White automobile body tail doorframe checking tool and tail doorframe size detection method

A detection tool and size detection technology, which is applied in the field of car body manufacturing, can solve the problems of increased site costs, high cost of laser scanning point detectors, and inability to measure online, achieving the effect of high relative position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

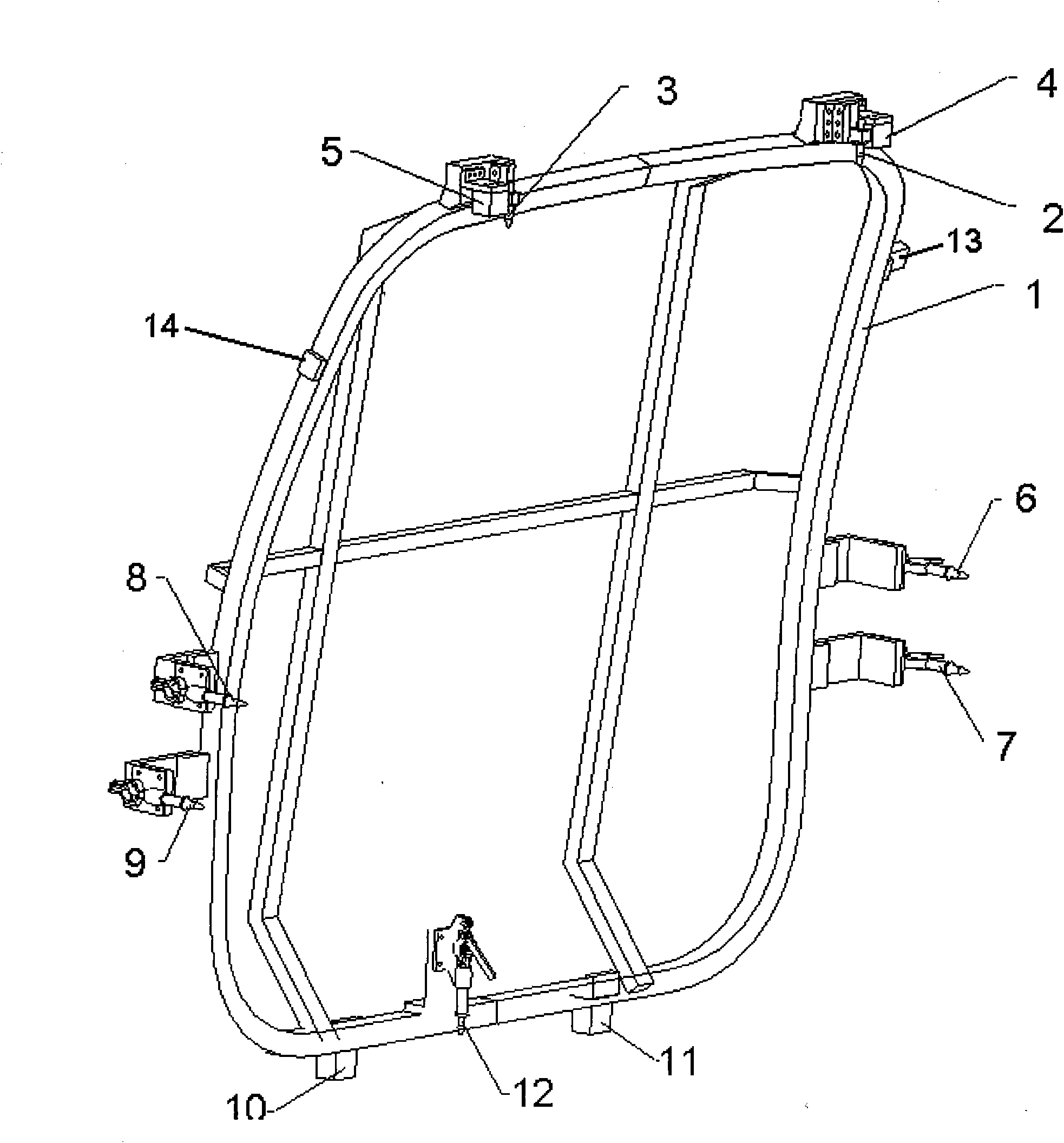

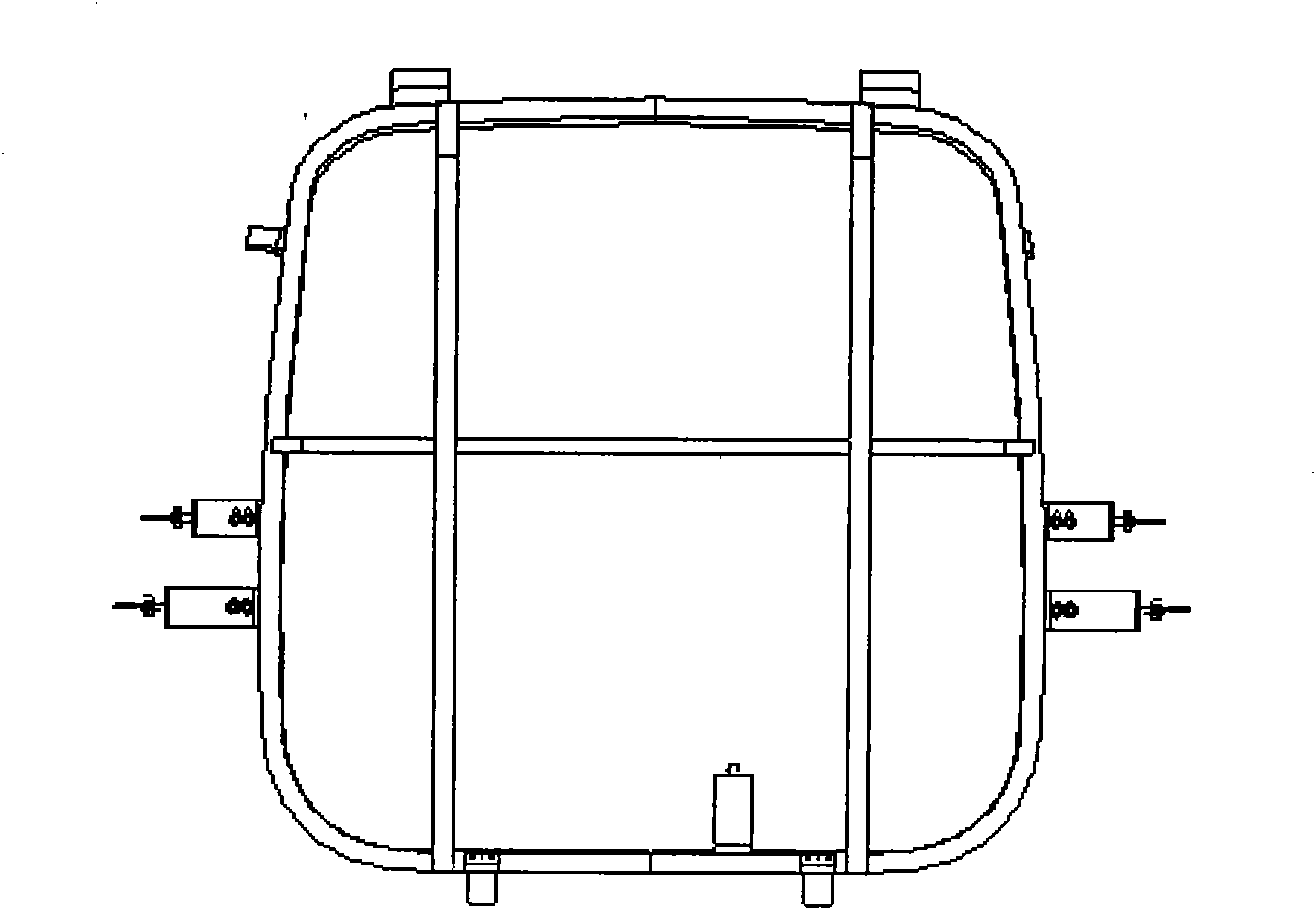

