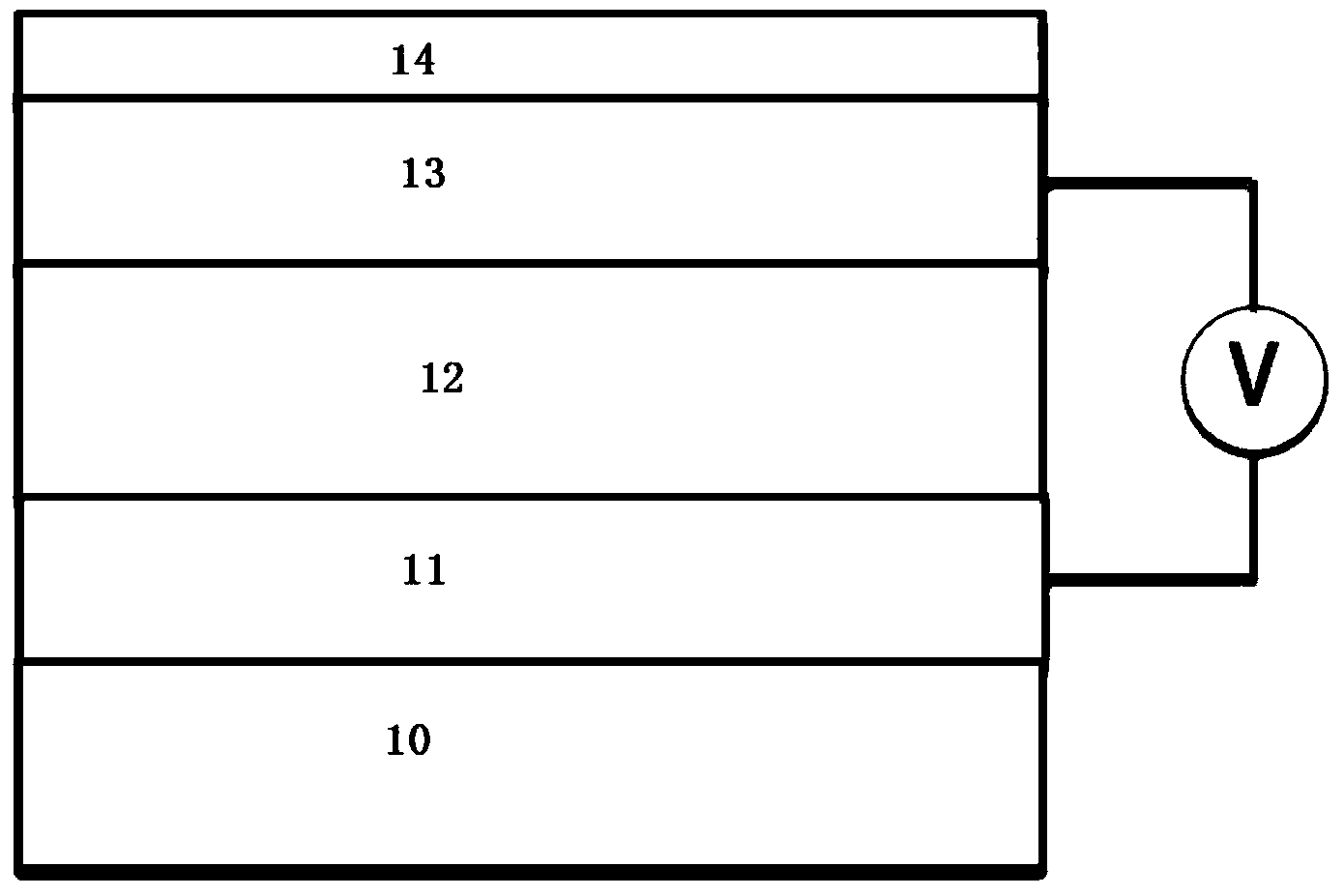

Thin-film solar cell

A technology for solar cells and thin films, applied in the field of solar cells, can solve the problems of limited development, low service life, large resistance of transparent conductive films, etc., and achieve the effects of reducing production costs, improving service life, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

