Patents

Literature

101results about How to "Control appearance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-permeable agent for water-permeable bricks or water permeable concrete and application of water-permeable agent

The invention discloses a water-permeable agent for water-permeable bricks or water permeable concrete and application of the water-permeable agent. The water-permeable agent comprises, by weight, 75-110 parts of water reducing agent, 150-300 parts of retarder, 100-150 parts of binder, 55-70 parts of air entraining agent and 55-100 parts of water. The water-permeable agent has the advantages that the water-permeable agent can increase the workability of a water-permeable layer, increase water permeability and increase the durability and later strength of the water-permeable bricks and is low in adding amount and low in cost. The water-permeable bricks have the advatnages that the bricks use haycite and regenerated porous coarse aggregate as the aggregate of the water-permeable layer and use the water-permeable agent, the features of porosity, good water absorption performance and high strength of the aggregate and the good performance of the water-permeable agent are utilized to increase the strength and water permeability of the water-permeable bricks, and the bricks are lightweight and convenient to carry.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

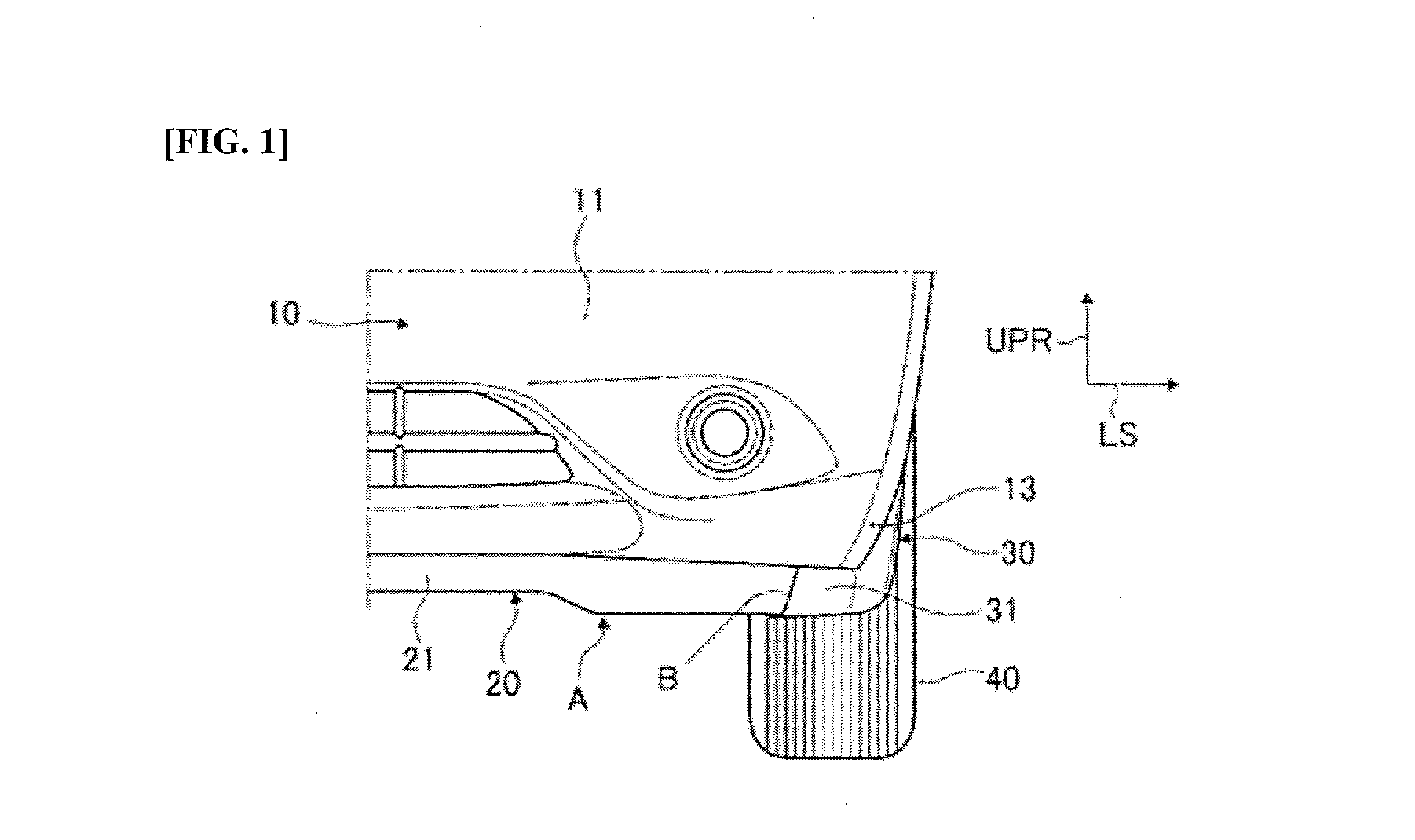

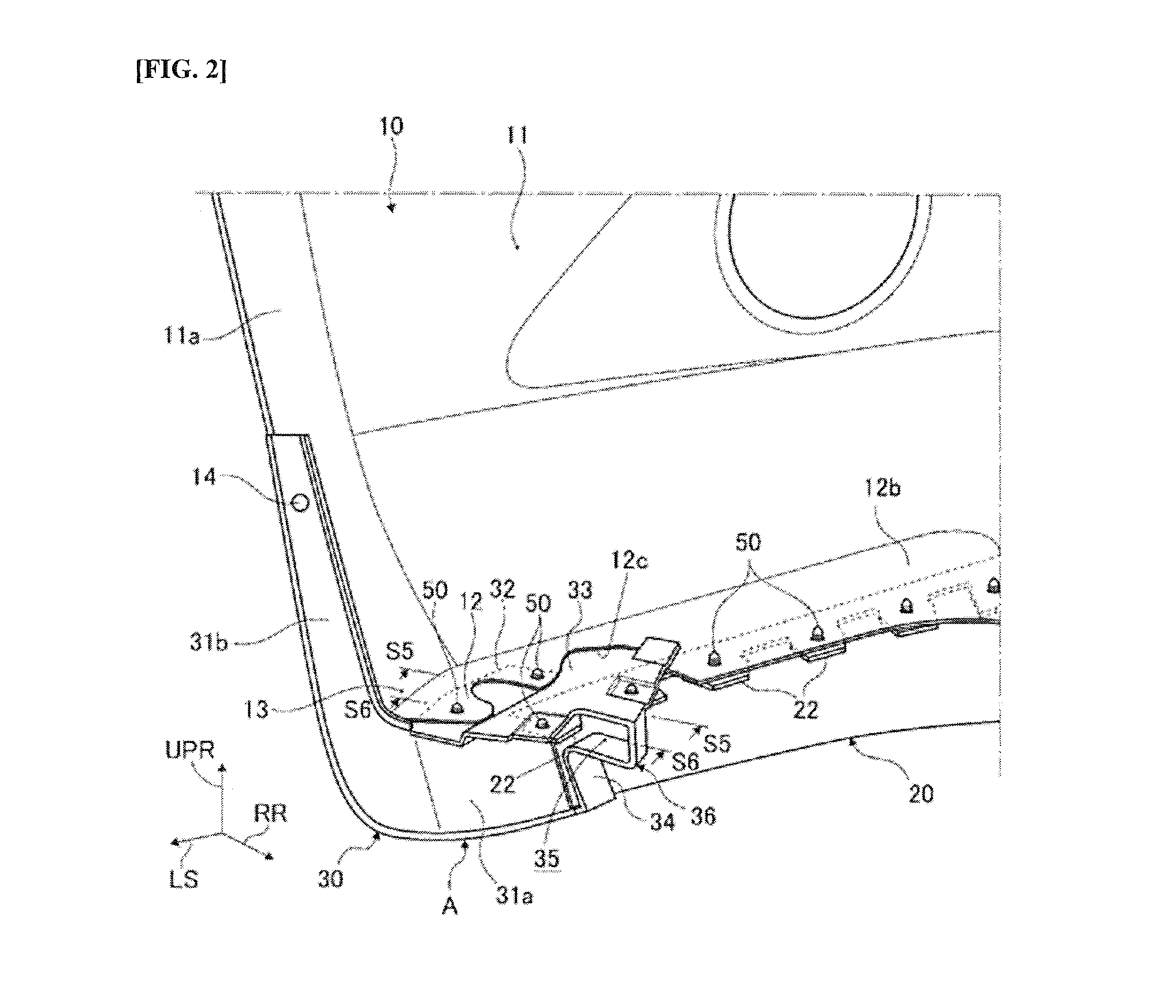

Front spoiler device

ActiveUS20150210324A1Improve aerodynamicsControl appearance qualityVehicle seatsWindowsFlangeAerospace engineering

A front spoiler device configured to be installed on a vehicle having a vehicle width direction, a vehicle upward direction, a vehicle downward direction, a vehicle forward direction, and vehicle rearward direction, has a front bumper, a bumper fascia that forms an outer surface of the front bumper, a spoiler supporting flange portion extending in the vehicle rearward direction from a lower end of the bumper fascia, a spoiler body extending along the lower end of the bumper fascia in the vehicle width direction, the spoiler body being provided with a vertical wall portion facing the vehicle forward direction, and two diffuser portions, each of which is connected to each lateral end of the spoiler body, each of which extends in the vehicle downward direction and in the vehicle width direction along a corner portion of each lateral end on the lower end of the bumper fascia.

Owner:NISSAN MOTOR CO LTD

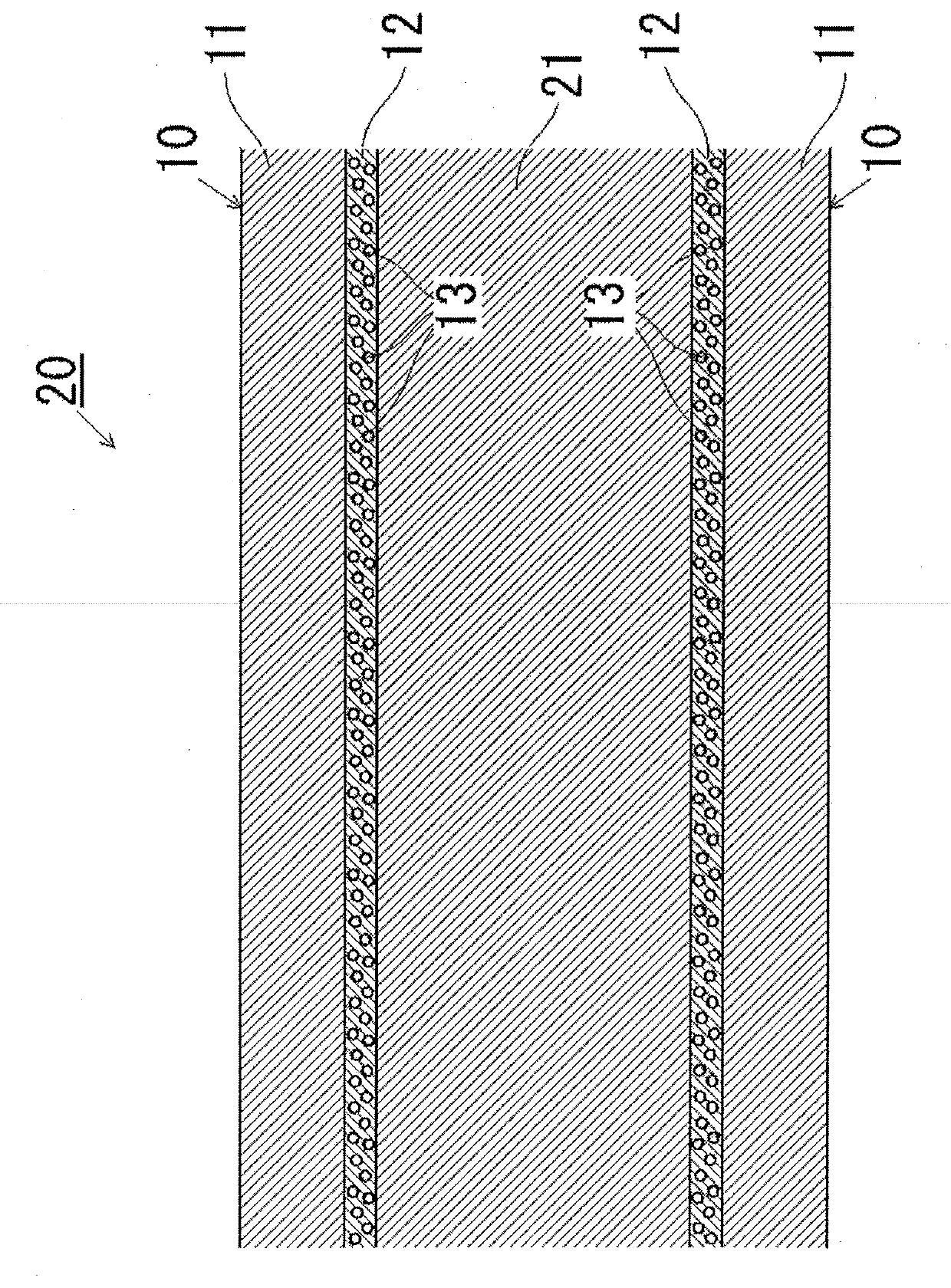

Pressure-sensitive adhesive sheet and surface protective film

InactiveUS20120202055A1Reduce thicknessLower performance requirementsLayered productsFilm/foil adhesivesConductive polymerIonic liquid

A pressure-sensitive adhesive sheet 1 provided by the present invention is provided with a substrate film 12 comprising a transparent resin material, an antistatic layer 14 provided on a first side 12A thereof, and a pressure-sensitive adhesive layer 20 provided on a second side 12B thereof. The antistatic layer 14 contains an antistatic component (for example, an electroconductive polymer) and a binder resin, and has an average thickness Dave of 1 nm to less than 100 nm. The pressure-sensitive adhesive layer 20 contains an acrylic polymer as a base polymer and an ionic compound (such as an ionic liquid and alkaline metal salt) as an antistatic component.

Owner:NITTO DENKO CORP

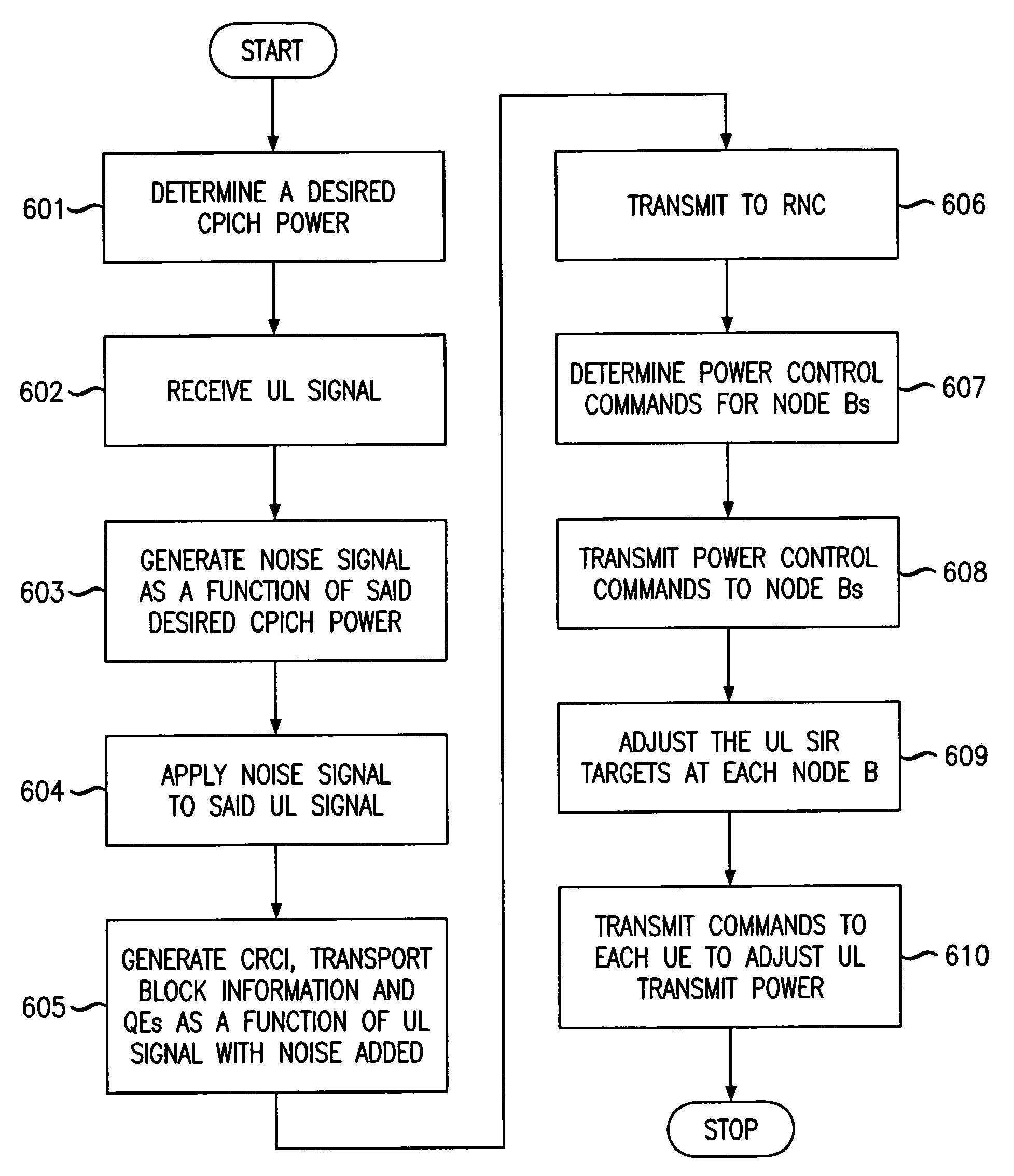

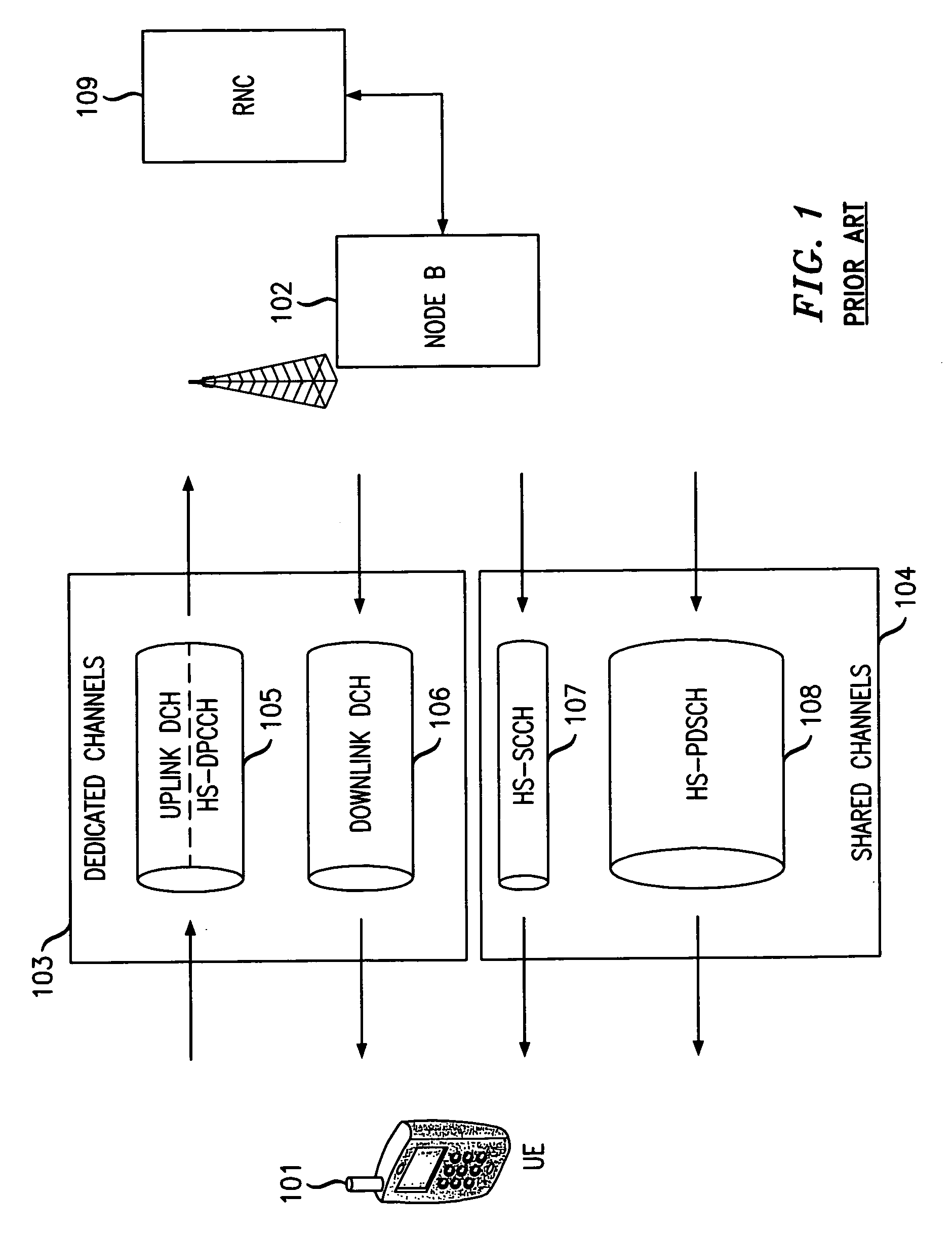

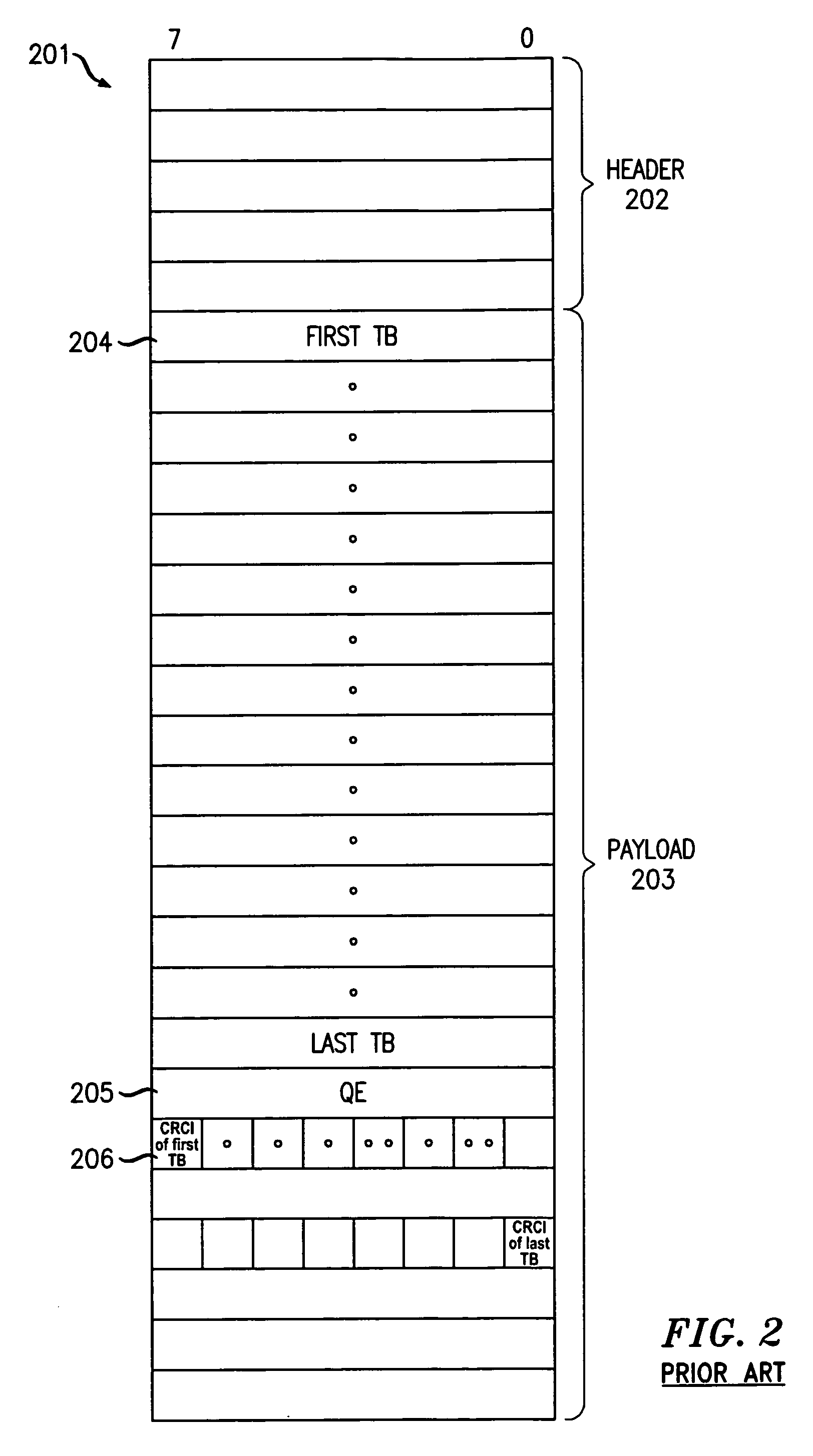

Method and apparatus for path imbalance reduction in networks using high speed data packet access (HSDPA)

InactiveUS20070281728A1Reduced powerIncrease loss of synchronizationPower managementResonant long antennasPower controlTransmitted power

A method and apparatus are disclosed whereby noise is introduced at one or more base stations in non-HSDPA cells into the uplink signal from one or more user devices. As a result, the apparent quality of the uplink channel in those cells will appear to be lower than the actual quality of that channel. The power control commands issued from the base station to the user device will, therefore, reflect this lower estimated channel quality and, as a result, the user device will follow power control commands from the base station in the HSDPA cell. Therefore, the transmit power of the user device will remain adequate to communicate with the base station in the HSDPA cell and, as a result, the UL and DL in the HSDPA cell will remain synchronized.

Owner:ALCATEL-LUCENT USA INC

Production process of high tower melt-granulated compound fertilizer

InactiveCN101993277ALower melting temperatureReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumSlurry

The invention relates to a production process of a high tower melt-granulated compound fertilizer. Potassium chloride is added in the process of melting urea, and the temperatures of urine and slurry are reduced according to a characteristic that the melting temperature is reduced after the urea is mixed with the potassium chloride serving as a cosolvent. The liquid solid ratio of the slurry can be regulated so as to reduce the melting temperature of the urea, the melting capacity of urea melting equipment is improved, and the foundation for improving the yield is laid.

