Calcium carbonate vitamin D3 composition and water-free-swallowing granules thereof

A vitamin and calcium carbonate technology, applied in the directions of aluminum/calcium/magnesium active ingredients, medical preparations with non-active ingredients, organic active ingredients, etc., can solve the problems of easy degradation of vitamin D3, inaccurate preparations, etc. Difficulty swallowing, suitable for a wide range of people, good taste of the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

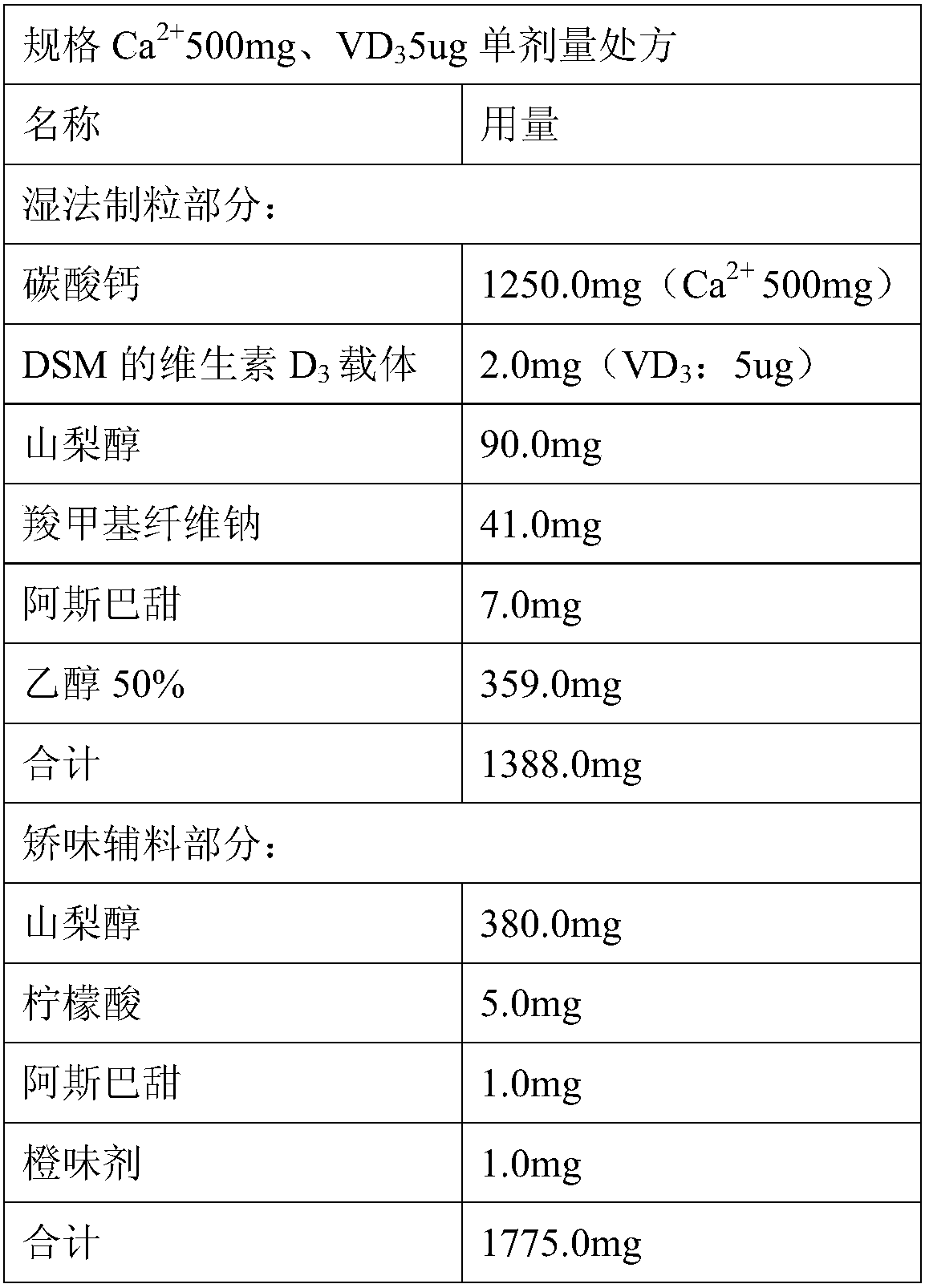

[0032] According to the dosage of 500 units, the feeding is carried out:

[0033]

[0034]

[0035] Preparation Process:

[0036] 1. Wet granulation: mix calcium carbonate, sorbitol, sodium carboxymethyl cellulose, aspartame, etc. in a wet granulator to mix the materials, add 50% ethanol solution by spraying, and make The material is formed into sand grains to ensure the formability of the particles after the material is dried. Use a 20-mesh sieve for wet granulation.

[0037] Wherein, before mixing, the calcium carbonate is passed through a 100-mesh sieve, and the sorbitol is crushed through a 60-mesh sieve to ensure that the materials are evenly mixed.

[0038] 2. Drying: Control the material temperature: 40-50°C, control the dry moisture at the end of granulation: 1%-3%, and granulate the obtained granules through a 20-mesh sieve.

[0039] 3. Final mixing: adding flavoring auxiliary materials and mixing to obtain calcium carbonate vitamin D3 anhydrous swallowable g...

