Construction method for prefabricated box girder

A construction method and box girder technology, which is applied in the direction of manufacturing tools, ceramic molding machines, mold fixing devices, etc., can solve the problems of difficult adjustment of formwork seams and flatness, easy falling of welding slag or sundries, and appearance quality of prefabricated box girders Reduce problems, achieve the effect of improving appearance and installation quality, improving appearance quality, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

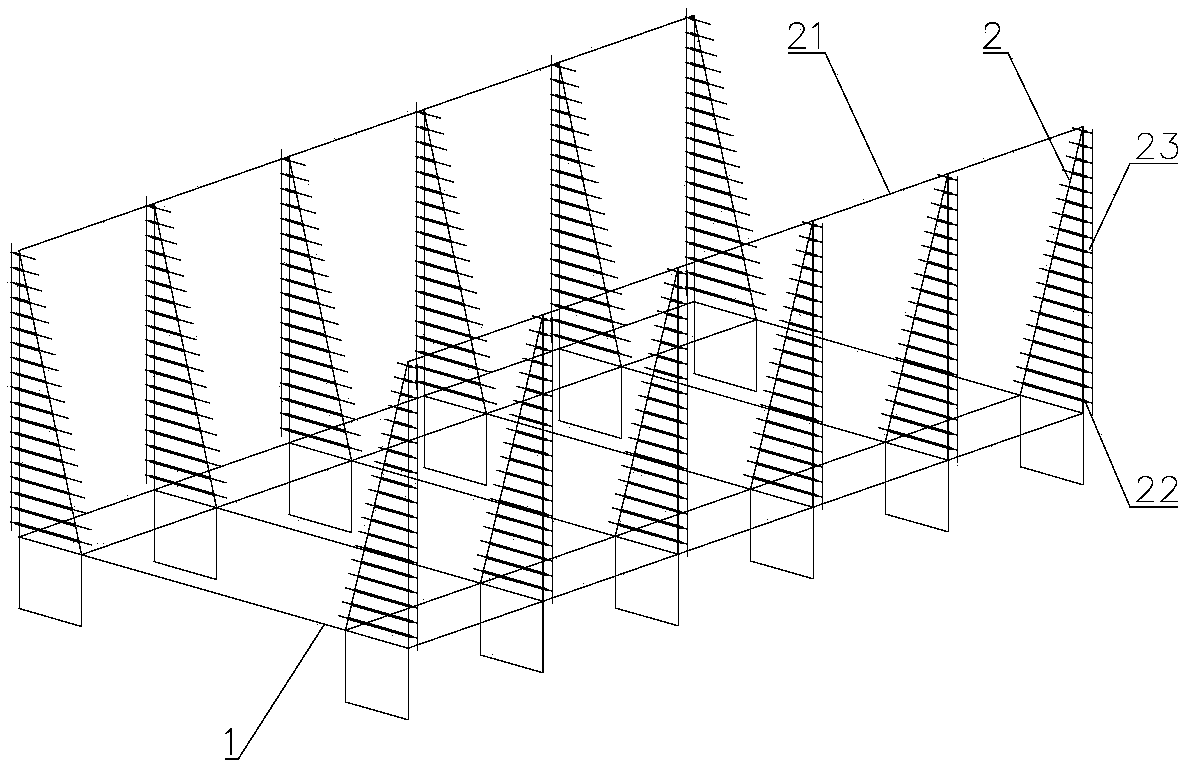

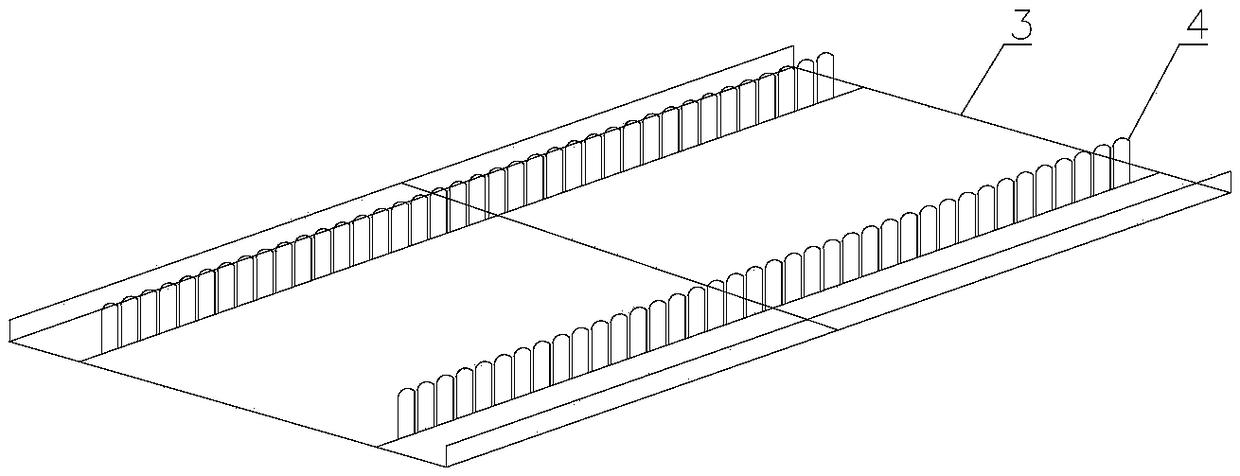

[0028] The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate embodiments consistent with the application and together with the description serve to explain the principles of the application.

