Patents

Literature

264 results about "Composite strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

COMPOSITE STRENGTH. Composite Motion® Technology provides the integration of functional exercises using controlled movement patterns for a safer and more effective workout experience that simultaneously works multiple muscle groups for more efficient calorie burning.

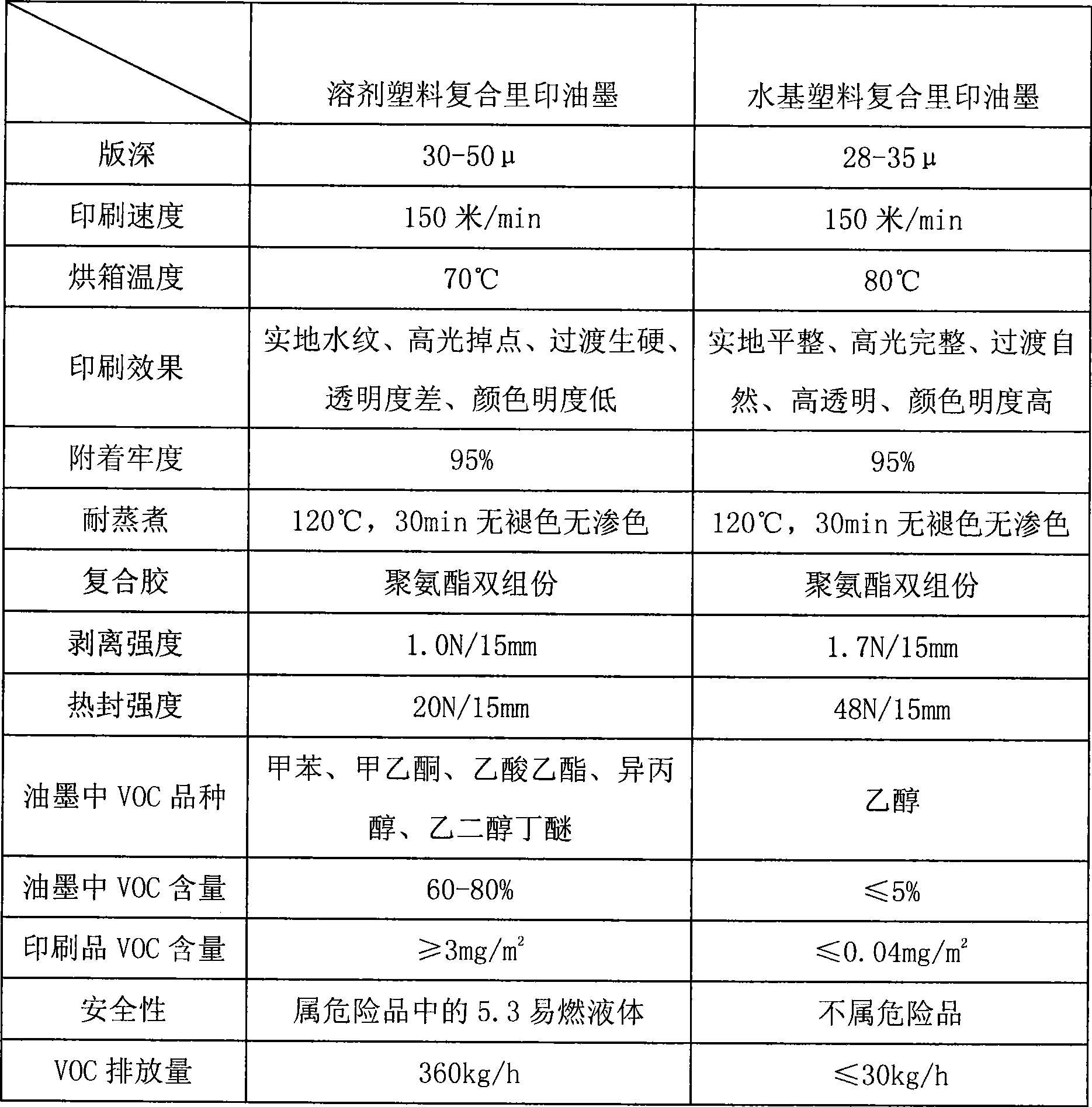

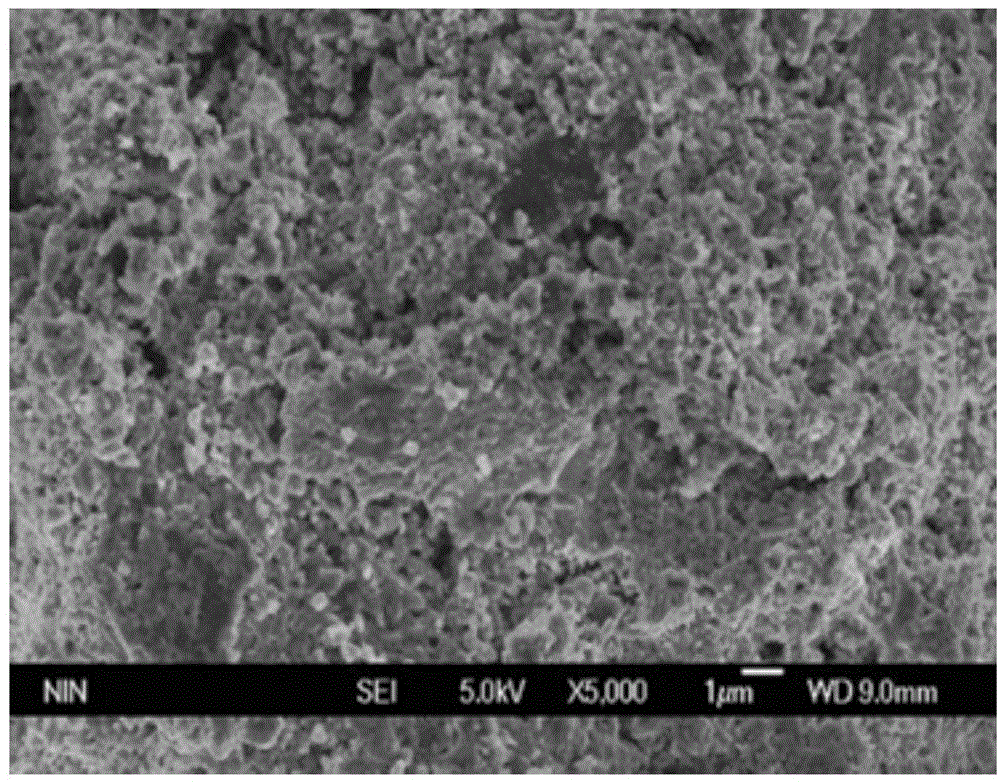

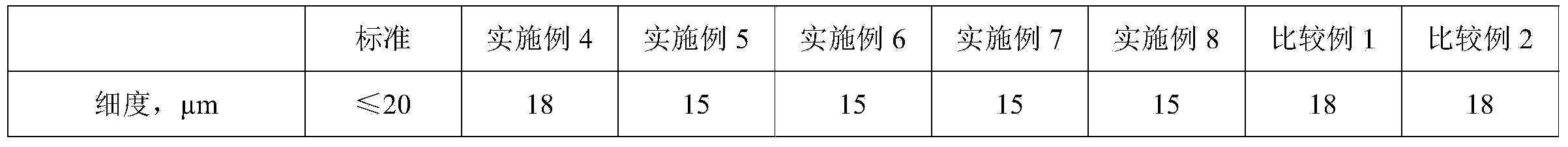

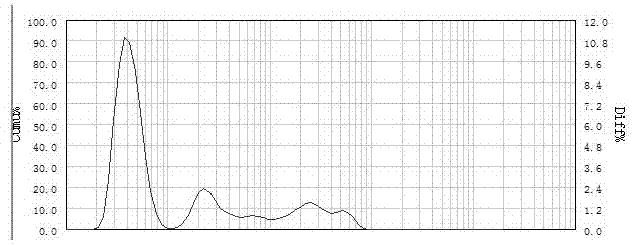

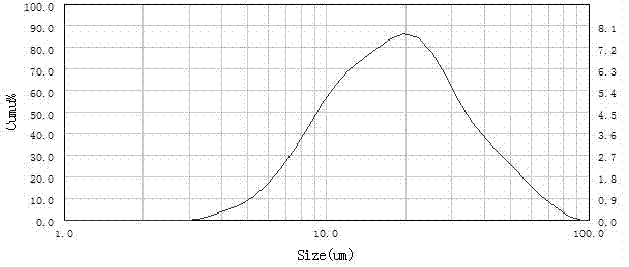

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

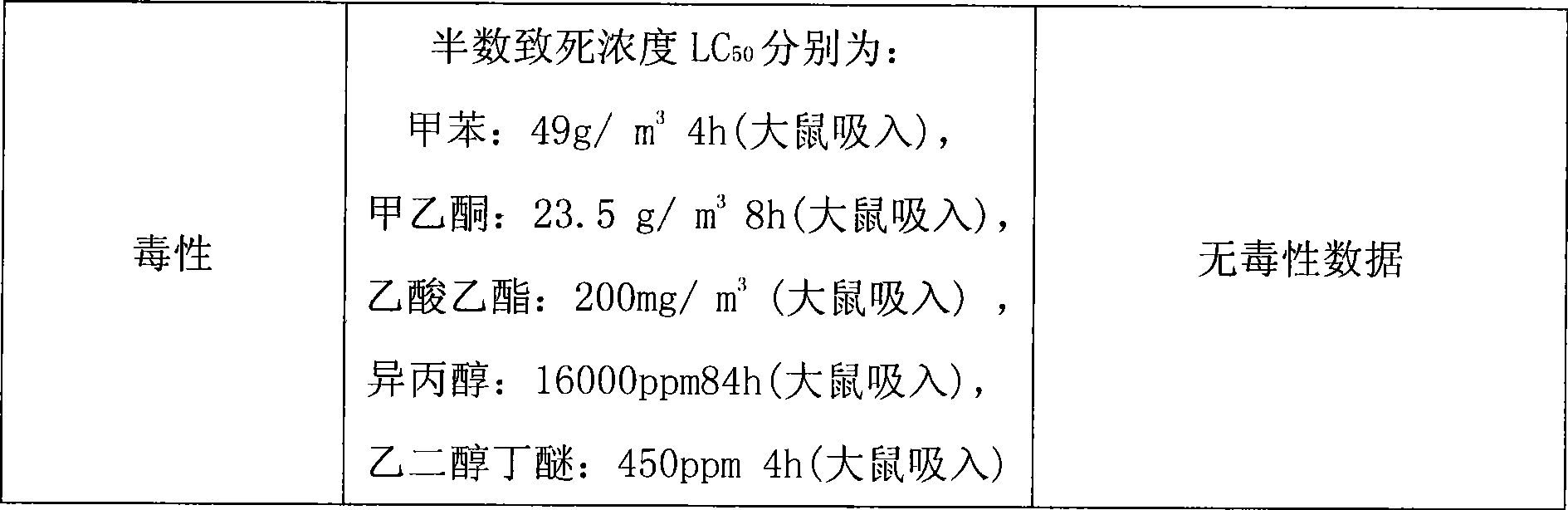

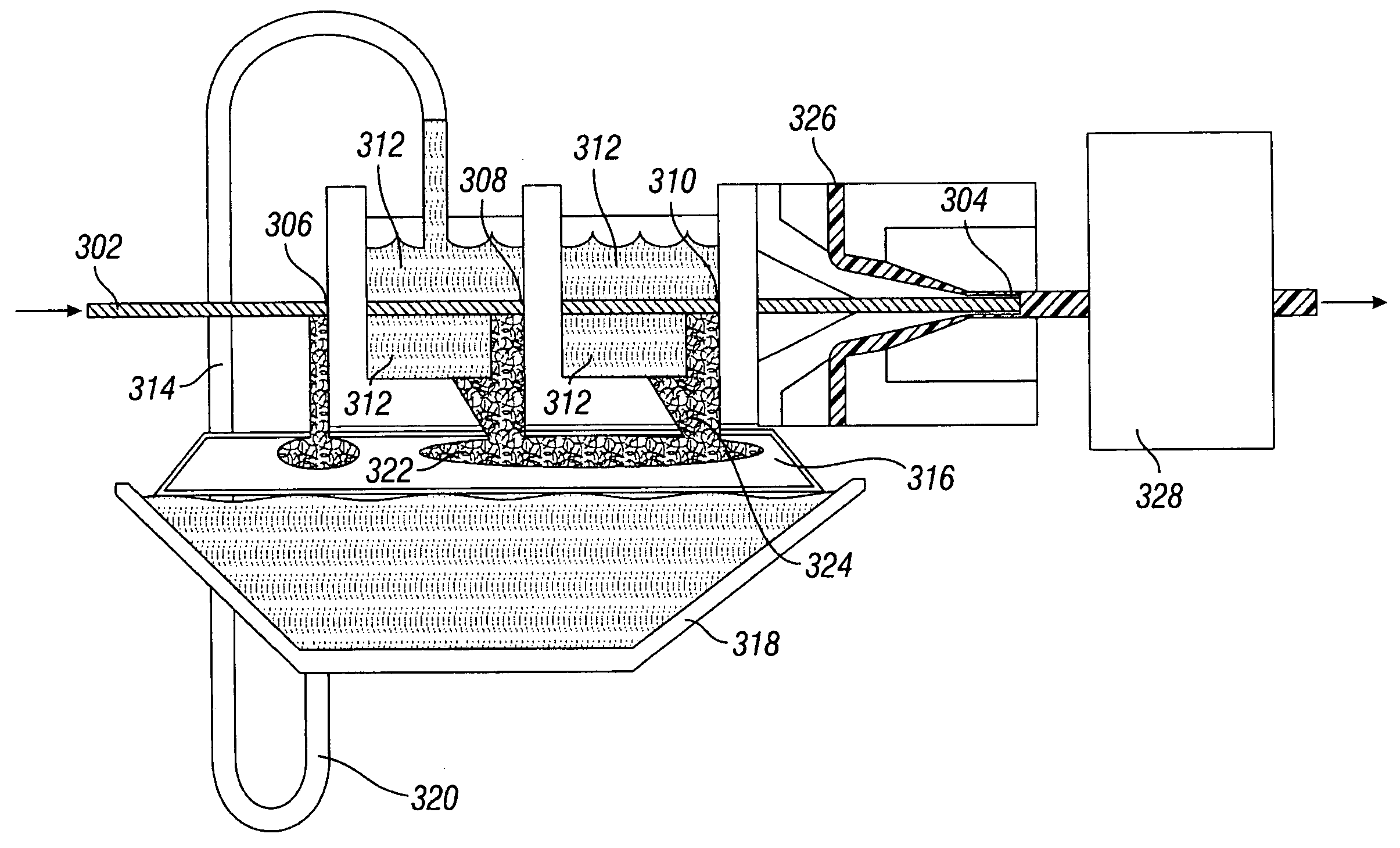

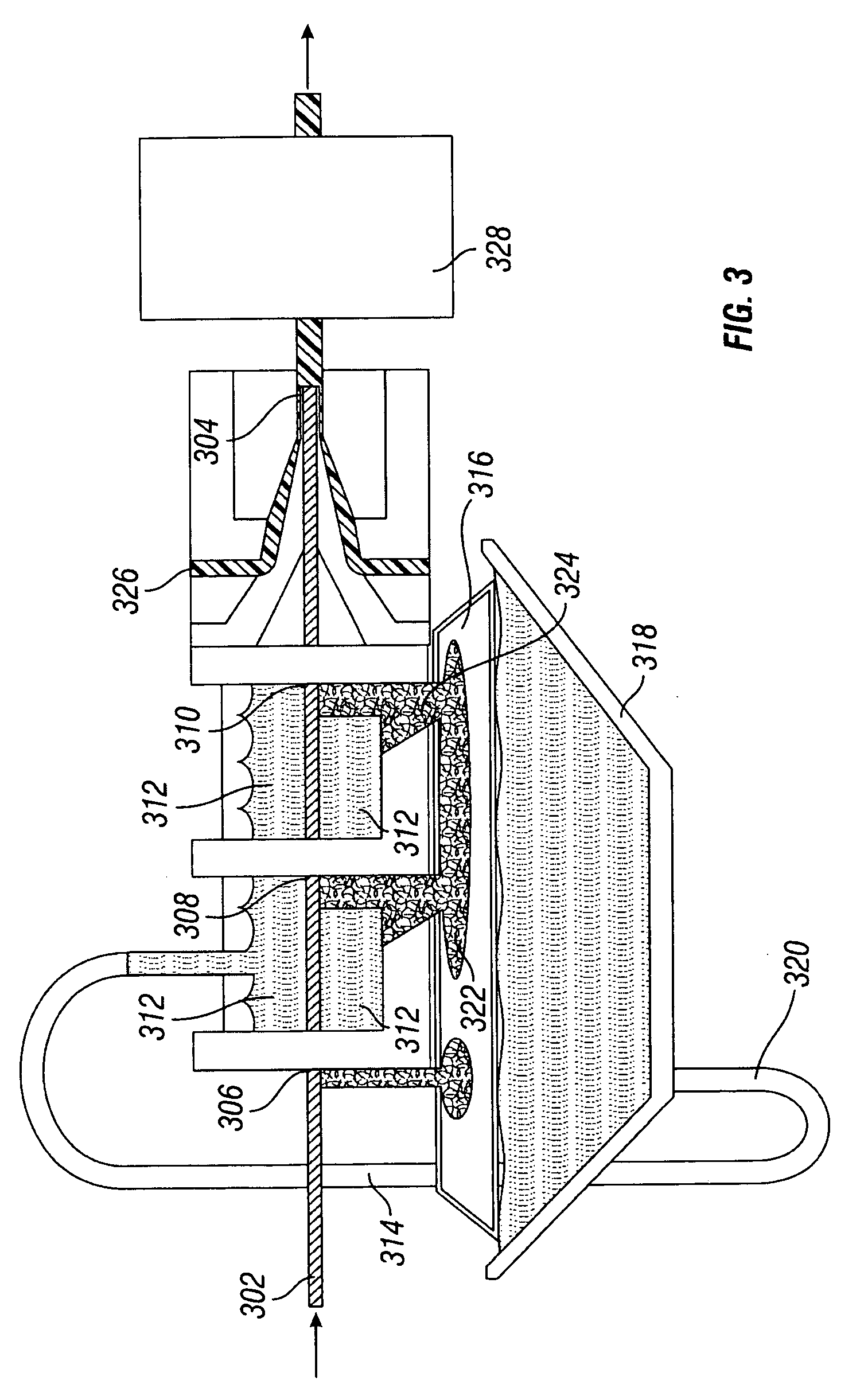

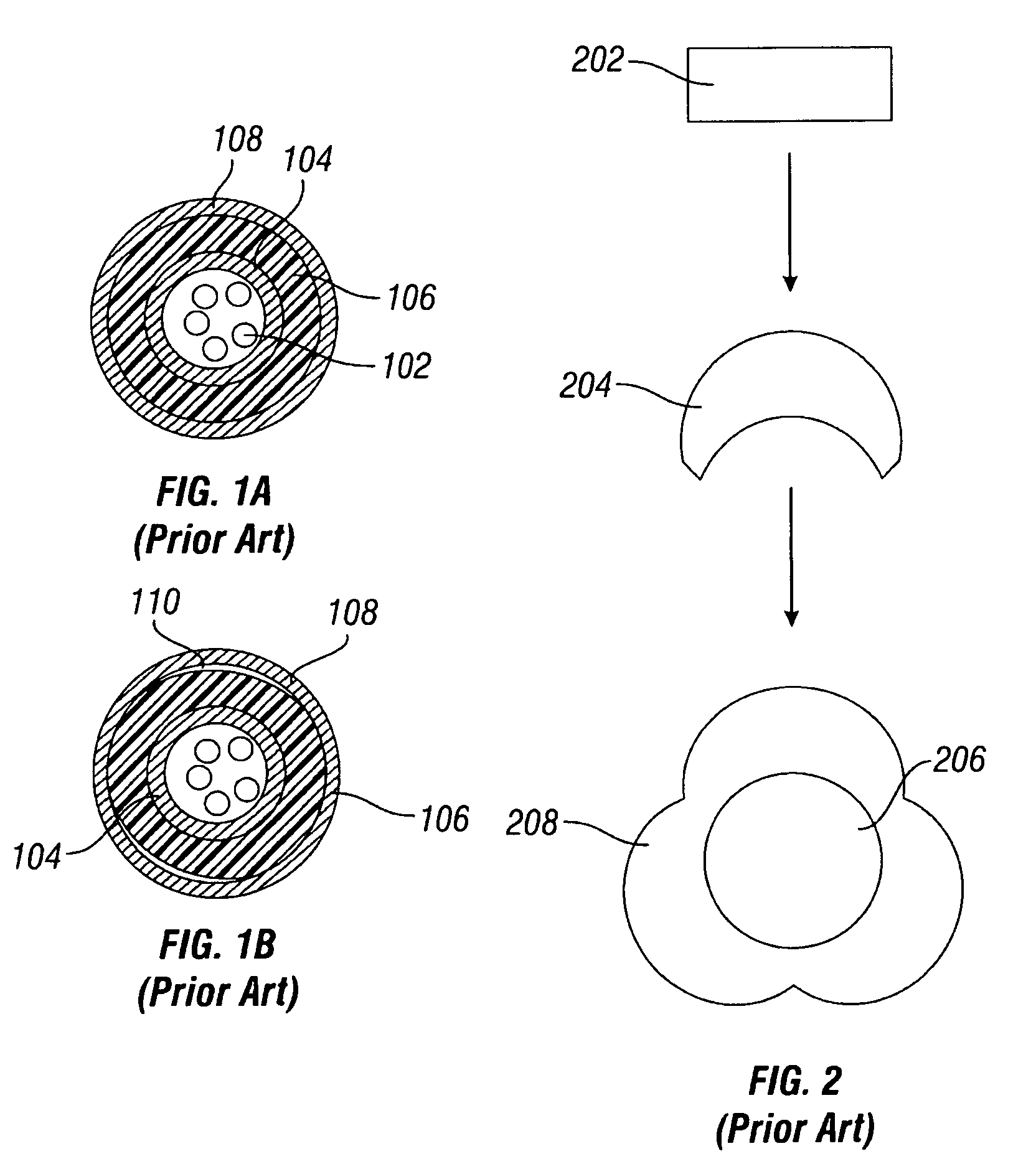

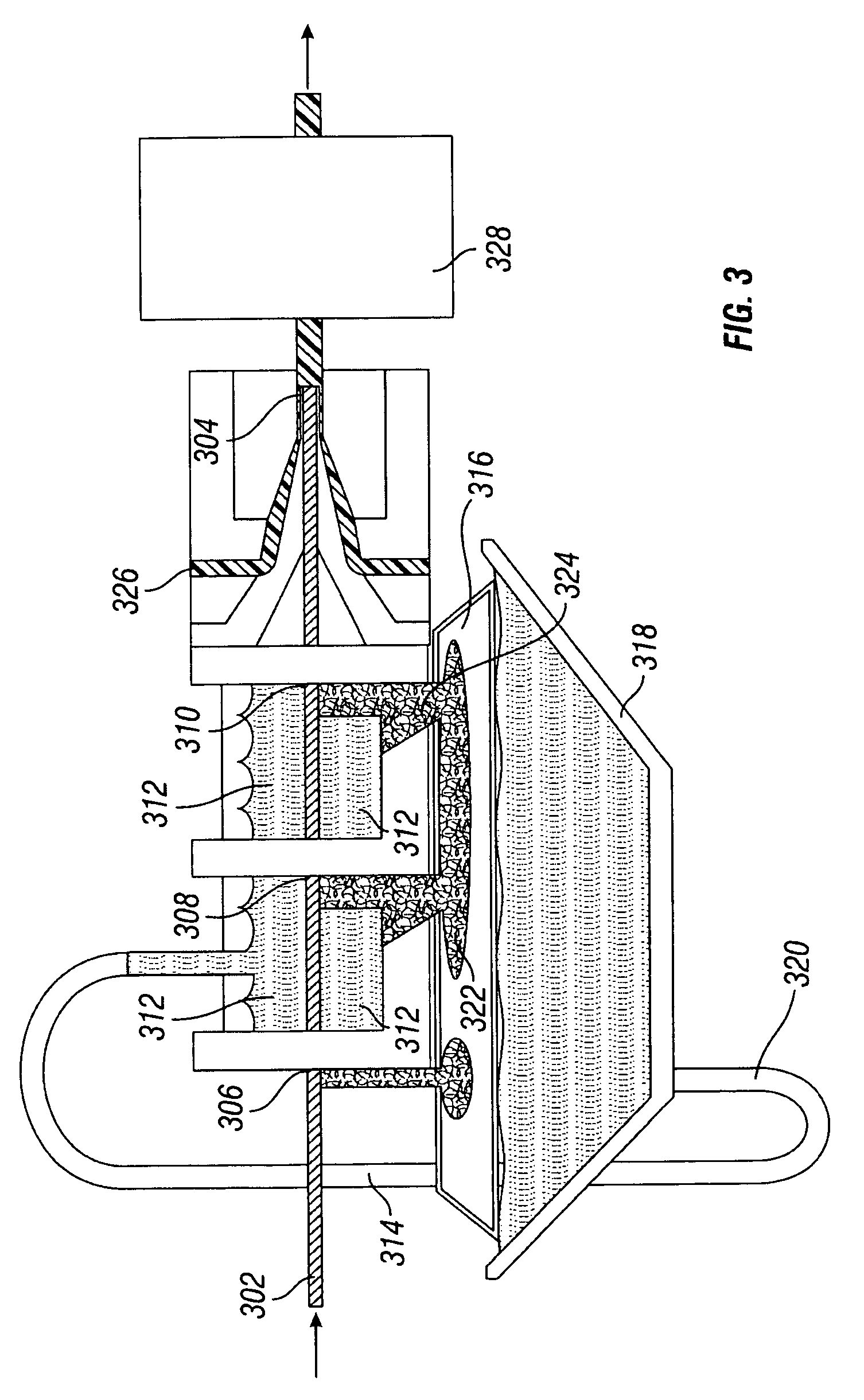

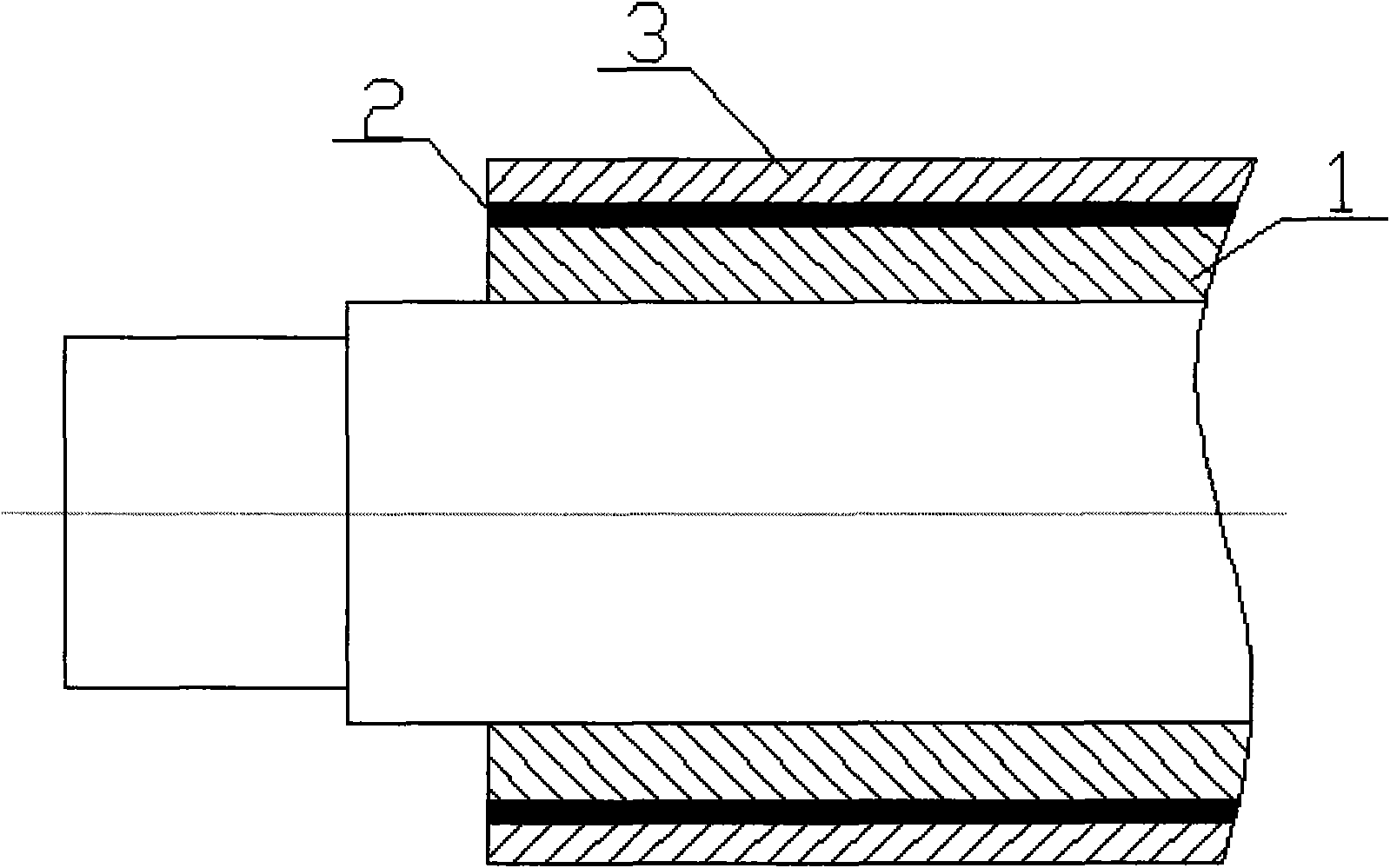

Methods of manufacturing composite slickline cables

ActiveUS20060260739A1Minimizing variation in diameterUniform circular cross-sectional shapeLamination ancillary operationsLaminationComposite strengthElectrical conductor

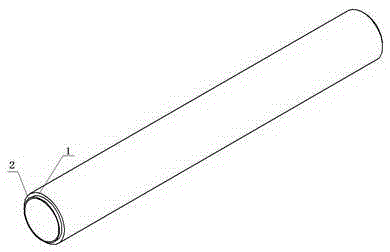

Disclosed are wellbore electric cables, and methods of manufacturing such cables, and in one aspect, methods of manufacturing wireline composite slickline cables. Some embodiments are methods which include preparing a slickline cable by providing an inner metallic tube containing at least one conductor (such as an optical fiber), disposing an epoxy / fiber composite strength layer substantially upon the outer periphery of the inner metallic tube, and exposing the combination of the inner metallic tube and composite strength layer to at least one technique for minimizing the variation in diameter and providing a substantially uniform circular cross-sectional shape of the combination. Further, an outer metallic tube is draw around the combination of the composite strength member and the inner metallic tube, to form a wellbore slickline. Cables prepared using such methods are also disclosed.

