Metal sheet laminated with metal foil and method for manufacturing metal sheet laminated with metal foil

A technology of metal foil layer and metal plate, which is applied in the manufacture of metal foil laminated metal plates, and in the field of metal foil laminated metal plates, can solve problems such as the unimaginable manufacture of such a wide decorative metal plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

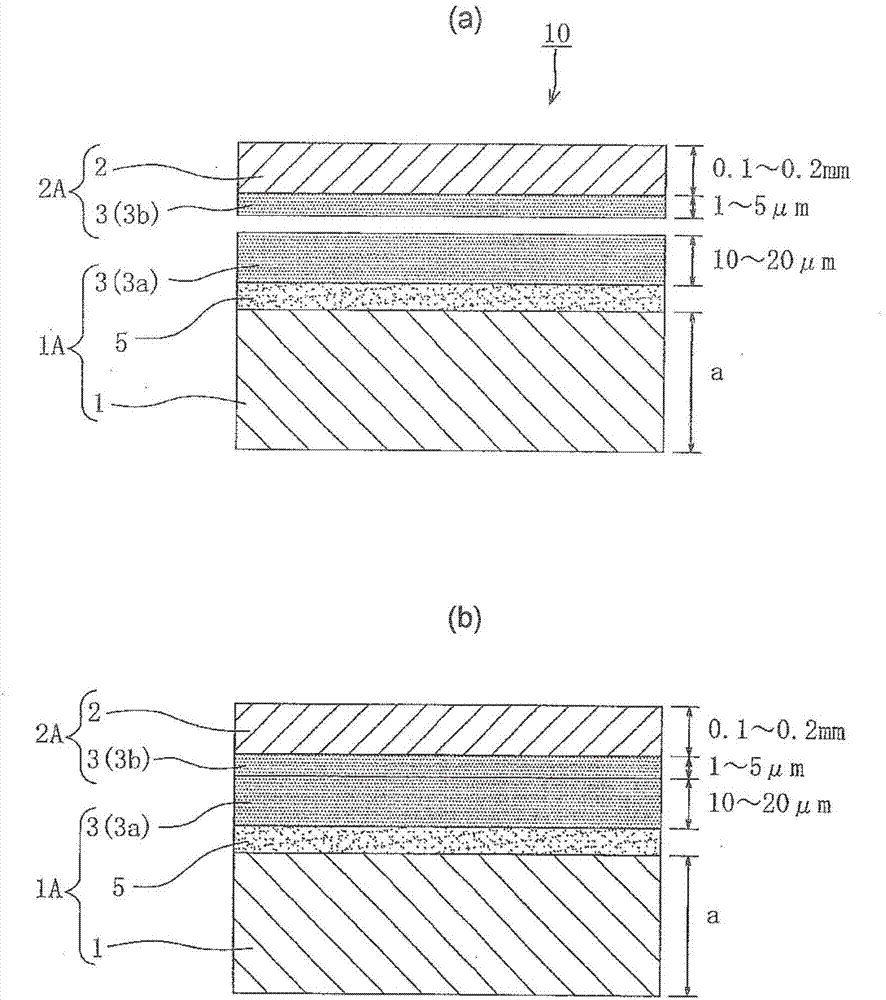

[0068] Tables 1 to 6 show properties of samples (metal foil-laminated metal sheets) produced under various conditions in order to obtain the above-mentioned metal foil-laminated metal sheets of the present invention.

[0069] All of the metal sheets of the samples were hot-dip galvanized steel sheets subjected to chromate treatment as the surface treatment. Metal foil is stainless foil.

[0070] The binder used was the thermosetting polyester resin described in paragraph number [0019].

[0071] All the adhesive strength tests were performed by the 180 degreeC peeling test in 25 mm width based on JISZ0237.

[0072] In the expansion molding process for confirming the adhesive strength, a 6 mm extrusion was performed by the JIS Z 2247 Erichsen test method, and it was confirmed whether the stainless foil peeled off.

