Patents

Literature

113results about How to "Good anti-adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

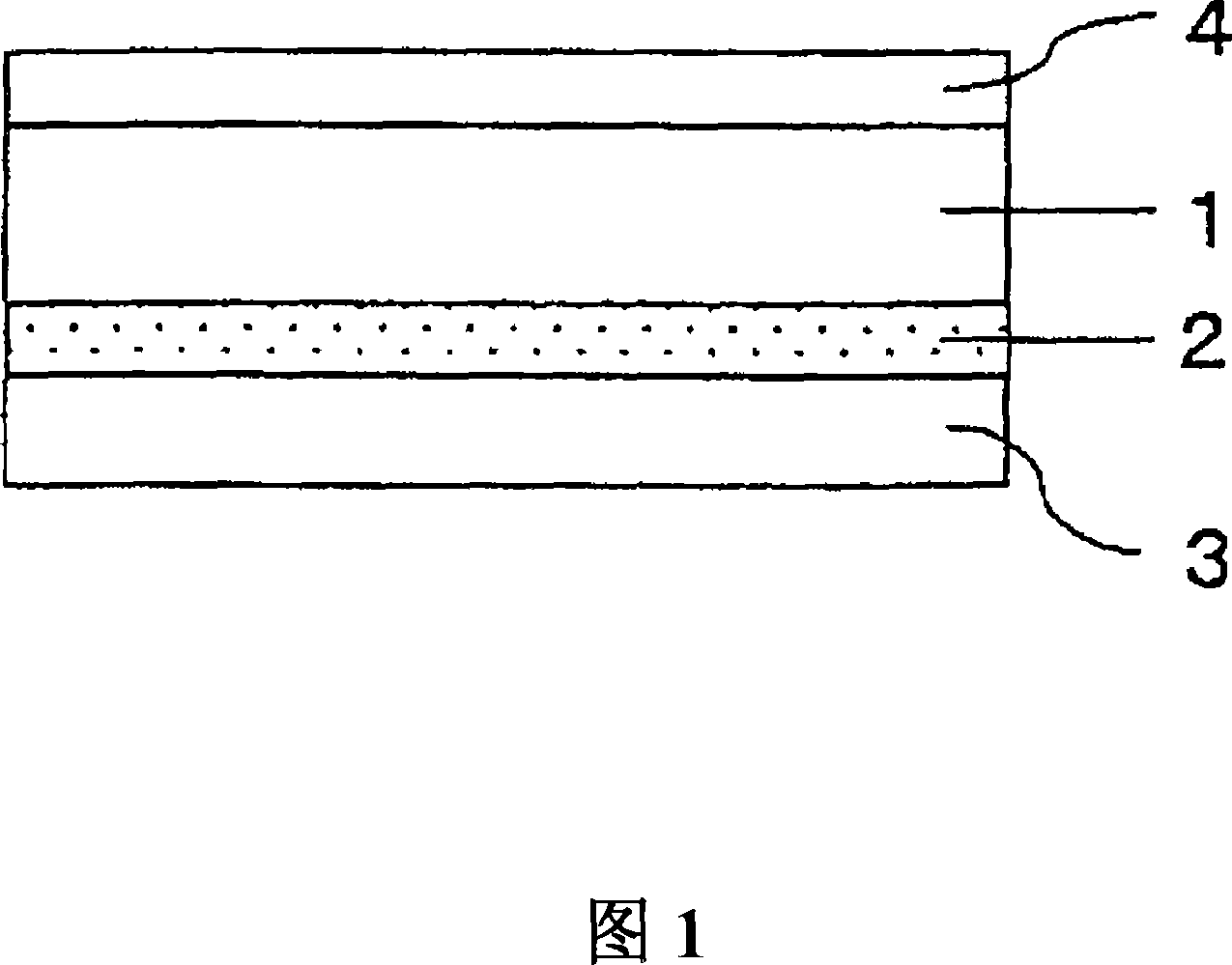

Thermal transfer sheet

ActiveCN101052534AImprove adhesion strengthHigh reflection densityThermographyOther printing apparatusHigh humidityInorganic pigments

This invention provides thermal transfer sheets that have excellent strength of adhesion between a dye layer and a base material, have high reflection density, have good releasability from an image receiving sheet at the time of printing even after storage under high temperature and high humidity conditions, can produce thermally transferred images with high sharpness and can produce satisfactory prints. Specifically, there are provided a thermal transfer sheet characterized in that an undercoating layer formed of a thermoplastic resin and colloidal inorganic pigment ultrafine particles and a dye layer are provided in that order on one side of a base material, and a thermal transfer sheet characterized in that an undercoating layer formed of colloidal inorganic pigment ultrafine particles and silicate or aluminum alcoholate, and a dye layer are provided in that order on one side of a base material.

Owner:DAI NIPPON PRINTING CO LTD

Toner, method for its production and image forming method

InactiveCN1797222ADoes not cause diffusionGood charge stabilityDevelopersElectrographic processes using charge patternEngineeringAqueous medium

The object of the present invention is to provide a toner having a uniform composition of toner materials among toner particles, excelling in charge stability, enabling high-quality images without substantially causing fog and toner scattering, and having a small diameter and a narrow particle size distribution. The present invention also provides an effective production method of the toner, and an image forming method and the like using the toner. For this end, the present invention provides a method for producing a toner in which a dissolved and dispersed solution of toner materials is dispersed as dispersion particles in an aqueous medium containing no organic resin fine particles to prepare an oil droplet-in-water dispersion, and organic resin fine particles are added to the oil droplet-in-water dispersion to thereby granulate a toner in the presence of the organic resin fine particles.

Owner:RICOH KK

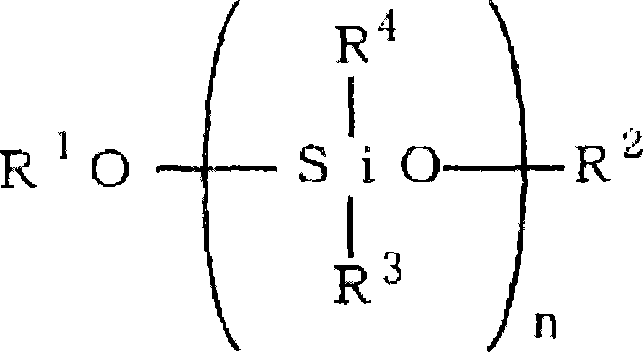

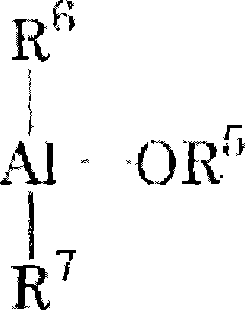

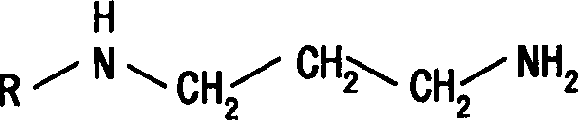

Organosilicon coating agent and preparation method thereof

InactiveCN106398523AStrong UV resistanceImprove antioxidant capacityCoatingsChemical reactionUltraviolet

The invention provides an organosilicon coating agent and a preparation method thereof. According to the invention, an organosilicon material is used as a basic raw material which is allowed to have a film forming function through a normal-temperature chemical reaction; an organosilicon material film is allowed to be firmly bonded with the surface of an object in virtue of the action of an adhesion promoter and a diluent, so the effect of long-lasting anti-adhesion effect is obtained; meanwhile, the organosilicon coating agent provided by the invention has good ultraviolet resistance and antioxidation capability and is suitable for brush coating of an external surface. The organosilicon coating agent can be applied onto the surfaces of decorative coatings and exterior coatings; after curing, the organosilicon coating agent has good adhesion, is hard to fall, enables the surfaces of the coatings to be bright and smooth and shows excellent anti-adhesion effect; with the organosilicon coating agent, advertisement labels cannot be firmly bonded on the surfaces of the coatings and can be easily taken off, and marks written on the surfaces of the coatings by marking pens can be directly erased without solvent or water; and the organosilicon coating agent has long-lasting anti-adhesion effect and presents good anti-adhesion effect after having been coated on the surfaces for one year.

Owner:湖北新四海化工股份有限公司

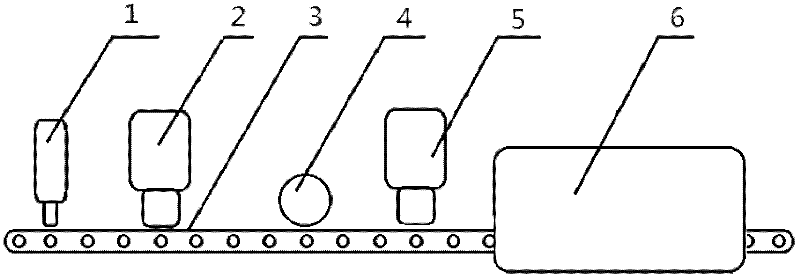

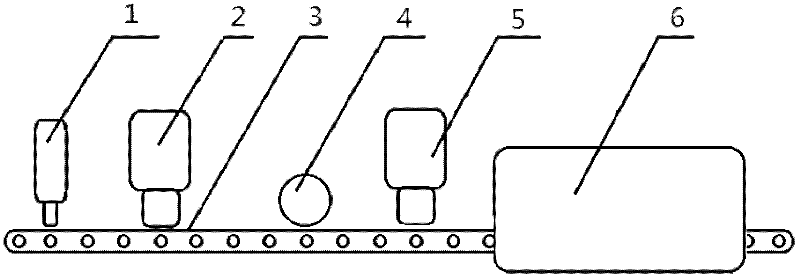

Production technology for silicone oil paper

ActiveCN106958167AImprove bindingGood quality and safetyPaper coatingPhysical paper treatmentPaper sheetEmulsion

The invention discloses a production technology for silicone oil paper. The key point of the technical scheme includes the following steps: S1) preparing a coating material, namely mixing and uniformly homogenizing emulsion silicone oil, a catalyst and a cross-linking agent at certain ratio; S2) coating, namely uniformly coating the coating material onto a paper surface through a coating machine; S3) drying, namely inputting a paper sheet after press polishing into a drying box, and heating and drying at the drying temperature of 80 DEG C to 150 DEG C; S4) re-wetting, namely wetting the dried paper sheet; S5) secondarily drying, namely drying the wetted paper sheet in the drying box again at the drying temperature of 80 DEG C to 150 DEG C; S6) press-polishing, namely press-polishing the dried paper sheet with a press-polishing machine; S7) cutting: cutting the paper sheet after press-polishing with a cutting machine; S8) coiling. The food-grade baking paper prepared according to the invention has a uniform and glossy surface, has a good anti-sticking effect, is free from edge warping and is high in yield.

Owner:MINFENG SPECIAL PAPER

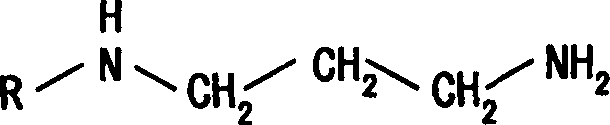

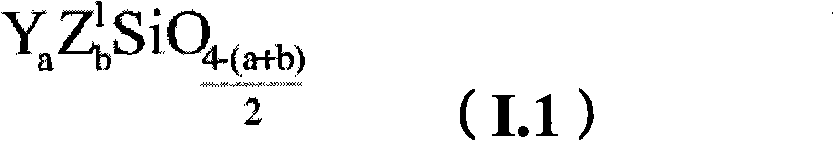

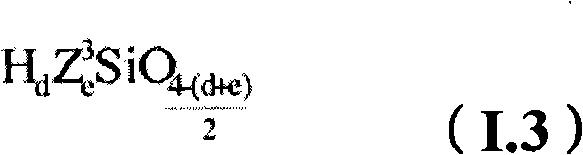

Cross-linkable silicone composition for the production of non-stick coatings for flexible substrates and an attachment-promoting additive contained in said composition

ActiveCN103154164AImprove peel forceGood anti-adhesiveFilm/foil adhesivesSpecial surfacesPlatinumPolymer science

The invention relates to cross-linkable or cross-linked silicone compositions that can be used, in particular, to form a non-stick water-repellent coating for flexible substrates, for example paper or similar, in the form of natural or synthetic polymer films. Said compositions are of the type that comprise cross-linking polyorganosiloxanes bearing SiH units and unsaturated polyorganosiloxanes, preferably vinylated, capable of reacting with the cross-linking agent by means of an addition reaction in the presence of platinum in order to form the non-stick cross-linked coating on the flexible substrate and at least one attachment-promoting and cross-linking additive X. The aim of the invention is to provide novel liquid silicone coating compositions which are advantageously free of solvents and which can be cross-linked instantaneously into a water-repellent and / or non-stick coating for a flexible substrate, thereby producing cross-linked silicone coatings of a very high quality in terms of their attachment / adhesion to the substrate, high "rub-off" resistance and anti-adhesion profile (sufficiently high separation force at high speed), which properties are the product, in particular, of an attachment promoting additive.

