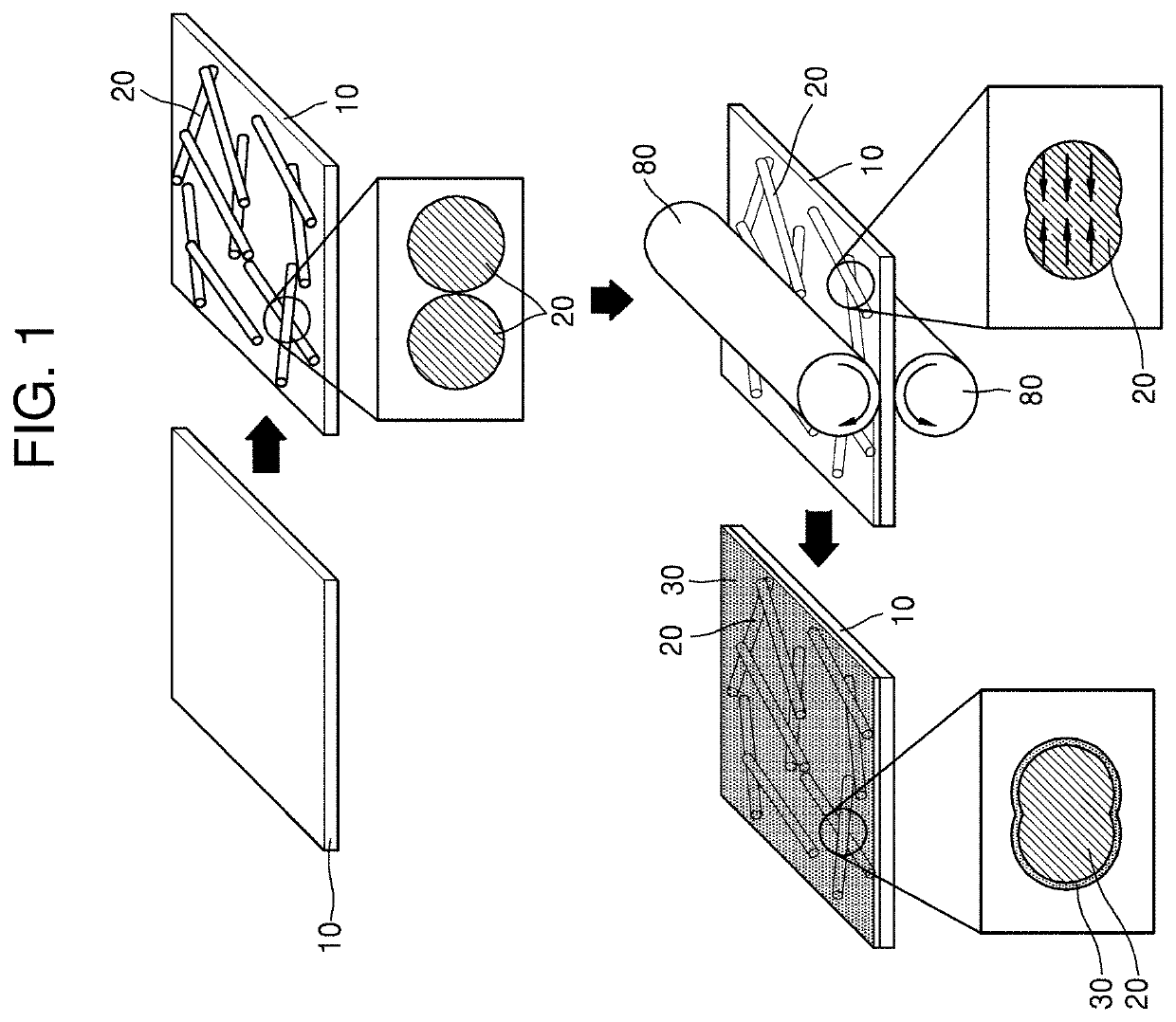

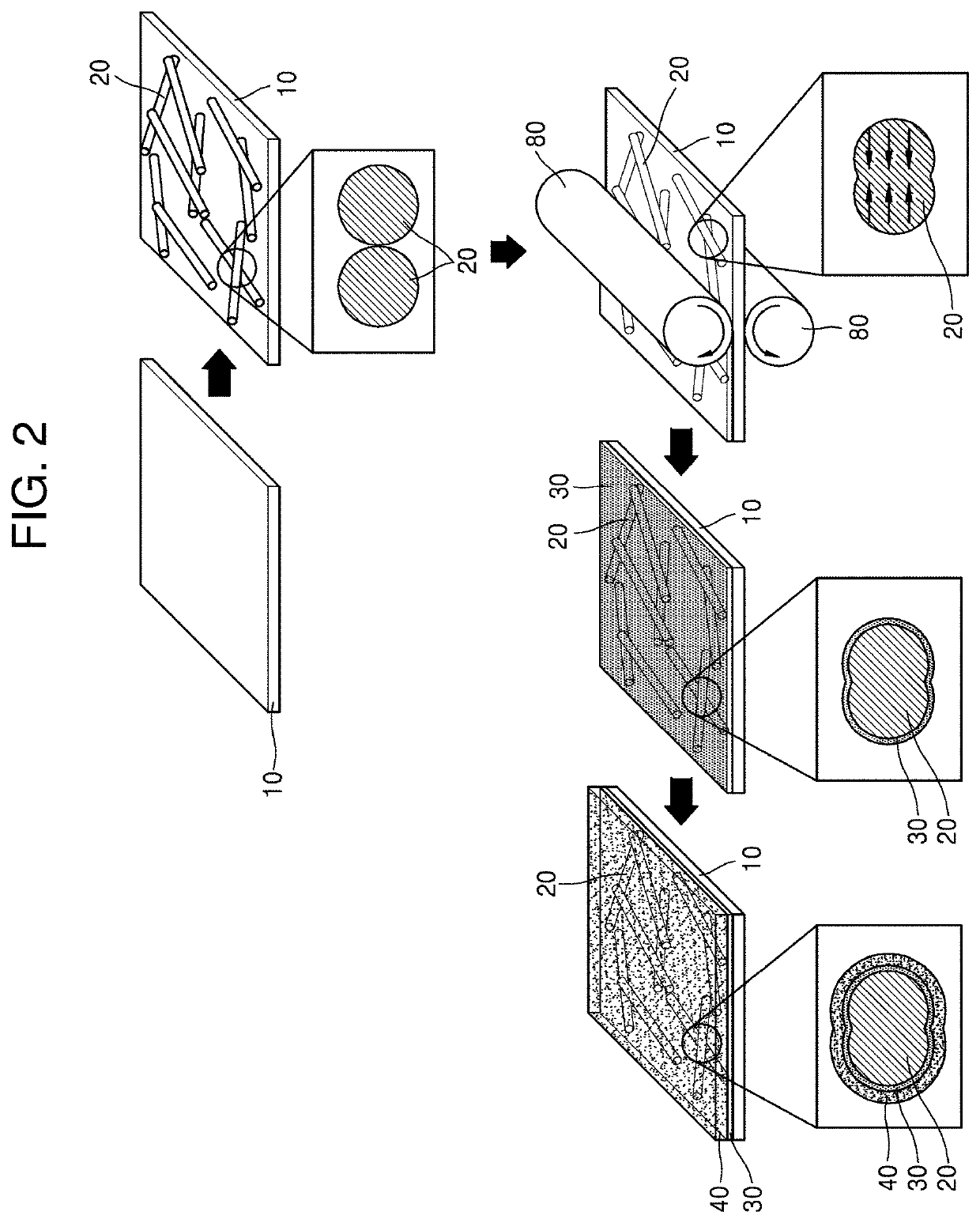

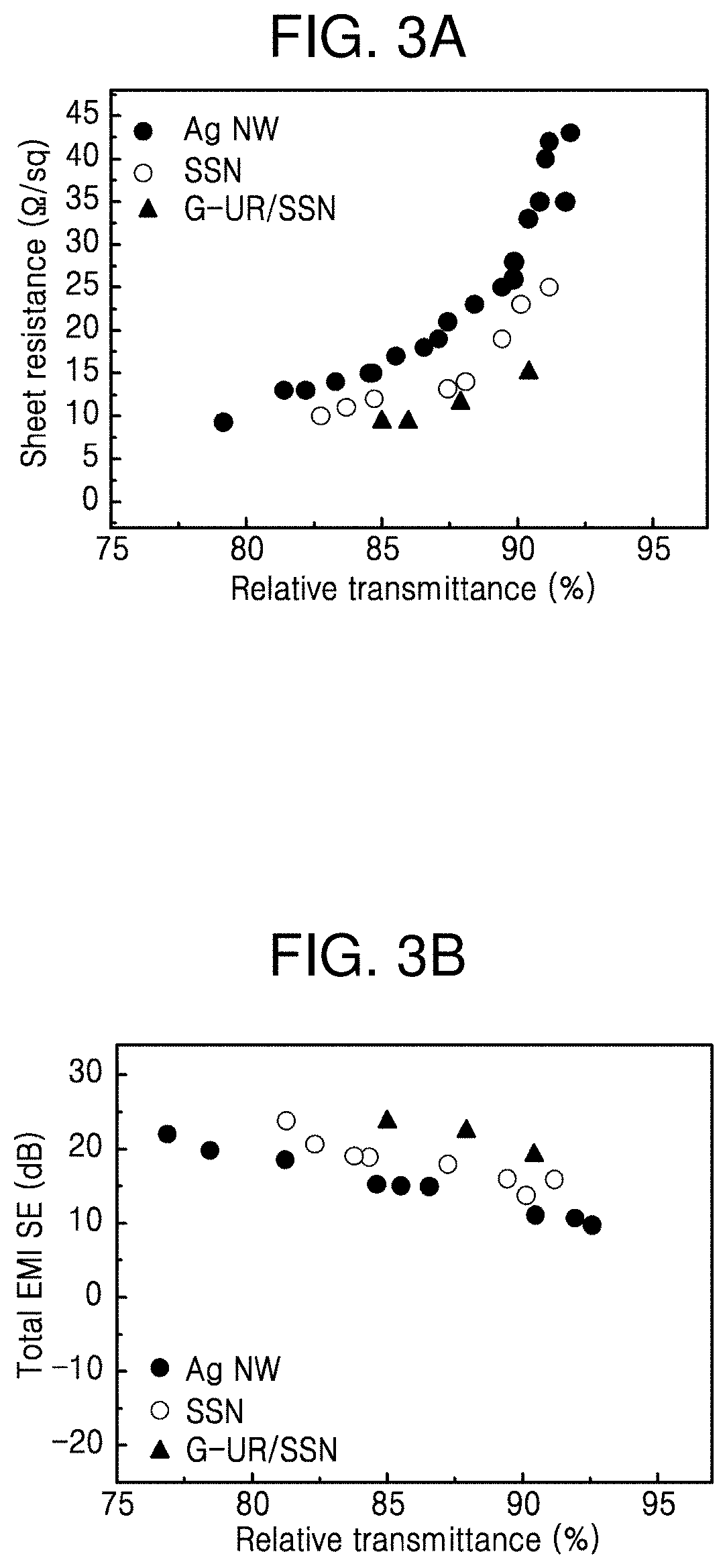

ActiveUS10736250B1Excellent electrical conductivityConductive layers on insulating-supportsMagnetic/electric field screeningThin membraneElectrically conductive

A method of manufacturing a transparent flexible silver nanowire-based conducting film and a transparent flexible silver nanowire-based conducting film are provided. The method includes coating conductive nanowires, which shield and absorb electromagnetic interference, on a flexible substrate, sintering the conductive nanowires using a wet sintering process, and coating a polymer layer in which graphene flakes are dispersed on the flexible substrate with the conductive nanowires formed thereon.