Owner:SCHLUMBERGER TECH CORP

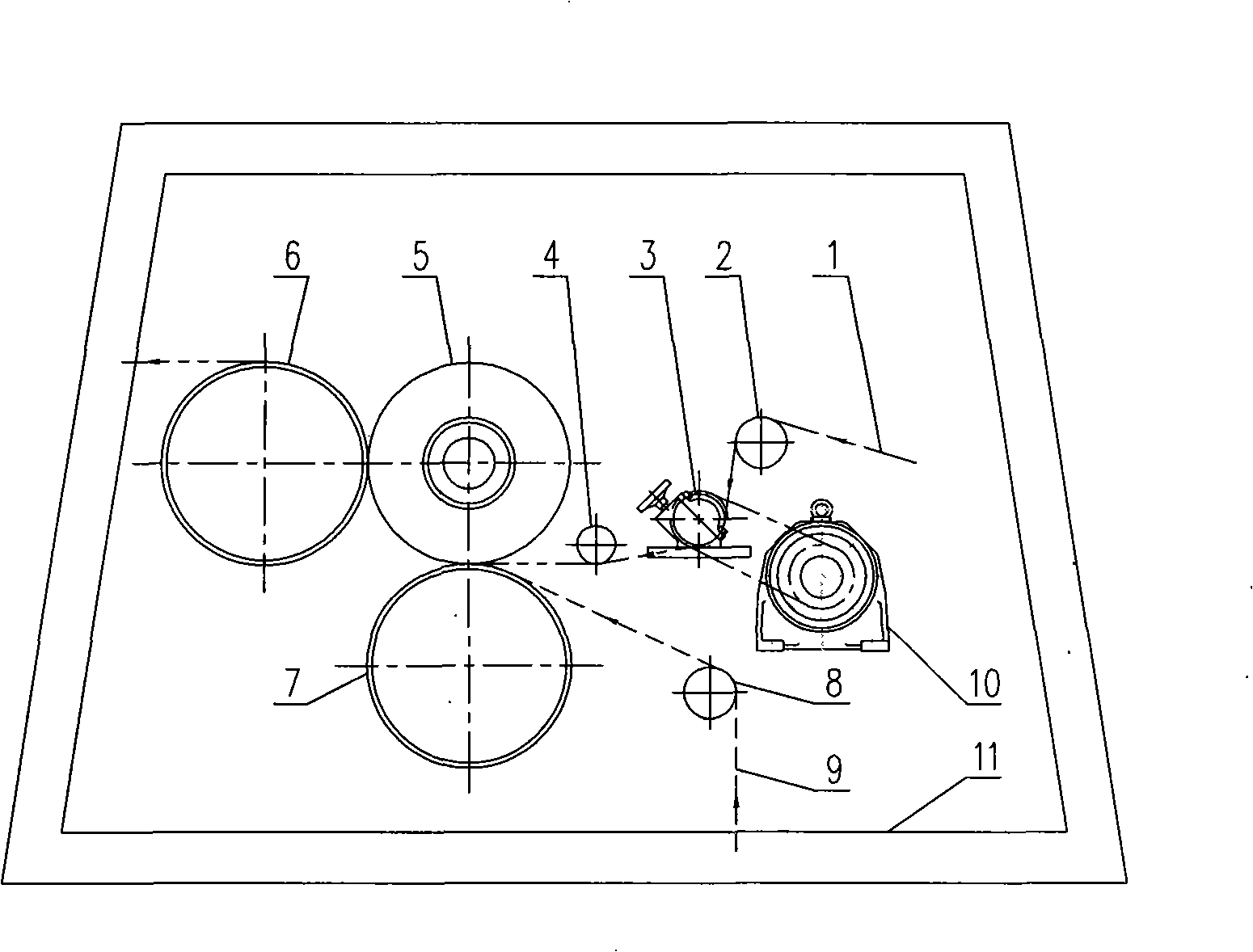

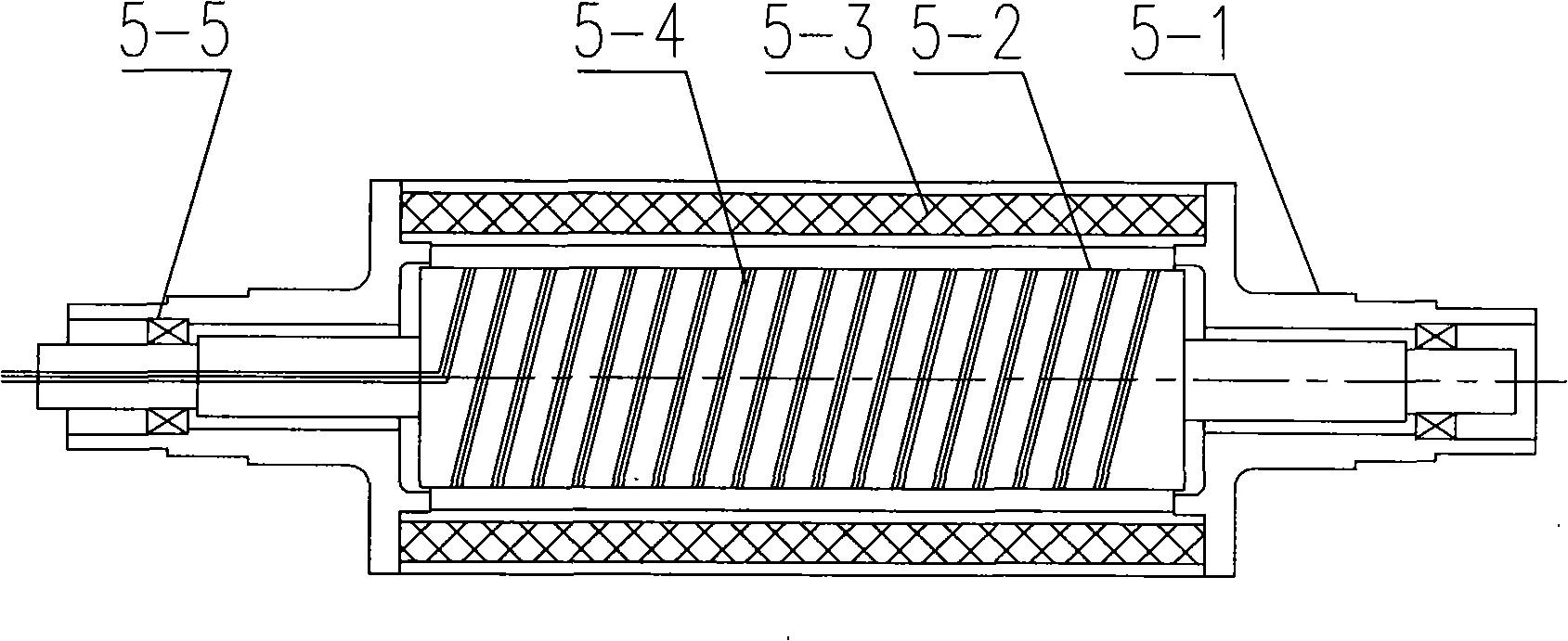

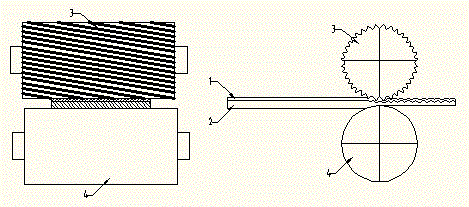

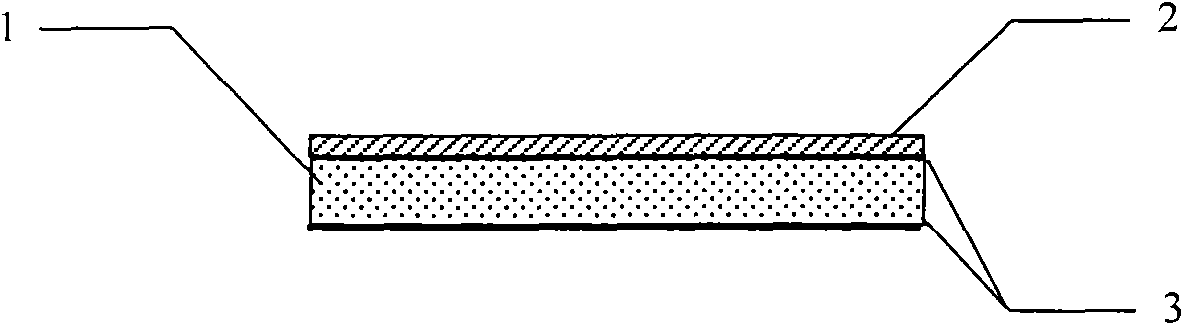

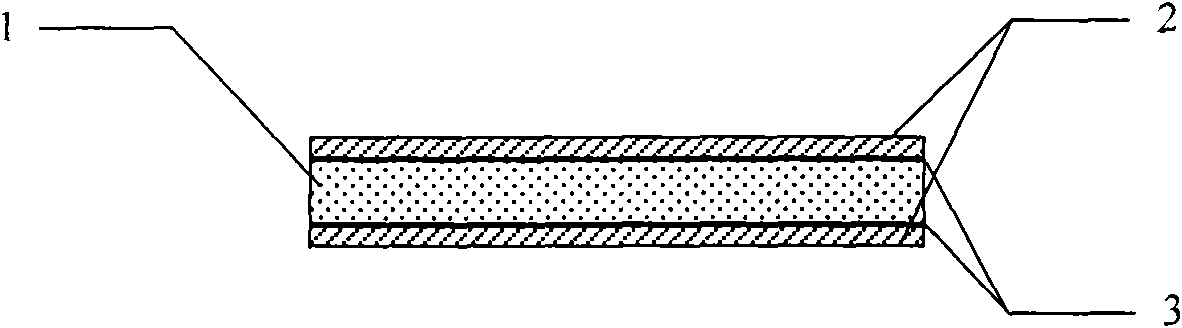

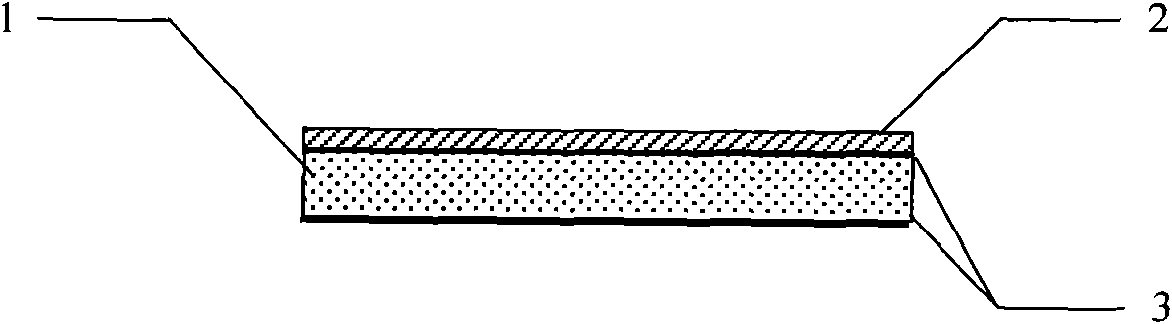

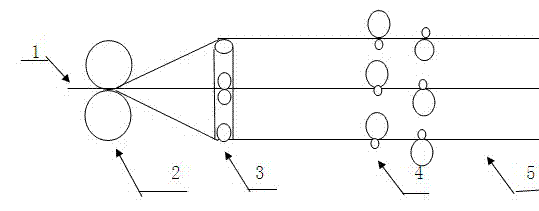

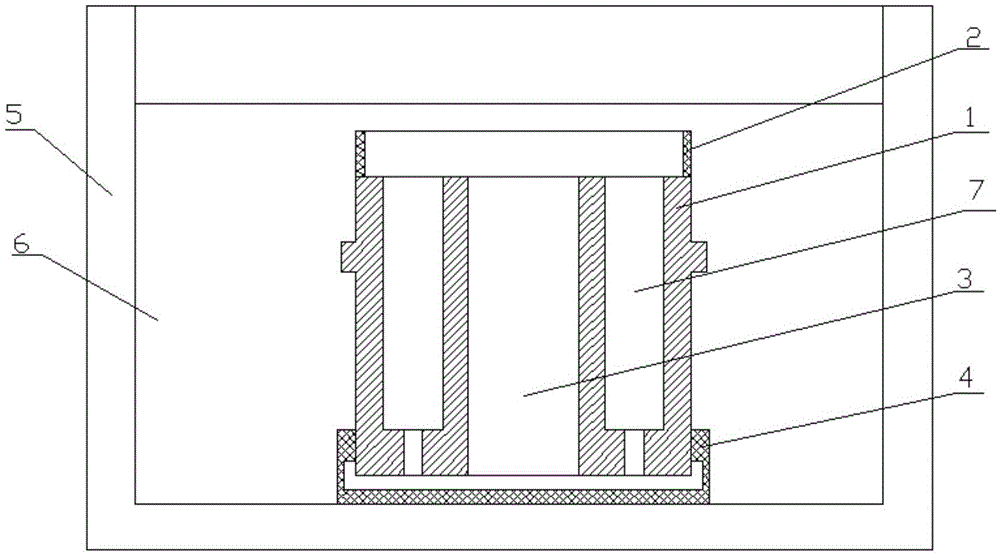

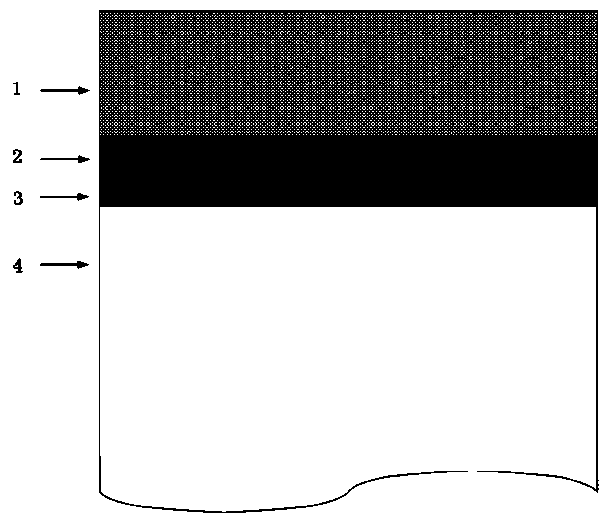

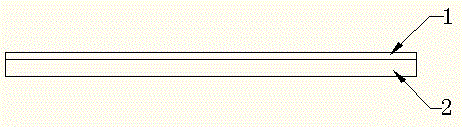

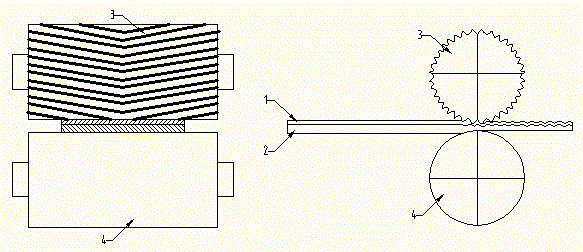

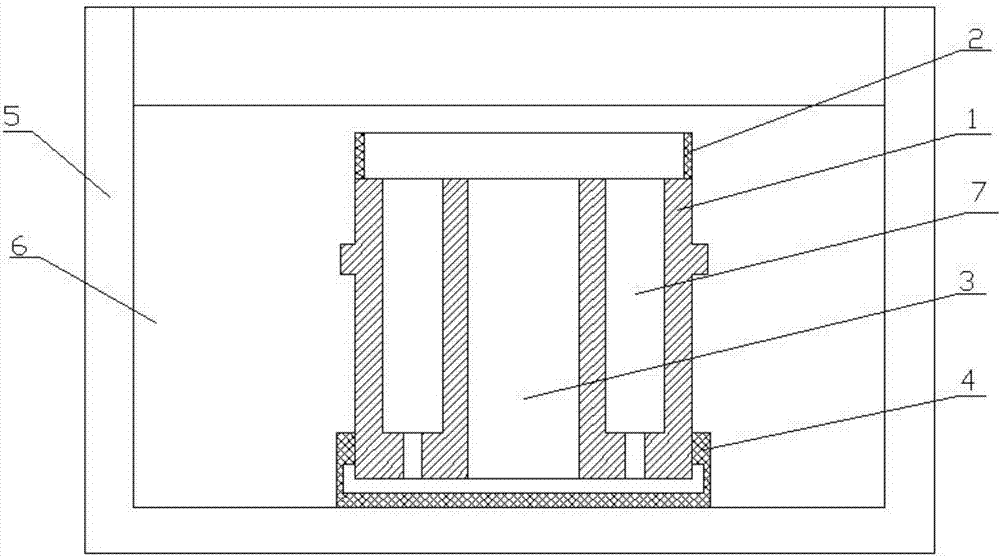

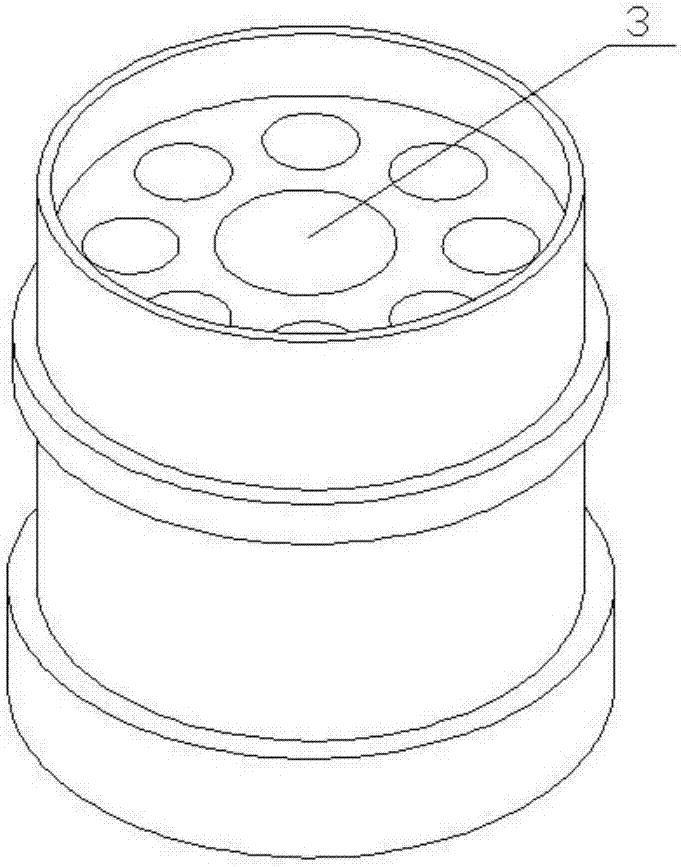

Compound technique of film filtering material and equipment

ActiveCN101279524APreserve physical and chemical propertiesImprove breathabilitySynthetic resin layered productsLaminationComposite strengthGlass fiber

The invention provides a composite technique for membrane filter material and an equipment. Polytetrafluoroethylene membrane and glass fiber base cloth are synchronously input between the heating roller and the press roller of a composite equipment at a speed ranging from 3 to 5m per min, and the polytetrafluoroethylene membrane is input in the direction of the tangent between the heating roller and a lower press roller and is formed by hot pressing with a linear pressure ranging from 15 to 30kN / m at the temperature ranging from 260 to 360 DEG C; after the membrane filter material formed by the hot press is heated by the one-fourth surface of the heating roller and then is formed by hot pressing with a linear pressure ranging from 15kN / m to 20kN / m. The technique method realizes rubber-free hot pressing compounding of the polytetrafluoroethylene membrane and the glass fiber base cloth, thus effectively saving the original physical and chemical property of the polytetrafluoroethylene membrane, enhancing the permeability and filtration efficiency of the membrane filter material, strengthening the composite strength of the membrane filter material and extending the service life of the membrane filter material; simultaneously, the hot pressing composite equipment has reasonable structure, thus ensuring the production and preparation of the membrane filter material.