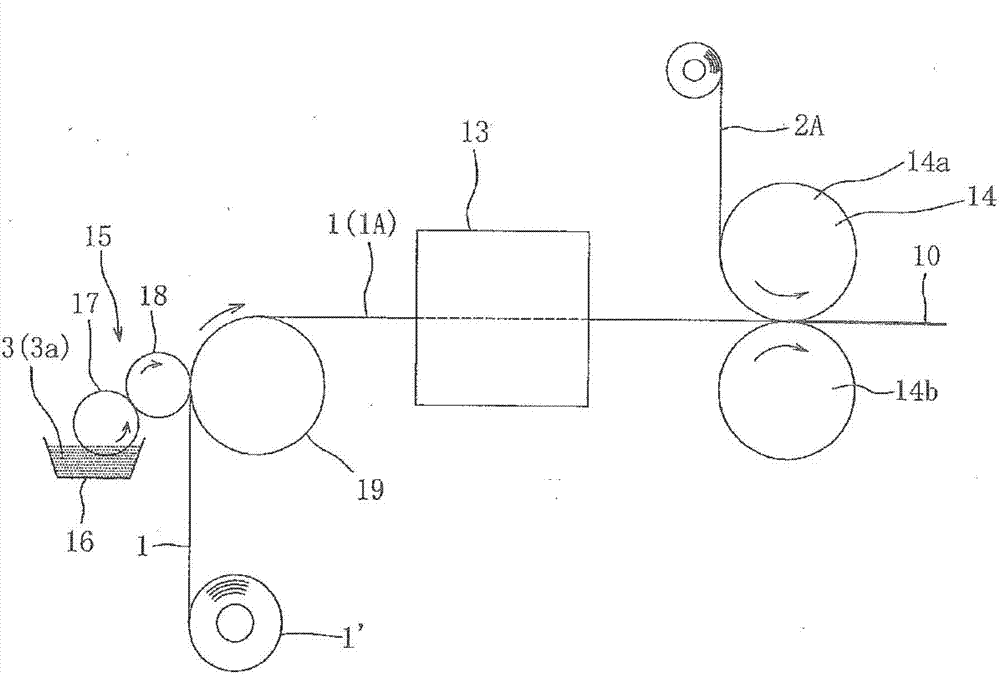

[0073] Table 1 shows the results of experiments for investigating the influence of lamination temperature. That is, the heating temperature of the metal plate is ...

Embodiment 2

[0087] Table 2 shows the experimental results for investigating the influence of the temperature of the lamination roll. That is, the experimental results of various samples obtained by laminating metal plates and stainless foils by changing the temperature of the lamination roll as a parameter in the range of 25°C to 200°C, and keeping other conditions approximately constant. .

[0088] In this case, regarding the metal plate, the thickness of the metal plate is mainly 0.4 mm (there are four other samples with a thickness of 0.6 to 1.2 mm), the thickness of the adhesive is 10 μm, and the heating temperature is mainly 150°C (other The temperature is 160°C, 180°C and 190°C each). Regarding the stainless foil, the plate thickness is 0.1 mm, and the adhesive thickness is 1 μm.

[0089] As shown in the column of adhesive strength in Table 2, when the temperature of the laminating roll was not 70° C., the adhesive strength in the peel test was less than 40 N, and the adhesive str...

Embodiment 3

[0099] Table 3 shows the results of experiments investigating the effect of the thickness of the metal sheet adhesive. That is, various experiments were made by laminating the metal plate and the stainless foil by changing the thickness of the adhesive applied to the metal plate as a parameter in the range of 4 μm to 20 μm, and keeping other conditions approximately constant. Such experimental results.

[0100] In this case, regarding the metal plate, the thickness of the metal plate is mainly 0.4 mm (there are 5 other samples having a thickness of 0.8 to 2.3), and the metal plate heating temperature is 150°C. Regarding the stainless foil, the plate thickness is 0.1 mm, and the adhesive thickness is 1 μm. The lamination roll temperature was 70°C.

[0101] As shown in the column of adhesive strength in Table 3, when the thickness of the metal plate adhesive is less than 10 μm, the adhesive strength is less than 40 N, so the adhesive strength is insufficient, and the result of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com