Owner:河南财鑫实业化工有限责任公司

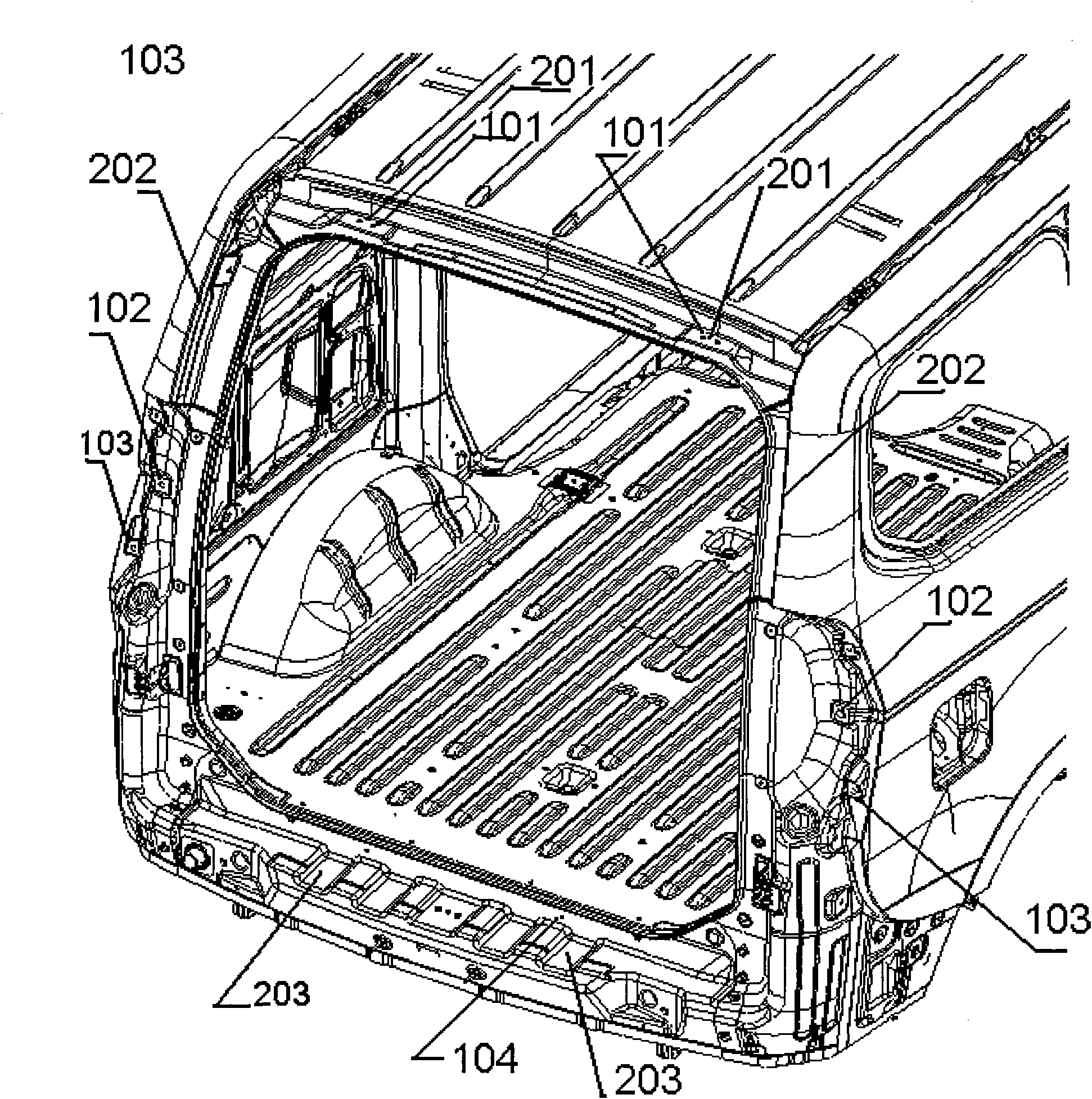

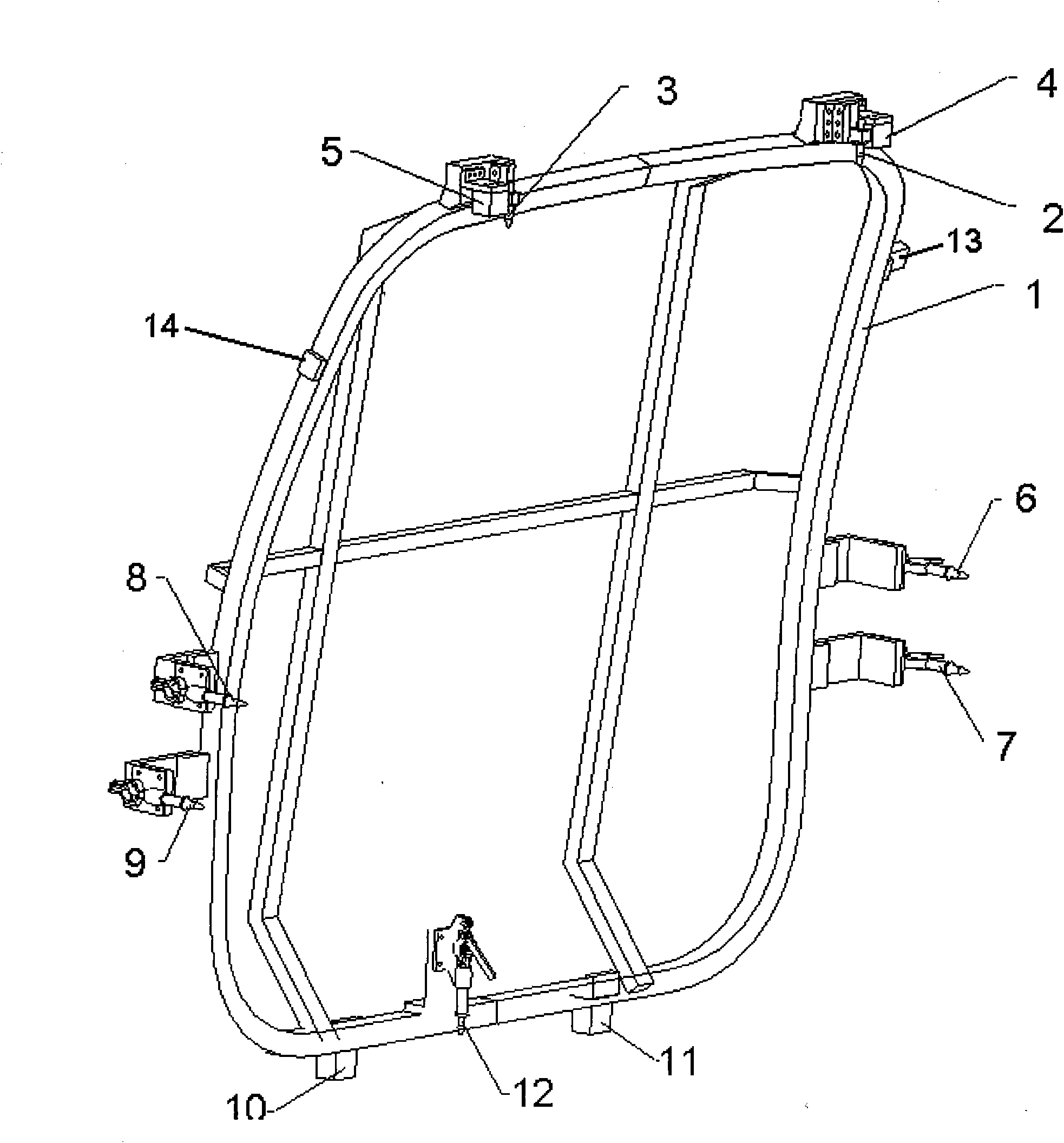

White automobile body tail doorframe checking tool and tail doorframe size detection method

InactiveCN102486364ARealize online detectionTo achieve the purpose of quality controlMechanical clearance measurementsFeeler gaugeEngineering

The invention relates to the field of manufacturing of automobiles, and provides a white automobile body tail doorframe checking tool and a tail doorframe size detection method. The tool comprises a frame as well as a first locating standard pin, a second locating standard pin, a first locating standard block, a second locating standard block, and an auxiliary locating pin which are arranged on the frame and also comprises a measuring pin and a measuring block which are arranged on the frame. The method comprises the following steps: A, debugging a measuring tool on an entire car measuring inspection device, and leading and fastening each pin and each block at theory positions; B, selecting the top of a tail doorframe and a hole as positioning standards, leading the measuring tool on a welded automobile body, and insetting the auxiliary positioning pin and the measuring pin; and C, using a feeler gauge to detect the gap between the measuring pin and the measuring block and the gap between the hole and top of the tail doorframe, if the gaps are within a specialized range, judging that the gaps are qualified, and if the gaps are out of the specialized range, judging that the gaps are disqualified. The tool provided by the invention can be used for simply, conveniently and accurately detecting the size of the tail doorframe, thereby realizing real-time monitoring on the size variation of the tail doorframe, and effectively controlling the appearance quality of an entire car.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Hot-dipped aluminum technique method of heavy duty automobile exhaust tube

InactiveCN101392360ASimple methodExtended service lifeHot-dipping/immersion processesAcid washingExisting Treatment

The invention discloses a technological method of aluminizing by hot dipping of an exhaust pipe of a heavy-duty car. The technological method solves the problems that the existing treatment method of the exhaust pipe of the heavy-duty car can not meet the requirement of corrosion resistance, and the like, and has the advantages of being simple, prolonging the service life of the exhaust pipe of the heavy-duty car, rendering the exhaust pipe more artistic in appearance and indirectly prolonging the service life and increasing the reliability of an exhaust gas braking system, and the like. The technological method of the invention comprises the steps: (1) the exhaust pipe is done with surface treatment; (2) the exhaust pipe is treated with alkali cleaning; (3) clean water is used for removing residual alkali liquor on the surface of the exhaust pipe; (4) acid washing is followed; (5) clean water is used for removing residual acid liquor on the surface of the exhaust pipe; (6) the dip coating of plating supporting agent is done to the surface of the exhaust pipe; (7) the exhaust pipe is put into a drying oven to be dried; (8) after being dried, the exhaust pipe is put into an infiltration agent; (9) the aluminizing by hot dipping is then followed; (10) the product is cooled; and (11) the post treatment is carried out to the product to obtain the finished product.

Owner:黄虹

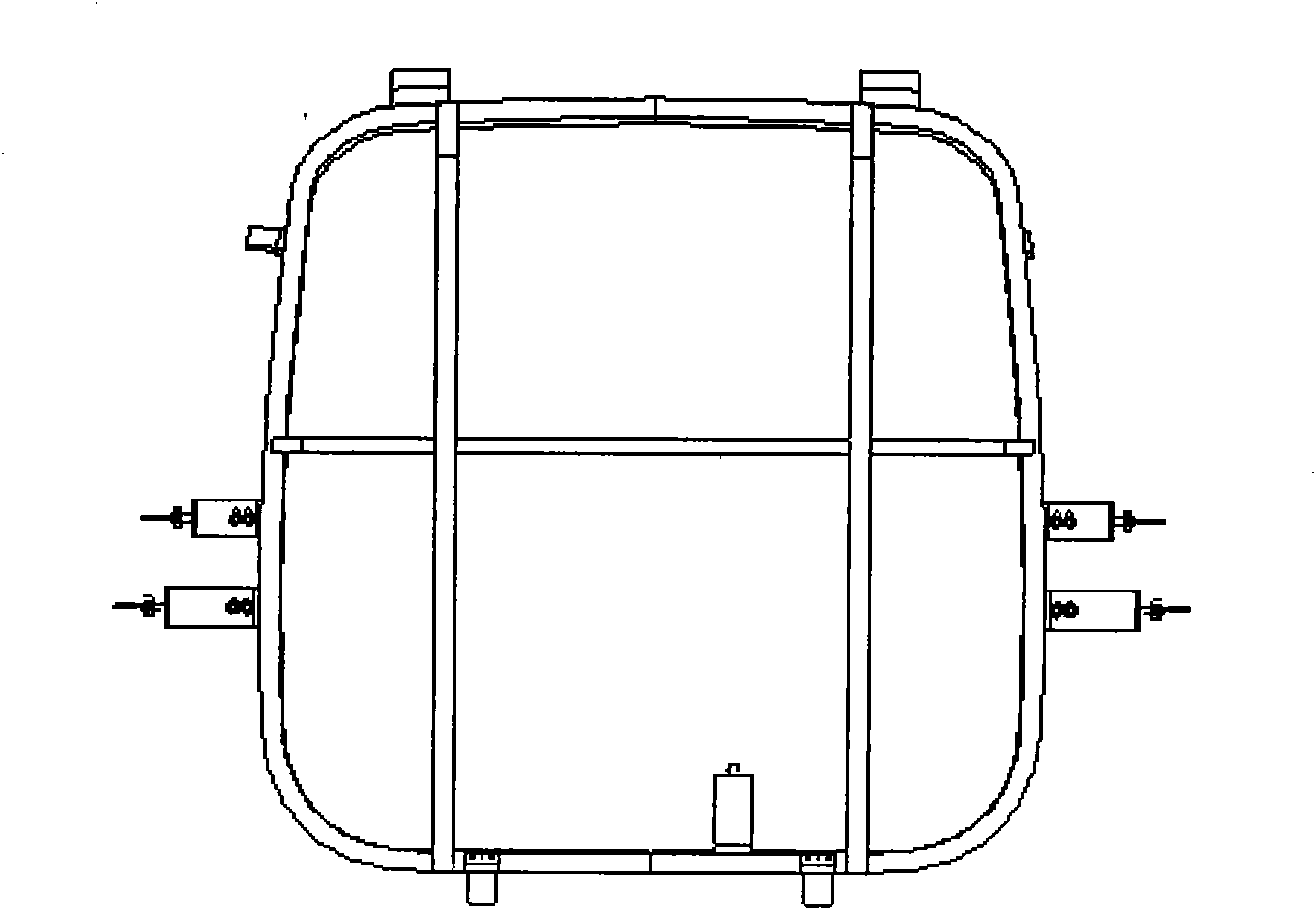

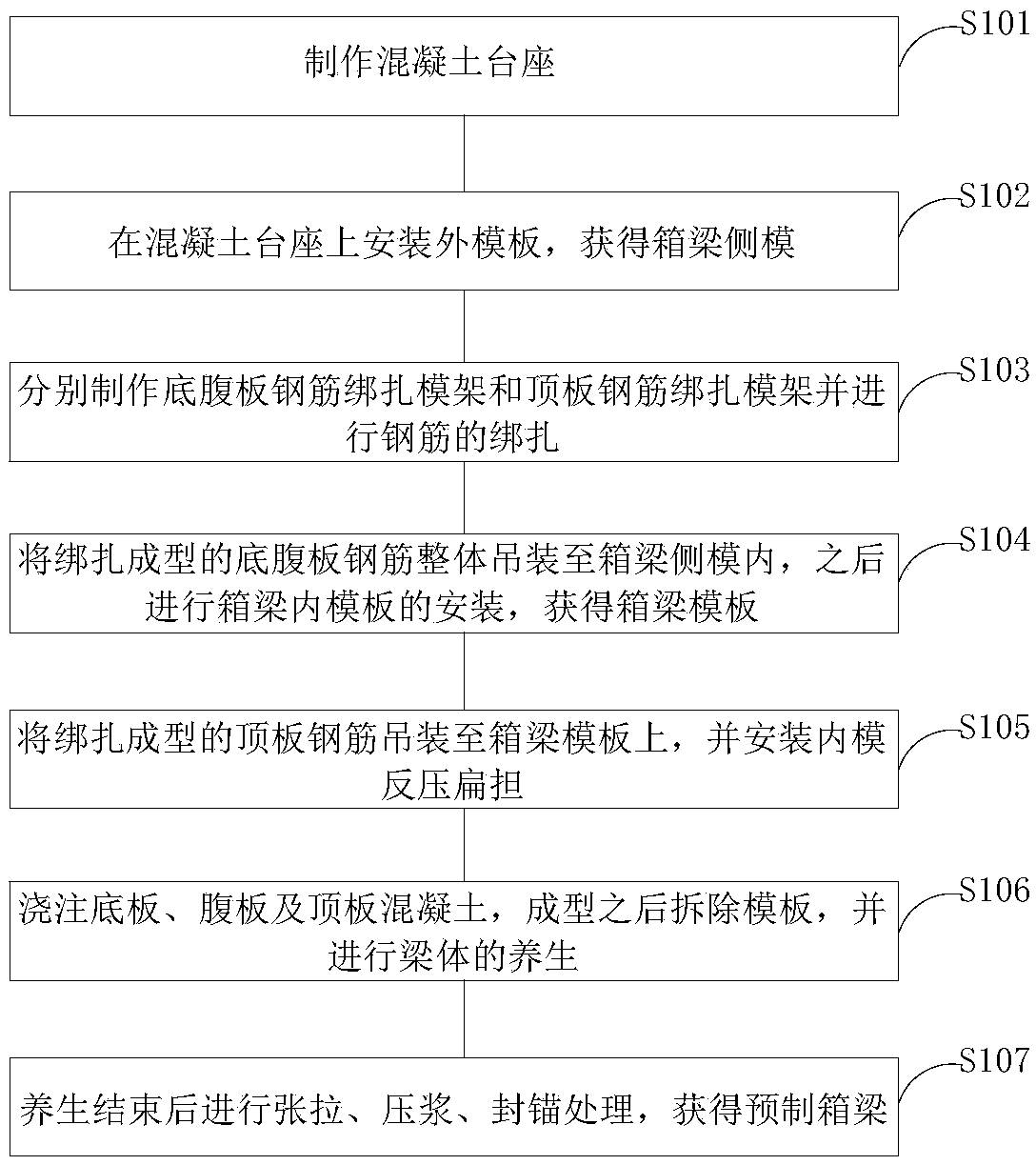

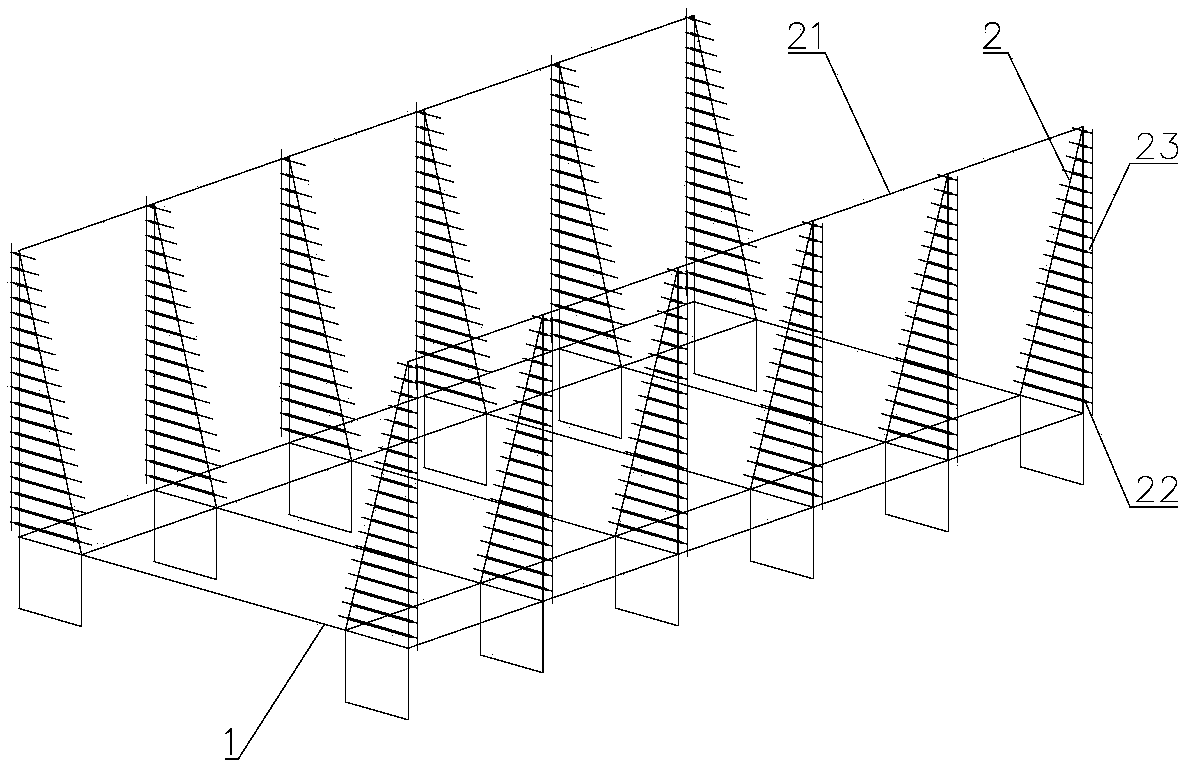

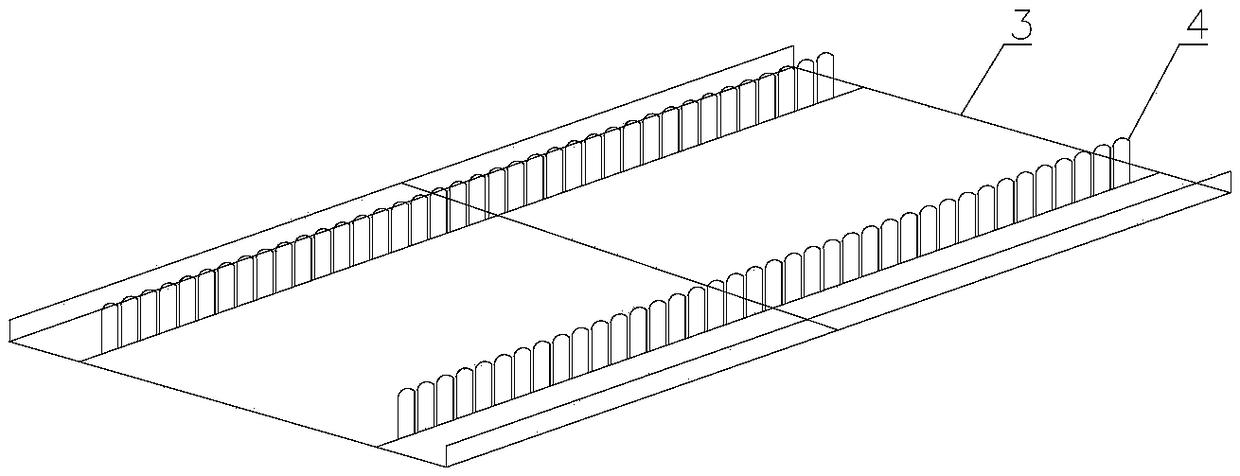

Construction method for prefabricated box girder

InactiveCN108638324AImprove appearance qualityImprove construction efficiencyMould fastening meansCounter pressureRebar

The invention provides a construction method for a prefabricated box girder. The construction method comprises the steps that a concrete pedestal is manufactured; an outer form board is arranged on the concrete pedestal so as to obtain a box girder side form; a bottom web reinforcement binding formwork and a top plate reinforcement binding formwork are manufactured separately, and reinforcement binding is carried out; a bottom web reinforcement which is bound and formed is integrally hoisted into the box girder side form, and then a box girder inner form board is arranged so as to obtain a boxgirder form board; a top plate reinforcement which is bound and formed is hoisted onto the box girder form board, and an inner form counter-pressure carrying pole is arranged; concrete of a base plate, a web and a top plate are poured, after forming, the form board is disassembled, and curing of a girder body is carried out; and after curing is finished, tensioning, mud jacking and anchor sealingtreatment are carried out so as to obtain the prefabricated box girder. The construction method has the advantages that the outer form board is assembled on the pedestal, the reinforcements are integrally hoisted into the form after being bound on the special formworks, so that the problems of joint treatment of the outer form board, flatness adjustment and the like can be conveniently solved, the phenomenon that the appearance of the base plate is affected due to the fact that welding slag impurities fall onto the pedestal can be avoided, and the appearance quality of the box girder can be effectively improved.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

