Robot workpiece assembly and form and location tolerance detection system and method based on face laser sensor

A shape tolerance and detection system technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of high cost of binocular vision detection methods, complicated hand-eye calibration, shape and position tolerance of key points, etc., to achieve convenient information The effect of centralized management, strong scalability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

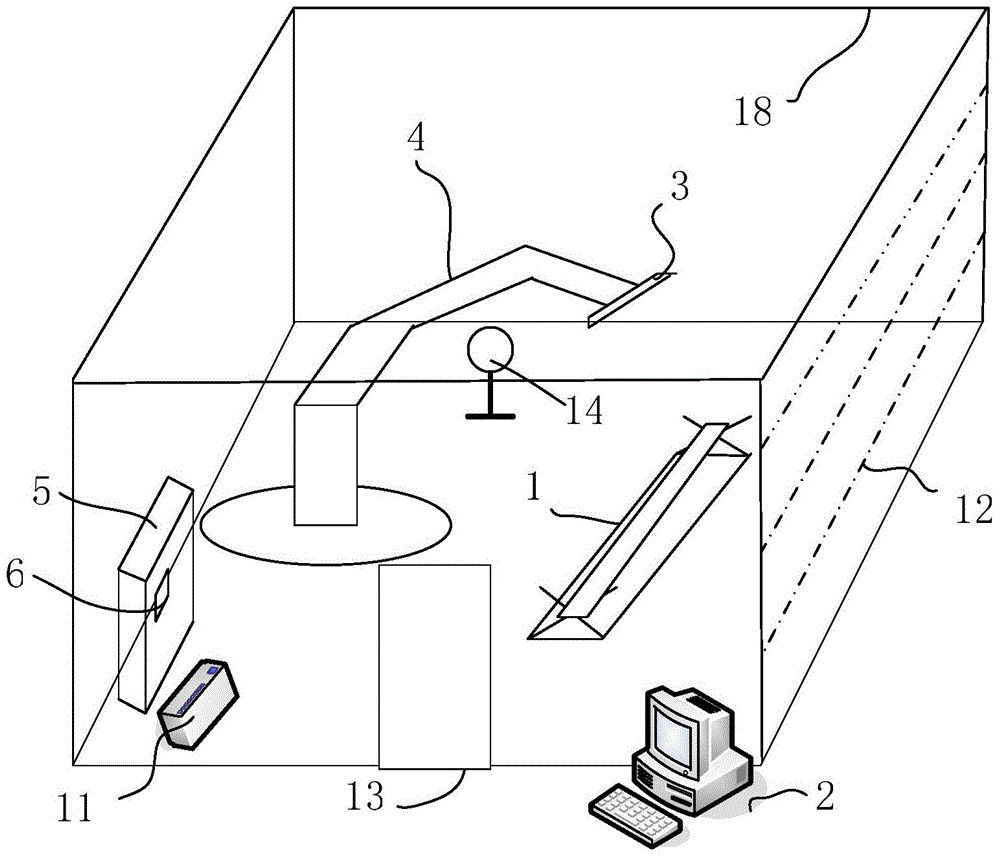

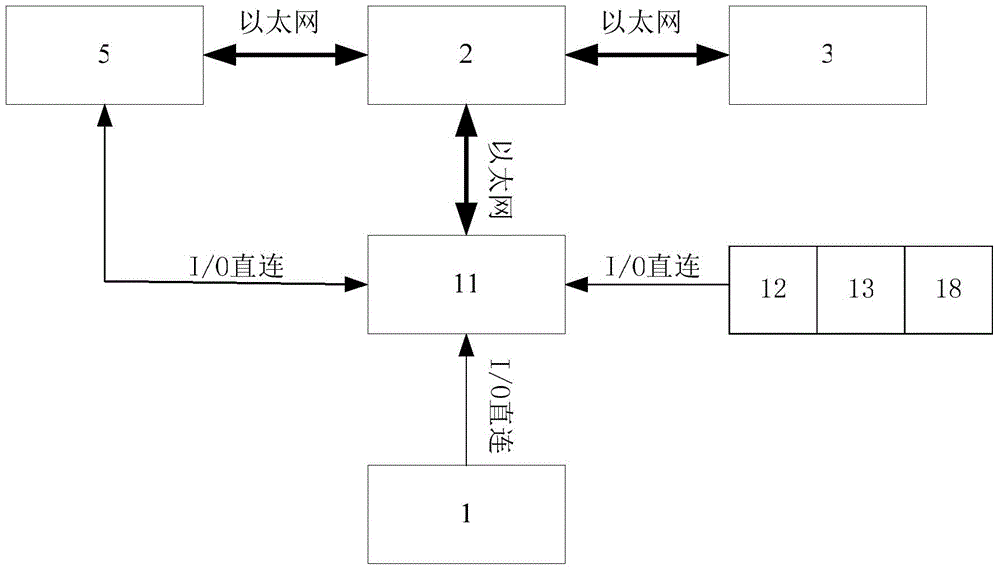

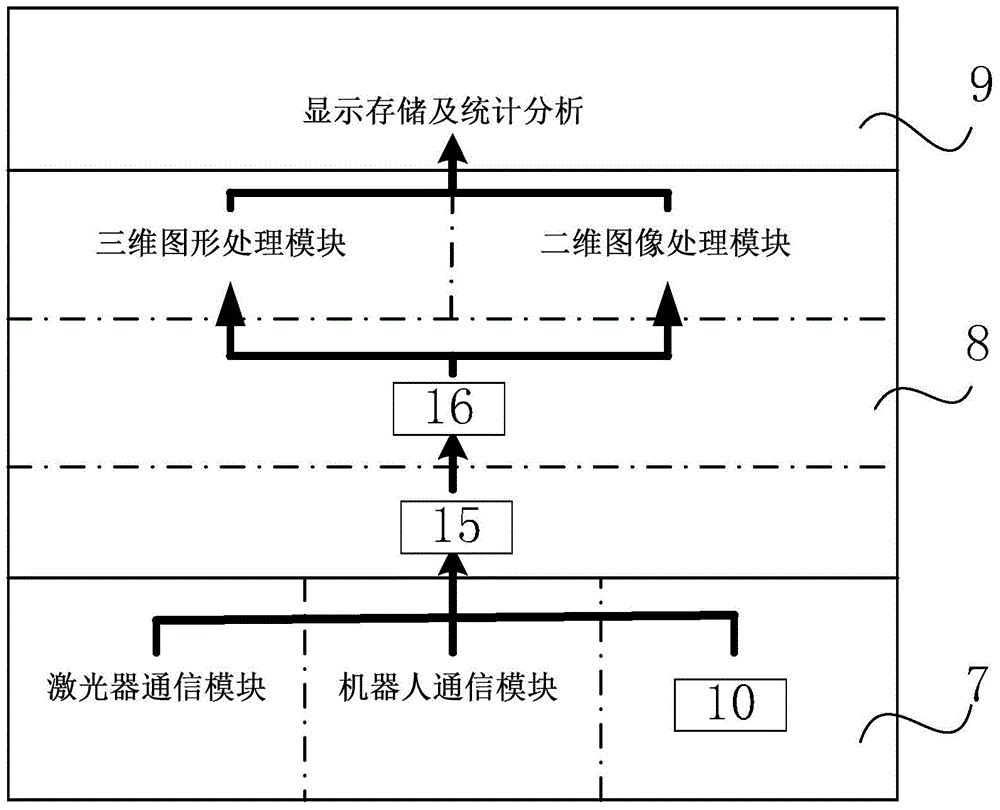

[0028] Such as Figure 1~5 The shown robot workpiece assembly and geometric tolerance detection system based on the surface laser sensor includes a positioning component 1 for clamping the measured workpiece. The difference is that the positioning component 1 is preferably a tooling fixture, and its periphery is It is composed of a surface laser sensor 3, a robot device and an industrial computer 2 that communicate with each other. Specifically, the surface laser sensor 3 is installed at the end of the robot body 4, and the robot body 4 carries it to collect three-dimensional data on the surface of the workpiece at the measured position within the movement range of the robot body 4. As a result, the surface laser sensor 3 also collects grayscale image data while collecting three-dimensional data on the workpiece surface. The collected three-dimensional data on the workpiece surface is used for shape and position tolerance detection of key points of the workpiece, and the colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com