Coaxiality detection tool for transmission shaft

A technology for detecting tooling and transmission shafts, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of reducing the appearance quality of products, scratches on the surface of transmission shafts, and reducing detection accuracy, so as to achieve accurate and reliable detection results. The effect of avoiding appearance quality and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

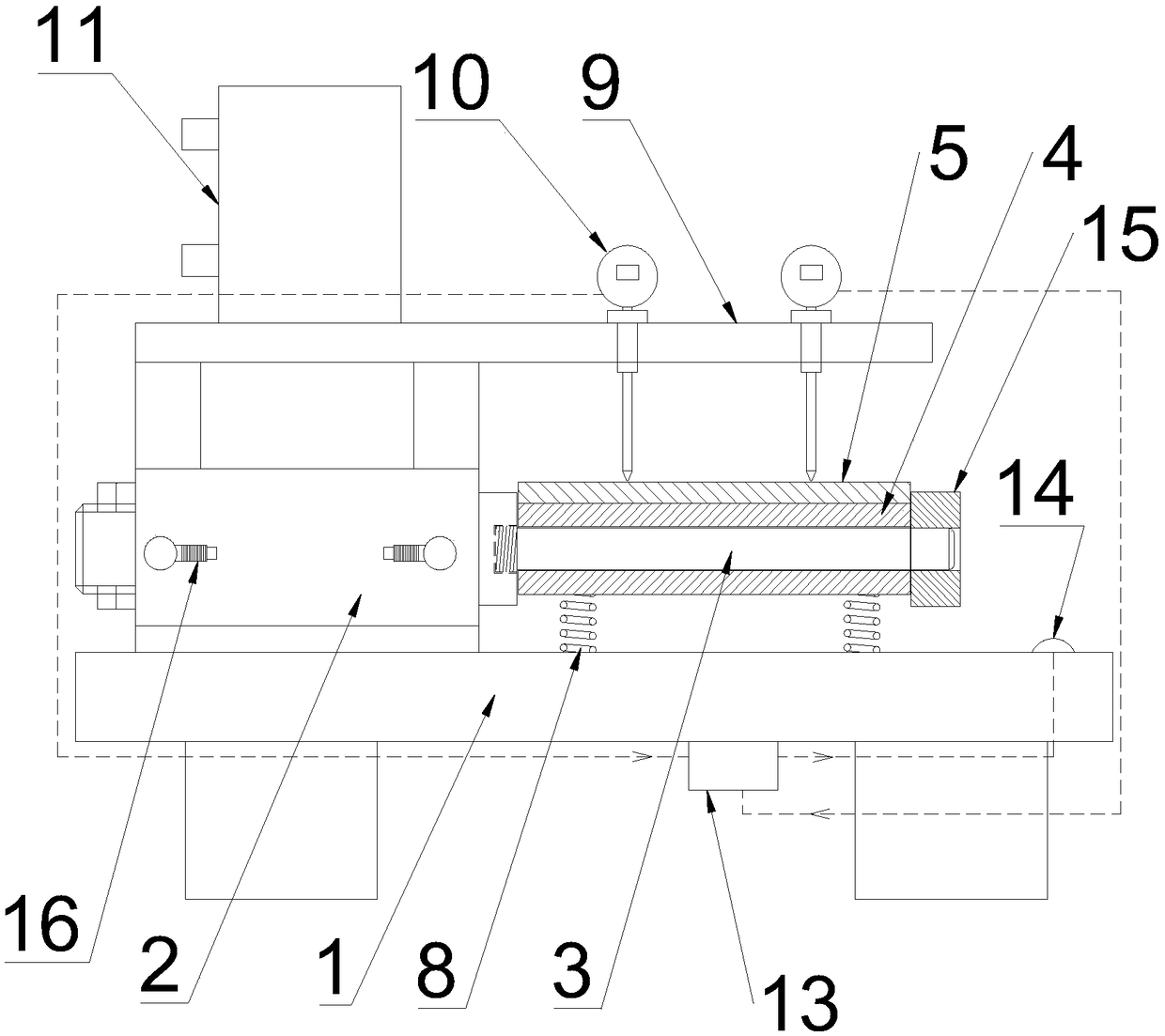

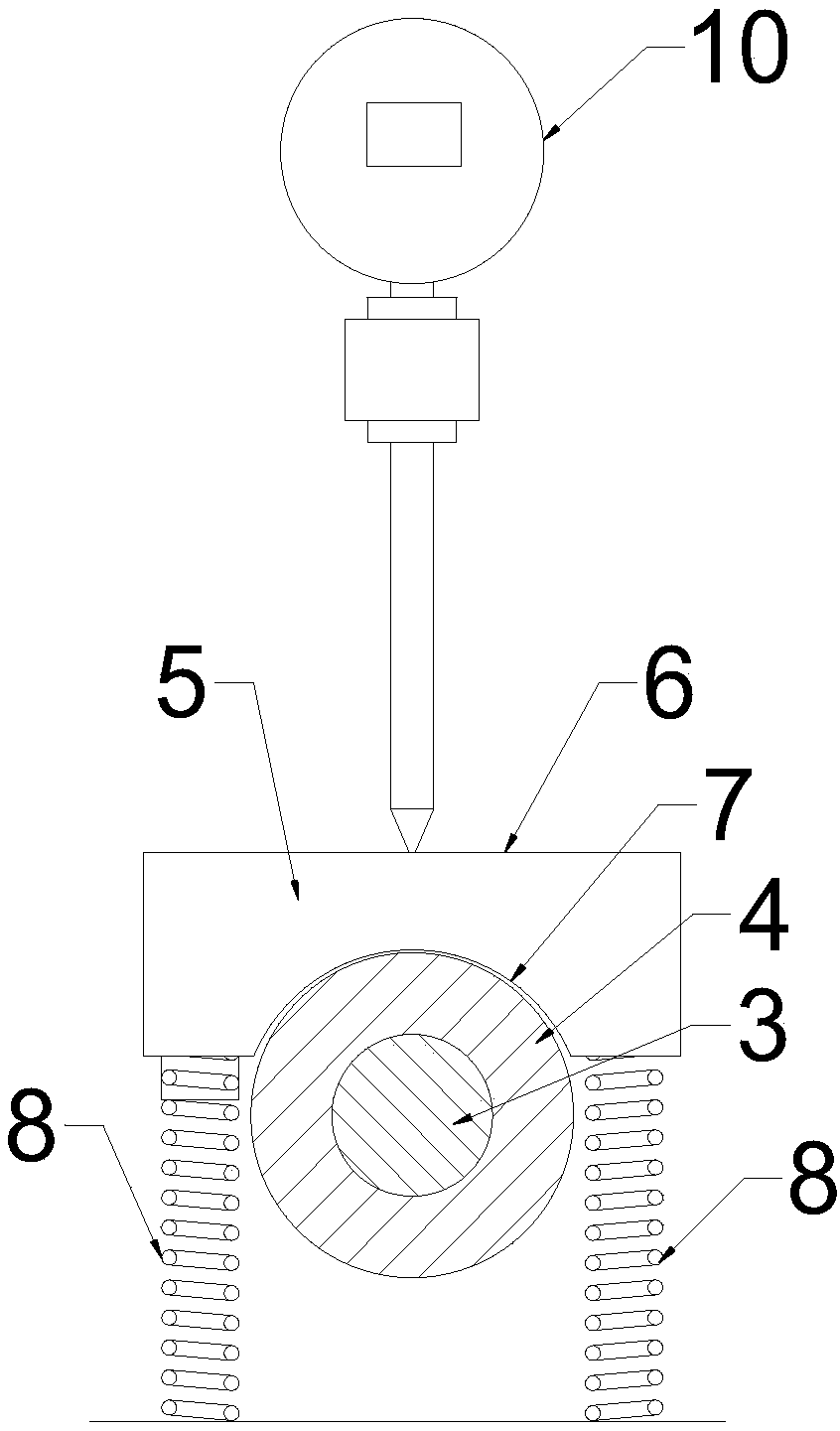

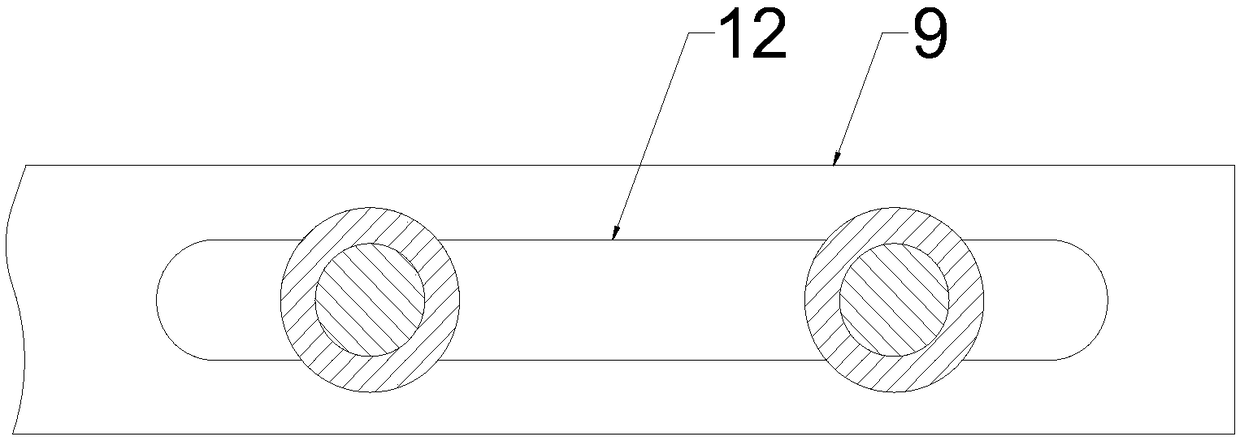

[0020] Such as figure 1 and figure 2 As shown, a transmission shaft coaxiality detection tool includes a workbench 1, a rotary cylinder 2 is installed on the workbench 1, the rotary cylinder 2 can rotate 360°, and a workpiece fixing shaft 3 is installed on the output shaft of the rotary cylinder 2 , the workpiece fixed shaft 3 is sleeved with a transmission shaft 4, the inner wall of the transmission shaft 4 is in close contact with the surface of the workpiece fixed shaft 3; a balance weight 5 is arranged above the workpiece fixed shaft 3, and the balance weight 5 includes an upper plane 6 arranged horizontally and the concave arc-shaped limit bottom surface 7, the arc-shaped limit bottom surface 7 and the transmission shaft 4 are approximately coaxially arranged, the upper side of the transmission shaft 4 can be embedded in the arc-shaped limit bottom surface 7, the bottom surface of the balance weight 5 The left and right sides are respectively symmetrically connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com