Patents

Literature

124results about How to "No defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

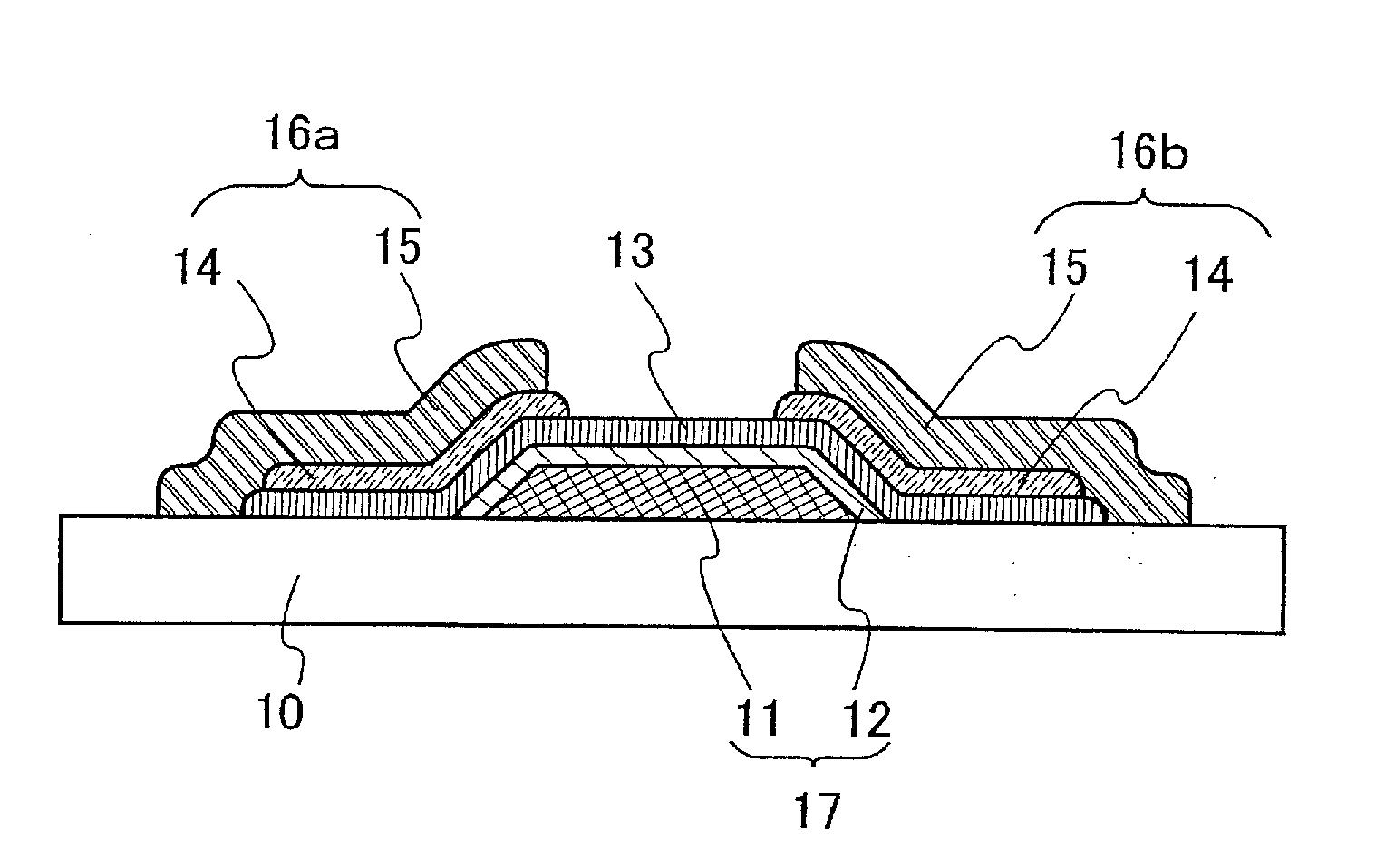

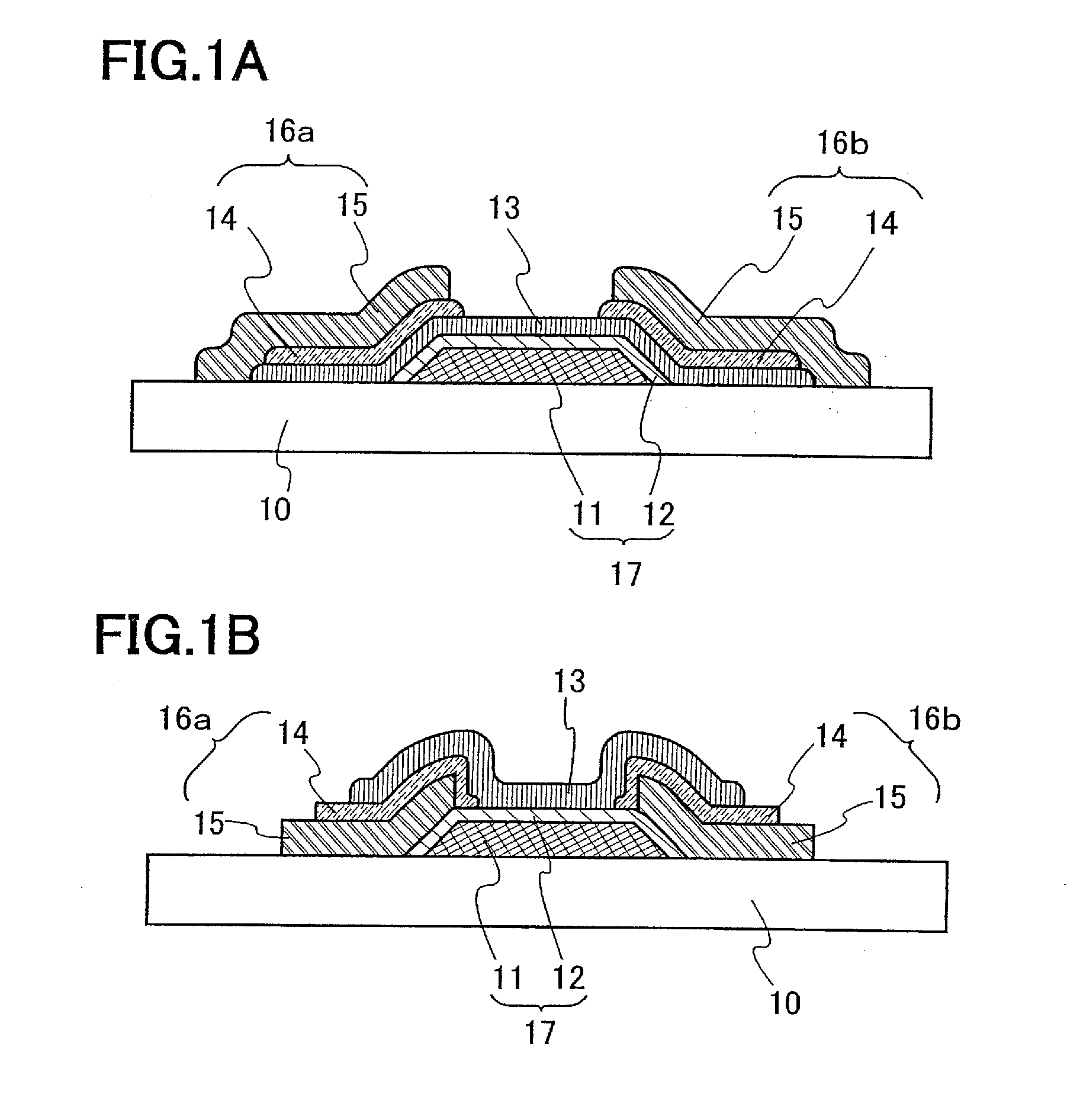

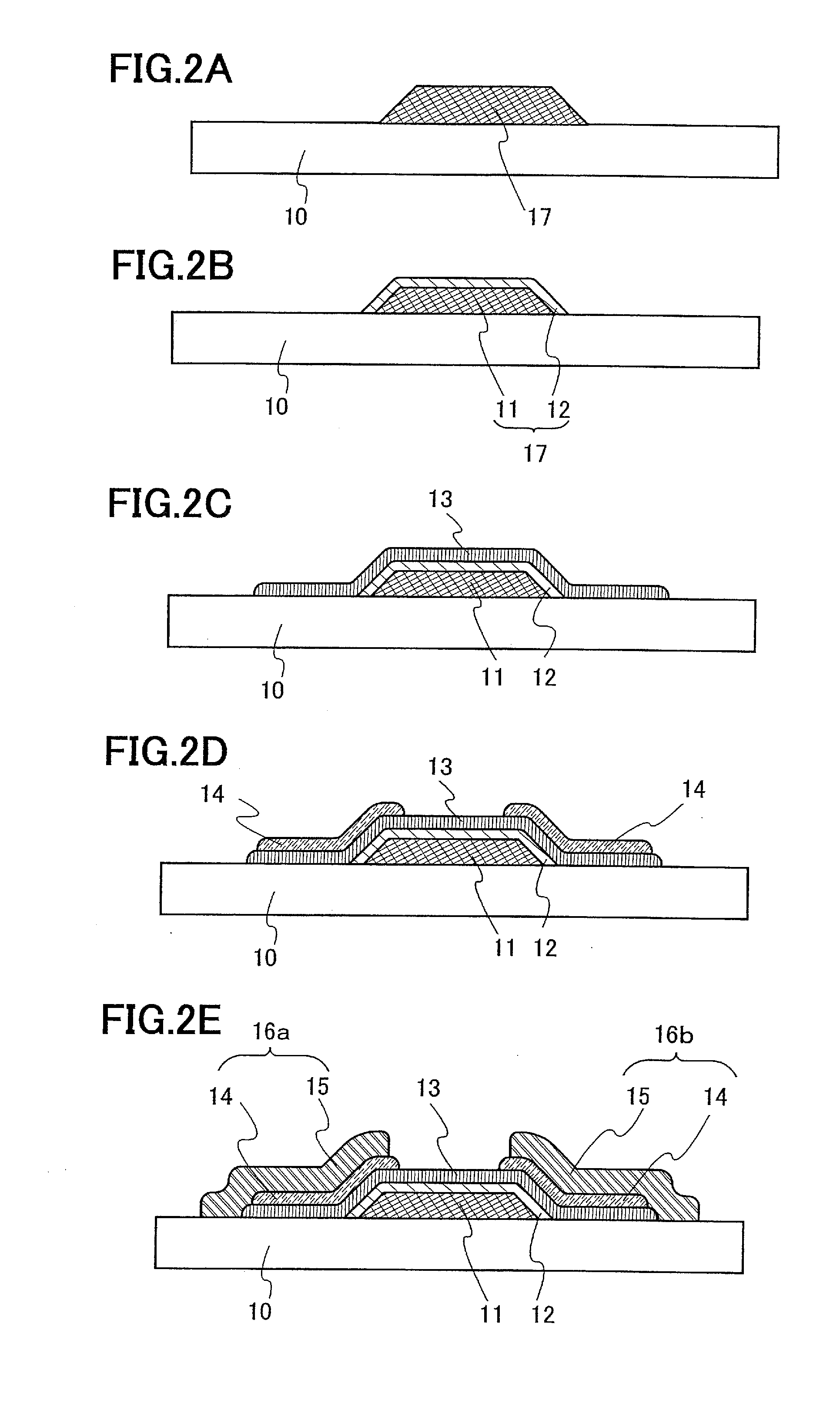

Organic transistor, manufacturing method of semiconductor device and organic transistor

InactiveUS20060270066A1Reduce leakage currentReduce tunnel leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingConductive polymerPlasma activation

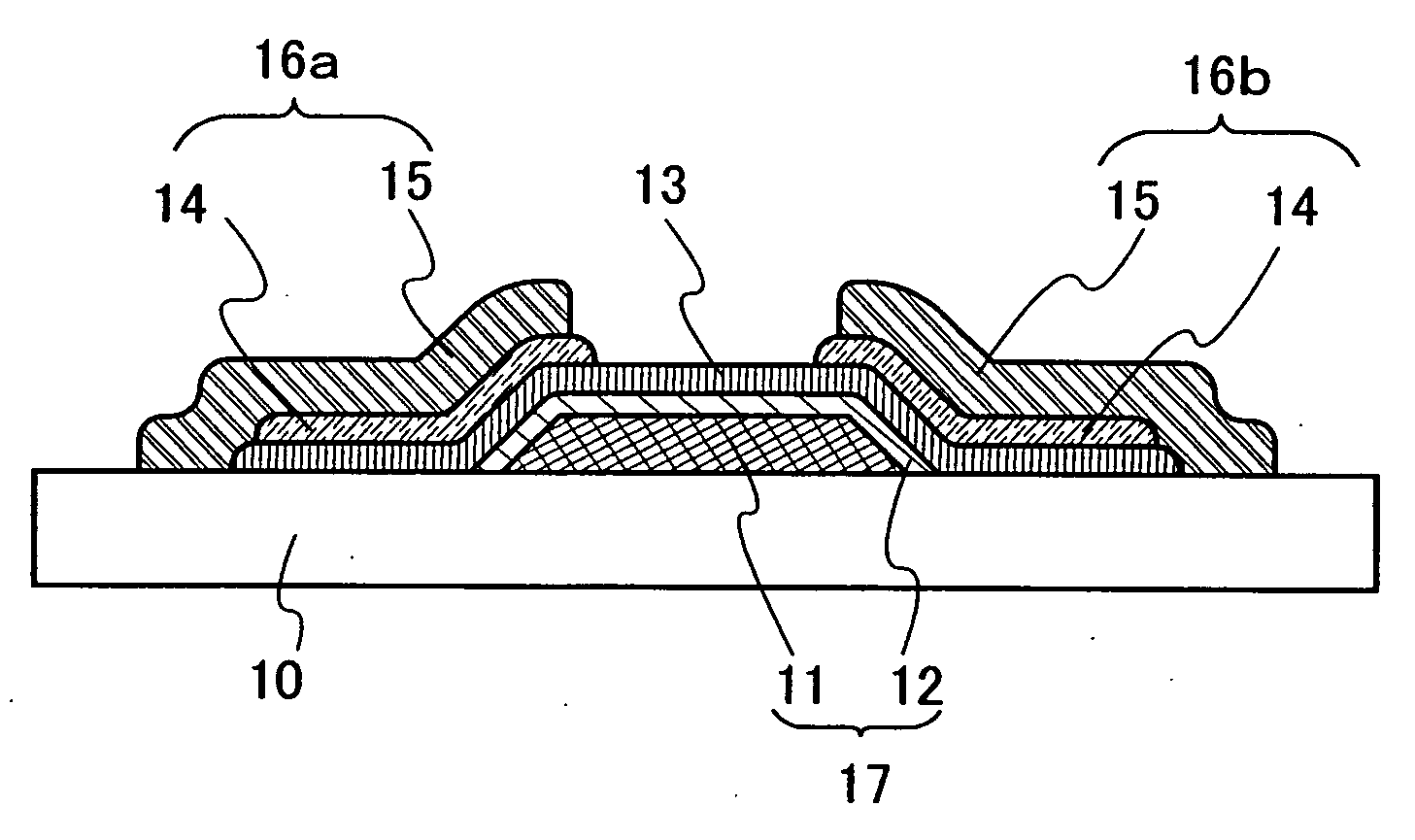

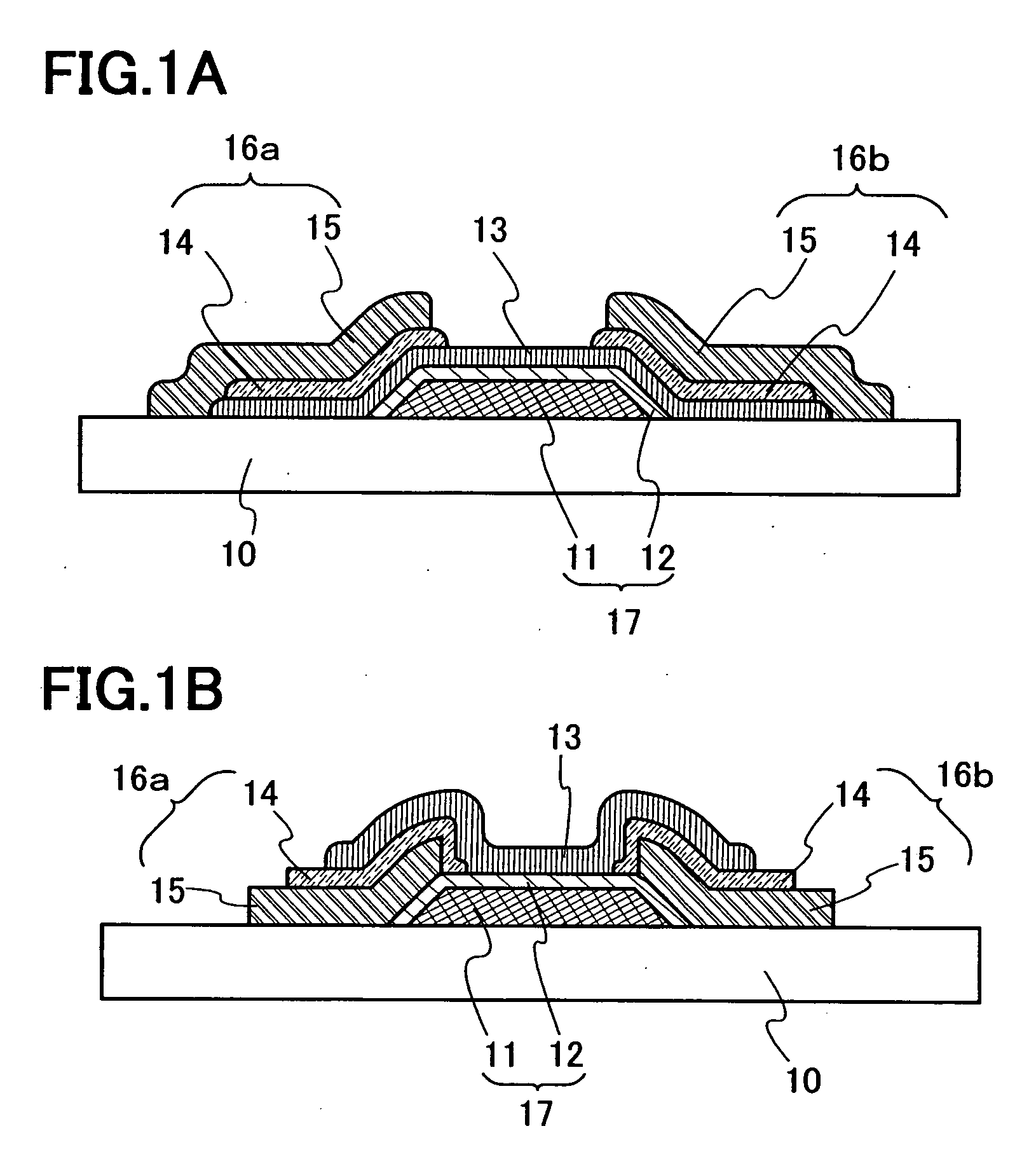

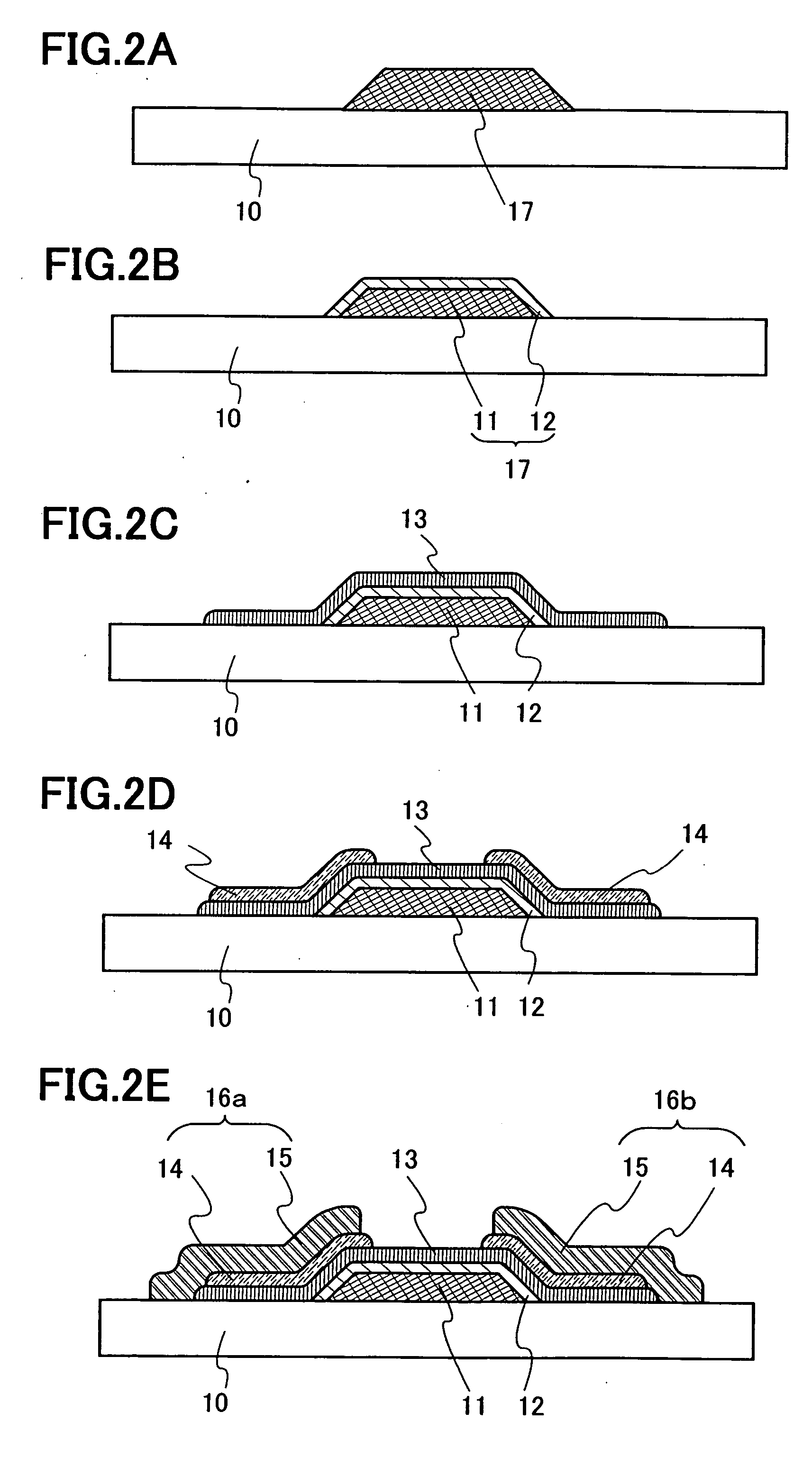

It is an object to form a high quality gate insulating film which is dense and has a strong insulation resistance property, and to propose a high reliable organic transistor in which a tunnel leakage current is little. One mode of the organic transistor of the present invention has a step of forming the gate insulating film by forming the conductive layer which becomes the gate electrode activating oxygen (or gas including oxygen) or nitrogen (or gas including nitrogen) or the like using dense plasma in which density of electron is 1011 cm−3 or more, and electron temperature is a range of 0.2 eV to 2.0 eV with plasma activation, and reacting directly with a portion of the conductive layer which becomes the gate electrode to be insulated.