Owner:KOREA INST OF SCI & TECH

Composite carbon brush for massage chair motor and preparation method thereof

PendingCN109818225AExcellent electrical conductivityGood mechanical propertiesRotary current collectorBrushes manufactureLubricationHigh conductivity

The invention belongs to the technical field of massage chair motors, and particularly relates to a composite carbon brush for a massage chair motor. The composite carbon brush comprises an upper low-resistance high-conductivity layer and a lower high-resistance ultrahigh-lubrication layer, and further comprises a carbon brush wire. One end of the carbon brush wire is vertically inserted into thelow-resistance high-conductivity layer, and crescent arc notches are formed in the front ends of the low-resistance high-conductivity layer and the high-resistance ultrahigh-lubrication layer. The invention also relates to a preparation method of the carbon brush. The preparation method comprises the following steps: step 1, 70-80 parts of natural flake graphite and 5-20 parts of dendritic electrolytic copper powder and 10-15 parts of modified phenolic resin are subjected to stirring, mixing and pinching, pelletizing and grinding, to prepare a mixture A; step 2, 75-85 parts of natural flake graphite and 5-15 parts of high-temperature lubricant molybdenum disulfide and 10-15 parts of resin are subjected to stirring, mixing and pinching, pelletizing and grinding, to prepare a mixture B; andstep 3, 30% of the mixture B is uniformly filled into a mold cavity, 70% of the mixture A is uniformly filled into the mold cavity, and the carbon brush wire is implanted from the rear end of the right side surface in a manner of being perpendicular to the pressing direction.