Owner:BLUESTAR SILICONES FRANCE SAS

High-temperature self-lubricating material for manufacturing bearings and preparation method thereof

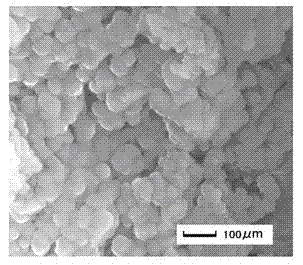

InactiveCN102925808AReduce coefficient of frictionImprove efficiencyMolybdenum disulfideEnergy consumption

The invention discloses a high-temperature self-lubricating material for manufacturing bearings and a preparation method thereof. The high-temperature self-lubricating material comprises, by weight, 1%-5% of barium fluoride, 1%-10% of graphite, 1%-10% of molybdenum disulfide, 10%-20% of copper, 40%-50% of alloy powder and 40%-55% of iron powder. The preparation method includes: (1) alloy raw materials are mixed fully on a V-shaped mixing machine; (2) mixed liquid of water and sodium stearate is added and mixed evenly; (3) drying is performed; (4) the mixture is shaped by pressing of a mould; and (5) sintering is performed. The high-temperature self-lubricating material has the advantages of being low in friction coefficient, strong in agglutination and abrasion resistance, high in bearing capacity, low in energy consumption, small in heating, stable in operation and the like. The novel high-temperature self-lubricating material is used for manufacturing the bearings, cost is reduced, bearing capacity is improved, service life is prolonged, and comprehensive performance is improved remarkably.

Owner:镇江中孚复合材料有限公司

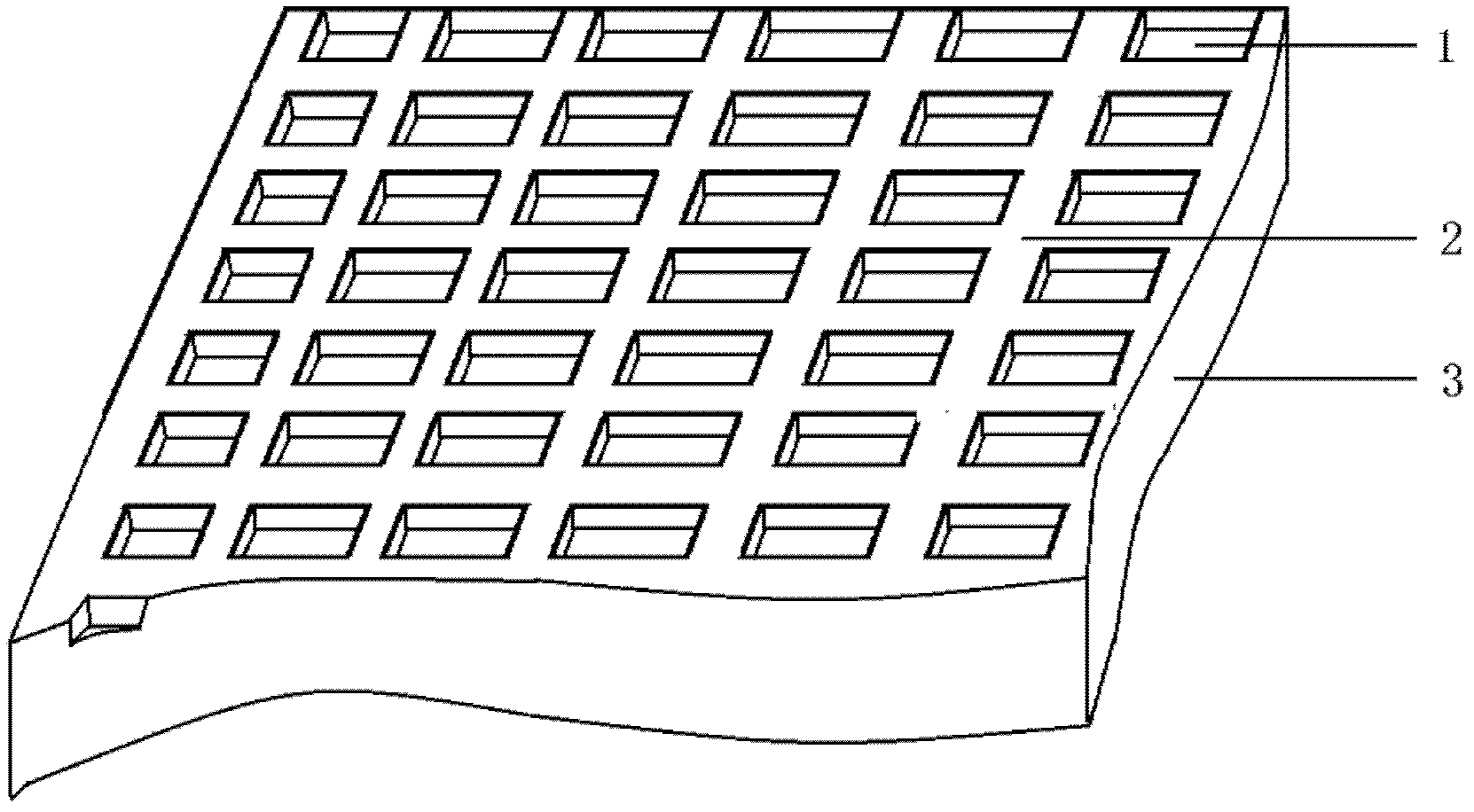

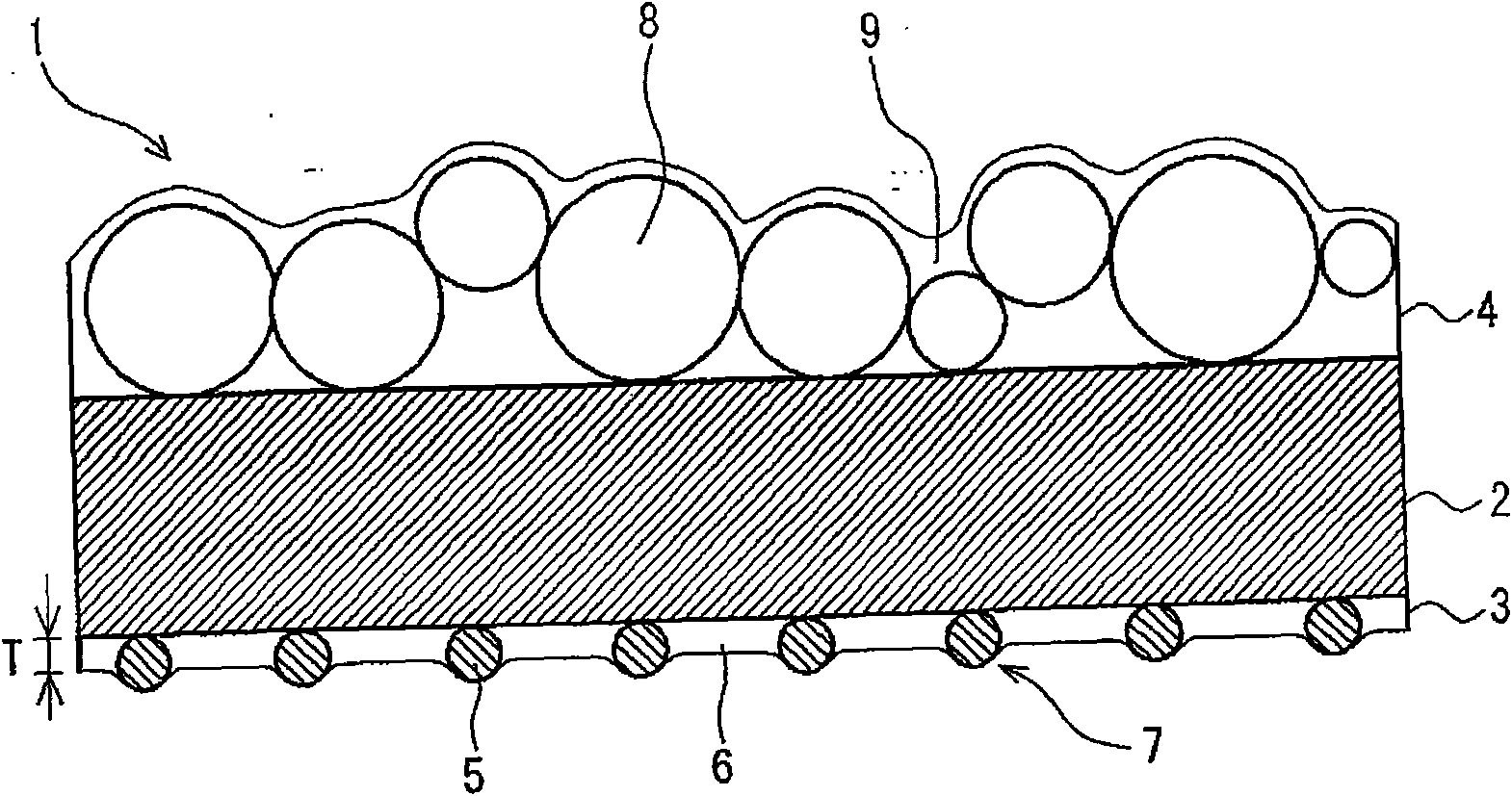

Anti-sticking paper preparation method with low consumption of silicone oil

InactiveCN102359031AReduce usageReduce dosageMechanical working/deformationPaper/cardboardPapermakingPolyolefin

The invention belongs to the field of light industry papermaking, and relates to an anti-sticking paper preparation method. The method comprises: uniformly mixing polyethylene and modified polyolefin according to a mass ratio of 1:0.1-0.5; heating and melting; then laminating the molten material on corona-pretreated base paper, wherein the laminating amount is 5-20 g / m<2>; cooling to obtain the laminated paper; carrying out rolling for the laminated paper by a roller with concave-convex-shaped embossing patterns, wherein the surface of the laminated paper shows the concave-convex-shaped embossing grooves; adopting a coater to uniformly coat the silicone oil on the convex surfaces of the embossing patterns on the laminated paper surface, wherein the coating amount of the silicone oil is 0.5-1.0 g / m<2>; drying at a temperature of 100-200 DEG C in three temperature stages; cooling to obtain the anti-sticking paper. With adopting the method of the present invention, the anti-sticking paper is rolled to form the strip concave-convex-shaped embossing patterns, the concave parts of the anti-sticking paper are not coated with the anti-sticking agent, such that the use amount of the silicone oil is reduced, the use amount of the organic solvent is reduced, the production cost is reduced, and the requirements of environmental protection and energy saving are achieved.