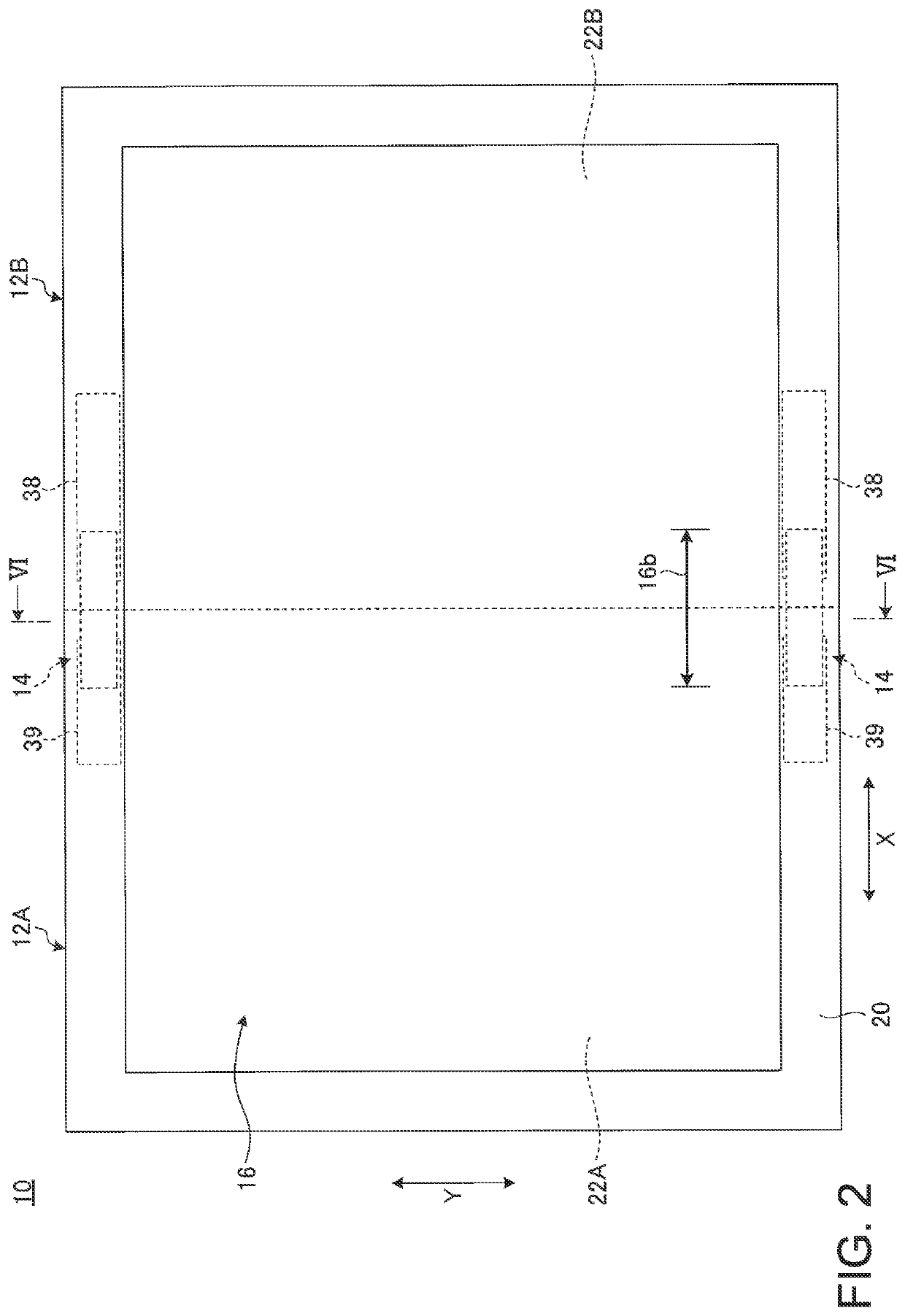

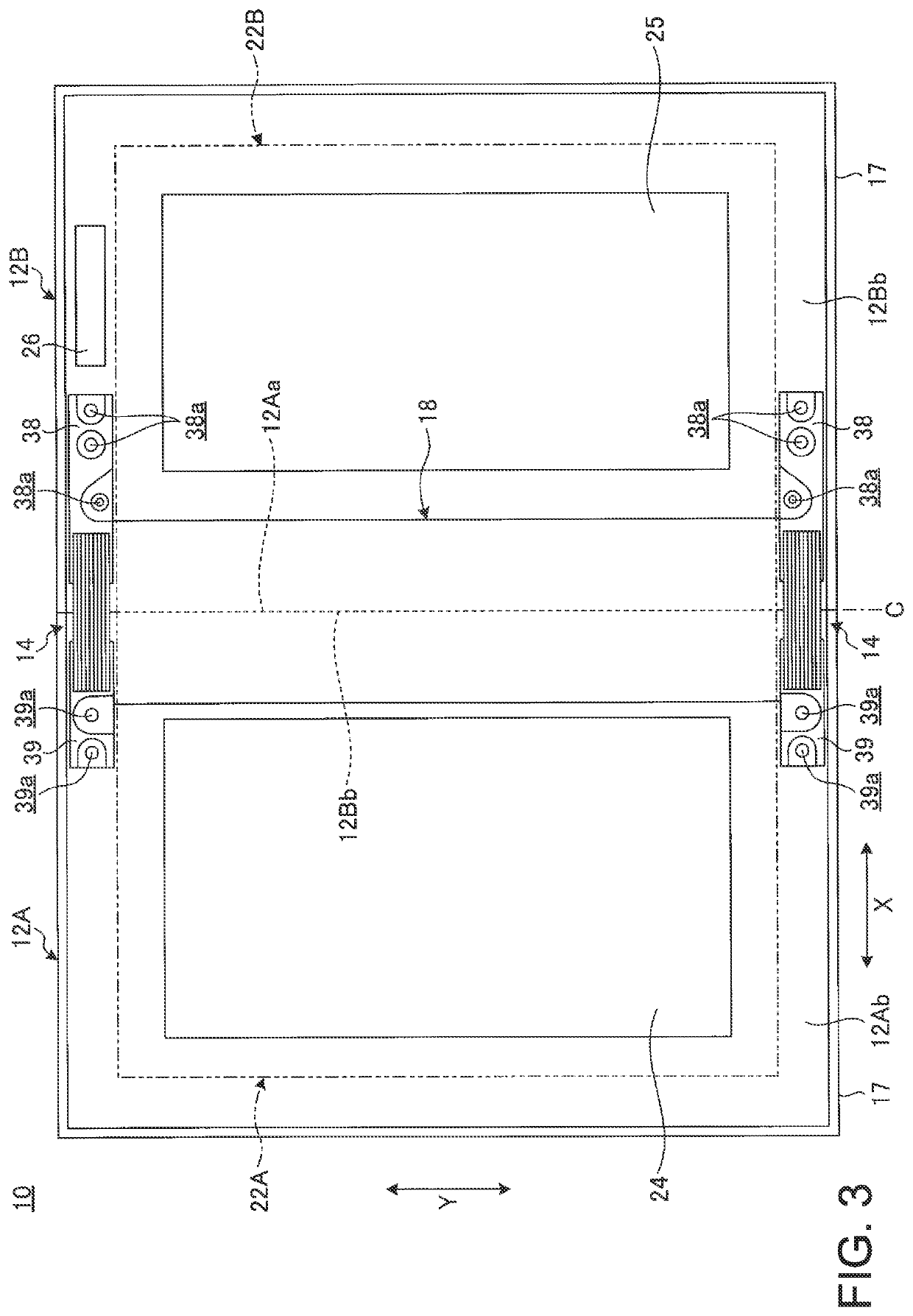

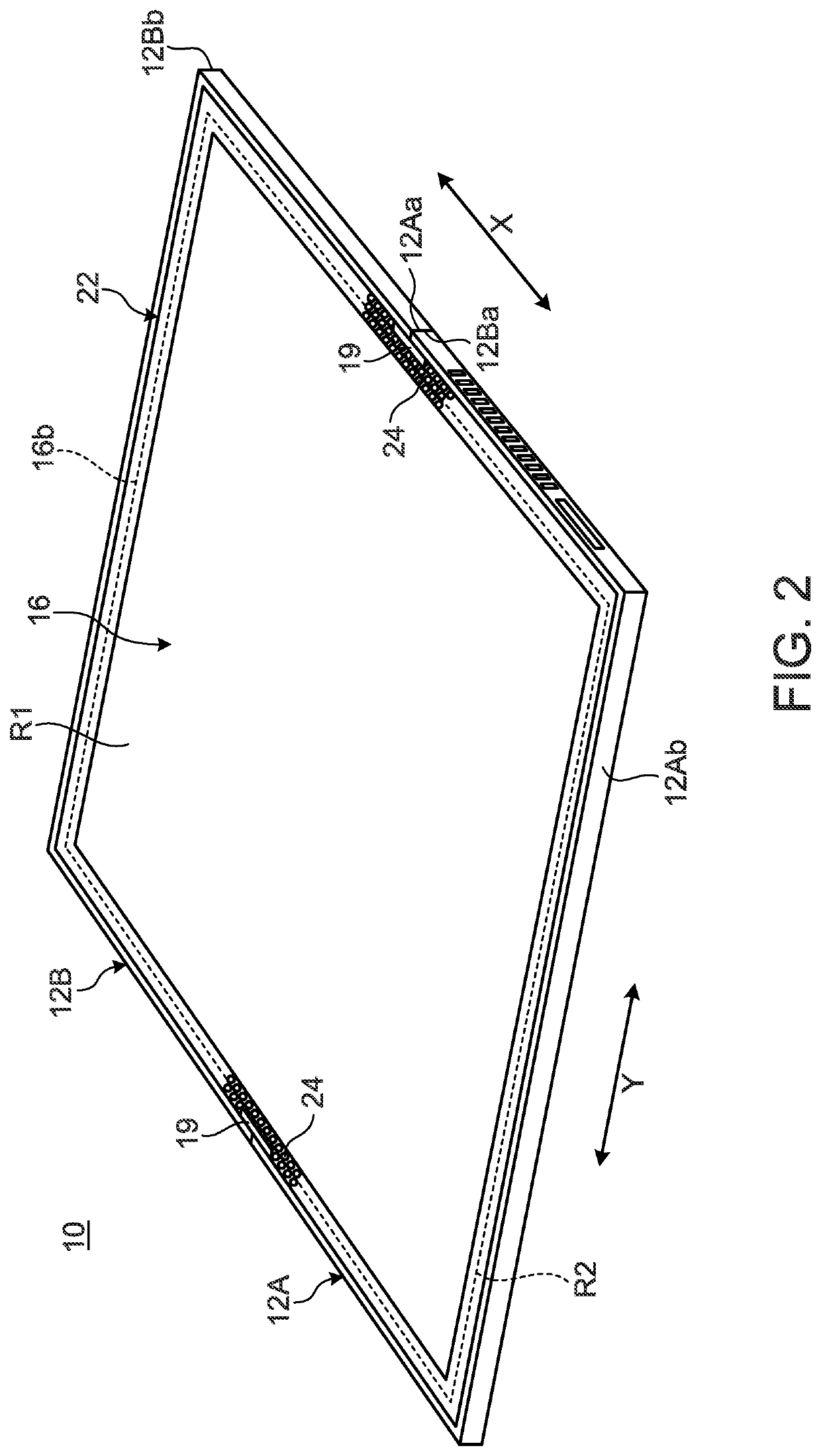

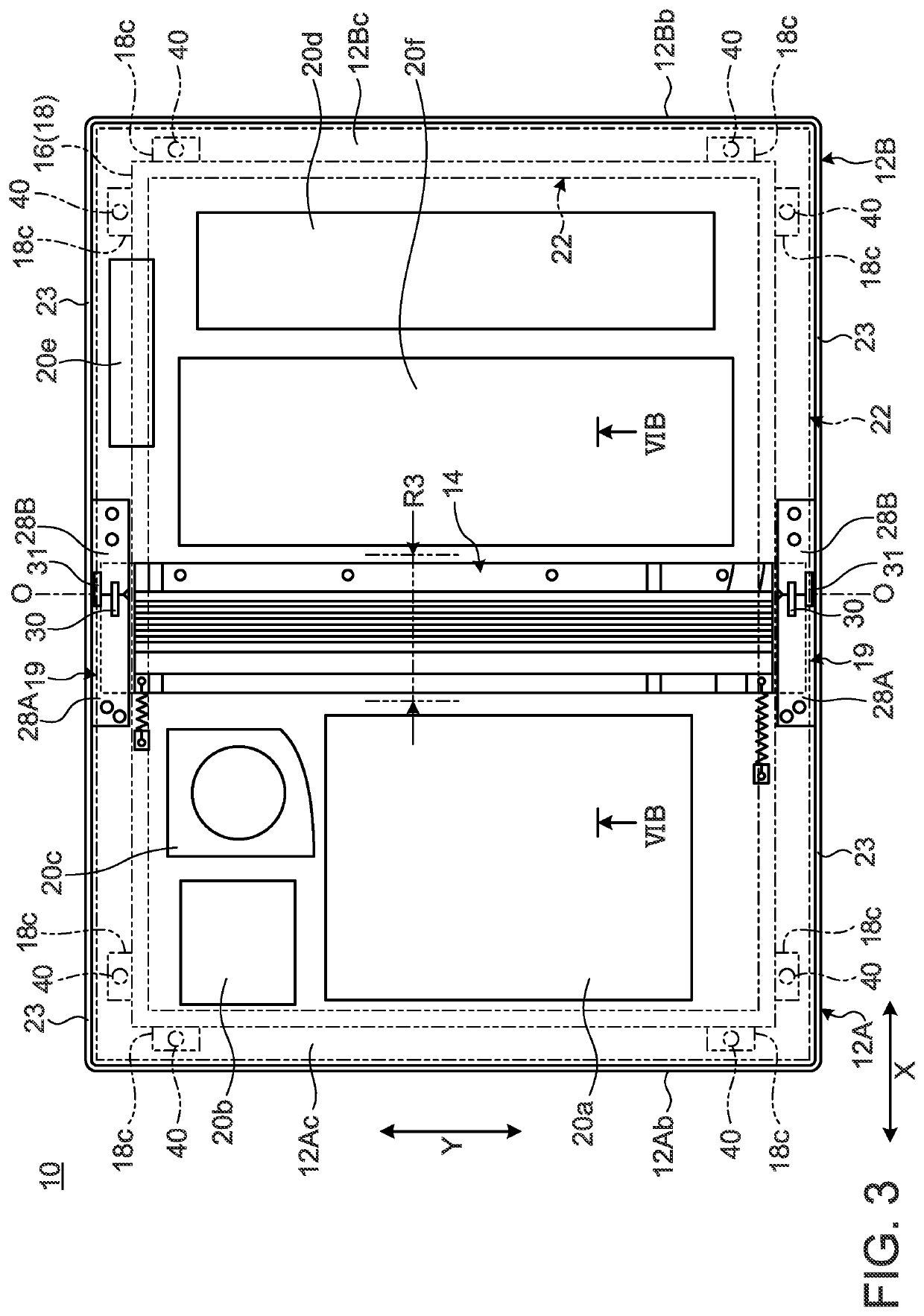

Portable information device

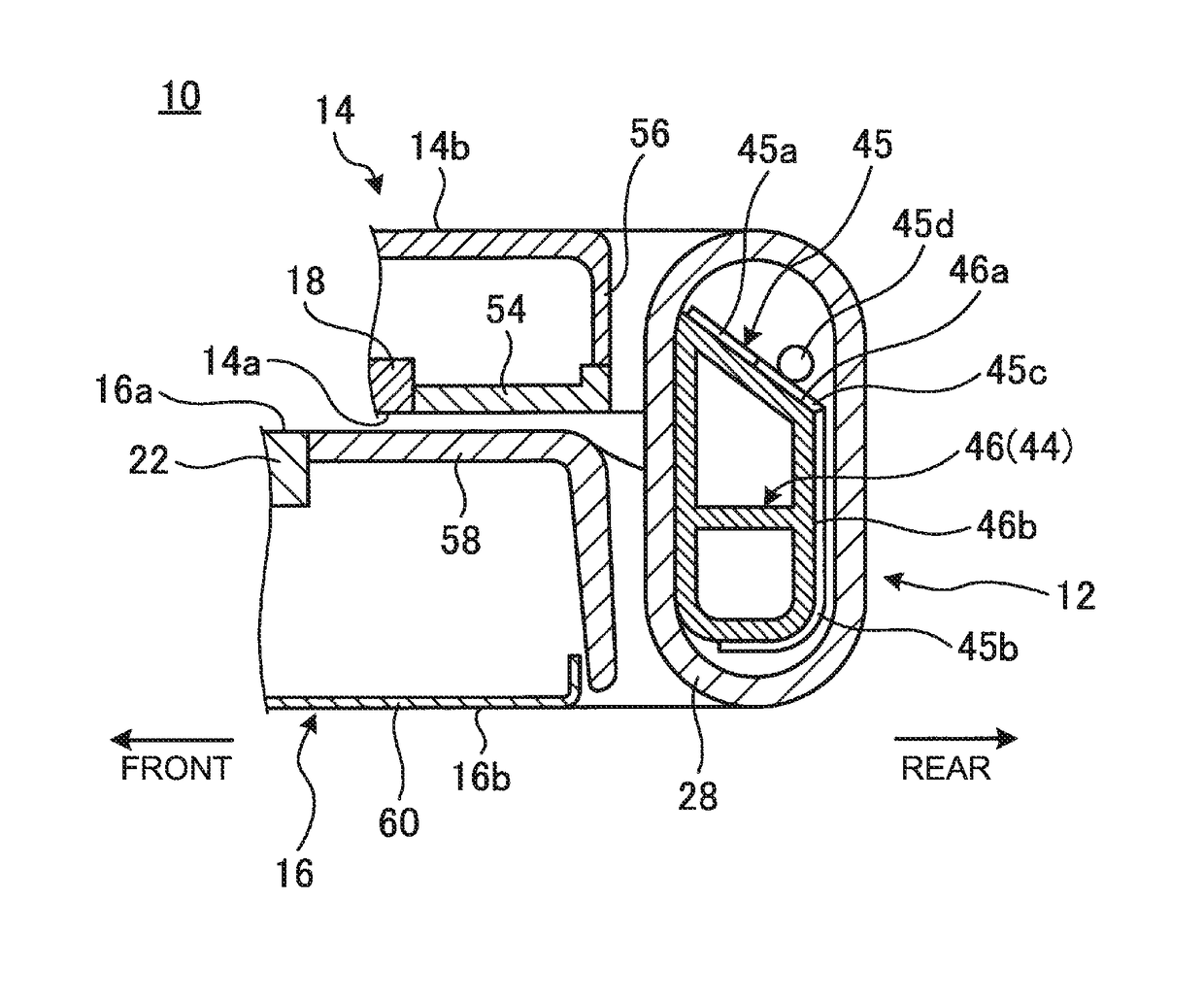

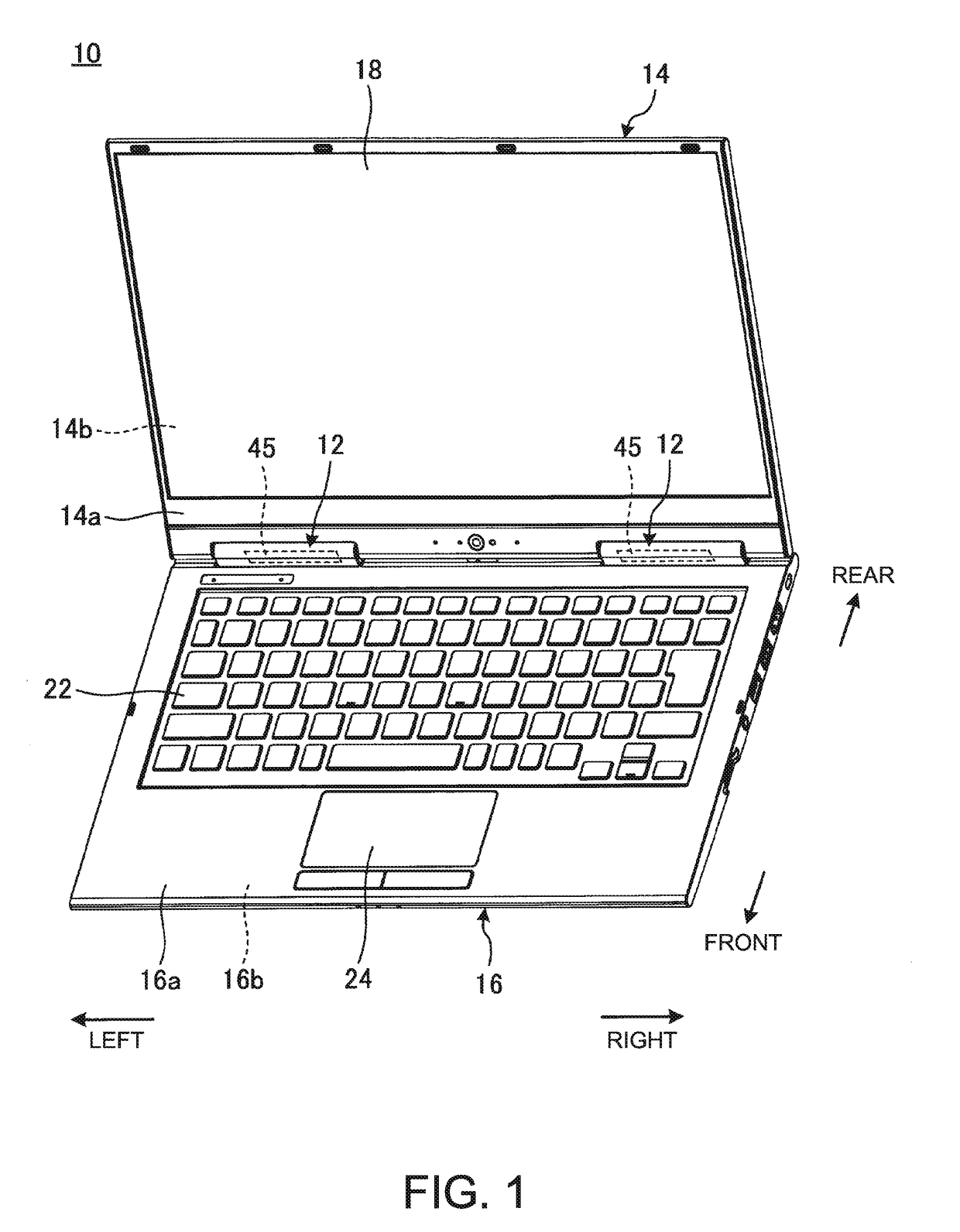

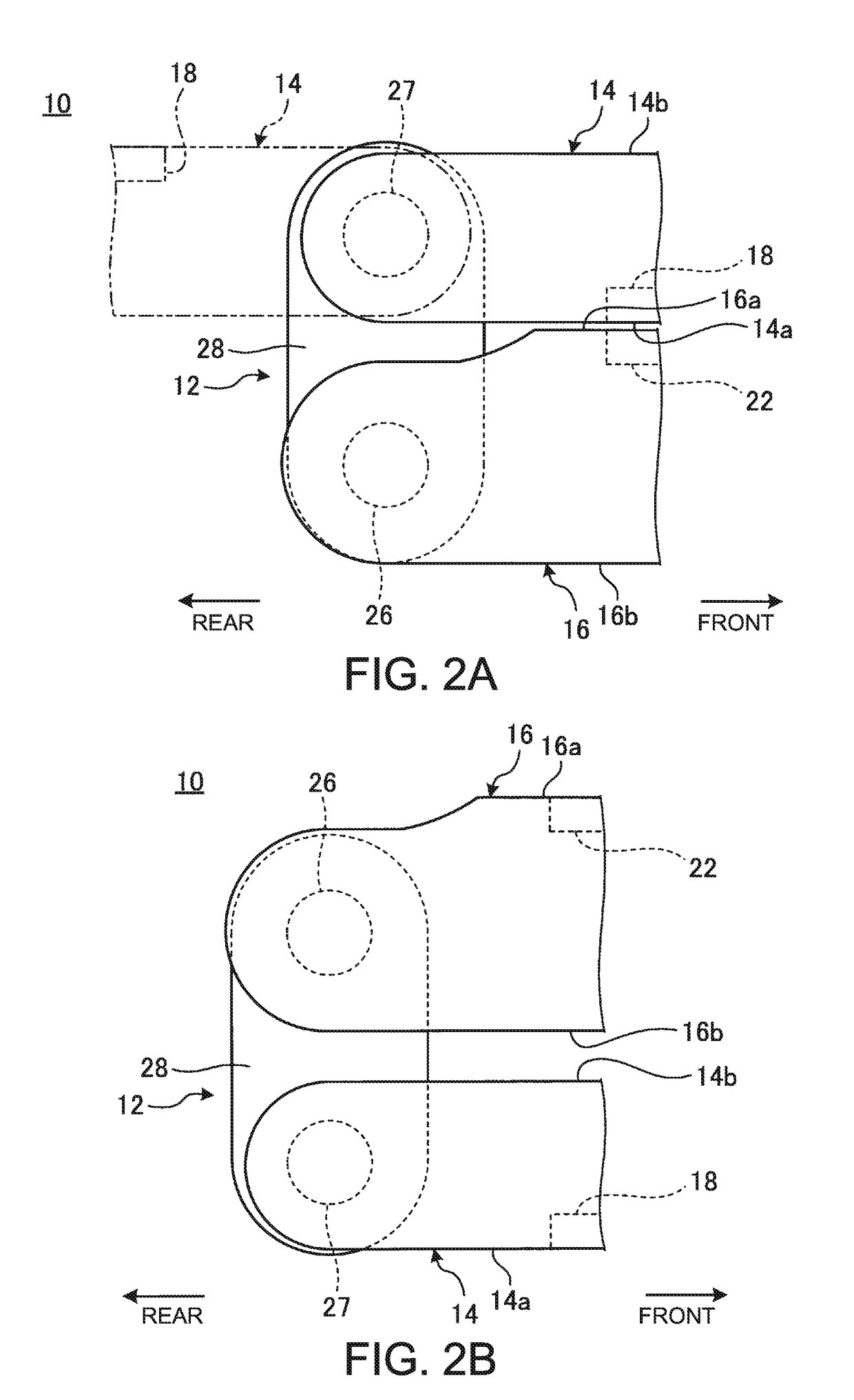

ActiveUS11016530B2Guaranteed uptimeControl appearance qualityDetails for portable computersDisplay deviceControl theory

A portable information device includes a hinge device, a foldable display, and a bezel member. The hinge device has a first base plate fixed to the first chassis, a second base plate fixed to the second chassis, a first link arm having a first end portion rotatably connected to the first base plate through a first shaft, a second link arm having a first end portion rotatably connected to the second base plate through a second shaft, and a coupling plate having a first end portion rotatably connected to a second end portion of the first link arm through a third shaft and a second end portion rotatably connected to a second end portion of the second link arm through a fourth shaft. The hinge device as a whole is disposed under a display surface, regardless of opening / closing state of the second chassis with respect to the first chassis.

Owner:LENOVO PC INT

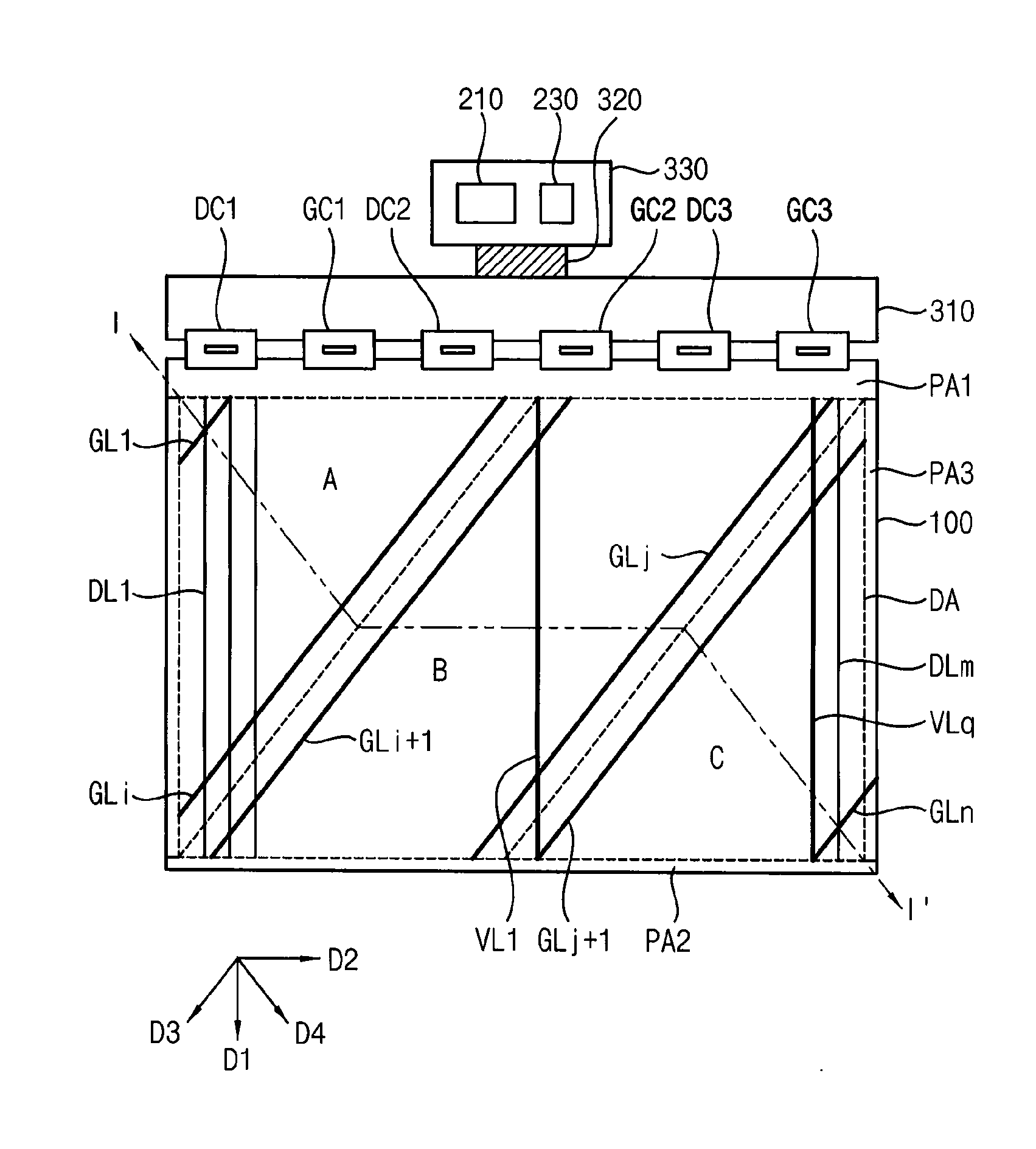

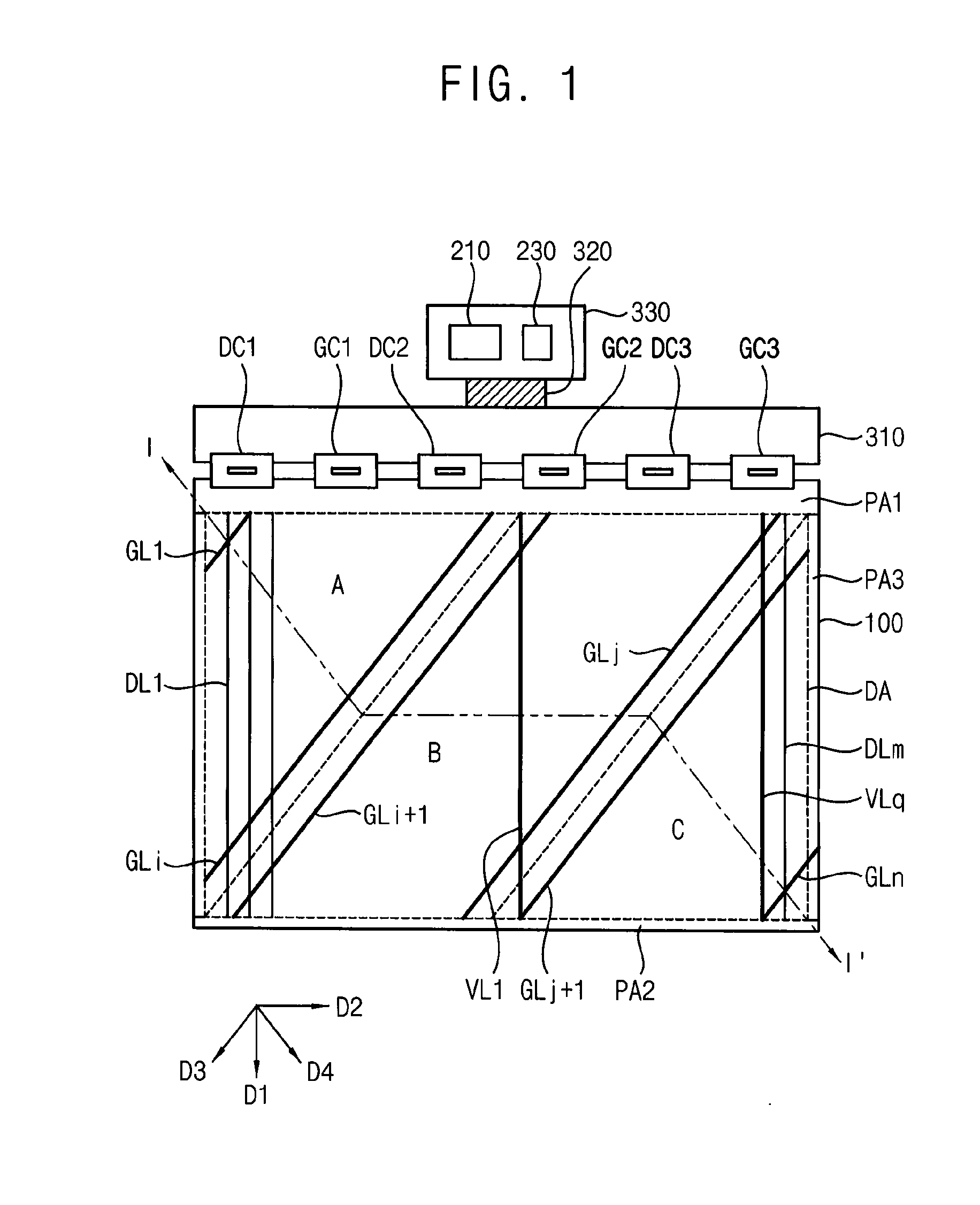

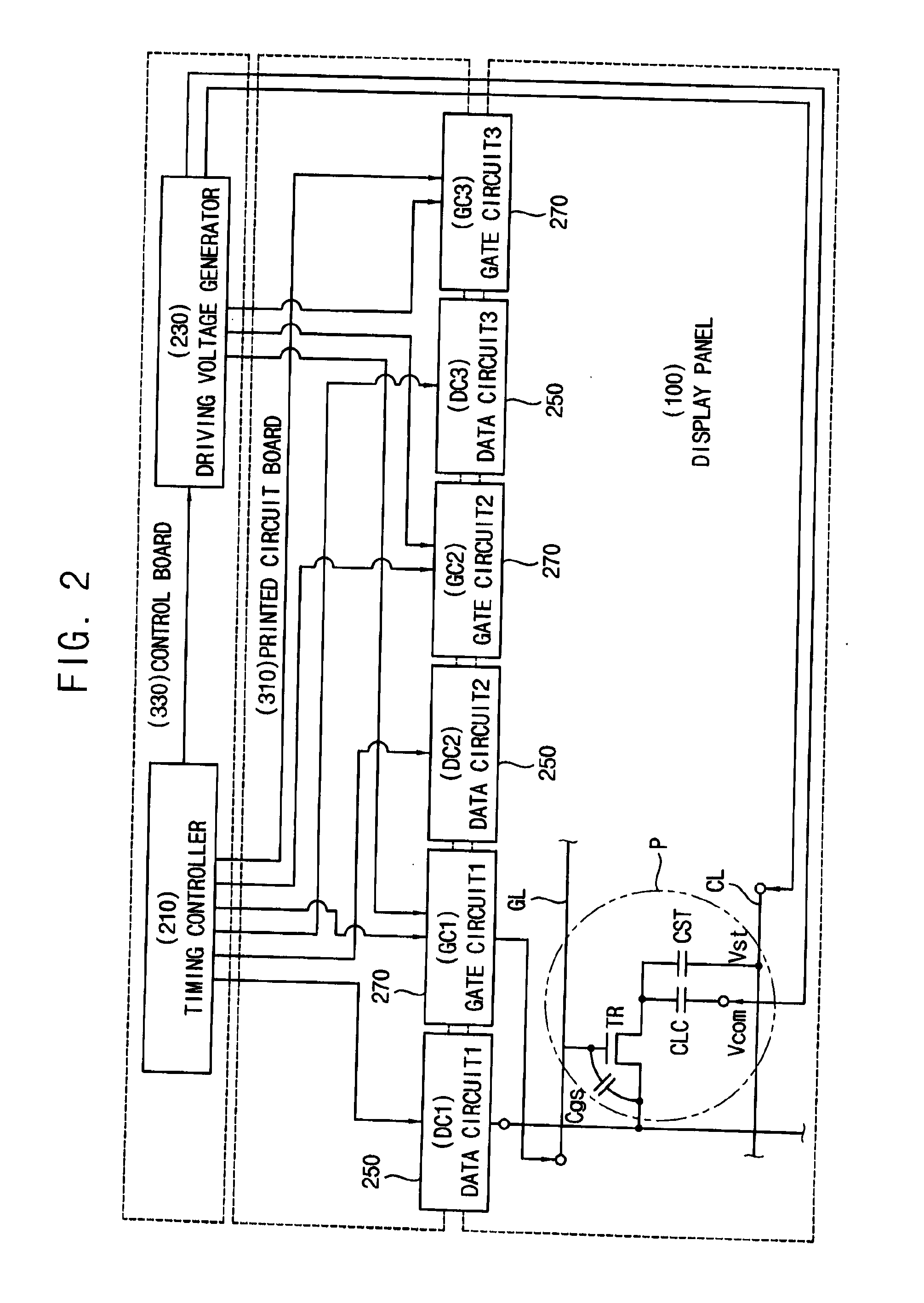

Display apparatus

InactiveUS20160133216A1Control appearance qualityQuality improvementCathode-ray tube indicatorsInput/output processes for data processingGate driverEngineering

A display apparatus includes a display panel comprising a plurality of gate lines extending in a first diagonal direction of a display area, and a plurality of vertical lines extending in a vertical direction, the gate lines comprising a plurality of first gate lines disposed in a first sub-area of the display area, a plurality of second gate lines disposed in a second sub-area of the display area, a plurality of third gate lines disposed in a third sub-area of the display area, the third gate lines respectively connected to the vertical lines, and a gate driver disposed in the first peripheral area in which the data driver is disposed and configured to provide at least one of the first, second and third sub-areas with a gate signal different from a reference gate signal.