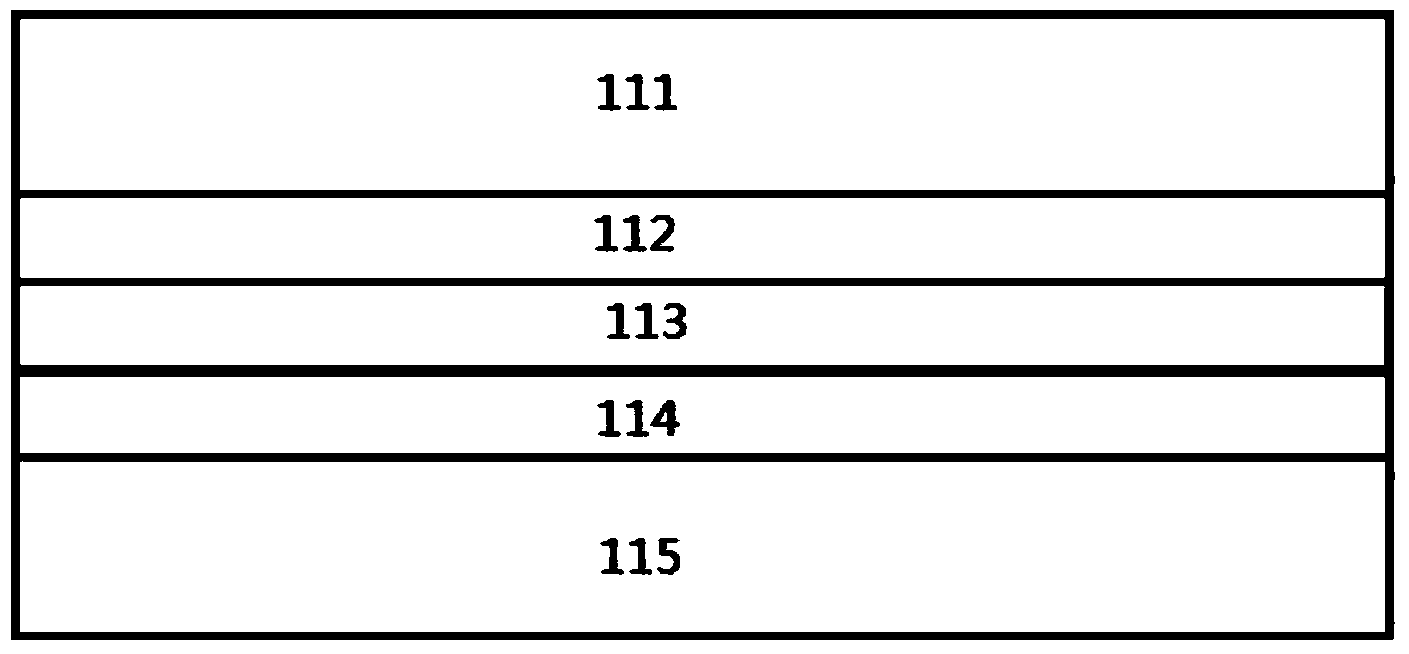

[0034] As mentioned in the background technology, the existing thin-film solar cells are limited by the disadvantages of the ITO thin film itself, and there is a problem of low photoelectric conversion efficiency. In order to improve this problem, it is necessary to add an additional anti-reflection film and increase the Thickness can be improved, but the overall thickness of the thin film solar cell will be further increased, and at the same time, the cost will be increased.