Owner:HUNAN FUTAI DIGITAL MATERIAL TECH

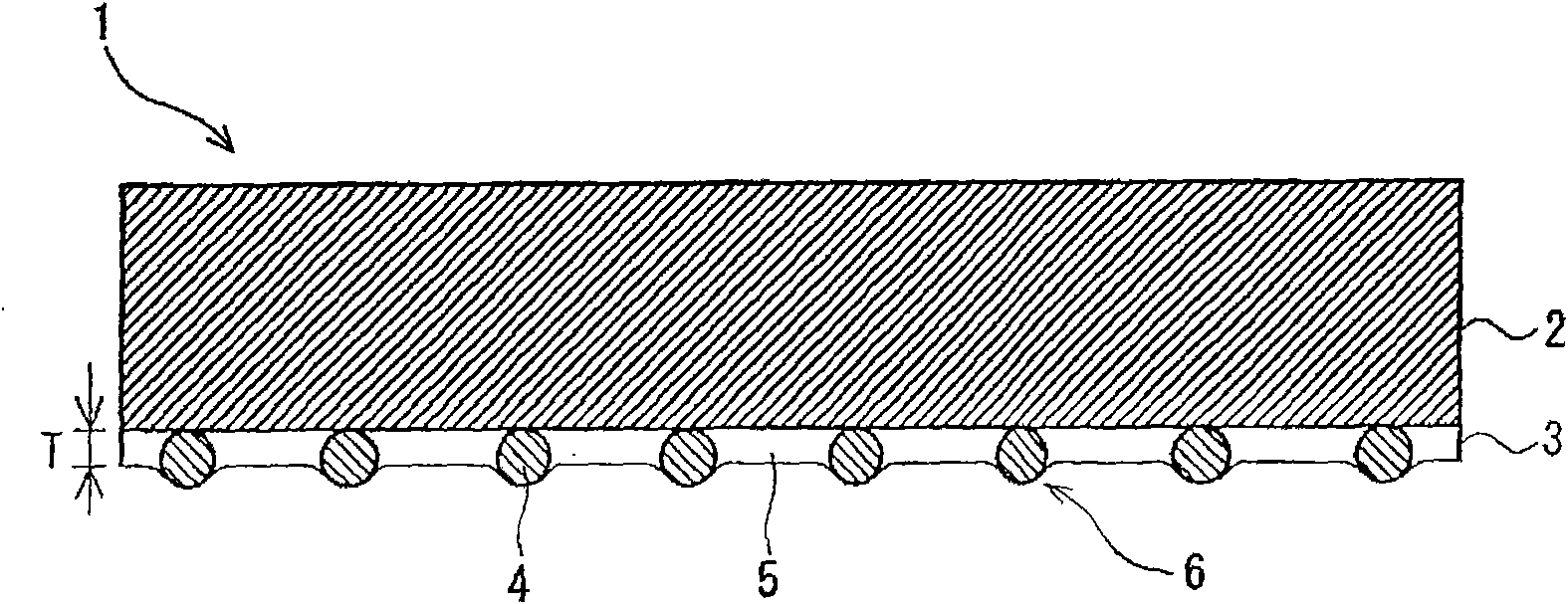

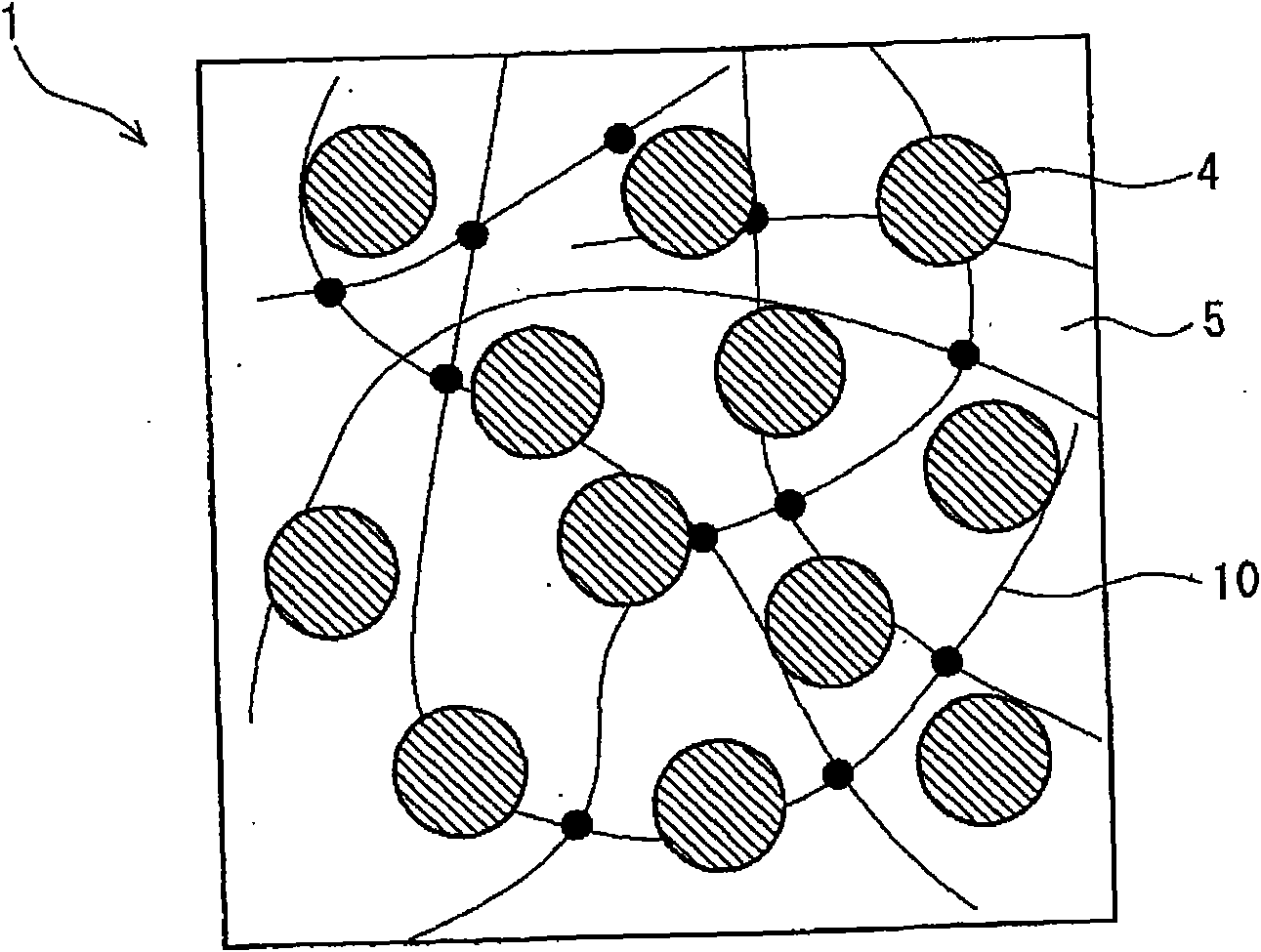

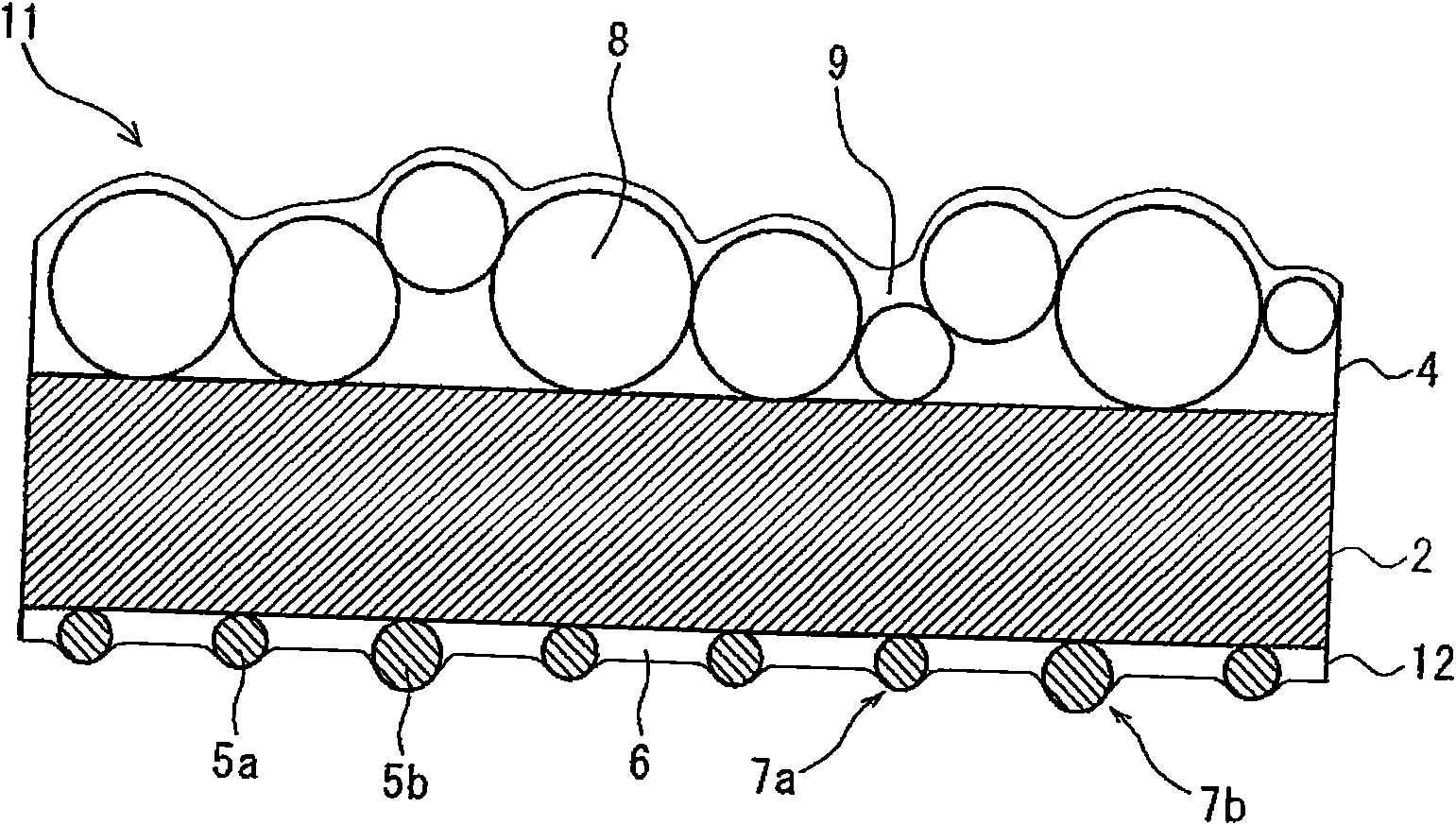

Base sheet for optical sheet

ActiveCN101630029AContributes to high brightnessUniform brightnessPrismsMirrorsMembrane permeabilityPolymer science

The invention provides a base sheet for optical sheet having excellent antisticking properties, high total transmittance, capability of inhibiting interference phenomenon and uneven brightness, and high economical efficiency and membrane permeability, consisting of a transparent base film and an antisticking layer laminated on one surface of the base film, and characterized in that the antisticking layer has filling materials and resin binder; the average thickness of the flat part of the antisticking layer is more than 50nm and less than 15nm; the average grain diameter of the filling materials is more than 70nm and less than 200nm; the average grain diameter of the filling materials can be larger than the average thickness of the flat part of the antisticking layer; the content of the filling materials of the antisticking layer is preferably more than 20 mass percent and less than 50 mass percent; and bonder polymer can have a three-dimensional crosslinking structure.

Owner:KEIWA INCORPORATED

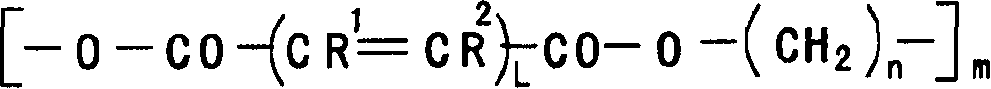

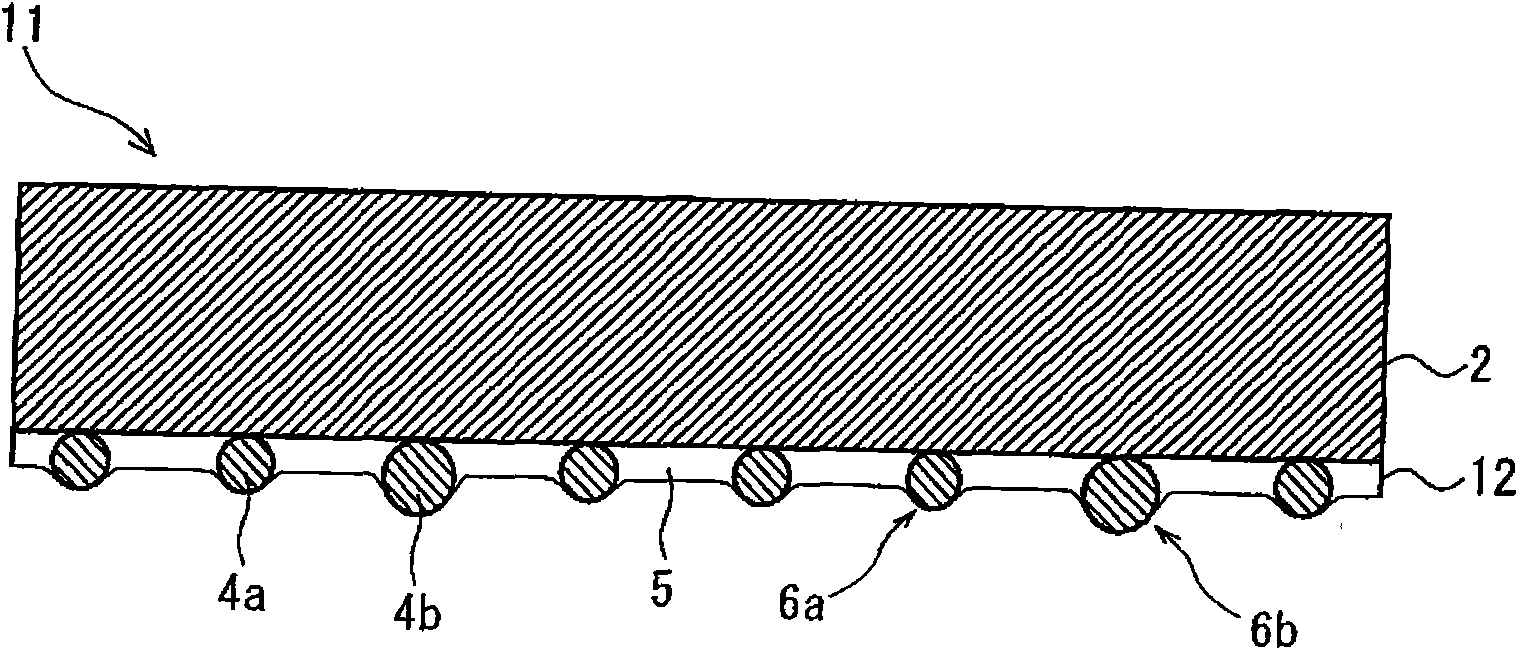

Laminated polyester film

ActiveCN102741050AEasy to slideGood anti-adhesiveSynthetic resin layered productsCoatingsPolyesterLiquid-crystal display

Disclosed is a laminated polyester film which is suitable for use in instances when an item exhibiting good slipperiness and anti-stick properties is required,such as in members which form LCD displays.The laminated polyester film has:a coating layer containing a resin and particles on one surface of a polyester film,said particles having an area content ratio of 1-50%;and a coating layer containing a resin on the other surface of the polyester film.

Owner:MITSUBISHI CHEM CORP

Release paper for adhesive tape and preparation method of release paper

InactiveCN106012670AGood anti-adhesiveReduce usageMechanical paper treatmentPaper coatingCross-linkEnvironmental resistance

The invention discloses release paper for adhesive tape and a preparation method of the release paper. The release paper for the adhesive tape comprises a base material, a lamination layer, an anti-sticking agent layer, a thin film layer, a matte coating and a release agent coating. The matte coating is prepared from, by weight, nano-silica powder, nano-alumina powder, a silane coupling agent, vinyl siloxane, hydrosiloxane, a solvent, platinum and an initiating agent; the release agent coating is prepared from, by weight, amino silicon oil, a cross-linking agent, a chromium-containing organic complex, an active thinning agent, an antioxidant, a photoinitiator, high-viscosity methyl silicone oil, 3-methyl-1-pentyn-3-ol and an azo-compound foaming agent. According to the release paper for the adhesive tape, gaps are coated with an anti-sticking agent, therefore, the usage amount of silicon oil is reduced, and the usage amount of the organic solvent is reduced; the produced release paper is good in anti-sticking property, the production cost is reduced, the environmental protection and energy saving requirements are met, and great development potential and market need are achieved.