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

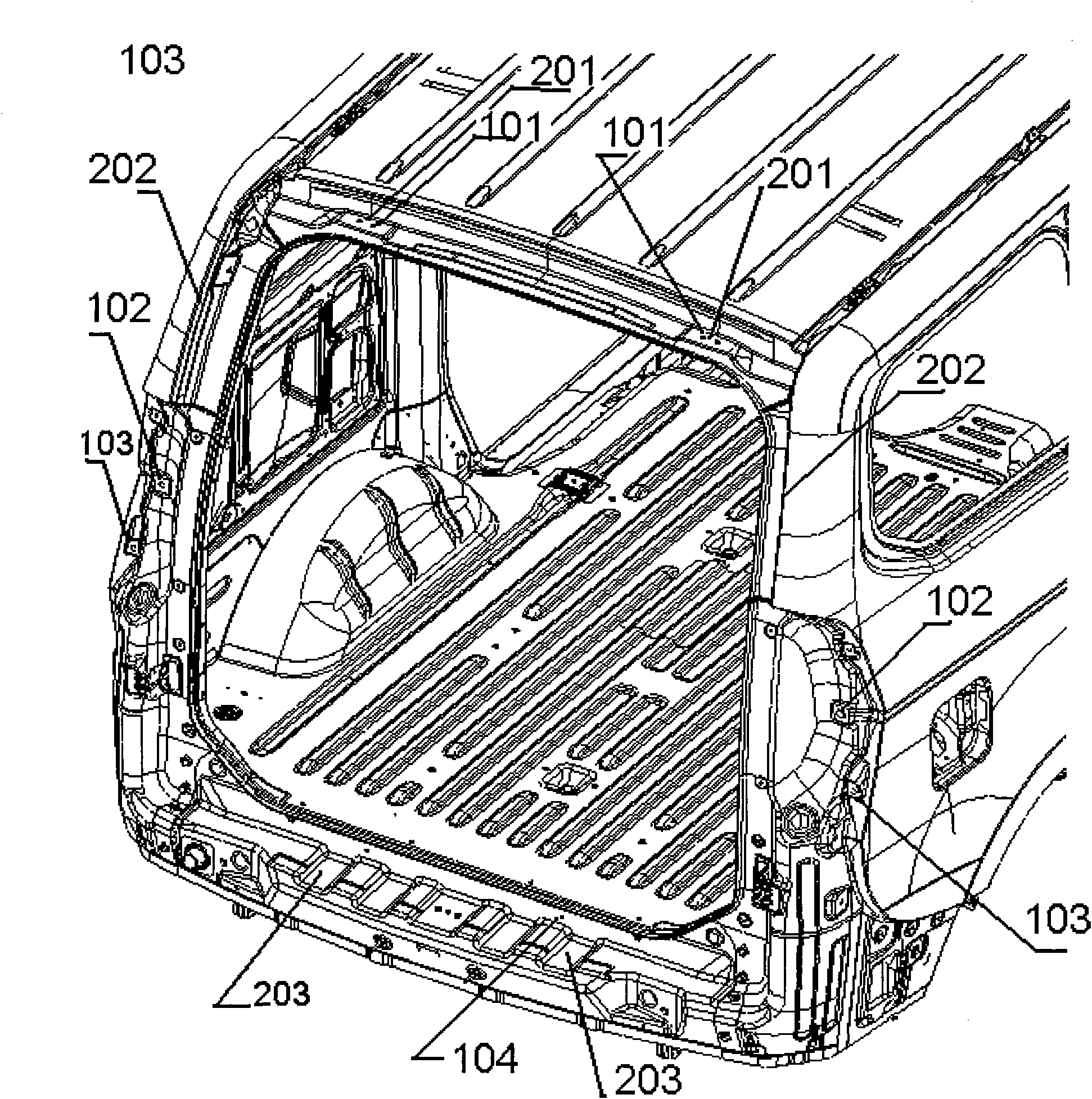

[0030] Such as figure 1 shown, select figure 1 The shown tailgate hinge mounting hole 101 and the mounting surface 201 of the tailgate hinge are used as the positioning reference of the measuring tool, and the process hole 104 on the rear floor part of the vehicle is an auxiliary positioning reference. The measurement elements are surfaces: the profile 202 of the upper part of the car D-pillar, the profile 203 of the rear end plate;

[0031] The reasons for choosing the mounting hole 101 of the tailgate hinge and the mounting surface 201 of the tailgate hinge as the positioning reference are:

[0032] The mounting surface of the tailgate hinge is flat, which is beneficial to the positioning of the measuring tool.

[0033] The tailgate hinge mounting hole 101 is a hole that is stamped and formed simultaneously on a single piece of the top cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com