Polyurethane composition, and thermosetting polyurethane composite prepared therefrom

A composite material and polyurethane technology, which is applied in the field of thermosetting polyurethane composite materials, can solve the problems of low fiber content and insufficient comprehensive mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

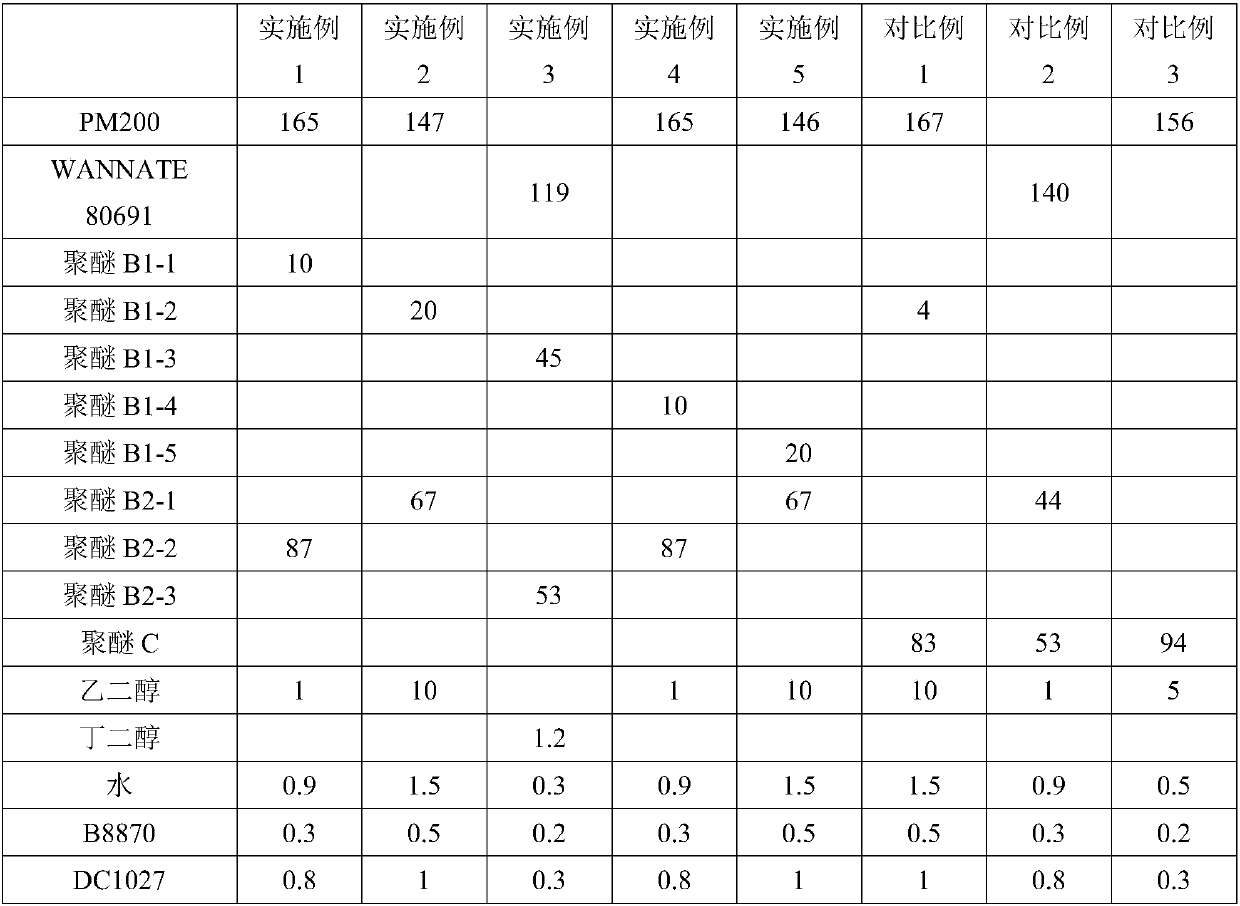

Embodiment 1-5、 comparative example 1-3

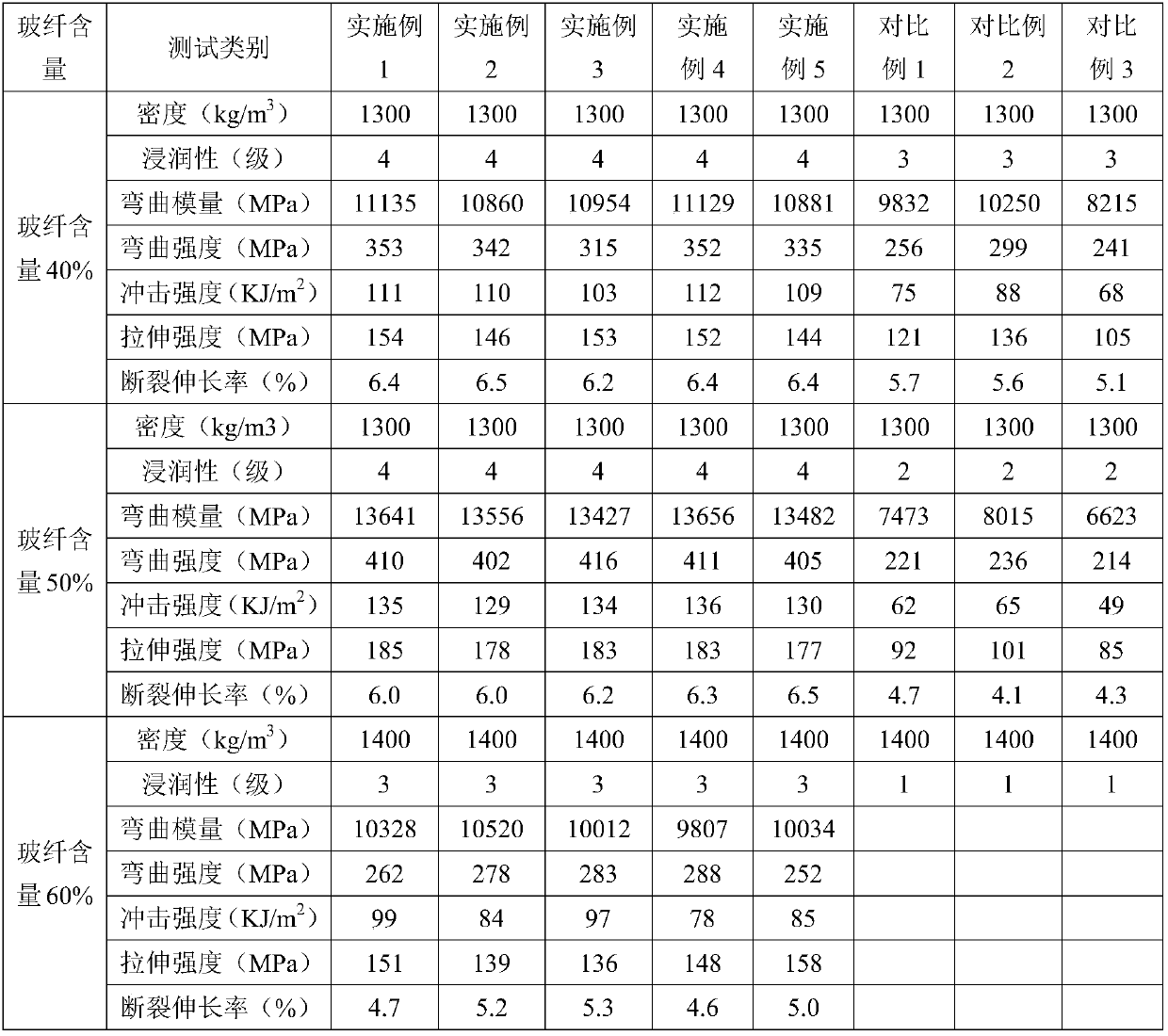

[0101] Embodiment 1-5, comparative example 1-3 composite material preparation method:

[0102] (1) Adopt Krauss-Maffei's LFI special equipment, the equipment pressure is (140±10)bar, the raw material temperature is (25±1)℃, the mold temperature is (50±3)℃, and the mold pressure is (200±10) kN, the fiber cutting length is set to 1cm;

[0103] (2) Add each raw material into the equipment, open the mold and pour, the pouring rate is 200g / s, close the mold and hold the pressure for 5 minutes, then open the mold to obtain a composite material product.

[0104] Among them, the composite materials of Examples 1-5 and Comparative Examples 1-3 were prepared according to the glass fiber content of 40%, 50%, and 60%, respectively, and the obtained composite materials were tested, and the test results are listed in Table 2.

[0105] Table 2

[0106]

[0107] Note: The performance data not filled in Table 2 indicates that the comparative sample cannot be tested because it cannot be mo...