Owner:SAMSUNG DISPLAY CO LTD

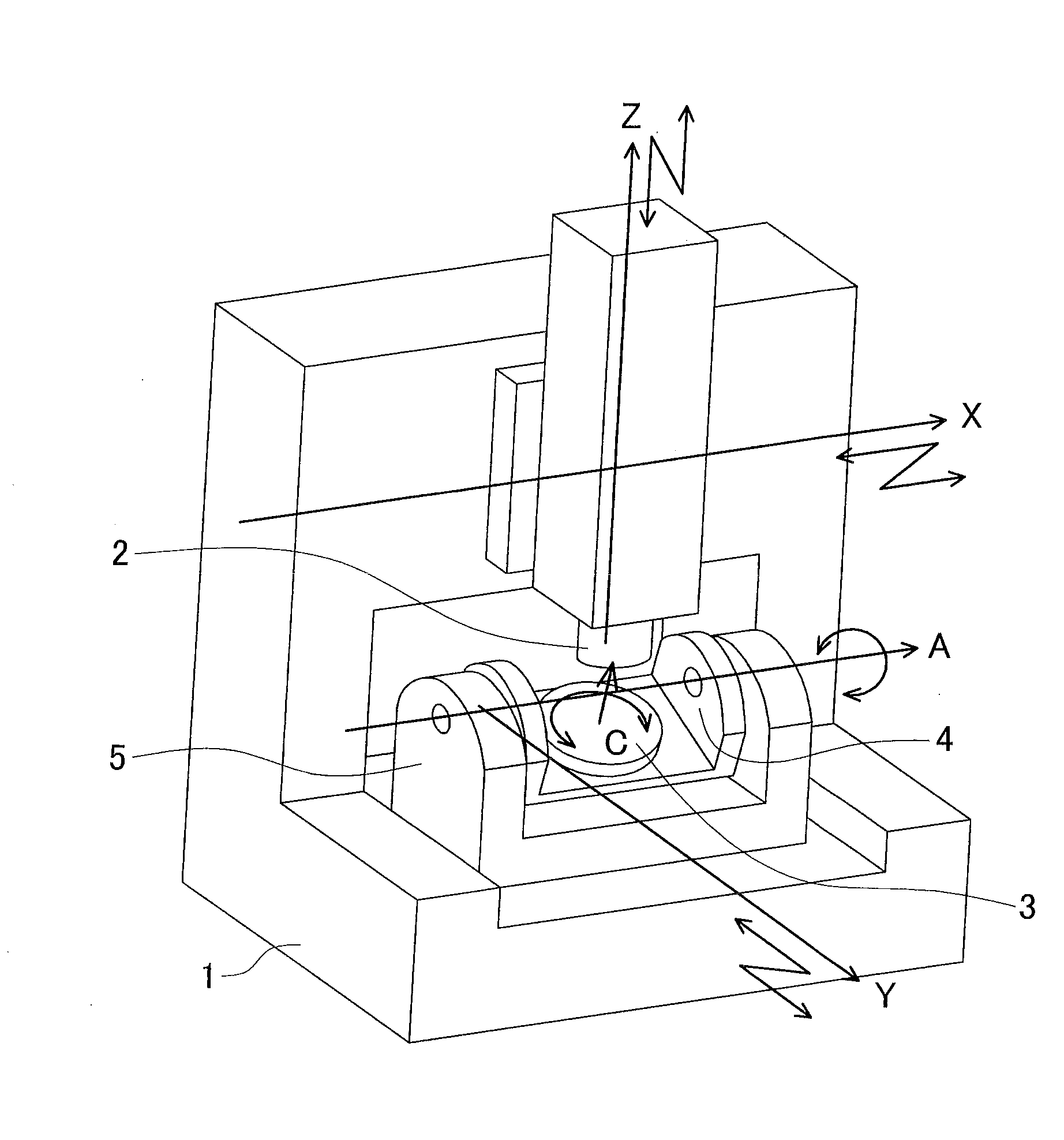

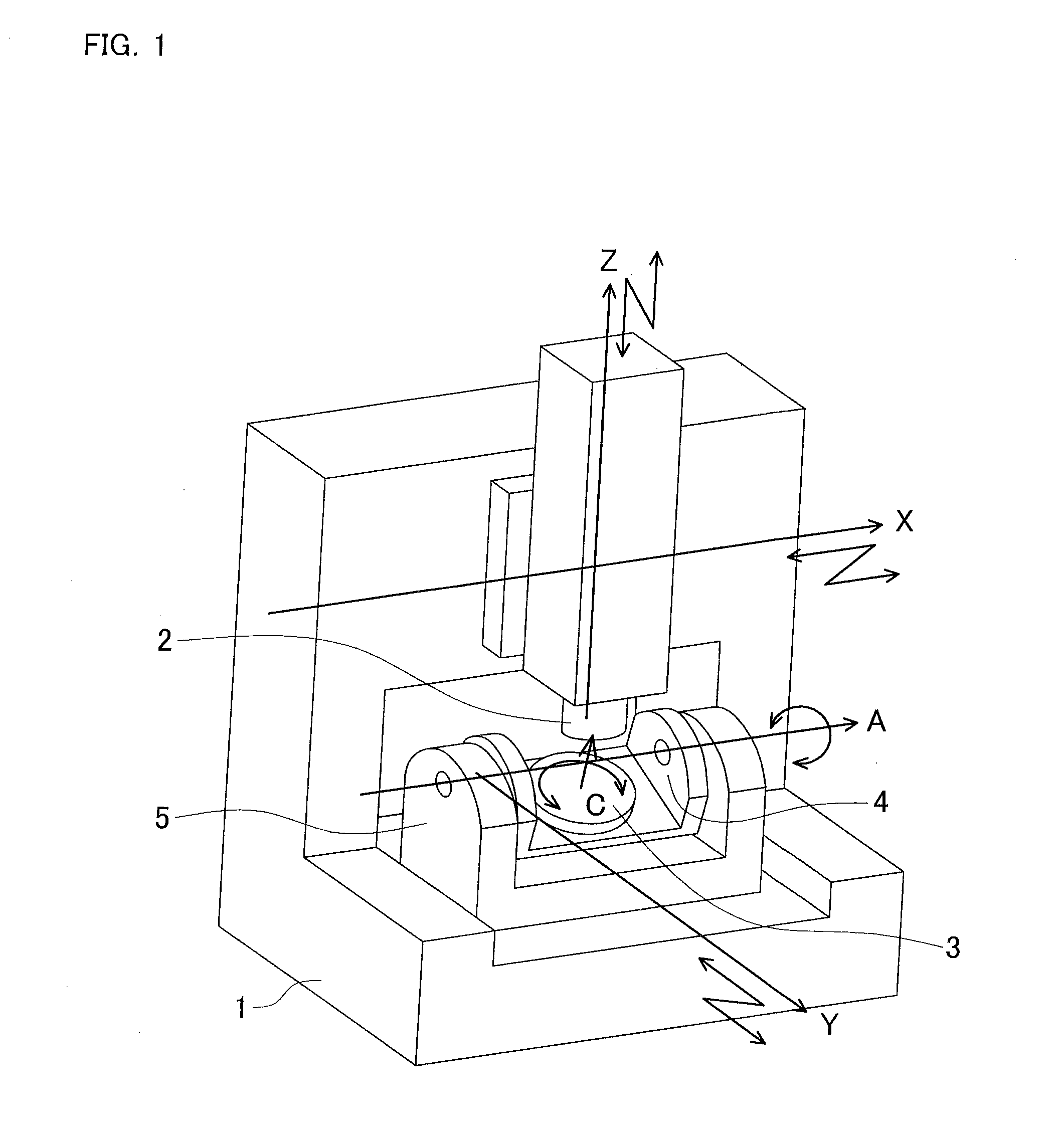

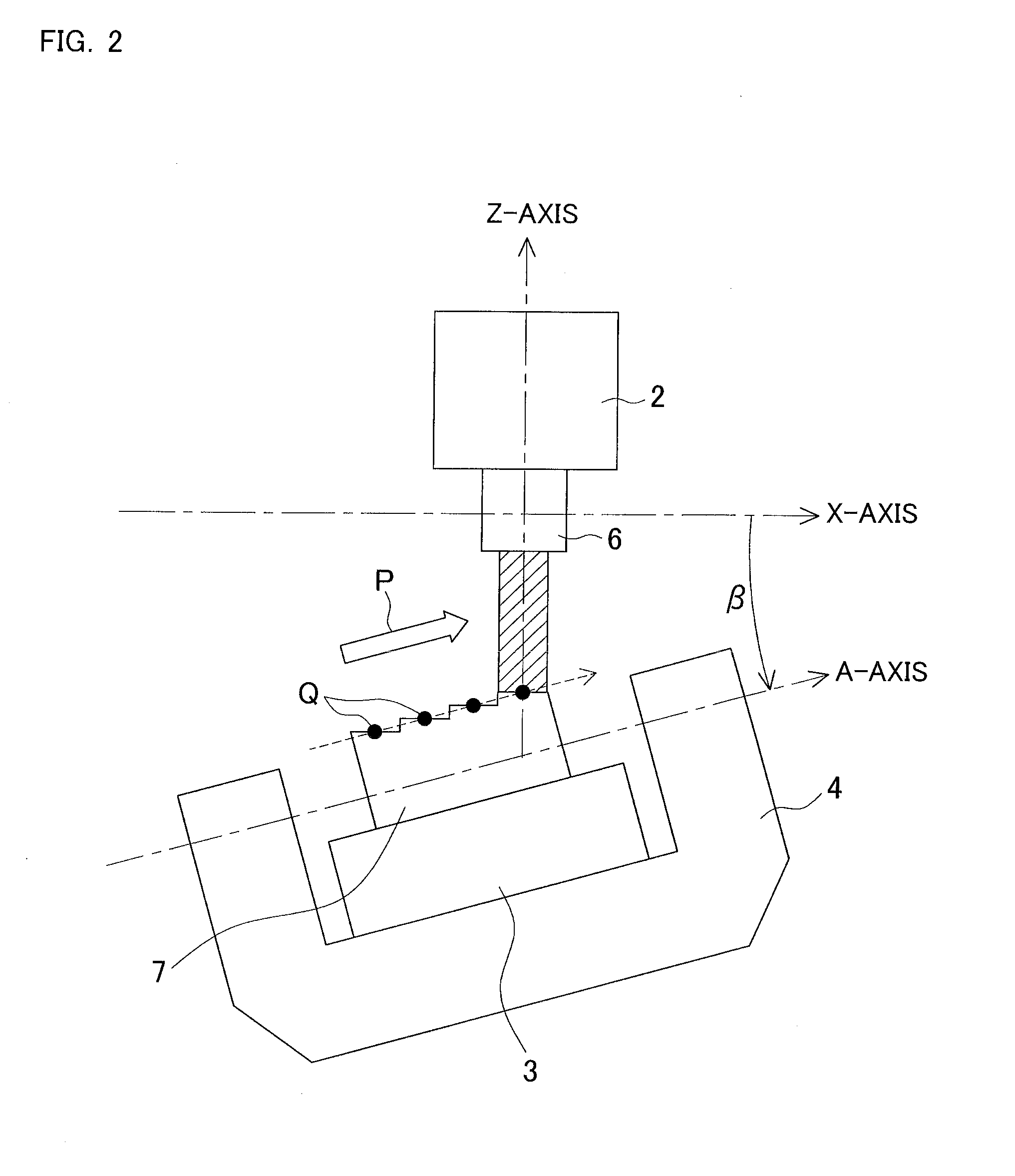

Method and program for calculating correction value for machine tool

ActiveUS20120253506A1Convenient and accurateControl appearance qualityMilling machinesLarge fixed membersGeometric errorRotational axis

The present invention provides a method and the like that are capable of calculating a correction value for a rotational axis and make it possible to correct an error in position or position and posture of a tool, which results from a geometric error, correct an error in posture of the tool, and also enhance the accuracy in machining by preventing a translational axis from operating in an infinitesimal manner due to a correction command. In a machine tool having two or more translational axes and one or more rotational axes, a correction value for each of the translational axes is calculated using a command position of each of the rotational axes, a coordinate value of a correction reference point as one point designated in advance in a command position space of each of the translational axes, and a geometric parameter representing the geometrical error.

Owner:OKUMA CORP

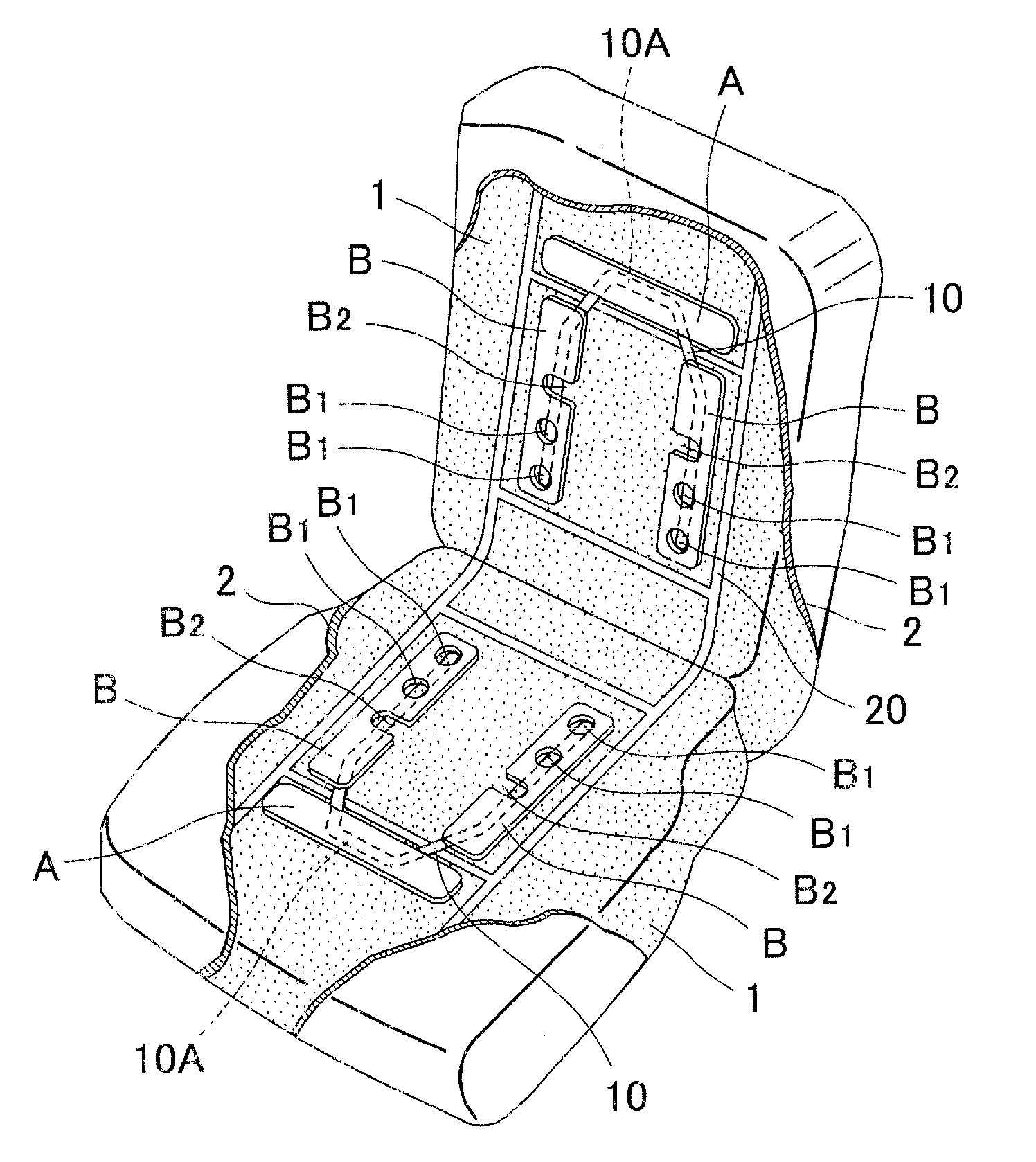

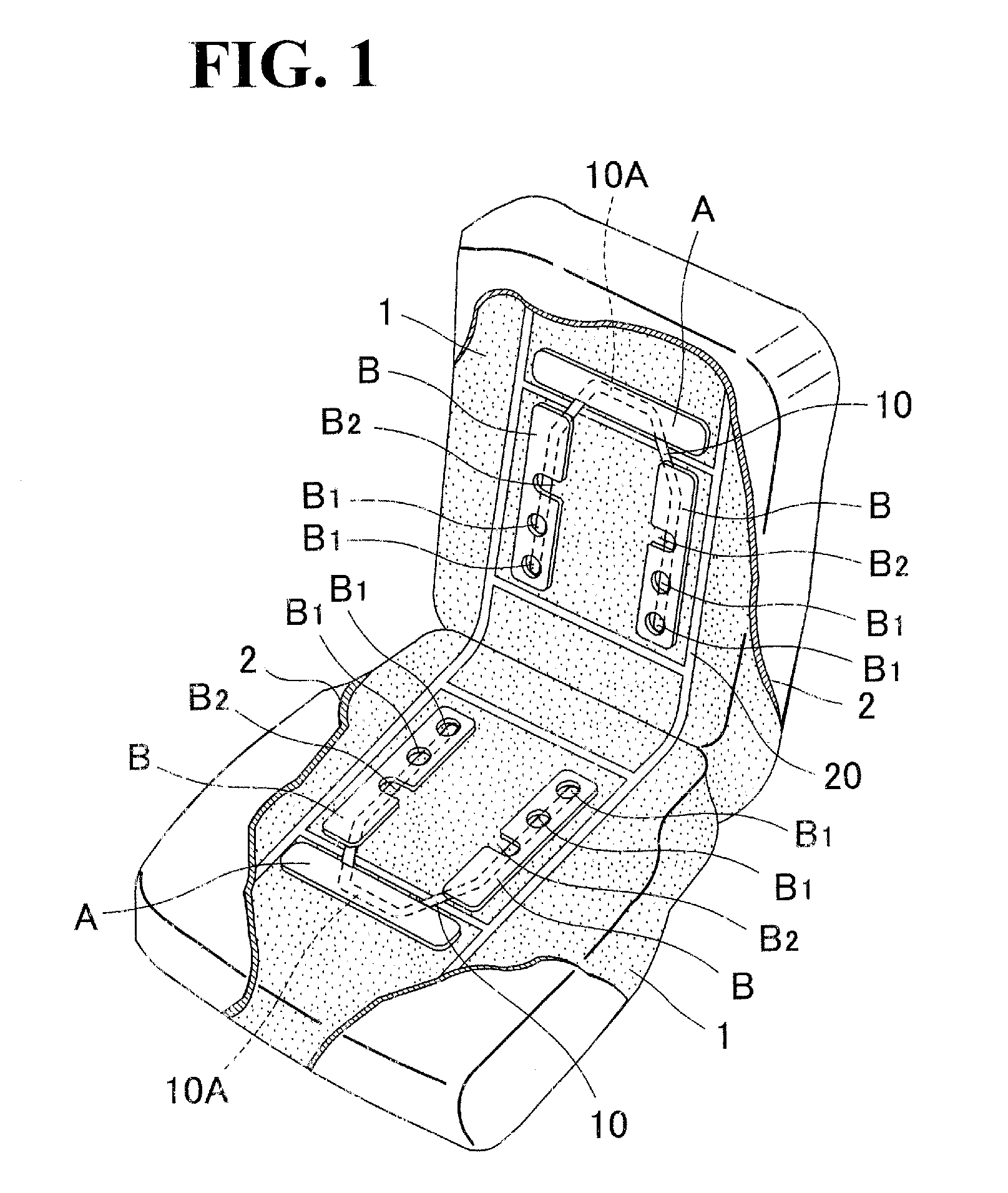

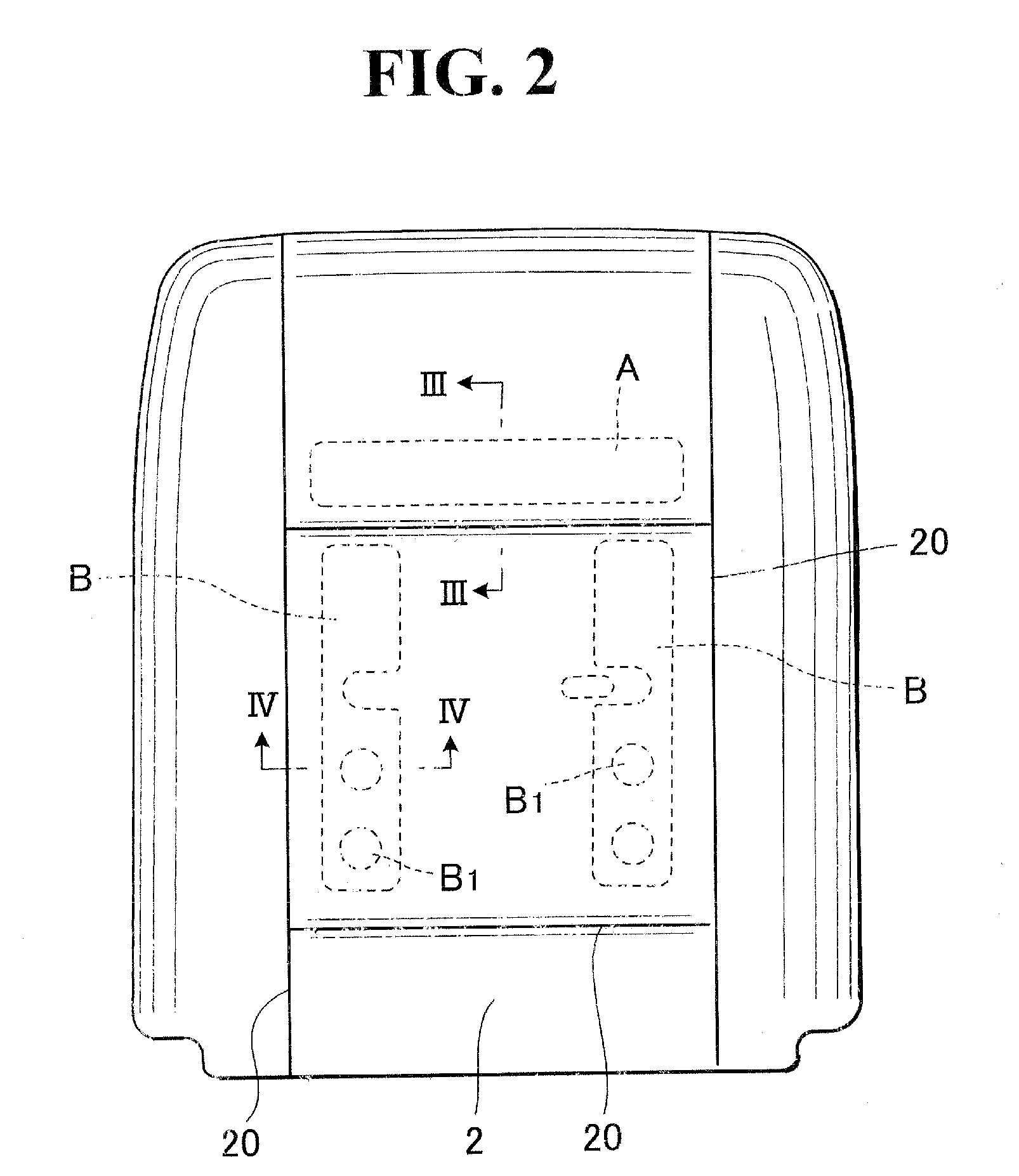

Vehicle seat with a temperature control unit

InactiveUS20090243350A1Prevent decline of appearance qualityDecline in quality of appearanceVehicle seatsStoolsEngineeringElectrical and Electronics engineering

A vehicle seat with a temperature control unit is composed of a plurality of ditches installed on a surface of a seat pad covered with the second plate having a vent and a divergence department on a surface of a seat pad covered with the first plate, wherein the presence of a plurality of ditches on a surface of a seat pad and a divergence department to diverge a heated or cooled air sent from a blower to each ditch give good ventilation of a heated or cooled air.

Owner:HONDA MOTOR CO LTD +1

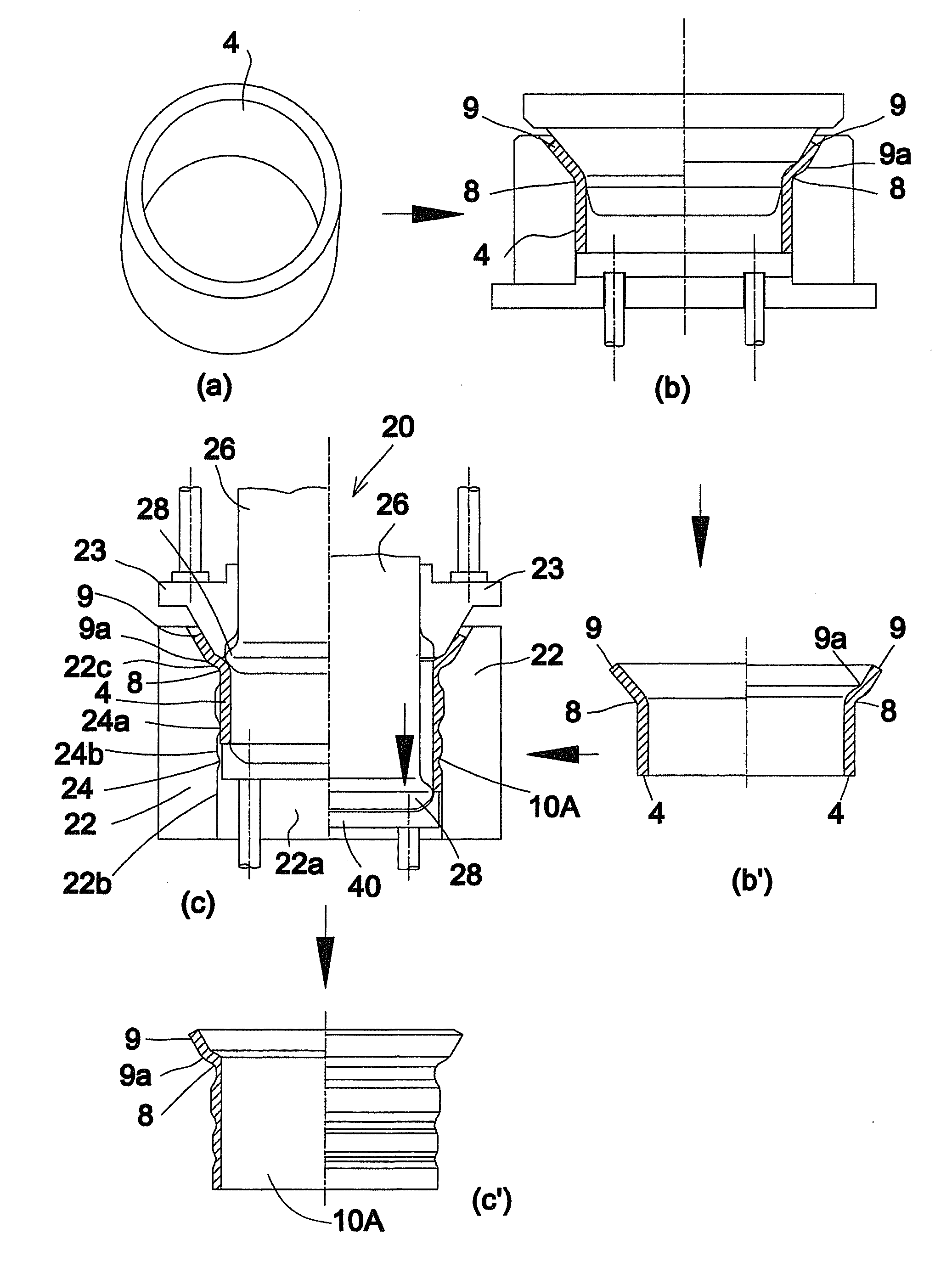

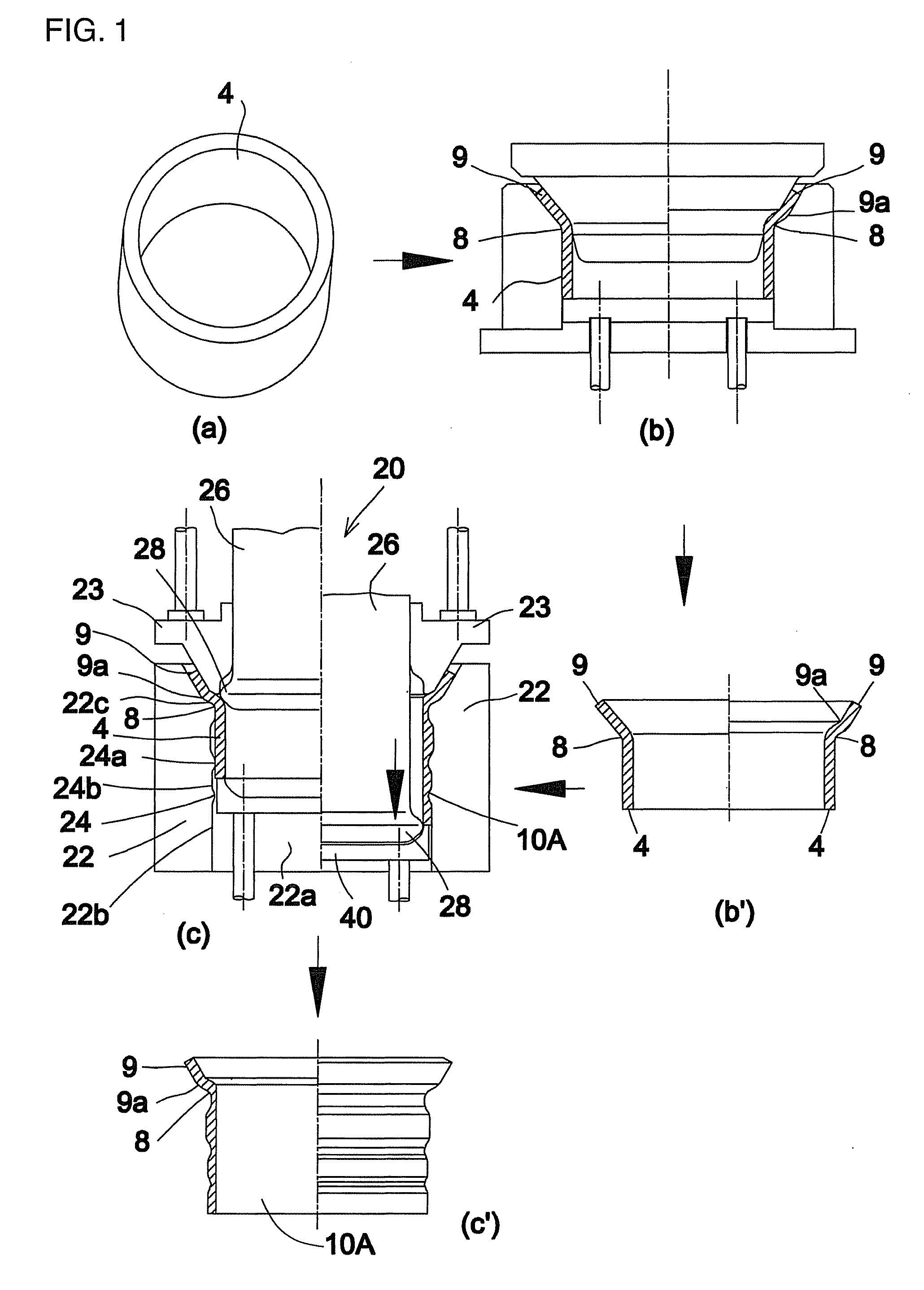

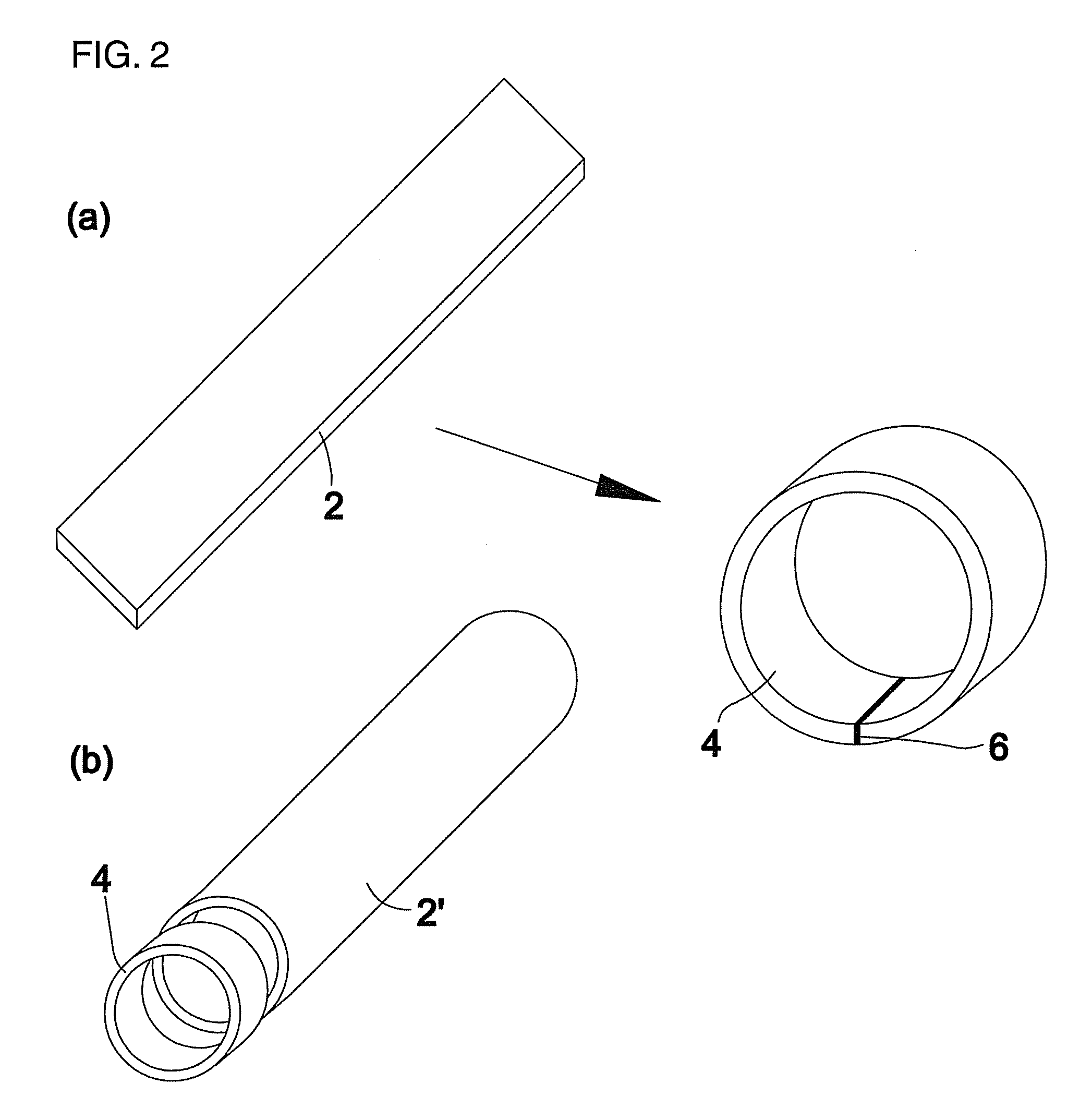

Method of manufacturing a wheel rim for a vehicle

ActiveUS20120304723A1Well formedImprove productivityRimsDisc wheelsEngineeringMechanical engineering

A method of manufacturing a wheel rim for a vehicle includes an ironing step for ironing a tubular material to manufacture a tubular member having a non-constant thickness, using an ironing apparatus provided with a punch, a die whose side surface opposing the punch is a convex and concave surface, and a pressing member. At the ironing step, a flange portion of the tubular material is set at the die, then the pressing member is moved relative to the die thereby to squeeze the flange portion of the tubular material by the pressing member and the die, and then the punch is moved relative to the die to iron at least a portion of the tubular material except the flange portion of the tubular material to manufacture the tubular member having a non-constant thickness.