Owner:中材科技膜材料(山东)有限公司

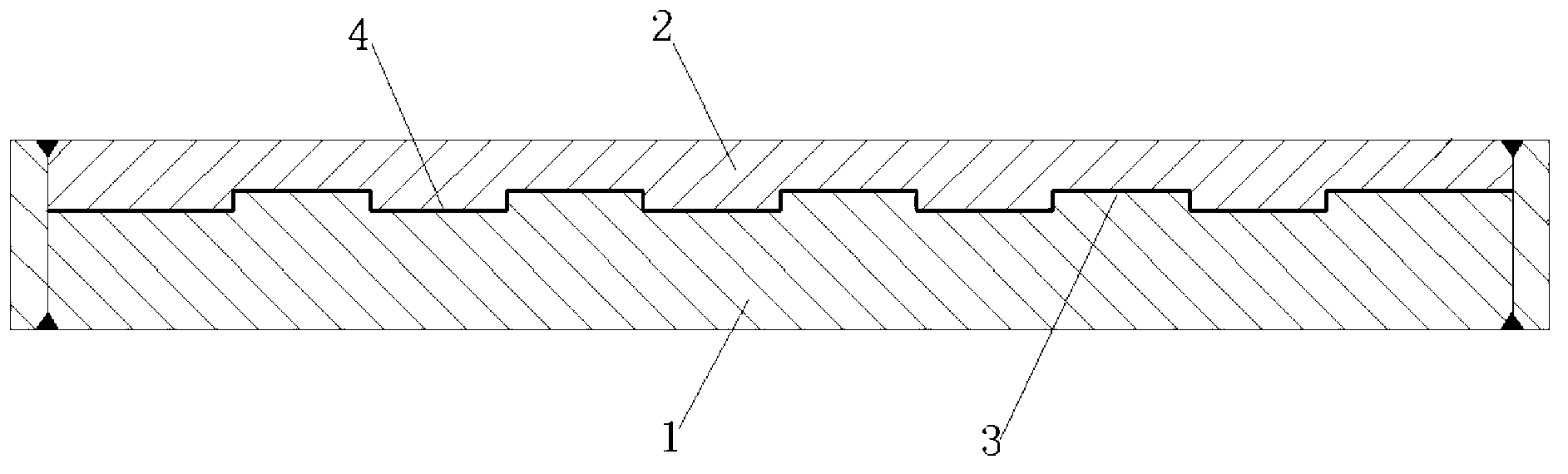

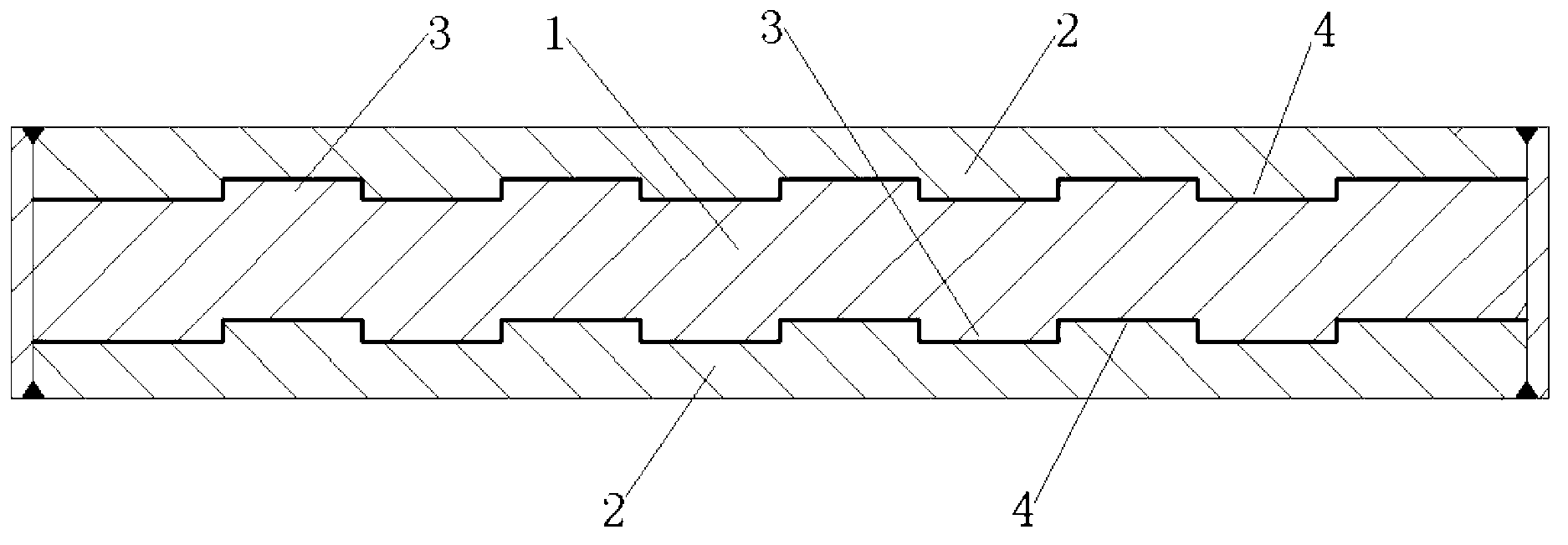

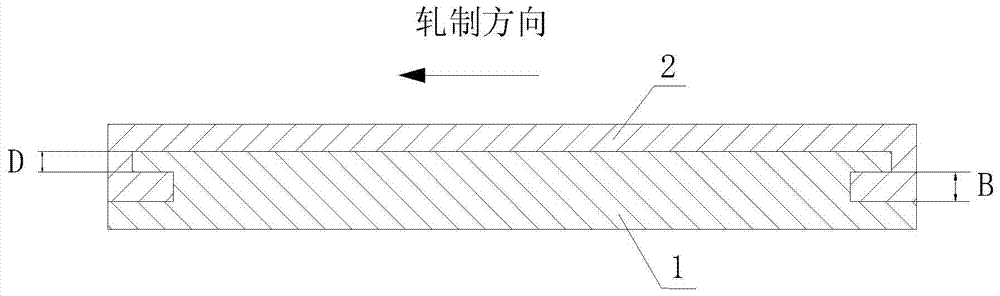

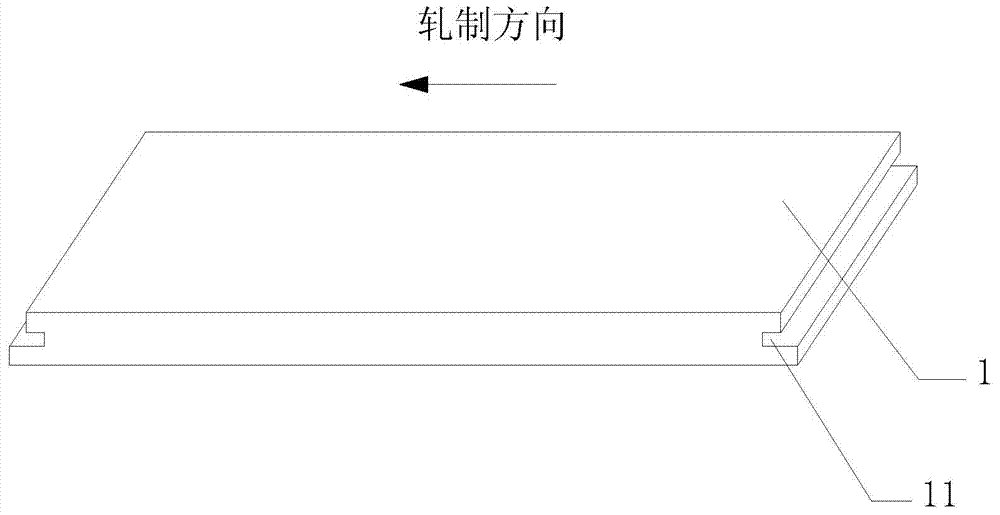

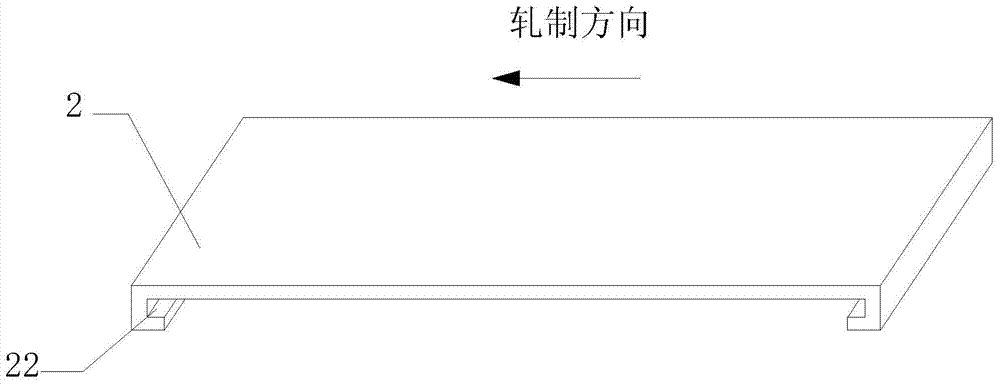

Meshing type composite plate vacuum rolling preparation method

InactiveCN103272842AImprove fitAvoid separationAuxillary arrangementsMetal rolling arrangementsComposite strengthComposite filter

The invention discloses a meshing type composite plate vacuum rolling preparation method. The meshing type composite plate vacuum rolling preparation method includes the steps: processing base plate protrusions and covering plate protrusions, which are matched mutually, on compositing surfaces of a base plate and a covering plate respectively; cleaning the compositing surfaces of the base plate and the covering plate; overlaying the base plate and the covering plate, and enabling the base plate protrusions on the base plate and the covering plate protrusions on the covering plate to be meshed mutually; obtaining a composite plate blank by means of blank assembly; and performing hot rolling so that a composite plate is obtained. The meshing type composite plate vacuum rolling preparation method has the advantages that the base plate protrusions and the covering plate protrusions which are matched mutually are processed on the compositing surfaces of the base plate and the covering plate respectively, so that fitting force between the base plate and the covering plate is increased by the aid of meshing force among the base plate protrusions and the covering plate protrusions, separation of the base plate from the covering plate during rolling is avoided, and rolling quality is improved while process is simple; meanwhile, contact area between the base plate and the covering plate is enlarged (namely, the area of a compositing interface is enlarged), so that compositing strength of the composite plate is enhanced; and the meshing type composite plate vacuum rolling preparation method is applicable to preparation of composite plates.