Owner:浙江凯威碳材料有限公司

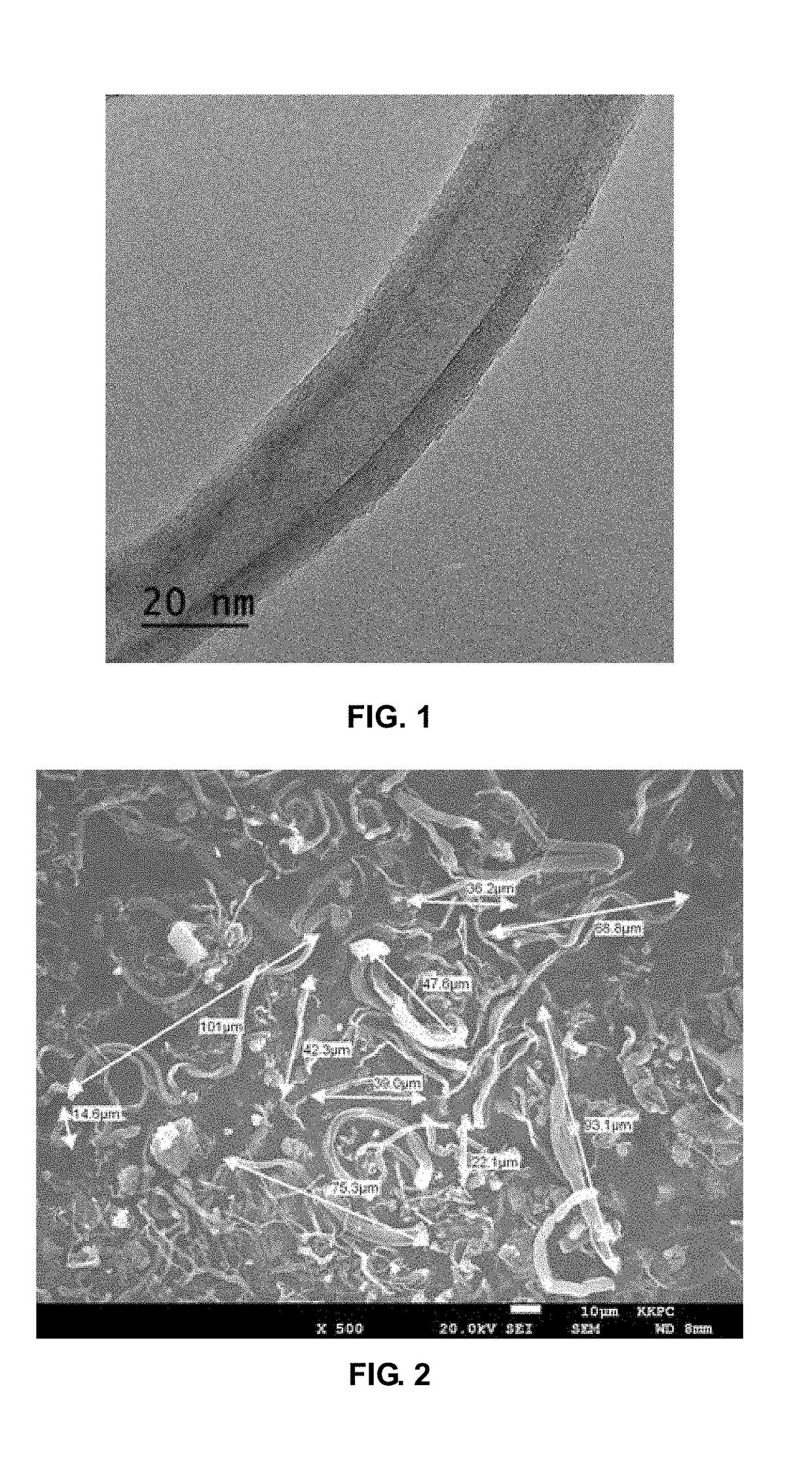

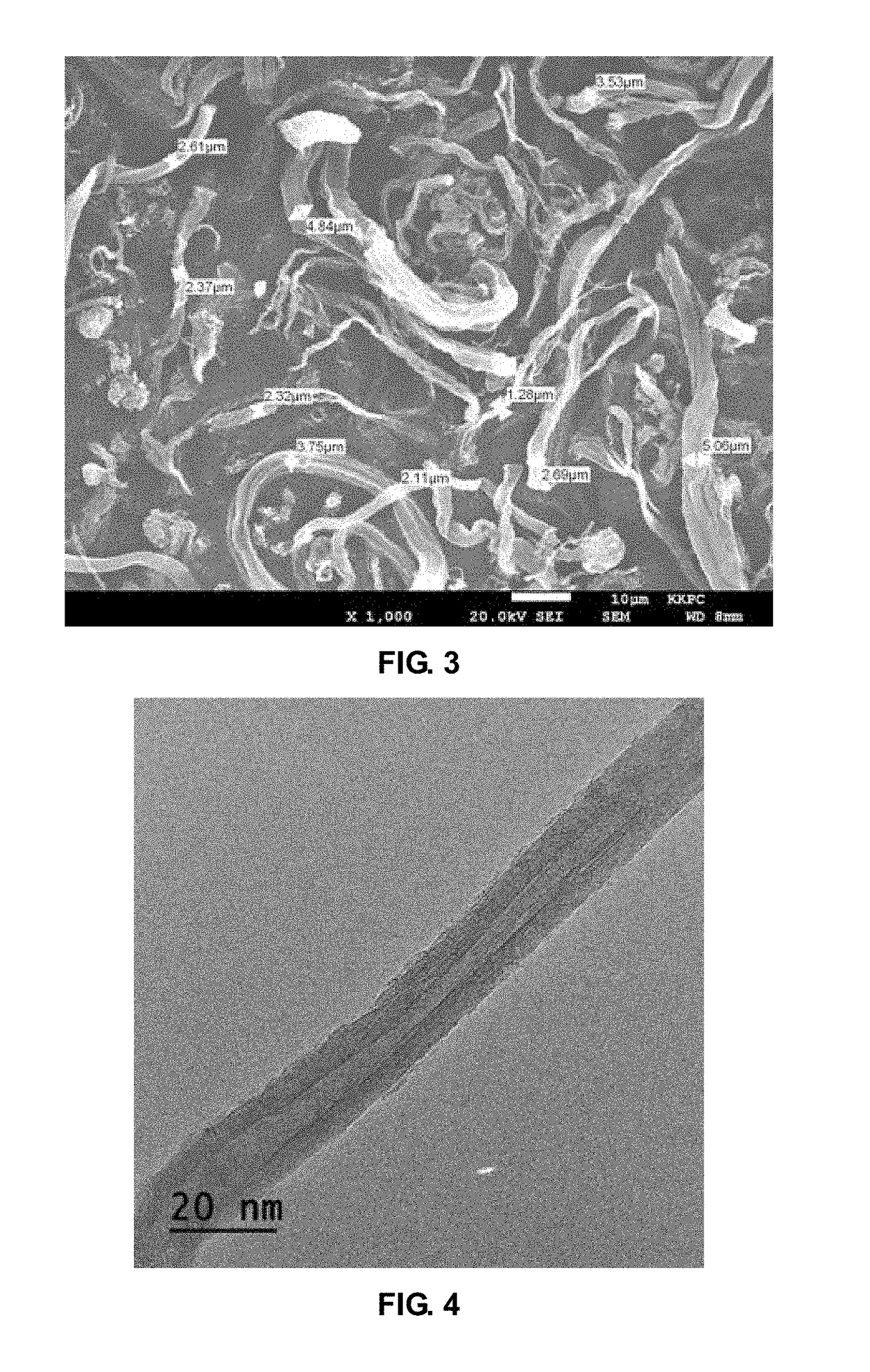

Conductive resin composition and plastic molded product using the same

ActiveUS20170243669A1Excellent electrical conductivityImprove conductivityMaterial nanotechnologyNon-conductive material with dispersed conductive materialChemistryCarbon nanotube

According to one aspect of the present invention, carbon nanotubes whose diameter, length, crystallinity, purity and the like are adjusted to predetermined ranges are added to a thermoplastic resin, and thus the thermoplastic resin can be provided with improved electrical conductivity.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Preparation method of current collection sliding material and application of product prepared from material

InactiveCN104846223ASimple processExcellent electrical conductivityPower current collectorsIngotCopper

The invention provides a preparation method of a current collection sliding material. The preparation method comprises the steps of: step one. melting copper with high quality in an electric furnace, and degassing, thus forming copper melt; step two. melting iron with high quality in the electric furnace, and degassing, thus forming iron melt; step three. mixing the copper melt and the iron melt to form mixed melt, wherein the mixed melt comprises 20-40 parts of iron and 60-80 parts of copper in parts by weight; and step four. cooling, namely injecting the mixed melt into a mold to form ingot bars. A pantograph manufactured by using the current collection sliding material is used on carriages of high-speed railways in harsh environments and has good wear-resisting property and electrical conductivity.