Owner:TOPY INDUSTRIES

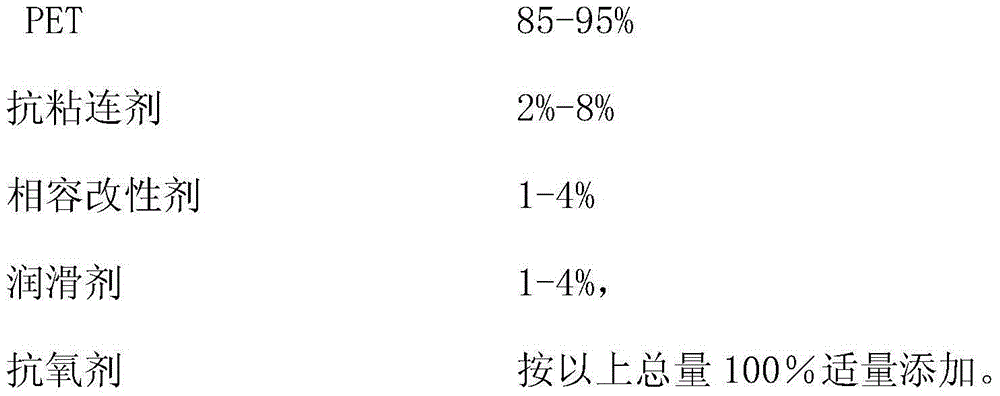

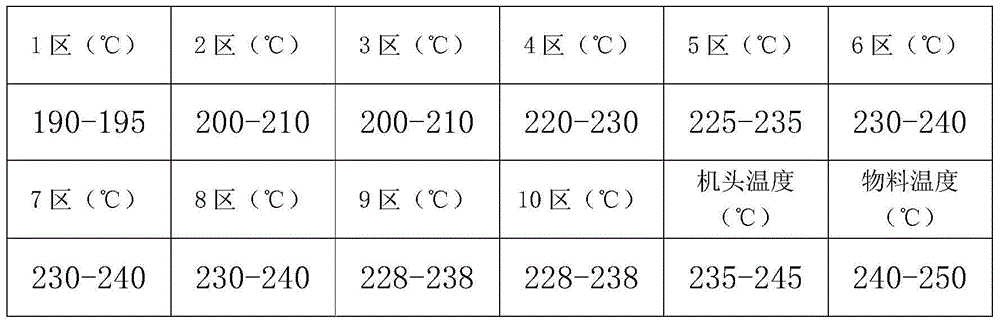

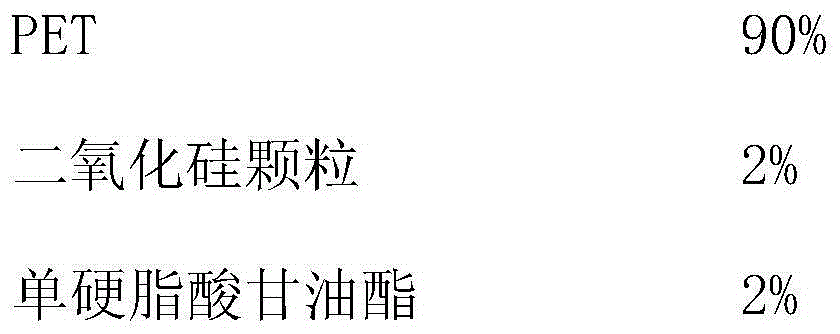

Anti-sticking masterbatch special for printable PET (Poly Ethylene Terephthalate) sheet material and preparation method thereof

The invention discloses an anti-sticking masterbatch special for a printable PET (Poly Ethylene Terephthalate) sheet material and a preparation method thereof. The anti-sticking masterbatch is prepared from the following components in parts by weight: 85% to 95% of PET, 2% to 8% of anti-sticking agent, 1% to 4% of compatible modifier, 1% to 4% of lubricant and a proper amount of antioxidant, wherein the adding amount of the antioxidant is based on the adding total amount of all components. The preparation method comprises the following steps: weighing all component materials and evenly mixing so as to form a mixture; carrying out melting extrusion on the mixture by using a melt extrusion; and drying, cooling and cutting into granules for molding. The PET sheet material utilizing the anti-sticking masterbatch has the good anti-sticking performance; the influences to the transparency and the haze of the PET sheet material are minimized; and the subsequent machining and manufacturing process of the sheet material is smooth and fluent, so that the production efficiency is improved, the problems of the appearance quality of the PET sheet material are reduced and the influence to the surface tension of the sheet material is not serious. Thus, the PET sheet material has the good printability for inks.

Owner:中山京工高分子材料有限公司

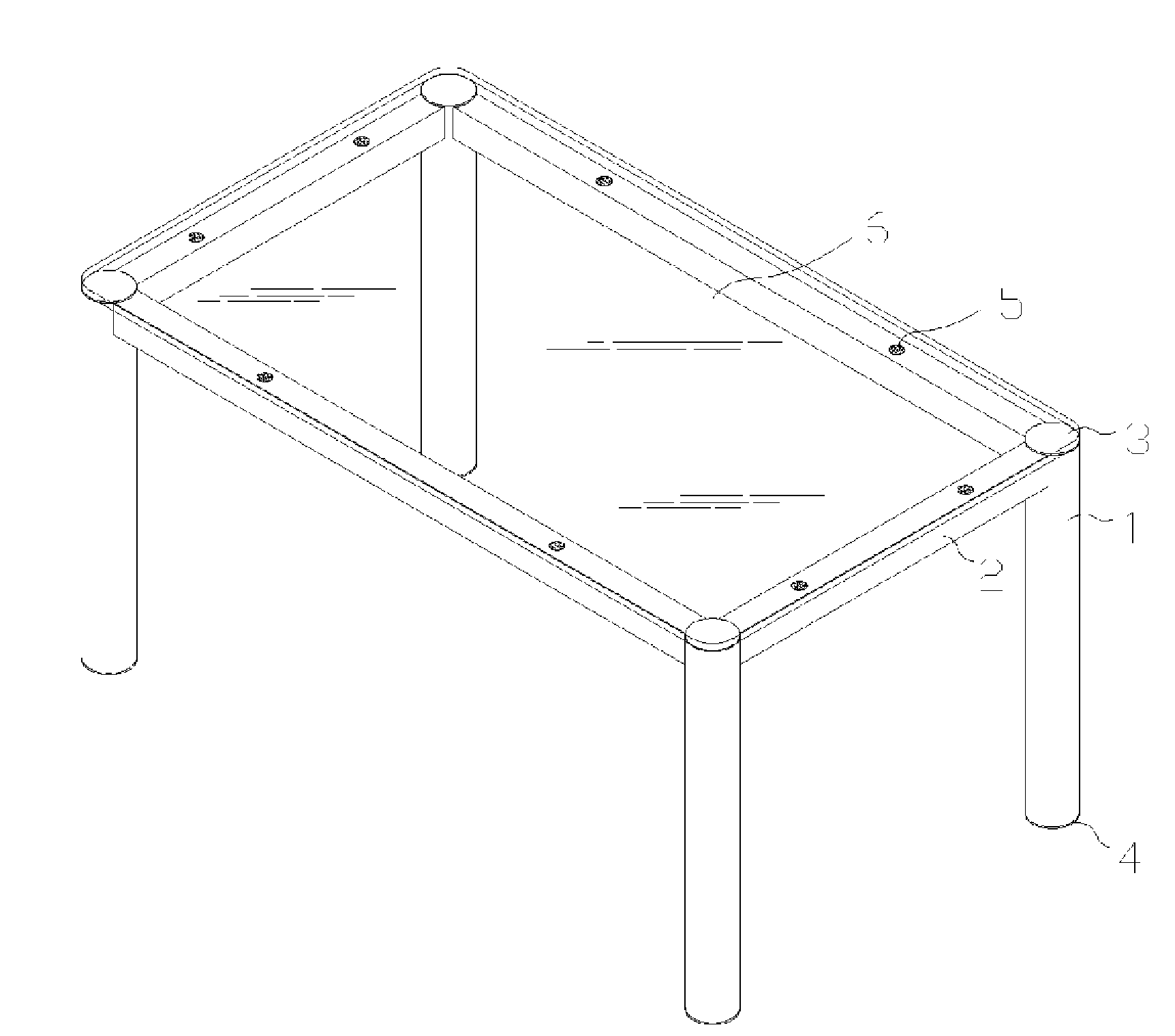

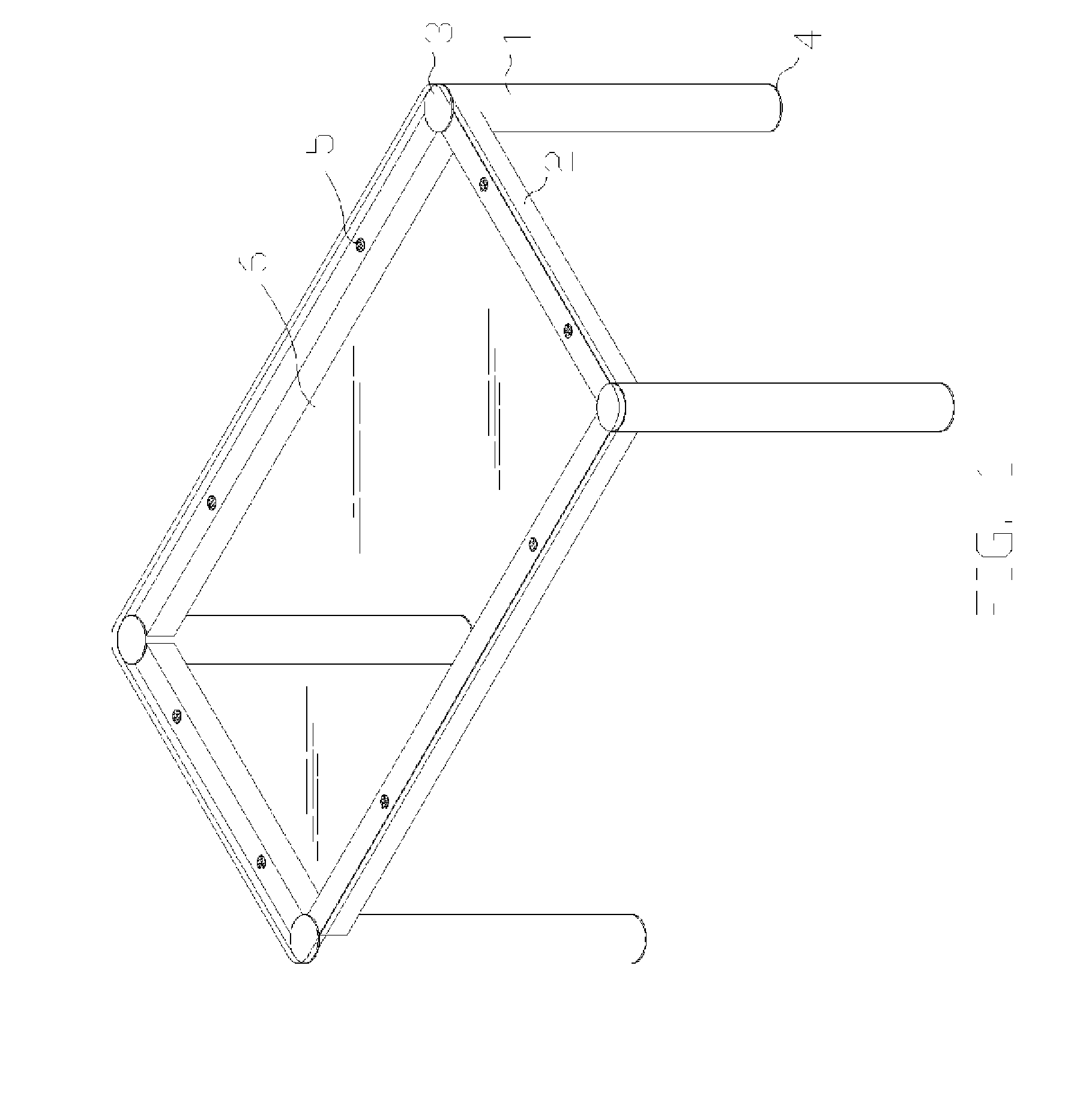

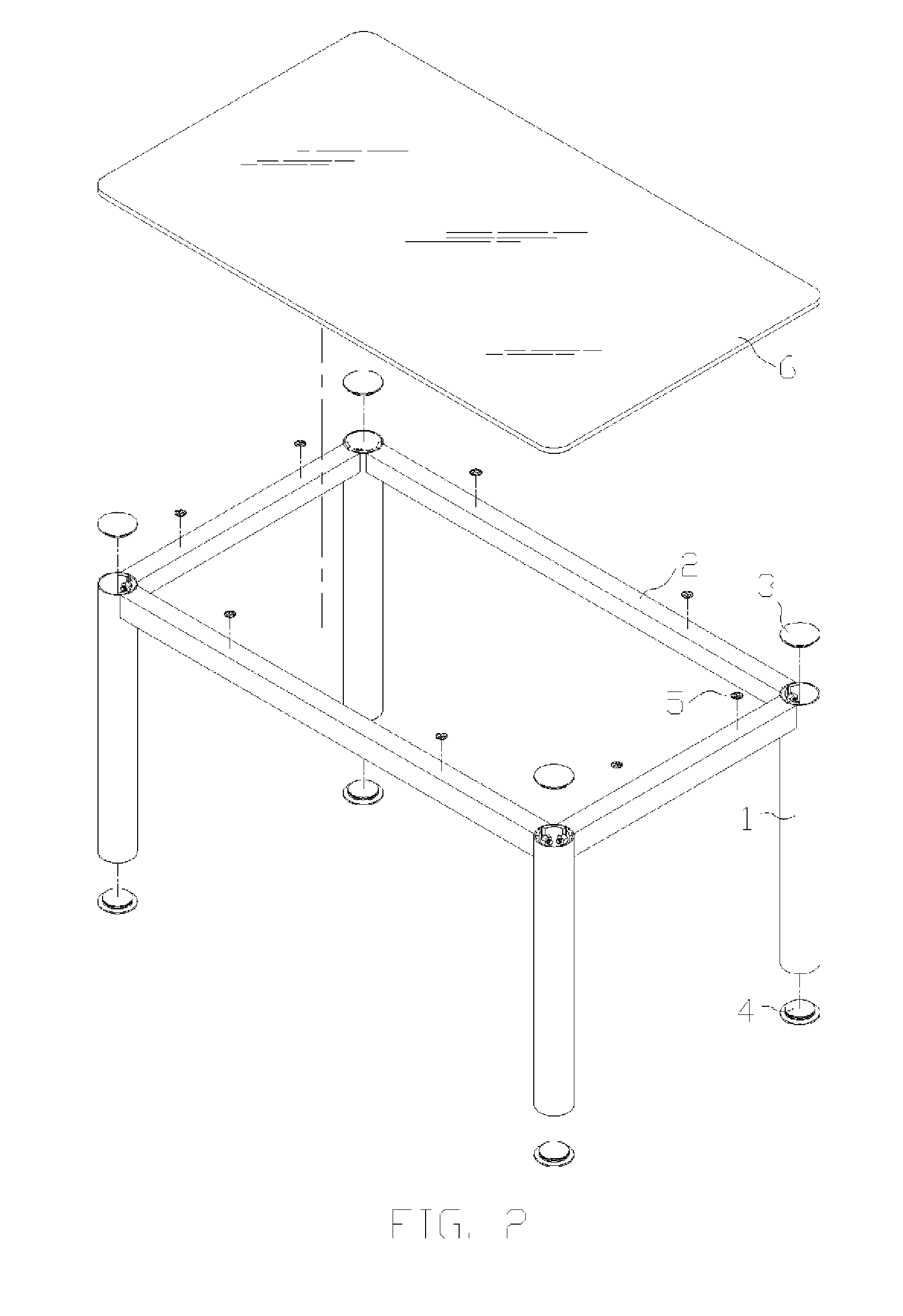

Table component assembly

InactiveUS20080029677A1Control appearance qualityAssure positioning convenienceFurniture partsStands/trestlesEngineering

An assembly table has a leg of a round tube, a beam, a combining unit, and wherein a table body is assembled by the upper end of the leg by using of the combining unit to combine the beam. The leg is a hollow tube. The straight positioning holes are opened at the upper end of the leg and serves to combine the combining unit. Each side of the straight positioning hole has one enhancing body. The beam is a hollow tube. The each end of the beam has a combining unit. The combining unit is welded directly to the hollow tube of the beam. The combining unit has a substrate, a stud, a washer, a nut and a positioning pin. The stud and the positioning pin are fixed firmly on the substrate. The washer is looped on the stud. The nut is screwed in the stud.