Owner:湖南省和祥润新材料有限公司

A kind of anti-adhesive paper preparation method with well-tac-toe groove structure

InactiveCN102277793AReduce usageGood anti-adhesiveNon-fibrous pulp additionPaper coatingPolymer sciencePolyolefin

The invention belongs to the field of light industry papermaking, and relates to a method for preparing anti-adhesive paper with a well-shaped groove structure. In this method, polyethylene and modified polyolefin are evenly mixed in a mass ratio of 1:0.1 to 0.2, heated and melted, and coated onto the corona pretreated backing paper with a coating amount of 10- 20g / m2, after cooling, the coated paper is obtained; after the coated paper is rolled by a roller with a convex module, grooves appear on the surface; the silicone oil is coated with 1.0-2.0g / m2 of dry silicon by a coating machine The amount of coating is evenly coated on the surface of the coated paper; then it is dried at 100°C to 200°C in three temperature sections, and the release paper is obtained after cooling. With the method of the present invention, after the anti-adhesive paper is rolled into grooves, the concave part of the anti-adhesive paper is not coated with anti-adhesive agent, thereby reducing the amount of silicone oil used, the amount of organic solvent used, the production cost, and environmental protection. Energy saving requirements.

Owner:FUJIAN NORMAL UNIV

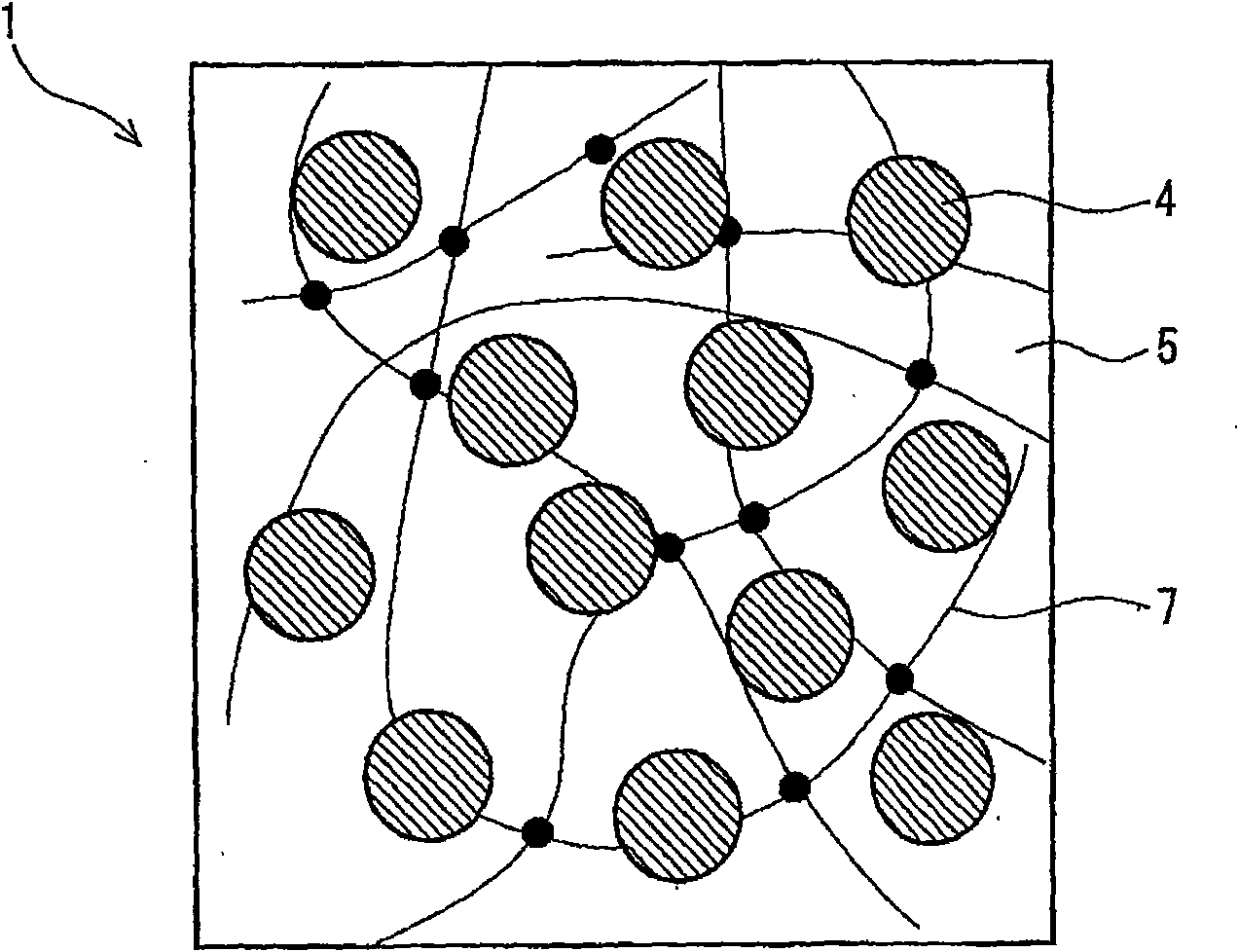

Optical sheet and backlight unit using the same

ActiveCN101630030AGood anti-adhesiveHigh light transmittancePrismsDiffusing elementsInterference phenomenonEngineering

The invention provides an optical sheet having excellent viscosity resistance, high total light transmission ratio, capability of suppressing interference phenomenon and illumination unevenness and thereby having high economical efficiency and film property, and a backlight unit using the same. The optical sheet of the invention comprises a transparent substrate film, an optical layer laminated on one side of the substrate film, and an anti-adhesion layer laminated on the other side of the substrate film, wherein the anti-adhesion layer contains filler and resin bonding agent thereof; the average thickness of a flat part of the anti-adhesion layer is more than 50 nm but less than 150 nm; the average particle diameter of the filler is more than 70 nm but smaller than 200 nm; a small-diameter filler containing main ingredients and a big-diameter filler containing auxiliary ingredients are used as filler; the average particle diameter of the small-diameter filler can be set to be more than 50 nm but less than 150 nm.

Owner:KEIWA INCORPORATED

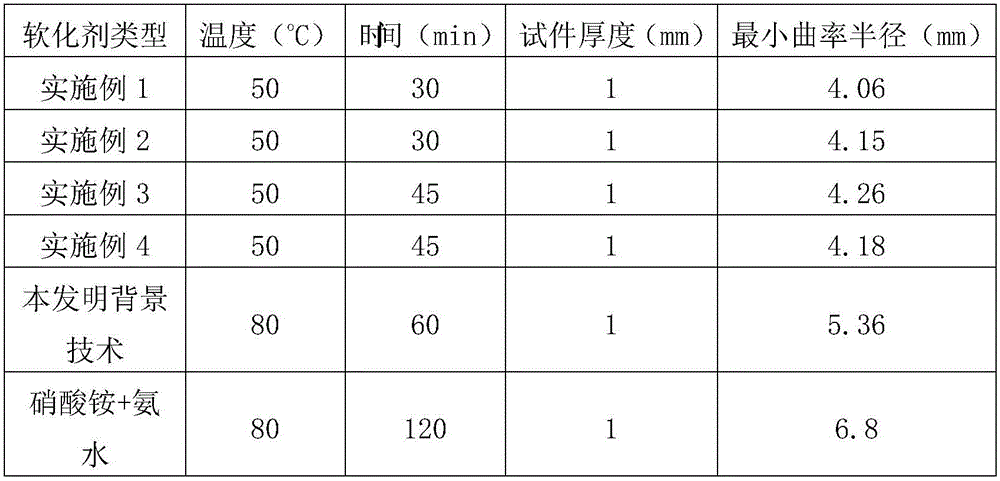

Wood permeable softening agent

InactiveCN105690522AImprove softening effectReduce processing timeWood treatment detailsWood impregnation detailsSodium BentoniteBetaine

The invention discloses a wood permeable softening agent which is prepared from the following components in parts by weight: 2-4 parts of talcum powder, 2-6 parts of organic bentonite, 10-15 parts of polyoxyethylene fatty acid ester, 1-3 parts of dodecyl dimethyl betaine, 1-3 parts of lauryl sodium sulfate, 1-3 parts of sodium lignin sulfonate, 2-4 parts of zinc stearate, 3-5 parts of calcium stearate, 40-60 parts of chlorinated paraffin, 1-3 parts of polyacrylamide, 4-6 parts of polyglycerol fatty acid ester, 1-2 parts of polydimethylsiloxane, 1-2 parts of ethylenediaminetetraacetic acid disodium salt, 1-2 parts of triethanolamine, 30-40 parts of ethanol and 100-120 parts of deionized water. The wood permeable softening agent disclosed by the invention has the advantages of reasonable formula, good softening effect, short treatment time and high safety, and can be applied to soften various woods.

Owner:王璐

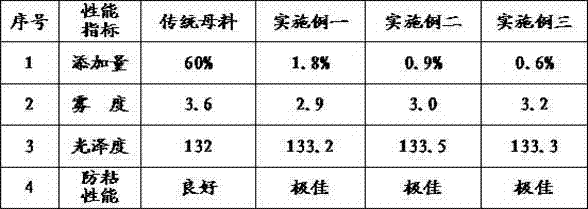

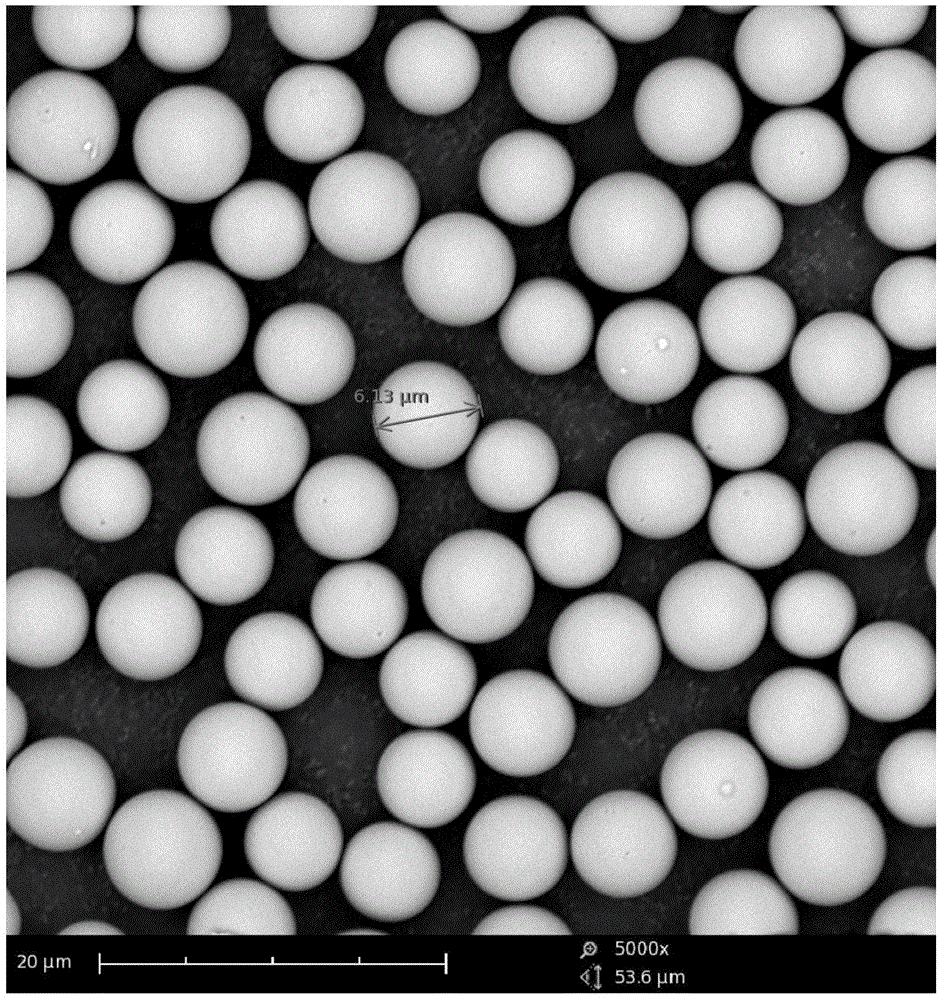

Anti-bonding master batch for optical-grade biaxially-oriented PET (polyethylene terephthalate) films/sheets and production process thereof

InactiveCN102585458AMitigating the impact of optical performanceElimination of Optical Performance EffectsMasterbatchPolymer science

The invention provides an anti-bonding master batch for optical-grade biaxially-oriented PET (polyethylene terephthalate) films / sheets and a production process thereof. The anti-bonding master batch comprises the following components in parts by weight: 65-99 parts of PET and 1-35 parts of an anti-bonding agent, wherein the anti-bonding agent is composed of inorganic particles which are regular in shape and 0.5-10 mu m in mean particle size, and the melting point of the anti-bonding agent is more than 220 DEG C. The production process is implemented through the following steps of S1, pre-drying; S2, production implemented by using a double-screw extruder, wherein the temperature of each area of the extruder is 250-290 DEG C, the rotating speed of a principal machine is 200-450 r / min, the current is 300-400 A, 1-3 sections carry out vacuum exhaust, and the vacuum degree is minus 0.05mPa to plus 0.1mPa; S3, granulation; and S4, finished product drying. According to the invention, the detects in the prior art are overcome; and through adopting a direct mixing and melting machine-shaping method implemented by using the double-screw extruder, the preparation of the master batch which is simple in process, super-transparent, and excellent in anti-bonding effect is realized.