Owner:XIAOFENG INTPROP HLDG CO

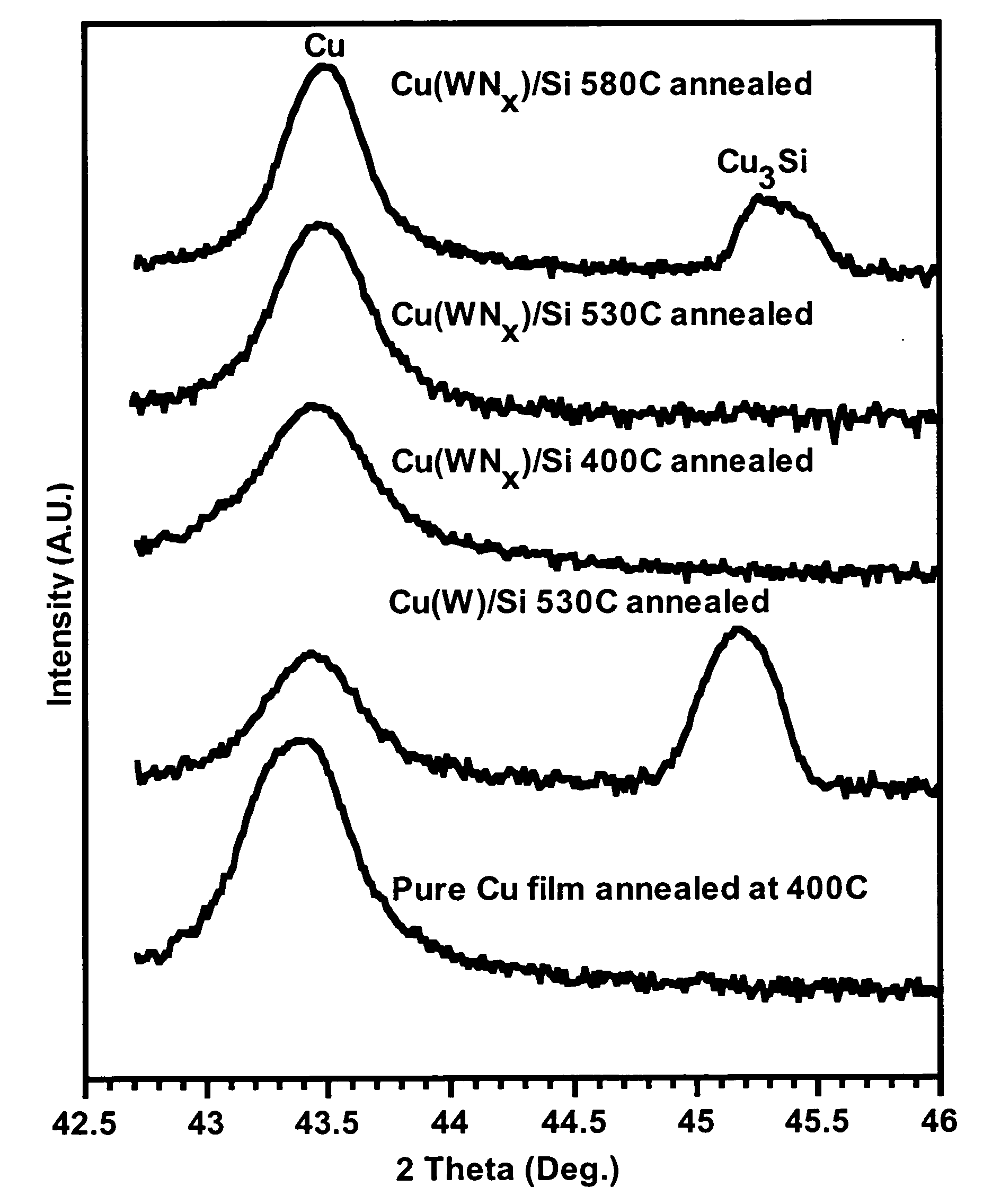

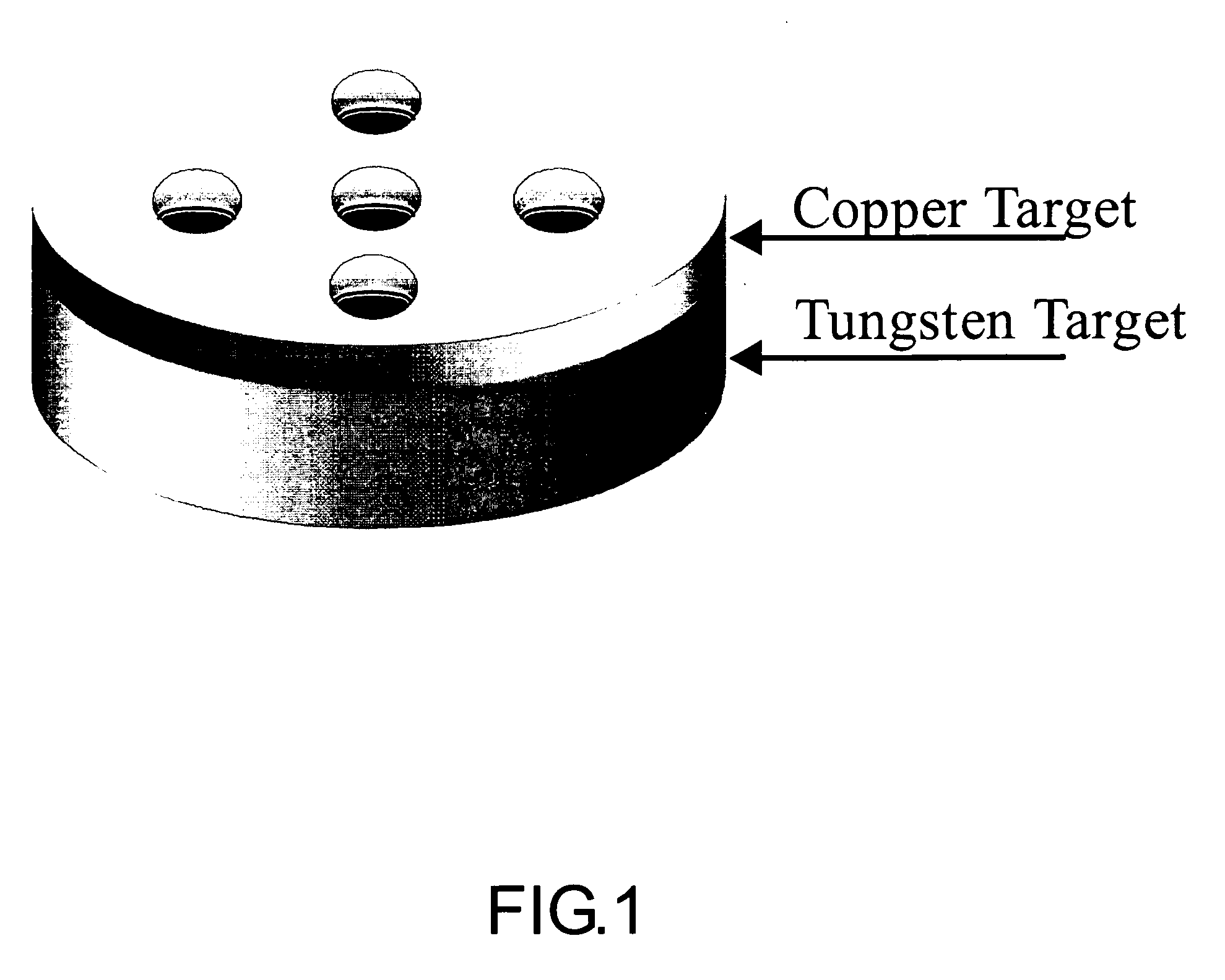

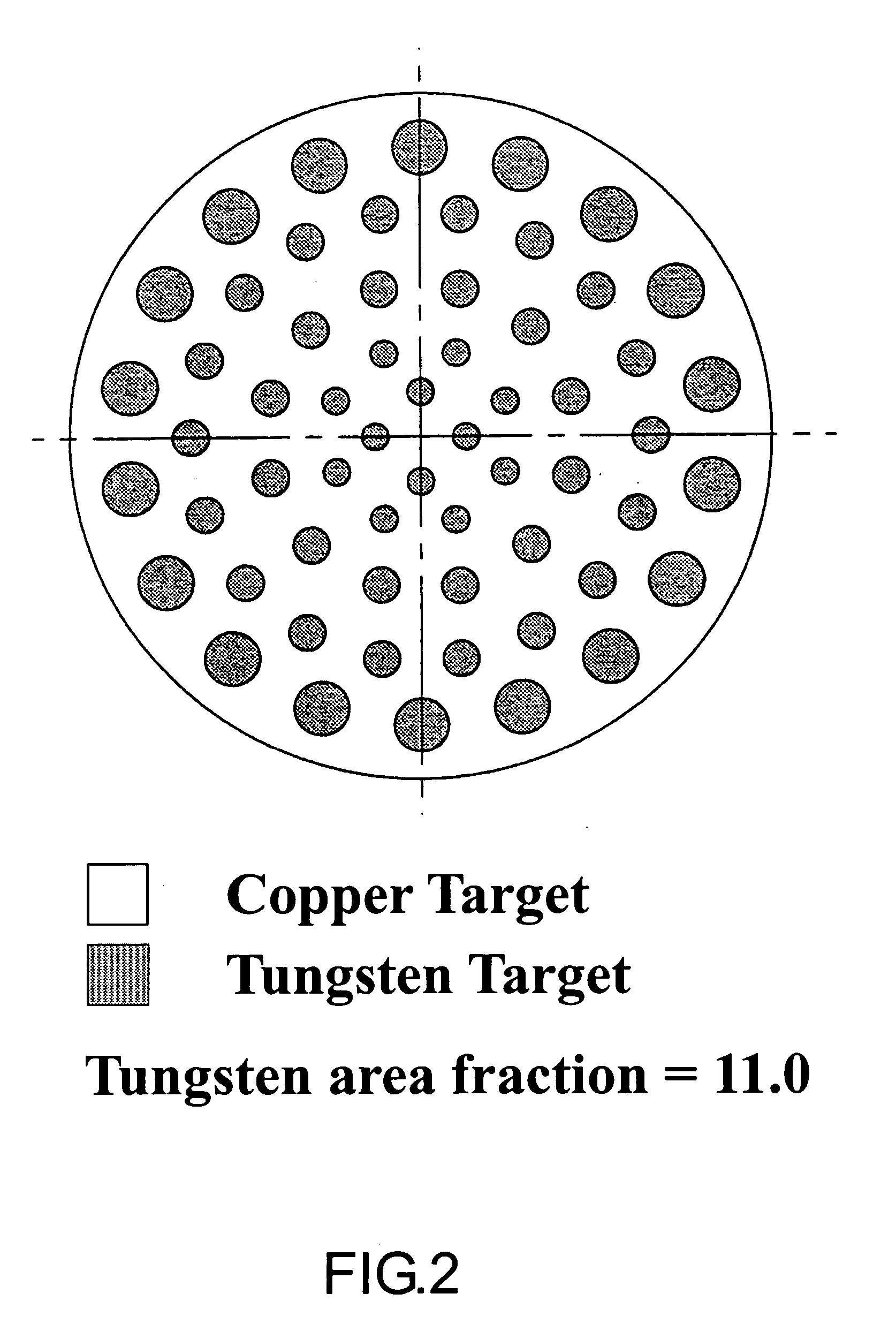

Copper film containing tungsten nitride for improving thermal stability, electrical conductivity and electric leakage properties and a manufacturing method for the copper film

InactiveUS20050252583A1Fine crystallite in microstructureExcellent electrical conductivityVacuum evaporation coatingSurface reaction electrolytic coatingTungsten nitrideNitrogen

A copper film containing tungsten nitride is manufactured by co-sputtering method under an Ar / N2 atmosphere and has a composition in ratio of tungsten nitride contained in the copper layer in atomic ratios of more than 97.5% in copper, 0.5 to 1.5% in tungsten and of less than 2.0% in nitrogen. By adding the tungsten nitride, the copper film has improvements in thermal stability, good electrical conductivity and low electrical leakage current. Moreover, the copper film attached on a silicon substrate will generate a self-passivated silicon compound layer to serve as a diffusion barrier layer between the copper film and the silicon substrate during annealing.

