Anti-sticking masterbatch special for printable PET (Poly Ethylene Terephthalate) sheet material and preparation method thereof

An anti-adhesive and sheet technology, which is applied in the field of anti-adhesive masterbatch for PET sheet and its preparation, special anti-adhesive masterbatch for printable PET sheet and its preparation. , sheet surface tension drop and other issues, to achieve the effect of smooth manufacturing process, reduce appearance quality problems, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

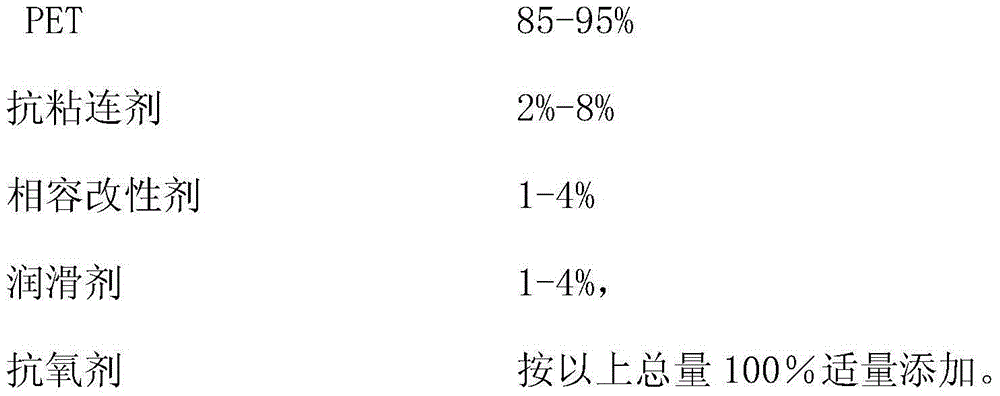

[0029] The weight percent composition of the special anti-adhesive masterbatch for PET sheets is as follows:

[0030]

[0031]

[0032] The production process of Example 1 is as follows: Weigh the raw materials of each component, mix the raw materials of each component through a high-speed mixer at a speed of 80r / min, and then melt and extrude the mixed raw materials through a twin-screw extruder, and dry , cooling, pelletizing and molding;

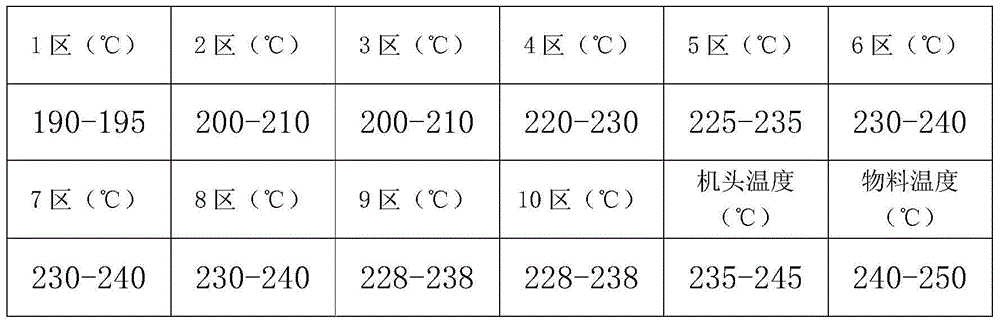

[0033] Among them, the production temperature of each zone of the twin-screw extruder is shown in Table 2. The melt pressure of the twin-screw extruder is 4.1Mpa, the main engine current is controlled at 45A, the main engine speed is controlled at 325r / min, and the feeding is controlled at 25HZ. The speed is controlled at 550r / min.

[0034] Table 2:

[0035]

Embodiment 2

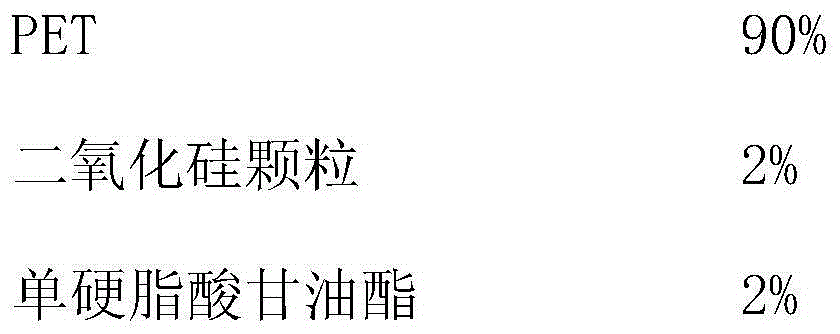

[0037] The weight percent composition of the special anti-adhesive masterbatch for PET sheets is as follows:

[0038]

[0039] The production process of Example 2 is as follows: Weigh the raw materials of each component, mix the raw materials of each component through a high-speed mixer at a speed of 80r / min, and then melt and extrude the mixed raw materials through a twin-screw extruder, and dry , cooling, pelletizing and molding;

[0040] Wherein the production temperature of each zone of the twin-screw extruder is the same as that of Example 1, the melt pressure of the twin-screw extruder is 3.8Mpa, the melt temperature is controlled at 240°C, the main engine current is controlled at 45A, and the main engine speed is controlled at 300r / min , The feeding is controlled at 30HZ, and the speed of the pelletizer is controlled at 550r / min.

Embodiment 3

[0042] The weight percent composition of the special anti-adhesive masterbatch for PET sheets is as follows:

[0043]

[0044] The production process of Example 3 is as follows: Weigh the raw materials of each component, mix the raw materials of each component through a high-speed mixer at a speed of 80r / min, and then melt and extrude the mixed raw materials through a twin-screw extruder, and dry , cooling, pelletizing and molding;

[0045] Among them, the production temperature of each area of the twin-screw extruder is shown in Table 3. The melt pressure of the twin-screw extruder is 2.5Mpa, the main engine current is controlled at 45A, the main engine speed is controlled at 350r / min, and the feeding is controlled at 30HZ. The speed is controlled at 550r / min.

[0046] table 3:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com