Owner:武钢集团有限公司

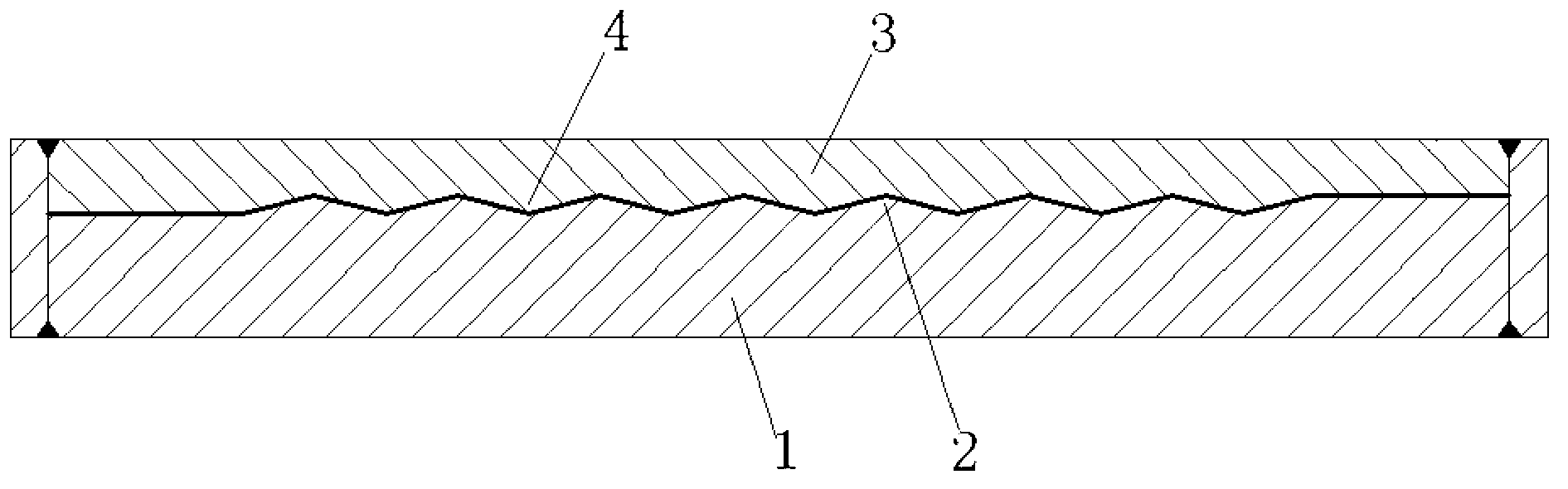

Method of rolling composite plate and strip by slanting corrugating roll

ActiveCN105798062AImprove bindingHigh composite strengthRollsMetal rolling arrangementsComposite strengthAxial force

The invention discloses a method of rolling composite plate and strip by a slanting corrugating roll. The method is characterized by comprising the following steps that a composite slab which is composed of a basal plate and a multilayer plate is rolled by a composite roughing mill with the slanting corrugating roll to prepare a semi-finished slanting corrugated composite plate, and then the semi-finished slanting corrugated composite plate is rolled by a composite finishing mill with a flat roll until the needed thickness to obtain a composite plate, wherein an axial included angle between slanting corrugation and the roll is 10-80 degrees. According to the method, the problems that instant impact is generated during rolling of a transverse corrugating roll, and the plate and strip are in deviation due to the axial force during rolling of a longitudinal corrugating roll are solved, and meanwhile, the combination area of the composite plates after being roughly milled is increased, so that the binding force between the basal plate and the multilayer plate is improved, and the composite strength and the composite efficiency of the composite plate are greatly improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Film magnetoelectric composite material and preparation method thereof

InactiveCN102044626AAvoid reactionAvoid eddy current lossPiezoelectric/electrostrictive device manufacture/assemblyDevice material selectionPhase reactionComposite strength

The invention relates to a film magnetoelectric composite material and a preparation method thereof, and belongs to the technical field of magnetic functional materials and preparation thereof. The magnetoelectric composite material is characterized by being prepared by compounding a magnetostrictive film layer, a conductive film layer and a piezoelectric ceramic substrate. In the preparation method, the magnetostrictive film layer is deposited on the piezoelectric substrate with a prepared electrode by physical vapor deposition (PVD) technology. The magnetoelectric composite material has high interfacial composite strength, a simple structure, a high magnetoelectric conversion coefficient, low high-frequency eddy current loss, stable performance and thin and light size, effectively avoids phase reaction between ferroelectric and ferromagnetic phases, and is particularly suitable for preparing a micro sensor; in addition, the preparation method is simple and feasible, and low in cost, and overcomes the defects of a complicated preparation process, high cost and the like of a laminated magnetoelectric composite material and the conventional film magnetoelectric composite material.

Owner:GRIREM ADVANCED MATERIALS CO LTD

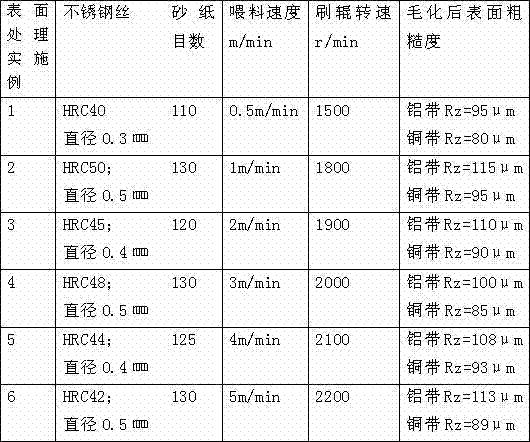

Cold-rolled copper and aluminum composite material production process

InactiveCN103394510AAuxillary arrangementsMetal rolling arrangementsComposite strengthSurface roughness

The invention discloses a cold-rolled copper and aluminum composite material production process. The process includes using an aluminum strip as a base strip and a copper strip as a strip covering material, performing surface treatment, performing composite rolling prior to heat treatment at the temperature of 605-610 DEG C, keeping the temperature for 8-10min, and finally forcedly cooling to the normal temperature by water cooling, wherein the thickness of the copper strip is 18-22% of that of the aluminum strip, the surface roughness of the aluminum strip satisfies that Rz=95-115 micrometers, and the surface roughness of the copper strip satisfies that Rz=80-95 micrometers. Optimum matching of deformation, layer thickness ratio and composite strength can be realized, and the process has the advantages of high interface composite strength and good dynamic thermal stability.

Owner:SHANDONG LAIWU JINSHI GROUP

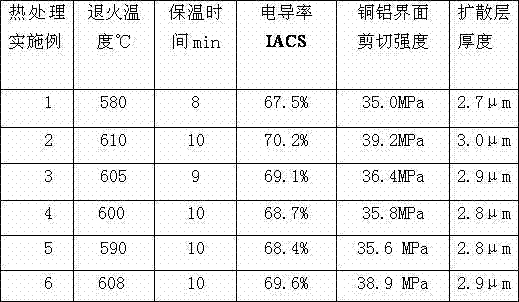

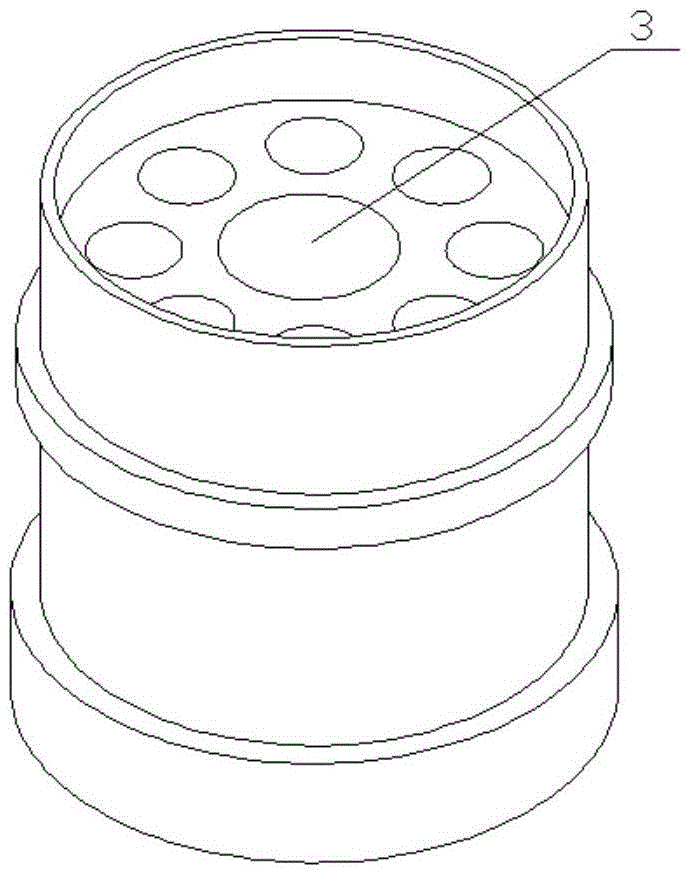

Method for manufacturing multi-core MgB2 superconductive wires through extrusion technology

ActiveCN104091651AImprove compactnessHigh yield strengthCable/conductor manufactureComposite strengthMachining deformation

The invention discloses a method for manufacturing multi-core MgB2 superconductive wires through the extrusion technology. The method includes the steps that first, precursor powder is prepared; second, the precursor powder is installed in a pipe to prepare a primary complex, and single-core wires are obtained through drawing machining; third, the precursor powder is installed in a pipe to prepare a secondary complex; fourth, the secondary complex processed through pre-heating seal welding is extruded, and multi-core rods are obtained; fifth, the multi-core rods are stripped and drawn to obtain multi-core wires, the multi-core wires are subjected to heat treatment, and then the multi-core MgB2 superconductive wires are obtained. According to the method, on the basis of a traditional power pipe-installing technology, a large single-pass machining deformation amount is adopted for manufacturing the multi-core MgB2 superconductive wires, in other words, the extrusion technology is adopted for manufacturing the multi-core MgB2 superconductive wires, because the secondary complex is in a very favorable three-dimensional stress state in extrusion, good metallurgical bonding will be achieved between different metal interfaces in the secondary complex along with the large extrusion deformation amount, the manufactured multi-core rods are high in composite strength, and the compactness and the yield strength of the multi-core MgB2 superconductive wires can be significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

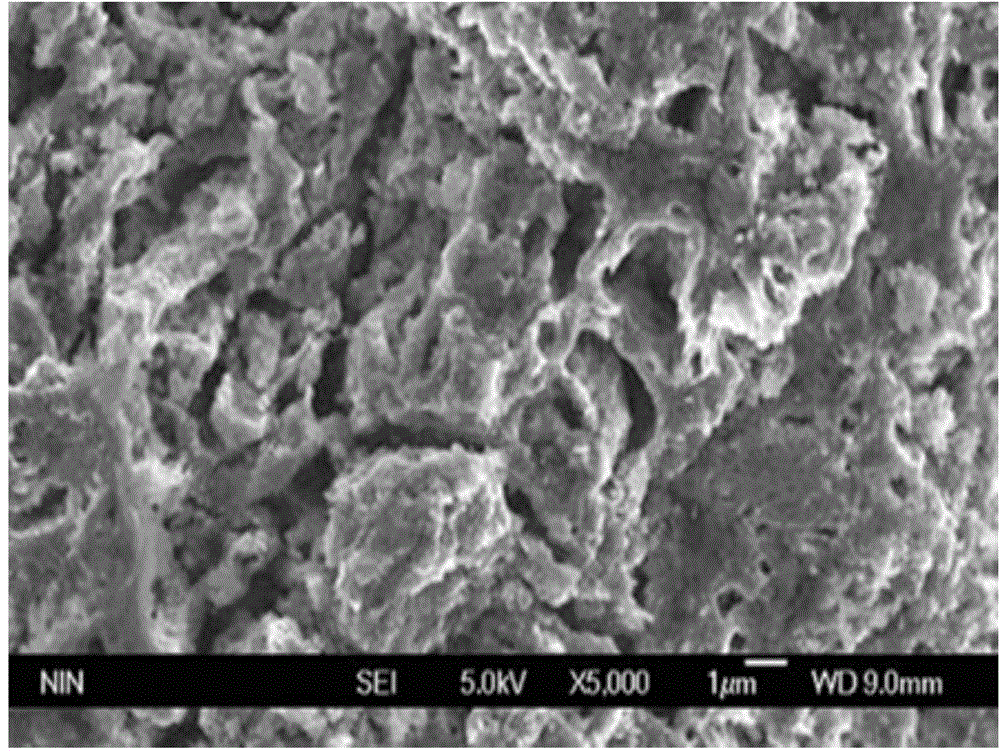

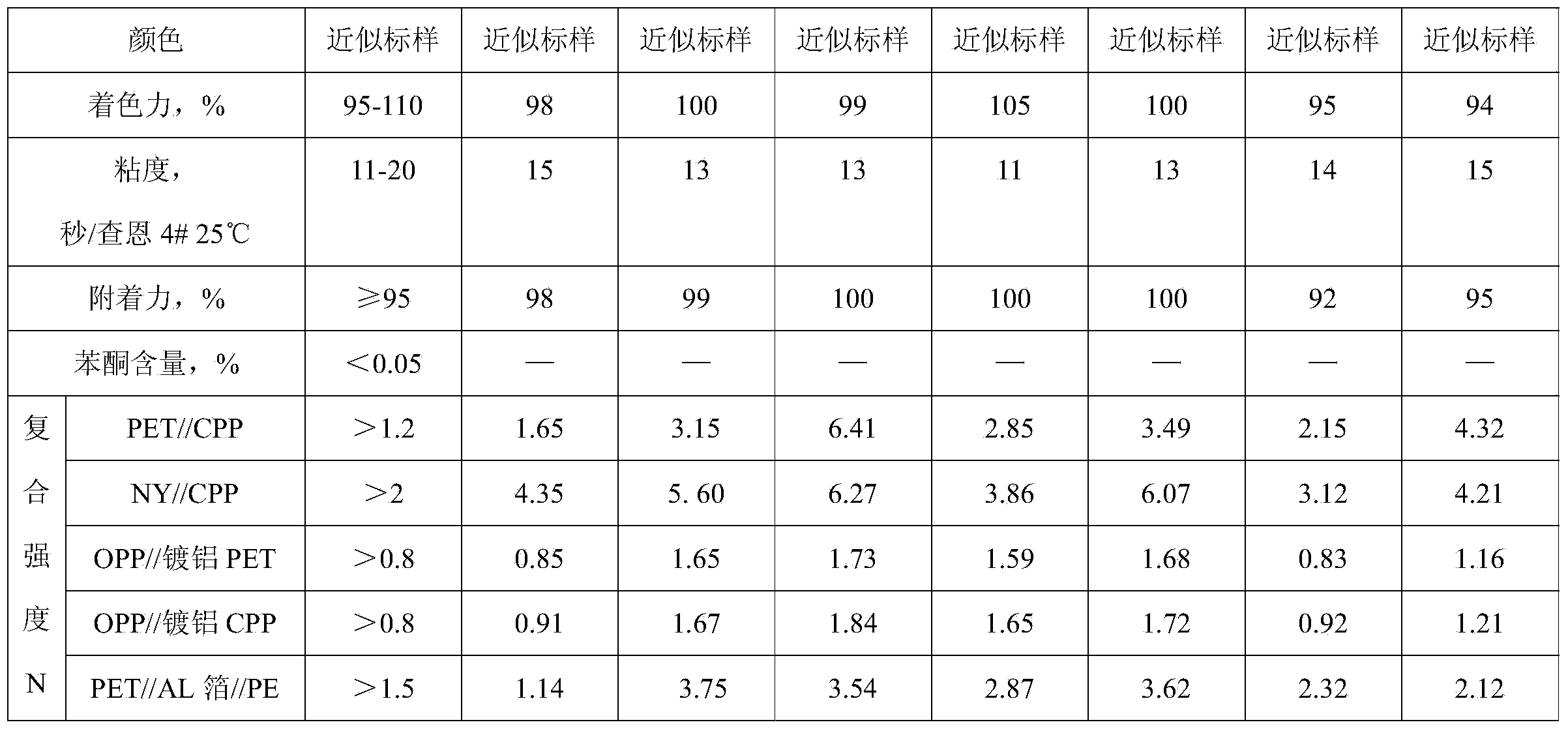

Ester-soluble polyurethane compound printing ink with high composite strength and preparation method thereof