Owner:SEMICON ENERGY LAB CO LTD

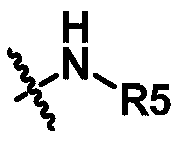

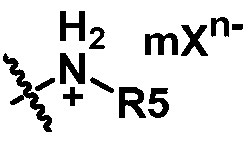

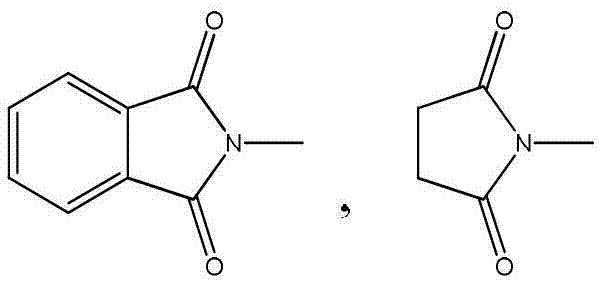

Degradable organic amines and organic aromatic ammonium salts latent epoxy resin curing agent and application

ActiveCN103254406AHigh quality recoveryClean surfaceOrganic compound preparationPlastic recyclingSolventChemistry

The invention provides a degradable organic amines and organic aromatic ammonium salts latent epoxy resin curing agent. The curing agent can be polymerized with epoxy resin to generate a degradable cross-linked polymer, and the degradable cross-linked polymer can be degraded in a mixed system of acid and solvent under the condition of heating and stirring. The invention also provides a prepreg which is composed of the curing agent, the epoxy resin, an auxiliary material and a reinforcing material. The invention also provides a reinforced composite material which is prepared by the curing agent, the epoxy resin, the auxiliary material and the reinforcing material. The reinforced composite material can be prepared by virtue of a prepreg forming method. The reinforced composite material can be degraded in the mixed system of the acid and the solvent under the condition of heating and stirring and recycled after neutralization. The reinforced composite material has excellent mechanical property and is suitable for different composite material application field. The degraded recycling method of the reinforced composite material is simple, economical, temperate in condition and easy to control.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

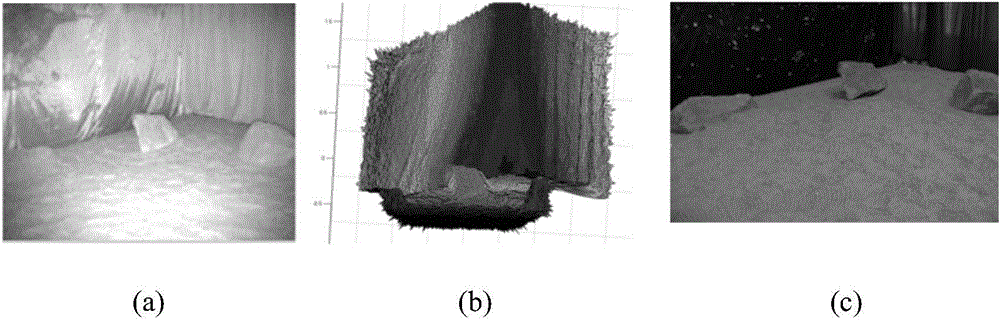

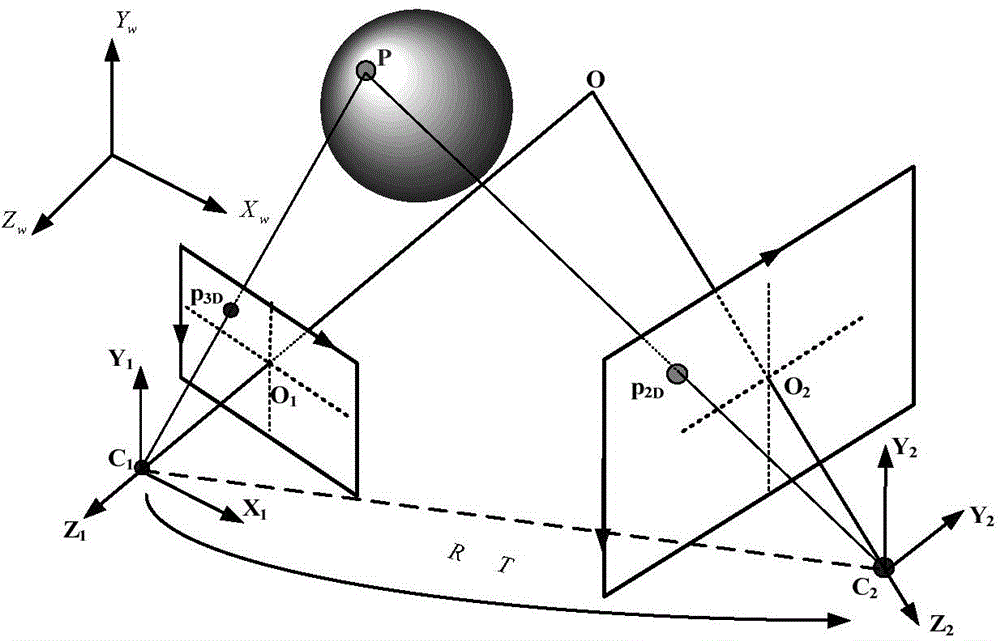

Three-dimensional visual information acquisition method based on two-dimensional and three-dimensional video camera fusion

InactiveCN104134188AAchieve acquisitionImprove image qualityGeometric image transformationRobot visionTriangular decomposition

The invention discloses a three-dimensional visual information acquisition method based on two-dimensional and three-dimensional video camera fusion. According to the method, a two-dimensional video camera and a three-dimensional video camera form a composite video camera to respectively image a scene synchronously; by establishing a matched mapping model of three-dimensional video camera depth images and two-dimensional video camera images, matched mapping points and mapping areas of the pixels of the three-dimensional camera video depth images in the two-dimensional video camera images are obtained; the mapping areas in the two-dimensional video camera images are processed through triangular decomposition, and a depth curved surface interpolation function of a triangulation area is established on the basis of depth information of adjacent mapping points; depth information of image pixels in the triangulation area is calculated through interpolation, and then depth images corresponding to high-resolution two-dimensional video camera images can be acquired. According to the method, the two-dimensional video camera image information and the three-dimensional video camera depth information are kept to the maximum degree, and the method has the advantages of being high in precision, little in information loss and the like and can be widely applied to the fields of industrial visual measurement, visual assembly, robot visual navigation and the like.

Owner:HUNAN UNIV

Water-permeable agent for water-permeable bricks or water permeable concrete and application of water-permeable agent

The invention discloses a water-permeable agent for water-permeable bricks or water permeable concrete and application of the water-permeable agent. The water-permeable agent comprises, by weight, 75-110 parts of water reducing agent, 150-300 parts of retarder, 100-150 parts of binder, 55-70 parts of air entraining agent and 55-100 parts of water. The water-permeable agent has the advantages that the water-permeable agent can increase the workability of a water-permeable layer, increase water permeability and increase the durability and later strength of the water-permeable bricks and is low in adding amount and low in cost. The water-permeable bricks have the advatnages that the bricks use haycite and regenerated porous coarse aggregate as the aggregate of the water-permeable layer and use the water-permeable agent, the features of porosity, good water absorption performance and high strength of the aggregate and the good performance of the water-permeable agent are utilized to increase the strength and water permeability of the water-permeable bricks, and the bricks are lightweight and convenient to carry.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

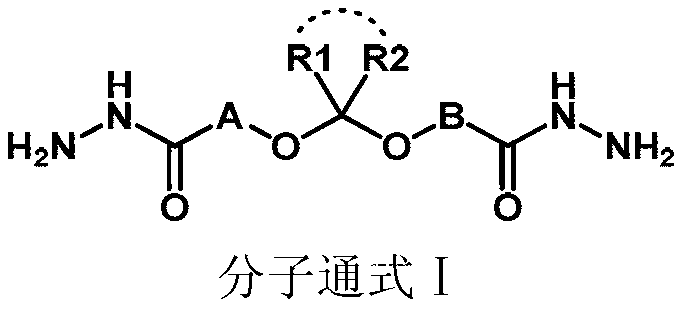

Degradable hydrazide latent epoxy resin curing agent and application thereof

ActiveCN103193959AOptimize operating timeModerate viscosityHydrazide preparationPlastic recyclingEpoxyCrosslinked polymers

The invention provides a degradable hydrazide latent epoxy resin curing agent. The curing agent can be polymerized with epoxy resin to generate a degradable crosslinked polymer; and the degradable crosslinked polymer can be degraded in a mixed system of an acid and a solvent under the conditions of heating and stirring. The invention also provides a prepreg, consisting of the curing agent, the epoxy resin, an auxiliary material and a reinforcing material. The invention also provides a reinforcing composite material which is prepared from the curing agent, the epoxy resin, the auxiliary material and the reinforcing material. The reinforcing composite material can be prepared by a prepreg forming method. The reinforcing composite material can be degraded in the mixed system of the acid and the solvent under the conditions of heating and stirring, and can be recycled and reused after being neutralized. The reinforcing composite material has excellent mechanical property and is suitable for the field of application of different composite materials; and the degrading and recycling method of the reinforcing composite material is simple, economic, mild in condition and easy to control.

Owner:芜湖天道绿色新材料有限公司

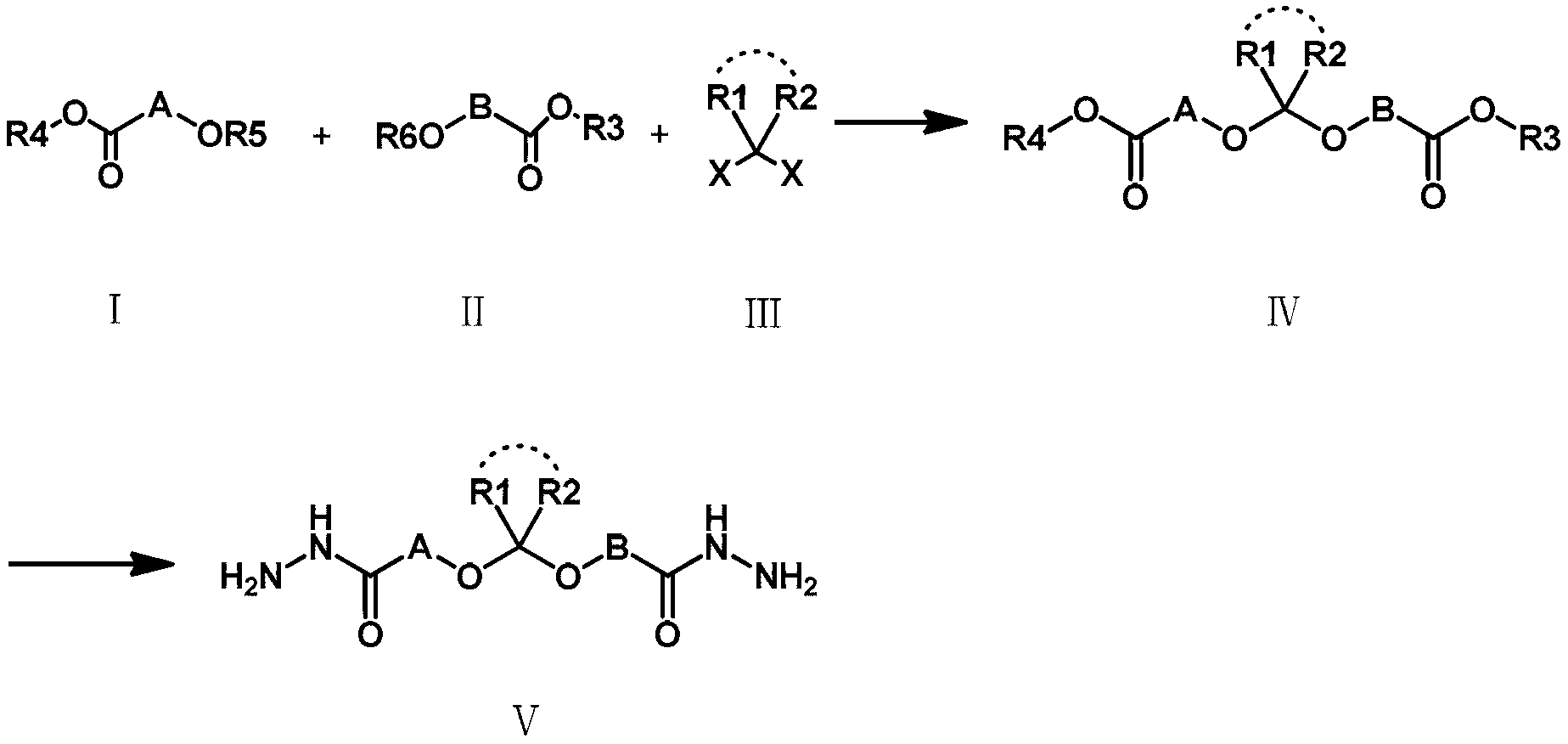

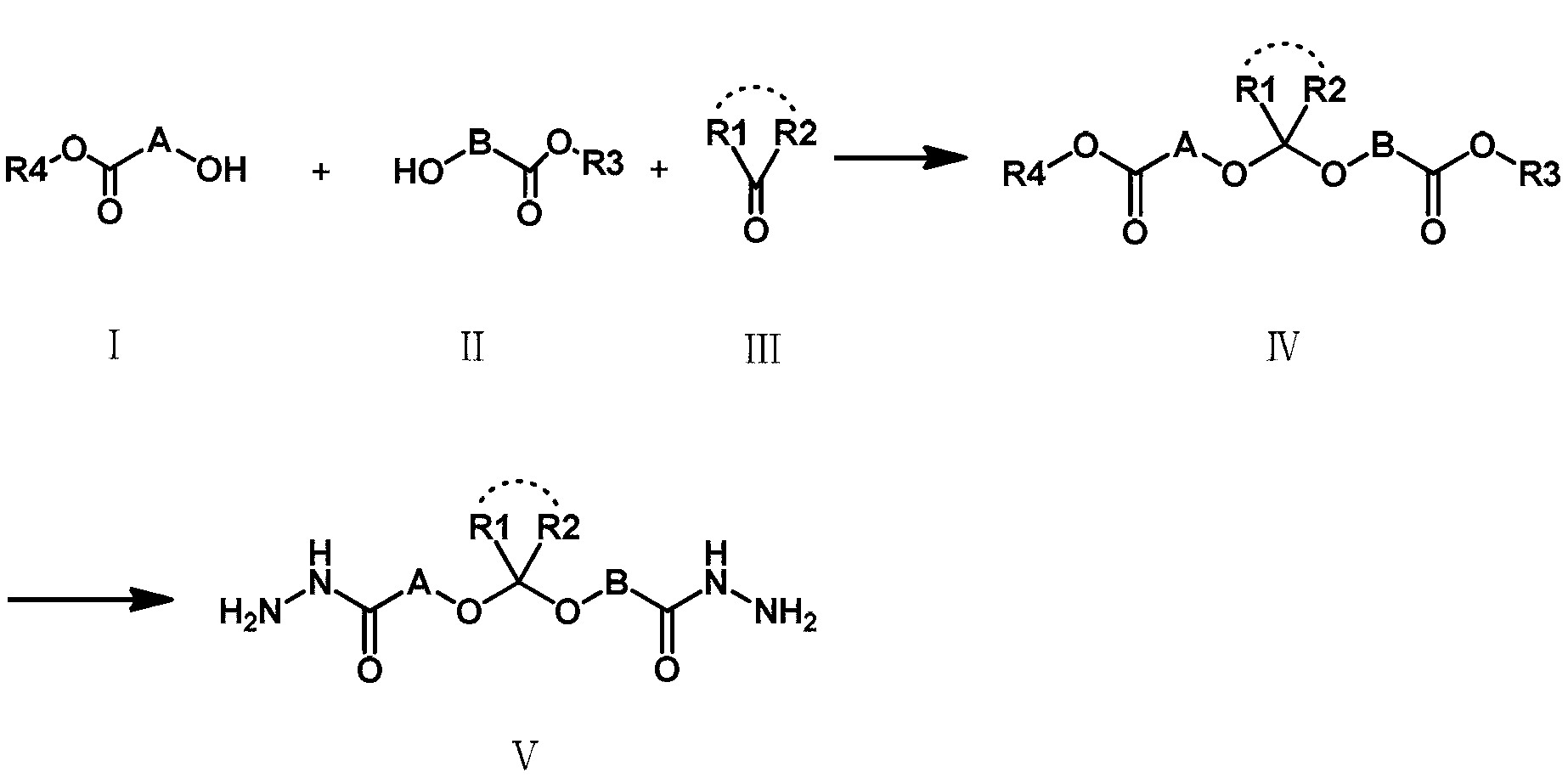

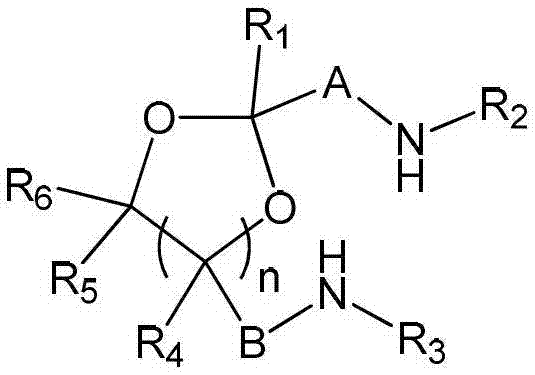

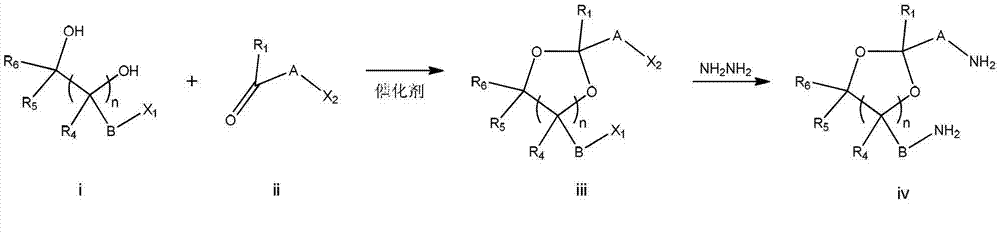

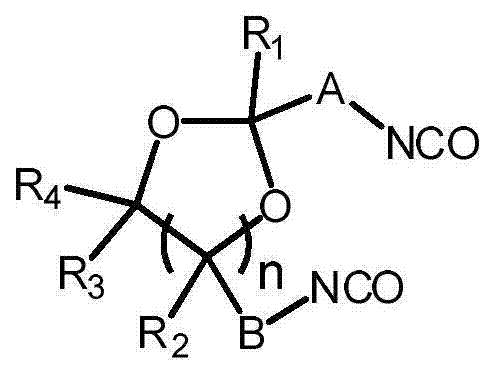

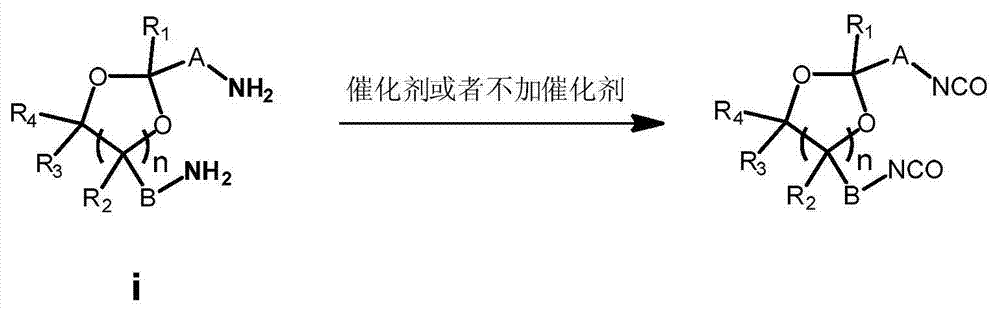

Degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent and application thereof

ActiveCN103242509ARetain mechanical propertiesImprove recycling efficiencyOrganic chemistryFibre chemical featuresPolymer scienceFirming agent

The invention provides a degradable cyclic acetal and cyclic ketal diamine epoxy resin curing agent. The curing agent can be polymerized with an epoxy resin so as to generate a degradable cross-linking polymer, wherein the degradable cross-linking polymer can be degraded in a mixing system of acid and solvents under the heating and stirring condition. The invention further provides an enhanced composite material which is prepared from the curing agent, the epoxy resin, auxiliary materials and enhancing materials; and the enhanced composite material can be degraded in the mixing system of acid and solvents under the heating and stirring condition, and can be recycled and reused after being neutralized. The enhanced composite material has excellent mechanical properties, is applicable to application fields of different composite materials, and the degrading and recycling method is simple, economic, mild in condition and easy to control.