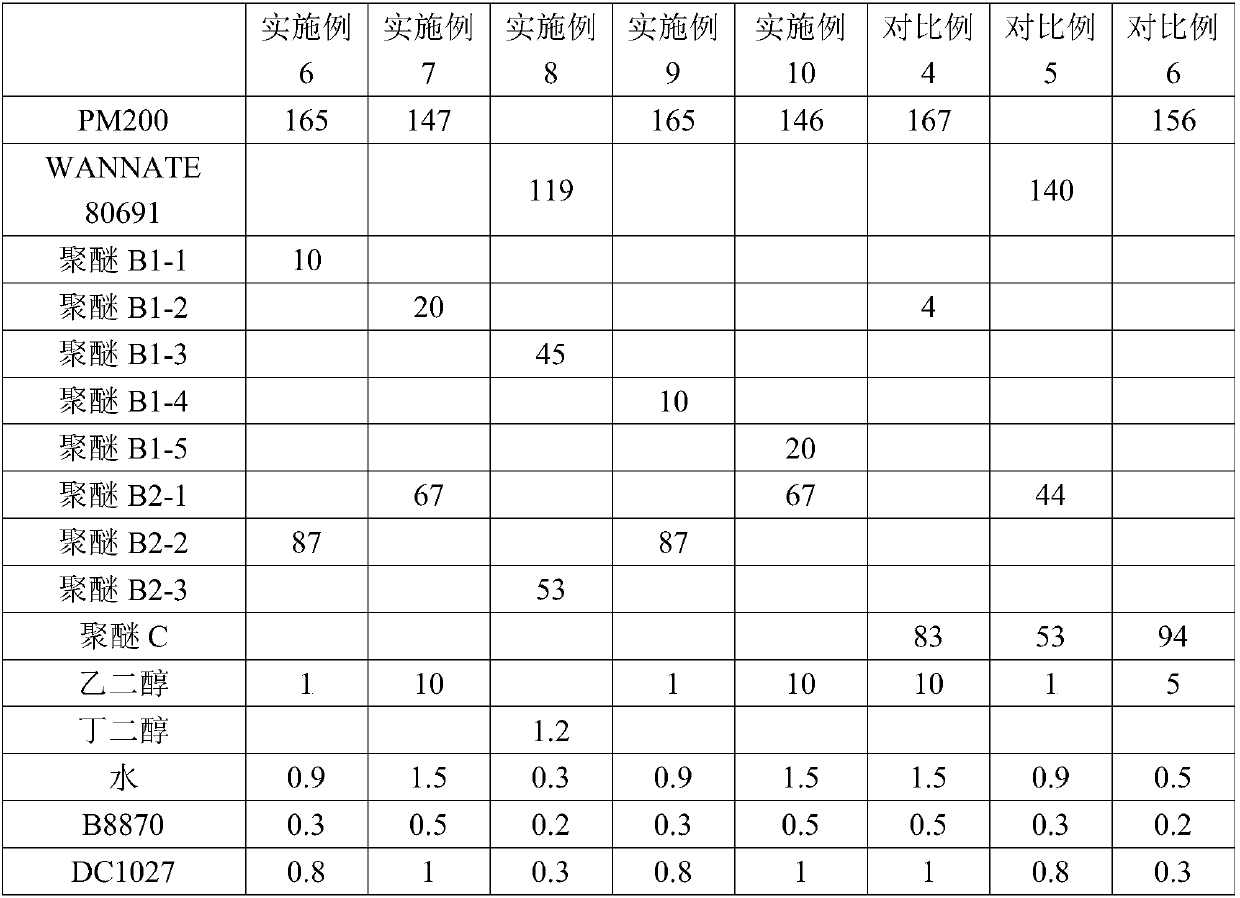

Embodiment 6-10、 comparative example 4-6

[0111] Embodiment 6-10, comparative example 4-6 composite material preparation method:

[0112] (1) Special equipment for foaming and pultrusion is adopted, the pultrusion speed is 1m / min, the total length of the mold is 20m, the cross section is 200mm×50mm, and the molding temperature of the mold is 90°C;

[0113] (2) Pouring the raw material of the polyurethane composition into the resin tank of the equipment with a pouring rate of 100 g / s, mixing and infiltrating, molding, cooling and cutting to obtain a composite material product.

[0114] Among them, the preparation of the composite materials of Examples 6-10 and Comparative Examples 4-6 is carried out according to the glass fiber content of 40%, 50%, 60%, and 70%, respectively, and the obtained composite materials are tested, and the test results are listed in Table 4 .

[0115] Table 4

[0116]

[0117]

[0118] Note: The performance data not filled in Table 4 indicates that the comparative sample cannot be test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com