The invention relates to compound printing ink, in particular to ester-soluble polyurethane compound printing ink and a preparation method thereof. The compound printing ink comprises the following components by weight percentage: 27 to 32 percent of modified polyurethane resin, 6 to 15 percent of vinyl chloride-vinyl acetate copolymer liquid, 8 to 33 percent of a pigment, 0.4 to 0.8 percent of a dispersing agent, 0.3 to 0.5 percent of wax powder, 0.2 to 0.8 percent of an antistatic agent, 0.2 to 0.5 percent of an anti-precipitating agent, 0.5 to 1.5 percent of an adhesive force reinforcing agent, 10 to 25 percent of propyl acetate, 5 to 15 percent of ethyl acetate, and 10 to 20 percent of butyl acetate. The compound ink prepared in the invention has the advantages as follows: the tinting strength is high; the color is bright; the transparency is high; the printing adaptability is high, so that the compound printing ink can be widely applied to high-low speed printing of plastic flexible packaging composite materials such as PET, NY and BOPP; the adhesive force to various plastic film base materials is great, and firmness is achieved; resistance to corrosion of acid, alkali and the like is high; hot adhesion phenomena are avoided; the water resistance is high; the temperature resistance is high, so that the compound printing ink can meet the processing requirements of follow-up processes such as boiling, high-temperature cooking, food refrigerating, and is high in storage stability.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

Preparation method of integrated plastic gravure alcohol-soluble aqueous composite ink resin

ActiveCN102010485APolarity can be effectively adjustedStrong adhesionInksSolubilityFunctional monomer

The invention relates to a resin for plastic gravure composite ink, in particular to an integrated plastic gravure alcohol-soluble aqueous composite ink resin and a preparation method thereof. In the preparation method of the integrated plastic gravure alcohol-soluble aqueous composite ink resin for gravure, the integrated plastic alcohol-soluble aqueous composite ink resin is obtained by polymerizing the raw materials of a polymerizable polyurethane macromonomer, (methyl) acrylic ester, vinylacetate and active functional monomer through solution radicals. Due to the introduction of a polyurethane chain, the ink has favorable adhesive force on various plastic film substrates (BOPP (Biaxially-oriented Polypropylene), PET (Polyethylene Terephthalate), PA (Polyamide), PVC (Polyvinyl Chloride), PE (Poly Ethylene), PC (Polycarbonate) and the like), good printing adaptability and high composite strength, adapts to various laminating glues (ester-soluble type, alcohol-soluble type), and can be boiled in water with the high temperature of 98 DEG C. The preparation method of the plastic gravure composite ink resin is simple, the prepared ink has good printing effect and strong adaptability, realizes the integrated adaption of the substrates and the laminating glues, and can be used for printing various plastic substrates; without using crosslinking components, the ink can be boiled in water with the high temperature of 98 DEG C and has the advantages of convenience in operation and high composite strength; the resin has alcohol solubility, economy, environmental protection and wide application prospect in the field of plastic gravure composite inks.

Owner:CHENGDU XINJIN TUOZHAN PRINTING INK

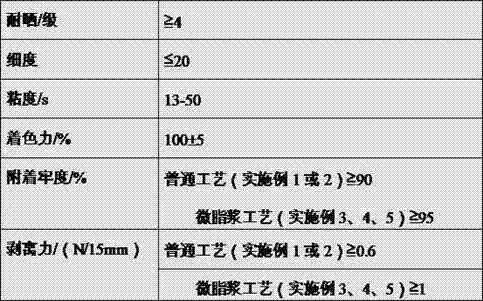

Water-based composite gravure plastic reverse printing ink and preparation method thereof

The invention discloses water-based composite gravure plastic reverse printing ink. The ink is prepared from, in percentage by weight, 10%-40% of pigments, 30%-60% of a water-based ink binder, 0.1%-5% of a wetting agent, 0.1%-1% of a defoaming agent and 24%-50% of a solvent. The invention further discloses a preparation method of the composite gravure plastic reverse printing ink. The water-based ink prepared in the formula with the method has higher color saturation concentration than that obtained with a traditional process; the adhesion capacity of the water-based ink on various plastic base materials is almost the same with that of solvent type ink and even superior to that of the solvent type ink; the water-based ink has good storage stability and high composite strength, and the release force can reach 1N / 15mm or higher. The water-based ink prepared in the optimized formula with the method successfully solves the problems of clogging, serious doctor marks and the like occurring in the gravure plastic printing process.

Owner:山西精华科工贸有限公司 +3

Method of lock catch type vacuum rolling metal composite plate

InactiveCN103495604AHigh composite strengthEasy to separateAuxillary arrangementsMetal rolling arrangementsComposite strengthVacuum pumping

A method of a lock catch type vacuum rolling metal composite plate comprises the following steps that penetrated grooves are machined in the end faces of the two ends, vertical to the rolling direction, of a base plate respectively, and correspondingly, L-shaped embedding strips are welded to corresponding positions at the two ends of a shroud plate respectively; greasy dirt on the surface to be compounded is cleaned; the L-shaped embedding strips at the two ends of the shroud plate slide into the grooves in the two ends of the base plate to enable a composite slab formed by the shroud plate and the base plate to be in an embedded state. Sealing plates are connected to the periphery of the composite slab in a welded mode to enable composite space to be sealed; holes are formed in the sealing plates, air between the shroud plate and the base plate is extracted through the holes, and the holes are blocked after vacuum pumping is carried out; the composite slab is heated to 950-1300 DEG C to be rolled until the composite slab reaches a needed thickness to form the metal composite plate; edge cutting is carried out on the rolled metal composite plate, the sealing plates are removed, and rolling of the composite plate is completed. According to the method, mutual movement of adjacent slabs in the rolling direction and the slab thickness direction can be effectively constrained, rolling stability is improved, and meanwhile composite strength of the metal composite plate is greatly increased.

Owner:武汉钢铁有限公司

Production technology of fire-proof high strength heat insulating corrugated paper cellular composite material

InactiveCN100999147ARealize continuous automatic productionImprove flame retardant performanceLamination ancillary operationsLaminationComposite strengthWater based

The present invention relates to a production process of fire-proof high-strength heat-insulating corrugated sheet honeycomb composite material. Said production process includes the following steps: (1), impregnating single corrugated sheet with water base flame-retardant or water base flame-retardant anti-mildew agent or spray-coating said single corrugated sheet with said water base flame-retardant or water base flame-retardant anti-mildew agent; (2), then utilizing impregnation method or spray-coating process to cover said single corrugated sheet with fire-resisting adhesive; and (3), making the above-mentioned obtained corrugated sheets be successively superimposed together so as to obtain the invented product.

Owner:淄博豪特集成房屋制造有限公司

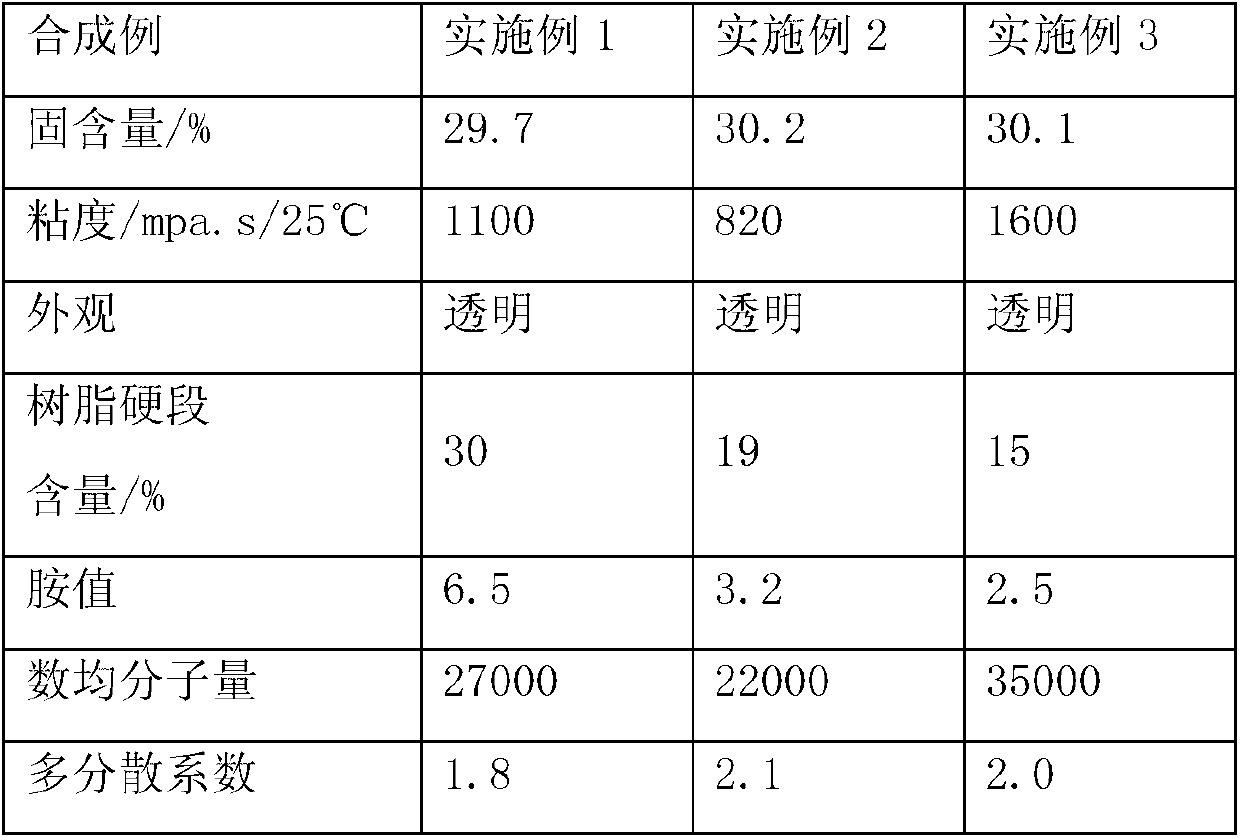

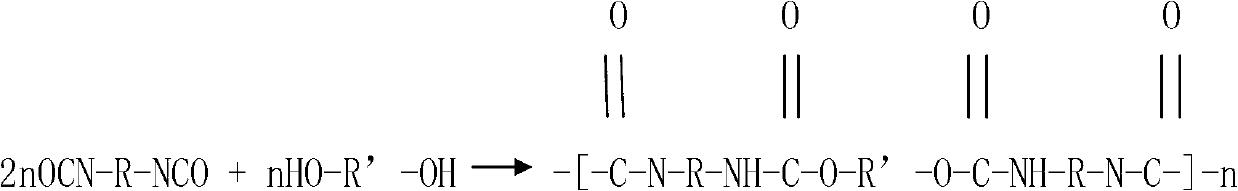

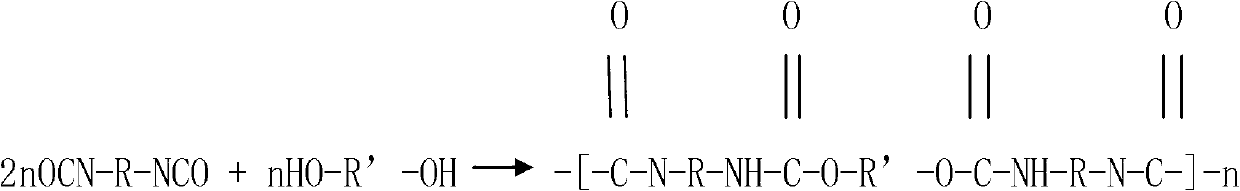

Preparation method of polyurethane resin for gravure composite ink

ActiveCN103012724AMild responseThe chain extension process is stable and controllableInksEnd-groupPolyethylene glycol

The invention discloses a preparation method of polyurethane resin for gravure composite ink, wherein the polyurethane resin is alcohol ester-soluble polyurethane resin not containing free cyanate ester radicals. Large amounts of allophanate radicals are introduced into the resin so that the ink prepared from the resin has excellent adhesion fastness to substrates such as PET (Polyethylene Glycol Terephthalate), NY (Nylon) and PP (Polypropylene) and the like. The preparation method is characterized in that diisocyanate is reacted with high-molecular polyol to generate NCO-terminated prepolymers, and then the prepolymers are added into a solvent containing an amine chain extender to achieve the polyurethane resin for the ink. The soft and hard segment of the resin has the advantages of wide adjustable range, large cohesive energy, good anti-aftertack property and good heat resistance; and the prepared ink has high binding strength to various printing substrates and has high composite strength. The preparation method provided by the invention has obvious characteristics of stable reaction in the synthesis process of the resin, easiness in control of the preparation process, narrow distribution of the molecular weight and good dissolubility of the resin.