Owner:LEE SHAW MING

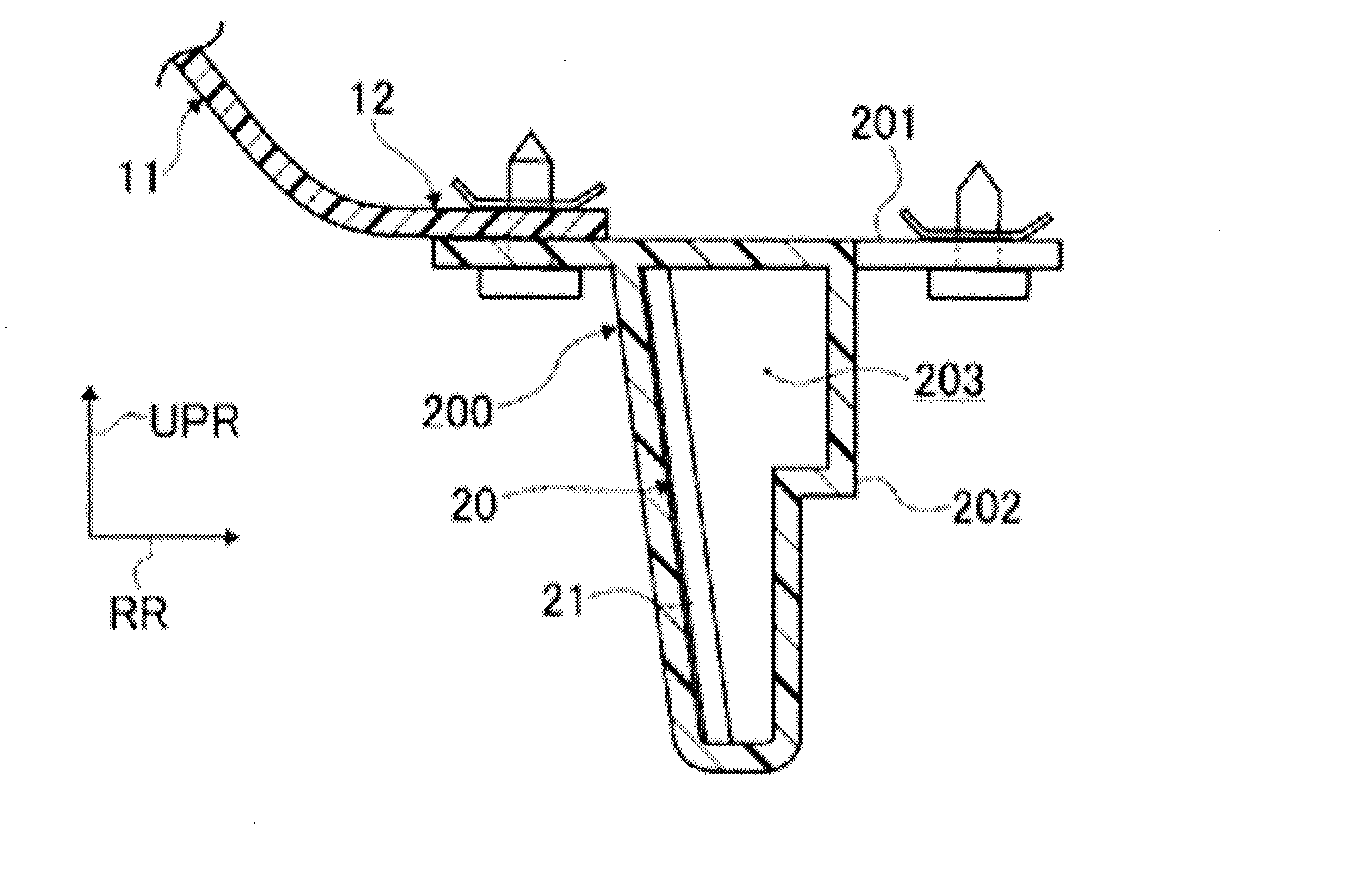

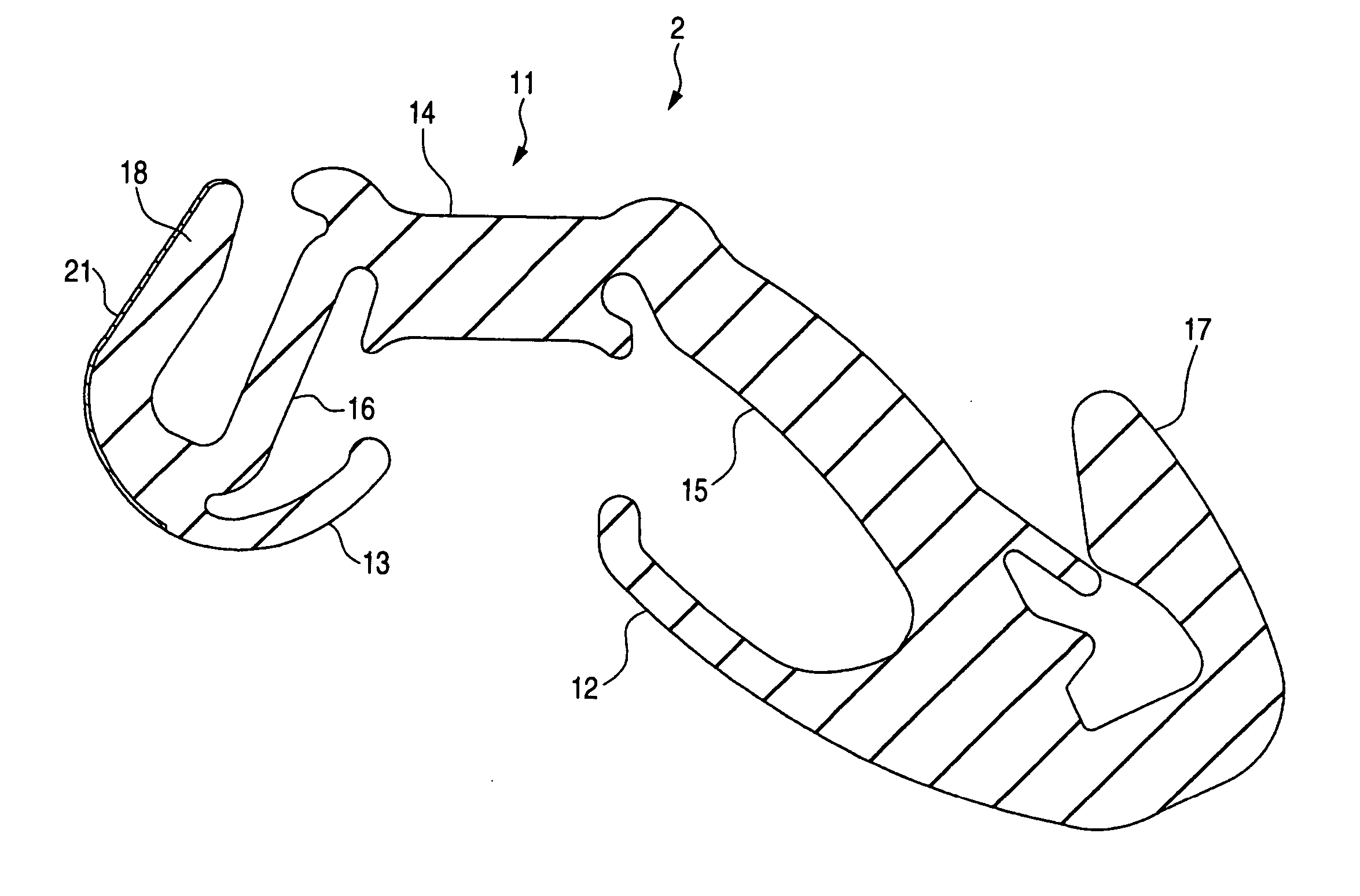

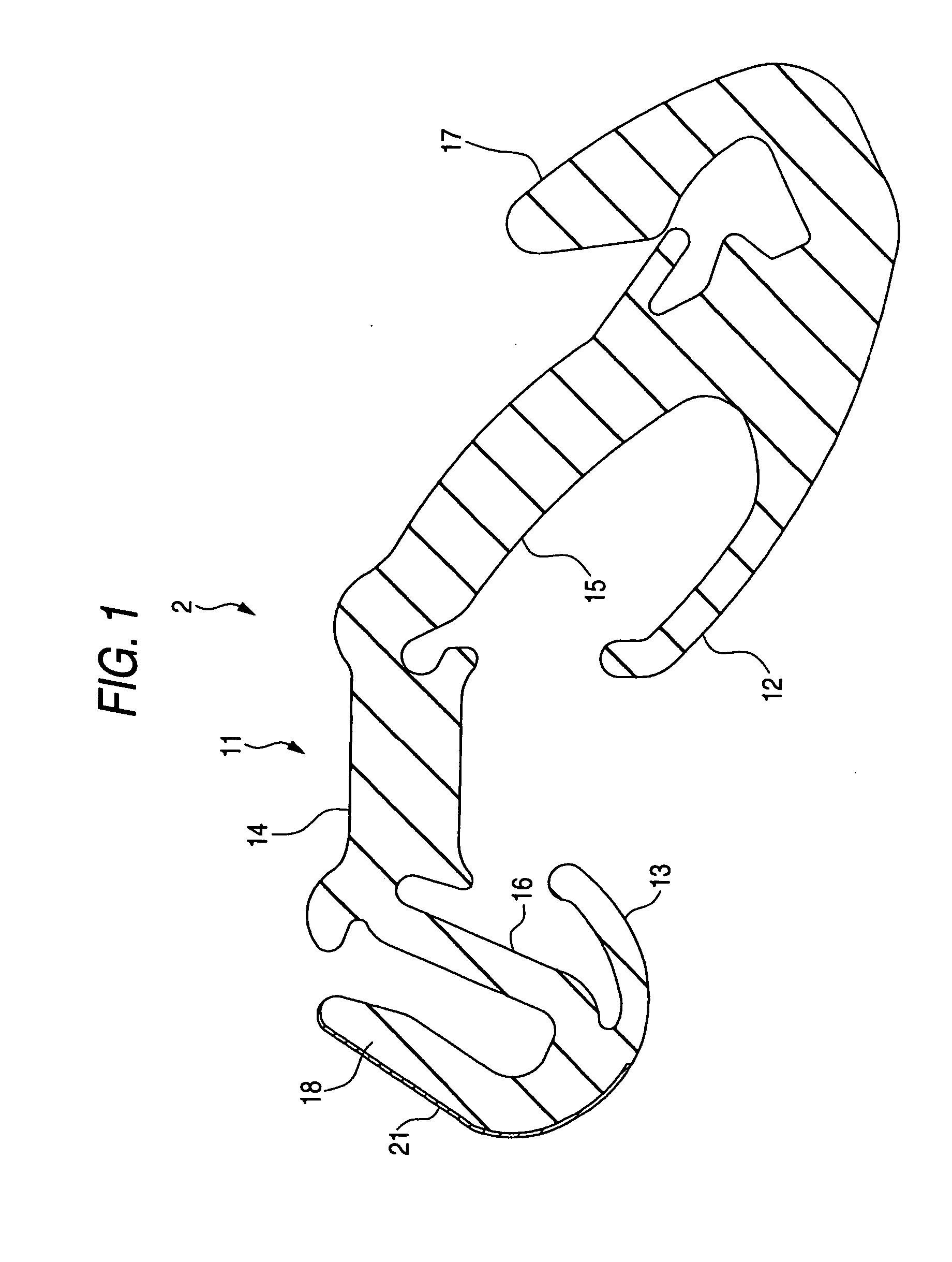

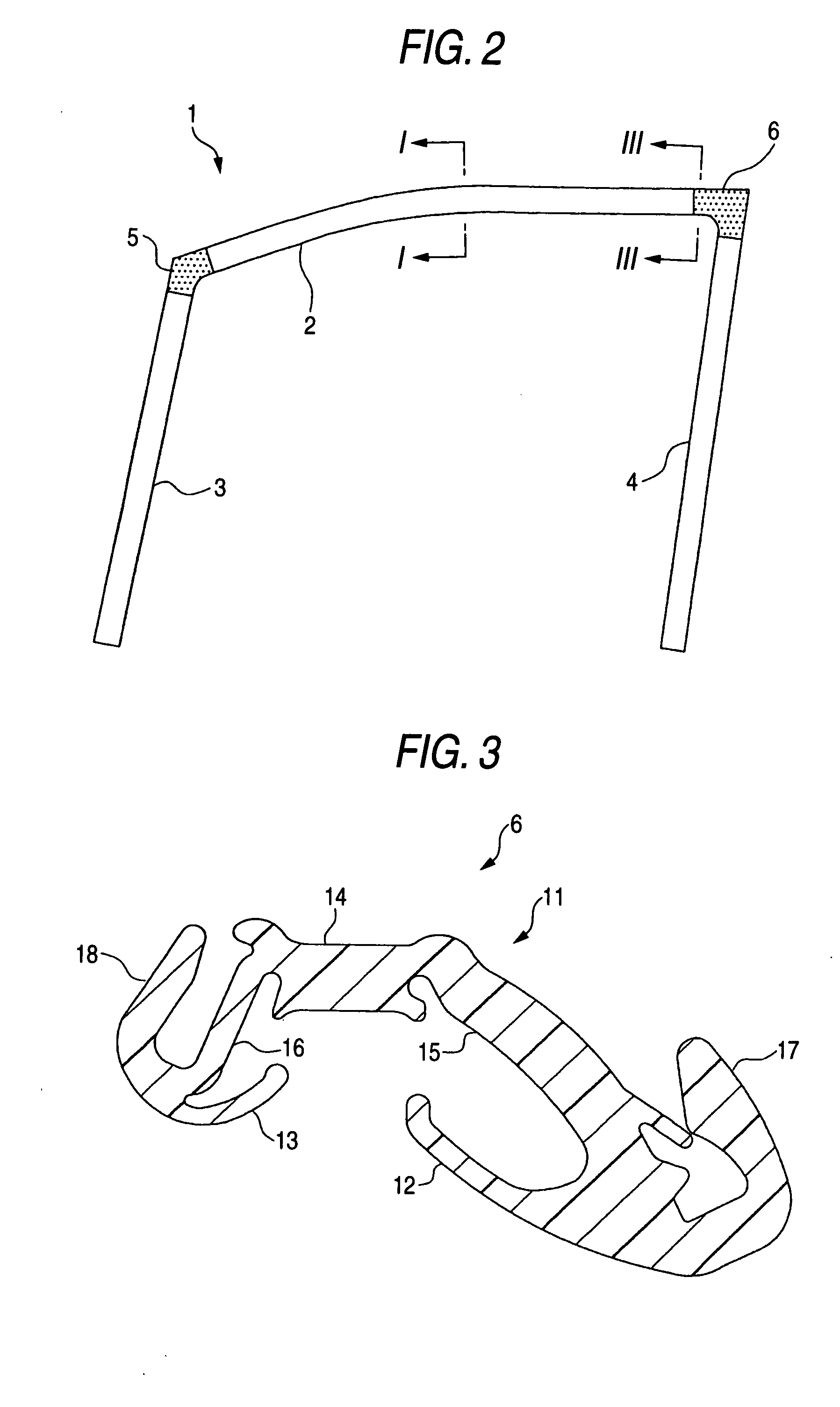

Weather strip and glass run

InactiveUS20050031830A1Increase temperatureControl appearance qualityLayered productsVehicle sealing arrangements

A glass run includes extruded parts and molded parts connecting the extruded parts together. Each of the extruded parts and the molded parts has a main body portion and seal lips. An interior design lip is formed on an interior side wall portion located on an interior side of a vehicle so as to extend therefrom, while an exterior design lip is formed on an exterior side wall portion located on an exterior side of the vehicle so as to extend therefrom. A film made of an olefin resin material, which is same to the material of each of the molded parts is bonded to the exterior surface of the exterior design lip of each of the extruded parts so as to present the same color and luster as those of the molded parts.

Owner:TOYODA GOSEI CO LTD

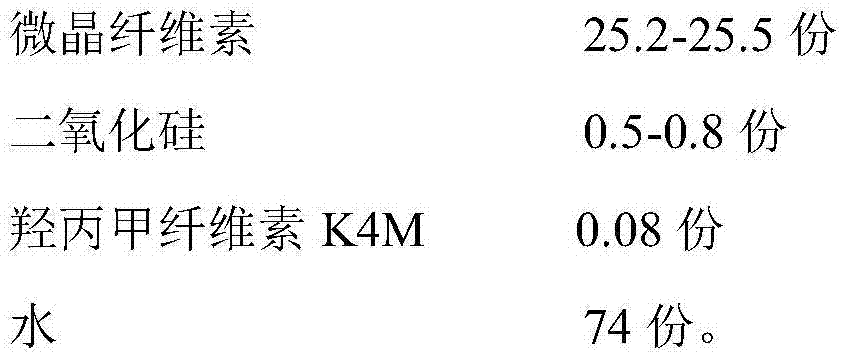

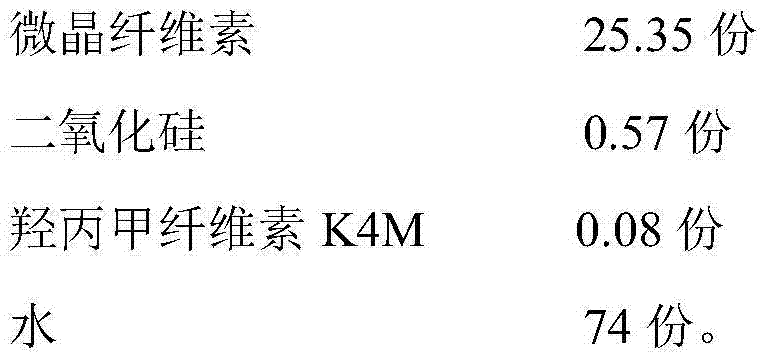

Silicified microcrystalline cellulose composite auxiliary material and preparation method thereof

InactiveCN104258411AUniform contentImprove liquidityPill deliveryPharmaceutical non-active ingredientsRevolutions per minutePeristaltic pump

The invention discloses a silicified microcrystalline cellulose composite auxiliary material and a preparation method thereof, belonging to the field of medical premixed composite auxiliary materials. The silicified microcrystalline cellulose composite auxiliary material disclosed by the invention consists of the following components in parts by mass: 25.2-25.5 parts of microcrystalline cellulose, 0.5-0.8 part of silicon dioxide, 0.08 part of hydroxypropyl methylcellulose K4M and 74 parts of water. The preparation method comprises the following steps: (1) dissolving the hydroxypropyl methylcellulose K4M and water, adding the dissolved substances into a stirrer, adding the silicon dioxide, stirring, adding the microcrystalline cellulose, and stirring, thereby obtaining uniform suspension A; (2) setting the air inlet temperature at 160 DEG C by using a centrifugal spray dryer, setting the outlet temperature at 95 DEG C, setting the rotating speed of an atomizer at 8000 revolutions per minute, setting the rotating speed of a peristaltic pump at 20 revolutions per minute, and drying, thereby obtaining a material B; (3) adding the material B into a screening machine, vibrating and screening to the granularity of 80 meshes, thereby obtaining sieve residues C; and (4) testing the samples of sieve residues C, thereby obtaining the product of which the quality accords with the regulation, namely the composite auxiliary material. According to the composite auxiliary material and the preparation method thereof provided by the invention, the requirement of directly pressing the powder is met, so that the product is uniform in tablet weight, large in tablet hardness, smooth in tablet and qualified in dissolution rate.

Owner:安徽山河药用辅料股份有限公司

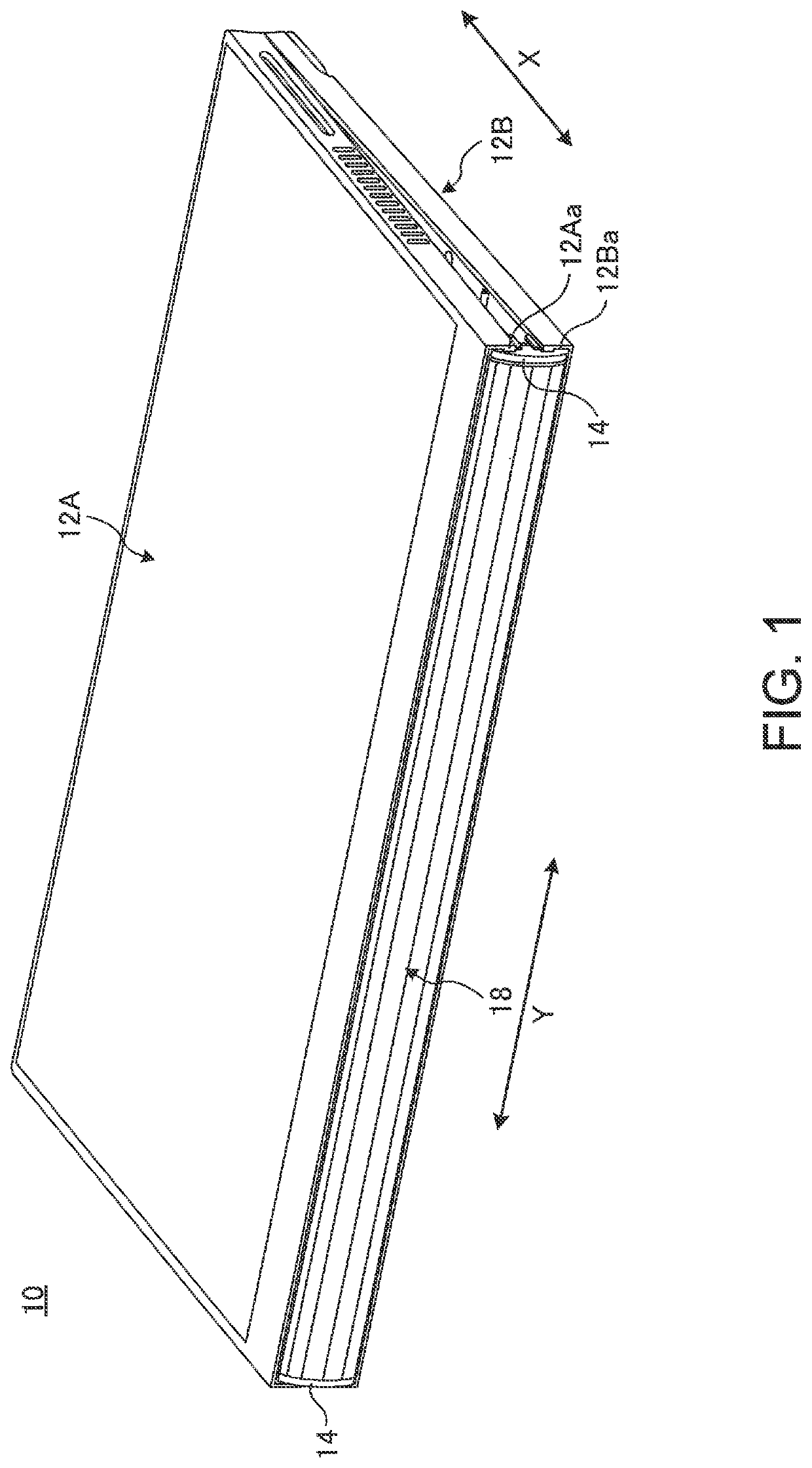

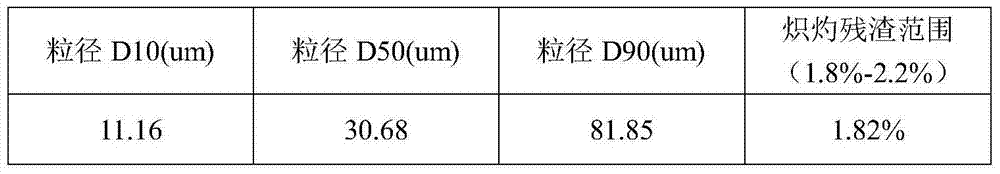

Portable information device

ActiveUS10908639B2Smooth bending operation of displayControl appearance qualityDetails for portable computersDisplay deviceEngineering

A portable information device includes a first chassis member, a second chassis member, a hinge mechanism, a display and a bezel member provided to bridge an outer peripheral edge portion of the display and an outer peripheral edge portion of the first and second chassis members. The bezel member is arranged farther away from the inner surfaces of the first and second chassis members than a rotation center of the hinge mechanism. The bezel member has a buffer portion at least at a position overlapping a bent portion of the display. The buffer portion can absorb compressive force F applied thereto as the first and the second chassis members are folded from a flat opened state.

Owner:LENOVO (SINGAPORE) PTE LTD

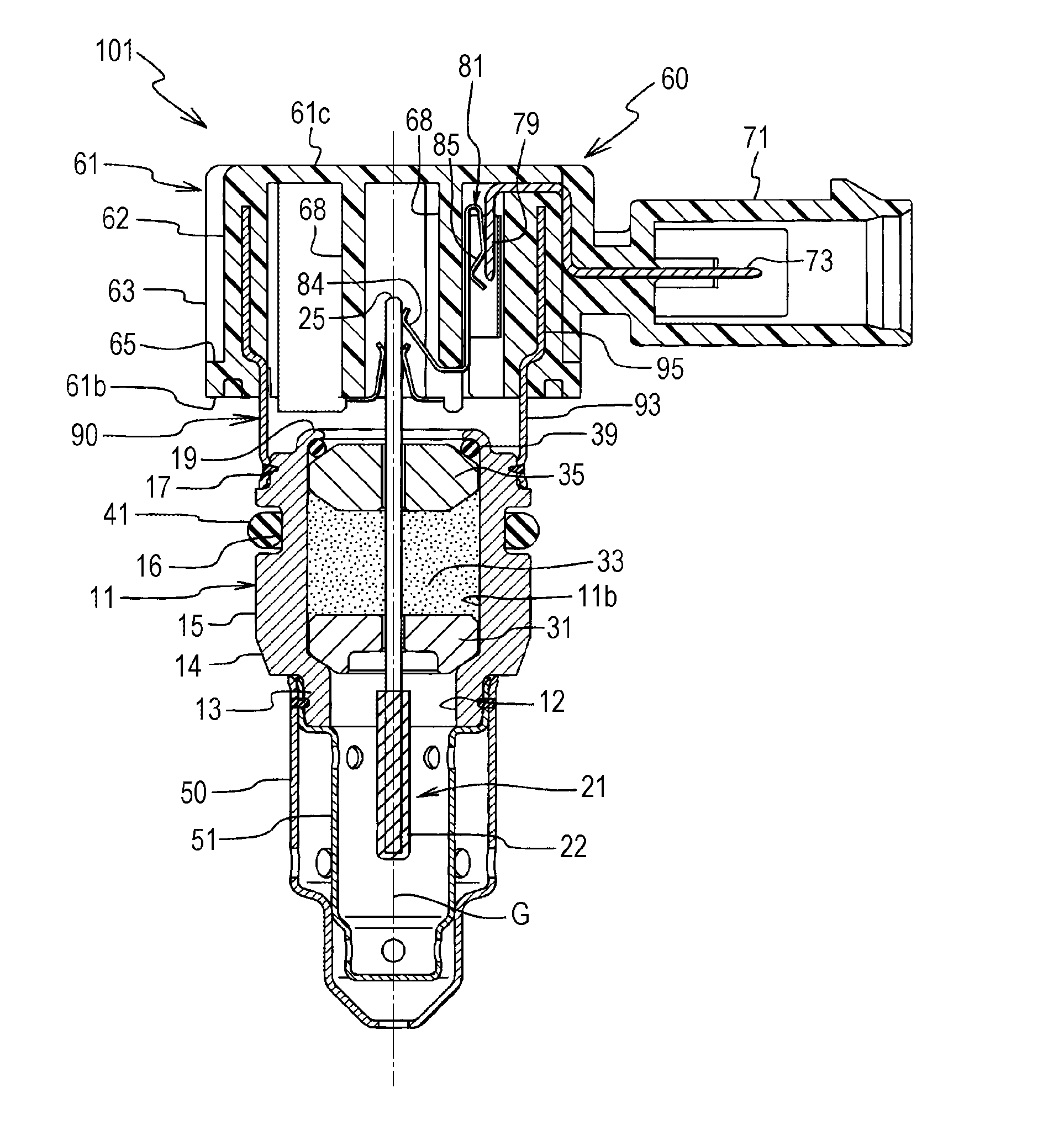

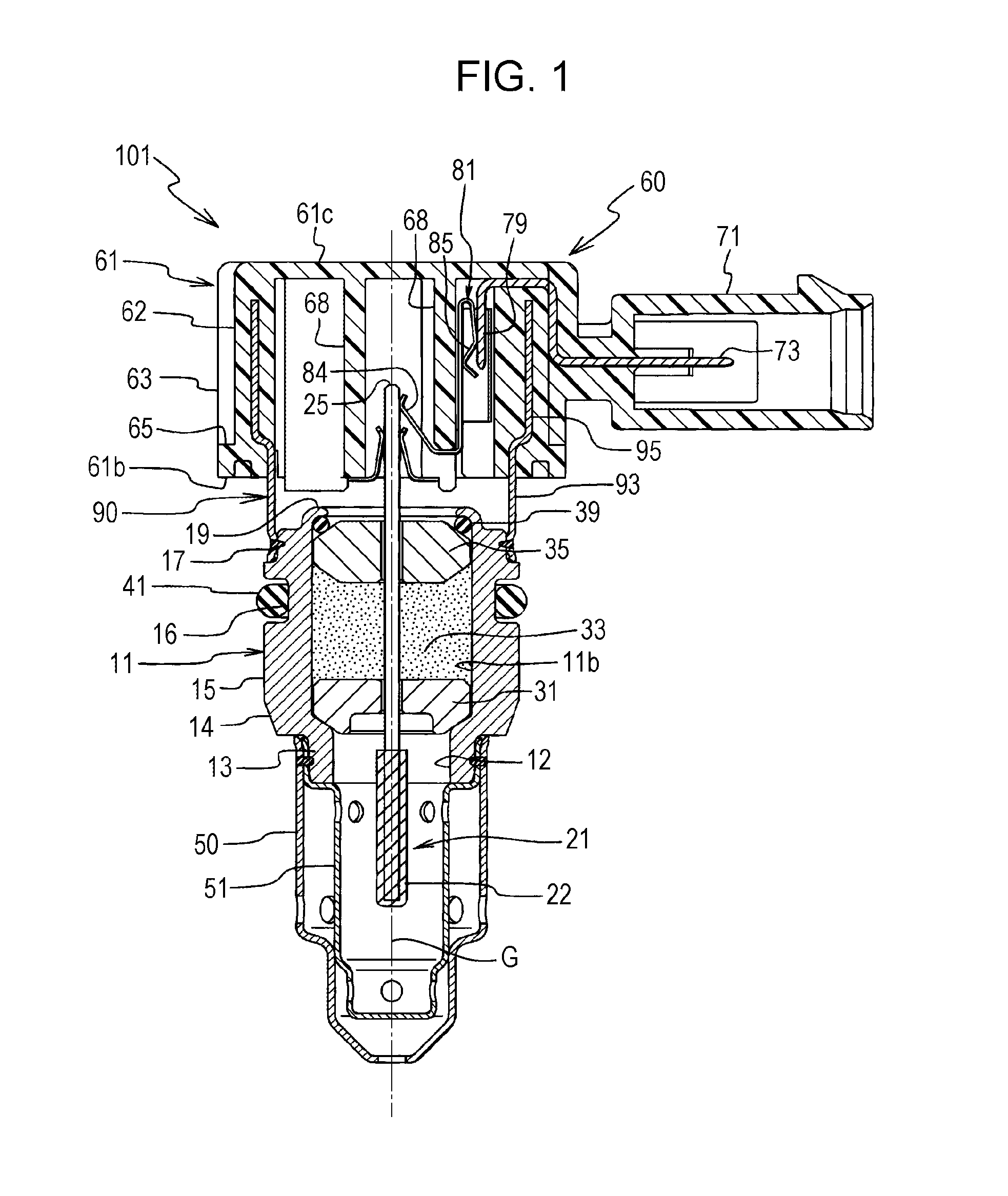

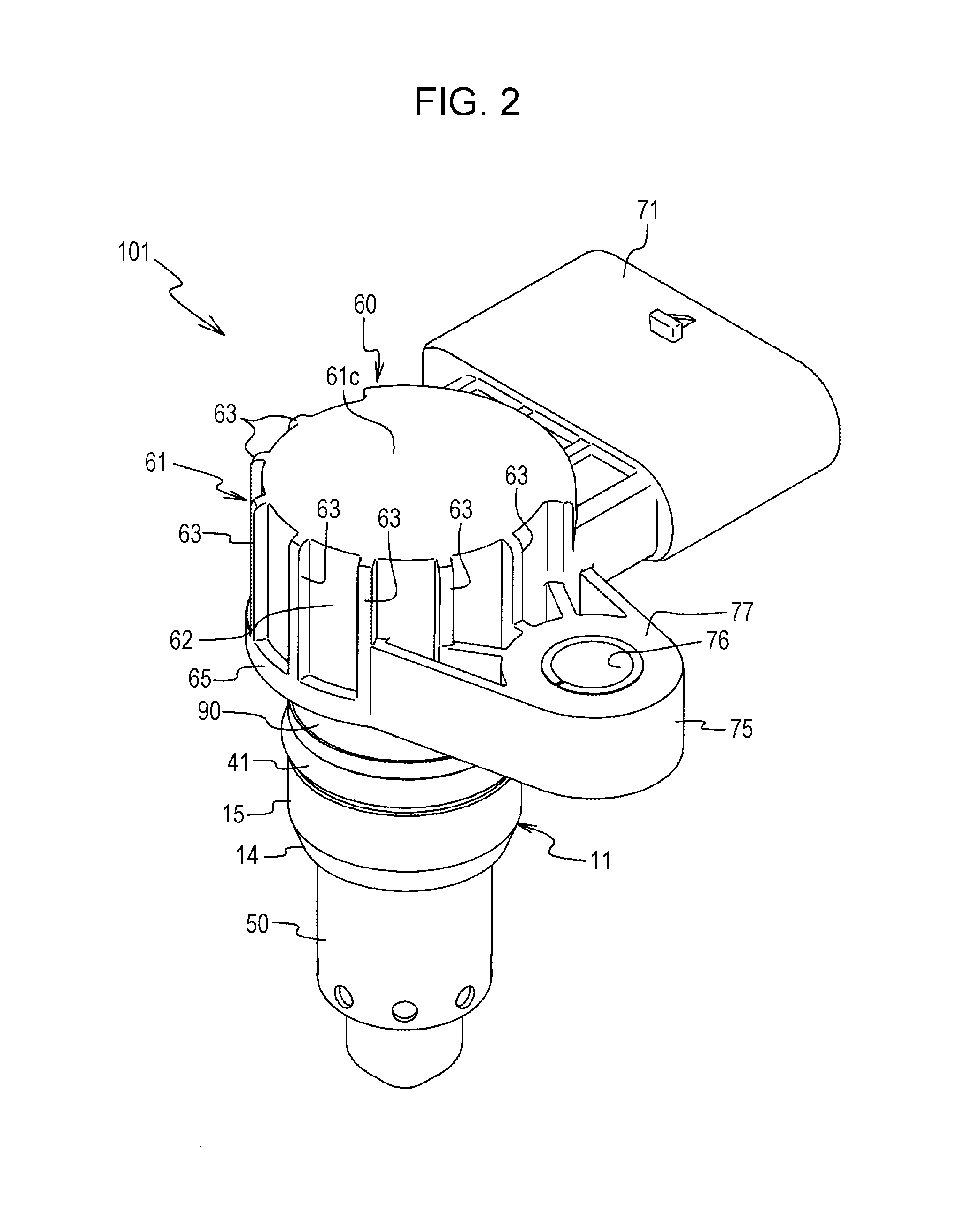

Gas sensor

InactiveUS20160223504A1Prevent slippingSignificant differenceInternal-combustion engine testingMaterial analysis by electric/magnetic meansEngineering

A gas sensor includes a protective cover having a resin cylindrical cover portion at a rear end thereof, that can be airtightly attached to an attachment hole, and that can prevent a decrease in quality and a molding defect. A plurality of vertical ribs, which extend substantially parallel to an axis of a cylindrical cover portion, are formed on an outer peripheral surface of the cylindrical cover portion so that protrusions and recesses are provided in a circumferential direction. Due to the presence of the vertical ribs, as compared with an existing cylindrical cover portion that has a smooth outer peripheral surface without the vertical ribs, defects of the outer peripheral surface are not likely to occur in a molding process. Moreover, because slipping is not likely to occur when an operator holds and twists the cylindrical cover portion with his / her fingers, an attachment operation can be smoothly performed.

Owner:NGK SPARK PLUG CO LTD

Rapid forming method of thermoplastic fiber-reinforced composite material plate

InactiveCN107214980AResolutionResolution cycleLaminationLamination apparatusTemperature controlSheet film

The invention relates to a rapid forming method of a thermoplastic fiber-reinforced composite material plate. The rapid forming method is characterized by comprising the following steps that (1) forming equipment and materials are prepared, specifically, the special equipment with presoaking, laying, superimposing, temperature control and pressure control, vacuum lamination forming, cutting, heating and mould pressing forming structures is arranged, a resin solution with a thermoplastic-forming function and the fiber-reinforced materials are prepared; (2) the fiber-reinforced materials are soaked into the resin solution with the thermoplastic-forming function, and fiber glue pieces are prepared; (3) the fiber glue pieces obtained in the step (2) are superimposed by 1-5 layers, the superimposed fiber glue pieces are placed in a vacuum press with a programmable temperature control and pressure control function, and a thermoplastic fiber-reinforced laminated composite material is prepared; (4) a mould plate is cut; (5) the mould plate is heated and softened; (6) mould pressing forming is conducted; and (7) the finished product is prepared. The rapid forming method of the thermoplastic fiber-reinforced composite material plate has the characteristics and beneficial effects of high mechanization degree, short processing period, high efficiency, low product cost and the like.