Owner:SHANTOU BEST SCI & TECH

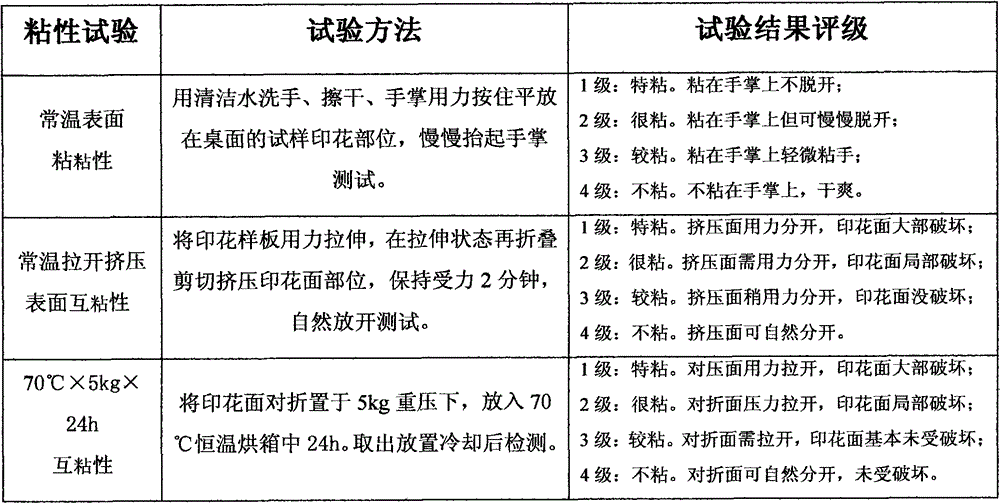

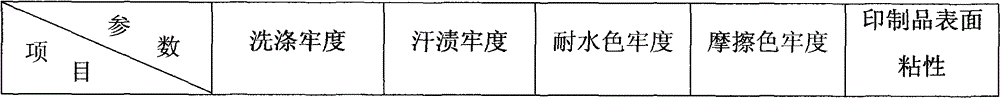

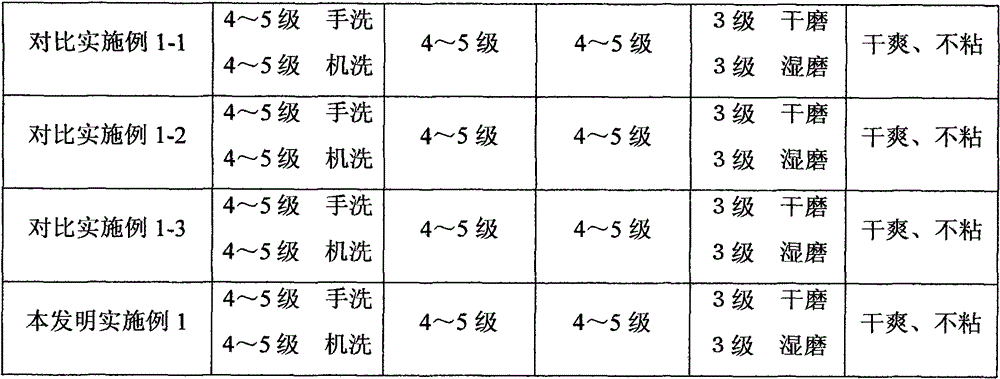

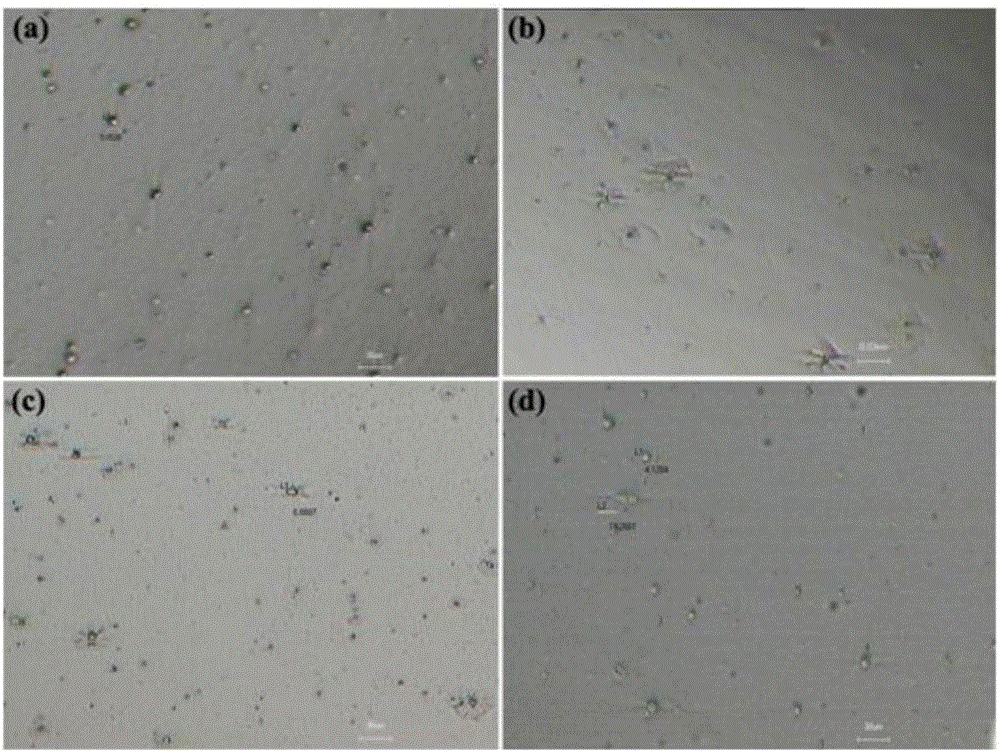

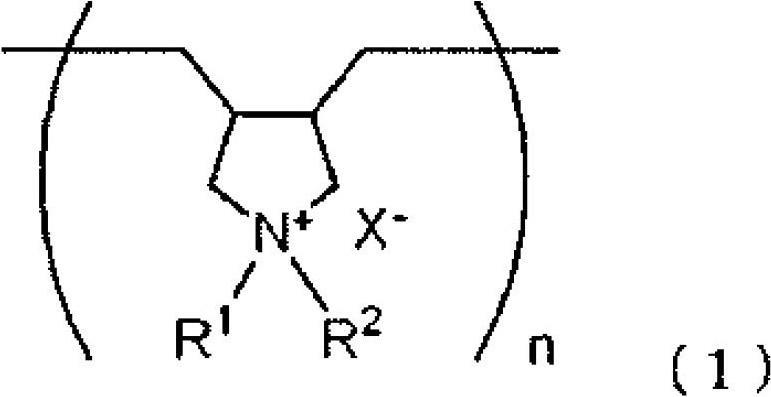

Polyacrylate emulsion printing paste adhesion preventer and preparation method thereof

The invention relates to polyacrylate emulsion printing paste adhesion preventer and a preparation method thereof and belongs to the technical field of screen printing. The polyacrylate emulsion printing paste adhesion preventer comprises at least two of silicon oil, mineral oil, animal and vegetable oil, PE-wax (polyethylene wax) and high-grade fatty acid ester. Components and proportion are regulated according to surface adhesion and internal adhesion difference in printing paste printed products, adhesion of the common polyacrylate emulsion printing paste printed products can be overcome effectively, and water resistance, heat resistance and the like are improved.

Owner:DONGGUAN CTL NEW MATERIAL TECH

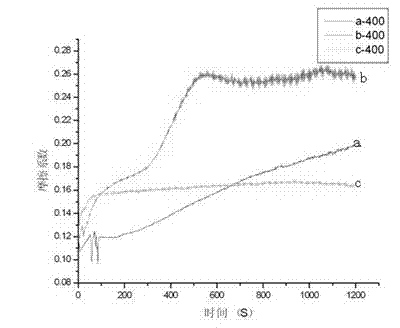

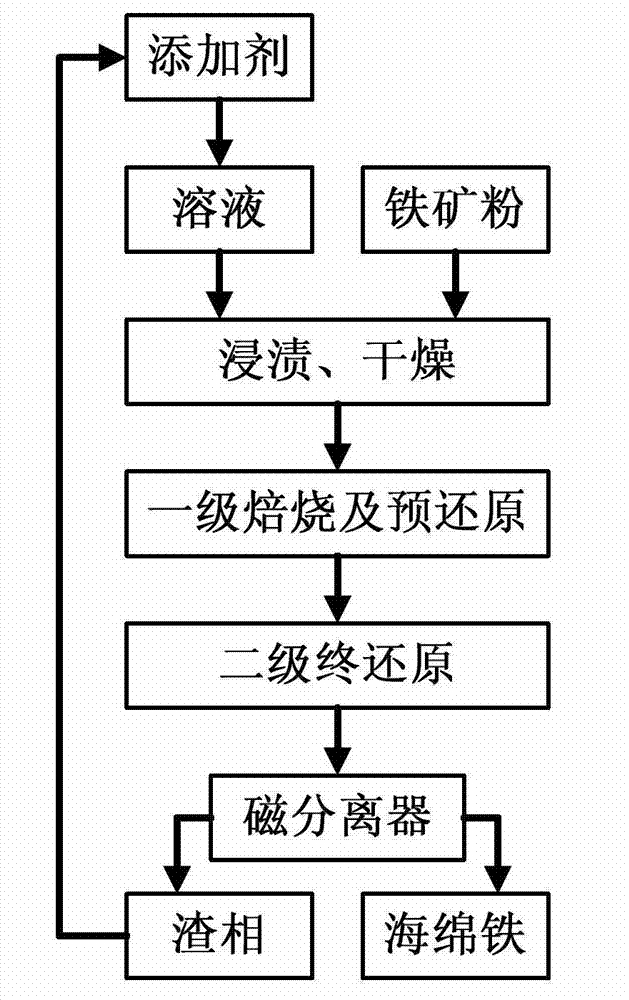

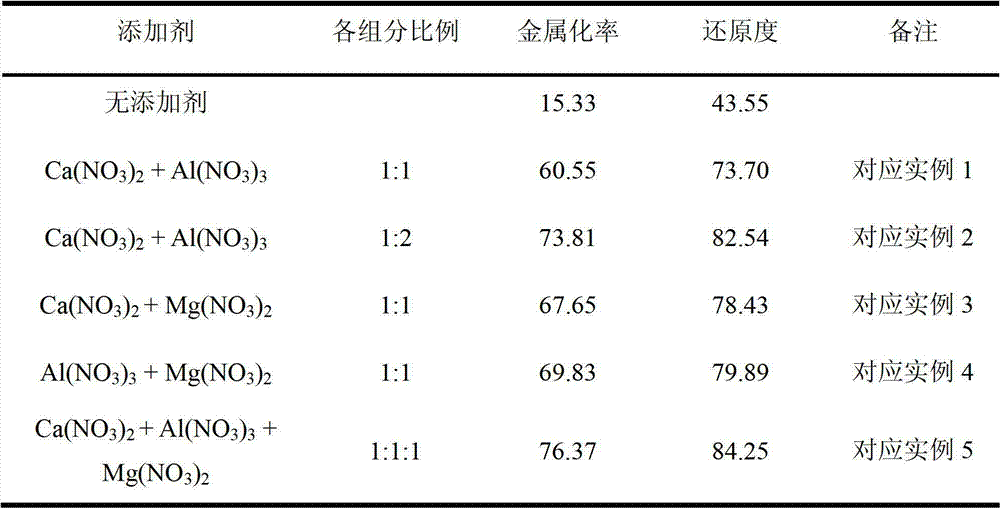

Method for modifying iron ore powder by composite additive to prevent sticking and defluidizing during fluidization reduction

InactiveCN102925611AImprove reduction efficiencyInhibition of cohesive lossFluidised-bed furnacesIron powderMaterials science

The invention relates to a method for modifying iron ore powder by utilizing a composite additive to prevent sticking and defluidizing during fluidization reduction. The method comprises the following steps of: modifying the iron ore powder before a fluidization reduction process step, firstly preparing a 0.5%-60% additive solution, then dipping the iron ore powder in the additive solution, adsorbing the additive onto the surface of the iron ore powder or a pore canal by utilizing the adsorption performance of the iron ore powder, and performing fluidization preheating treatment on the modified iron ore powder. According to the method disclosed by the invention, the occurrence of sticking and defluidizing during the fluidization reduction can be effectively inhibited, and the reduction degree and the metallization rate are respectively improved by 45%-55% and 30%-40%. Simultaneously, the additive can realize cyclic utilization by magnetic separation so as to ensure product quality. The method disclosed by the invention has the advantages of a wide range of applications of ore, and capability of adjusting the composition of the composite additive against the characteristics of the type of the iron ore powder to achieve the best anti-sticking effect; and simultaneously, the process flow of the fluidization reduction process is not changed, and the method is simple to operate and economic and practical.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

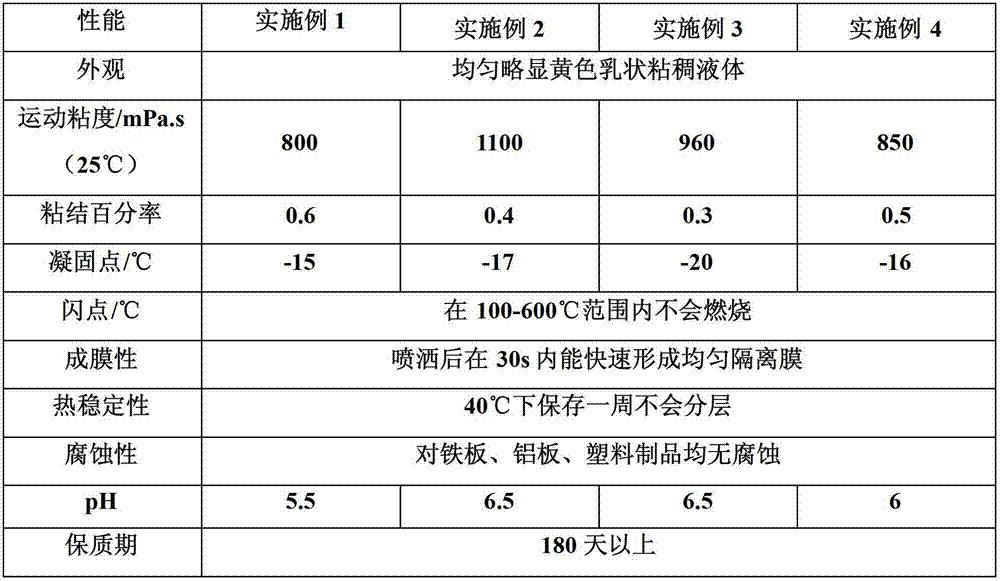

Asphalt concrete isolating agent for adhesion prevention of paver and transportation car hopper and preparation method thereof

ActiveCN102807818ANo damageGuaranteed road performanceAnti-corrosive paintsPolyvinyl alcoholMaterial resources

The invention discloses asphalt concrete isolating agent for adhesion prevention of a paver and a transportation car hopper and a preparation method thereof, and belongs to the field of preparation of asphalt concrete isolating agents. The asphalt concrete isolating agent is prepared by mixing long-chained alkyl modified silicone fluid, monoethanolamine, triethanolamine, oleic acid, polyethylene alcohol solution, water and other additives. The isolating agent has performance such as high temperature and low temperature resistance, weather resistance, flame resistance, corrosion resistance, physiological inertia, good biological compatibility and the like. Due to the adoption of the isolating agent, the asphalt concrete can be prevented from adhering to a transportation vehicle hopper and a paver, so that the waste of the asphalt concrete can be greatly reduced, the cost of the labor and the material resource in the mixing, transportation and paving process can be saved, and the economical benefit is remarkable. The asphalt concrete isolating agent is a kind of novel energy-saving and environment-friendly asphalt concrete isolating agent.