Owner:ADESSO ADVANCED MATERIALS WUHU CO LTD

Degradable isocyanate and application thereof

InactiveCN103694140AEasy to controlEfficient recyclingIsocyanic acid derivatives preparationOrganic compound preparationPolymer scienceFirming agent

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

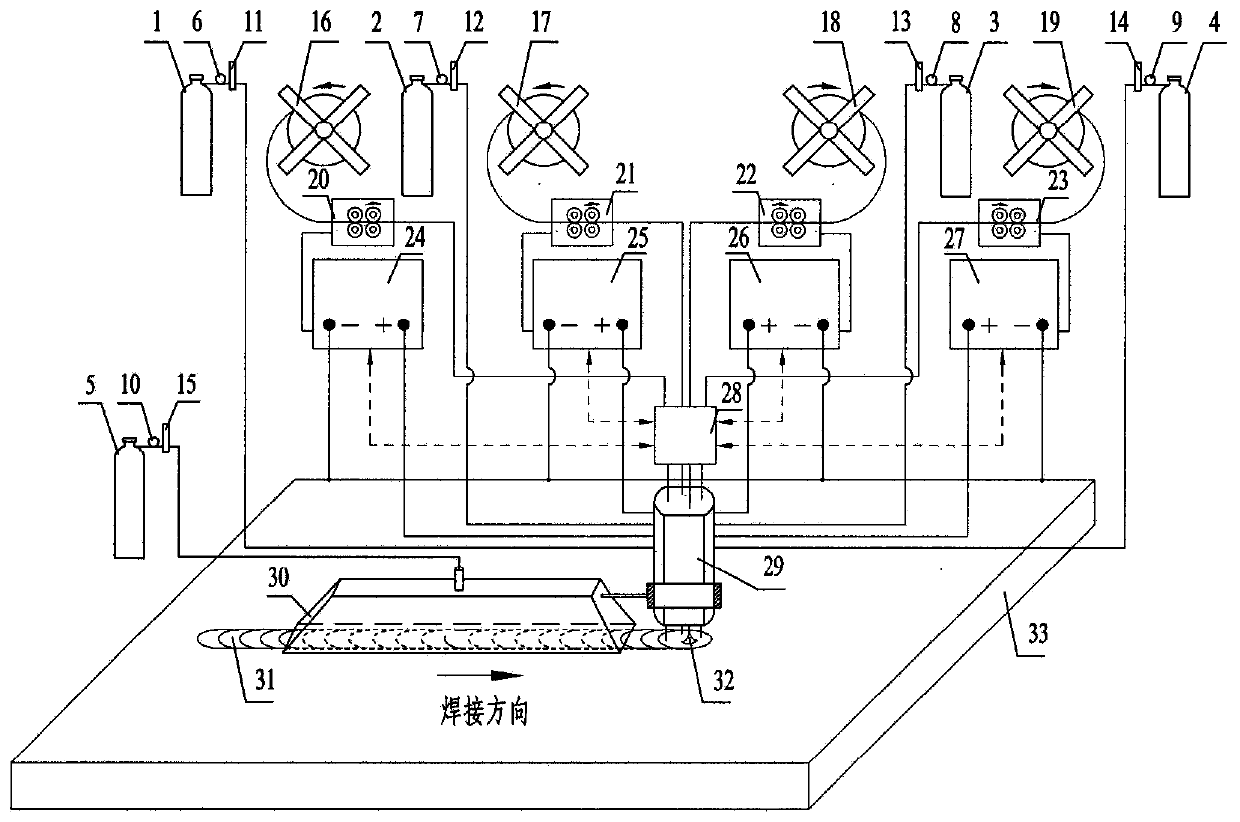

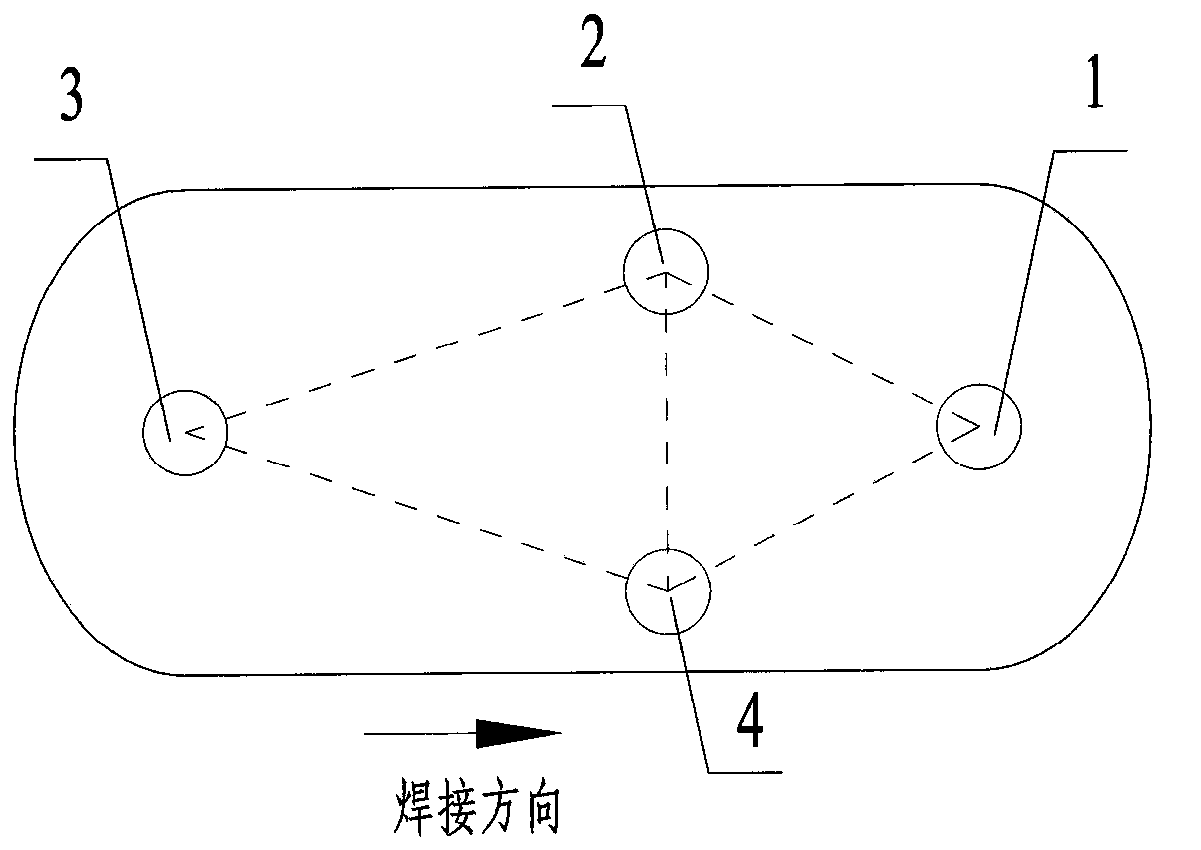

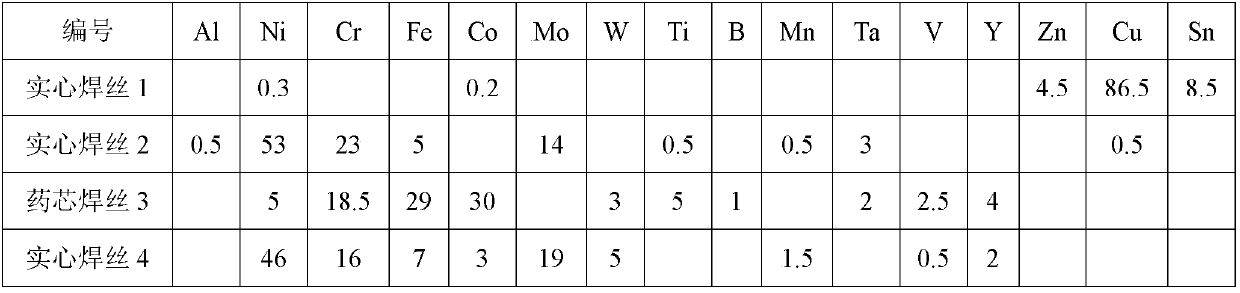

High-entropy alloy double technology preparation method

The invention relates to the technical field of high-entropy alloy, in particular to a high-entropy alloy double technology preparation method. The high-entropy alloy double technology preparation method comprises the steps that firstly, types of four welding wires and components, contents, existence forms and existence positions of welding wire elements are decomposed and designed according to the element components, contents and physico-chemical properties of high-entropy alloy needing to be prepared, and the welding wires are prepared; secondly, an integrated four-wire pulse gas shielded welding technology is adopted to cooperate with additional materials to manufacture the high-entropy alloy; and finally, a vacuum self-consumption remelting technology is adopted to refine the high-entropy alloy. According to the high-entropy alloy double technology preparation method provided by the invention, the technology is stable, the preparation efficiency is high, the cost is low, the heat input adjusting range is wide, the optional alloy element range is wide, the quantity of types of prepared high-entropy alloy is large, alloy component adjusting is convenient and accurately controllable, chemical components are uniform, the structure is compact and uniform, the degree of purity is high, and the inner quality is good.

Owner:SHIJIAZHUANG TIEDAO UNIV

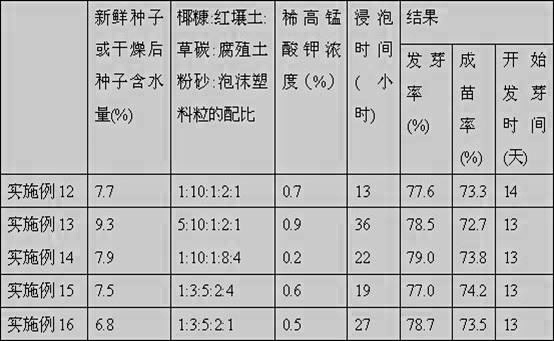

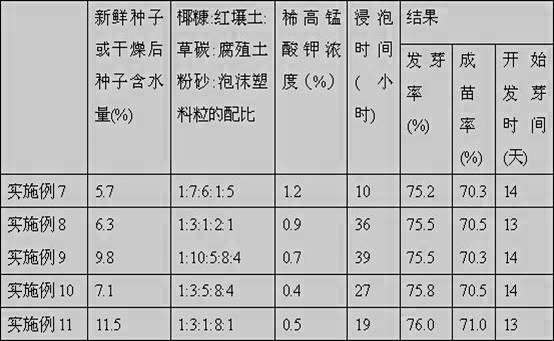

Method for improving sprouting rate and seedling rate of callicarpa nudiflora

ActiveCN102487749ASuitable for scattered cultivationImprove germination rateSeed and root treatmentCultivating equipmentsCallicarpa nudifloraSeed treatment

The invention provides a method for improving sprouting rate and seedling rate of callicarpa nudiflora. The method comprises: a material preparation stage, a seed treatment stage and a subsequent management stage. After treatment with the method provided by the invention, the sprouting rate of the callicarpa nudiflora is more than 75%, the seedling rate of the callicarpa nudiflora is more than 70%, and initial sprouting time is from 9 days to14 days. Compared with the prior art, the method has the advantages that the sprouting time is obviously shortened, the sprout uniformity is good, and the sprouting rate and the seedling rate are high; and the treatment method is simple and suitable for intensification non-polluted cultivation and farmer scattered cultivation and has strong applicability and popularization property, thereby solving the problems that the existing callicarpa nudiflora is low in the sprouting rate and seedling rate and is not uniform in sprouts.

Owner:JIUZHITANG +1

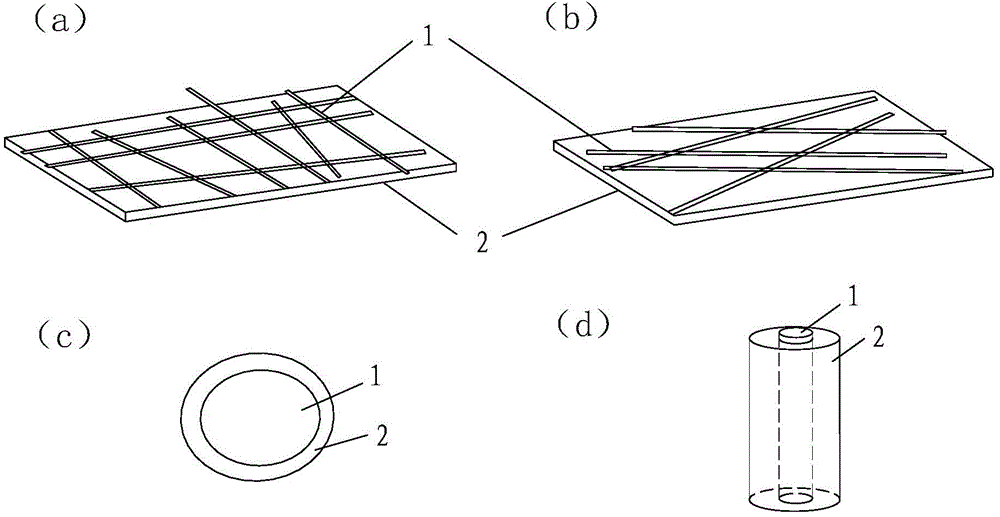

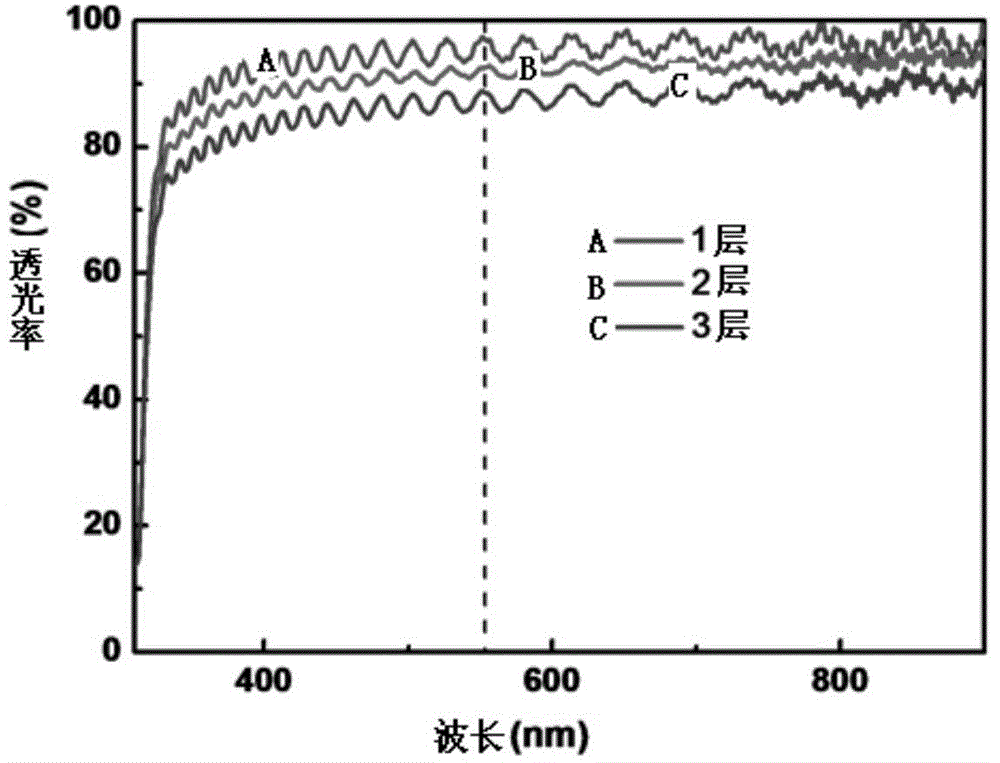

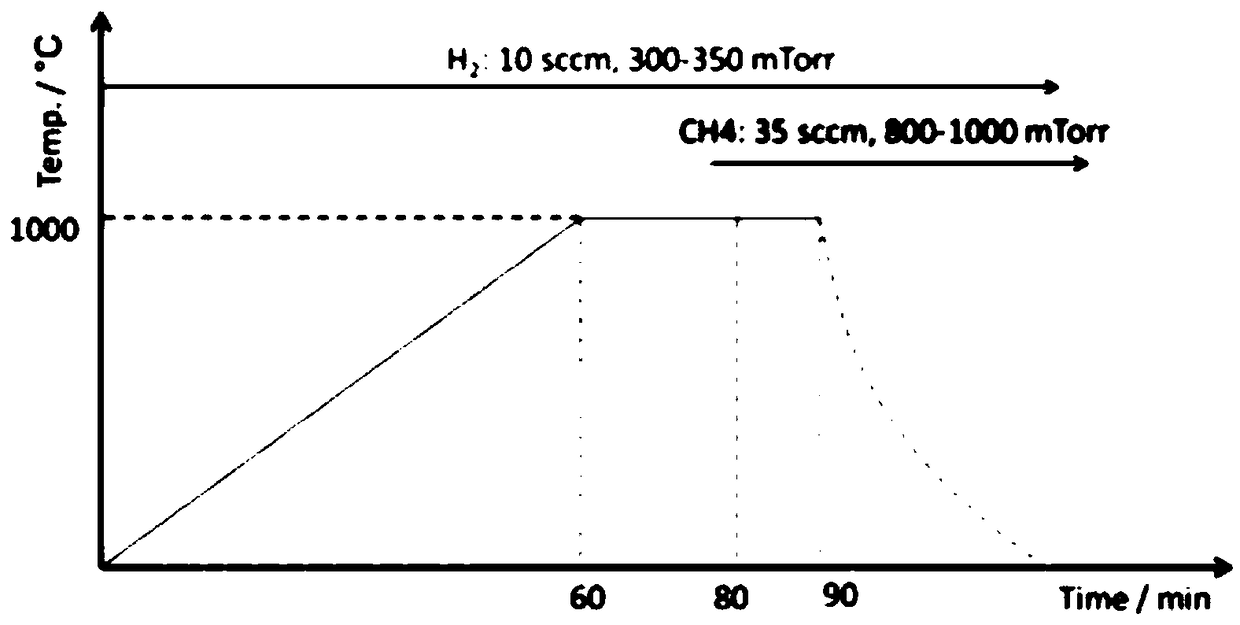

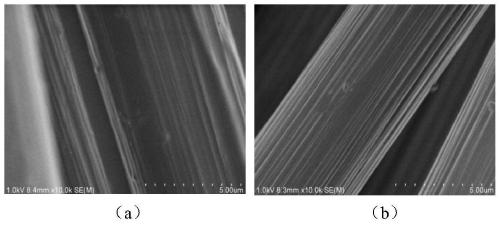

Composite conductive material of graphene film and metal nanometer structure and preparation method thereof

ActiveCN104616717APrevent oxidationImprove conductivityMaterial nanotechnologyMetal/alloy conductorsOrganic solventConductive materials

The invention discloses a composite conductive material of graphene film and metal nanometer structure; the composite conductive material of graphene film and metal nanometer structure comprises a metal nanometer structure and a graphene film which sticks onto the metal nanometer structure; the graphene film directly sticks onto the metal nanometer structure by chemical vapor deposition method or carbon segregation method; the layer number of the graphene film is 1-30 layers. The provided conductive material has mechanical flexibility and high conductivity as well as adjustable light transmission; meanwhile, the transparent material also has a characteristic of preventing the metal from being oxidized. The square resistance of the provided conductive material is 5Omega / to 1000Omega / , the transparency is 5%-97%, and the bending radius is less than 10mm. The invention also discloses a preparation method of the conductive material; the provided preparation method of the conductive material does not need to transfer the graphene film; the operation is simple without using an organic solvent; the conductive material and preparation method are green and environment-friendly, as well as saving cost.