Owner:JINN P CHU

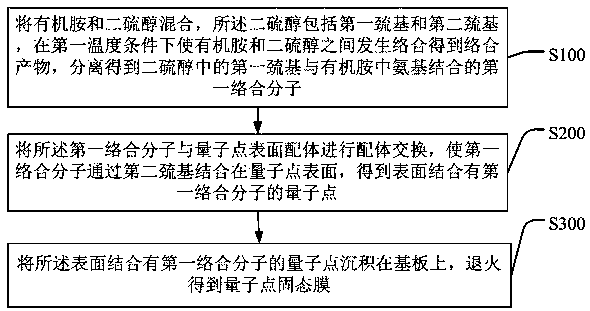

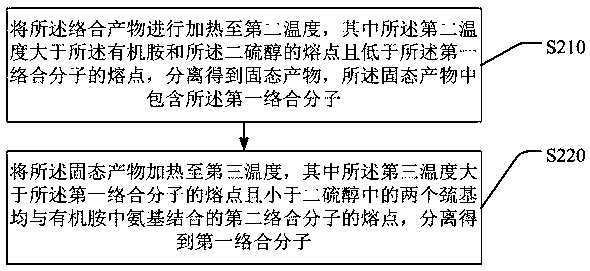

Preparation method of quantum dot film

PendingCN111378435AEasy to prepareExcellent electrical conductivityLuminescent compositionsQuantum dotPhotochemistry

The invention discloses a preparation method of a quantum dot film, which comprises the following steps: carrying out mixed reaction on organic amine and dithiol to generate a complexing product, andseparating from the complexing product to obtain a first complexing molecule in which a first sulfydryl group in the dithiol is combined with an amino group in the organic amine; carrying out ligand exchange on the first complexing molecule and a quantum dot surface ligand, so that the first complexing molecule is combined on the surface of the quantum dot through a second sulfydryl to obtain thequantum dot of which the surface is combined with the first complexing molecule; and depositing the quantum dots of which the surfaces are combined with the first complexing molecules on a substrate,and annealing to obtain the quantum dot film. The preparation method of the quantum dot film provided by the invention is simple and easy to realize, and the prepared quantum dot film can realize quantum dot crosslinking and has excellent electrical conductivity.

Owner:TCL CORPORATION

Copper alloy and application thereof

ActiveUS11255000B2Excellent electrical conductivityImprove conductivityElectro conductivityCrystal orientation

The present invention discloses a copper alloy, which includes: 5 wt % to 15 wt % of Zn, 0.2 wt % to 2.5 wt % of Sn, 0.1 wt % to 2.0 wt % of Ni, 0.01 wt % to 0.3 wt % of P, 0 to 0.3 wt % of Mg, 0 to 0.5 wt % of Fe, and a balance of Cu and inevitable impurities. Preferably, it is controlled that 1.0 wt %≤Ni+Sn≤3.5 wt %, the weight ratio of Ni to Sn is 0.08 to 10; the weight ratio of Ni to P is 2 to 15, Ni and P form a NiP compound in a matrix. During the crystal orientation analysis using EBSD measurement, the area in a Brass orientation {011}<211> at a derivation angle of less than 15° accounts for 10% to 25%. The yield strength 600 MPa, the electrical conductivity is ≥25% IACS, and the bending machinability is excellent because the value R / t in a GW direction is ≤1 and the value R / t in a BW direction is ≤2.

Owner:NINGBO POWERWAY ALLOY MATERIAL

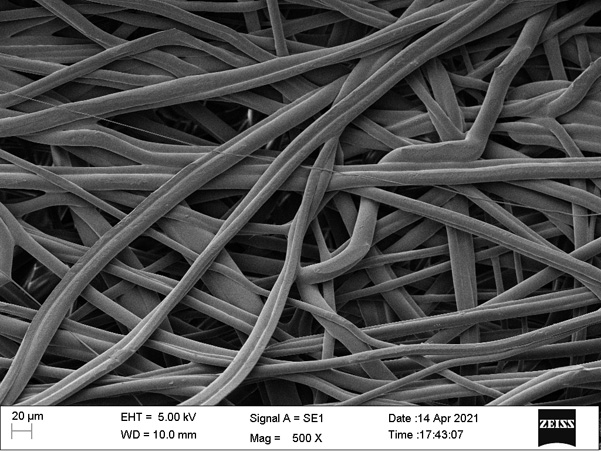

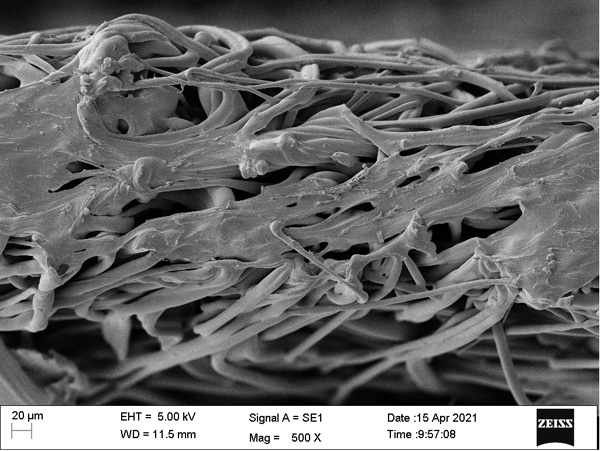

Conductive elastic non-woven material and preparation method thereof

PendingCN114481626AExcellent electrical conductivityIncrease elasticityElectroconductive/antistatic filament manufactureFibre typesElastomerMicro nano

The invention provides a conductive elastic non-woven material and a preparation method thereof, which are used for solving the technical problems of poor heating performance, complex preparation process, low softness and poor wearing comfort of heating fabrics, the conductive elastic non-woven material comprises a porous membrane and a superfine fiber aggregate, the porous membrane and the superfine fiber aggregate are embedded with each other, the superfine fiber aggregate comprises micro-nano conductive whiskers and a polyolefin elastomer, the porous membrane is prepared by drying a conductive coating, and the conductive coating comprises a graphene dispersion liquid, waterborne polyurethane, a wetting agent and water. The conductive elastic non-woven material prepared by the invention not only has excellent thinness, softness, elasticity and elasticity, but also has controllable conductivity; the heating device is applicable to multiple fields such as intelligent wearable, medical treatment and public health and industry, and is also applicable to intelligent heating; meanwhile, the preparation method has the characteristics of short process flow, high production speed and low cost, and is suitable for large-scale industrial production.