Owner:东莞市海旭新材料技术有限公司

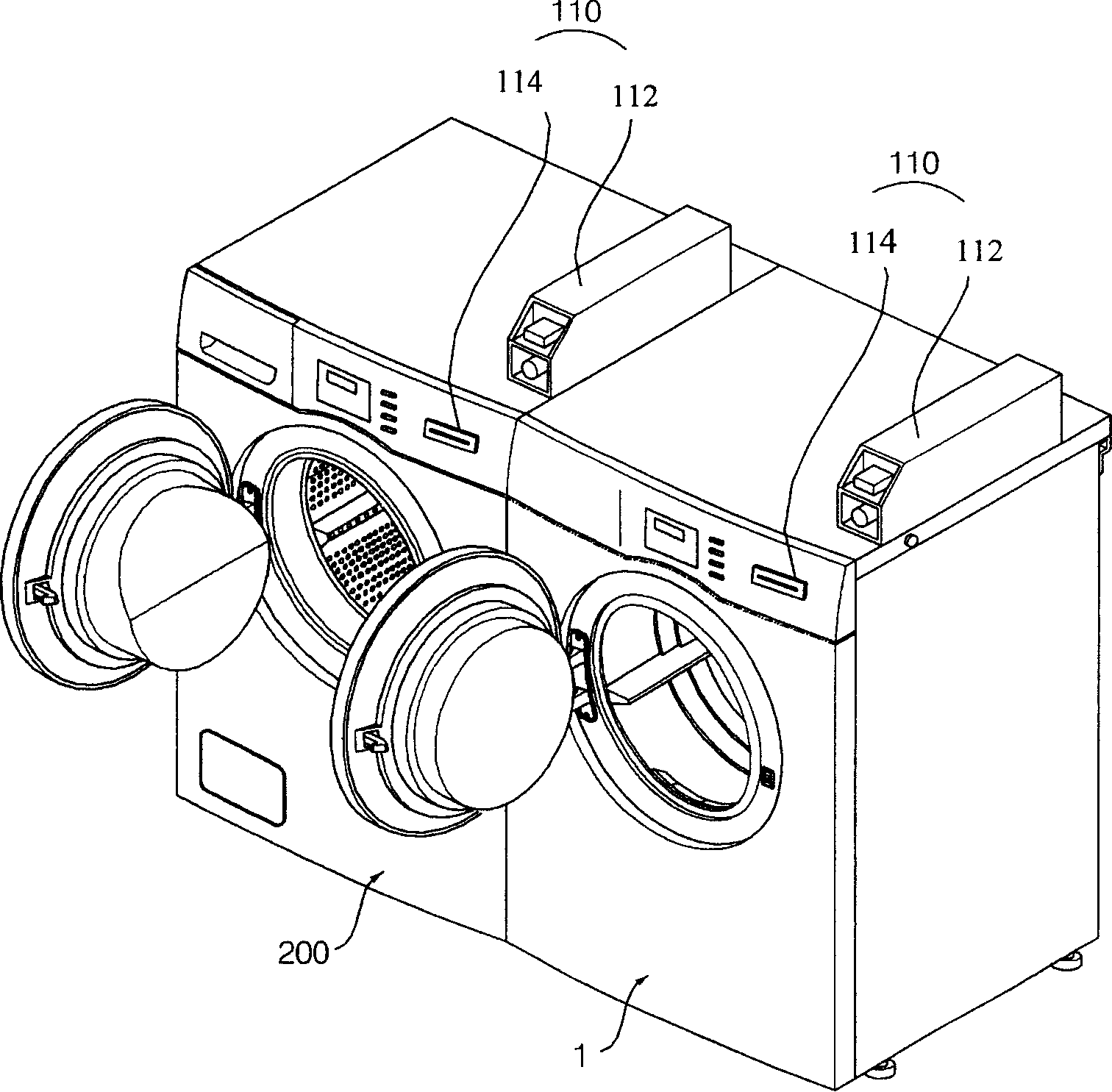

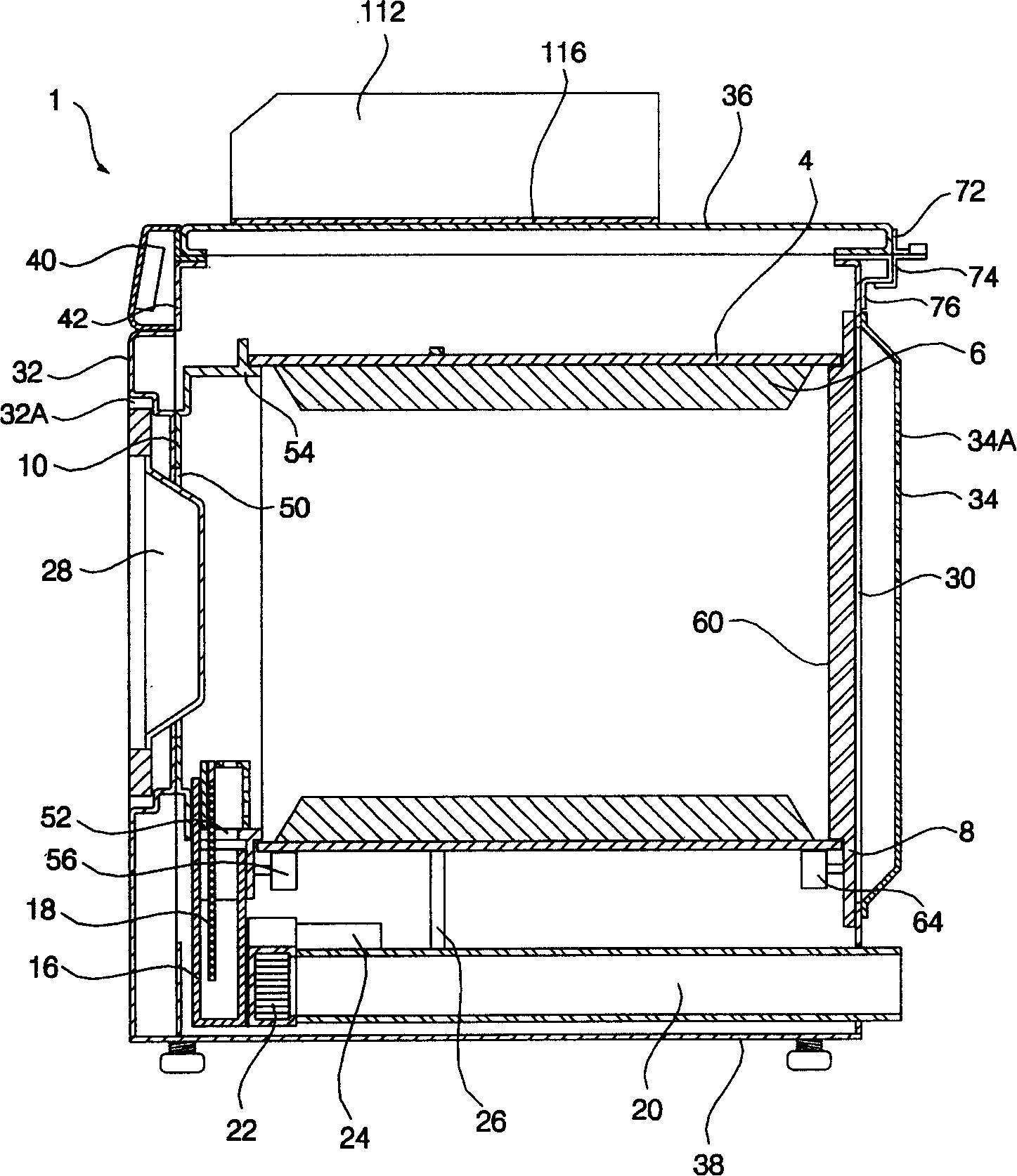

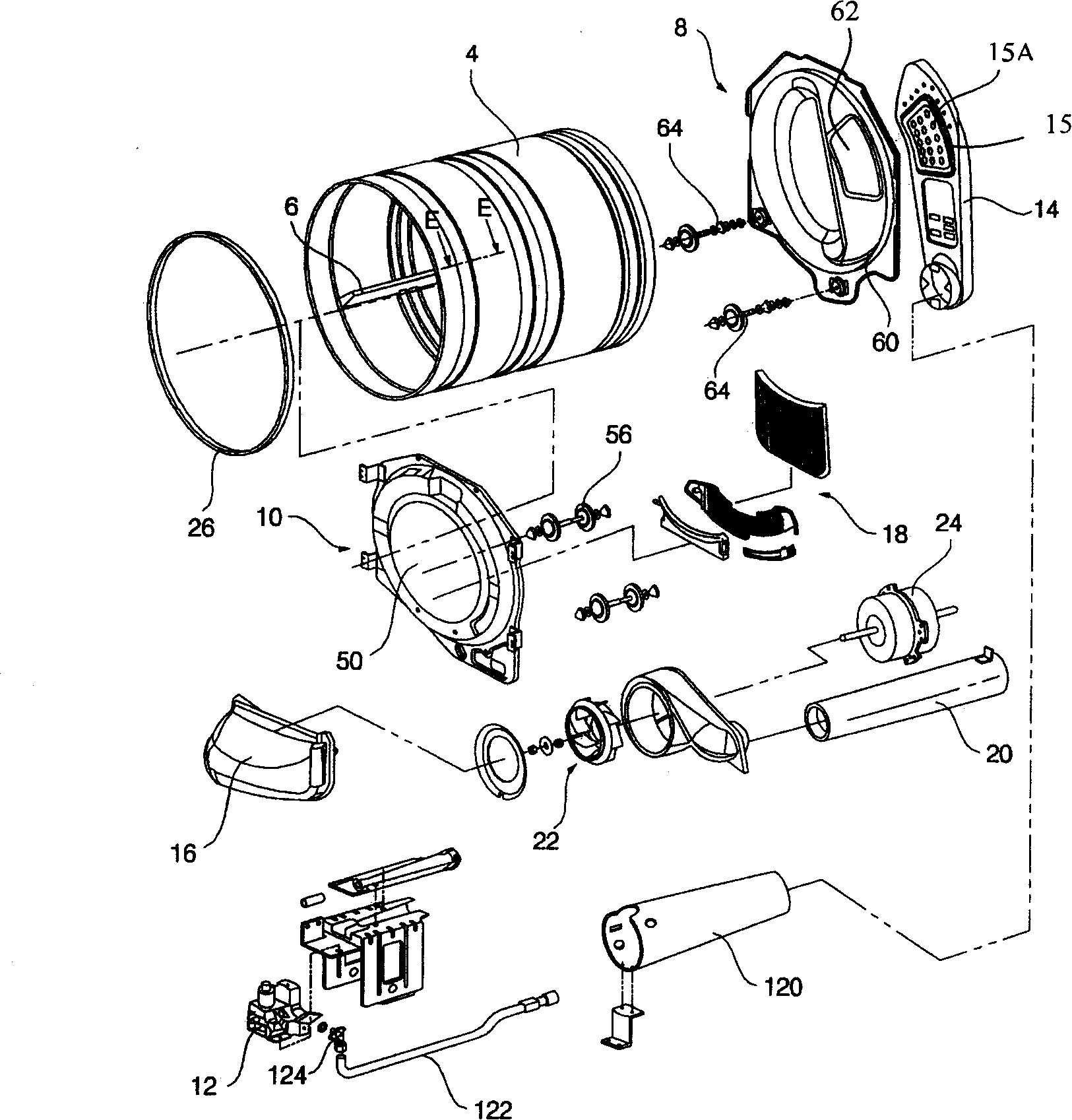

Clothes dryer

InactiveCN101168918AImprove wear resistanceIncreased durabilityTextiles and paperLaundry driersResin coatingEngineering

The invention relates to a clothes drier. The clothes drier comprises: a rolling tube arranged at the inner part of a casing body in a rotary way; a front supporting part supporting the front side part of the rolling tube and facilitating the front side part of the rolling tube to rotate and arranged in front of the casing body; a rear supporting part supporting the rear side part of the rolling tube supporting part and facilitating the rear side part of the rolling tube to rotate and arranged behind the casing body; and an air feeding tube arranged between the rear supporting part and a heater, communicated with the rear supporting part and the heater, and exhausting the air heated by the heater off to the inner part of the rolling tube. The invention has the following advantages that: a fluor resin coating layer is formed on the surface of at least one of any of the rolling tube, the front supporting part and the rear supporting part. Under the function of the fluor resin coating layer, the wearability is greatly improved, and the durability is also improved. In addition, because the fluor resin coating layer is formed, the metachromasia caused by the reaction of the surface and the dye or colorant of the washed matter at a high temperature can be prevented.

Owner:NANJING LG PANDA APPLIANCES

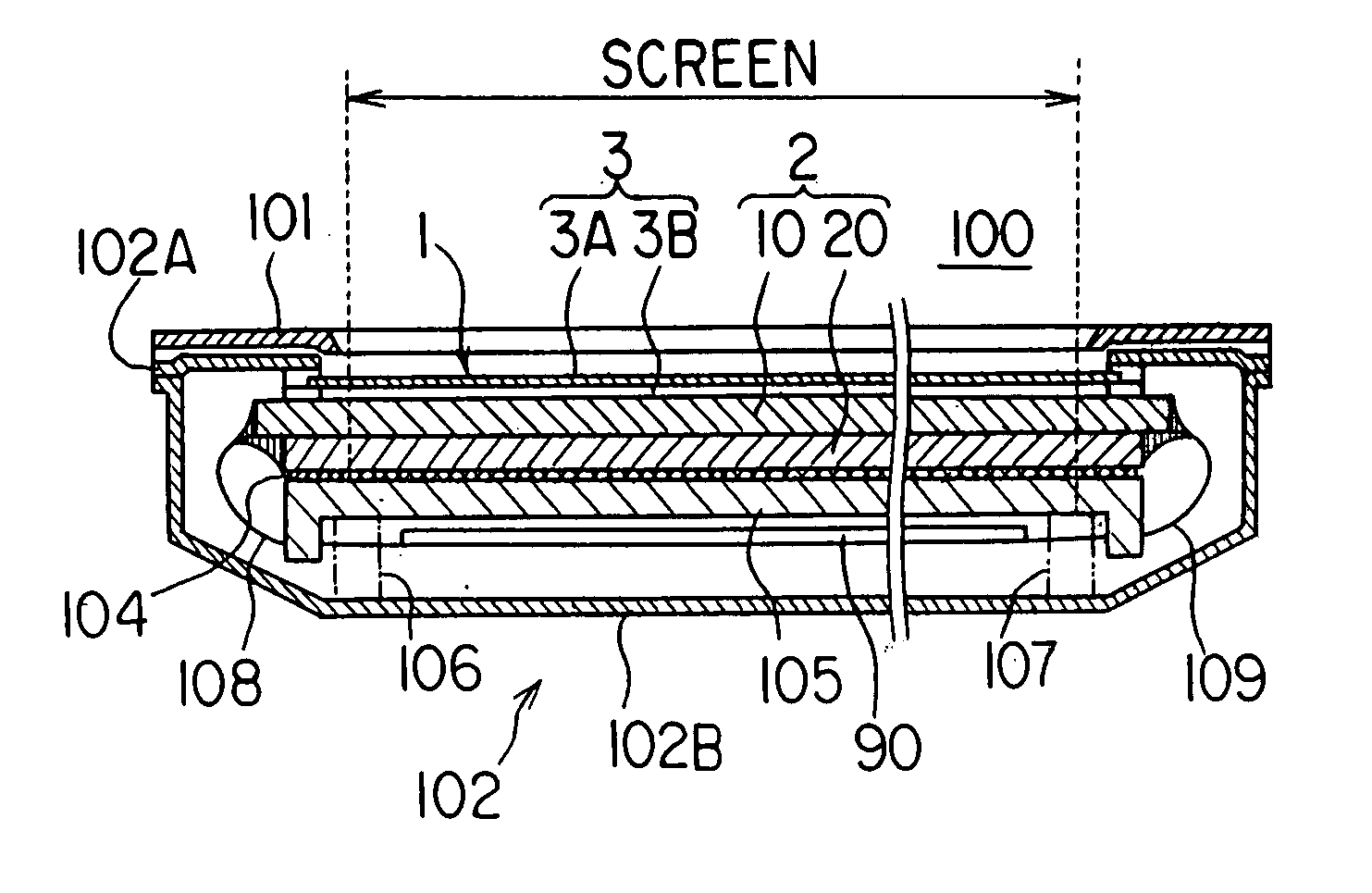

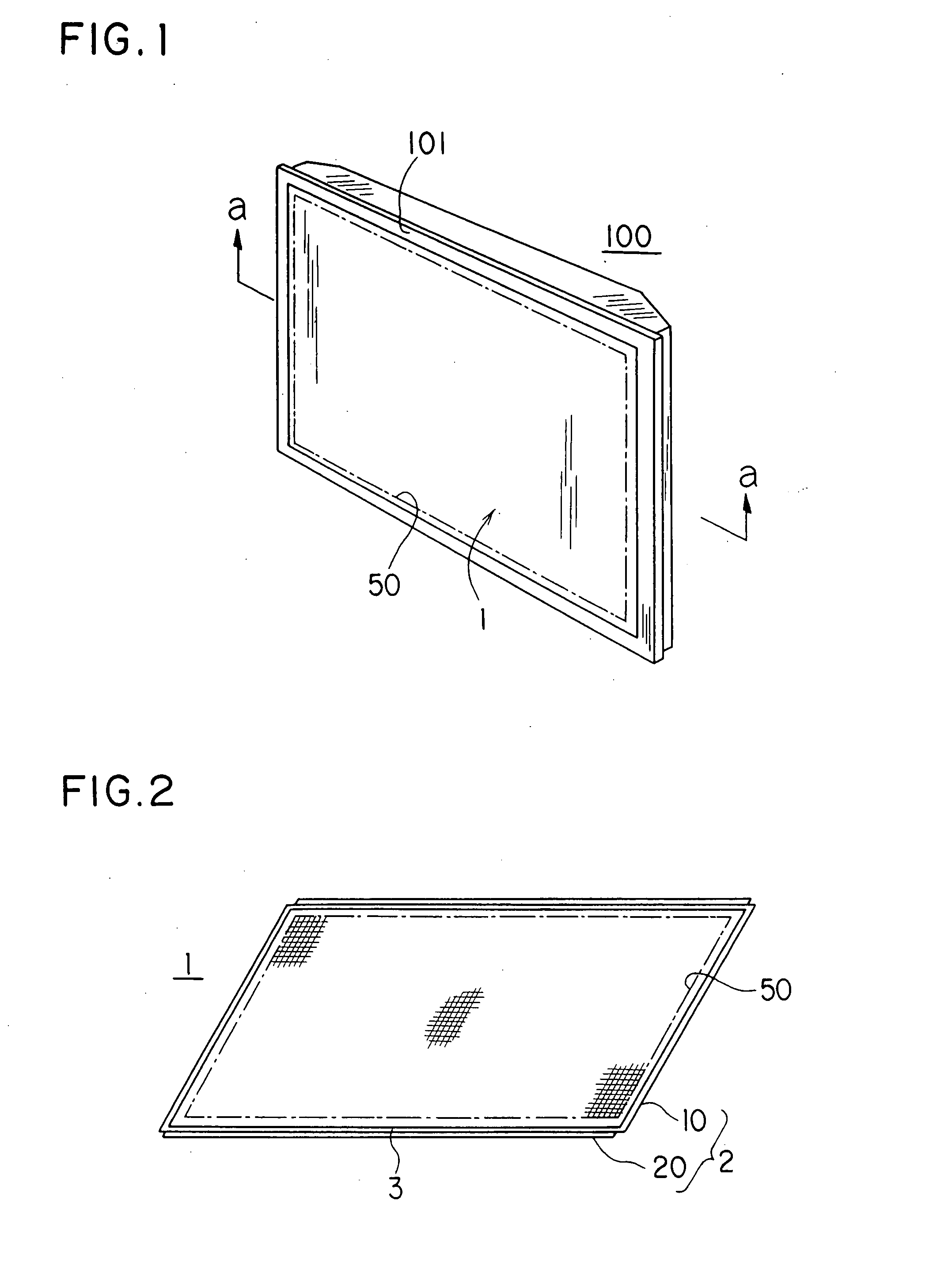

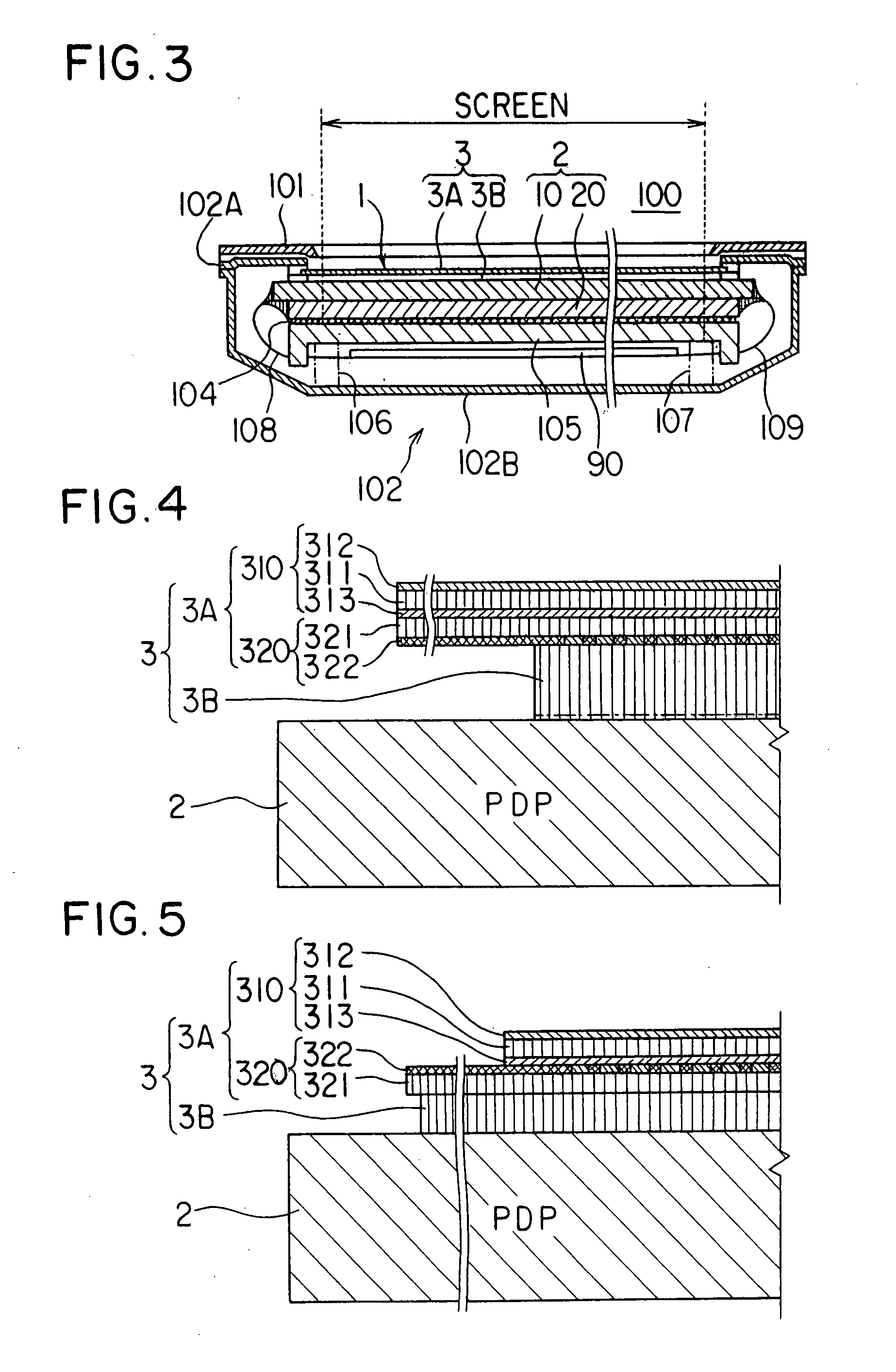

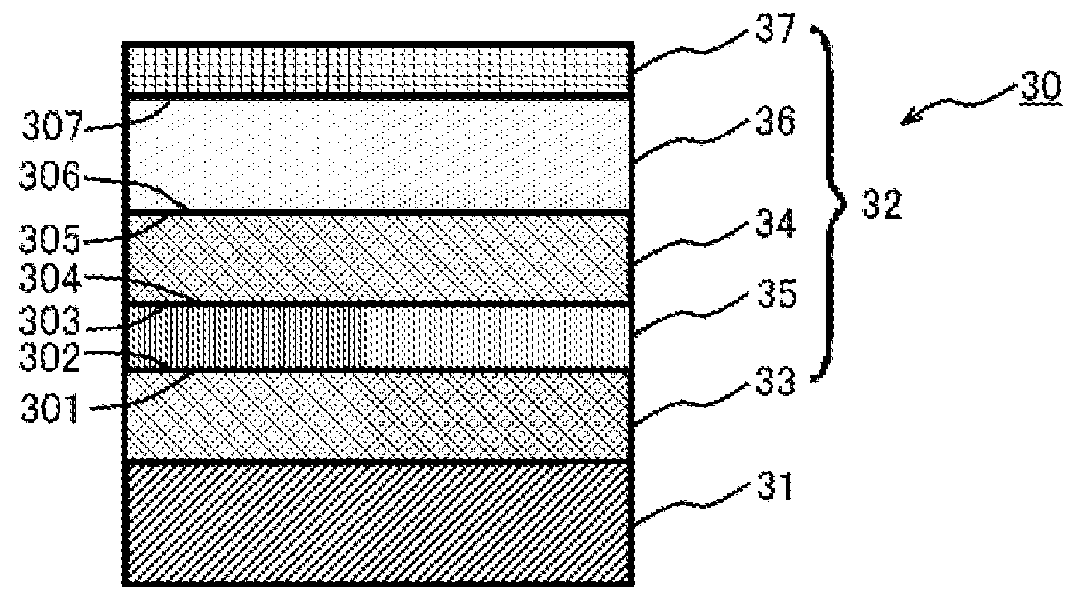

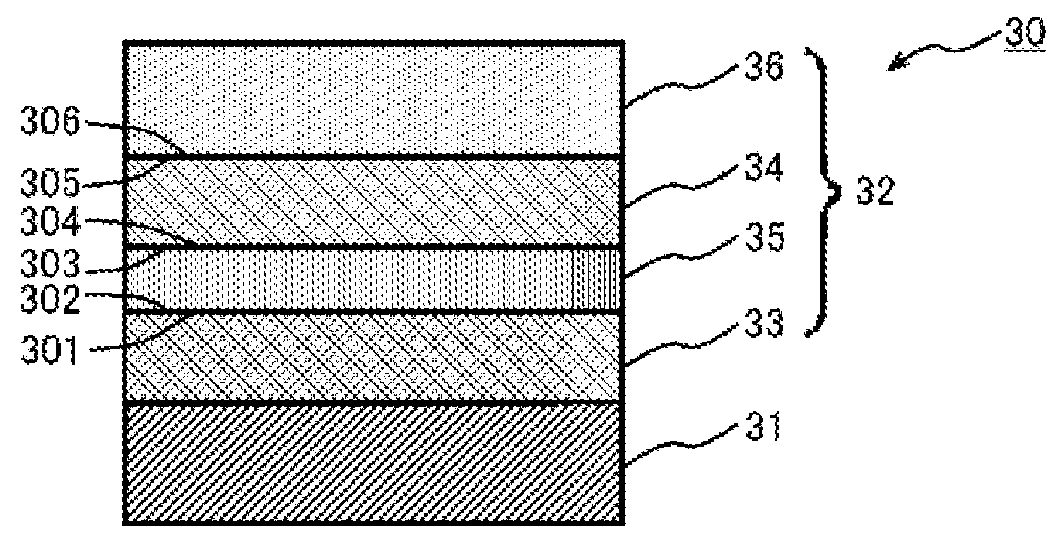

Display Panel Module and Manufacturing Method Therefor

InactiveUS20080055833A1Improve appearance qualityReduce manufacturing costSparking plugsDigital data processing detailsEngineeringSurface plate

A display panel module includes a display panel and a function film adhered onto the front surface of the display panel. The function film includes at least one transparent substrate and an adhesive layer which adheres the display panel and the function film together. A thickness of the at least one transparent substrate and a thickness of the adhesive layer have a predetermined relation so as to substantially prevent occurrence of a concave portion with a depth greater than 3 um on the front surface of the function film, wherein a scratch resistance of the function film is improved.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

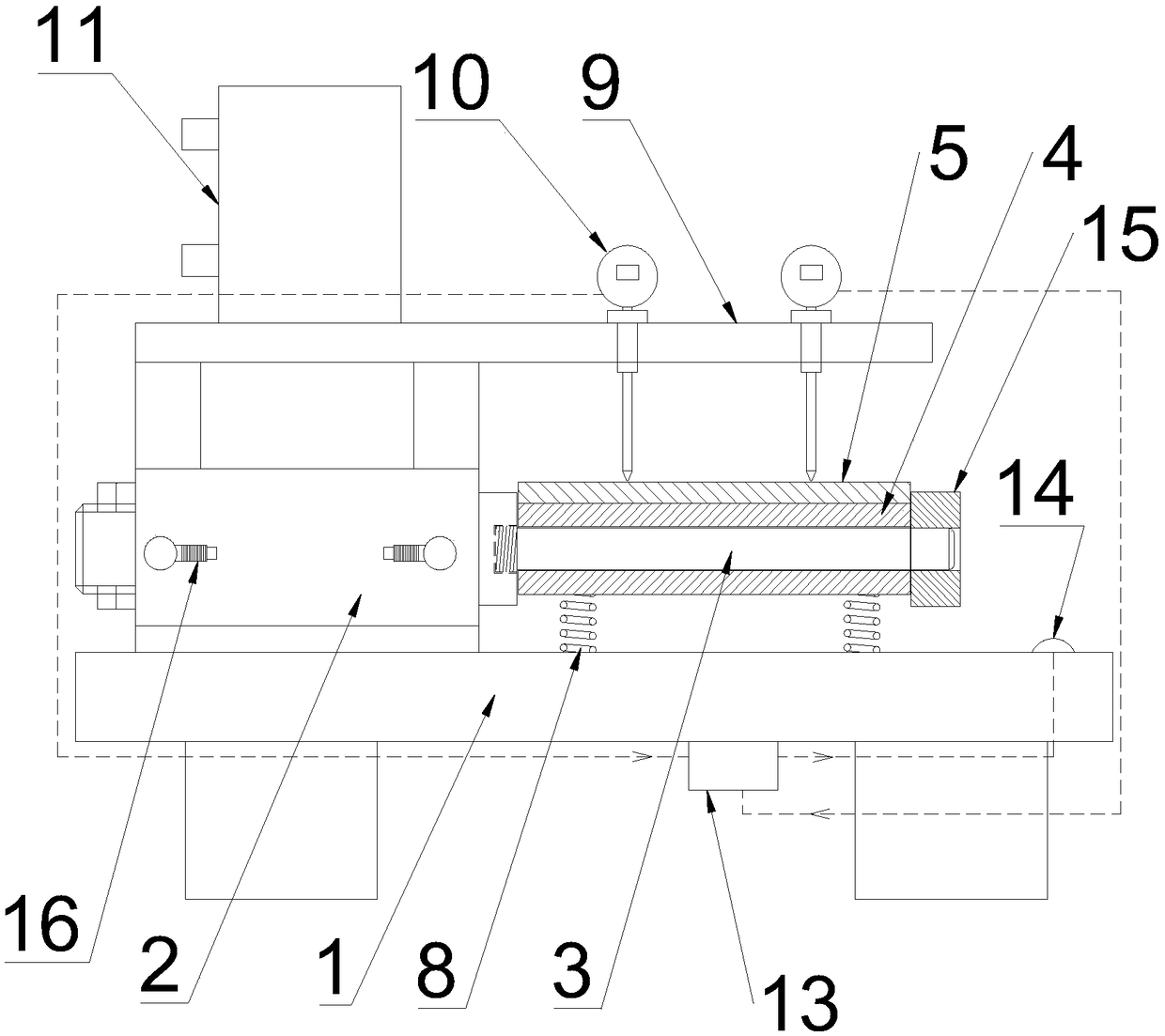

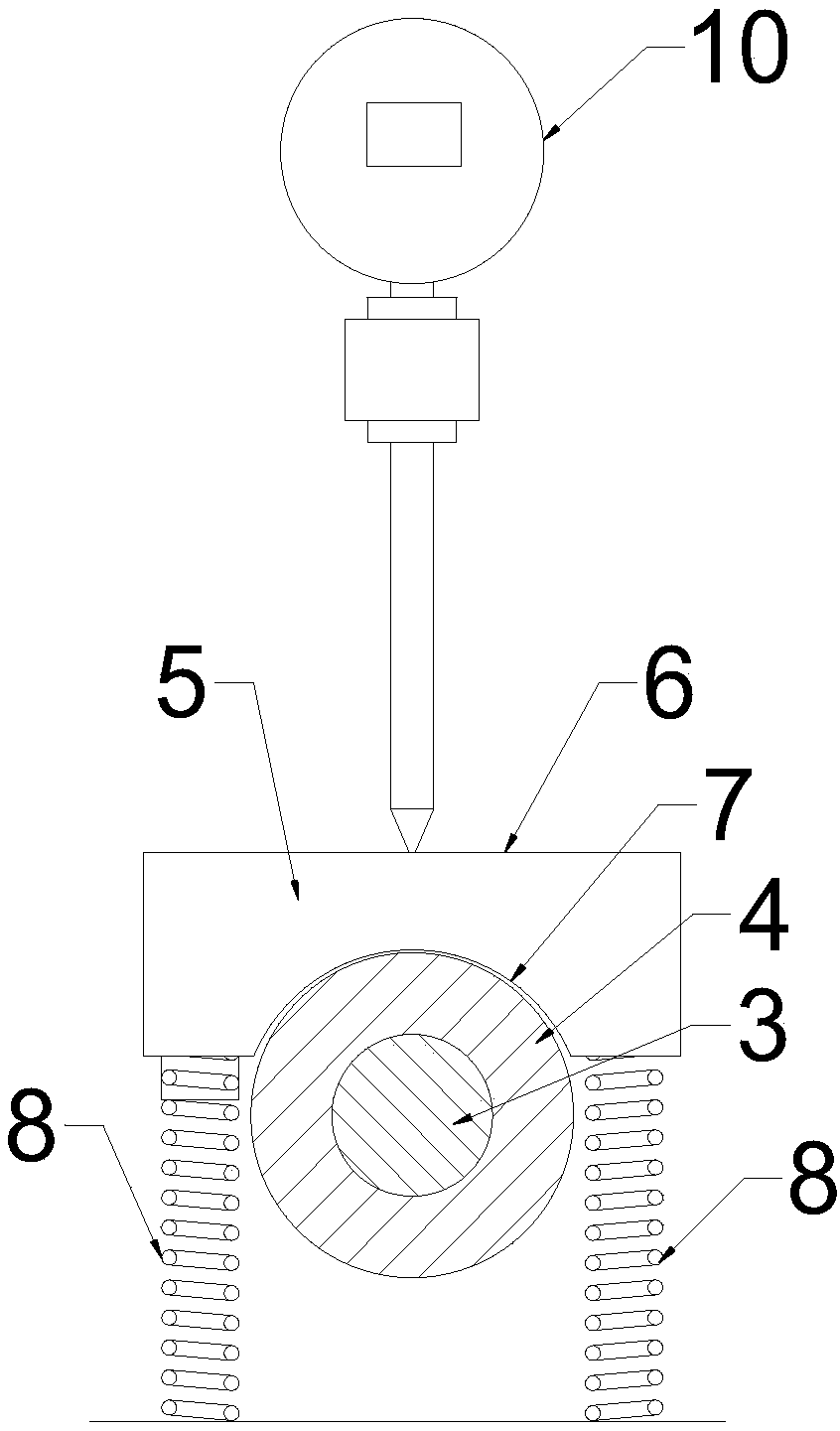

Coaxiality detection tool for transmission shaft

ActiveCN108844445AImprove balanceImprove detection accuracyMechanical measuring arrangementsDrive shaftAgricultural engineering