Owner:ZHEJIANG UNIV

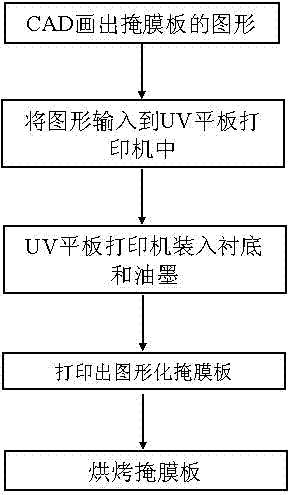

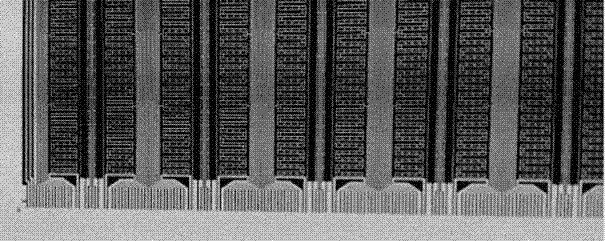

UV-curing ink and method for preparing masking plate by using ink

InactiveCN104710869ASimple preparation routeFast trackInksOriginals for photomechanical treatmentSemiconductor electrodeCooking & baking

The invention belongs to the technical field of semiconductor manufacture, and particularly relates to a UV-curing ink and a method for preparing a masking plate using the ink. The UV-curing ink is composed of a photoactive pre-polymer, a photoinitiator, an active monomer, pigment and additives. The UV-curing ink is put into a UV plate inkjet printer; a graphical masking plate is printed on a substrate through the UV plate inkjet printer; the graphical masking plate is put into an oven for baking to prepare the masking plate; and furthermore, electrodes of organic electronic devices are prepared on the masking plate through photolithography. The masking plate prepared by the method in the invention is tidy in appearance edge and smooth in surface, has no stain, is simple in operation process, requires no special technology and special equipment, is suitable for the normal masking plate for manufacturing semiconductor electrodes, and is easy for popularization and use.

Owner:方圆环球光电技术盐城有限公司 +1

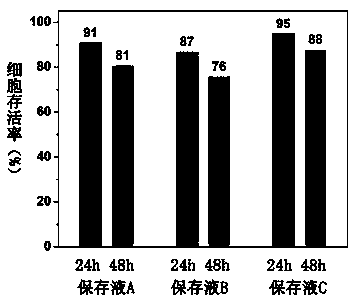

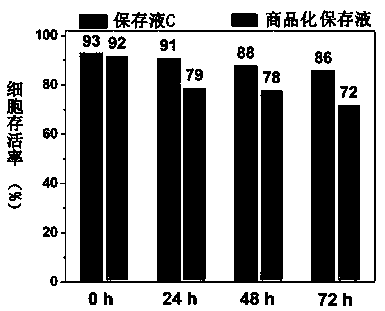

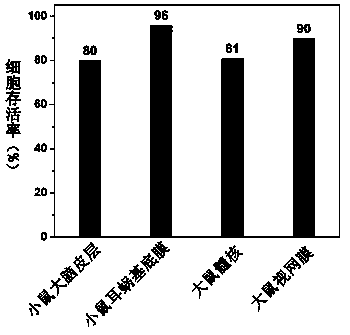

Preserving fluid and preserving method for maintaining high cell activity of tissue sample

InactiveCN111418581AImprove cell activityHigh activityMicrobiological testing/measurementDead animal preservationHigh cellFresh Tissue

The invention provides a preserving fluid and a preserving method for maintaining high cell activity of a tissue sample, wherein the preserving fluid comprises the components: ion buffer solution components, carbohydrate components,, components avoiding the generation of ice crystals in and out solutions of tissue cells at a low temperature of 0-6 DEG C, components providing supplement, antioxidant and anti-apoptosis components for anabolism of the tissue cells; the preserving fluid has good biocompatibility, does not contain toxic or harmful components, and also does not contain components such as animal-derived protein, antibiotics and hormones influencing tissue gene expression. Different from traditional ultralow-temperature cryopreservation (-80 DEG C), the cryopreservation method disclosed by the invention can effectively realize low-temperature storage (0-6 DEG C) of fresh tissue samples of human beings and animals, maintains high cell activity of tissues, maintains tissue morphology, and is used for preservation and transportation of the tissue samples. Meanwhile, the nucleic acid integrity of the tissue and the stability of gene expression can be effectively maintained, the original state of the tissue is maintained, and the method can be used for gene detection, scientific research and other related experiments.

Owner:上海伯豪生物技术有限公司

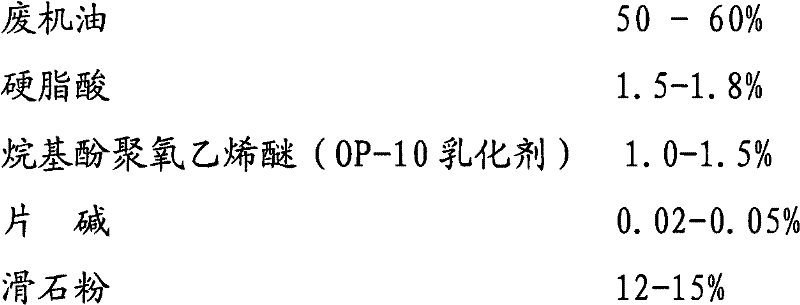

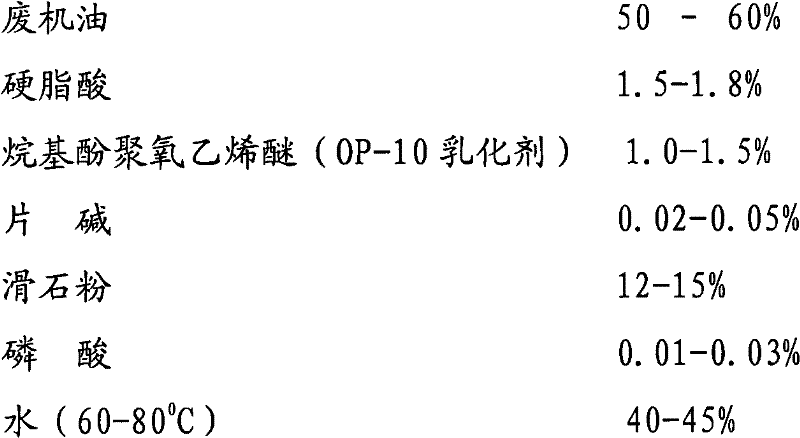

Foam concrete preform release agent and preparation method thereof

InactiveCN102191120ABroaden applicationFast film formationLubricant compositionFoam concretePhosphoric acid

The invention relates to a foam concrete preform release agent and a preparation method thereof. The foam concrete preform release agent comprises the following components by weight percent: 50-60% of waste oil, 1.5-1.8% of stearic acid, 1.0-1.5% of alkylphenol polyoxyethylene ether (OP-10 emulsifier), 0.02-0.05% of flake caustic soda, 12-15% of talc, 0.01-0.03% of phosphoric acid and 40-45% of water (60-80 DEG C). When the release agent prepared by adopting the formula is used for mould release, the foam concrete preform has no oil stain on the surface, no spallation and no edge defect and is good for second construction; and the preform has low dimensional deviation, the film-forming speed is high, the production cycle is short and the work efficiency is increased. In addition, the prepared release agent can be used to prevent the wooden mould from warping and deforming.

Owner:ZUNYI JIANTAI LIGHT ENERGY SAVING MATERIAL

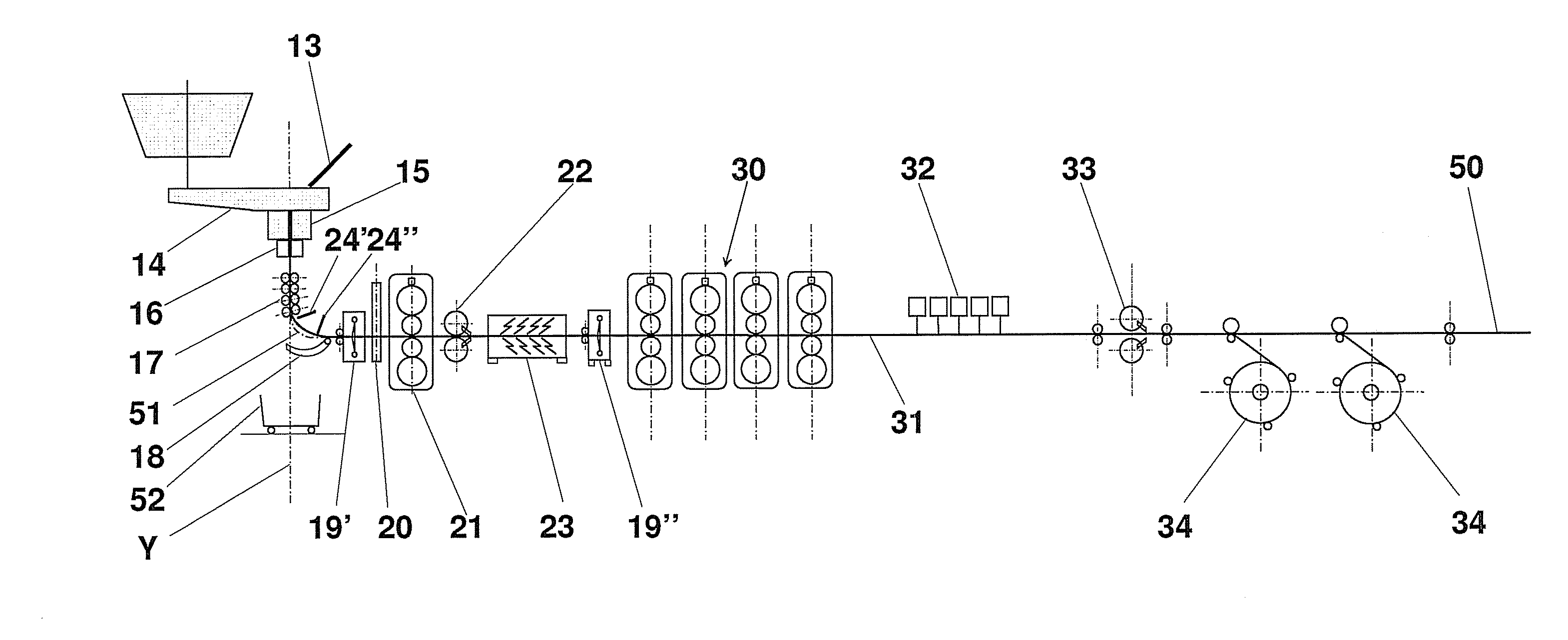

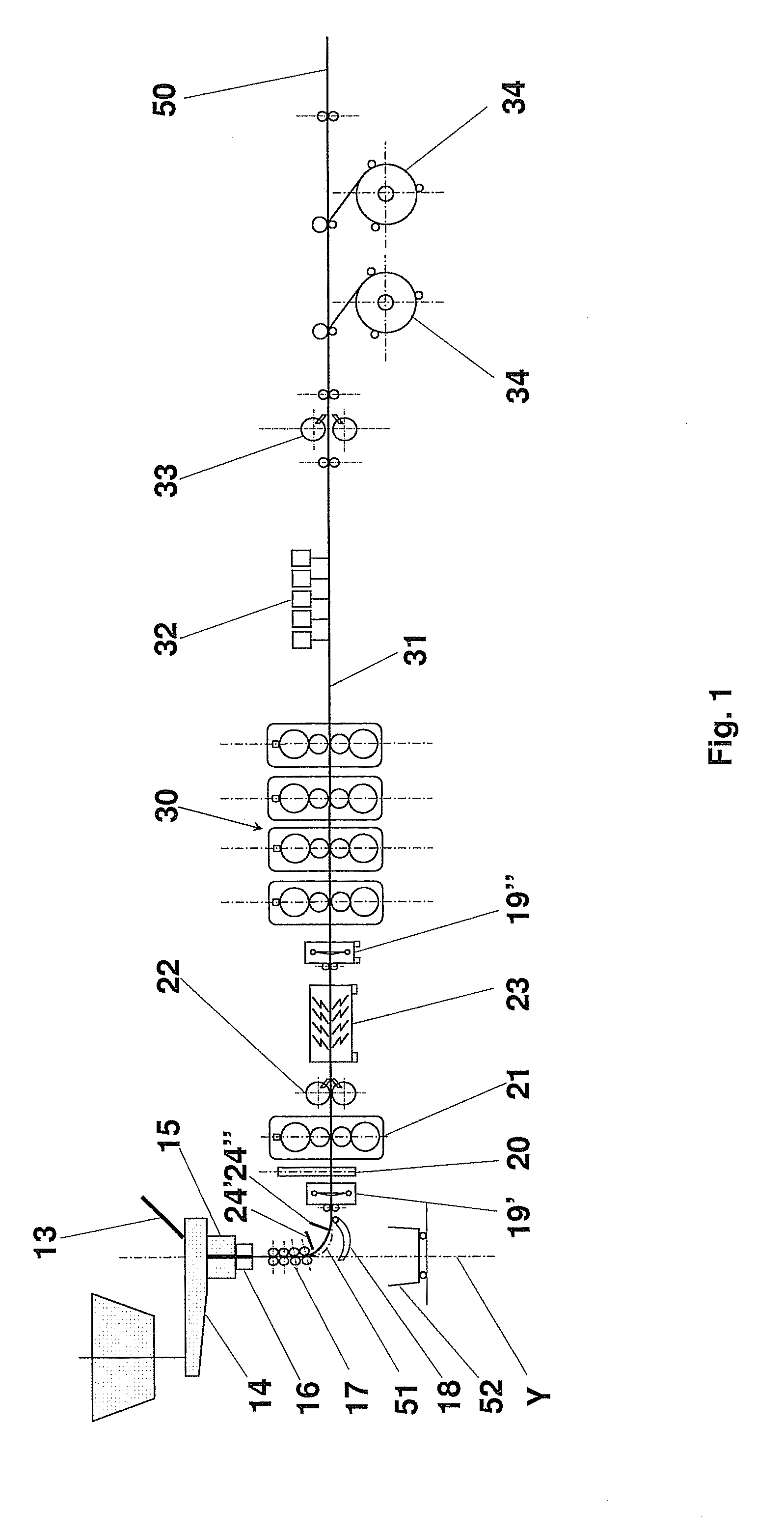

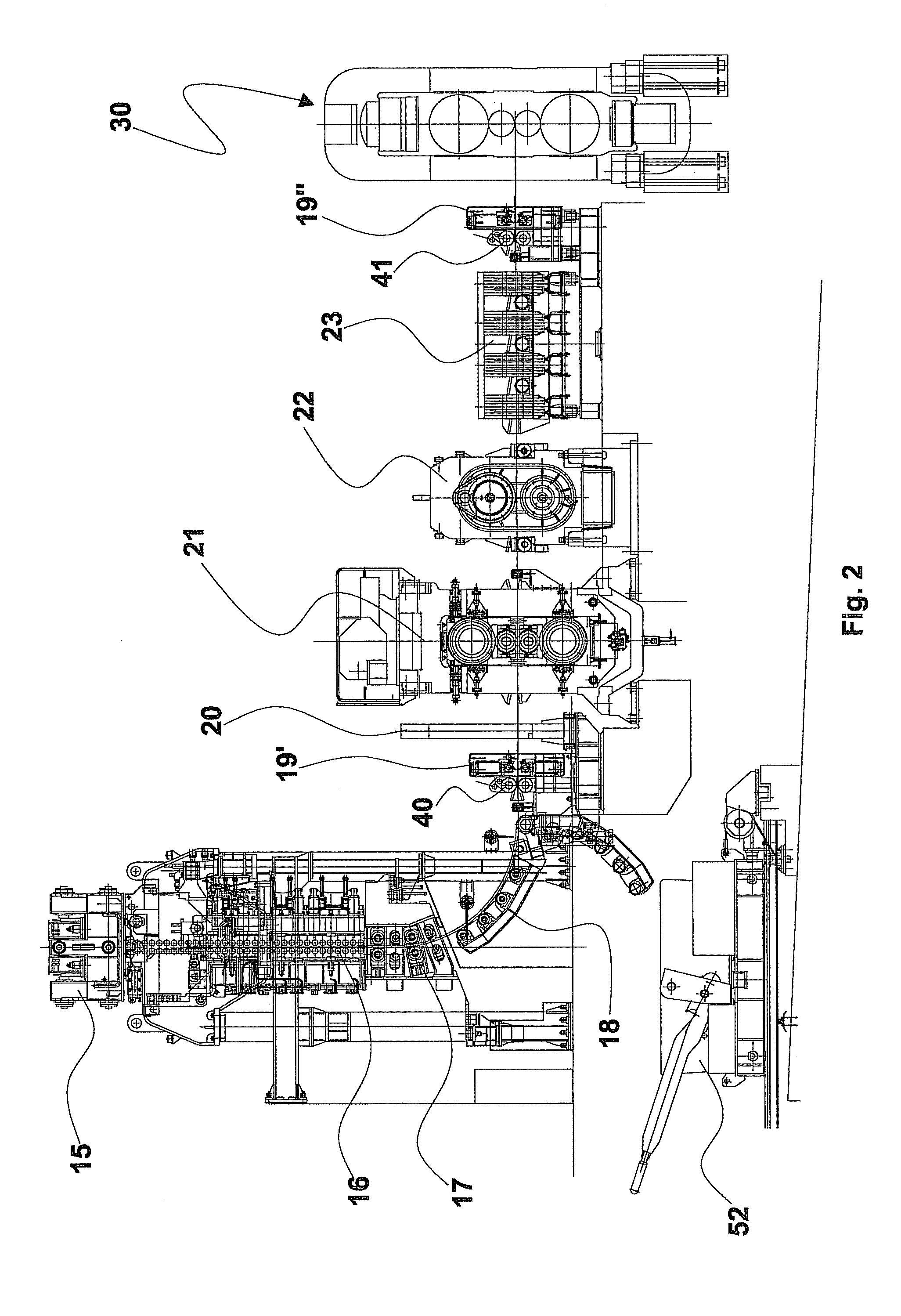

Process and a plant for the production of metal strip

ActiveUS20100116456A1High rateIncrease chanceProduct rolling machinesMetal rolling stand detailsThin slabInductor

A process and an ultracompact plant for the endless production of hot rolled steel strip comprising an ingot mould (15) that produces a very thin slab, having narrow sides with thickness in the range between 40 and 55 mm and a central swelling, at a speed in the range between 4 and 16 m / min. Such a slab, which displays a core in which the steel is still liquid, is passed through a vertical pre-rolling device (16) that reduces the thickness of the slab and flattens it. The solidified slab may thus be subjected to a first mild rolling by a conveyor (17) and, by forming a free curve, takes a horizontal position where it is subjected to a first surface descaling, a first rolling, a heating in an inductor (23), a second surface descaling and a series of reductions in a rolling mill (30) formed by at least two stands, by maintaining its temperature along the mill above the recrystallisation point Ar3. Downstream of the rolling mill (30) there are provided a roller runway with cooling showers, a flying shear (33) for cutting to length the strip produced, pinch rolls and at least two spinning wheels (34) for the formation of coils of the hot rolled strip.

Owner:DANIELI & C OFF MEC SPA

Electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe

ActiveCN103982142AExtended service lifeIncreased microhardnessDrilling rodsCorrosion preventionWear resistantAcid washing

The invention relates to an electroplated amorphous state nickel-based alloy corrosion-resistant wear-resistant oil pipe, and belongs to the field of oil field oil pipes. The inner surface of the oil pipe is electroplated with an amorphous state nickel-based alloy corrosion-resistant wear-resistant protection layer. The thickness of the protection layer is 20-50 microns. The protection layer is electroplated by the steps of oil removing, water washing, acid washing, water washing, activating, deionized water cleaning, electroplating, water washing and thermal treatment. Treatment is performed in oil removing liquid for 5-10 minutes; in acid washing, an oxide film is removed from a sulfur solution till the natural color of metal is exposed; in electroplating, nickel alloy electroplating liquid is adopted, the PH value is adjusted to 2-6 by using nickel carbonate, the temperature is more than or equal to 60 DEG C, the current density is 2-8 A / dm<2>, and the electroplating time is 2 hours; in thermal treatment, the temperature is kept at 200-300 DEG C for 1.5 hours. The oil pipe has the advantages of high microhardness, resistance to acid and alkali corrosion, high wear resistance and long service life.