[0029] In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, for those of ordinary skill in the art, In other words, other drawings can also be obtained from these drawings without paying creative labor.

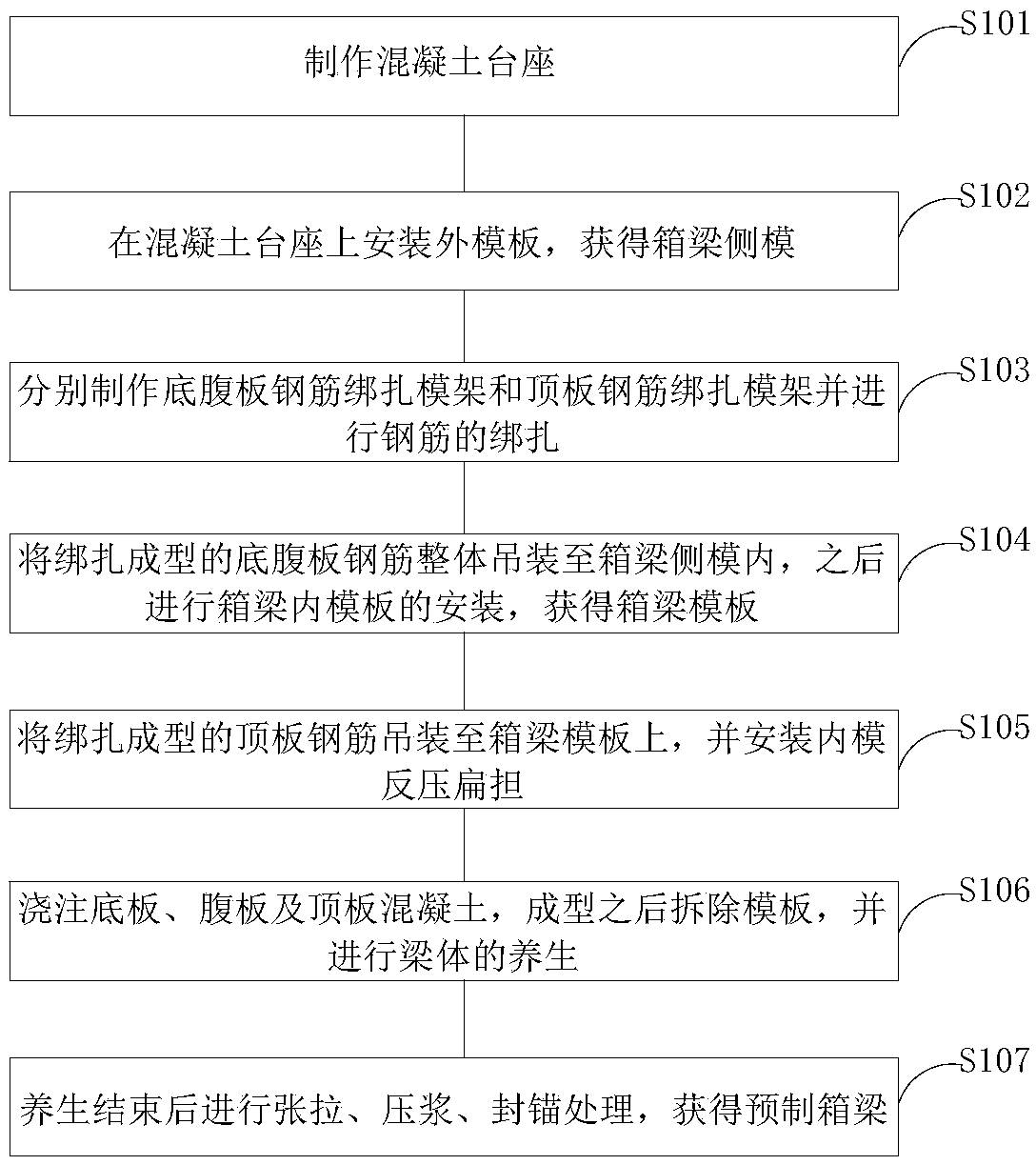

[0030] figure 1 It shows a flow chart of the construction method of a prefabricated box girder provided by the embodiment of the present application, see the attached figure 1 , the method includes the following steps:

[0031] Step 1 (S101): making a concrete pedestal.

[0032] As the bottom form of the prefabricated beam, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com