Embodiment 2

[0043] prescription:

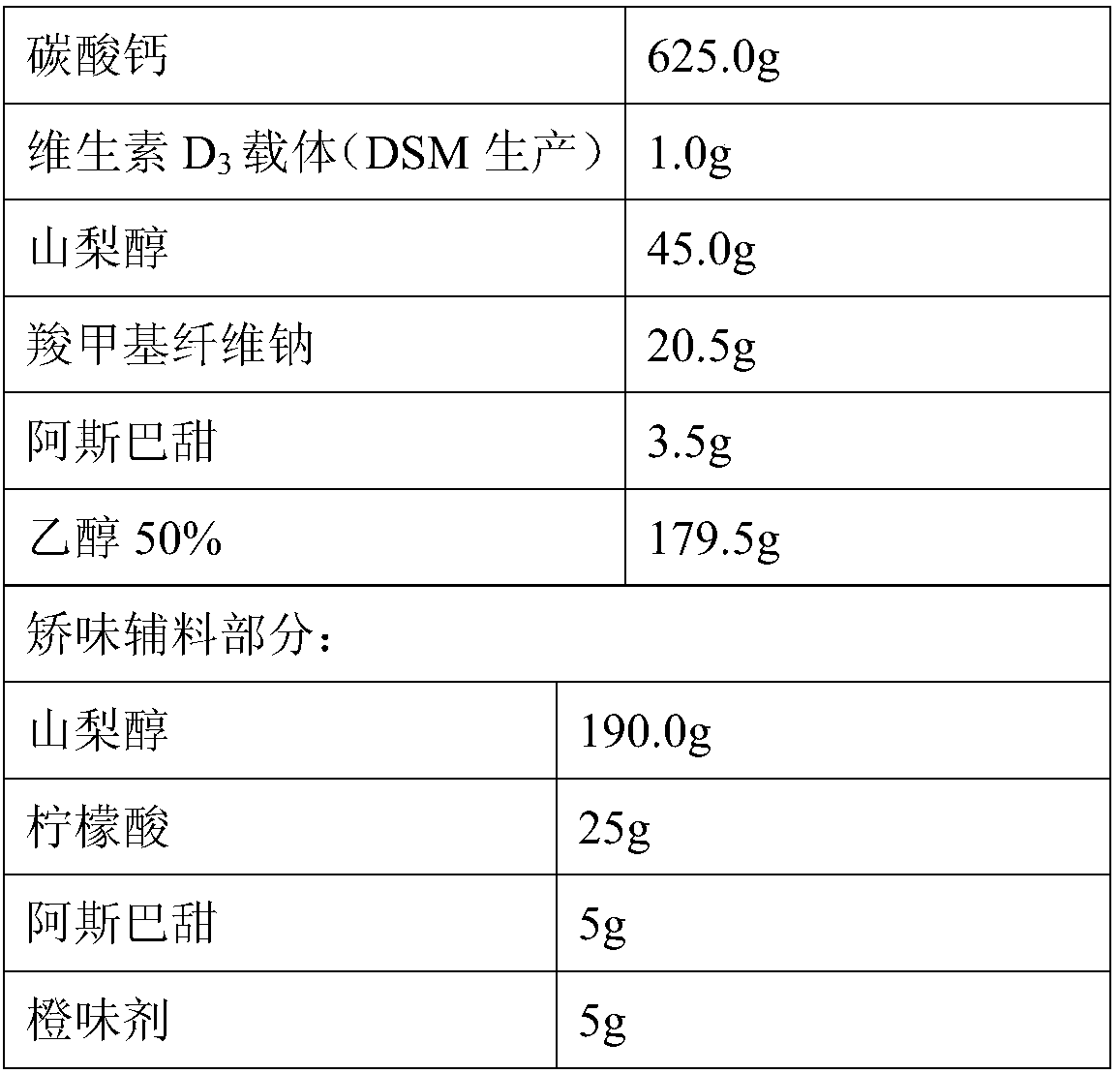

[0044] According to the dosage of 400 units, the feeding is carried out:

[0045]

[0046] Preparation Process:

[0047] Mix calcium carbonate, sorbitol, starch 1500, and VD3 carrier in a wet granulator, add soft material made of 65% ethanol, and granulate with a 20-mesh sieve. Add maltodextrin 19D and citric acid into purified water to prepare a 50% top spray granulation solution, control the temperature in the fluidized bed top spray granulator at 40-50°C to top spray granulate the soft material, and control the temperature after drying. Moisture is 1%-3%. Sorted with a 20-mesh sieve, added sorbitol, sodium carboxymethylcellulose 7H4XF, citric acid, sucralose, and orange flavor, and mixed for 5 minutes.

[0048] Wherein, the sorbitol is crushed and passed through an 80-mesh sieve, and the citric acid is crushed and passed through a 60-mesh sieve.

[0049] The finished product has uniform granules, slightly cool taste, smooth swallowing, and good t...

Embodiment 3

[0051] According to the dosage of 400 units, the feeding is carried out:

[0052] prescription:

[0053]

[0054]

[0055] Preparation Process:

[0056] Same as Example 2 preparation process.

[0057] Among them: the wet granulation part of the sorbitol particle size is below 80 mesh sieve; the fluidized bed granulation process, the taste-masking auxiliary material is used to coat the granules. The particle size of citric acid and sorbitol for flavoring should be over 60 mesh after pulverization.

[0058] Result: uniform taste, smooth swallowing without water, and good flavor modification effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com