Owner:胜利油田金岛实业有限责任公司

Method for cleanly transferring single layer graphene by using PMMA

The invention discloses a method for cleanly transferring single layer graphene by using PMMA, and relates to a method for transferring the single layer graphene, aiming to solve the problems of an existing graphene transferring method that existing graphene grows unstably on a specific substrate such as a silicon wafer and the transferring is incomplete and curling easily occurs. The method disclosed by the invention is as follows: first, single layer graphene is grown on a copper foil substrate; second, then the copper foil substrate is coated with a PMMA glue in a suspending way, and then placed on a heating plate, heated, solidified, and trimmed; third, the copper foil is floated on the liquid-level of corrosive liquid, and fished out until the copper foil becomes transparent; fourth,standing in water is performed; fifth, the operation of the fourth step is repeated; sixth, the target substrate is picked up, blow-dried with nitrogen, and baked in an oven until the surface turns purple; seventh, PMMA is added dropwise, and standing is performed; and eighth, soaking in acetone, heating and washing are performed to complete the transfer of the single layer graphene. The method disclosed by the invention has broad prospects in the fields of optoelectronic devices and the like.

Owner:HARBIN INST OF TECH

Recovery method of fiber reinforced composite material

InactiveCN111171373ARealize resource reuseGood compatibilityPlastic recyclingEpoxyCatalytic oxidation

The invention discloses a recovery method of a fiber reinforced composite material. The fiber reinforced composite material is catalytically oxidized through an organic catalyst to depolymerize thermosetting epoxy resin into thermoplastic linear macromolecules and rapidly dissolve the thermoplastic linear macromolecules in an organic solvent, so that the fiber material and the thermoplastic polymer are separated and recovered. The method disclosed by the invention has the advantages of mild degradation conditions, simple process operation, small amount of three wastes, environmental friendliness and the like, and is a green method for recycling the fiber reinforced composite material.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

Method for degradation of composite material by directional bond breaking and recovery of fiber from composite material

ActiveCN110527137ASimple componentsEasy to separate, purify and reusePlastic recyclingSolvent effectsFiber strength

The invention provides a method for degradation of a composite material by directional bond breaking and recovery of fibers from the composite material. The method comprises the following steps that (1) the composite material is cut into composite material blocks with the target size for standby application; (2) the composite material blocks, solvents, metal salts, ligands, pH regulators and oxidants are mixed evenly, and then heated, the composite material blocks are naturally cooled to the room temperature after being completely degraded, and then high-speed centrifugal separation is conducted to obtain crude fiber products; and (3) the crude fiber products are washed and dried, and finally fiber fine products are obtained. According to the method, through the hot solvent effect, unsaturated complexation and weak complexation, the solvents, the metal salts, the ligands, the pH regulators, the oxidants and the composite material are mixed, and then heated, directional bond breaking degradation of resin is achieved, finally the fibers with little surface resin residue, basically no defect and the fiber strength retention rate up to 97.1% are obtained, and the degradation rate of the resin is as high as 100%.

Owner:WUHAN UNIV OF TECH

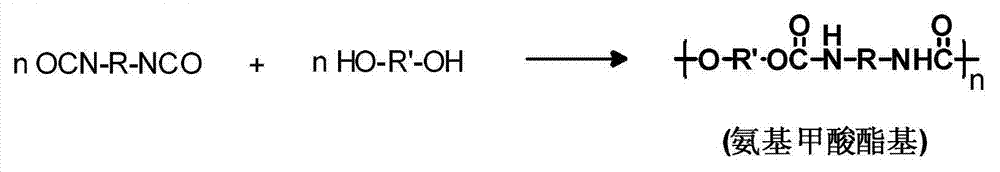

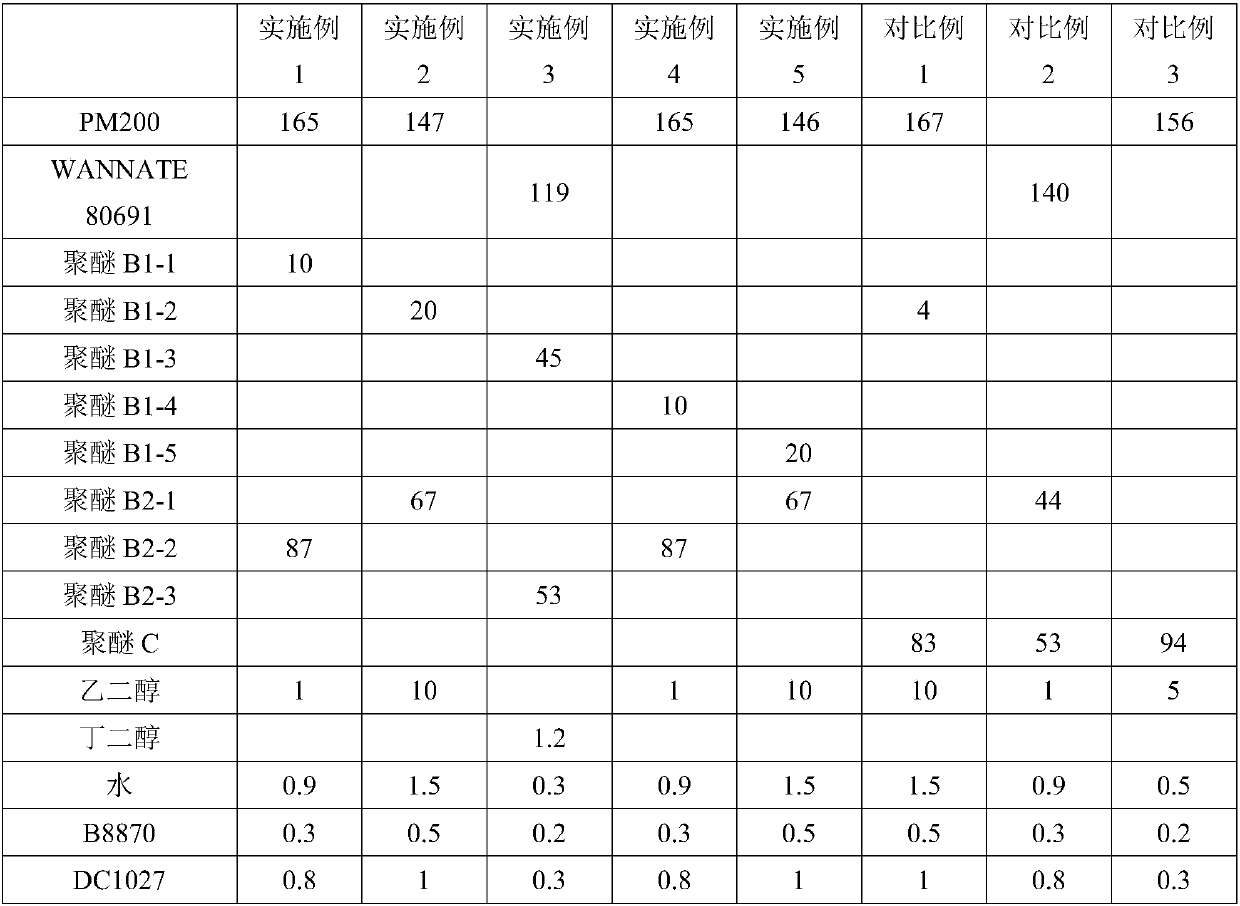

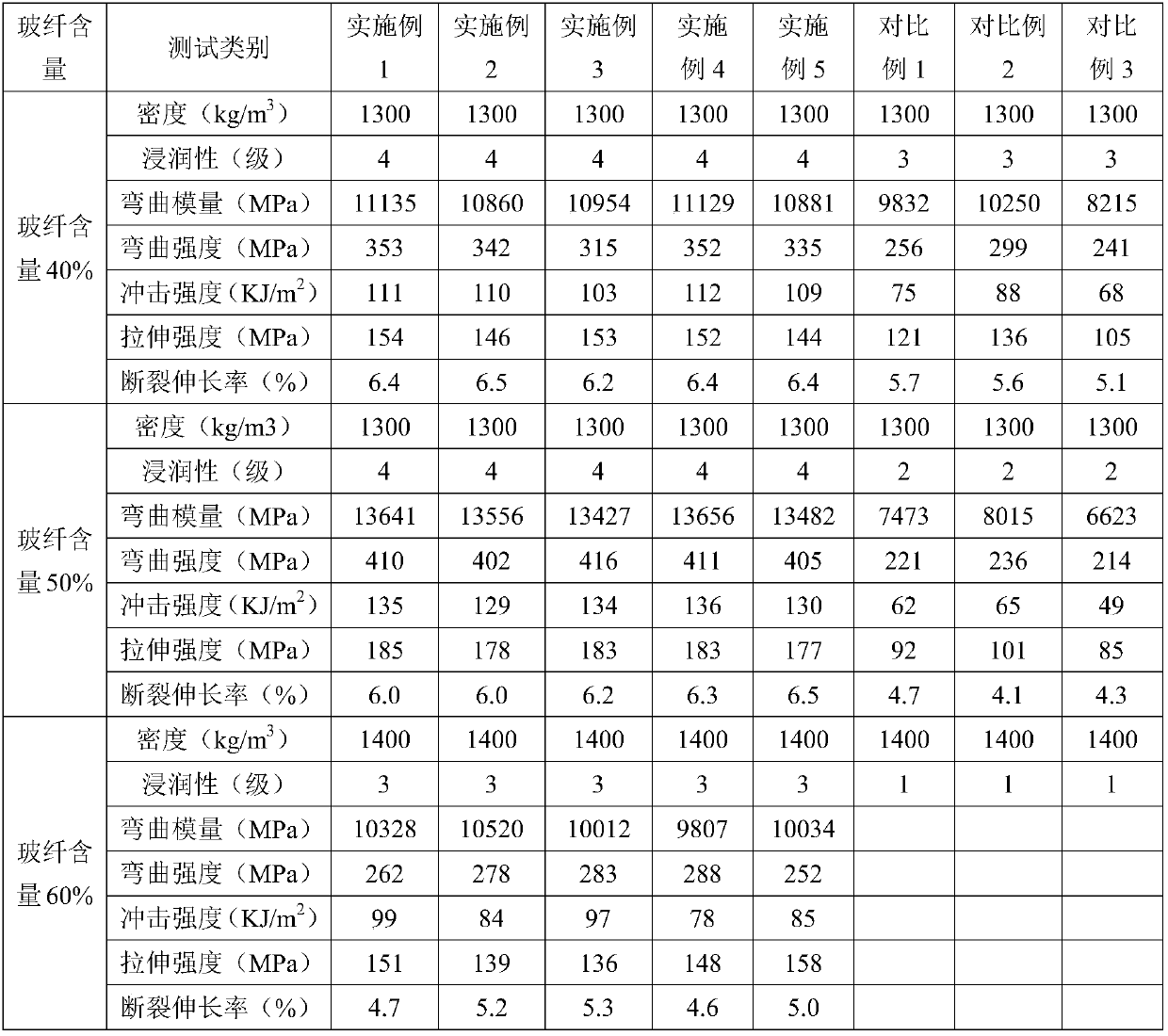

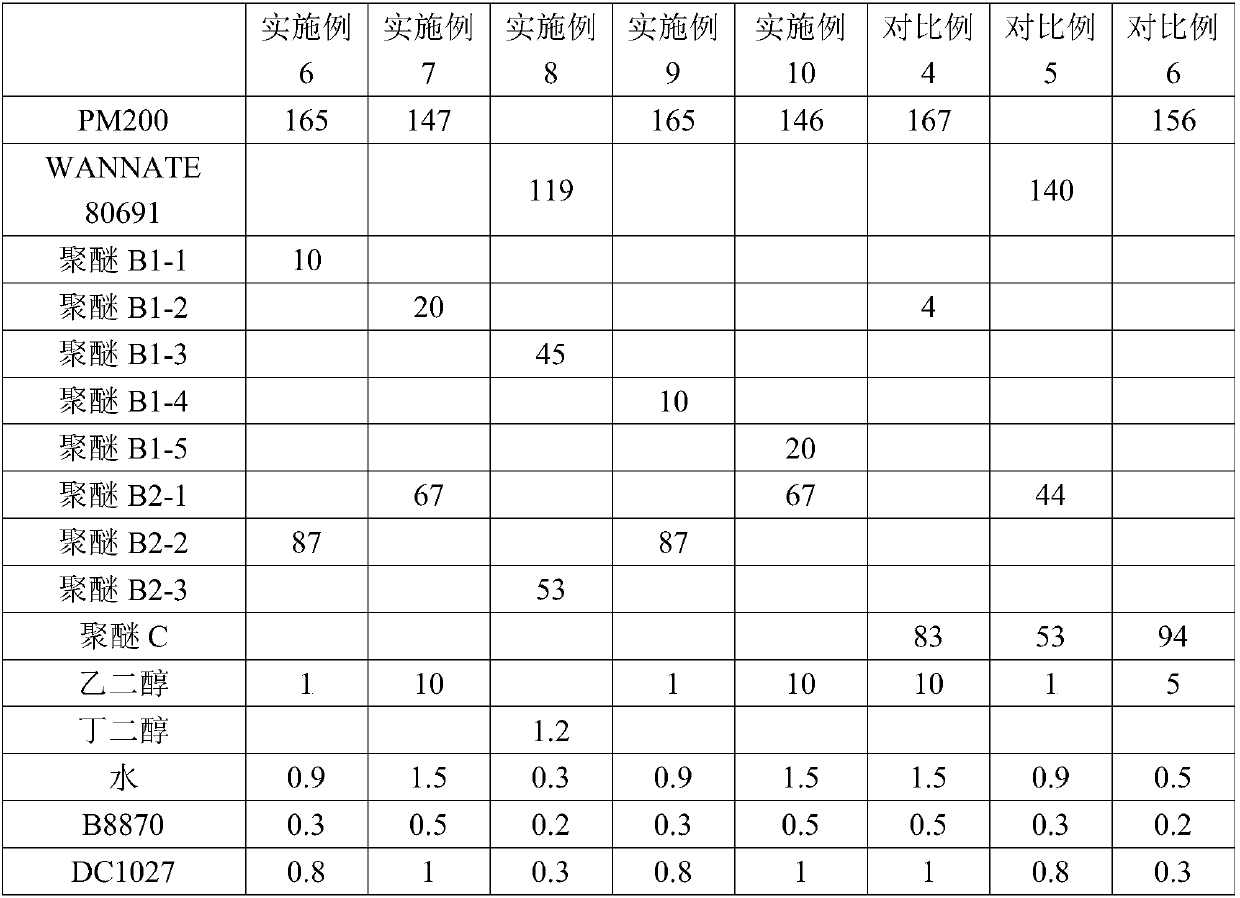

Polyurethane composition, and thermosetting polyurethane composite prepared therefrom

The present invention provides a polyurethane composition, and a thermosetting polyurethane composite prepared therefrom. The composition comprises an organic isocyanate component A and an isocyanatereactive component B. The polyurethane composition has a good wettability with a reinforcing material when used to prepare t he polyurethane composite material, and the content of the fiber reinforcing material in the prepared composite material can reach up to 80%, so the composite material has high mechanical properties. In addition, the composite material provided by the invention has the advantages of simple process and low cost.

Owner:WANHUA CHEM BEIJING +1

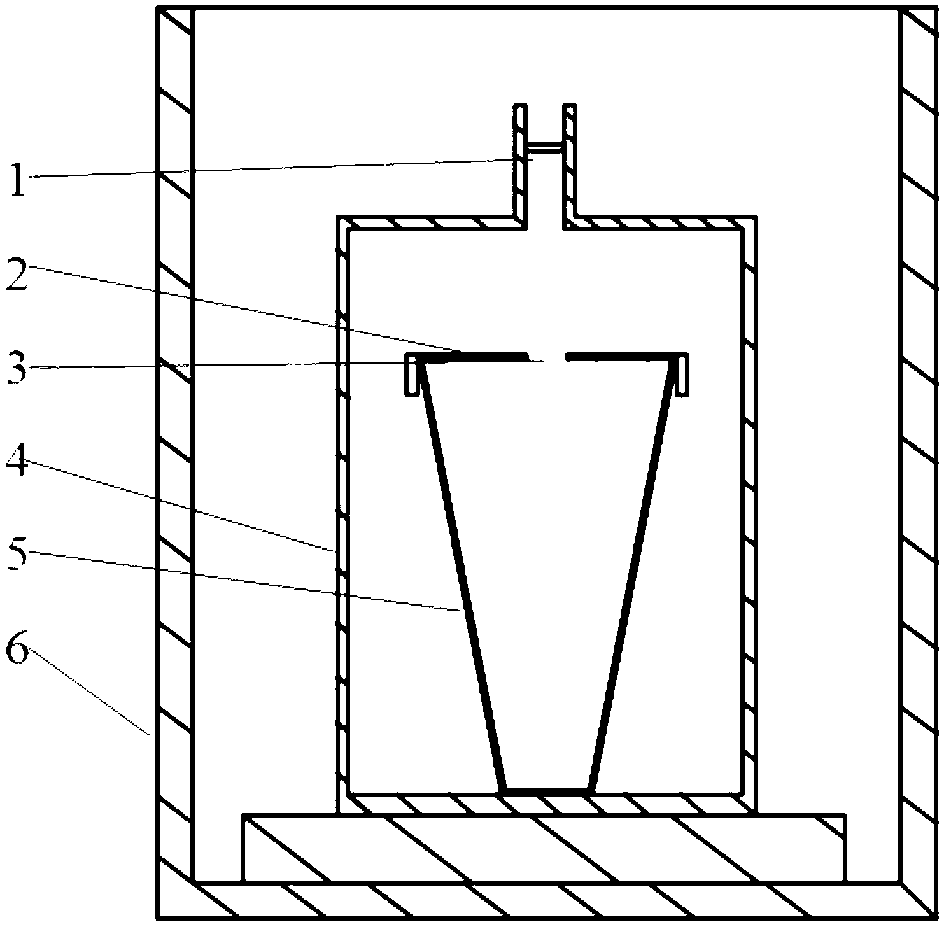

Organic transistor, manufacturing method of semiconductor device and organic transistor

InactiveUS20100297809A1Reduce leakage currentReduce tunnel leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

It is an object to form a high quality gate insulating film which is dense and has a strong insulation resistance property, and to propose a high reliable organic transistor in which a tunnel leakage current is little. One mode of the organic transistor of the present invention has a step of forming the gate insulating film by forming the conductive layer which becomes the gate electrode activating oxygen (or gas including oxygen) or nitrogen (or gas including nitrogen) or the like using dense plasma in which density of electron is 1011 cm−3 or more, and electron temperature is a range of 0.2 eV to 2.0 eV with plasma activation, and reacting directly with a portion of the conductive layer which becomes the gate electrode to be insulated.