Owner:苏州多瑈新材料科技有限公司

3D printing material for producing electric conduction members

InactiveCN106947222AExcellent electrical conductivityHigh precision mechanical strengthAdditive manufacturing apparatusConductive polymerPolystyrene

The invention provides a 3D printing material for producing conductive parts. The composition and mass percentage of each component are: clay material: 32-47%, conductive fiber: 21-31%, polyaniline: 10-20% %, polystyrene: 6-15%, auxiliary agent: 7-17%; the composition of the clay material and the mass percentage of the clay material accounted for by each component are: attapulgite: 45-67%, bentonite: 26-41% %, graphite powder: 7 to 15%. The invention can be applied to the production of conductive parts with high requirements on conductivity and precision and complex shape and structure; the preparation process is simple and the cost is moderate; after being formed by 3D printing, it is durable and stable in use.

Owner:张丹丹

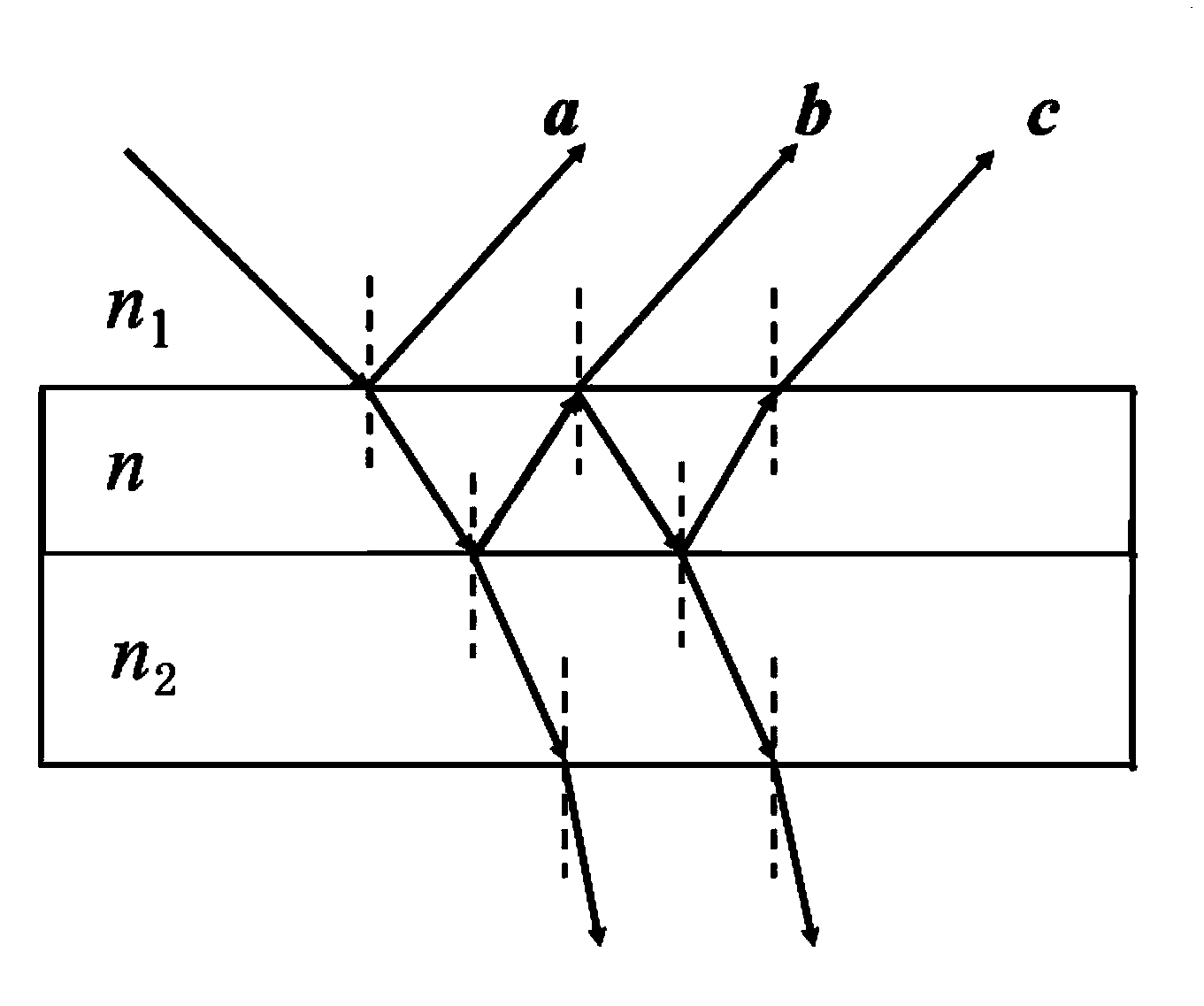

Thin-film solar cell

ActiveCN103746015AExcellent permeabilityExcellent electrical conductivityPhotovoltaic energy generationSemiconductor devicesOxidation resistantMetal

The invention discloses a thin-film solar cell, which comprises a PN junction and transparent conducting films, wherein the PN junction is located above a base material; the transparent conducting films are respectively located at both sides of the PN junction; the two layers of transparent conducting films are used as an upper electrode and a lower electrode of the solar cell; each transparent conducting film comprises a substrate and an antireflection structure attached to the substrate; each antireflection structure comprises two dielectric layers, a conducting metal layer and two antioxidant metal layers, wherein the two dielectric layers are respectively located at the upper outer side and the lower outer side; the conducting metal layer is located in the middle; the two antioxidant metal layers are respectively clamped between the conducting metal layer and the two dielectric layers, wherein the antioxidant metal layers are made of zinc or titanium. By utilizing antireflection structures, under the condition that total thickness is far smaller than the thickness of a traditional ITO (indium tin oxide) film, excellent optical property and electrical property are realized, and moreover, the flexible base material can be selected; through a reel-to-reel magnetron sputtering method, large-scale and large-area production is realized.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com