Owner:SHANXI PROVINCIAL RES INST OF COMM

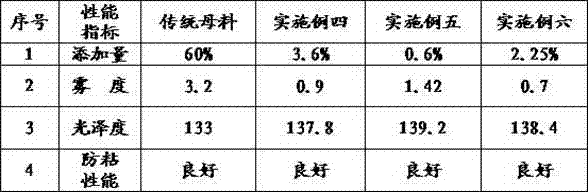

Low-friction coefficient anti-bonding master batch special for metallized base film and preparation method thereof

ActiveCN106519455ADoes not affect heat sealing temperatureDoes not affect heat sealing performanceMetallised filmPolypropylene

The invention relates to a low-friction coefficient anti-bonding master batch special for a metallized base film and a preparation method thereof. The low-friction coefficient anti-bonding master batch mainly comprises, by weight, 90-95 parts of polypropylene resin and 5-10 parts of polymethylsesquisiloxane-polyphenylsilsesquioxane. The polymethylsesquisiloxane-polyphenylsilsesquioxane is a ladder polymer with R3SiO terminated. The molecular formula of the polymethylsesquisiloxane-polyphenylsilsesquioxane is [CH3SiO1.5]n-[PhSiO1.5]m, wherein n is 5-8 and m is 2-5. According to the preparation method, an anti-sticking agent is added by means of side feeding through precision electronic weight loss scales, and pelleting is performed after melt blending by means of the special double-screw process. By the adoption of the method, the problem that no slipping agent (master batch) can be added into the metallized film and thus the friction coefficient is high and the problem that the low friction coefficient is required under the condition that no migration slipping agent can be added into an aluminum laminated film are effectively solved. The friction coefficient of the obtained metallized base film is lowered to 0.4 or below from 0.8 or above, the slipping property is good, no migration happens, and the product surface is not greasy, high in glossiness, resistant to abrasion, lasting and effective.

Owner:SHANTOU BEST SCI & TECH

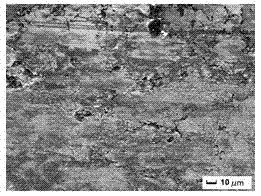

Preparation method of abrasion-resistant and corrosion-resistant non-sticky coating

InactiveCN106010163AGood anti-adhesiveImprove wear resistanceAnti-corrosive paintsPolyester coatingsSolventWax

The invention relates to a preparation method of an abrasion-resistant and corrosion-resistant non-sticky coating and belongs to the field of coatings. Aiming at the problems that organic fluorine resin in a current traditional non-sticky coating fluoro coating is high in fusion temperature and is not dissolved in common solvents, an organosilicone non-sticky coating can achieve a good non-sticky effect but is poor in hardness and cannot meet shovel test requirements, a nano-ceramic coating is high in hardness, but a film is crispy, and paint easily falls off after the film encounters hard objects, kieselguhr is subjected to high-temperature activation and acid modification, the kieselguhr is loaded with silicon carbide, the hardness of the kieselguhr is improved, the kieselguhr and polybutadiene are mixed, wrapped and fixed, and then the mixture is mixed with alkyd resin easily dissolved in the common solvents; the mixture, oil-soluble silicone wax, paraffin and the like generate a mixed reaction, finally through a maleic anhydride modification reaction, corrosion resistance is improved, and therefore the abrasion-resistant and corrosion-resistant non-sticky coating is prepared.

Owner:梅庆波

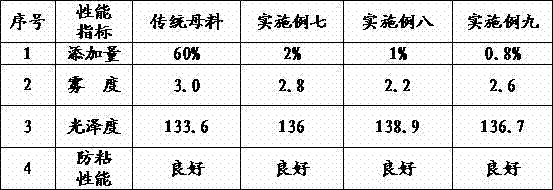

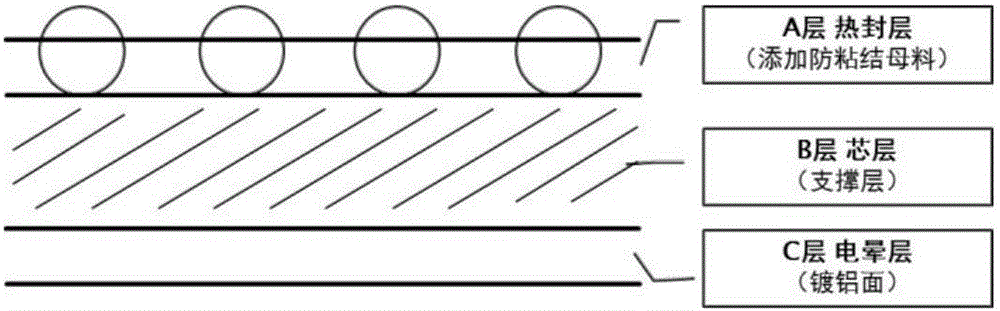

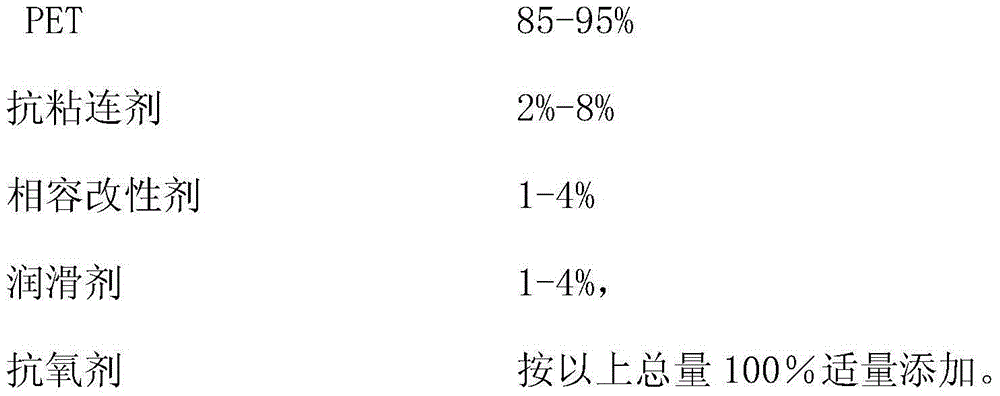

Anti-sticking masterbatch special for printable PET (Poly Ethylene Terephthalate) sheet material and preparation method thereof

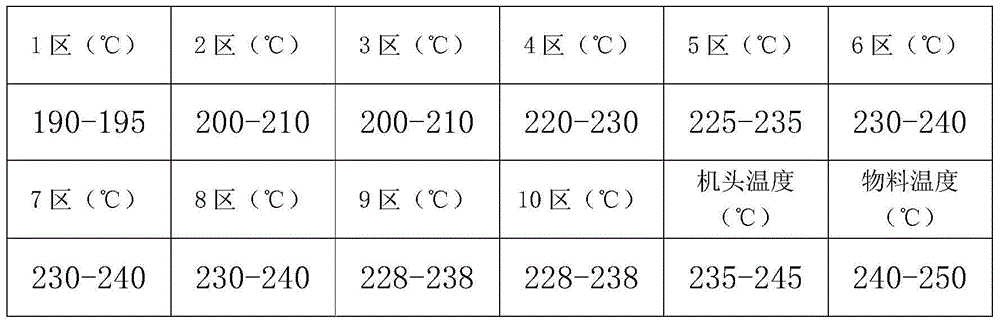

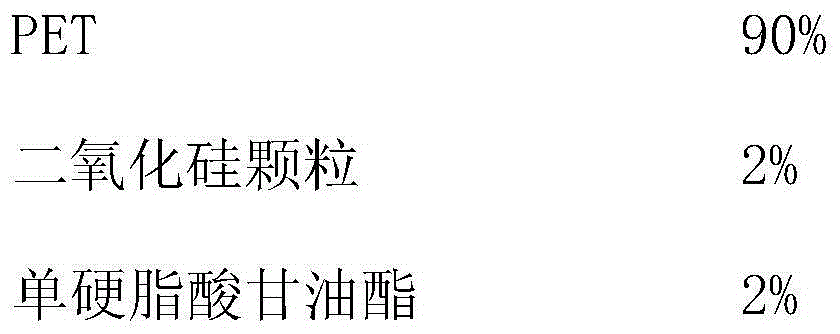

The invention discloses an anti-sticking masterbatch special for a printable PET (Poly Ethylene Terephthalate) sheet material and a preparation method thereof. The anti-sticking masterbatch is prepared from the following components in parts by weight: 85% to 95% of PET, 2% to 8% of anti-sticking agent, 1% to 4% of compatible modifier, 1% to 4% of lubricant and a proper amount of antioxidant, wherein the adding amount of the antioxidant is based on the adding total amount of all components. The preparation method comprises the following steps: weighing all component materials and evenly mixing so as to form a mixture; carrying out melting extrusion on the mixture by using a melt extrusion; and drying, cooling and cutting into granules for molding. The PET sheet material utilizing the anti-sticking masterbatch has the good anti-sticking performance; the influences to the transparency and the haze of the PET sheet material are minimized; and the subsequent machining and manufacturing process of the sheet material is smooth and fluent, so that the production efficiency is improved, the problems of the appearance quality of the PET sheet material are reduced and the influence to the surface tension of the sheet material is not serious. Thus, the PET sheet material has the good printability for inks.