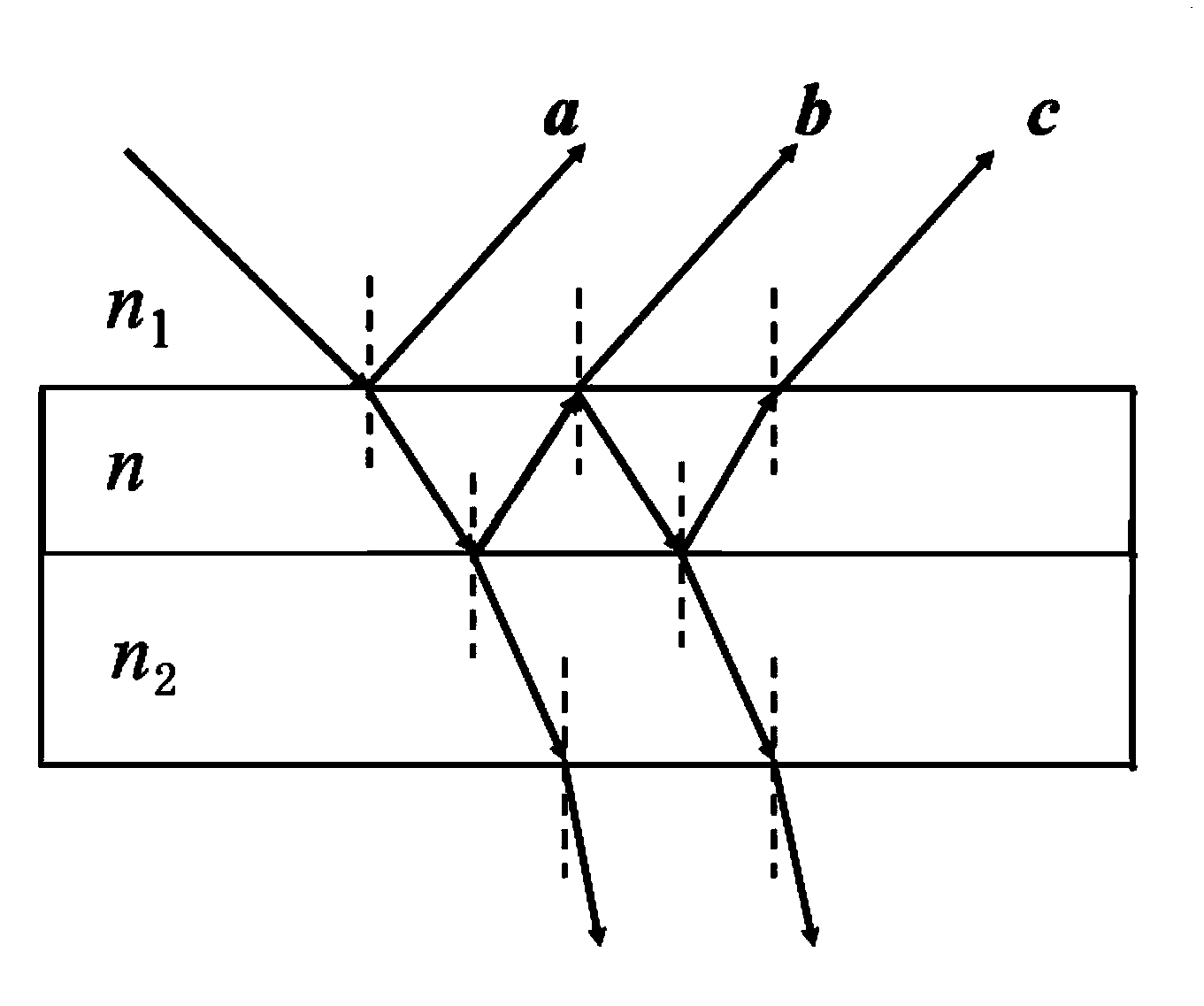

[0035] The current high-transmittance and low-resistance multilayer film structure is generally a so-called sandwich structure of metal oxide / conductive layer / metal oxide, as reflected in the patent application number 03116461.7. However, this structure mainly has There are two disadvantages. First, the conductive layer should not be too thick, otherwise it will have a bad impact on the permeability. However, a conductive metal layer that is too thin (such as below 10nm) can easily form an island structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com