Owner:SEMICON ENERGY LAB CO LTD

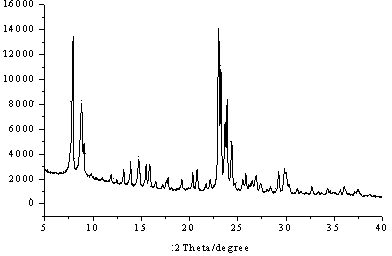

Preparation method of Silicalite-1/ZSM-5 composite molecular sieve

ActiveCN104415784AWell mixedGuaranteed continuityMolecular sieve catalystsMicroballoon preparationMolecular sieveIsomerization

The invention discloses a preparation method of a Silicalite-1 / ZSM-5 composite molecular sieve, which comprises the following steps: 1)dispersing a ZSM-5 molecular sieve in water under ultrasonic effect, adjusting pH value to 2-6 or 8-13, adding a template, then adding silicon source, uniformly stirring, performing solid-liquid separation, drying to obtain the pretreated ZSM-5 molecular sieve; 2)adding the pretreated ZSM-5 molecular sieve in a mixing solution containing sodium hydroxide and water, uniformly stirring, crystallizing, washing, and drying to obtain the Silicalite-1 / ZSM-5 molecular sieve. According to the invention, the composite molecular sieve Silicalite-1 is completely covered on the ZSM-5 external surface, thickness is uniform, operation is simple, the composite molecular sieve is convenient for large scale production, and the composite molecular sieve has latent application value in toluene methanol alkylation and xylene isomerization reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surface sulfur seepage prevention coating for furan resin-sand production wind power nodular iron casting

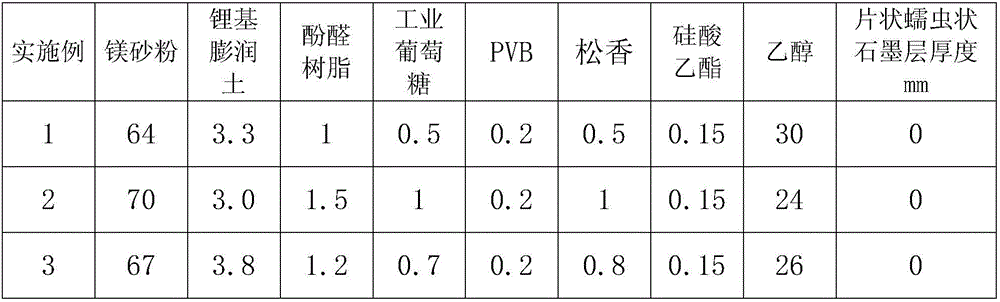

InactiveCN106180542ANo defectQuality improvementFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention provides surface sulfur seepage prevention coating for a furan resin-sand production wind power nodular iron casting. The surface sulfur seepage prevention coating is prepared from the following components in parts by weight: 62 to 70 parts of magnesia powder, 2 to 3 parts of lithium-based bentonite, 1 to 1.5 parts of organic bentonite, 0.8 to 1.5 parts of phenolic resin, 0.5 to 1 part of industrial glucose, 0.2 part of polyvinyl butyral (PVB), 0.5 to 1 part of rosin, 0.15 part of ethyl silicate and 24 to 30 parts of ethyl alcohol. The surface sulfur seepage prevention coating of the technical scheme disclosed by the invention can be used for production of all the furan resin-sand production wind power nodular iron castings; for a common mechanical casting, the quality can be improved, and the wind power nodular iron casting and an outlet nodular iron casting can meet the technical requirement of a user more easily; and the surface layer, subjected to sanding cleaning, of the nodular iron casting does not have a sulfur seepage shortcoming, so that the loss on defective product is greatly reduced, and the surface sulfur seepage prevention coating is relatively high in practical value.