Owner:中山京工高分子材料有限公司

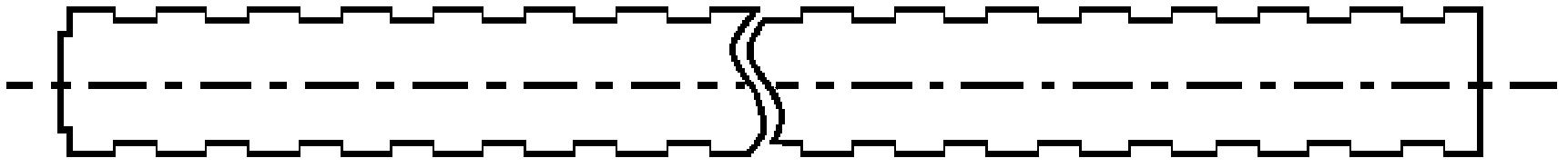

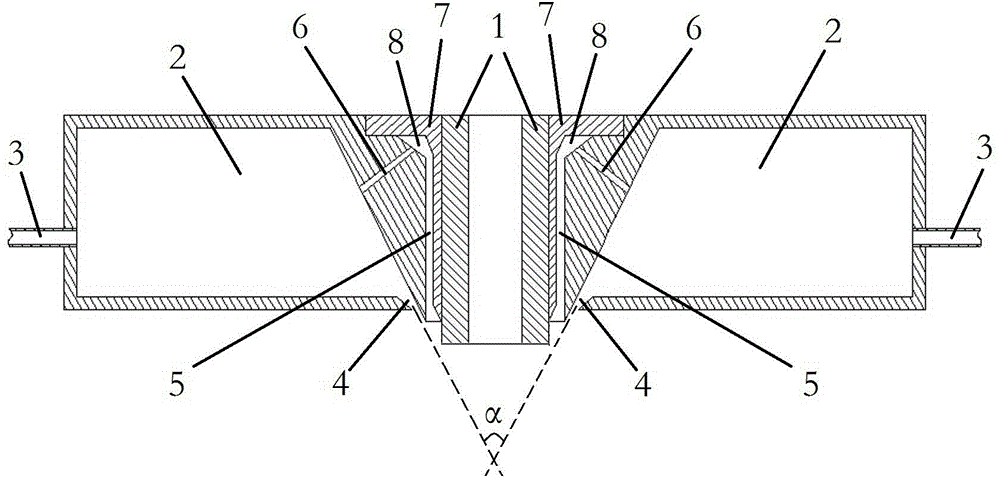

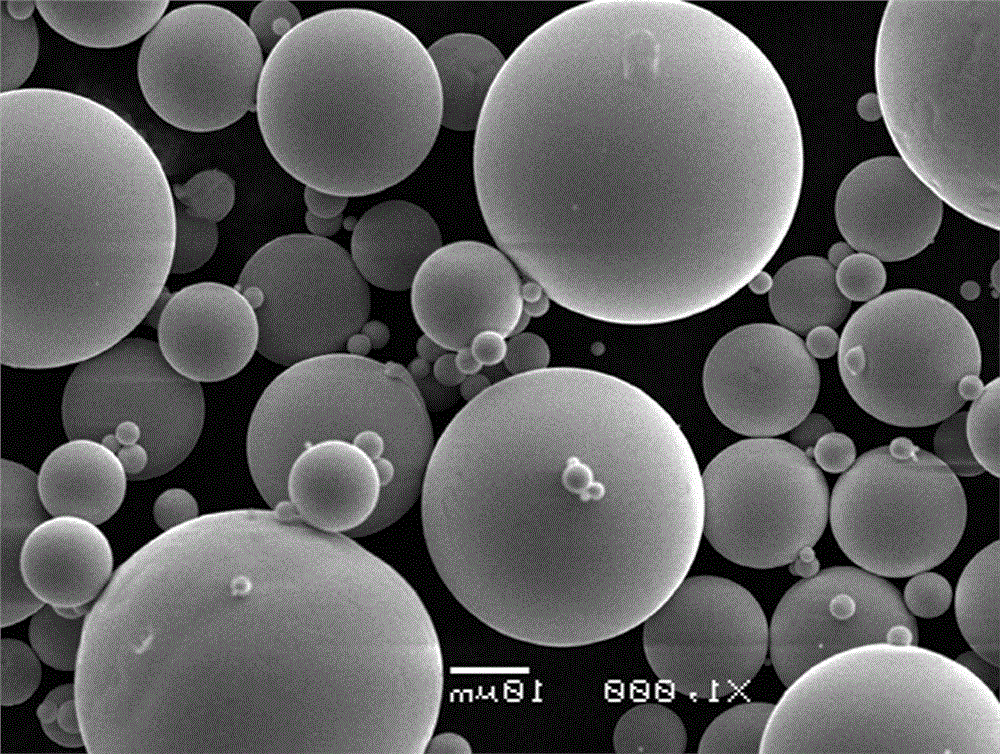

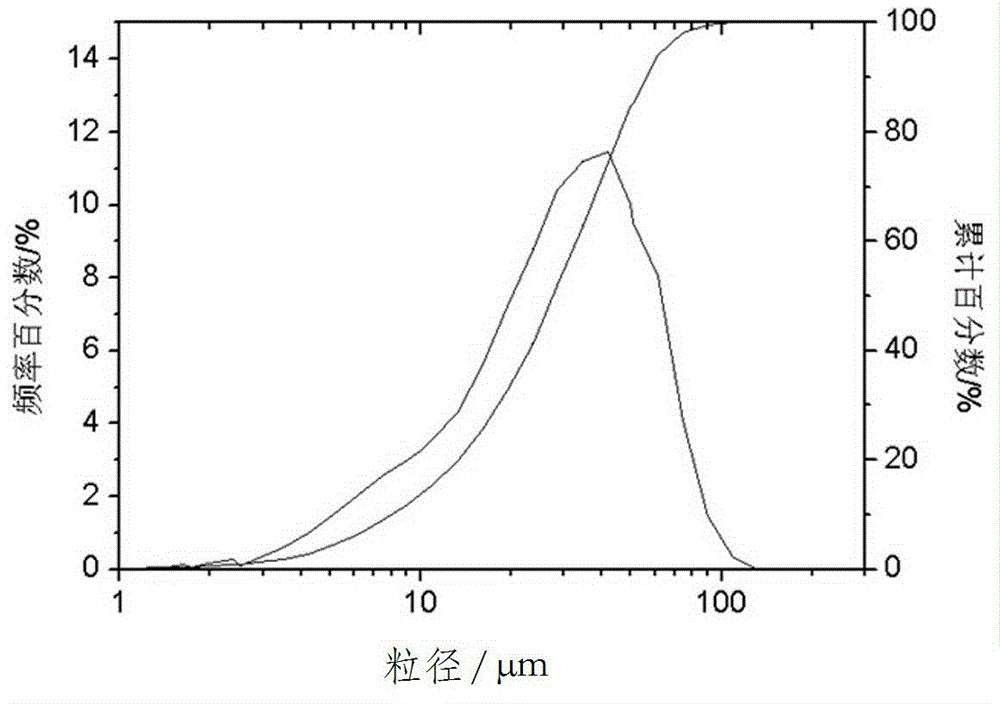

Blocking-preventing nozzle device used for preparing metal powder through gas atomization method

The invention relates to a blocking-preventing nozzle device used for preparing metal powder through a gas atomization method. The blocking-preventing nozzle device comprises a flow guiding pipe and a gas cavity located around the flow guiding pipe. The gas cavity is connected with a gas inlet pipe, and a nozzle circular seam communicated with the gas cavity is formed in the periphery of the lower end of the flow guiding pipe; a gas guiding seam surrounding the flow guiding pipe is formed between the gas cavity and the flow guiding pipe, and an opening of the gas guiding seam is located between the flow guiding pipe and the nozzle circular seam; a gas guiding hole communicated with the gas guiding seam is formed in the wall of the gas cavity. The blocking-preventing nozzle device can reduce nodulation of molten metal at a nozzle and prevent the flow guiding pipe from being blocked.

Owner:HUNAN METALLURGY MATERIAL RES INST

Preparation method of release paper with less silicone oil for sticking resistance

InactiveCN105421151AReduce usageReduce dosageMechanical working/deformationPaper/cardboardPolyolefinPapermaking

The invention belongs to light industry papermaking and relates to a preparation method of release paper with less silicone oil for sticking resistance. The preparation method includes the steps of: 1) uniformly mixing polyethylene with modified polyolefin according to the mass ratio of 1:0.1-0.5, heating and fusing the mixture, performing film lamination to the mixture onto base paper which is subjected to corona pre-treatment with lamination quantity being 5-20 g / m<2>, and cooling the paper to obtain laminated paper; 2) grinding the laminated paper through a roller shaft having uneven embossing to form uneven embossed troughs on the surface of the paper; 3) uniformly coating convex faces of the uneven embossing on the surface of the laminated paper with silicone oil through a coating machine with dry silicon coating quantity being 0.5-1.0 g / m<2>; and 4) drying the laminated paper at 100-200 DEG C through three temperature sections, and cooling the laminated paper to prepare the release paper. By means of the method, when the release paper is ground to form the bar-shaped uneven embossing, the concave parts on the release paper are not coated with the anti-sticking agent, thereby reducing the use amount of the silicone oil and organic solvents, reducing production cost and achieving an environment-protective and energy-saving demand.

Owner:QUANZHOU NAISI MATERIAL TECH

Laminated polyester film

ActiveCN102695614AEasy to slideGood anti-adhesiveSynthetic resin layered productsElectrical equipmentPolyesterAntistatic agent

Disclosed is a laminated polyester film which is suitable for applications wherein good silppability, sticking prevention and antistatic properties are required, for example, applications such as a constituent member of a liquid crystal display. Specifically disclosed is laminated polyester film that comprises a coating film, which contains a resin and an antistatic agent and does not substantially contain particles, while having a difference in height of 0.04 [mu]m or more, on one surface of a polyester film. The laminated polyester film also comprises a coating film, which contains a resin, on the other surface of the polyester film.

Owner:MITSUBISHI CHEM CORP

Heat resistant antisticking no-lead black glaze for automobile glass and its prepn process

The present invention relates to one kind of heat resistant antisticking no-lead black glaze for automobile glass and its preparation process. The black glaze is prepared with the material including glass powder 30-80 wt%, inorganic pigment 10-40 wt%, polymer resin 1-8 wt%, antisticking agent 1-2 wt%, and solvent 5-20 wt%. Its preparation process includes the technological steps of compounding carrier, compounding glaze slurry, preparing black glaze, etc. The black glaze is applied in pressure formation to produce toughened glass and sandwiched glass for automobile, and has excellent antisticking demolding effect, high capacity of shielding conductive silver slurry line, high blackness and environment friendship.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Soft capsule

InactiveUS20070042035A1High qualityEfficiently manufacturePretreated surfacesPharmaceutical non-active ingredientsBiomedical engineeringWater activity

It is an object of the present invention to provide a capsule anti-sticking agent which can provide excellent anti-sticking effect on a soft capsule without impairing various properties such as water activity, disintegration property and safety, a coated soft capsule of high quality which is coated with the capsule anti-sticking agent and excels in anti-sticking effect, and an efficient method for manufacturing the coated soft capsule. The present invention includes a capsule anti-sticking agent containing an enzymatically decomposed lecithin, a coated soft capsule wherein a surface is coated with the capsule anti-sticking agent, and a method for manufacturing the coated soft capsule in which a surface of a soft capsule is coated with the capsule anti-sticking agent.

Owner:EISIA R&D MANAGEMENT CO LTD

Polyethersulfone antistatic anticorrosive paint, and preparation method and application thereof

InactiveCN104830224ASimple construction processThickness is easy to controlAnti-corrosive paintsElectrically-conductive paintsPetrochemicalCorrosion

The invention provides a polyethersulfone antistatic anticorrosion coating, and a preparation method and application thereof, belonging to the technical field of paints. The paint is composed of the following components in parts by mass: 80 parts of thermoplastic polyethersulfone resin, 30 parts of high-temperature-resistant fluororesin, 1.35-3.85 parts of conducting filler and 280 parts of composite solvent and assistant. The preparation method comprises the following steps: mixing the thermoplastic polyethersulfone resin, high-temperature-resistant fluororesin, conducting filler, composite and assistant, stirring at the rate of 500-800 r / min for 30-60 minutes, and grinding at the rate of 3500-5000 r / min for 4-8 hours. The paint provided by the invention has the characteristics of favorable adhesive force with the metal substrate and high acid / alkali corrosion resistance. The alternating-current conductivity of the prepared coating under the frequency of 10<3>Hz is 1.71*10<-8>-3.20*10<-4>S / m. The paint has favorable antistatic capacity and is applicable to electronics, electric appliances, aviation, petrochemical industry and other industries.

Owner:JILIN UNIV

Anti-adhesion coating

InactiveCN107189622AStrong adhesionImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySurface-active agents

The invention discloses an anti-adhesion coating, and belongs to the field of anti-adhesion coatings. The anti-adhesion coating comprises following components including, by mass, 45-55 parts of epoxy resin, 4-15 parts of Teflon, 20-30 parts of a curing agent, 2-10 parts of a lubricating agent, 3-5 parts of a surface active agent and 80-95 parts of an organic solvent. The mass ratio of the Teflon to the epoxy resin is 1:10, the Teflon is 800-mesh powder, the curing agent is polyamide, the lubricating agent is molybdenum disulfide, and the granularity of the molybdenum disulfide is 800 meshes. Compared with the prior art, the anti-adhesion coating has the beneficial effects that due to the fact that the anti-adhesion coating contains the Teflon, the surface tension of the teflon is very low, the surface tension of the coating prepared through the Teflon is very low as well, the anti-adhesion performance is good, and the anti-adhesion coating can be repeatedly used many times; the epoxy resin has excellent adhesion force for metal, meanwhile, extremely good corrosion resisting performance and high mechanical strength are achieved, the anti-adhesion coating has high adhesion force for a metal base material, and meanwhile high hardness is achieved.

