Silicified microcrystalline cellulose composite auxiliary material and preparation method thereof

A technology of microcrystalline cellulose and composite excipients, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, pill delivery, etc., which can solve the problem of uneven mixing of mixed materials and the inability to meet the requirements of direct powder compression, etc. problems, to achieve the effect of reducing friability, increasing hardness and smoothness, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

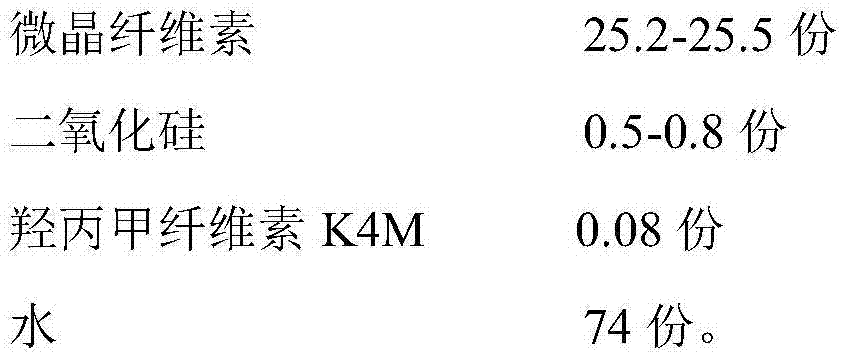

[0026] A kind of silicified microcrystalline cellulose composite auxiliary material of the present invention and preparation method thereof, its component and quality are as follows:

[0027] Weigh 25.2kg of microcrystalline cellulose, 0.5kg of silicon dioxide, 0.08kg of hypromellose K4M, and 74kg of water. Among them, microcrystalline cellulose, silicon dioxide, and hypromellose come from Anhui Shanhe Pharmaceutical Excipients Co., Ltd.

[0028] The preparation method of the silicified microcrystalline cellulose composite auxiliary material of the present embodiment, its preparation method is:

[0029] ① Mixing: After dissolving the hypromellose K4M and water in the above-mentioned weighed raw materials, put them into a U-shaped blender, put the weighed silicon dioxide into the blender, turn on the blender and stir for 10 minutes, and continue to Drop into the weighed microcrystalline cellulose and stir for 50 minutes to form a uniform suspension A;

[0030] ②Centrifugal sp...

Embodiment 2

[0036] A kind of silicified microcrystalline cellulose composite auxiliary material of the present invention and preparation method thereof, its component and quality are as follows:

[0037] Weigh 25.5kg of microcrystalline cellulose, 0.8kg of silicon dioxide, 0.08kg of hypromellose K4M, and 74kg of water.

[0038] The preparation method of the silicified microcrystalline cellulose composite auxiliary material of the present embodiment, its preparation method is:

[0039] ① Mixing: After dissolving the hypromellose K4M and water in the above-mentioned weighed raw materials, put them into a U-shaped blender, put the weighed silicon dioxide into the blender, turn on the blender and stir for 25 minutes, and continue to Drop into the weighed microcrystalline cellulose and stir for 40 minutes to form a uniform suspension A;

[0040] ②Centrifugal spray drying: Turn on the high-speed centrifugal spray dryer, set the air inlet temperature to 160 degrees, and the outlet temperature t...

Embodiment 3

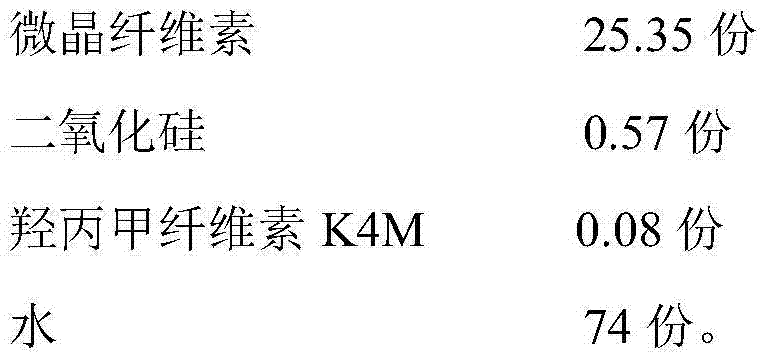

[0046] A kind of silicified microcrystalline cellulose composite auxiliary material of the present invention and preparation method thereof, its component and quality are as follows:

[0047] Weigh 25.35kg of microcrystalline cellulose, 0.57kg of silicon dioxide, 0.08kg of hypromellose K4M, and 74kg of water.

[0048] The preparation method of the silicified microcrystalline cellulose composite auxiliary material of the present embodiment, its preparation method is:

[0049] ① Mixing: After dissolving the hypromellose K4M and water in the above-mentioned weighed raw materials, put them into a U-shaped blender, put the weighed silicon dioxide into the blender, turn on the blender and stir for 30 minutes, and continue to Drop into the weighed microcrystalline cellulose and stir for 60 minutes to form a uniform suspension A;

[0050] ②Centrifugal spray drying: Turn on the high-speed centrifugal spray dryer, set the air inlet temperature to 160 degrees, and the outlet temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com