Owner:高红星

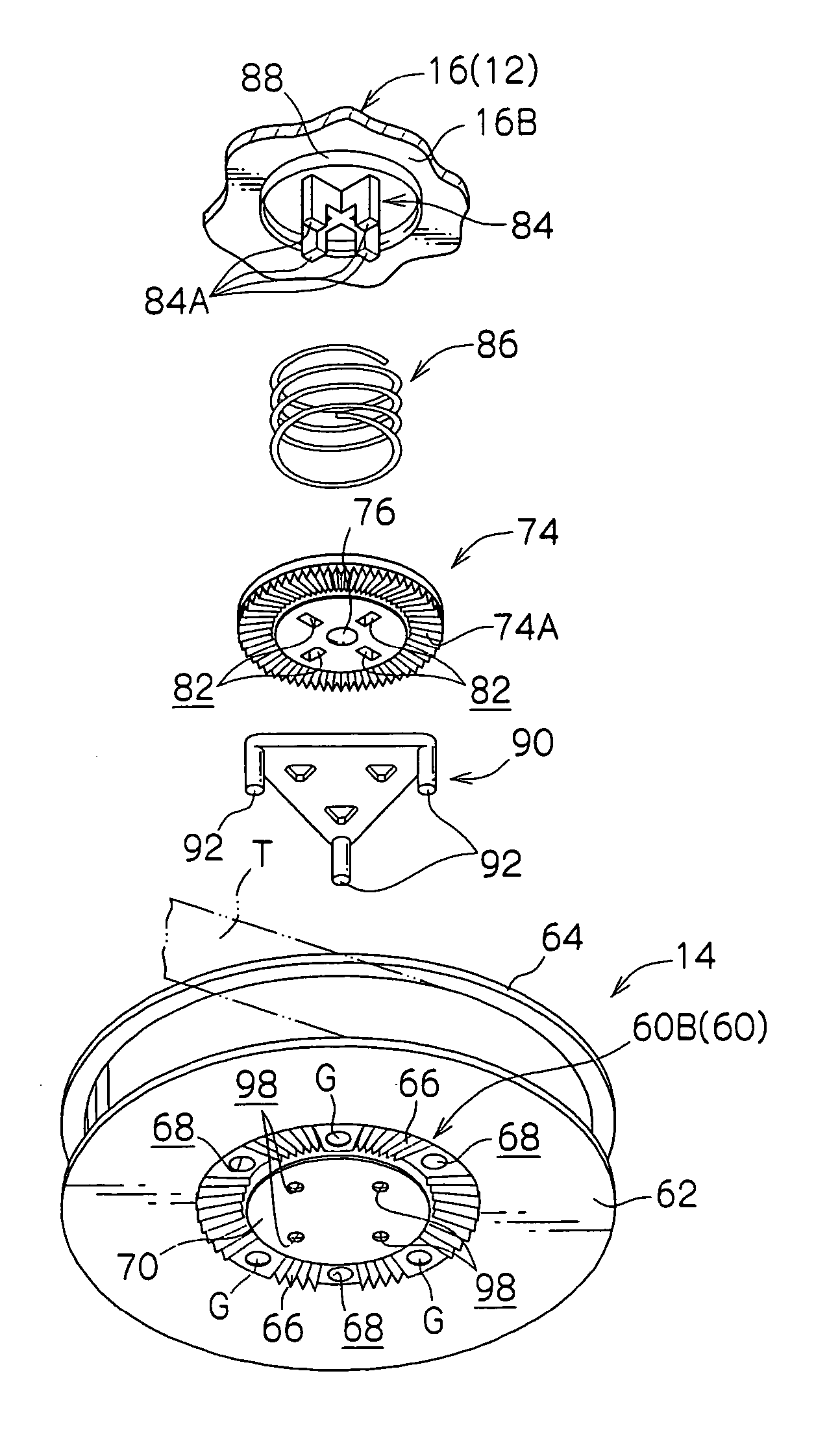

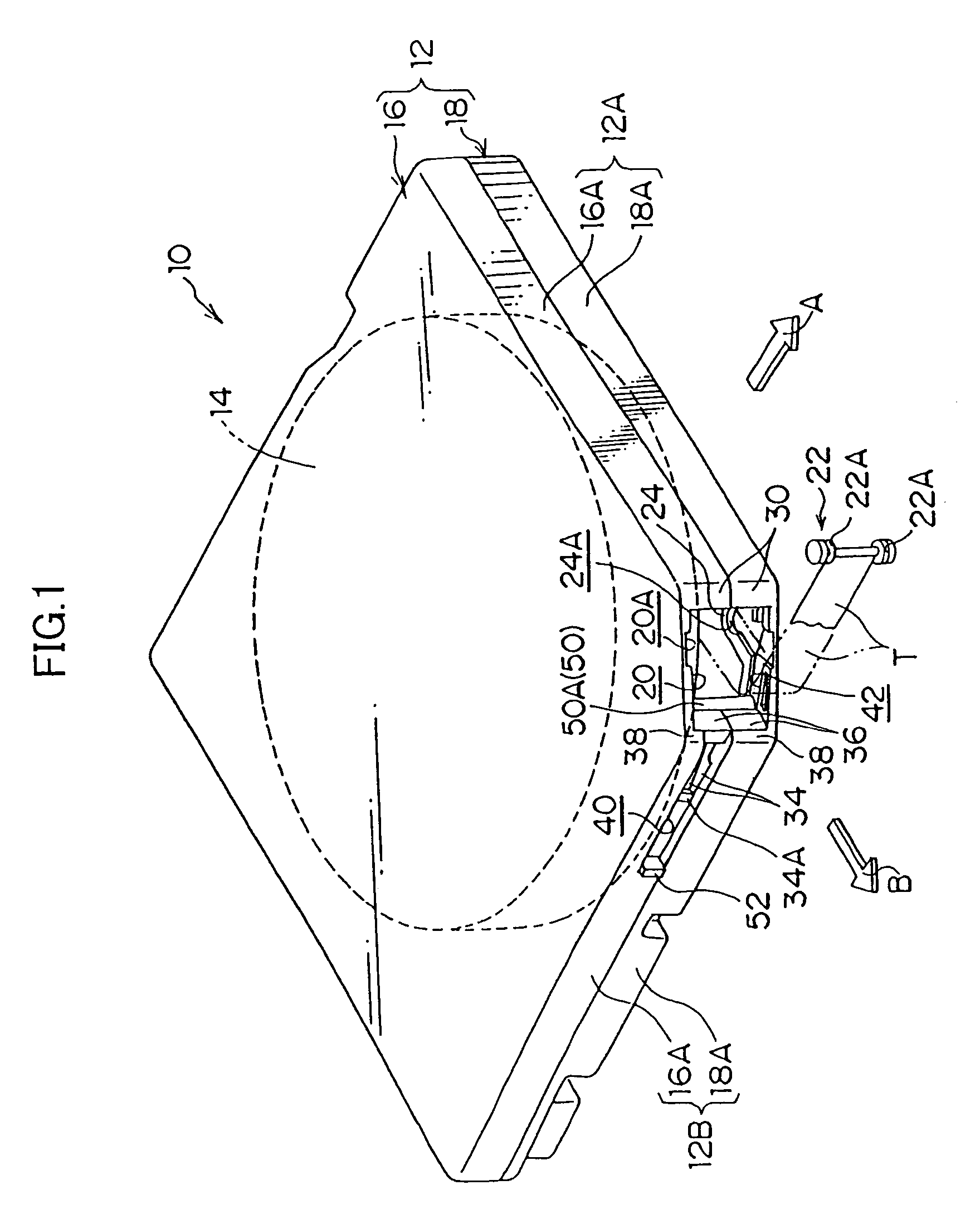

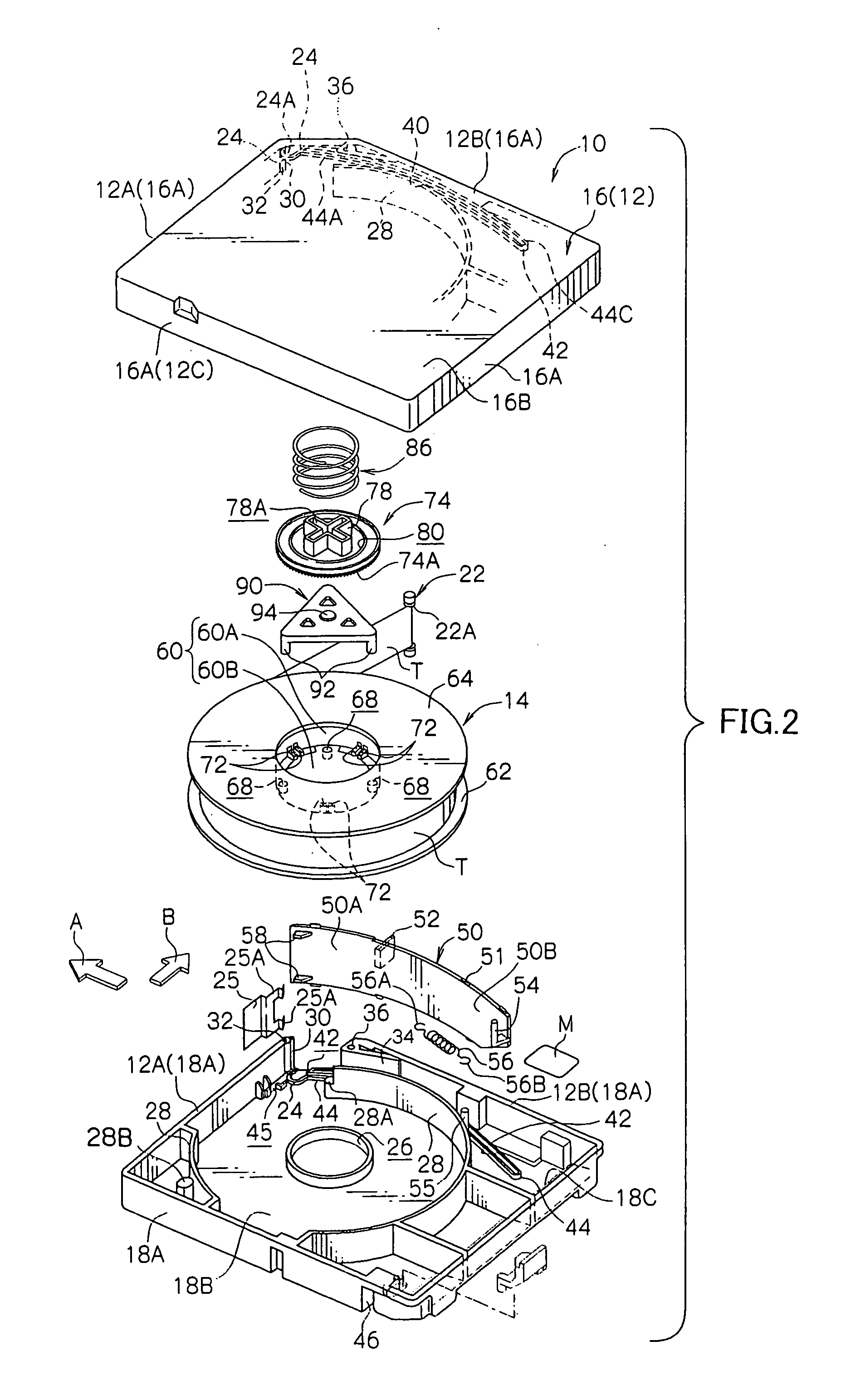

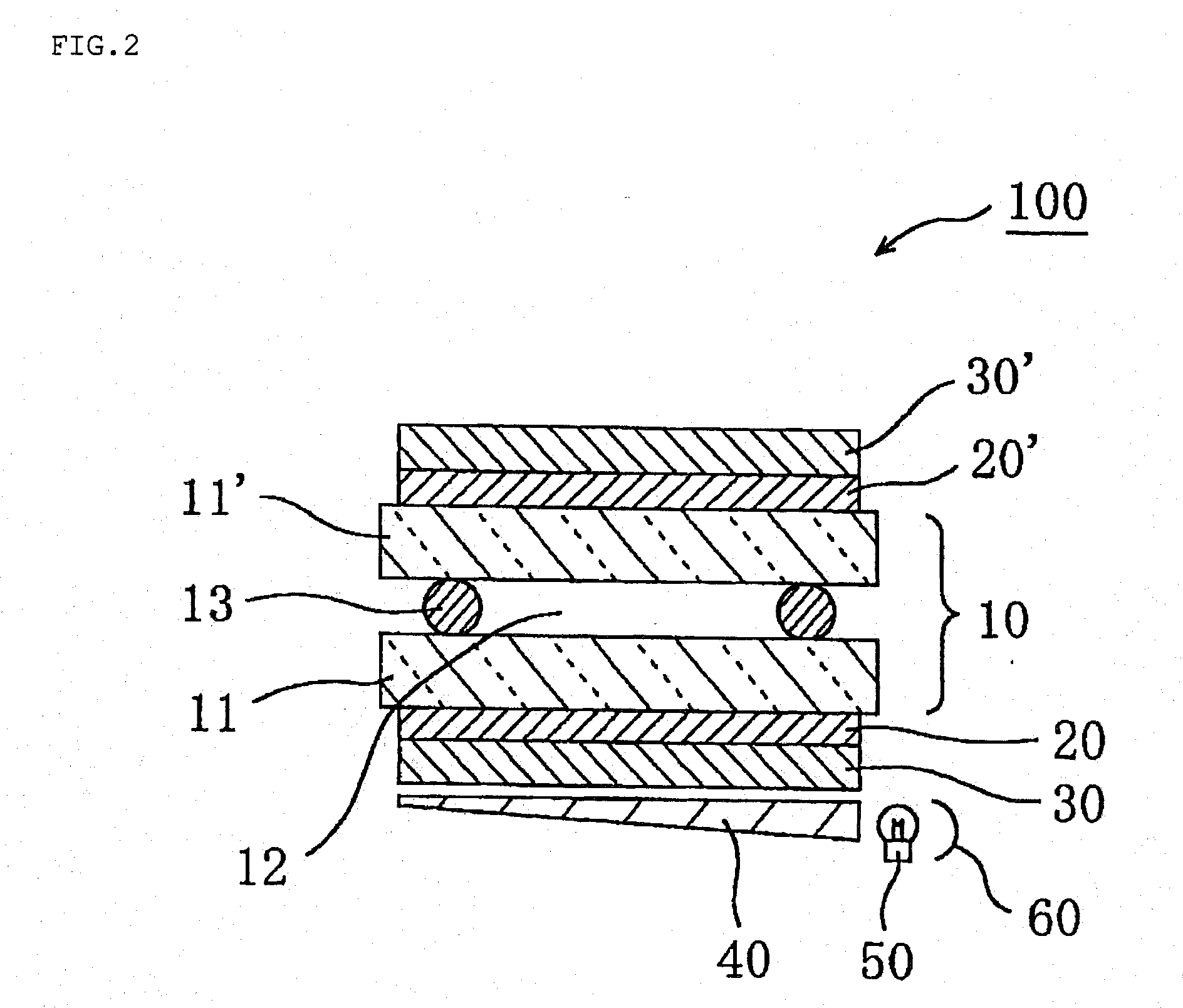

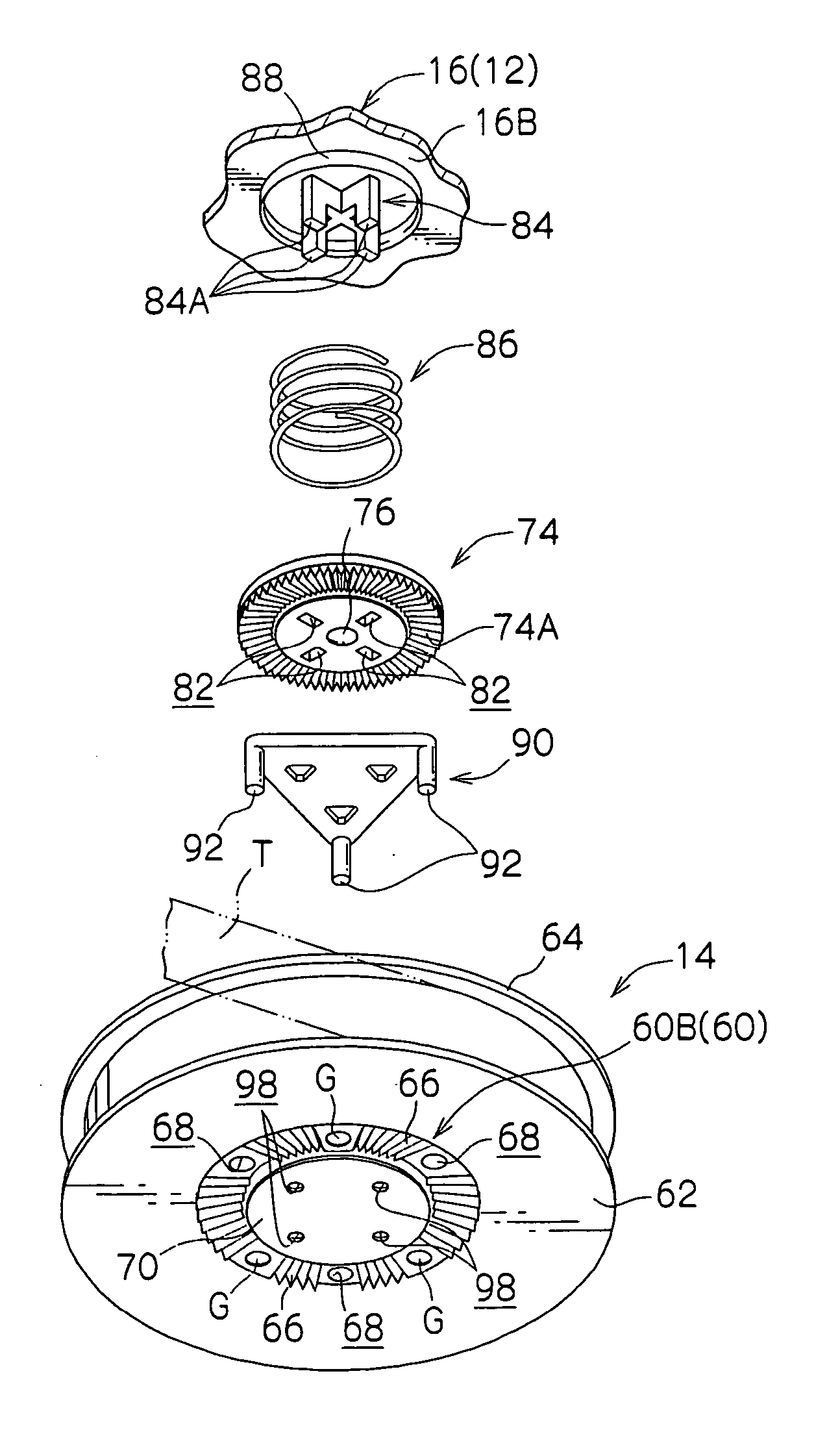

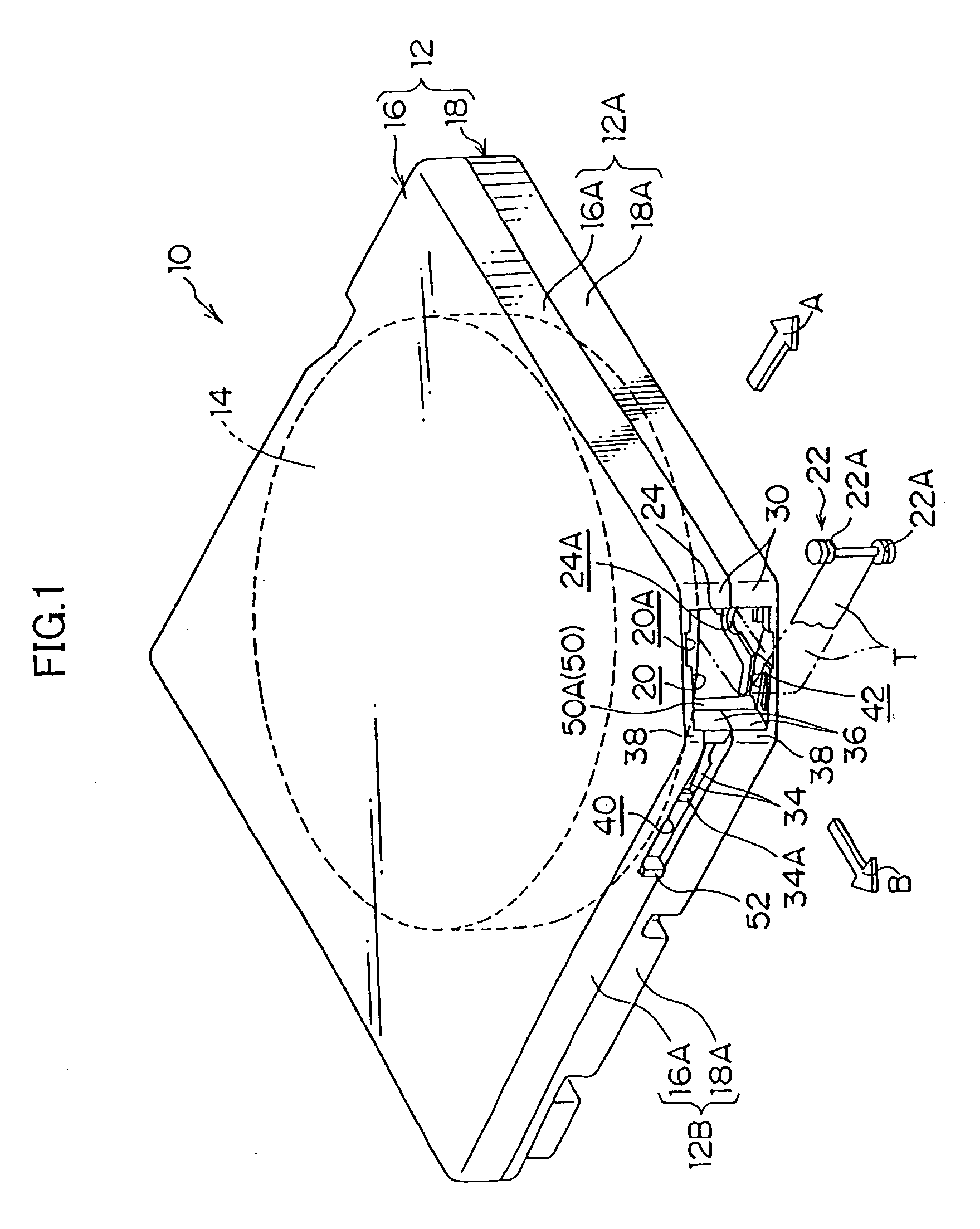

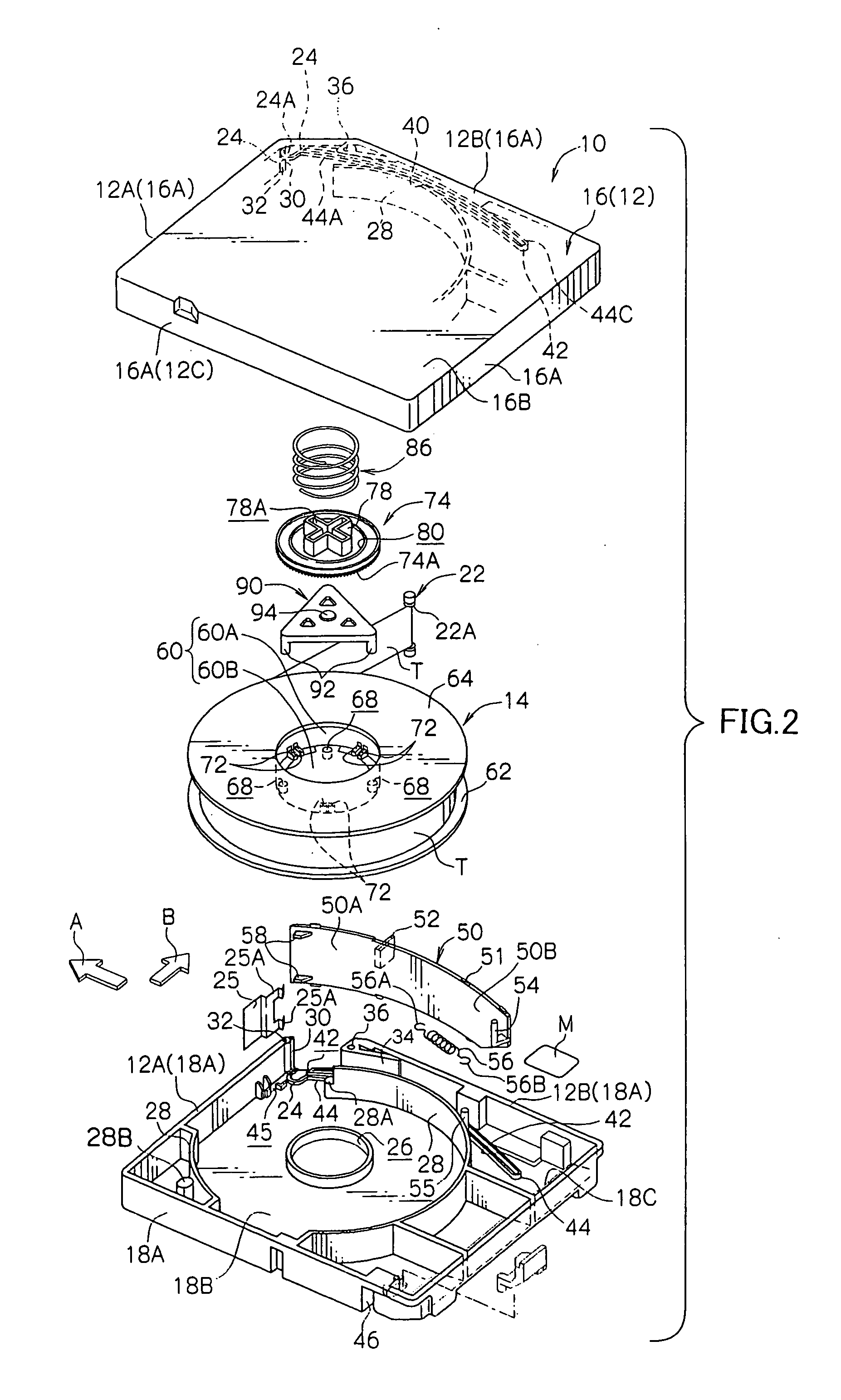

Recording tape cartridge

ActiveUS7252258B2Reduce areaImpairing mounting accuracyPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

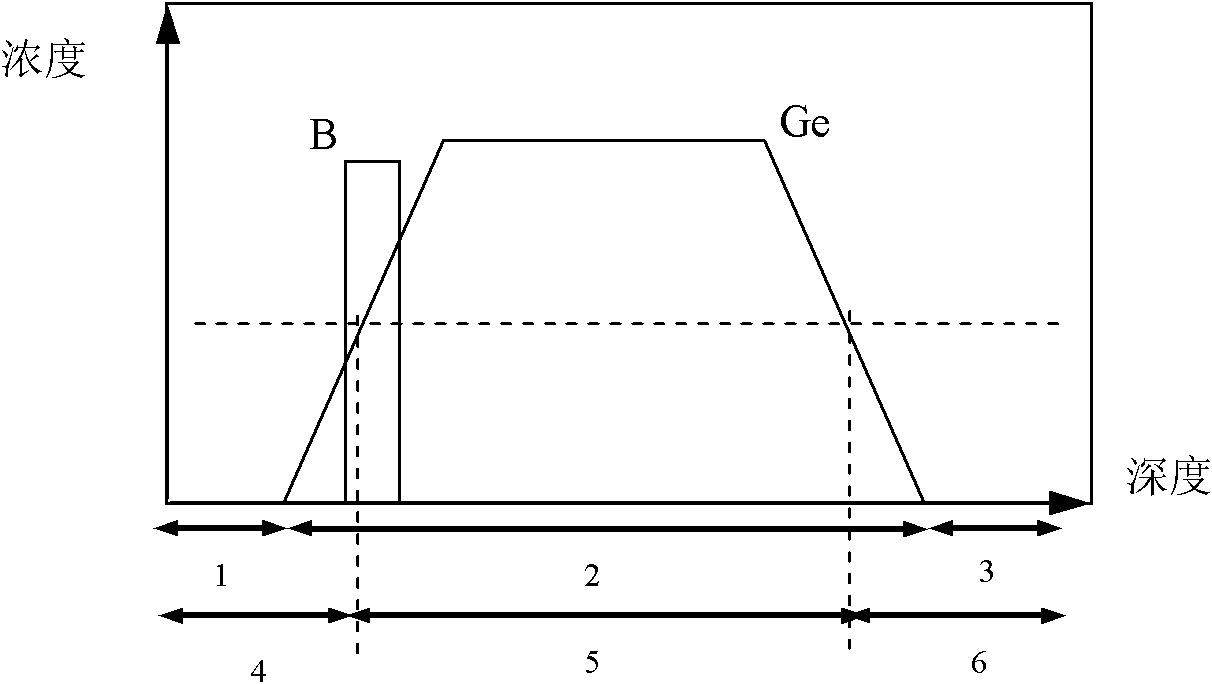

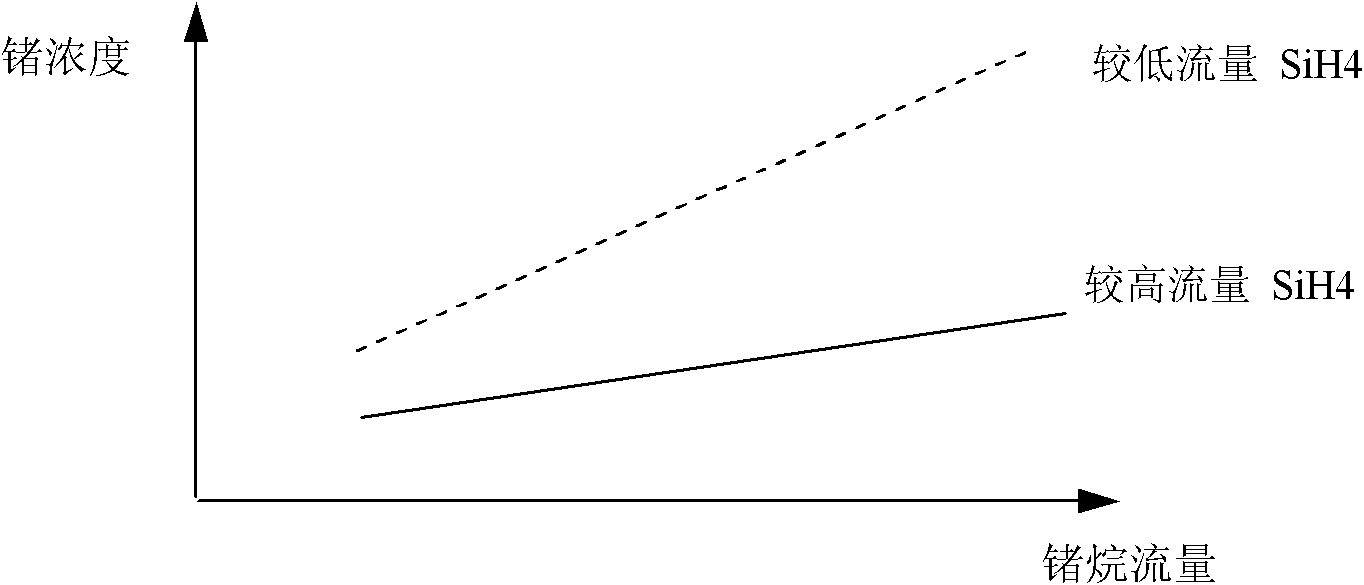

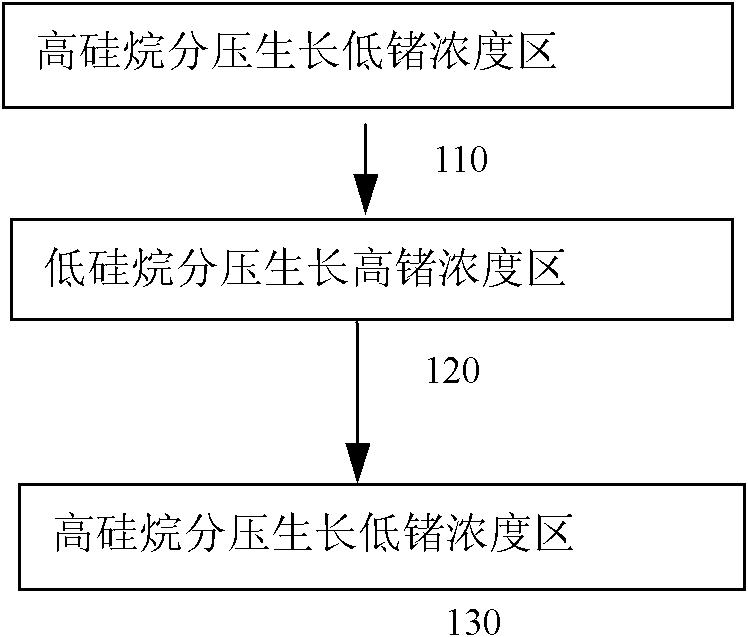

Method for germanium-silicon epitaxy of high germanium concentration

ActiveCN102465336ANo defectHigh germanium concentrationPolycrystalline material growthFrom chemically reactive gasesSilanesGermane

The invention discloses a method for a germanium-silicon epitaxy of high germanium concentration. According to the method, when silane and germane gases are introduced, the germanium content of a germanium-silicon epitaxy can be increased by lowering the percentages of silane and germane. At a same germanium source flow rate, and with the reduction of a silicon source flow rate, the germanium concentration is substantially enhanced, and finally a defect-free germanium-silicon epitaxial film with 25-35% of germanium atoms can be obtained. Under the premise of utilizing existing equipment, the method of the invention balances a growth rate and the doping concentration of germanium. While obtaining a high germanium concentration, the epitaxy growth rate is reduced by only a small degree. And the germanium-silicon epitaxy can be guaranteed to have no defect, meet device requirements, and have enough throughput simultaneously.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Method and apparatus for producing thermoelectric conversion material, and sputtering target production method

ActiveCN103290249AChange the bandgapImproved thermo-electric performanceVacuum evaporation coatingSputtering coatingSemiconductor materialsBismuth telluride

The present invention relates to the field of semiconductor materials, particularly to a method and an apparatus for producing a thermoelectric conversion material, and a method for producing a sputtering target by using the material. The thermoelectric conversion material production method comprises the following steps: (A) mixing 0-15% by mass of bismuth, 25-40% by mass of antimony and 56-63% by mass of tellurium to form a raw material; and (B) carrying out a vacuum smelting treatment on the raw material to obtain a semiconductor thermoelectric conversion material BiSbTe metal compound. According to the present invention, the vacuum smelting method is adopted to uniformly dope the metal-like element antimony (Sb) in a metal alloy of bismuth telluride in the conventional bismuth telluride material to form the metal compound BiSbTe so as to change an energy band gap of the material, such that a free hole concentration of electric carriers in the semiconductor alloy are increased, a thermal-electrical performance (ie., ZT parameter) of the material are substantially increased, and the doped element does not generate segregation or crystal defects.