Owner:NANTONG GAOMENG NEW MATERIAL

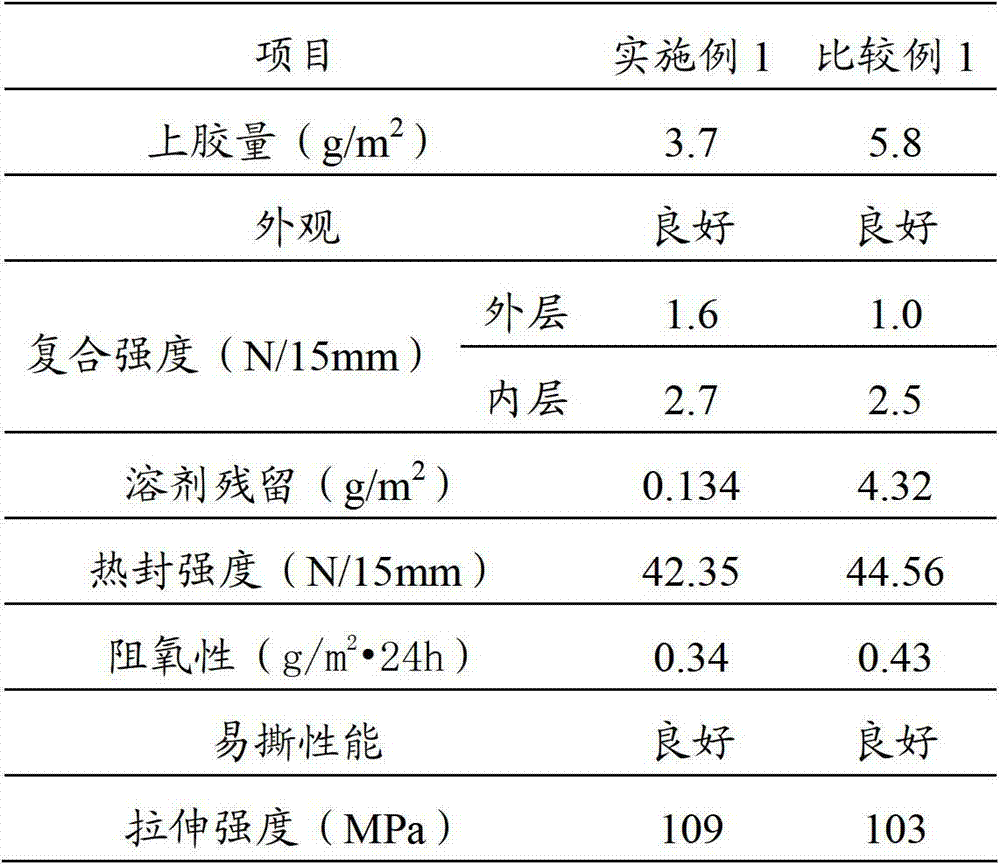

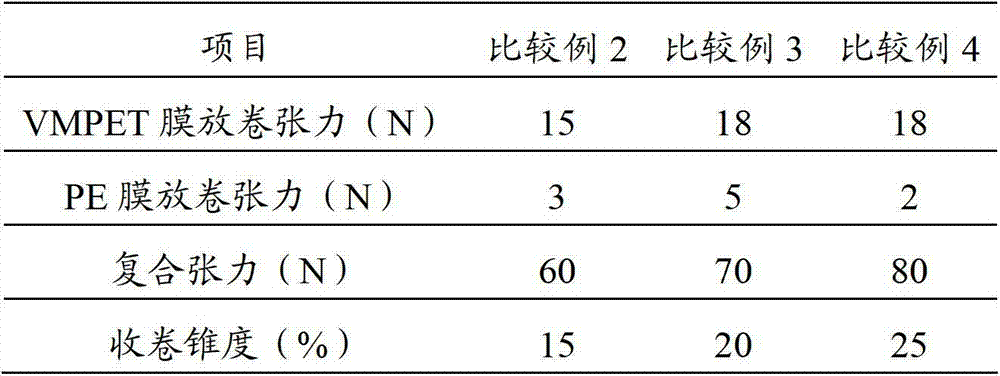

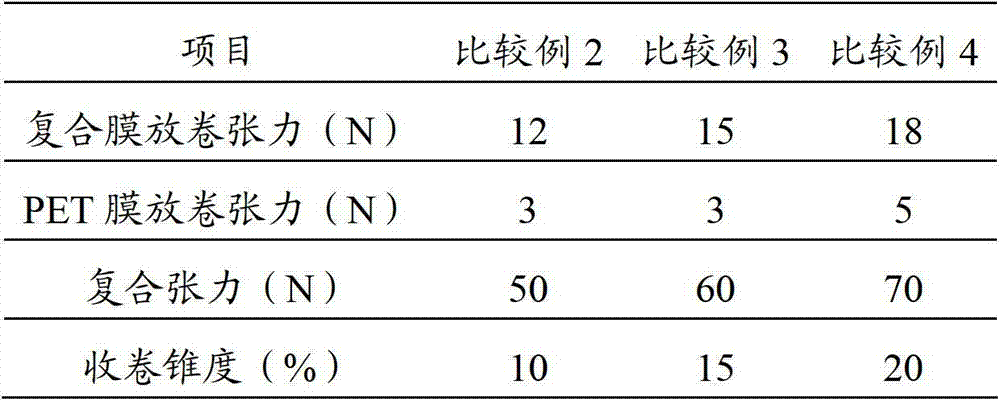

Preparation method of environment-friendly aluminum-plated composite membrane

InactiveCN104118191AReduce dosageControl unwind tensionLamination ancillary operationsLaminationComposite strengthAdhesive

The invention provides a preparation method of an environment-friendly aluminum-plated composite membrane. The method comprises the following steps: a. coating the aluminum surface of an aluminum-plated membrane with a solvent-free adhesive, wherein the gluing amount of the solvent-free adhesive is 2.2g / m<2>-2.5g / m<2>, and the unwinding tension of the aluminum-plated membrane is 13N-18N; b. compositing the aluminum-plated membrane with an outer membrane layer, wherein the composting tension is 40N-45N and the unwinding tension of the outer membrane layer is 4N-7N; and c. winding the composite membrane obtained in the step b and curing the wound composite membrane to obtain the environment-friendly aluminum-plated composite membrane. The gluing amount, the unwinding tension of the aluminum-plated membrane, the unwinding tension of the outer membrane layer, and the composting tension of the aluminum-plated membrane and the outer membrane layer are controlled to obtain the environment-friendly aluminum-plated composite membrane with good compositing strength and without aluminum-layer transferring or solvent residue.

Owner:梧州市广川科技发展有限公司

Casting method for steel-copper composite cylinder

A casting method for a steel-copper composite cylinder comprises the steps that three-dimensional modeling, casting technology designing and technology simulating and optimizing, steel base heat treatment, machining and tool machining and welding and steel base surface treatment are sequentially carried out, preheat treatment on a steel base before production is carried out, anhydrous borax is melted, the steel base is placed into a borax solution, copper alloy is smelted, the copper alloy is cast into the steel base, the steel base is placed into a water trough and is cooled and solidified to the room temperature, and then the steel-copper composite cylinder is manufactured. The method solves the problems about the steel-copper cylinder composite casting technology and composite components. The bi-metal cylinder is high in composite strength, high in yield and low in cost, the size of the cylinder is not limited, the forming process is easy to control, and the quality is stable.

Owner:徐宏

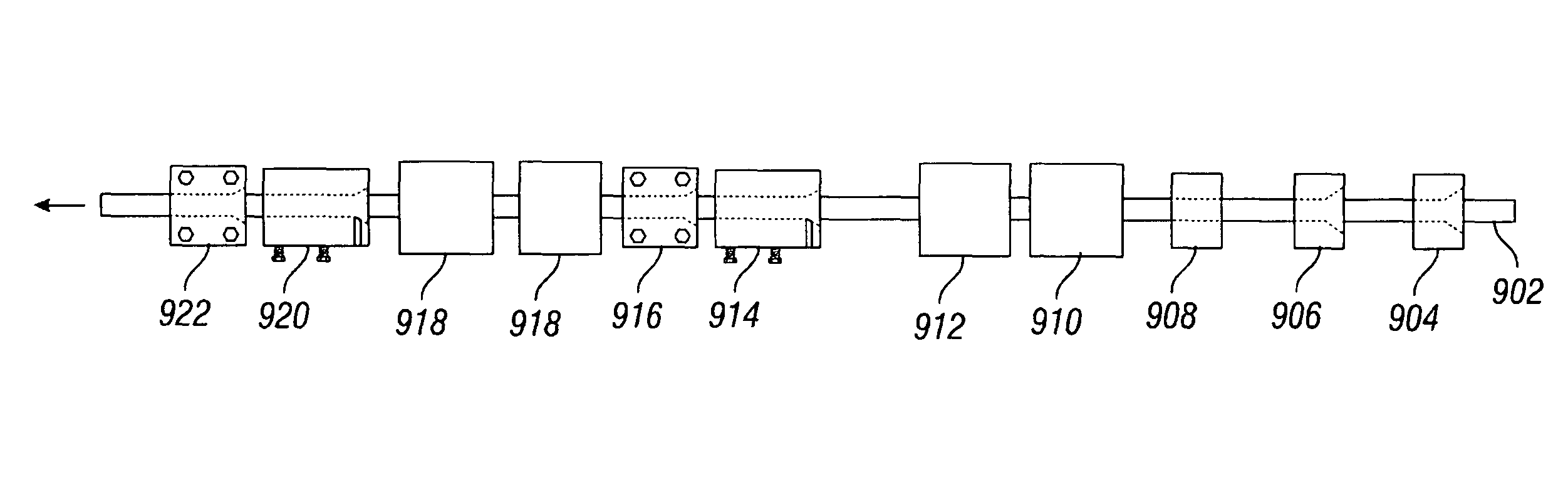

Methods of manufacturing composite slickline cables

ActiveUS8000572B2Variation in diameterUniform cross-sectional shapeLamination ancillary operationsLaminationEpoxyComposite strength

Disclosed are wellbore electric cables, and methods of manufacturing such cables, and in one aspect, methods of manufacturing wireline composite slickline cables. Some embodiments are methods which include preparing a slickline cable by providing an inner metallic tube containing at least one conductor (such as an optical fiber), disposing an epoxy / fiber composite strength layer substantially upon the outer periphery of the inner metallic tube, and exposing the combination of the inner metallic tube and composite strength layer to at least one technique for minimizing the variation in diameter and providing a substantially uniform circular cross-sectional shape of the combination. Further, an outer metallic tube is draw around the combination of the composite strength member and the inner metallic tube, to form a wellbore slickline. Cables prepared using such methods are also disclosed.

Owner:SCHLUMBERGER TECH CORP

Yttrium modified chromium aluminium carbonitride/silicon nitride nano composite coating and deposition method thereof

ActiveCN103436841AHigh bonding strengthGood heat matchingLayered productsVacuum evaporation coatingRare-earth elementAlloy

The invention relates to a yttrium modified chromium aluminium carbonitride / silicon nitride nano composite coating and a deposition method thereof. Chromium aluminium carbonitride and silicon nitride are subjected to nano composite design to form a nano composite structure with nanocrystal chromium aluminium carbonitride implanted into amorphous silicon nitride, so that the rigidity of the coating is improved; the toughness of the coating and bonding strength of the coating and a matrix are both considered; a rare earth element Y is introduced simultaneously, so that the mechanical property and high-temperature oxidation resistance of the coating are further improved; and the nano composite coating which is strong in bonding force, high in rigidity, good in toughness, low in friction coefficient and prominent in thermostability and is used for high-speed steel and hard alloy cutters and molds is obtained. The coating comprises a chromium-aluminum-yttrium bonding layer, a chromium-aluminum-yttrium nitride transition layer and a nano composite layer; the membrane / matrix bonding strength of the obtained coating reaches 40-90N; the surface composite strength under 10g load reaches 40-65 GPa; and the friction coefficient is 0.2-0.5 when matched with GCr15.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Preparation method for aluminum-stainless steel clad metal plate and strip

ActiveCN101797583ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsComposite strengthBond strength

The invention discloses a preparation method for an aluminum-stainless steel clad metal plate and strip. The method comprises: carrying out anaerobic continuous casting and rolling on semisolid aluminum or aluminum alloy and a solid stainless steel plate strip to prepare the aluminum-stainless steel clad metal plate strip. In the preparation method of the invention, the non-oxidation metallurgy composite of the solid stainless steel plate strip and aluminum liquid is realized, the oxidation problem of the aluminum is solved, the composite strength is high, and the bond strength of the stainless plate and the aluminum is larger than or equal to 100Mpa; continuous casting and rolling is carried out on the stainless plate strip and the aluminum liquid to prepare the aluminum-stainless steel clad metal plate strip, the production efficiency is greatly improved by up to dozens of times, and the product quality is stable; the prepared aluminum-stainless steel clad metal plate strip product maintains the intrinsical surface quality of the stainless steel plate strip, and the stainless steel layer has even thickness and can be performed with cold rolling and deep processing; various stainless steel plate and strips with different components and the aluminum liquid can be adopted, the sorts of products are more, and the applicability is wide; and the invention has the advantages of advanced production process, less working procedure, energy conservation, materials saving and remarkable economic effects.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

Method utilizing herringbone ripple roller to roll composite plate strip

InactiveCN105618479ASolve deviationImprove bindingMetal rolling arrangementsComposite strengthWork in process

The invention discloses a method utilizing a herringbone ripple roller to roll a composite plate strip. The method is characterized in that a composite plate blank consisting of a basal plate and a composited plate is rolled into a herringbone ripple composite plate semi-finished product by a composite roughing mill provided with a herringbone ripple roller, and then, the herringbone ripple composite plate semi-finished product is rolled into a composite plate at a required thickness through a composite finishing mill provided with a flat roller. Herringbone ripples are symmetrically distributed relative to the radial central plane of the roller or symmetrically distributed relative to the axial central plane of the roller, and axial included angles between the herringbone ripples and the roller are 10-80 degrees. According to the invention, the problems that instant shock is produced during transverse ripple rolling and axial force drives the plate strip to shift during longitudinal ripple rolling are solved; and at the same time, the bonding area of the composite plate roughed is increased, so that bonding force between the basal layer and the composited layer is increased, and the compositing strength and compositing efficiency of the composite plate are greatly improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Connecting material for printing composite ink in polyurethane by using high-speed printer and preparation method for connecting material

The invention discloses a connecting material for printing composite ink in polyurethane by using a high-speed printer and a preparation method for the connecting material. The connecting material consists of 65-70 percent of organic solvent and 30-35 percent of solid content, wherein the solid content comprises polyester polyol, isocyanate and micromolecule chain extender. The connecting material prepared by the method is high in composite strength and the peeling strength of white ink can be 5-7N / 15mm; and the peeling strength of single color ink can be 3-5N / 15mm; the connecting material can be excellently compatible with vinyl chloride, NC and other dispersion resins; the connecting material is high in attachment fastness on a PET film and an NY film, so that the connecting material cannot be pulled off by a 3M adhesive tape or the adhesive falls off the adhesive tape is avoided; with excellent pyrolysis resistance and hydrolysis resistance, the connecting material can be applied to high-grade polyurethane ink capable of resisting the boiling of water being 100 DEG C and boiling at high temperature of 121DEG C; and the connecting material has the characteristics of thermal adhesion resistance, freeness of after tack of a dry film and the like.

Owner:新东方油墨有限公司

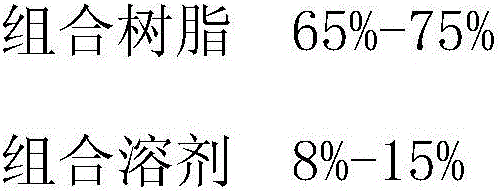

Water-based gravure composite ink for plastic film and preparation method thereof

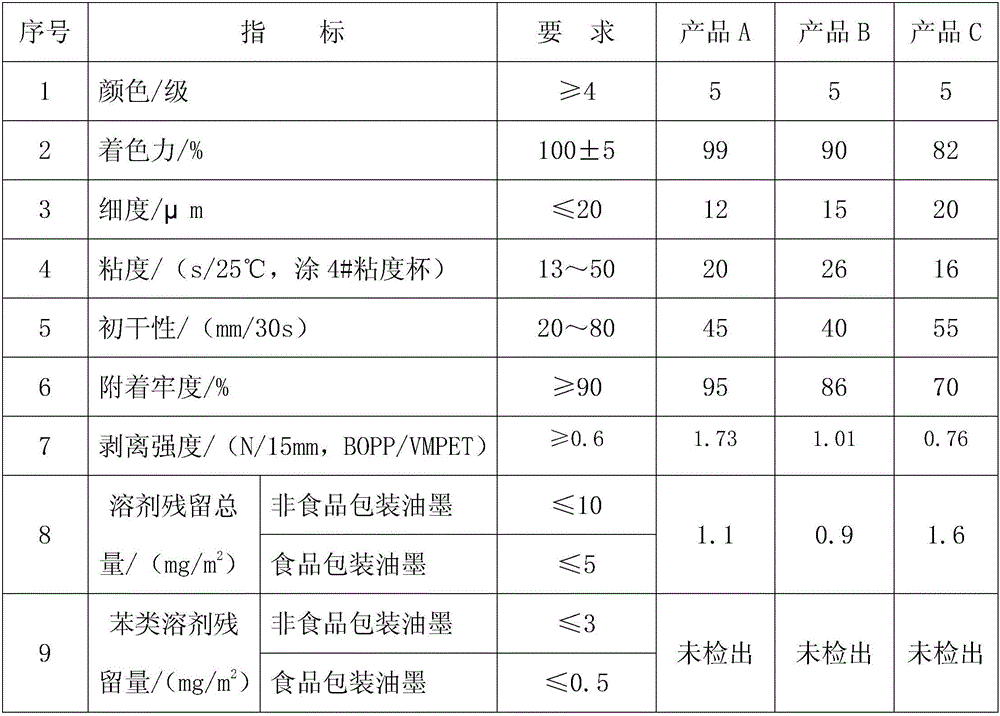

The invention discloses water-based gravure composite ink for plastic film and belongs to the field of inks. The water-based gravure composite ink for plastic film is made from, by weight, 65-75% of combined resin, 8-15% of a combined solvent, 14-24% of a pigment, and 2-4% of an aid, wherein the combined resin is from water-based polyurethane resin, modified acrylic resin and three-component hydroxyl-modified vinyl resin copolymer; the combined solvent is from water and ethanol; the ink of the invention has good film surface wetting property, high adhesive power, high composite strength, good ink leveling property, and adaptive to printer speed of 80-280 m / min; the ink of the invention is free of toxic benzene substances or ester and ketone substances and is environment-friendly, and the VOCs (volatile organic compounds) emission problem is effectively solved; in addition, the ink of the invention has high ignition point, is uninflammable, and is convenient to transport and store.

