Combining device and method of composite PTFE (polytetrafluoroethylene) plate

A composite device and composite plate technology, applied in the field of fluoroplastic composite devices, can solve the problems of easy failure of the surface activation layer, reduced composite strength, limited surface treatment, etc., and achieve excellent anti-penetration performance, high composite strength, and good welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

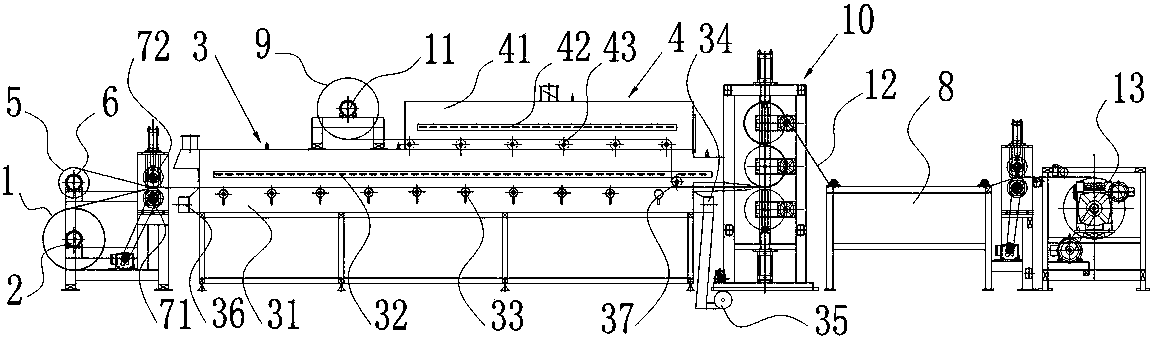

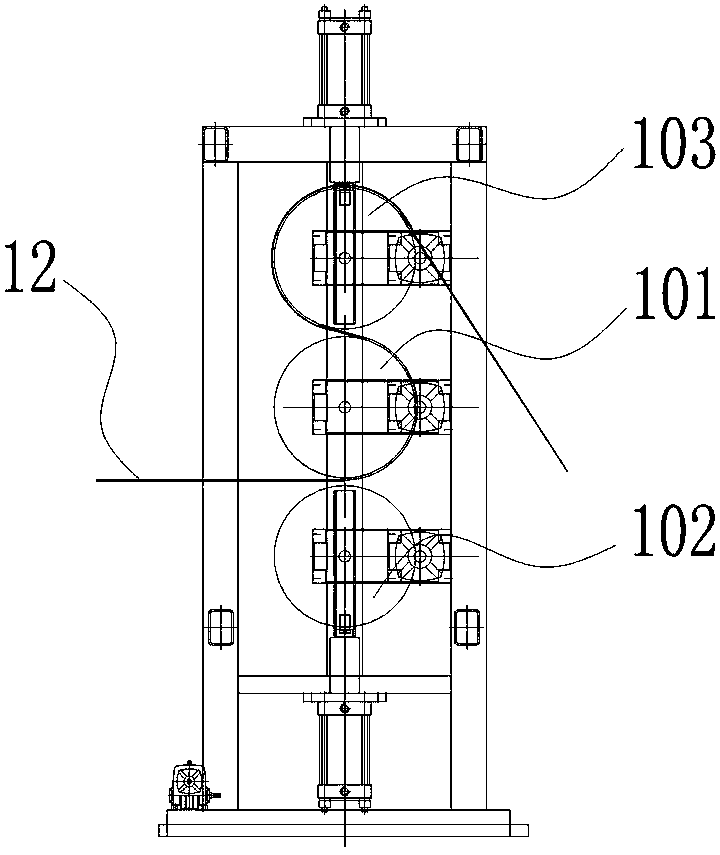

[0032] Such as figure 1 As shown, a kind of PTFE composite plate composite device of the present invention comprises the first drying tunnel 3 and the second drying tunnel 4 that are arranged side by side, and the second drying tunnel 4 is located at the top of the first drying tunnel 3 in parallel, and its length is the first 60% of the length of the drying tunnel 3, and the outlet ends of the two are even, and a PTFE plate unwinding machine 2 wrapped with a PTFE sheet 1 and a composite film 5 wrapped around it are installed side by side at the inlet end of the first drying tunnel 3 Composite film unwinder 6, wherein the composite film 5 is a PFA film, the composite film unwinder 6 is vertically arranged on the top, and the PTFE plate unwinder 2 is vertically arranged at the bottom, and is unwound with the PTFE plate at the entrance end of the first drying tunnel Between the machine 2 and the composite film unwinding machine 6, a constant-speed transmission mechanism is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com