Owner:PIONEER MATERIALS INC CHENGDU

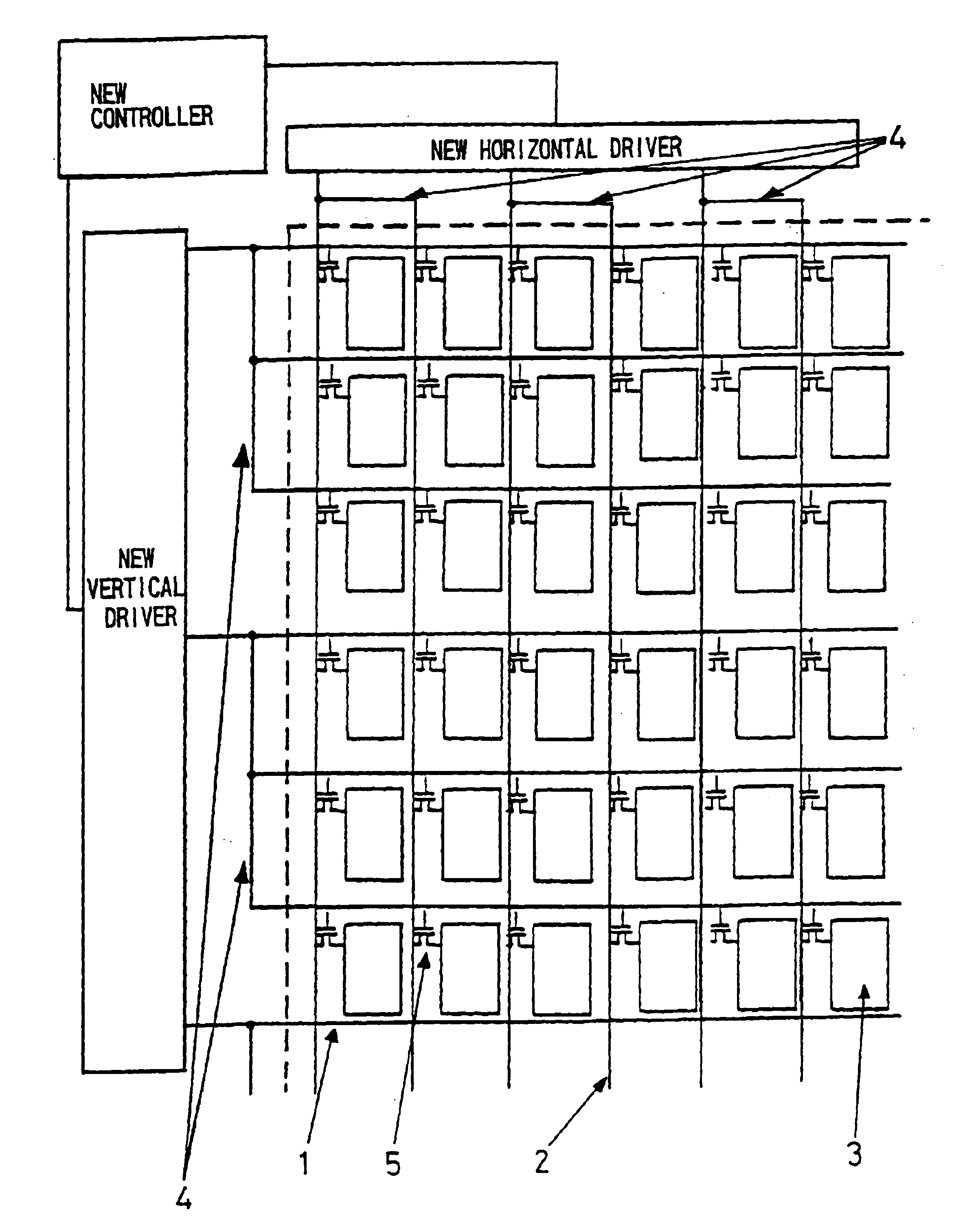

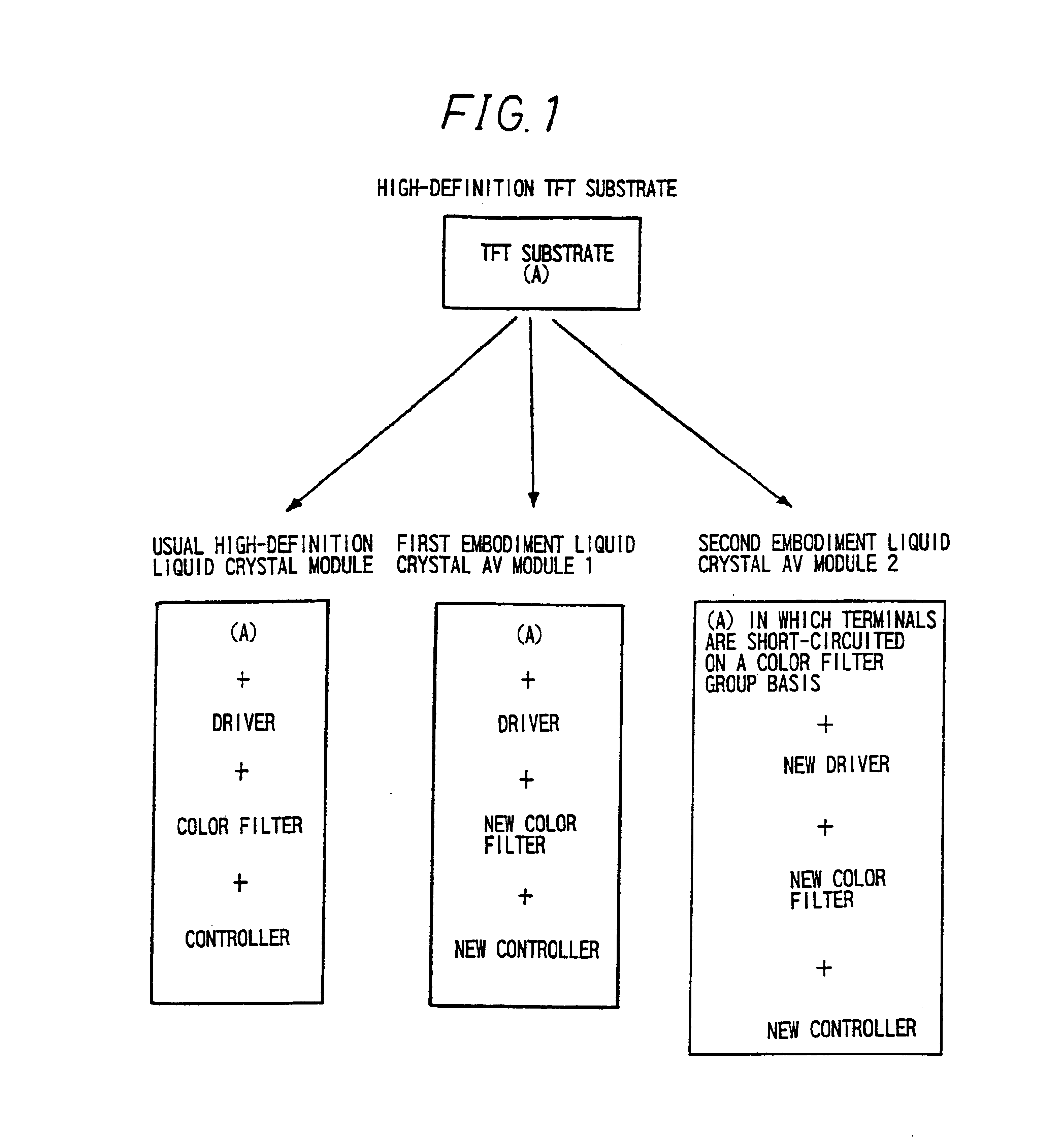

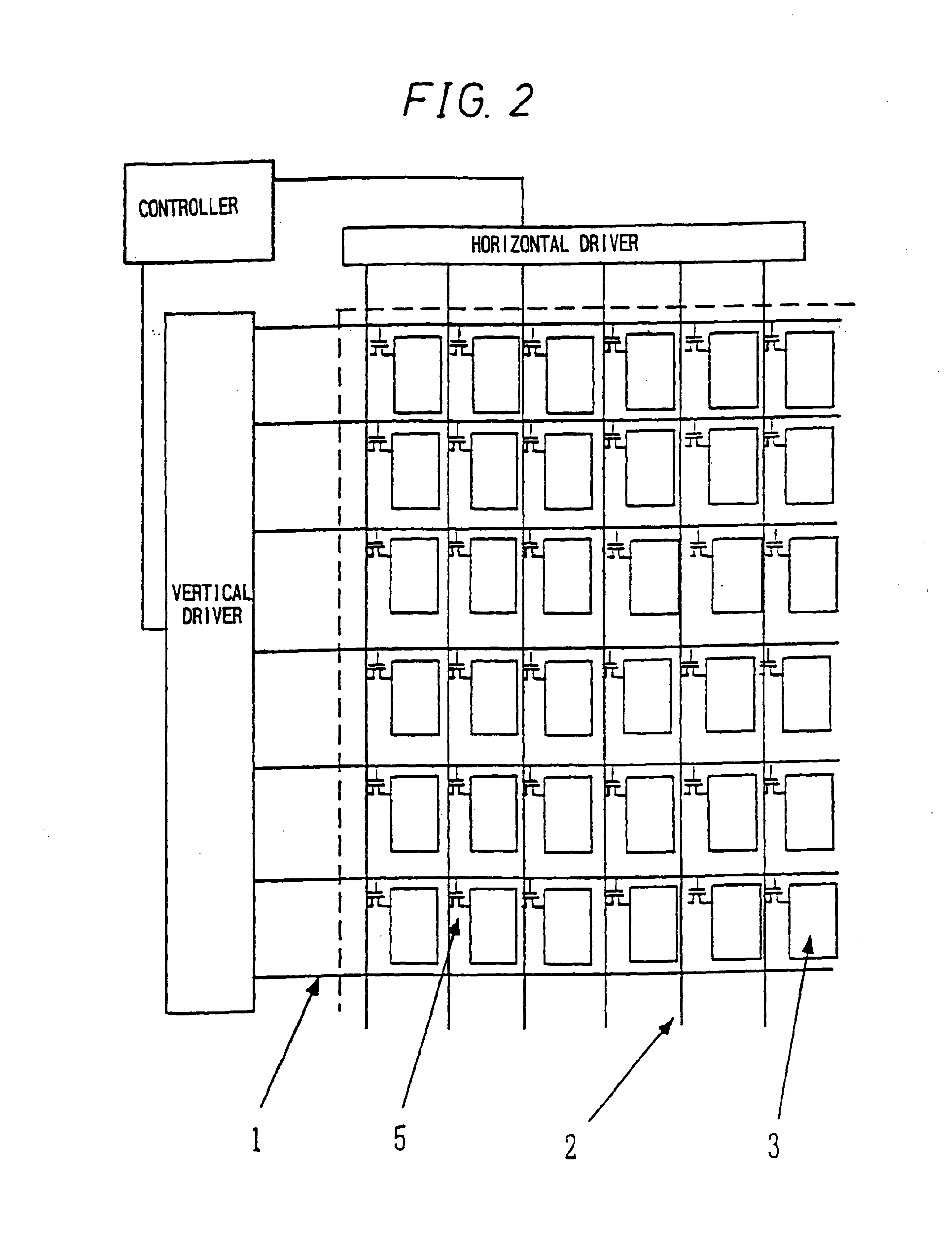

Liquid crystal display apparatus and method of manufacturing the same via short-circuited bus lines

InactiveUS6864940B2Improve production efficiencyHigh yieldLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayElectrical polarity

A method of driving an LCD is provided, where adjacent bus lines are short-circuited during LCD driving operations. In certain example embodiments, an inverse driving technique is used to invert the polarity of a video signal at every one row for instance. In certain example embodiments, short-circuited adjacent data lines (source lines) are in communication with pixels of the same color.

Owner:SHARP KK

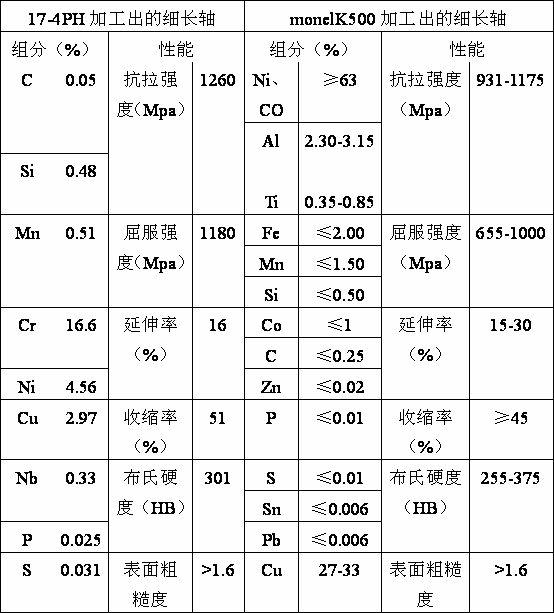

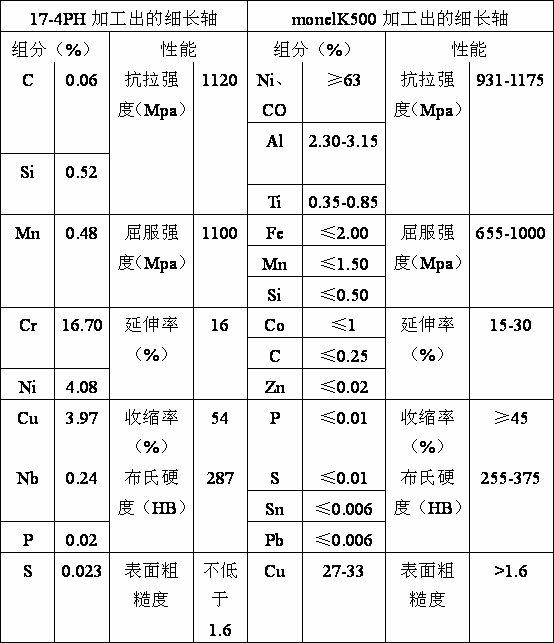

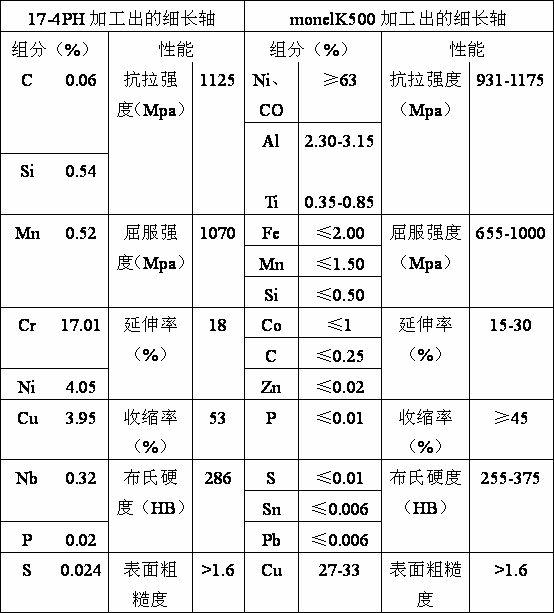

Method for processing spindly shaft by utilizing 17-4PH stainless steel

The invention relates to a method for processing a spindly shaft by utilizing 17-4PH stainless steel, which comprises the following steps of: taking the 17-4PH stainless steel as a raw material; putting the raw material in a vacuum melting furnace so as to carry out vacuum melting; pouring the melted solution after vacuum melting furnace into a mould which is arranged in a vacuum chamber and is provided with a cylindrical cavity so as to form a ingot casting; forging; hot rolling; hot drawing; cold drawing and age-hardening. Due to the adoption of the technical scheme, the invention provides the method for processing the spindly shaft by utilizing the 17-4PH stainless steel, a metallographic structure of the 17-4PH stainless steel is still kept in an austenite state in a processing process, and the spindly shaft is processed through cold drawing and forming, so that the processed spindly shaft has high strength, high hardness and good deformability.

Owner:ZHEJIANG ZHENXING PETROCHEM MACHINERY

Method for preparing garnet single crystal and garnet single crystal prepared thereby

InactiveCN1878892AUniform thicknessLow viscosityPolycrystalline material growthLiquid-phase epitaxial-layer growthAlkali metal oxideCarbide

Disclosed herein is a method for manufacturing a magnetic garnet single crystal from a melt containing an alkali metal oxide or carbide, garnet single crystal raw materials and Bi2O3-B2O3-PbO as a flux by liquid phase epitaxy (LPE) wherein the garnet single crystal is grown at a relative low temperature due to a reduced viscosity of the melt, and the grown garnet single crystal has a uniform thickness and a specular surface without any crystal defects. Further disclosed is a magnetic garnet single crystal manufactured by the method.

Owner:金裕坤

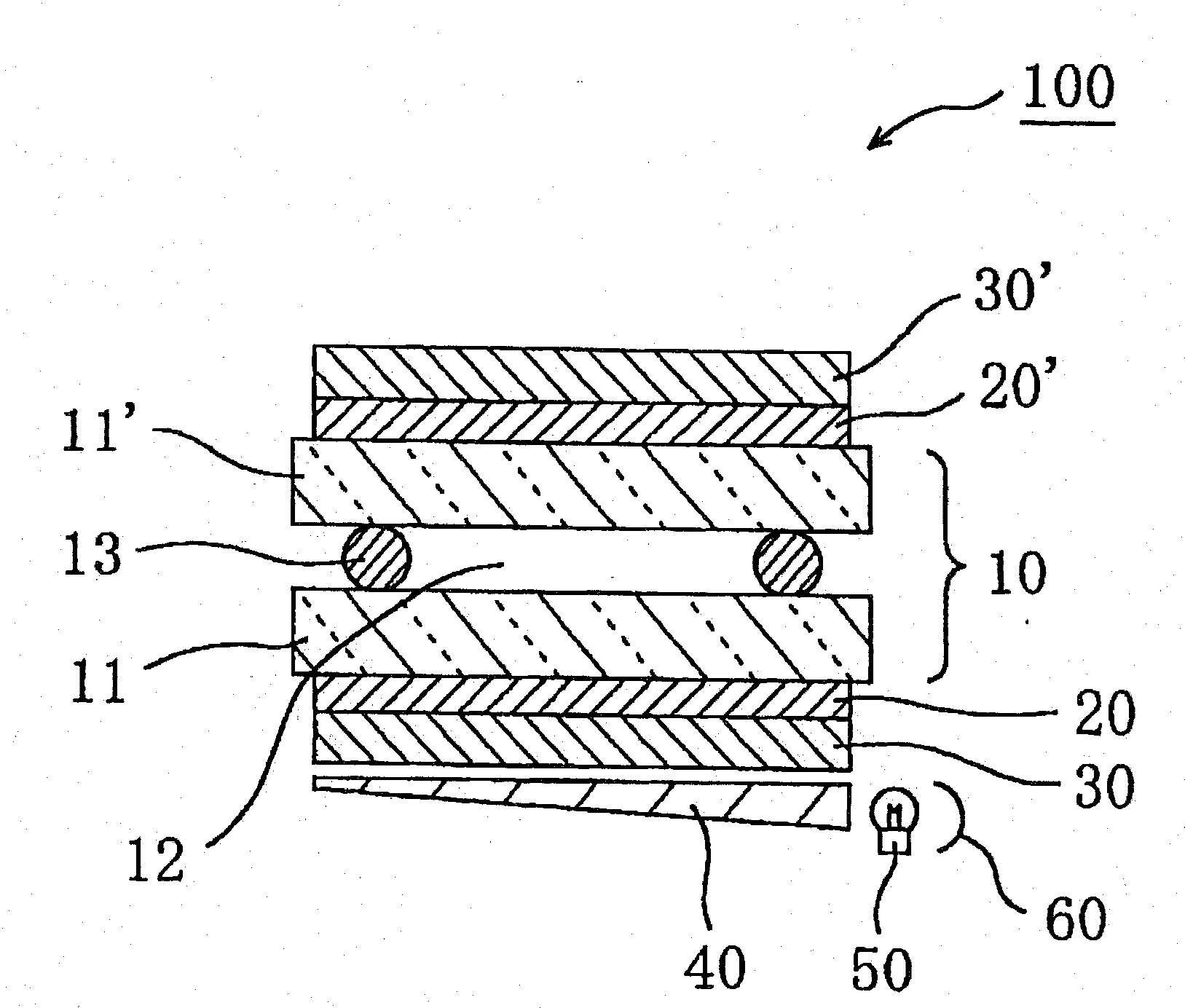

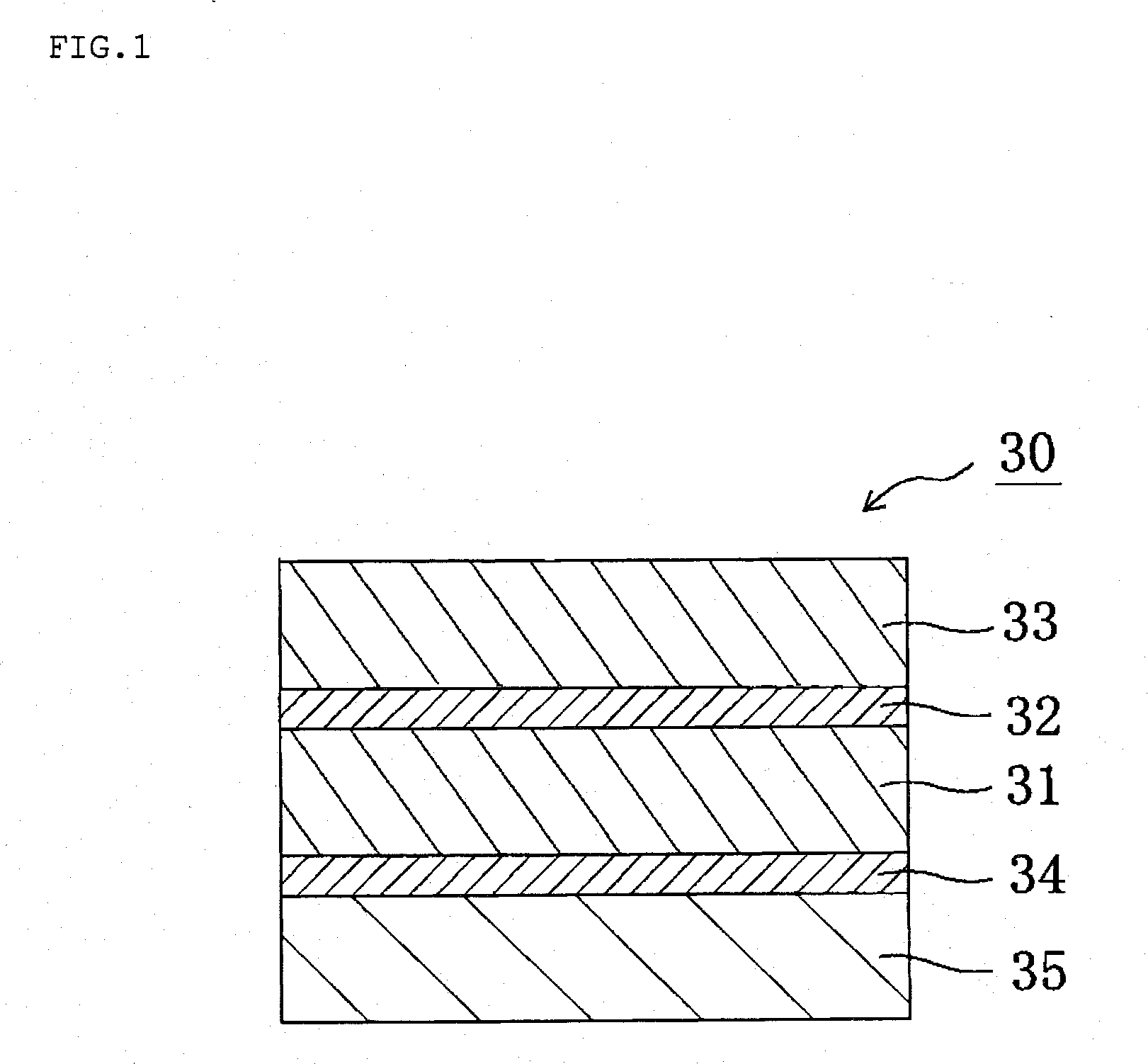

Polarizing plate and image display apparatus

InactiveUS20080158676A1No defect of unevennessExcellent in optical characteristic and in external appearancePolarising elementsOptical propertyMeth-

Provided are a polarizing plate which has no defects of unevenness and is excellent in optical characteristics as well as in external appearance, and an image display apparatus of high quality using such a polarizing plate. The polarizing plate of the present invention includes a polarizer and a protective layer (A) placed on at least one surface of the polarizer, in which the protective layer (A) is a (meth)acrylic resin layer having a thickness of 1 to 50 μm with a surface hardness of B or more in terms of a pencil hardness, and an adhesive layer having a thickness of 50 to 150 nm is placed between the polarizer and the protective layer (A).

Owner:NITTO DENKO CORP +1

Recording tape cartridge

ActiveUS20050145737A1Inhibition effectReduce areaPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com