Owner:深圳市睿华涂布科技有限公司

Wear-resistant anti-sticking high-strength coating, composition for forming wear-resistant anti-sticking high-strength coating, and conveying device containing wear-resistant anti-sticking high-strength coating

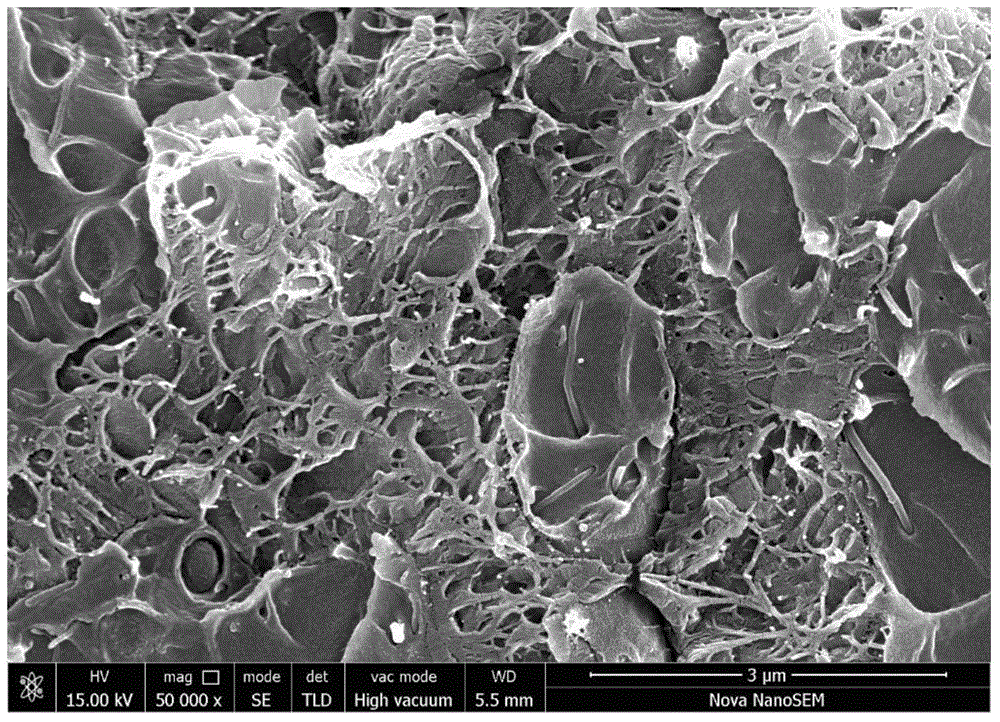

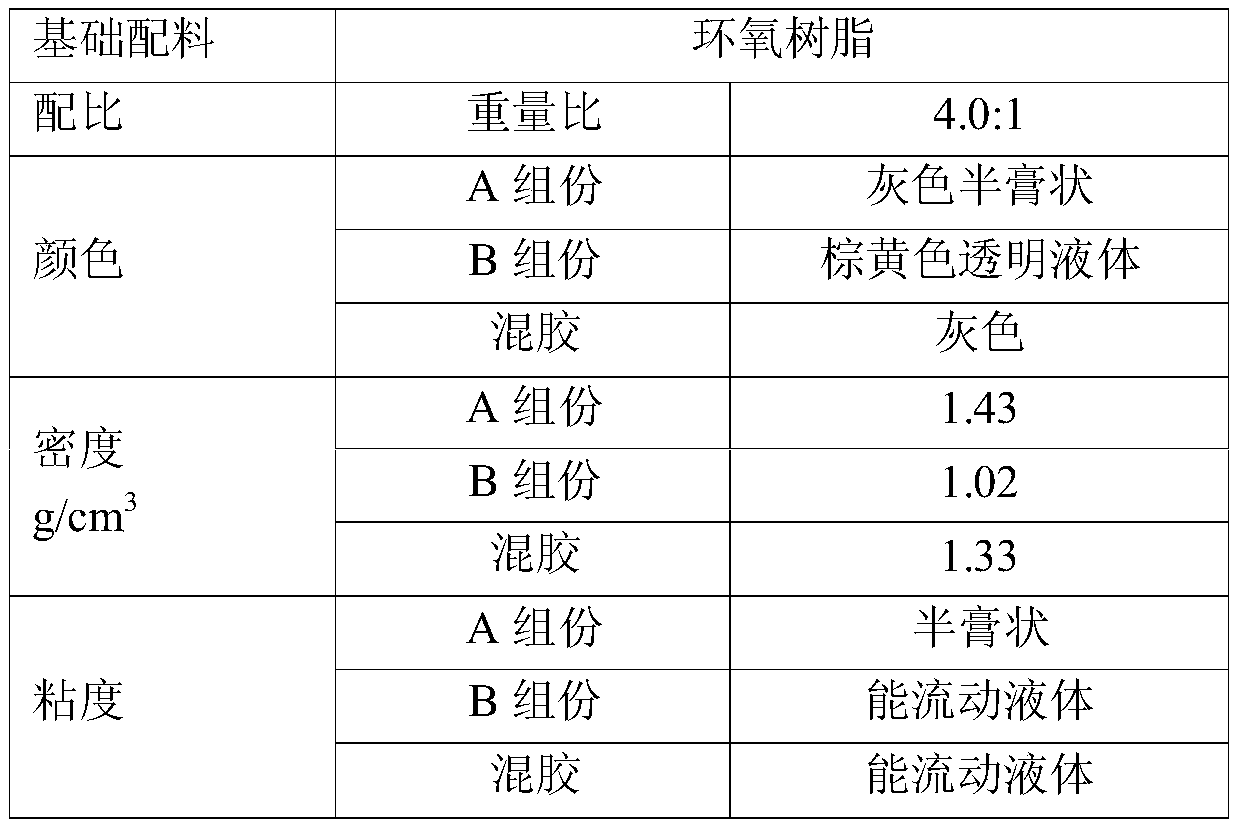

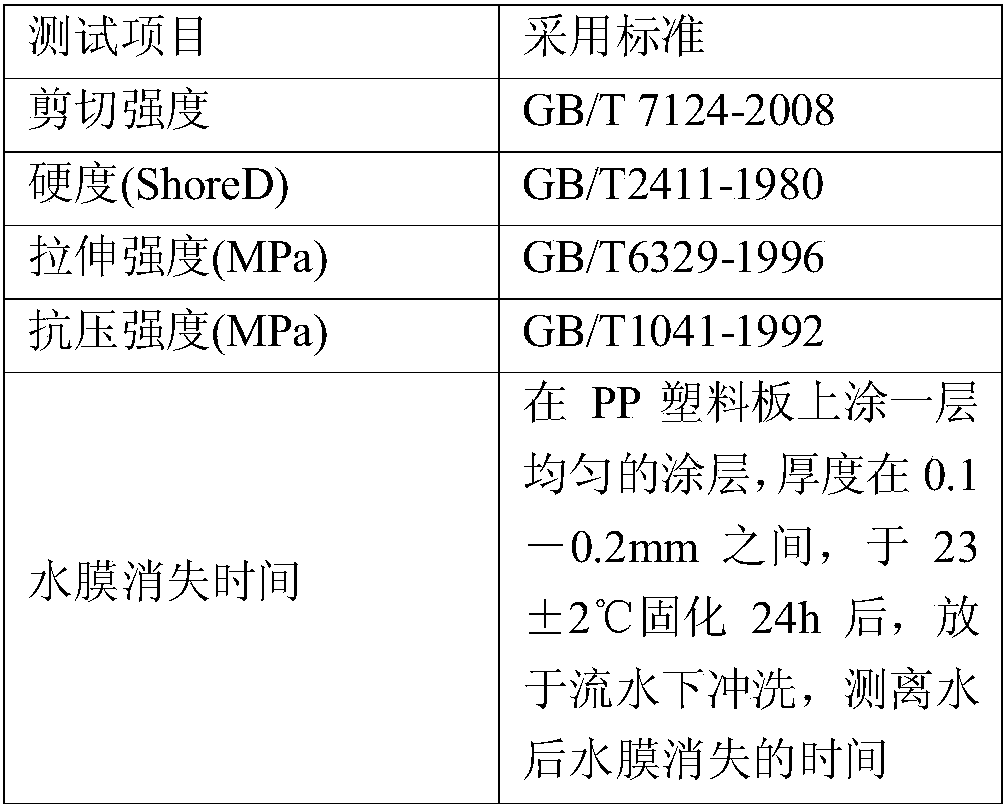

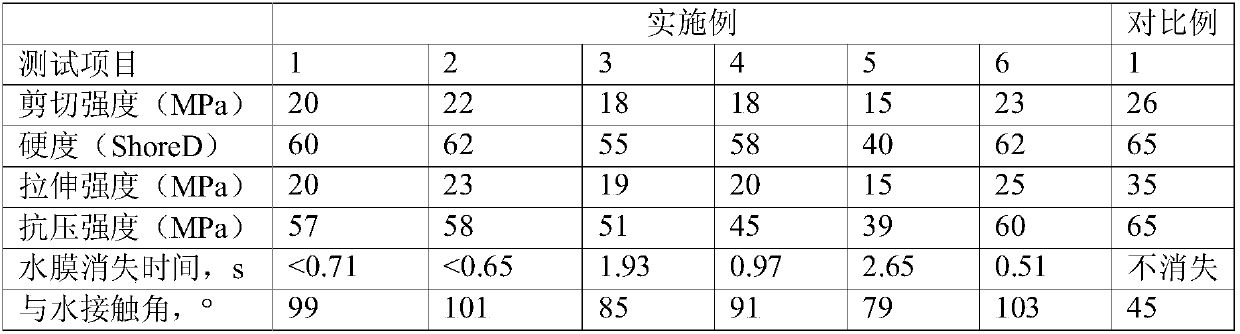

The invention provides a wear-resistant anti-sticking high-strength coating, a composition for forming the wear-resistant anti-sticking high-strength coating, and a conveying device containing the wear-resistant anti-sticking high-strength coating. The composition comprises a component A and a component B, wherein the component A comprises an epoxy resin, the component B comprises a curing agent,and the curing agent comprises a polymethylene diamine modified amine curing agent and / or cashew nut shell oil modified amine curing agent. The coating formed by coating and curing the composition with the components has good wear resistance, good anti-sticking property and high strength. The composition does not contain a solvent, so that the coating forming process does not discharge VOC, and issafety and environmentally friendly.

Owner:TONSAN ADHESIVES INC

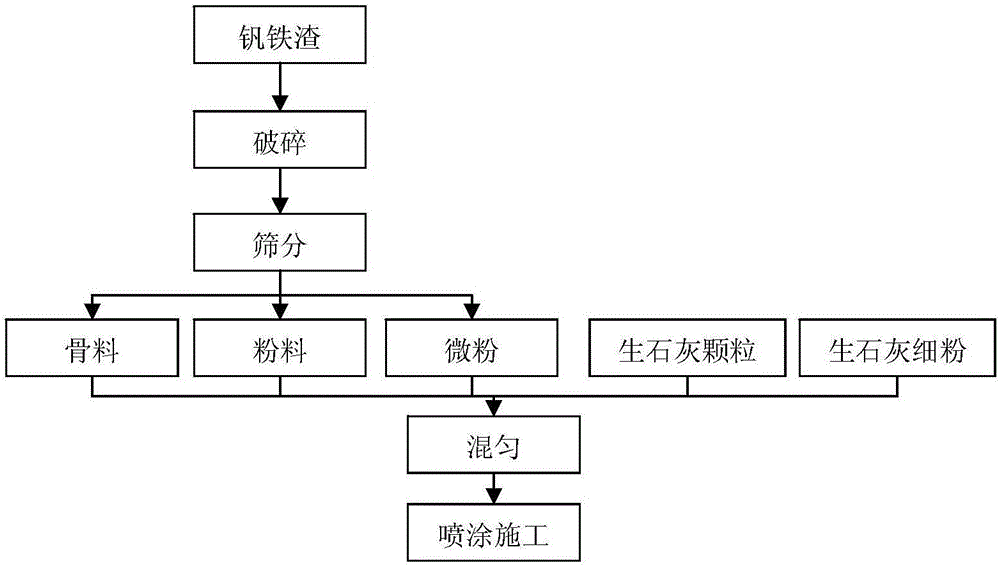

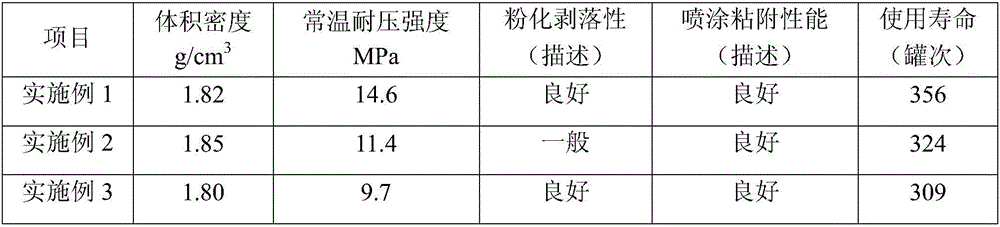

Anti-adhesion spray coating material used for molten iron tank, preparation method and spray coating method thereof

The invention relates to an anti-adhesion spray coating material used for a molten iron tank, and a preparation method and a spray coating method thereof. The spray coating material includes vanadium iron slag, quick lime, and an additive dispersing agent, wherein the vanadium iron slag includes vanadium iron slag aggregate, vanadium iron slag powder and vanadium iron slag micro-powder; the quick lime includes quick lime granules and quick lime powder; the weight ratios of the vanadium iron slag aggregate, the vanadium iron slag powder, the vanadium iron slag micro-powder, the quick lime granules and the quick lime powder are described as follows: 50-60% of the vanadium iron slag aggregate, 10-30% of the vanadium iron slag powder, 5-10% of the vanadium iron slag micro-powder, 10-20% of the quick lime granules and 5-10% of the quick lime powder; wherein the addition quantity of the dispersing agent is 0-0.5%. The spray coating material can be effectively adhered onto surface of a liner of the molten iron tank so as to protect the liner during usage.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of aqueous transparent heat-insulating glass coating

ActiveCN108912871AStrong light transmittanceLow critical surface tensionAntifouling/underwater paintsPaints with biocidesCarbon dioxidePolytetrafluoroethylene

The invention relates to a preparation method of an aqueous transparent heat-insulating glass coating, and belongs to the technical field of preparation of architectural coatings. Modified polytetrafluoroethylene resin is creatively used as a matrix, and nano titanium dioxide is used as filler so as to prepare the glass coating, wherein the polytetrafluoroethylene resin which is modified by an adhesion promoter has ultra-high adhesion so that the performance of the aqueous transparent heat-insulating glass coating is more comprehensive, and organic pollutants adsorbed on the surface of the nano titanium dioxide are decomposed into carbon dioxide and oxygen through selection of the nano titanium dioxide as the filler, so that the original brightness of glass is maintained, and a good heat insulating effect is achieved without influence on the transparency of the glass. The aqueous transparent heat-insulating glass coating has the advantages of strong adhesion, long service life, good water resistance, strong viscosity resistance, strong anti-staining performance, strong UV resistance, high transparency and a good thermal insulation effect, formaldehyde and other indoor harmful organic compounds can be decomposed, and therefore the coating has a very broad application prospect and advantage.

Owner:上海金泰子建筑装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com