The invention provides a coaxiality detection tool for transmission shaft, which comprises a workbench, whereupon a rotating air cylinder is arranged, a workpiece fixing shaft is arranged on the output shaft of the rotary air cylinder, a transmission shaft is arranged on the fixed shaft of the workpiece, and the inner wall of the transmission shaft is in close contact with the surface of the workpiece fixing shaft; a balance block is arranged above the workpiece fixing shaft, the balance block comprises an upper plane and an inner concave arc-shaped limiting bottom surface which are horizontally arranged, the arc-shaped limiting bottom surface is coaxially arranged with the transmission shaft, and the transmission shaft can be embedded in the arc-shaped limiting bottom surface; a spring issymmetrically connected on the left and right sides of the bottom surface of the balance block, and the lower end of the spring is fixed on the workbench; also comprises a fixing frame, wherein the fixed frame is provided with a dial indicator, and the dial gauge of the dial indicator can be contacted with the upper plane of the balance block. The balance block of the invention converts the point-to-point instantaneous discrete type contact between the dial indicator and the transmission shaft into stable continuous contact of the point-to-surface of the transmission shaft, which improves thedetection precision, and the needle will not scratch the surface of the transmission shaft, thereby ensures the appearance quality of the transmission shaft.

Owner:DANYANG YABANG PRECISION MACHINERY

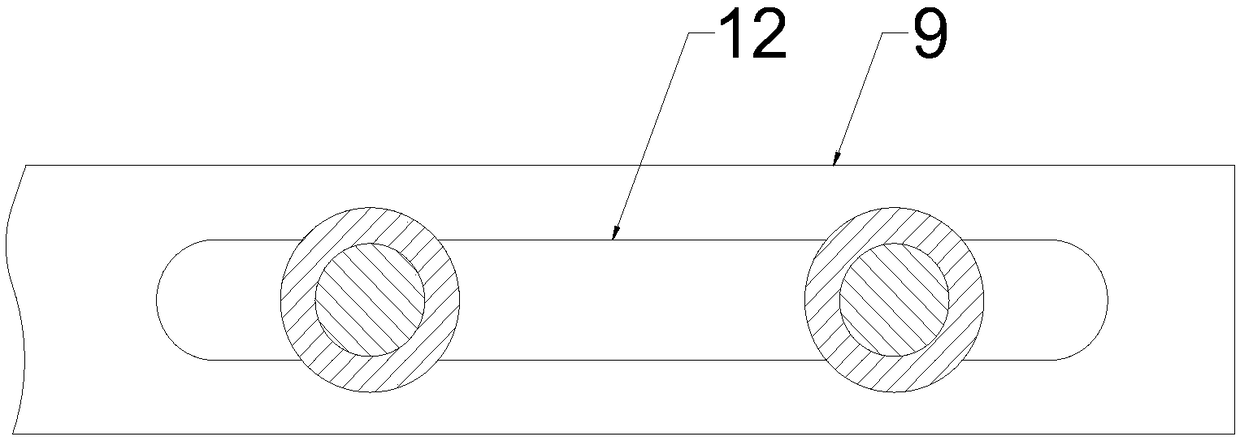

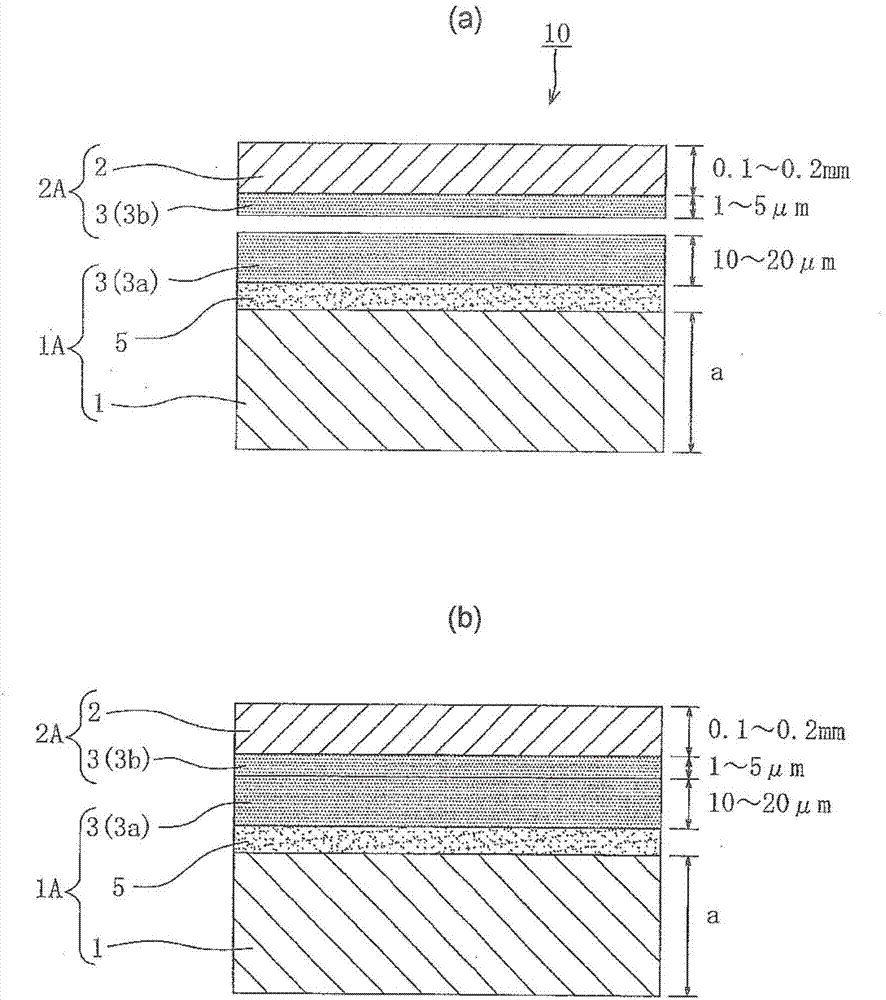

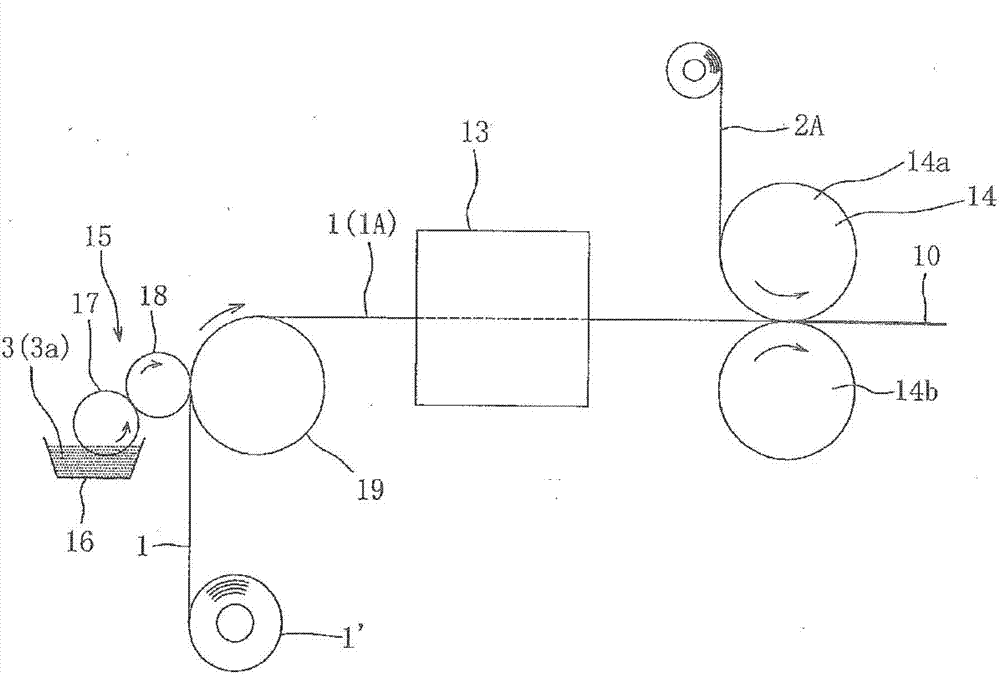

Metal sheet laminated with metal foil and method for manufacturing metal sheet laminated with metal foil

ActiveCN104203566AHigh bonding strengthReduce peelingLamination ancillary operationsLayered product treatmentCoated surfaceMetal foil

This metal sheet laminated with metal foil is formed by: placing, opposite each other, a thermosetting-adhesive-coated surface of each of a stainless steel foil having a thickness of 0.1 to 0.2 mm, to which a thermosetting adhesive has been applied in advance at a thickness of 1 to 5 mum and dried to the touch or is semi-cured, and a metal sheet to which a thermosetting adhesive with the same constituents as the aforementioned thermosetting adhesive has been applied with a coater at a thickness of 10 to 20 mum and heated to 150 to 250°C; and then feeding the stainless steel foil and metal sheet to a laminating roll so as to continuously bond said surfaces. The metal sheet laminated with metal foil is characterized in that the laminating adhesive strength of the stainless steel foil and the metal sheet is at least 50 N according to a peel test conducted at a width of 25 mm and 180°C.

Owner:NIPPON STEEL & SUMIKIN METAL PROD CO LTD

Method of applying a varnish to a component, in-particular to a vehicle headlight reflector

InactiveUS6773761B2Good application effectLimit tendencyPretreated surfacesInductances/transformers/magnets manufactureEngineeringSolvent

A method of applying a varnish, whether or not it includes a solvent, on a component, in particular a vehicle headlight reflector, comprises the following steps: (i) selecting a varnish having a viscosity at ambient temperature of about 500 to 2000 mPa.s, and a viscosity at the application temperature which is lower than about 200 mPa.s, with a viscosity which is substantially independent of variation in the temperature within the range of application; (ii) heating the surface of the component before the step of moistening the varnish at a selected temperature thetap1; (iii) heating the varnish at the moment of application to a selected temperature thetav; and (iv) during the spreading step, maintaining the component at a selected temperature thetap2 for a selected time tp2.

Owner:VALEO VISION SA

Portable information apparatus

ActiveUS10108224B2Guaranteed communication qualityControl appearance qualityAntenna supports/mountingsWing accessoriesCommunication qualityDisplay device

Owner:NEC PERSONAL COMPUTERS LTD

Decorative article having black hard coating film

ActiveUS20160053371A1Control appearance qualityImprove the decorative effectLayered productsChemical vapor deposition coatingDiamond-like carbonHydrogen content

Provided is a decorative article including a black hard coating film which is excellently inhibited from suffering a deterioration of appearance quality such as a scratch due to use thereof, and which has excellent decorativeness. The decorative article according to the present invention is a decorative article including: a base; and a black hard coating film which is formed on the base, and which includes diamond-like carbon, wherein the hydrogen content of a surface, reverse to a surface closer to the base, of the black hard coating film is more than the hydrogen content of the surface, closer to the base, of the black hard coating film; and the hydrogen content of the surface, reverse to the surface closer to the base, of the black hard coating film is 30.0 to 75.0 atm %.

Owner:CITIZEN WATCH CO LTD

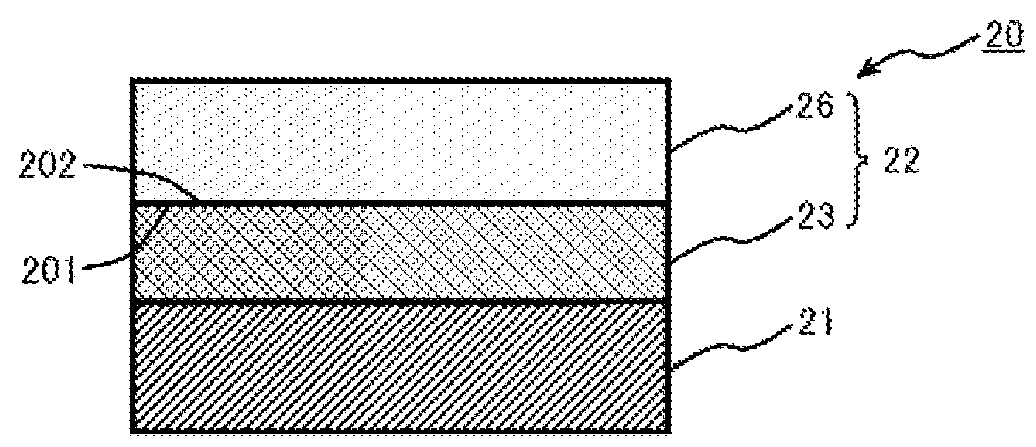

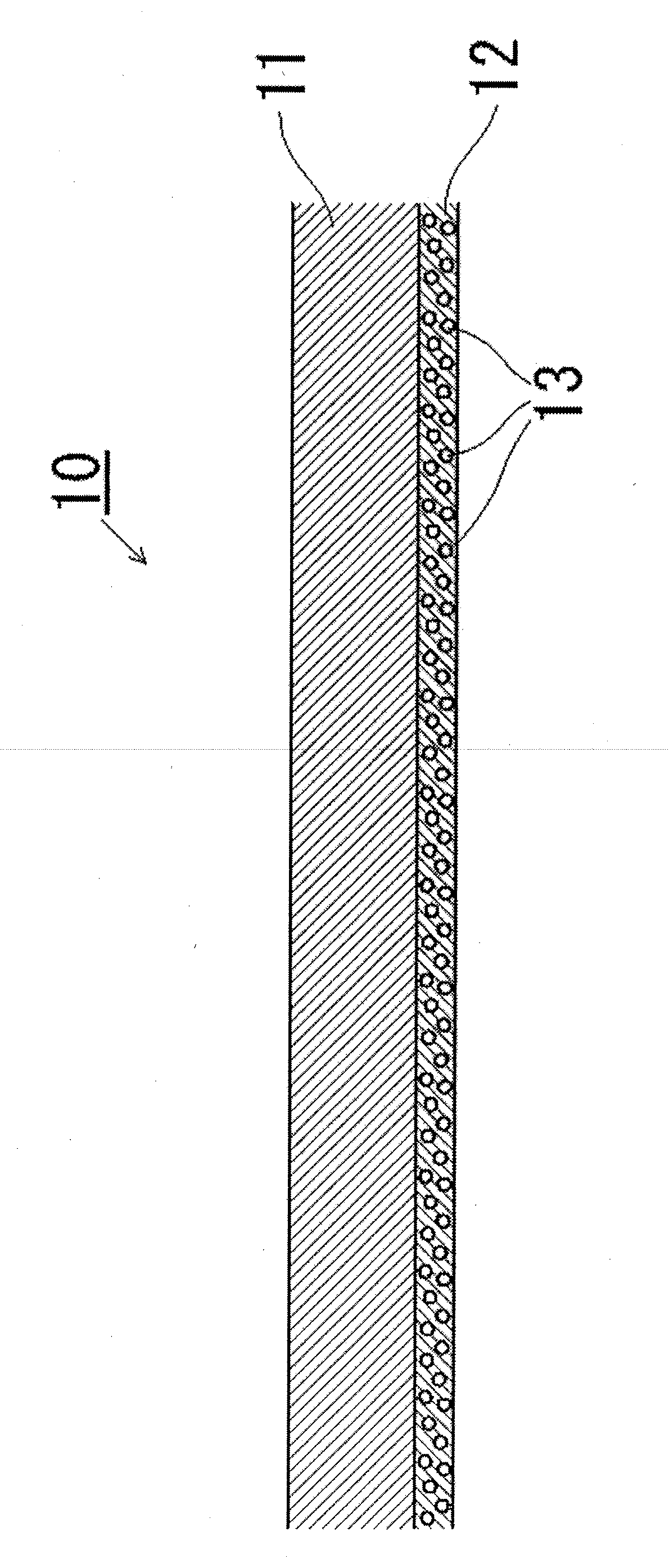

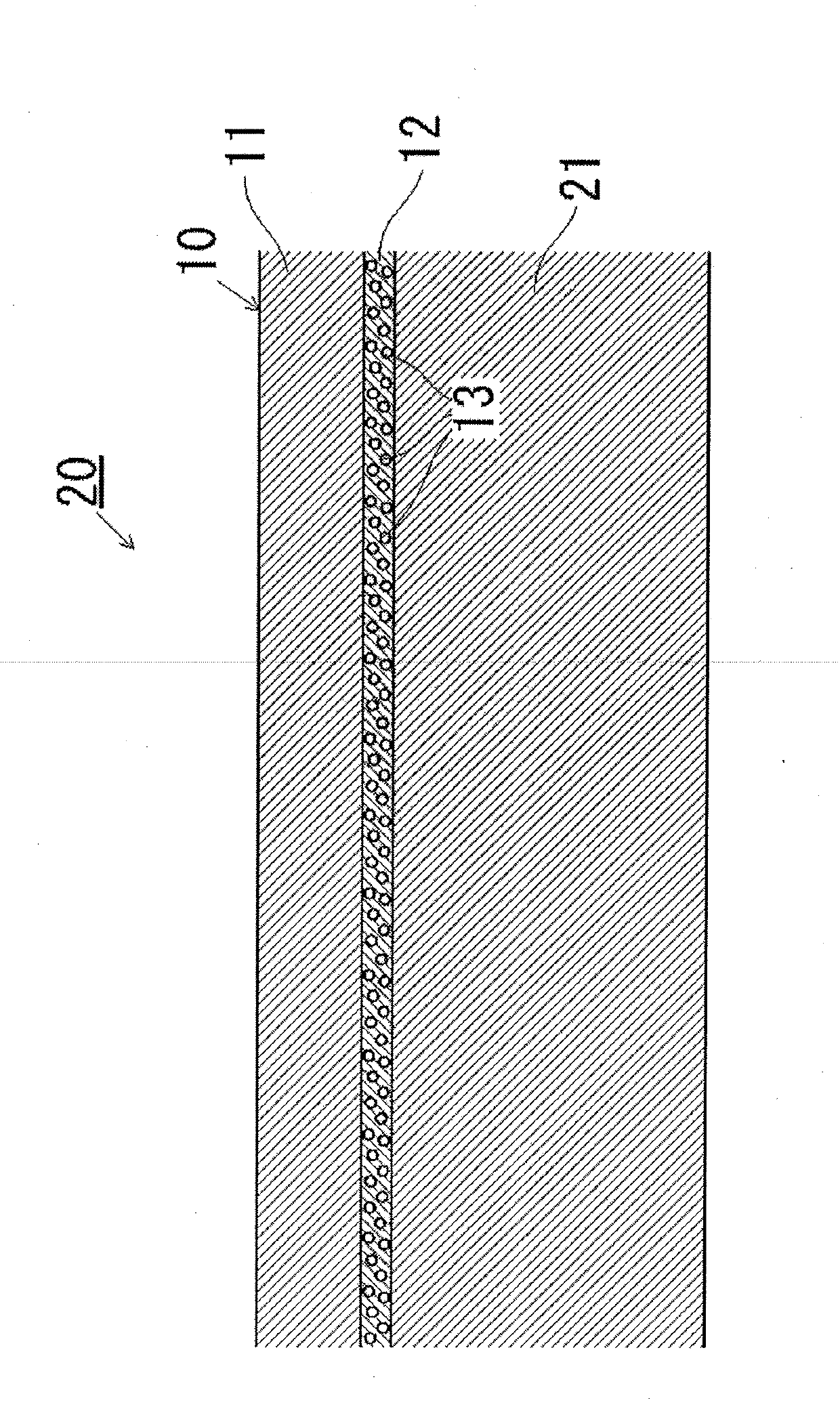

Sound-absorbing outer covering material and sound-absorbing material

ActiveUS20200055293A1Promote absorptionSuitable appearance qualitySynthetic resin layered productsSound proofingNonwoven fabricAcoustics

A sound-absorbing membrane and a sound-absorbing material, which can improve sound absorbing performance and can improve releasability, are provided. A sound-absorbing membrane 10 includes a base sheet 11 made of a nonwoven fabric impregnated with a water-soluble polymer, and a resin film 12 made of a thermosetting resin covering one surface of the base sheet 11, in which a thickness of the resin film 12 is 0.01 to 0.2 mm, fillers 13 are dispersed in the resin film 12, and a whole airflow resistance is 0.2 to 5.0 kPa·s / m. A sound-absorbing material 20 includes the sound-absorbing membrane 10, and a sound absorbing base sheet 21 made of a porous material, in which the sound-absorbing membrane 10 is laminated on a surface of the sound absorbing base sheet 21, and then formed into a predetermined shape.

Owner:NAGOYA OIL CHEM CO LTD

Process for processing anti-wave seal head of tank container

InactiveCN104308030AGuarantee molding qualityGuaranteed appearance size requirementsHollow articlesPunchingTank container

The invention relates to a process for processing the anti-wave seal head of a tank container. The process comprises the following steps: performing discharge design; selecting and using a steel plate; discharging and cutting; forming the seal head; forming a groove; forming a hole; punching; performing acid-pickling. According to the process, the high-quality steel plate is selected and used to guarantee the forming quality of the seal head; after the process is changed, the seal head can be made by the whole plate without welding, so that the appearance quality of the seal head due to welding is prevented from being reduced; an accurate mould is selected and used to guarantee the appearance and size requirements of the seal head; a special punching mould is used to guarantee the accuracy of the central hole of the seal head; the seal head does not need to be cut by a customer during the later period, so that materials and resources are reduced by 40%.

Owner:CHANGZHOU KUANGDA WEIDE MACHINERY

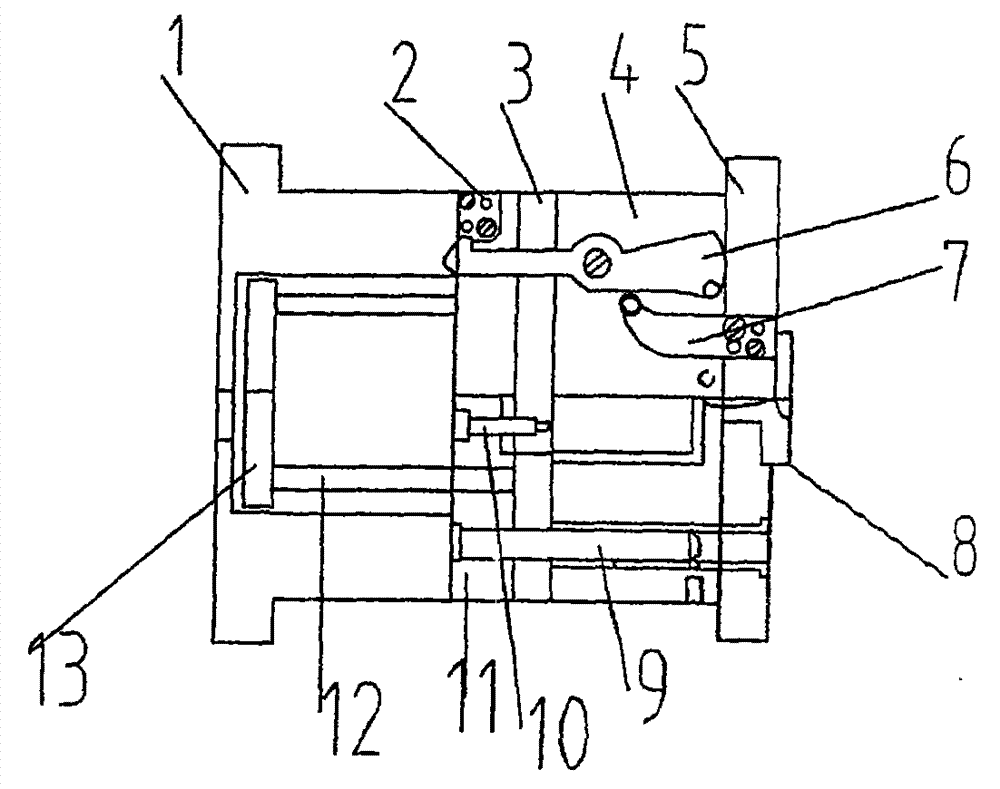

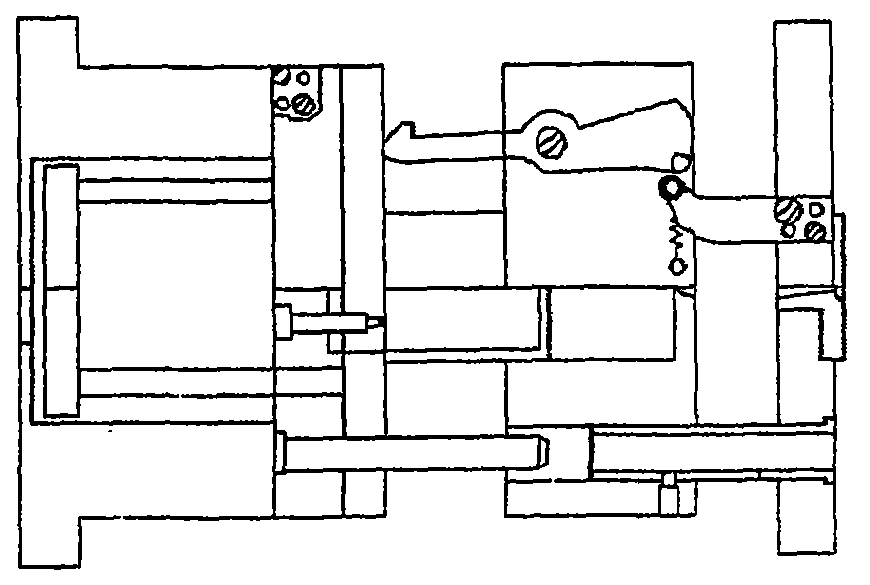

Metal pressure casting die swing hook dual-division swage die mechanism

A metal pressure casting die swing hook dual-division swage die mechanism comprises a die fixed clamping plate, a fixed die plate, a moving die plate, a moving die base plate, a moving clamping plate, a push plate arranged inside the die and a venting pin, a swing hook (6) is movably connected onto the outer side face of the fixed die plate(4) through screws, a pulling hook (7) is fastened onto the outer side face of the fixed clamping plate (5), a limited block (2) is fastened onto the outer side face of the moving die plate (11), the swing hook (6) and the limited block (2) are in buckled fitting, and a roller on the swing hook (6) and a roller on the pulling hook (7) are in sliding fitting. The action of the swing hook and the action of the pulling hook are adopted in the die, so that when the die is opened, a sprue of a gating system is automatically cut off, the problem that a sprue cannot be cut off automatically in a metal pressure casting die is solved, meanwhile, the design is optimized, it is achieved that the structure is simple, the sprue is cut off by utilizing the time of die opening, clotted materials fall out of the die as a result of the self weight, the motion is firm and reliable, and the demoulding is conducted smoothly.

Owner:牟维军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com