Owner:CHENGDU PRESSTER NEW MATERIALS

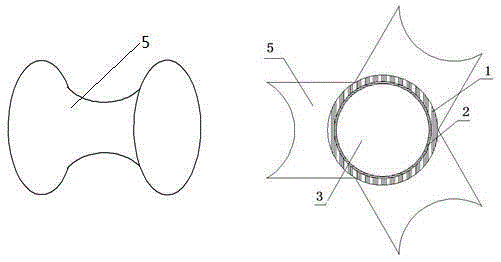

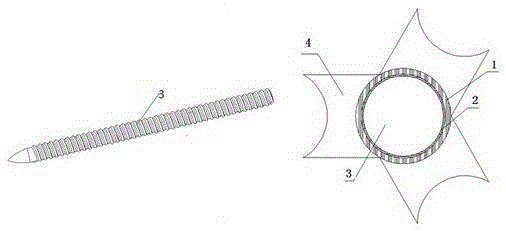

Process for rolling inner-corrugated combined surface metal composite tube

The invention provides a process for rolling an inner-corrugated composite surface metal composite tube. The process for rolling the inner-corrugated composite surface metal composite tube comprises the steps: selecting a metal parent tube and a metal coated tube, and manufacturing a tube blank by combining the coated tube outside and the parent tube inside, wherein the deformation resistance of the coated tube is smaller than the deformation resistance of the parent tube; rolling the manufactured composite tube blank in a composite roughing mill, in which a spiral corrugated mandril is mounted, thereby obtaining a composite tubular billet, the inner surface and the composite surface of which have a spiral corrugated shape, wherein the spiral corrugated shape can be circular arc, ellipse, sine wave, triangle, trapezoid or rectangle, the corrugated height is (0.1-10) times of the thickness of the coated tube, and the width of the corrugated is (3-20) times of the height of the corrugated; putting the composite tubular billet in a composite finishing mill, in which a smooth circular hole is formed, to roll the corrugated shape of the inner surface to be level and round till the required tube wall thickness is obtained, thereby obtaining a composite tube. According to the process for rolling the inner-corrugated composite surface metal composite tube, by utilizing corrugated composite surfaces of the roughly rolled coated tube and parent tube, the difference of metal plastic deformation caused by dissimilar metal deformation resistance difference is solved, the composite strength and force of metal layers are increased, and the composite rate is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of aluminum plating composite film

ActiveCN103112236AReduce dosageHigh composite strengthLamination ancillary operationsLaminationComposite strengthComposite film

The invention provides a preparation method of an aluminum plating composite film. The preparation method comprises the following steps of: coating a solventless adhesive onto the aluminum surface of an aluminum plating film, wherein the gluing quantity of the solventless adhesive is 2.6-3.0g / m<2>; compounding the aluminum plating film coated with the solventless adhesive with an external film, wherein the compound tension during compounding is 45-55N; rolling the obtained compound film; and curing the rolled compound film to obtain the aluminum plating composite film. By controlling the gluing quantity of the solventless adhesive to be 2.6-3.0g / m<2> and controlling the compound tensions of the aluminum plating film and the external film to be 45-55N, the obtained aluminum plating composite film is provided with good compounding strength and tensile strength when the adhesive dosage is reduced at the same time. As no solvent is used and basically no solvent residue is generated, the preparation method of the aluminum plating composite film disclosed by the invention has little effect on the packaged contents, ecological environment and human health.

Owner:HUANGSHAN NOVEL

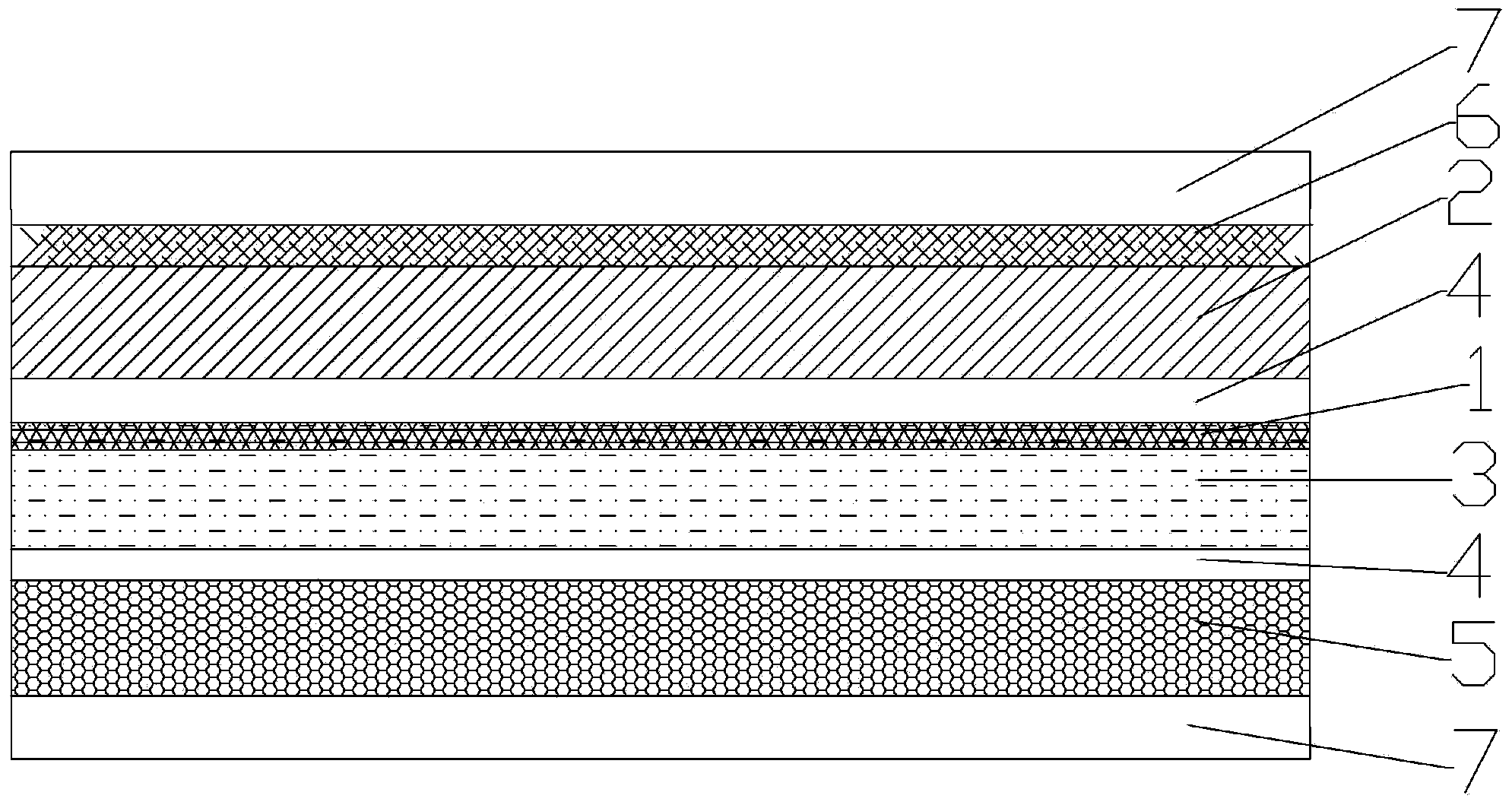

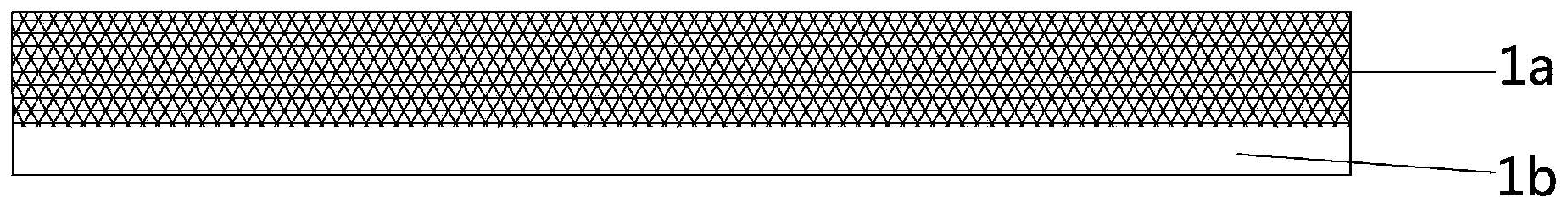

Composite bulletproof plate containing adhesive-bonding synergistic layer and manufacturing method thereof

ActiveCN103528442AImprove wettabilityIncrease the number ofSynthetic resin layered productsCeramic layered productsComposite strengthCompressive strength

The invention provides a composite bulletproof plate containing an adhesive-bonding synergistic layer and a manufacturing method thereof. According to the composite bulletproof plate containing the adhesive-bonding synergistic layer, the adhesive-bonding synergistic layer 1 used for improving an adhesive-bonding effect is added on the surface to be adhered to ceramic, and the synergistic layer 1 is woven fabric obtained through mixing of ultra-high molecular weight polyethylene fibers and polarity fibers according to the mass ratio from 1:99 to 99:1. An adhesive film 2 is arranged on the woven fabric in a single coating mode, and the type of resin contained in ultra-high molecular weight polyethylene non-weft cloth is the same as the type of resin contained in the adhesive film. By combining with the manufacturing method of the composite bulletproof plate, the composite bulletproof plate containing the adhesive-bonding synergistic layer can overcome the defects that adhesive commonly used in the composite bulletproof plate is not good in wettability, and the composite strength between the ceramic and the composite bulletproof plate is poor in the prior art.

Owner:四川东材绝缘技术有限公司

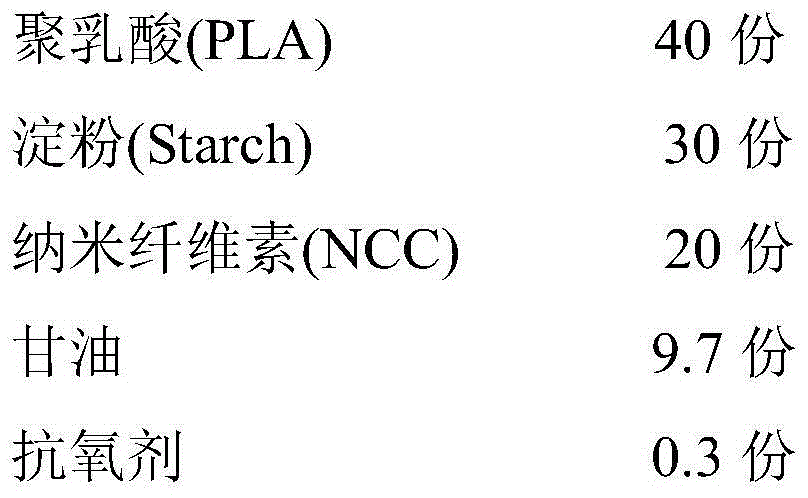

Polylactic acid degradable composite material and preparation method thereof

InactiveCN104861600AReduce manufacturing costEasy to make costComposite strengthCompressive strength

The invention discloses a polylactic acid degradable composite material, comprising the following components in parts by weight: 40-70 parts of polylactic acid, 10-50 parts of filler, 2-10 parts of glycerinum and 0.2-2 parts of antioxygen. In order to reduce the manufacturing costs of the polylactic acid, starch with good biological degradability is added as the filler when in preparation, as the starch is abundant in resource, low in cost and fine in particle, so that the manufacturing costs of the polylactic acid can be reduced; however, the polylactic acid is not ideal enough in mechanical property due to the addition of the starch, in order to overcome the defect, nano-crystalline cellulose is added as an additive, as the nano-crystalline cellulose is strong in mechanical strength, the defect that the composite material is insufficient in mechanical strength due to the addition of the starch is made up, and thereby the composite strength still has high mechanical strength even lots of starch is filled.

Owner:常州龙骏天纯环保科技有限公司 +1

High wear-resistant roller screen roll and build-up welding process

InactiveCN101623688AImprove wear resistanceStrong toughnessSievingScreeningHigh resistanceWear resistant

The invention discloses a high wear-resistant roller screen roll and a build-up welding process, and manufactures a roller screen roll with high surface hardness and high composite strength. The technical proposal is as follows: the screen roll utilizes an ordinary carbon steel tube as a substrate, the build-up welding layer on the surface of the substrate utilizes a composite material with gradually increased hardness, and the first layer of the build-up welding layer is a transitional layer and utilizes Austenitic stainless steel of which the hardness is higher than that of the ordinary carbon steel and the welding strength is high; and the second layer and the third layer are wear-resistant layers, namely work layers and are welded by special 00Cr13 serial wear-resistant welding wire, with high hardness and high wear resistance. The build-up welding process of the screen roll is as follows: lathe machining on the substrate before welding; preheating temperature; transition layer build-up welding; temperature detection; wear-resistant layer build-up welding; tortuosity checking; rough turning; surface flaw inspection; finish turning, grinding; product finishing. The invention adopts the build-up welding process to carry out local optimization, the hardness is increased from inner to surface in a gradient manner; the build-up layer and the substrate are metallurgical combined, and the combining strength is high without crack and falling off; the surface of the roll has strong wear resistance and toughness; the service life is improved by 2 to 3 times; and the cost is low.

Owner:DALIAN XINZHONG GRP +2

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

Super-thick T2-316L explosion welding superconducting corrosion-resisting composite board

InactiveCN101524906AEliminate the effects ofEliminate influence of welding qualityNon-explosive/non-thermic compositionsMetal layered productsLower limitComposite strength

The invention relates to a super-thick T2-316L explosion welding superconducting corrosion-resisting composite board. Firstly, the explosion velocity of explosive is controlled to be about 1000-1300 m / s by an explosive composition optimization design; secondly, the water content and the density are controlled by adopting a principle of explosive-charging principal parameter lower limit selection through an explosive-charging auxiliary parameter, such as a gap and the reasonable design and selection of basic composite board explosive-charging dimensions, and by collocating a sandy soil ground base added with water, thus the invention ensures that the one-time composite rate of the super-thick T2-316L explosion welding superconducting corrosion-resisting composite board reaches 100 percent, the composite strength of the super-thick T2-316L explosion welding superconducting corrosion-resisting composite board reaches or even surpasses the national standards, and finally, the super-thick T2-316L explosion welding superconducting corrosion-resisting composite board can not be layered during the sequential mechanical processing by being formulated by a heat processing parameter.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Fabric internally-enhanced block polyolefin waterproof roll

InactiveCN104790594AReduce photodegradationRoof covering using flexible materialsSynthetic resin layered productsComposite strengthPolyolefin

A fabric internally-enhanced block polyolefin waterproof roll at least comprises two block polyolefin layers and a fabric enhancement layer, and the three structure layers are compounded into a whole. Each block polyolefin layer is an elastic body which comprises, by weight, 30-70 parts of block polyolefin, 30-70 parts of polyolefin, 20-90 parts of fire retardant, 1-2 parts of compatilizer, 3-6 parts of pigment, 0.3-0.6 part of antioxygen and 0.3-0.6 part of light stabilizer. The fabric internally-enhanced block polyolefin waterproof roll solves the problems that a common waterproof roll is high in hardness, the composite strength of an upper thermoplastic polyolefin layer and a lower thermoplastic polyolefin layer is low, and welded joints are not reliable after being used for a long time, and the waterproof roll has the advantages of being soft, high in composite strength, reliable in welded joints and the like, thereby being an advanced waterproof roll.

Owner:TANGSHAN DESHENG WATERPROOF

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com